Patents

Literature

761 results about "Cleaning station" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cleaning station is a location where aquatic life congregate to be cleaned by smaller creatures. Such stations exist in both freshwater and marine environments, and are used by animals including fish, sea turtles and hippos.

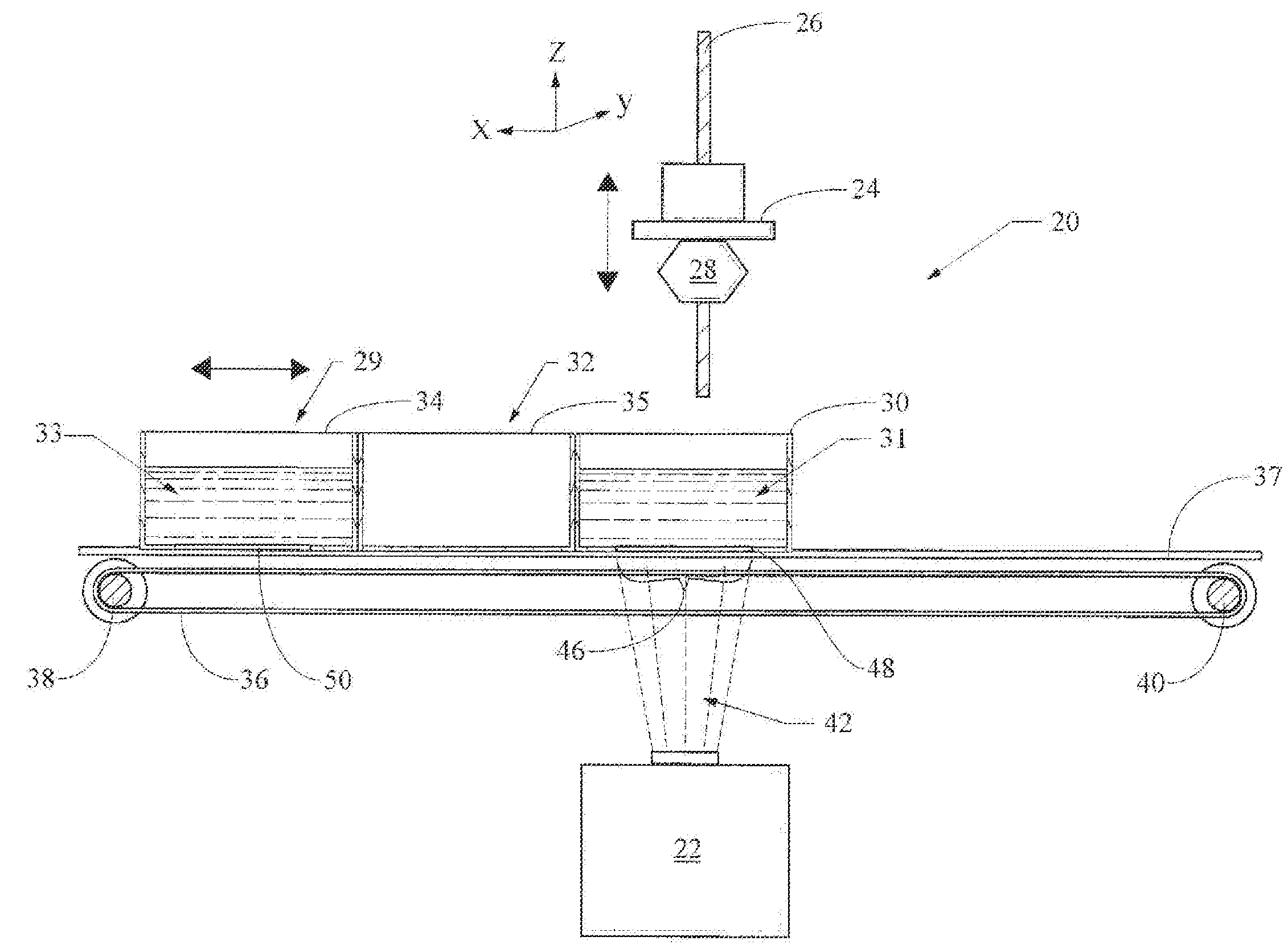

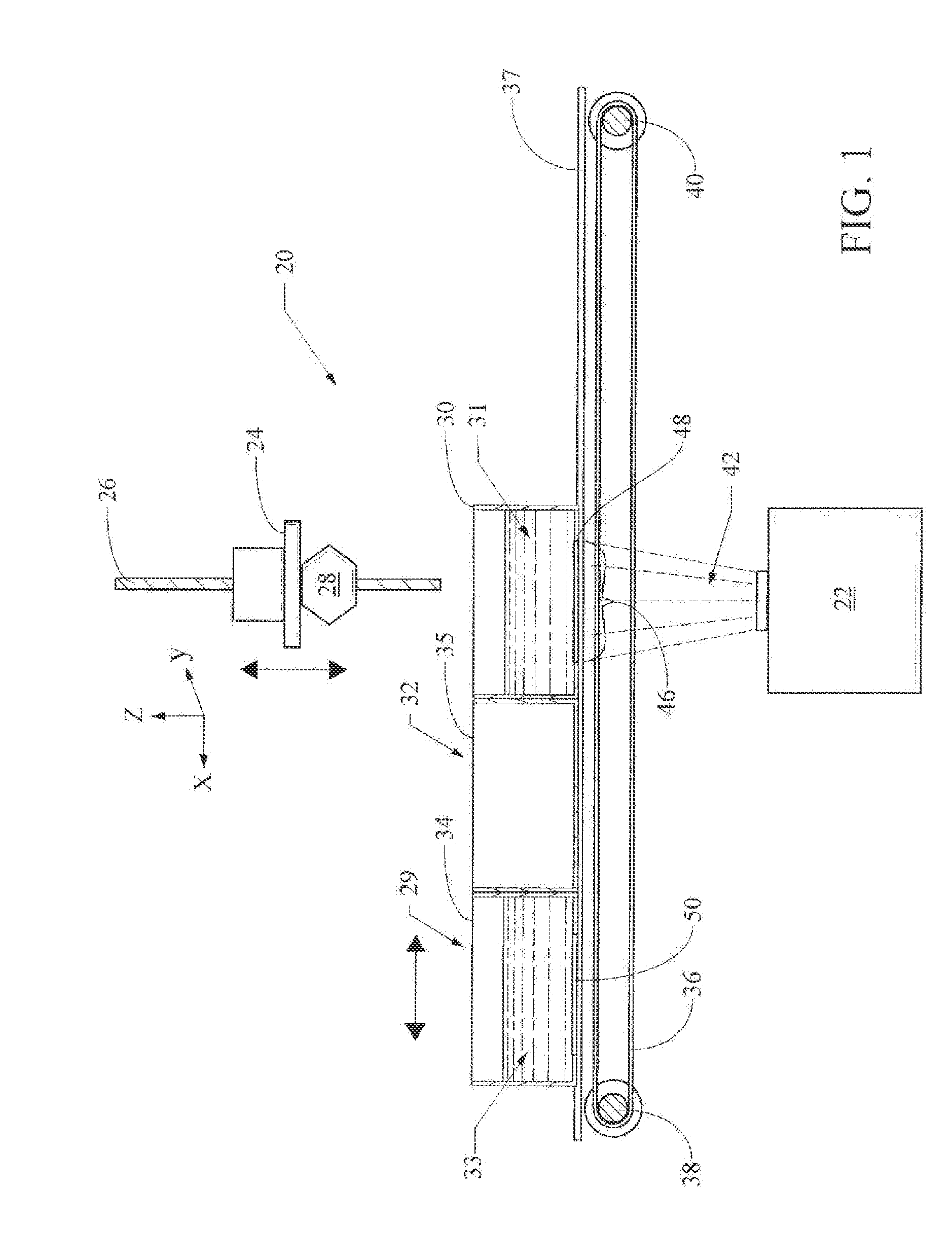

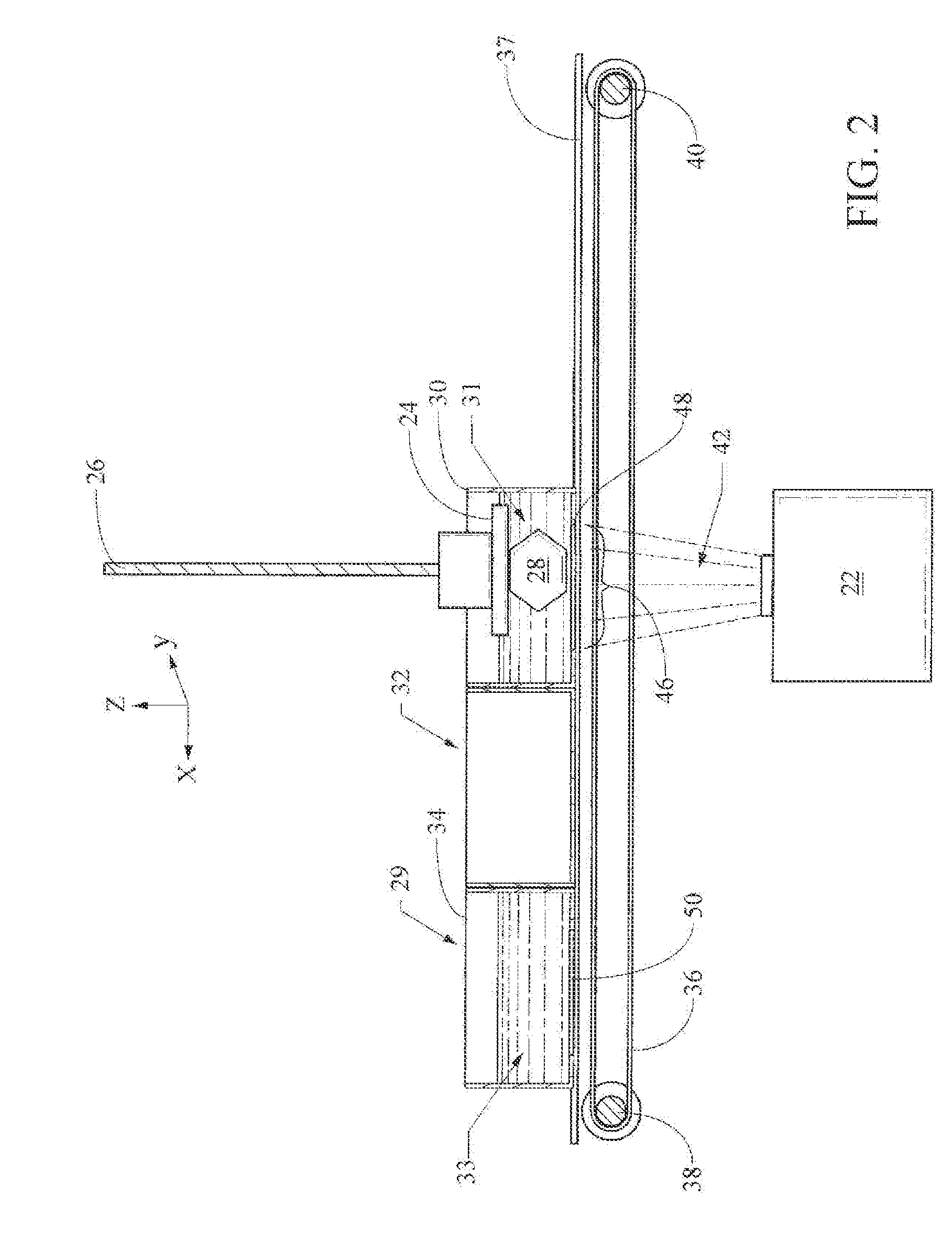

Method and apparatus for making three-dimensional objects from multiple solidifiable materials

