Portable Bucky solar battery assembly and its manufacture method

A portable, unit cell technology, applied in the field of solar cells, can solve the problems of inability to carry, the battery is bulky, and cannot be moved, and achieves the effects of easy folding and unfolding, novel product structure, and firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

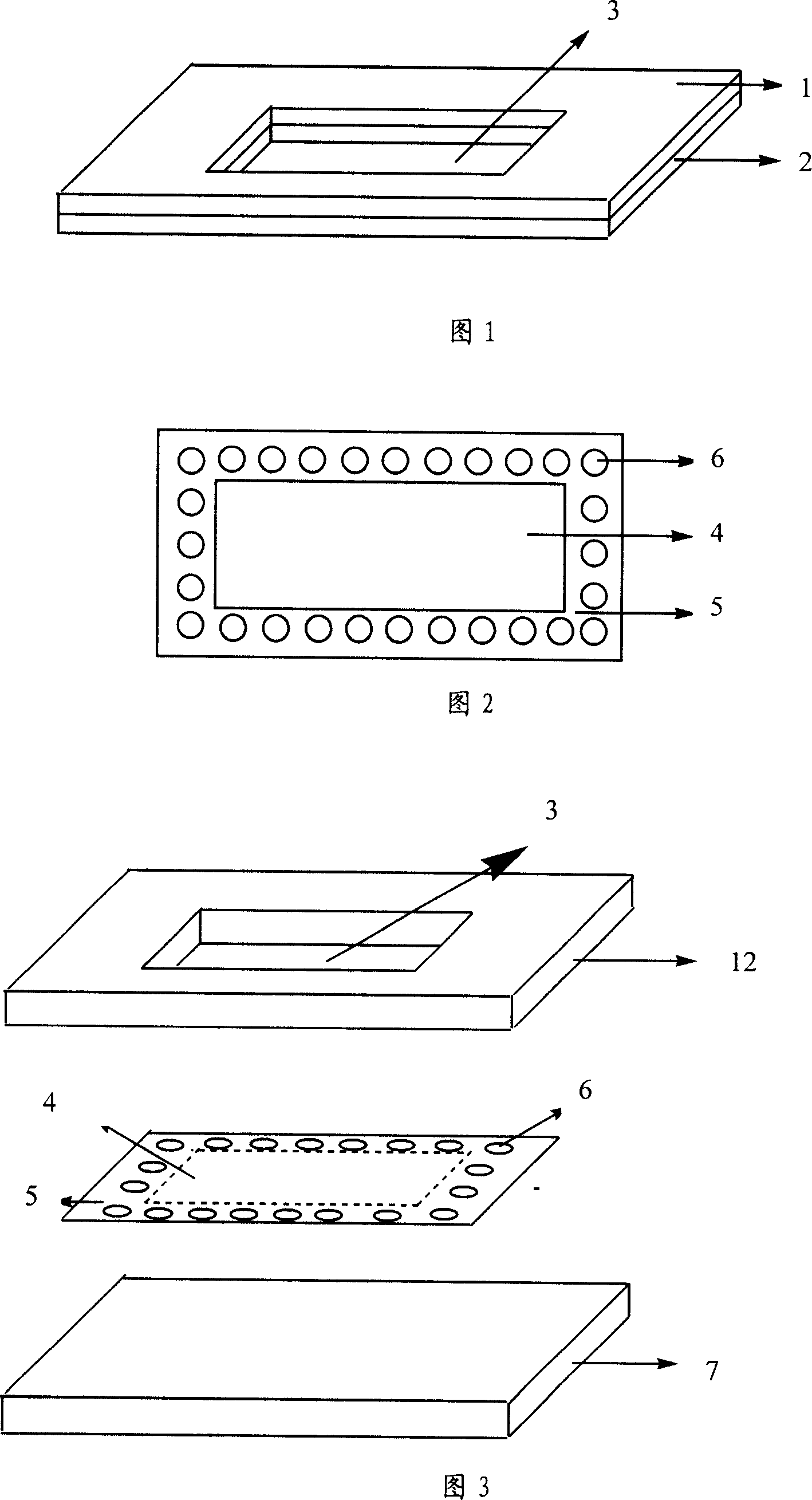

[0044] Referring to Figures 1-5, the preparation process is as follows:

[0045] 1) Prepare a composite layer of cloth 1 and polymer film 2 on a laminator, and control the temperature to melt the polymer film.

[0046] 2) Cut out the hole 3 in the upper layer of cloth or cloth / polymer film composite layer corresponding to the light-receiving part of the unit cell (see Figure 1); if the upper layer only has polymer film, it is not necessary to cut the hole.

[0047] 3) Punch holes 6 on the fluoroplastic film 5 around the unit cells 4 that have been encapsulated with the fluoroplastic film (see FIG. 2 ).

[0048] 4) Connect each unit cell with a wire; the wire connection is sealed and protected with epoxy resin (ie, A / B glue).

[0049] 5) Stack the lower layer (cloth, polymer film or polymer film / cloth composite layer) 7, the unit cell sheet 4 and the upper layer (cloth, polymer film or Cloth / polymer film composite layer) 12 materials, so that the light-receiving part of the u...

