Patents

Literature

782results about How to "Improve bonding fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-dimensional printing forming material with toughness and high adhesive property and preparation method thereof

The invention discloses a three-dimensional printing forming material with toughness and high adhesive property. The three-dimensional printing forming material comprises a powder material and an adhesive material and is characterized in that the powder material comprises the following components in parts by weight: 40-85 parts of polyamide resin, 5-40 parts of pigments, 5-30 parts of filler, 1-6 parts of pigment and filler dispersing and wetting aid, 0.1-1.5 parts of flatting agent and 0.1-0.5 part of degassing agent; the adhesive material comprises the following components in parts by weight: 60-95 parts of epoxy resin, 5-40 parts of filler, 1-10 parts of toughening agent, 0.1-1.5 parts of flatting agent, 1-4 parts of pigment and filler dispersing and wetting aid, 0.1-0.5 part of degassing agent and 0.1-0.5 parts of powder flowing aid; and when the three-dimensional printing forming material is used, 1 part by weight of powder material and 0.01-0.5 part by weight of adhesive material are cooperatively used. A solid component printed by using the material disclosed by the invention has the advantages of higher adhesion strength and firmness, good flexibility and scratching resistance.

Owner:ZHONGSHAN POLYTECHNIC

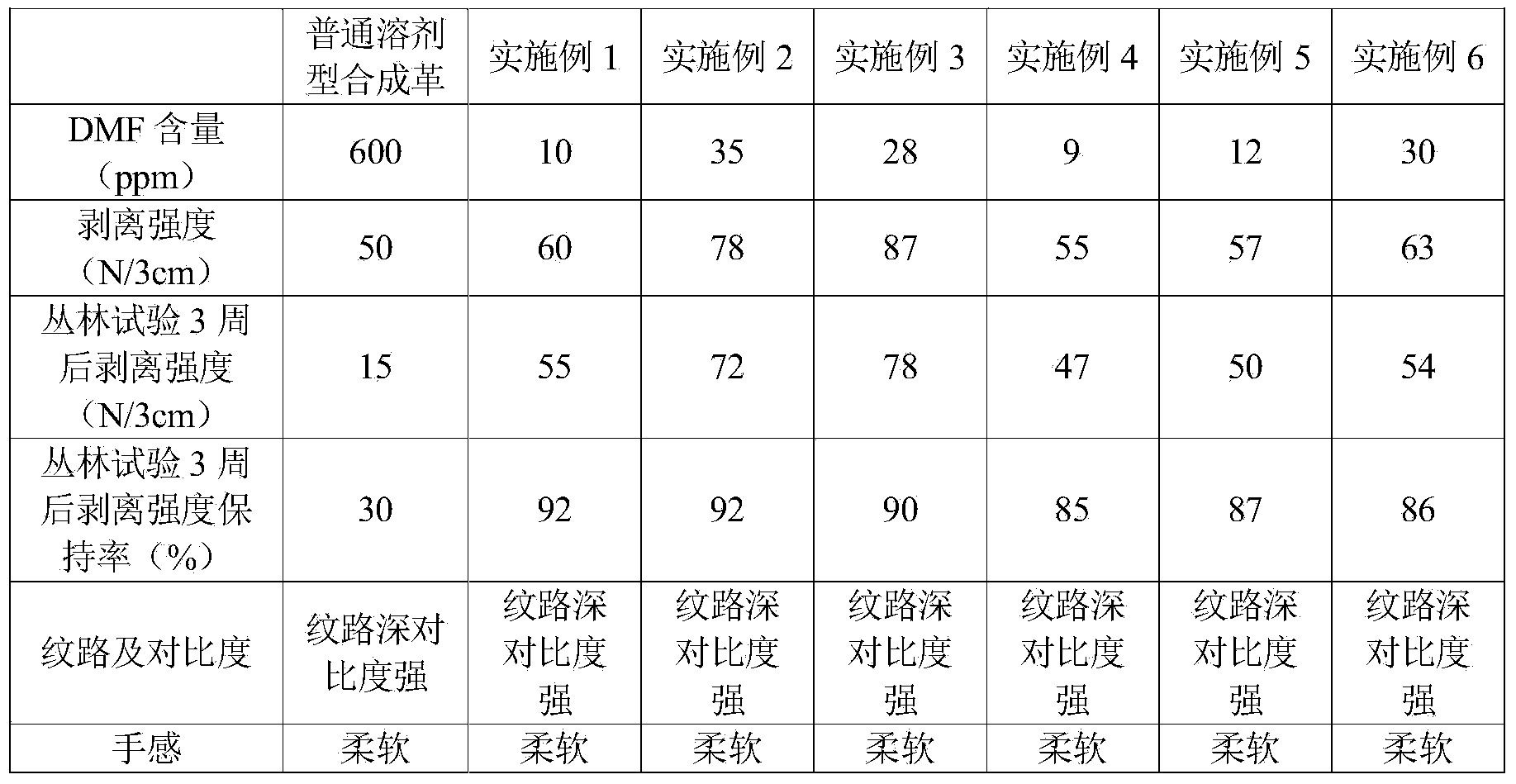

Foaming synthetic leather manufacturing technology based on waterborne polyurethane (WPU)

ActiveCN102409554AFeel plumpSoft touchSynthetic resin layered productsTextiles and paperManufacturing technologyMicrosphere

The invention provides a foaming synthetic leather manufacturing technology based on waterborne polyurethane (WPU). In the manufacturing technology, the WPU is taken as a main raw material, and a hollow microsphere foaming agent is taken as a foaming material; and the technology can be widely used for manufacturing synthetic leathers such as clothing leathers, luggage leathers, shoe upper leathers, sofa leathers, home interior trim leathers and the like. The content of volatile organic compounds (VOC) in the finished leather is lower than 2mg / kg (leather), and the air permeability and moisture penetrability are good, thus meeting the EU (European Union) requirements for the ecological synthetic leather; and in addition, the foaming synthetic leather has the advantages of moderate foaming multiplying power, uniform and compact foaming holes, bulky and firm hand feel as well as good comprehensive performance which is equivalent to or superior to that of a solvent-borne product. The foaming synthetic leather manufacturing technology based on the WPU provided by the invention has the beneficial effects that by adopting the WPU instead of the traditional solvent-borne PU, organic pollution is eliminated from a source, organic solvent resources are saved, the comprehensive energy consumption is lowered, the employment environment of laborers is improved, and the ecological grade of the synthetic leather and the international market competitiveness of the product are enhanced, thus achieving obvious innovativeness and remarkable social and economic benefits.

Owner:DONGTAI FUAN SYNTHETIC MATERIAL CO LTD

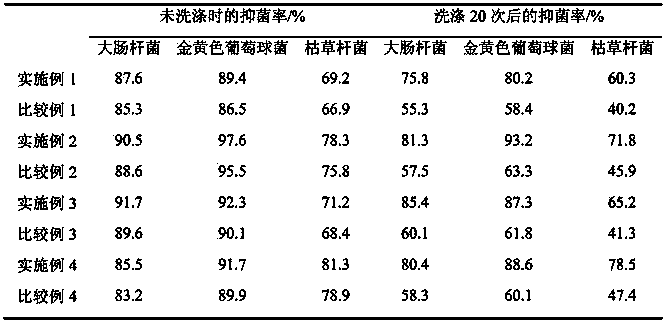

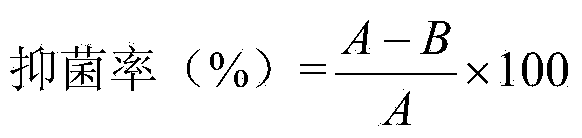

Antibacterial finishing method for textile containing cellulose

ActiveCN103614927AImprove stabilityLess irritatingVegetal fibresMicroballoon preparationStaphylococcus aureusCellulose fiber

The invention relates to an antibacterial finishing method for textile containing cellulose. The method uses natural polymer chitosan and sodium alginate as wall materials; traditional Chinese medicine extracts are used as a core material and are subjected to encapsulation by a micro capsule technology; then an afterfinishing method is employed to treat the microcapsule to the partially carboxymethylated textile containing cellulose, so as to endow the textile with antibacterial performance and good wash fastness through electrostatic attraction between the carboxyl on cellulose fiber and chitosan, as well as the crosslinking effect of the cross-linking agent. The raw materials employed by the invention are green, environment-friendly, safe and high-efficiency, and the obtained textile has good antibacterial effect on common staphylococcus aureus, Eschierichia coli and bacillus subtilis.

Owner:成都艾蒂浮兰科技有限公司

Method and device for printing pictures and texts on surface of irregular object

InactiveCN101734030ASimple color printingEfficient Color PrintingDecorative surface effectsDuplicating/marking methodsPlastic moldingElectrical and Electronics engineering

The invention relates to a method and a device for printing pictures and texts, particularly to a method and a device for printing fine pictures and texts on the surface of an irregular object, which comprises the following steps of: a. manufacturing a compound transfer printing film; b. pre-deforming the compound transfer printing film; c. placing the deformed compound transfer printing film in a plastic hollow blow molding mould, realizing transfer printing in the plastic molding process, or clinging the deformed compound transfer printing film to a printing undertaking object, and sharing through one or more modes of heating, infrared illumination, ultraviolet illumination and pressurization to realize transfer printing; and d. removing a substrate layer and a stripping layer. The invention has the advantages that the printing of fine pictures and texts can be carried out on the surfaces of a regular object and the irregular object, pictures and texts are continuous, whether the local surface or the entire surface can be printed once through the invention, and the invention has a good solution particularly for an object with a complicated surface.