Owner:GLOBAL FILTRATION SYST

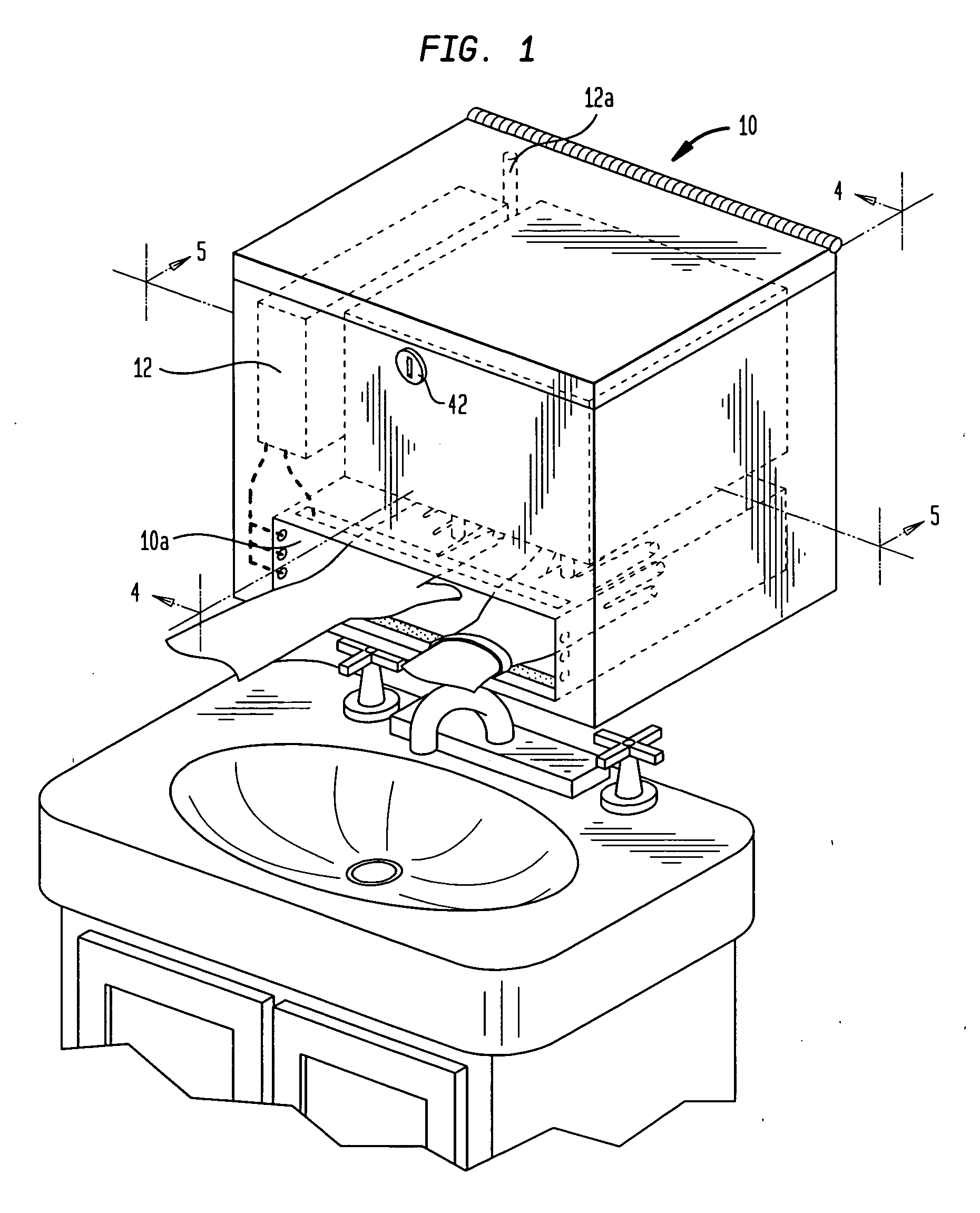

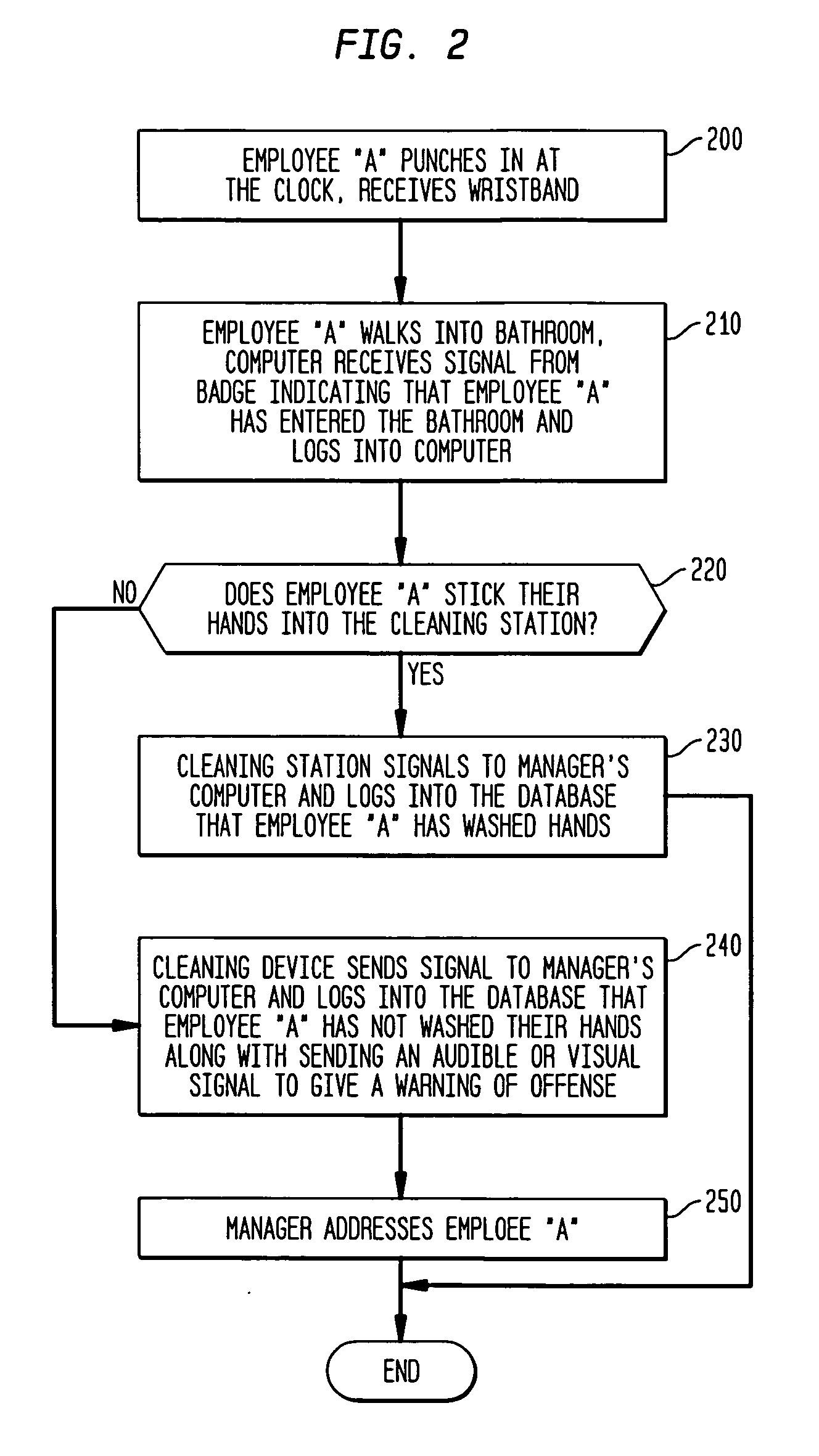

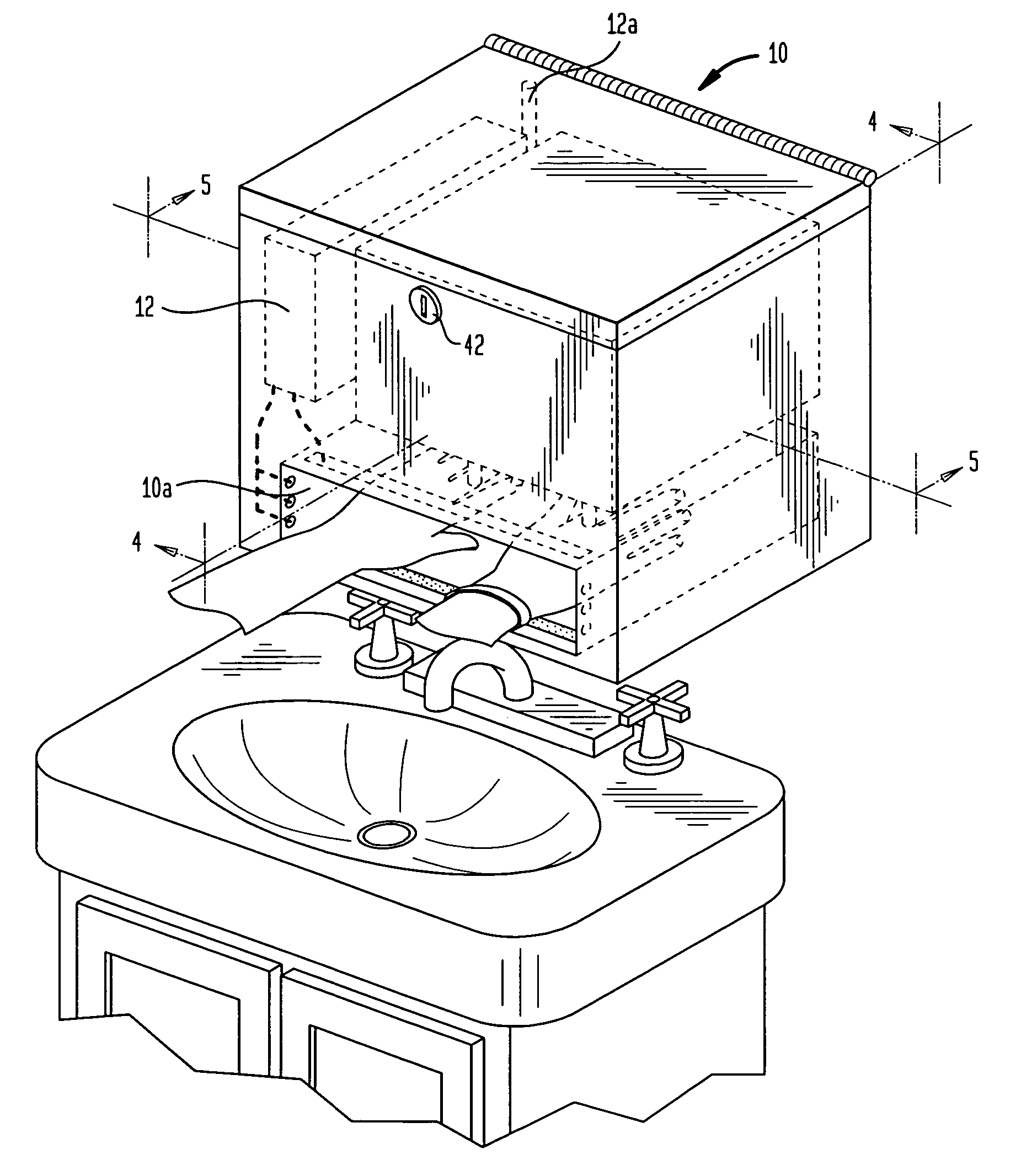

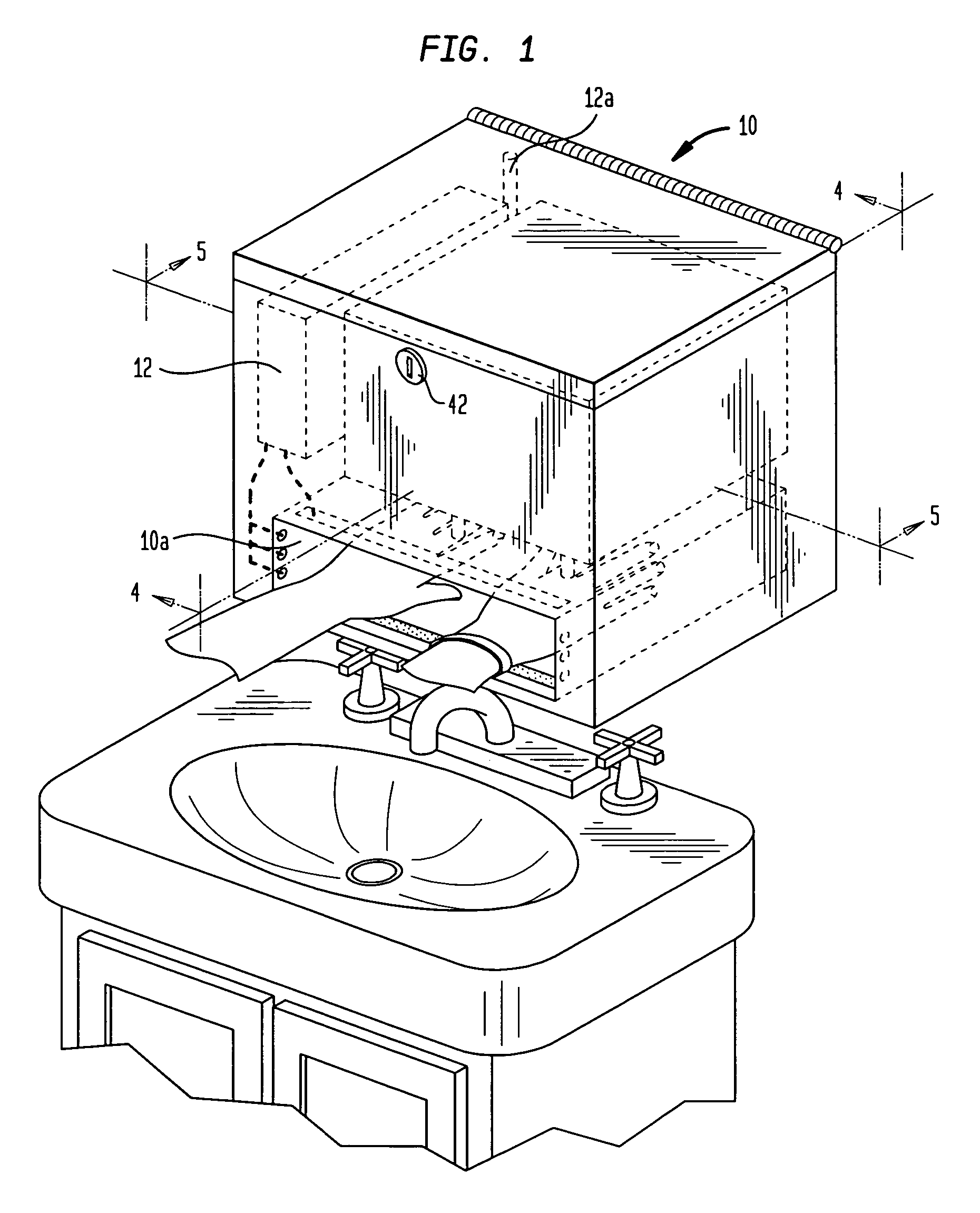

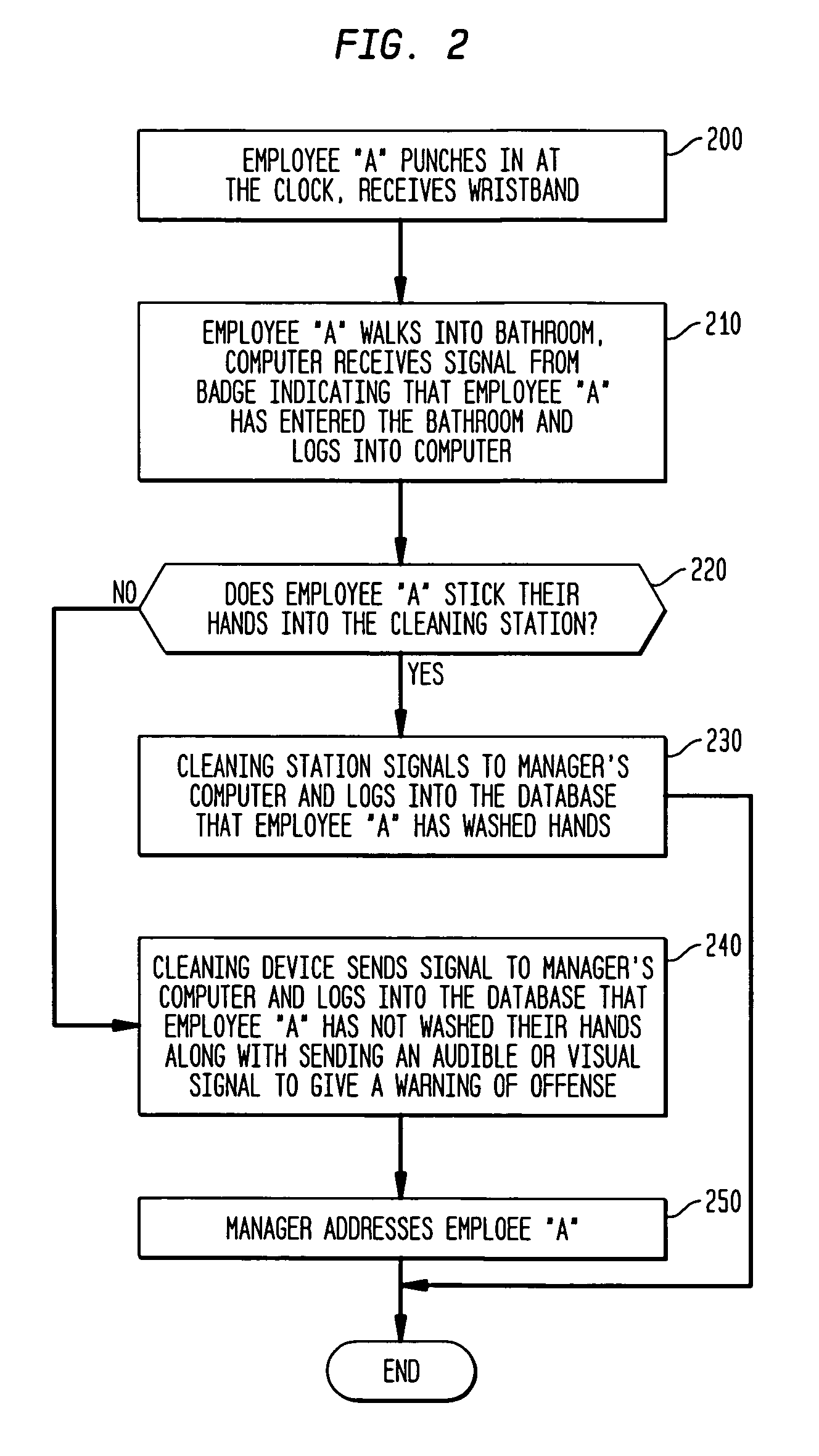

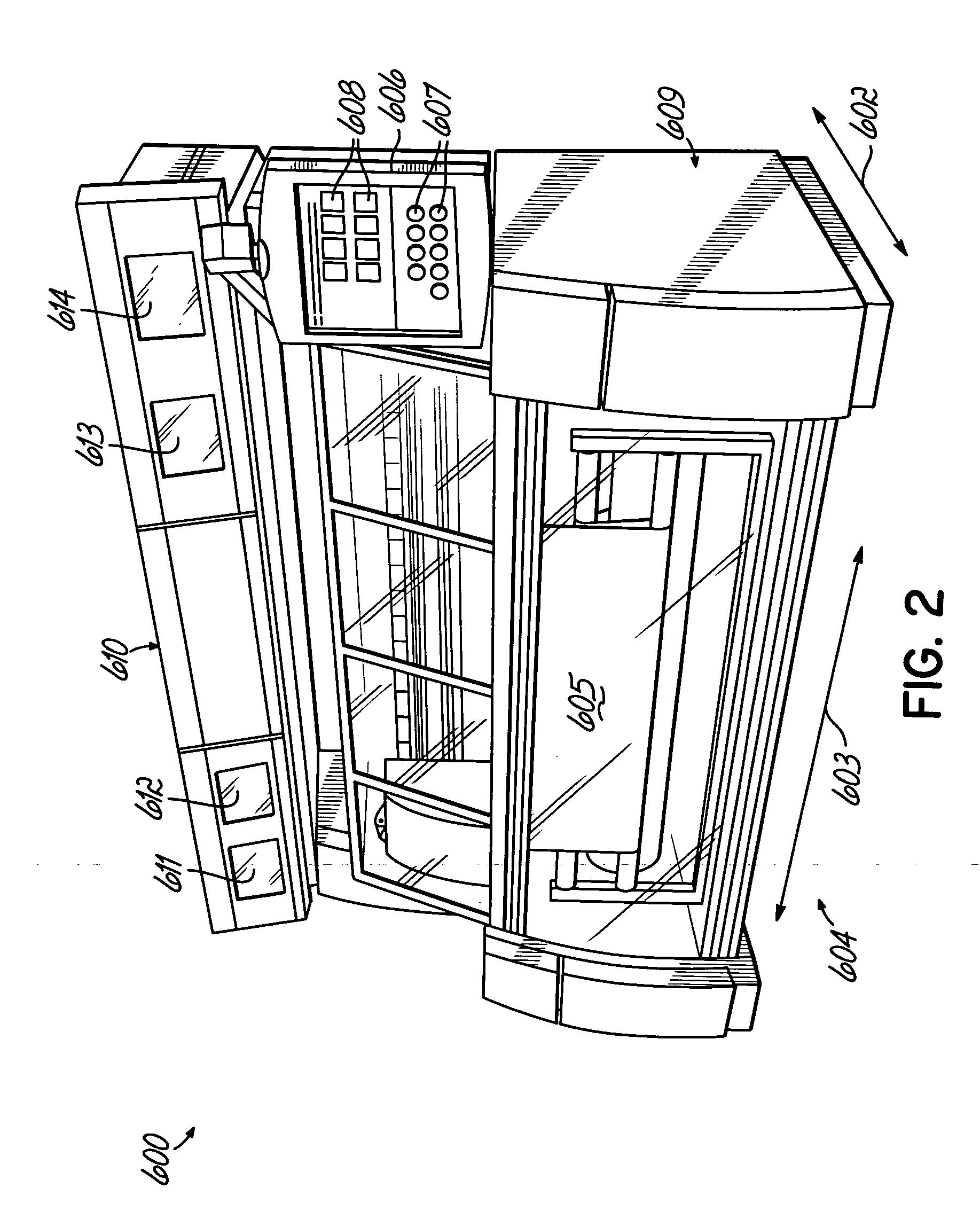

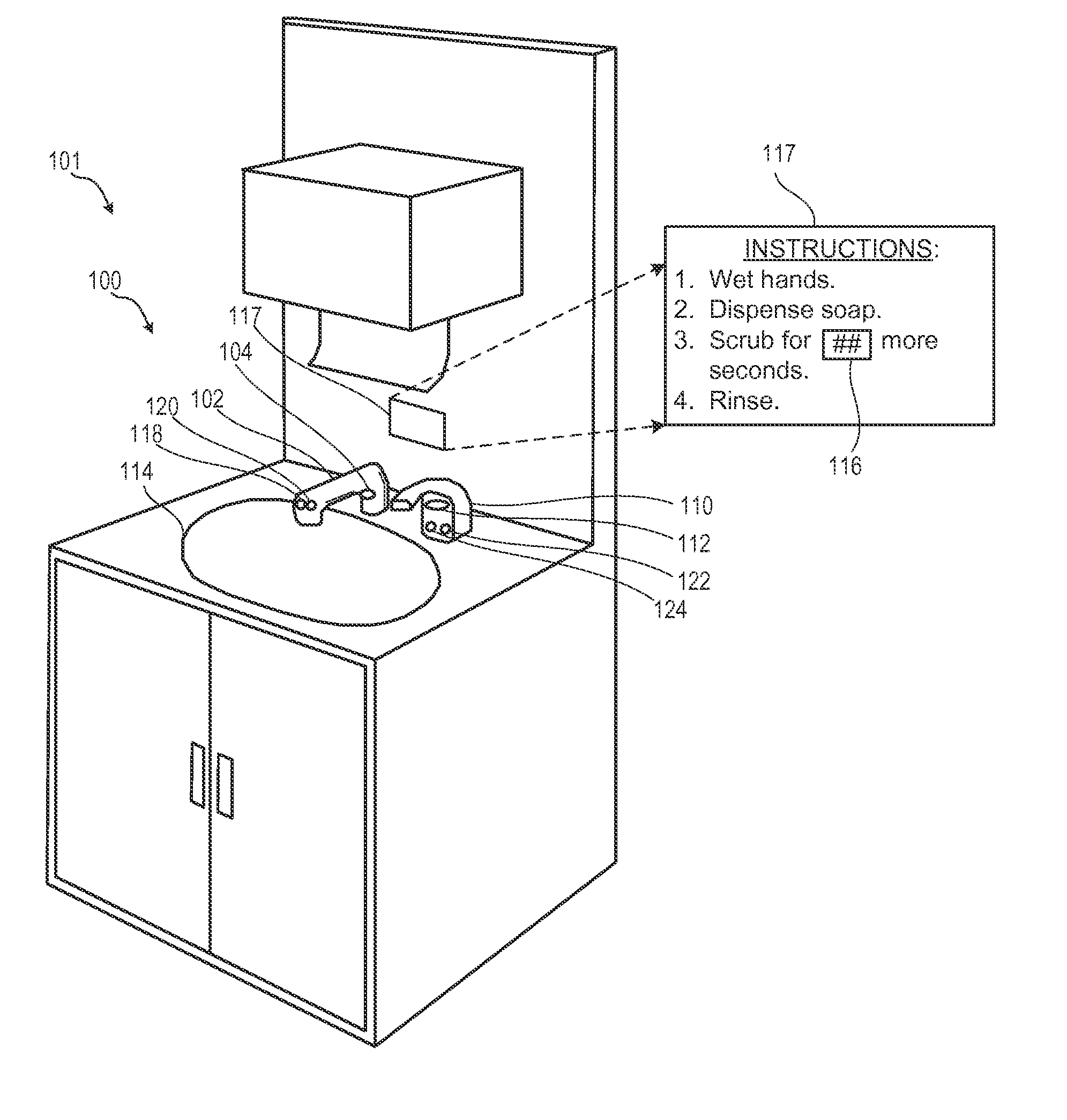

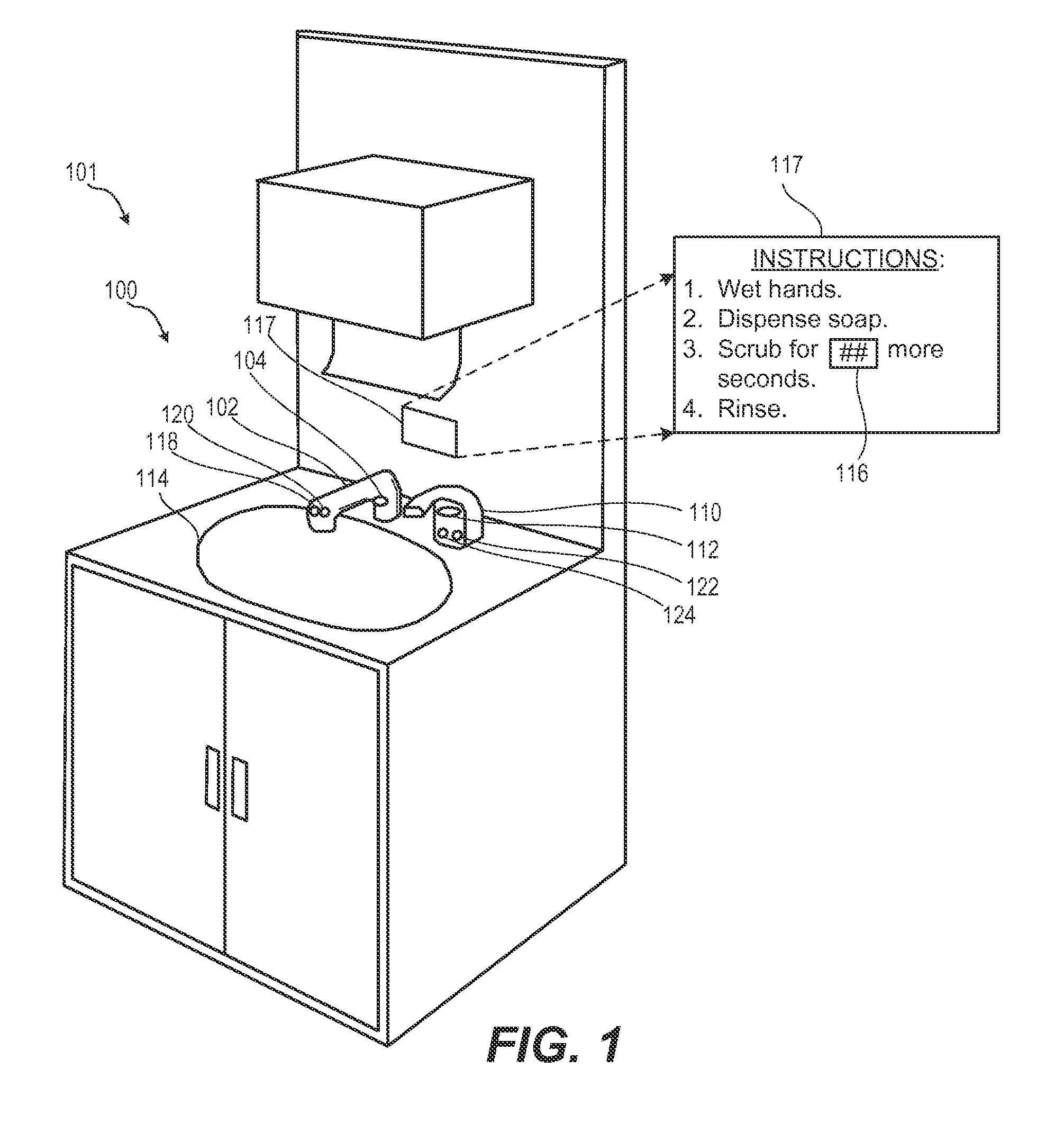

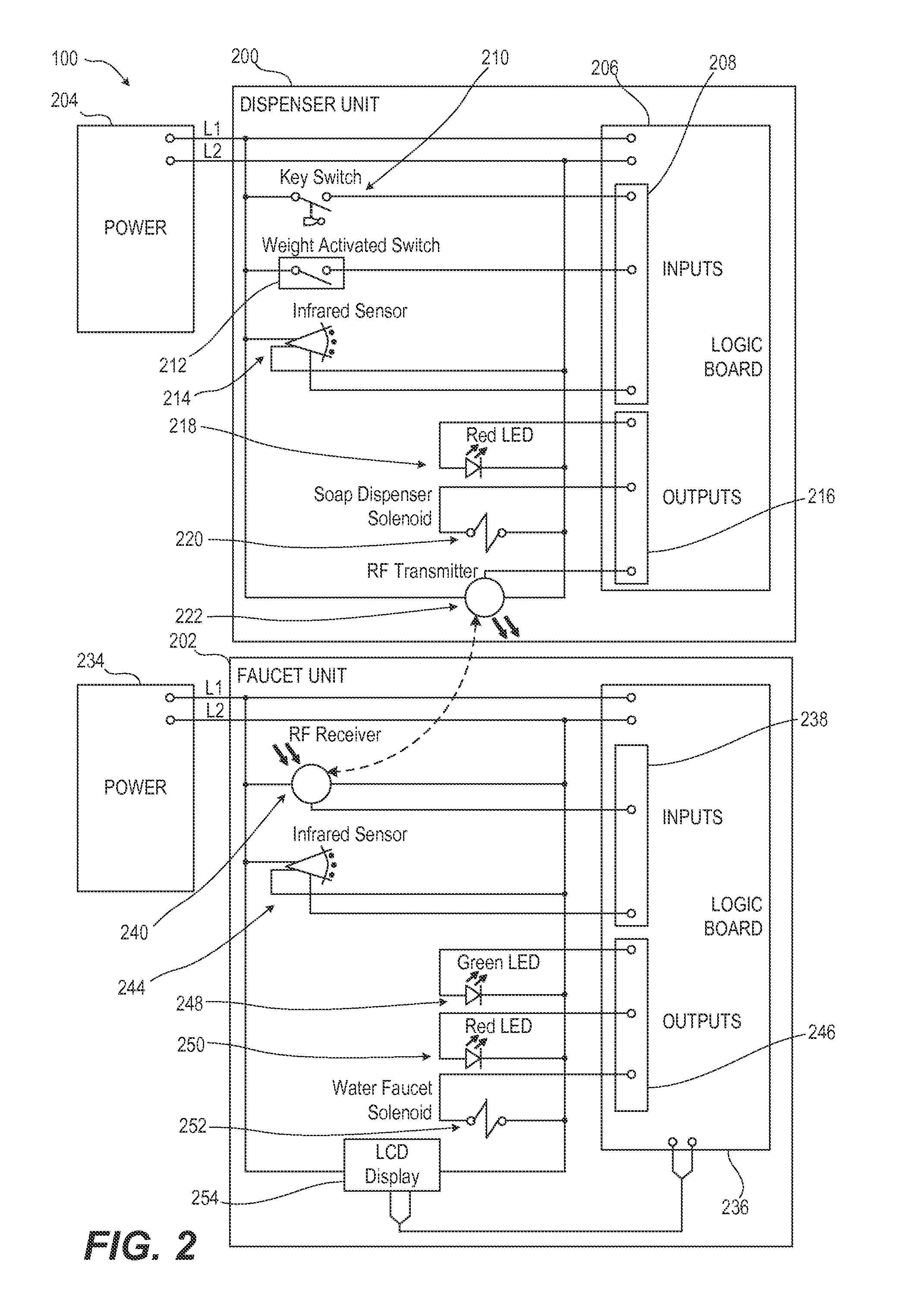

Hand wash monitoring system and method

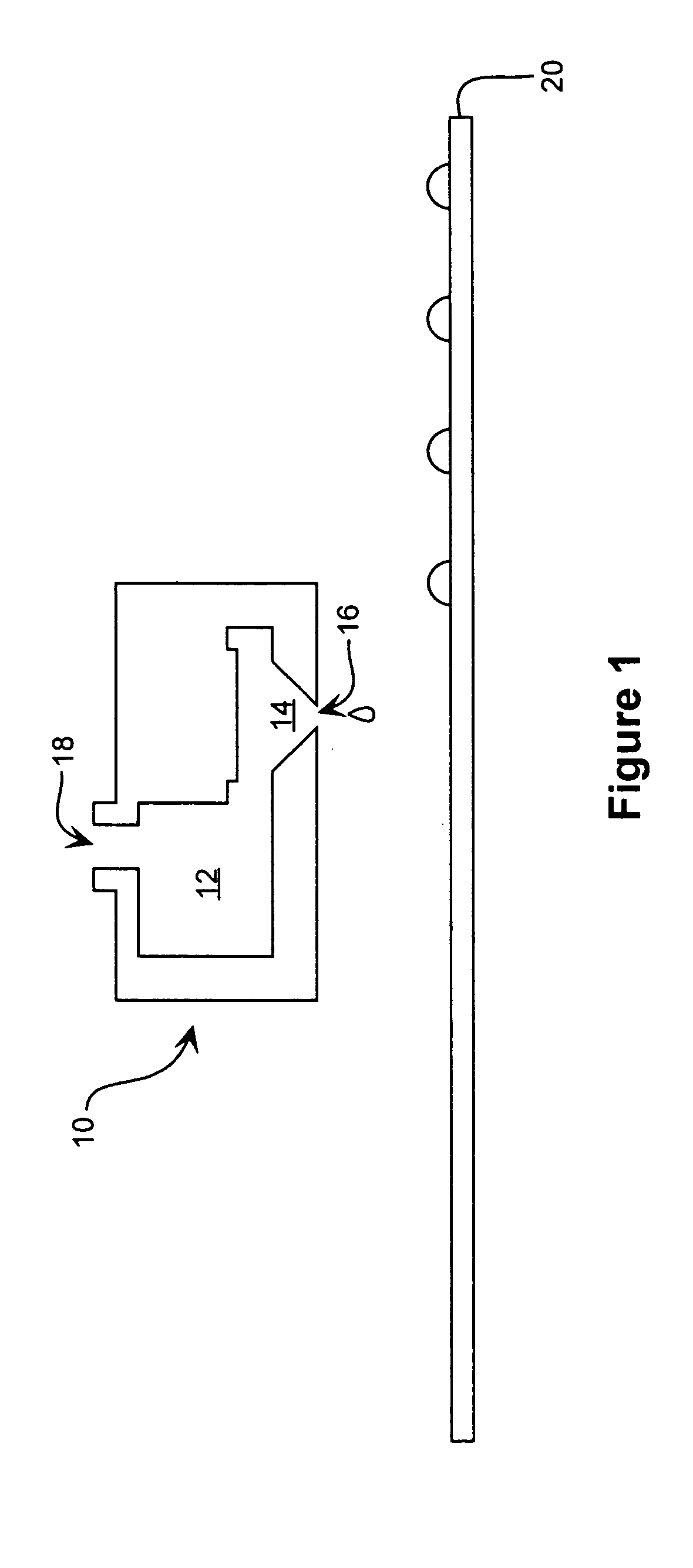

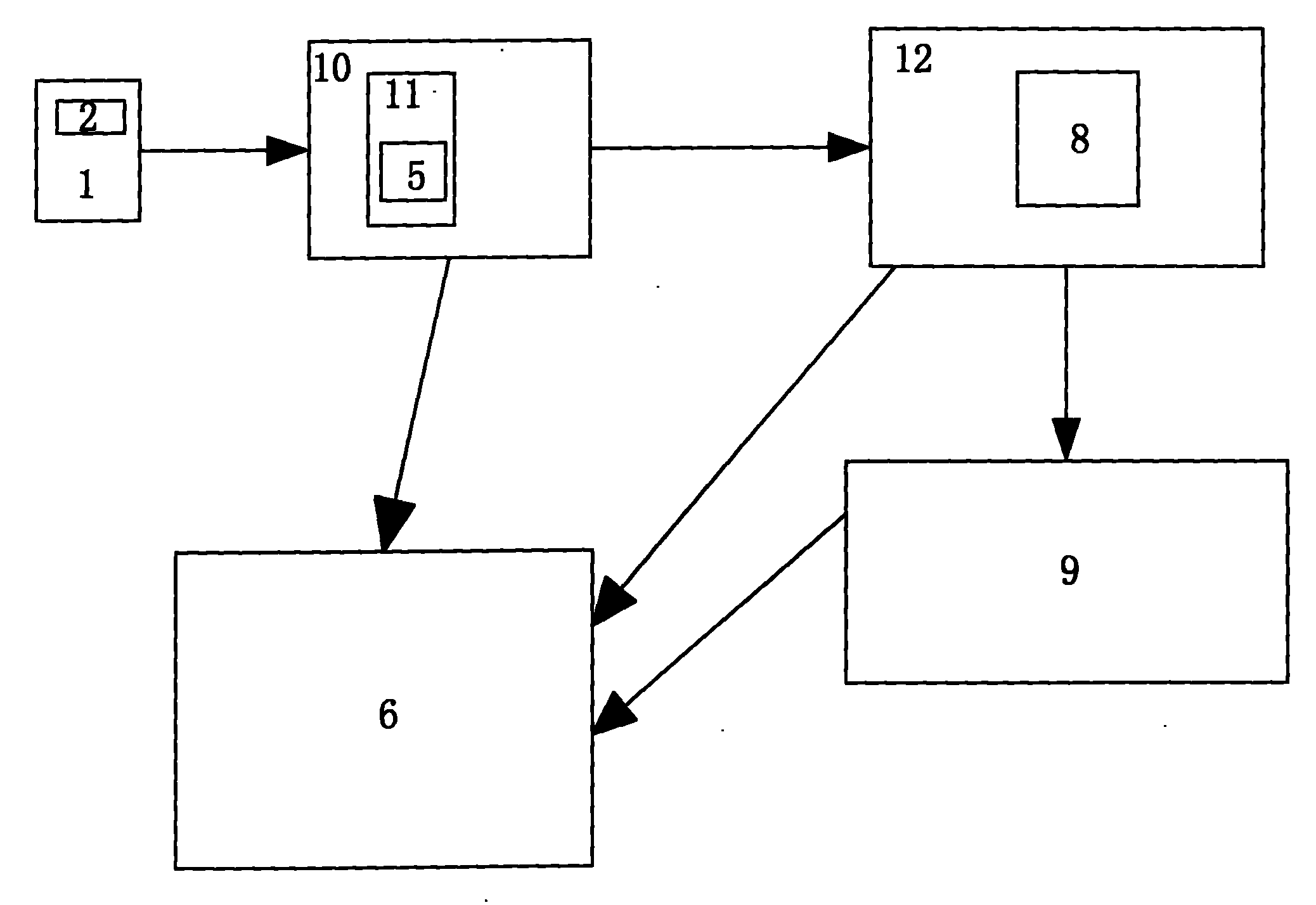

An identification badge worn by an individual is sensed when that individual enters a lavatory. The individual is also provided with an indication device which is worn on or about the hands. Inside the lavatory, there is also provided a hand cleaning station which includes a sensor that determines whether the indicating device is in close proximity and dispenses soap on the individual's hands, then provides an appropriate indication to a computer system. Should the badge sensor sense the individual's departure from the lavatory without an appropriate indication being generated by the indicator sensor, a warning signal is generated, which is sent to the computer system and to an appropriate officer, who can then address the individual.

Owner:VERDIRAMO VINCENT L

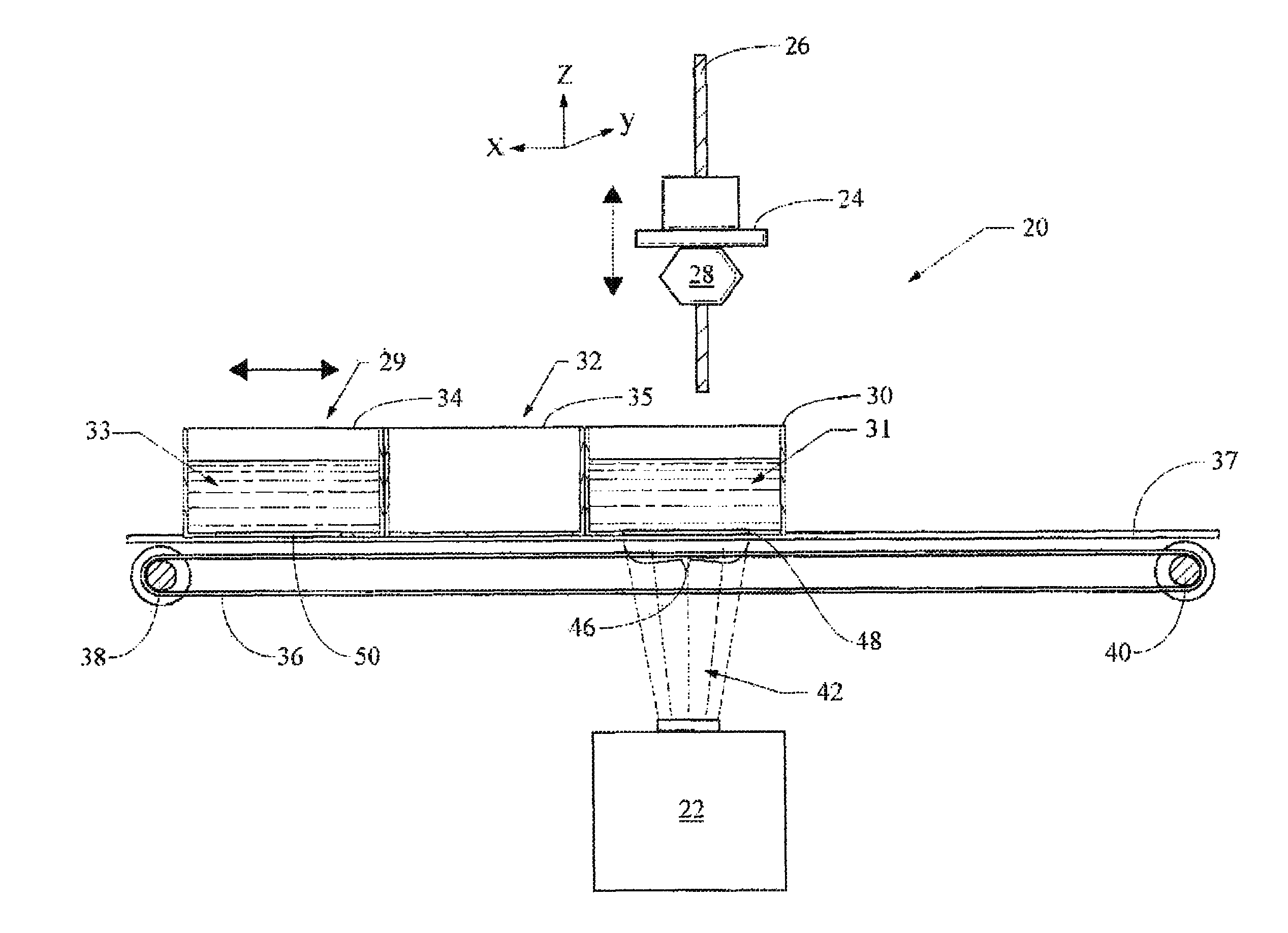

