Method for preparing silane coupled agent of preforming film before painting dressing metals

A technology of silane coupling agent and group silane coupling agent, which is applied in the field of metal coating pretreatment process, can solve the problems of difficult product quality assurance, unstable production process, and no large-scale implementation, so as to achieve low cost and improve anti-corrosion Ability, combined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

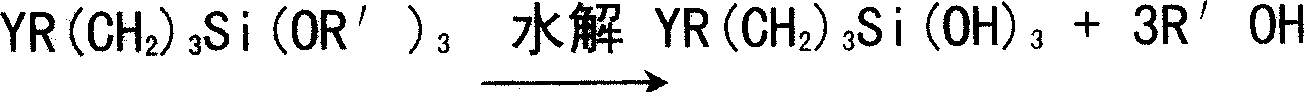

Method used

Image

Examples

Embodiment 1

[0014] A kind of preparation method of silane coupling pre-film agent before metal coating, in the container that injects 100 parts of deionized water, stirring speed is 2000 revolutions per minute, successively add first strengthening agent, stabilizing agent, second strengthening agent, Silane coupling agent, dispersant, wherein the first strengthening agent adopts nano-silica, the addition is 1% of the weight of deionized water, the stabilizing agent is selected ethanol, and the addition is 26% of the weight of deionized water, the second strengthening agent Adopt epoxy resin emulsion, add-on is 1% of deionized water weight, the silane coupling agent mixed by functional group silane coupling agent and non-functional group silane coupling agent, its weight ratio is 1: 1, add-on is 2.6% of the weight of deionized water, the dispersant adopts nonylphenol polyoxyethylene ether NP, and the addition amount is 1% of the weight of deionized water; the pH value is adjusted to 6 with ...

Embodiment 2

[0016] A kind of preparation method of silane coupling pre-film agent before metal coating, in the container that injects 100 parts of deionized water, stirring speed is 2200 revolutions per minute, successively add first strengthening agent, stabilizing agent, second strengthening agent, Silane coupling agent, dispersant, wherein the first strengthening agent adopts nano silicon dioxide, the addition amount is 6.5% of the weight of deionized water, the stabilizing agent propanol, the addition amount is 1% of the weight of deionized water, the second strengthening agent Adopt epoxy resin emulsion, add-on is 6.5% of deionized water weight, the silane coupling agent mixed by functional group silane coupling agent and non-functional group silane coupling agent, its weight ratio is 1: 3, add-on is 0.13% of the weight of deionized water, the dispersant is nonylphenol polyoxyethylene ether NP, and the addition amount is 1.3% of the weight of deionized water; the pH value is adjusted ...

Embodiment 3

[0018] A kind of preparation method of silane coupling pre-film agent before metal coating, in the container that injects 100 parts of deionized water, stirring speed is 2100 revolutions per minute, successively add first strengthening agent, stabilizing agent, second strengthening agent, Silane coupling agent, dispersant, wherein the first strengthening agent adopts nano silicon dioxide, the addition is 3.5% of the deionized water weight, the stabilizing agent is selected isopropanol, and the addition is 13% of the deionized water weight, the second The reinforcing agent adopts epoxy resin emulsion, and the addition amount is 3.5% of the weight of deionized water, and the silane coupling agent mixed by functional group silane coupling agent and non-functional group silane coupling agent, its weight ratio is 1: 2, add The amount is 1.3% of the weight of deionized water, and the dispersant adopts nonylphenol polyoxyethylene ether NP, and the addition amount is 1.2% of the weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com