Patents

Literature

475results about How to "Strong combination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

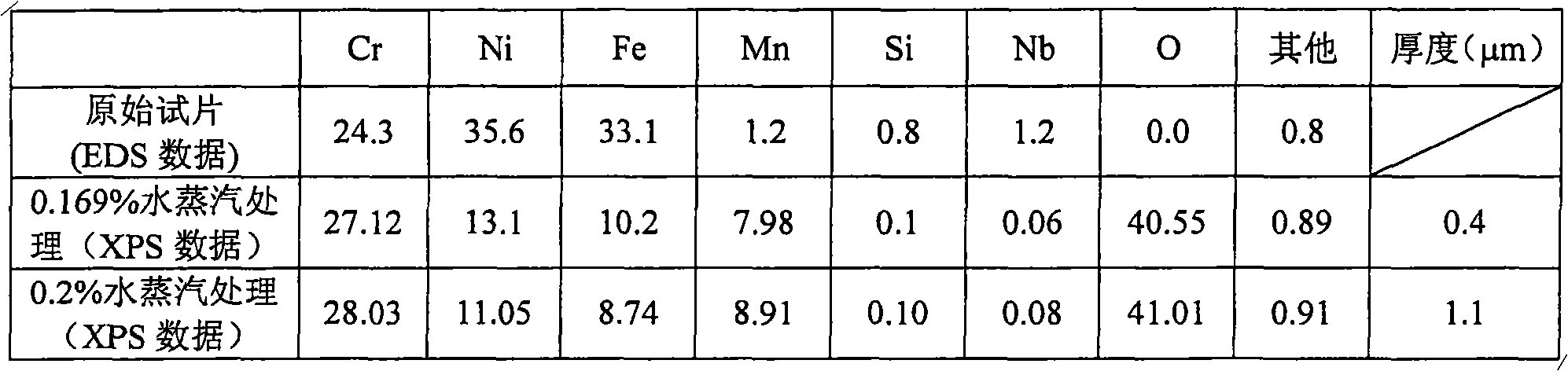

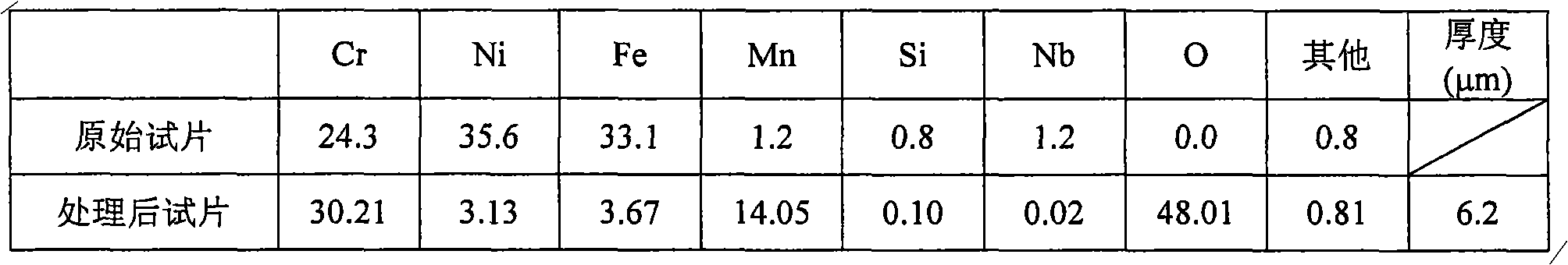

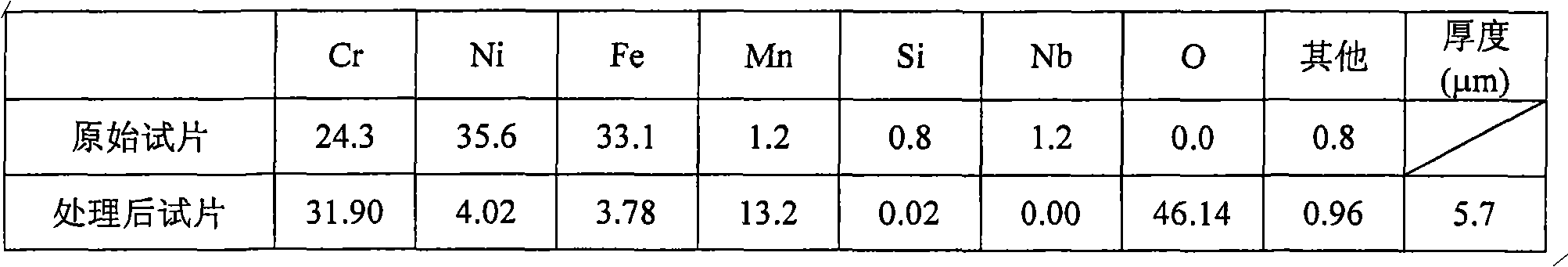

Method for processing high-temperature alloy furnace tube

ActiveCN101565807AStrong combinationMitigation of catalytic cokingSolid state diffusion coatingProduct gasMetallurgy

The invention relates to a method for processing a high-temperature alloy furnace tube, which comprises the following steps: controlling the pressure of low-oxygen partial pressure gas to 0-3 atmospheric pressure; introducing the low-oxygen partial pressure gas into an atmosphere furnace provided with the high-temperature alloy furnace tube; raising the temperature to between 600 and 1,100 DEG C; keeping the temperature for 5 to 80 hours; and forming an oxidized protective layer on the surface of the high-temperature alloy furnace tube to obtain the processed high-temperature alloy furnace tube, wherein the low-oxygen partial pressure gas comprises one or two kinds of H2 and CO, and water vapor accounting for 0.17 to 2 percent of the volume fraction of the low-oxygen partial pressure gas. The method for processing the high-temperature alloy furnace tube is adopted to process a furnace tube of a hydrocarbon cracking furnace and the like, so that the compact and stable oxidized protective layer on the surface of the furnace tube, and the requirement for long-term use can be met; and the method can inhibit or retard the phenomena of catalysis and coking, reduces the carburization degree of the furnace tube, and prolongs the decoking cycle and the service life of the furnace tube.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method for organic/inorganic hybridization cladding aluminum composite particle

InactiveCN102516831AStrong combinationGood dispersionPigment treatment with organosilicon compoundsAluminum compositesOrganosilicon

The invention discloses a preparation method for an organic / inorganic hybridization cladding aluminum composite particle, which includes mixing leafing aluminum powder and solvent alcohol evenly to be transferred to a reactor to be stirred for a period of time, then adding alcoholic solution containing an organic silicon source and an inorganic silicon source at a constant speed and mixed solution of catalyst, water and alcohol, reacting for a period of time at the constant temperature, and finally filtering, washing and vacuum drying to obtain the organic / inorganic hybridization cladding aluminum composite particle. The organic / inorganic hybridization cladding aluminum composite particle has the following advantages of being capable of scattering in hydrosolvent and the alcohol solvent well and good in compatibility with resin, keeping good metal glossy, and simultaneously having good performance for resisting acid and alkaline corrosion. The organic / inorganic hybridization cladding aluminum composite particle can be used as environment-friendly metallic pigment for water-based paint.

Owner:SUN YAT SEN UNIV

Preparation method of macroporous aluminum oxide with diplopore distribution

InactiveCN101214454AStrong combinationOvercoming low mechanical strengthCatalyst carriersCarbon blackPetroleum

A preparation method of a large-pore aluminum oxide with double-pore spread structure. First, aluminum oxide, a poreforming agent and solid silica are mixed, and receive ball-milling treatment in a ball milling machine; the mixture after treatment is kneaded into a plastic body by aqueous solution with cationic surfactant, extrusion aid, peptizator, etc. dissolved in, and put into the water vapor atmosphere to be treated; and the prepared mould is dried and baked, to obtain the final aluminum oxide carrier. The poreforming agent is one or the mixture of carbon black, cellulose and starch, and the loading is 3.0 to 15w percent of the weight of the aluminum oxide; the solid silica is silica aerogel, and the loading is 1.0 to 10w percent of the weight of the aluminum oxide; in the ball milling machine, the ball-material ratio is 15:1 to 10:1, and the ball milling time is 0.5 to 3.0h; the treatment temperature of the water vapor is 120 DEG C to 180 DEG C, and the treatment time is 0.5 to 6.0h. The aluminum oxide prepared by the invention has double-peak channel structure and high strength, and is applicable in fields of petrochemical, petroleum processing, environmental protection, etc.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