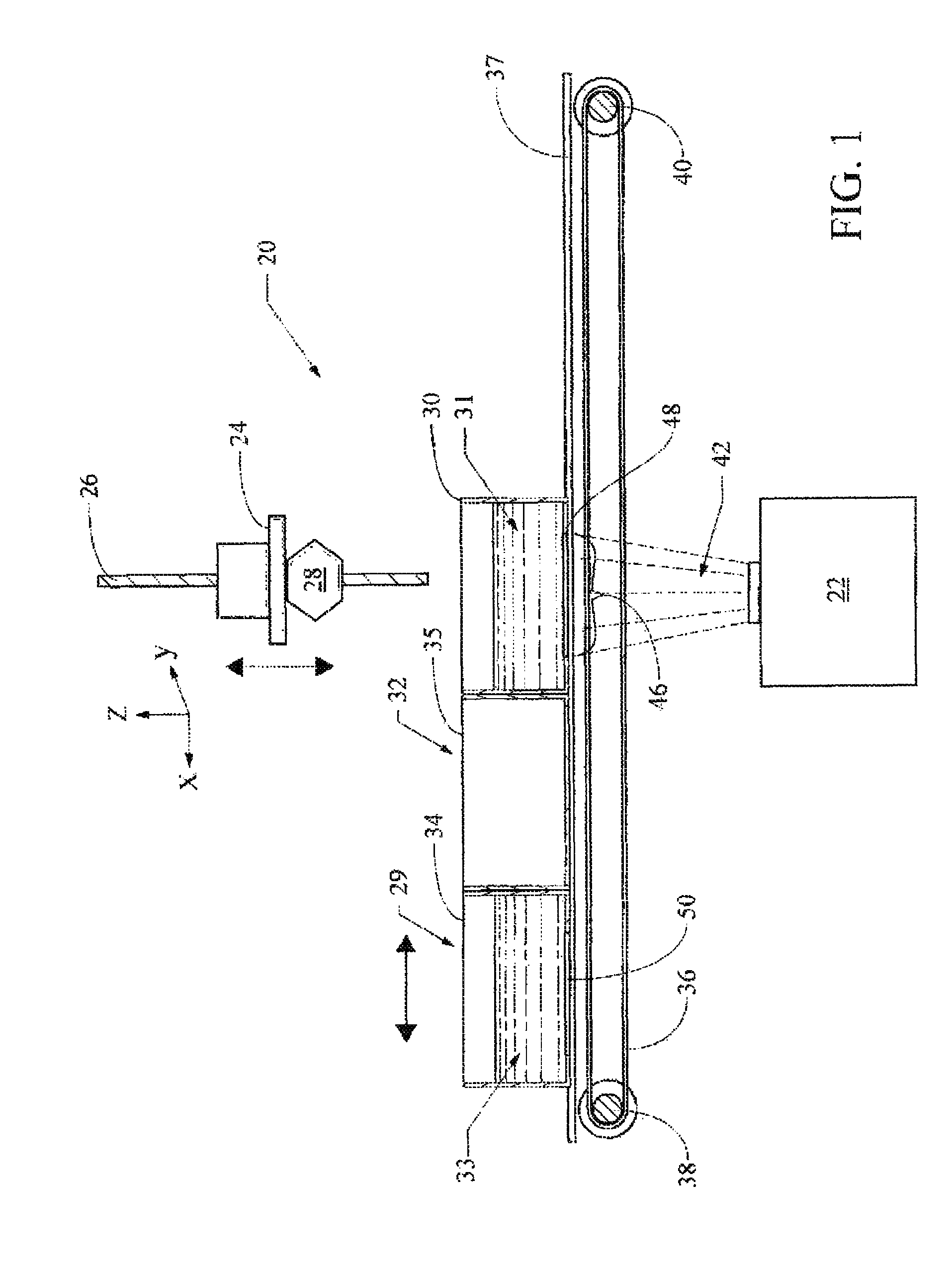

Method and apparatus for making three-dimensional objects from multiple solidifiable materials

Owner:GLOBAL FILTRATION SYST

Hand wash monitoring system and method

An identification badge worn by an individual is sensed when that individual enters a lavatory. The individual is also provided with an indication device which is worn on or about the hands. Inside the lavatory, there is also provided a hand cleaning station which includes a sensor that determines whether the indicating device is in close proximity and dispenses soap on the individual's hands, then provides an appropriate indication to a computer system. Should the badge sensor sense the individual's departure from the lavatory without an appropriate indication being generated by the indicator sensor, a warning signal is generated, which is sent to the computer system and to an appropriate officer, who can then address the individual.

Owner:VERDIRAMO VINCENT L

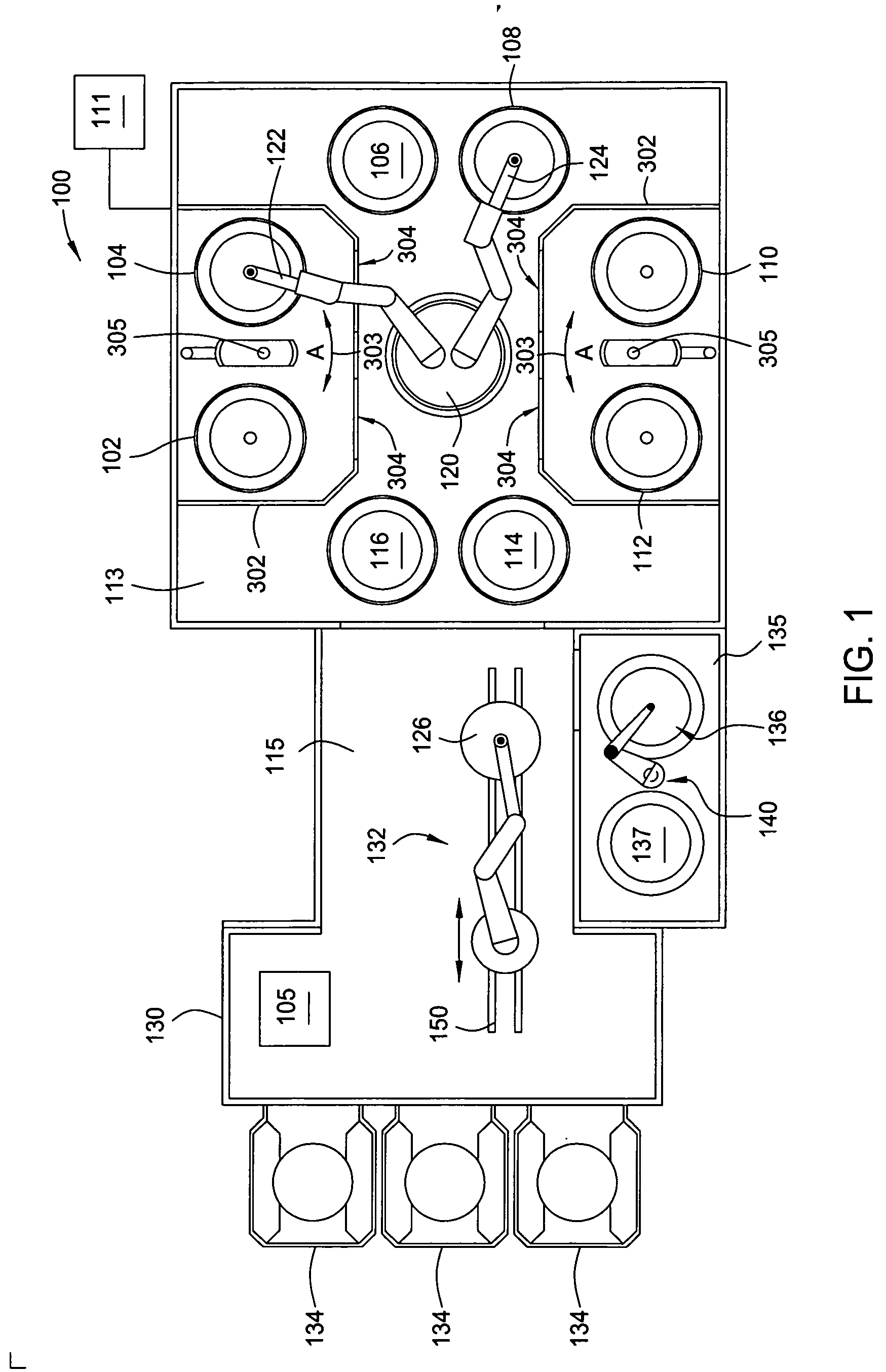

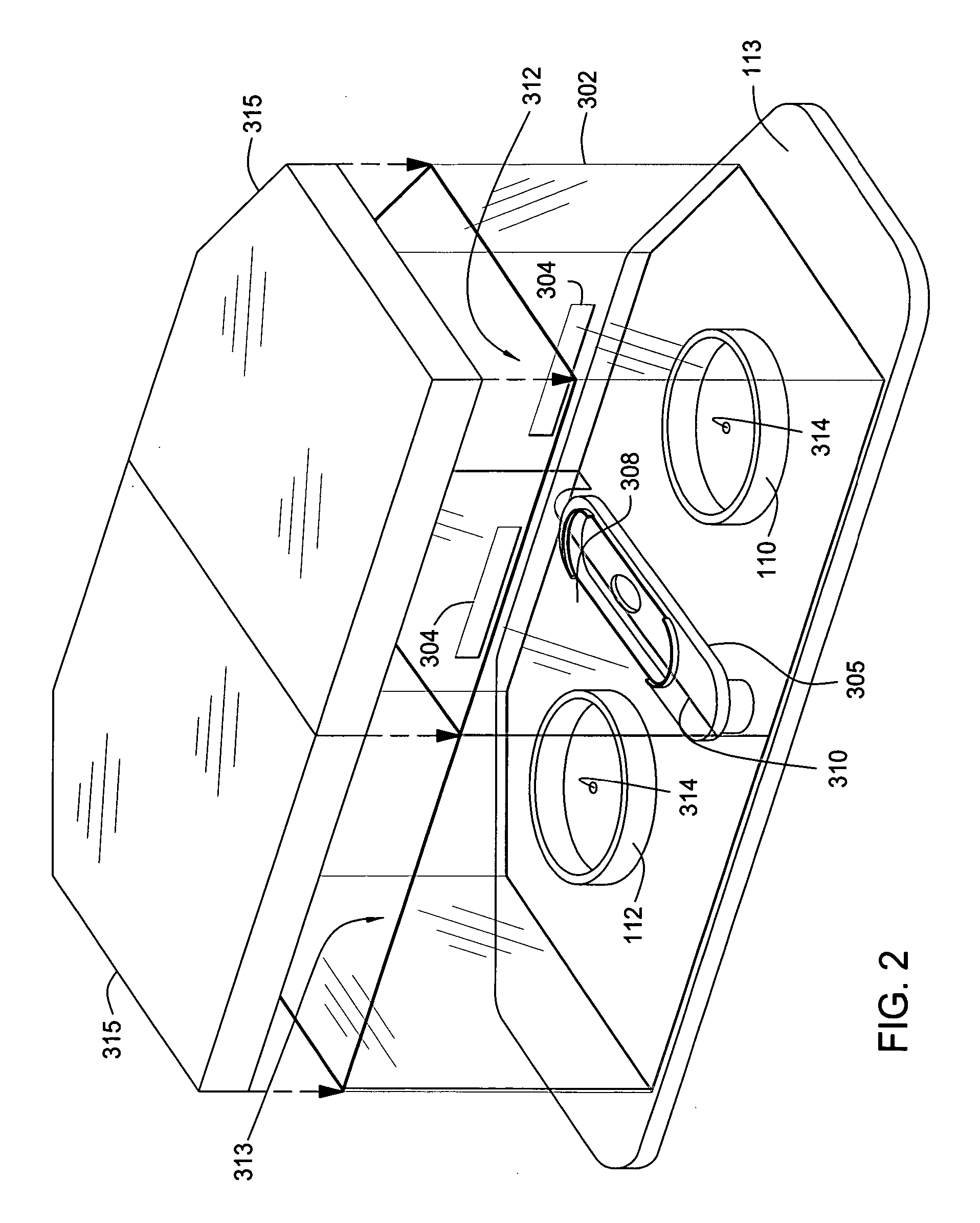

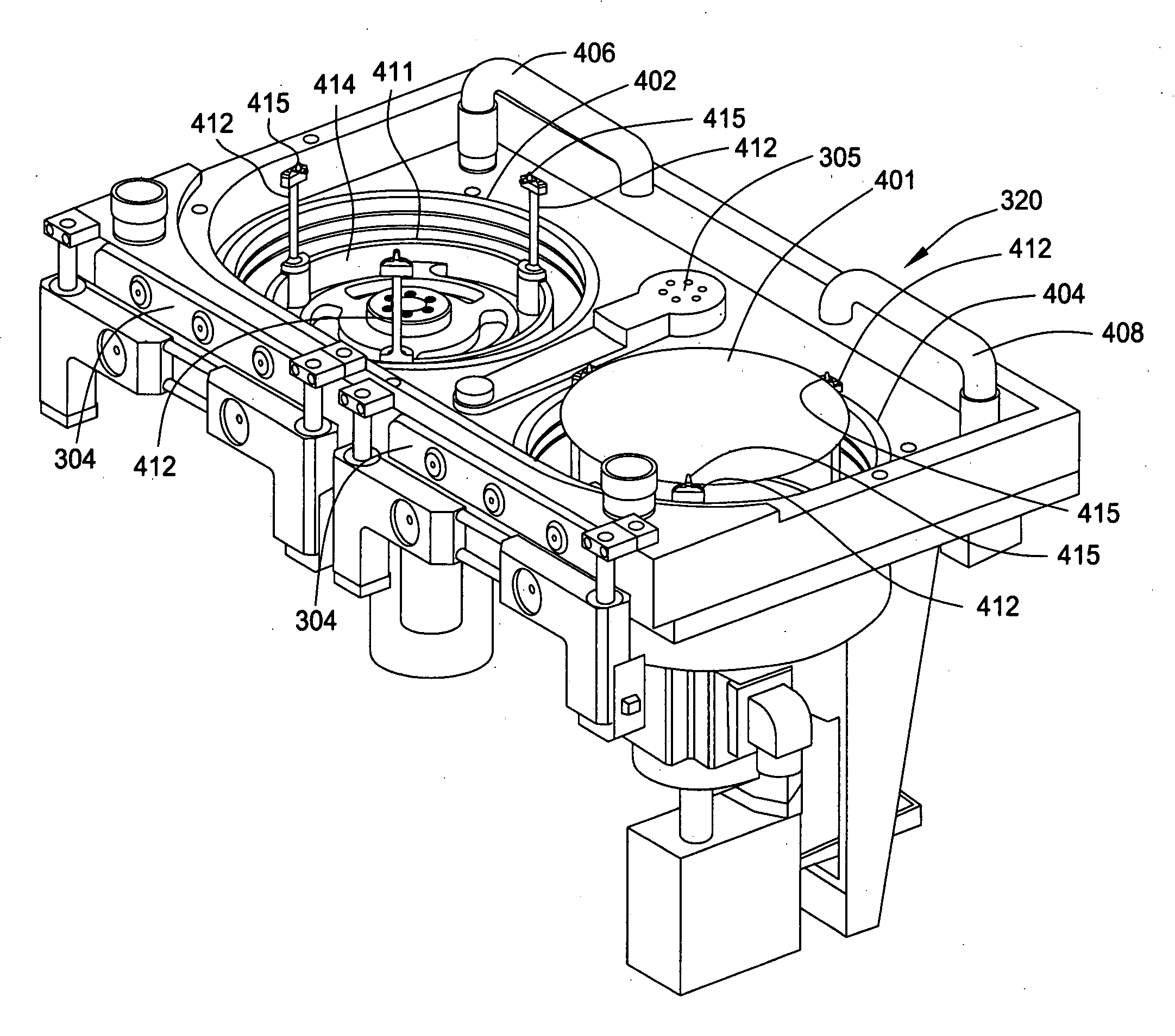

Apparatus for electroless deposition of metals onto semiconductor substrates

InactiveUS20050263066A1Efficient depositionMinimal defectSpraying apparatusPretreated surfacesRobot positionEngineering

