Patents

Literature

52 results about "Energy Dispersive Spectrometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An instrument that focuses high energy electromagnetic radiation toward a sample and measures the resulting X-rays emitted.

Processing of spectrometer pile-up events

InactiveUS20080319714A1Increase the number ofImprove throughputRadiation pyrometryMaterial analysis using wave/particle radiationImage resolutionEngineering

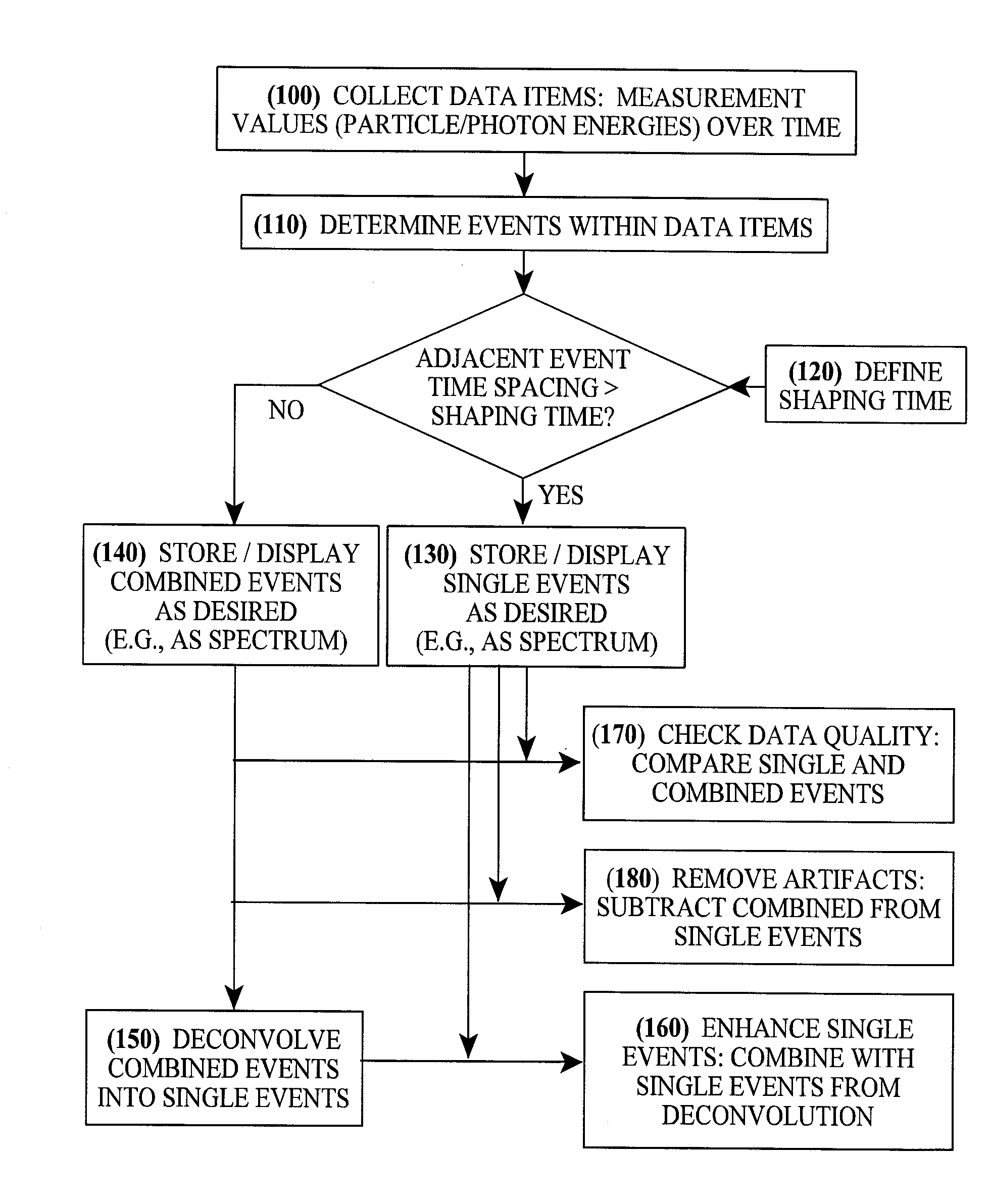

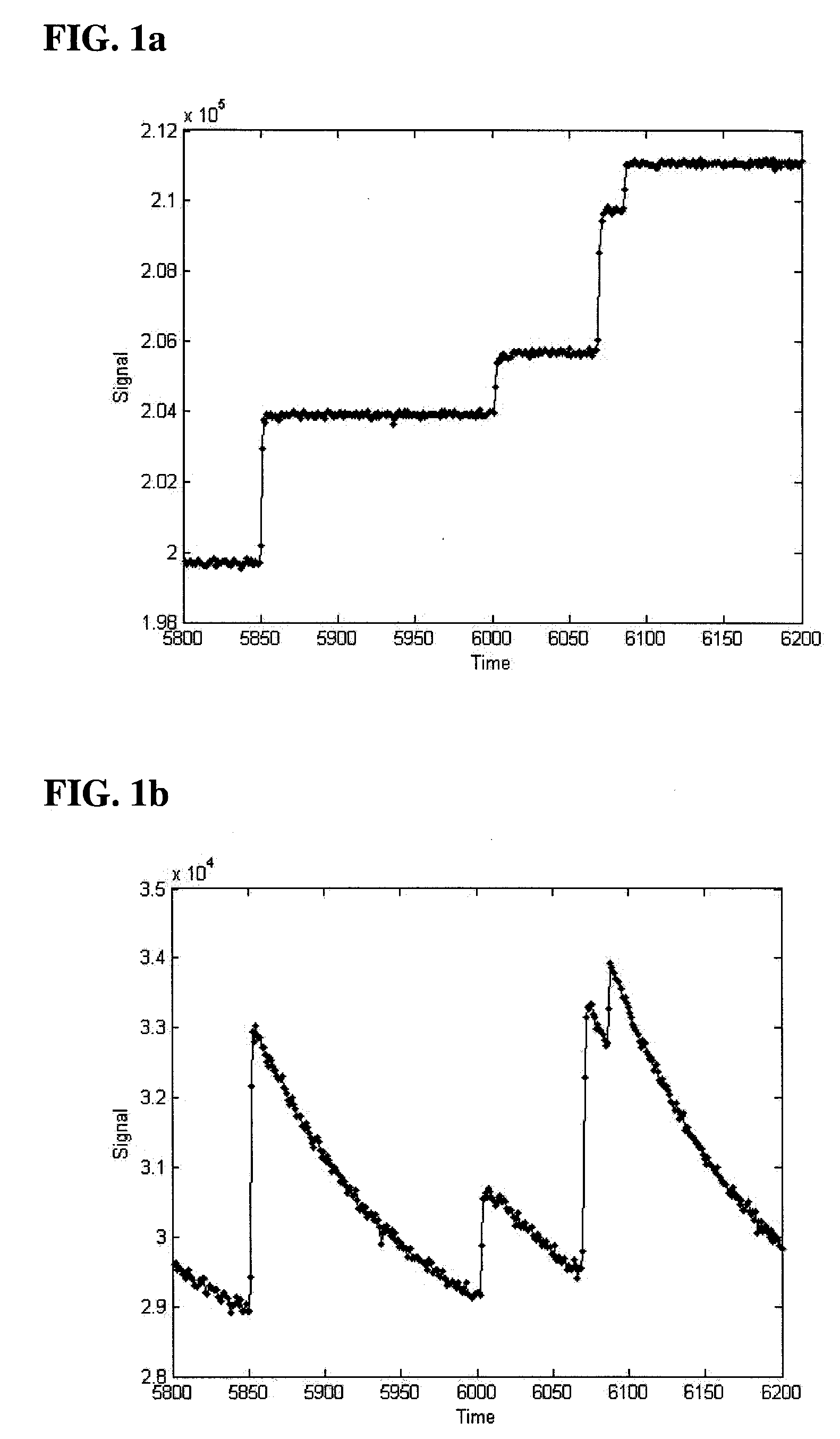

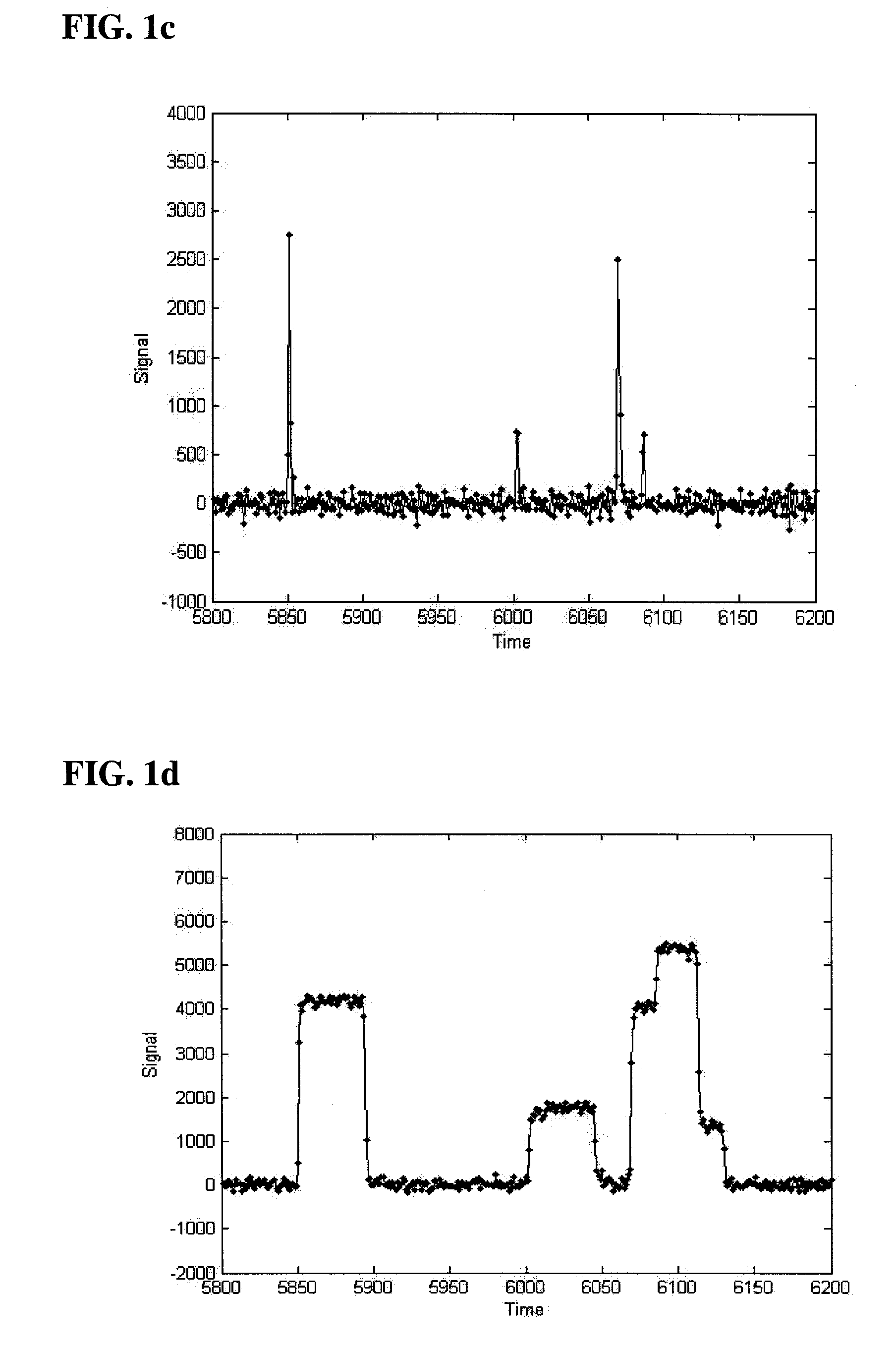

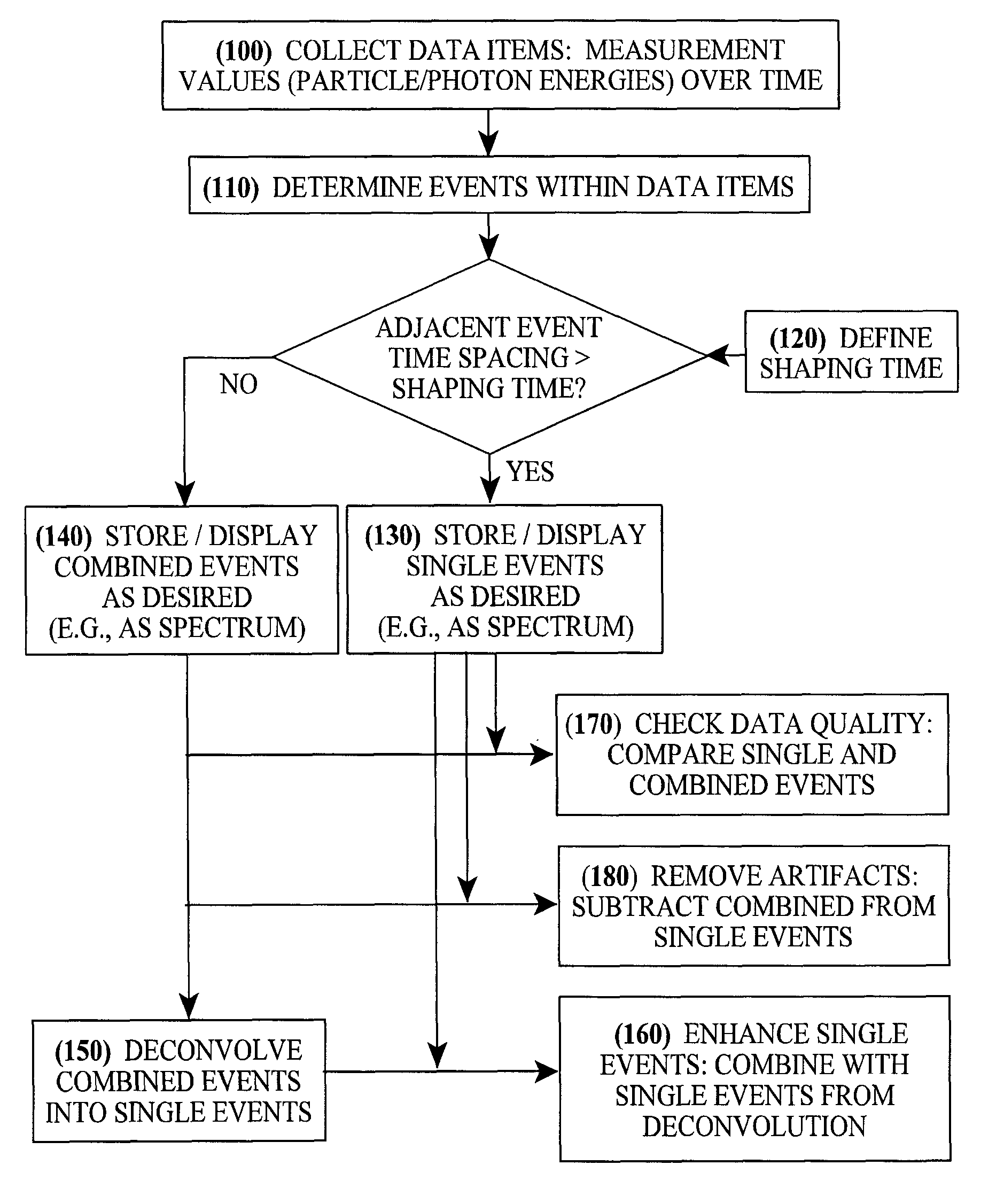

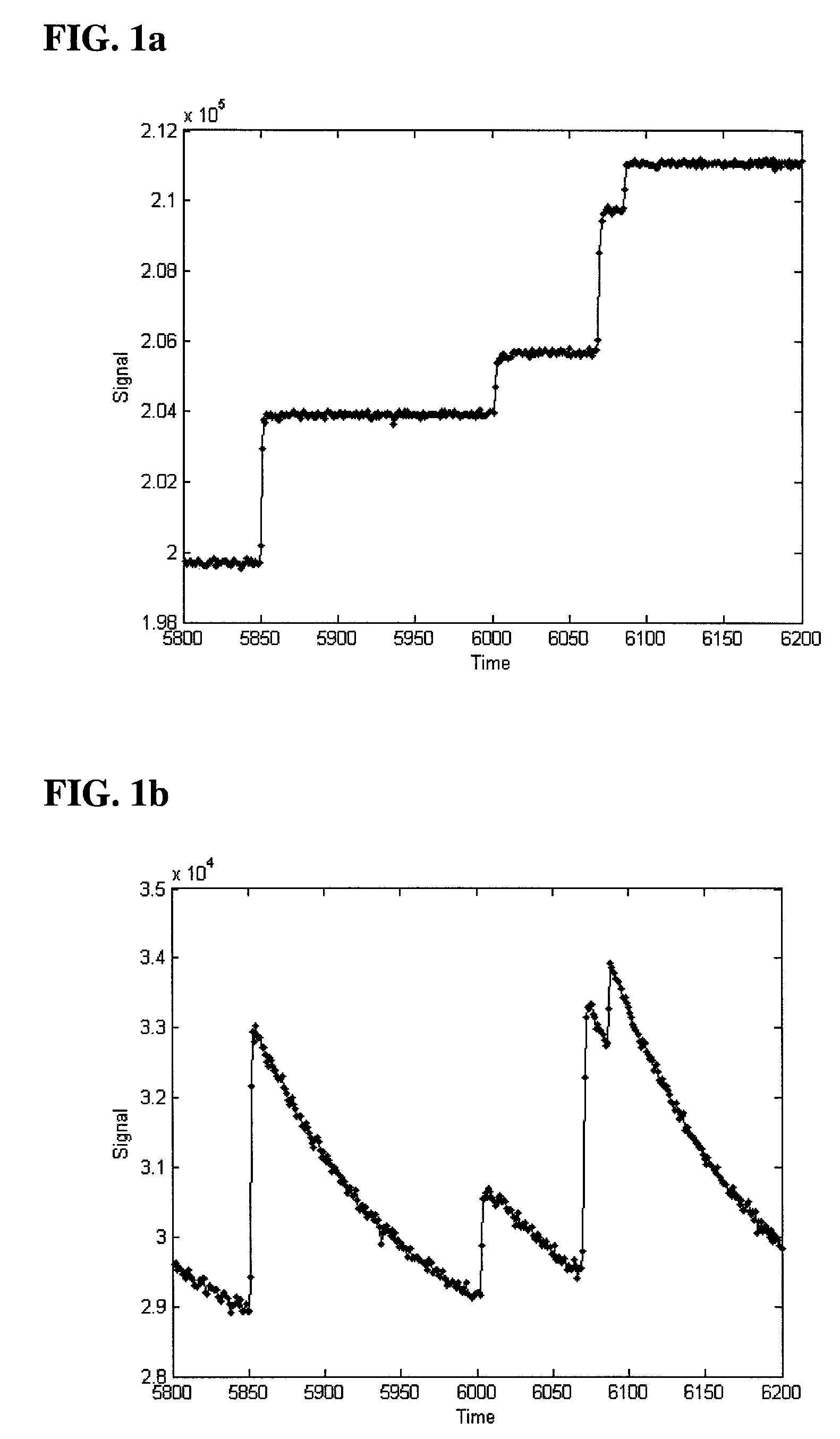

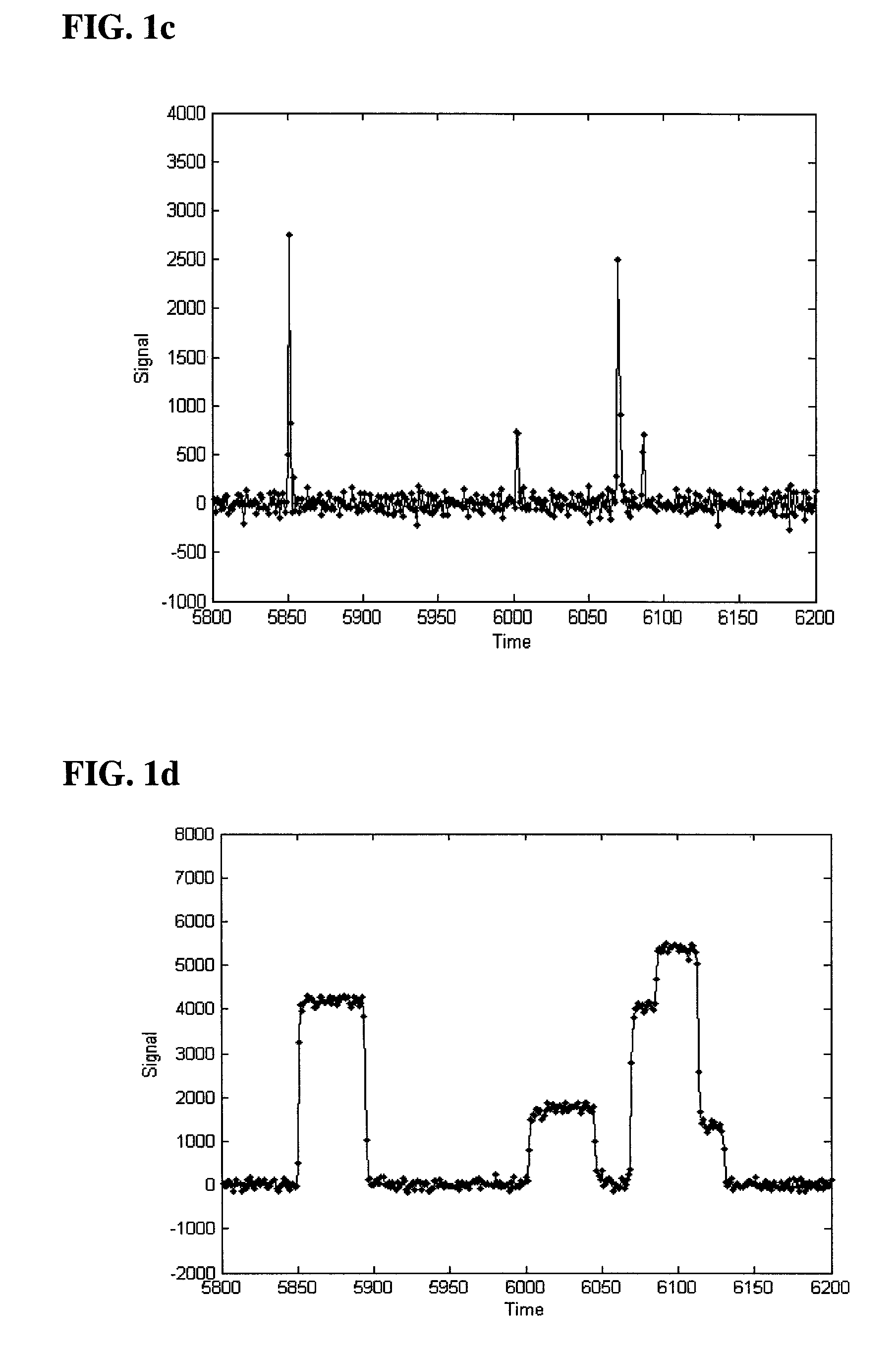

In an energy dispersive spectrometer wherein event (particle / photon) detection is performed by counting events spaced by greater than a shaping time, events which are spaced by less than the shaping time are also collected and counted. These “combined events” are treated similarly to “single events” which are spaced by greater than the shaping time, and can be used to generate combined-event spectra for comparison and / or use with the conventional single-event spectra. The combined-event spectra can be compared to the single-event spectra to provide an indication of data quality; can be subtracted from the single-event spectra to remove artifacts, and / or can be deconvolved into a single-event spectrum to increase the resolution of the single-event spectrum.