Owner:赵东林

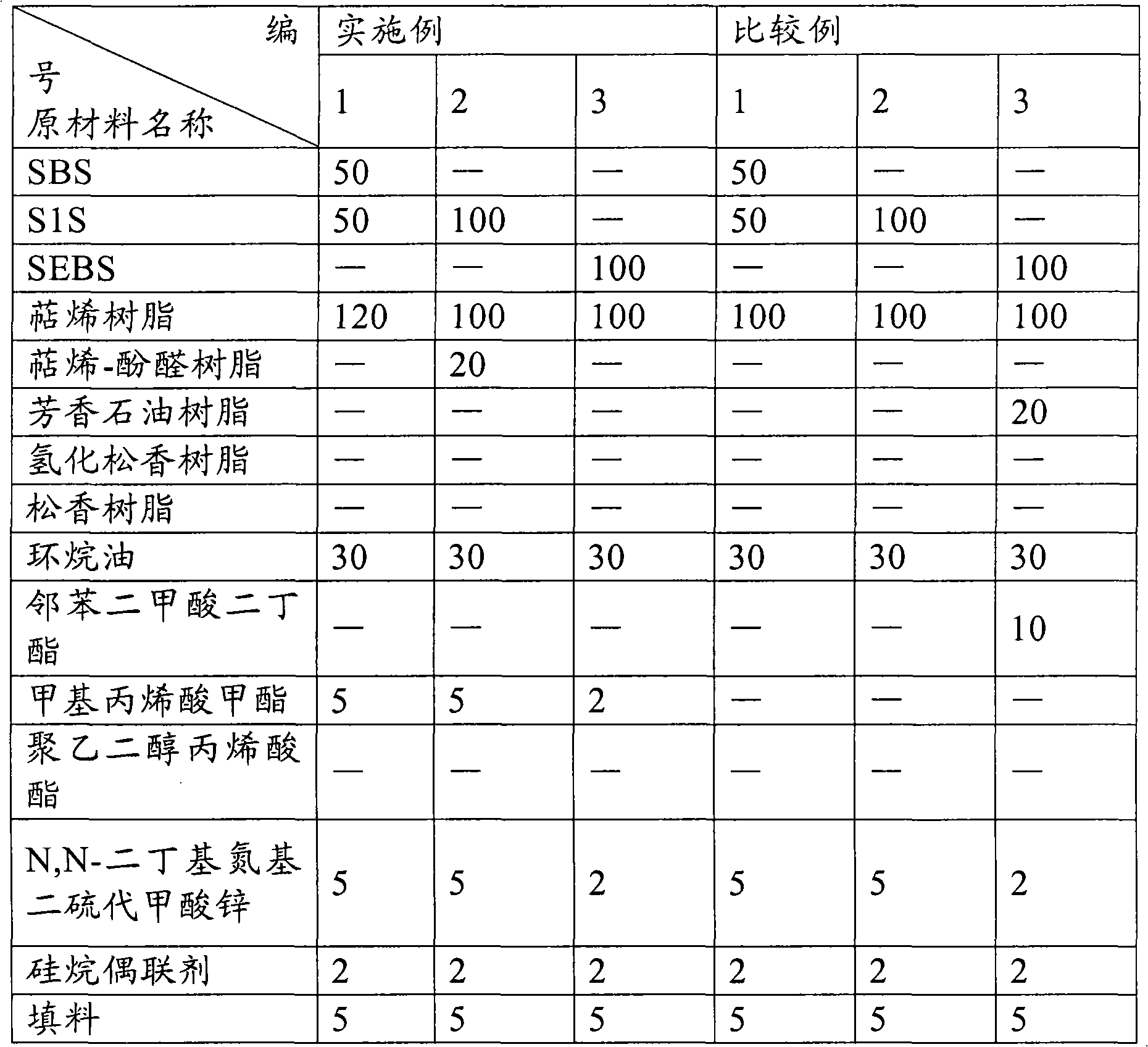

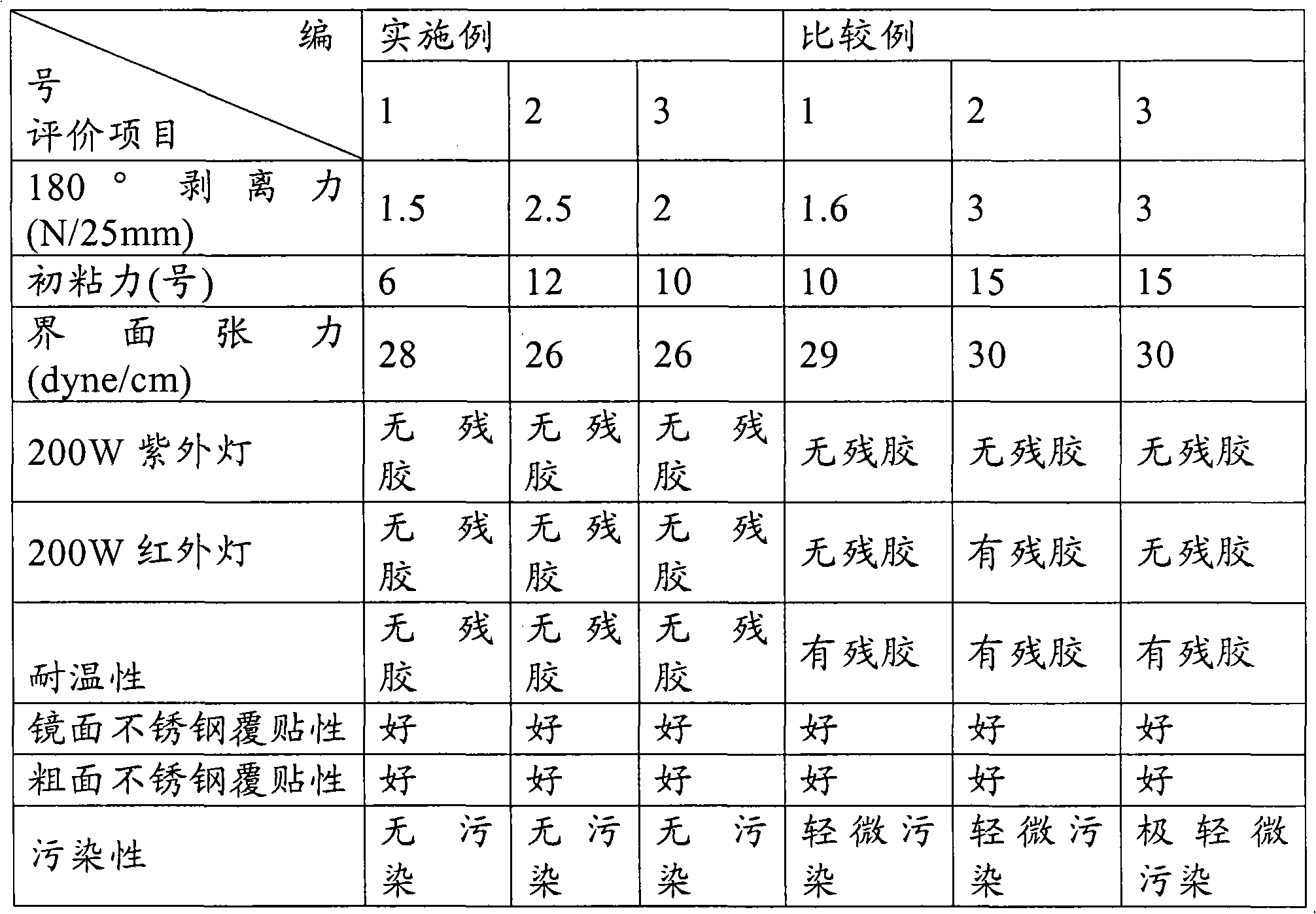

Preparation methods of hot melt pressure-sensitive adhesive and protective film as well as hot melt pressure-sensitive adhesive

ActiveCN102051149AImprove heat resistanceGood weather resistanceLiquid surface applicatorsNon-macromolecular adhesive additivesTectorial membranePolyolefin

The invention discloses preparation methods of a hot melt pressure-sensitive adhesive and a protective film as well as the hot melt pressure-sensitive adhesive. The preparation method of the hot melt pressure-sensitive adhesive comprises the following steps: adding thermoplastic elastomers, a tackifier, a plasticizer, an antiager, an antioxidant, a crosslinker, a filler and the like into a double-mixed column mixer, stirring, heating until the materials are melted down, and uniformly mixing to obtain the pressure-sensitive adhesive. The preparation method of the protective film comprises the following steps: directly pumping the melted and uniformly mixed pressure-sensitive adhesive into a coating roll of the a hot melt coating machine by a heat transfer pump, coating the pressure-sensitive adhesive onto one face of a polyolefin plastic film or thin plastic-coated paper, cooling, and rolling to obtain the protective film (paper). The hot melt pressure-sensitive adhesive disclosed by the invention can obtain good initial stickiness, cohesion and age stripping property by changing the different ratio of the thermoplastic elastomer as well as the variety and usage amount of the tackifier. The prepared polyethylene (PE) film substrate protective film has low interfacial tension, good initial stickiness, high cohesion and high temperature resistance, light resistance and weather resistance, and the comprehensive performance and product cost of the hot melt pressure-sensitive adhesive disclosed by the invention are better than those of the traditional solvent pressure-sensitive adhesive taking natural rubber as the main material.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

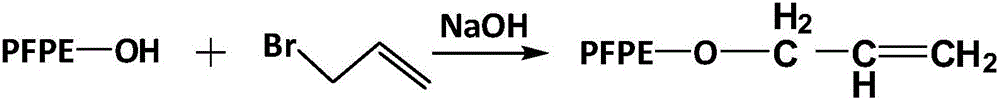

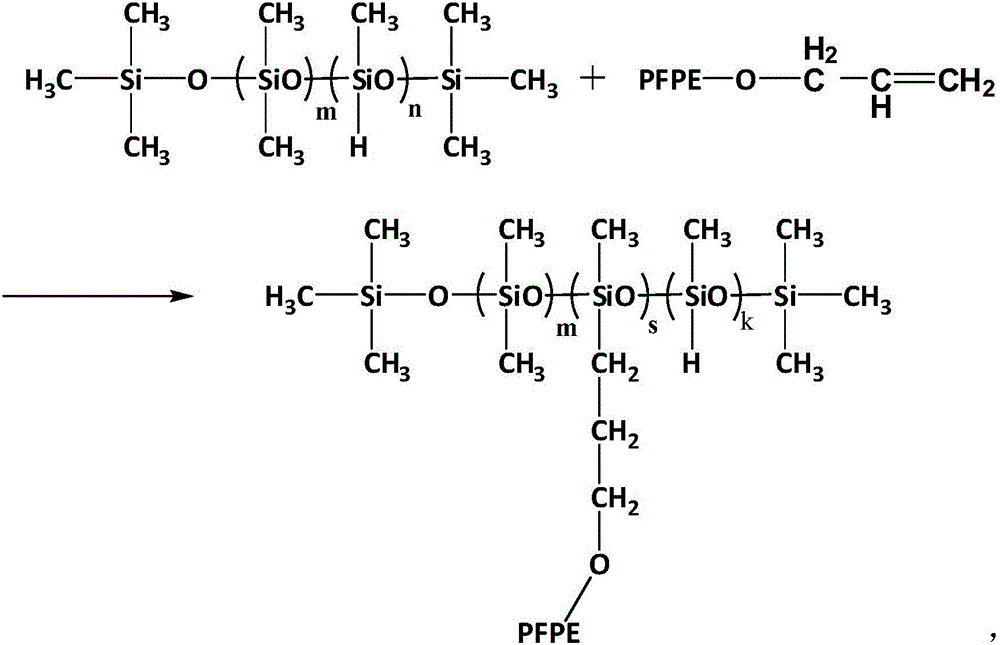

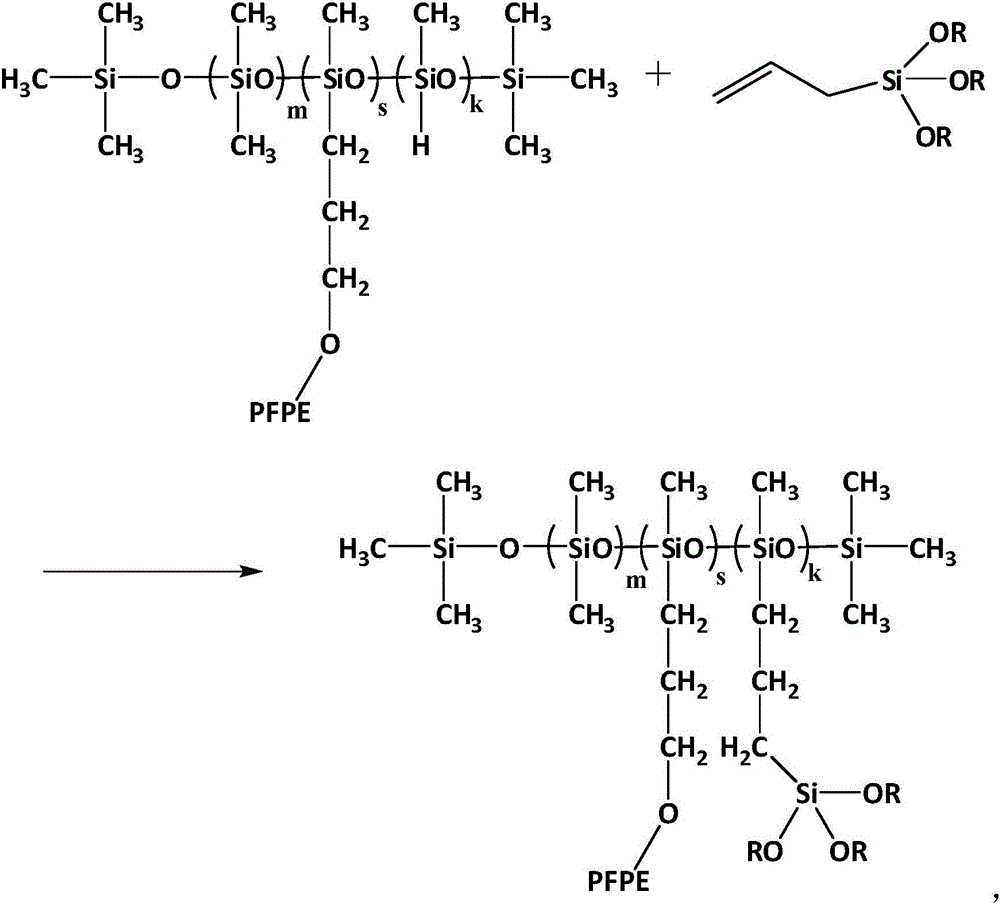

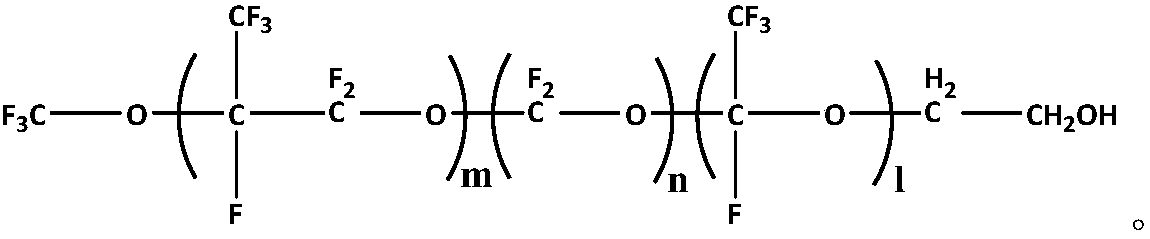

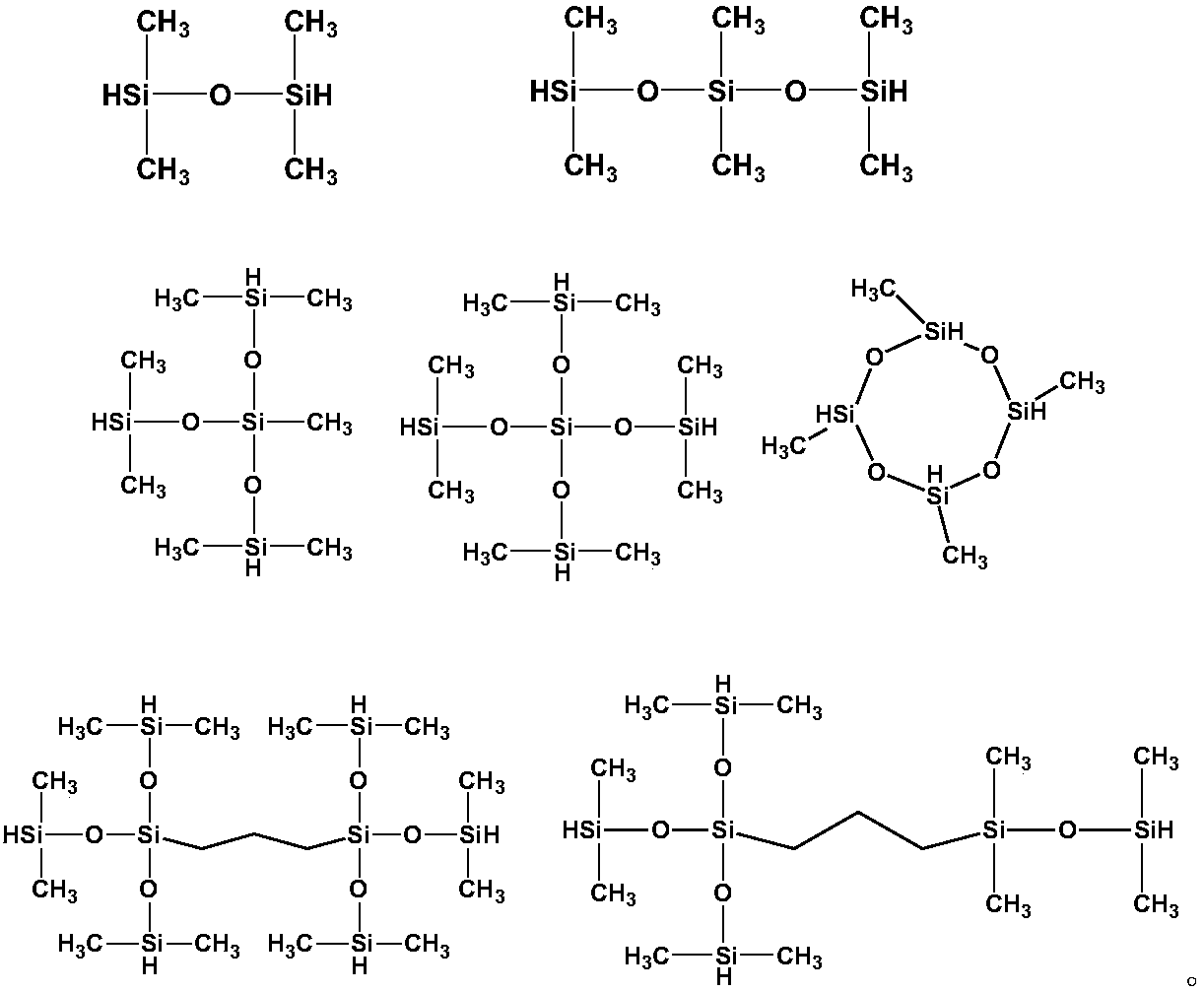

Preparation method of high-performance fingerprint-resistant agent

ActiveCN106085227AHigh hardnessImprove wear resistanceAntifouling/underwater paintsPaints with biocidesHydrogenPerfluoropolyether