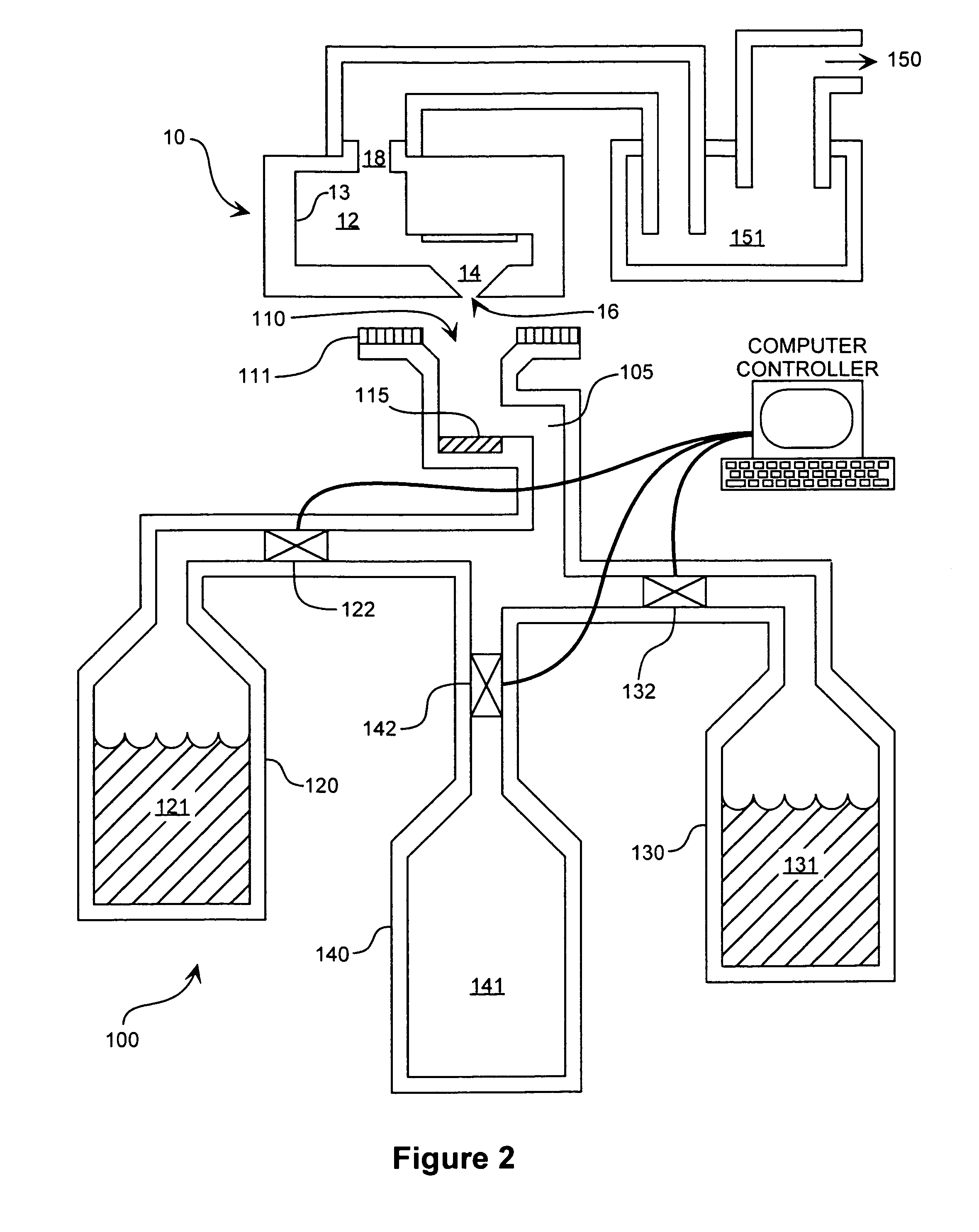

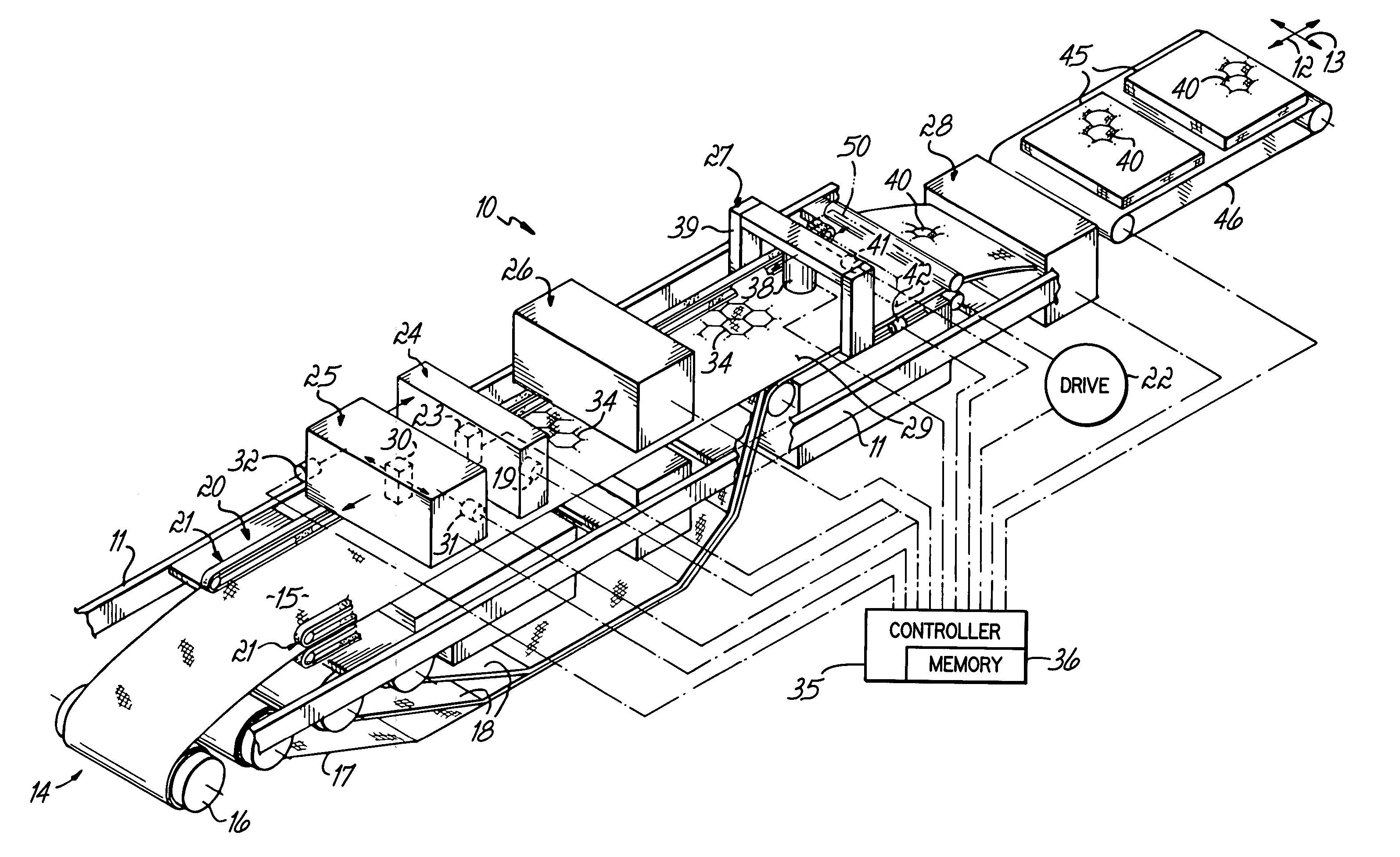

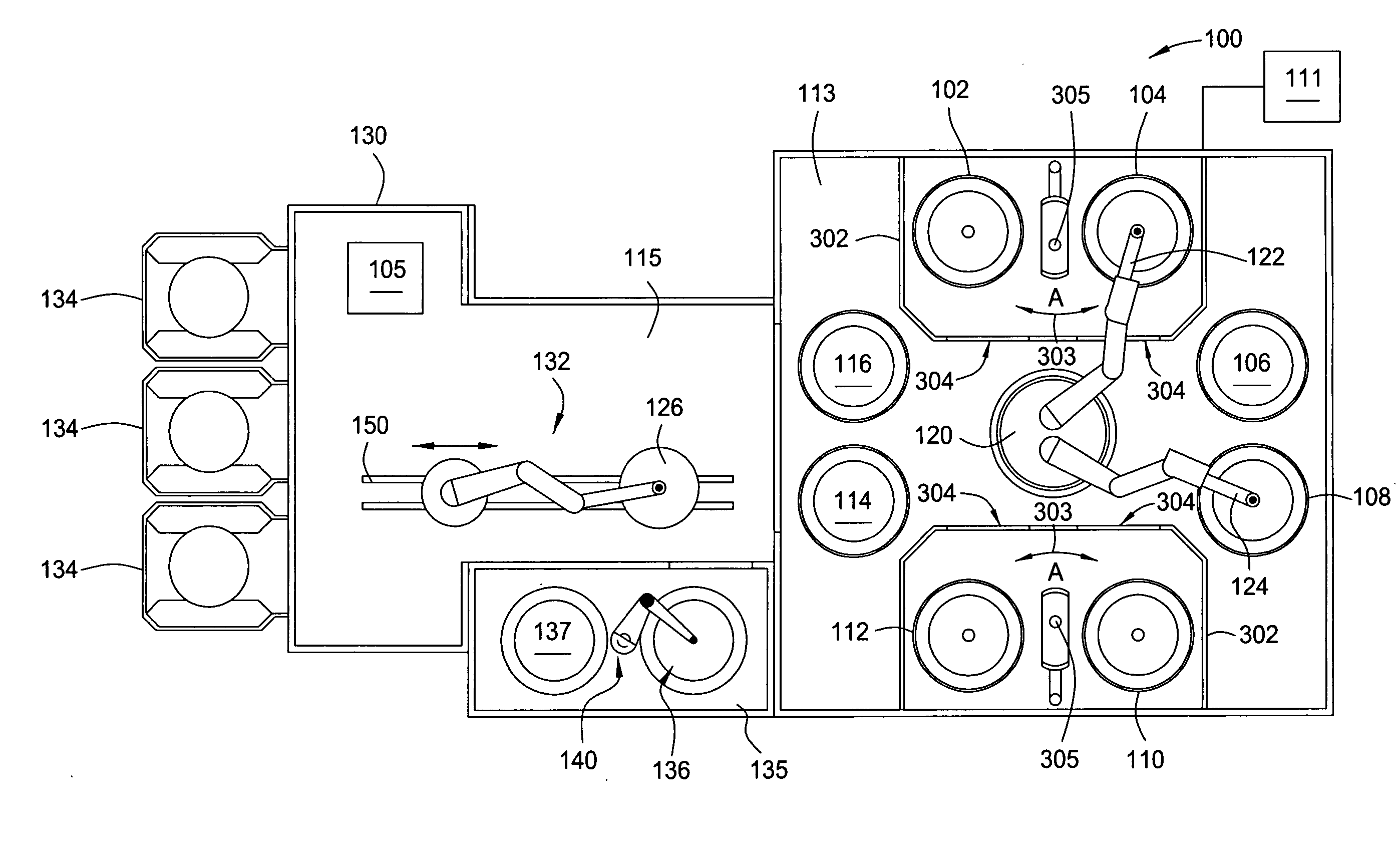

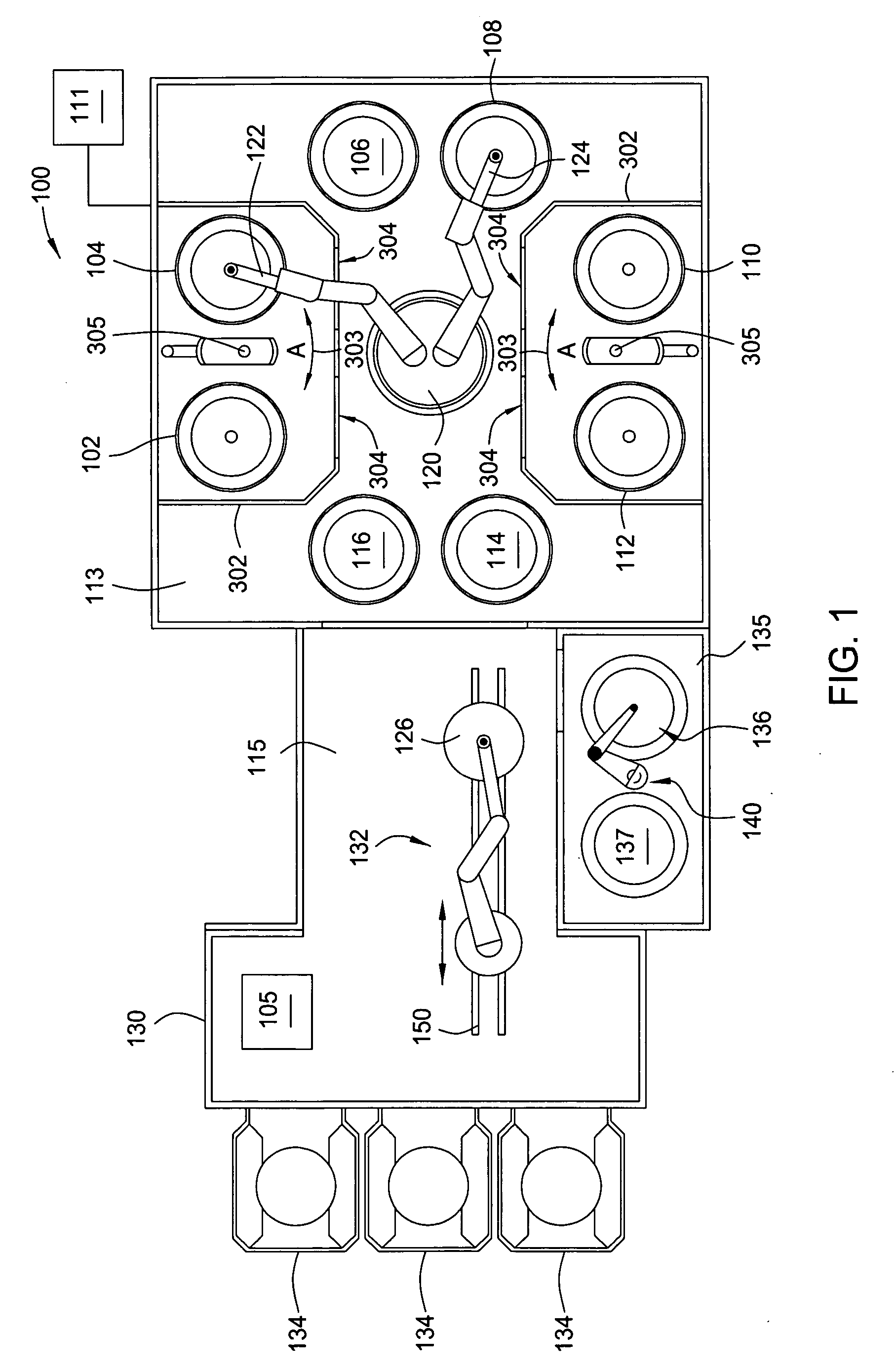

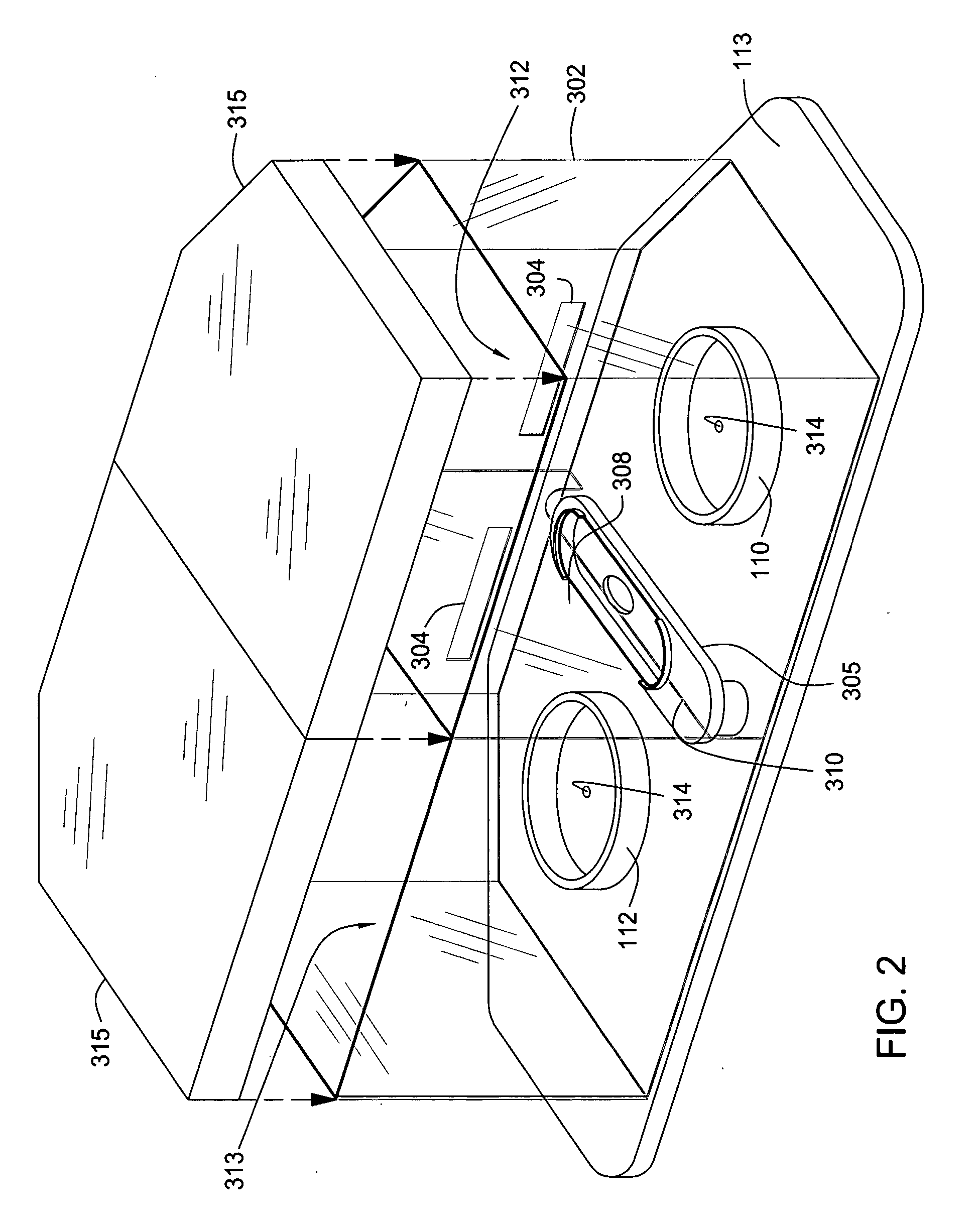

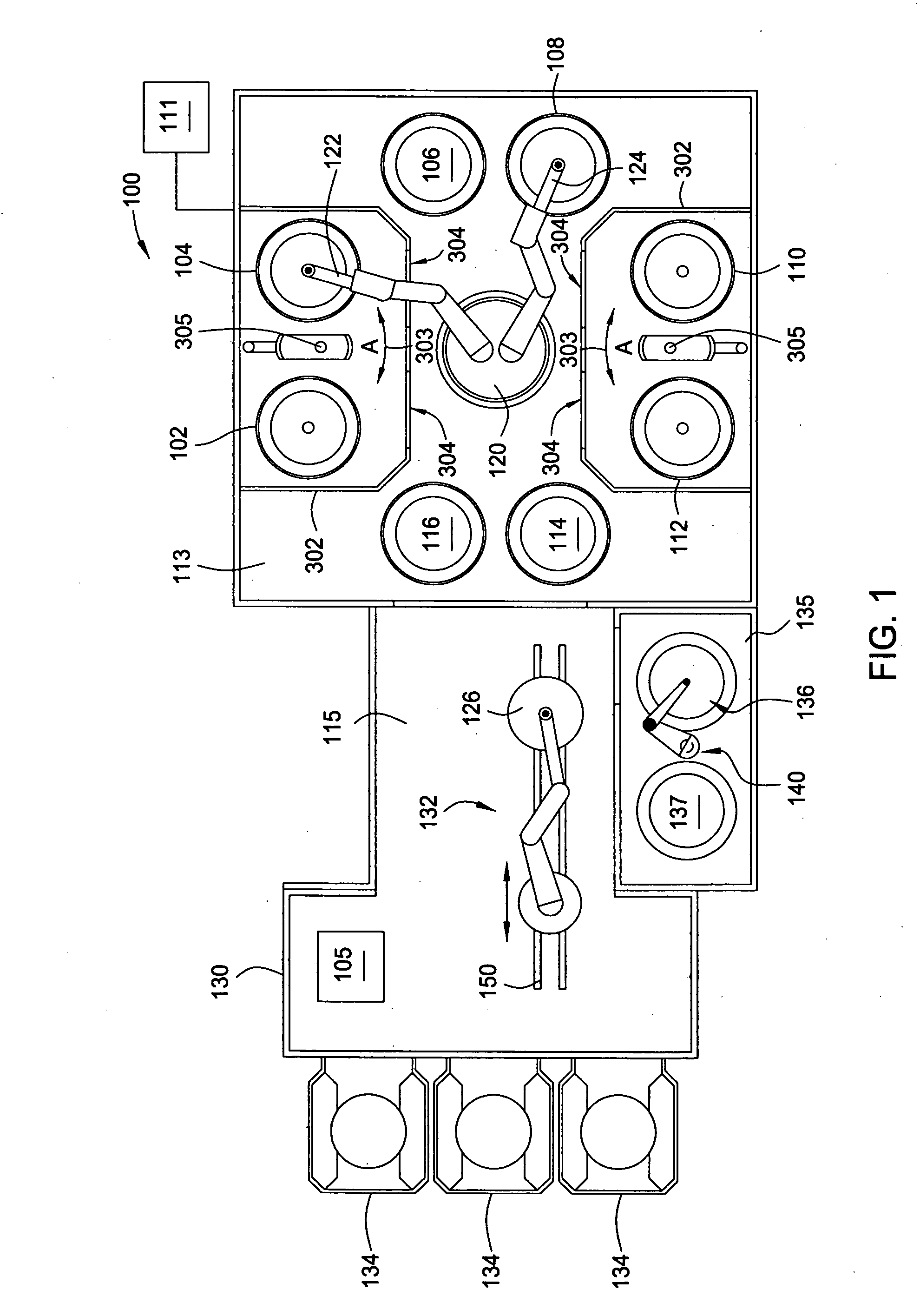

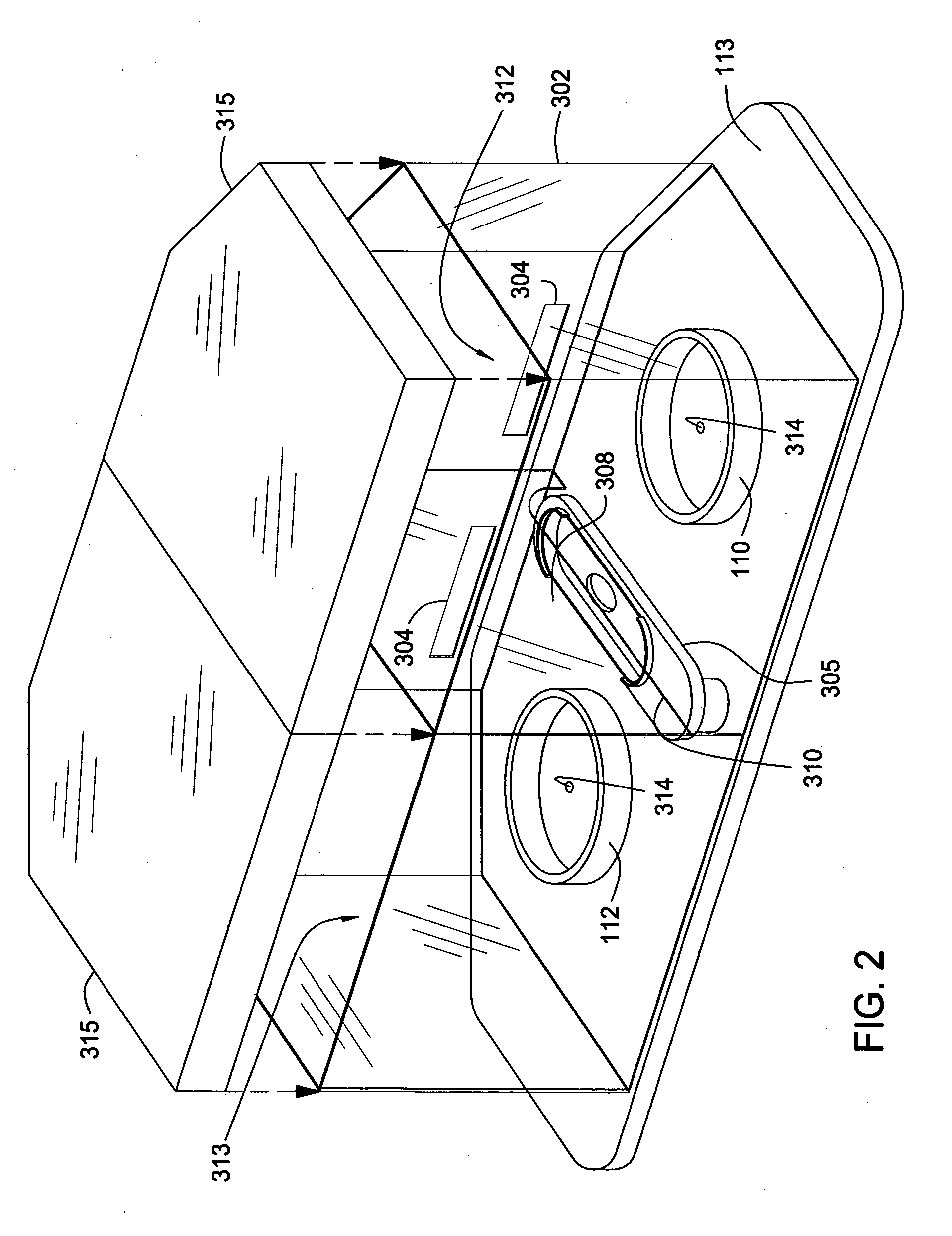

An electroless deposition system is provided. The system includes a processing mainframe, at least one substrate cleaning station positioned on the mainframe, and an electroless deposition station positioned on the mainframe. The electroless deposition station includes an environmentally controlled processing enclosure, a first processing station configured to clean and activate a surface of a substrate, a second processing station configured to electrolessly deposit a layer onto the surface of the substrate, and a substrate transfer shuttle positioned to transfer substrates between the first and second processing stations. The system also includes a substrate transfer robot positioned on the mainframe and configured to access an interior of the processing enclosure. The system also includes a substrate a fluid delivery system that is configured to deliver a processing fluid by use of a spraying process to a substrate mounted in the processing enclosure.

Owner:APPLIED MATERIALS INC

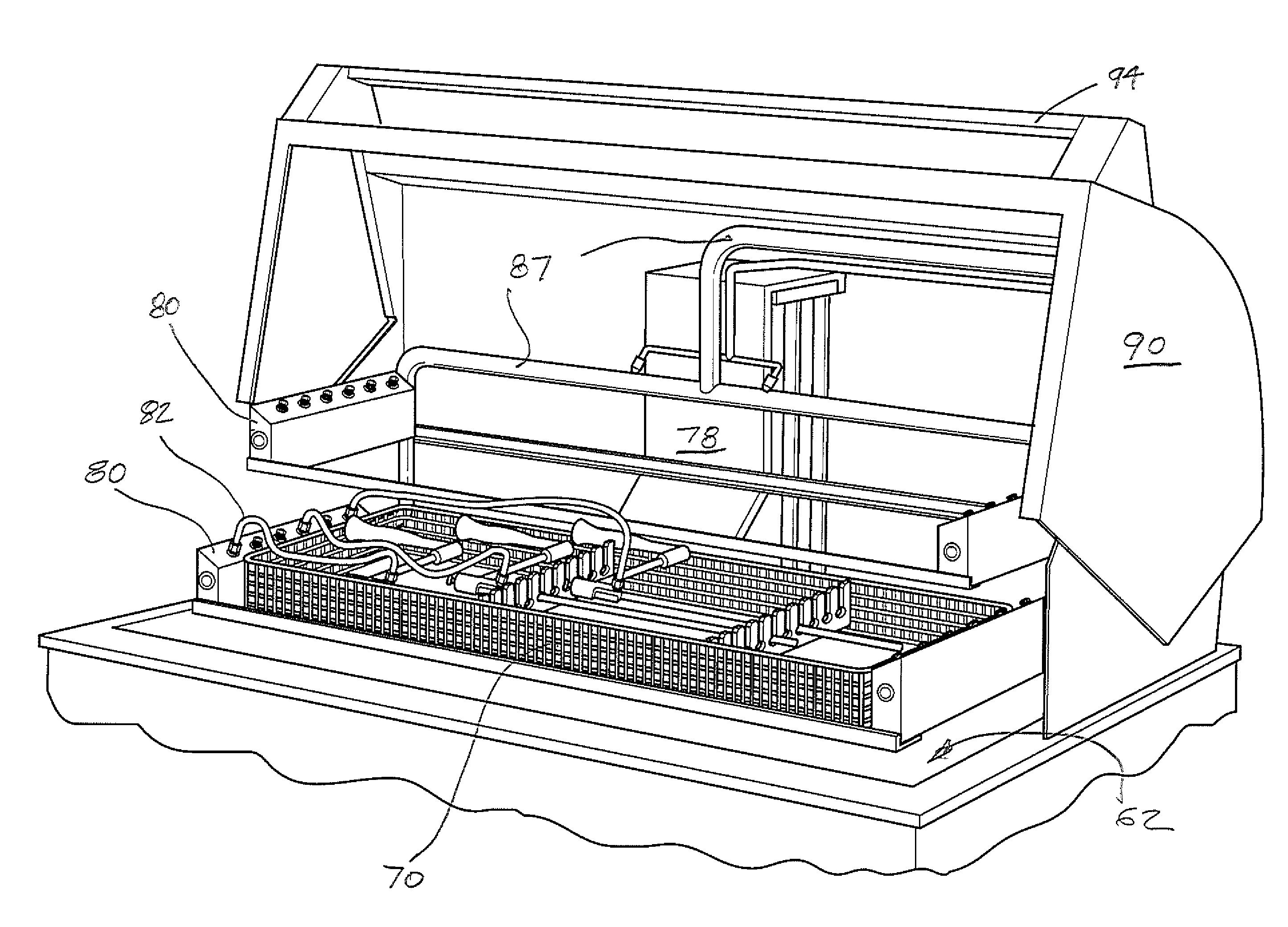

Method and apparatus to clean an inkjet reagent deposition device

InactiveUS7008037B2Overcome disadvantagesSequential/parallel process reactionsNucleotide librariesCombined useCleaning station