Embodiment 2

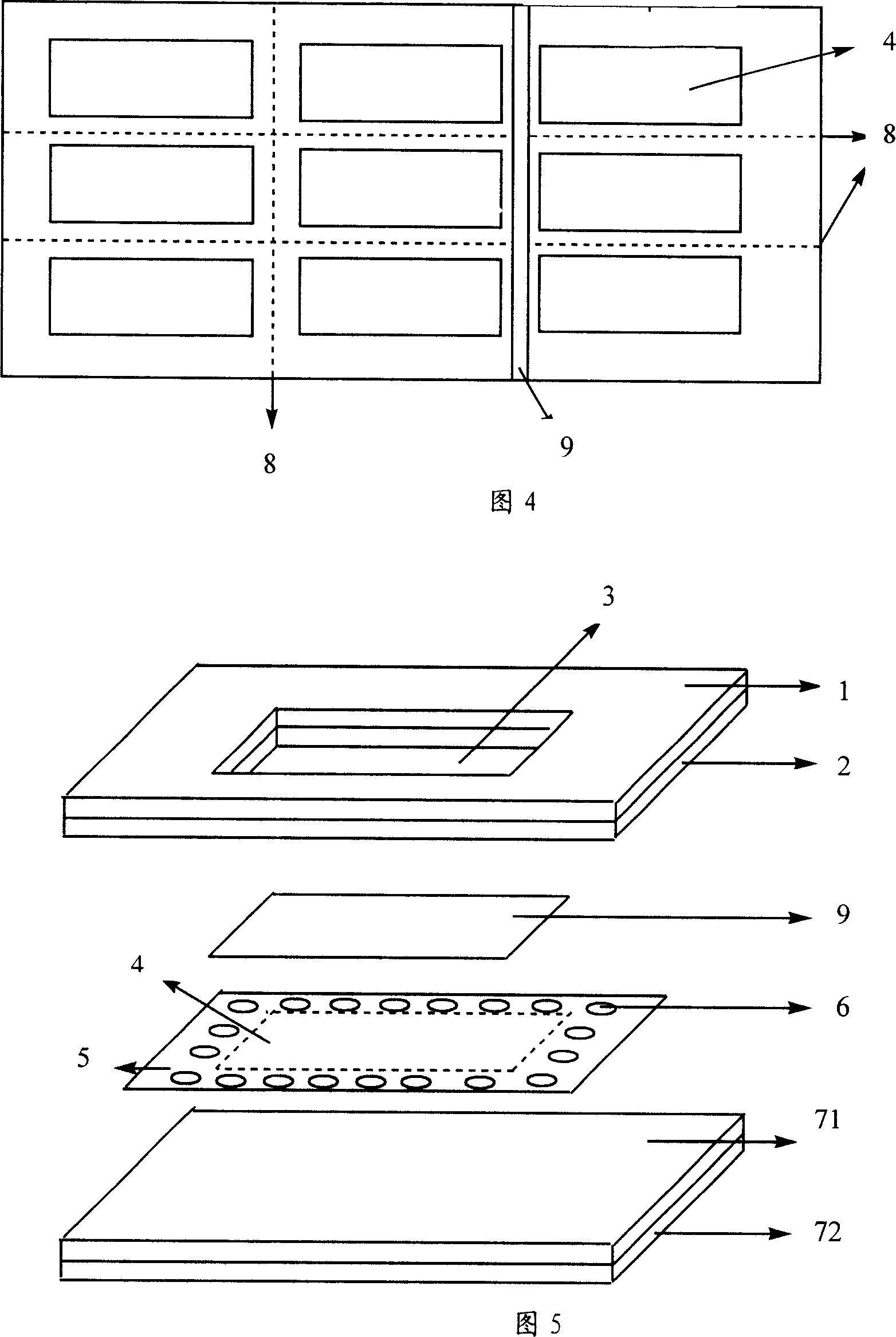

[0055] Its preparation process is similar to embodiment 1, and in embodiment 2, referring to Fig. 5, the polyester cloth (500g / cm2) that will have PU back glue 2 )1 and EVA film (containing 15% VA, cross-linking degree of 85%, thickness of 0.2mm, transparent, fast-curing type) 2 are laminated at 100°C for 3 minutes to form a composite layer in advance. Cut off half of the polyester cloth / EVA film composite layer at the light-receiving position of the corresponding unit cell to form a cavity 3 for use as the upper layer; the other half of the polyester cloth 72 / EVA film 71 composite layer is reserved as the lower layer . Drill holes 6 around the fluoroplastic film 5 of the unit cell sheet 4 encapsulated with the ETFE film. Connect each unit battery piece 4 in the assembly with a flat copper wire, and seal and protect the connection of the wires with epoxy resin (ie, A / B glue). Stack the materials from bottom to top in the following order: Polyester cloth / EVA film composite la...

Embodiment 3

[0057] Its preparation process is similar to embodiment 1, and in embodiment 3, nylon cloth (1000g / cm 2 ) and EVA film (containing 20% VA, 90% cross-linking degree, 0.5mm thick, translucent, fast-curing type) at 90°C for 5 minutes to form a composite layer in advance. Cut out the composite layer at the light-receiving position of the corresponding unit cell sheet in the nylon cloth / EVA film composite layer. Drill round holes around the fluoroplastic film of the unit cells that have been packaged with F30 film. Properly connect each unit cell in the assembly with flat copper wire, and seal and protect the wire connection with epoxy resin (ie A / B glue). Stack the materials from bottom to top in the following order: nylon cloth / EVA film composite layer-unit battery sheet-nylon cloth. Use adhesive tape to stick the light-receiving part of the unit cell. A stainless steel wire with a diameter of 3 mm is placed where the fold is required. First raise the temperature to 100°C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com