Patents

Literature

564 results about "Scan electron microscopy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scanning Electron Microscopy. A scanning electron microscope (SEM) scans a focused electron beam over a surface to create an image. The electrons in the beam interact with the sample, producing various signals that can be used to obtain information about the surface topography and composition.

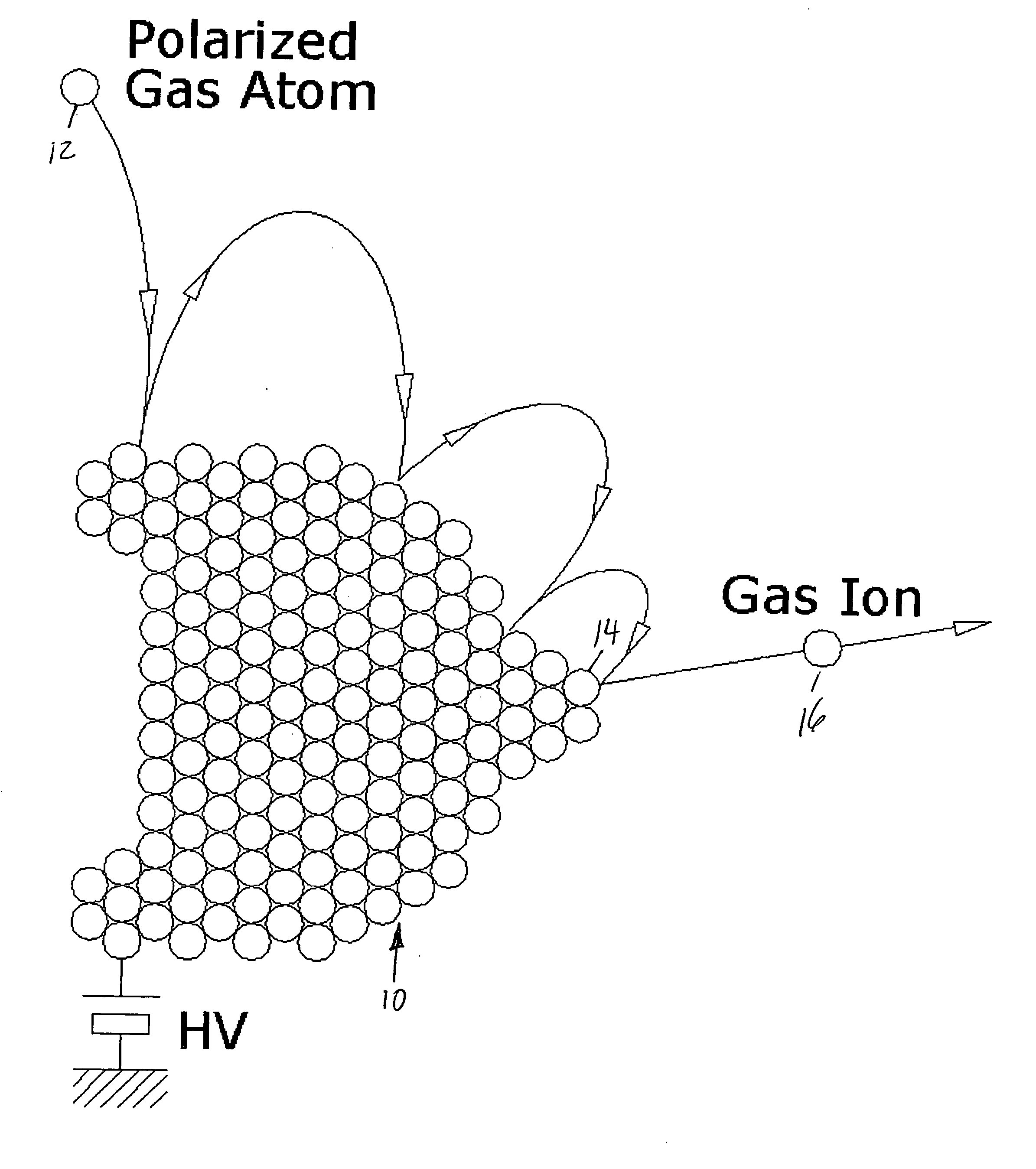

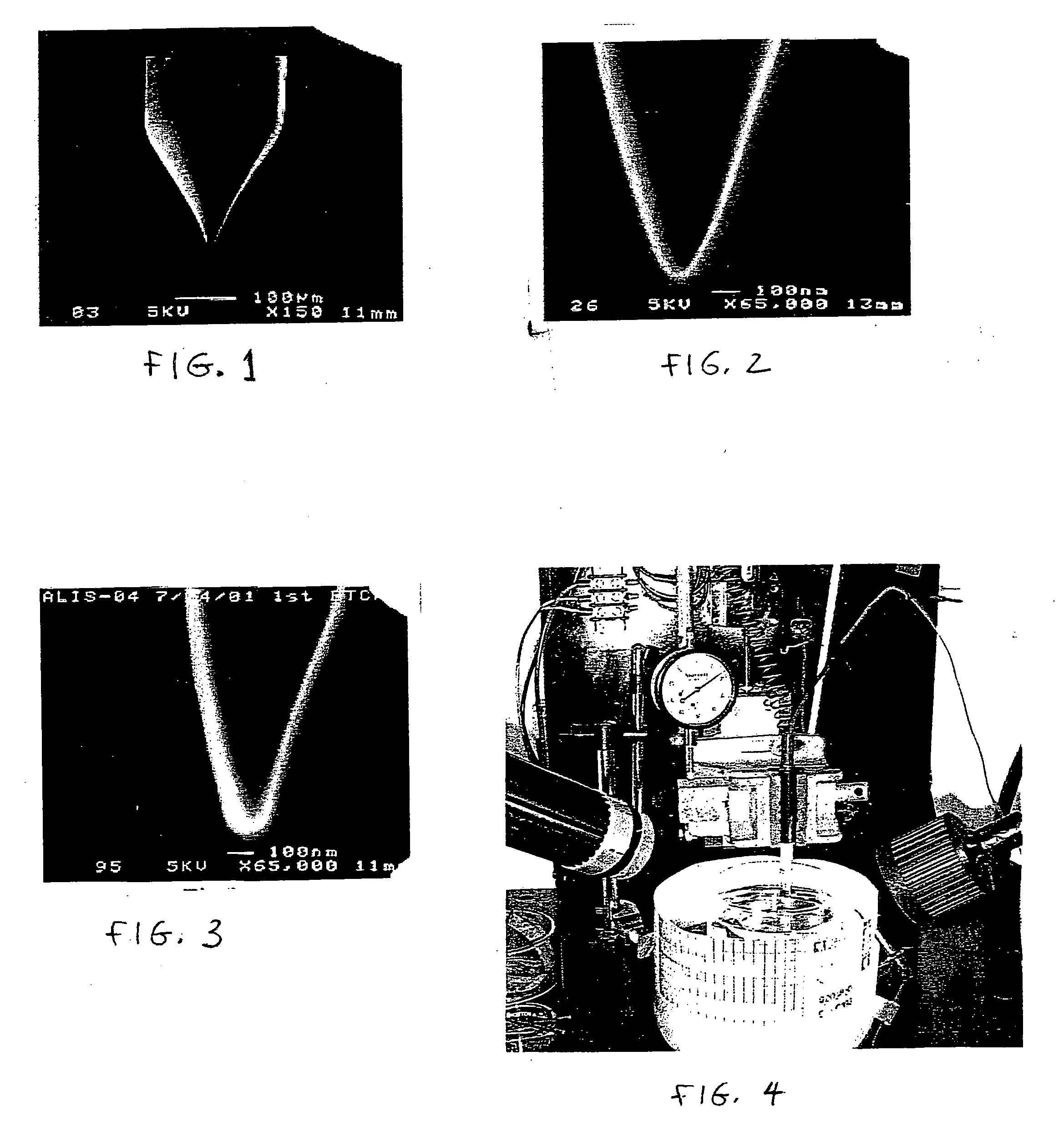

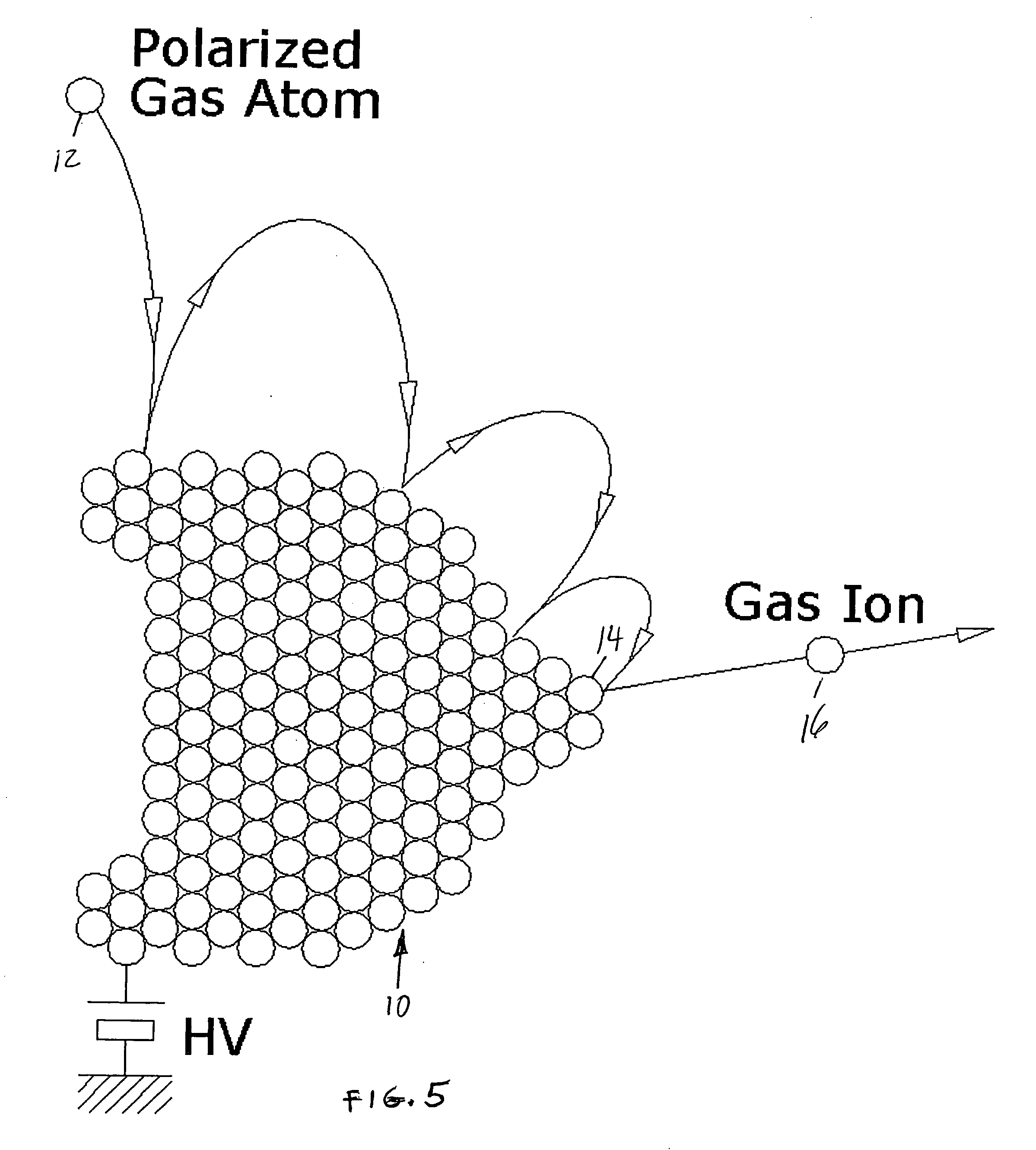

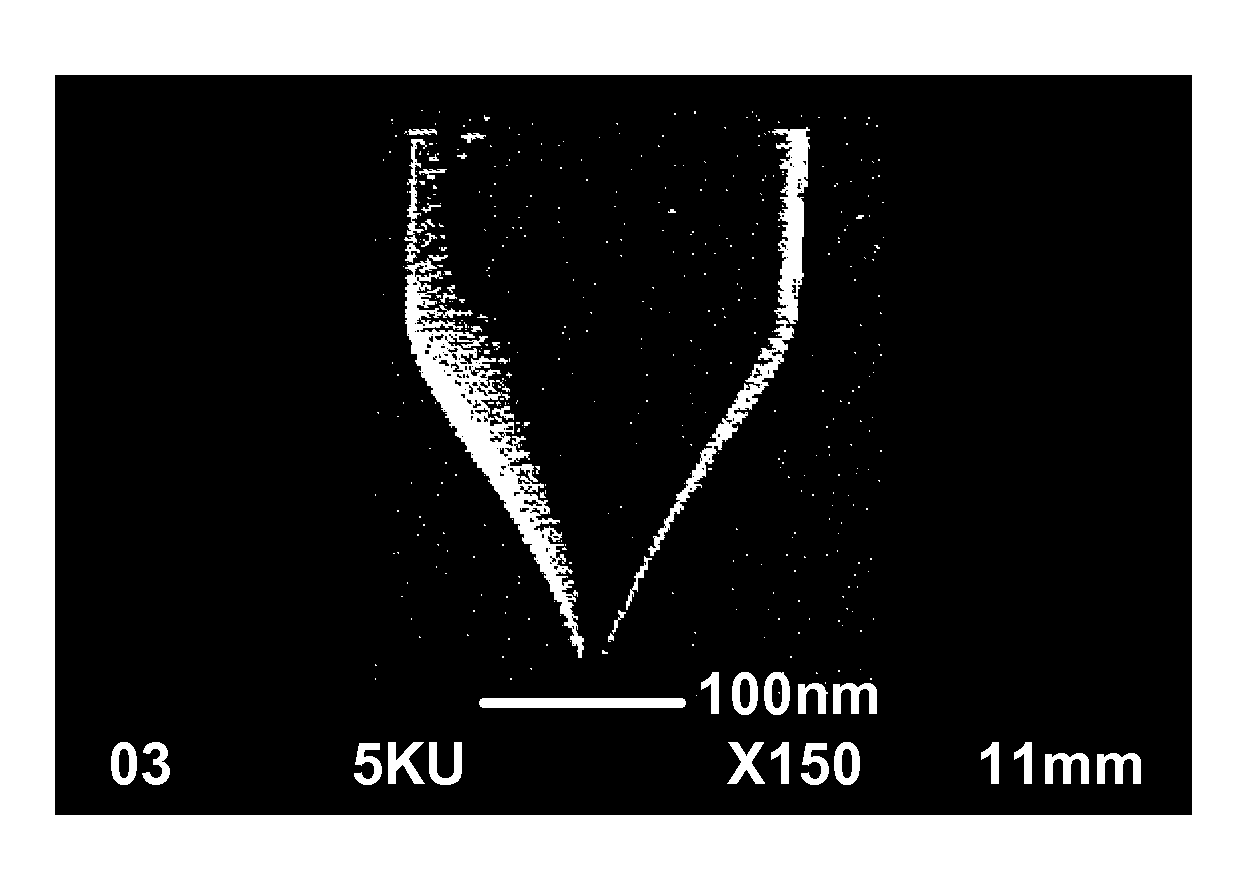

Atomic level ion source and method of manufacture and operation

ActiveUS20070051900A1Long-term performanceLong-term reliabilityMaterial analysis using wave/particle radiationMaterial analysis by optical meansElectrical conductorScanning electron microscope

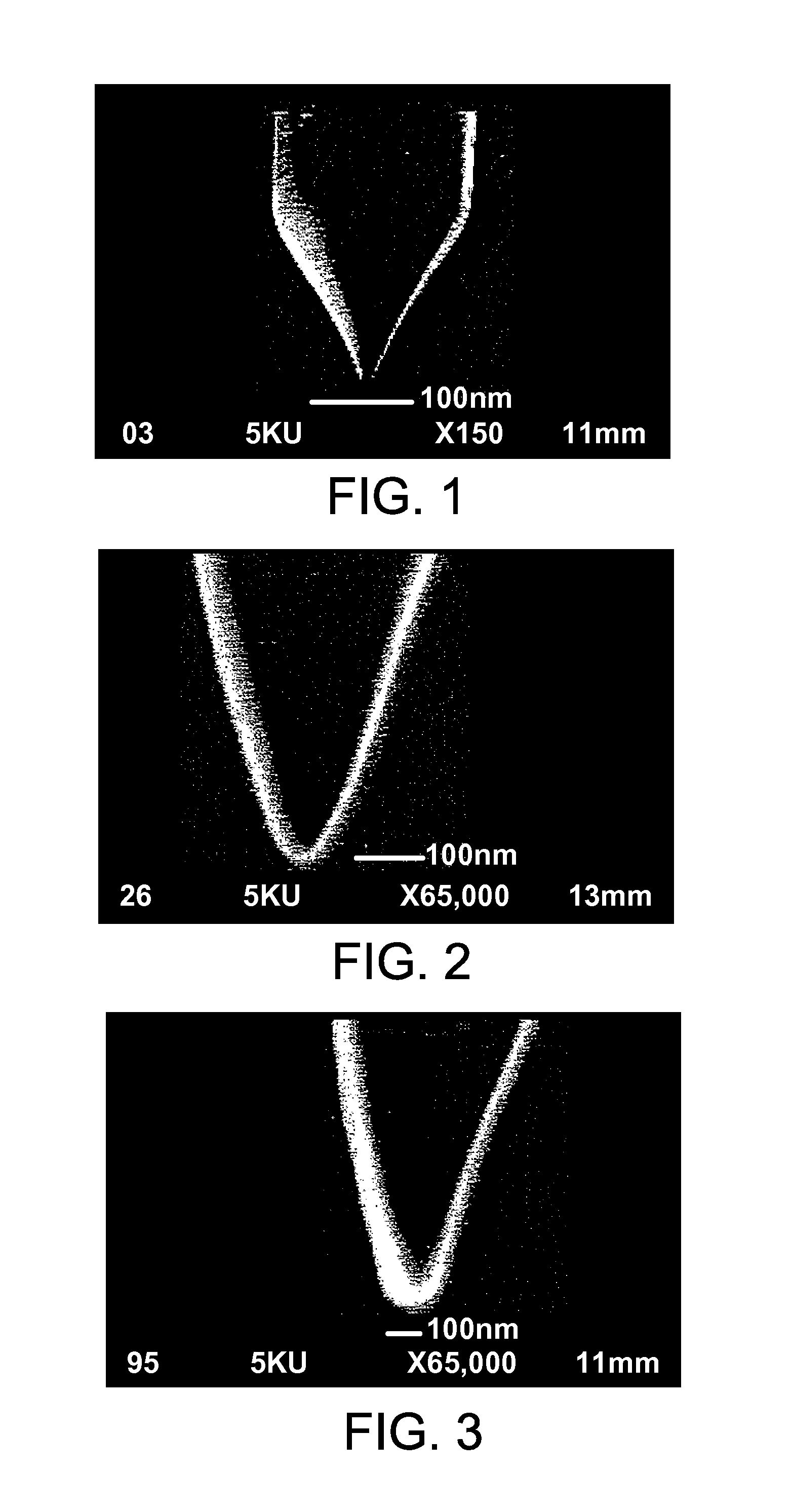

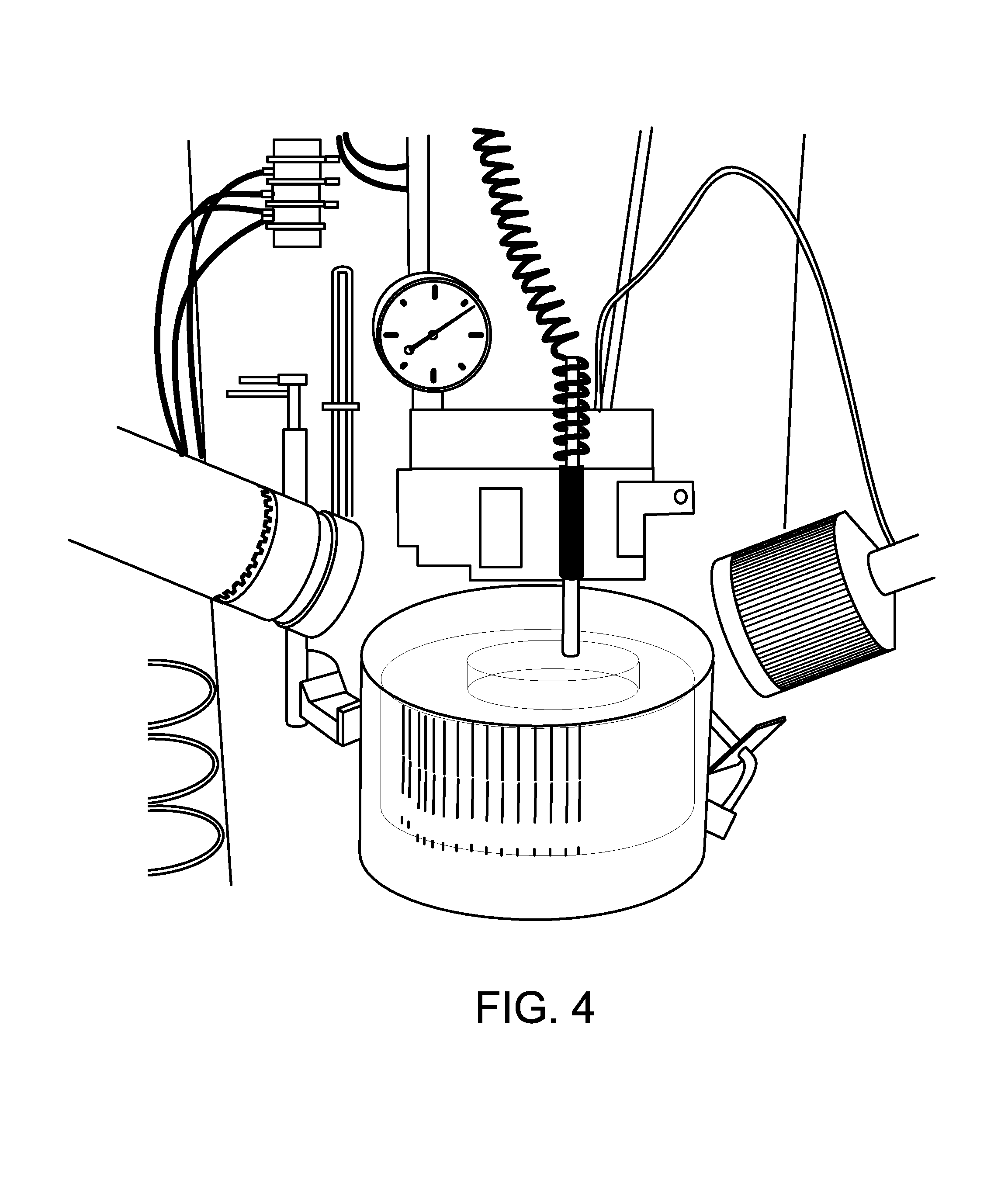

Ion source and method of making and sharpening. The ion source is a single crystal metal conductor having a substantially conical tip portion with substantial rotational symmetry. The tip portion terminates with a tip radius of curvature in the range of 50-100 nanometers. The ion source is made by electrochemical etching so that a conical tip of a selected geometry is formed. The ion source is then sharpened to provide a source of ions from a volume near the size of a single atom. Further, this ion source makes possible a stable and practical light ion microscope which will have higher resolution than existing scanning electron microscopes and scanning metal-ion microscopes.

Owner:ALIS CORP

Atomic level ion source and method of manufacture and operation

ActiveUS7368727B2Good symmetryLong-term performance and reliabilityMaterial analysis using wave/particle radiationMaterial analysis by optical meansElectrical conductorScanning electron microscope

Ion source and method of making and sharpening. The ion source is a single crystal metal conductor having a substantially conical tip portion with substantial rotational symmetry. The tip portion terminates with a tip radius of curvature in the range of 50–100 nanometers. The ion source is made by electrochemical etching so that a conical tip of a selected geometry is formed. The ion source is then sharpened to provide a source of ions from a volume near the size of a single atom. Further, this ion source makes possible a stable and practical light ion microscope which will have higher resolution than existing scanning electron microscopes and scanning metal-ion microscopes.

Owner:ALIS CORP

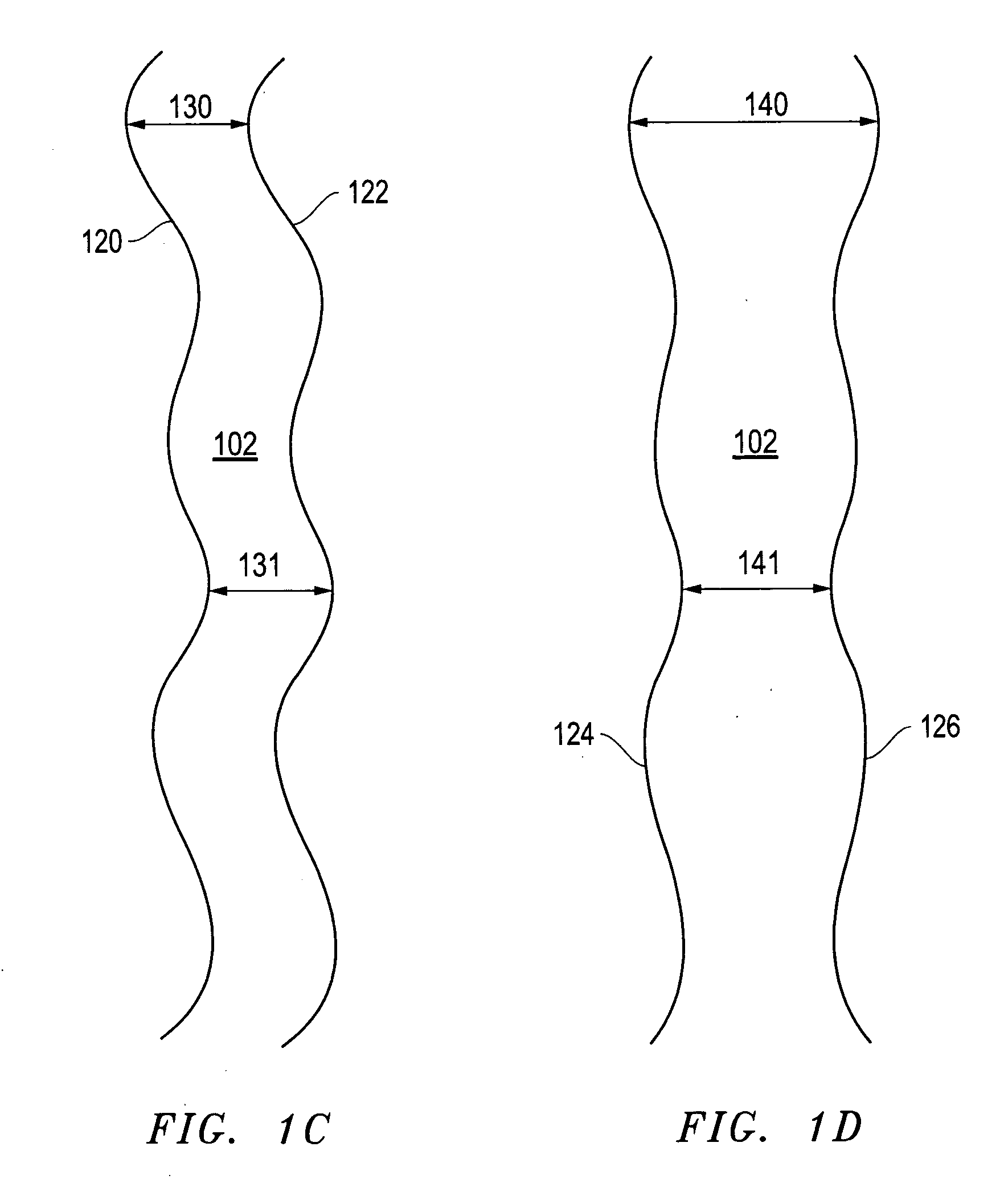

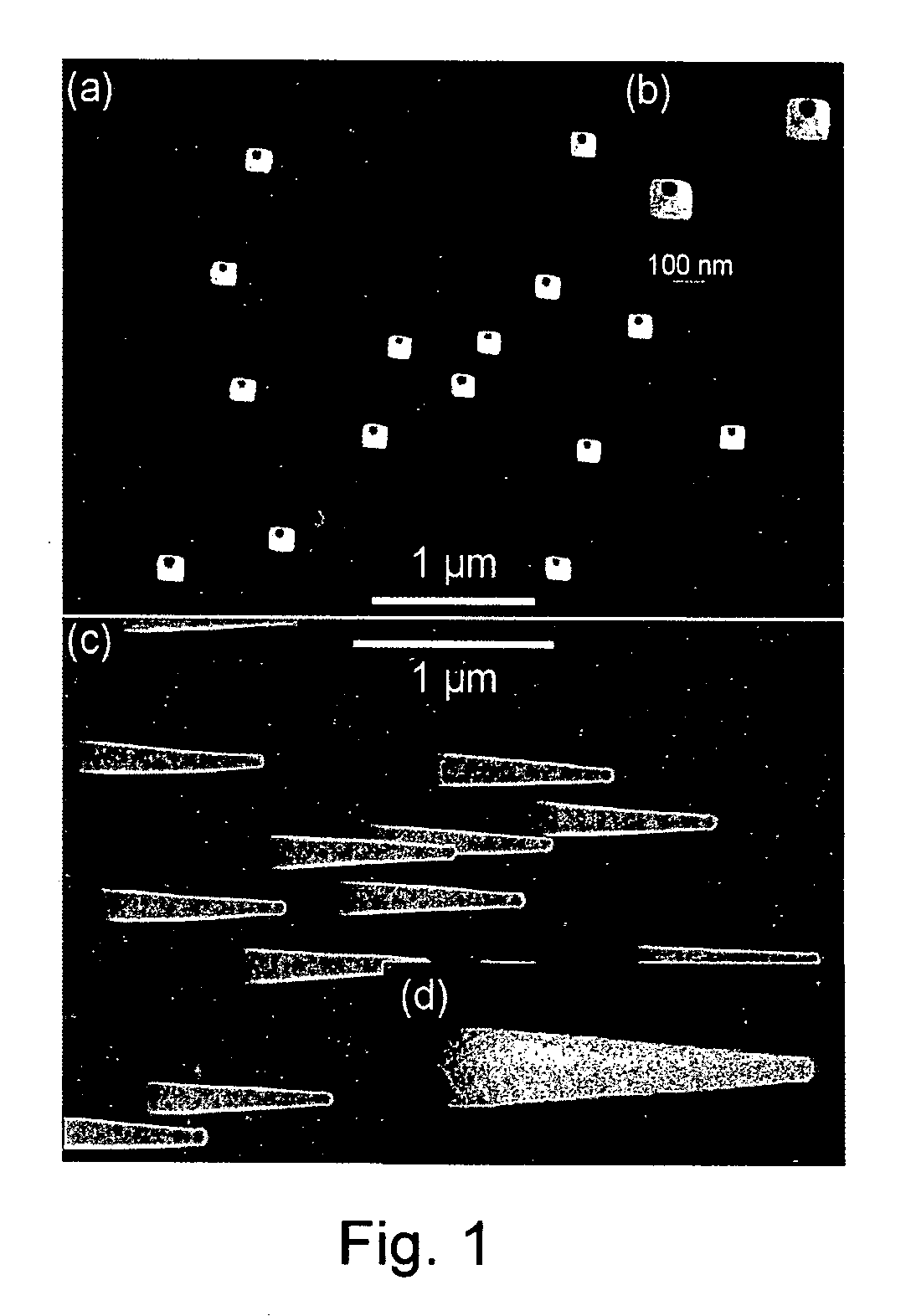

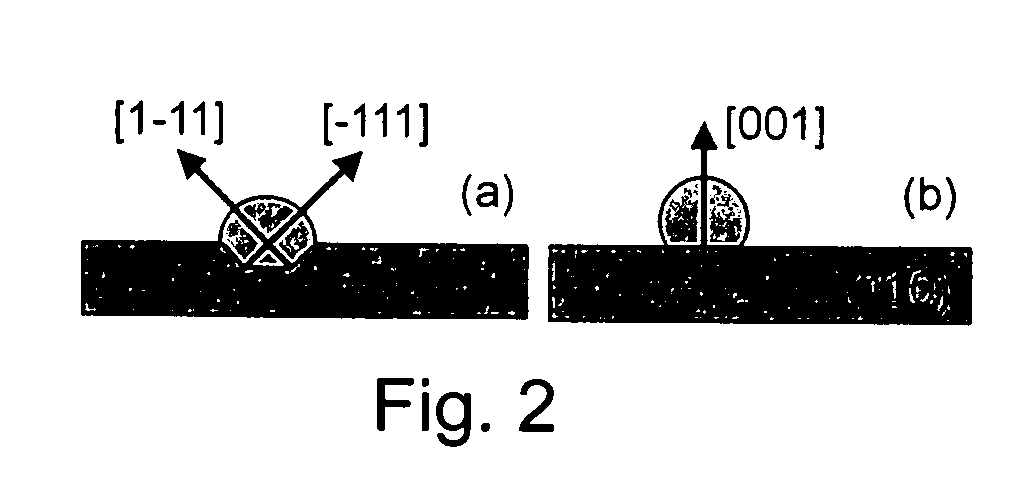

Directionally controlled growth of nanowhiskers

InactiveUS7354850B2Optimized structural formWell-defined surfaceMaterial nanotechnologyPolycrystalline material growthStacking faultOrganic vapor

