Non-destructive detection method for pollutant components on surface of part

A non-destructive detection and component technology, applied in the detection field, can solve the problem that metal pollutants cannot be detected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0049] It is suitable for the surface contamination analysis of an alumina ceramic ring component.

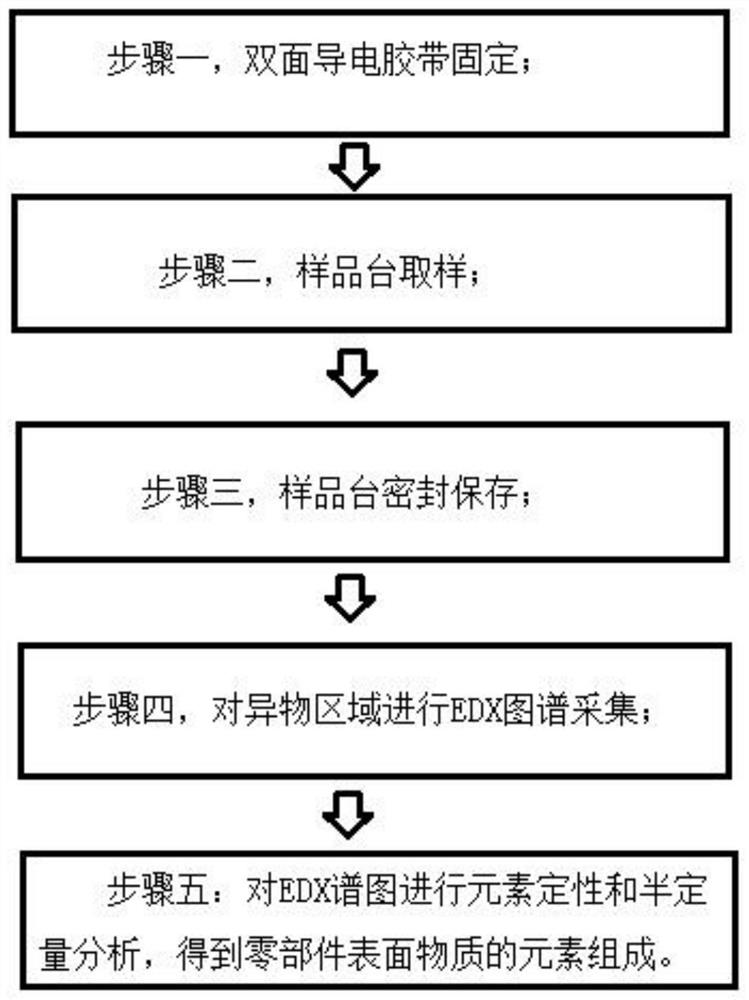

[0050] A method for non-destructive detection of pollutant components on the surface of parts, specifically comprising the following steps:

