Preparation method of high-performance anti-fingerprint agent

An anti-fingerprint agent, high-performance technology, applied in the field of preparation of high-performance anti-fingerprint agents, can solve problems such as performance degradation and durability problems, and achieve the effects of increased hardness, firm bonding, and excellent lubricating feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

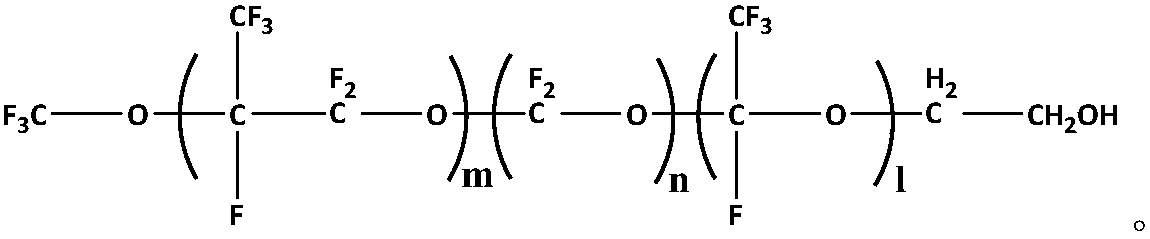

[0026] A kind of preparation method of high-performance anti-fingerprint agent of the present invention comprises the following steps:

[0027] (1): Under nitrogen protection, allyl perfluoropolyether (PFPE-CH 2 -CH=CH 2 ) in the fluoroether solution, add Pt catalyst, then add the siloxane compound containing silicon-hydrogen bond, reflux reaction for 6 to 8 hours, wash with methanol, and then remove the fluoroether solvent by distillation under reduced pressure to obtain the complete compound containing silicon-hydrogen bond Fluoropolyether silane compound (A), the structural formula is as follows:

[0028]

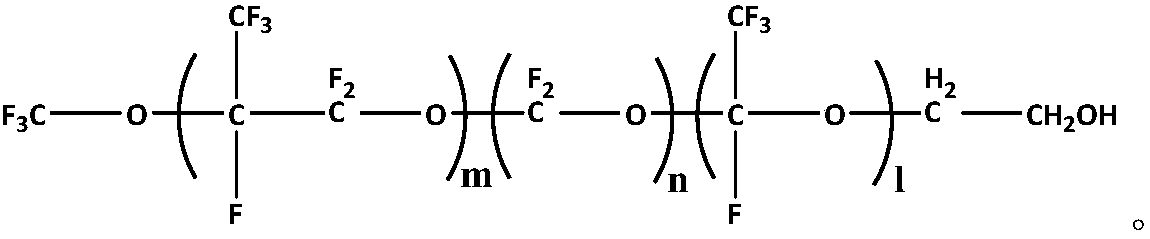

[0029] Allyl-terminated perfluoropolyether (PFPE-CH 2 -CH=CH 2 ) has a molecular weight of 2000 to 8000, and the structural formula is as follows:

[0030]

[0031] Where m is an integer of at least 1, n and l are each an integer of at least 0, and each repeating unit can be randomly combined.