A method is described for removing residue from a fluid deposited on the interior surface of an inkjet printhead after the printhead has contained or dispensed the fluid at least once. The method makes use of a reverse flushing technique optionally used in combination with sonication. A cleaning station for flushing an inkjet printhead with a wash fluid, rinse fluid, and / or inert gas is provided as well.

Owner:AGILENT TECH INC

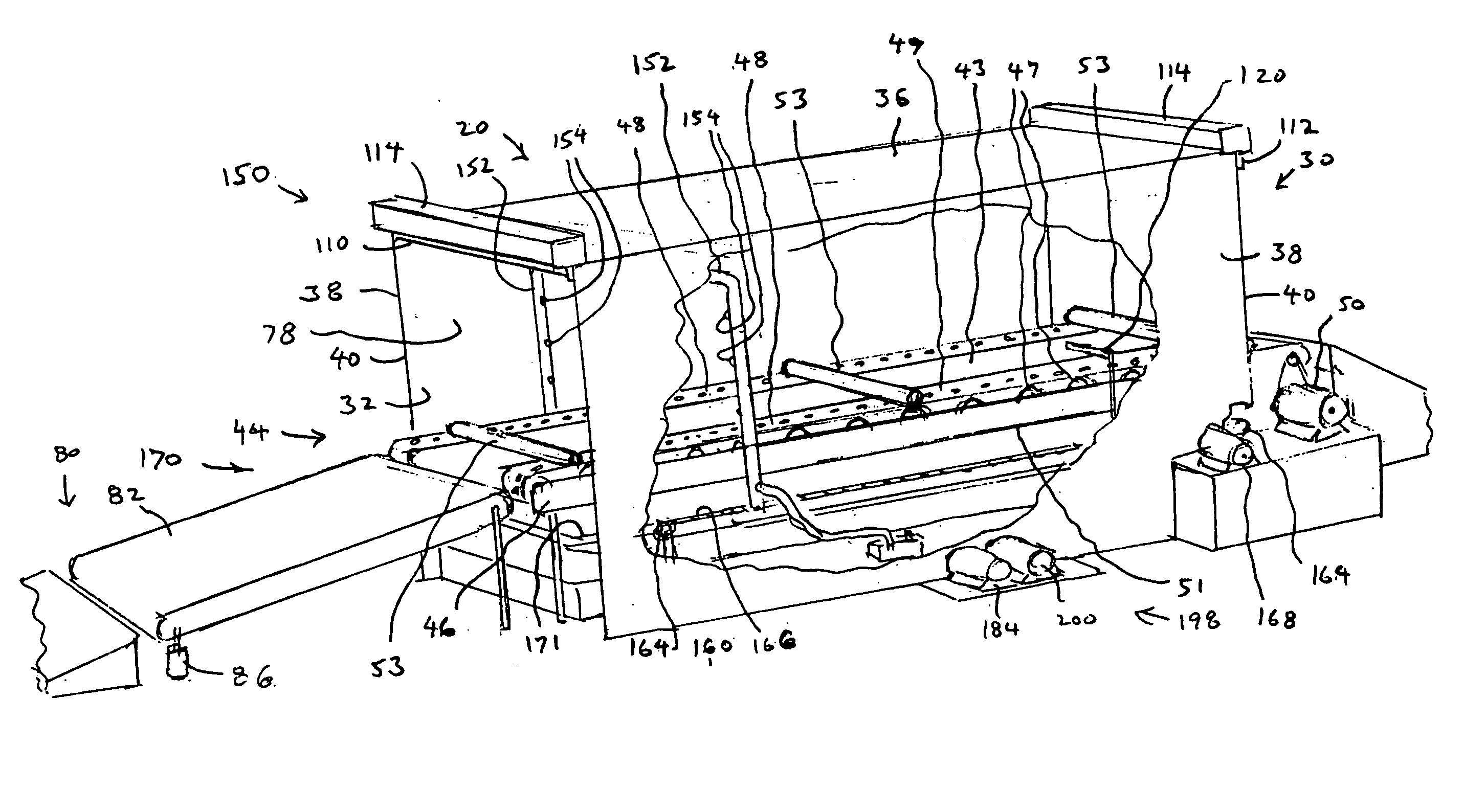

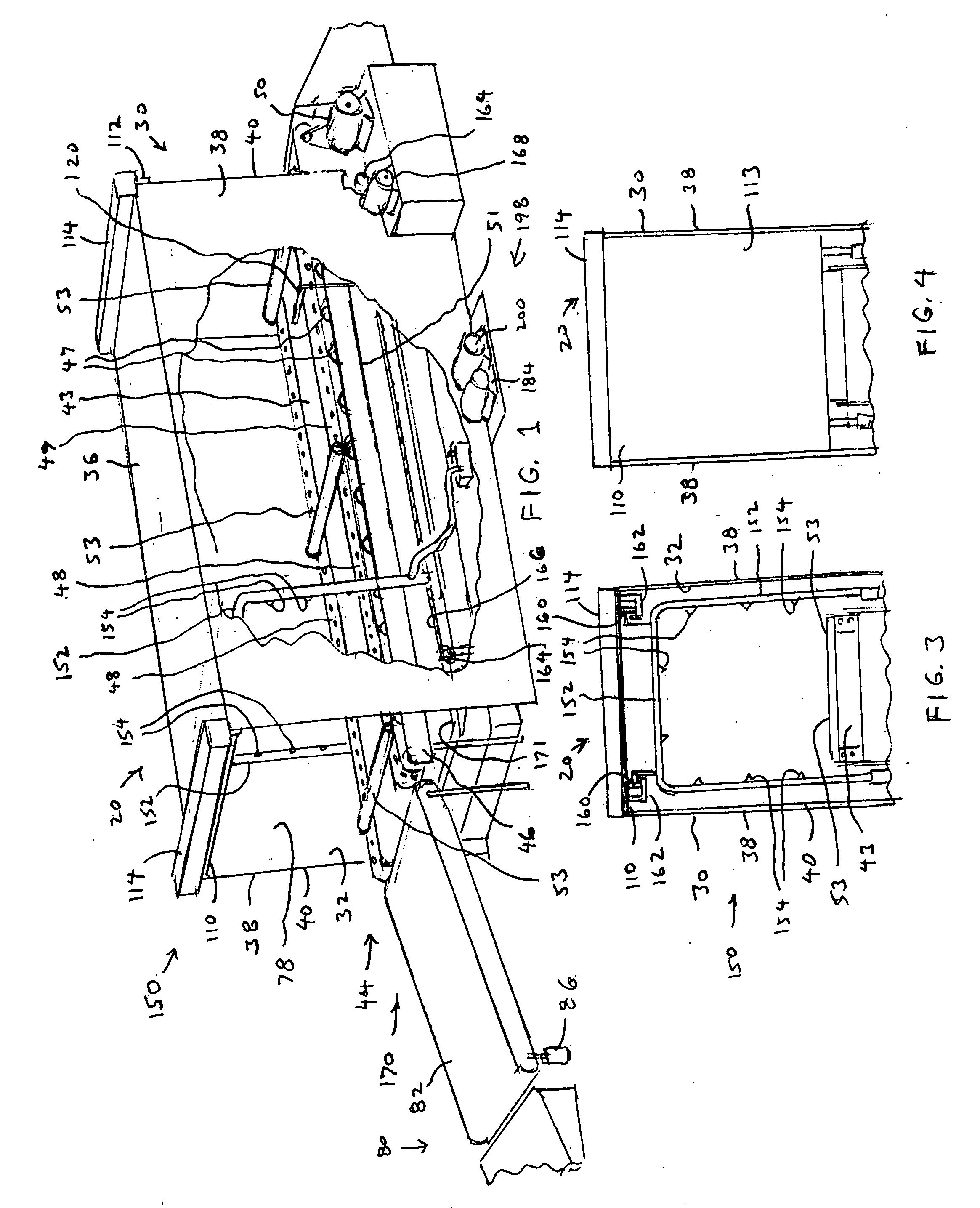

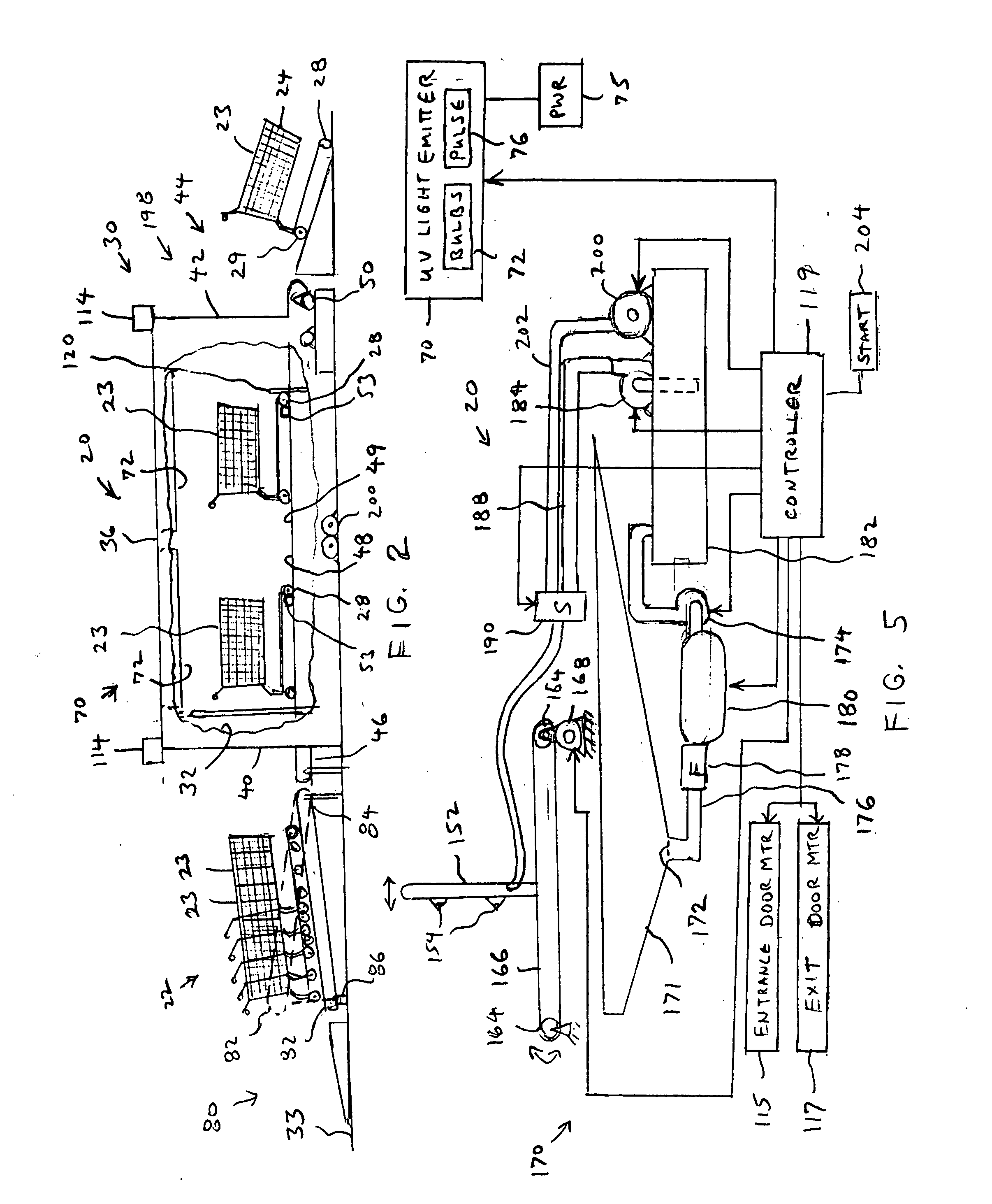

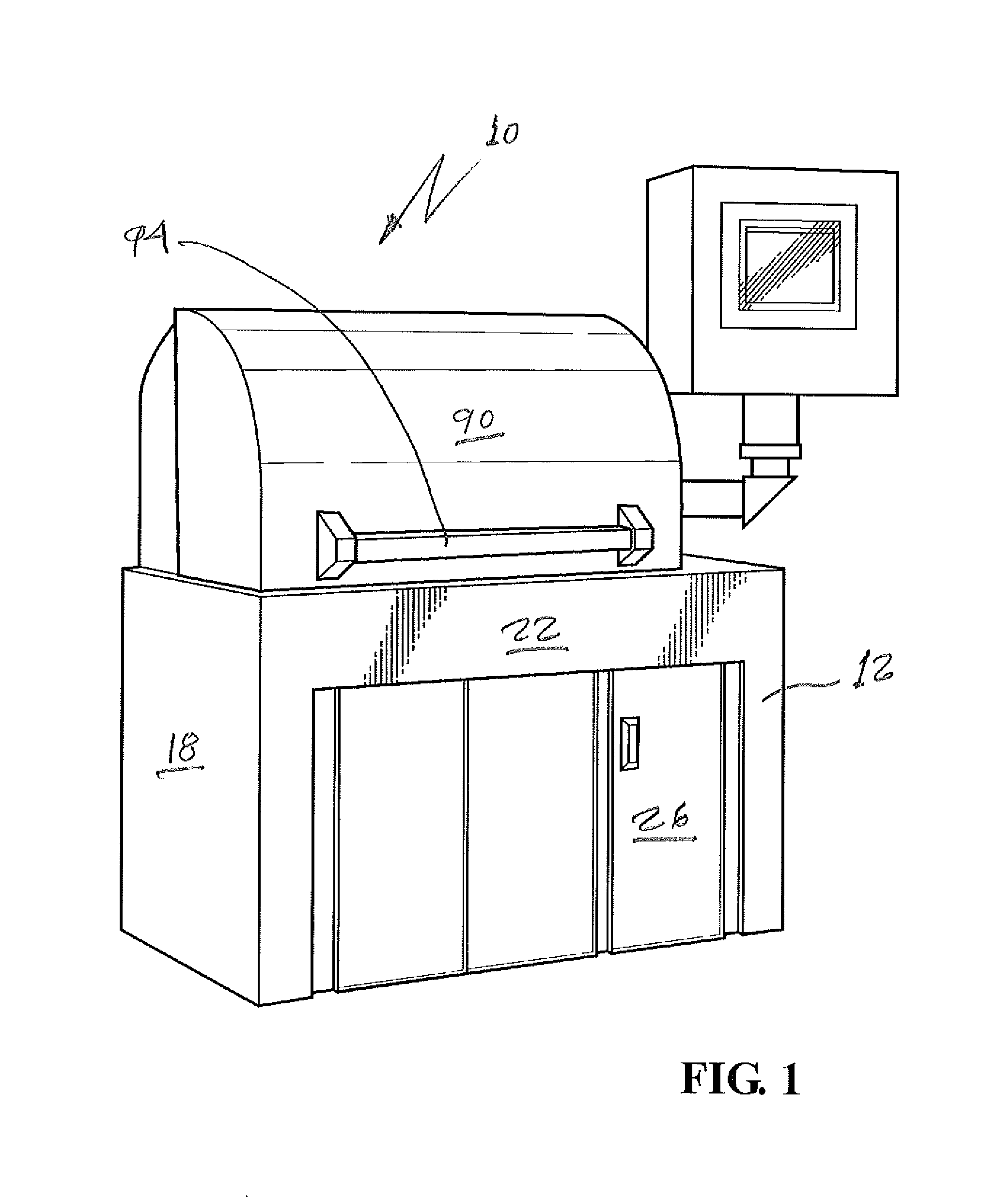

System and method for cleaning or sanitizing items intended for re-use

A system and method for sanitizing or cleaning an item, such as a grocery store shopping cart or a child stroller, for re-use utilizes a passageway having an entrance and an exit and a sanitizing or cleaning station between the entrance and exit. The item is conveyed through the passageway into the station, and pulsating beams of ultraviolet (UV) light are directed toward the item to sanitize the surfaces of the item which are struck by the pulsating beams of light. The system can be supplemented with an arrangement for directing water toward the item for rinsing purposes and for subsequently directing air toward the item for drying purposes. Moreover, the rinse water can be collected and sanitized after it has been directed toward the item during a rinsing operation for subsequent re-use.