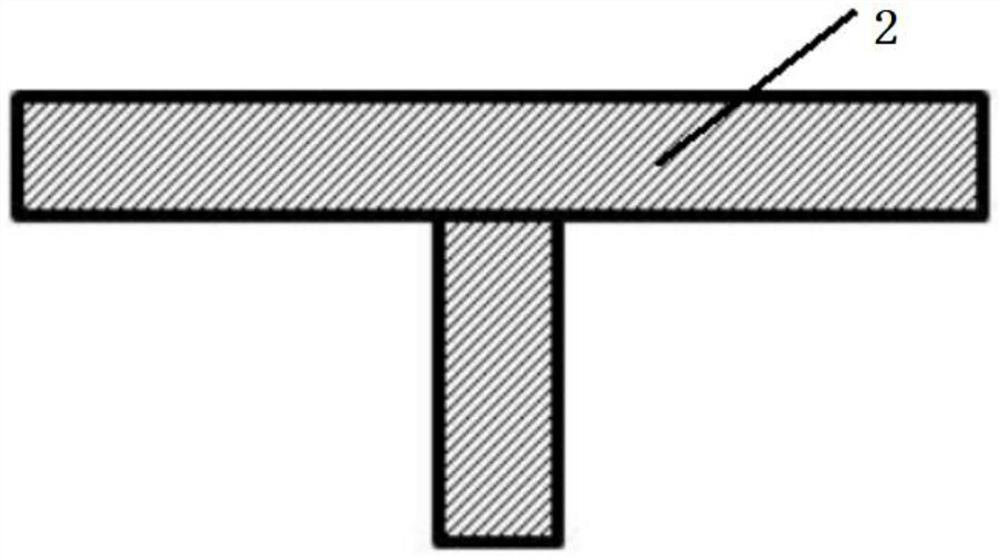

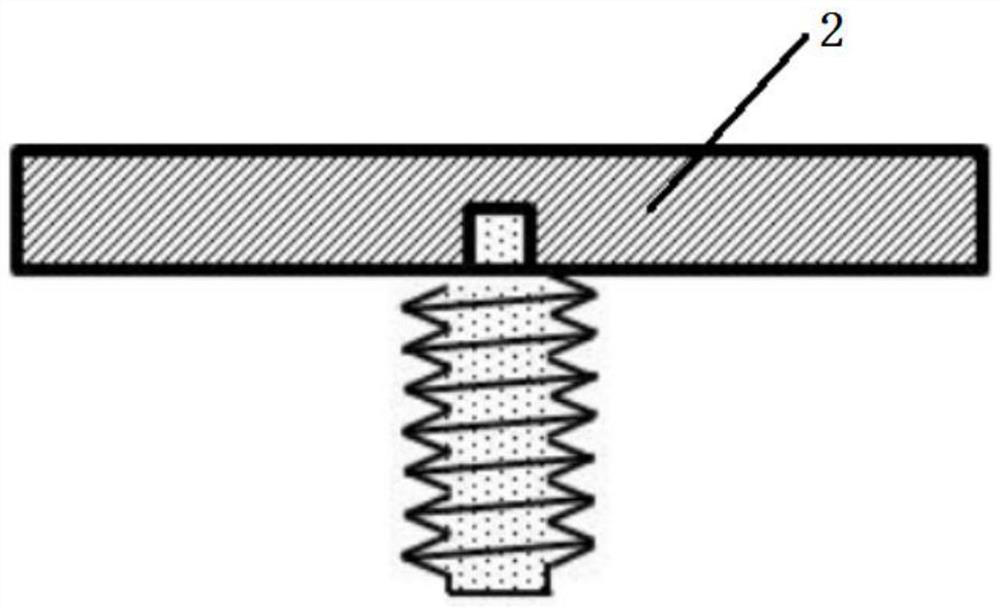

[0051] Step 1: Lay double-sided conductive tape on the sample stage of the scanning electron microscope; the bottom of the sample stage is provided with internal threads;

[0052] The sample stage is 30mm in diameter and 6mm in height.

[0053] The conductive adhesive is a double-sided conductive carbon tape with a width of 8mm, and the tape base is high-purity aluminum foil.

[0054] Step 2: Connect the threaded rod to the internal thread plane sample stage, peel off the protective strip on the conductive tape, and hold the threaded rod to adhere the front of the sample stage with the conductive tape to the surface area of the ceramic ring component to be tested.

[0055] Step 3: After the sample stage adheres to the surface of the a...

specific Embodiment 2

[0062] A surface contamination analysis of yttria-coated chamber components.

[0063] A method for non-destructive detection of pollutant components on the surface of parts, characterized in that it comprises the steps of:

[0064] Step 1: Lay double-sided conductive tape on the sample stage of the scanning electron microscope; the bottom of the sample stage is provided with internal threads;

[0065] The sample stage is 15mm in diameter and 6mm in height. The conductive adhesive is a double-sided conductive carbon tape with a width of 8mm, and the tape base is high-purity aluminum foil.

[0066] Step 2: Connect the threaded rod with the internal thread plane sample stage, remove the protective strip on the conductive tape, and adhere the front of the sample stage with the conductive tape on the surface area of the cavity part to be tested.

[0067] Step 3: After the sample stage adheres to the surface of the cavity parts for two minutes, remove the sample stage, quickly p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com