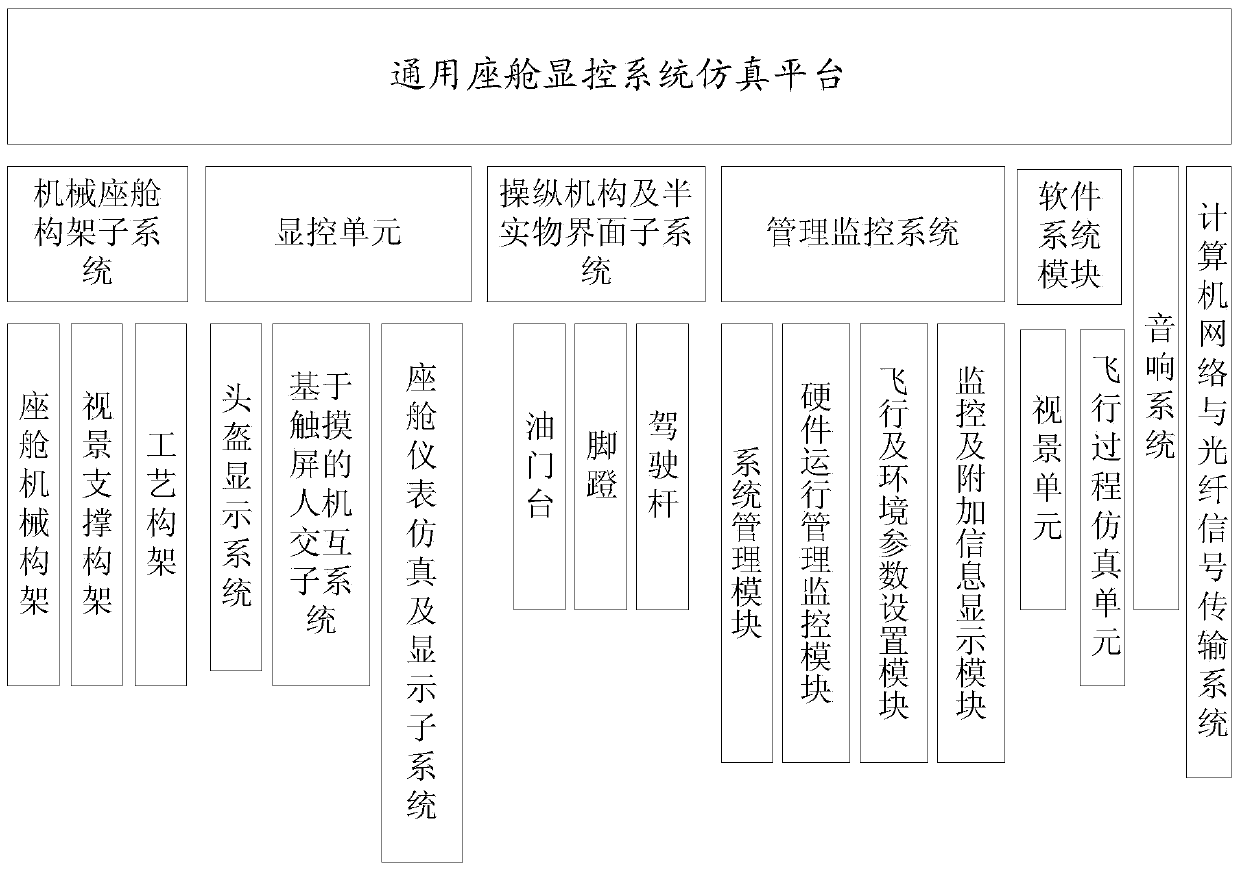

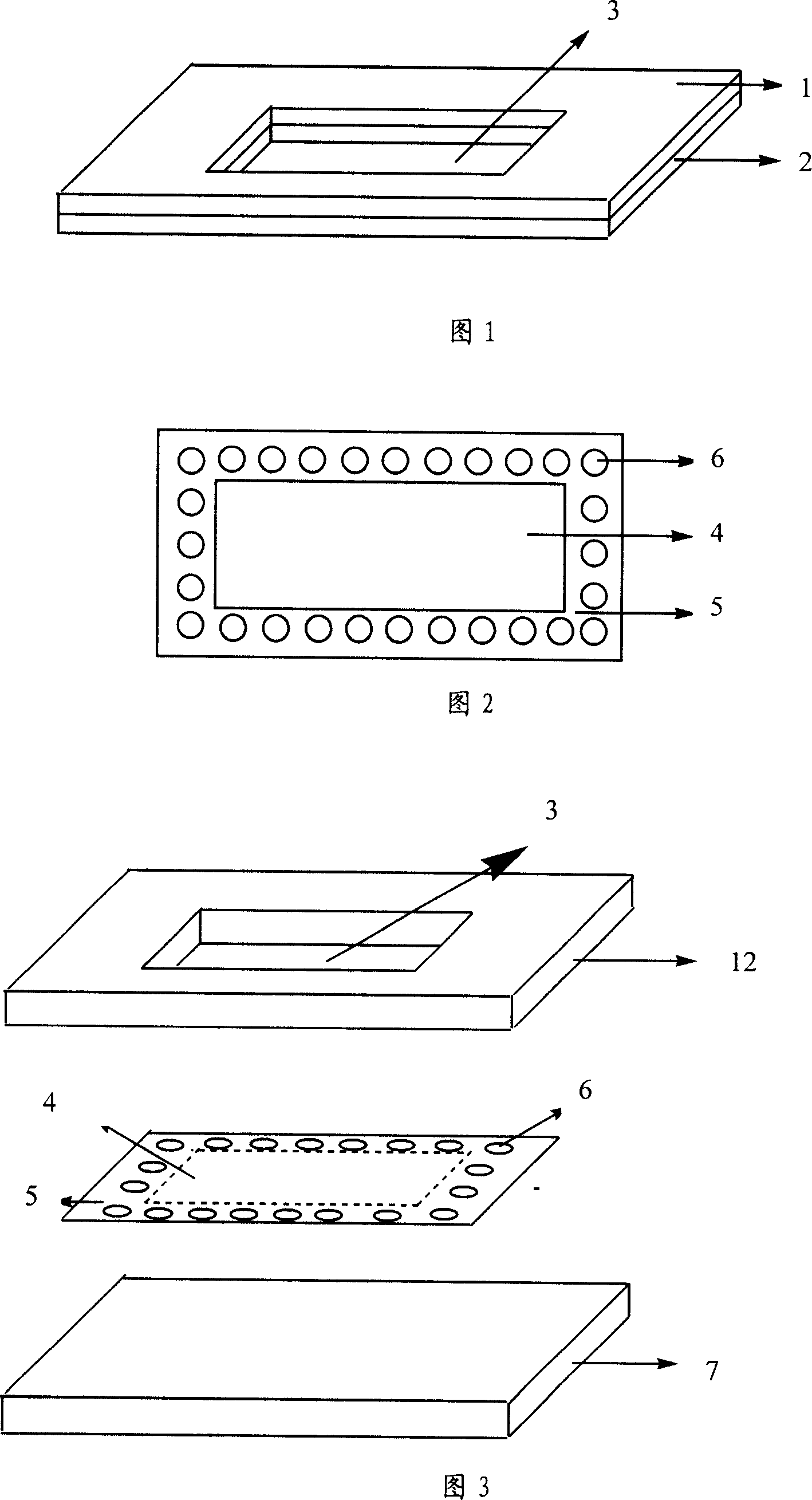

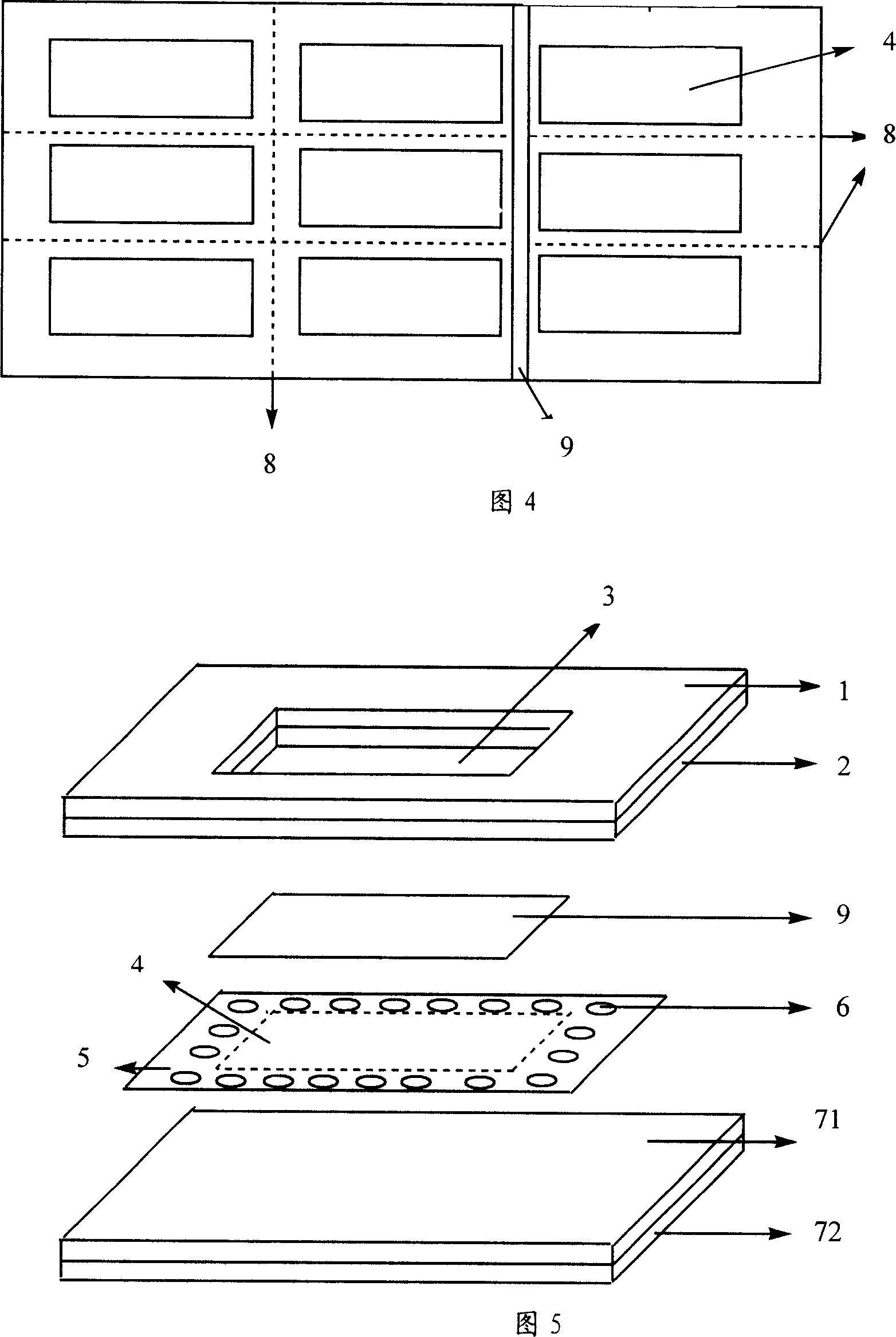

Universal simulation platform of cockpit display control system

The invention discloses a universal simulation platform of a cockpit display control system. The universal simulation platform of the cockpit display control system comprises a cockpit mechanical structure subsystem, a display control unit, a control mechanism and half-entity interface subsystem, a management and monitoring system, a software system module, an audio system, and a computer network and optical fiber signal transmission system. Through combination of the above modules, the simulation platform of the cockpit display control system has the advantages of being capable of being reconstructed, simple in structure, high in universality, high in performance-price ratio and the like. Each part is designed according to the modularized design thought and each module is provided with an independent function and a good connection interface, so that strong combination ability is achieved. A functional hierarchical structure is adopted for the software system so that higher transportability, higher configurability, and higher extensibility can be achieved.

Owner:CHINESE AERONAUTICAL RADIO ELECTRONICS RES INST

Lithium ion battery anode and preparation method thereof

ActiveCN103715394ALight in massStrong combinationCell electrodesCell component detailsCarbon nanotubeCurrent collector

The invention discloses a lithium ion battery anode and a preparation method thereof. The anode utilizes a carbon nano pipe film formed by a carbon nano pipe macroscopic pipe as a current collector, and an anode material layer is formed on the carbon nano pipe film. Compared with the traditional aluminum foil current collector anode, the lithium ion battery anode has the advantages that the weight of the lithium ion battery anode prepared by the method is light, and the anode material layer and the current collector are firmly combined. The preparation method comprises the following steps of preparing a high strength carbon nano pipe on a glass substrate by utilizing a carbon nano pipe macroscopic pipe continuum generated by a reactor port, generating the anode material layer on the carbon nano pipe film layer, separating the carbon nano pipe film layer with the anode material layer from and the glass substrate, and mounting a pole ear on a pole piece. Under the same size, the carbon nano pipe film is far lighter than the aluminum foil, the weight of the saved part can be replaced by the anode material, and the capacity of the battery is 15%-50% higher than that of a battery which takes the aluminum foil as an anode current collector. The lithium ion battery anode is low in cost, high in generation efficiency, simple in equipment, capable of realizing semicontinuous operation and suitable for mass production.

Owner:北京旭江科技有限公司

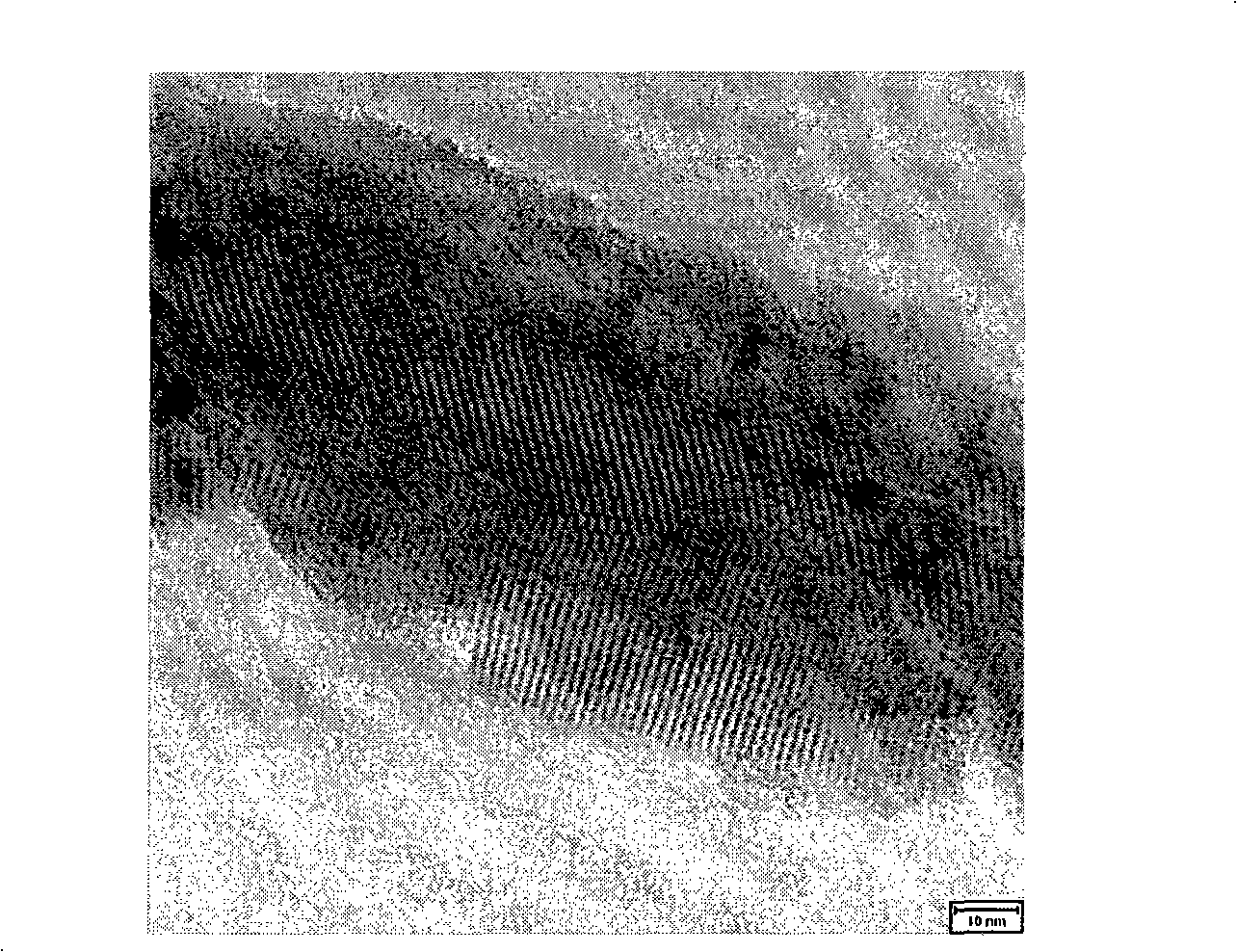

Nano-molybdenum disulfide magnetic lubricant and preparation method thereof

ActiveCN105087105AGuaranteed MagneticStable ratioMaterial nanotechnologyAdditivesLubricationMolybdenum disulfide

The invention discloses a nano-molybdenum disulfide magnetic lubricant and a preparation method thereof, and particularly relates to a nano-Fe3O4@IF-MoS2-graphene. In the lubricant, the mass ratio of Fe3O4 to IF-MoS2 to graphene is 1:(2-20):(0.02-0.5), furthermore, each component is of a specific size and structure. The preparation method comprises the following steps: firstly, dispersing nano-Fe3O4 to the surface of graphene oxide; and then, in-situ synthesizing an MoS3 precursor outside Fe3O4, and reducing and desulfurizing to obtain the nano-molybdenum disulfide magnetic lubricant. The prepared lubricant product has the advantages of high yield, good purity, good dispersion, excellent magnetism and excellent lubricity, and has important application values in the fields of precision machinery lubrication, long-term lubrication and the like.

Owner:HEFEI UNIV OF TECH

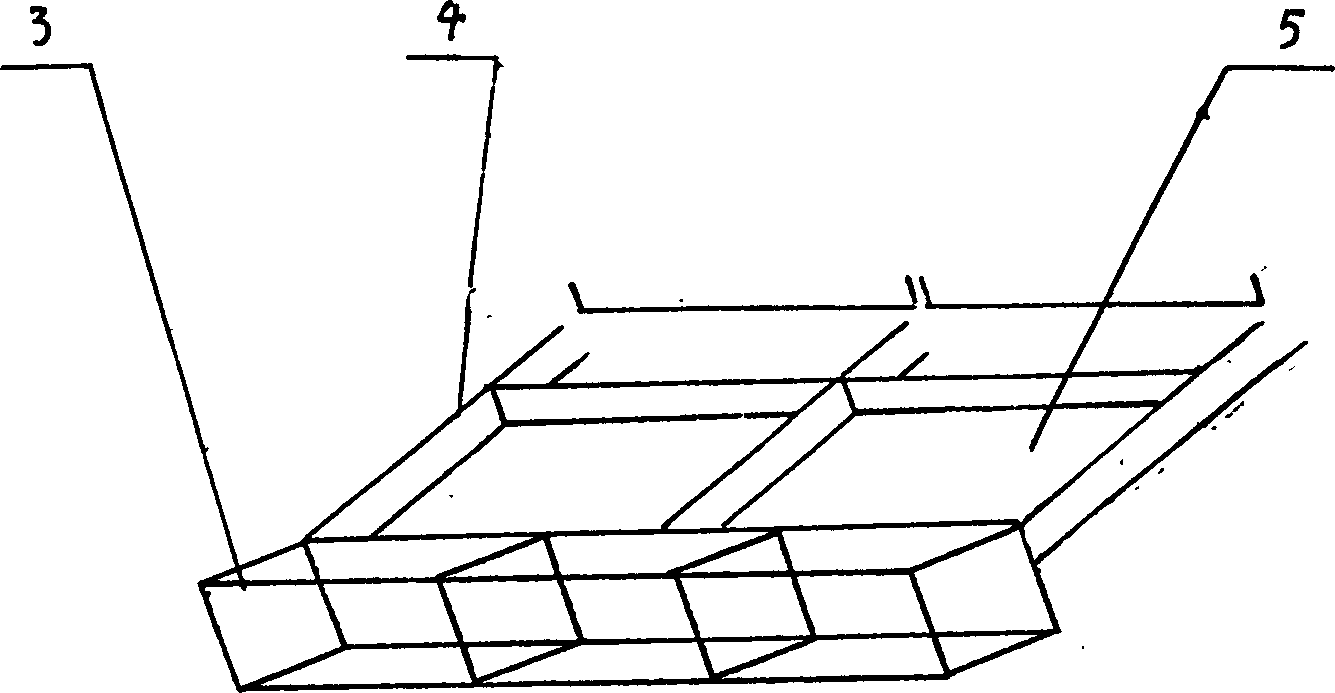

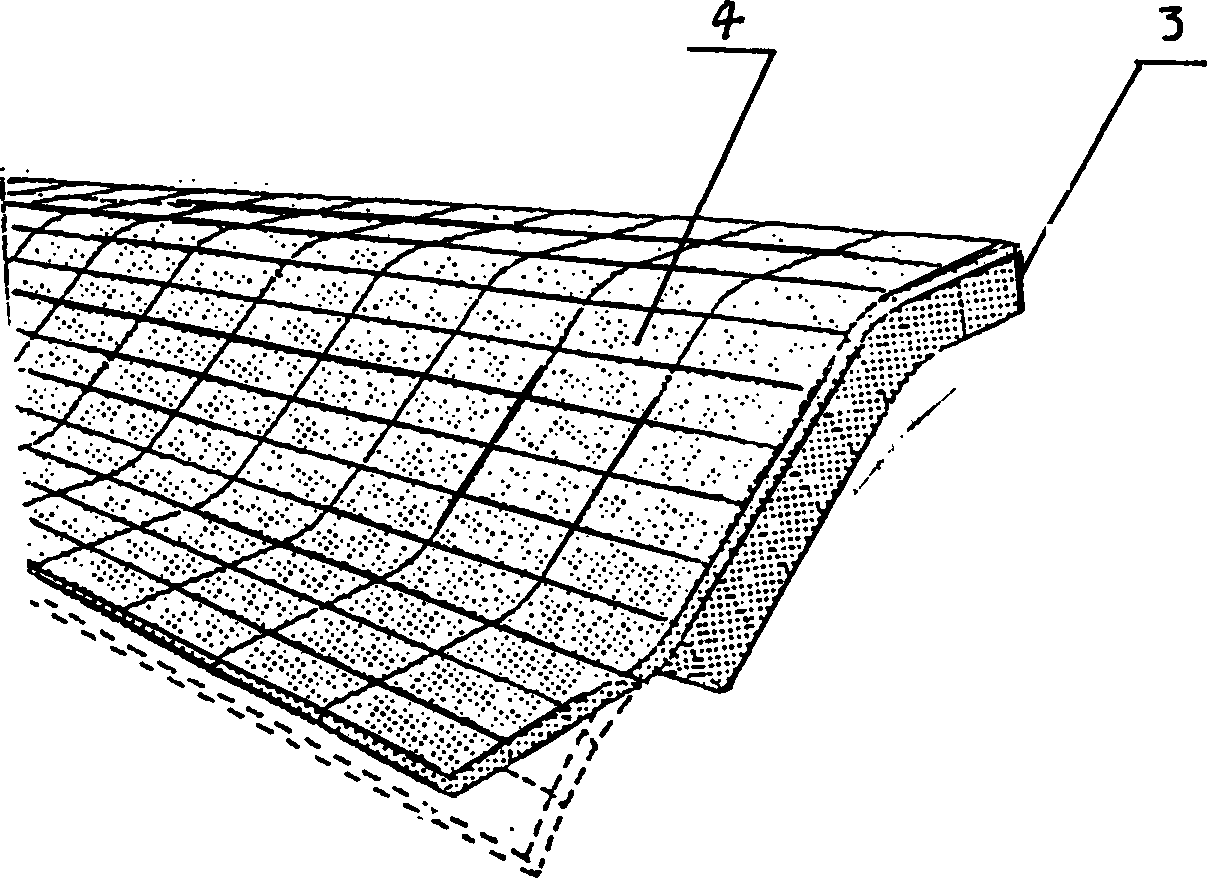

Method of proceeding engineering surface protection using ecological material

InactiveCN1534141AImprove durabilityHigh tensile strengthAfforestationExcavationsVegetationEngineering