Owner:ENVIRONMENTAL CART CLEANING

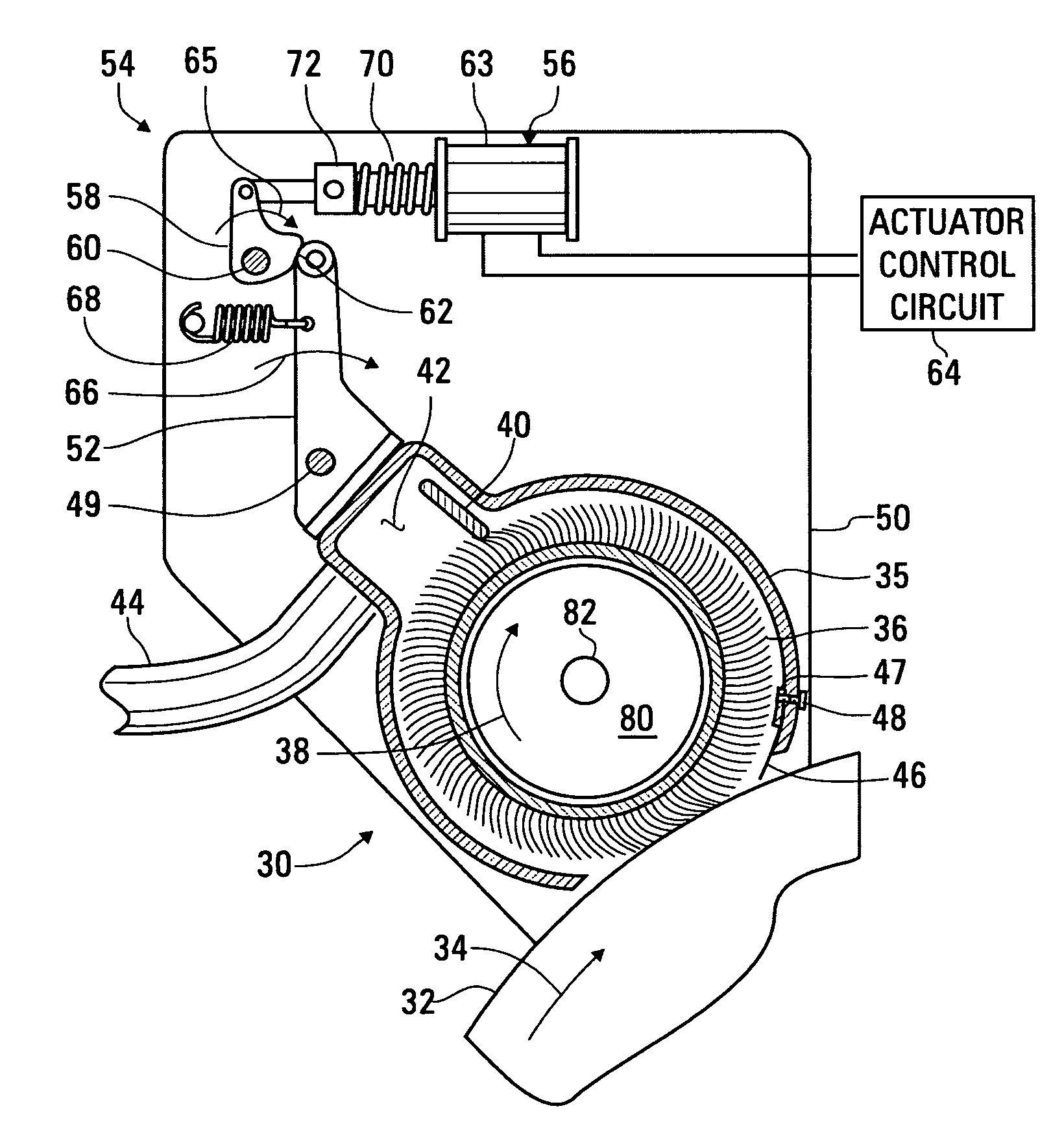

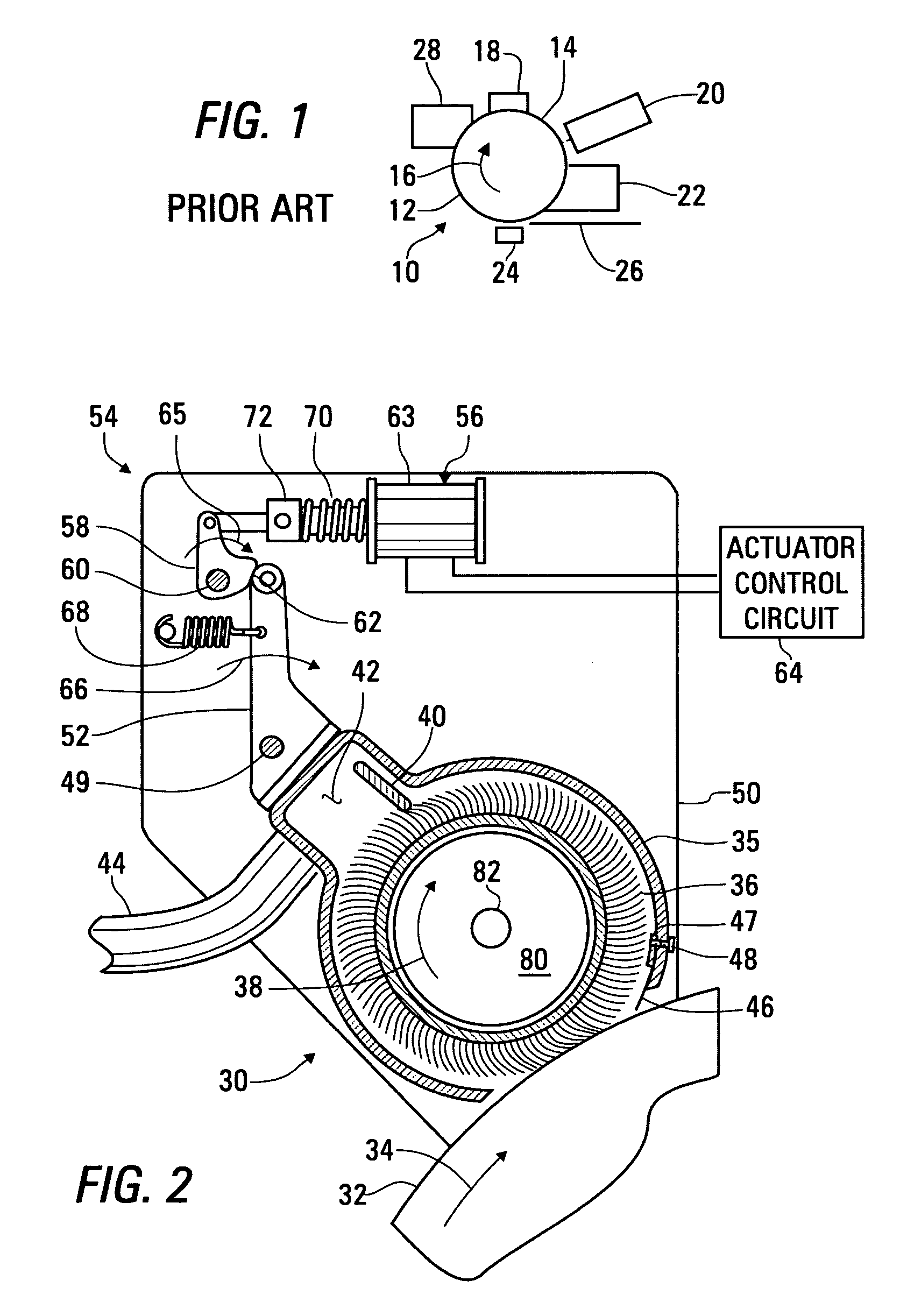

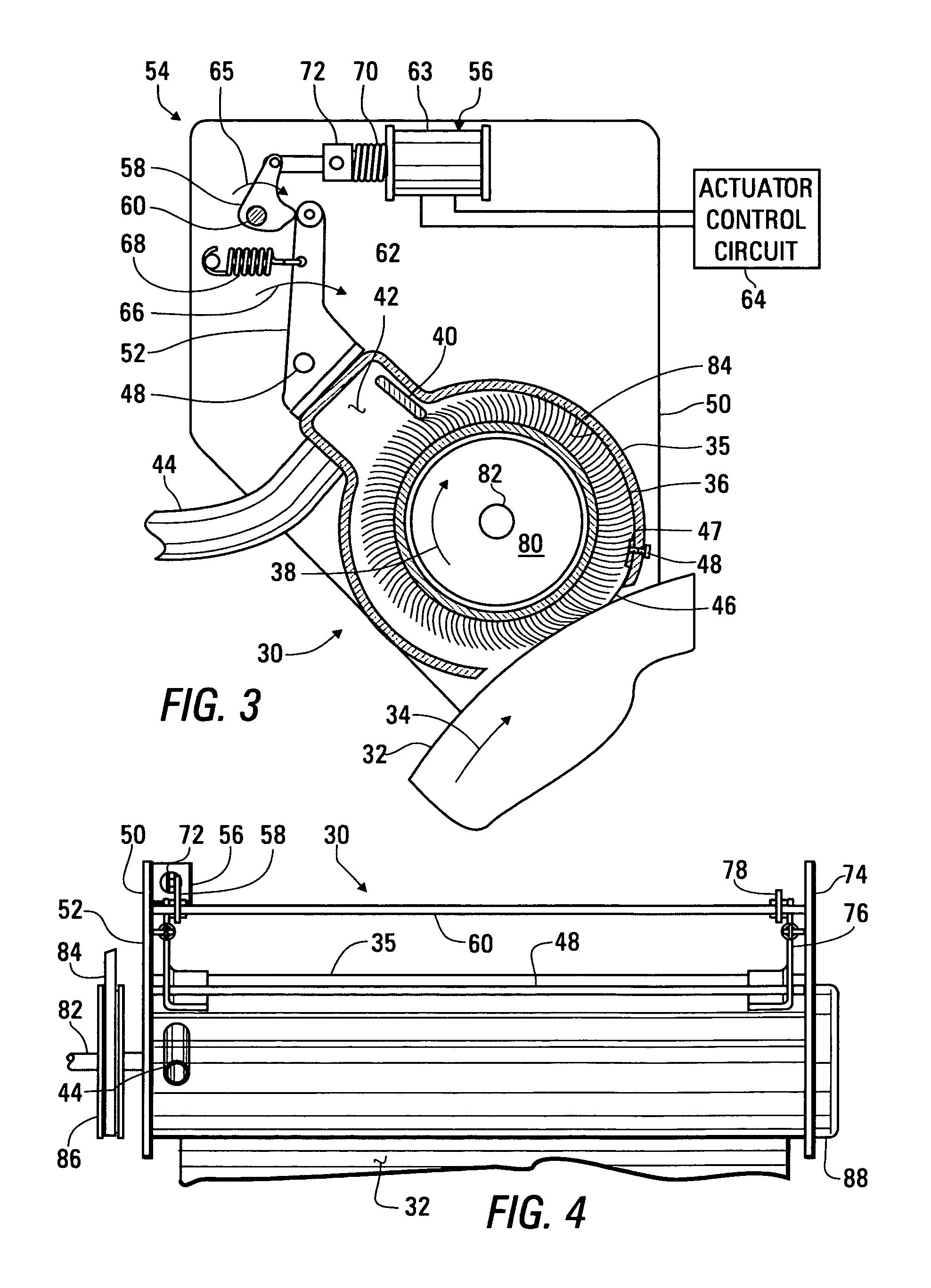

Method and apparatus for ink jet printing

InactiveUS20050174412A1Efficient curingHigh color saturation potentialDuplicating/marking methodsSpacing mechanismsPolyesterPorous substrate

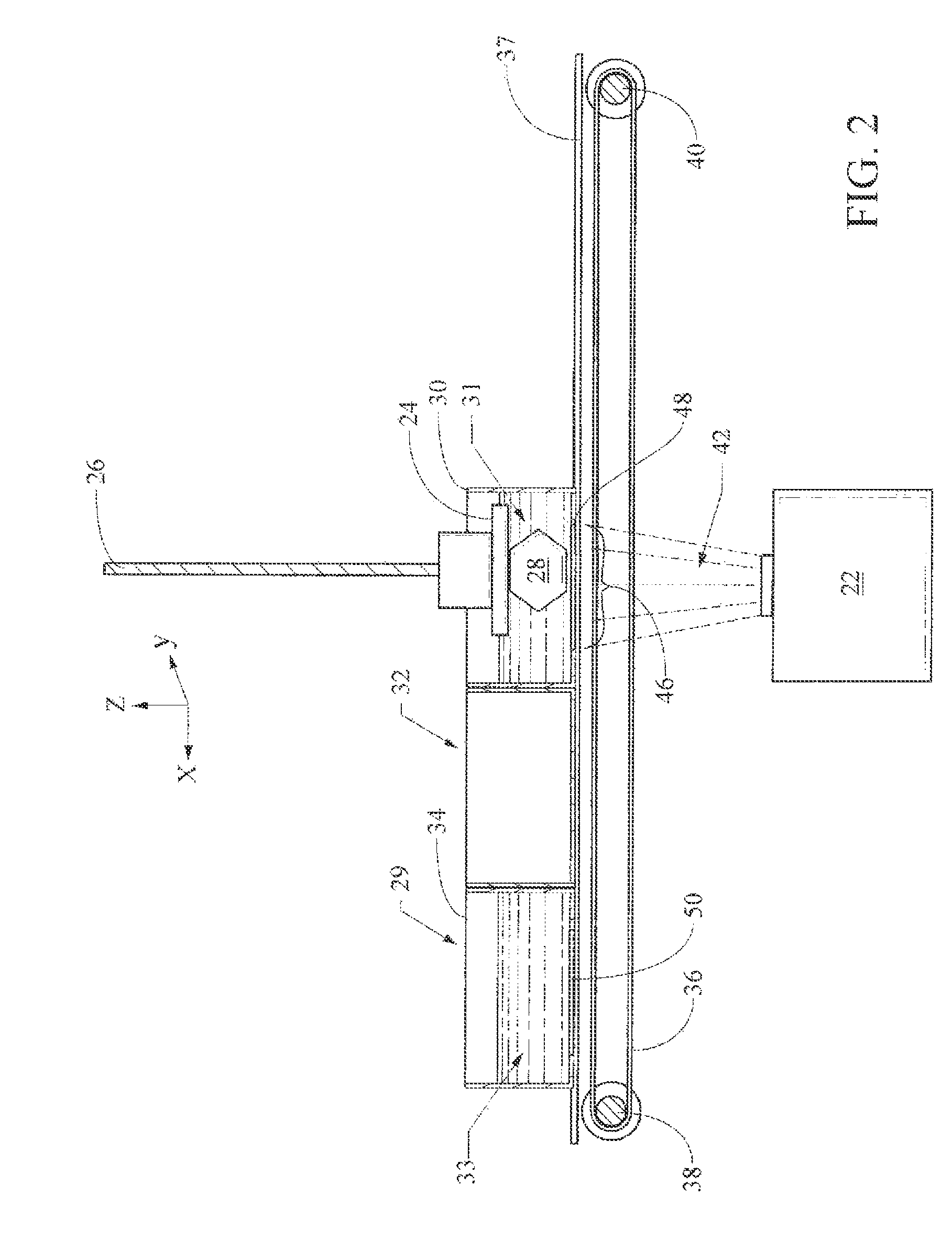

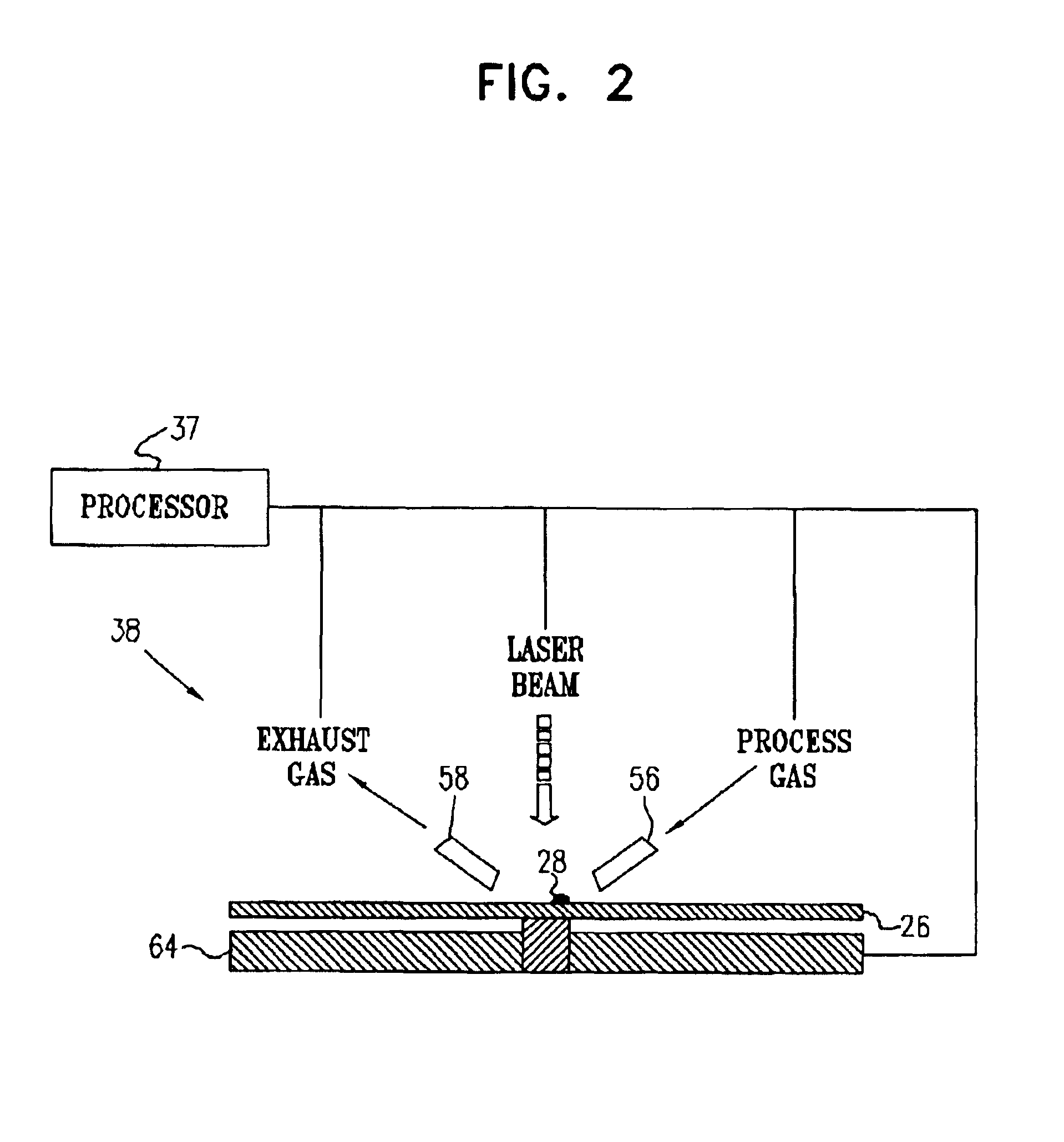

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors (633) across a bridge (630) that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads (640,641), so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light (645,646) and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate. Preferably, the heat is applied by contacting the substrate with a heated plate (661,662). Ink jet printing is provided using ultraviolet (UV) light curable or other curable composition or stable or other printable substance. In certain embodiments the UV ink has a dye-component therein. The ink is jetted onto a substrate, the composition is cured, then heated to set the dye. Sublimation dye-based UV ink printing onto polyester is preferred. A release layer of protective material (702,704), such as a TEFLON film or sheet, covers a substrate support (705,706). A porous substrate to be printed, such as a textile material (711), is supported on or above the support. Ink is jetted onto the substrate, with some of the ink passing through pores in the substrate and landing on the protective material. UV curable ink is preferably used and is exposed by UV light from a UV light curing head, which solidifies the ink on the substrate. The UV curing light has a long enough focal length to focus on the surface of the substrate and also, where it passes through pores in the substrate, on ink on the protective material, thereby solidifying the ink on the protective material. When the substrate is removed from the support, the solidified ink on the protective material may be wiped from the protective material. The protective material may be a coating on the support over which the substrate slides or a belt that moves with the substrate. A textile substrate may be preconditioned by singeing or shaving to remove fuzz from the fabric that could clog the printheads. A printhead cleaning station is also provided.

