Method for processing high-temperature alloy furnace tube

A high-temperature alloy and furnace tube technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of poor film performance and low water vapor content, and prolong the coke cleaning cycle and service life Life, reduce the degree of carburization, slow down the effect of catalytic coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

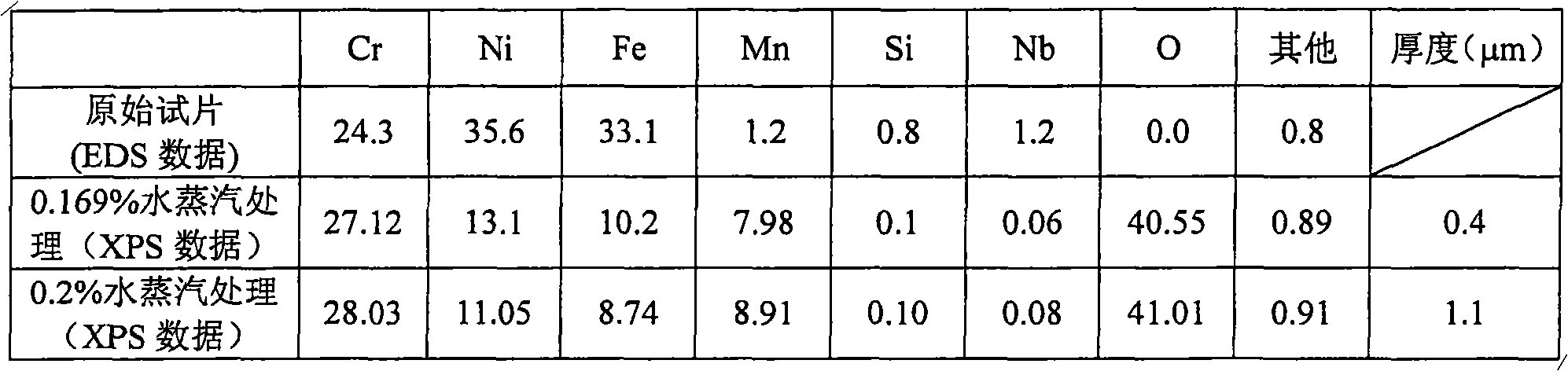

[0028] Cut the superalloy HP40-Nb furnace tube into a square test piece with a side length of 10 mm and a thickness of 4 mm. The material composition of the test piece was analyzed by X-ray energy dispersive spectrometer (EDS), and the results are shown in Table 1. From the data in Table 1, it can be concluded that there are a large amount of iron and nickel elements on the surface of the superalloy furnace tube, which is the reason for catalytic coking.

[0029] Two test pieces were put into two tube furnaces respectively, hydrogen gas (containing 0.169% and 0.2% water vapor by volume fraction respectively) was introduced, and the gas pressure was controlled to be 1.01 atmospheres. After heating the atmosphere furnace to 900 degrees Celsius, heat preservation treatment for 30 hours, and take out the test piece after cooling with the furnace.

[0030] X-ray photoelectron spectroscopy (XPS) was used to test the surface composition of the treated specimens, and the energy spect...