A method for using the ecological material in the slope surface protecting engineering includes using steel wire to braid the ecological nets, bending them to become cages, combining them together to become a whole, filling stone and soil in it, and planting tree or grass on it. A biotic earthwork fabric containing nutritive soil and grass seeds can also be used along with piles for protecting the slope surface.

Owner:刘燕翊

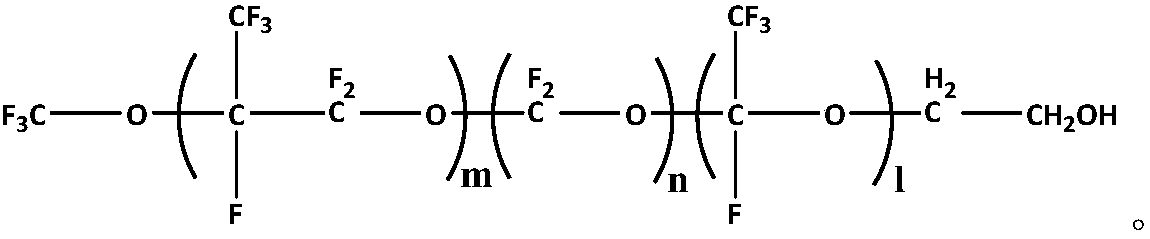

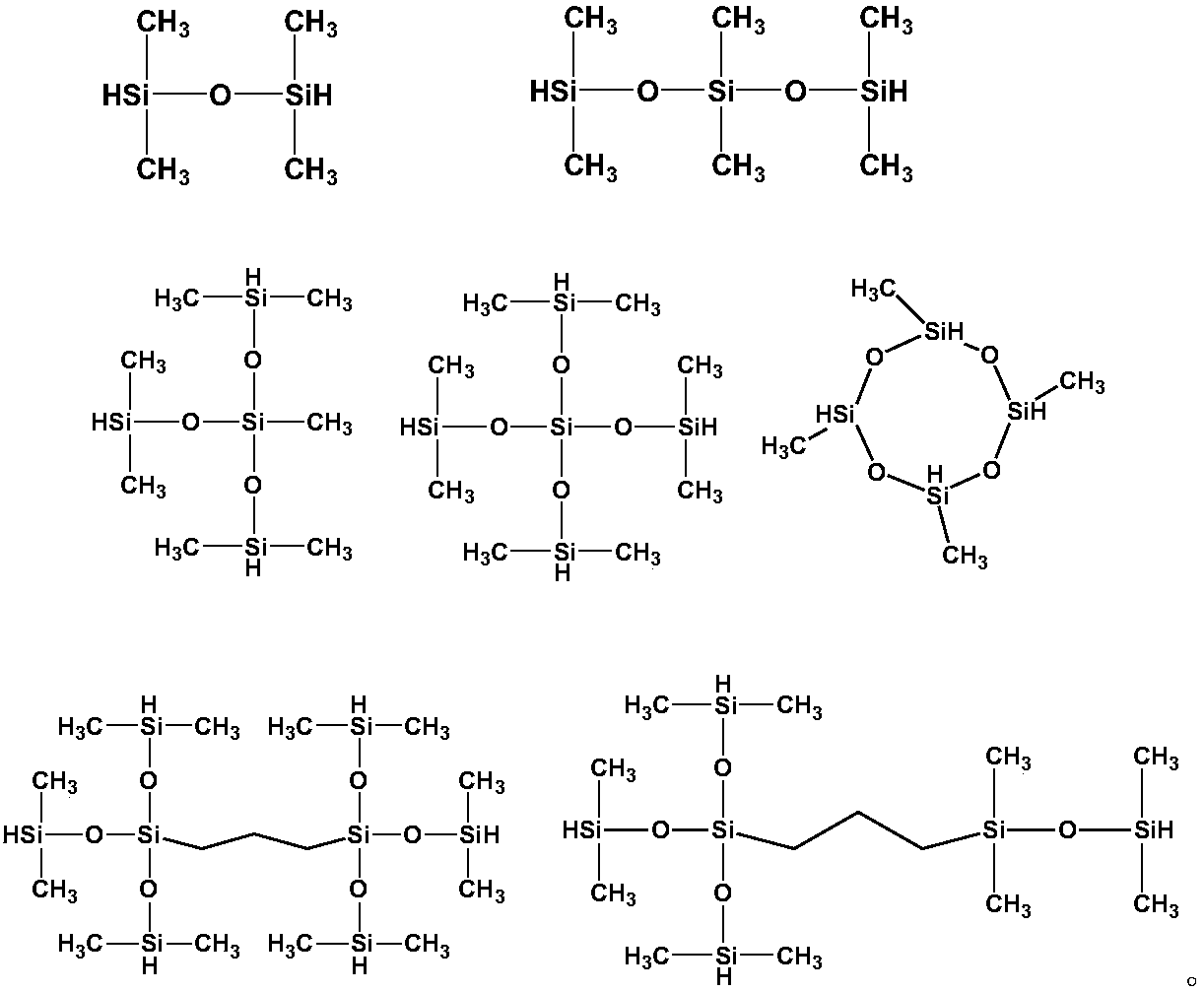

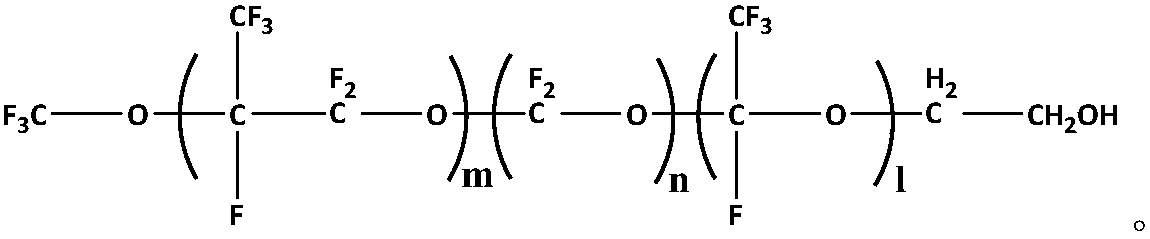

Preparation method of high-performance anti-fingerprint agent

InactiveCN107698768AStrong combinationImprove bond fastnessAntifouling/underwater paintsPaints with biocidesFingerprintWear resistance

The invention discloses a preparation method of a high-performance anti-fingerprint agent. The preparation method comprises the following steps that firstly, allyl terminated perfluoropolyether reactswith a siloxane compound containing silicon-hydrogen bonds for obtaining a perfluoropolyether silane compound containing silicon-hydrogen bonds, the obtained product reacts with methyl vinyl dichlorosilane for obtaining perfluoropolyether-silane with dichlorosilane modified terminal groups, the obtained perfluoropolyether-silane with dichlorosilane modified terminal groups reacts with allyl magnesium bromide for obtaining terminal allyl modified perfluoropolyether-silane with polyfunctional groups, the obtained terminal allyl modified perfluoropolyether-silane with polyfunctional groups reacts with methyldichlorosilane for obtaining dichlorosilane modified perfluoropolyether-silane, dendritic terminal allyl modified perfluoropolyether-silane is obtained by repeated reaction; and then theobtained dendritic multi-functional perfluoropolyether-silane reacts with a siloxane compound containing silicon-hydrogen bonds for obtaining the dendritic perfluoropolyether alkoxy silane compound with polyfunctional groups. The anti-fingerprint agent prepared by the method provided by the invention has a good hydrophobic oleophobic property and excellent antifouling property, and has excellent bonding fastness to glass substrates, and the wear resistance and the durability are greatly improved.

Owner:QUZHOU FLUORIDE & SILICON RES INST

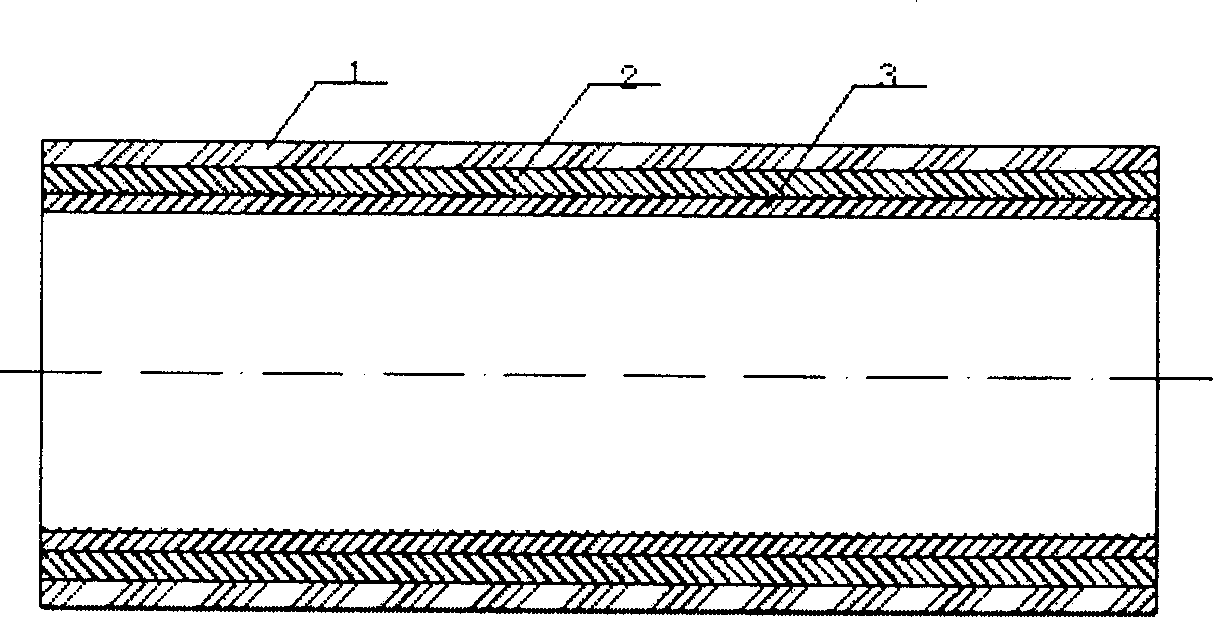

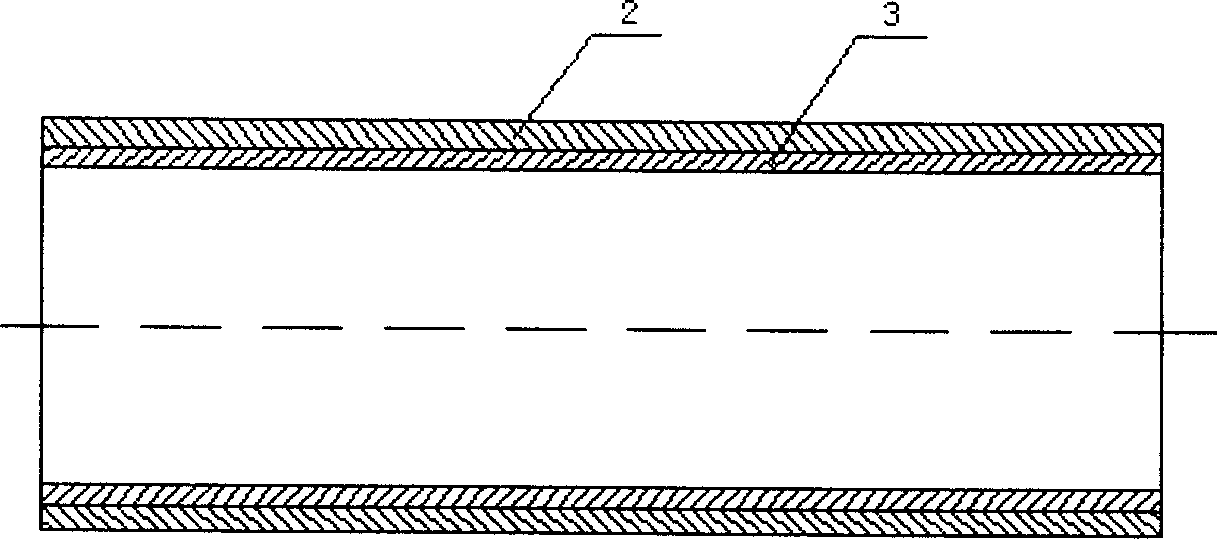

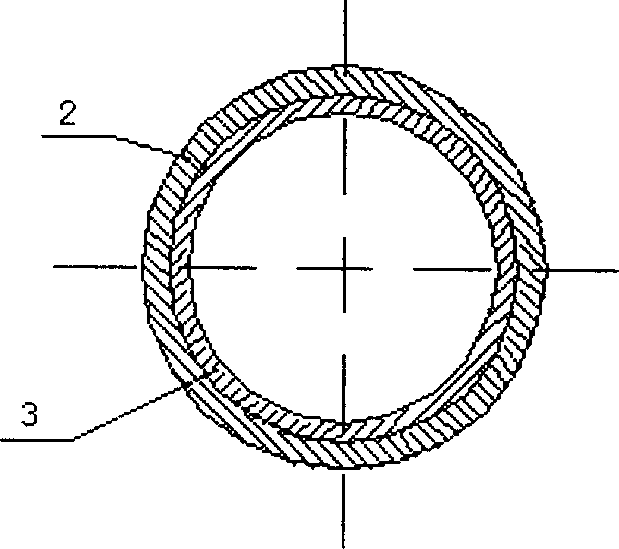

Method for manufacturing bimetal composite wear resistant tube through centrifugal molding double fluids

A technology for manufacturing the antiwear bimetal tube by dual-liquid casting includes such steps as spraying graphite paint onto inner surface of a moulding pipe on centrifugal machine, baking, closing, high speed rotating while pouring molten steel, solidifying to become external steel tube, pouring molten antiwear alloy, solidifying, cooling and cleaning.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Nickel pre-coating process and nickel pre-coating solution for magnesium alloy surface

InactiveCN101021009AStrong combinationImprove corrosion resistanceHot-dipping/immersion processesSuperimposed coating processPre treatmentCopper plating

The present invention is nickel pre-coating process and nickel pre-coating solution for the surface of magnesium alloy. The technological process features that magnesium alloy is pre-treated through immersion coating of zinc and then nickel pre-coated, and may be used to replace traditional cyaniding copper pre-coating. The pre-treatment may be any of available zinc immersing processes. The pre-coating solution has nickel sulfate as main component and citrate as accessory ingredient. The present invention has great cathode current range and high current efficiency, and the obtained coating has compact structure, high adhesion and excellent anticorrosive performance.