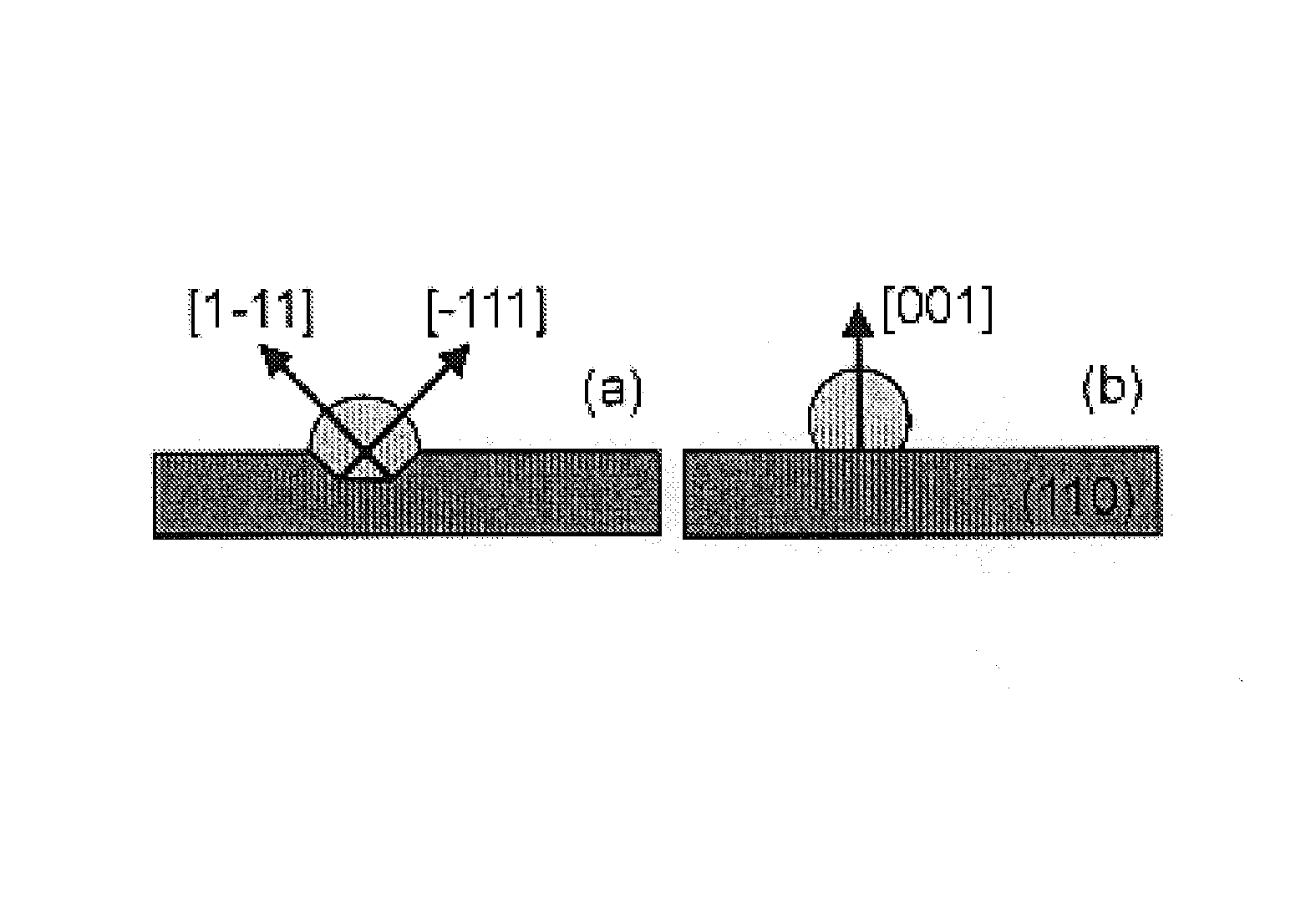

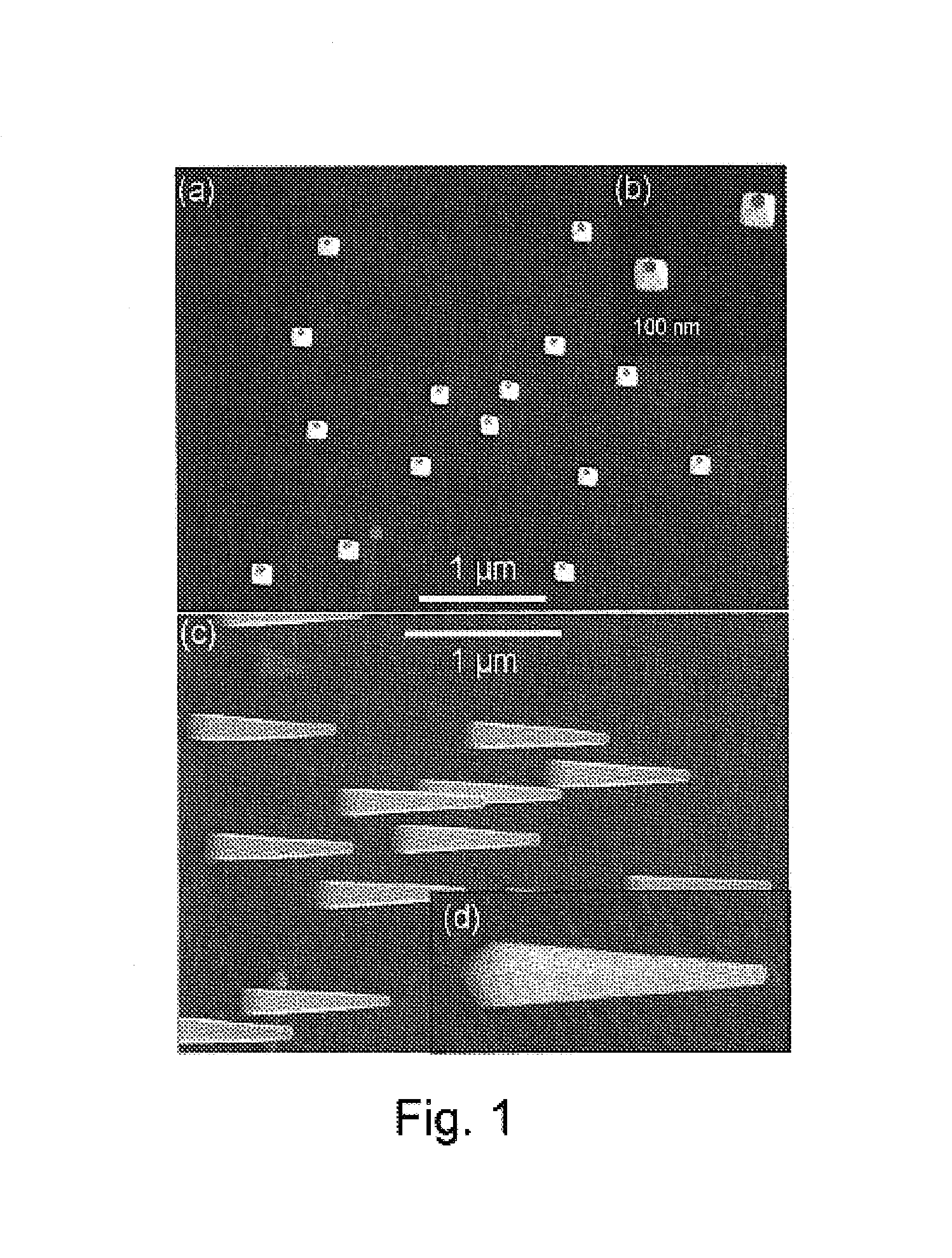

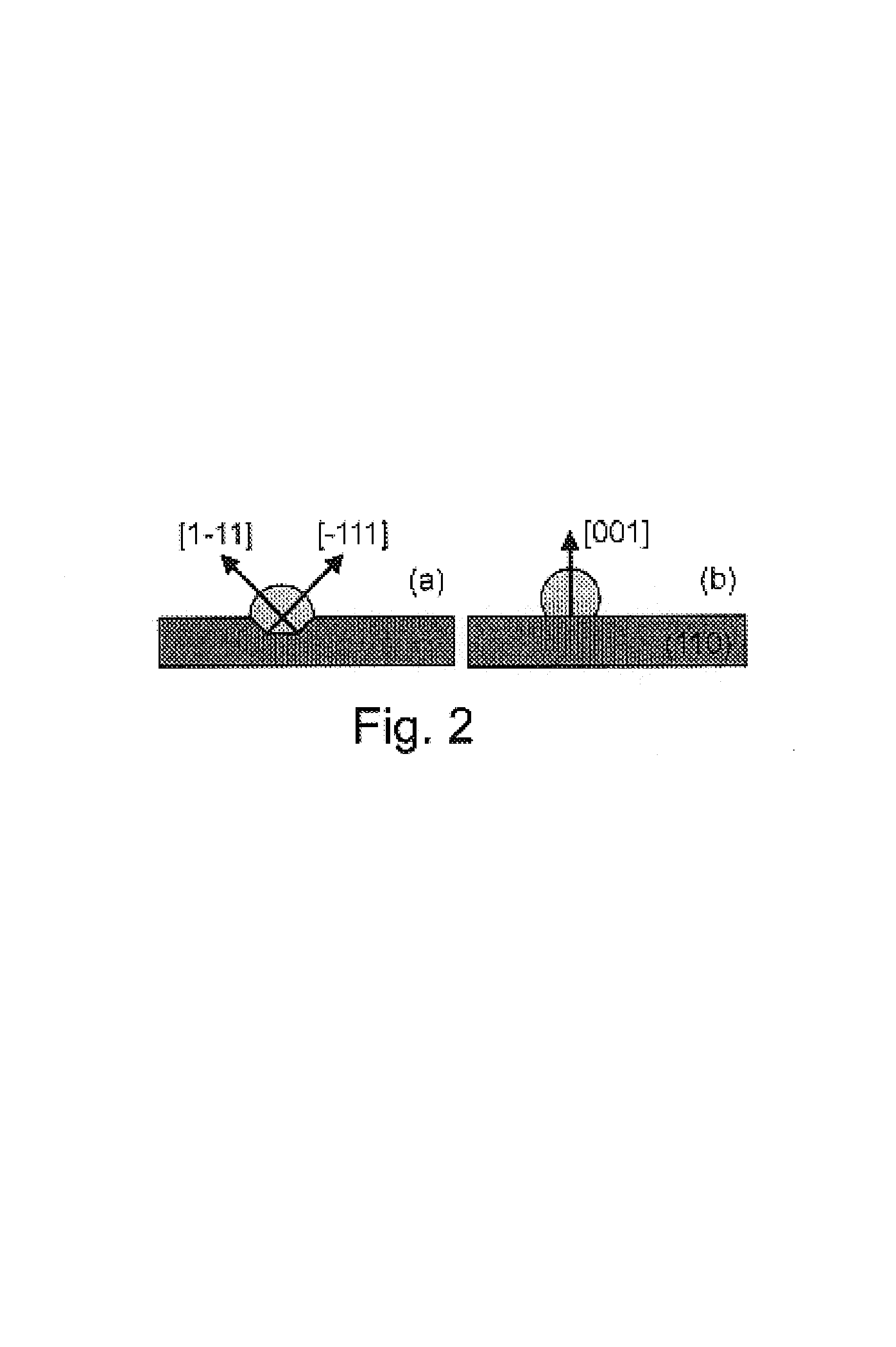

Nanowhiskers are grown in a non-preferential growth direction by regulation of nucleation conditions to inhibit growth in a preferential direction. In a preferred implementation, <001> III-V semiconductor nanowhiskers are grown on an (001) III-V semiconductor substrate surface by effectively inhibiting growth in the preferential <111>B direction. As one example, <001> InP nano-wires were grown by metal-organic vapor phase epitaxy directly on (001) InP substrates. Characterization by scanning electron microscopy and transmission electron microscopy revealed wires with nearly square cross sections and a perfect zincblende crystalline structure that is free of stacking faults.

Owner:QUNANO

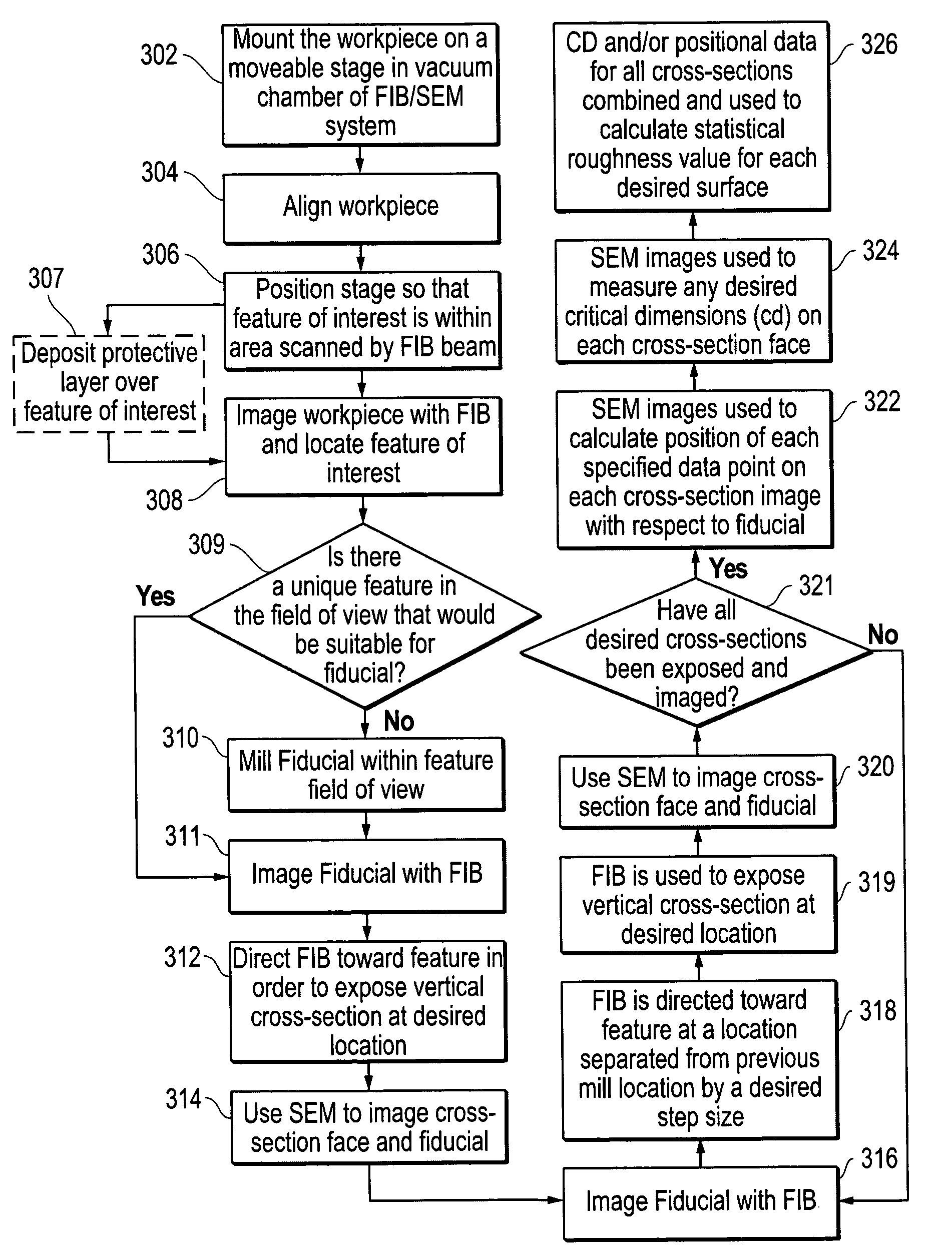

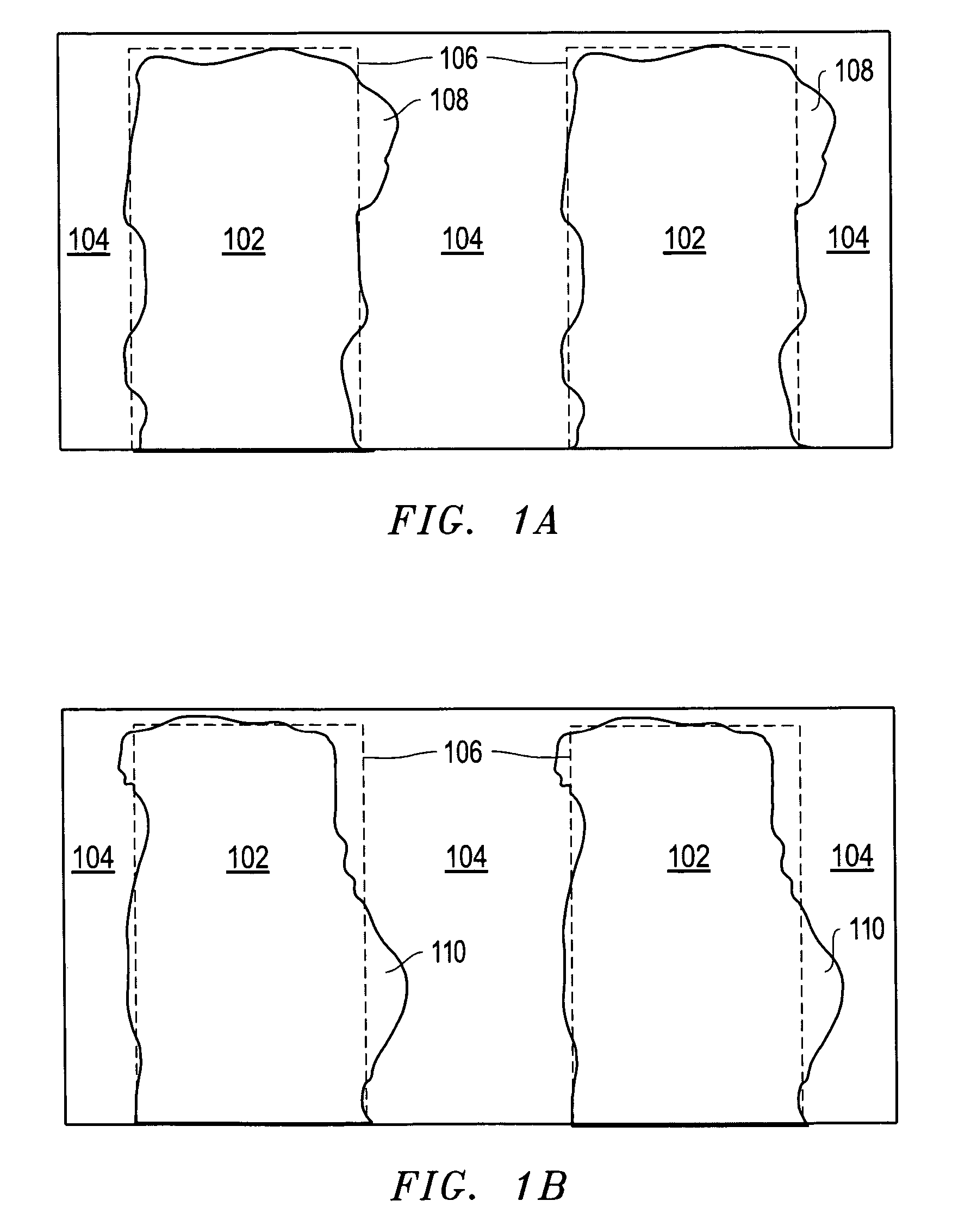

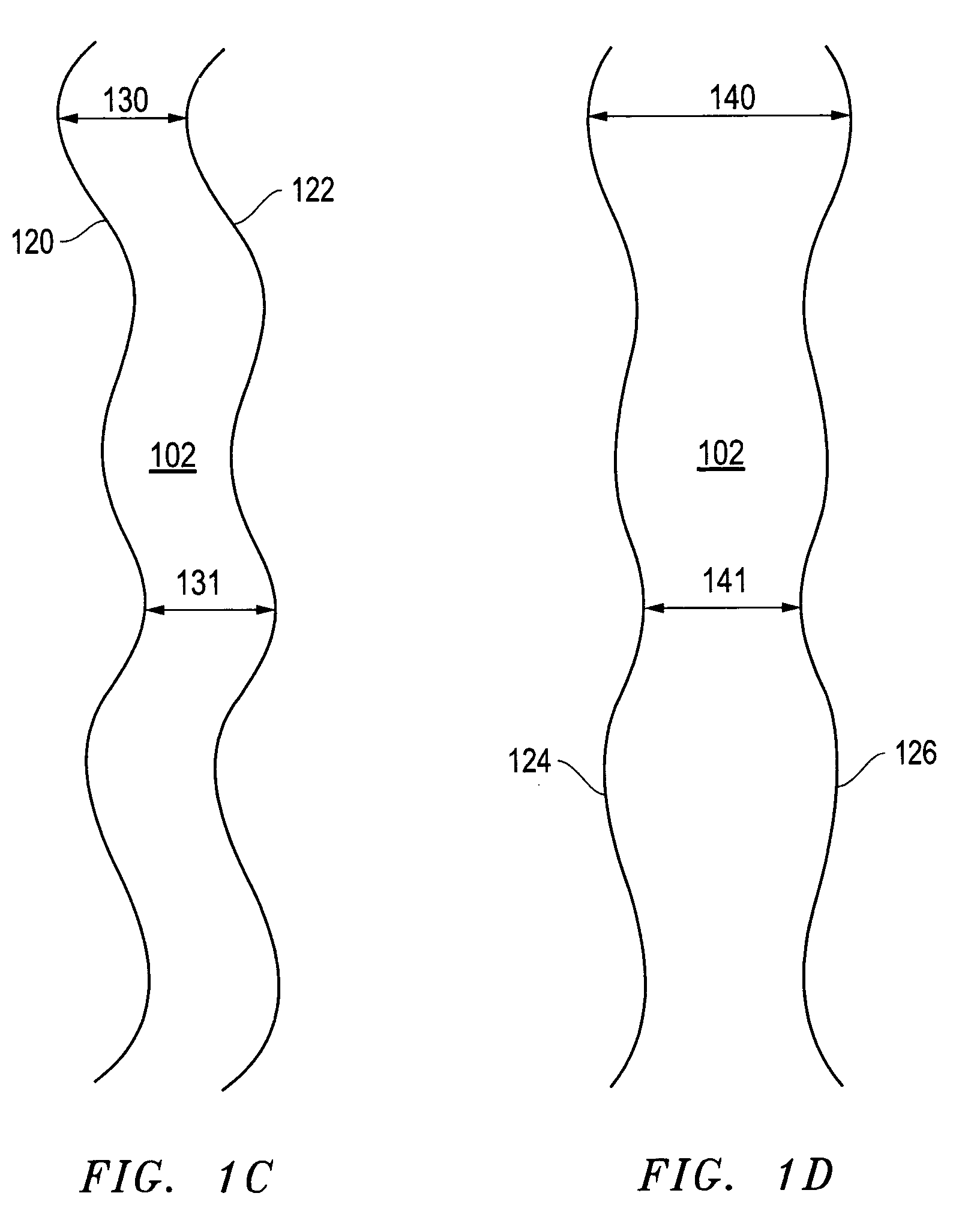

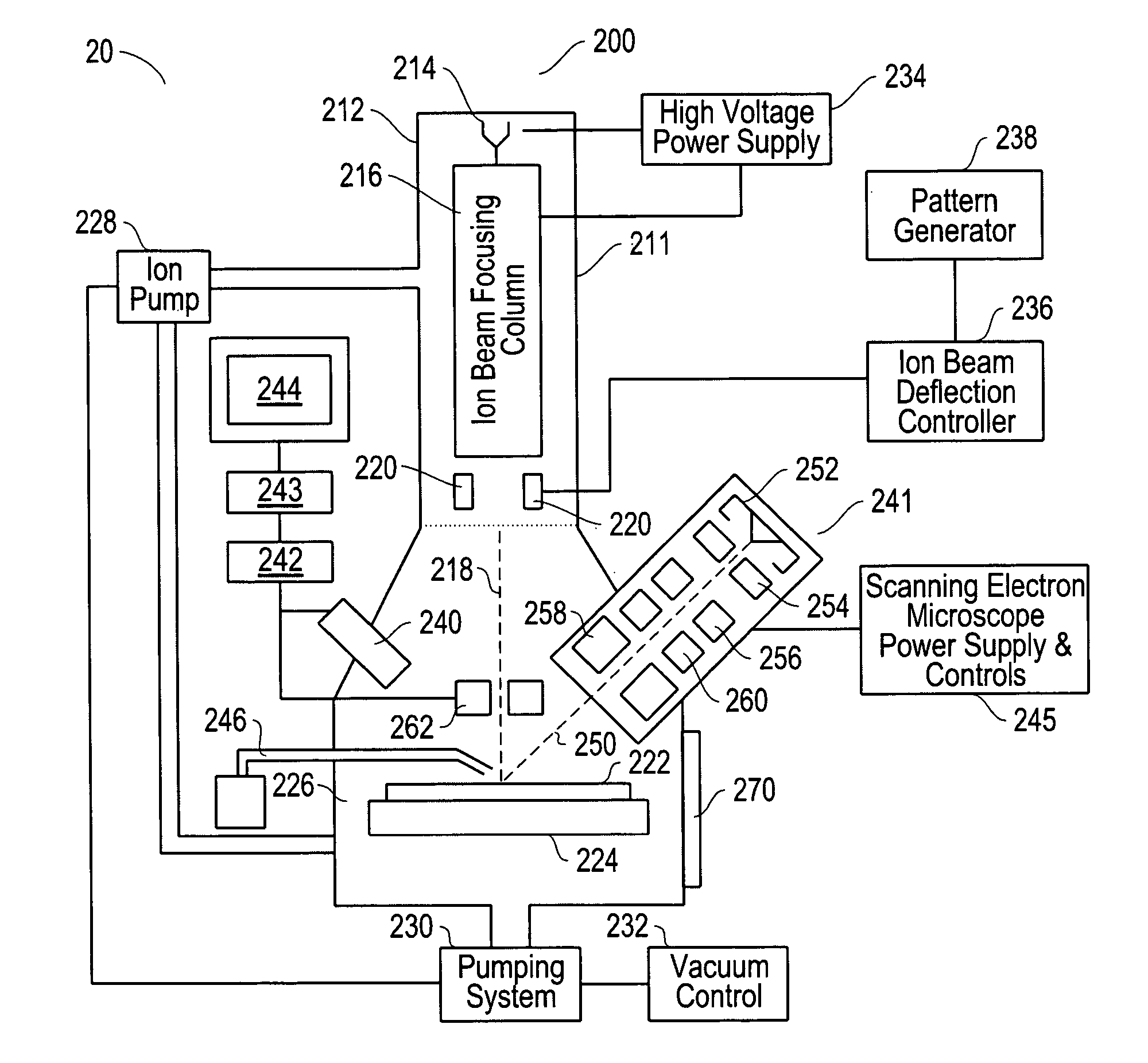

Method of measuring three-dimensional surface roughness of a structure

InactiveUS7348556B2Material analysis using wave/particle radiationElectric discharge tubesIon beamSurface roughness

An improved method of measuring the three-dimensional surface roughness of a structure. A focused ion beam is used to mill a succession of cross-sections or “slices” of the feature of interest at pre-selected intervals over a pre-selected measurement distance. As each cross-section is exposed, a scanning electron microscope is used to measure the relevant dimensions of the feature. Data from these successive “slices” is then used to determine the three-dimensional surface roughness for the feature.

Owner:FEI CO

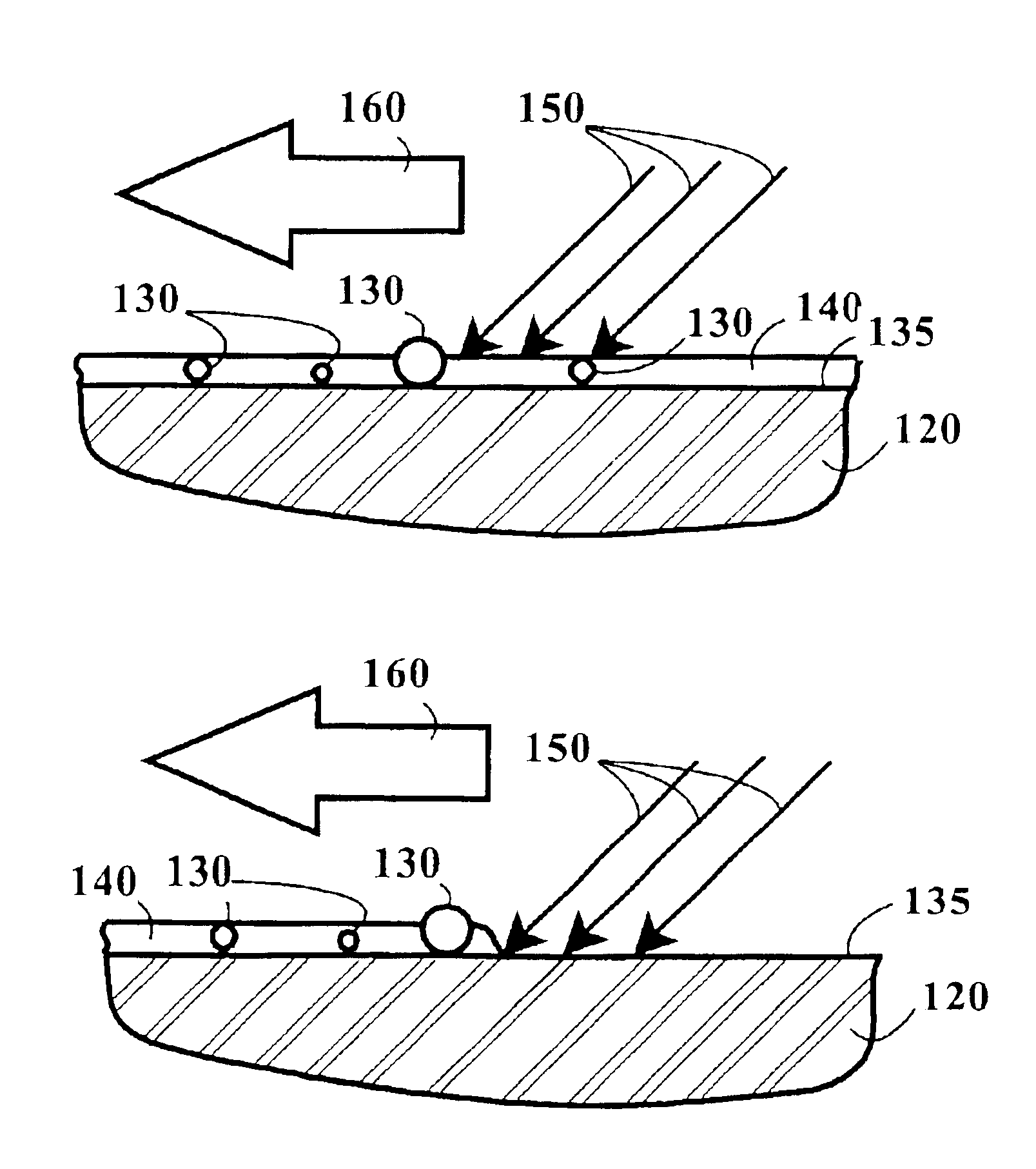

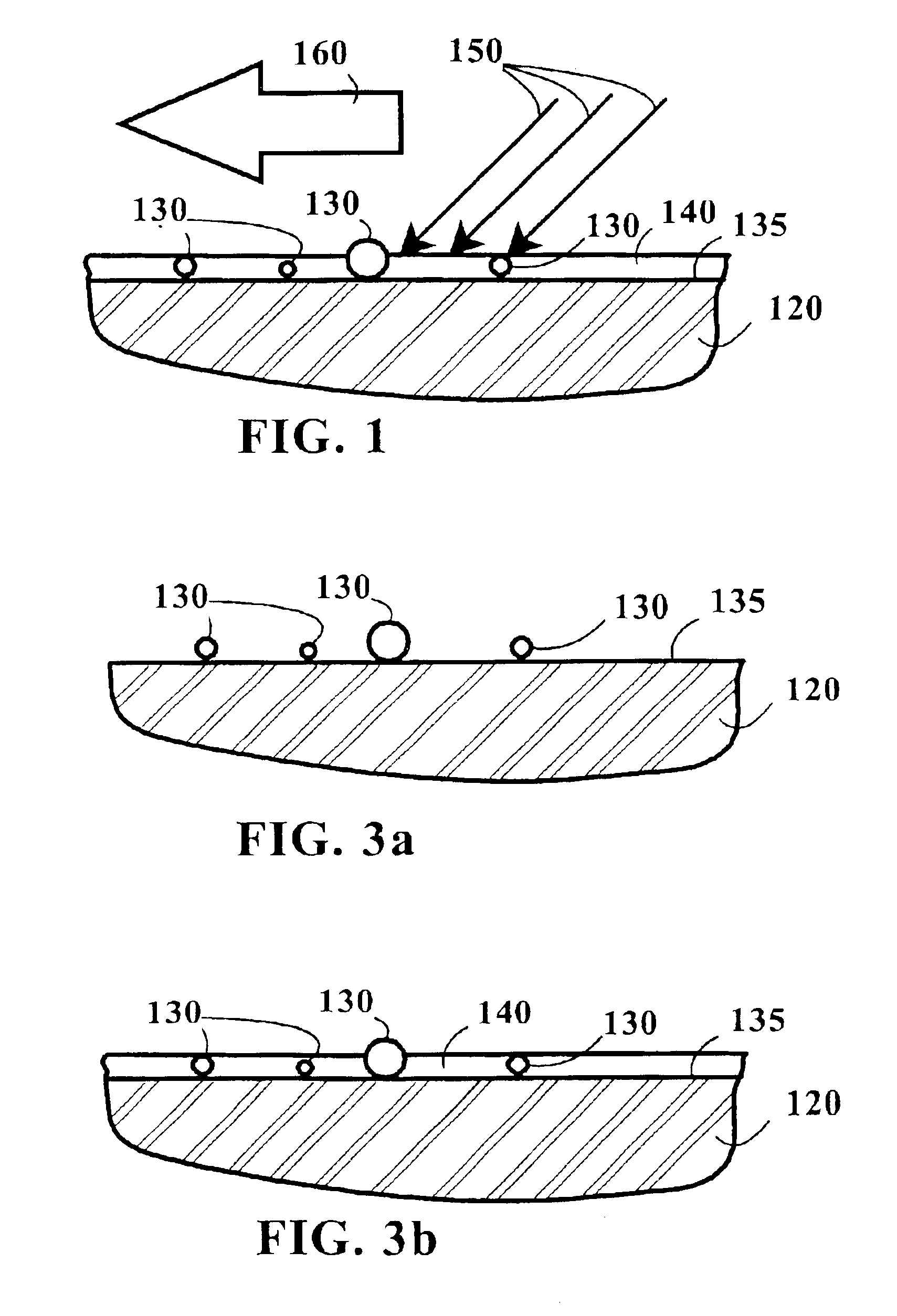

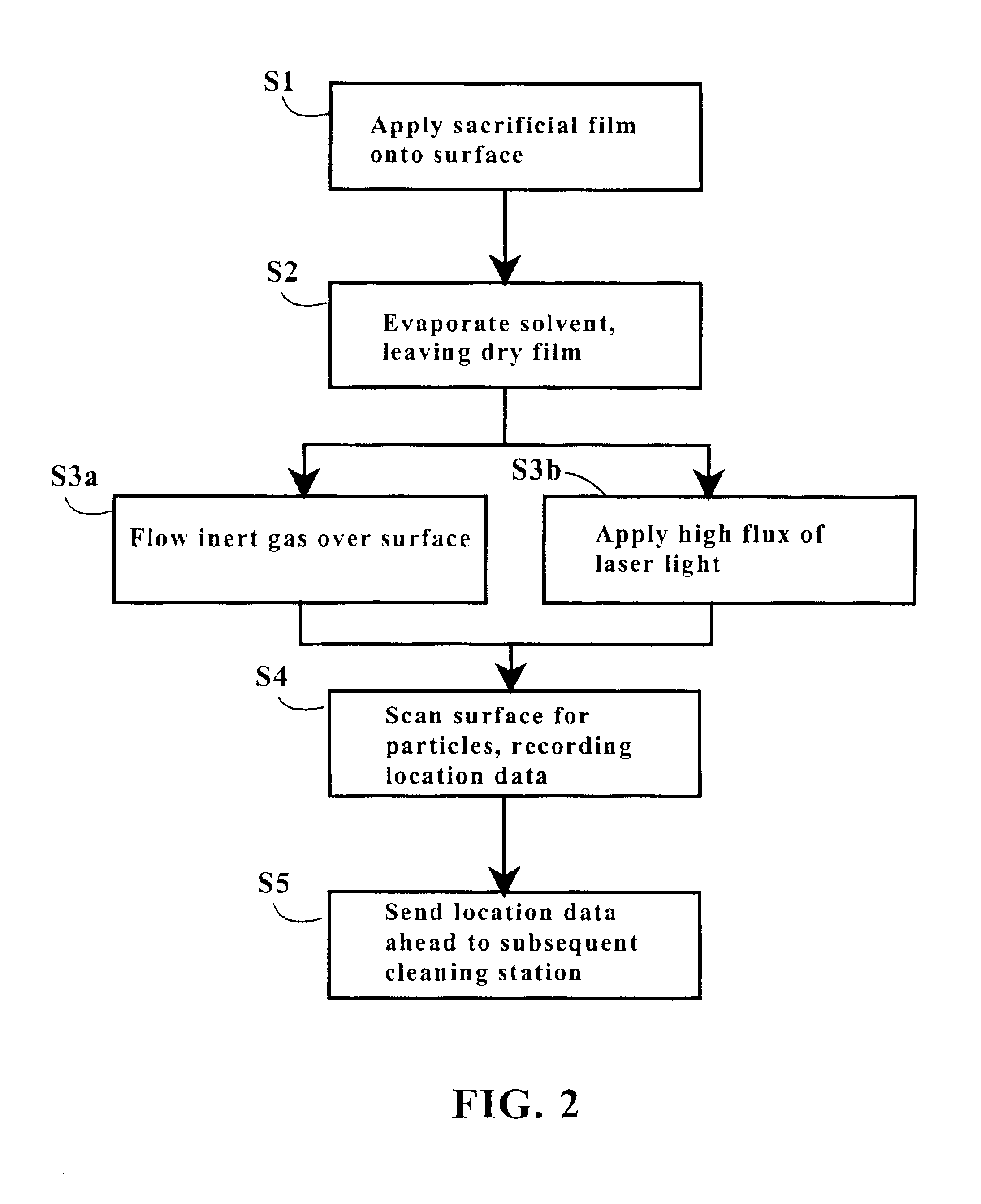

Method for laser cleaning of a substrate surface using a solid sacrificial film

InactiveUS6881687B1Adversely affect functionality and performanceImproved yieldElectrostatic cleaningSemiconductor/solid-state device manufacturingEngineeringData records

An improved semiconductor wafer processing apparatus 10 includes a series of processing stations combined in one form, coupled together by computer-controlled cluster tooling. Wafers are supplied in a pod to an input station 28 which initiates a data record for recording processing results at each station. A sacrificial film 140 is applied to the surface 135 of each wafer. Individual wafers are transferred to a computer-controlled defect-mapping station 14 where particulate defects 130 are identified and their position coordinates recorded. Defect-mapped wafers are transferred to a computer-controlled laser area cleaning station 11 which lifts the defects and sweeps the wafer surface clean, except for stubborn defects. Clean wafers are transferred to a final mapping station 20 or 22, followed by transfer of the wafers to an output station 30. Wafers having remaining stubborn defects are transferred to a second defect-mapping station 16 where stubborn defects are located by coordinates, after which the wafers are transferred to a defect review tool incorporating a scanning electron microscope (SEM-DRT) 24. A SEM image review of stubborn defects includes chemical analysis of the stubborn defects. A laser point-cleaning station 13 lifts and sweeps each stubborn defect individually from the wafer surface. Cleaned wafers are transferred to a third defect-mapping station 18 for recording any stubborn defects remaining, then to a second laser area cleaning station 12 for a final cleaning, followed by transfer of the wafers to a final mapping station 20 or 22 for mapping of any remaining stubborn defects. The accompanying data records are updated followed by transfer of the wafers to an output station 30.