The invention discloses a preparation method of a high-performance fingerprint-resistant agent. The preparation method includes the following steps that hydroxyl-terminated perfluorinated polyether and allyl bromide react to obtain allyl-terminated perfluorinated polyether; allyl-terminated perfluorinated polyether and hydrogen-containing silicone oil are subjected to a layer adding reaction through silicone hydrogen, and perfluorinated polyether-hydrogen-containing silicone oil (unreacted hydrogen still exists in silicone oil) is obtained; the obtained product and allyl siloxane continue to be subjected to a silicone hydrogen water adding reaction to obtain a needed target product pectinate perfluorinated polyether-siloxane; then pectinate perfluorinated polyether-siloxane is prepared into the fingerprint-resistant agent. The prepared fingerprint-resistant agent has the advantages of being good in hydrophobic and oleophobic performance, excellent in anti-fouling property and good in fingerprint easy-to-move property, a fingerprint-resistant coating and a glass base material are high in bonding force, the product is good in abrasion resistance, and compared with the prior art, the durability and abrasion resistance of the fingerprint-resistant agent are greatly improved.

Owner:QUZHOU FLUORIDE & SILICON RES INST

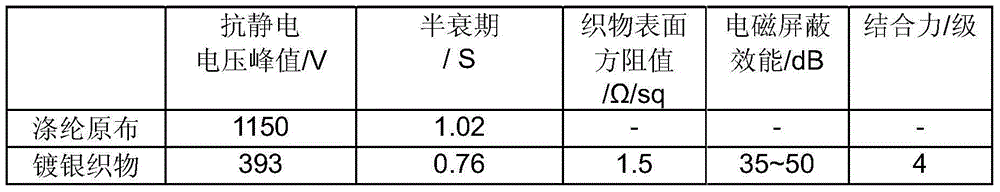

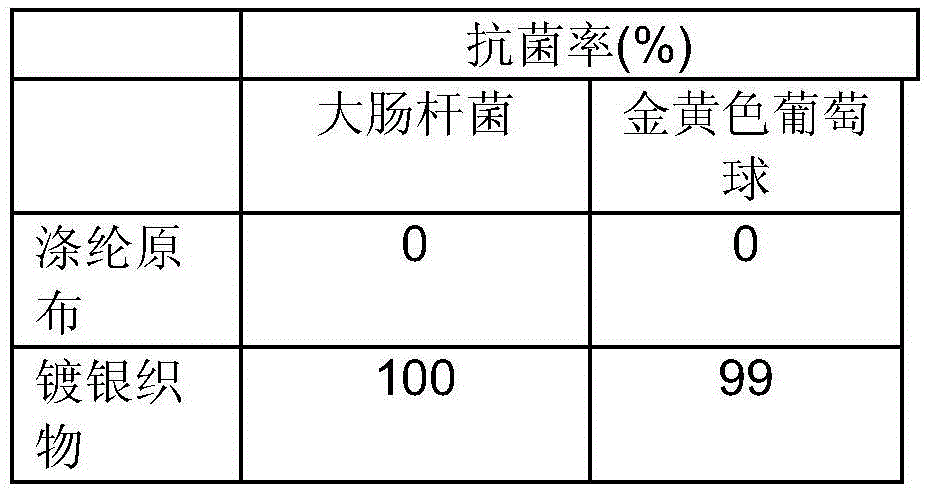

Method for making conductive fabric through polyaniline-triggered chemical slivering

InactiveCN104452309ABig pollutionReduce pollutionVegetal fibresAnimal fibresElectromagnetic shieldingBiological activation

The invention relates to a method for making conductive fabric through polyaniline-triggered chemical slivering. Fabric is soaked in a mixed solution of aniline and protonic acid, ammonium persulfate is added to the mixed solution, a reaction is carried out for 2-10 hours, and then the processed fabric is obtained after washing; the processed fabric is soaked in a silver nitrate solution, washed, dried, and then soaked in a silvering solution for being silvered for 30-60 min at the temperature of 30-40 DEG C, then the processed fabric is washed and dried, and finally the conductive fabric is obtained. According to the method, the process conditions of sensitization and activation are omitted, polyaniline and silver nitrate replace stannous chloride and palladium chloride high in price, cost is lowered, and environment pollution is reduced. The conductive fabric obtained through the method is good in conductivity, the binding strength of metal and fabric is high, the electromagnetic shielding performance is excellent, and the conductive fabric has an antistatic function, an antibacterial function and the like.

Owner:DONGHUA UNIV

Conductive fibers and preparation method

Conductive fibers and preparation method thereof are characterized in that the fibers are used for carrying out chemical copper plating re-electrosilvering in continuous advancing manner, that is, the fibers are trimly arranged and coiled into shafts, and strands are unwinded so that silver covered copper conductive fibers are prepared by each working procedure of activation, chemical plating, electroplating, and the like; in the invention, chemical fiber continuous yarns are used for carrying out chemical copper plating re-electrosilvering in continuous advancing manner, thereby greatly reducing the production cost and improving the production efficiency on the premise of guaranteeing the conductive performance of fibers.

Owner:ZHEJIANG SCI-TECH UNIV

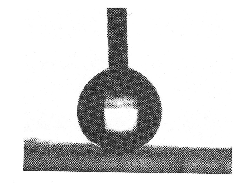

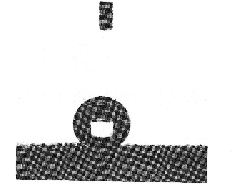

Superhydrophobic inorganic organic nano composite polymeric coating material and preparation method thereof

InactiveCN101824278AWide range of usesReduce resistancePretreated surfacesSpecial surfacesChemical reactionFunctionalized nanoparticles

The invention discloses a superhydrophobic inorganic organic nano composite polymeric coating material and a preparation method thereof. The coating material is prepared from 30 to 98 mass percent of thermosetting polymeric precursor and 10 to 70 mass percent of surface functionalized nanoparticle under the action of 0 to 5 mass percent curing agent, wherein the obtained surface water contact angle and rolling angle of the material are 120 to 180 DEG and 1 to 20 DEG respectively; and a falling water drop which is spherical can bounce up and can freely roll on the surface. The method has the characteristic of simple preparation process by using the chemical reaction between organic groups on the surfaces of the polymeric precursor and the modified nanoparticle in the solution. The coating material has the functions of stain resistance, dust prevention and self cleaning.