Owner:HUNAN UNIV

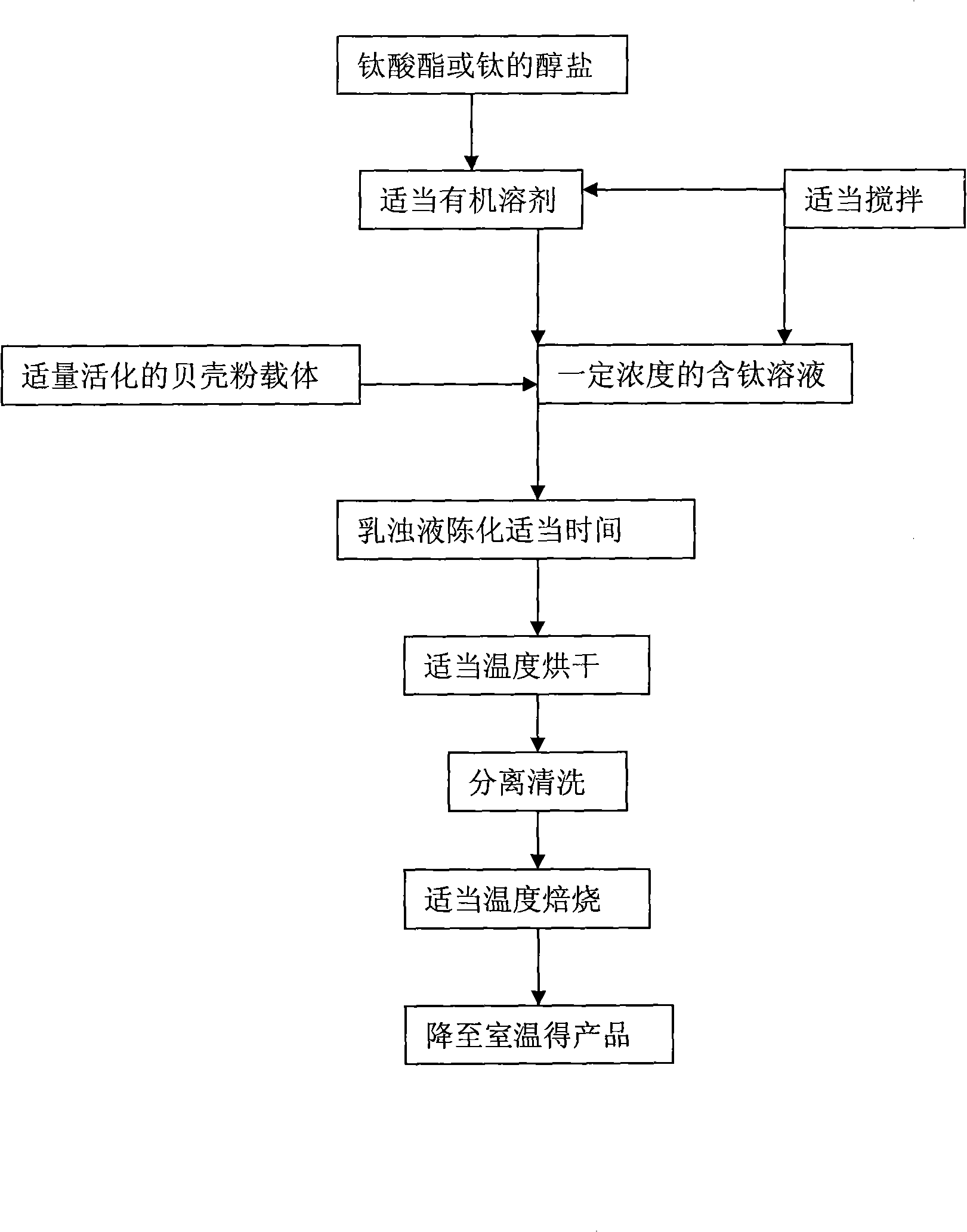

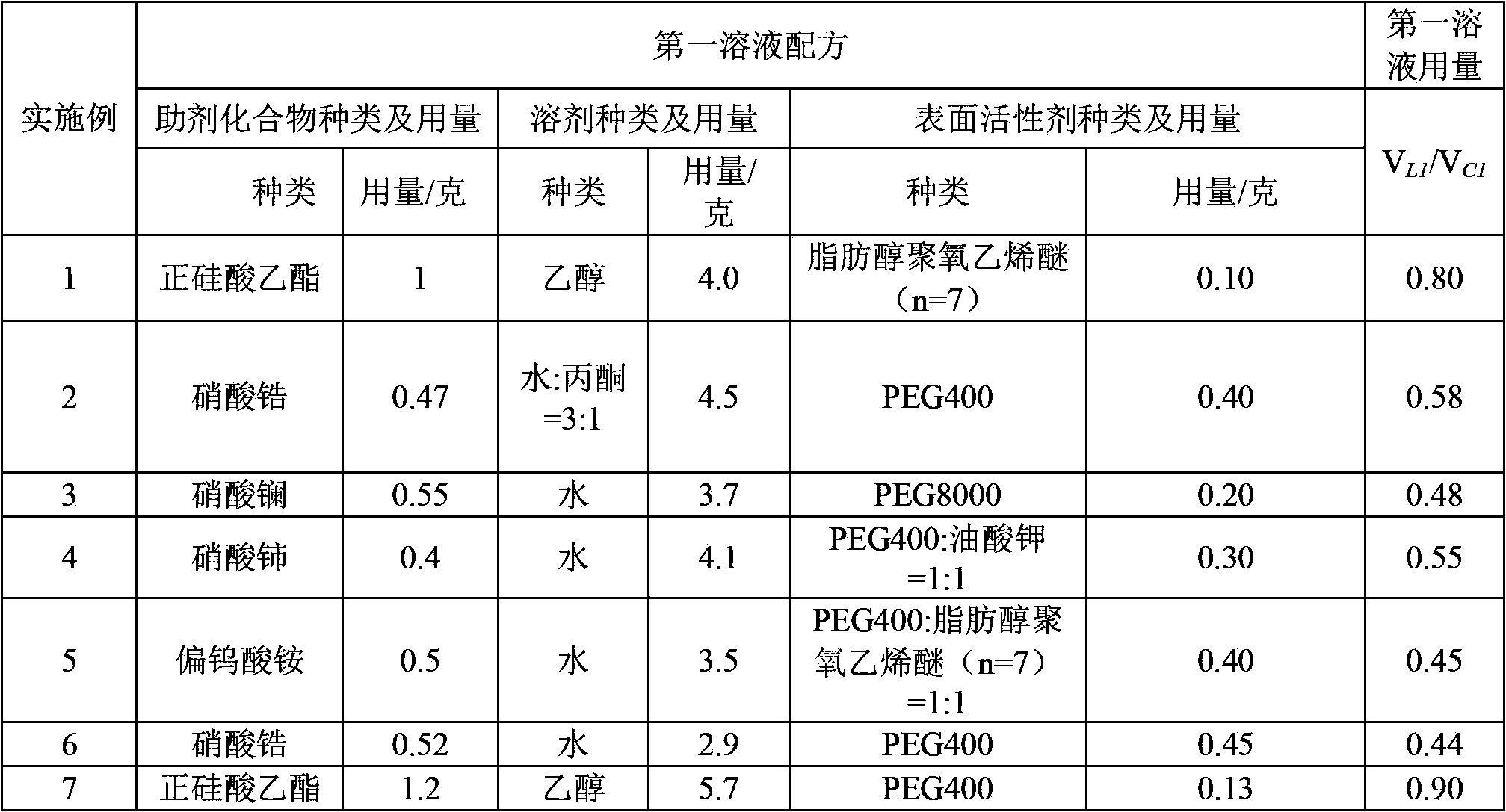

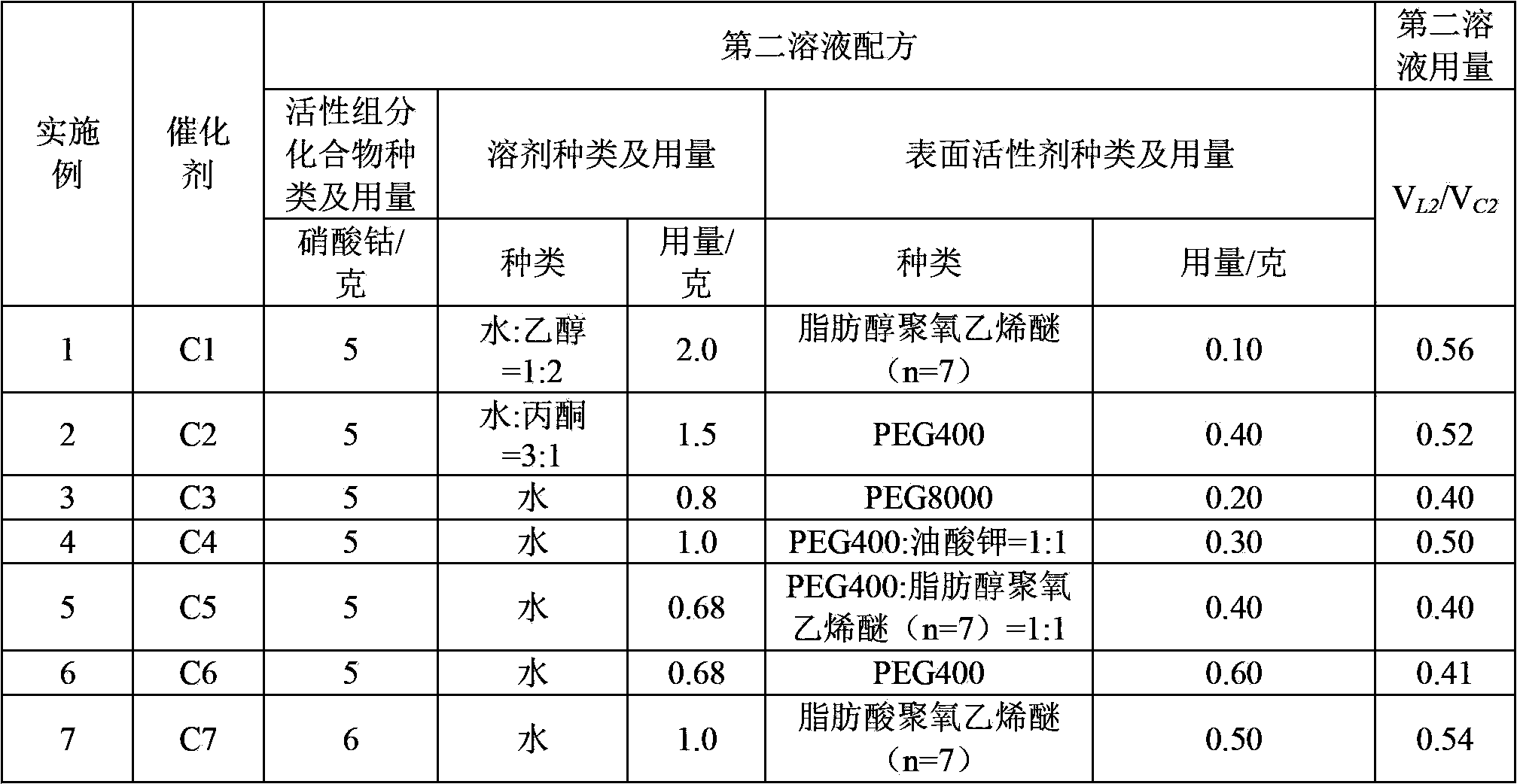

Nano titanic oxide impregnation preparation method using shell powder as carrier

InactiveCN101352674ASolve associativitySolve for uniformityCatalyst carriersCatalyst activation/preparationFiberTitanium oxide

The invention discloses an impregnation preparation method of nanometer titanium oxide which takes shell powder as a carrier, and in particular relates to a reproducible porous nanometer titanium oxide powder which takes the shell powder as the carrier and the preparation method thereof. In the method, titanium oxide is loaded on a shell powder carrier by impregnation; firstly, alkoxide solution of titanium ester or titanium with appropriate concentration is prepared, then an activated shell powder carrier with certain proportion is impregnated in the alkoxide solution, then the obtained solution is stirred and stayed for a certain time, and treated by low temperature and abstersion pretreatment and finally roasted at high temperature, so the nanometer TiO2 forms high-strength bond with the shell powder and promotes the catalytic activity of the nanometer TiO2 at the same time. Impregnation can be conducted for a plurality of times to increase load. The nanometer TiO2 is characterized by small particle size, good compatibility with materials, high catalytic efficiency, good stability, good regenerability, and the like, and can be applied to the fields of plastics, rubbers, fibers, coatings, home electronic appliances, paints, ceramics, water and environmental manipulation, pharmaceutical and hygienic articles, etc. In terms of sources of raw materials and production technology, the preparation method not only reduces the production cost of the nanometer TiO2 catalyst but also is helpful for disposal of the increasingly serious environmental problems, thus bearing great environmental protection significance.