Owner:SEIKO INSTR INC

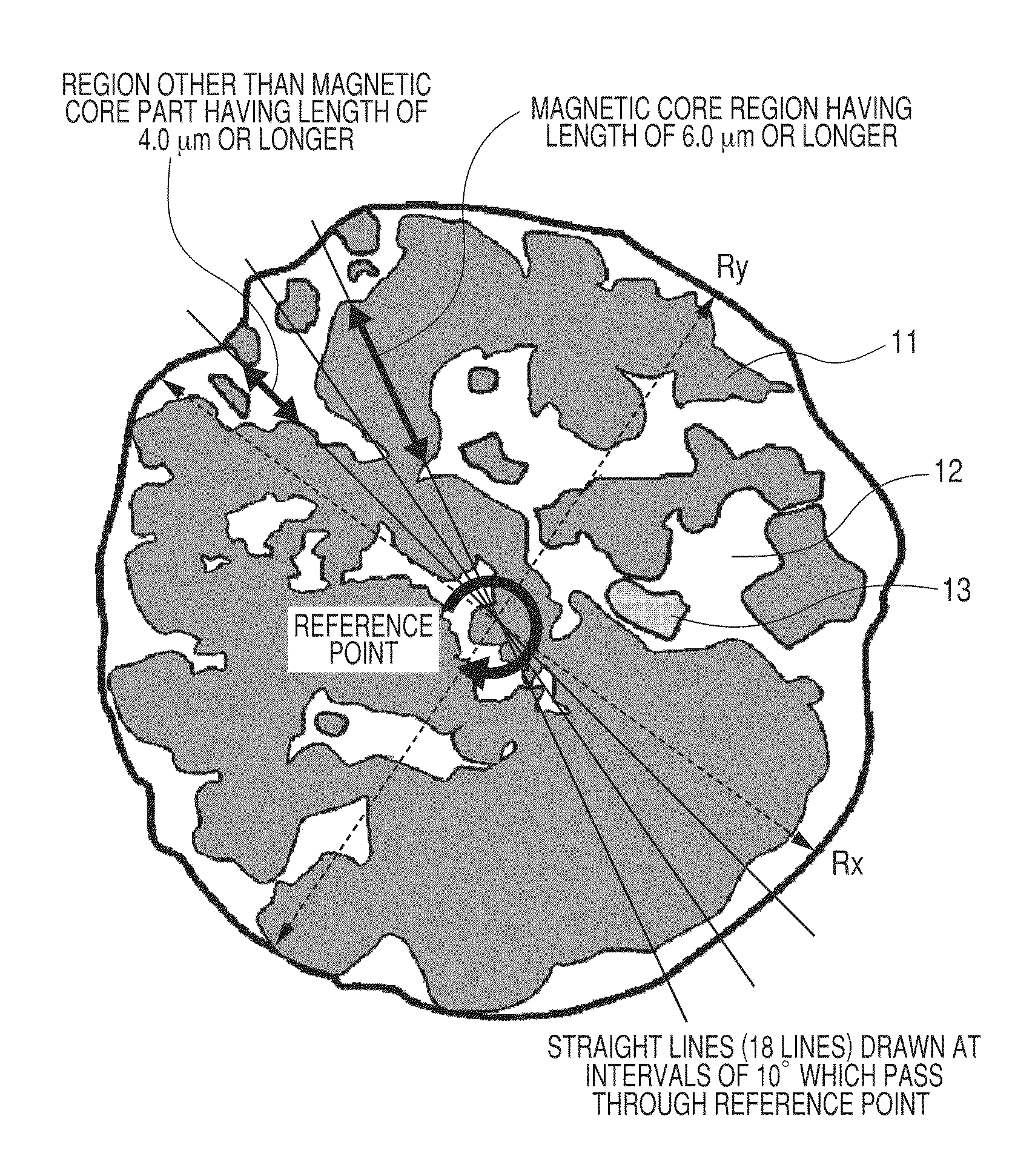

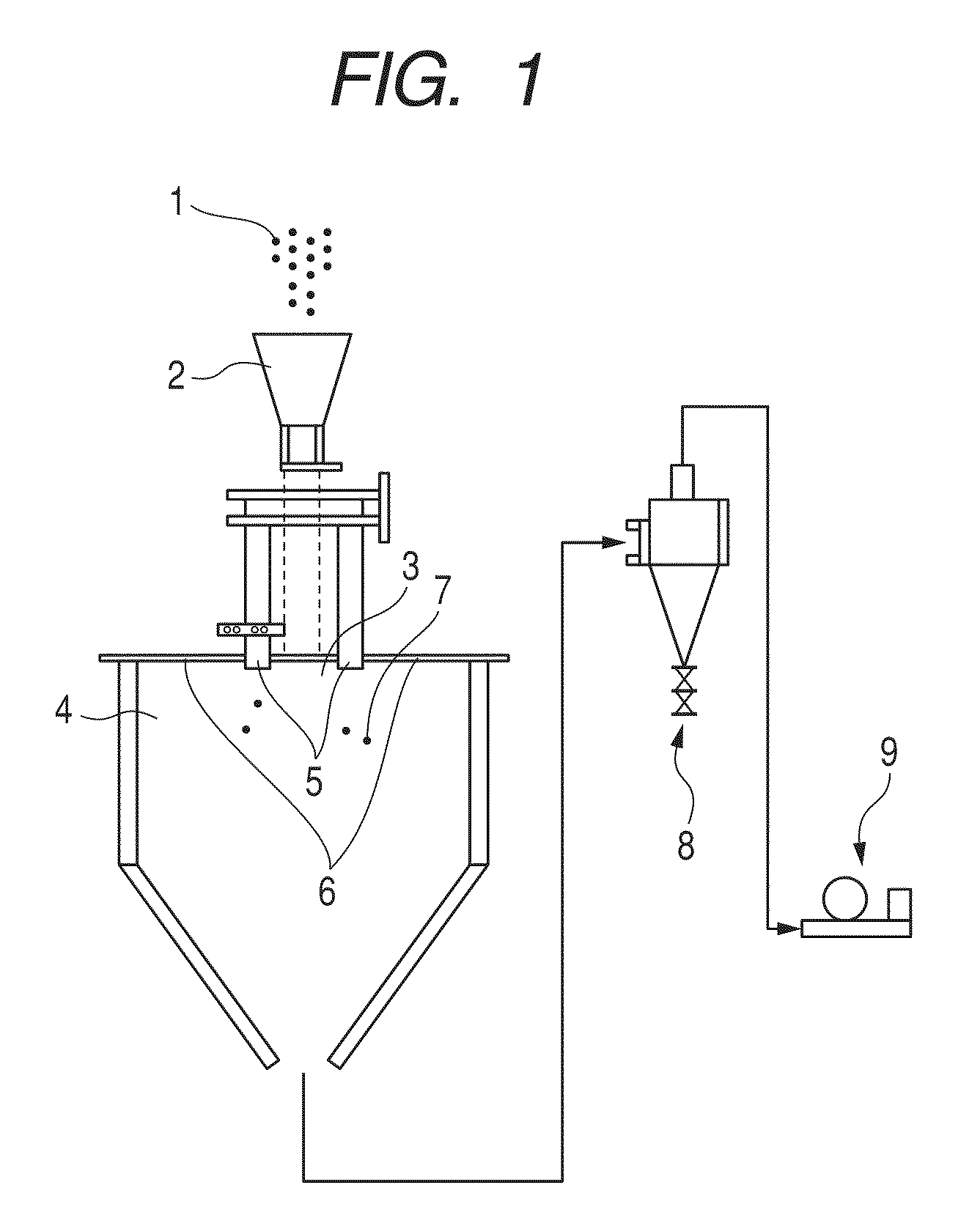

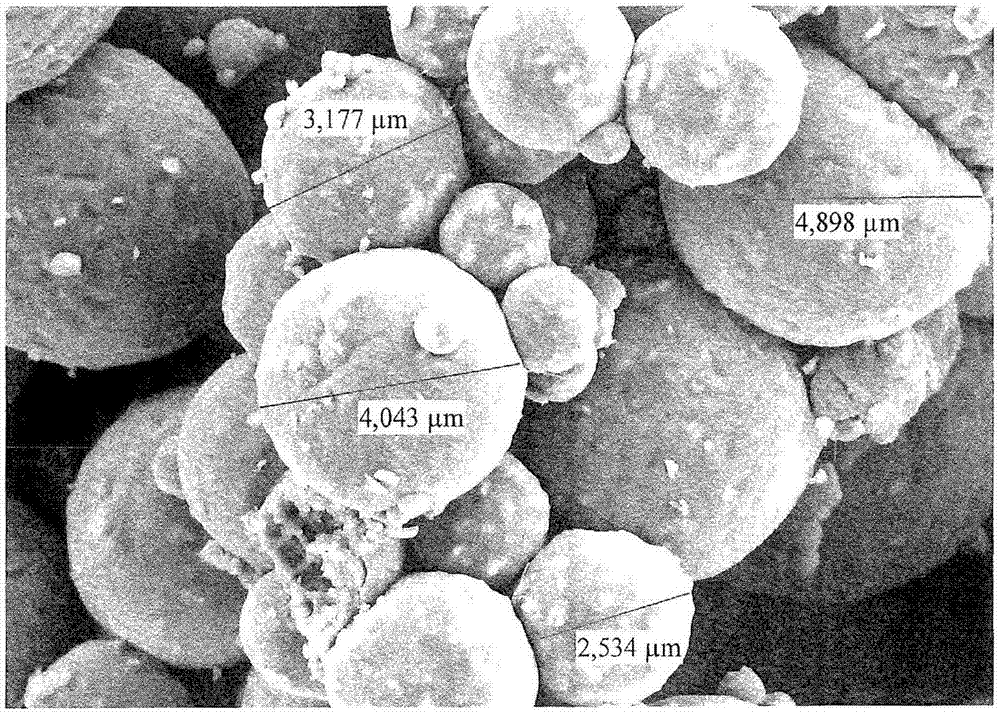

Magnetic carrier and two component developer

ActiveUS7927775B2Quality improvementGood reproducibilityDevelopersScanning electron microscopeVolumetric Mass Density

Provided is a magnetic carrier giving a high quality image free of density variation without the occurrence of fogging or carrier adhesion and having excellent dot reproducibility even during long-term use. The magnetic carrier has magnetic carrier particles produced by filling pores of porous magnetic core particles with a resin. The magnetic carrier contains 80% by number or more of the magnetic carrier particles satisfying the specific conditions (a) and (b) when 18 straight lines passing through a reference point of a cross section of the magnetic carrier particle are drawn at intervals of 10° in a reflected electron image of the cross section of the magnetic carrier particle photographed by a scanning electron microscope.

Owner:CANON KK

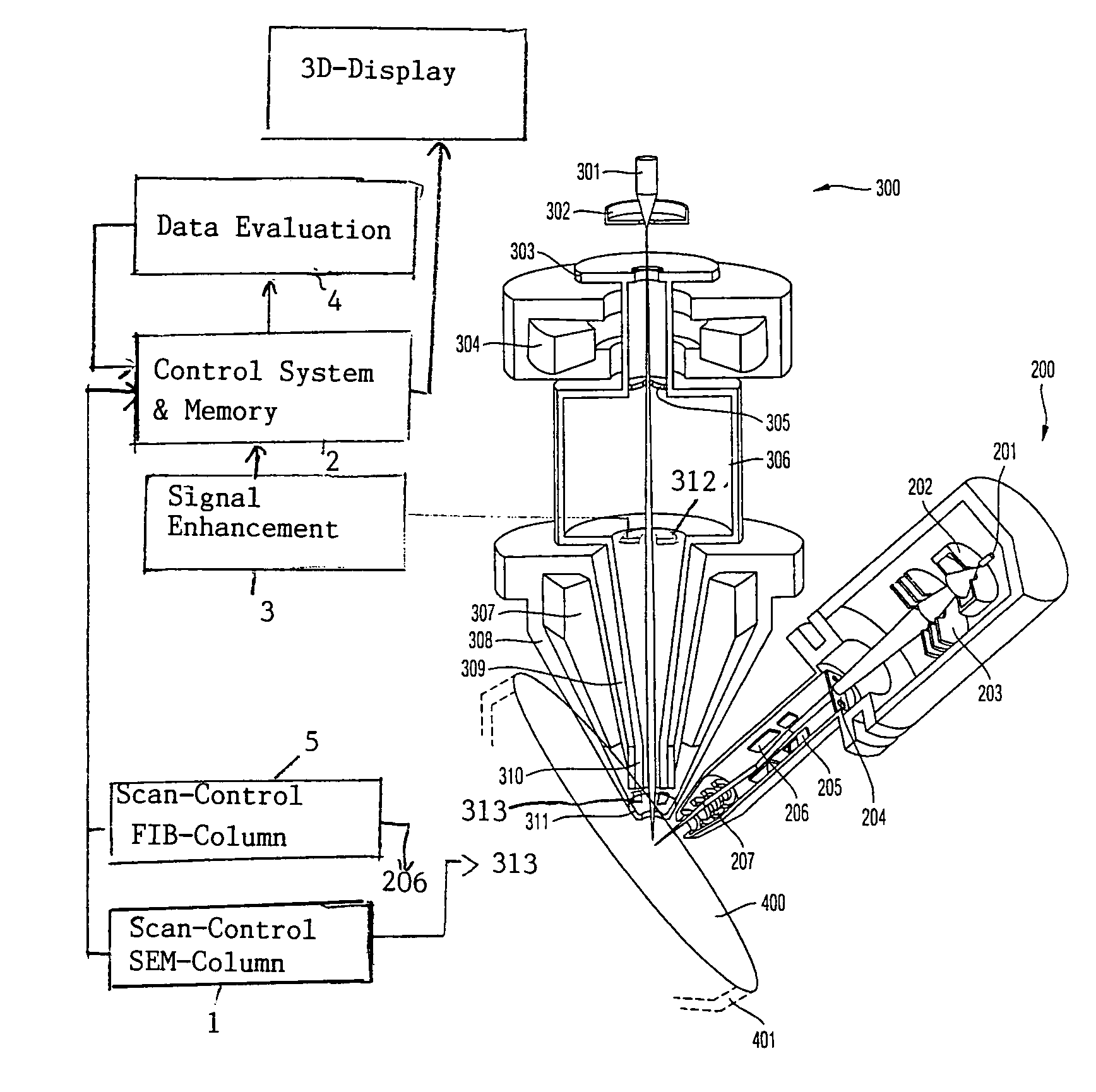

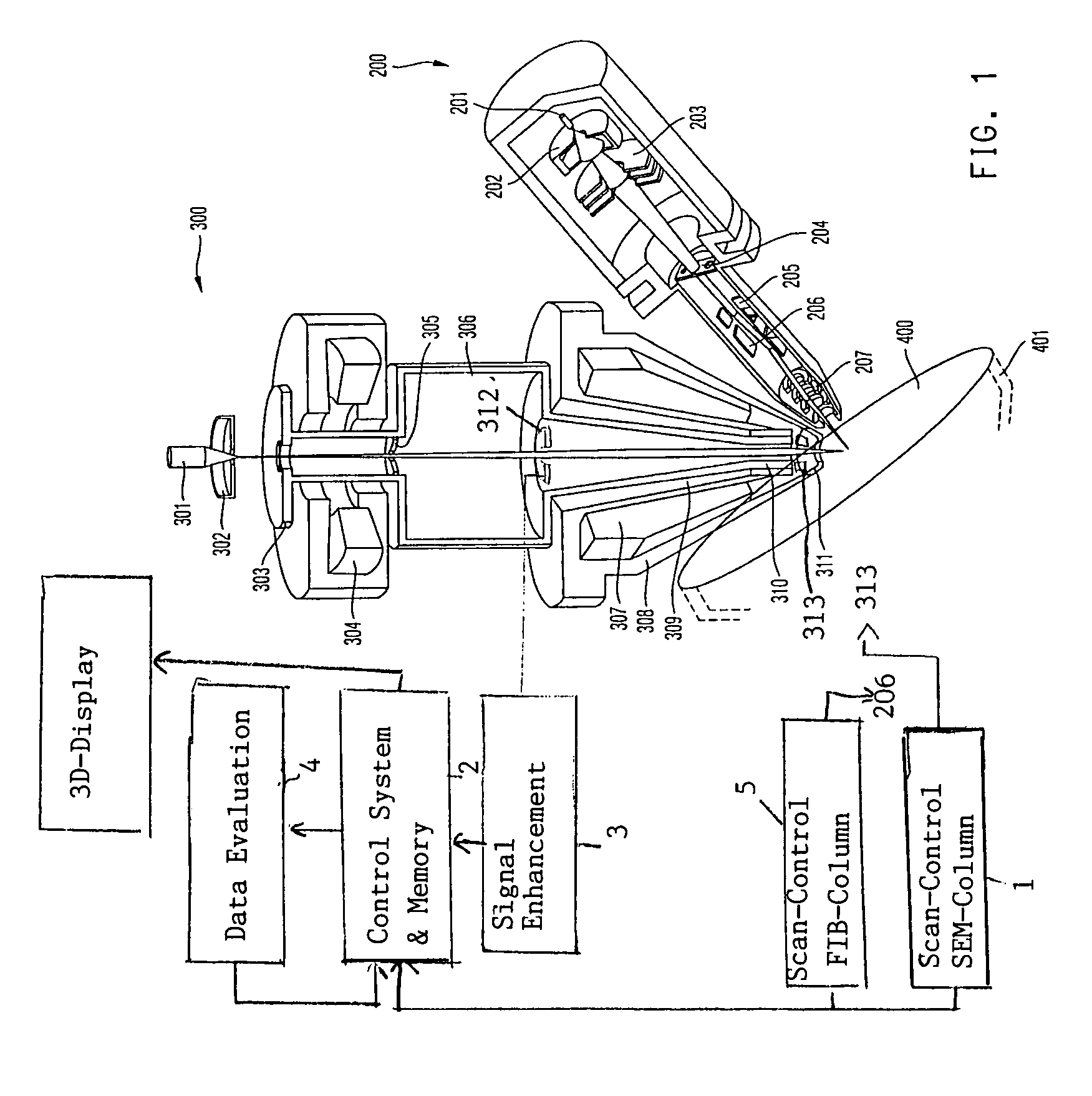

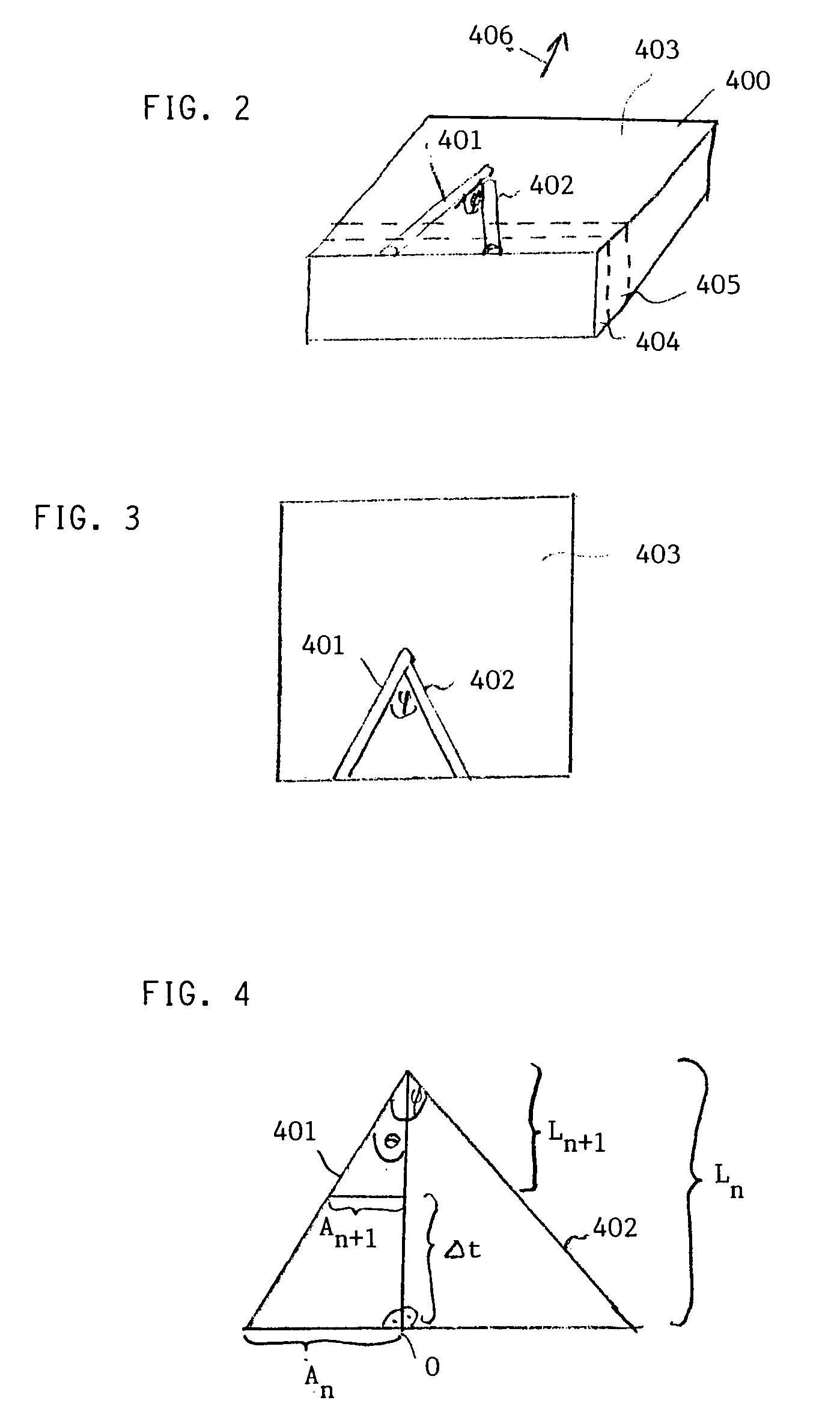

Method of measuring three-dimensional surface roughness of a structure

InactiveUS20070018099A1Great precisionMaterial analysis using wave/particle radiationElectric discharge tubesScanning electron microscopeFocused ion beam

An improved method of measuring the three-dimensional surface roughness of a structure. A focused ion beam is used to mill a succession of cross-sections or “slices” of the feature of interest at pre-selected intervals over a pre-selected measurement distance. As each cross-section is exposed, a scanning electron microscope is used to measure the relevant dimensions of the feature. Data from these successive “slices” is then used to determine the three-dimensional surface roughness for the feature.

Owner:FEI COMPANY

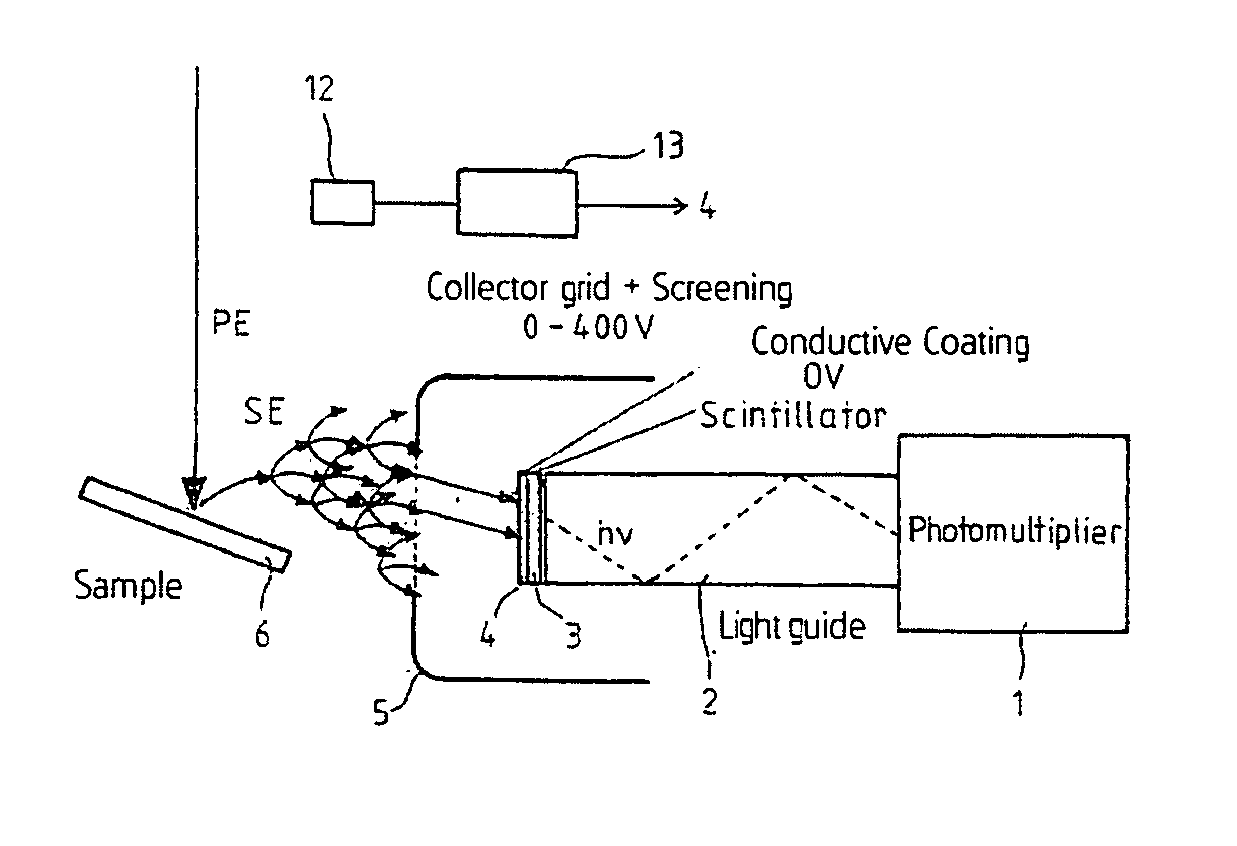

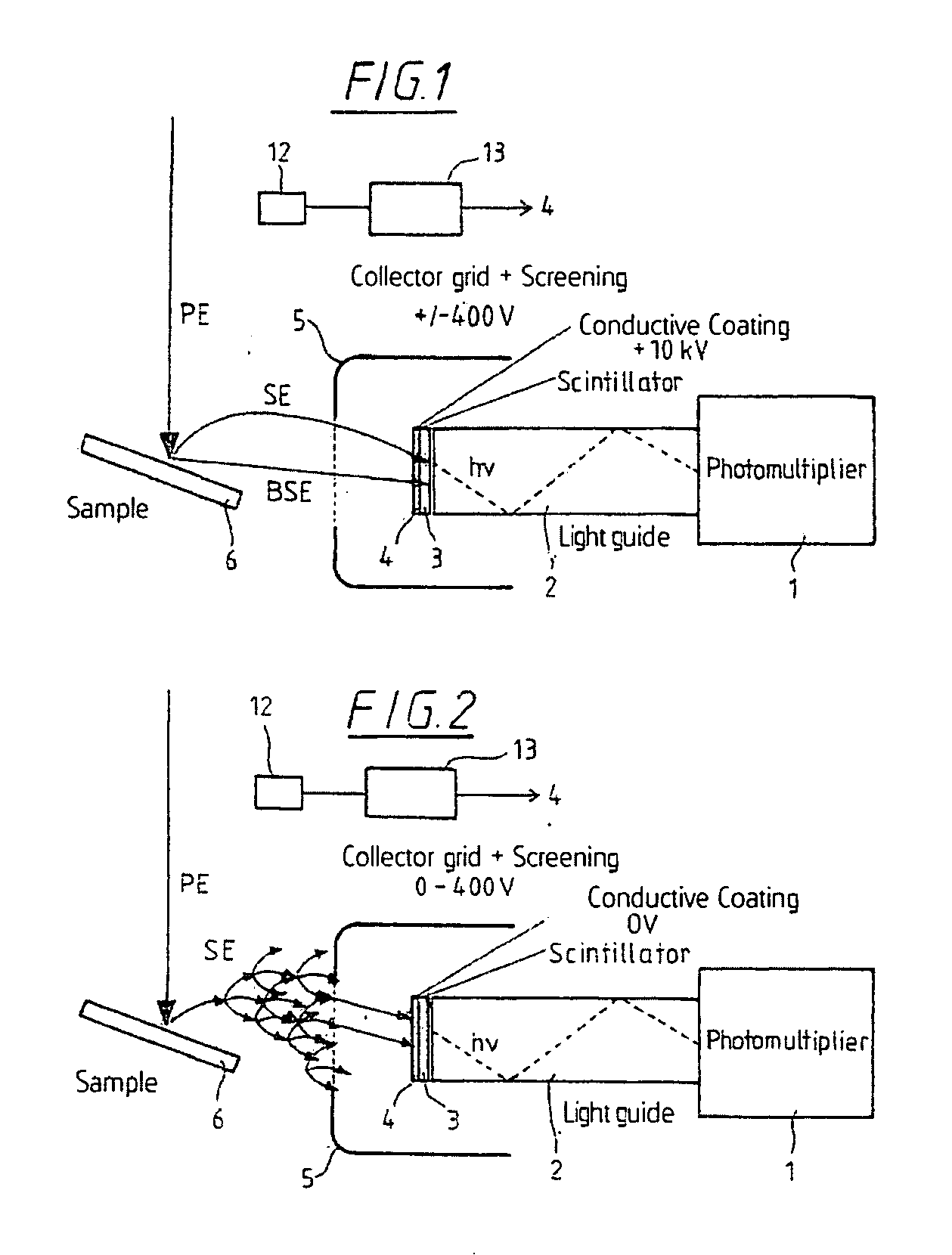

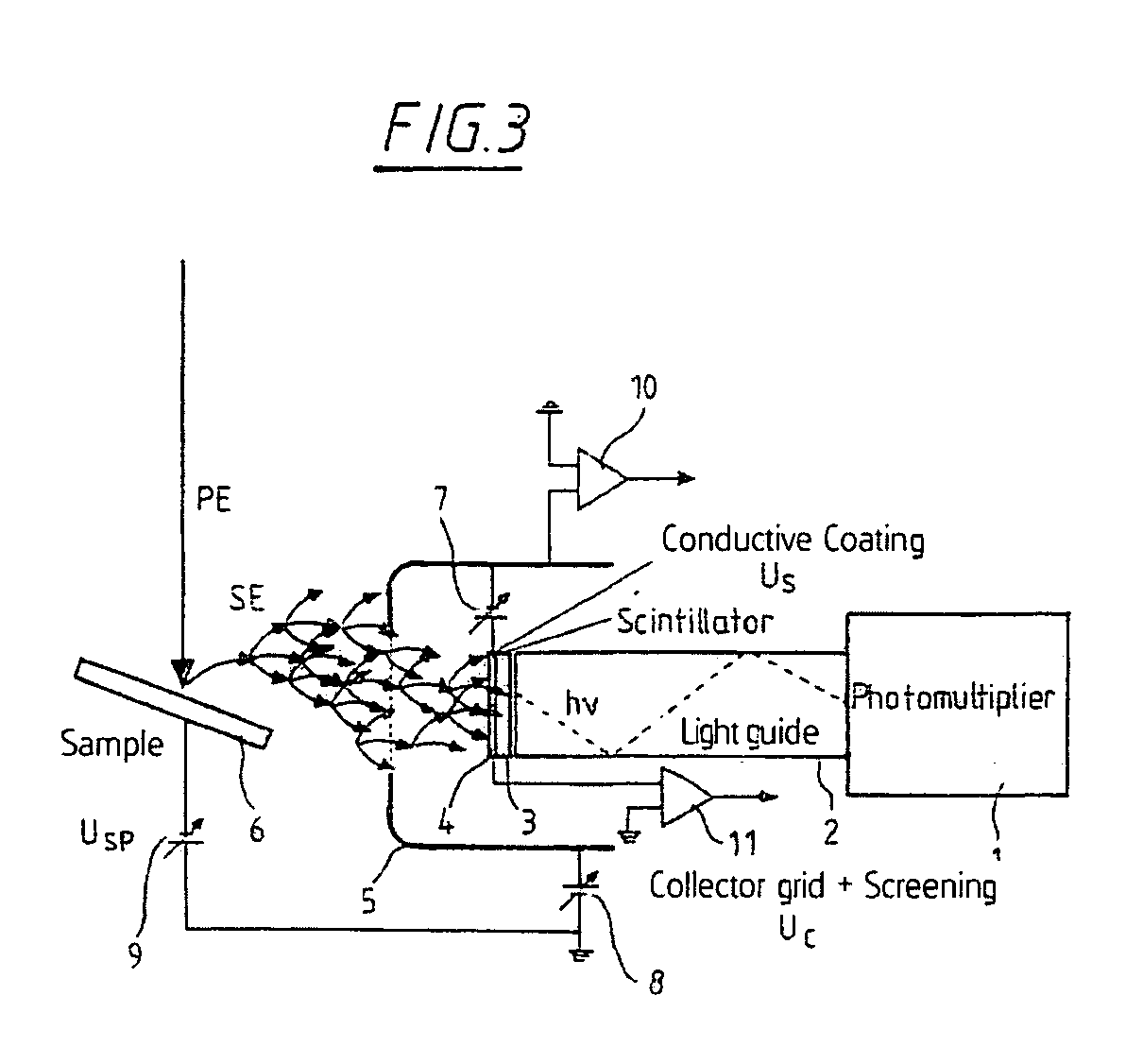

Detector for variable pressure areas and an electron microscope comprising a corresponding detector

InactiveUS20050173644A1Increase pressureEfficiently conduct photon producedThermometer detailsMaterial analysis using wave/particle radiationPhotovoltaic detectorsPhotodetector

A detector for scanning electron microscopes, which can be used under different pressure conditions in the specimen chamber of the electron microscope, designed for the detection of both electrons and light. For this purpose, the detector has a photodetector and a scintillator of a material transmissive for visible light connected before the photodetector. The scintillator can be provided with a coating transparent to visible light. By the application of different potentials, the detector is suitable for the detection of electrons in high vacuum and for the detection of light with high pressures in the specimen chamber.

Owner:CARL ZEISS SMT GMBH

Method and apparatus for quantitative three-dimensional reconstruction in scanning electron microscopy

ActiveUS7312448B2Material analysis using wave/particle radiationElectric discharge tubesSlice thicknessScanning confocal electron microscopy

A method and an apparatus are for three-dimensional tomographic image generation in a scanning electron microscope system. At least two longitudinal marks are provided on the top surface of the sample which include an angle therebetween. In consecutive image recordings, the positions of these marks are determined and are used to quantify the slice thickness removed between consecutive image recordings.

Owner:CARL ZEISS SMT GMBH

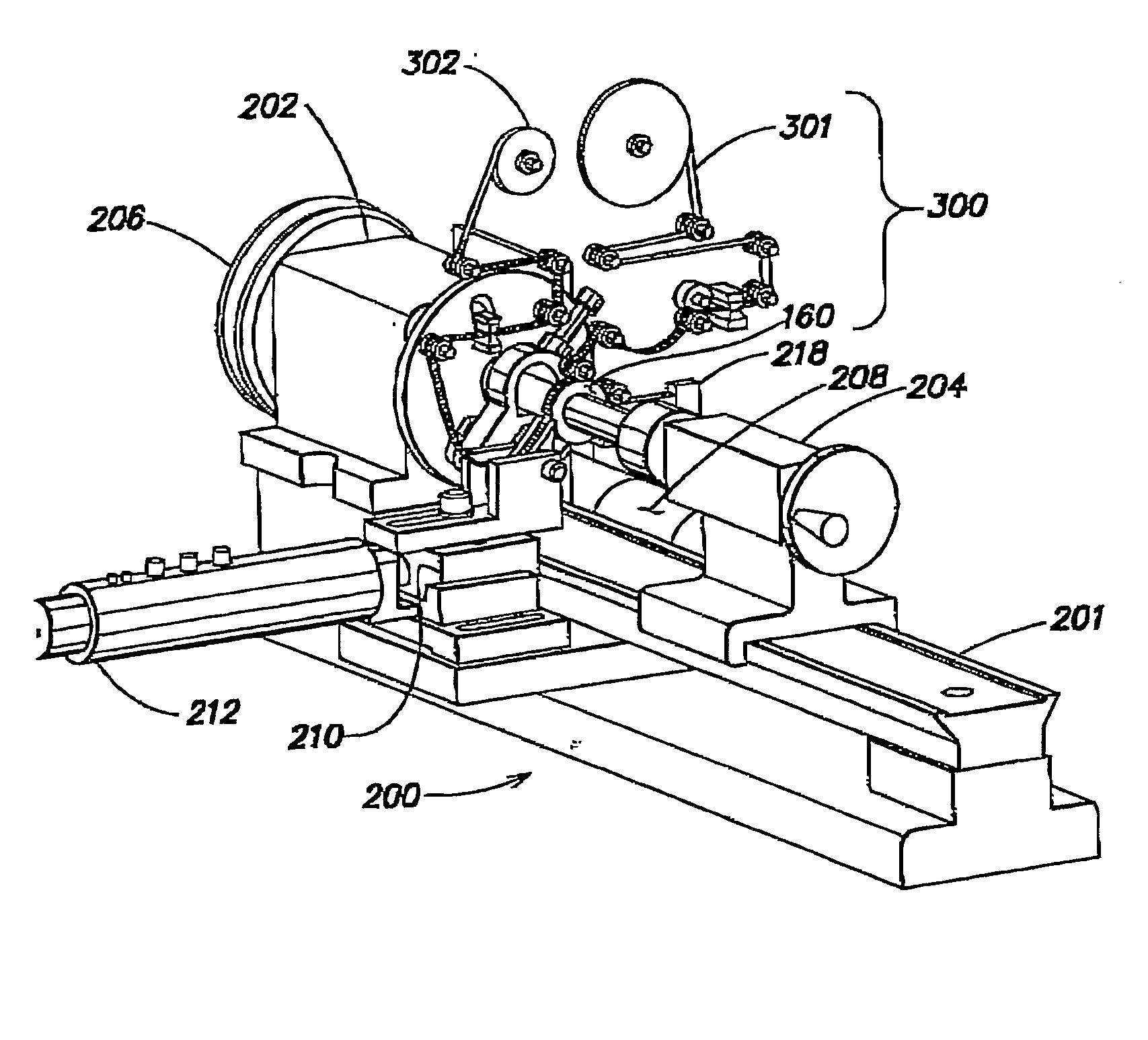

Methods and apparatus for providing and processing sliced thin tissue

InactiveUS20100093022A1Facilitate subsequent imagingPromote the fullTemperatue controlStatic/dynamic balance measurementSlice thicknessTissue sample

Methods and apparatus for providing and processing serial tissue sections. In one example, an “automatic tape collecting lathe ultramicrotome” (ATLUM) slices a block of tissue sample having various geometries into a continuous ribbon of thin tissue, or multiple thin tissue sections, and disposes the sliced thin tissue on an appropriate substrate to facilitate subsequent imaging of the sliced thin tissue. Closed-loop control of section thickness of the sliced thin tissue sections or ribbons is implemented to produce thinner sliced tissue sections or ribbons and tightly regulate thickness. Thin tissue sections or ribbons may be particularly processed / prepared to facilitate imaging with a scanning electron microscope (SEM). Collected thin tissue sections or ribbons may be used to create UltraThin Section Libraries (UTSLs) that allow for fully automated, time-efficient imaging in the SEM to facilitate expansive tissue studies.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