Owner:THERMO ELECTRON SCI INSTR

Inorganic coating method for titanium dioxide

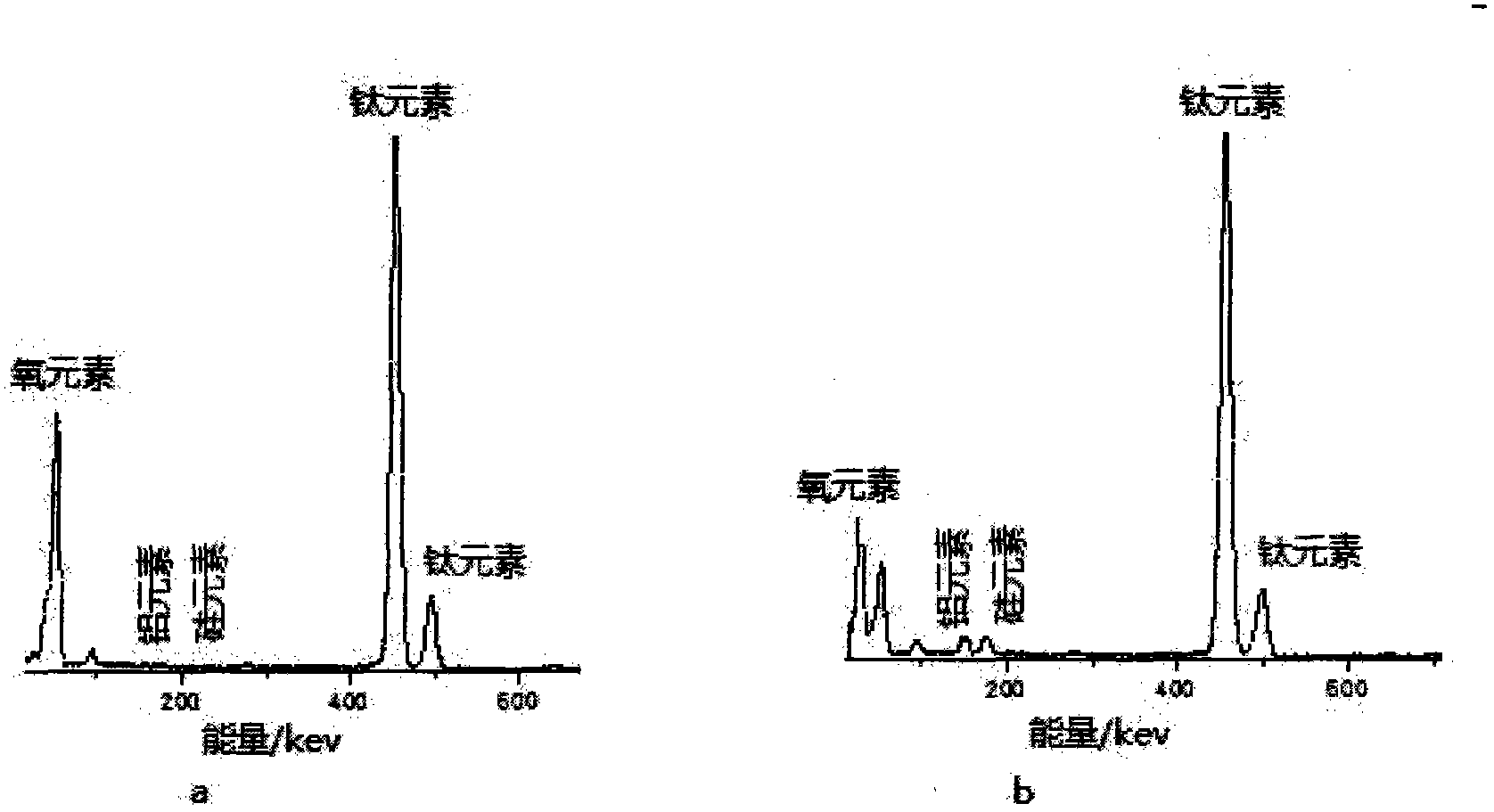

InactiveCN103214880AReduce the number of trialsStrong representativeInorganic pigment treatmentScanning tunneling microscopeRutile

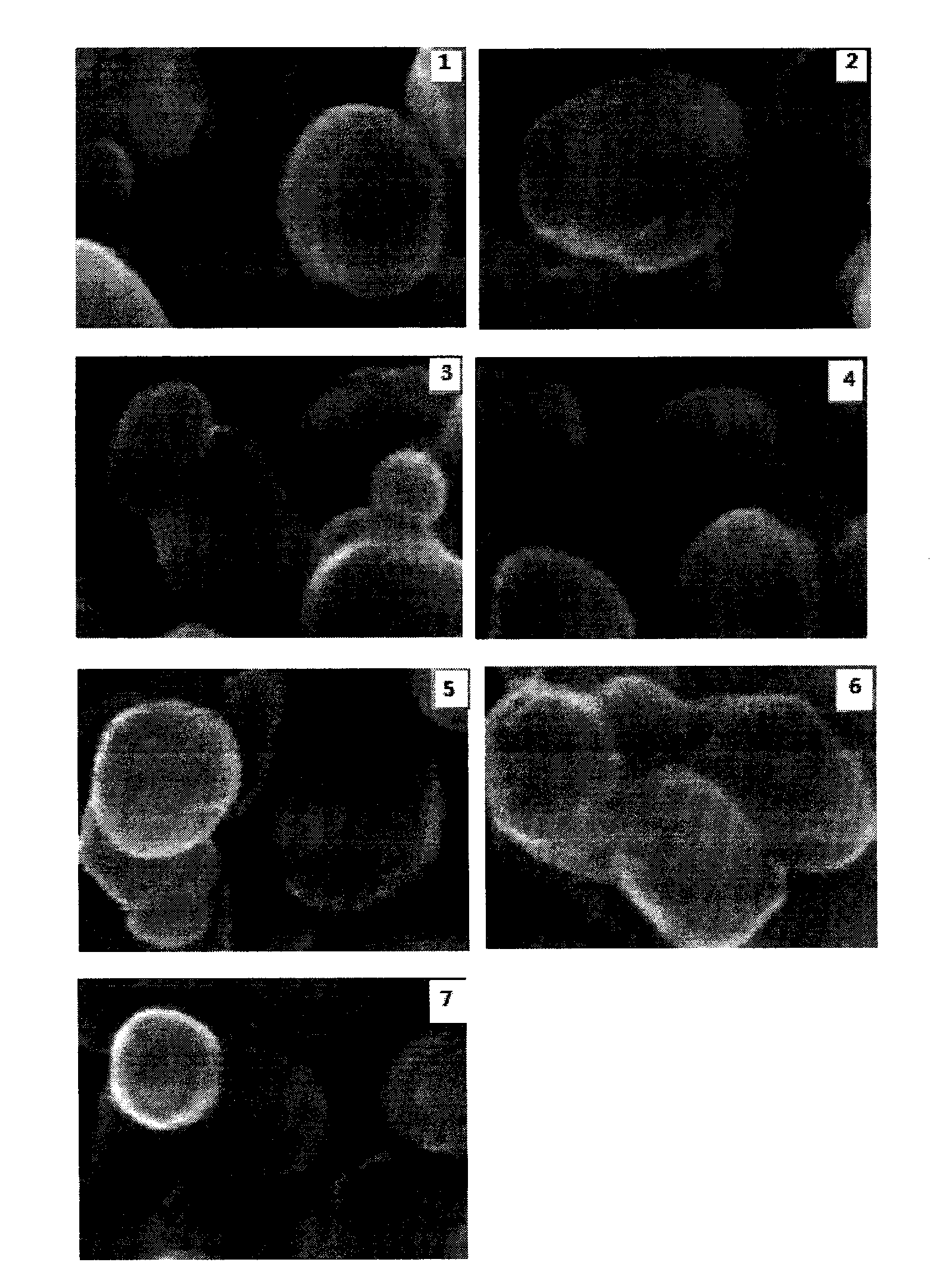

The invention researches a novel process for Zr-Si-Al ternary inorganic coating for rutile titanium dioxide by using a sol-gel method. Through a uniform test design, the influences of various factors to the ternary inorganic coating performance of the rutile titanium dioxide are researched by a system, and the ternary inorganic coating effect of the rutile titanium dioxide is inspected through testing measures such as Nano-ZS, a Fourier infrared spectrometer (FT-IR), a scanning electron microscope (SEM), a transmission electron microscope (TEM), an energy dispersive spectrometer (EDS) and the like. The process for the ternary inorganic coating for the rutile titanium dioxide has the optimized formula as follows: 0.20% of dispersing agent, 0.6% of zirconium, 3.0% of silicon and 1.6% of aluminum, wherein the rotating speed is 340r / min.

Owner:HUNAN UNIV OF TECH

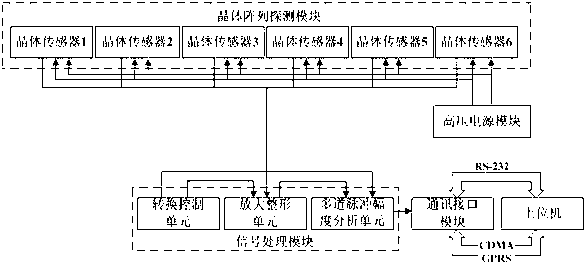

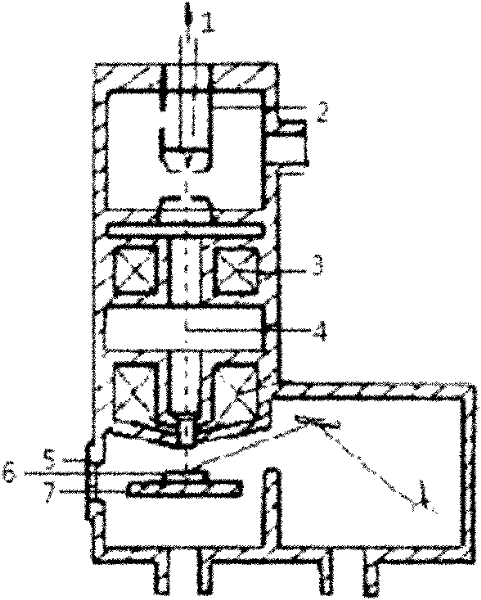

Low background gamma energy dispersive spectrometer for ocean radioactive measurement

ActiveCN103217702ARealize real-time monitoringHigh sensitivity detectionX-ray spectral distribution measurementGamma energyField monitoring

The invention discloses a low background gamma energy dispersive spectrometer for ocean radioactive measurement. The low background gamma energy dispersive spectrometer for the ocean radioactive measurement comprises a crystal array detecting module composed of six NaI (T1) crystal sensors, a signal processing module and an upper computer. The six NaI (T1) crystal sensors are evenly divided into three groups. The two NaI (T1) crystal sensors in each group are arranged oppositely. Crystal end faces of the six NaI (T1) crystal sensors are adjacent so that a zone used for placing a sample box is defined. Six ways of output detected signals are detected by the six NaI (T1) crystal sensors, transmitted to the signal processing module, processed to energy spectrum signals through the signal processing module and transmitted to the upper computer. The energy dispersive spectrometer can be used for conducting rapid detection on radionuclide content in a marine environment, suitable for laboratory detection and field monitoring of vehicle mounting and ship mounting and capable of being popularized and used in detection works of other samples with low radioactivity except for the marine environment.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

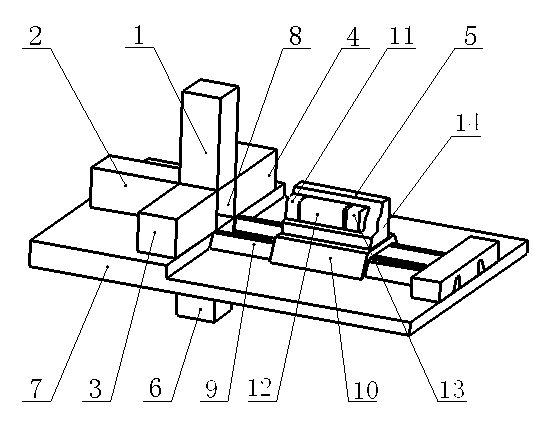

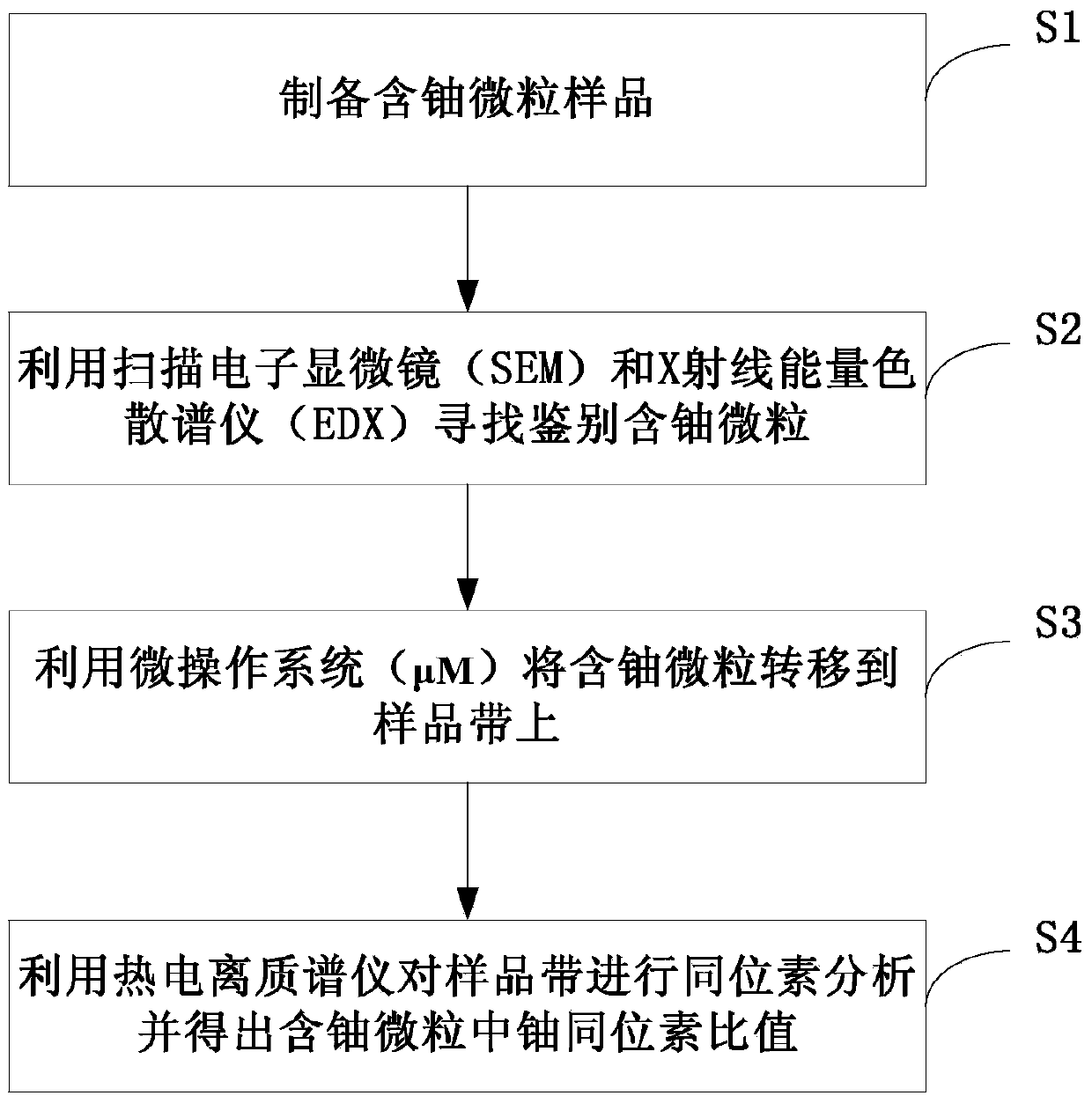

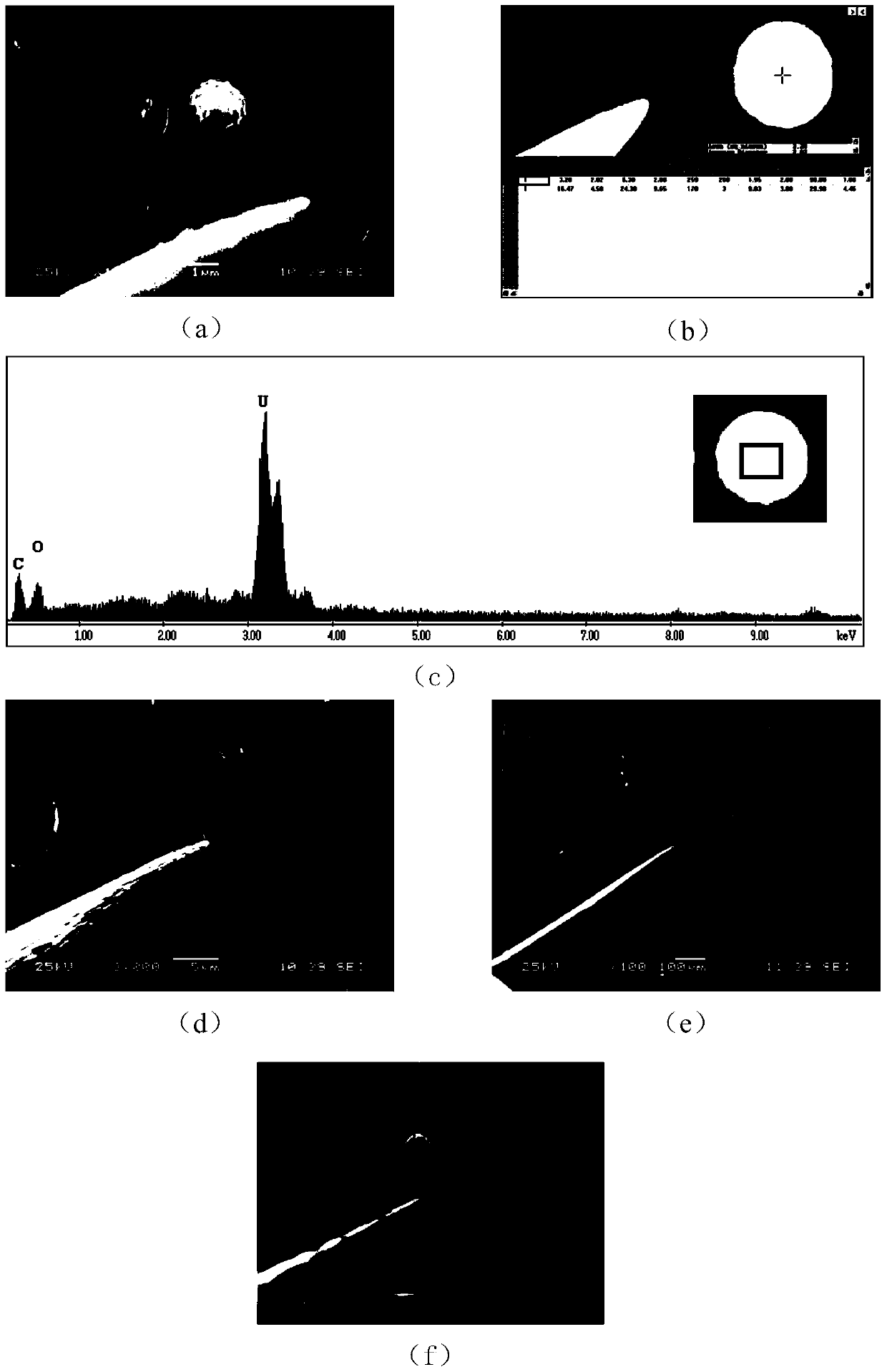

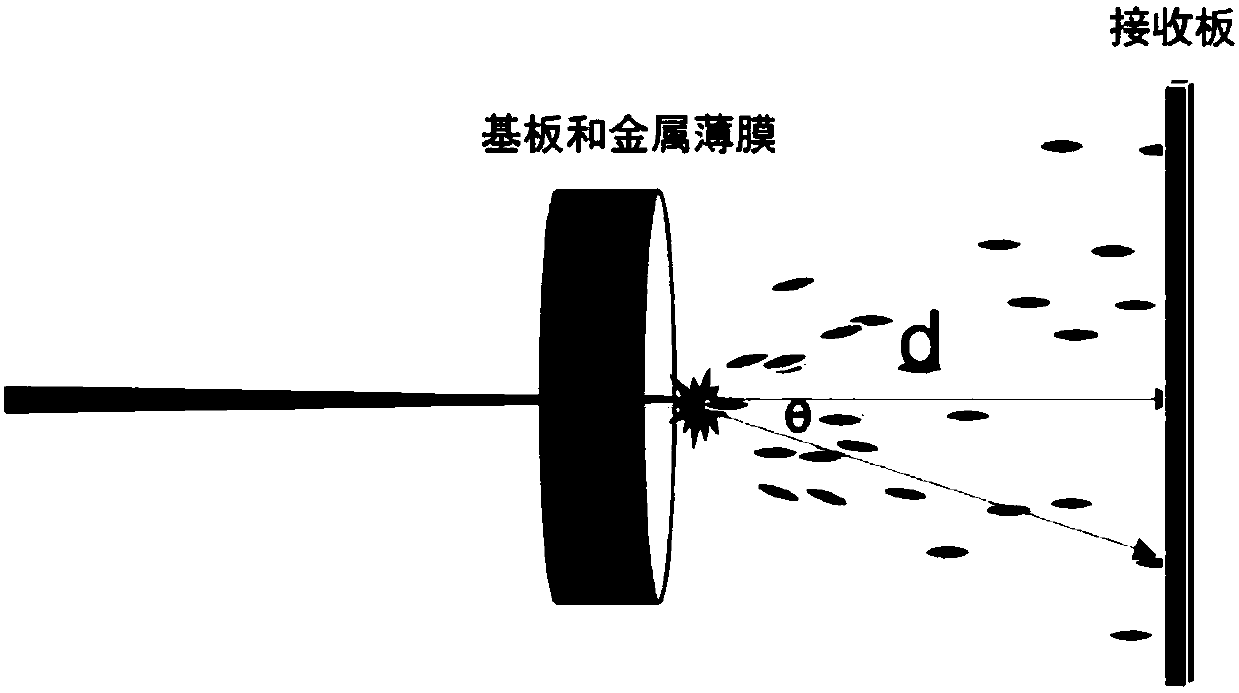

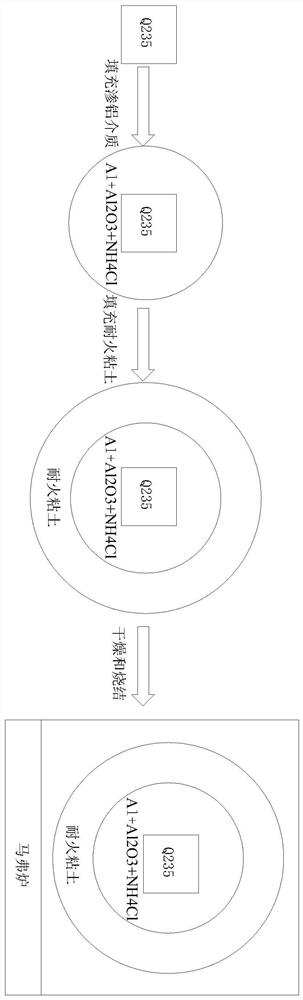

Method for measuring uranium isotope ratio in single particles

InactiveCN103728327AShort measuring cycleImprove analysis efficiencyMaterial analysis using wave/particle radiationPreparing sample for investigationX-rayIsotope