Owner:L & P PROPERTY MANAGEMENT CO

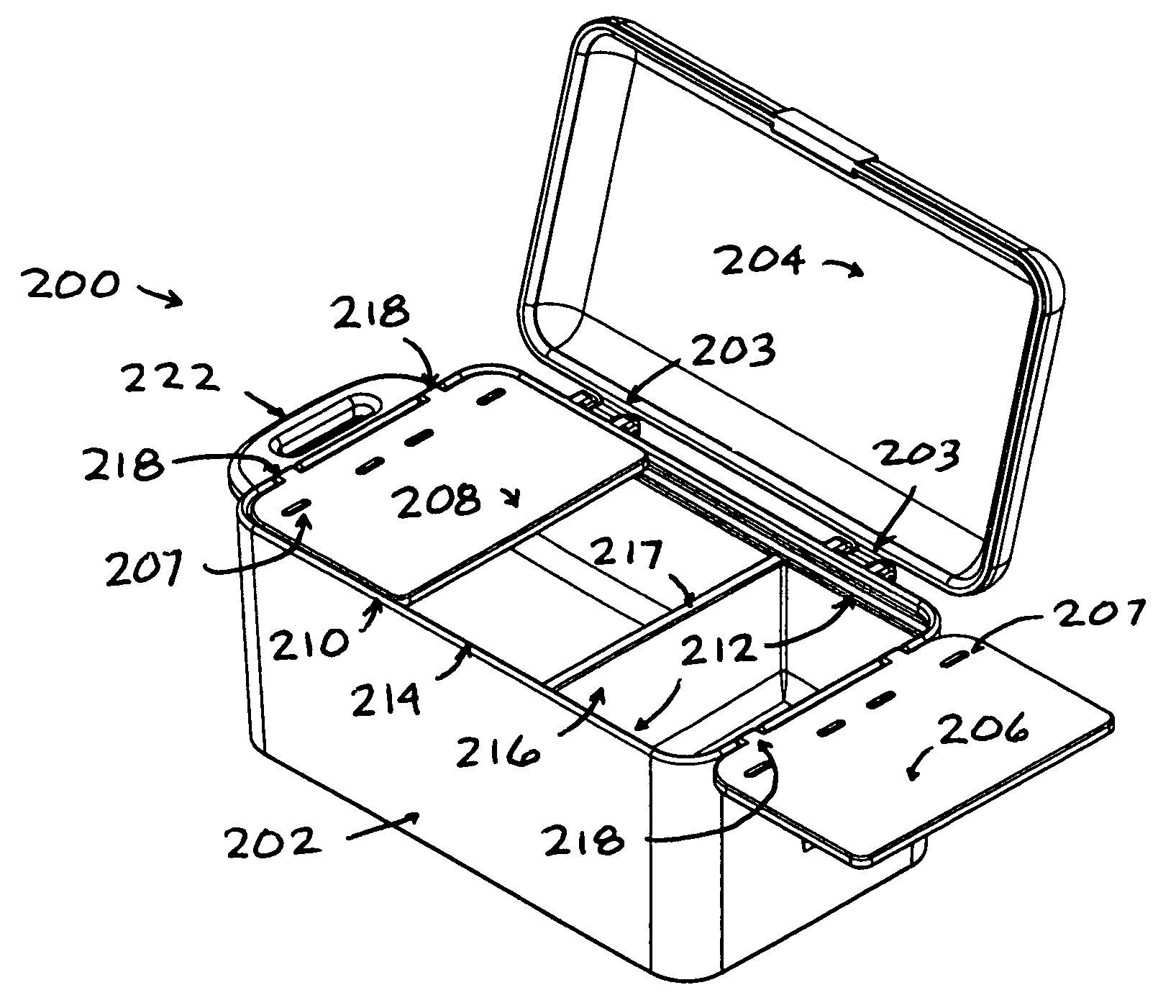

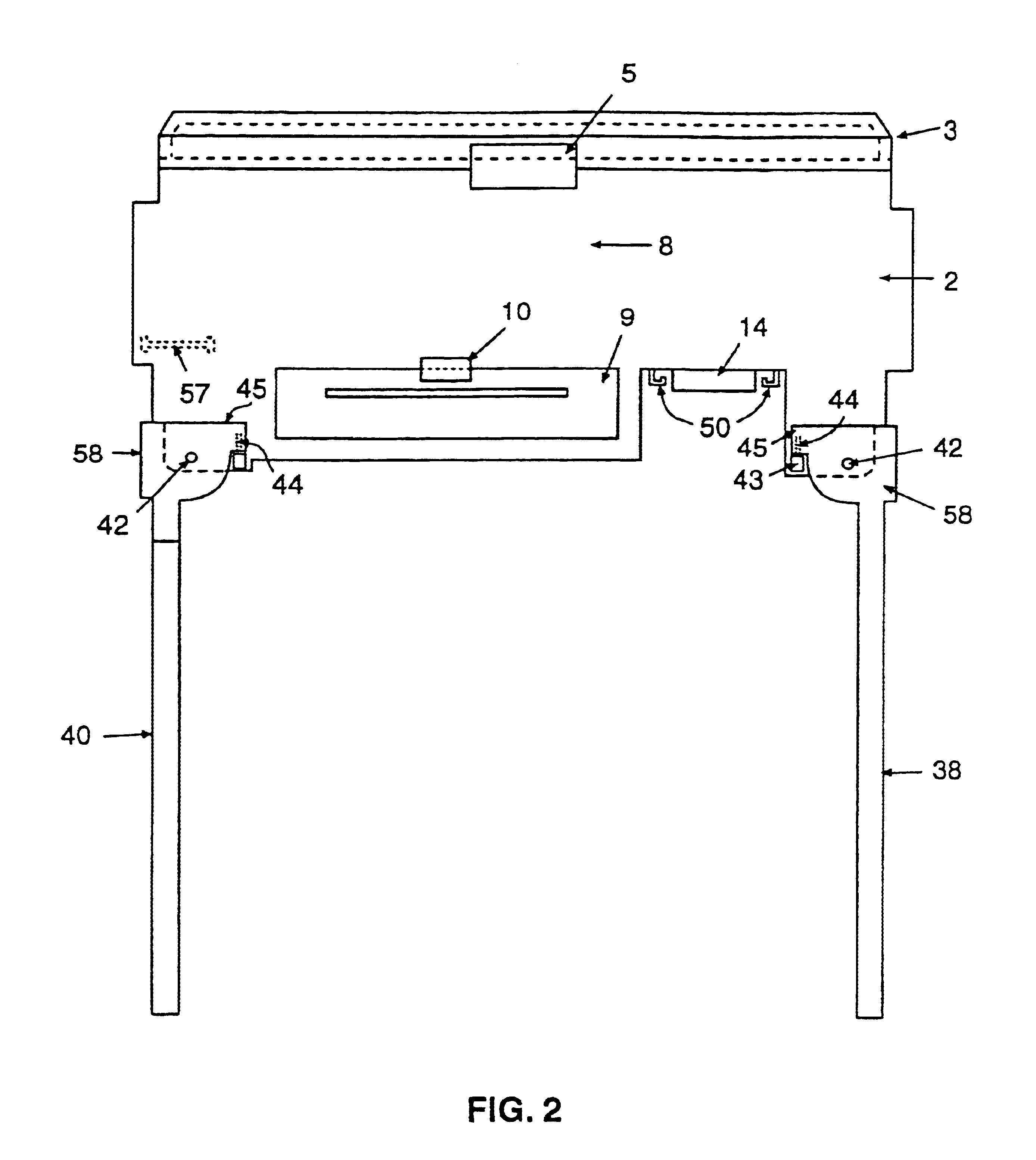

Combination game cleaning station, portable sink and ice chest

Owner:CAWTHON ENTERPRISES

Full-automatic table for making tea

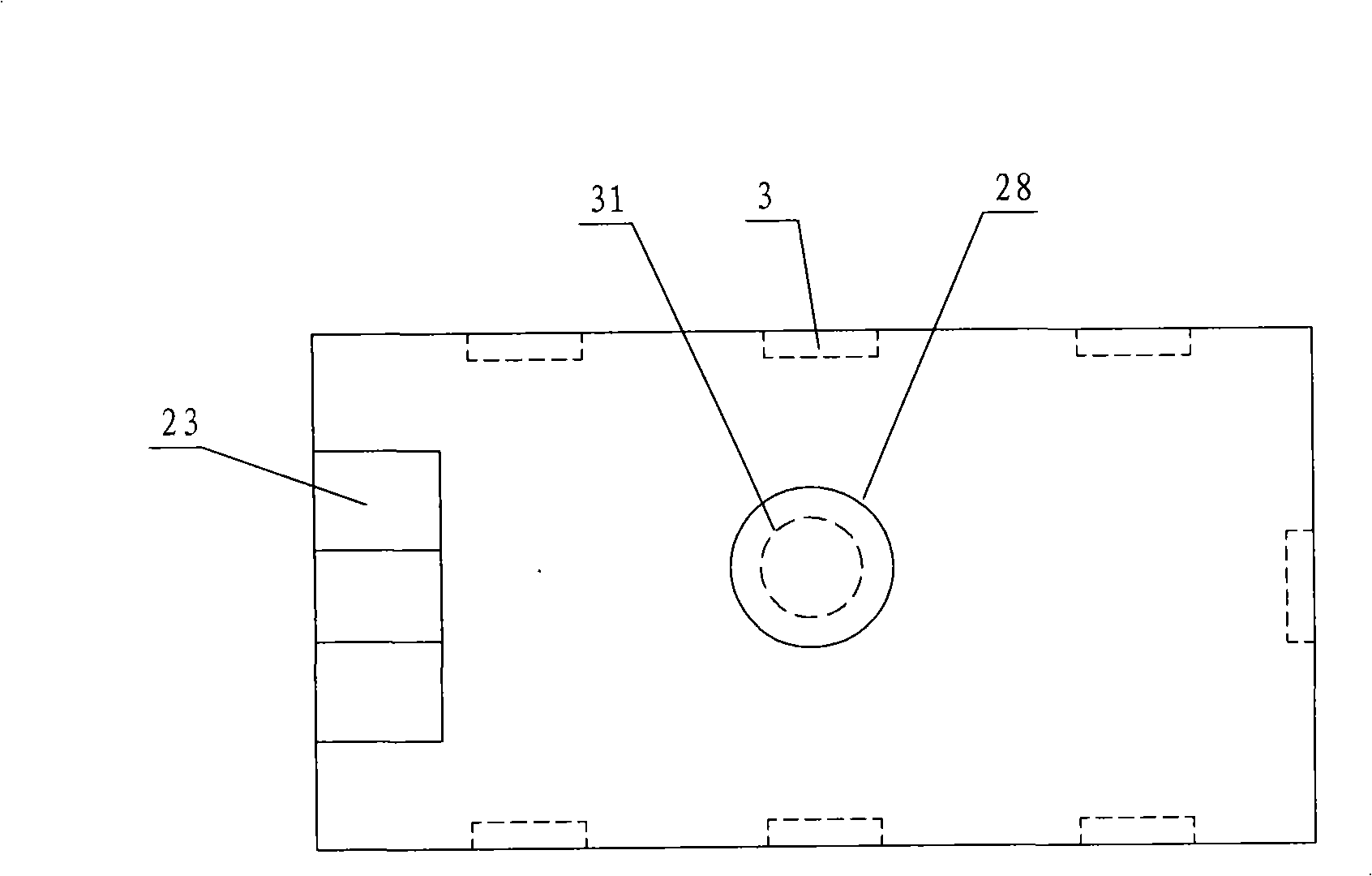

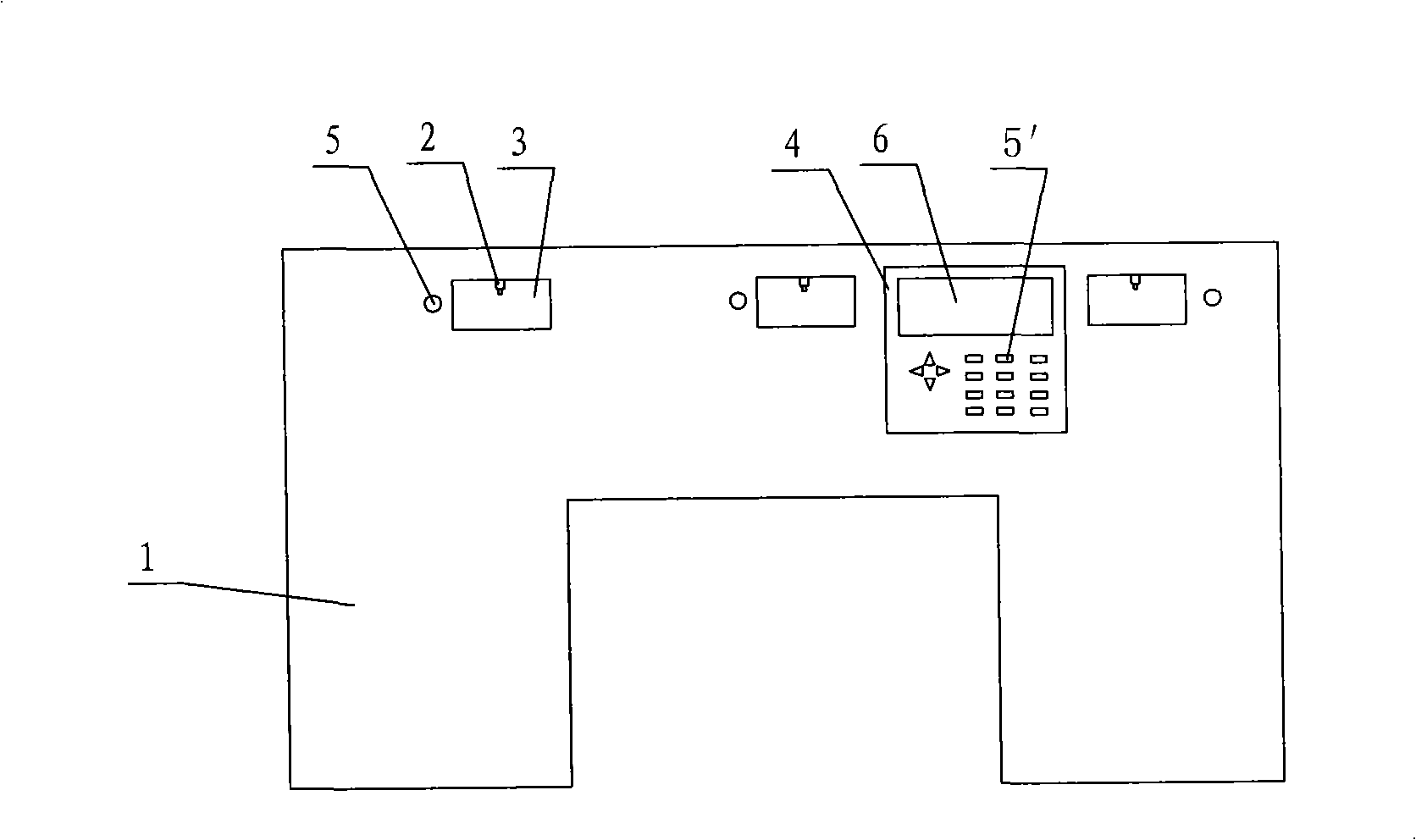

The invention discloses a full-automatic tea-making table which comprises a table body and tea-charging devices, a tea-making cup, a thermoflask, a water heater, a tea residue tank and a drinking-water tank inside the table body. The tea-making cup operates under the tea-charging devices and is provide with a horizontal driving mechanism and a overturn driving mechanism, and three stations for tea receiving, tea making, and cleaning are provided for the tea-making cup. A high-pressure cleaning sprayer is arranged under the cleaning station. The water heater communicates with the drinking-water tank through a tube and communicates with the tea-making cup through outlets on the bottom. The tea-making cup is provided with a solenoid valve on the bottom and communicates with the thermoflask through a hose, water outlets of the thermoflask communicate with tea water outlets in the table body. A CPU chip with programs inside is arranged in the control console, and the surface of the control console is provided with a liquid crystal screen and a plurality of control buttons. The tea-making table integrates functions of water heating, tea charging, tea making, heat preservation, tea residue emptying and cleaning, and has advantages of high automaticity, simple operation and stable performance, and is widely applicable to different places such as teahouse, restaurant, office or dwelling house.