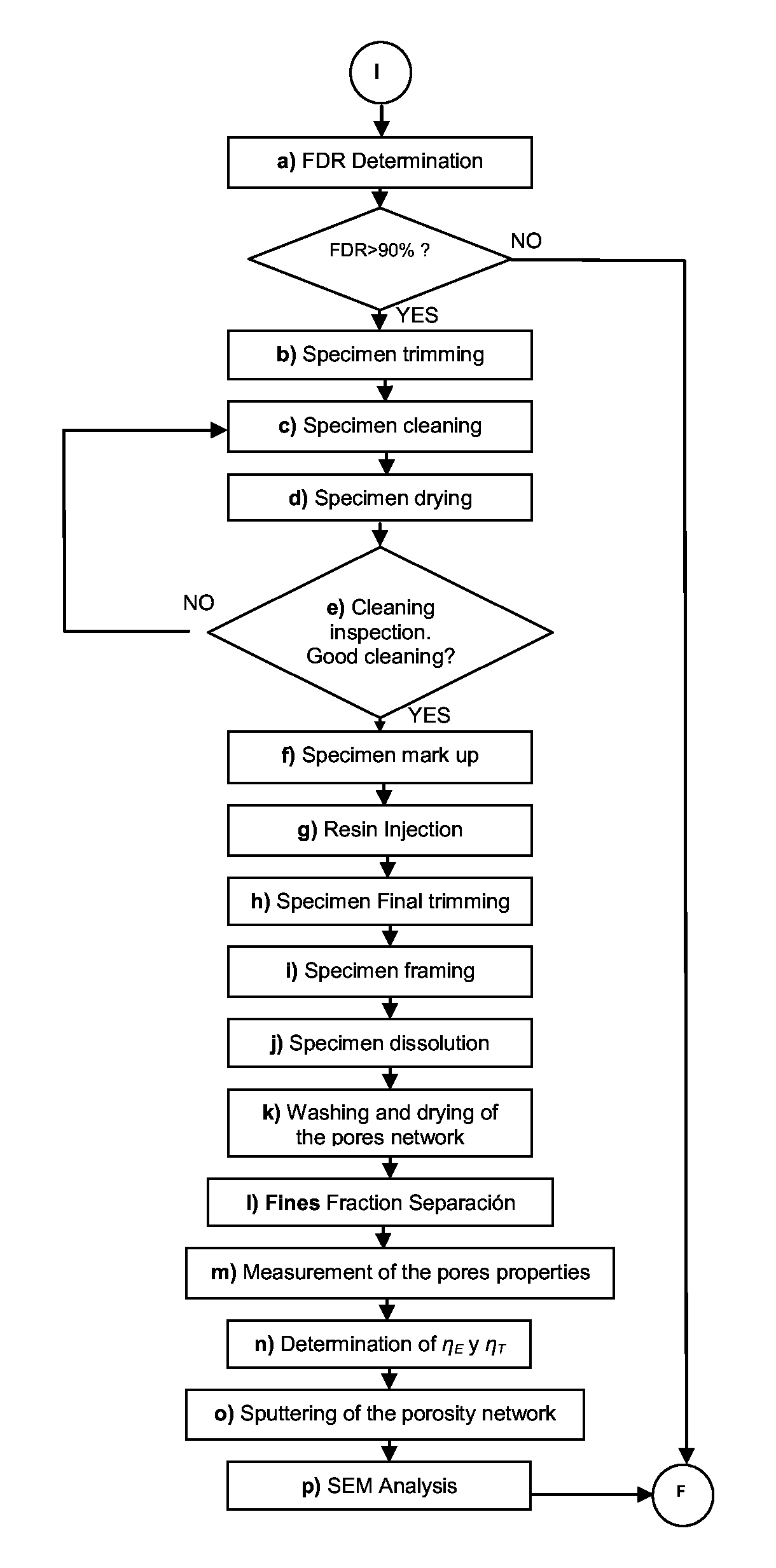

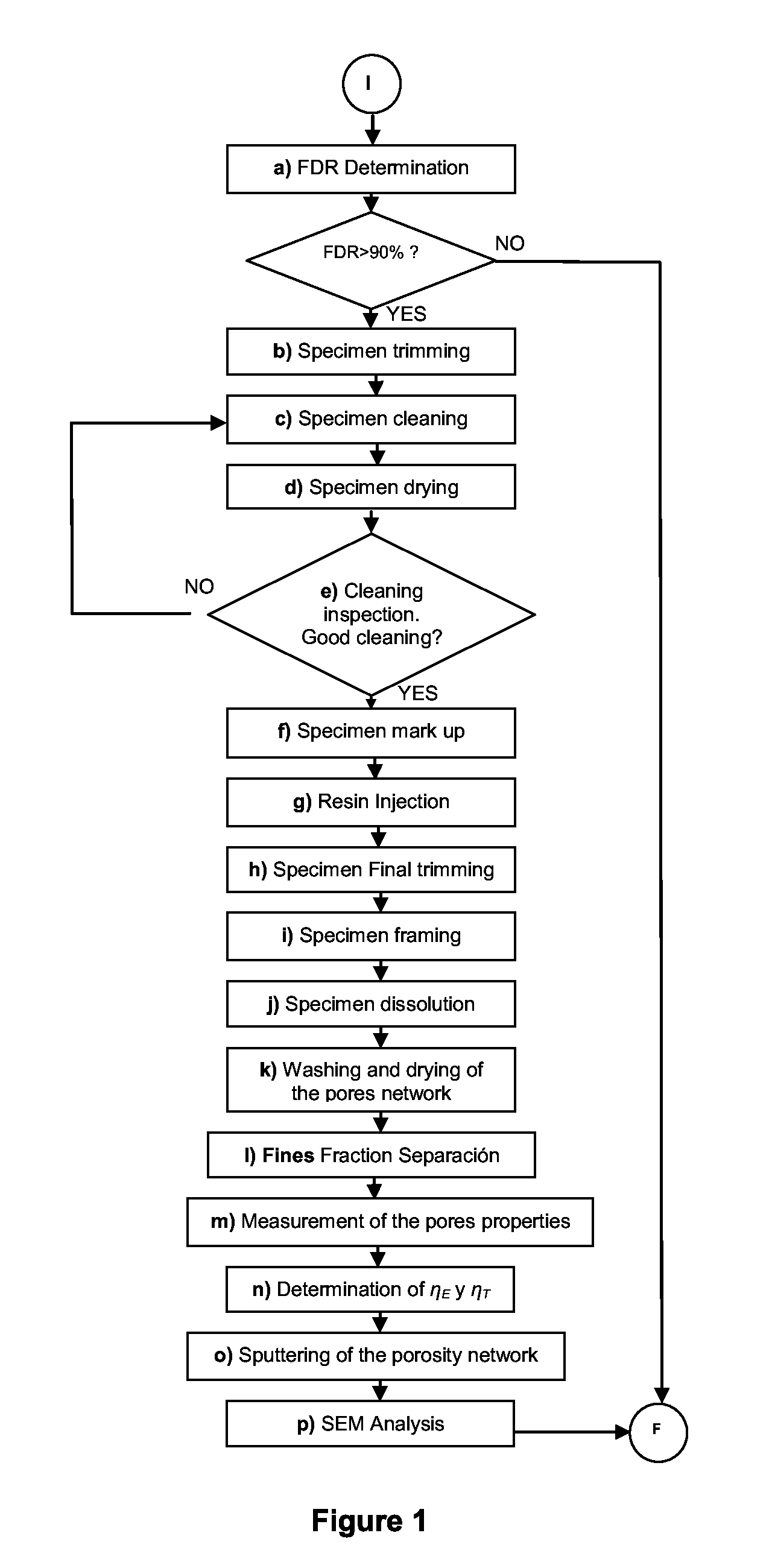

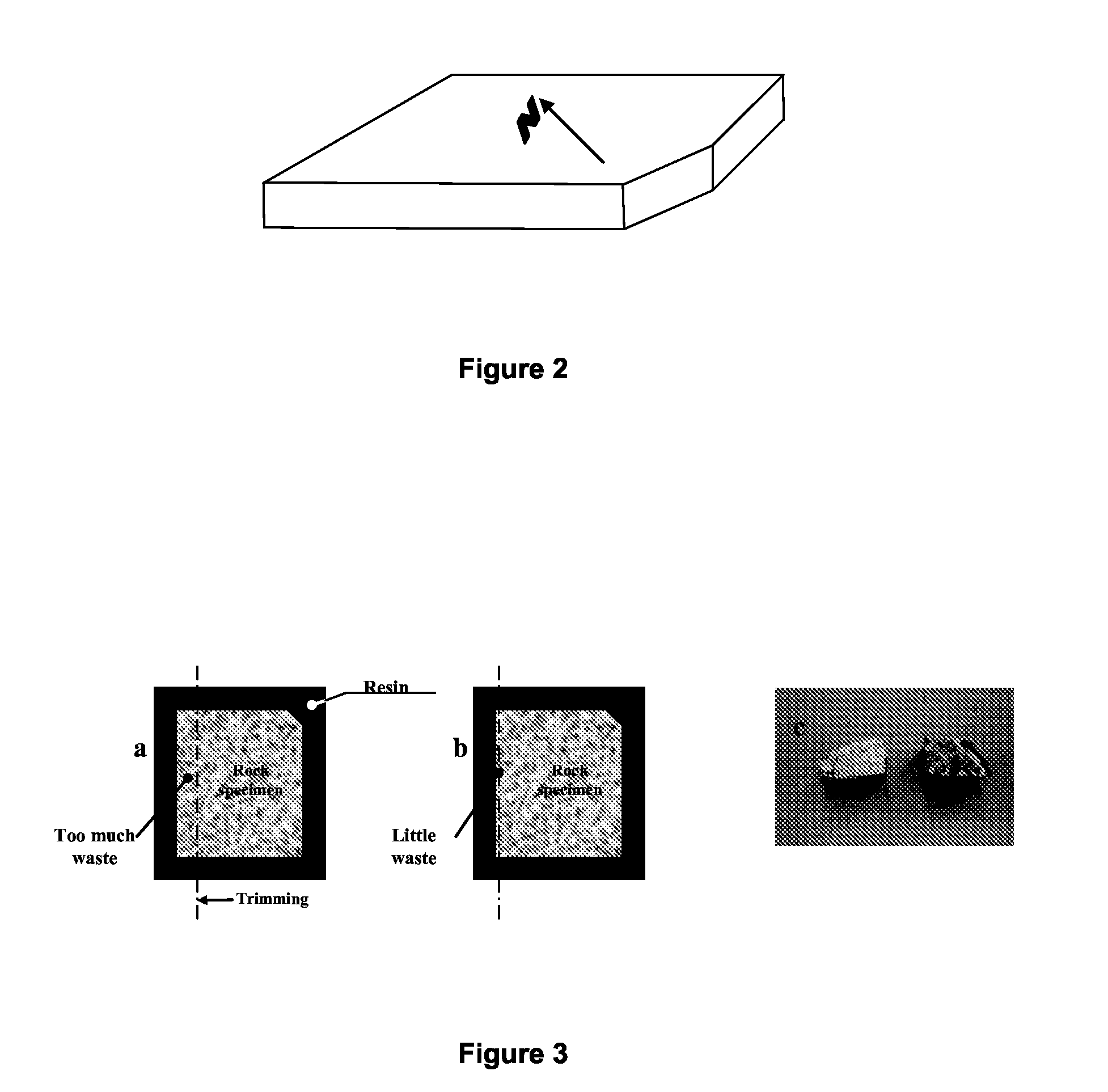

Procedure for the determination of effective and total porosity of carbonated sedimentary rocks, and morphology characterization of their micro and nanopores

InactiveUS20120197526A1Reliable applicationMeasure quickly and accuratelyElectric/magnetic detectionSpecial data processing applicationsThroatStructure of the Earth

The present invention is concerned with a procedure to quantitatively determine both, total and effective porosity of carbonated sedimentary rocks, and is based on the elaboration of molds of the rock pores-structure and on the determination of the volumetric and gravimetric properties of the rock and its mold.Determination of the effective porosity is achieved by using an original formula, developed by the authors of the present invention.Additionally, the structure of micro and nanopores in the rock is characterized by scanning electron microscopy (SEM), to identify relevant properties for permeability analyses such as: dimensions, shapes, type of connections, pore-structure patterns and pore throats. These and other parameters are used as indicators of the reservoir production and storage capacity.

Owner:INST MEXICANO DEL GASOLINEEO

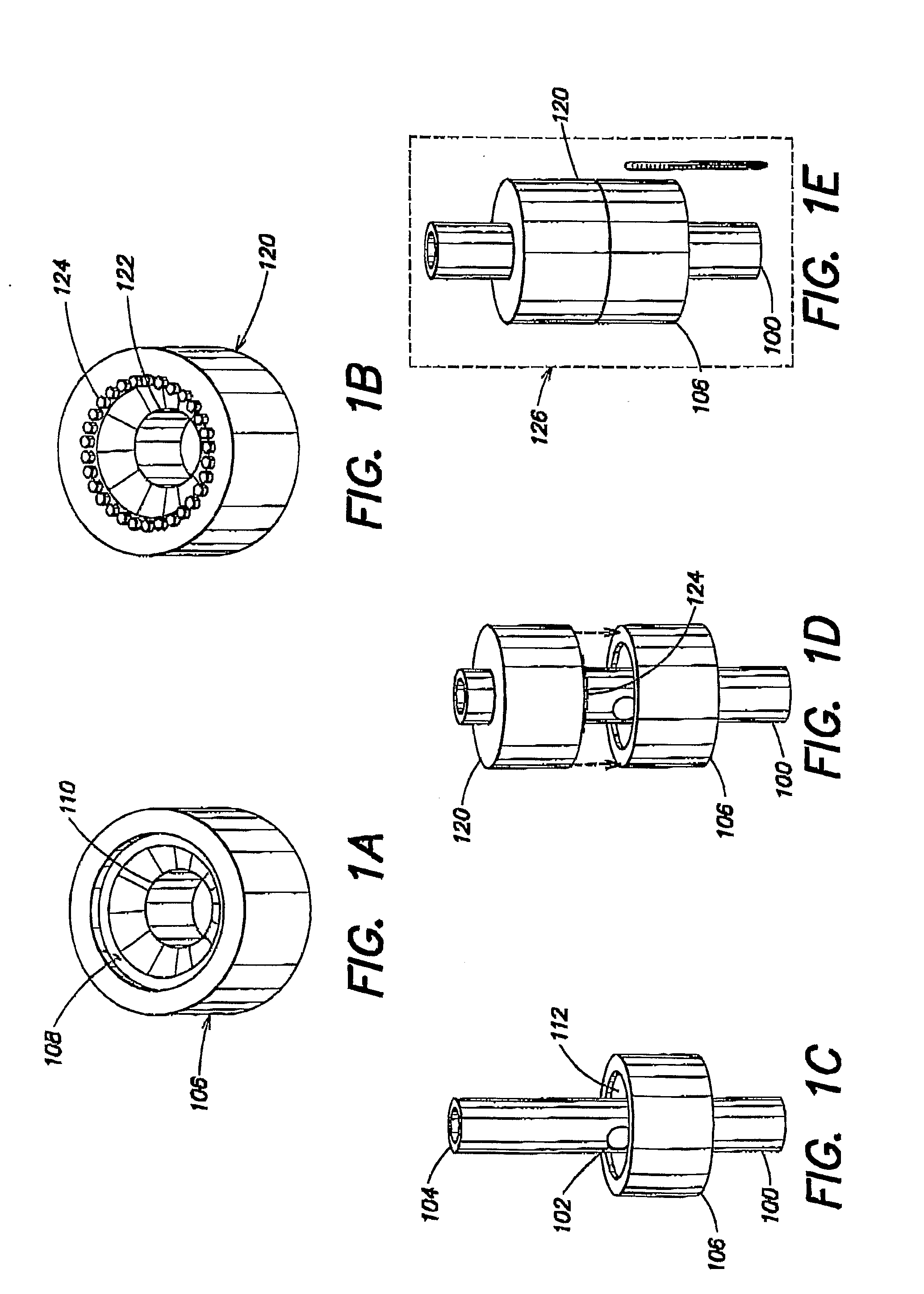

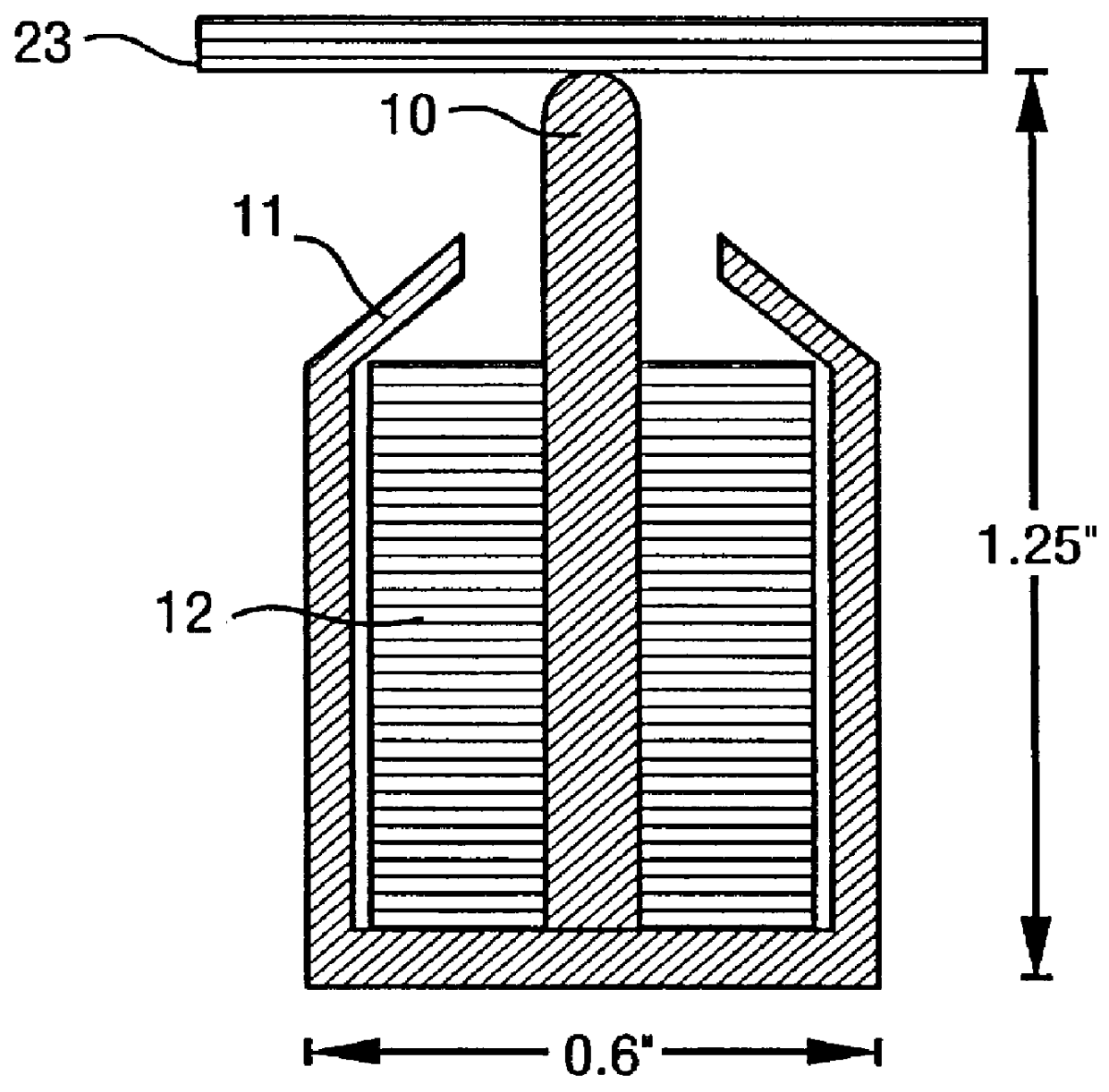

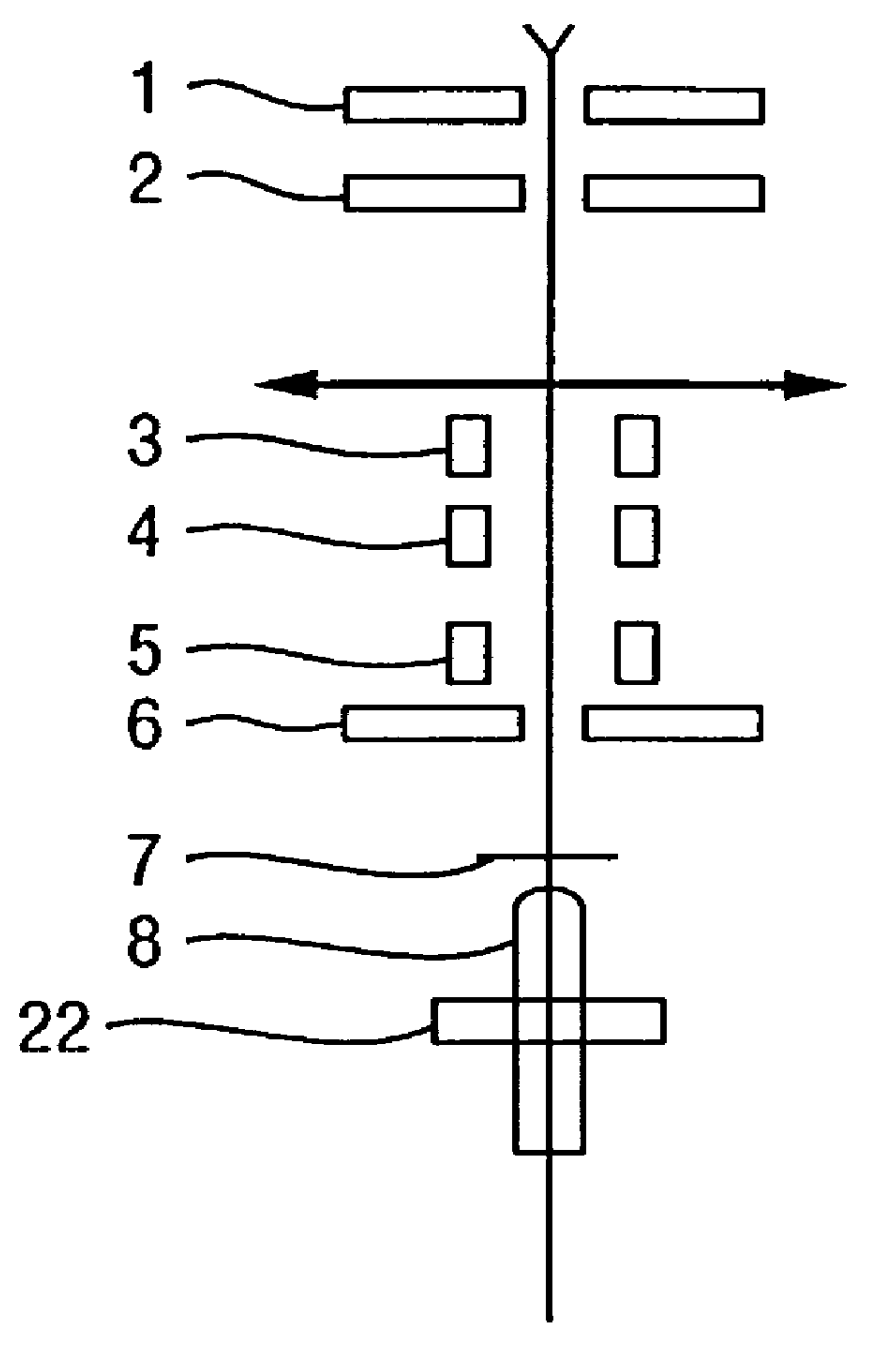

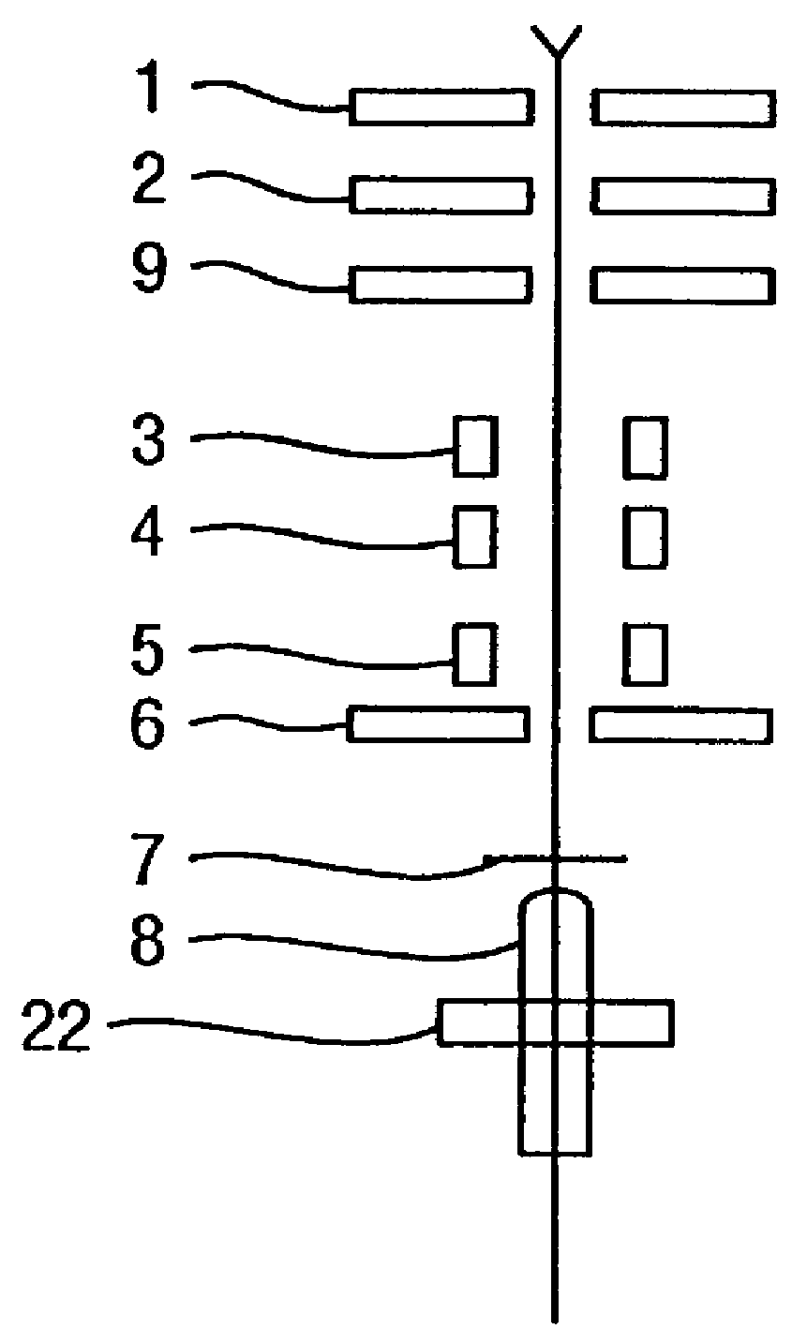

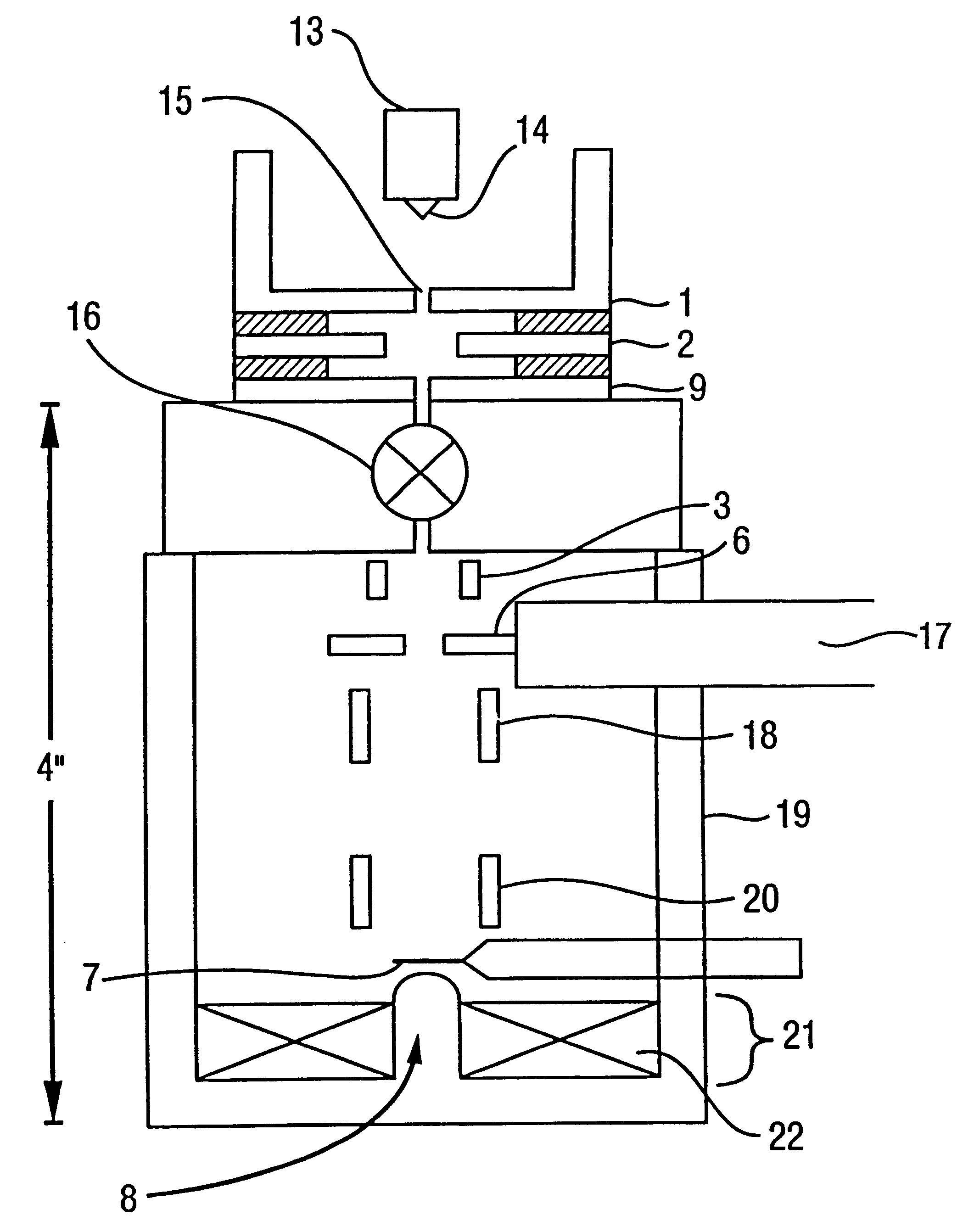

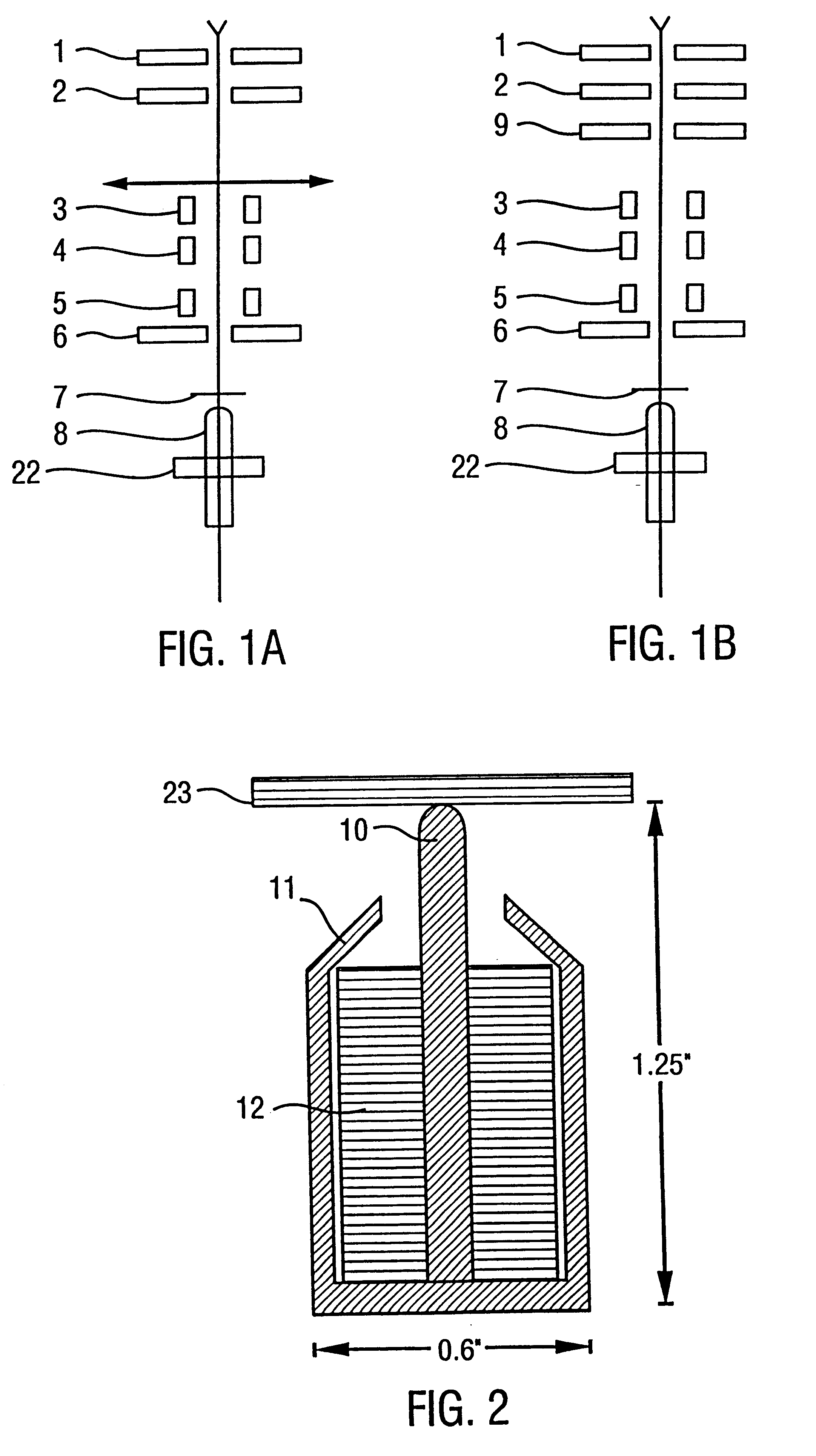

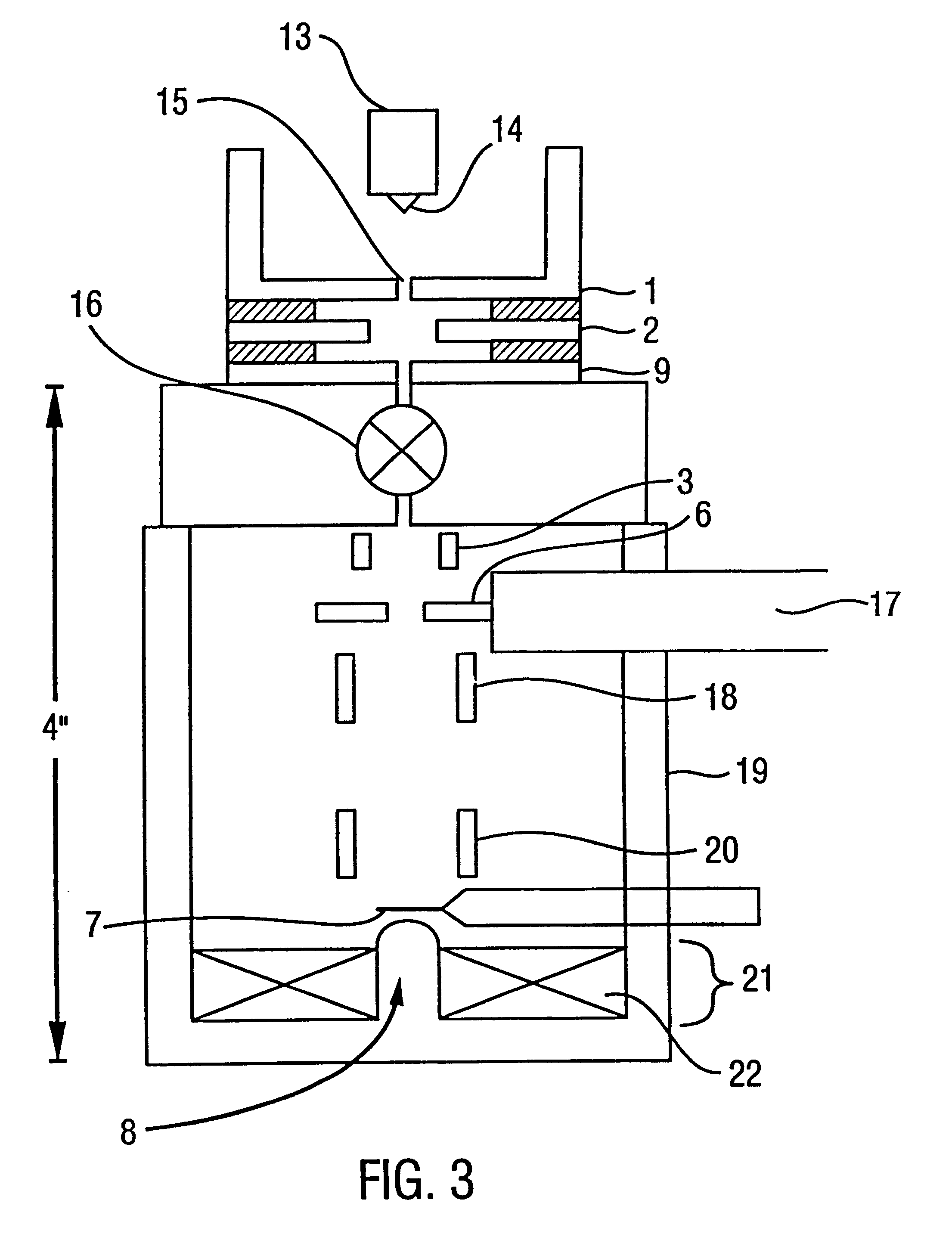

Magnetic lens apparatus for use in high-resolution scanning electron microscopes and lithographic processes

InactiveUS6051839AReduce resolutionEasy constructionMaterial analysis using wave/particle radiationElectric discharge tubesMagnetic polesScanning electron microscope

PCT No. PCT / US96 / 09906 Sec. 371 Date Mar. 9, 1998 Sec. 102(e) Date Mar. 9, 1998 PCT Filed Jul. 6, 1996 PCT Pub. No. WO96 / 41362 PCT Pub. Date Dec. 19, 1996Disclosed are lens apparatus in which a beam of charged particlesis brought to a focus by means of a magnetic field, the lens being situated behind the target position. In illustrative embodiments, a lens apparatus is employed in a scanning electron microscopeas the sole lens for high-resolution focusing of an electron beam, and in particular, an electron beam having an accelerating voltage of from about 10 to about 30,000 V. In one embodiment, the lens apparatus comprises an electrically-conducting coil arranged around the axis of the beam and a magnetic pole piece extending along the axis of the beam at least within the space surrounded by the coil. In other embodiments, the lens apparatus comprises a magnetic dipole or virtual magnetic monopole fabricated from a variety of materials, including permanent magnets, superconducting coils, and magnetizable spheres and needles contained within an energy-conducting coil. Multiple-array lens apparatus are also disclosed for simultaneous and / or consecutive imaging of multiple images on single or multiple specimens. The invention further provides apparatus, methods, and devices useful in focusing charged particle beams for lithographic processes.