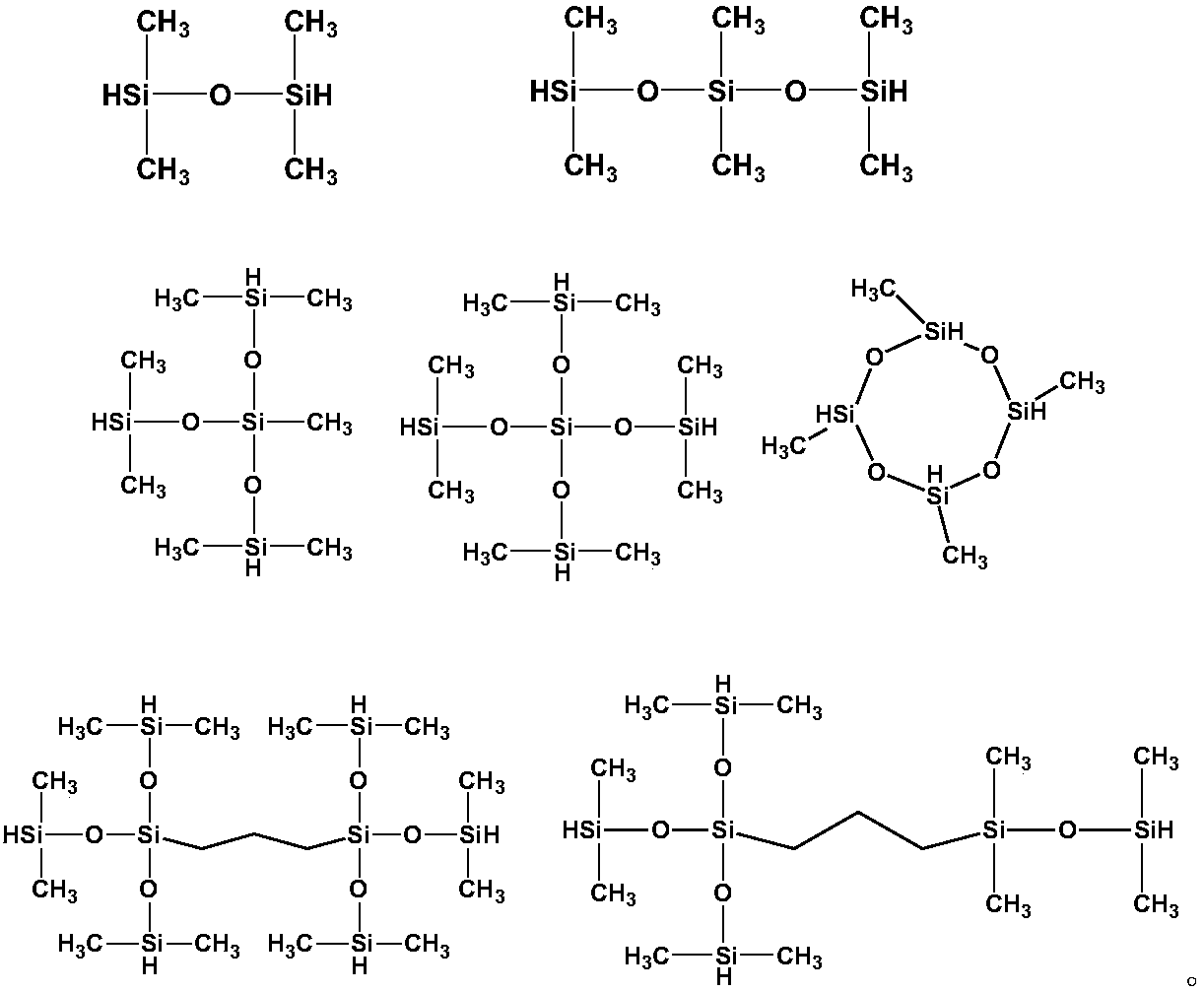

[0032] Silicon-hydrogen bond-containing siloxane compounds are on...

Embodiment 1

[0047] (1): Under the protection of nitrogen, 20g terminal allyl perfluoropolyether (PFPE-CH 2 -CH=CH 2 , the molecular weight is 2000) in the fluoroether solution (3M 7200) of adding Pt catalyst, then adding 4.92g siloxane compound containing silicon-hydrogen bond, reflux reaction for 6 hours, washing with methanol, and removing the fluoroether solvent by distillation under reduced pressure to obtain 22g contains the perfluoropolyether silane compound (A) of silicon-hydrogen bond, and the structural formula of the siloxane compound containing silicon-hydrogen bond is represented by the following formula:

[0048]

[0049] (2): Using a three-necked flask device with a reflux condenser, add 20 g of perfluoropolyether silane compound (A) containing silicon-hydrogen bonds obtained in step (1), 2.82 g of methylvinyldichlorosilane, Pt Catalyst and 100ml fluoroether solution (3M 7200), stir and mix evenly, control the temperature at 70°C, add Pt catalyst, react for 8h, wash with...

Embodiment 2

[0055] (1): Under the protection of nitrogen, 20g terminal allyl perfluoropolyether (PFPE-CH 2 -CH=CH 2 , Molecular weight is 4000) in the fluoroether solution (3M 7100) of adding Pt catalyst, then adding 2.4g siloxane compound containing silicon-hydrogen bond, reflux reaction for 7 hours, washing with methanol, removing the fluoroether solvent by distillation under reduced pressure to obtain 21g contains the perfluoropolyether silane compound (A) of silicon-hydrogen bond, and the structural formula of the siloxane compound containing silicon-hydrogen bond is represented by the following formula:

[0056]

[0057] (2): Using a three-necked flask device with a reflux condenser, add 20 g of perfluoropolyether silane compound (A) containing silicon-hydrogen bonds obtained in step (1), 4.26 g of methylvinyldichlorosilane, Pt Catalyst and 100ml fluoroether solution (Solvay HT110), stir and mix evenly, control the temperature at 70°C, add Pt catalyst, react for 7h, wash with tet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com