The invention provides a method for measuring a uranium isotope ratio in single particles. The method comprises the following steps: S1, preparing a uranium-containing particle sample; S2, searching and identifying uranium-containing particles in the uranium-containing particle sample by utilizing a scanning electron microscope and an X-ray energy dispersive spectrometer; S3, after finding out the uranium-containing particles, transferring the uranium-containing particles onto a sample belt by utilizing a microoperation system; S4, carrying out isotope analysis on the sample belt by utilizing a thermal ionisation mass spectrometer and obtaining the uranium isotope ratio in the uranium-containing particles. Compared with the prior art, the method for measuring the uranium isotope ratio in the single particles, provided by the invention, does not need to carry out irradiation, cooling and etching, can greatly shorten the measurement period of particle analysis and improves analysis efficiency.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

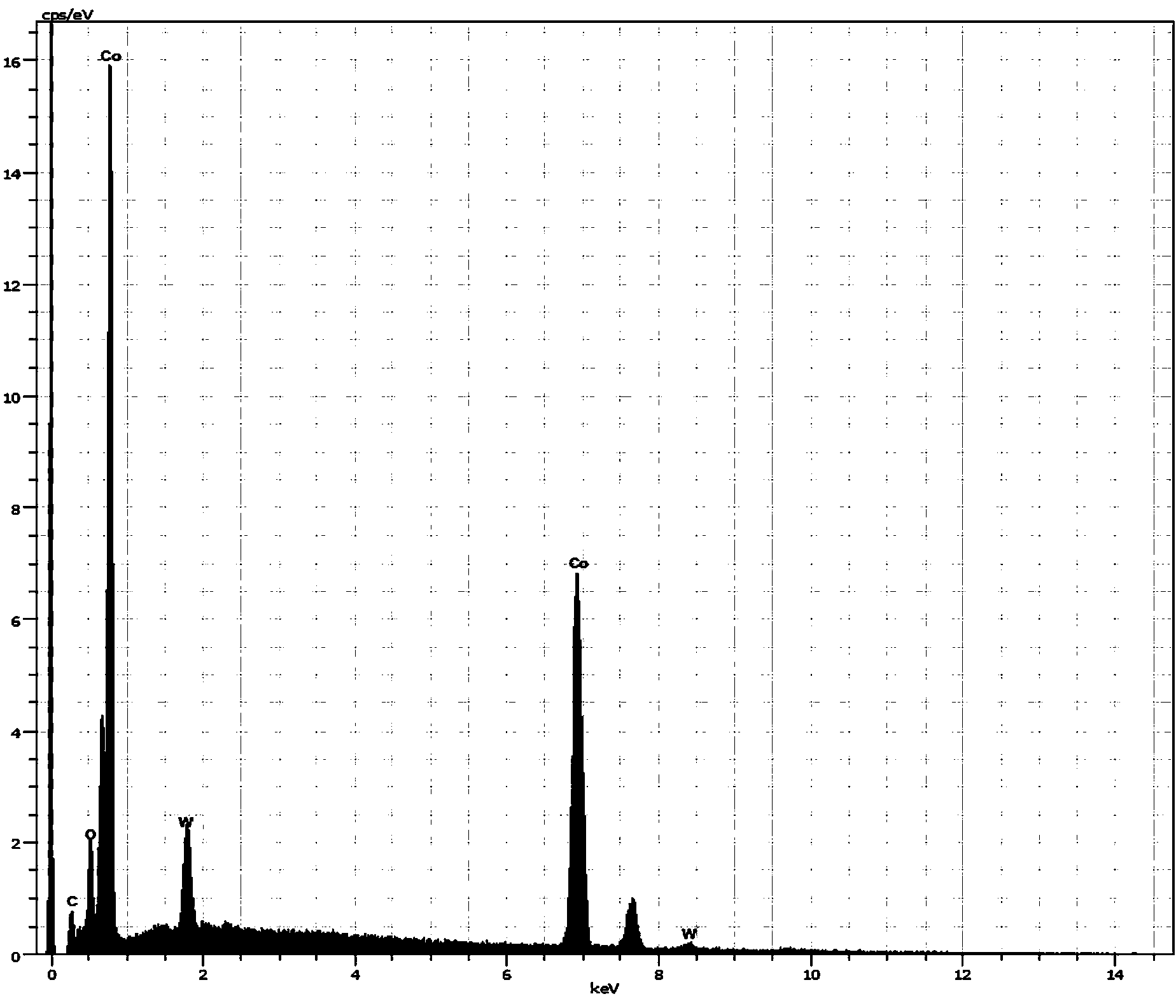

Method for analyzing and detecting solid solubility of tungsten in cemented carbide binding phase

The invention discloses a method for analyzing and detecting solid solubility of tungsten in a cemented carbide binding phase. The method sequentially comprises the steps as follows: preparing a metallographic polished surface of a sample to be detected; stripping a hard phase on the metallographic polished surface by using an isolation technology, and eliminating surface impurities and oxide layers; optimizing an X-ray energy dispersive spectrometer calibration device by a pure Co binding phase sample; selecting a cobalt-base alloy sample with known components as an analysis standard sample, obtaining a correction factor with a matrix correction method (ZAF method) according to a theoretical value of the standard sample and the actual testing result, saving the correction factor as standard sample database, and determining working parameters of an optimum scanning electron microscope for analysis of the sample to the detected according to the detection result of the standard sample; and taking data and relevant parameters built by the cobalt-base alloy with solid solubility W of 5% as an X-ray energy spectrum quantitative standard database file, and performing repeated and multi-point measurement on the sample to the detected in different fields of view, wherein an arithmetic mean of the sample to be detected is the solid solubility of the tungsten in the binding phase of the sample to be detected. According to the method, the solid solubility of the tungsten in the cemented carbide binding phase is analyzed and detected, and the accuracy is high.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

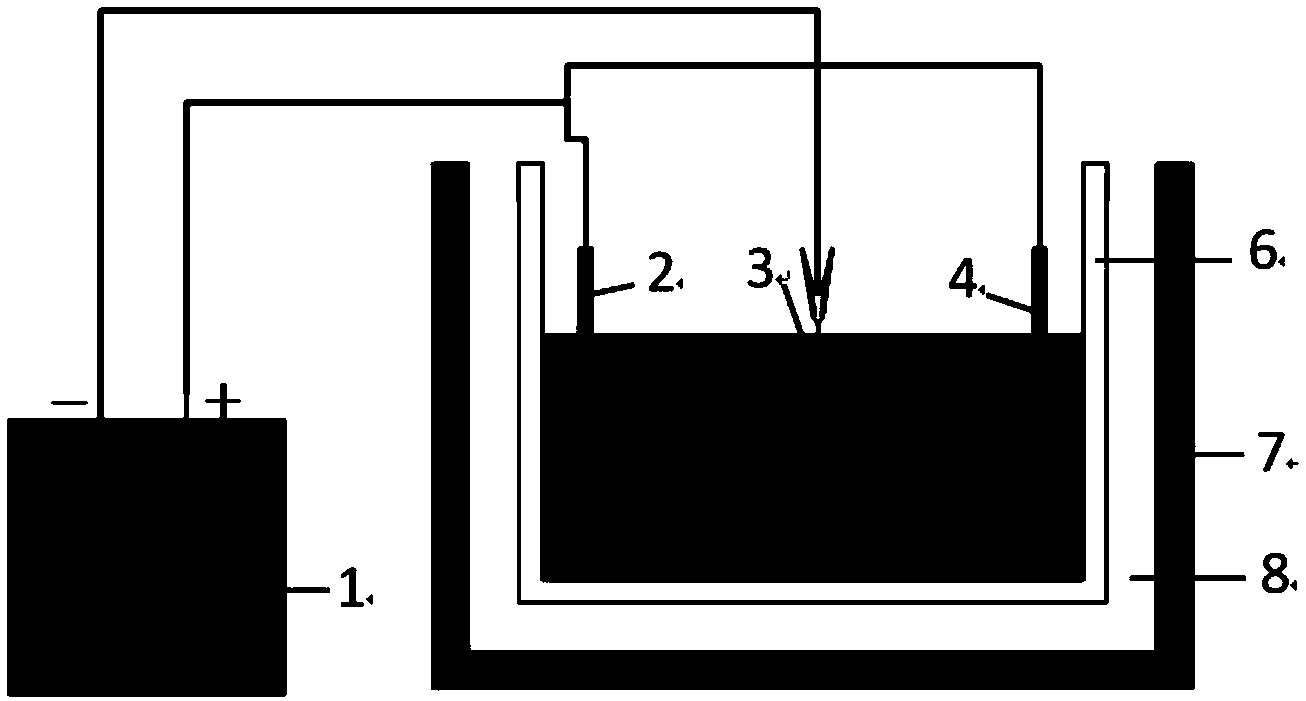

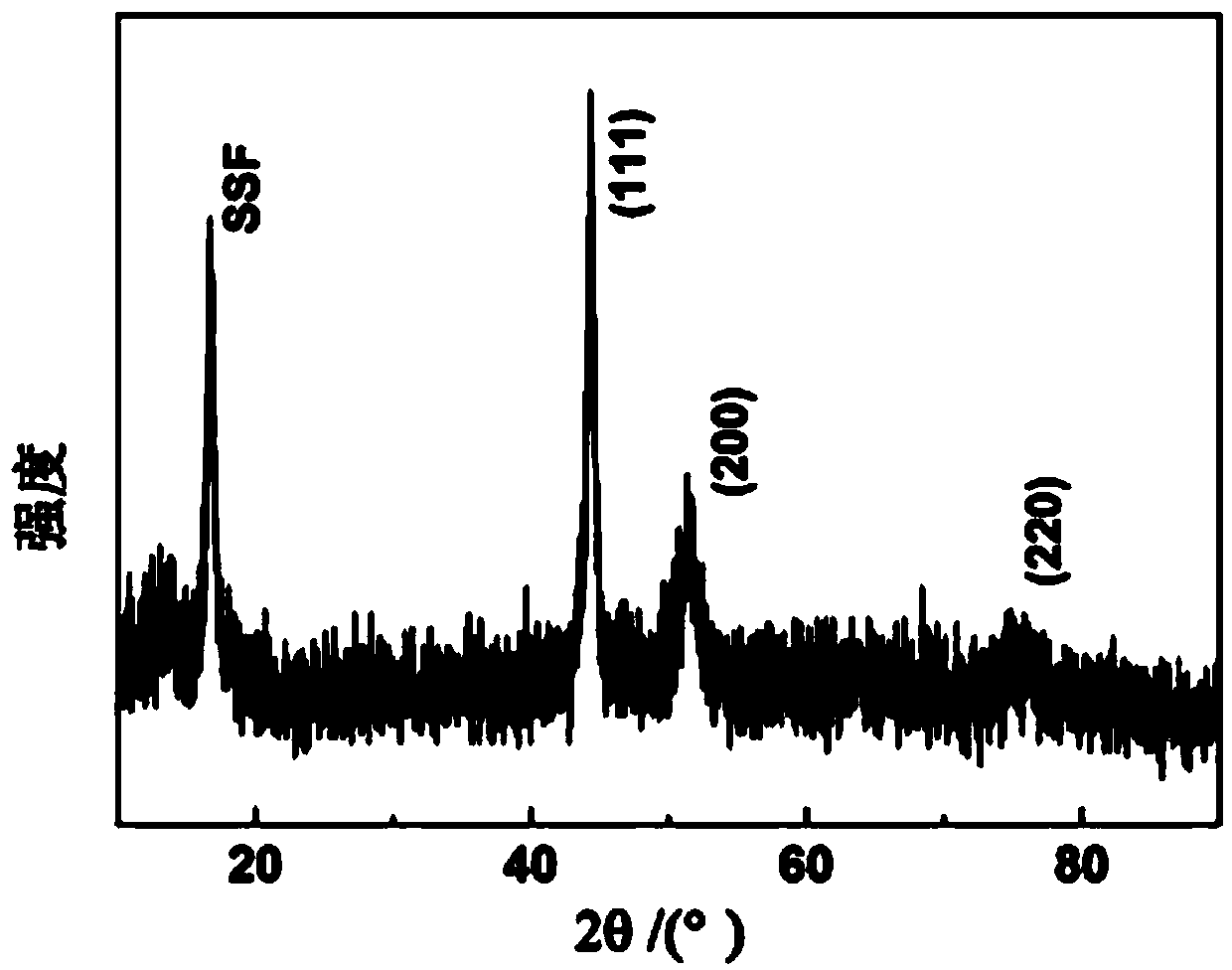

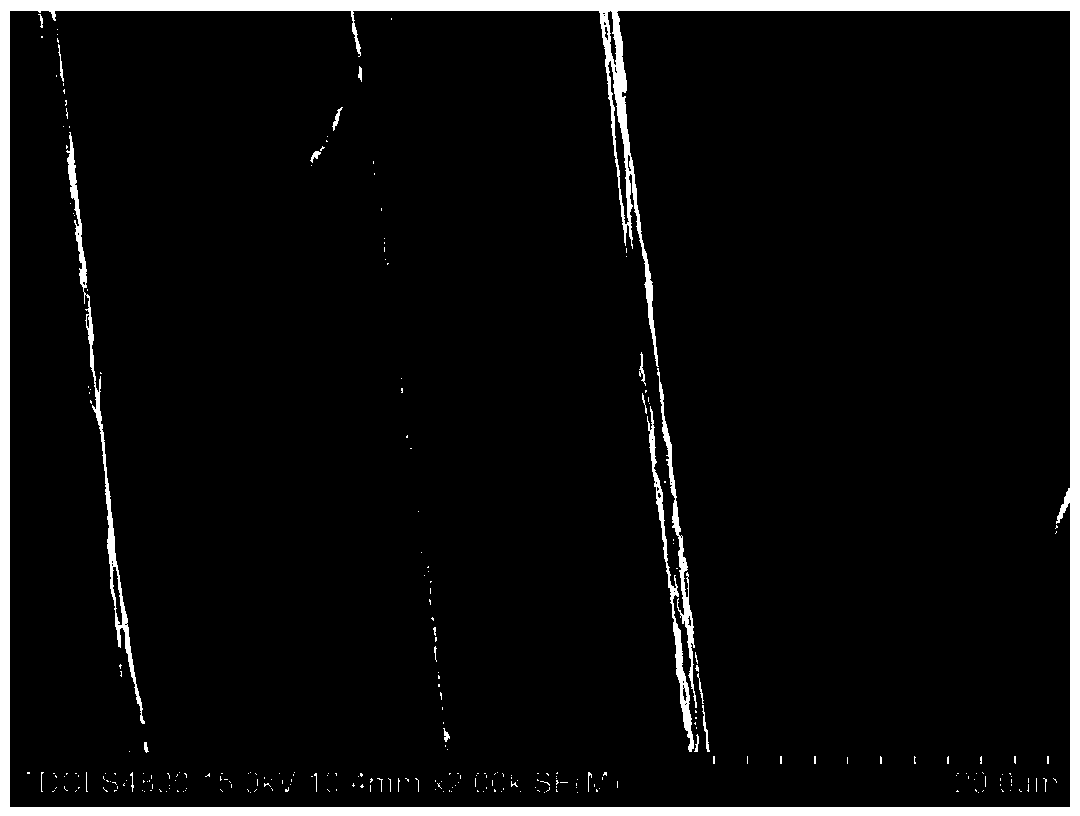

Preparation method of iron-nickel alloy magnetic layer on surface of stainless steel fiber

The invention relates to a preparation method of an iron-nickel alloy magnetic layer on the surface of a stainless steel fiber. The preparation method comprises the following steps: preprocessing the stainless steel fiber, electrically plating the stainless steel fiber and post-processing the stainless steel fiber after electrically plating. The method comprises the following specific steps of preparation of an electroplate liquid and carrying out XRD (X-Ray Diffraction) analysis, surface shape and surface component EDS (Energy Dispersive Spectrometer) analysis, notch morphology (Scanning Electron Microscope) observation and magnetic VSM (Vector Space Model) analysis after electrically plating the iron-nickel alloy magnetic layer. By adopting an electroplating technique, the iron-nickel alloy magnetic layer with excellent soft magnetic properties is deposited on the stainless steel fiber, so that components and the soft magnetic properties of the iron-nickel alloy magnetic layer are adjusted, and thus conductive properties and magnetic properties of the fiber are remarkably improved; the iron-nickel alloy magnetic layer has excellent comprehensive electromagnetic properties, so that the iron-nickel alloy magnetic layer has good performances of reflecting and absorbing electromagnetic waves; meanwhile, the iron-nickel alloy layer is simple in process, convenient to operate, low in cost and capable of realizing continuous production, and can be expected to be well used in electromagnetic shielding fields with wide frequency bands.

Owner:TIANJIN UNIV +1

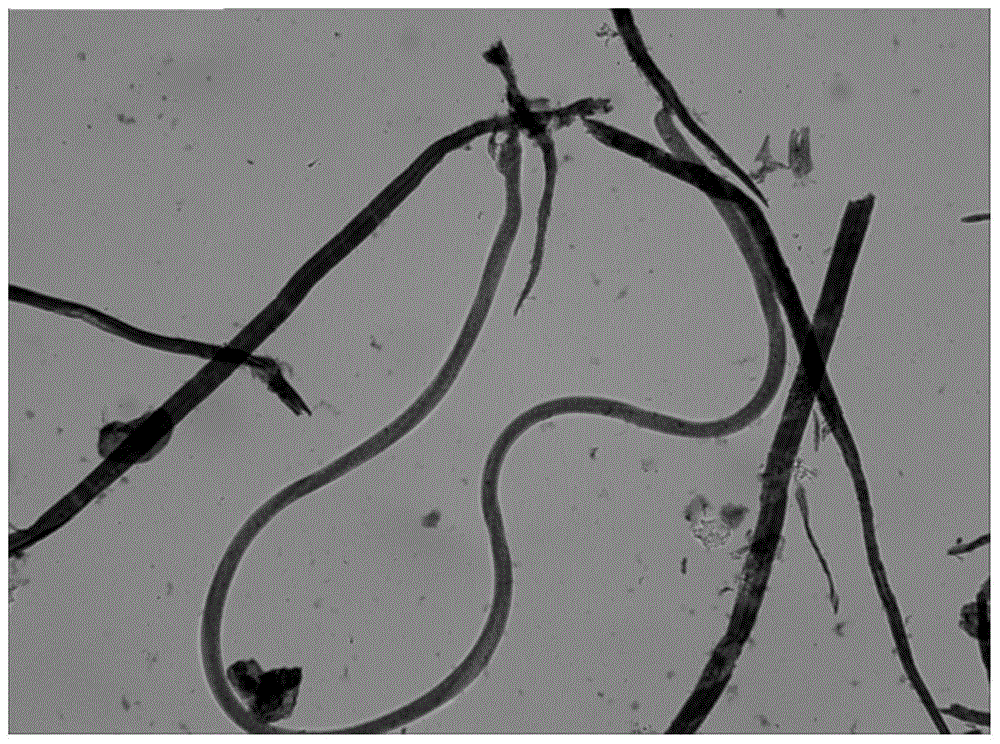

Ni-Cu-La-B quaternary alloy plating solution and method for chemically plating glass fibers by using same