Owner:ARCH DEVMENT

Directionally controlled growth of nanowhiskers

InactiveUS20060019470A1Well-defined surfaceReduce the temperatureMaterial nanotechnologyPolycrystalline material growthNanowireStacking fault

Nanowhiskers are grown in a non-preferential growth direction by regulation of nucleation conditions to inhibit growth in a preferential direction. In a preferred implementation, <001> III-V semiconductor nanowhiskers are grown on an (001) III-V semiconductor substrate surface by effectively inhibiting growth in the preferential <111>B direction. As one example, <001> InP nano-wires were grown by metal-organic vapor phase epitaxy directly on (001) InP substrates. Characterization by scanning electron microscopy and transmission electron microscopy revealed wires with nearly square cross sections and a perfect zincblende crystalline structure that is free of stacking faults.

Owner:QUNANO

Magnetic lens apparatus for use in high-resolution scanning electron microscopes and lithographic processes

InactiveUS6410923B1Reduce the background by a large factorEasy to adjustThermometer detailsMaterial analysis using wave/particle radiationMagnetic polesScanning electron microscope

Disclosed are lens apparatus in which a beam of charged particles is brought to a focus by means of a magnetic field, the lens being situated behind the target position. In illustrative embodiments, a lens apparatus is employed in a scanning electron microscope as the sole lens for high-resolution focusing of an electron beam, and in particular, an electron beam having an accelerating voltage of from about 10 to about 30,000 V. In one embodiment, the lens apparatus comprises an electrically-conducting coil arranged around the axis of the beam and a magnetic pole piece extending along the axis of the beam at least within the space surrounded by the coil. In other embodiments, the lens apparatus comprises a magnetic dipole or virtual magnetic monopole fabricated from a variety of materials, including permanent magnets, superconducting coils, and magnetizable spheres and needles contained within an energy-conducting coil. Multiple-array lens apparatus are also disclosed for simultaneous and / or consecutive imaging of multiple images on single or multiple specimens. The invention further provides apparatus, methods, and devices useful in focusing charged particle beams for lithographic processes.

Owner:ARCH DEVMENT

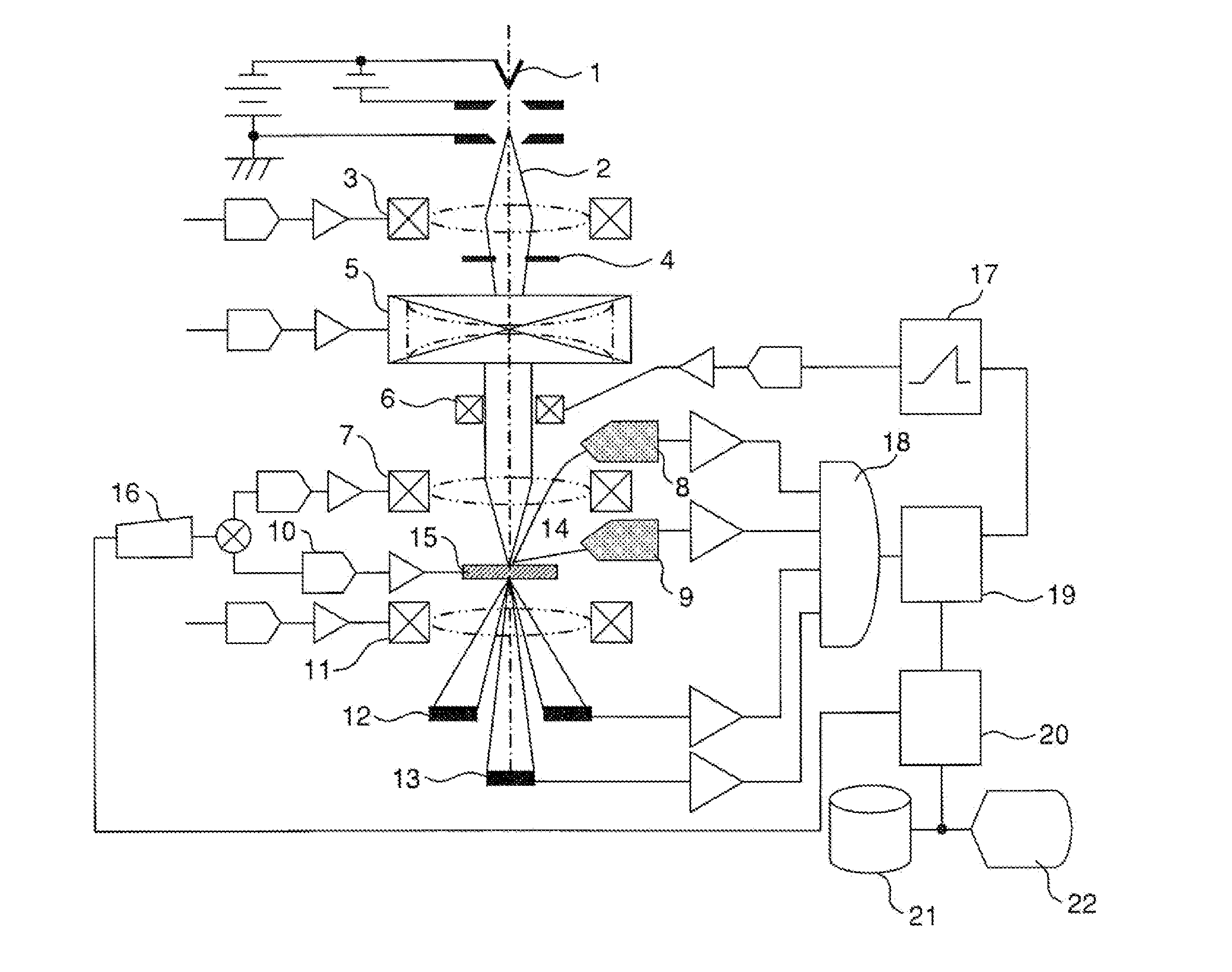

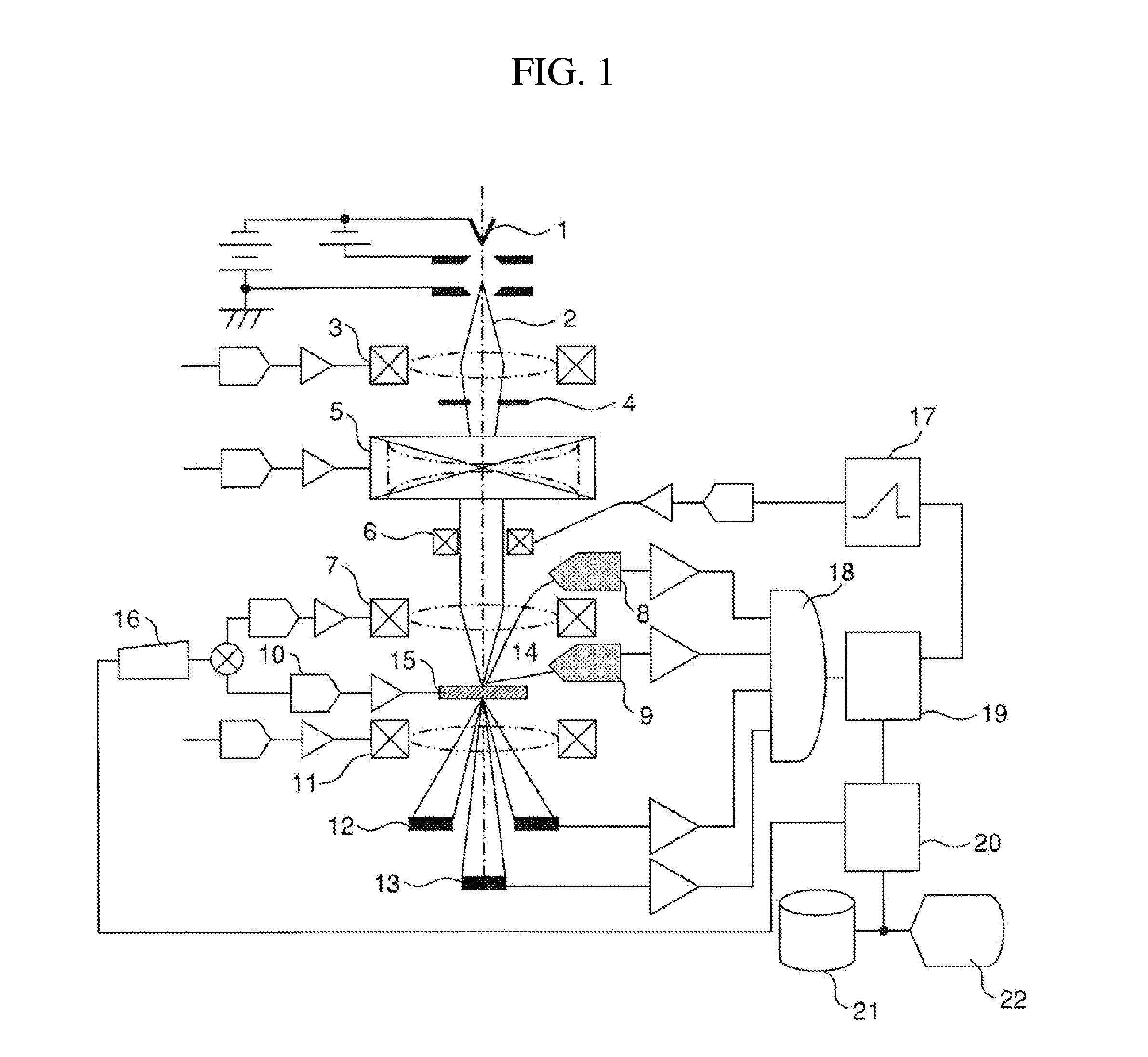

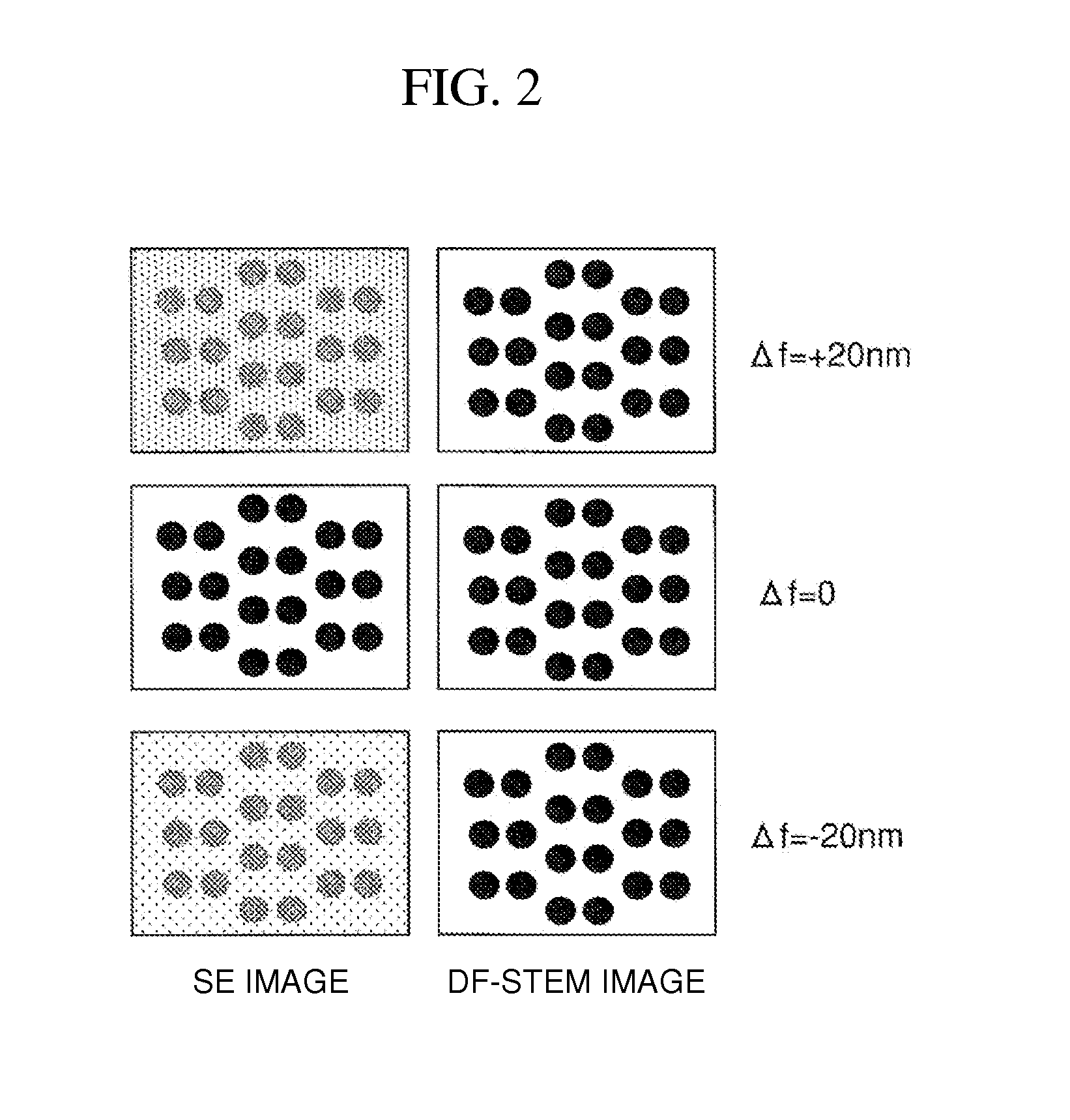

Scanning electron microscope and scanning transmission electron microscope

ActiveUS20140138542A1Improve visualizationMaterial analysis using wave/particle radiationElectric discharge tubesOphthalmologyMedicine

A scanning transmission electron microscope according to the present invention includes an electron lens system having a small spherical aberration coefficient for enabling three-dimensional observation of a 0.1 nm atomic size structure. The scanning transmission electron microscope according to the present invention also includes an aperture capable of changing an illumination angle; an illumination electron lens system capable of changing the probe size of an electron beam probe and the illumination angle; a secondary electron detector (9); a transmission electron detector (13); a forward scattered electron beam detector (12); a focusing unit (16); an image processor for identifying image contrast; an image processor for computing image sharpness; a processor for three-dimensional reconstruction of an image; and a mixer (18) for mixing a secondary electron signal and a specimen forward scattered electron signal.

Owner:HITACHI HIGH-TECH CORP

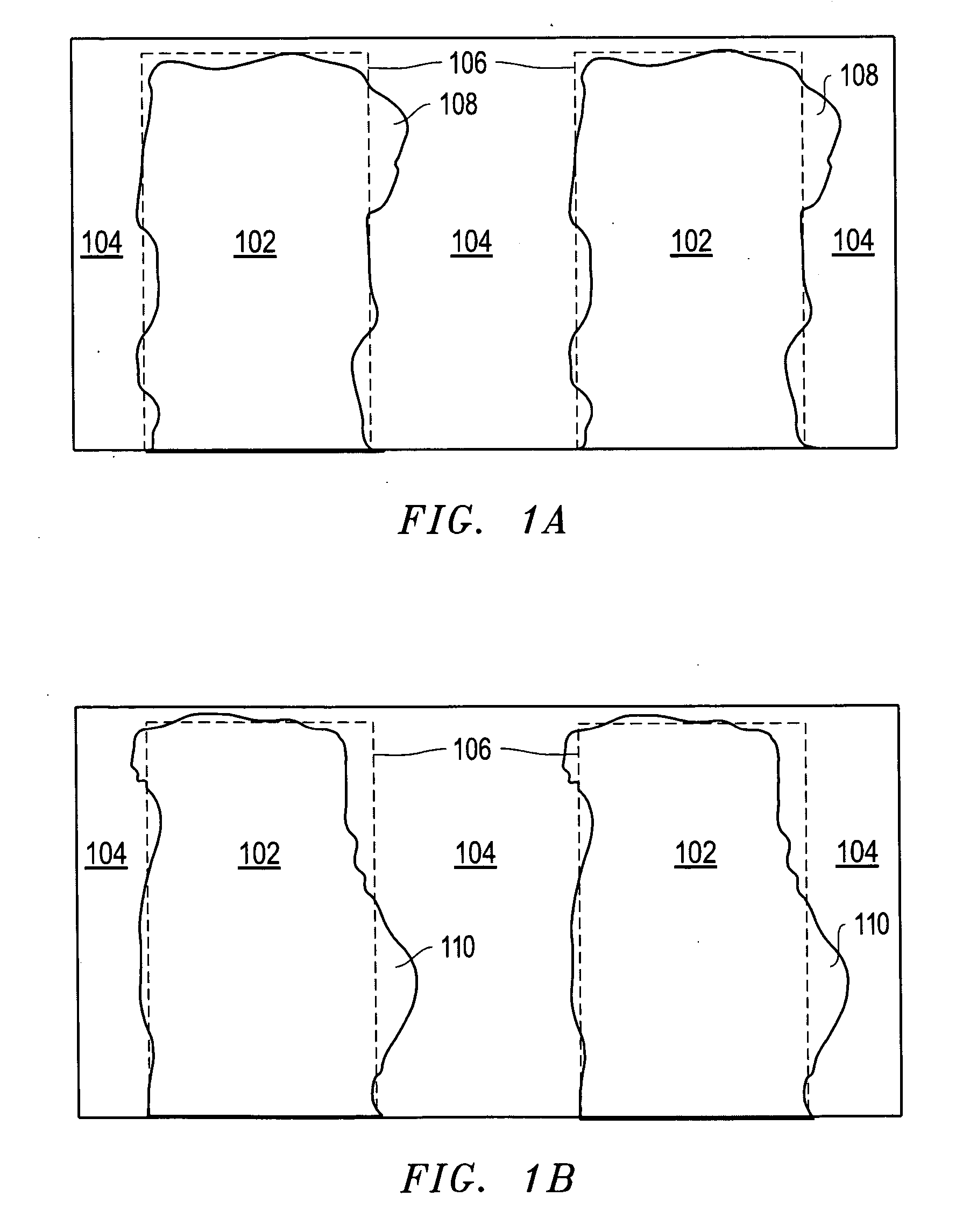

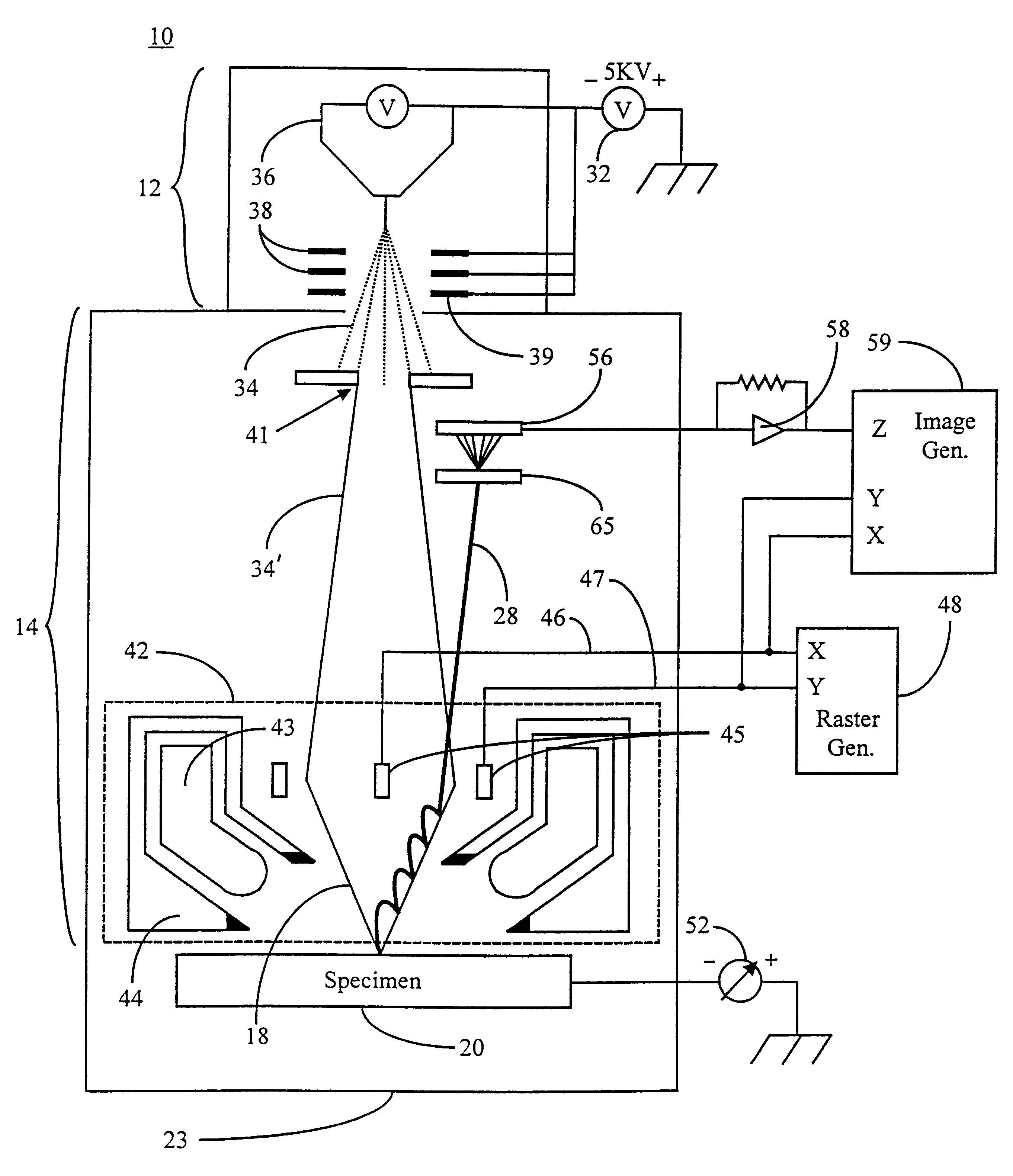

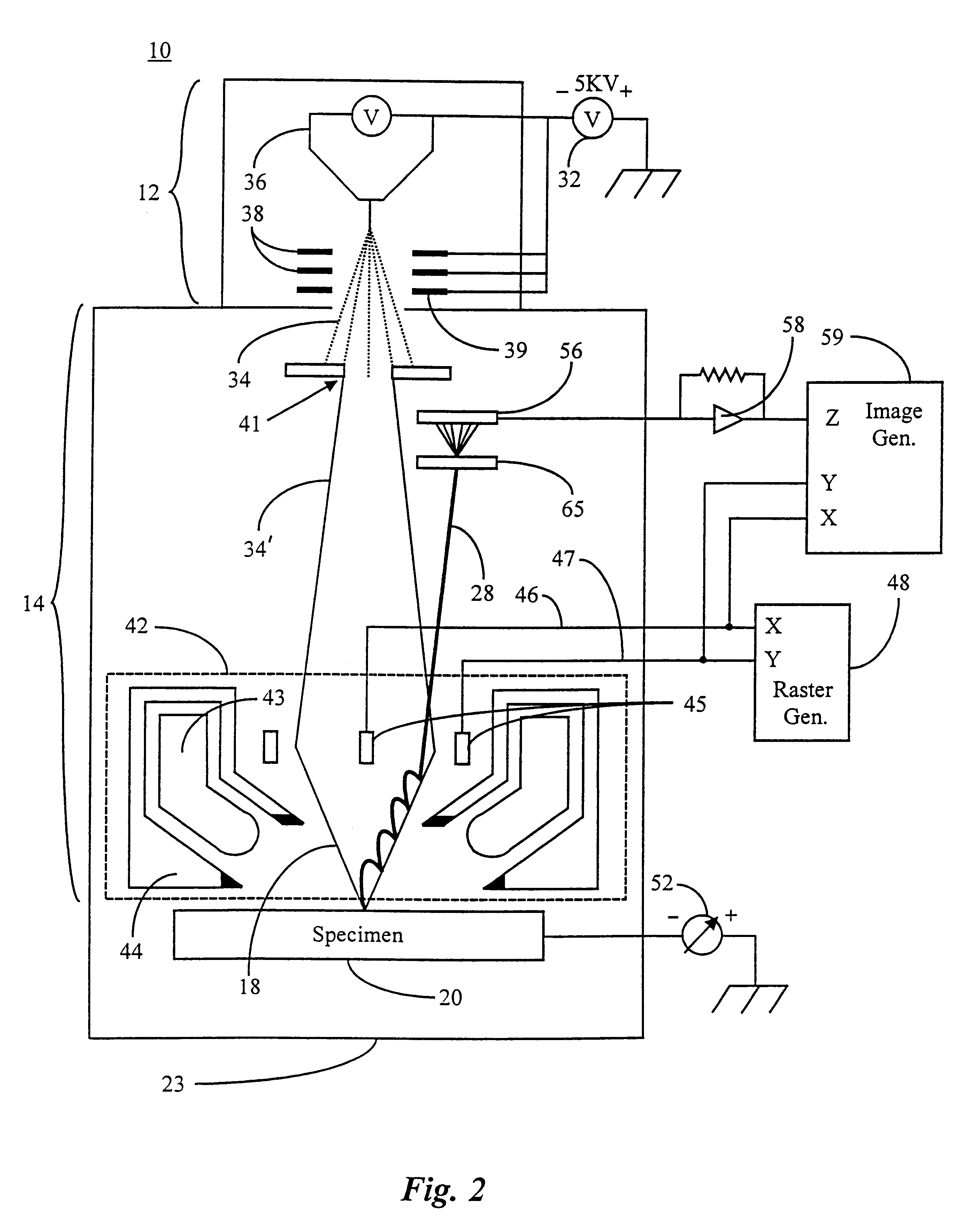

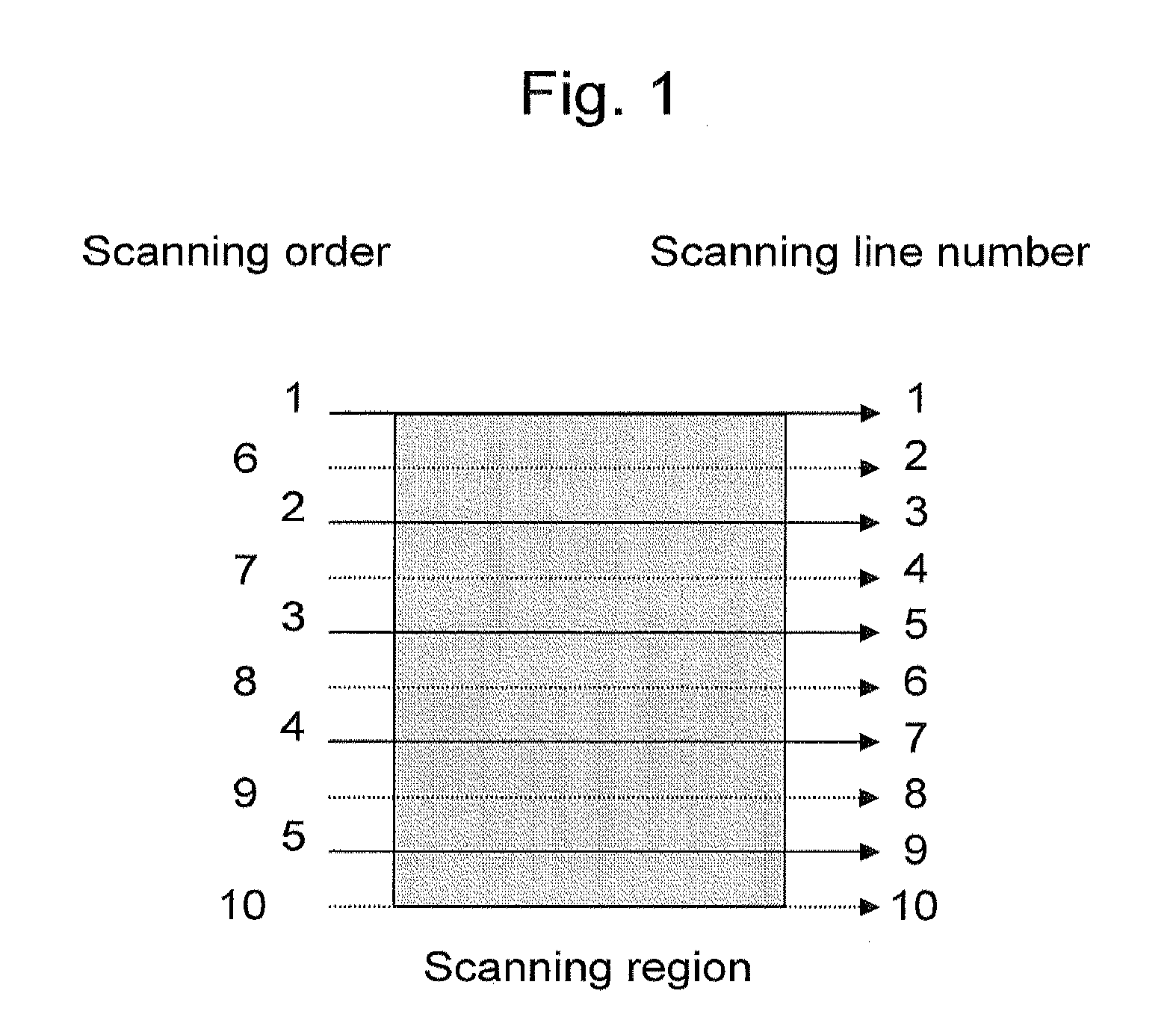

Electron beam dose control for scanning electron microscopy and critical dimension measurement instruments

InactiveUS6211518B1Minimizes charge build-upLaser detailsMaterial analysis using wave/particle radiationPeak currentRaster scan

A system and method for controlling electron exposure on image specimens by adjusting a raster scan area in-between scan frame cycles. A small, zoomed-in, scan area and the surrounding area are flooded with positive charge for a number of frame cycles between scan frames to reduce the voltage differential between the scan area and surrounding area, thereby reducing the positive charge buildup which tends to obscure small features in scanned images. The peak current into a pixel element on the specimen is reduced by scanning the beam with a line period that is very short compared to regular video. Frames of image data may further be acquired non-sequentially, in arbitrarily programmable patterns. Alternatively, an inert gas can be injected into the scanning electron microscope at the point where the electron beam impinges the specimen to neutralize a charge build-up on the specimen by the ionization of the inert gas by the electron beam.

Owner:KLA TENCOR TECH CORP

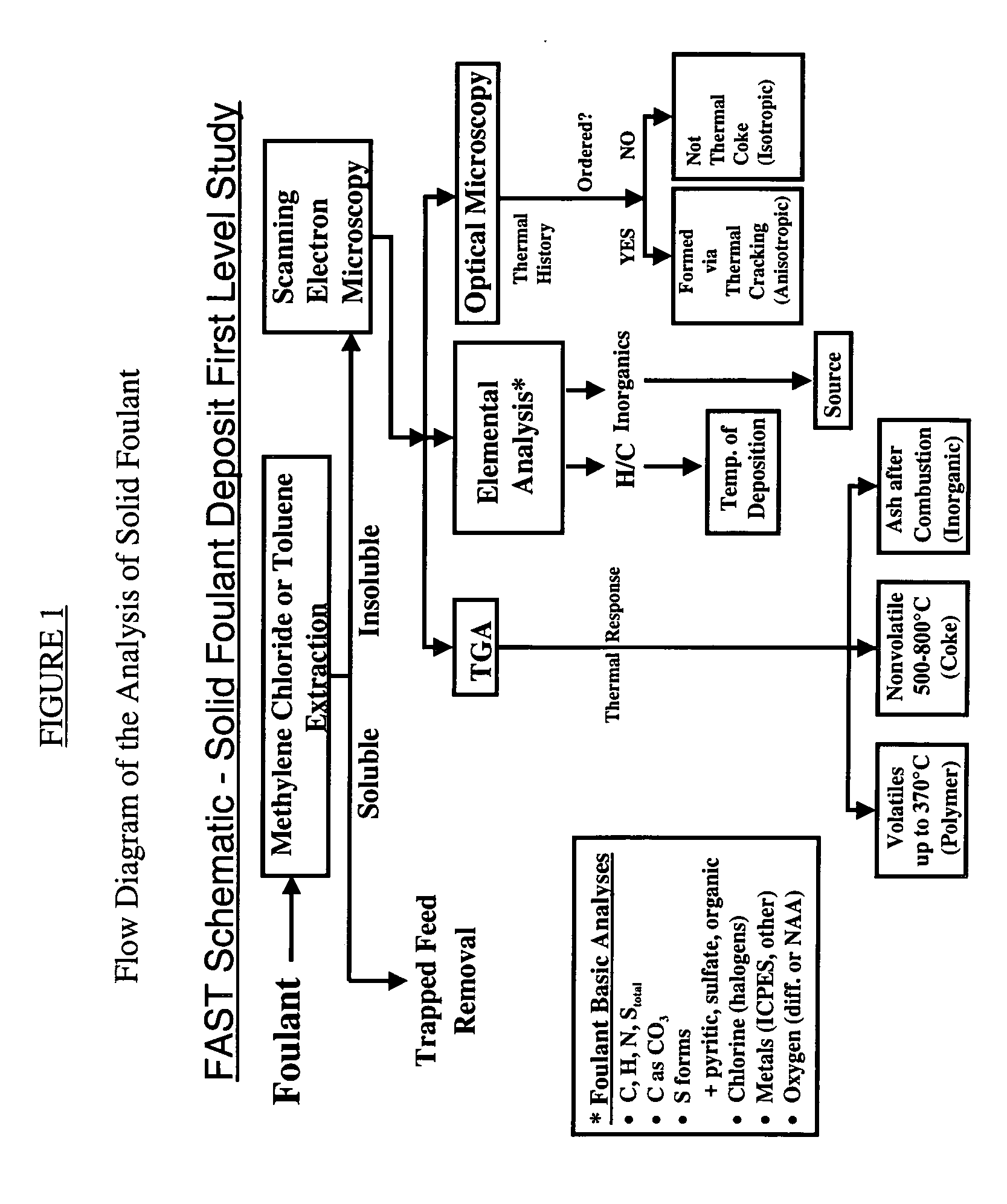

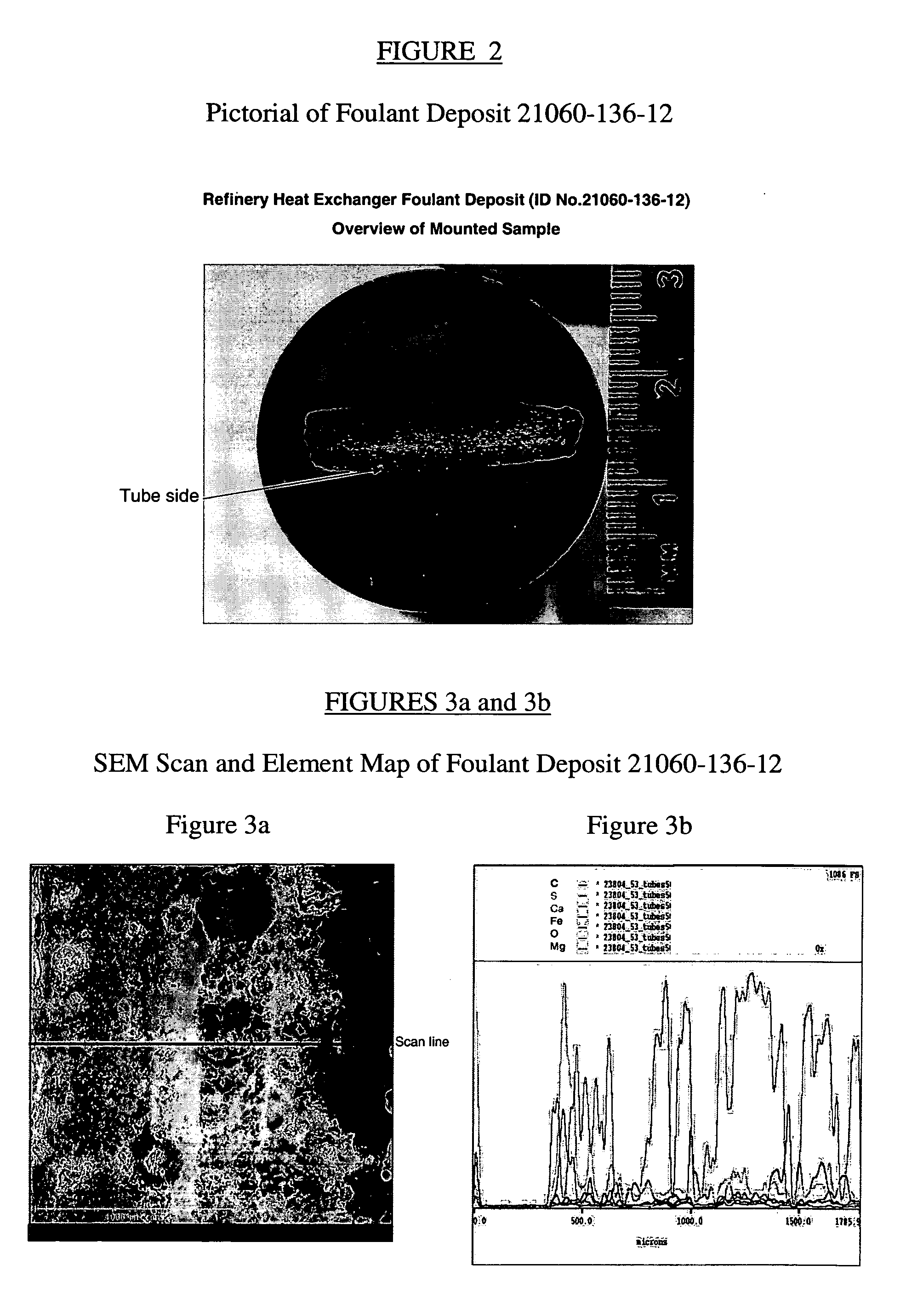

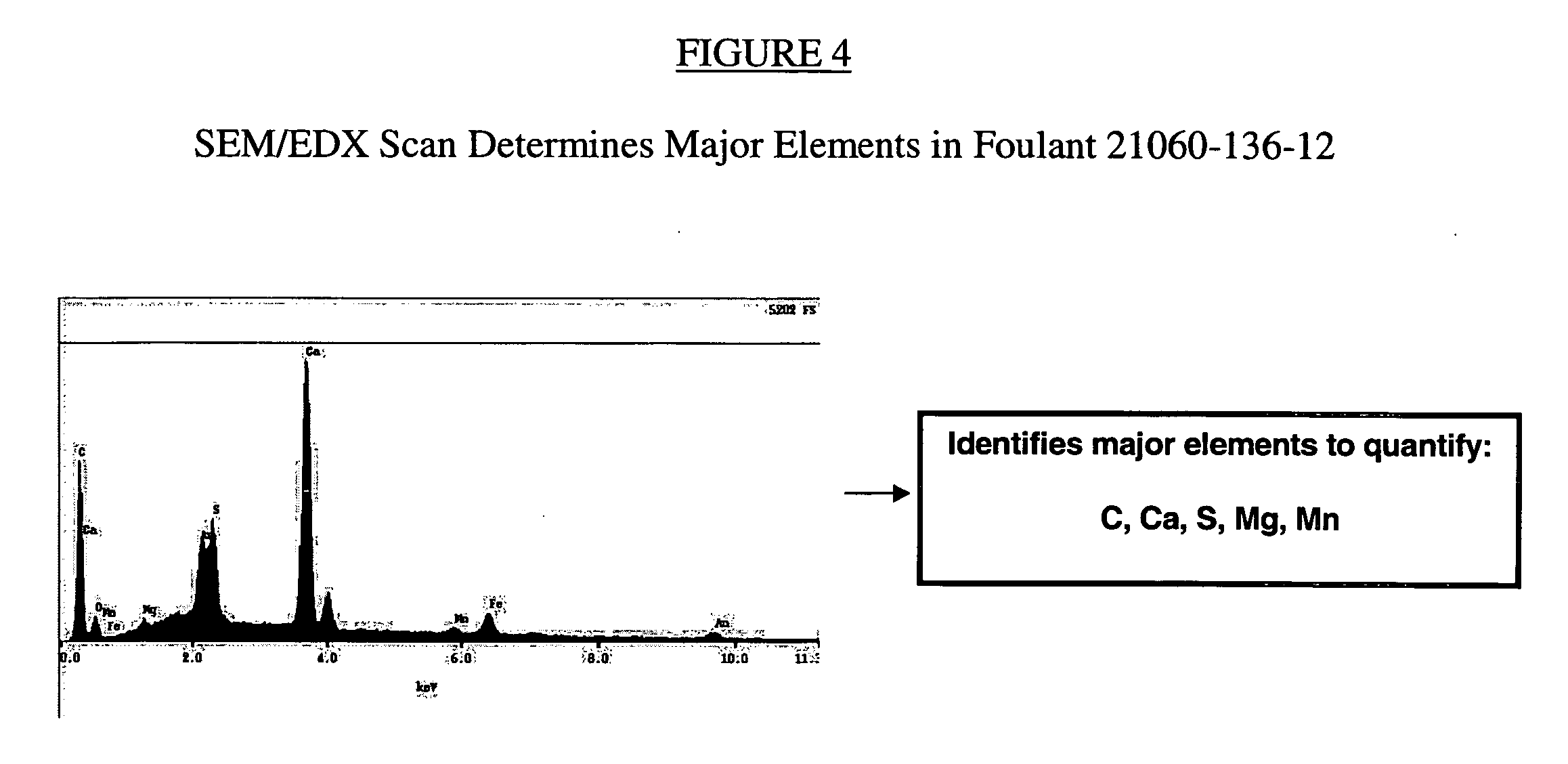

Method for refinery foulant deposit characterization

The present invention is a method to identify a refinery solid foulant of unknown composition including the following steps: obtaining a solid foulant sample, removing trapped feed from the sample with a solvent to obtain an insoluble sample, scanning the insoluble sample with a scanning electron microscope and energy dispersive x-rays, performing a thermal gravimetric analysis including an ash test on the insoluble sample to determine the presence of polymer, coke and inorganic elements, performing an elemental analysis on the insoluble sample for the elements carbon, hydrogen, sulfur, nitrogen, halogens, and metals, performing an optical microscopy on the insoluble sample to determine the presence of wax, asphaltenes, anisotropic coke and isotropic coke, and identifying the solid foulant.