Owner:GUANGDONG OCEAN UNIVERSITY

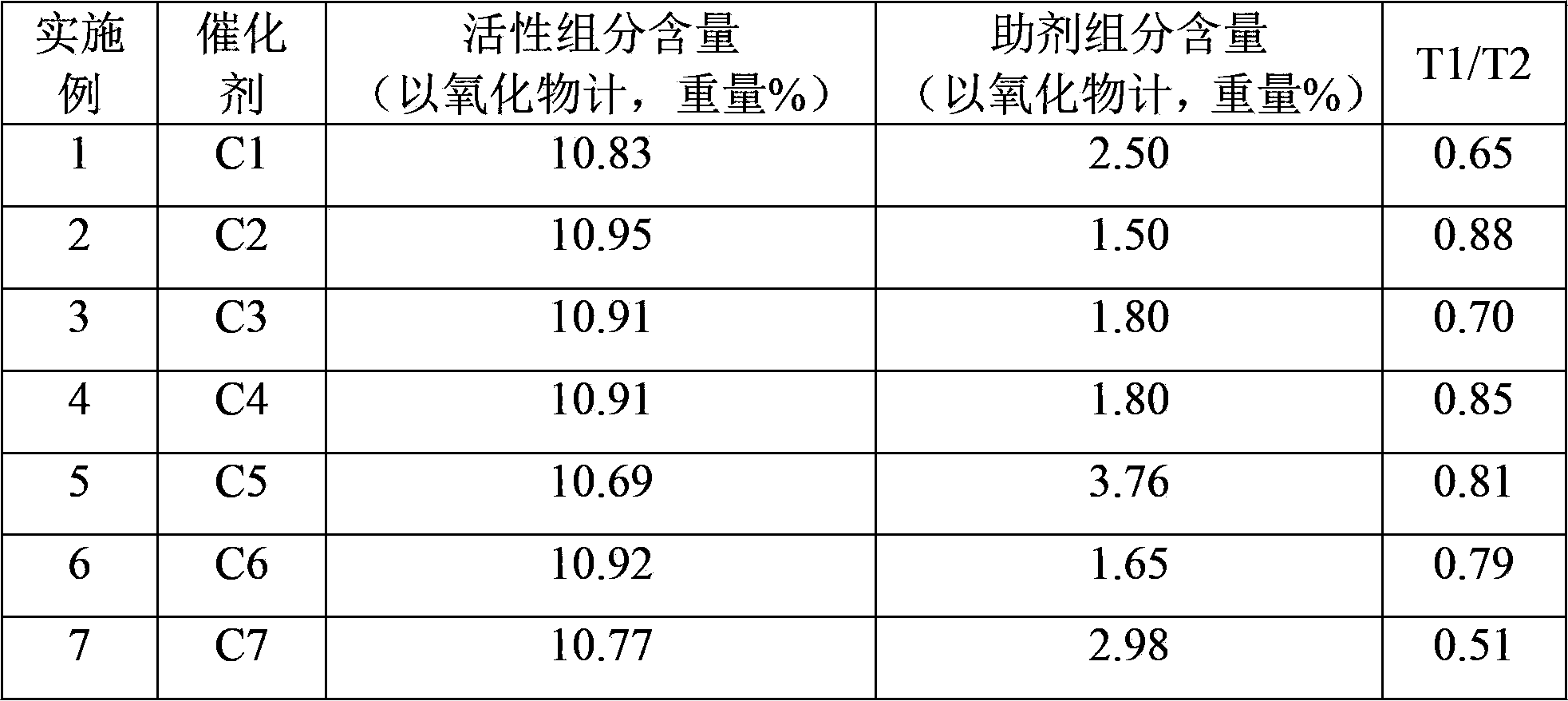

Shell distributed catalyst and application thereof

ActiveCN103769235AStrong combinationHigh activityLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsStructural distributionActive compound

The invention provides a shell distributed catalyst and an application thereof. The catalyst is prepared and obtained according to the following steps: soaking a carrier in a first solution containing assistant compounds, drying, and controlling the soaking condition and the type of the first solution to allow the assistant compounds to distribute on the carrier in a shell manner so as to obtain the carrier carrying the assistant compounds; soaking the carrier carrying the assistant compounds in a second solution containing active compounds, drying, and controlling the soaking condition and the type of the second solution to allow the active compounds to distribute on the carrier in the shell manner so as to obtain a catalyst carrying the assistant compounds and the active compounds. The catalyst provided by the invention is firm in homonuclear combination of shell, long-periodic stability of structural distribution can be kept, and the catalyst is applied to F-T synthetic reaction and is higher in activity and good in stability; the activity and structure of the catalyst remain unchanged basically after long-time operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carried by CeO2 based composite oxides coated carrier Pd catalyst, its prepn. method

InactiveCN1903428AStrong combinationNot easy to fall offDispersed particle separationCatalyst activation/preparationCordieriteComposite oxide

A catalyst for catalytic combustion features that a coated composite oxide layer based on CeO2 is carried by cellular ceramic carrier. It contains the cellular cordierite ceramic matrix, coated composite oxide layer based on CeO2, and Pd. Its preparing process is also disclosed.

Owner:ZHEJIANG NORMAL UNIVERSITY

Molecular sieve coating load manganese based composite oxide integrated catalyst and preparation method thereof

InactiveCN102407154AStrong combinationNot easy to fall offMolecular sieve catalystsDispersed particle separationComposite oxideMolecular sieve

The invention provides a molecular sieve coating load manganese based composite oxide integrated catalyst with easy material acquisition, low preparation cost and firm combination of active constituents and carrier of catalyst, and a preparation method thereof for the defects that the noble metal catalyst has few noble metal resources, high price and high preparation cost. The catalyst provided by the invention is a cellular catalytic combustion catalyst, which comprises a molecular sieve coating, a manganese based composite oxide and a cellular carrier. The catalyst provided by the invention is prepared by the following steps of: uniformly mixing a precursor with the manganese based composite oxide, the molecular sieve and the water to obtain a grout with manganese based composite oxide precursor; soaking the cellular carrier into the grout with manganese based composite oxide precursor; and drying and baking to obtain the molecular sieve coating load manganese based composite oxide integrated catalyst.

Owner:ZHEJIANG NORMAL UNIVERSITY +1

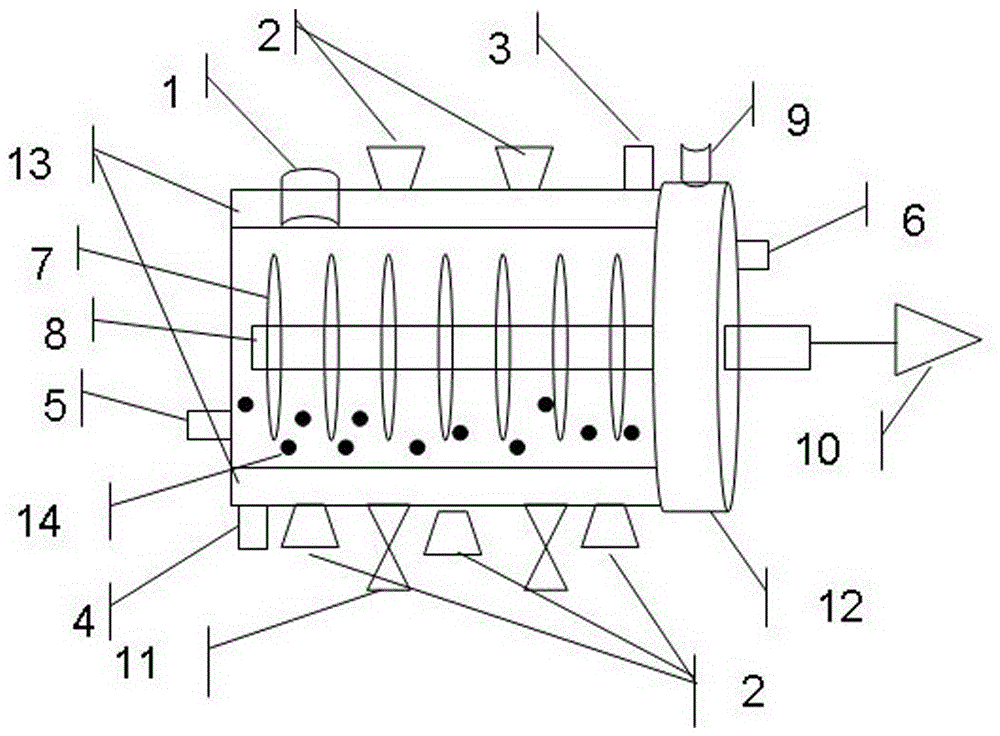

Multifunctional ball-milling device capable of manufacturing nanopowder or slurry efficiently and manufacturing process of multifunctional ball-milling device

InactiveCN105921222ANanoization speed increasedImprove particle size distributionGrain treatmentsMicrowaveHigh energy

The invention discloses a multifunctional ball-milling device capable of manufacturing nanopowder or slurry efficiently and a manufacturing process of the multifunctional ball-milling device. The high-energy ball-milling device comprises a motor, a grinding cylinder, functional auxiliary assemblies, a circulating cooling device, a protecting atmosphere assembly and a support. The grinding cylinder comprises a stirring rod, grinding discs, a material and grinding medium feeding opening, a filtering and separating device and a discharging opening. The circulating cooling device is arranged on the grinding cylinder and comprises a circulating cooling jacket, a cooling liquid inlet and a cooling liquid outlet. The functional auxiliary assemblies are at least one of a microwave generation device, an ultrasonic generator, a discharging device and a magnetic field generation device. The protecting atmosphere assembly is arranged on the grinding cylinder and comprises a protecting gas inlet, a protecting gas outlet and vacuumizing equipment. The functional auxiliary assemblies have the functions and beneficial effects of microwaves, ultrasound, discharging, magnetic fields, temperature fields and the like, so that the device meets the requirements on different conditions, and the operability of the device is improved.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

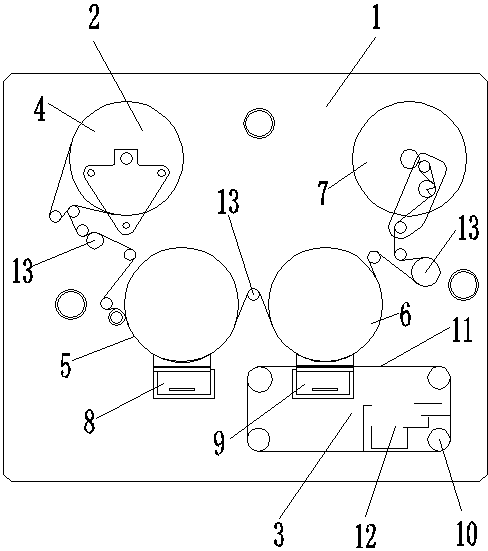

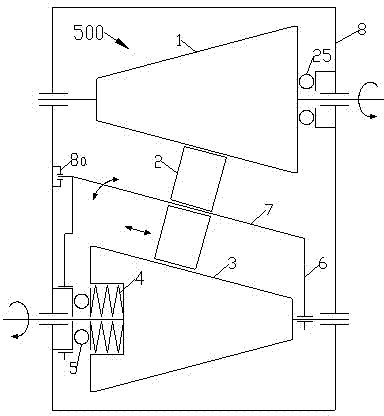

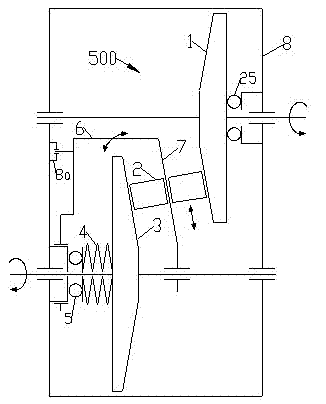

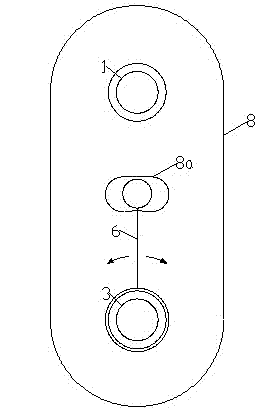

Winding evaporation type vacuum coating machine

InactiveCN103361623AStrong combinationHigh pressureVacuum evaporation coatingSputtering coatingAluminiumEvaporator

The invention belongs to the technical field of vacuum coating, and especially relates to a winding evaporation type vacuum coating machine. The vacuum coating machine comprises a vacuum chamber, and a rolling evaporation system, a shielding system and a motor which are arranged in the vacuum chamber. An unwinding shaft is arranged at the top left corner of the vacuum chamber, a winding shaft is arranged at the top right angle of the vacuum chamber, a first evaporation coating drum and a second evaporation coating drum are arranged between the unwinding shaft and the winding shaft side by side, and are positioned below the unwinding shaft and the winding shaft. A first aluminum evaporator is positioned just below the first evaporation coating drum, and a second aluminum evaporator is positioned just below the second evaporation coating drum; and the shielding system is positioned at the bottom right corner of the vacuum chamber, the shielding steel band of the shielding system traverses between the second aluminum evaporator and the second evaporation coating drum, and the aluminum recovery device of the shielding system is arranged at the bottom right of the shielding system. Each of the winding evaporation system and the shielding system is connected with the motor. The vacuum coating machine has the advantages of one-time completion of the coating and edge thickening, long storage time, stable and unchanged performances, simple operation and production efficiency increase.