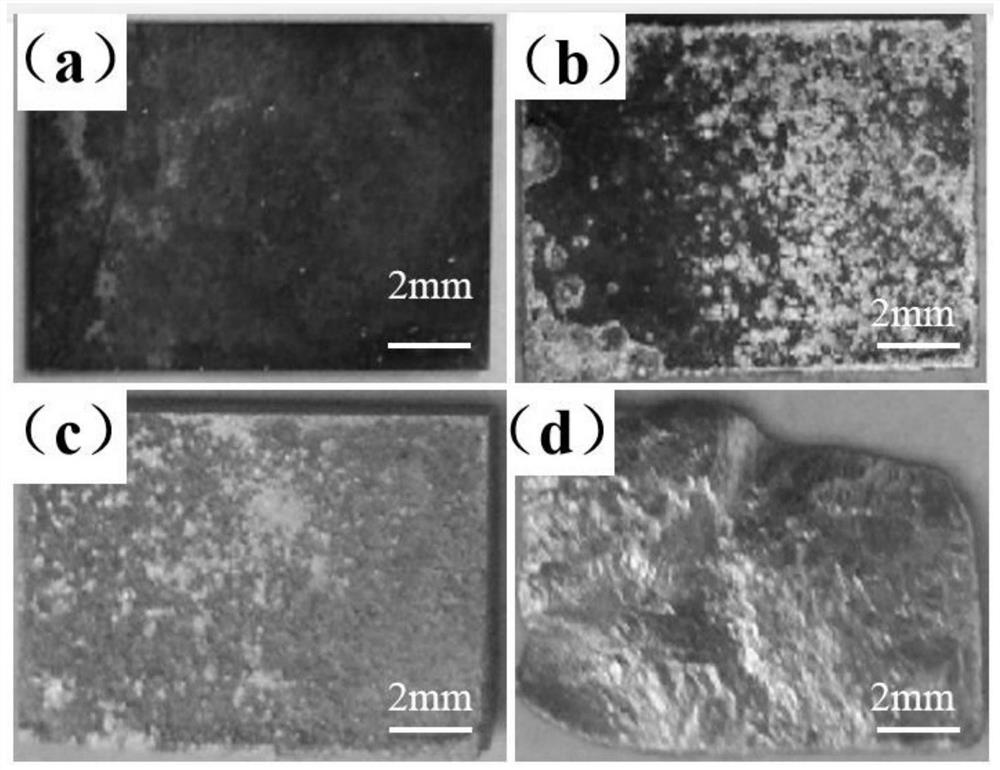

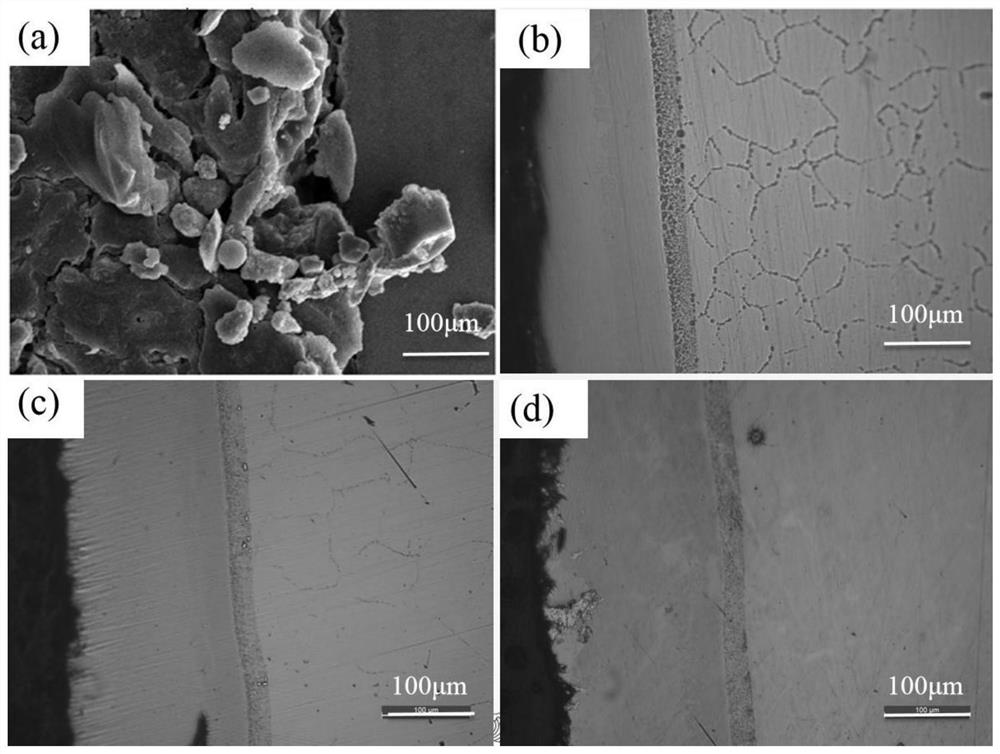

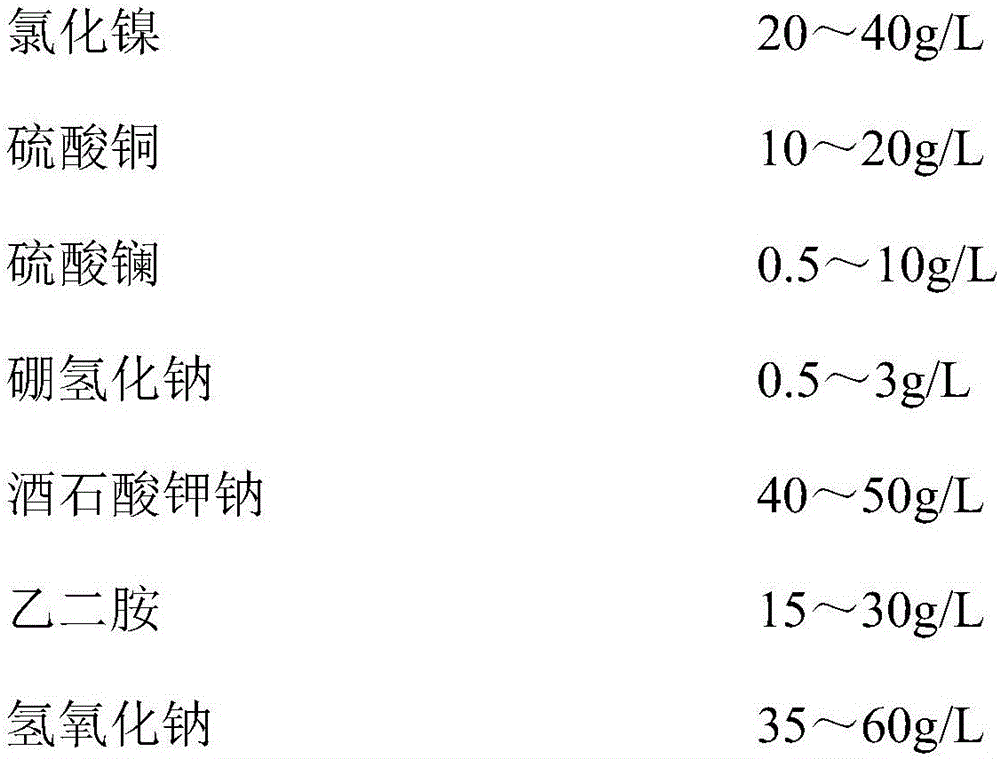

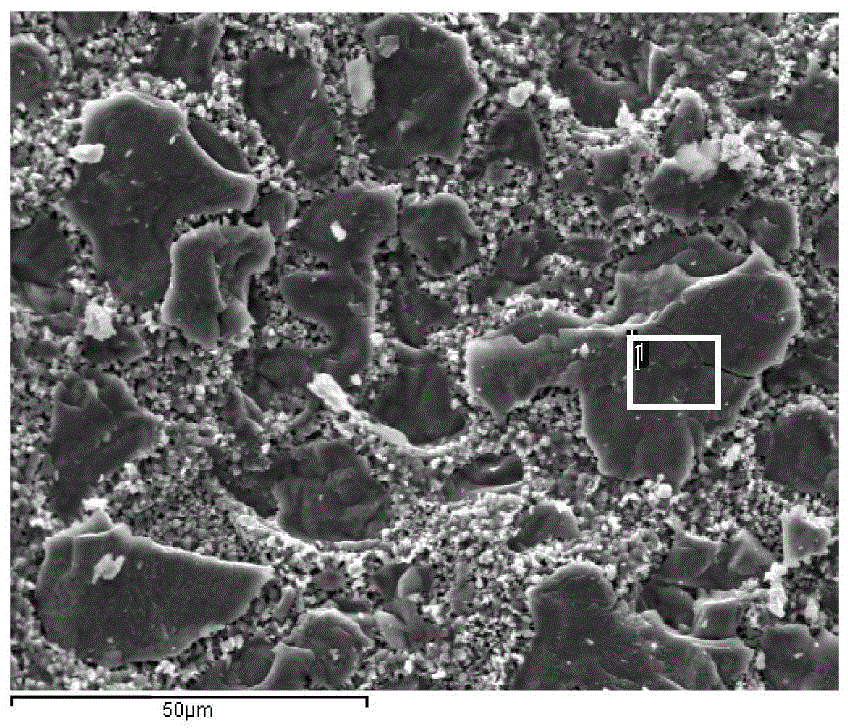

ActiveCN103757617AReduce contentIncreased nickel contentLiquid/solution decomposition chemical coatingEthylenediamineMicroscopic observation

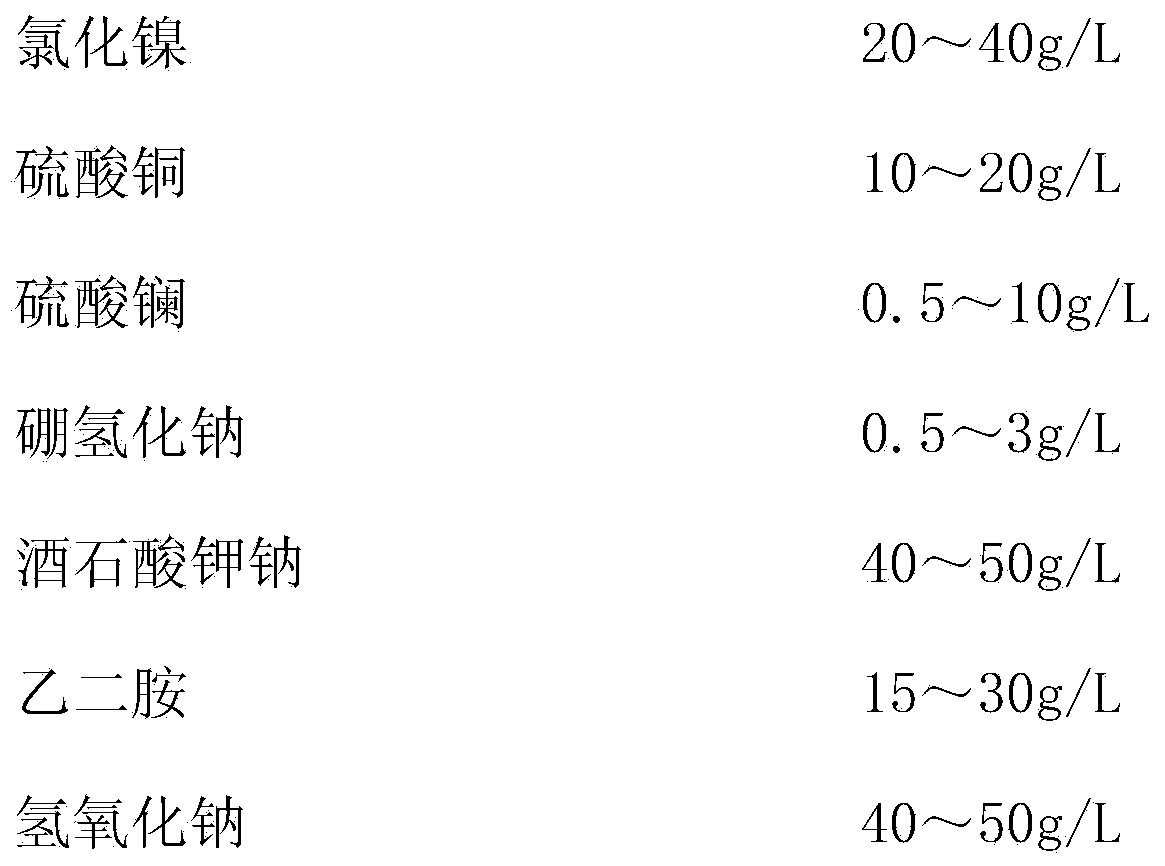

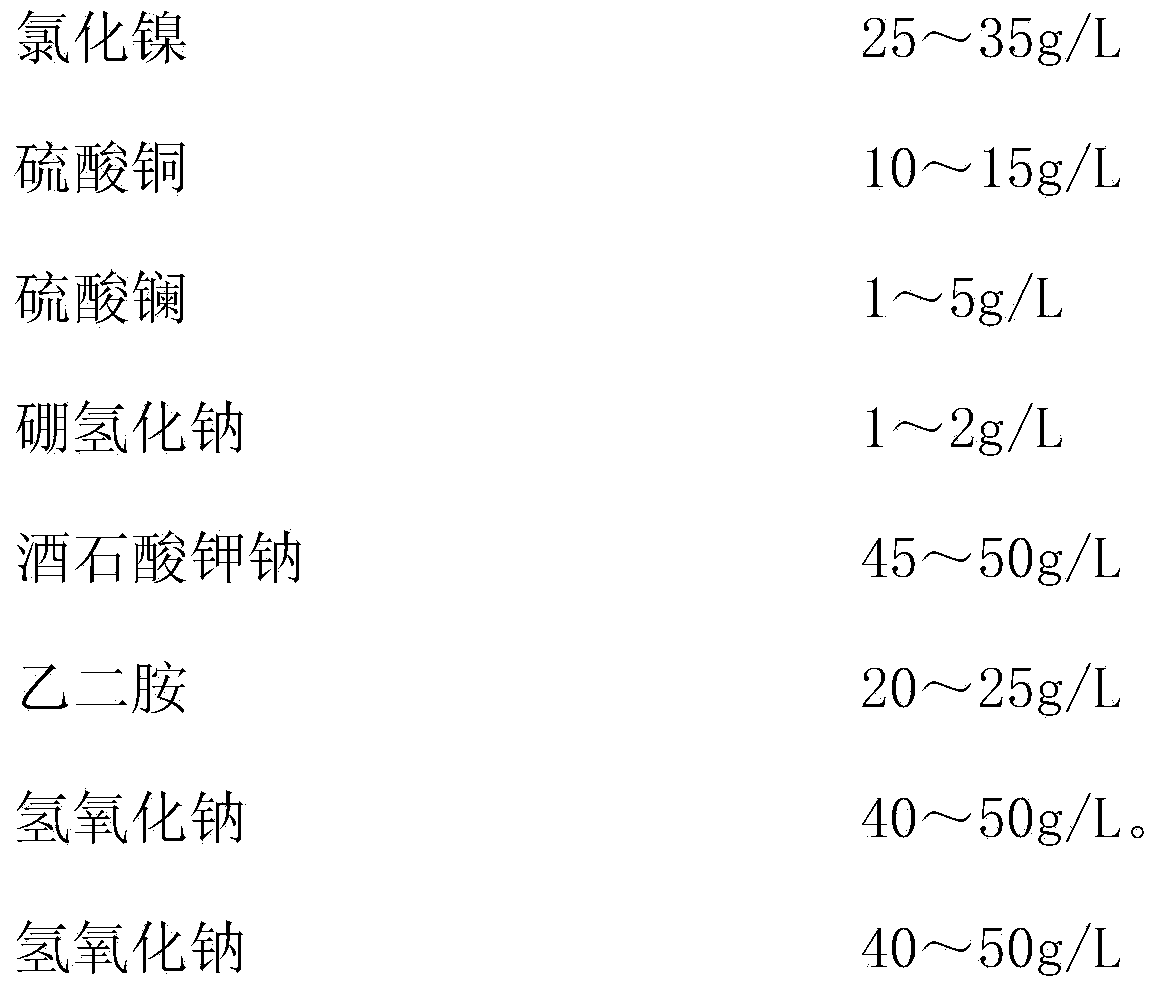

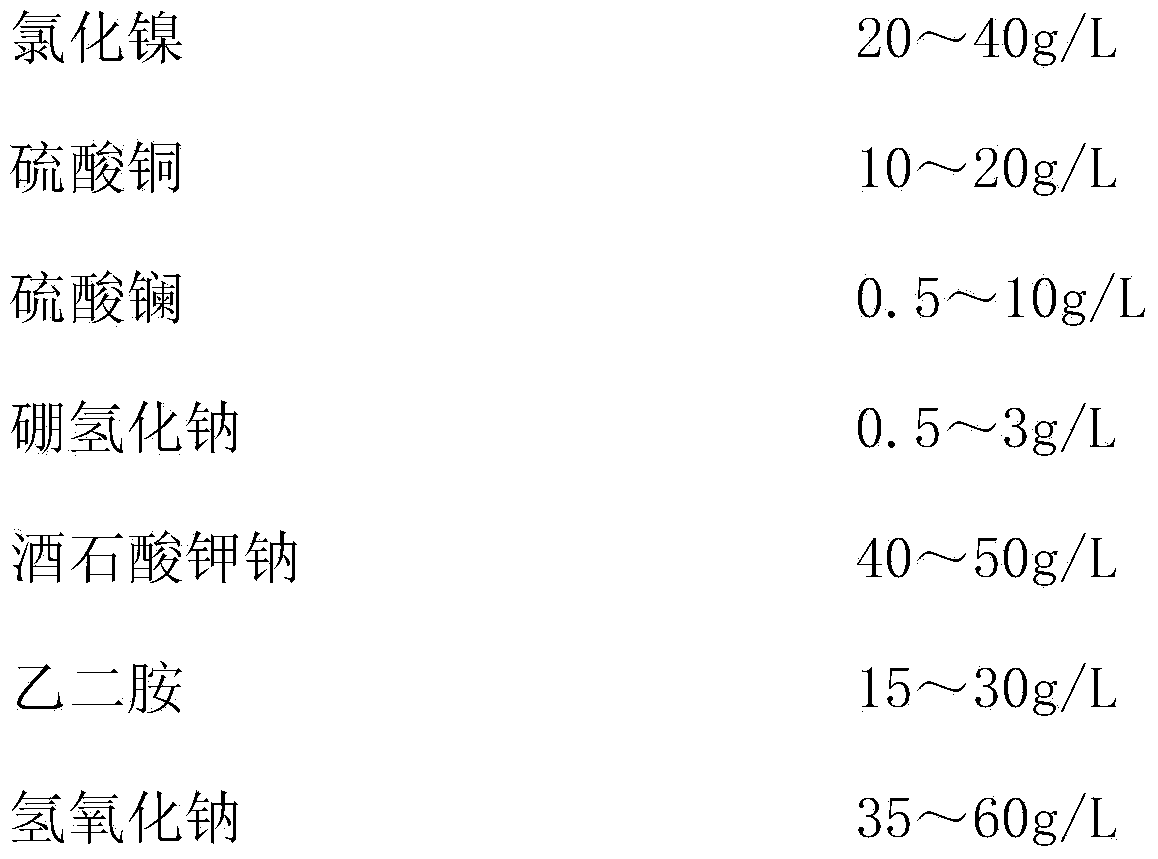

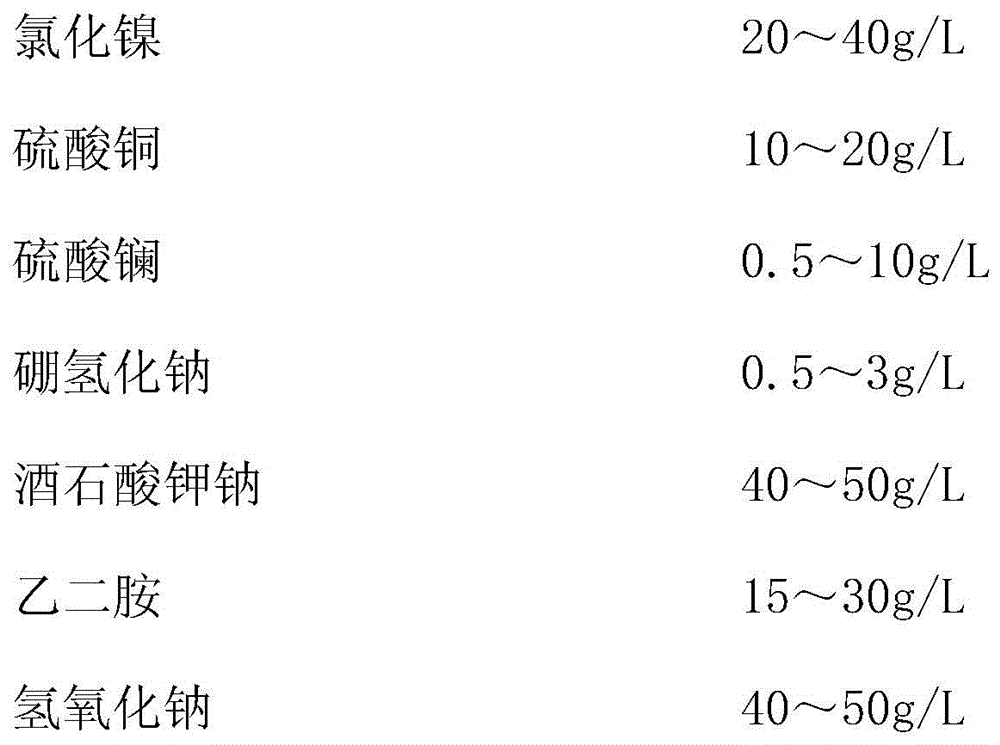

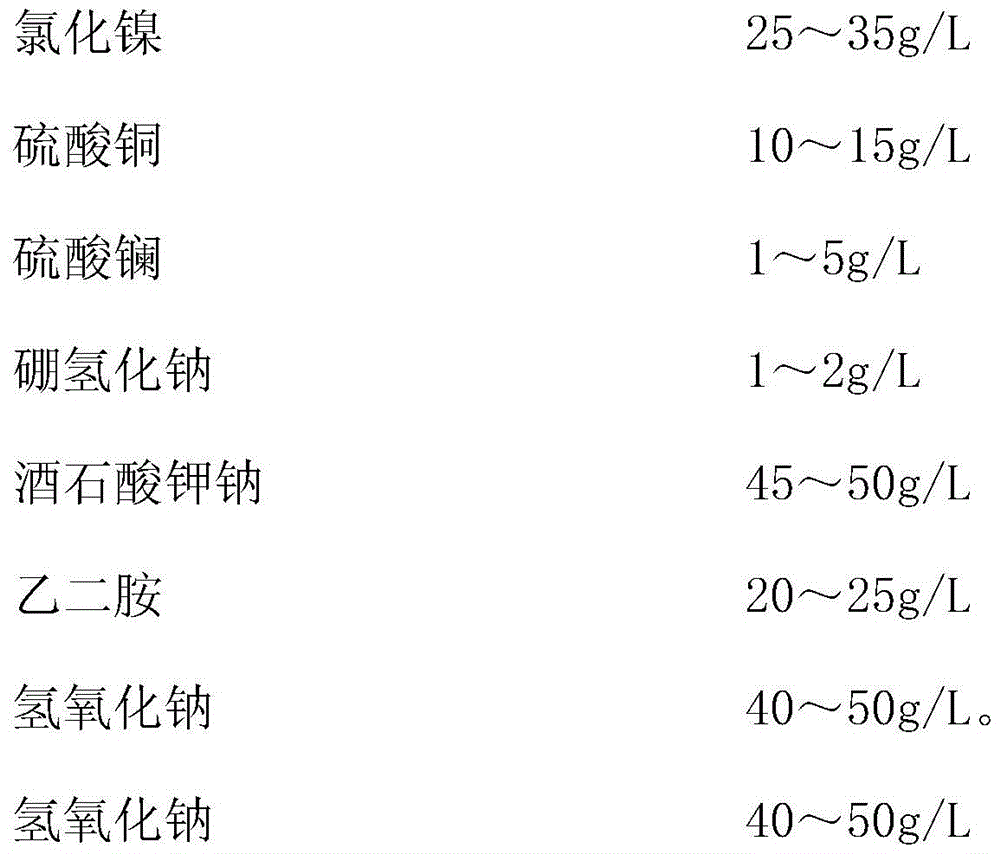

The invention discloses a Ni-Cu-La-B quaternary alloy plating solution. The Ni-Cu-La-B quaternary alloy plating solution comprises the following components: 20-40g / L of nickel chloride, 10-20g / L of copper sulfate, 0.5-10 g / L of lanthanum sulfate, 0.5-3 g / L of sodium borohydride, 40-50g / L of potassium sodium tartrate, 15-30g / L of ethylenediamine and 35-60g / L of sodium hydroxide. A method for chemically plating the glass fibers by using the Ni-Cu-La-B quaternary alloy plating solution comprises the following steps: using sodium borohydride as a reducing agent, adding the water-soluble lanthanum sulfate, and chemically plating the glass fibers by using the Ni-Cu-La-B quaternary alloy plating solution under the conditions of strong base and low temperature; plating layers are Ni-Cu-La-B alloy plating layers, wherein the content of boron is low (only about 0.5-5wt%), the content of nickel in the plating layers is high; the plating layers have good bonding force, electrical conductivity and wear resistance. Through observation with microscopes, the plating layers of the Ni-Cu-La-B quaternary alloy plated glass fibers prepared by using the method are compact; testing with an X-ray energy dispersive spectrometer shows that the surface chemistry components of the Ni-Cu-La-B quaternary alloy plated glass fibers contain 15-50wt% of Ni, 2-15wt% of Cu, 0.5-5wt% of La and 0.5-5wt% of B. The electric conducting glass fibers can be applied to the special fields of electromagnetic wave shielding, microwave absorption, invisibility, anti-static electricity and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

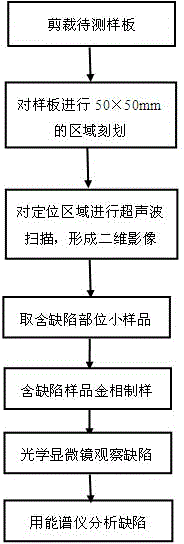

Detection method of internal defects of thin-gauge cold rolled steel plates for automobiles

InactiveCN105738475ARealize detection and identificationQuick analysisAnalysing solids using sonic/ultrasonic/infrasonic wavesOptically investigating flaws/contaminationSheet steelElement analysis

The invention relates to a detection method of internal defects of thin-gauge cold rolled steel plates for automobiles to mainly solve the technical problem of unable identification, difficult positioning and long detection time of internal defects of present cold rolled steel plates for automobiles, with the thickness of 0.5-1.5mm. The detection method of internal defects of thin-gauge cold rolled steel plates for automobiles comprises the following steps: 1, marking a detection area on a plate sample to be detected; 2, positioning the defect position of the plate sample through using an ultrasonic scanner; 3, cutting the plate sample containing a defect part to make a metallographic sample; 4, observing the defect part of the metallographic sample by using an optical microscope; and 5, carrying out element analysis on the defect part of the metallographic sample by using an energy dispersive spectrometer. Defects are analyzed and detected through adopting combination of ultrasonic scanning and positioning, the optical microscope and the energy dispersive spectrometer to realize positioning and detection analysis of the internal defects of the thin-gauge cold rolled steel plates for automobiles; and the method has the advantages of simplicity, fastness, high precision, and meeting of mass quality examination requirements of the cold rolled steel plates for automobiles.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Method for coating aluminum alloy by using micro-arc oxidation green film layer

ActiveCN104831327AQuality improvementImprove toughnessAnodisationElectrolytic agentPlasma electrolytic oxidation

The invention relates to a method for coating aluminum alloy by using a micro-arc oxidation green film layer. The method comprises the following steps of using the 6063 aluminum alloy as a matrix; adding glycerinum and potassium fluoride (KF) in a system in which Na2SiO3-KOH serves as main electrolyte; preparing coloring electrolyte by using NH4VO3 as coloring agents; and preparing a green micro-arc oxidation ceramic film layer. Influences of electrolyte parameters and electric parameters on an organization structure and the performance of the micro-arc oxidation film layer are researched. Phase composition, microstructure and element contents of the film layer are respectively represented through an X-ray diffractometer (XRD), a scanning electron microscope (SEM) and an energy dispersive spectrometer (EDS), the thickness of the micro-arc oxidation ceramic layer and the strength of bonding between the micro-arc oxidation ceramic layer and the matrix are detected by an eddy coating thickness gage and a scratch spectrometer, the electrochemistry corrosion resisting property of the ceramic layer is analyzed by using an electrochemical corrosion method, technological parameters are optimized, and a green micro-arc oxidation film with high performance is prepared.