Owner:NANJING UNIV OF TECH

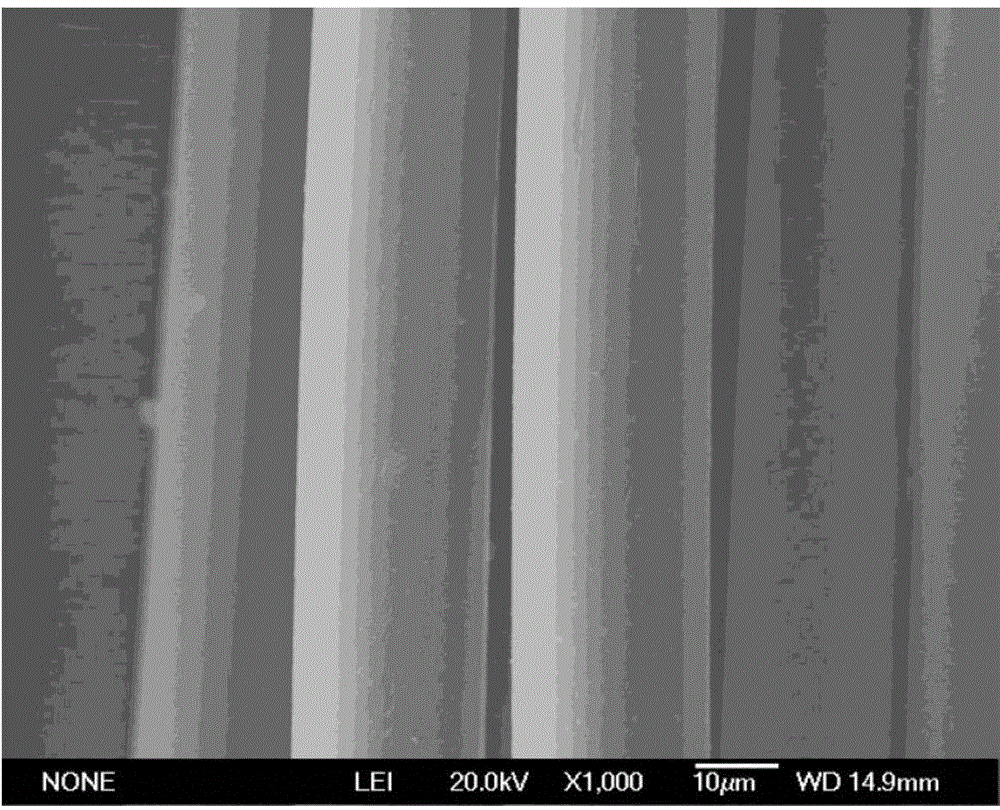

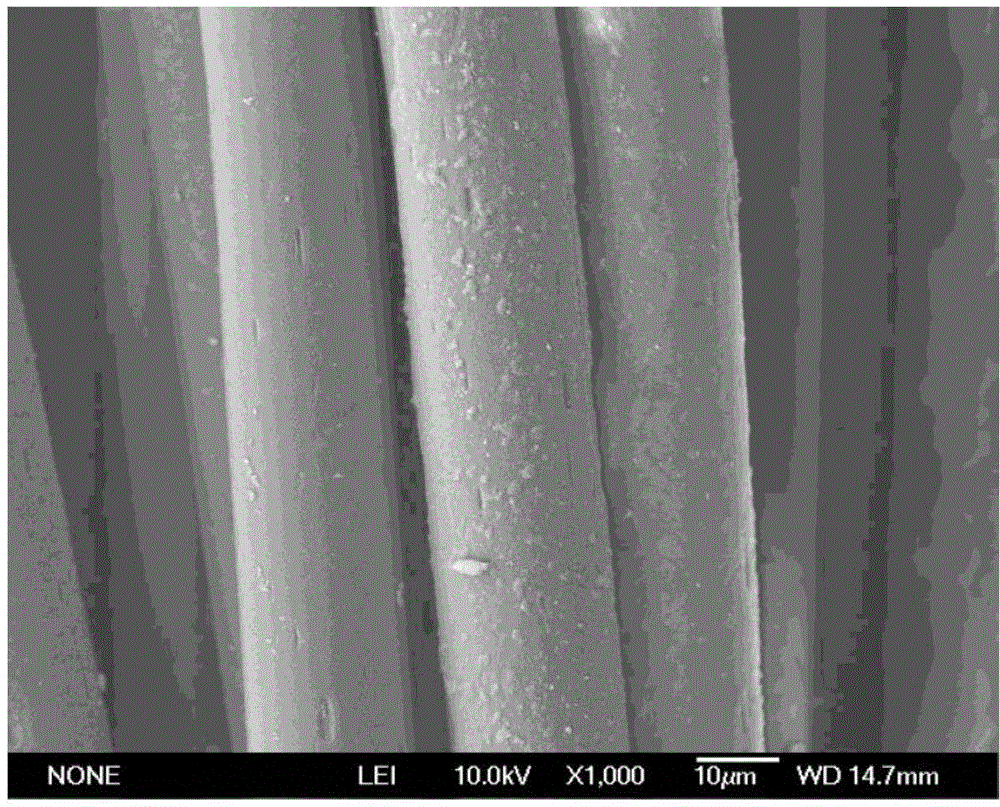

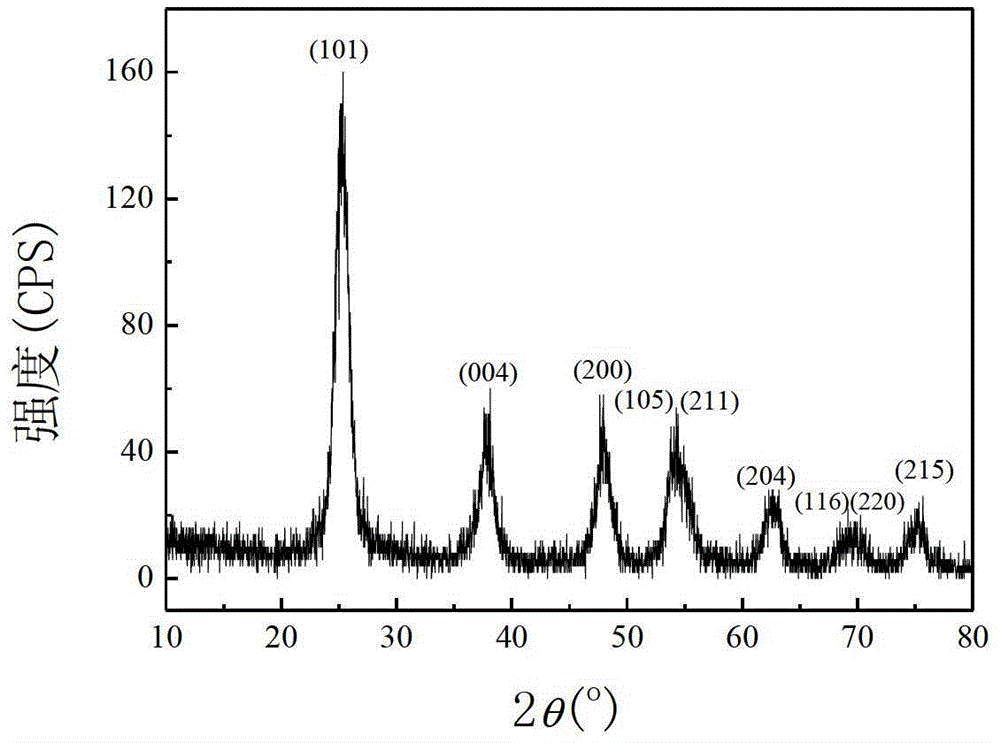

Method for modifying nanometer titanium dioxide polyester fiber with high photocatalytic activity

InactiveCN102912620AImprove photocatalytic activityImprove bonding fastnessFibre typesPolyesterFiber

The invention discloses a method for modifying nanometer titanium dioxide polyester fibers with high photocatalytic activity; and the method comprises the following steps of: (1) soaking the polyester fibers in a sodium hydroxide solution; etching the polyester fibers; and washing and drying the etched polyester fibers; (2) preparing a modifying solution; and modifying the etched polyester fibers by using the modifying solution; and (3) washing and drying the modified polyester fibers. Through the adoption of the method disclosed by the invention, metal ions are directly loaded on the surfaces of the polyester fibers and anatase-phase nanometer titanium dioxide films are doped on the surfaces of the polyester fibers; the modified polyester fibers obtain good photocatalytic efficiency; the spectral response ranges of the polyester fibers are enlarged; and the self-cleaning capacities of the polyester fibers are improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

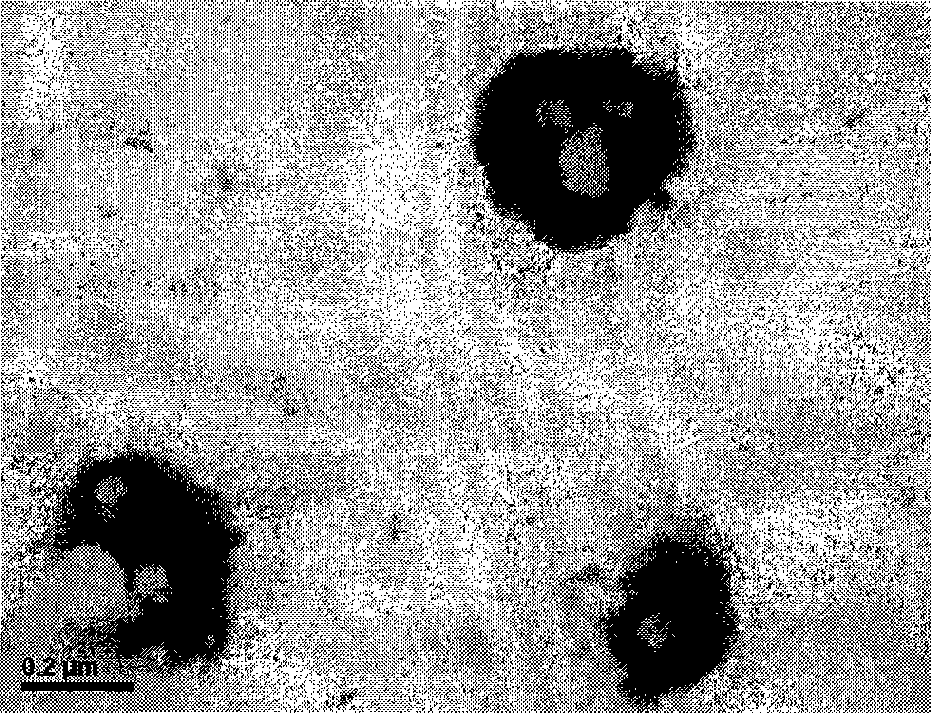

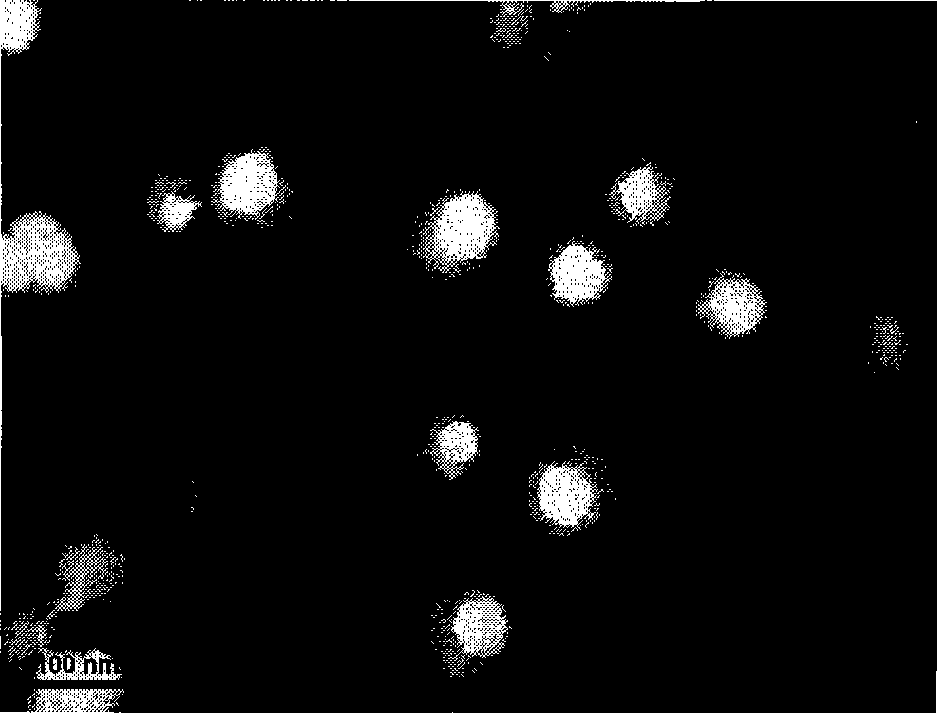

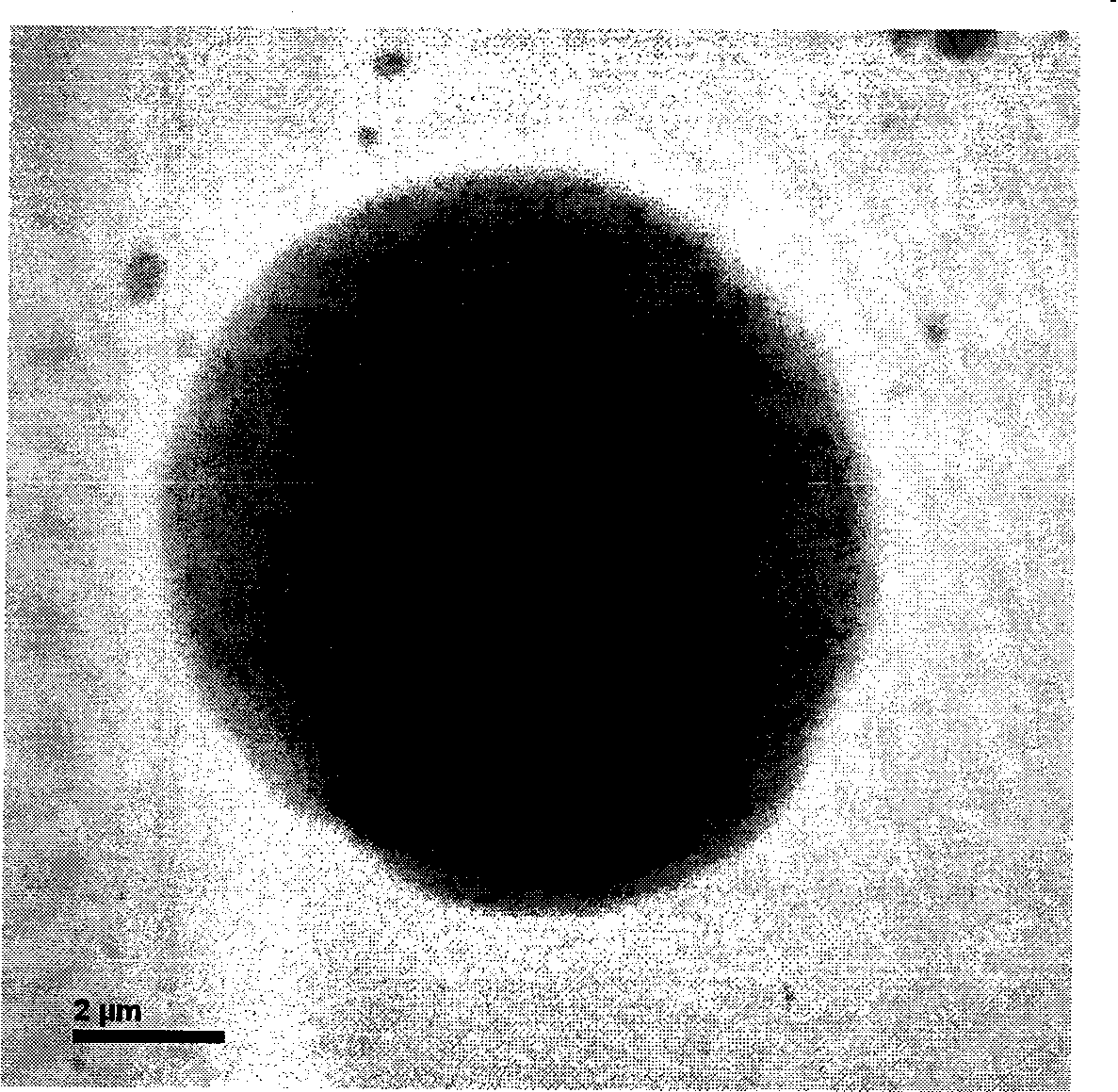

Core-shell type paint dyeing and printing adhesive agent emulsion and preparation method thereof

InactiveCN101368342AImprove bonding fastnessImprove stabilityDyeing processPotassium persulfatePolymer science

The invention discloses a method for preparing core-shell emulsion type adhesive which is modified by hydroxyl-terminated acrylic ester and is used in fabric printing and dyeing processes. The adhesive is prepared through the following steps: soft monomers copolymerize with crosslinking monomers and portions of hard monomers to produce core-shell particles; then a small portion of soft monomers and a large portion of crosslinking monomers copolymerize with hard monomers to coat the surface of the core layer, thus obtaining a shell layer and forming stable core-shell type emulsion. One or the mixture of two or more from 2-hydroxyethyl acrylate, hydroxypropyl acrylate, hydrobutyl acrylate and hydrohexyl acrylate is taken as a portion of soft monomers and crosslinking monomers; one or the mixture of two or more from hydroxylmethyl methacrylic acid, 2-hydroxyethyl acrylate methacrylic acid and hydroxypropyl methacrylic acid is taken as a portion of hard monomers and crosslinking monomers; one from butyl acrylate, ethyl acrylate and 2 ethylhexyl acrylate is taken as main soft monomers; one or the mixture of two or more from methyl methacrylate, crylic acid, cinnamene, acrylonitrile and methacrylic acid is taken as the hard monomers; surfactant sodium dodecyl sulfate, sodium dodecyl benzene sulfonate and octyl phenol polyethylene glycol are taken as emulsifying agent; potassium persulfate or ammonium persulfate is taken as initiator; and the copolymer emulsion is produced through emulsion copolymerization. Observed by transmission electron microscopy, the particles of the emulsion have visible core-shell structure and are even in distribution; the emulsion is stable, absolutely has no formaldehyde release both during the machining and using processes; the emulsion can be used both for pigment printing and for pigment dyeing.