Owner:郑州华翔电子信息技术有限公司

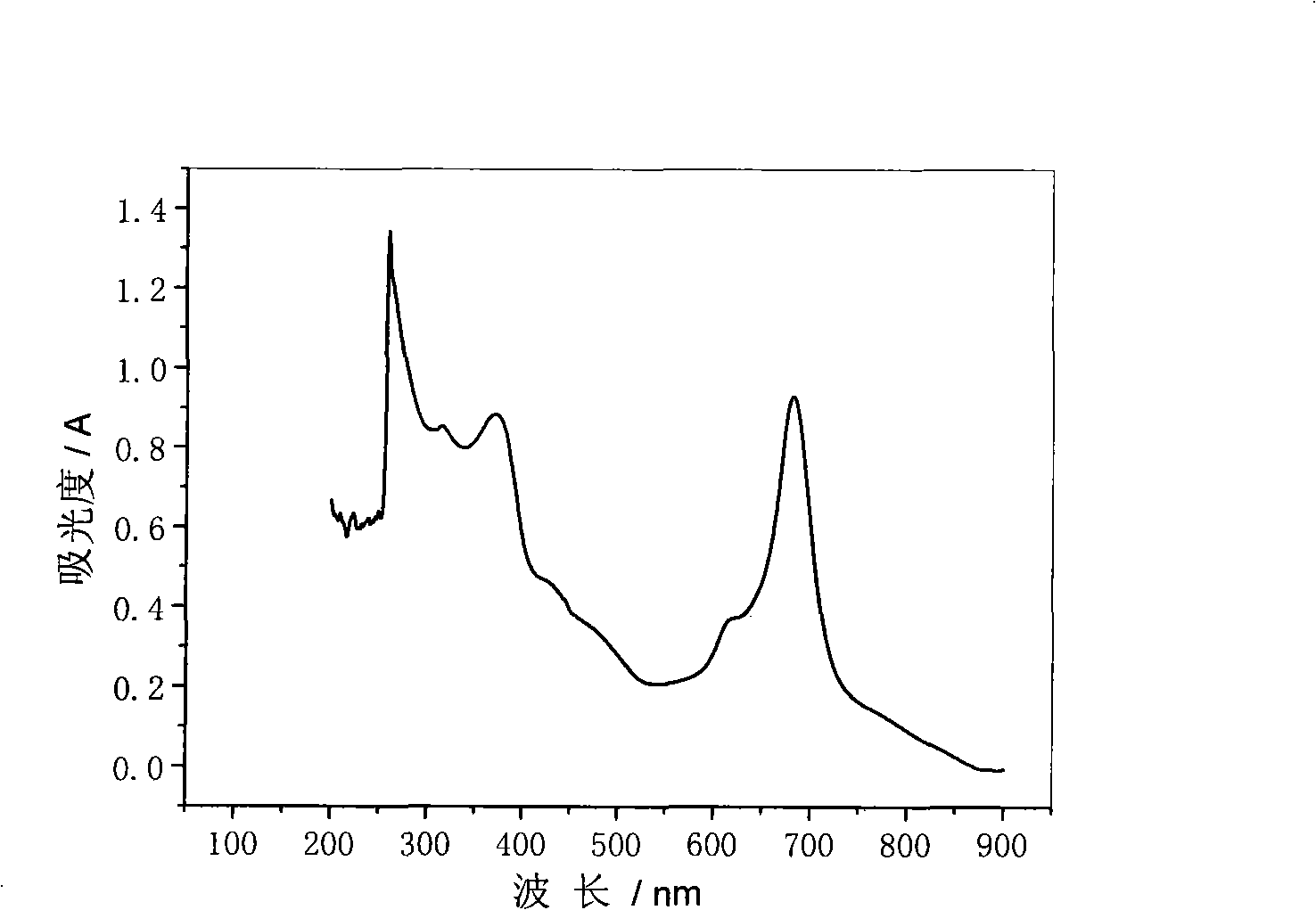

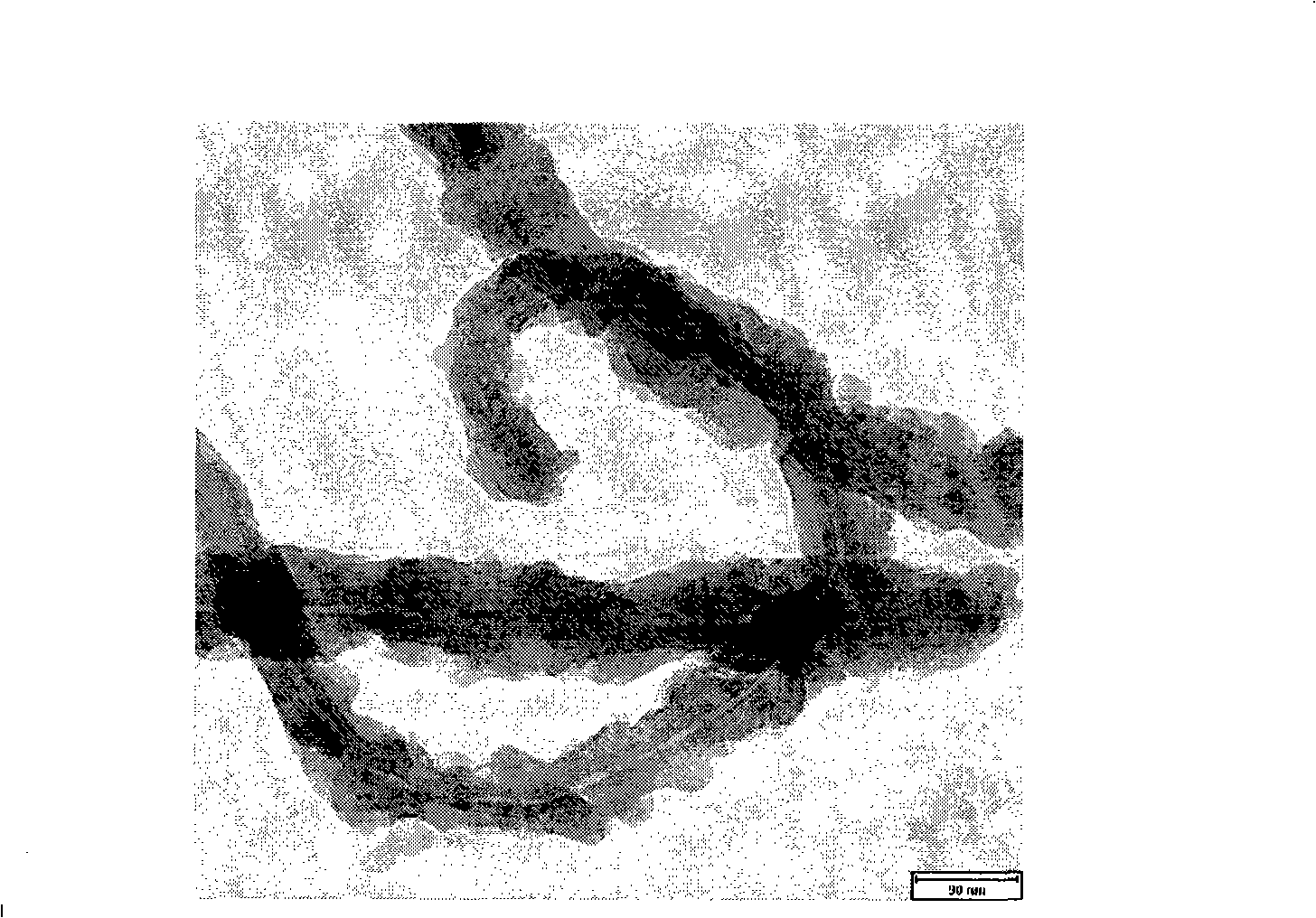

Method for in-situ synthesis of metal phthalocyanine/carbon nano-tube compound

The invention relates to an in situ synthetic method of metalphthalein / carbon nanotube composite, which belongs to the field of the inorganic / organic nanometer composite material research. The invention solves the problems of metalphthalein / carbon nanotube composite prepared by physical blend method, including weak combination between phthalocyanine molecule and carbon nanotubes, and non-uniform distribution of the phthalocyanine molecule on the surface of the carbon nanotubes. The synthetic method includes adding the carbon nanotubes to the organic solvent, and ultrasonic dispersing for 10-40min to obtain the suspension; and mixing the precursor with metal-salt at a molar ratio of 3-8:1, adding to the suspension at a weight ratio of mixture to the carbon nanotubes of 3-11:1, stirring and reacting at 160-240 DEG C in the nitrogen protecting atmosphere for 1-6h, filtering the resultant, rinsing with he absolute ethanol until the filtrate is colorless, and vacuum drying at 50-100 DEG C for 5-30h to obtain the objective product. The phthalocyanine molecule and the carbon nanotubes are combined tightly, and the phthalocyanine molecule can uniformly grow on the external wall of the carbon nanotubes to form microcrystals.

Owner:BEIJING UNIV OF TECH

Method for preparing silane coupled agent of preforming film before painting dressing metals

ActiveCN101003900AStrong combinationProduct stabilityMetallic material coating processesIonSilane coupling

This invention discloses a method for preparing silane coupling-prefilming agent before metal coating. The method comprises: adding deionized water 100 parts into a container, stirring at a speed of 2000-2200 rpm, and adding a first reinforcer, stabilizer, a second reinforcer, silane coupling agent and dispersing agent to obtain silane coupling-prefilming agent before metal coating. The ultrathin organic film thus formed can be used to replace traditional phosphating film, and the weight in unit area is only 5% of phosphating film, thus has a low cost. The Si-O-Me covalent bonding is strong, thus the product is stable, and has improved corrosion resistance. The silane coupling-prefilming agent is easy to apply, and the preparation process only needs to control the pH value and the electrical conductivity. The environmental pollution is little. The prefilming treatment does not need to modify the previous apparatus.

Owner:ZHEJIANG WUYUAN TECH CO LTD

Antibacterial hollow activated carbon fiber of negative ion, and preparation method

InactiveCN1760415AStrong combinationRealize bearerHollow filament manufactureActivated carbonSol-gel

The present invention relates to a negative ion anti-bacterial hollow carbon fibre and its preparation method. It includes (by weight ratio) 5-13 portions of tourmaline, 0.6-4 portions of Ag anti-bactrial agent, 15-25 portions of Ti (OC5H11)4 and 100 portions of hollow active carbon. Its preparation method includes the following steps: using hollow active carbon as carrier, adopting vacuum repeated impregnation process to make the micro-size tourmaline powder be fed into central pore of hollow active carbon fibre, and utilizing the combination of vacuum repeated impregnation and sol-gel to make the surface of hollow active carbon fibre be coated with nano-size silver series anti-bacterial agent and nano-size TiO2 series anti-bacterial agent. The number of negative ions released by the invented hollow active carbon fibre can be up to 2200-2250 / cu cm. For Escherichia coli the diameter the diameter of its bacteriostatic ring can be up to 22 mm, and for staphylococcus aureus the diameter of its bacteriostatic ring can be up to 21.5 mm.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