Owner:SHANDONG UNIV

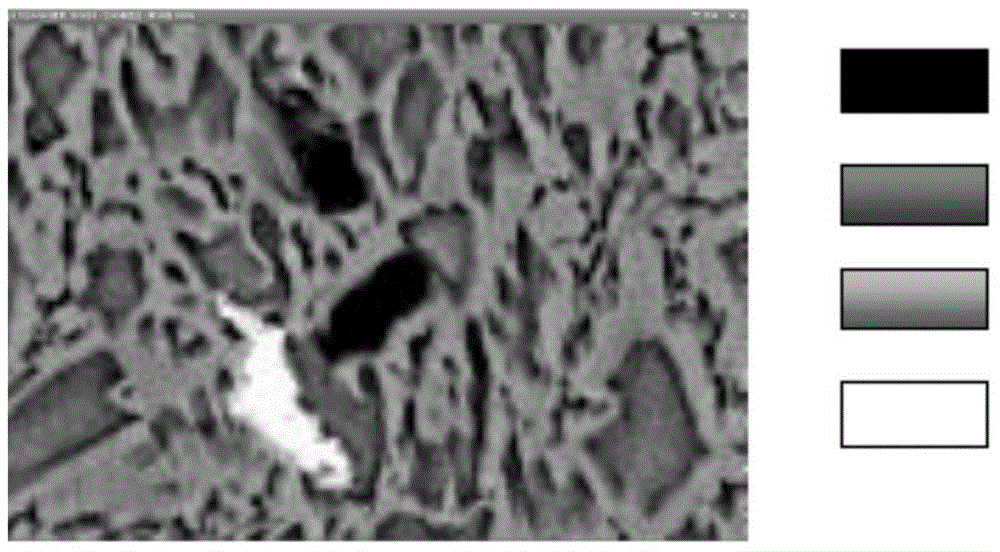

Component automatic measurement method based on image color feature

A component automatic measurement method based on an image color feature belongs to the field of image analysis. The method provided by the invention realizes automatic measurement of components of paper, metal and the like containing mixtures. Component analysis of a paper based relic and a metal relic is a necessary part before maintenance and protection processing. The current component analysis mostly adopts two methods: one is manual observation of a microscopic image and manual speculation; and the other is measurement based on high-end scientific instruments, such as mass spectrometers, energy dispersive spectrometers, etc., and the method is higher in cost. An image analysis model automatically measures the components by analyzing the microscopic image and realizes automation of the measurement, so that costs are lowered and the image analysis model is green, efficient and low in consumption. The image analysis model can process color and greyscale images, and is widely applicable and has a relatively favorable application prospect.

Owner:刘畅 +1

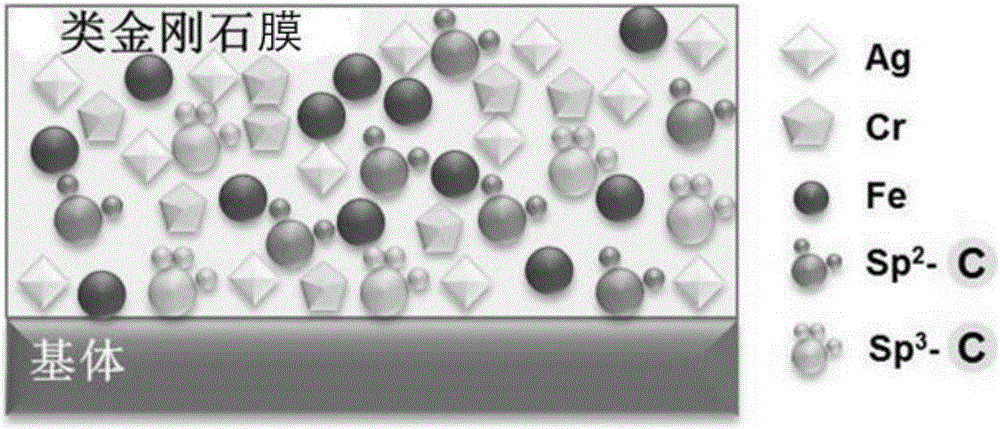

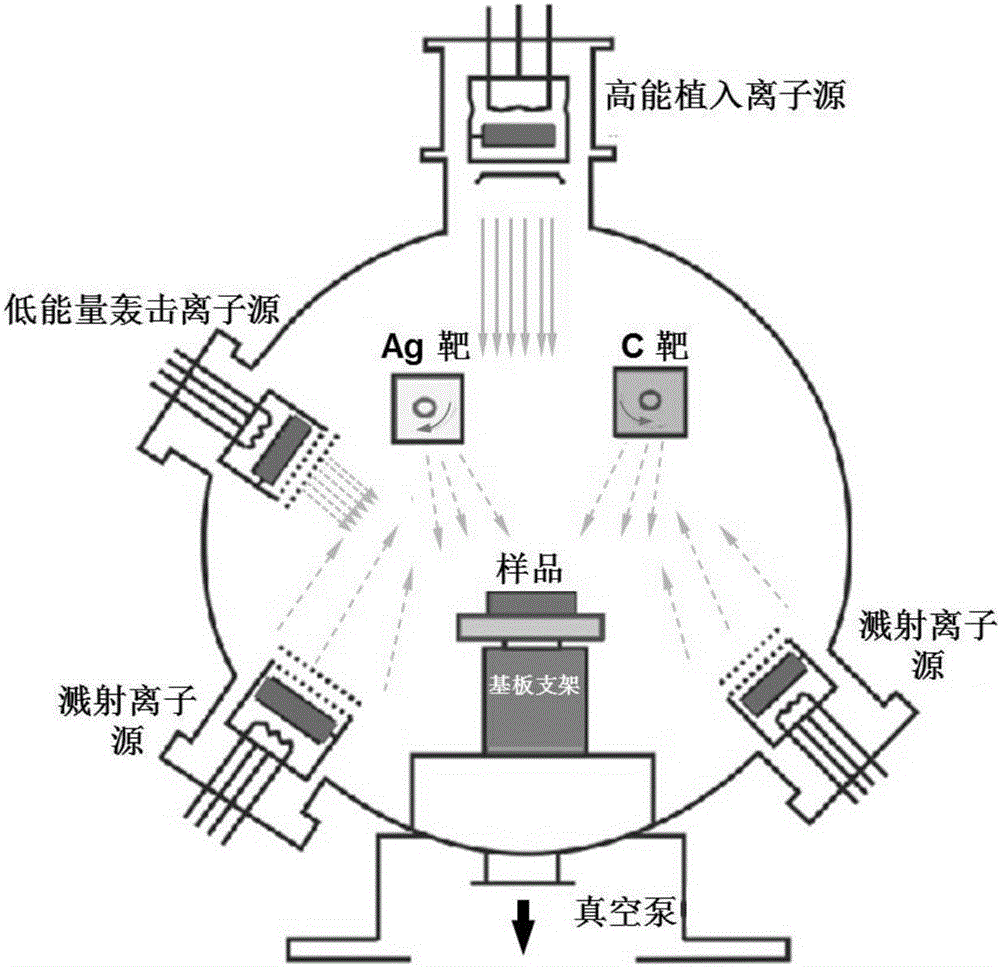

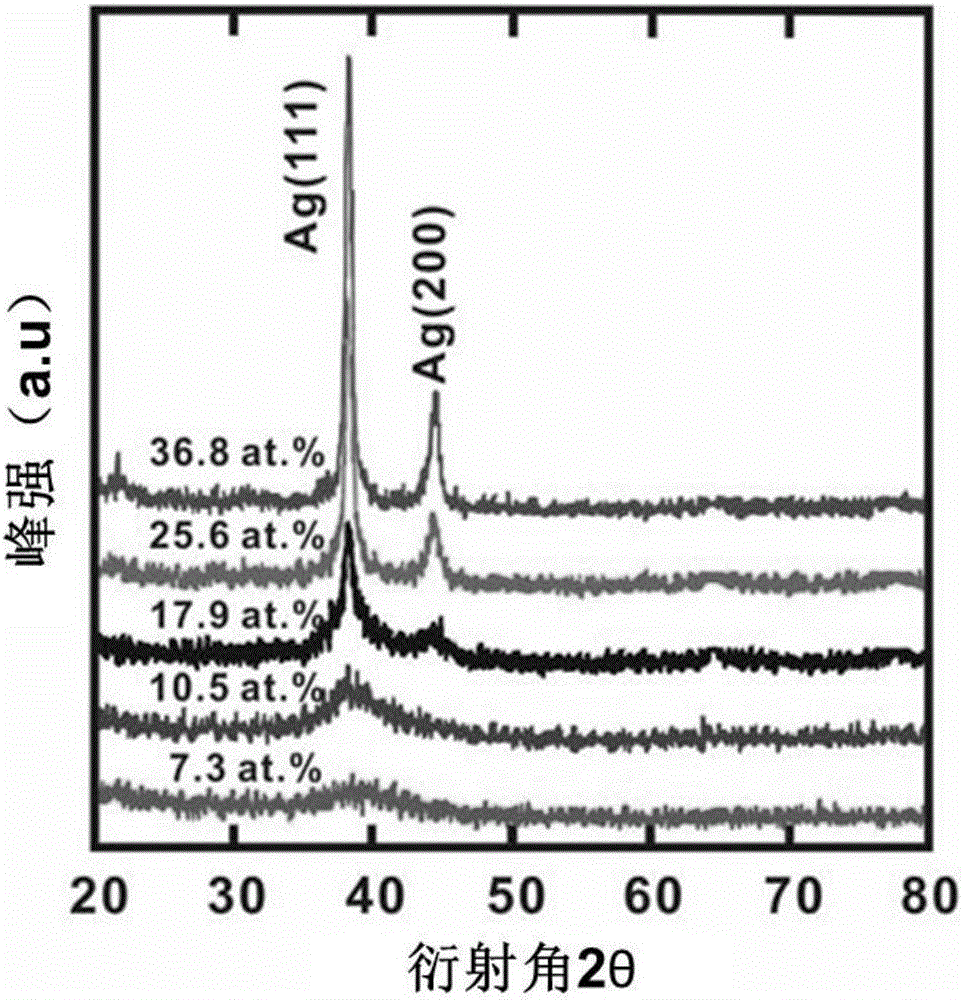

Method for analyzing ability of diamond-like carbon film to seal hydraulic servo actuator of aircraft

InactiveCN106442193AImprove tribological propertiesHigh hardnessVacuum evaporation coatingSputtering coatingCarbon filmDiamond-like carbon

The invention discloses a method for analyzing the ability of a diamond-like carbon film to seal a hydraulic servo actuator of an aircraft, and belongs to the technical field of hydraulic servo actuators of aircraft. In order to improve the defect in the ability to seal an aircraft hydraulic servo actuator, the invention is acquired by the applicant through mass experiments based on the analysis of actuator failure, a plurality of diamond-like carbon films different in silver content are prepared by using a multifunctional ion beam deposition system, microstructure and mechanical property changes of various diamond-like carbon films are analyzed by using an X-ray diffractometer, an energy dispersive spectrometer, Raman spectroscopy, a nano indenter, a three-dimensional white light interferometry profilometer, and a high-speed reciprocating friction-wear tester, the influence of carbon bonds and internal stress upon the mechanical properties of a film are described systematically, and theoretical and practical blanks are filled.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

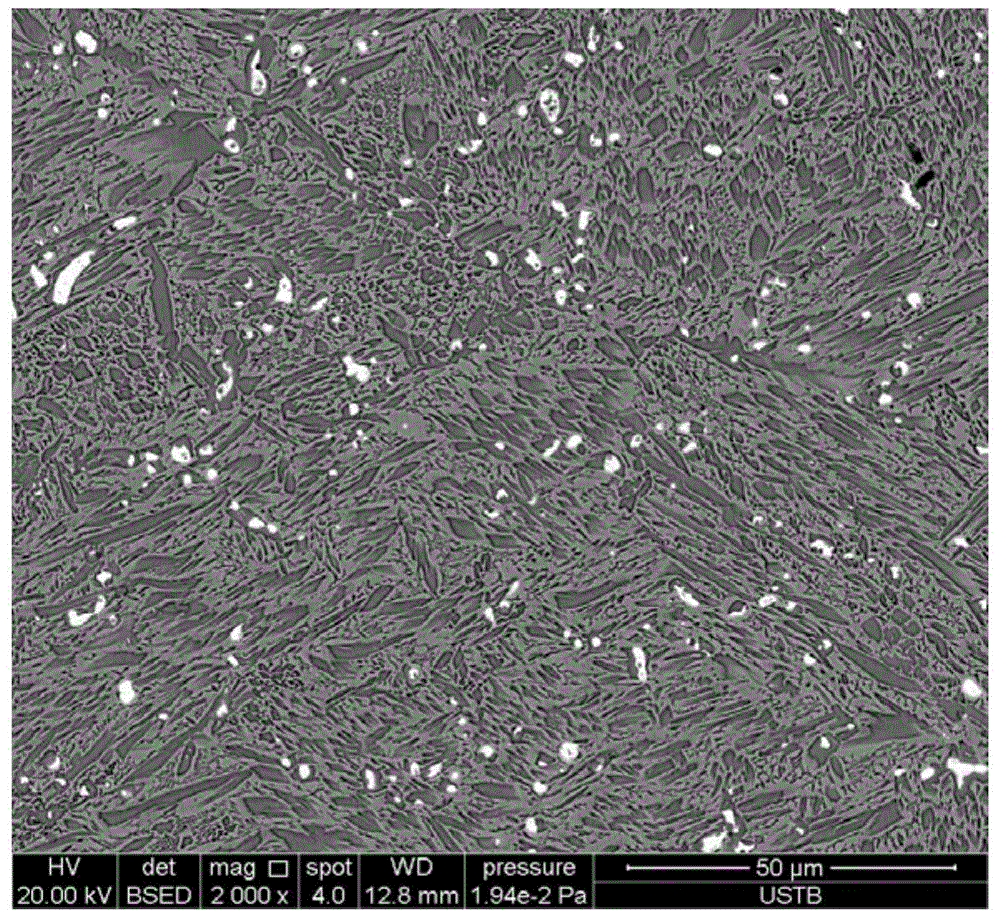

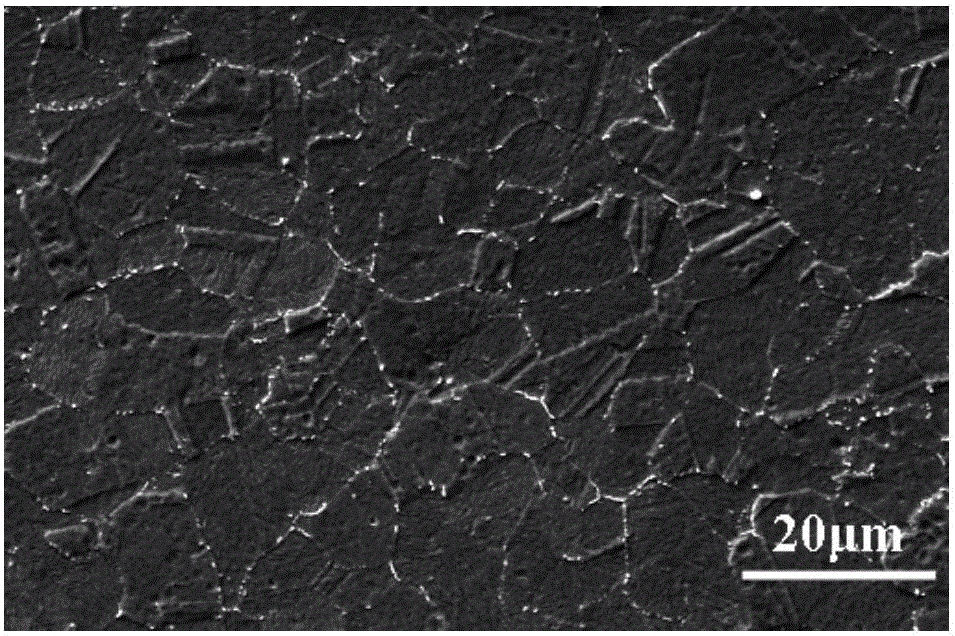

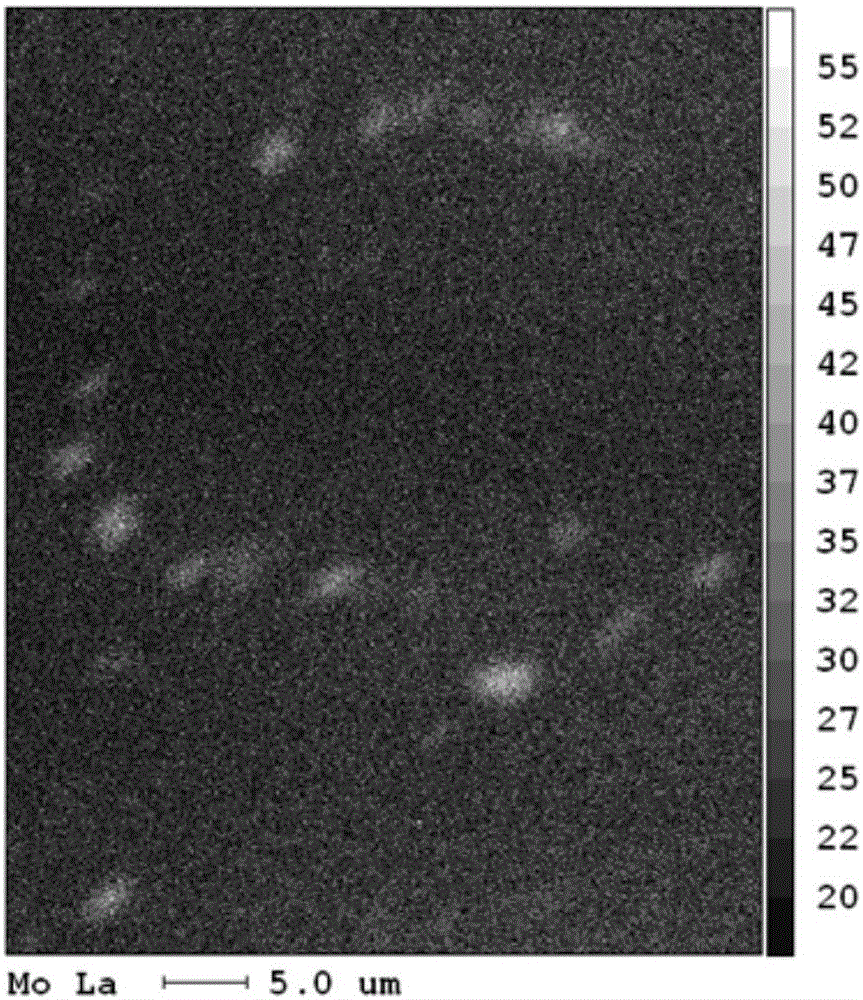

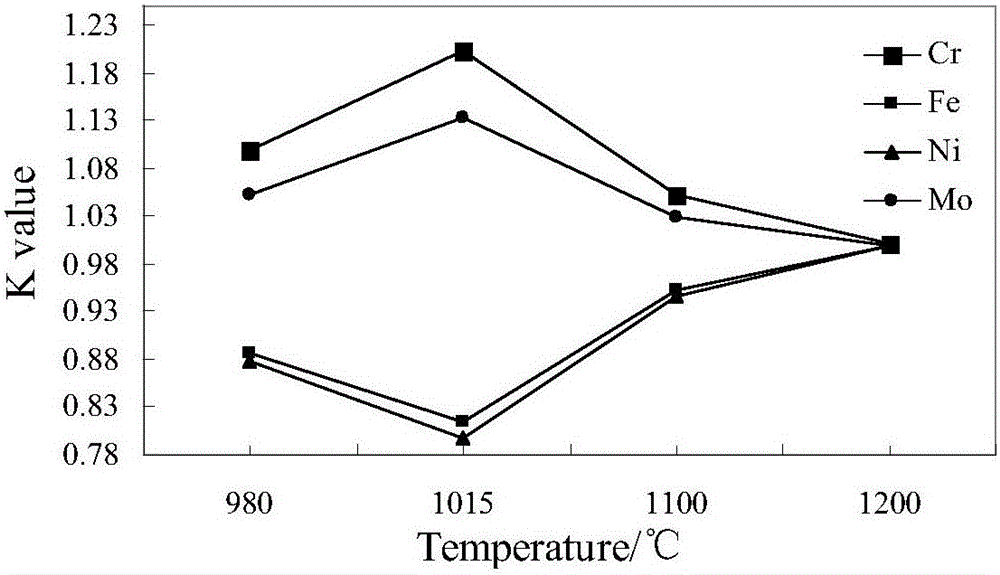

Analytical method for quantitative evaluation of alloy element segregation in high-temperature alloy

