Method for preparing grapheme through organic amine solvothermal method

An organic solvent and organic amine technology, which is applied in the field of preparing large sheets of high-quality graphene by organic amine solvothermal method, can solve the problems that graphene cannot take into account the output, graphene quality, poor quality of graphene, etc., and achieves good application prospects and oxidation degree. Light, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

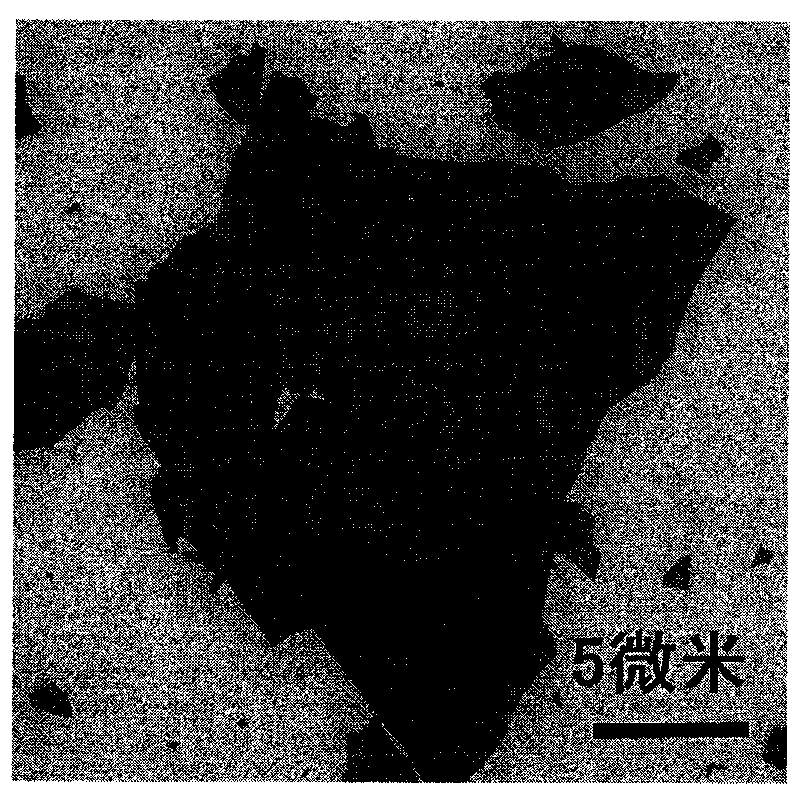

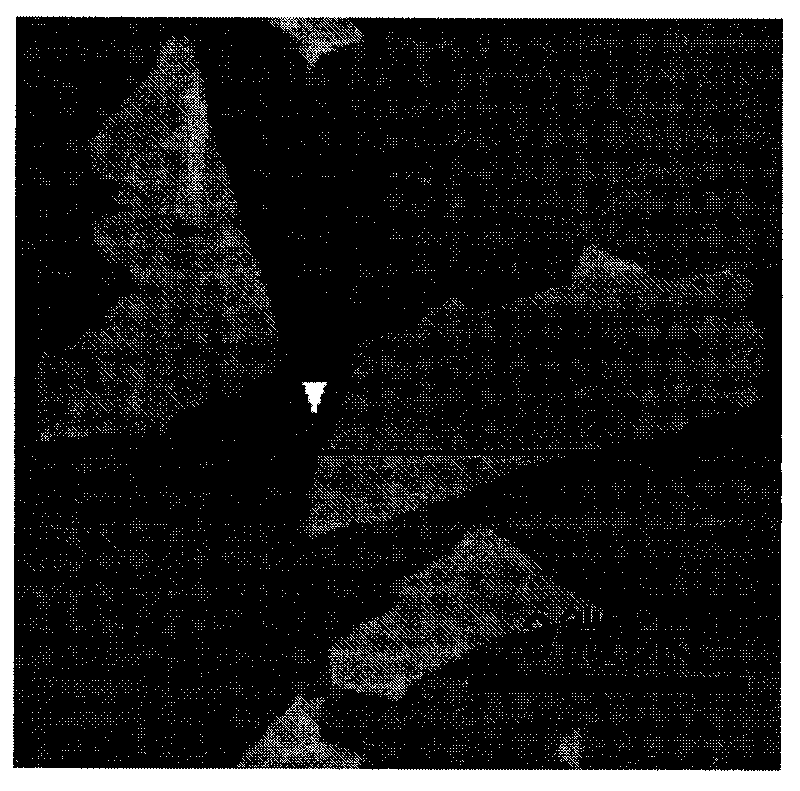

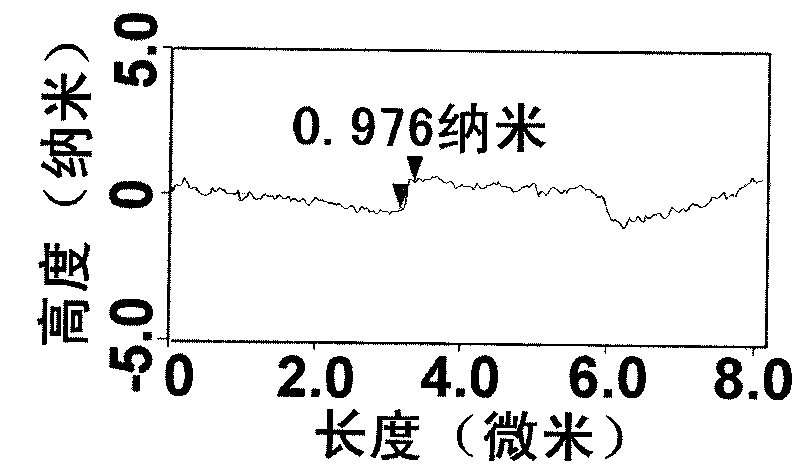

[0044] Embodiment 1, prepare graphene

[0045] 1) Preparation of expanded graphite

[0046] Under the condition of water bath at 20°C, add 15ml of sulfuric acid with a mass fraction of 95% and 5ml of concentrated nitric acid with a mass fraction of 65% into a 50ml three-neck flask, add 1g of graphite and 0.01g of potassium dichromate to the above mixed acid solution, and keep stirring at 30°C 40 minutes. After the reaction was completed, the mixture was poured into 200ml of water, vacuum filtered, the filter residue was rinsed with double distilled water, and the filter residue was dried at 50°C for 12 hours to obtain a large amount of black solid, namely expanded graphite.

[0047] 2) Preparation of graphene semi-dispersion

[0048] Add 30 mg of expanded graphite to 10 ml of oleylamine. Sealed in an autoclave under a nitrogen-protected environment, reacted at 170°C for 72h, and cooled to room temperature to obtain pasty semi-dispersed graphene.

[0049] 3) Preparation of ...

Embodiment 2

[0069] Embodiment 2, prepare graphene

[0070] The preparation method of graphene is basically the same as embodiment 1. The difference is: when preparing expanded graphite, 0.01 gram of potassium dichromate in Example 1 was replaced with 0.01 gram of potassium permanganate. Single-layer graphene can also be obtained with this method (see Figure 9 ).

Embodiment 3

[0071] Embodiment 3, prepare graphene

[0072] The preparation method of graphene is basically the same as embodiment 1. The difference is that when the graphene semi-dispersion is prepared, the reaction temperature is changed to 150°C, and graphene can also be obtained, but the concentration of the graphene dispersion is as low as 0.05mg / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com