Owner:EXXON RES & ENG CO

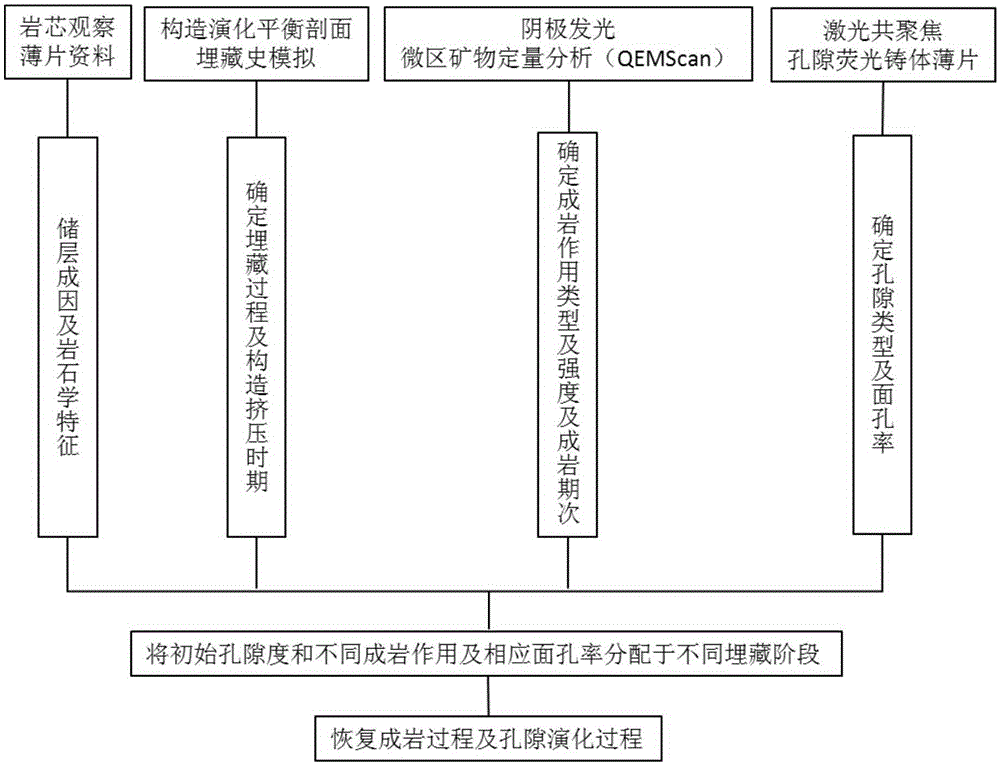

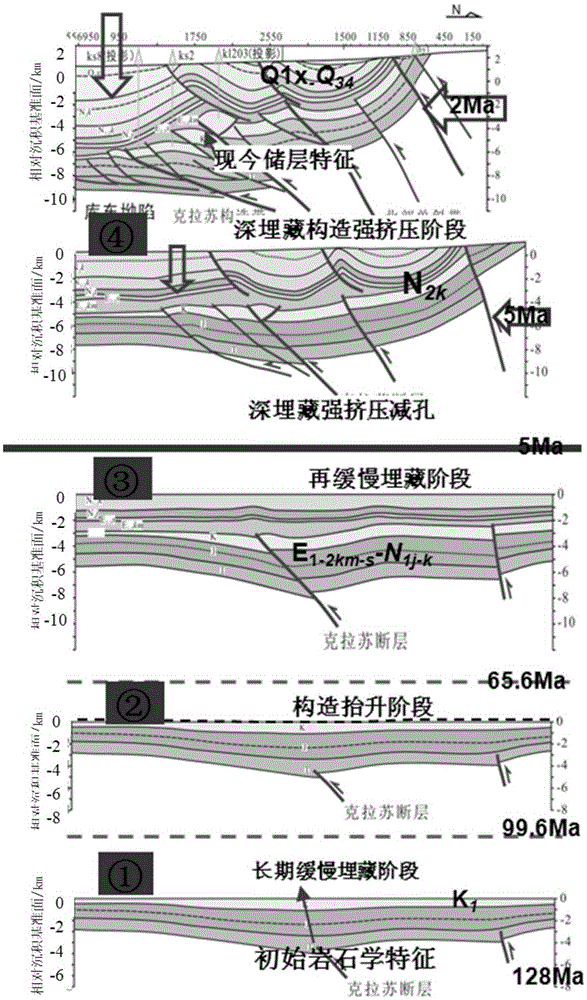

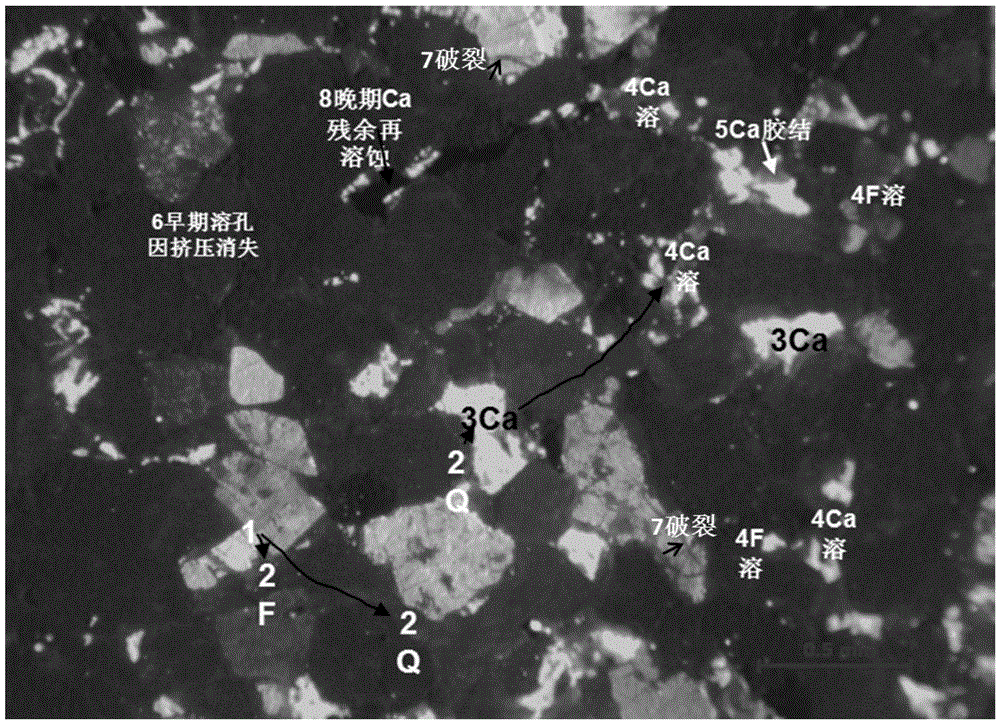

Method for determining diagenetic process and porosity evolution process of foreland basin sandstone reservoir

InactiveCN105334150AContribute to fine-grained forecasting researchImprove the accuracy of pore identificationPermeability/surface area analysisConfocal laser scanning microscopePorosity

The invention provides a method for determining a diagenetic process and a porosity evolution process of a foreland basin sandstone reservoir. The method comprises steps as follows: determining reservoir genesis and petrologic features; determining a burial process and tectonic uplift and subsidence periods; determining a diagenesis type, features and strength of the reservoir by a cathodoluminescence microscope and / or through QEMScan (Quantitative Evaluation of Minerals by SCANning electron microscopy), and recovering the diagenetic process; determining reservoir space features and the porosity evolution process by a fluorescence microscope and / or a confocal laser scanning microscope. With the adoption of the method, the diagenetic process and the porosity evolution process of the ultra-deep compact foreland basin sandstone reservoir with complicated burial process, extremely great depth, extremely small pores and extremely low porosity and permeability can be effectively analyzed; the method can be used for predicating the quality of the sandstone reservoirs in different areas in the plane and the vertical profile, so that more and larger oil and gas fields can be discovered.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

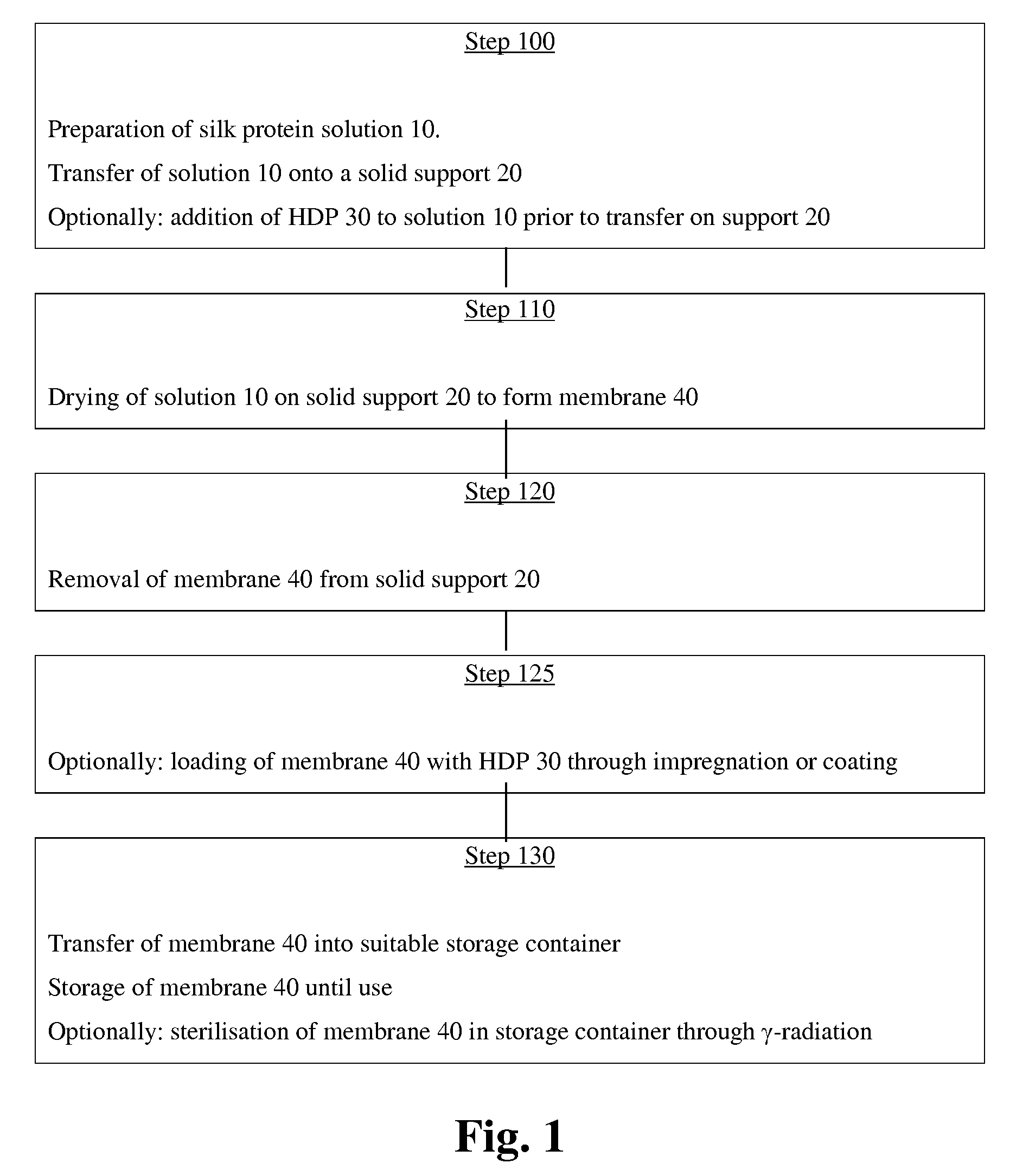

Antibiotic dressing for the treatment of infected wounds

InactiveUS20090297588A1Simple methodExtended retention timePeptide/protein ingredientsMetabolism disorderWound dressingCfu - colony-forming unit

A silk protein membrane is described which is loaded with an antimicrobial compound and has a substantially non-granular ultrastructure which is (i) substantially devoid of micellar silk fibroin substructures and (ii) substantially devoid of pores when analysed by scanning electron microscopy at 0.2 μm resolution. The antimicrobial compound comprises, in one aspect of the invention, a host defense peptide. The silk protein membrane of the invention can be used in a method for the treatment of wounds and allows the wound dressing to be kept in place after removal of that wound dressing from a wound the wound has less than 105 colony forming units per gram. A method for manufacturing a wound dressing is also disclosed which comprises transferring a cast precursor material and optionally a host defense peptide, into a solid support and then drying the precursor material on the solid support to form a silk protein membrane for use as the wound dressing.

Owner:SPINTECH ENG

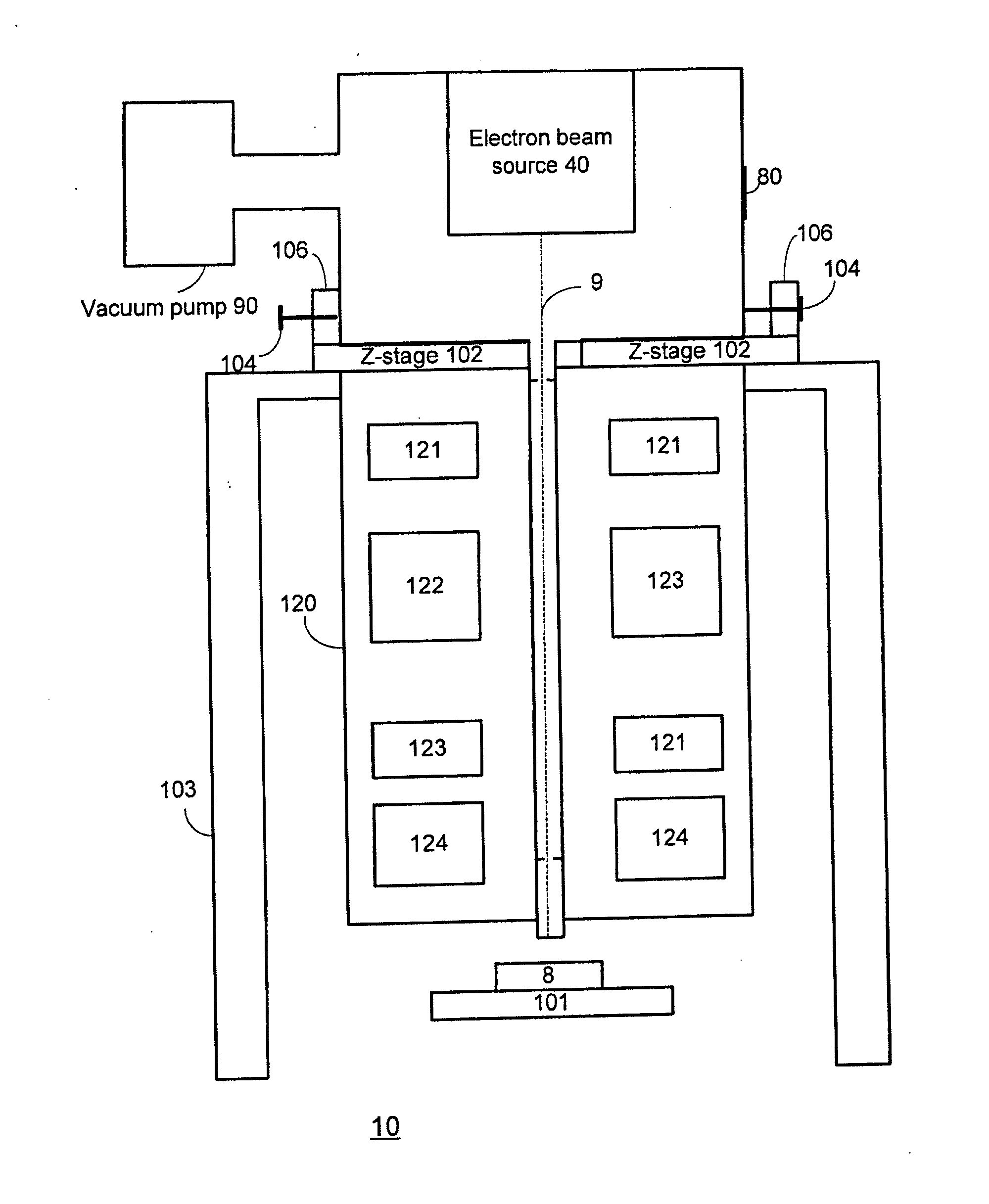

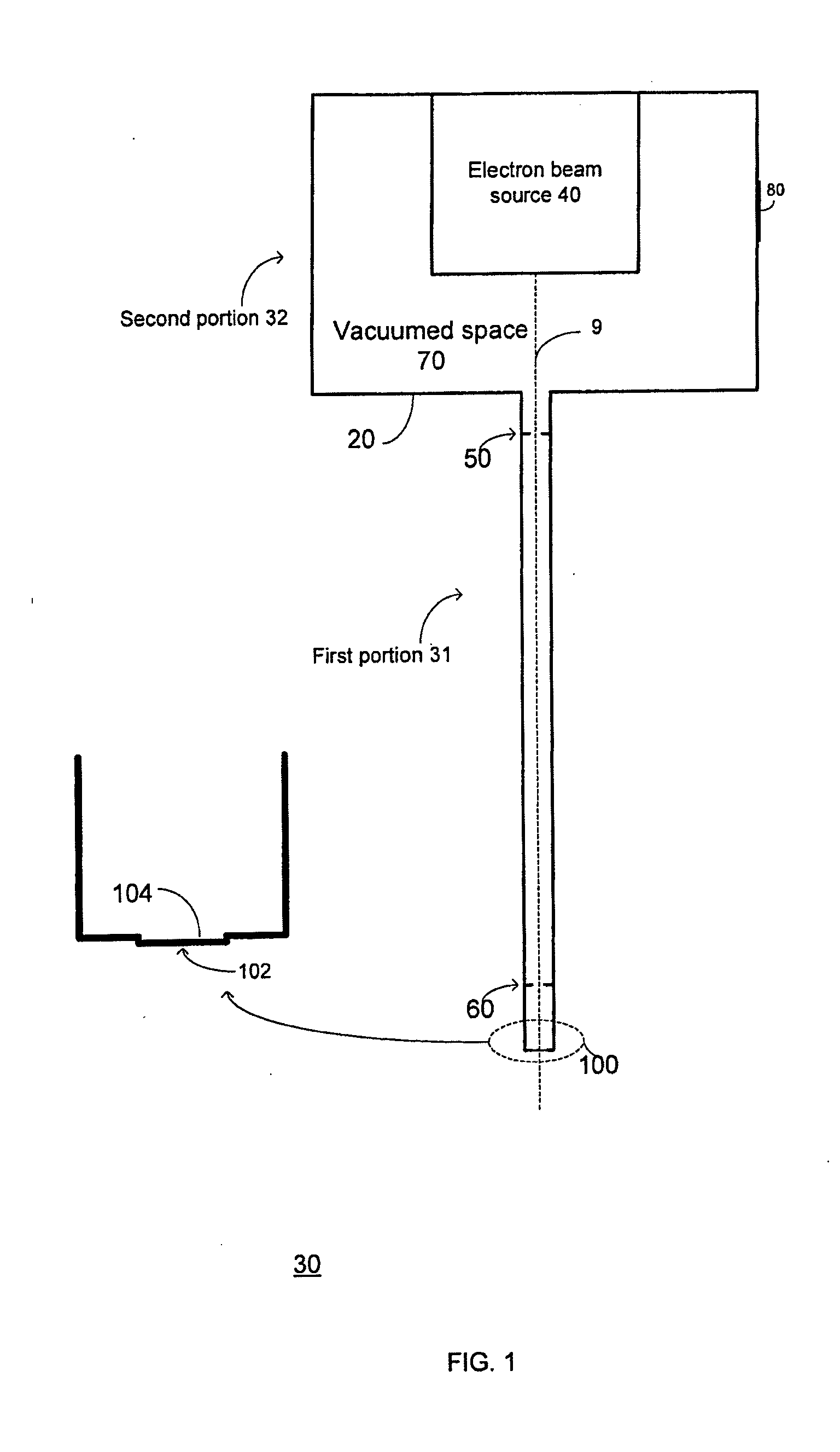

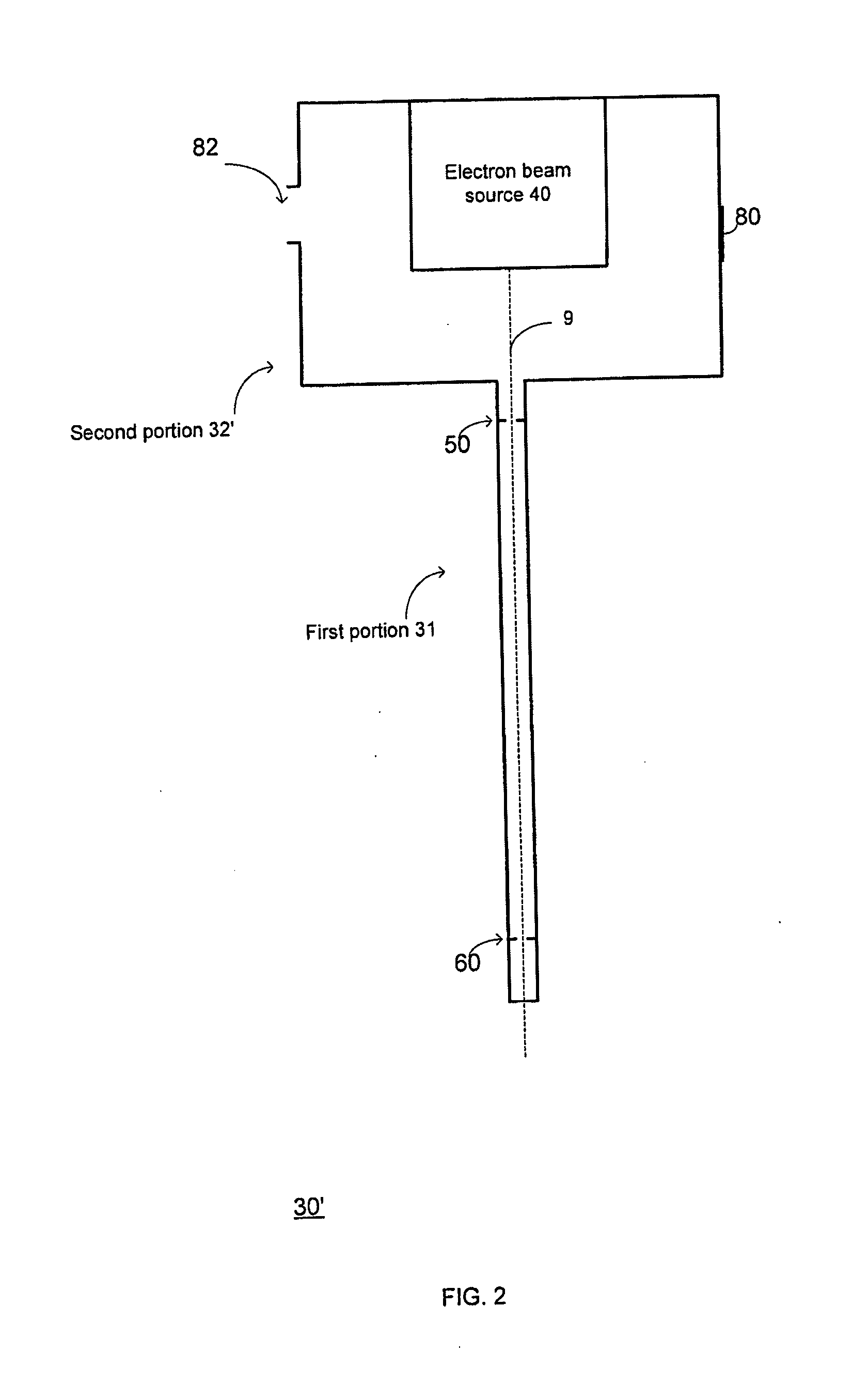

Vacuumed device and a scanning electron microscope

ActiveUS20110210247A1Stability-of-path spectrometersMaterial analysis using wave/particle radiationBeam sourceScanning tunneling microscope

A vacuumed device that includes: a sealed housing, an electron beam source, an electron optic component, a thin membrane, and a detector. The thin membrane seals an aperture of the sealed housing. The sealed housing defines a vacuumed space in which vacuum is maintained. The electron beam source is configured to generate an electron beam that propagates within the vacuumed space, interacts with the electron optic component and passes through the thin membrane. A first portion of the sealed housing is shaped to fit a space defined by non-vacuumed scanning electron microscope components that are maintained in a non-vacuum environment.

Owner:B NANO

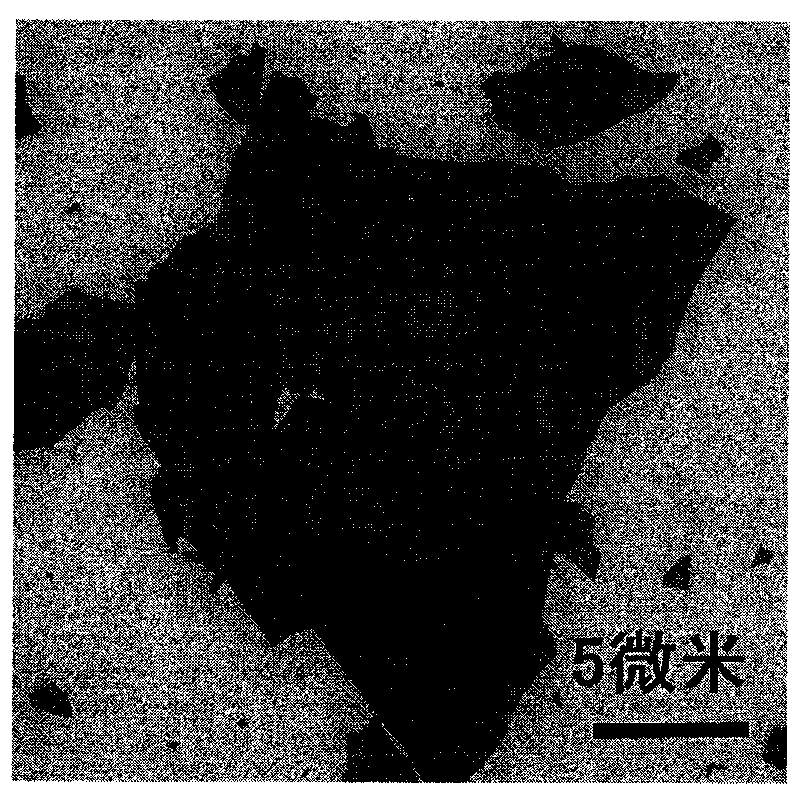

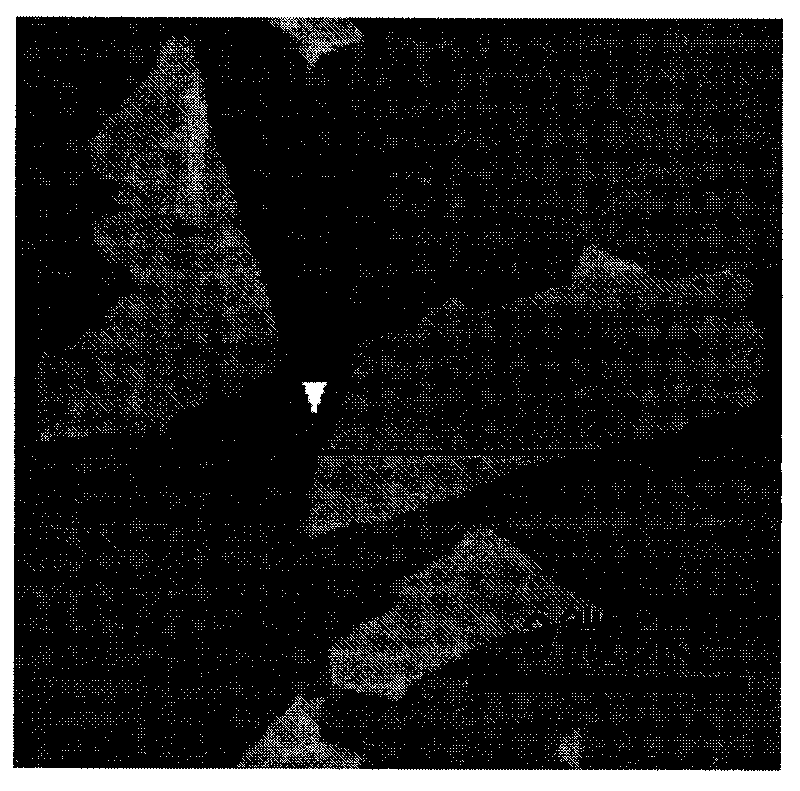

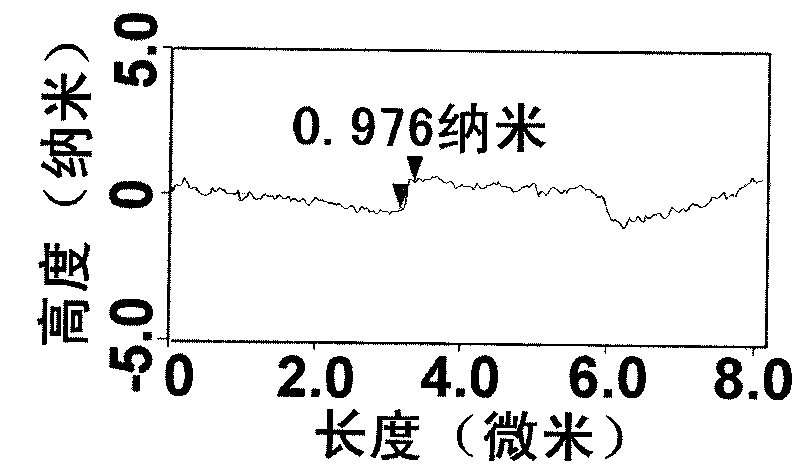

Method for preparing grapheme through organic amine solvothermal method

The invention discloses a method for preparing grapheme through organic amine solvothermal method, which comprises the following steps: 1) adopting the solvothermal method to lead expanded graphite to react with organic amine or organic amine solvent to obtain the semi-discrete liquid of grapheme; 2) implementing ultrasonic dispersion and then implementing centrifugation on the semi-discrete liquid of grapheme obtained from the step 1), and then collecting supernate, thus obtaining the grapheme. The invention obtains the grapheme by taking solvent thermal spalling as a means. A scanning electron microscope, a transmission electron microscope, and an atomic force microscope are adopted to represent the topogram of the grapheme; a Raman spectrum and an X-ray photoelectron spectroscopy are used to represent the density of imperfection and oxidation situation of the grapheme. The result shows that the grapheme synthesized by the method of the invention has the advantages of small size, high quality, less defects, light oxidation degree, etc. besides, the method for preparing grapheme through organic amine solvothermal method also has the advantages of simple synthetic route, low cost, high concentration and uneasy accumulation of the synthesized discrete liquid of grapheme, and excellent application prospect on the aspect of discrete liquid of grapheme materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