ActiveCN105806867AAchieving quantitative distinction of distributionsAchieve quantitative differentiationMaterial analysis using wave/particle radiationSuperalloyAnalysis method

The invention discloses an analytical method for quantitative evaluation of alloy element segregation in high-temperature alloy. The method includes: an energy dispersive spectrometer for determining main components of a grain boundary precipitate; by a spectrum area scanning function of an electronic probe, distinguishing grain boundary distribution and transgranular distribution of corresponding elements; extracting data of an element area profile; analyzing the data, calculating grain boundary and transgranular element concentration distribution coefficients and drawing a graph of relation to finally realize quantitative evaluation of alloy element segregation in high-temperature alloy. By the analytical method for quantitative evaluation of alloy element segregation in high-temperature alloy, quantitative distinction of distribution of alloy elements at different grain boundary and transgranular positions of the high-temperature alloy can be realized without consumption of a great quantity of standard samples, and extensive application range and evaluation reasonability are realized.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

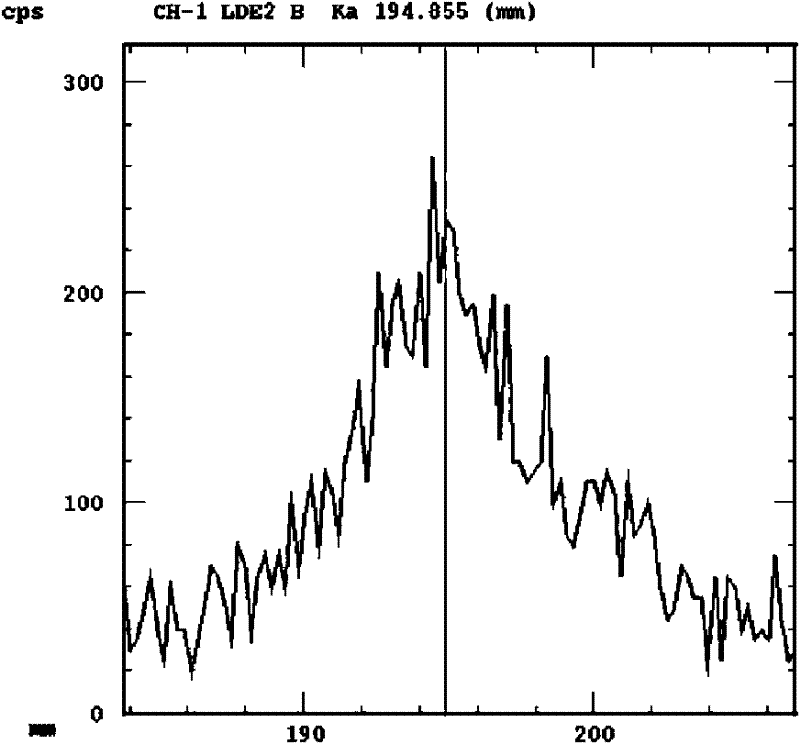

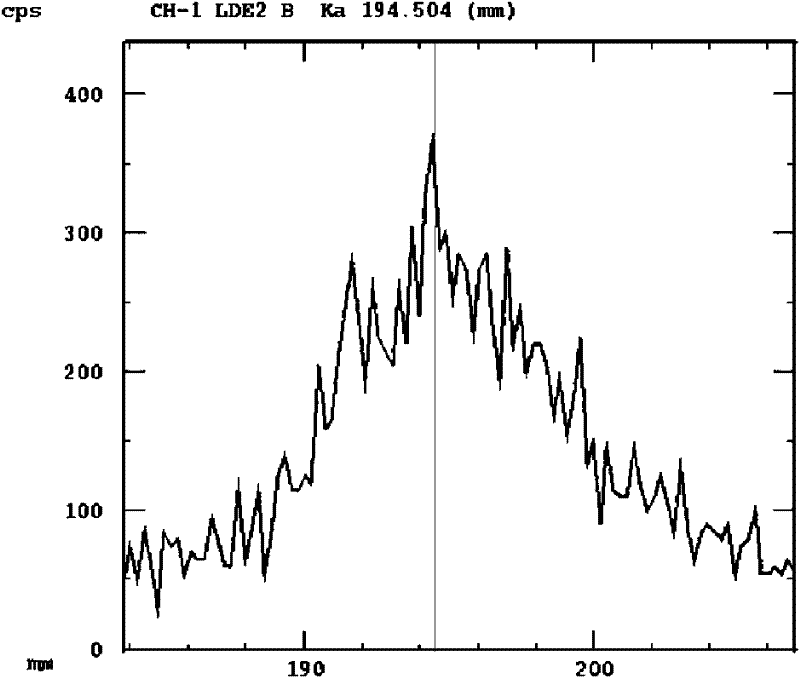

Quantitative analysis method for detecting boron content by electron probe

InactiveCN102128844ABest Quantitative Analysis MethodImprove signal-to-noise ratioMaterial analysis using wave/particle radiationElectric discharge tubesElectron probe microanalysisFluorescence

Elements, of which the atomic numbers are smaller than 10, are ultralight elements. At present, an electron probe mainly can detect elements such as boron, carbon, nitrogen, oxygen and fluorine. Due to long wavelength of characteristic X-rays, the penetration capacities of these elements are low, the fluorescence yield is low, the background strength is high, and the interference with overlapped peaks of L and M lines of heavy elements is serious. Therefore, it is difficult to analyze the ultralight elements by using the electron probe or scanning electron microscopy / energy dispersive spectrometer. When the method is used for quantitative analysis on a boron sample by the electron probe, quantitative analysis is performed by changing accelerating voltage, reducing electron penetration depth and selecting a 10KV accelerating voltage, so that more satisfactory boron micro area quantitative analysis and element area distribution results can be achieved.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

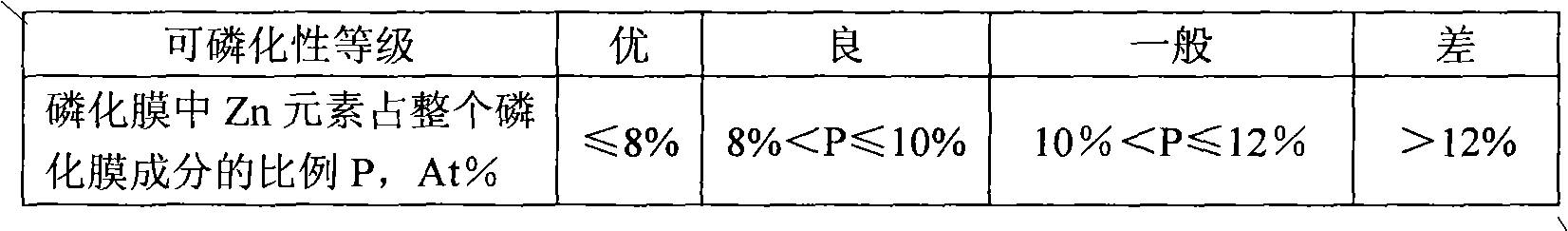

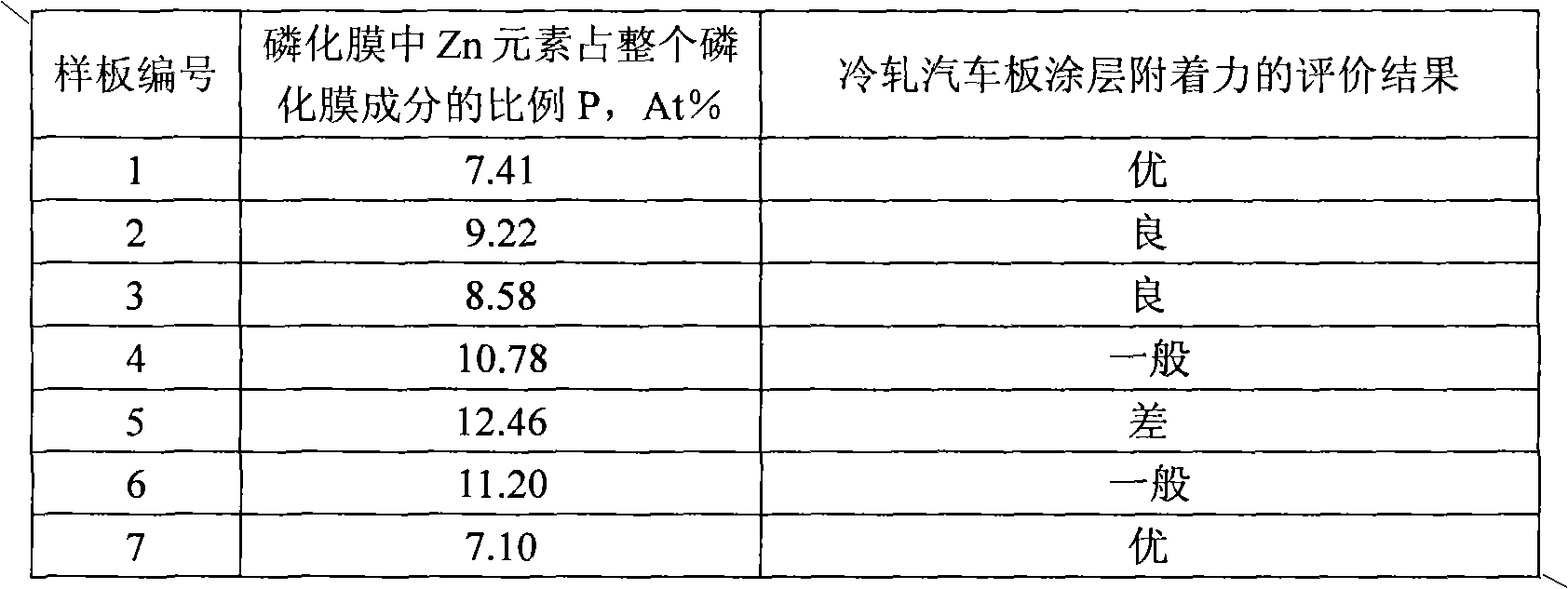

Method for evaluating adhesion performance of coating of cold rolled automobile sheet

InactiveCN101929966AAvoid harmImprove anti-interference abilityMaterial analysis using wave/particle radiationZincEnergy Dispersive Spectrometer

The invention discloses a method for evaluating the adhesion performance of a coating of a cold rolled automobile sheet phosphated by a zinc-system, which has the advantages of no harm to operators and simple and accurate evaluation. The method comprises steps of sample preparation, measurement and evaluation; the adhesion performance of the coating is predetermined by measuring the proportion of the Zn element in all phosphating film components in a phosphating film on the surface of the cold rolled automobile sheet; the proportion of the Zn element in all phosphating film components is determined by an energy dispersive spectrometer; when the proportion of the Zn element is less than or equal to 8 percent, the adhesion performance of the coating is excellent; when the proportion of the Zn element is more than 8 percent and less than or equal to 10 percent, the adhesion performance of the coating is good; when the proportion of the Zn element is more than 10 percent and less than or equal to 12 percent, the adhesion performance of the coating is general; and when the proportion of the Zn element is more than 12 percent, the adhesion performance of the coating is poor.

Owner:ANGANG STEEL CO LTD

Method for coating TiAlN on surfaces of titanium and titanium alloy surgical instruments

InactiveCN102392221AUniform thicknessDense tissueVacuum evaporation coatingSputtering coatingOxidation resistantTrichloroethylene

The invention provides a preparation method for coating TiAlN on the surfaces of titanium and titanium alloy, and relates to a preparation process for coating TiAlN on the surfaces of titanium and titanium alloy. The preparation method is conducted according to the following steps: a, titanium alloy sample materials are got ready, then examined before sample plating preparation, and subjected to ultrasonic cleaning in trichloroethylene, gasoline cleaning (twice), water cleaning, acid cleaning, ethanol cleaning and finally drying; b, TiAlN platings are prepared by adopting an eight-arc-source multi-arc ion plating machine, dried samples are charged into a furnace and cleaned in an ion bombardment manner, and then the TiAlN platings are prepared, cooled in a vacuum manner and discharged from the furnace; c, the preparation technological parameters of the TiAlN platings are that the target current is 60 to 70A, the substrate negative bias is minus 100 to minus 400V, the N2 partial pressure is 0.32Pa, the deposition temperatures are 500 DEG C and 600 DEG C, the total deposition time is 120min, the plating thickness is about three microns, and after the samples are discharged from the furnace after being cooled to a temperature of 80 DEG C in the vacuum furnace; d, energy-dispersive spectrometer (EDS) analysis of coating surfaces is conducted; and e, after the plating is completed, the TiAlN platings are subjected to water cleaning, wiping, drying, assembly and packaging. The TiAlN platings obtained by adopting the preparation method have the advantages of good chemical stability, high anti-oxidation-wear ability, high strength, and high wear resistance.

Owner:湖南迈迪科新材有限公司

Synergistic inhibition method for thermal decomposition of asphalt mixture by flame-retardant warm mixing agent

InactiveCN111925562AGood vibration dampingDriving safetyClimate change adaptationBuilding insulationsCombustionFire retardant

The invention relates to a synergistic inhibition method for thermal decomposition of an asphalt mixture by a flame-retardant warm mixing agent, belongs to the technical field of asphalt pavement firesafety, and solves the problems that the synergistic flame-retardant effect of various components of the existing composite flame retardant is poor, the whole thermal decomposition process is difficult to inhibit, and the synergistic inhibition effect of the flame-retardant warm-mixing agent on flame retardance and smoke inhibition of an asphalt mixture is difficult to accurately analyze. The method comprises the following steps: firstly, preparing a nano composite flame retardant, performing vacuum adsorption on the nano composite flame retardant and a zeolite warm-mixing agent by using a vacuum adsorption method to prepare a flame-retardant warm-mixing agent, then preparing a common asphalt mixture and a flame-retardant warm-mixing asphalt mixture, and comparing combustion behaviors ofthe two asphalt mixtures by using a cone calorimeter test; using a scanning electron microscope and an energy dispersive spectrometer to analyze the microstructure and elemental composition of residues after pyrolysis of the asphalt mixture. According to the method, all the components of the composite flame retardant can be sequentially decomposed in the heating process of the warm-mixed asphalt mixture to play flame-retardant and smoke-suppressing roles, and the synergistic flame-retardant and smoke-suppressing effects are achieved.

Owner:NANJING FORESTRY UNIV

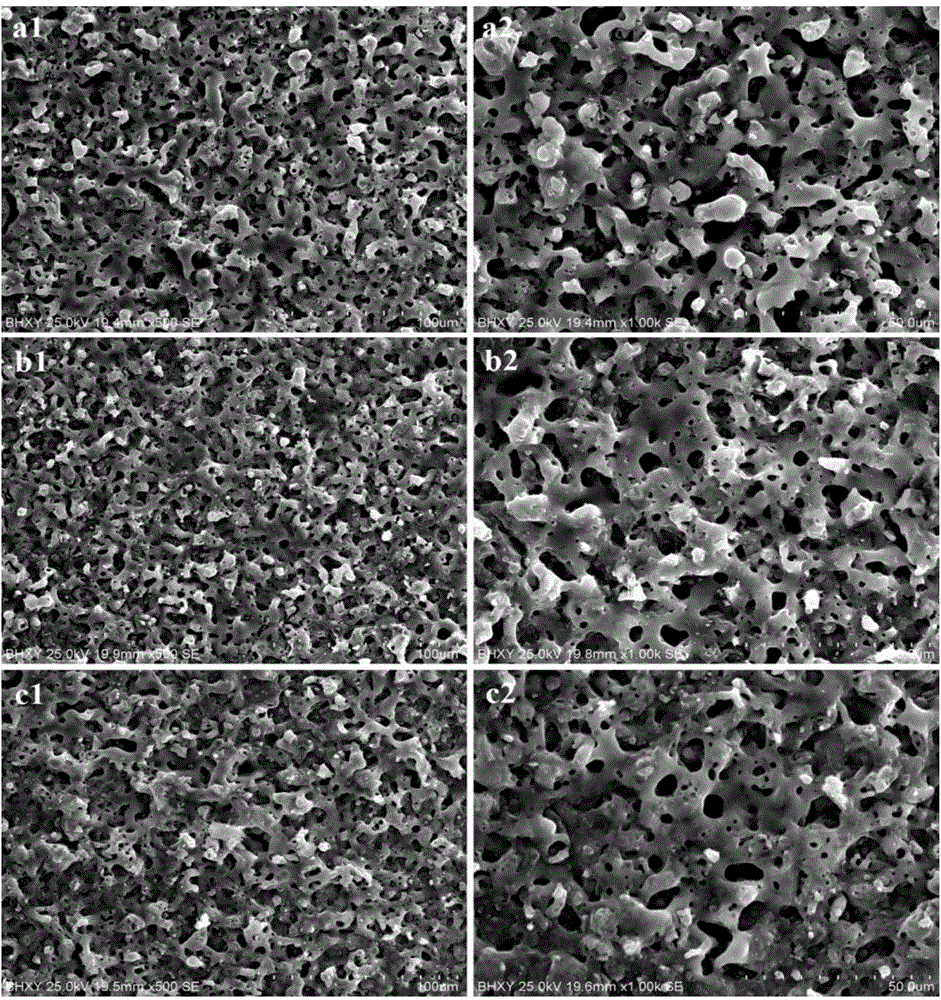

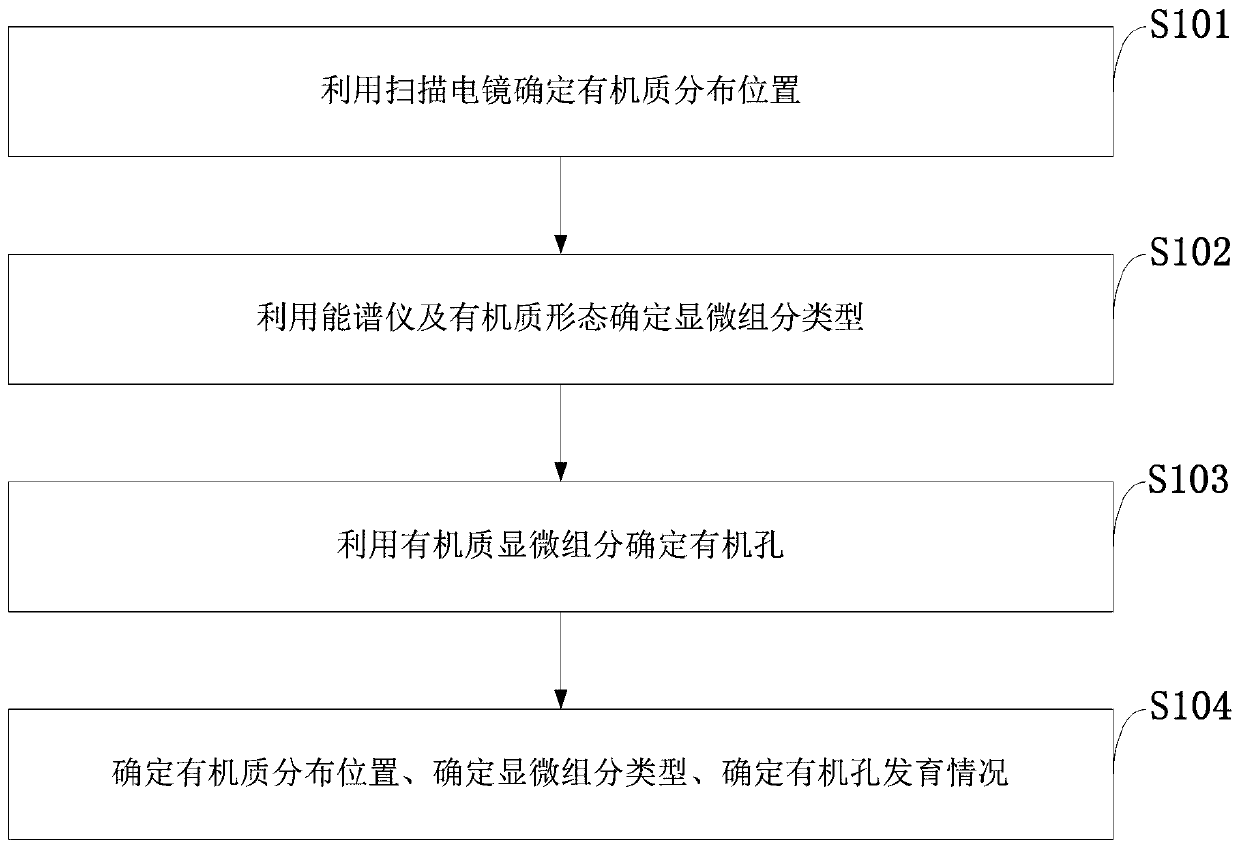

Quantitative characterization method for rapidly determining organic matter pores based on scanning electron microscope and application thereof

ActiveCN111208162AHigh magnificationStrong three-dimensional imageMaterial analysis using wave/particle radiationPermeability/surface area analysisResearch efficiencySimple sample

The invention belongs to the technical field of organic matter pore identification and discloses a quantitative characterization method for rapidly determining organic matter pores based on a scanningelectron microscope and an application thereof. The method comprises steps of determining the organic matter distribution position by using a scanning electron microscope; determining the type of themicrocomponents by using an energy dispersive spectrometer and an organic matter form; determining organic pores by utilizing the organic matter microcomponents, and determining the organic matter distribution position, determining the microcomponent type, and determining the organic pore development condition. The method is advantaged in that by adopting the scanning electron microscope to identify the organic matter microcomponents, problems of small observation vision field, high difficulty in finding organic holes, no development and long observation time when the scanning electron microscope is used for observing organic matter pores at present can be effectively solved, and experiment and scientific research efficiency is reduced; the scanning electron microscope =has advantages ofhigh magnification times, strong image stereoscopic impression and simple sample preparation method, the relationship between the organic matter pores and the microcomponents is established, an enrichment mode and morphological characteristics of each microcomponent and the contact relationship between each microcomponent and minerals can be directly observed, and the organic matter pores can be identified.