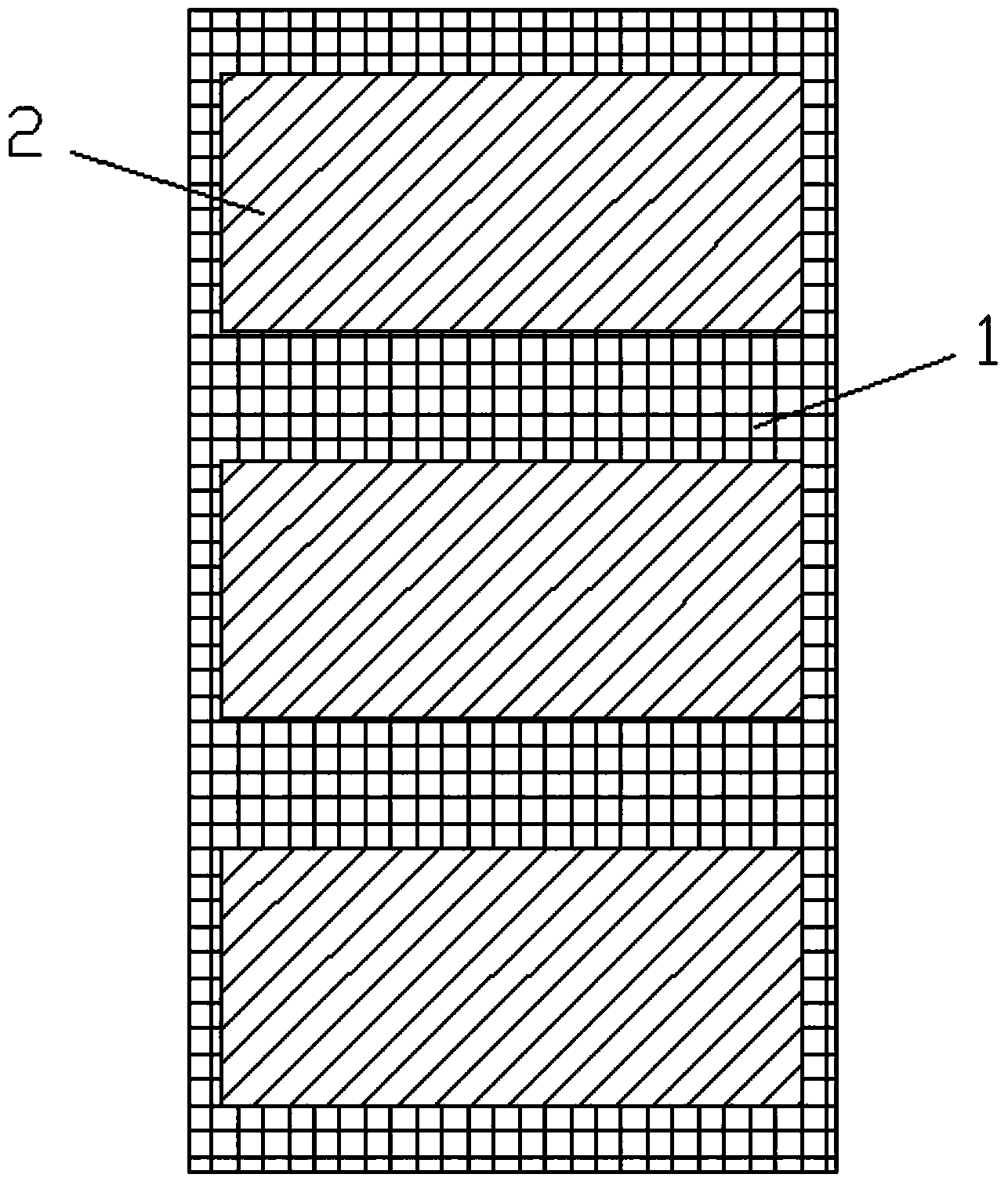

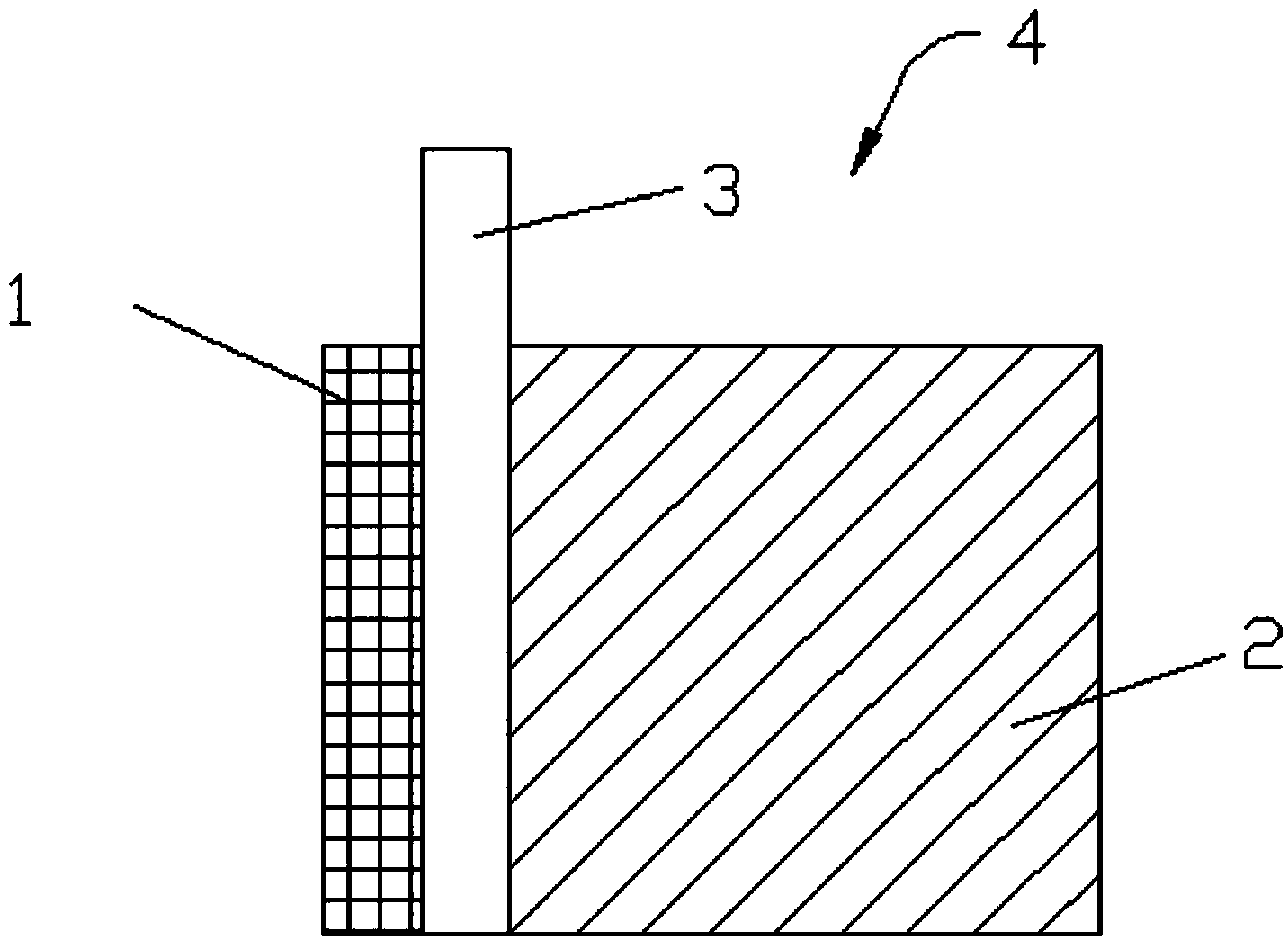

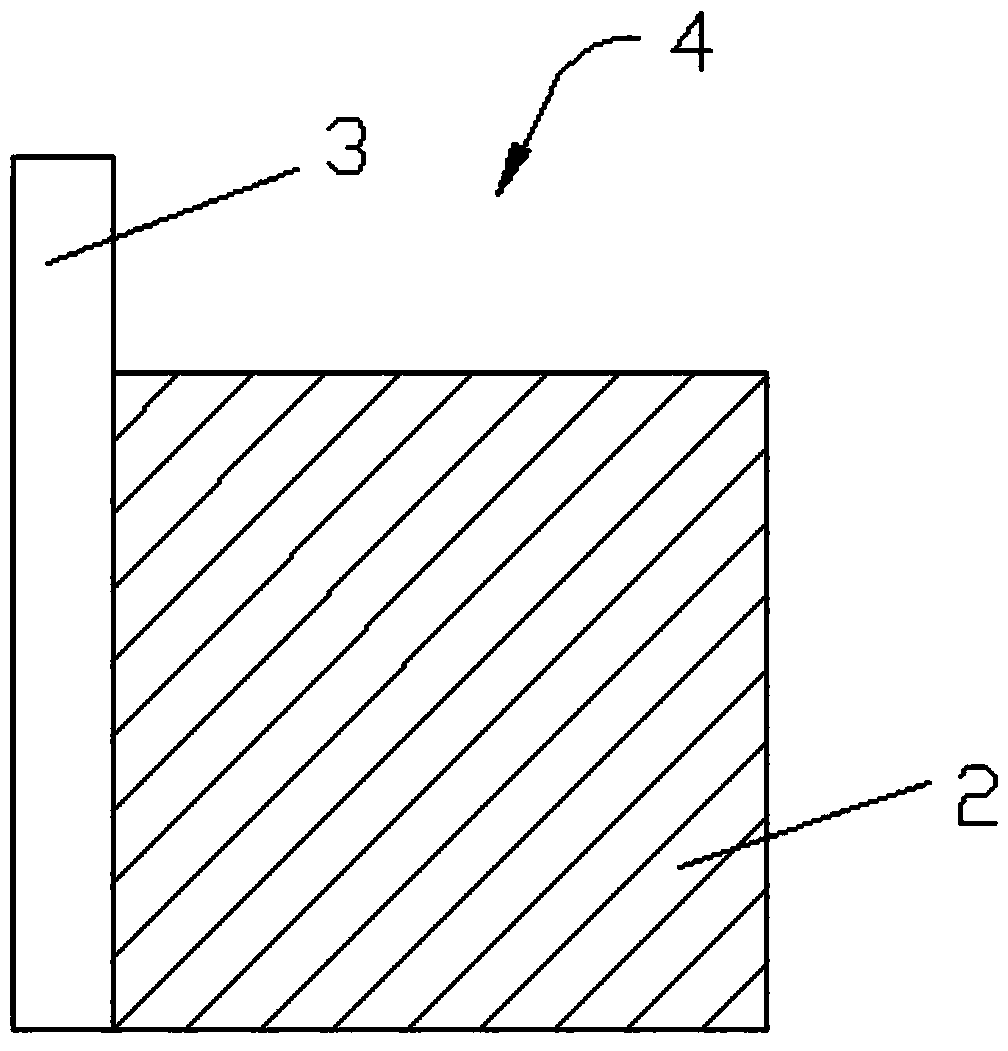

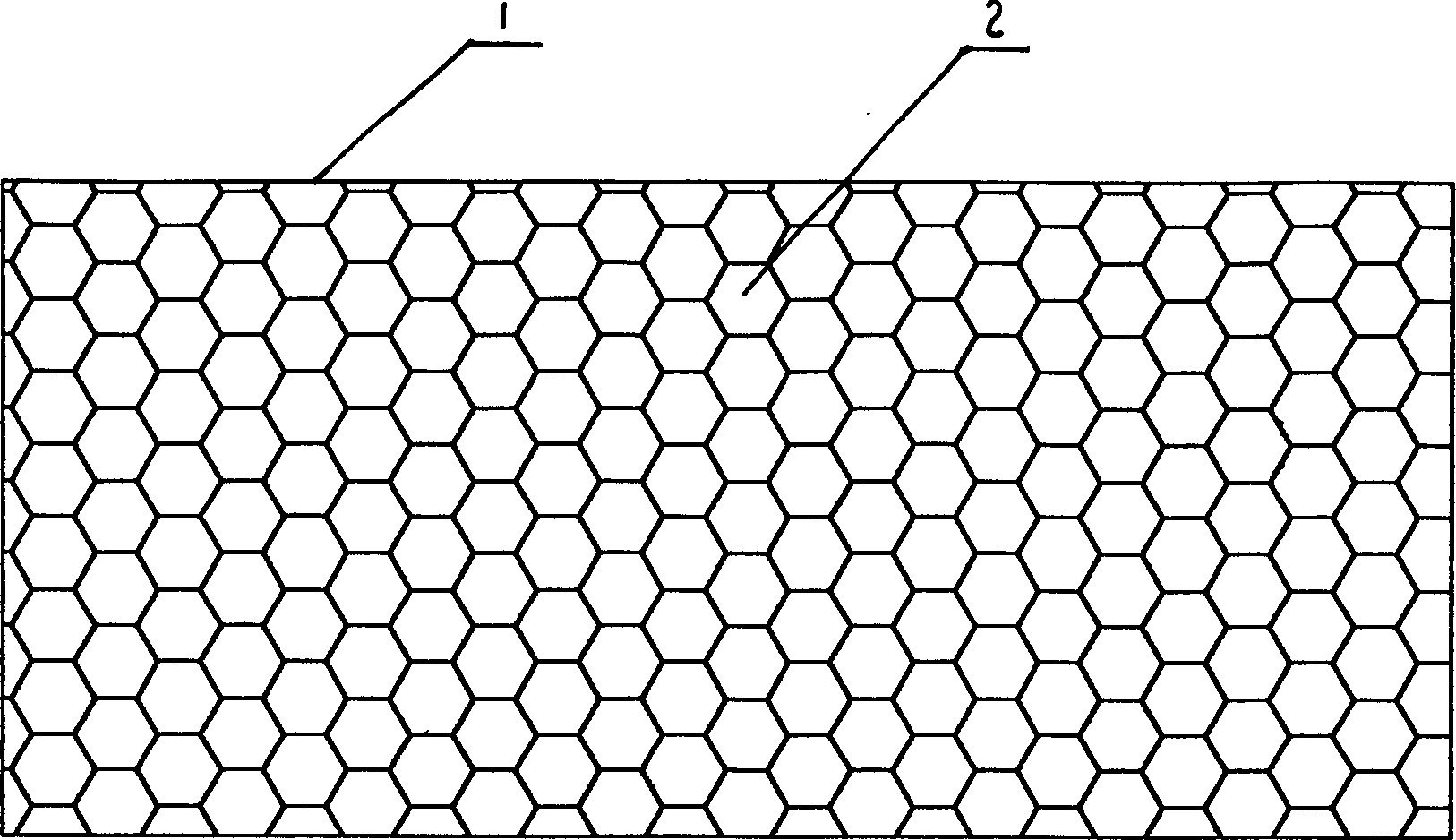

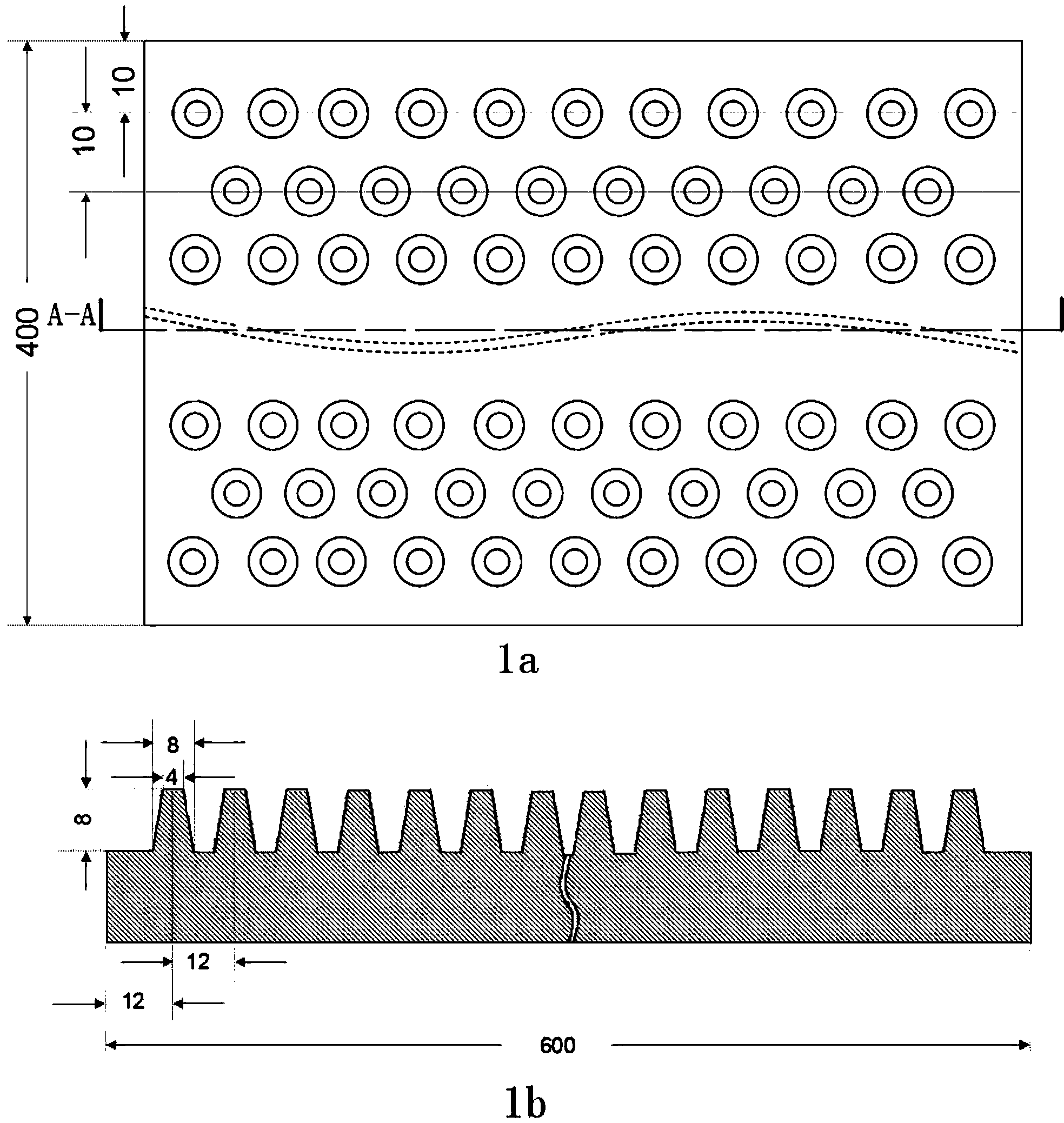

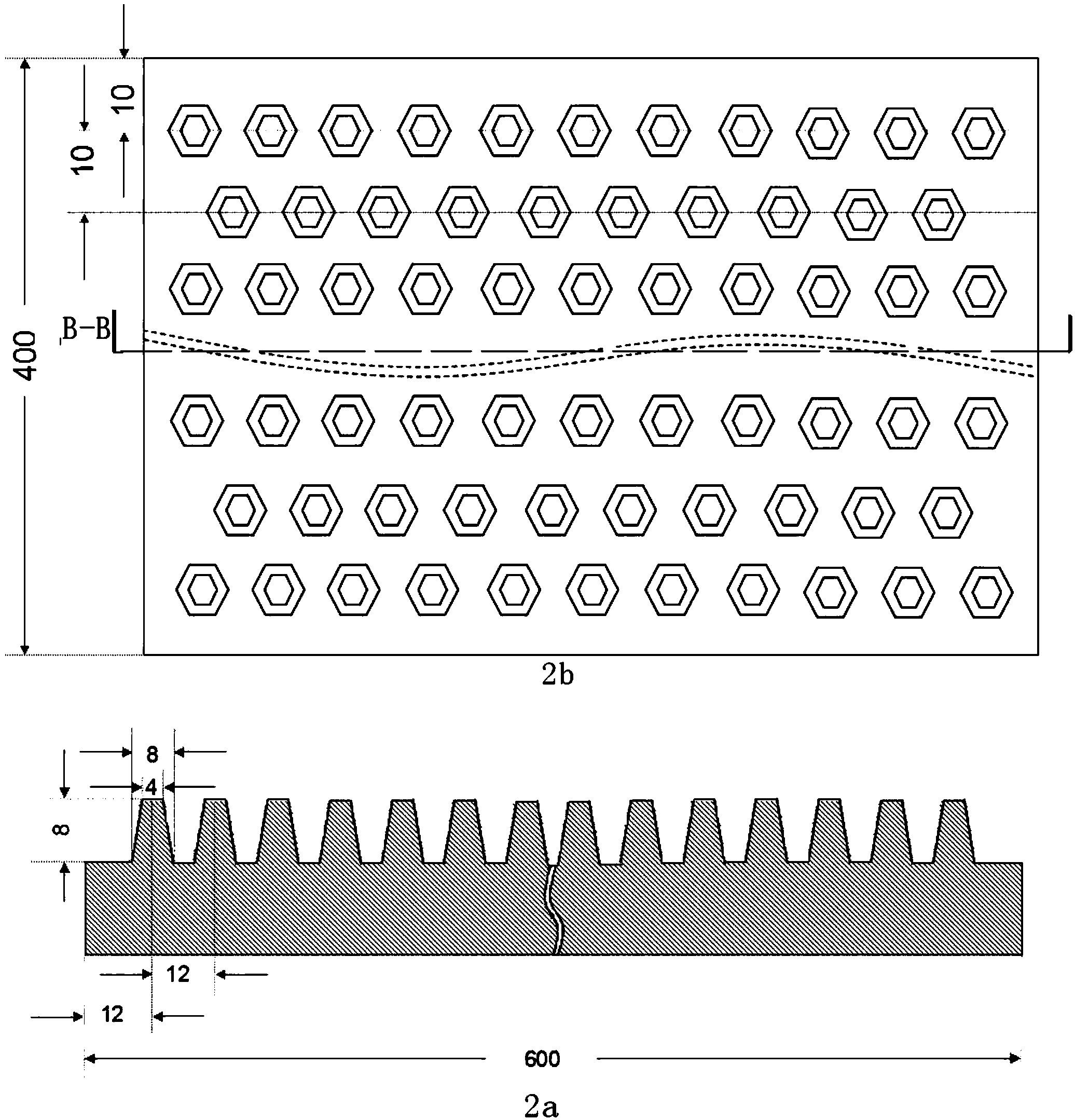

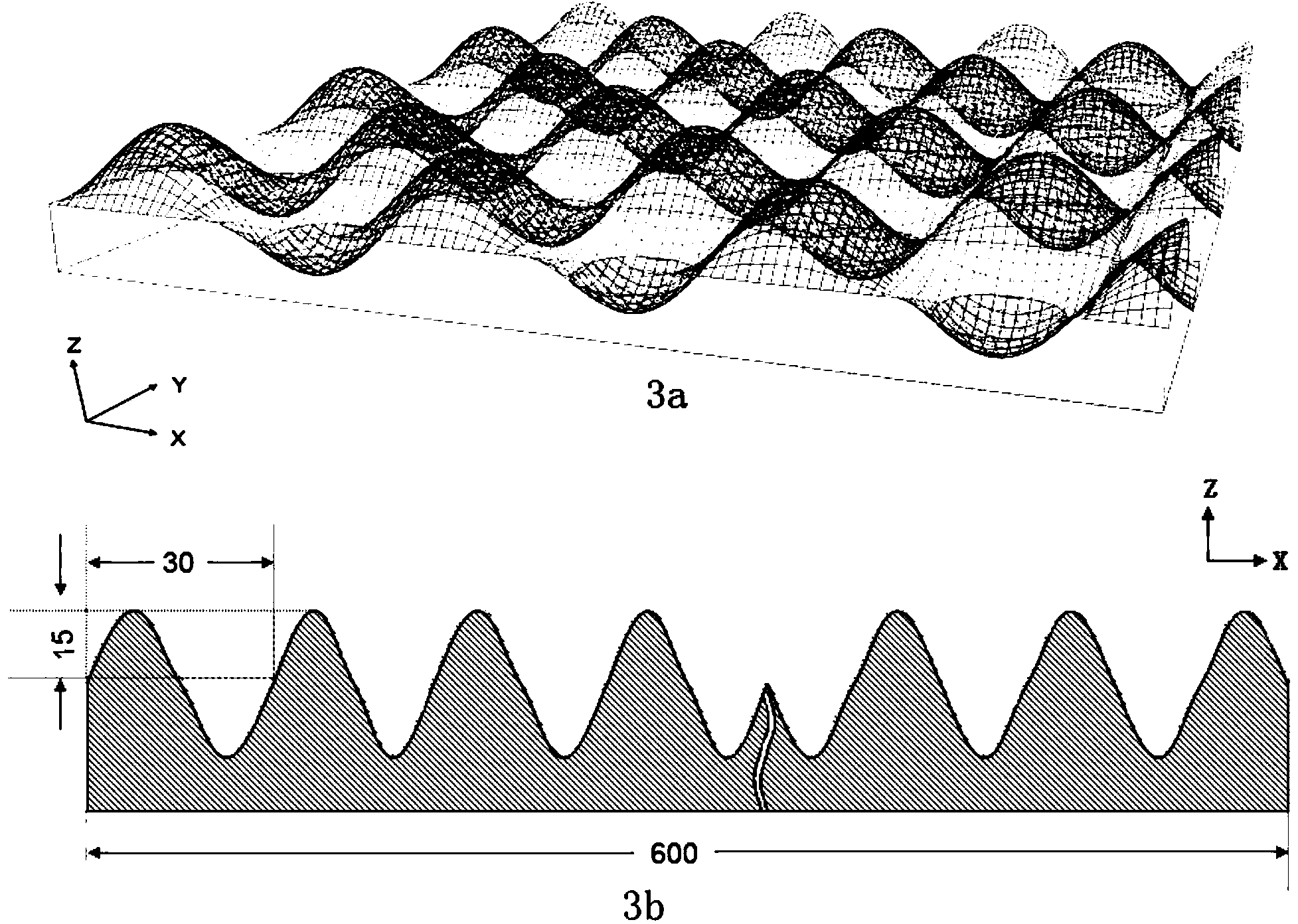

Infrared radiation reinforced composite ceramic fiber board and preparation method

ActiveCN103640284AHigh strengthStrong combinationCeramic layered productsAluminium silicateComposite ceramic

The invention discloses an infrared radiation reinforced composite ceramic fiber board. The composite ceramic fiber board is formed by compounding an aluminium silicate-based ceramic fiber board layer and a high infrared emittance layer, wherein the thickness of the high infrared emittance layer is 0.1-2mm, and bulges in periodic array distribution are arranged on the surface of the high infrared emittance layer. A method for preparing the infrared radiation reinforced composite ceramic fiber board disclosed by the invention comprises the steps that powder and gel materials are respectively prepared at first, then a wet preform body of the high infrared emittance layer with the periodic array structures on the surface is made by mixing the powder and the gel materials, finally, the surface of the ceramic fiber board is painted and covered with a glue stock and then the ceramic fiber board is reversed on the wet preform body, and the product is prepared after heating and pressuring. The infrared radiation reinforced composite ceramic fiber board disclosed by the invention has the advantages of being high in strength, firm in combination between the high infrared emittance layer and the aluminium silicate ceramic fiber board layer and capable of working at the temperature above 1100 DEG C for a long time, and having the hemispherical total emittance up to 0.91 at 800 DEG C and the comprehensive energy-saving efficiency above 10%.

Owner:重庆埃泰克能源科技有限公司 +1

Roller cone disc type continuously variable transmission

The invention discloses a roller cone disc type continuously variable transmission. A driving cone pulley and a driven cone pulley are connected with a cone pulley support in a rotating mode. A pressure device pushes the driving cone pulley to apply pressure in the axial direction. A roller makes contact with the circular conical surface of the driving cone pulley and the circular conical surface of the driven cone pulley for transmission, and is arranged on a roller support in a sliding mode parallel to the conicity line of the driving cone pulley. The roller support and the driving cone pulley are arranged on the cone pulley support in a reciprocating rotating mode within a certain angle range around the same axis. The swing angle of the roller support on the cone pulley support is controlled to change the positions of two transmission mass points on the roller so that the roller can move automatically in the axial direction; moreover, the transmission ratio of the driving cone pulley to the driven cone pulley is changed continuously to realize stepless speed change. The roller cone disc type continuously variable transmission can be applied to various fields such as vehicles, ships and mechanical transmission.

Owner:佛山市顺德华兴船厂

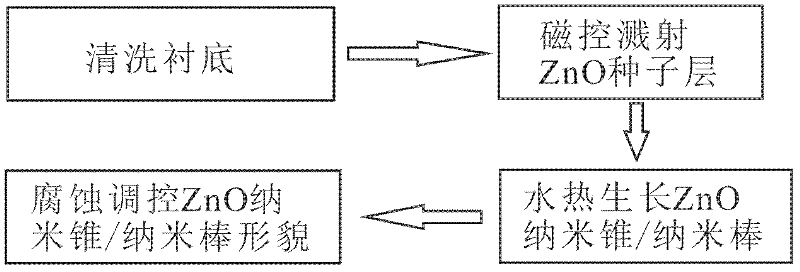

Method for preparation and regulation of surface-roughness ZnO nano-cone or nanorod array

InactiveCN102583504AStrong combinationGood crystal qualityZinc oxides/hydroxidesNanotechnologyNanometrePhotocatalysis

The invention discloses a method for preparation and regulation of a surface-roughness ZnO nano-cone or nanorod array. The method comprises the following steps that: (1) a substrate is selected and cleaned; (2) a magnetic-control sputtering apparatus performs sputtering at a normal temperature on the substrate to form a compact ZnO seeding layer with good crystallinity; (3) the ZnO nano-cone or nanorod array grows on the substrate with a hydrothermal method; and different acid or alkali corrosive liquids are chosen, and the concentration and corrosion time of the corrosive liquids are adjusted to form a surface-roughness nanometer structure with different corrosion degrees. According to the invention, the simple method is adopted for manufacturing the complicated nanometer structure, the range of appearance regulation is large, the operation is simple, the regulation and control are easy, the repeatability is good, the surface roughness of a nano-cone or nanorod can be regulated effectively, the specific surface area is enlarged, and the properties such as surface activity are improved, so that the method is greatly beneficial to improving transducer sensitivity more effectively and enhancing photocatalysis efficiency as well as light extraction efficiency of an LED (light-emitting diode).

Owner:SHANDONG UNIV

Pharmaceutical compositions primarily for the treatment and prevention of genitourinary infections and their extragenital complications

InactiveUS20050208152A1Decreasing necessary dosageDecrease of possible side effectBiocideInorganic boron active ingredientsNitroimidazoleFolic acid antagonist

Compositions having synergistic effective amounts of one or more antibacterial agents, a nitroimidazole, and / or a sulfonamide or a molecule or compound having folic acid antagonist effect and nitroimidazole substitution in addition, with or without an antifungal agent effective against a Candida species. The compositions are particularly useful in the treatment of genitourinary infections and their extragenital complications. Vaccination against pathogen microbes of the vagina provides a stronger and longer immune response, then the infection.

Owner:MILANKOVITS MARTON

Coloring agent used for nylon shell fabric

The invention provides a coloring agent used for nylon shell fabric. The coloring agent consists of the following components in parts by weight: 5-8 parts of hydroxyethyl methylacrylate, 2-3 parts of zinc stearate, 2-3 parts of dibutyl phthalate, 1-2 parts of triglyceride, 2-3 parts of styrene, 1.2-1.5 parts of sodium persulfate, 0.2-0.5 part of propylene glycol, 0.5-0.8 part of acetic acid vinyl ester, 0.4-0.6 part of sodium acetate and 100-110 parts of distilled water. The coloring agent provided by the invention is simple in preparation method; after the coloring agent provided by the invention is applied for coloring, the soaping fastness of the nylon shell fabric is 4-5 level, the coloring agent is firmly combined, the K / S value is 8.794-9.037, and the coloring performance is good.

Owner:WUXI DONGBEITANG HONGLIANG DYEING FACTORY

Air filtration membrane with functions of killing bacteria and removing formaldehyde

ActiveCN107051232AImprove filtering effectPurification and decompositionSemi-permeable membranesBreathing filtersAir filtrationParticulates