Owner:JIANGNAN UNIV

Manufacturing method and product for nickel screen die roll for fabric printing

InactiveCN101559662AImprove bonding fastnessExtended service lifePlate printingFoil printingDynamic balanceLaser engraving

The invention relates to a manufacturing method and a product for a nickel screen die roll for fabric printing. The process comprises the following steps: machining, electroplating, copper grinding and polishing, glue coating, description and typesetting, corrosion, and detection. The manufacturing method is characterized in that: the procedure of the description and typesetting is followed by laser engraving; the laser engraving has the concentricity jump of a calibrated printing roll less than or equal to 0.02, printing roll rotating speed of 700 r / min, dynamic balance less than 2, laser power of 20W and engraving length of 2,220 mm; the laser engraving is centrally symmetric; the shape of the nickel screen die roll is a hexagonal, square, diamond or circular mesh point die roll rotating15 degrees; mesh points are U-shaped; and a screen wall is fine and is almost perpendicular. The manufacturing method adopts a jointless laser engraving technique and a controllable corrosion process. The product has the U-shaped mesh points with a large bottom area so as to greatly improve the strength of binding with stuffed insulating rubber, prolong the service life of the die roll, and having relatively stable nickel screen aperture ratio and fewer changes.

Owner:上海希尔彩印制版有限公司

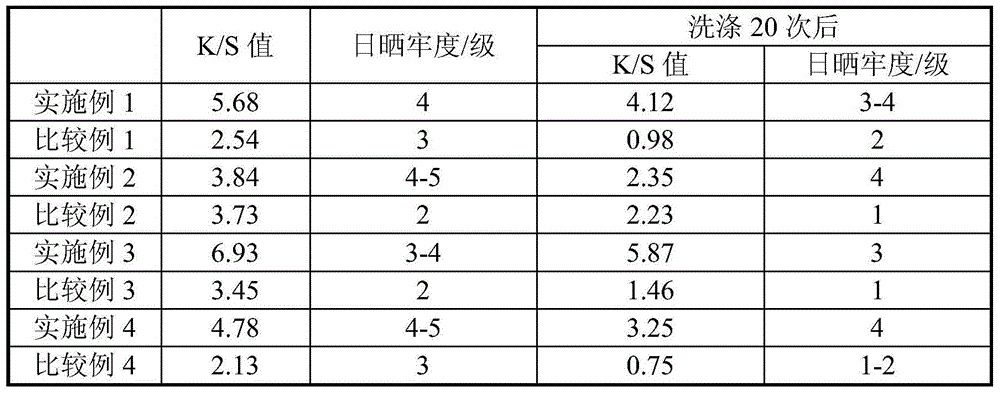

Method for improving color depth and light fastness of natural dye-dyed fabric

ActiveCN104088167AIncrease Shading DepthImprove bonding fastnessDyeing processVegetal fibresChemistryColor depth

The invention relates to a method for improving color depth and light fastness of a natural dye-dyed fabric. The method utilizes an association effect between polyvinylpyrrolidone and natural dye molecules to improve the color depth of the natural dye-dyed fabric; a polyhydric alcohol method is adopted to generate nano ZnO on the surface of the fabric in situ; the excellent anti-ultraviolet performance of nano ZnO is used for improving the light fastness of the natural dye-dyed fabric. With the adoption of the method, the color depth and the light fastness of the natural dye-dyed fabric are obviously improved and the washing-resisting performance of the natural dye-dyed fabric is good.

Owner:CHANGZHOU UNIV

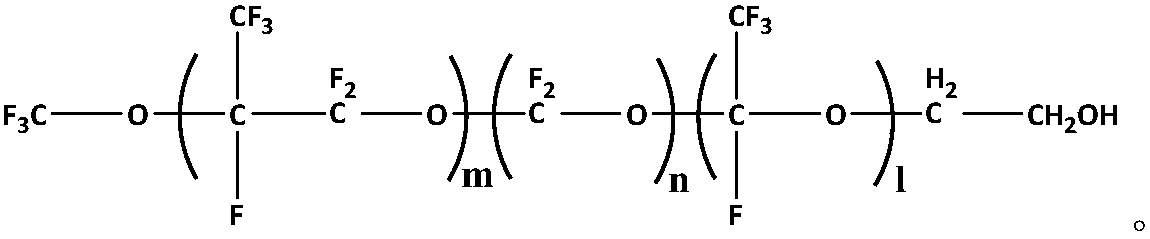

Preparation method of high-performance anti-fingerprint agent

InactiveCN107698768AStrong combinationImprove bond fastnessAntifouling/underwater paintsPaints with biocidesFingerprintWear resistance

The invention discloses a preparation method of a high-performance anti-fingerprint agent. The preparation method comprises the following steps that firstly, allyl terminated perfluoropolyether reactswith a siloxane compound containing silicon-hydrogen bonds for obtaining a perfluoropolyether silane compound containing silicon-hydrogen bonds, the obtained product reacts with methyl vinyl dichlorosilane for obtaining perfluoropolyether-silane with dichlorosilane modified terminal groups, the obtained perfluoropolyether-silane with dichlorosilane modified terminal groups reacts with allyl magnesium bromide for obtaining terminal allyl modified perfluoropolyether-silane with polyfunctional groups, the obtained terminal allyl modified perfluoropolyether-silane with polyfunctional groups reacts with methyldichlorosilane for obtaining dichlorosilane modified perfluoropolyether-silane, dendritic terminal allyl modified perfluoropolyether-silane is obtained by repeated reaction; and then theobtained dendritic multi-functional perfluoropolyether-silane reacts with a siloxane compound containing silicon-hydrogen bonds for obtaining the dendritic perfluoropolyether alkoxy silane compound with polyfunctional groups. The anti-fingerprint agent prepared by the method provided by the invention has a good hydrophobic oleophobic property and excellent antifouling property, and has excellent bonding fastness to glass substrates, and the wear resistance and the durability are greatly improved.

Owner:QUZHOU FLUORIDE & SILICON RES INST

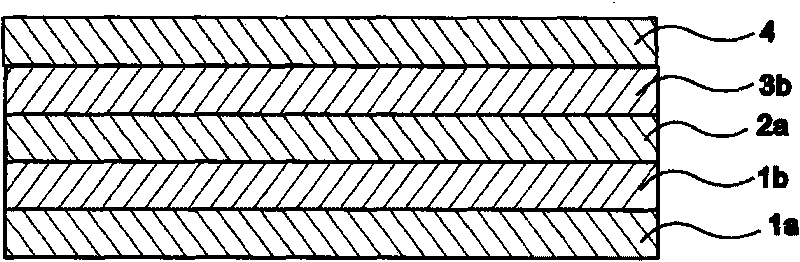

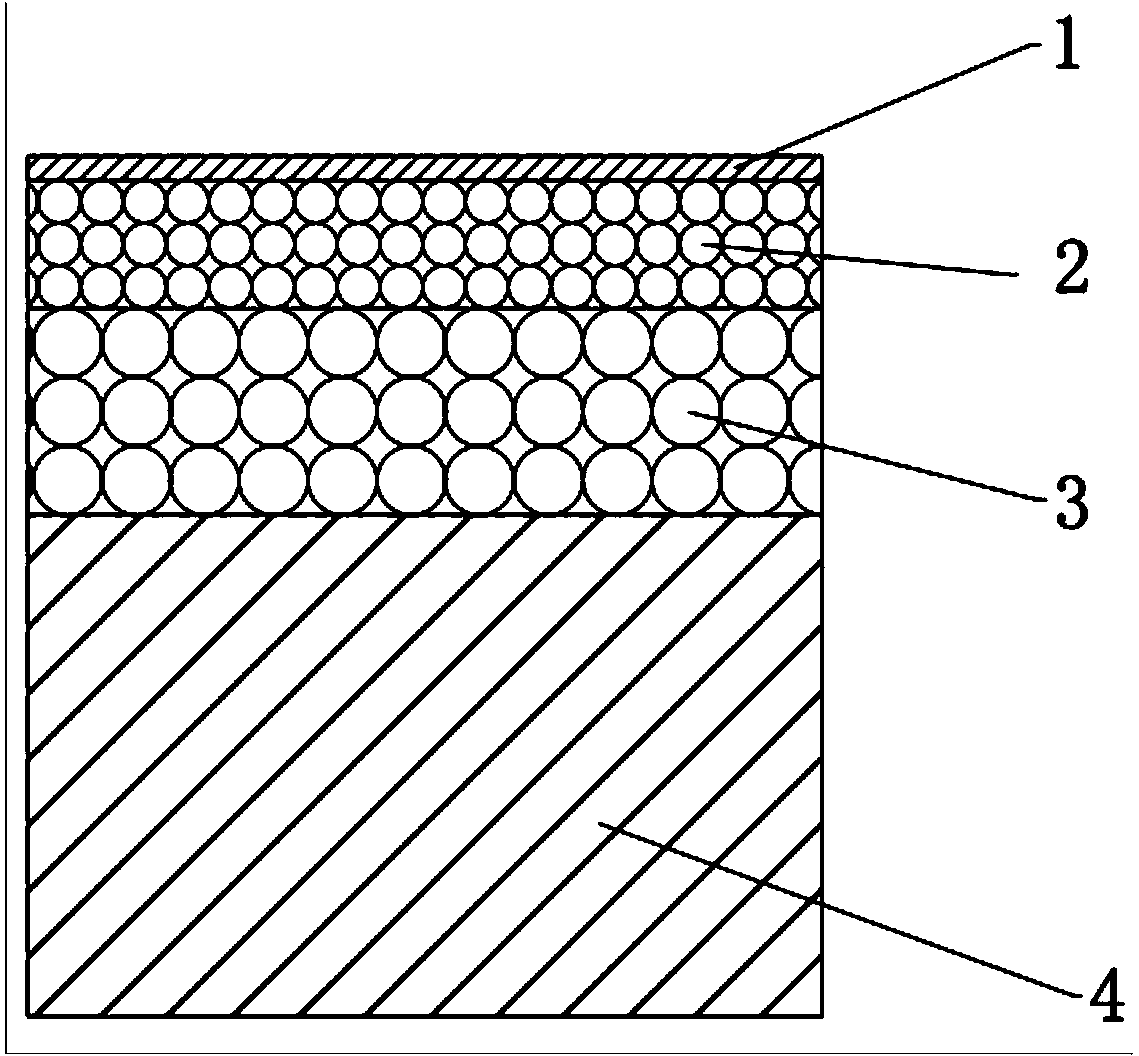

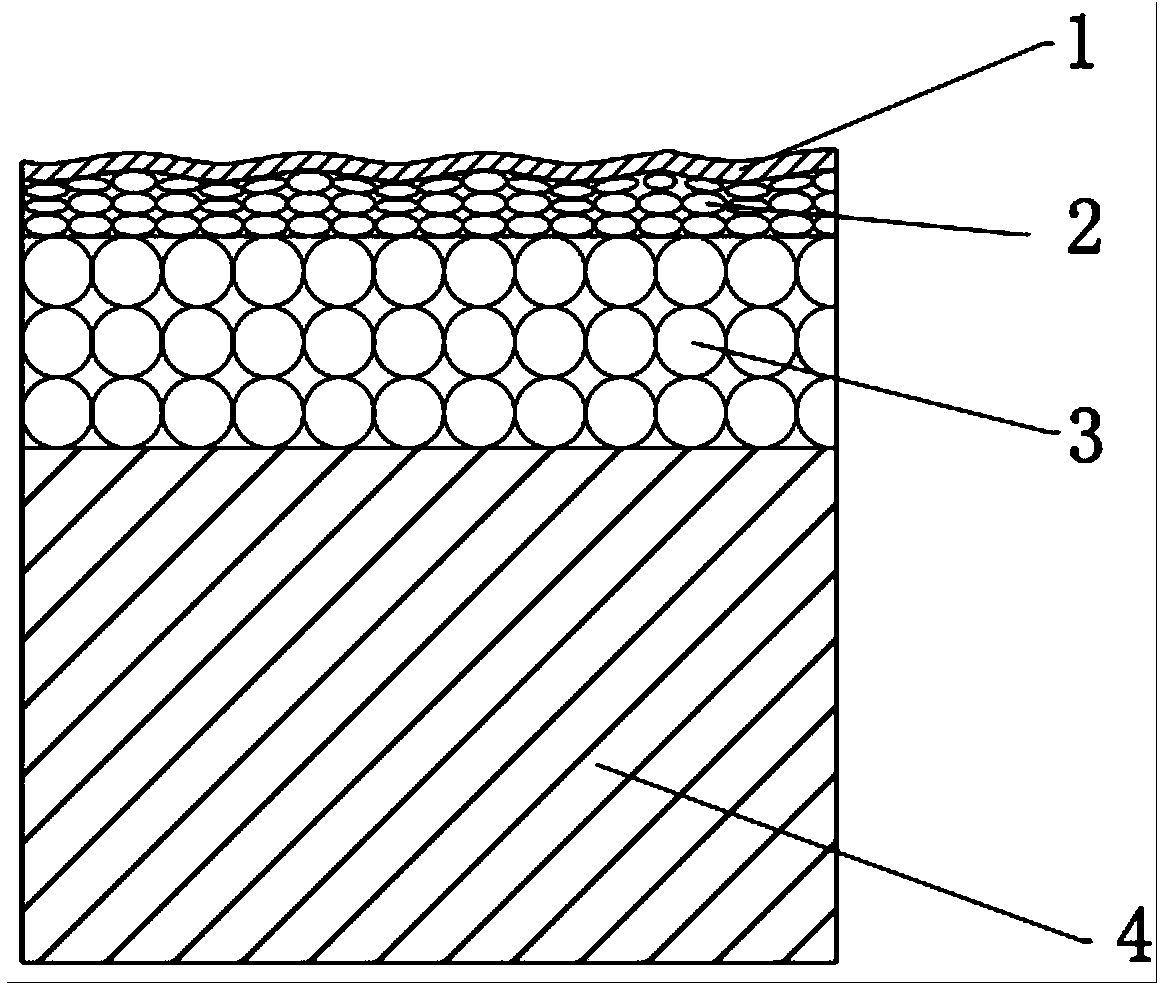

Twist-resisting polyvinyl chloride synthetic leather and manufacturing method thereof

InactiveCN102995451AGood flexibilityHas a natural and comfortable feelSynthetic resin layered productsLaminationPolyesterStearic acid

The invention discloses twist-resisting polyvinyl chloride synthetic leather which comprises a surface layer, a foaming layer, a bonding layer and fluffing cloth. The twist-resisting polyvinyl chloride synthetic leather is characterized by being prepared from the following components in parts by weight: 50-60 parts of SG-2 PVC (Polyvinyl Chloride) resin, 30-40 parts of SG-6 PVC resin, 20-25 parts of isophthalic ester, 10-15 parts of phthalic polyester, 10-15 parts of trioctyl trimellitate, 5-6 parts of PVC color cream, 1-2 parts of zinc stearate, 1-2 parts of protein powder, 20-25 parts of zinc oxide, 10-15 parts of magnesium oxide, 10-15 parts of N660 carbon black, and 5-10 parts of modified attapulgite. Through improvement of formula and process provided by the invention, the flexibility of the synthetic leather is enhanced, and the synthetic leather has a natural and comfortable handfeel similar to that of natural leather. The synthetic leather is not easy to damage or tear within 3-5 years.