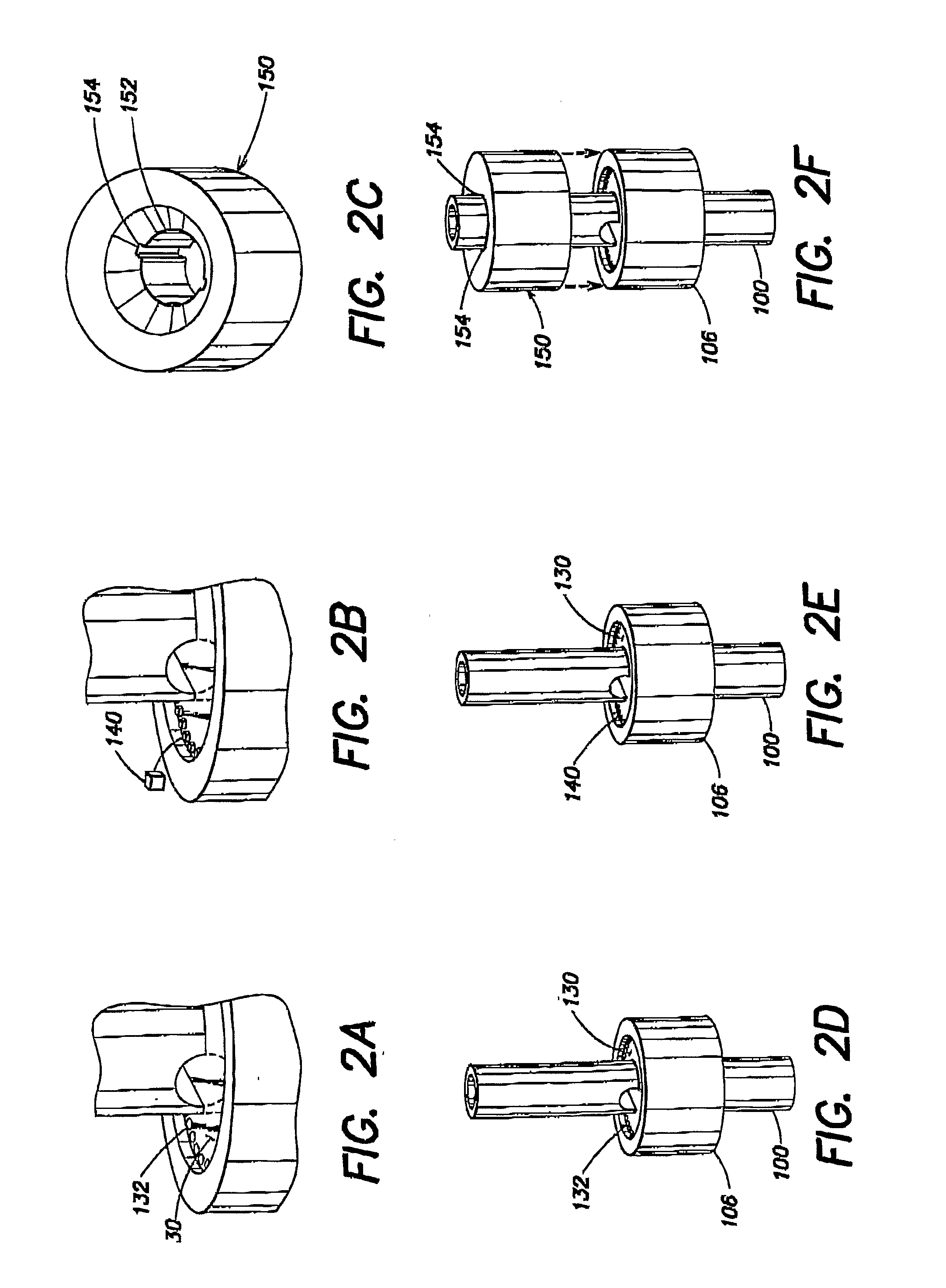

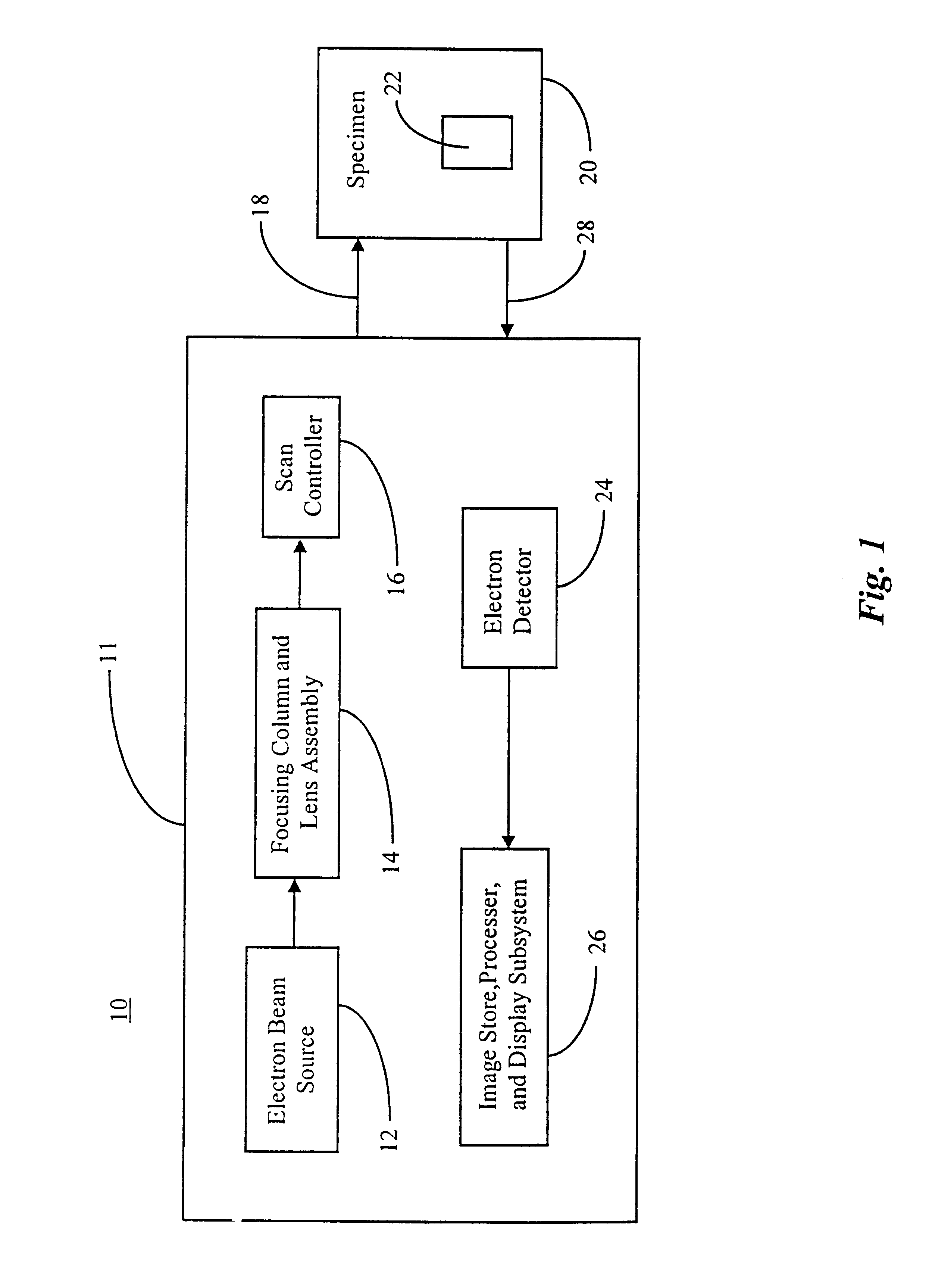

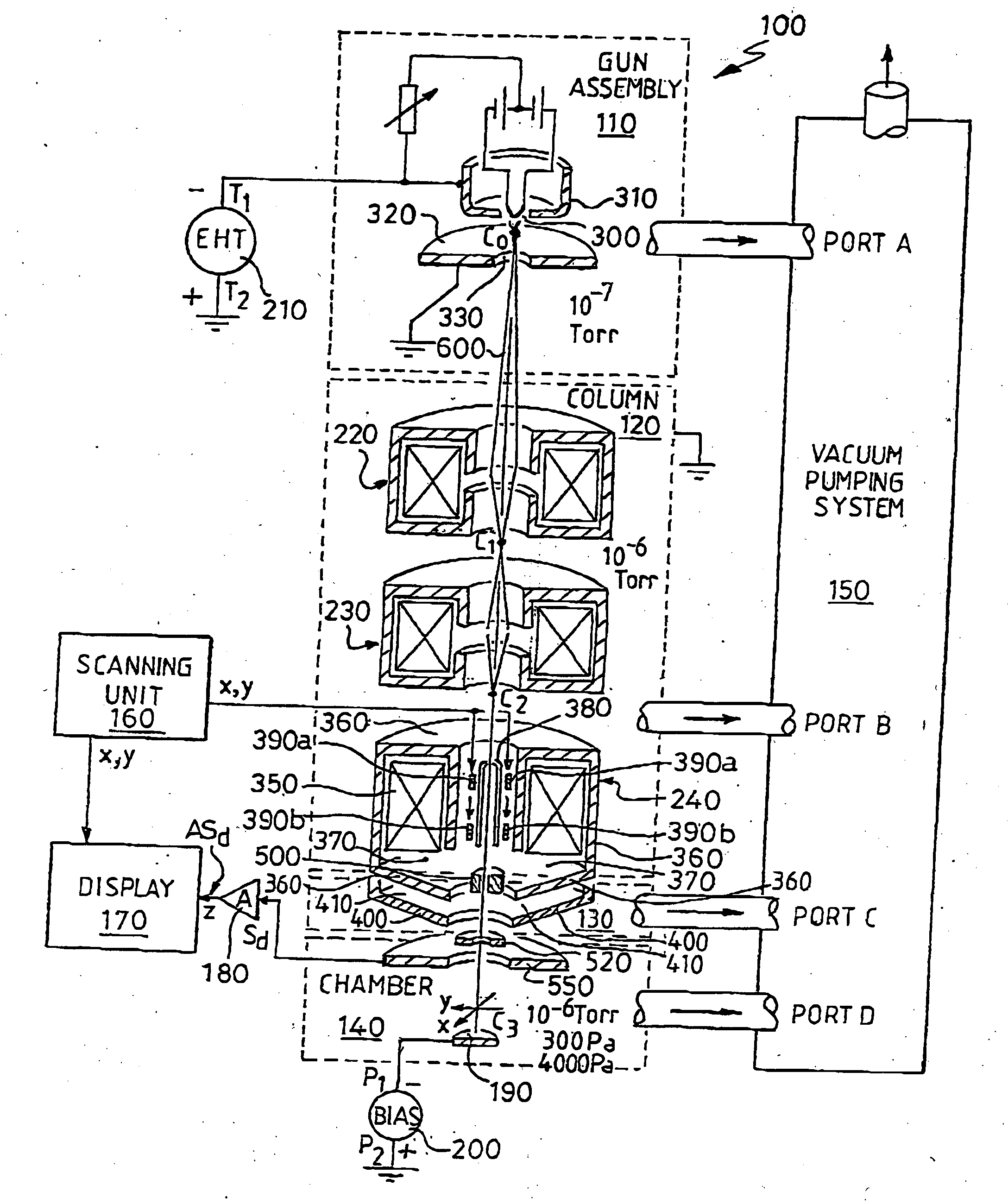

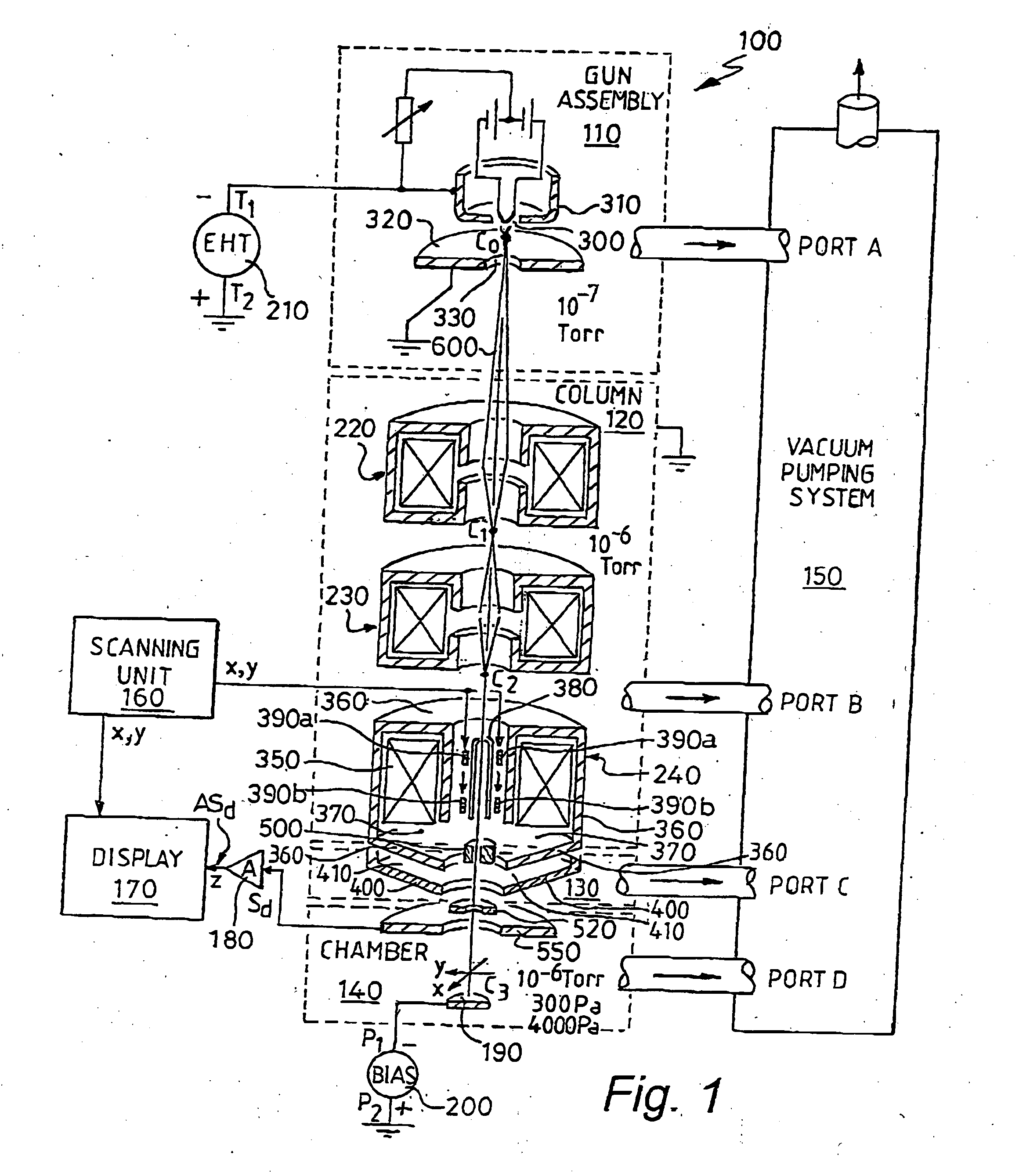

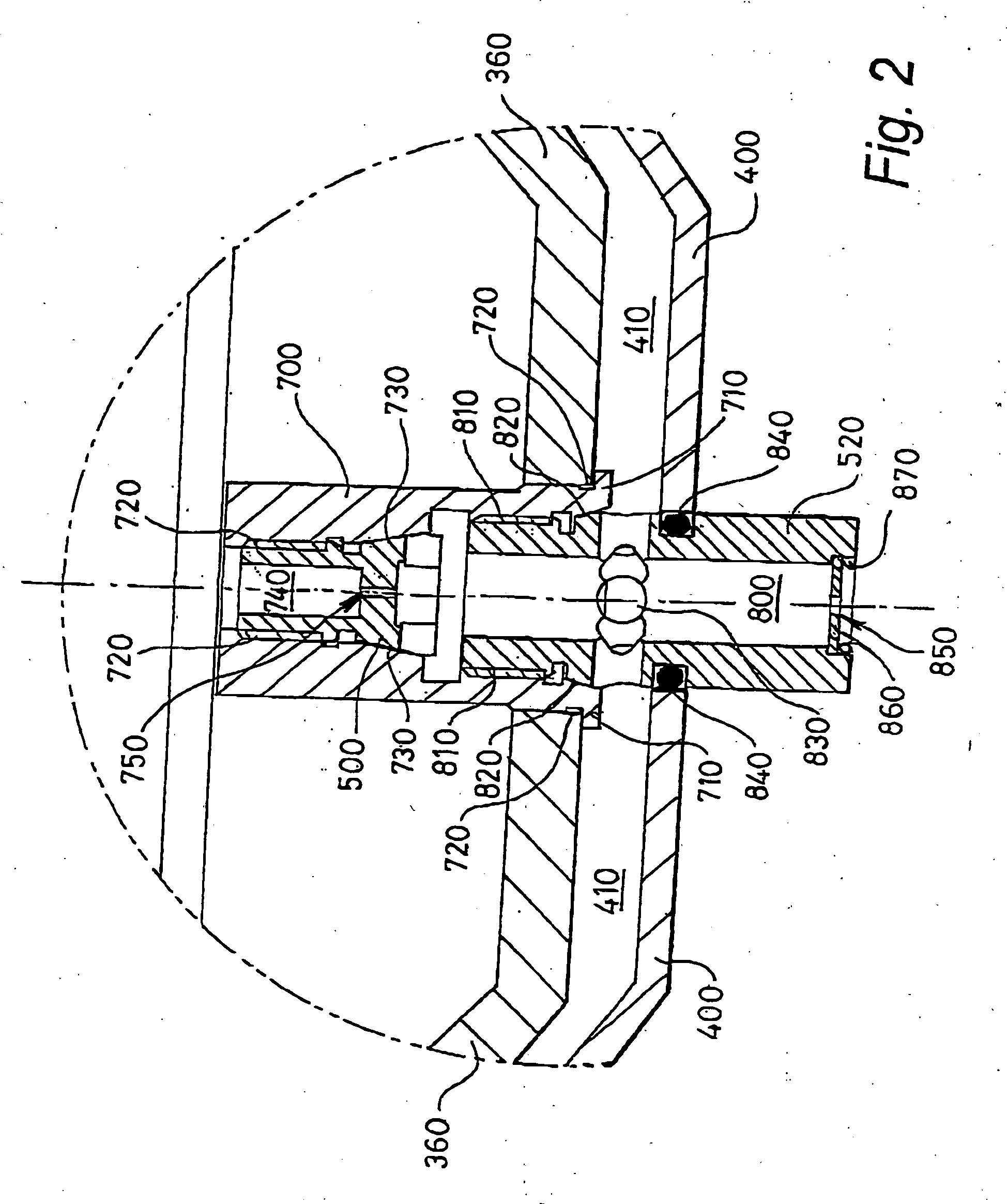

Scanning electron microscope

InactiveUS20040173747A1Easy to useMaterial analysis using wave/particle radiationElectric discharge tubesElectron probe microanalysisScanning tunneling microscope

There is provided a reconfigurable scanning electron microscope (RSEM) (100) comprising: (a) a gun assembly (110) and an associated electron optical column (120) for generating an electron beam (600), for demagnifying the electron beam (600) to generate an electron probe (C3) and for scanning the probe (C3) across a sample (190); (b) an electron detector (550) for detecting emissions from the sample (190) in response to scanned electron probe irradiation thereof and for generating a corresponding detected signal (Sd) indicative of the magnitude of the emissions; and (c) a display (170) for receiving the detected signal (Sd) and scanning signals (x, y) indicative of the position of the probe (C3) relative to the sample (190) for generating the image of the sample (190). The RSEM (100) is distinguished in that it further includes aperture bearing members (500, 520), each member (500, 520) including an associated electon-beam transmissive aperture, for at least partially gaseously isolating the gun assembly (110) and the electron optical column (110) from the sample (190), thereby enabling the RSEM (100) to be reconfigurable as a high-vacuum scanning electron microscope and also as an environmental scanning electron microscope, the RSEM (100) being reconfigurable to include no aperture members, one aperture member (500, 750) and a plurality of aperture members (500, 750; 520 850, 860).

Owner:CARL ZEISS SMT LTD

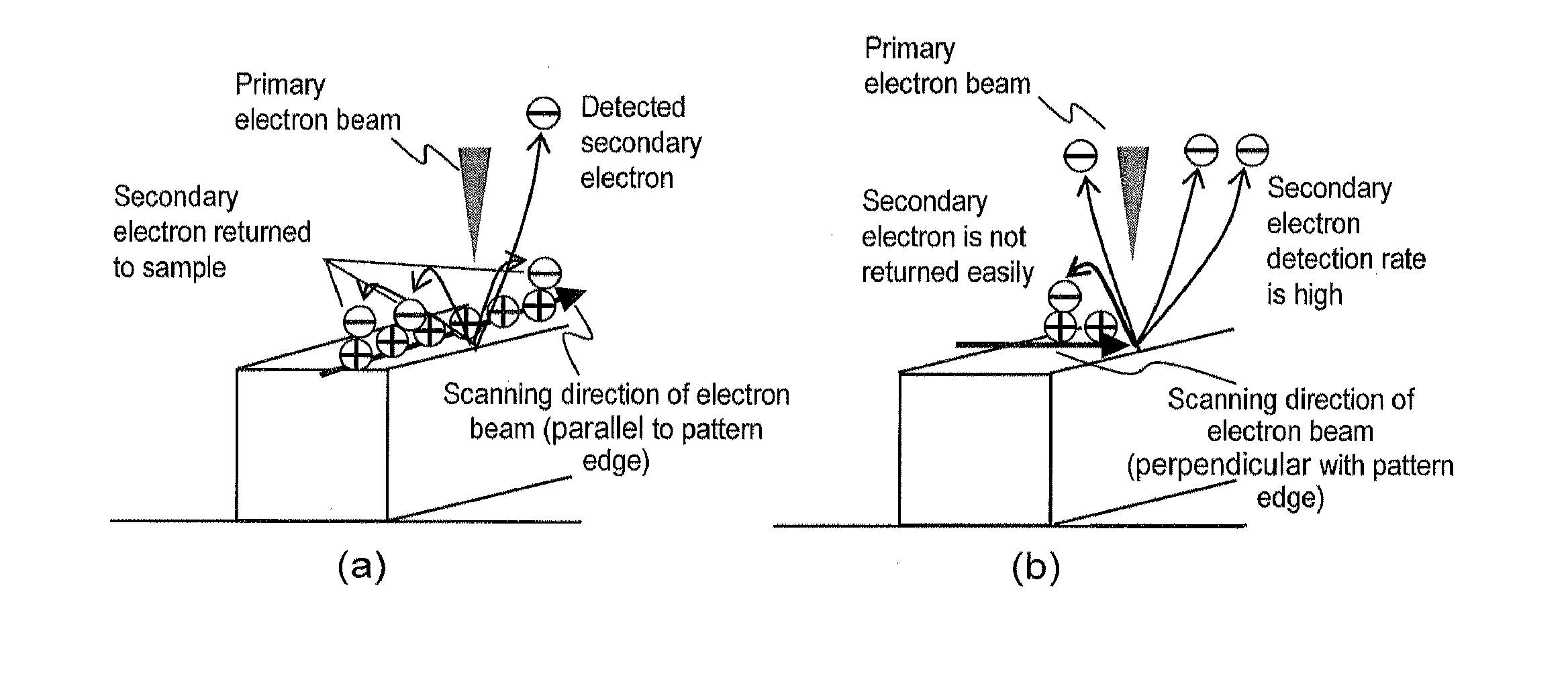

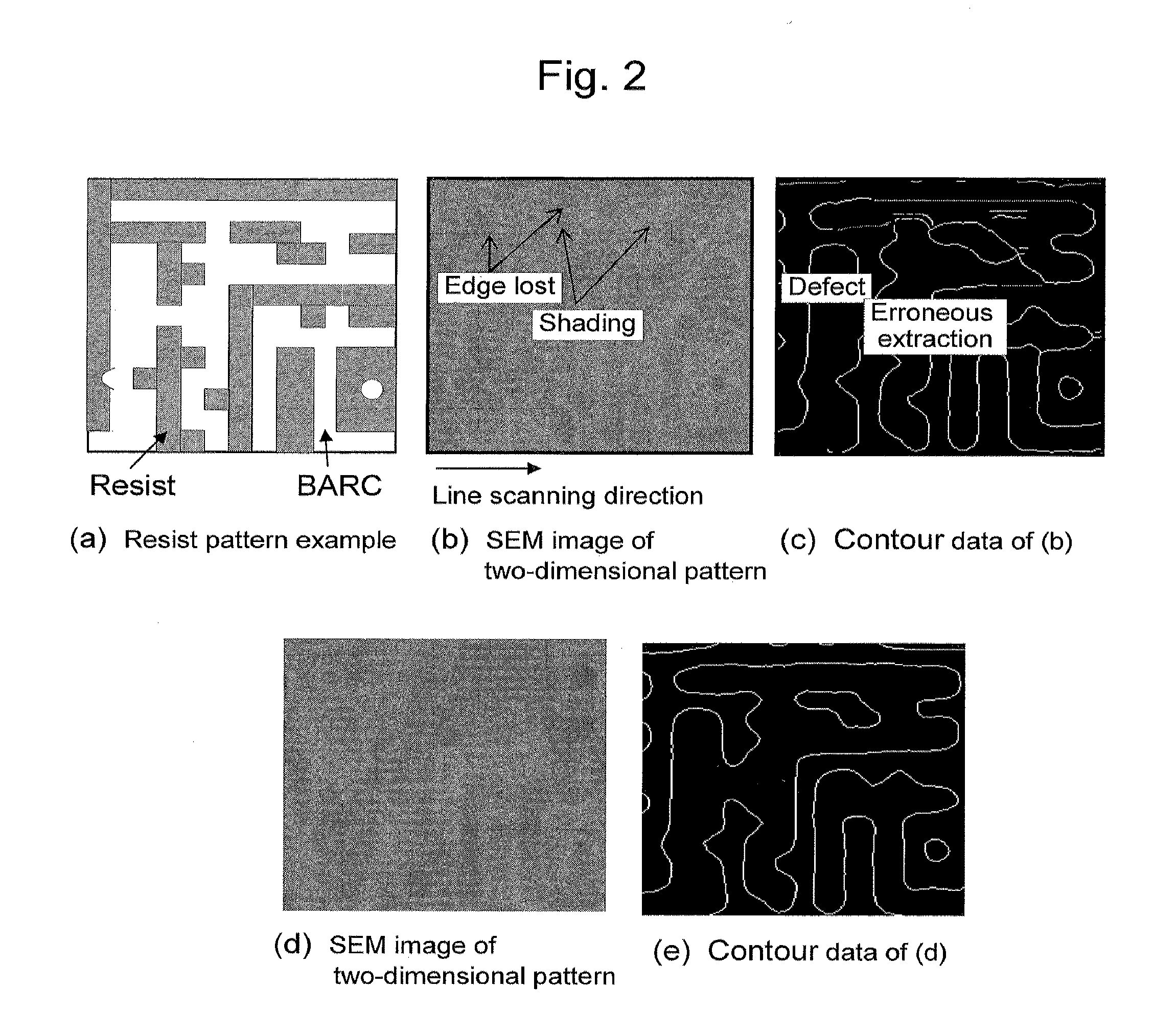

Scanning electron microscope and sample observation method

ActiveUS20120153145A1Increase contrastSuppress shadowsMaterial analysis using wave/particle radiationElectric discharge tubesSecondary electronsParticle physics

A scanning electron microscope of the present invention performs scanning by changing a scanning line density in accordance with a sample when an image of a scanned region is formed by scanning a two-dimensional region on the sample with an electron beam or is provided with a GUI having sample information input means which inputs information relating to the sample and display means which displays a recommended scanning condition according to the input and performs scanning with a scanning line density according to the sample by selecting the recommended scanning condition. As a result, in observation using a scanning electron microscope, a suitable scanning device which can improve contrast of a profile of a two-dimensional pattern and suppress shading by suppressing the influence of charging caused by primary charged particle radiation and by improving a detection rate of secondary electrons and a scanning method are provided.

Owner:HITACHI HIGH-TECH CORP

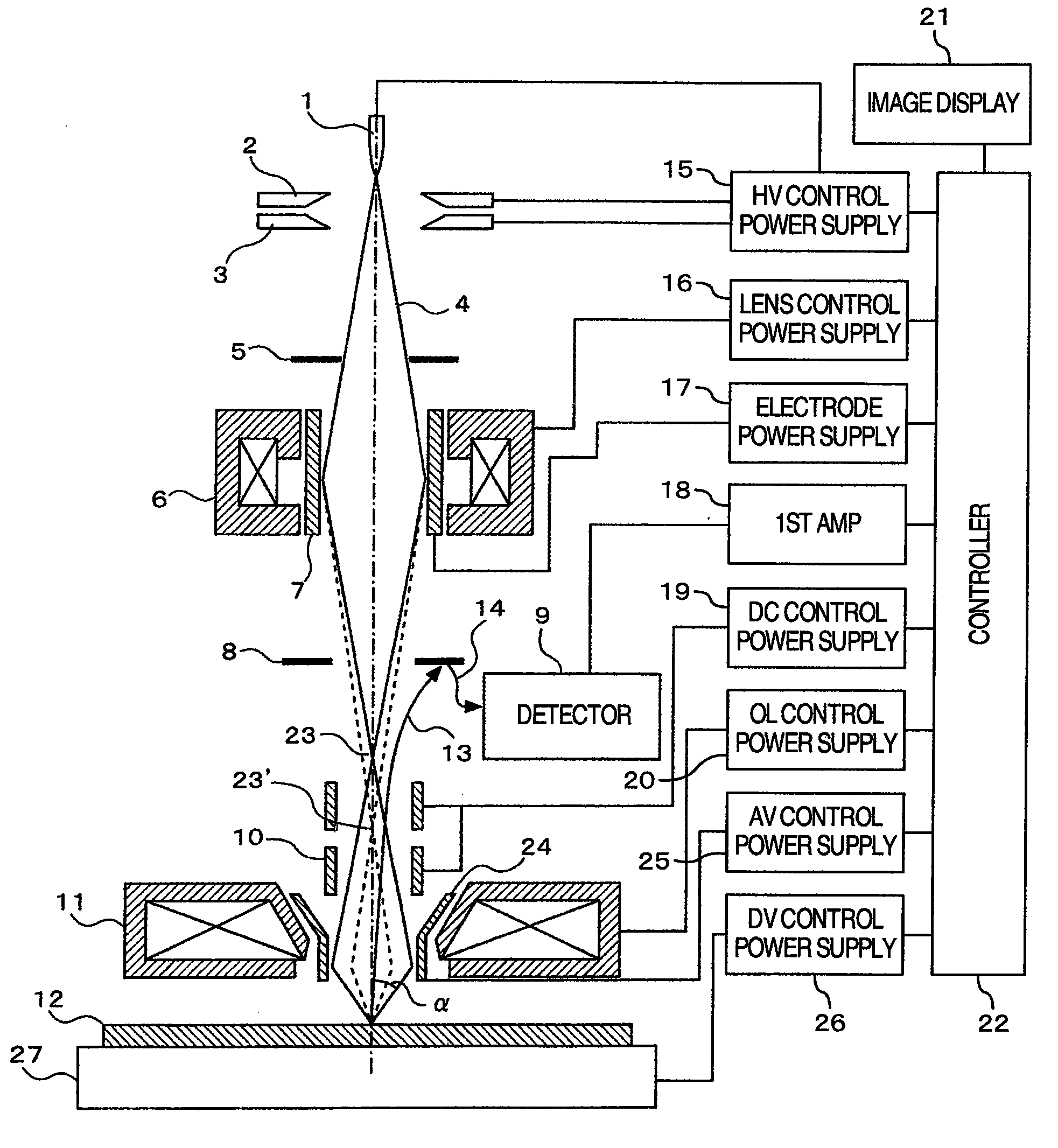

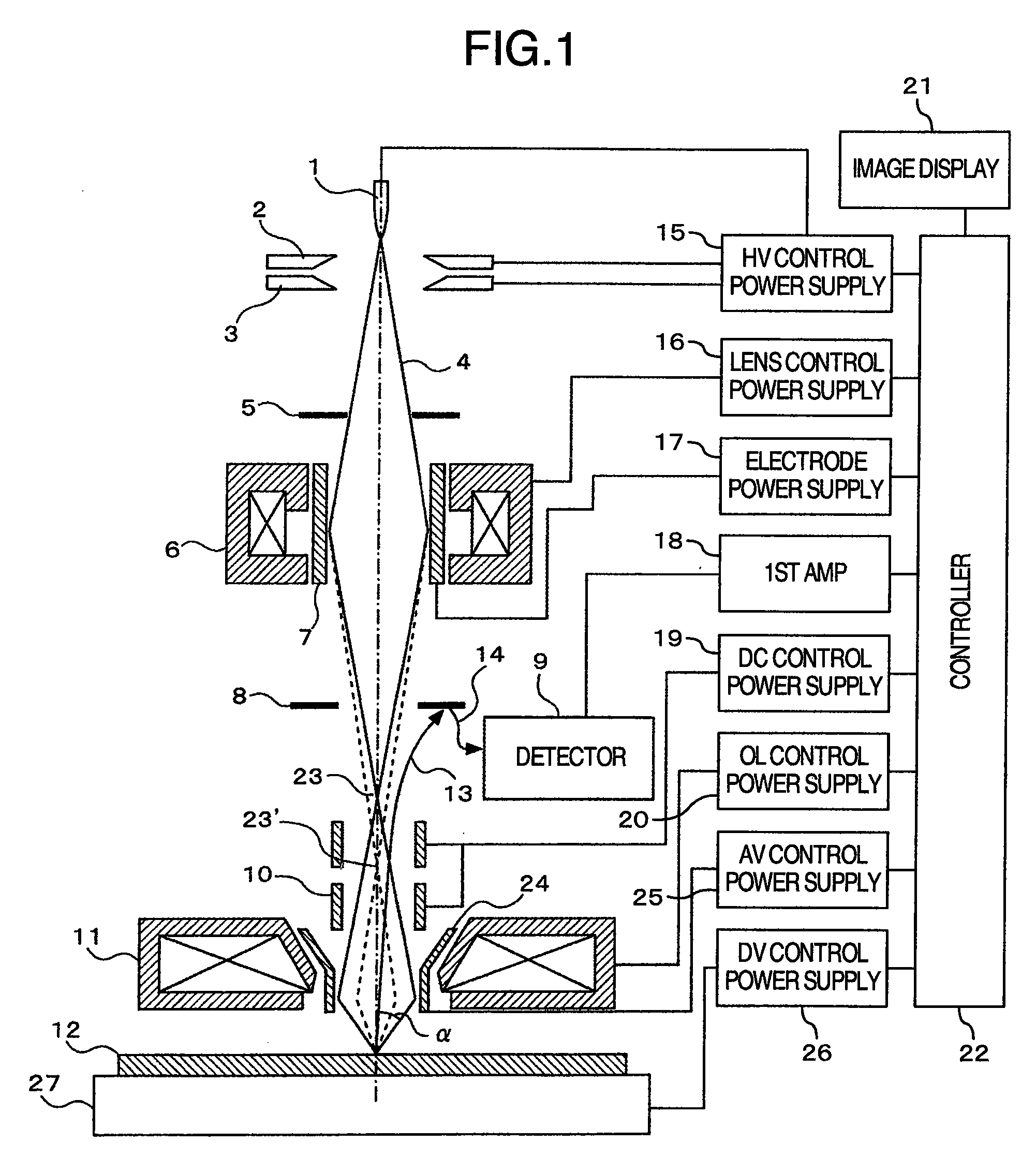

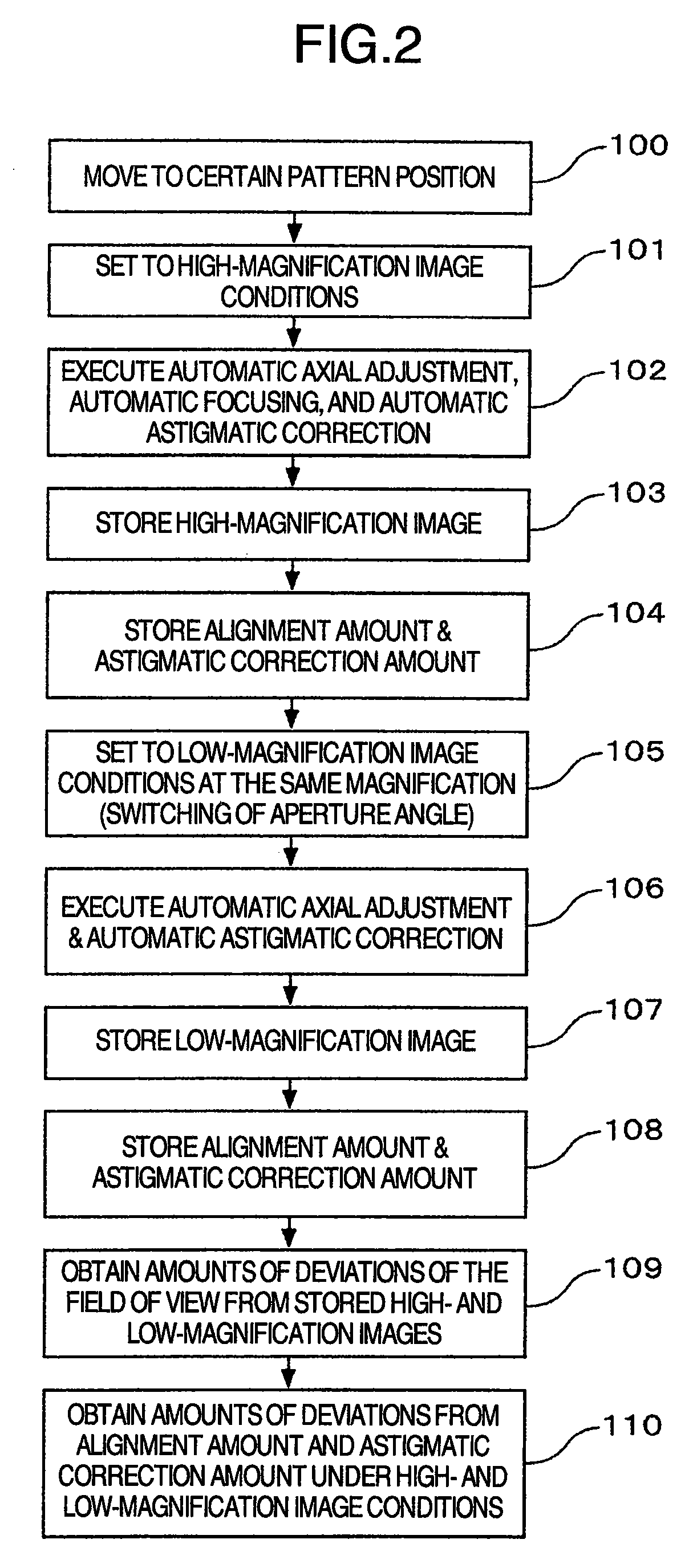

Scanning electron microscope and method of imaging an object by using the scanning electron microscope

InactiveUS20080310704A1Increase speedGood reproducibilityMaterial analysis using wave/particle radiationElectric discharge tubesBeam sourceFocal position

A scanning electron microscope capable of modifying the focal position of a condenser lens with high speed and high reproducibility in order that low-magnification images are obtained at large depths of focus and that high-magnification images are obtained at high resolution. The microscope has a specimen-holding portion, an electron beam source, a condenser lens for converging the electron beam, an objective lens for focusing the converged beam into a very small spot onto a specimen, scan coils, a detector for detecting a specimen signal emanating from the specimen, and a display portion for displaying the detected specimen signal as an image. An axisymmetric electrode is disposed within the magnetic field produced by the condenser lens. A voltage is applied to the electrode.