The invention discloses an air filtration membrane with functions of killing bacteria and removing formaldehyde. The air filtration membrane is of a three-layer nanofiber membrane composite structure, wherein the upper layer is an activated carbon nanofiber membrane, the middle layer is a pure TiO2 nanofiber membrane, and the lower layer is a nano-silver antibacterial fiber membrane; the pure TiO2 nanofiber membrane is prepared from a high polymer material / TiO2 precursor composite nanofiber membrane through heat treatment, and the high polymer material / TiO2 precursor composite nanofiber membrane is prepared with an electrospinning method; the activated carbon nanofiber membrane is an electrospun activated carbon nanoparticle / high polymer material composite nanofiber membrane; the nano-silver antibacterial fiber membrane is an electrospun nano-silver particle / high polymer material composite nanofiber membrane. The air filtration membrane not only can filter solid particulate pollutants very well, but also is good in breathability, and can remove and decompose formaldehyde in air and filter and kill harmful bacteria in air, thereby guaranteeing health of a respiratory system better.

Owner:保定源汉升新材料科技有限公司

Portable Bucky solar battery assembly and its manufacture method

ActiveCN1953212AEasy to fold and unfoldStrong combinationFinal product manufacturePhotovoltaicsEngineeringTextile

The invention relates to a portable laminate solar battery, and relative production. Wherein, said battery comprises upper, middle and lower layers; the upper and lower layers are laminated or / and macromolecule films, while at least one layer contains macromolecule film; the middle layer is packed unit battery plate; it uses fused film to prepare laminate macromolecule film composite layer; the part of composite layer relative to the lighted part of unit battery plate has holes; the circumference of middle layer has holes; the unit battery plate is connected by wires; layering lower, middle and upper layers on laminate compressor, to expose the lighted part; using thermal-insulated material to plaster the lighted part of middle layer; at the folded part, arranging narrow rigid object or holing the film; compressing it in compressor; cooling and furnishing edge.

Owner:XIAMEN TOPUNIVE TECH

Compound microbial inoculant for degrading COD (chemical oxygen demand) and preparation method of compound microbial inoculant

InactiveCN104894033AImprove adaptabilitySolve the problems of high cost of treatment process and unsatisfactory COD removal rateFungiBacteriaBacillus licheniformisCandida tropicalis

The invention discloses a compound microbial inoculant for degrading chemical oxygen demand and a preparation method of the compound microbial inoculant. The compound microbial inoculant comprises, by volume, 9-11% of candida tropicalis, 9-11% of candida parapsilosis, 28-32% of bacillus subtilis, 28-32% of bacillus licheniformis and 19-21% of enterococcus faecalis lactobacillus. The preparation method of the compound microbial inoculant includes that the candida tropicalis, the candida parapsilosis, the bacillus subtilis, the bacillus licheniformis and the enterococcus faecalis lactobacillus are respectively inoculated and cultured in sewage culturing media to obtain respective bacterium solutions, and the bacterium solutions are mixed according to the volume ratio to obtain the compound microbial inoculant, wherein the sewage culturing media are abundant in organic matter after being sterilized. The compound microbial inoculant is high in environment adaptability, applicable to microbial enhanced sewage treatment in different areas and various sewage including aquaculture sewage, domestic sewage, landfill leachate and the like which are abundant in organic matter, and capable of removing 95% of the COD in sewage.

Owner:湖北凌卓生物工程有限公司

Molybdenum disulfide quantum dot-modified graphene-zinc oxide nanotube array sensing material preparation method

ActiveCN107393721AImprove mobilityGood chemical stabilityLight-sensitive devicesPhotovoltaic energy generationMaterials preparationQuantum dot

The invention relates to the field of solar cells, and discloses a molybdenum disulfide quantum dot-modified graphene-zinc oxide nanotube array sensing material preparation method. A zinc oxide nanotube array is firstly prepared on conductive glass; carboxylic graphene oxide and zinc oxide are bonded together in a chemical bond mode through a silane coupling agent of aminopropyltrimethoxysilane; through spin coating of PDMS, molybdenum disulfide quantum dots are absorbed, and a flexible quantum dot-modified graphene / zinc oxide nanotube array sensing material is obtained. The sensor has an important development prospect in aspects such as environment monitoring and chemical gas detection.

Owner:杨婷

Flue gas purified anticorrosive conductive coating

ActiveCN1775879AGood mechanical propertiesStrong combinationDispersed particle separationAnti-corrosive paintsConductive coatingVinyl ester

The invention relates to an antisepsis conductive coating combination that contains vinyl ester resin 100 portions, conductive particle 5-70 portions, peroxide curing agent 1-10 portions, accelerant 0.5-10 portions, and styrene 0-20 portions. It has low cost for antisepsis and is easy to construct.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Preparing method of tin-nickel-carbon composite cathode material of lithium ion battery

InactiveCN102136567AImprove surface topographyStrong combinationCell electrodesCopper foilCurrent collector

The invention discloses a preparing method of tin-nickel-carbon composite cathode material of a lithium ion battery, which belongs to the technical field of lithium ion batteries. The tin-nickel-carbon composite cathode material is prepared through electrodeposition process; the electrodeposition process comprises the following processes: I. conducting graphite powder, surface chemical modification treatment for the graphite powder, pyrophosphate alloy bath adding and ultrasonic dispersion for the pyrophosphate alloy bath containing the graphite powder; II. conducting copper foil current collector and activating treatment; and III. by taking the copper foil current collector obtained in the process II as a cathode, taking a hard graphite plate as a cathode and taking bath obtained in the process I as an electrolyte, performing electrodeposition film coating, to obtain a composite deposited finally. Compared with the prior art, the preparing method adopting electrodeposition to prepare the tin-nickel-carbon composite cathode material has the characteristics of low cost, simple preparing process, excellent electrochemical performance, long service life and the like.

Owner:SHANDONG JIANZHU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com