Owner:HEFEI ANSHAN COATING FABRICS

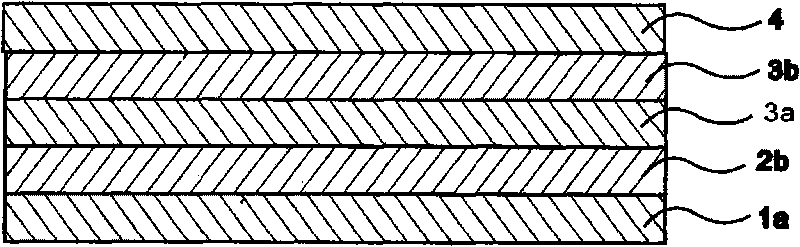

Method for preparing embossable solvent-free synthetic leather

ActiveCN104032587AHigh resistance to aging and hydrolysisReduce the amount of sizingLaminationLamination apparatusProduction linePolymer science

The invention discloses a method for preparing embossable solvent-free synthetic leather. The method comprises the following steps: (a) preparing an embossable solvent-free synthetic leather dry-method half-finished product, namely, uncoiling a piece of release paper, coating a surface layer, drying, cooling, coating a thermoplastic foaming middle layer, drying, cooling, coating a thermoplastic foaming adhesive bottom layer, pre-drying, semi-crosslinking, semi-foaming, adhering to a substrate, cross-linking, solidifying, and peeling off the release paper, so as to obtain an embossable solvent-free synthetic leather dry-method finished product; and (b) embossing and performing aftertreatment, namely, uncoiling the embossable solvent-free synthetic leather dry-method finished product, embossing, and performing other aftertreatment, so as to prepare an embossable solvent-free synthetic leather finished product. The made synthetic leather is of a two-layer foaming structure, the upper layer is a relatively thin thermoplastic foaming middle layer which can be softened, cooled and reformed and deforms at certain temperature, so that the synthetic leather has the characteristic of embossability; the lower layer is a relatively thick thermoplastic foaming bottom layer which can show main physical properties and the hand feeling of the synthetic leather. The synthetic leather can be produced by using an ordinary synthetic leather production line.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

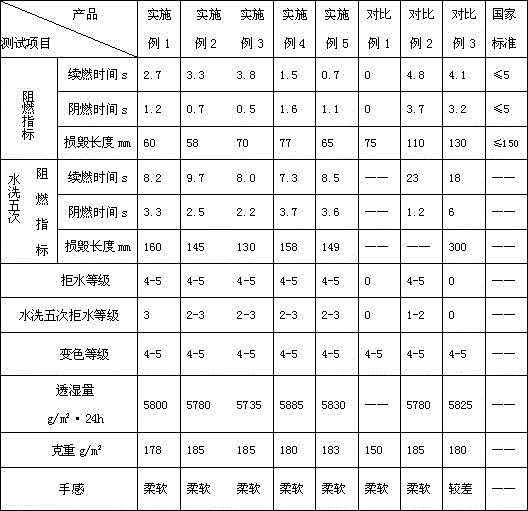

Durable flame-retardant, water-repellent, waterproof and moisture permeable finishing method of polyester fabric

ActiveCN106049049AEffective Flame RetardancyDoes not affect flame retardancyFireproof paintsHeat resistant fibresPolyesterAdhesive

The invention relates to a durable flame-retardant, water-repellent, waterproof and moisture permeable finishing method of a polyester fabric. A flame-retardant and water-repellent finishing agent is prepared from 20-30 parts of cyclic phosphate flame retardants, 60-70 parts of water, 1-1.5 parts of isocyanate cross-linking agents, 3-5 parts of fluorocarbon copolymer waterproof agents and 2-5 parts of NaOH with 10% mass concentration. A bottom coating adhesive is prepared from 100 parts of polyether polyurethane polymer under-coating adhesives, 5-10 parts of methylbenzene, 5-10 parts of butanone, 2 parts of isocyanate cross-linking agents, 1 part of accelerant and 25-35 parts of organic phosphorus-nitrogen flame retardants. A surface coating adhesive is prepared from 100 parts of polyether polyurethane polymer top-coating adhesives and 35-45 parts of methylbenzene. The fabric is padded, calendered, under-coated and top-coated with water repellents to achieve finishing by the flame-retardant and water-repellent finishing agent, the bottom coating adhesive and the surface coating adhesive.

Owner:DANDONG UNIK TEXTILE

Antistatic, conductive and electromagnetic shielding textile and preparation method thereof

InactiveCN101580998AImprove bonding fastnessFeel goodWeft knittingFibre treatmentTinningTextile fiber

The invention relates to an antistatic, conductive and electromagnetic shielding textile and a preparation method thereof, being characterized in that fiber filament is firstly processed by electroless plating copper in a way of continuous proceeding and then processed by electrolytic tinning to prepare conductive filament; then, the conductive filament is cut into conductive short fiber which is processed by pure spinning or blend spinning with other common textile fibers to be made into yarn, and the antistatic, conductive and electromagnetic shielding textile can be prepared by fabric manufacture as well as dyeing and finishing; or the conductive short fiber is blended with other common textile fibers and then processed into non-weaving cloth by pinprick or spunlace. The textile prepared by the invention has beautiful appearance and soft feel, and is safe to the skin.

Owner:ZHEJIANG SCI-TECH UNIV

Method for preparing antibacterial filter screen

InactiveCN101637679AAchieve antibacterial functionImprove bonding fastnessPhysical treatmentFiltration separationSputteringAir filtration

The invention discloses a method for preparing an antibacterial filter screen, belonging to a new spinning material with filter function. The new material consists of base material and films, whereinthe base material is latticed textile formed from chemical fibre by weaving, knitting or non-weaving manners, and the films with nanometer structure has an antibacterial function. The films are formedby metal or rare-earth metal antibacterial material by a low-temperature magnetron sputtering method. In order to improve the adhesion property of the films and the base material, the base material is preprocessed before sputtering, and the antibacterial target is directly sputtered on the surface of the latticed textile in preparation. The material is applicable to air filter screens and other filter fields, thereby improving the air or liquid quality and being beneficial to the health of human bodies.

Owner:JIANGNAN UNIV +1

Method for manufacturing high-performance electromagnetic wave shielding fabric

InactiveCN101302719AImprove folding resistanceImprove oxidation discolorationPhysical treatmentMagnetic/electric field screeningSputteringFolding endurance

The invention discloses a production method for a high-efficiency electromagnetic wave shielding fabric in the production of textile industries, comprises the working procedures of vacuum sputtering metallic film plating, chemical metallic film plating and protective layer applying of a fabric substrate, and is characterized in that an applied protective layer takes mixed wave absorbing materials, which comprises acrylic ester paste, carbon powder, ferrite, nano ferrite, titanium dioxide, an organic silicone softening agent and an dispersing agent, the mixed wave absorbing materials are applied onto the surface of a fabric that passes through the vacuum sputtering metallic film plating and the chemical metallic film plating through the ways of extrusion coating with a serum roller, blade coating with a knife or printing coating with a circular screen, and are solidified at high temperature. The invention has the advantages that the high-efficiency electromagnetic wave shielding fabric produced achieves the superimposed effect of electromagnetic wave reflecting and absorbing and plasma activating, improves the electromagnetic wave shielding performance further to be larger than 90 dB, simultaneously raises the combining fastness between a plated film and the fabric substrate, and improves the folding resistance of the product and the oxidative stain property of the metallic film.

Owner:SHANGHAI WEAVING SCIENCE RESEARCH INSTITUTE CO LTD

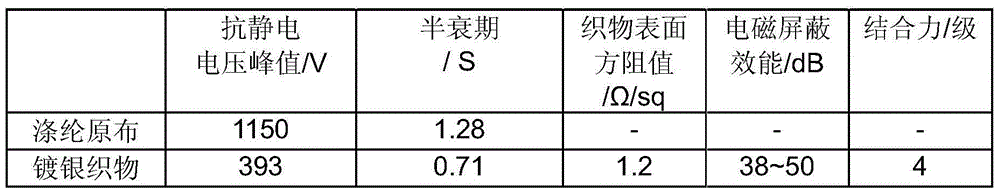

Nano silver in-situ formation silver-plating method based on plasma modification and silver-plated fabric

ActiveCN104988720AIncrease surface areaImprove wettabilityFibre typesUltrasonic/sonic fibre treatmentSilver plateSilver overlay

The invention relates to a nano silver in-situ formation silver-plating method based on plasma modification and a silver plated fabric. In the provided method, a plasma surface treatment modification technology is adopted to crack and etch the surface of synthetic fibers so as to form micro pits and fine cracks on the surface of fibers, thus the surface area of the fibers is enlarged, and the wettability of the fiber surface is improved. At the same time, the surface of the fibers is etched, and the binding strength between the metal coating and the fibers is enhanced. After the fibers are subjected to an oxygen gas plasma technology, hydrophilic and polar groups (-COOH, =C=O) are grafted on the fiber surface, thus silver ions can be adhered on the fiber surface more easily; in the presence of polyvinylpyrrolidone (PVC), sodium borohydride (NaBH4) is taken as the reducing agent to directly reduce the silver ions into nano silver particles, and a compact silver coating is in-situ generated on the etched fiber surface. The provided method has the advantages of simple technology, environment-friendliness, energy saving, and reduced cost. The silver coating on the produced silver-plated fabric is uniform and compact, the binding force between the silver coating and the fabric is strong, and the method is worth to promote.

Owner:SHANHAI CHENLONG TEXTILE NEW MATERIAL CO LTD

High copolymer pulp components for composite inorganic nanoparticles

The invention discloses a component of copolymer using in complex inorganic nanoparticles and relates to the pulp and sizing production and process technology of spinning warp sizing and paper-making glue processes. The said copolymer is a kind of ionic acrylic polymers and it is made of ionic monomers, hydrophilic monomers, acrylate monomers and few other monomers by free radical copolymerization reaction, or is made of polyacrylamide as the raw material by macromolecular chemical reaction. The said copolymer is used to prepare a new slurry component which substantial replaces PVA in the spinning warp sizing and paper-making glue processes. The said slurry contains of the mixture in a proportion of 0.1-50 % of copolymer, 0.1-50 % inorganic nanoparticles and residual water.

Owner:XUZHOU CITY ZHONGHENG FINE CHEM TECH

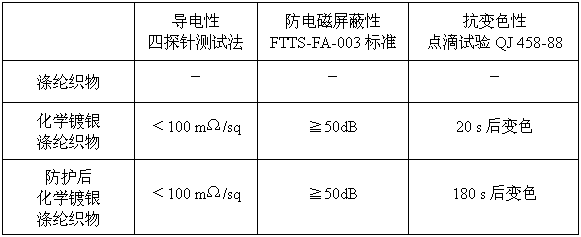

Silver plating solution for chemical silvering of polyester fabrics, silver plating method of silver plating solution and anti-tarnishing protection method of plating layer

The invention relates to a silver plating solution for chemical silvering of polyester fabrics, a silver plating method of the silver plating solution and an anti-tarnishing protection method of a plating layer. The silver plating solution is divided into a silver salt solution and a reducing agent solution, wherein constituents and concentrations of the silver salt solution are as follows: 5 to 10g / L of AgNO3, 55 to 65mL / L of ammonia water, 15 to 25mL / L of ethidene diamine, 5 to 10g / L of sodium thiosulfate and 5 to 10g / L of potassium hydroxide; and the constituents and the concentrations of the reducing agent solution are as follows: 5 to 10g / L of glucose, 1 to 5g / L of potassium sodium tartrate, 35 to 45mL / L of ethanol, and 70 to 80mg / L of polyethylene glycol 1000. The polyester fabrics with the plating layer prepared by the invention is durable in conductivity, excellent in anti-electromagnetic shielding capacity, and good in anti-tarnishing property, thereby being applied to preparation of conductive foam, conductive adhesive tapes, conductive hasps, shielding clothes and shielding caps and the like.