Owner:HITACHI HIGH-TECH CORP

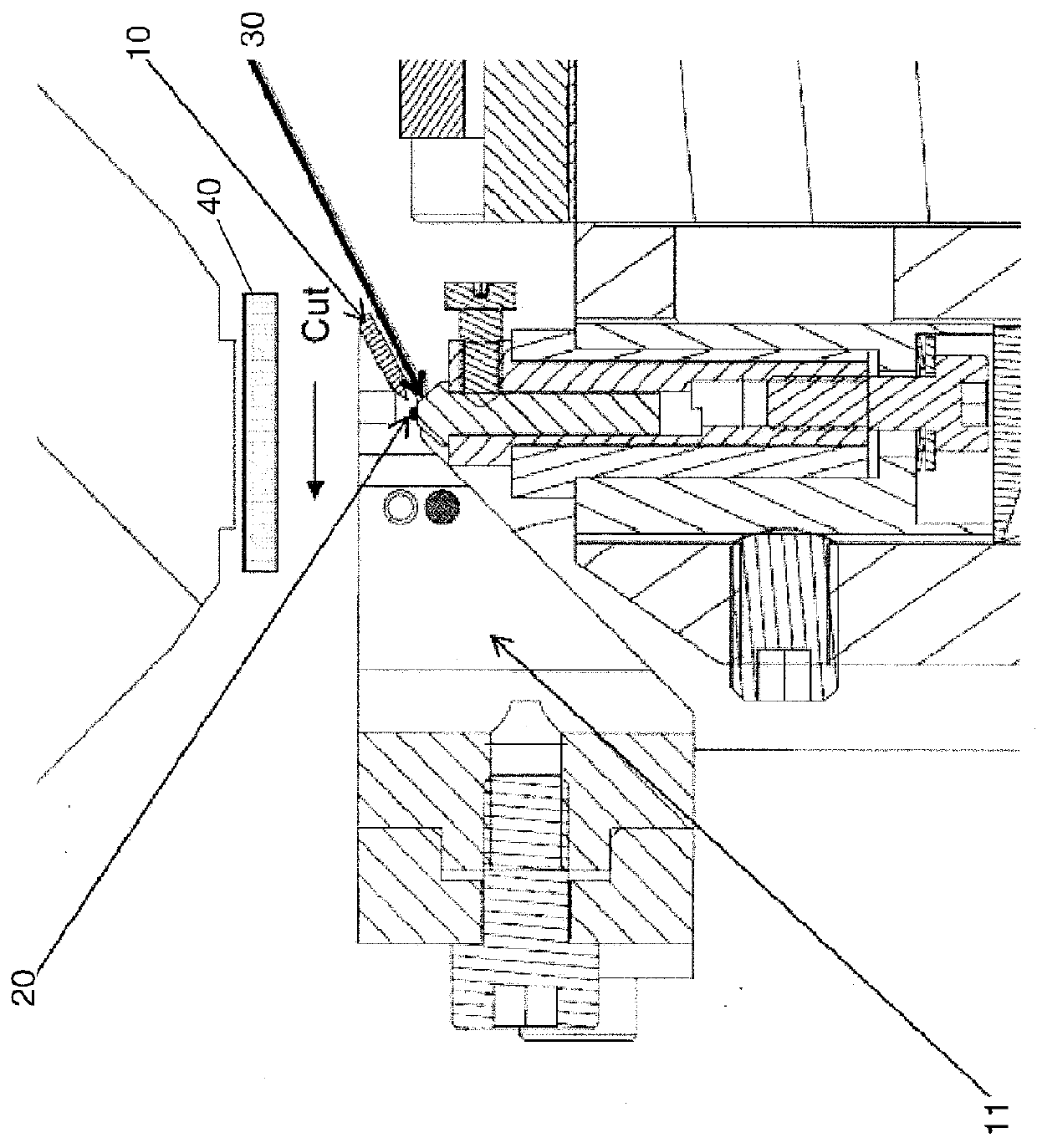

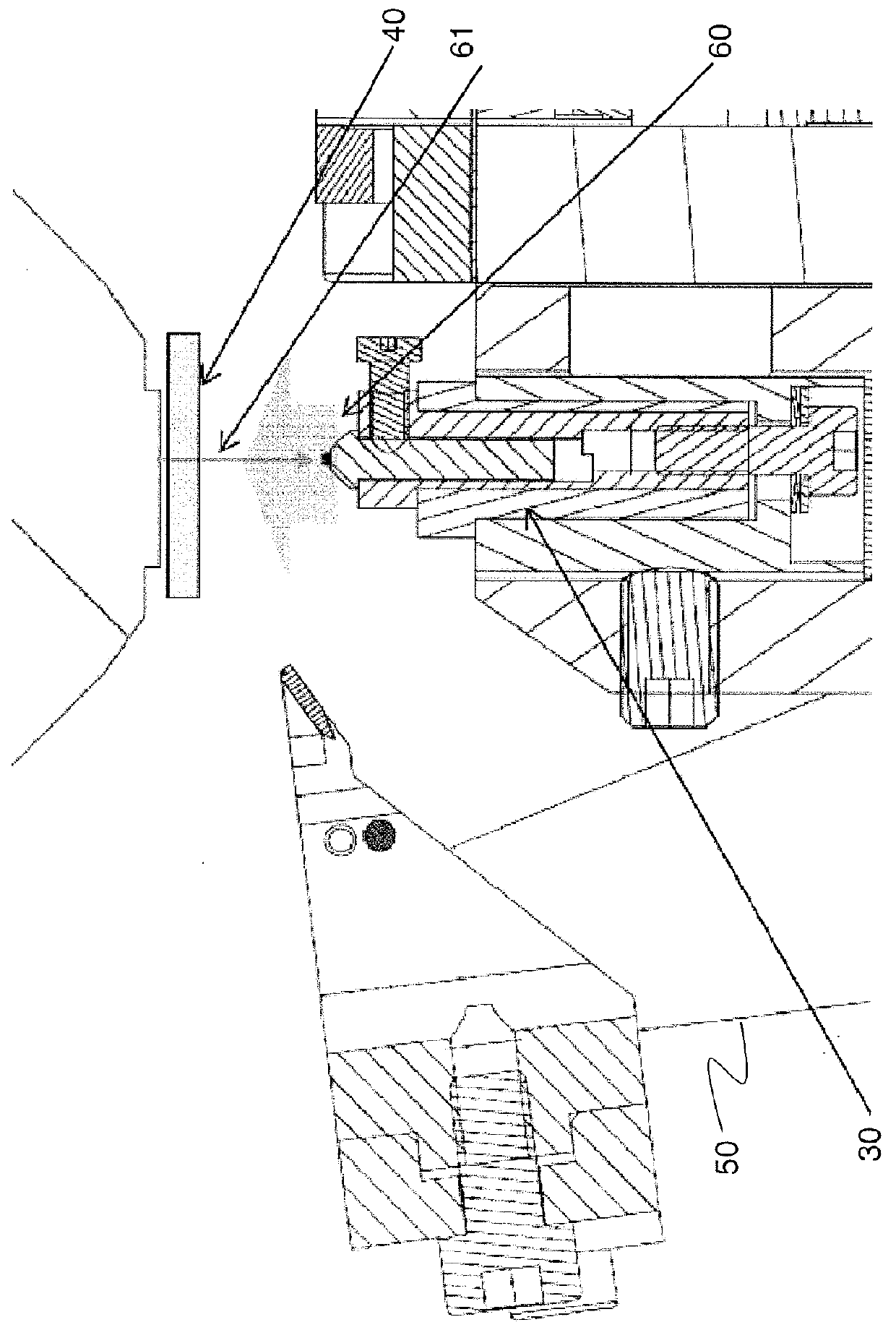

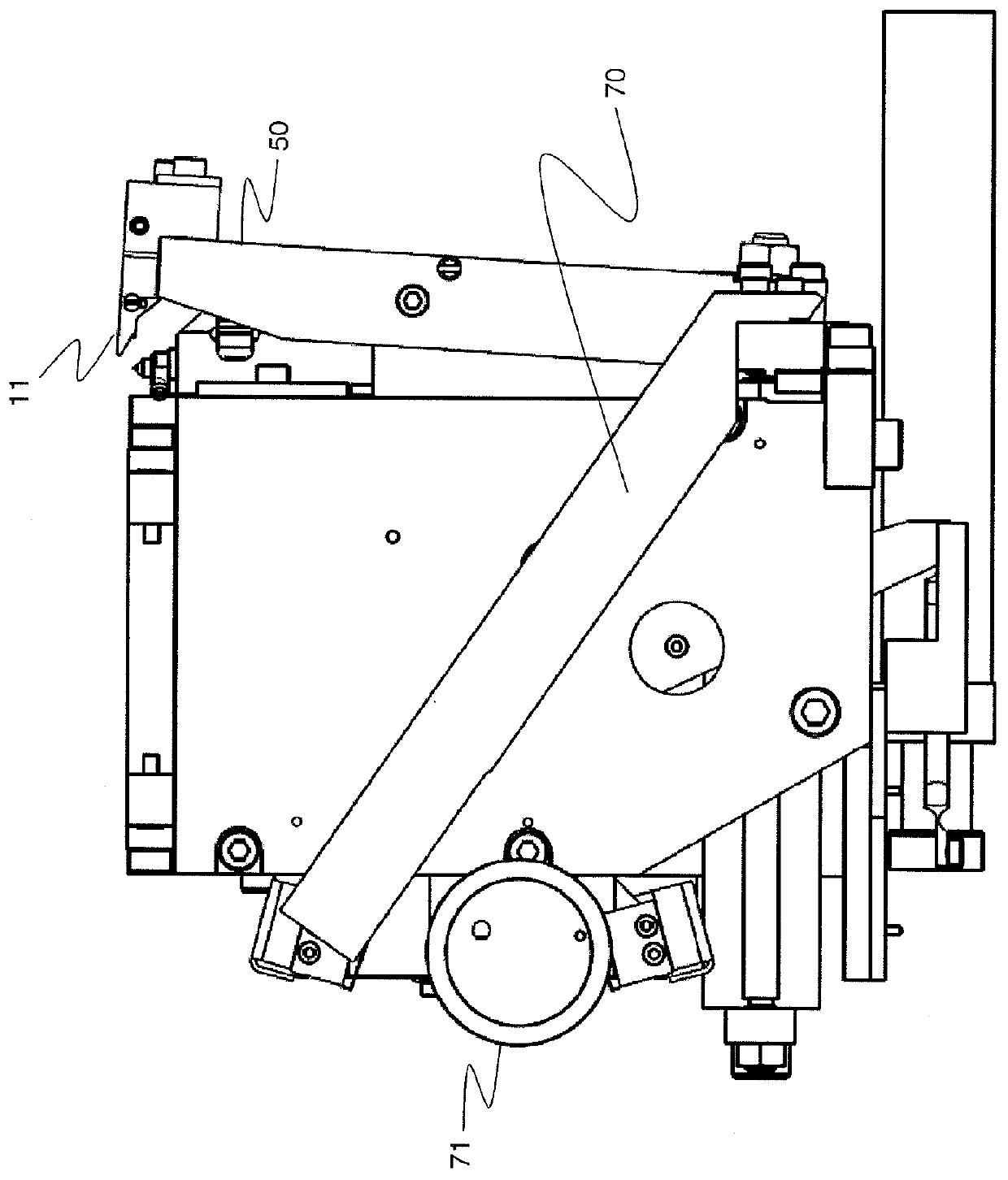

Microtome utilizing a movable knife in a retardation field scanning electron microscope and a retardation field scanning electron microscope including the same

ActiveUS20120223228A1Effect on imageHigh materialMaterial analysis using wave/particle radiationParticle separator tubesElectron microscopeHigh pressure

A microtome for in situ residence within a chamber of a scanning electron microscope (SEM) and a SEM including the microtome is disclosed. The microtome includes a specimen holder for holding a specimen thereon at high voltage to produce a retardation field thereat and a movable knife. The SEM includes a backscatter electron detector disposed adjacent to specimen holder. The knife arranged is to be carried into engagement with the specimen on the specimen holder to slice a portion of the specimen away to expose a new face of the specimen without interfering with the high voltage on the specimen, and is mounted so that after having engaged the specimen to expose a new face of the specimen it is withdrawn to a retracted position whereupon it does not interfere with the retardation field.

Owner:GATAN INC

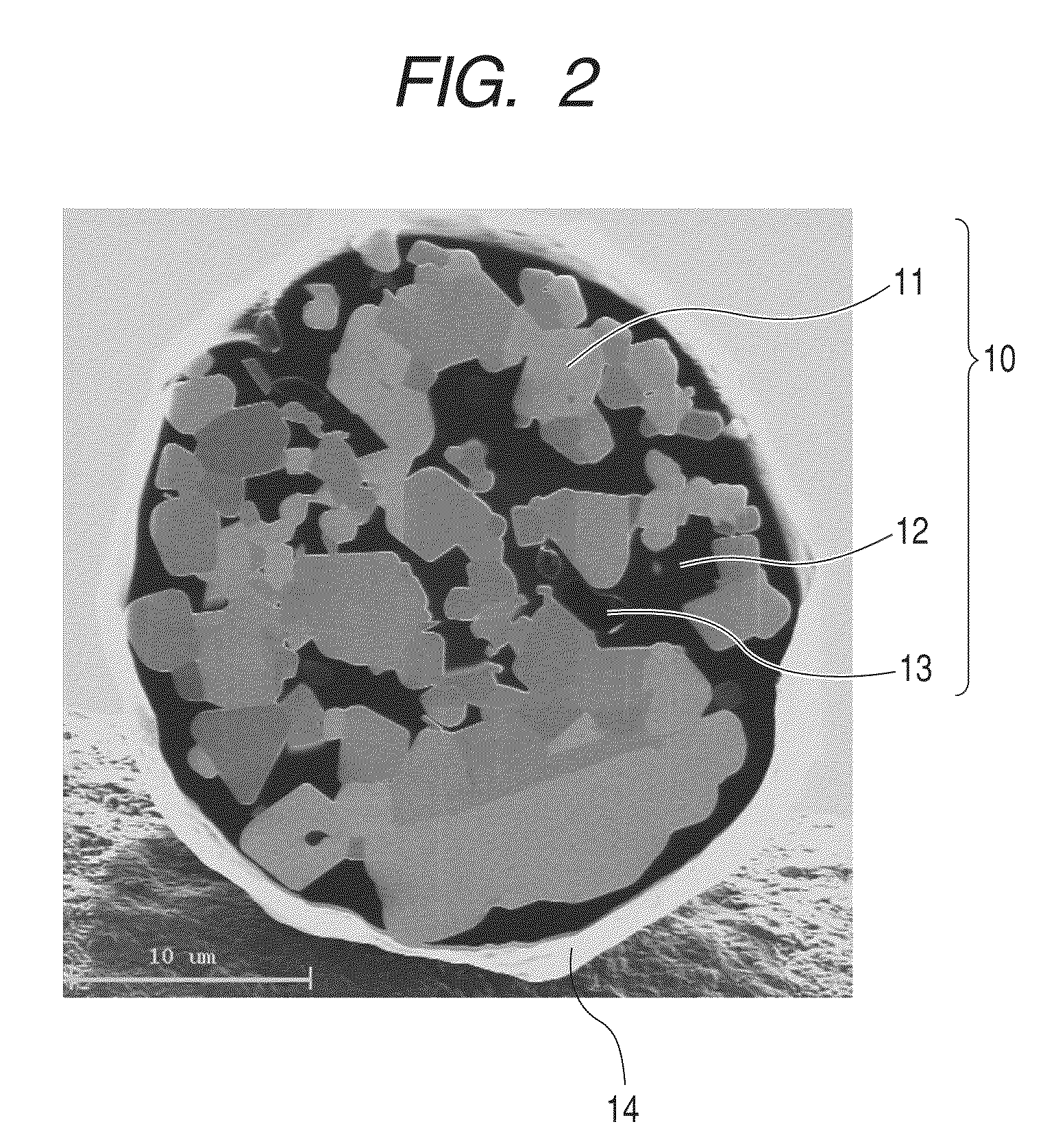

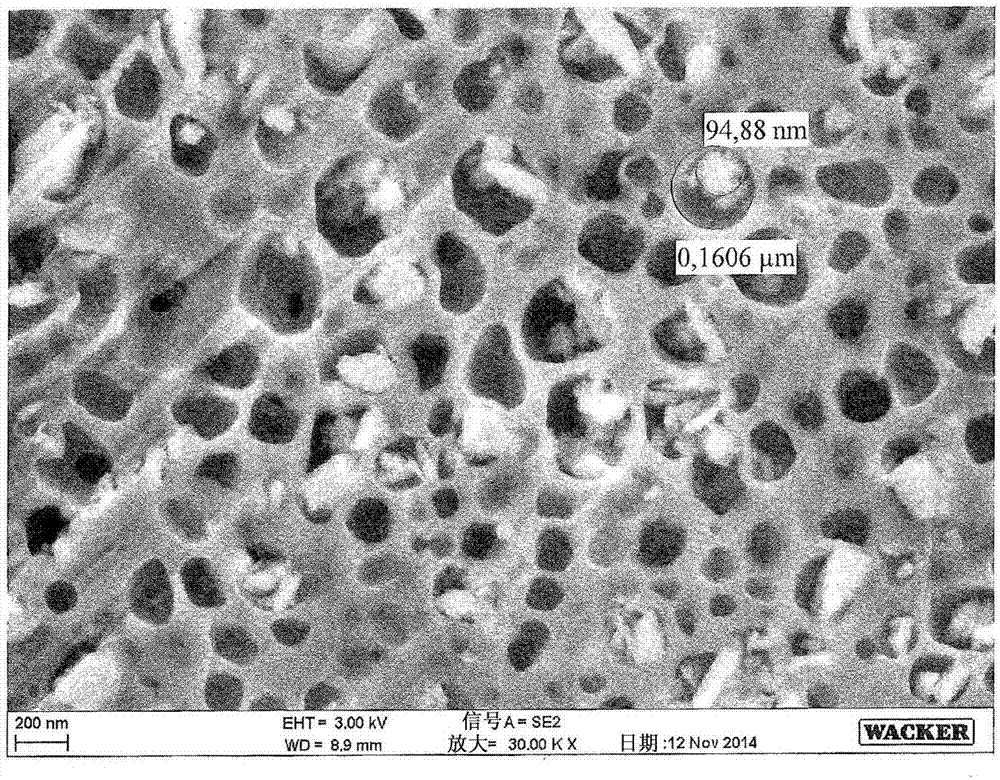

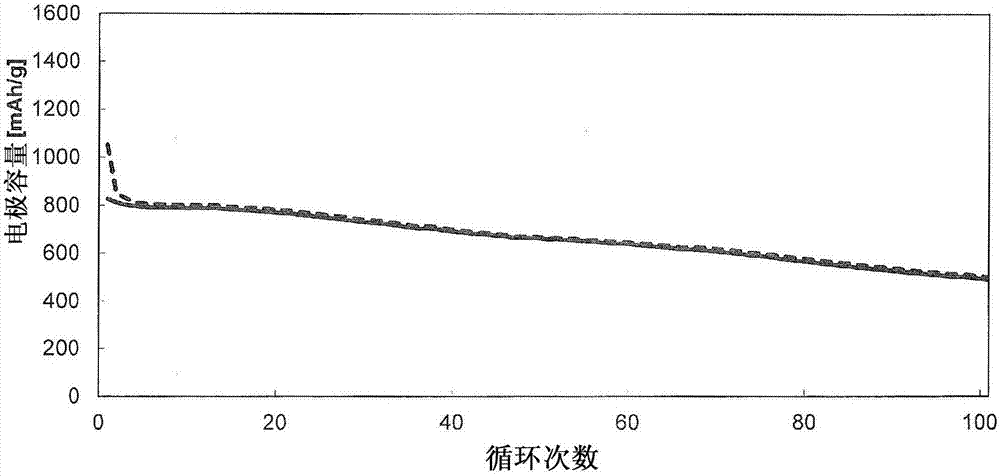

Composite core-shell particles

ActiveCN107431189AIncrease volume capacityImprove cycle stabilitySiliconSecondary cellsPorous carbonCarbonization

The invention relates to composite core-shell particles wherein the core is a porous, carbon-based matrix which contains silicon particles enclosed in pores of the matrix; the pores containing the silicon particles have a diameter of not less than 60 nm as determined by scanning electron microscopy (SEM); the shell can be obtained by carbonizing one or more carbon precursors selected from among the group comprising tars, pitches, hard carbon, soft carbon and hydrocarbons having 1 to 20 carbon atoms, resulting in a non-porous shell.

Owner:WACKER CHEM GMBH

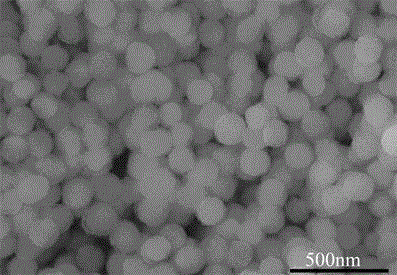

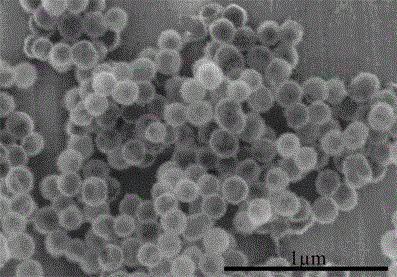

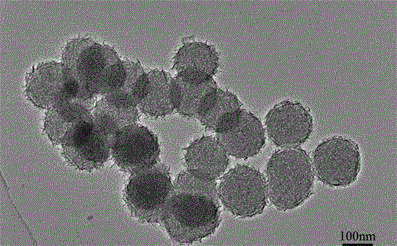

Sea-urchin-shaped nanometer nickel silicate hollow sphere and preparation method thereof

InactiveCN105129809APerfect control of size and shapeArbitrary control of morphologyMaterial nanotechnologySilicon compoundsNickel saltSilicic acid

The invention discloses a sea-urchin-shaped nanometer nickel silicate hollow sphere and a preparation method thereof. An appropriate quantity of silicon dioxide spherules and an appropriate amount of urea, soluble nickel salt and deionized water are added into a hydrothermal reaction kettle core, react for certain time inside a drying oven at the constant temperature of 80-150 DEG C and then are naturally cooled to indoor temperature; the prepared product is subjected to centrifugal washing and drying, an appropriate quantity of NaOH solutions and the product are together added into a hydrothermal reaction kettle and placed at the constant temperature of 100-200 DEG C to be subjected to hydrothermal reaction for certain time, and the product is subjected to centrifugal washing and drying and then calcined at certain temperature to prepare the sea-urchin-shaped nanometer nickel silicate hollow sphere. The prepared nickel silicate hollow sphere is tested by an X-ray diffractometer, a scanning electron microscope and a transmission electron microscope and is in a sea urchin shape, the wall of the sphere is quite thin, the specific surface area is large, particle size distribution is even, and the nickel silicate hollow sphere can serve as a material for manufacturing an electrochromic device and an electrode material for manufacturing a super capacitor.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

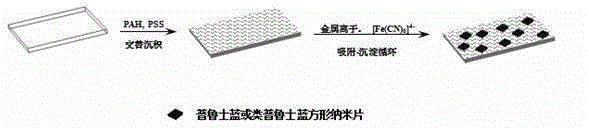

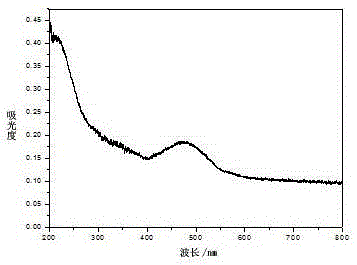

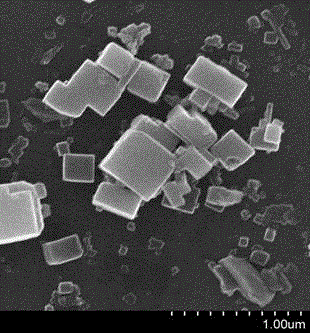

Prussian blue and Prussian blue analogue nanosheet film materials and in-situ preparation method thereof

The invention discloses Prussian blue and Prussian blue analogue nanosheet film materials and an in-situ preparation method thereof. A substrate is modified with two high-molecular polymers with opposite charges, namely PAH (poly allylamine hydrochloride) and PSS (sodium polystyrene sulfonate), and Prussian blue or Prussian blue analogue square nanosheets are synthesized in situ on the modified substrate with metal ionic salt and potassium ferrocyanide as raw materials. A test of a prepared nanosheet film through ultraviolet-visible spectroscopy, a scanning electron microscope and a transmission electron microscope proves that the nanosheets have controllable size and are uniformly dispersed. The growth direction of the nanosheets is limited by the porous network of the high-molecular polymers, so that the nanosheets are square or rectangular, water is used as a solvent in the whole preparation process of the film and is harmless to the environment, the preparation process is simple and feasible, the cost is low, equipment is simple, the film materials with different kinds of functionality are obtained by changing the variety of simple ions, and the in-situ preparation method has important application value in the field of material preparation.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Measuring method for dislocation density of heteroepitaxially grown gallium nitride

InactiveCN103487453AConvenient and quick analysis testAccurately Calculate DensityPreparing sample for investigationScanning probe microscopyPotassium hydroxideAfm atomic force microscopy

The invention relates to a method for observing the dislocation type of a heteroepitaxial growth material of gallium nitride (GaN) and measuring the dislocation density. The method is characterized by directly observing the dislocation type of the surface of a gallium nitride epitaxial film by using etching of molten potassium hydroxide and a potassium hydroxide and magnesia eutectic mixture in combination with a scanning electron microscope and an atomic force microscope, analyzing and researching the characteristics and the distribution of dislocations of different types and calculating the dislocation density. The method is convenient and fast and is suitable for analytical testing of nitrides which grow through different processes. The characteristics of dislocations of different types in different nitride samples can be researched to obtain the distribution of various dislocations on the surface, and the densities and the total dislocation density of the dislocations of various types can be accurately calculated.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

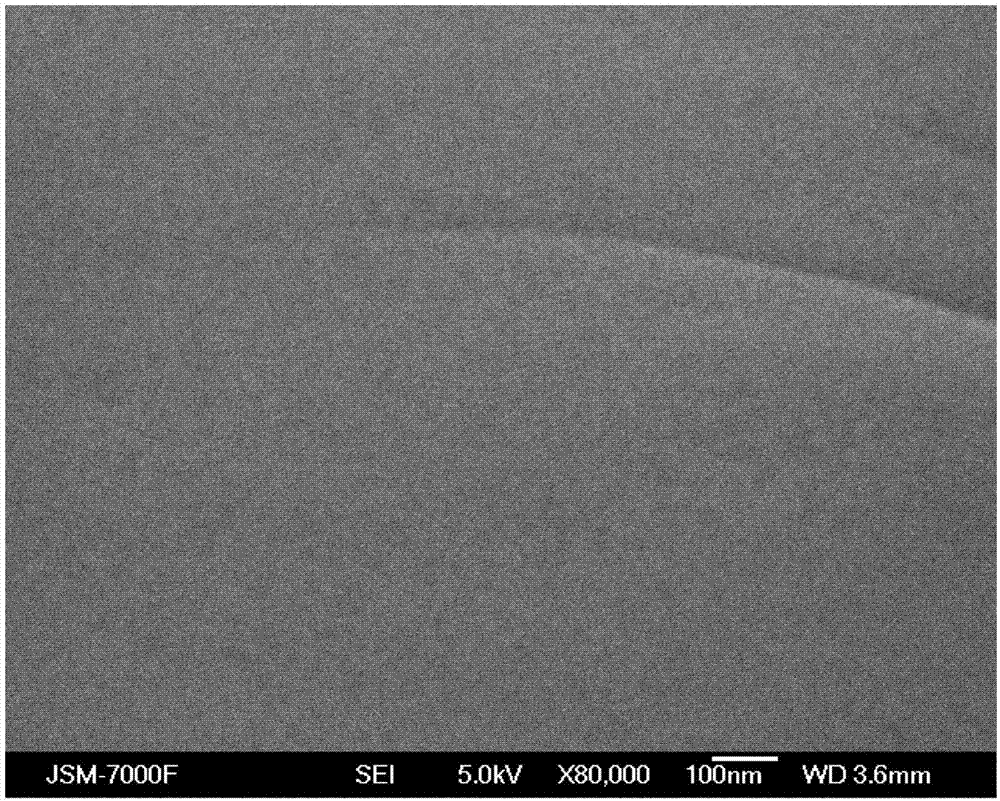

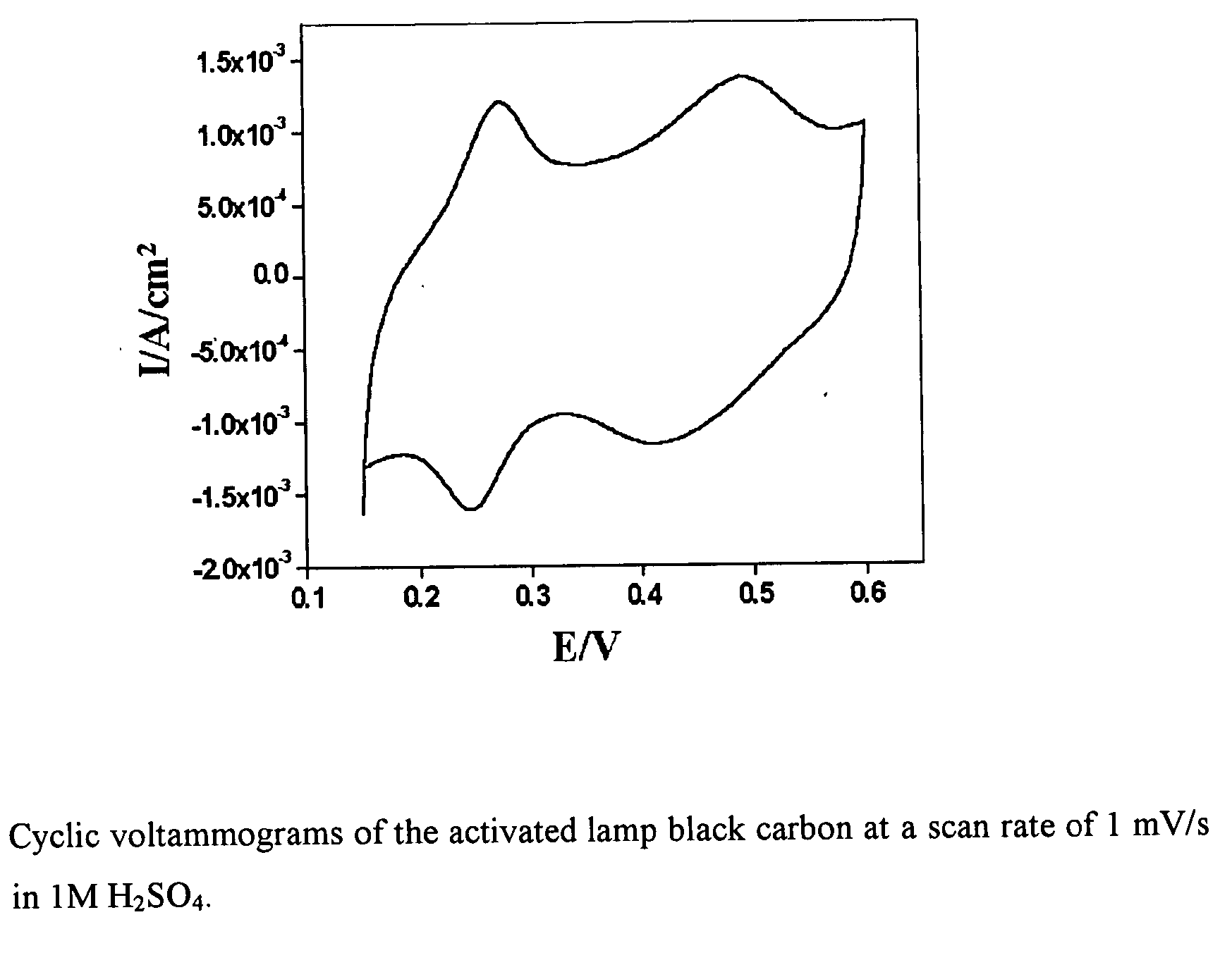

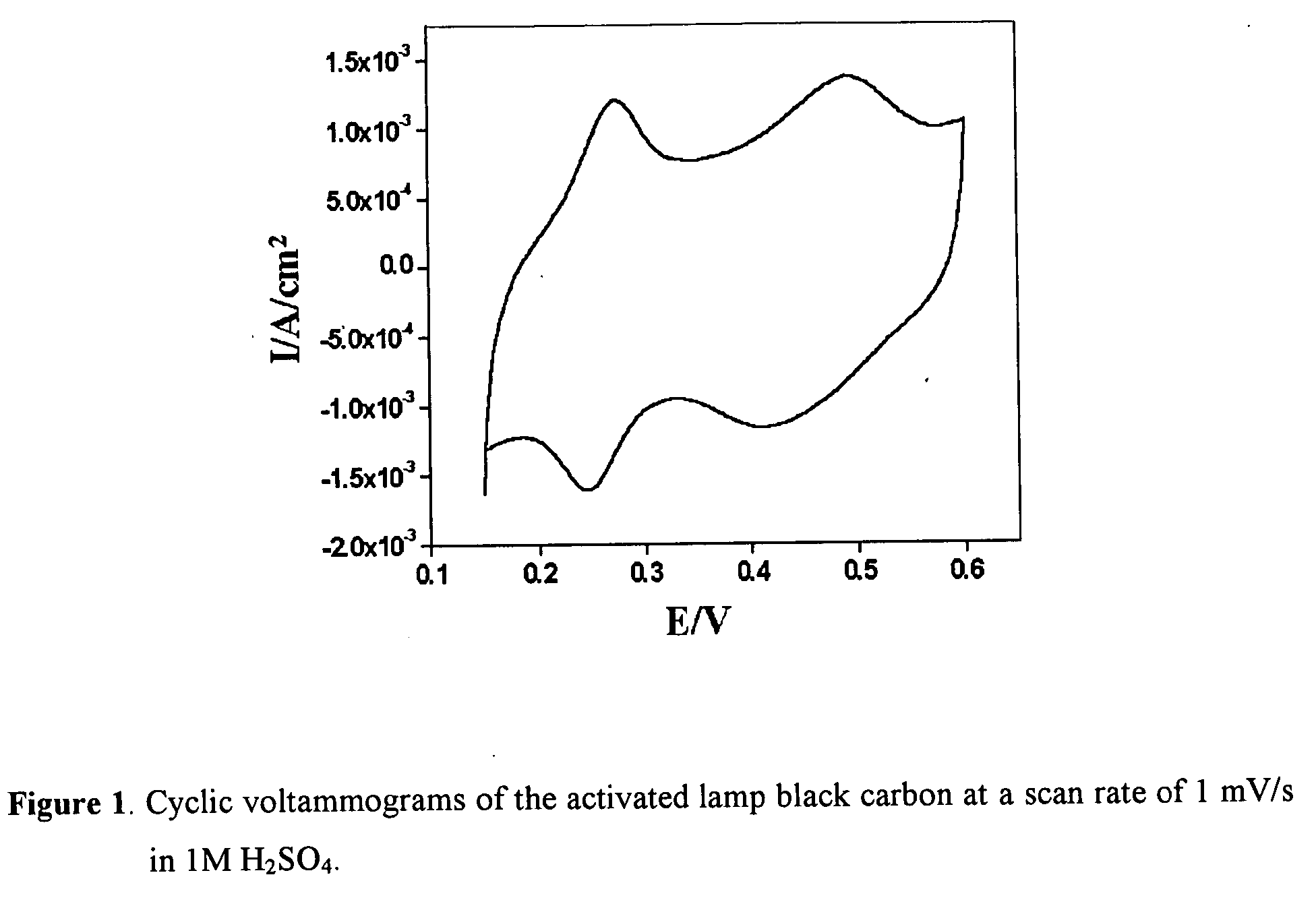

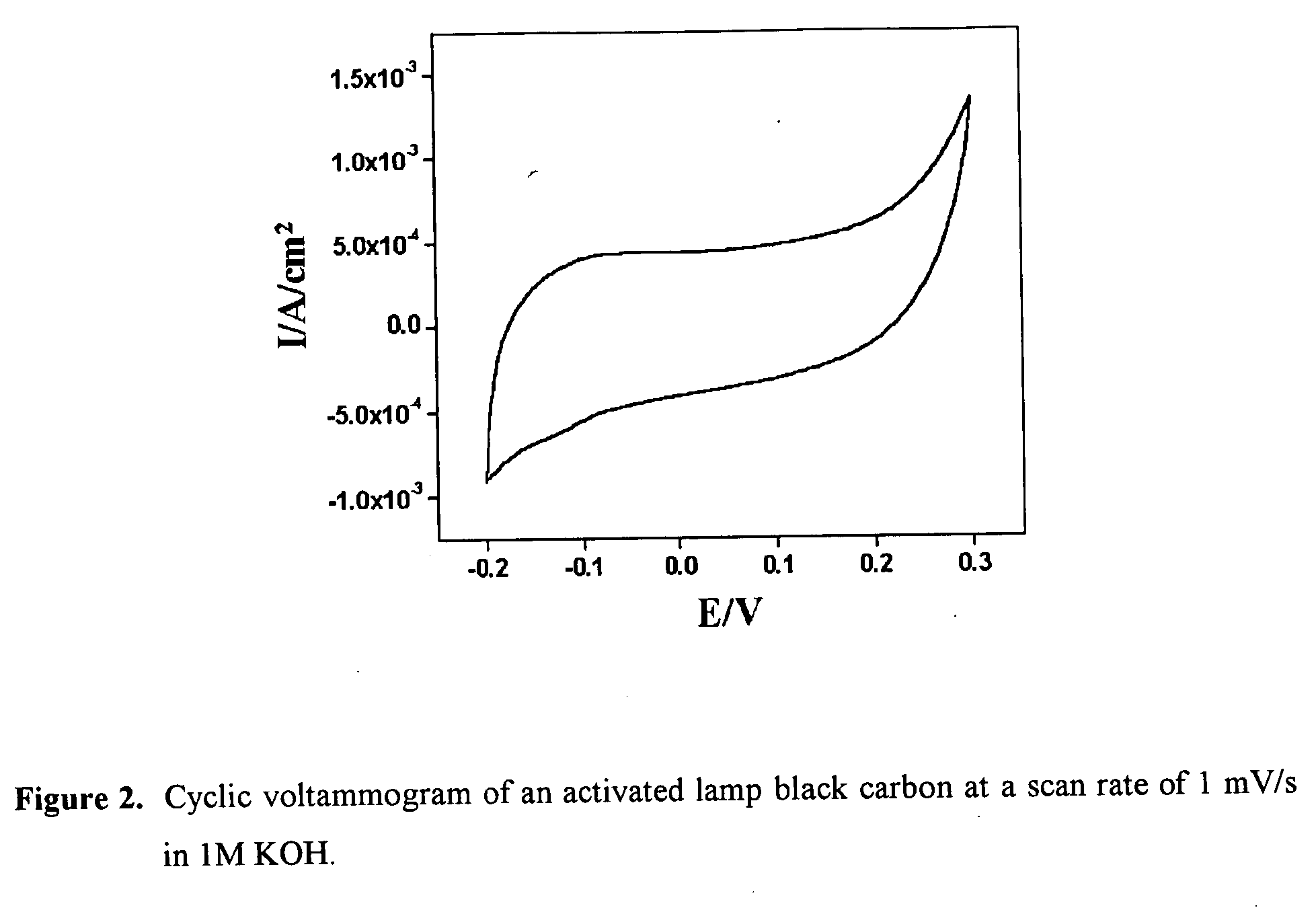

Process for fabrication of ultracapacitor electrodes using activated lamp black carbon

InactiveUS20060000071A1Easy to manufactureHybrid capacitor electrodesDouble layer capacitorsCapacitanceNitrogen gas

Activated carbon obtained from lamp black has a potential application as an electrode material for ultracapacitor. The process involves activation of the lamp black carbon in the temperature range of 600-900° C. for 5-9 hours in an inert atmosphere of nitrogen and argon followed by cooling to room temperature. Cyclic voltammetric studies reveal that the obtained activated carbon has a specific capacitance values in the range 50-82 F / g in 1M H2SO4, and 10-25 F / g in 1M KOH. The activated carbon has a highly porous nature as realized from scanning electron microscopy and has specific (BET) surface area in the range of 300-400 m2 / g.

Owner:COUNCIL OF SCI & IND RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com