Owner:成都悟石科技有限公司

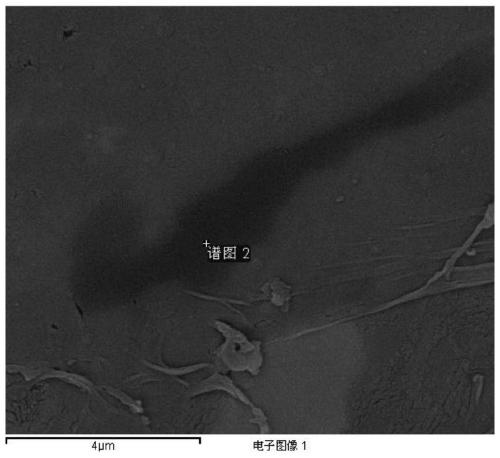

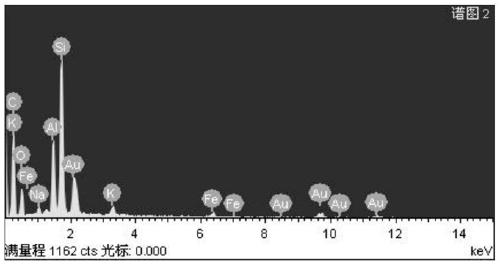

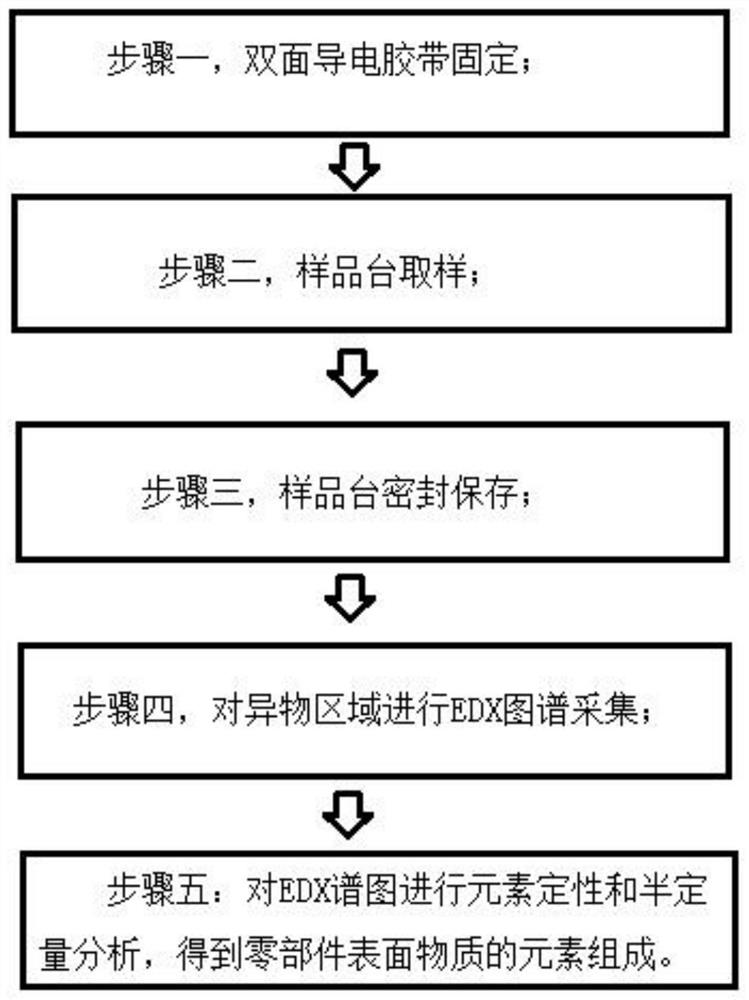

Non-destructive detection method for pollutant components on surface of part

The invention relates to the technical field of detection. The invention discloses a non-destructive detection method for pollutant components on the surface of a part. The method comprises the following steps: 1, fixing a double-sided conductive adhesive tape, and paving a double-sided conductive adhesive tape on a sample table of a scanning electron microscope; 2, sampling on a sample table, tearing off the protective strip on the double-sided conductive adhesive tape, and adhering the surface area of the to-be-tested part to the double-sided conductive adhesive on the sample table; 3, sealing and storing the sample table, taking down the sample table, putting the sample table into a clean sample table tube, fixing the sample table tube, and sealing the sample table tube; 4, performing EDX atlas acquisition on the foreign matter area, taking down the sample table from the sample table tube, putting the sample table into a sample cabin of a scanning electron microscope, observing foreign matters adhered to the double-sided conductive adhesive by using the scanning electron microscope, and performing EDX atlas acquisition on a foreign matter area by using an energy dispersive spectrometer; 5, carrying out element qualitative and semi-quantitative analysis on the EDX spectrogram to obtain the element composition of the substances on the surface of the part.

Owner:上海富乐德智能科技发展有限公司

Processing of spectrometer pile-up events

InactiveUS8027811B2Increase the number ofImprove reliabilitySpectrum investigationSolid-state devicesImage resolutionEngineering

In an energy dispersive spectrometer wherein event (particle / photon) detection is performed by counting events spaced by greater than a shaping time, events which are spaced by less than the shaping time are also collected and counted. These “combined events” are treated similarly to “single events” which are spaced by greater than the shaping time, and can be used to generate combined-event spectra for comparison and / or use with the conventional single-event spectra. The combined-event spectra can be compared to the single-event spectra to provide an indication of data quality; can be subtracted from the single-event spectra to remove artifacts, and / or can be deconvolved into a single-event spectrum to increase the resolution of the single-event spectrum.

Owner:THERMO ELECTRONICS SCI INSTR LLC

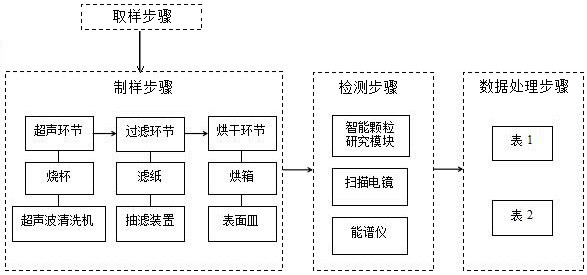

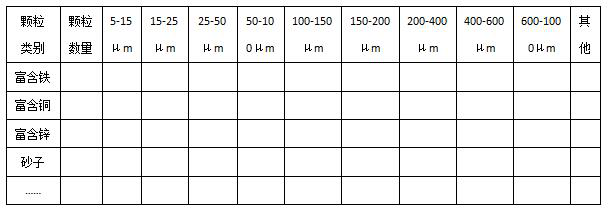

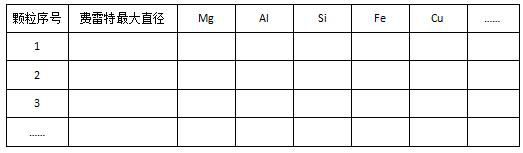

Oil particle multiple information detection method and application thereof

InactiveCN113484202AOvercoming incompletenessParticle size analysisIndividual particle analysisPhysical chemistryEnergy Dispersive Spectrometer

The invention relates to the technical field of oil detection, and discloses an oil particle multiple information detection method and application thereof. The oil particle multiple information detection method comprises a sampling step, a sample preparation step, a detection step and a data processing step. The method is characterized in that in the detection step, a scanning electron microscope integrated with an intelligent particle research module and an energy dispersive spectrometer are adopted for detecting oil liquid, and any one or more particle information data of the particle category, the particle number, the particle size range, the particle serial number, the proportion of main elements contained in a single particle and the Feret maximum diameter of the single particle are obtained; and the data processing step comprises integration of detected particle information data, so that the detection is more accurate, the analysis is more comprehensive, and the influence of human factors is greatly reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

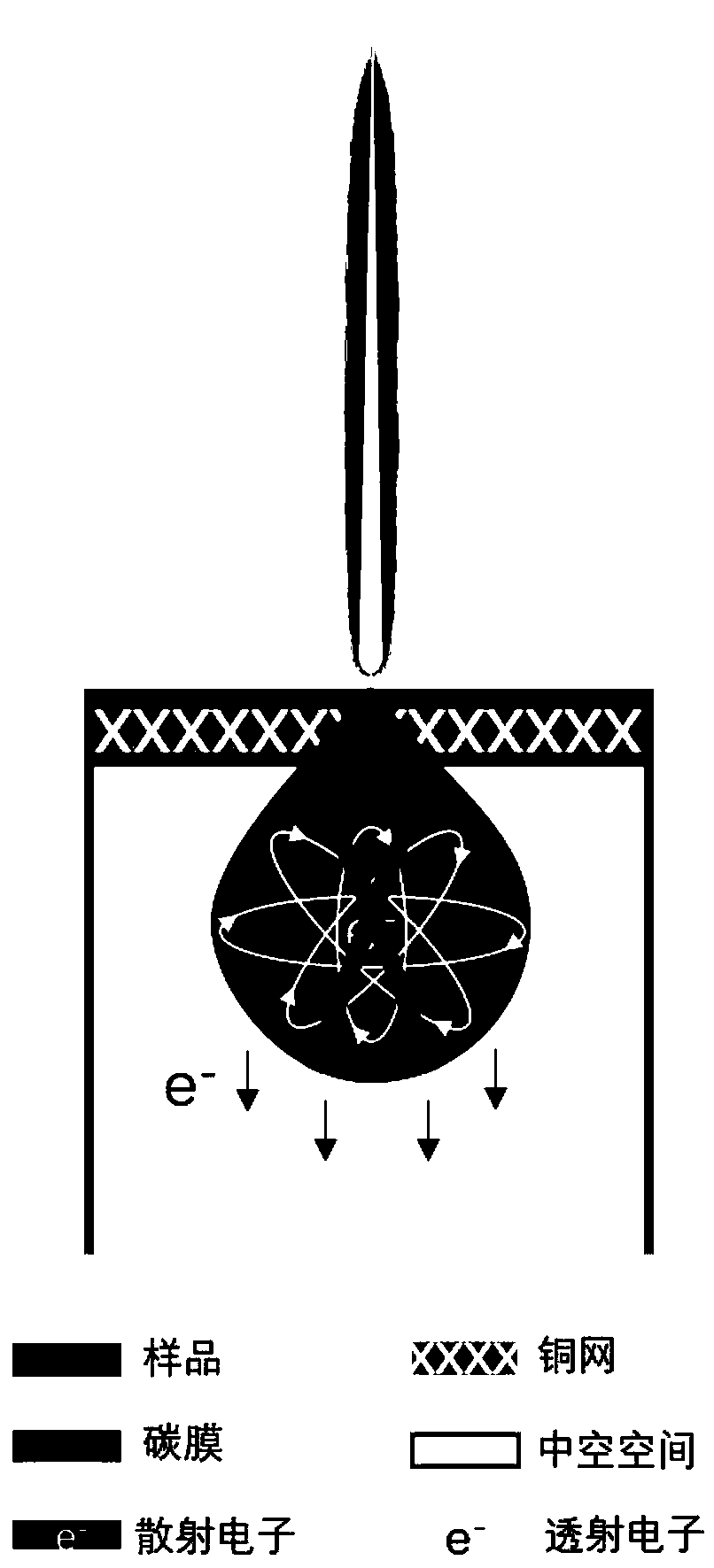

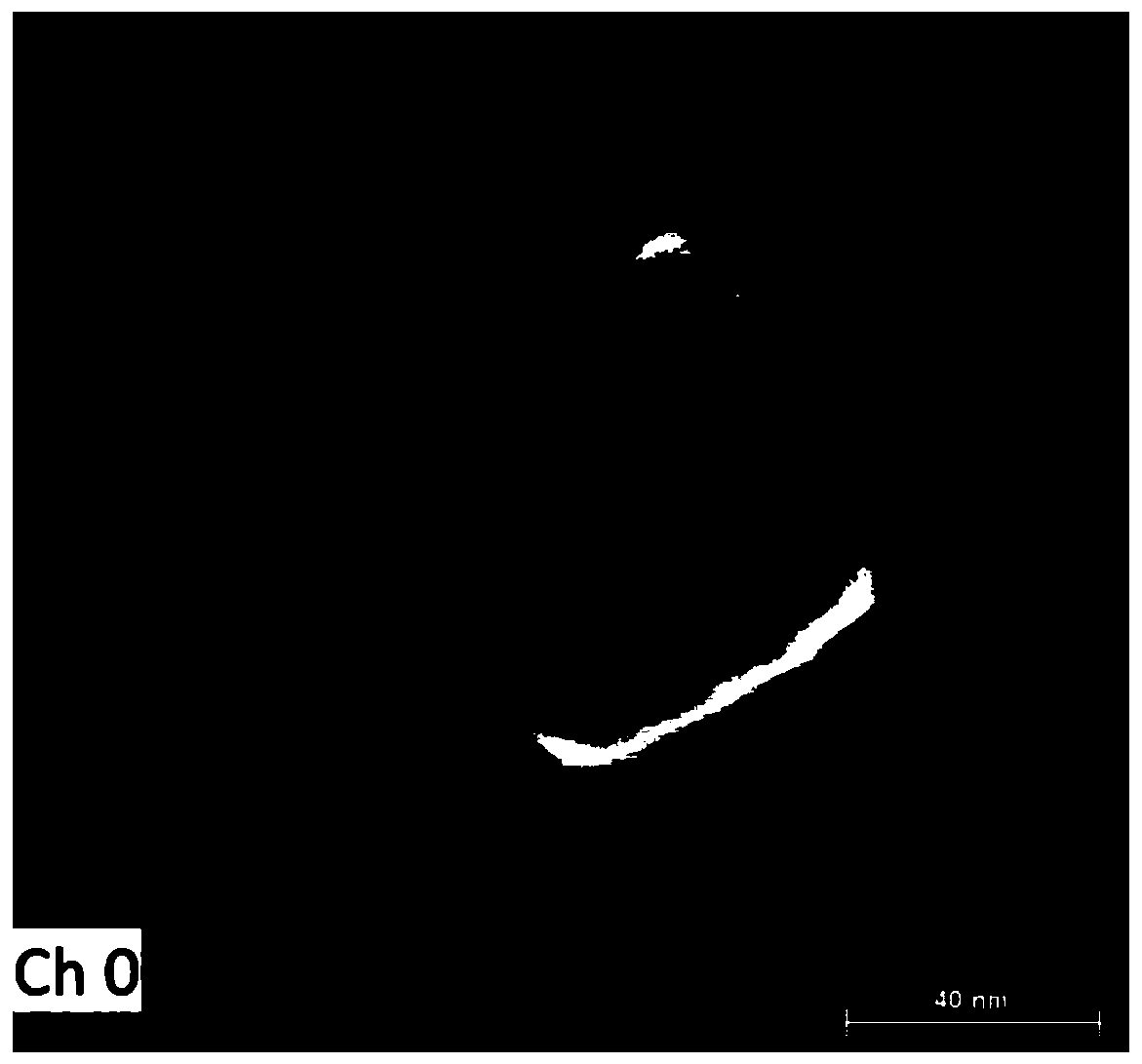

Method for improving spatial resolution of X-ray energy dispersive spectrometer for scanning electron microscope

ActiveCN109884102AReduce volumeImprove spatial resolutionMaterial analysis by measuring secondary emissionSilicon moldX-ray

The invention discloses a method for improving a spatial resolution of an X-ray energy dispersive spectrometer for a scanning electron microscope. The method comprises the following steps: mixing particles or fibrous samples into an embedding agent and a curing agent, stirring, pouring the particles or the fibrous samples into a silicon mold, curing, and demoulding and taking out the particles orfibrous samples after being cooled; cutting a sample sheet with a thickness of 10 to 500nm and then transferring the sample sheet to a copper mesh; fixing the copper mesh loaded with the sample sheeton a copper mesh bracket, and enabling the copper mesh bracket to be in contact and fixed with the edge of the copper mesh; and pushing a crystal detector to the vicinity of an objective pole shoe ofthe electron microscope to increase a solid angle to 0.01 to 0.05sr, adjusting relevant parameters, and then performing an energy spectrum test. According to the method for improving the spatial resolution of the X-ray energy dispersive spectrometer for the scanning electron microscope provided by the invention, the spatial resolution in the X-ray energy spectrum test can be greatly improved underthe synergistic effect of appropriate thinning of the thickness of the sample, proper setting of various test parameters and other treatment measures, and a basis is provided for accurate experimenttest results.

Owner:HUBEI UNIV

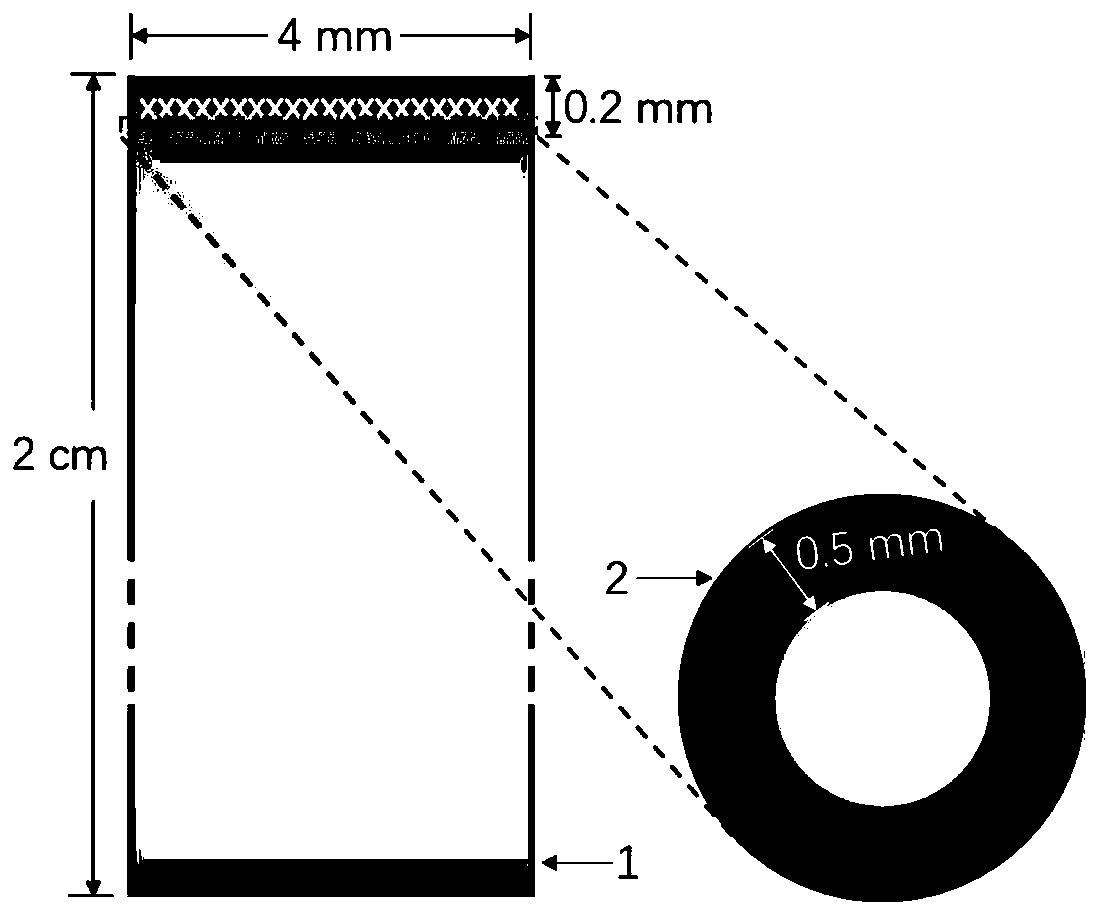

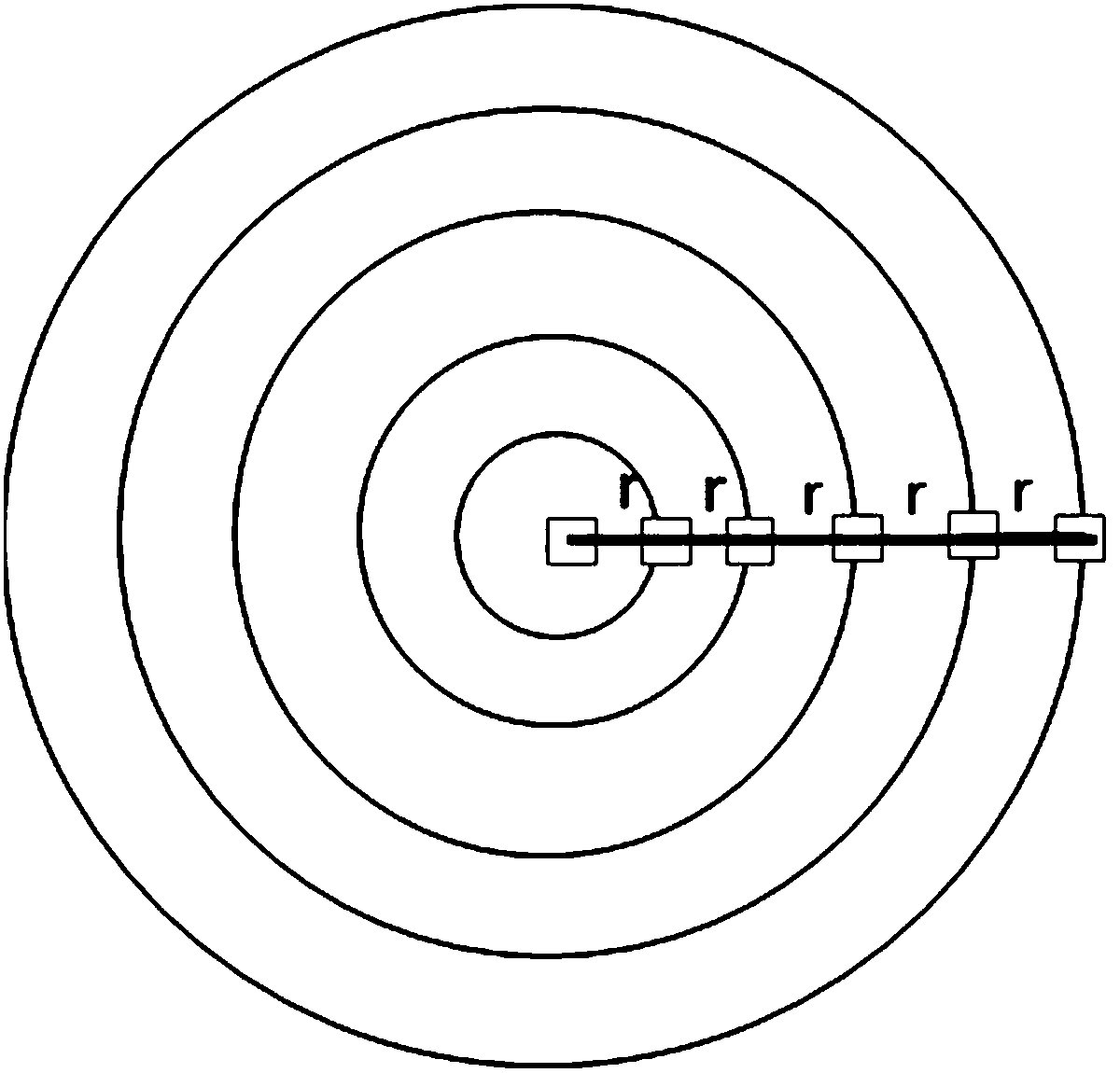

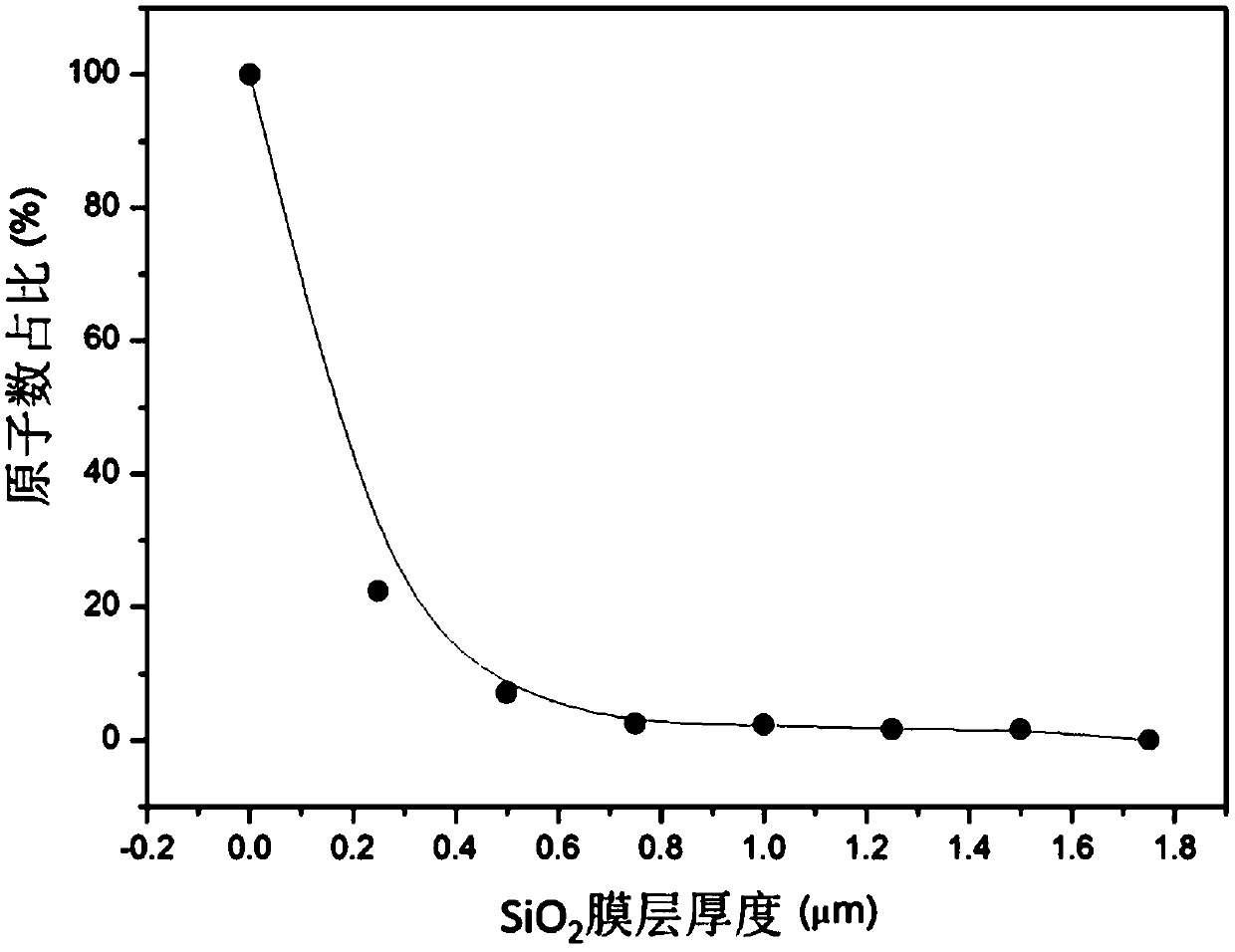

Calibration method of detection depth of energy dispersive spectrometer

ActiveCN109655475AEquivalent detection depthMaterial analysis using wave/particle radiationEnergy Dispersive SpectrometerMaterials science