Owner:SHANGHAI UNIV

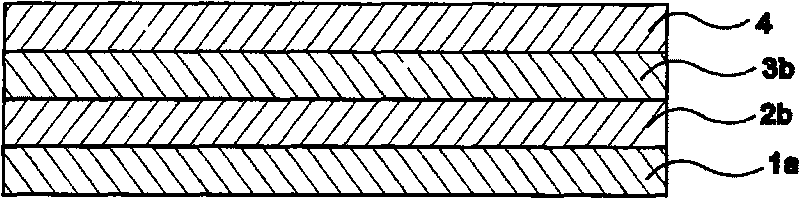

Polyvinyl chloride synthetic leather for luggage and manufacturing method thereof

InactiveCN102995450AGood flexibilityHas a natural and comfortable feelPolyureas/polyurethane adhesivesSynthetic resin layered productsSurface layerGlycerol

The invention discloses polyvinyl chloride synthetic leather for a luggage. The leather comprises a surface layer, a foaming layer, a bonding layer and fluffing cloth. The surface layer is slurry prepared from the following raw materials in parts by weight: 40-50 parts of SG-3 PVC (Polyvinyl Chloride) resin, 70-80 parts of SG-5 PVC resin, 30-35 parts of glycerol triacetate, 10-15 parts of epoxidized soybean oil, 20-25 parts of glycerol triglycerate, 5-6 parts of PVC color cream, 1-2 parts of bimercapto iso-octyl acetate di-n-octyl tin, 5-10 pats of zinc oxide and 5-10 parts of modified attapulgite. Through improvement of formula and process provided by the invention, the flexibility of the synthetic leather is enhanced, and the synthetic leather has a natural and comfortable handfeel similar to that of natural leather. The synthetic leather is not easy to damage or tear within 3-5 years, and suitable for use in lug gages.

Owner:HEFEI ANSHAN COATING FABRICS

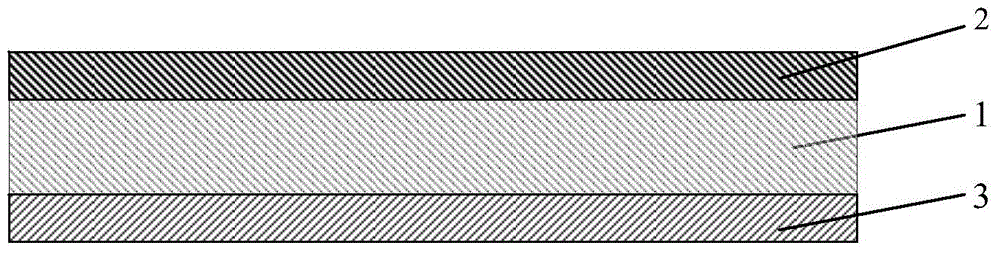

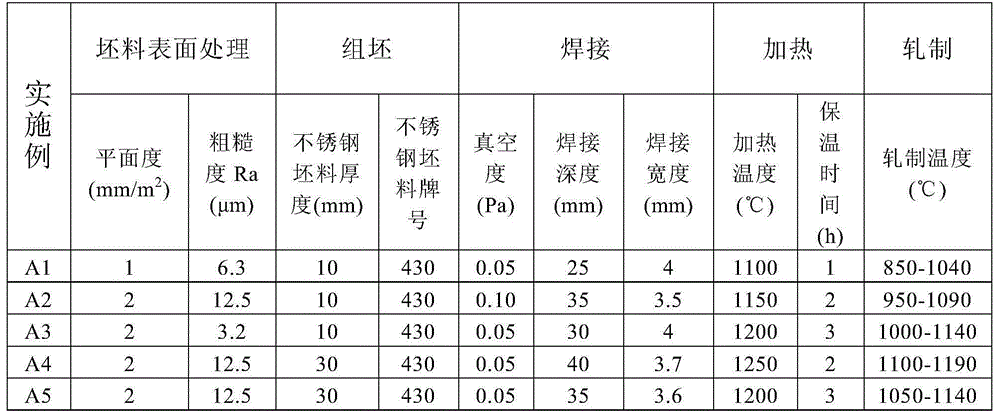

Steel plate for concrete precast element production line mould platform surface and manufacture method of steel plate

ActiveCN104786582AImprove composite effectHigh strengthAuxillary arrangementsMetal rolling arrangementsMechanical propertyAustenitic stainless steel

The invention provides a steel plate for a concrete precast element production line mould platform surface and a manufacture method of the steel plate. The steel plate for the mould platform surface comprises a carbon steel base material layer and a stainless steel composite layer(s) compounded on the upper surface or / and the lower surface of the carbon steel base material layer; the carbon steel base material layer and the stainless steel composite layer(s) are combined through the manner that atoms in the carbon steel base material layer and atoms in the stainless steel composite layer(s) mutually diffuse towards adjacent layers. The steel plate for the mould platform surface is formed by compounding ferritic stainless steel with extremely high magnetic conductivity and an ordinary carbon steel plate, and is good in corrosion resistance, excellent in wear resistance, good in machinability, high in solderability, good in forming property, excellent in both thermal conductivity and magnetic conductivity, high in mechanical strength and excellent in other comprehensive mechanical properties, the manufacture cost of the mould platform is effectively reduced and the service life of the mould platform is prolonged.

Owner:BAOSHAN IRON & STEEL CO LTD +1

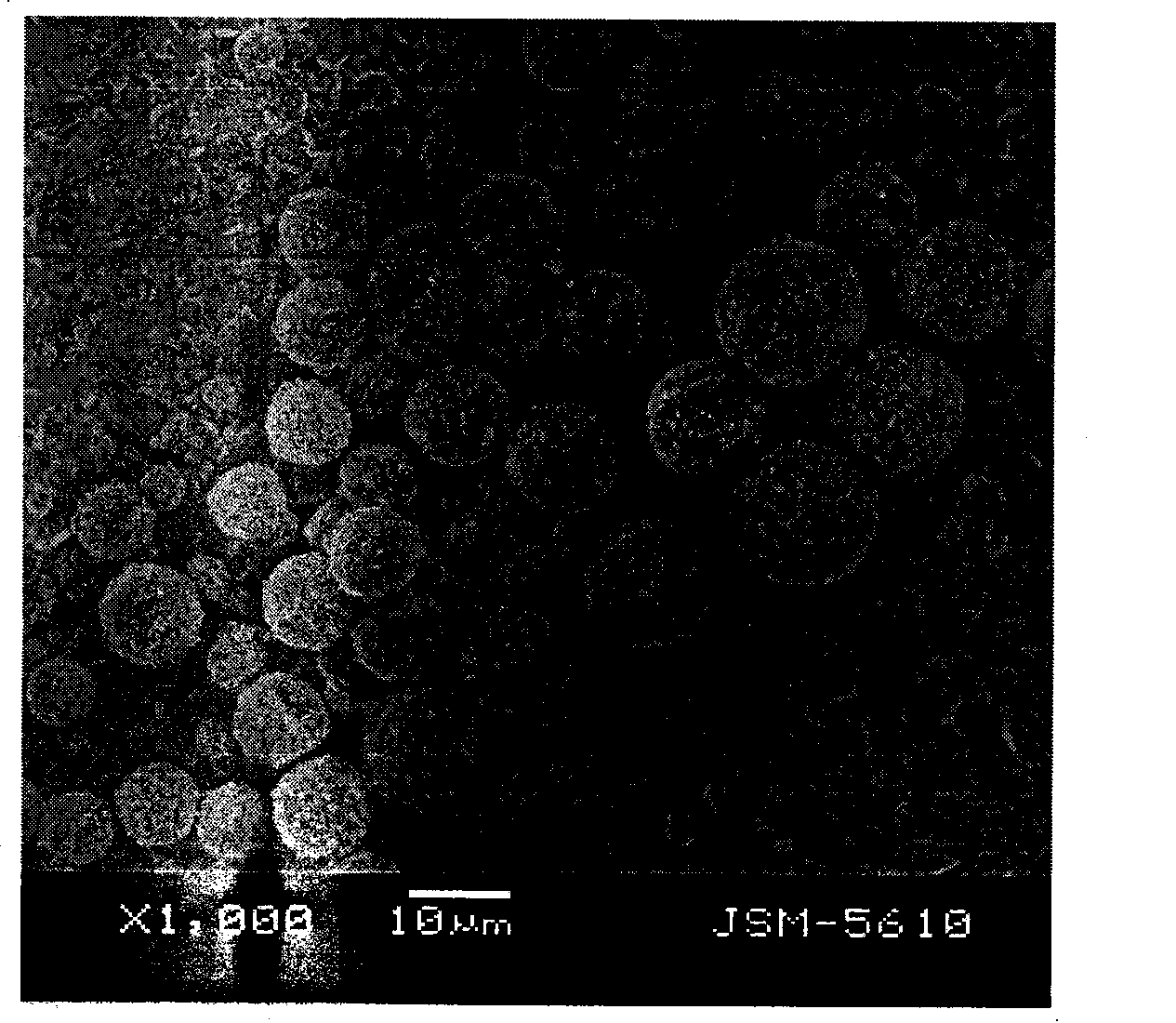

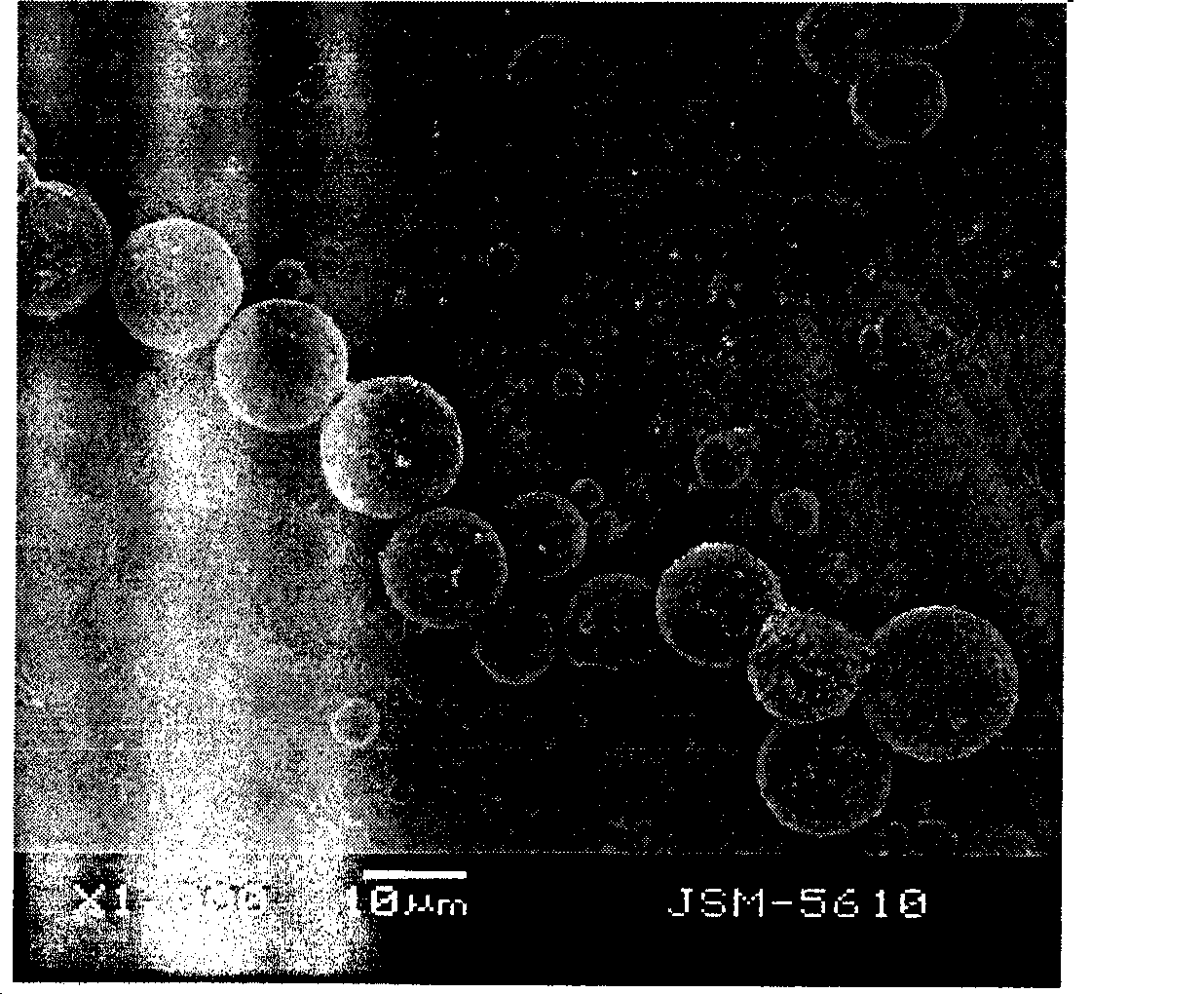

Preparation method of self-adhesive organic pigment microcapsules for pigment printing

ActiveCN101531830AImproves dispersibility and dispersion stabilityImprove hand feel and color fastnessOrganic dyesDyeing processSolventCyanine

The invention discloses a preparation method of self-adhesive organic pigment microcapsules for pigment printing; organic pigment cyanine green, reaction mixed monomer A and oil-soluble evocating agent dibenzoyl peroxide are uniformly dispersed in a water phase with the effect of dispersing agent magnesium hydrate; after polyreaction for 4h in an atmosphere of CN2 at the temperature of 65 DEG C, suspended dispersion liquid of composite microspheres is formed. Then, reaction monomer B is dropped in the dispersion liquid to carry out polyreaction for 3h in an atmosphere of nitrogen at the temperature of 80 DEG C, and organic pigment cyanine green microcapsules are obtained by normal temperature cooling, acid cleaning, water scrubbing, filtering and drying. The prepared cyanine green microcapsules can be directly in physical and chemical combination with fabric without using bonding material in the process of pigment printing, thereby efficiently improving the dry and wet resistance crockfastness of printed fabric and increasing the fabric feeling. The method in the invention has simple technology process but no solvent pollution problem in the process, and the products after simple treatment can be directly applied to pigment printing.