Embodiment 2

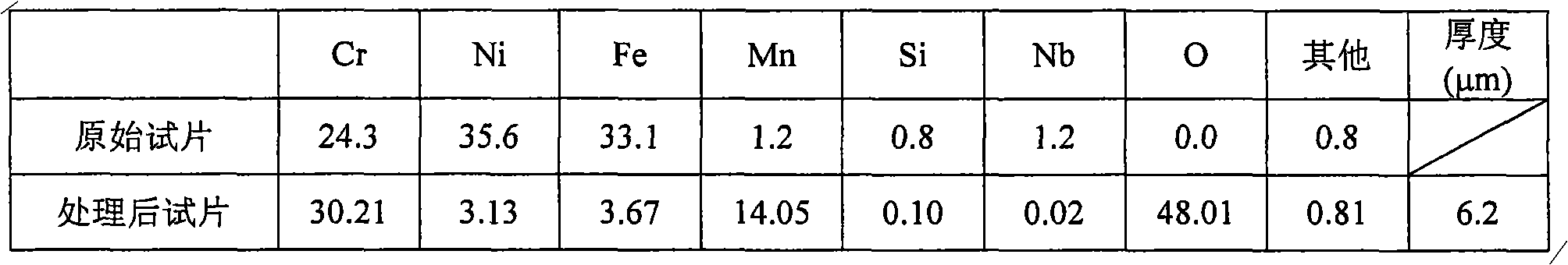

[0035] Cut the high-temperature alloy HP40-Nb alloy pipe into test pieces with a side length of 10 mm and a thickness of 4 mm. The material composition of the test piece was analyzed by X-ray energy dispersive spectrometer (EDS), and the results are shown in Table 2.

[0036] Put the test piece into a tube furnace, pass through hydrogen gas, containing 1.95% water vapor by volume, and the gas pressure is 1.01 atmospheres. After heating the atmosphere furnace to 1050 degrees Celsius, heat preservation treatment for 40 hours, and take out the test piece after cooling with the furnace.

[0037] X-ray photoelectron spectroscopy (XPS) was used to test the surface composition of the treated specimen, and the energy spectrum (EDS) values of different accelerating voltages were used to calculate the thickness of the oxidation protective layer. The results are shown in Table 2. It is found that the oxidation protection layer is mainly composed of elements such as manganese, chromium...

Embodiment 3

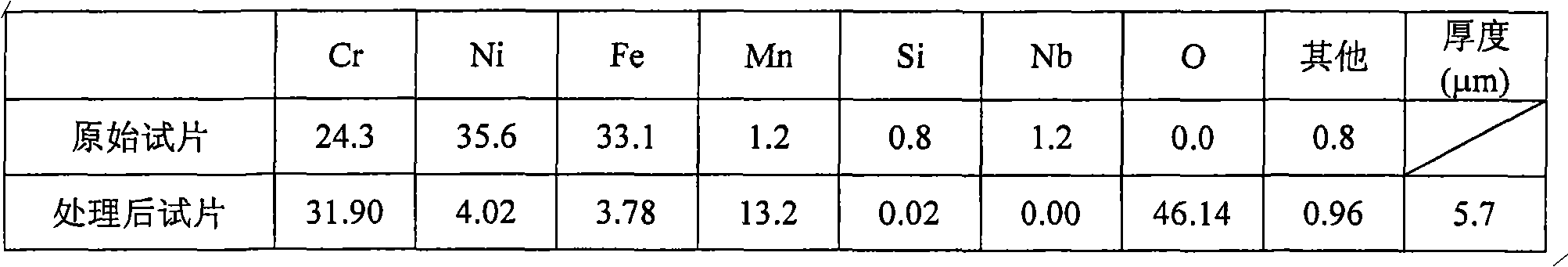

[0041] Use superalloy HP40-Nb to make a test piece, the size of the test piece is a square with a side length of 10mm and a thickness of 4mm. The composition of the test piece was analyzed by X-ray energy dispersive spectrometer (EDS), and the specific results are shown in Table 3.

[0042] Put the test piece into a tube furnace, pass through the mixed gas of hydrogen and argon, wherein the fraction of argon gas is 60%, the mixed gas contains 1.6% water vapor by volume, and the gas pressure is 1.01 atmospheres. After heating the atmosphere furnace to 1000 degrees Celsius, heat preservation treatment for 50 hours, and take out the test piece after cooling with the furnace.

[0043] X-ray photoelectron spectroscopy (XPS) was used to test the composition of the surface (oxidation protection layer) of the test piece, and it was found that it was mainly composed of manganese, chromium and oxygen, and the content of iron and nickel was reduced to a very low level. The energy spectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com