The invention relates to a calibration method of the detection depth of an energy dispersive spectrometer. The calibration method includes the following steps that 1, fused quartz substrates are plated with metal film layers with the thickness of d0 and then are marked as I-type samples; 2, the fused quartz substrates with the metal film layers are plated with SiO2 film layers with different thicknesses respectively and then are marked as II-type samples; 3, the energy dispersive spectrometer is adopted to measure the metal element M proportions of the I-type samples and the II-type samples separately, and the measurement results of the I-type samples are adopted to amend the metal element M proportions of the II-type samples; 4, a curve about the thicknesses of the SiO2 film layers and the metal element proportions after amendment is drawn, and the thickness of the SiO2 film layer when the metal element M proportion is 0 is obtained through fitting and then serves as the detection depth of the energy dispersive spectrometer to complete calibration. Compared with the prior art, the calibration method of the detection depth of the energy dispersive spectrometer has the advantages ofbeing simple and accurate in judgement and the like.

Owner:TONGJI UNIV

Failure analysis method for computer mainboard

InactiveCN102313743ADetection failure phenomenonElectrical testingOptically investigating flaws/contaminationMegasonic cleaningFailure analysis

The invention relates to a failure analysis method for a computer mainboard. The failure analysis method comprises the following steps of: (1) performing optical appearance inspection on the computer mainboard to judge whether the computer mainboard is contaminated or not; (2) performing electrical isolation testing on the computer mainboard judged to be contaminated in the step (1) to judge whether electrical abnormality exists or not; (3) performing SEM / EDS (Scanning Electron Microscopy / Energy Dispersive Spectrometer) analysis on the computer mainboard judged to undergo electrical abnormality in the step (2) to judge whether electroconductive elements exist in the computer mainbody or not; and (4) performing ultrasonic cleaning on the computer mainboard judged to be with the electroconductive elements in the step (3). According to the failure analysis method for the computer mainboard in the invention, by performing optical appearance inspection, the electrical isolation testing, the SEM / EDS analysis and the ultrasonic cleaning on the computer mainboard, failure phenomena of the computer mainboard can be detected effectively and rapidly.

Owner:SHANGHAI FALAB TEST

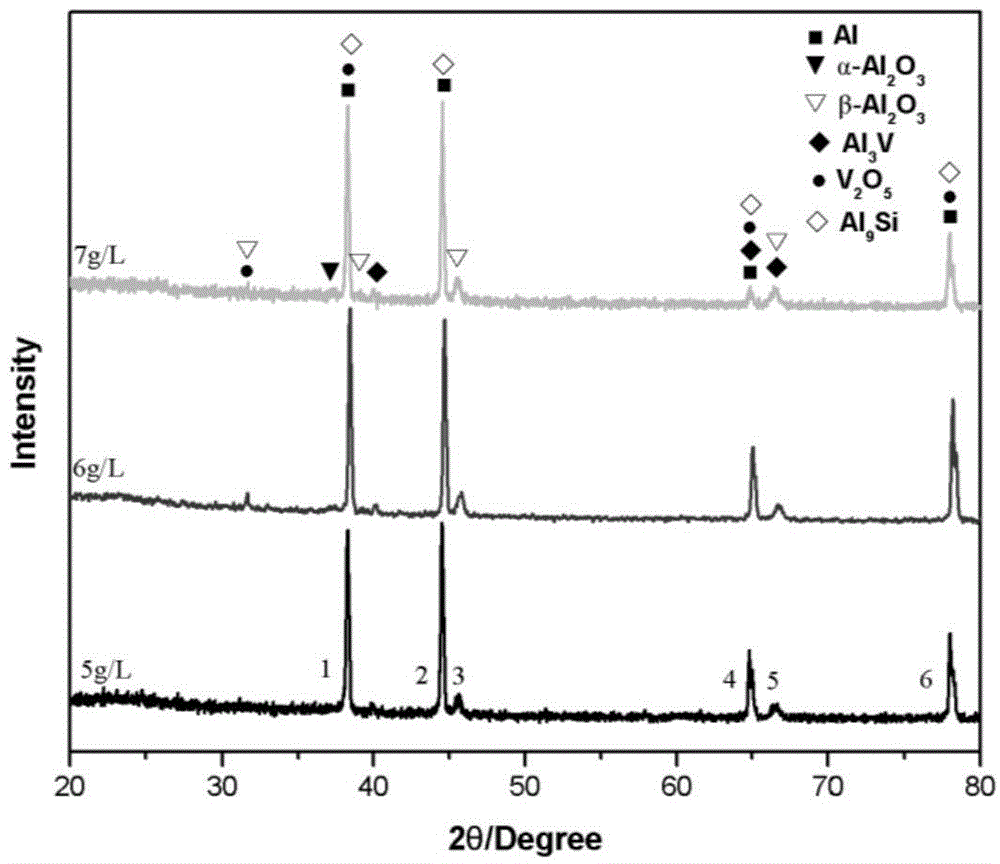

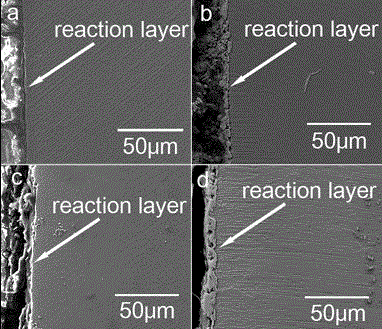

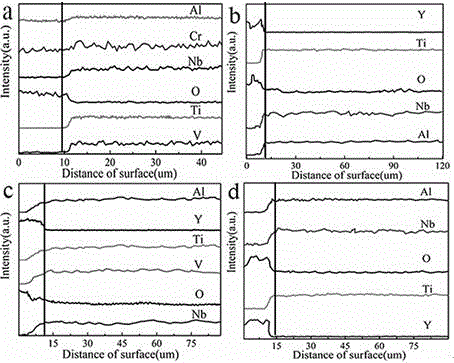

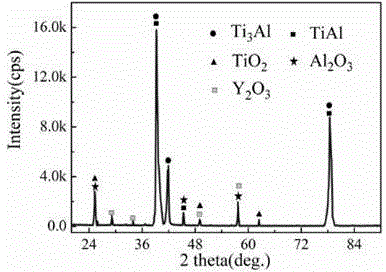

Alloy design method for reducing directionally-solidified titanium aluminum alloy interface reaction

InactiveCN105603533AQuality improvementLow costPolycrystalline material growthFrom frozen solutionsInterfacial reactionReaction layer

The invention discloses an alloy design method for reducing directionally-solidified titanium aluminum alloy casting member and casting mold coating interface reaction, and belongs to a method for improving titanium aluminum alloy casting quality. The specific steps are as follows: designing TiAl alloys with different Nb contents for directional solidification process to obtain casting members; and using a microhardness tester to test Vickers microhardness to determine interface reaction layer thickness. A German brooke Quantax400-10 energy dispersive spectrometer is used for sample interface element distribution analysis, a German Brook D8AdanceX ray diffractometer is used for sample surface phase analysis, and a United States FEIQuanta TM250 scanning electron microscope is used for casting memberreaction layer and casting member matrix tissue morphology observation and analysis. Through corresponding analysis and test of the directionally-solidified titanium aluminum alloy casting members obtained by the alloy design, interfacial reaction degree can be obtained specifically and vividly, corresponding titanium aluminum alloy casting member quality can be well evaluated, and a TiAl alloy casting member with optimized Nb content can be obtained.

Owner:CHINA UNIV OF MINING & TECH

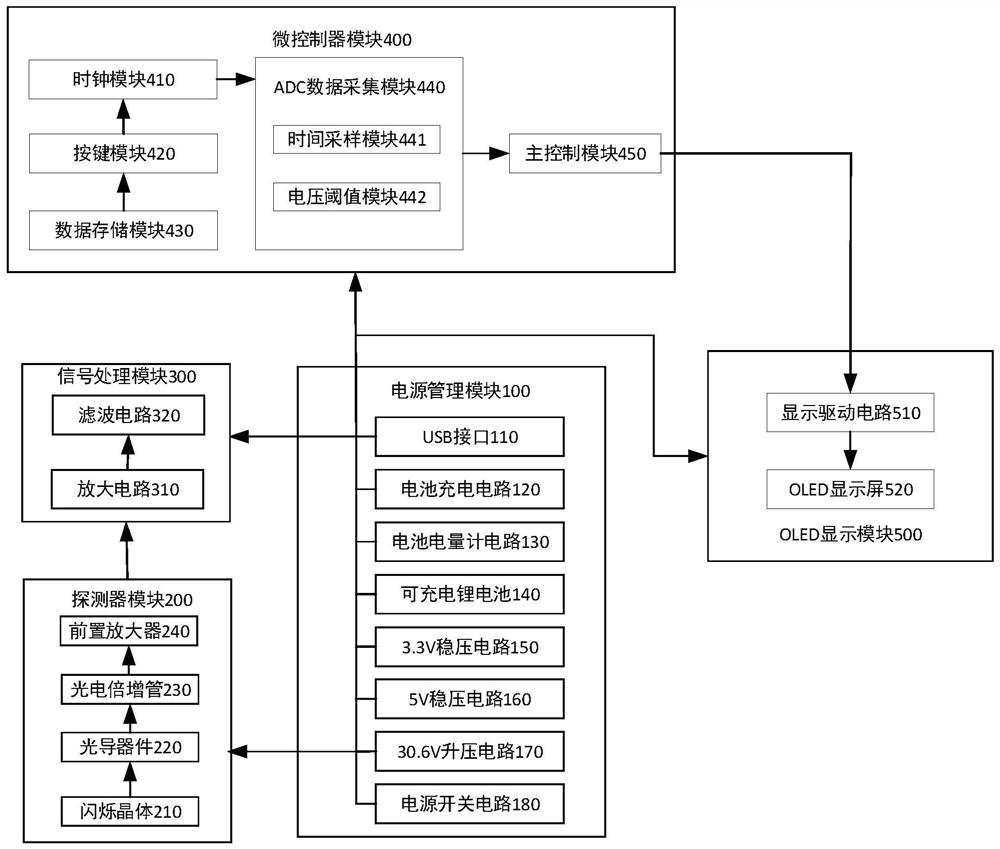

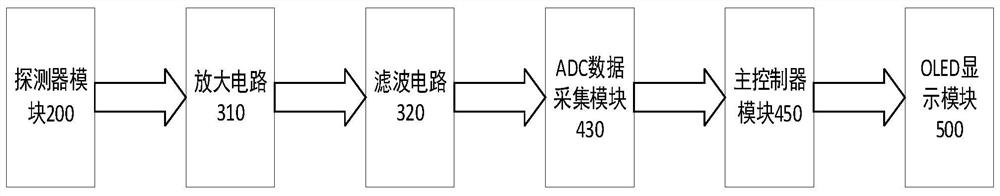

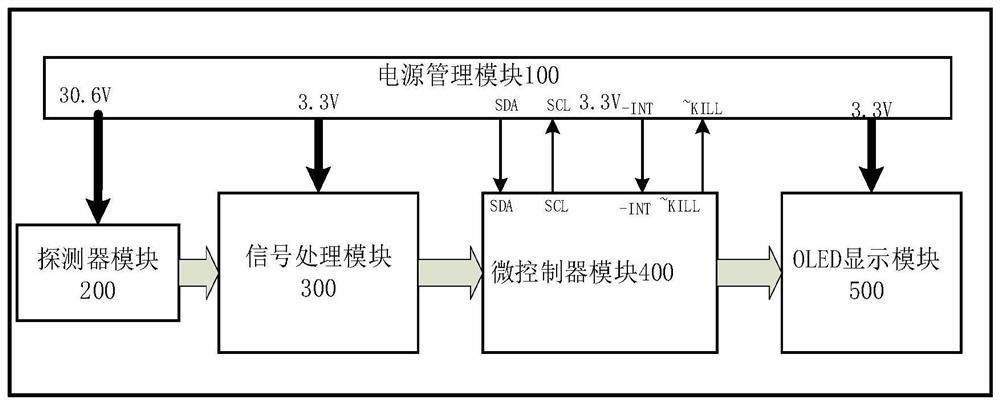

Flicker type handheld energy dispersive spectrometer based on sql digitization method and spectrum forming method

InactiveCN111610553AImprove performanceReduce volumeX-ray spectral distribution measurementMicrocontrollerScintillation crystals

The invention provides a flicker type handheld energy dispersive spectrometer based on an sql digitization method and a spectrum forming method. The flicker type handheld energy dispersive spectrometer comprises a shell, a power management module, a detector module, a signal processing module, a microcontroller module and an OLED display module, wherein the power management module, the detector module, the signal processing module, the microcontroller module and the OLED display module are arranged in the shell. The power supply management module is used for providing a working voltage for each module of an energy spectrometer system; the detector module comprises a scintillation crystal, a photoconductive device, a photomultiplier and a pre-amplification circuit, and is used for detectingflash generated by ionizing radiation when a substance generates ionizing radiation, converting gamma rays into electric signals and acquiring continuous pulse signals; the signal processing module is used for amplifying and filtering the electric signals output by the detector; the microcontroller module samples an analog pulse signal to realize A / D conversion of data, processes the converted digital signal and transmits the data to the OLED display module; and the OLED display module is used for displaying an operation interface and an energy spectrum diagram.

Owner:NANCHANG UNIV

Method for diagnosing regenerability of inactivating denitration catalyst

InactiveCN103364422AReduce processing costsImprove regeneration efficiencySurface/boundary effectMaterial analysis by measuring secondary emissionEnergy Dispersive SpectrometerEnergy spectrum

The invention aims at providing a method for diagnosing regenerability of an inactivating denitration catalyst, which can be used for judging and classifying the catalysts with different regenerability, and provides the basis for regeneration and process. The method comprises the following four diagnosis processes of SEM (scanning electron microscope), BET (Brunauer, Emmett and Teller) test, EDS (energy dispersive spectrometer) energy spectrum analysis, and XRF (x-ray fluorescence) analysis to diagnose the regenerability of the inactivating catalyst, the inactivating catalysts are tested in sequence, and the catalyst meeting the last step of requirement needs to be tested in the next step. The method is highly targeted, and can be used for judging the regenerability of catalysts which have different inactivating degrees and are inactive due to different reasons through the represented differences.

Owner:WUHAN UNIV

Q345 steel surface powder embedding aluminizing process in air environment

PendingCN113005396AIncreasing the thicknessHigh hardnessSolid state diffusion coatingDiffractometerMicroscopic observation

The invention discloses a Q345 steel surface powder embedding aluminizing process in an air environment. The Q345 steel surface is aluminized in the air environment by adopting a solid powder embedding method. An aluminized layer with high hardness and corrosion resistance is prepared on the surface of the Q345 steel. The influence of the aluminizing temperature and the heat preservation time on the surface quality of an aluminized layer sample and the thickness of the aluminized layer is researched, and the optimal aluminizing condition is determined. An electron microscope is used for observing the surface quality of the aluminized layer and measuring the thickness of the aluminized layer, an energy dispersive spectrometer is used for analyzing distribution of main elements of the aluminized layer, an X-ray diffractometer is used for analyzing phase composition of the aluminized layer, and a microhardness tester is used for detecting hardness change of the aluminized layer. Results show that when the heat preservation time is 3 h, a compact infiltrated layer with the infiltrated layer thickness of about 180 microns is obtained at the heating temperature of 800 DEG C, the surface quality is good, and the hardness and corrosion resistance are excellent. The complex process problem that a vacuum environment or a protective atmosphere is needed in the powder embedding aluminizing process is solved.

Owner:PANZHIHUA UNIV

A kind of ni-cu-la-b quaternary alloy plating solution and the method for glass fiber electroless plating

ActiveCN103757617BIncreased nickel contentImprove bindingLiquid/solution decomposition chemical coatingEthylenediamineMicroscopic observation

The invention discloses a Ni-Cu-La-B quaternary alloy plating solution. The Ni-Cu-La-B quaternary alloy plating solution comprises the following components: 20-40g / L of nickel chloride, 10-20g / L of copper sulfate, 0.5-10 g / L of lanthanum sulfate, 0.5-3 g / L of sodium borohydride, 40-50g / L of potassium sodium tartrate, 15-30g / L of ethylenediamine and 35-60g / L of sodium hydroxide. A method for chemically plating the glass fibers by using the Ni-Cu-La-B quaternary alloy plating solution comprises the following steps: using sodium borohydride as a reducing agent, adding the water-soluble lanthanum sulfate, and chemically plating the glass fibers by using the Ni-Cu-La-B quaternary alloy plating solution under the conditions of strong base and low temperature; plating layers are Ni-Cu-La-B alloy plating layers, wherein the content of boron is low (only about 0.5-5wt%), the content of nickel in the plating layers is high; the plating layers have good bonding force, electrical conductivity and wear resistance. Through observation with microscopes, the plating layers of the Ni-Cu-La-B quaternary alloy plated glass fibers prepared by using the method are compact; testing with an X-ray energy dispersive spectrometer shows that the surface chemistry components of the Ni-Cu-La-B quaternary alloy plated glass fibers contain 15-50wt% of Ni, 2-15wt% of Cu, 0.5-5wt% of La and 0.5-5wt% of B. The electric conducting glass fibers can be applied to the special fields of electromagnetic wave shielding, microwave absorption, invisibility, anti-static electricity and the like.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Preparation method for nickel molybdenum aluminum-molybdenum disilicide composite coating

The invention relates to a preparation method for a nickel molybdenum aluminum-molybdenum disilicide composite coating. The preparation method includes the steps that molybdenum disilicide particles are subjected to acid pickling, washing and drying; nickel salt, molybdenum compounds, aluminum salt, complexing agents and chloride are weighed, mixed and then dissolved in water, the pH value of the solution is regulated to be 7.3-9.7, and the nickel salt-molybdenum compound-aluminum salt-complexing agent-chloride mixed solution is obtained; the molybdenum disilicide particles, a first batch of the nickel salt-molybdenum compound-aluminum salt-complexing agent-chloride mixed solution and surface active agents are mixed and ground, then a second batch of the nickel salt-molybdenum compound-aluminum salt-complexing agent-chloride mixed solution is added, and an electroplating solution is obtained through stirring; and a part to be electroplated is placed in the electroplating solution to be electroplated, nickel is adopted as an anode, nickel alloy to be electroplated is adopted as a cathode, after electroplating is completed, the electroplated part is washed through water and air-dried, and therefore the nickel molybdenum aluminum-molybdenum disilicide composite coating is obtained. The aluminum content and the silicon content of the nickel molybdenum aluminum-molybdenum disilicide composite coating are measured to be 2.5%-9.2% and 1.2%-6.5% respectively through an energy dispersive spectrometer.

Owner:SHANGHAI INST OF TECH

Method for detecting source of oxide scale peeled off from inner wall of heated surface of boiler

InactiveCN104390992AEasy and convenientMaterial analysis by measuring secondary emissionX-rayElectron microscope

The invention relates to a method for detecting a source of a piece of oxide scale peeled off from the inner wall of a heated surface of a boiler. The method comprises the steps of selecting a piece of oxide scale with a light grey surface and a black or dark grey surface, observing the black or dark grey surface of the oxide scale by utilizing a scanning electronic microscope with an X-ray energy dispersive spectrometer, finding out residues on an inner layer of the oxide scale, and carrying out X-ray energy spectral analysis on the residues on the inner layer of the oxide scale so as to obtain an X-ray energy spectral analysis result; and comparing the X-ray energy spectral analysis result of the residues on the inner layer of the oxide scale with an alloy steel element in a tubular screen of the heated surface, and determining the source of the peeled oxide scale. By adopting the method, the oxide scale peeled off from the tubular screen can be easily and conveniently determined to be peeled from the inner wall of which material, so that the peel-off and pipe blockage problem of the oxide scale can be treated in a targeted manner in a power plant.

Owner:XIAN THERMAL POWER RES INST CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com