Owner:ZHEJIANG SCI-TECH UNIV

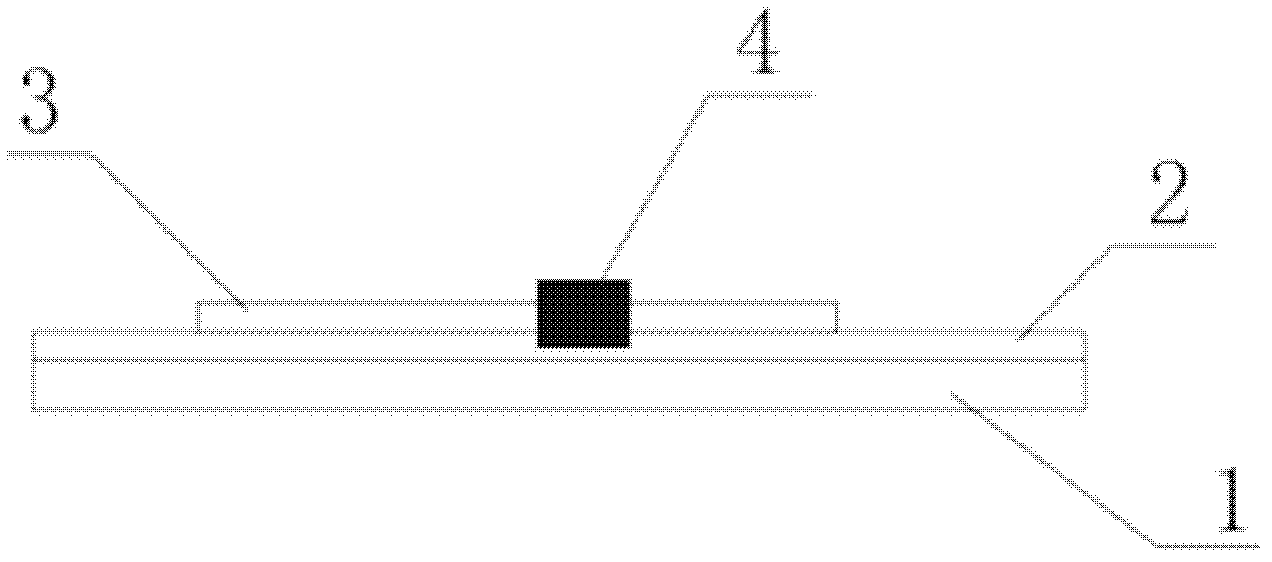

Radio frequency identification tag having diversion-proof function and manufacturing method thereof

ActiveCN102982364APrevent looseningAvoid breakingRecord carriers used with machinesEngineeringElectrical and Electronics engineering

The present invention provides a radio frequency identification tag having a diversion-proof function and a manufacturing method thereof. The radio frequency identification tag having a diversion-proof function is formed of a support layer, a release layer, antennas and a chip; the release layer is attached to one side of the support layer, the antennas are attached to the other side of the release layer, or, the antennas are attached to two sides of the support layer and the release layer, and connected through overbridge points on the antennas, and the overbridge points run through the support layer and the release layer so that antennas at two sides are switched into conduction; and the chip is bonded onto the antennas. When the diversion-proof RFID tag is stripped or diverted, the physical structure thereof is damaged, information contained therein cannot be read, so as to achieve the purpose of being incapable of reuse. At the same time, a thermally curable resin is organically combined according to the fabrication process of the RFID tag, so that high bonding fastness is provided between the bonding point of the chip as well as the overbridge points and the support layer, it is uneasy for the chip to drop off due to the release layer, the overbridge effect is better, and the yield of the diversion-proof RFID tag may be greatly improved.

Owner:SHANGHAI TECHSUN ANTI COUNTERFEITING TECH HLDG +1

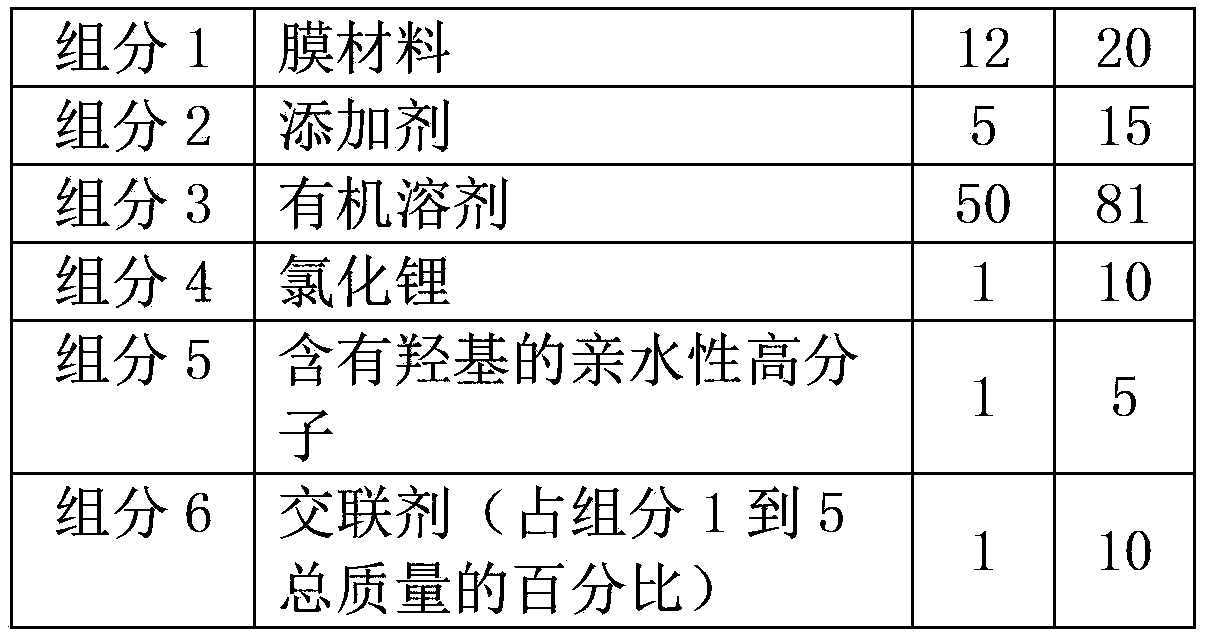

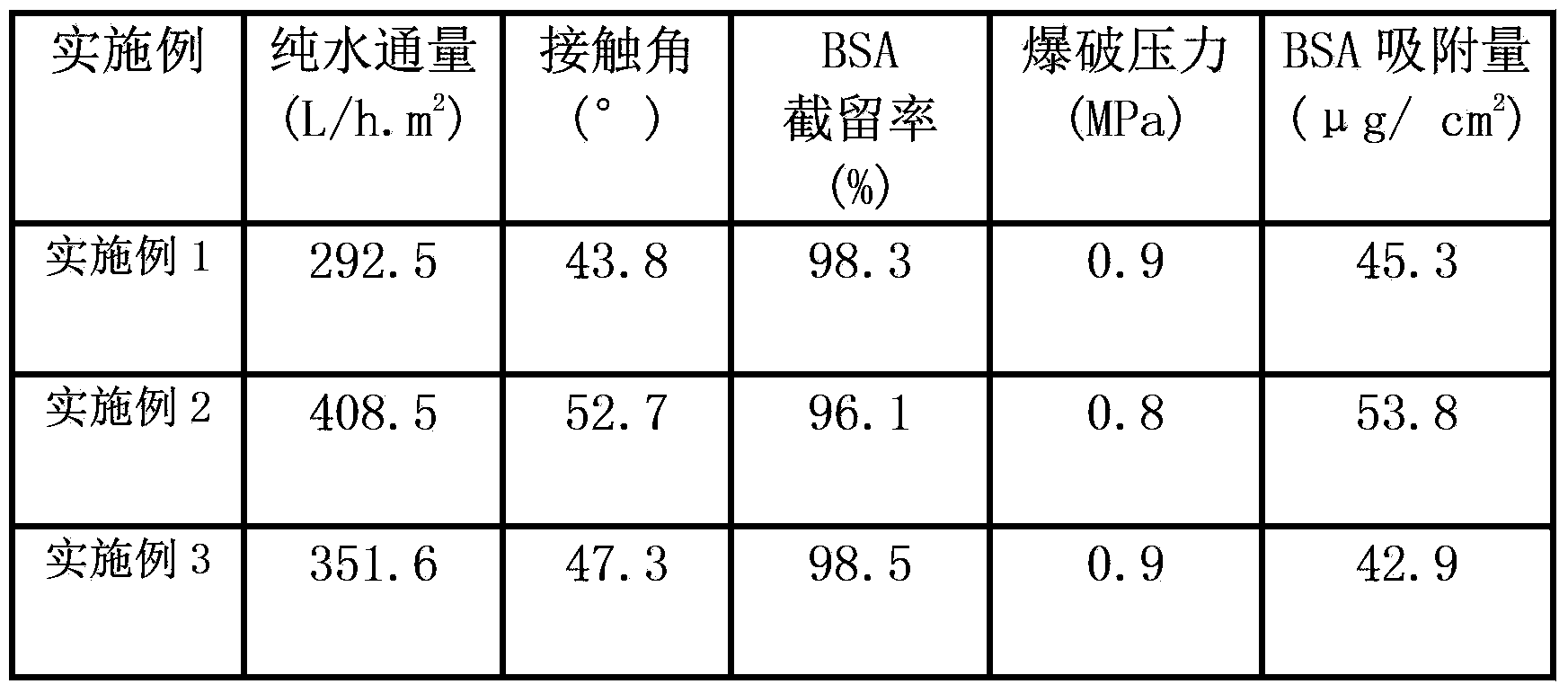

Method for preparing hydrophilic pollution-resistant composite ultrafiltration membrane by semi-interpenetrating network method

ActiveCN104248918AImprove hydrophilicityImprove mechanical propertiesSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisLithium chlorideMechanical property

The invention relates to a method for preparing a hydrophilic pollution-resistant composite ultrafiltration membrane by a semi-interpenetrating network method; a dried membrane material and an additive are added into an organic solvent, and stirred to dissolve to form a mixed solution; lithium chloride is added into the mixed solution, a hydrophilic polymer containing hydroxyl groups is also added for full swelling and dissolving, a crosslinking agent is added for crosslinking reaction, after the crosslinking reaction is completed, impurities are removed by filtering, a membrane casting solution is obtained by vacuum deaeration; a basement membrane is soaked with the crosslinking agent for pretreatment, the pretreated basement membrane is fixed on a membrane blade, the surface of the basement membrane is coated with the membrane casting solution, the basement membrane coated with the membrane casting solution is dipped into a coagulating bath for membrane formation to obtain a flat ultrafiltration composite membrane with a semi-interpenetrating network structure. The ultrafiltration membrane prepared by the method has good hydrophilicity and mechanical properties, high mechanical strength, pollution resistance and high pure water flux, and can reduce the cost of sewage treatment, and the preparation method is suitable for industrialized production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for nano composite porous netty superhydrophobic textile

InactiveCN107513863AExcellent superhydrophobic propertiesLower free energyLiquid repellent fibresVegetal fibresNanoparticleSolvent

The invention relates to a preparation method for a nano composite porous netty superhydrophobic textile; with adopting of a sol-gel method, a three-dimensional porous SiO2 aerogel is prepared through acid-base two-step catalysis, aging, solvent replacement and atmospheric drying; the SiO2 aerogel is mixed with polysiloxane to prepare a polysiloxane / SiO2 aerogel nanocomposite material; a textile is finished with the polysiloxane / SiO2 aerogel nanocomposite material by a one-step method; through cooperation of the characteristic of low surface energy of polysiloxane and a three-dimensional network nanoporous micro rough structure of the SiO2 aerogel, and combination of the crosslinked adhesion effect between polysiloxane and aerogel particles and the crosslinked adhesion effect between the aerogel particles and the textile, the durable nano composite porous netty superhydrophobic textile is obtained. The preparation method is different from a method for constructing a superhydrophobic textile through close packed arraying structure of nanoparticles, the preparation process is simple, the superhydrophobic property is excellent, stable and durable, and the product is suitable for mass production.

Owner:SHANGHAI UNIV OF ENG SCI

Method for carrying out real silk fabric anti-crease and antibacterial finishing by virtue of laccase-TEMPO process

InactiveCN105734981AImprove grafting efficiencyIncrease the amount of graftingBiochemical fibre treatmentAnimal fibresQuinoneNitrogen oxides

The invention discloses a method for carrying out real silk fabric anti-crease and antibacterial finishing by virtue of a laccase-TEMPO process. Quinones active groups are generated through catalyzing tyrosine residual groups in real silks by laccase so that chitosan molecules are grafted on the real silks; then 2,2,6,6-tetramethylpiperidine-nitrogen oxide (TEMPO) is added and is used for catalyzing chitosan and tyrosine in the real silks to generate formyl groups, so that the grafting amount and bonding firmness of the chitosan on the real silks are increased, and the real silk fabric anti-crease and antibacterial finishing is realized. The method comprises the following specific steps of: (1) catalytically oxidizing the tyrosine residual groups in the real silks by the laccase; (2) taking the chitosan and the quinones active groups in the real silks to react; (3) catalyzing the real silks by laccase-TEMPO to graft the chitosan; and (4) washing the real silks with water and then treating. Compared with traditional chemical cross-linking-process vacuum fabric anti-crease and antibacterial finishing, the method has the advantages that the grafting efficiency of the chitosan is high, enzyme treatment conditions are moderate, the real silk fabric anti-crease and antibacterial effect is relatively good and the strength of the fabric is improved.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com