Owner:唐仲湖

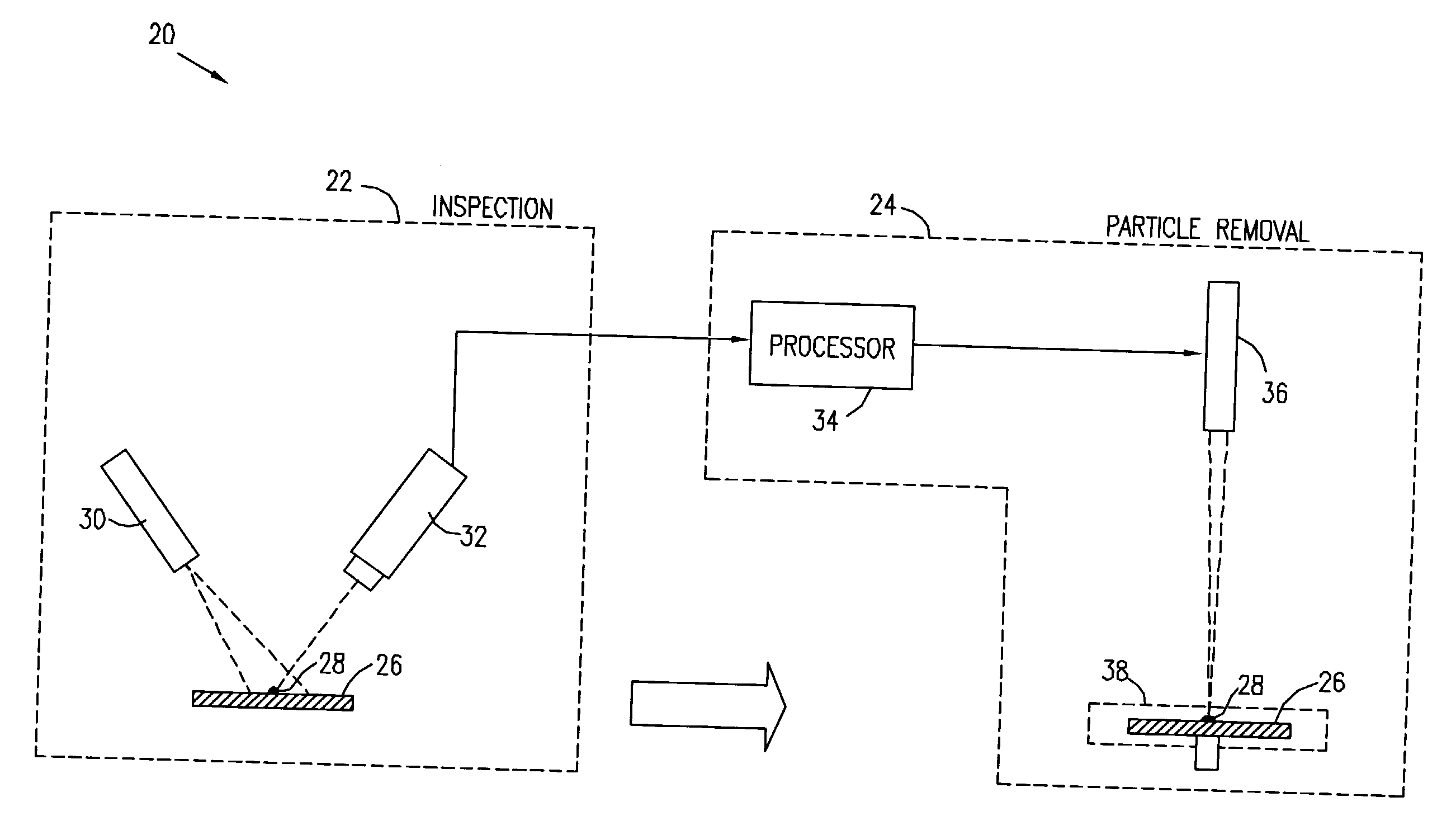

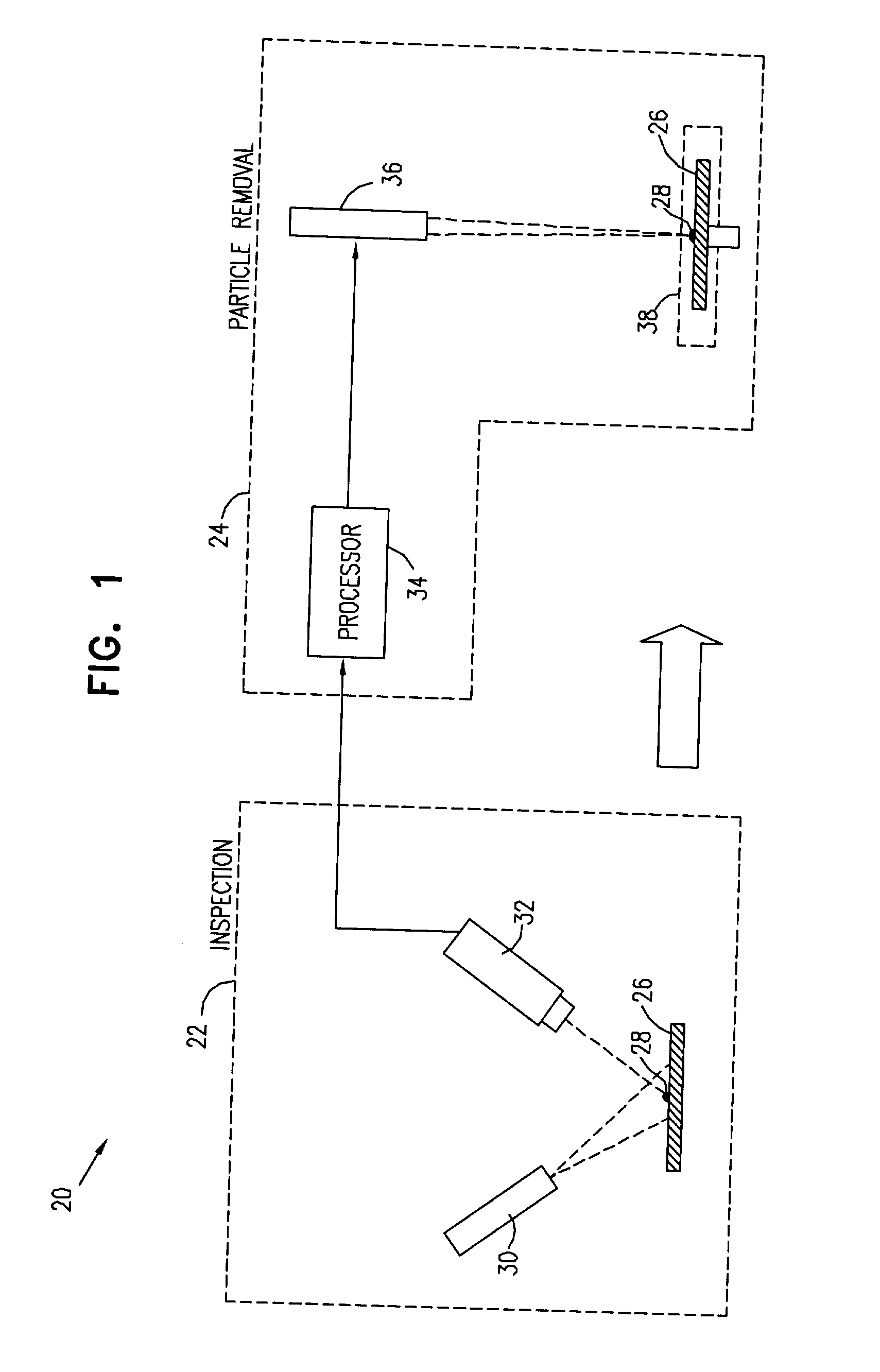

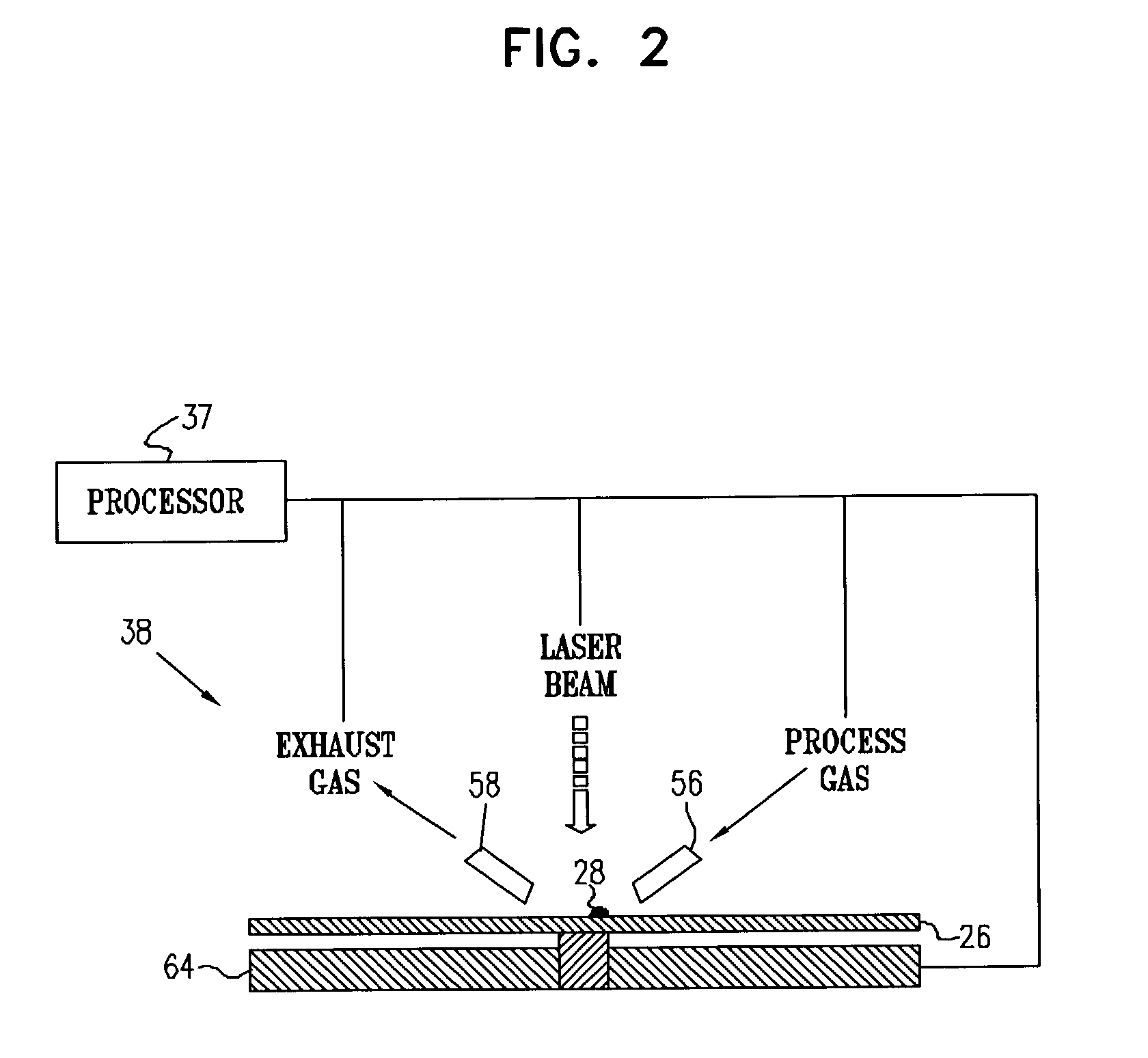

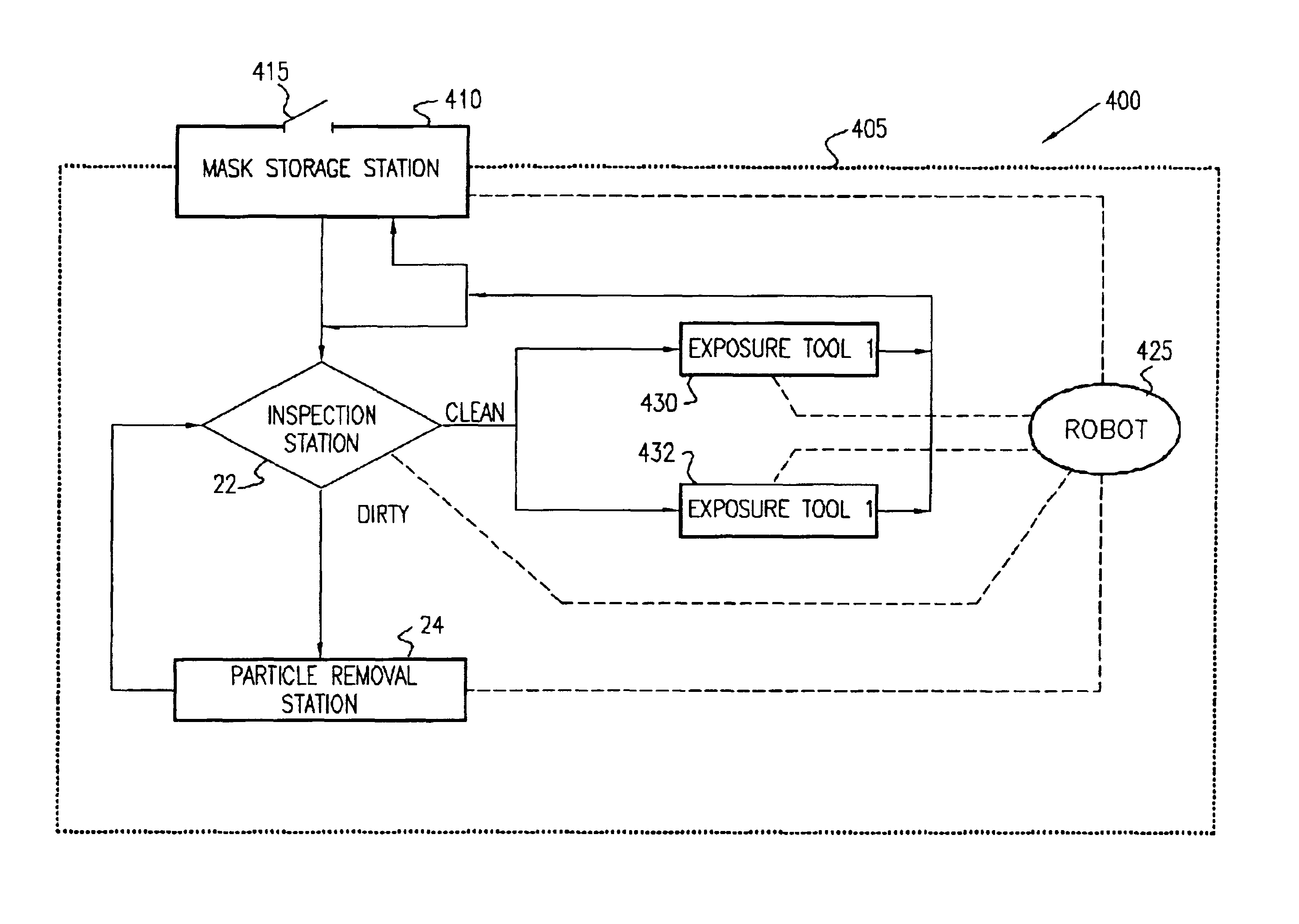

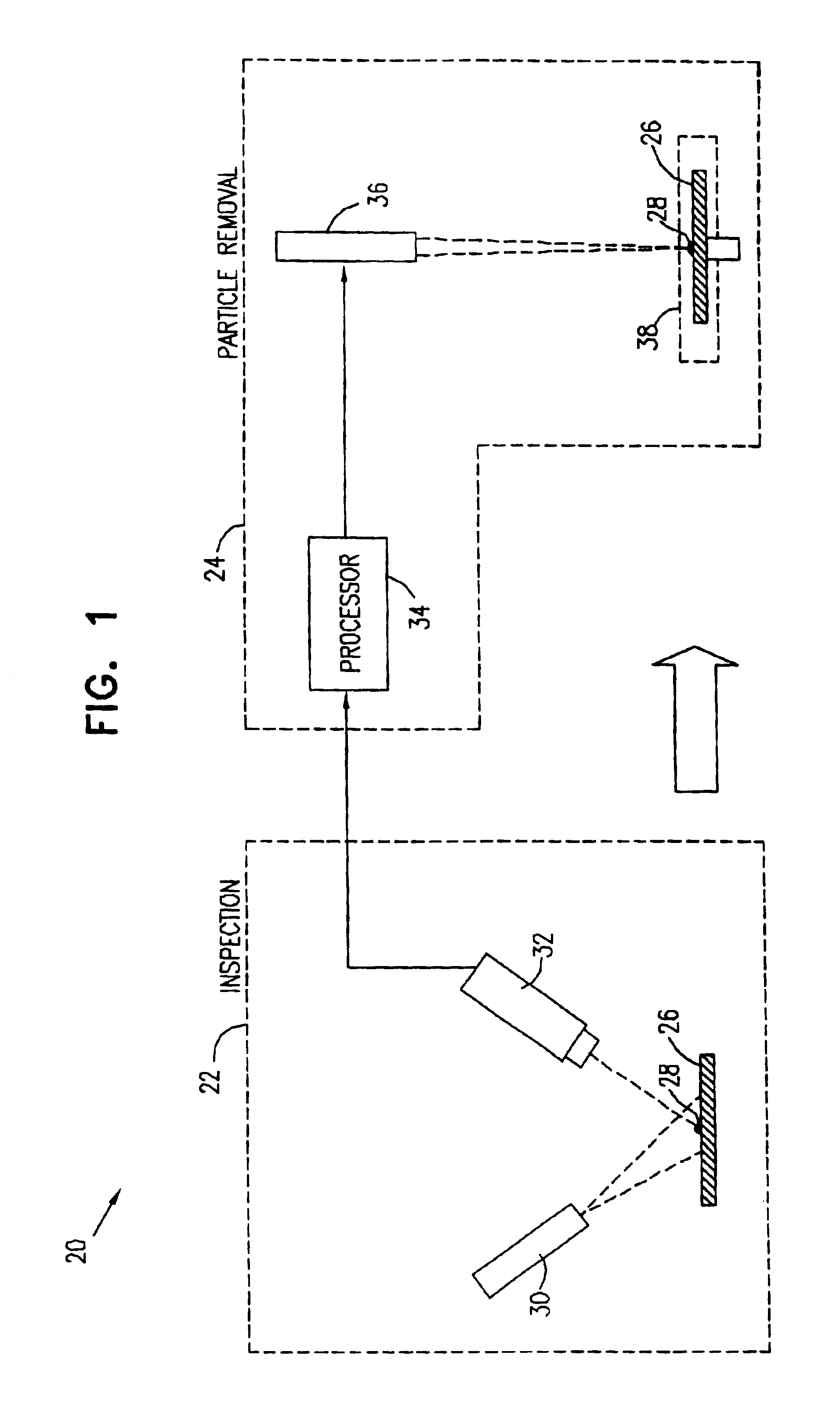

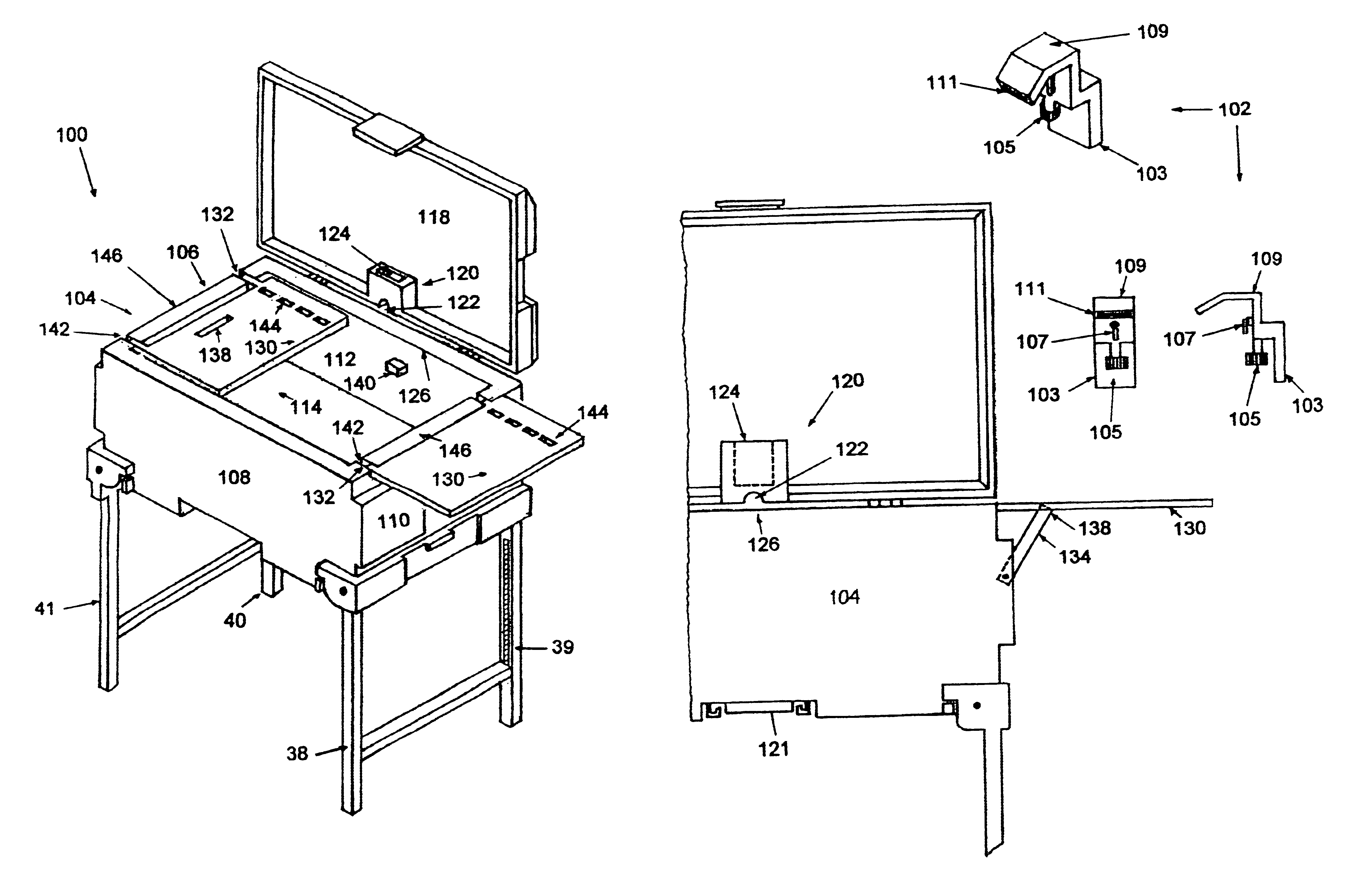

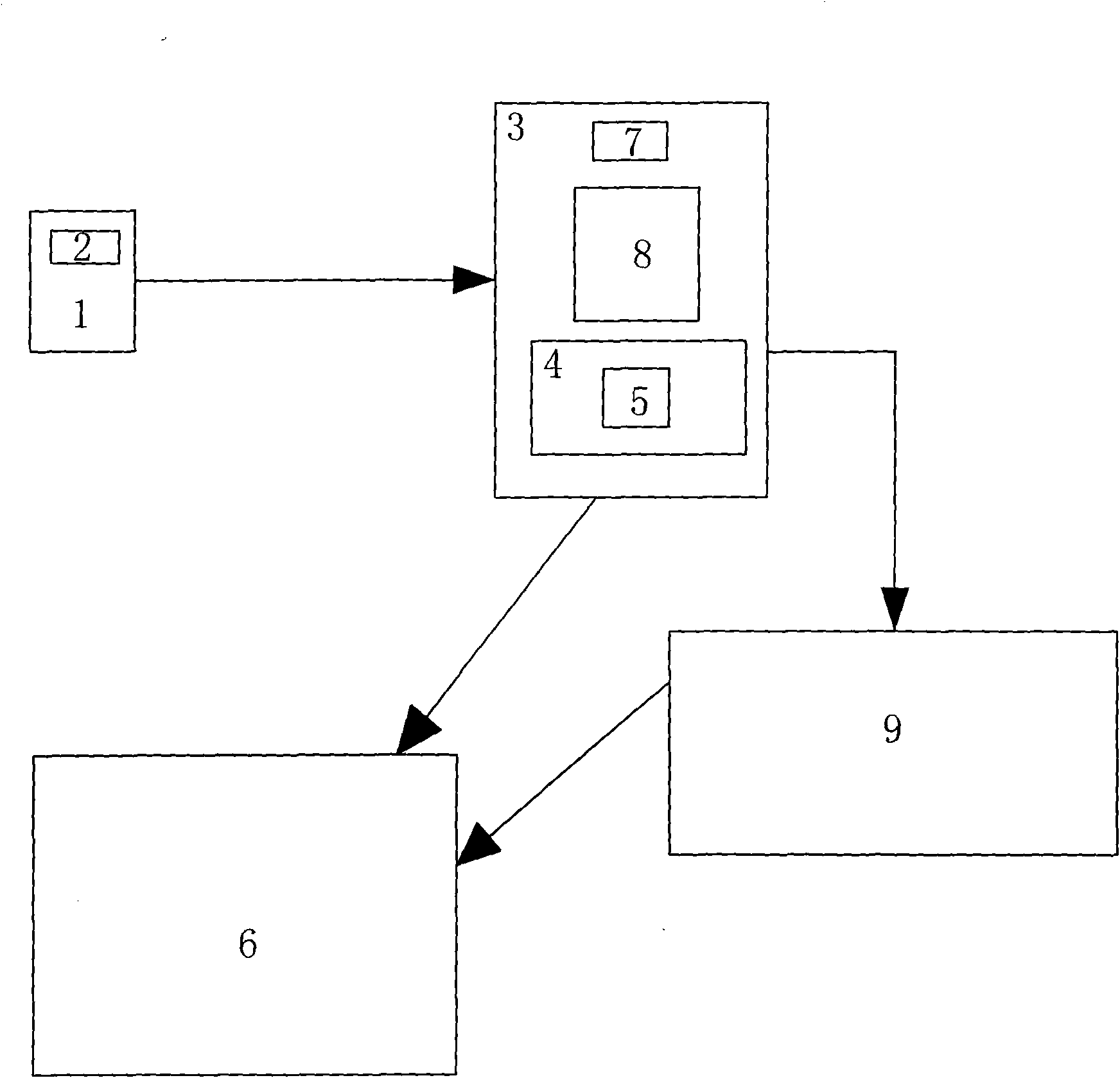

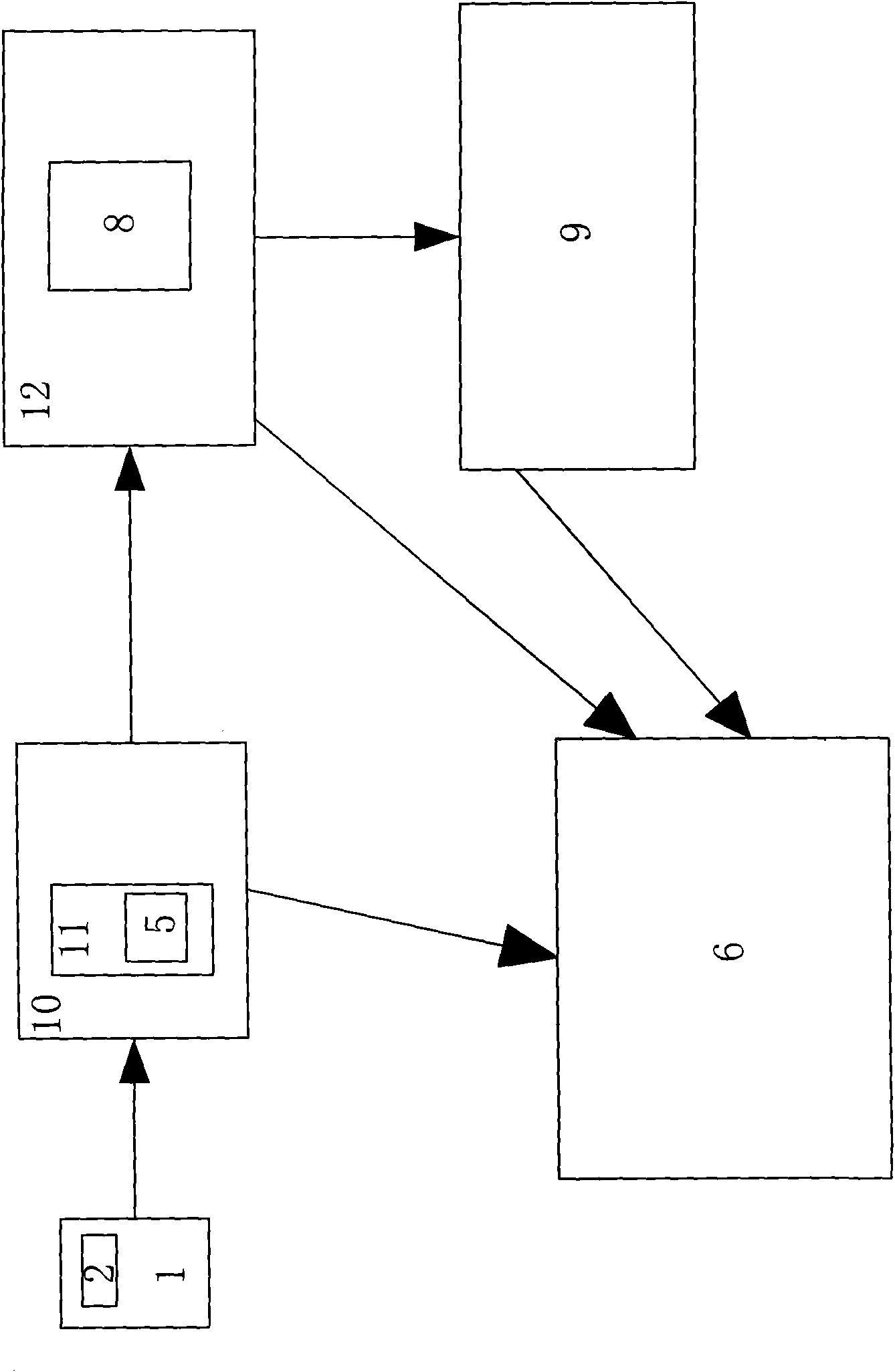

Advanced mask cleaning and handling

InactiveUS20040090605A1Facilitates high levelOptimal removal of contaminantInvestigating moving sheetsSemiconductor/solid-state device manufacturingLithographic artistEngineering

Apparatus for semiconductor device fabrication, includes at least one lithography station, which is adapted to project a pattern of radiation from a mask onto a semiconductor wafer. A mask cleaning station is adapted to receive the mask from the at least one lithography station, to clean the mask so as to remove a contaminant therefrom, and so that the cleaned mask may be returned to the at least one lithography station. A robot is adapted to convey the mask between the at least one lithography station and the mask cleaning station. An enclosure contains the at least one lithography station, the mask cleaning station and the robot, so that the mask is conveyed between the at least one lithography station and the mask cleaning station without human contact and without exposure to ambient air.

Owner:APPL MATERIALS ISRAEL LTD

Variable cut-off offset press system and method of operation

InactiveUS7066088B2Aid in smooth operation of systemIncrease frictionCylinder pressesTransfer printingImage transferCleaning station

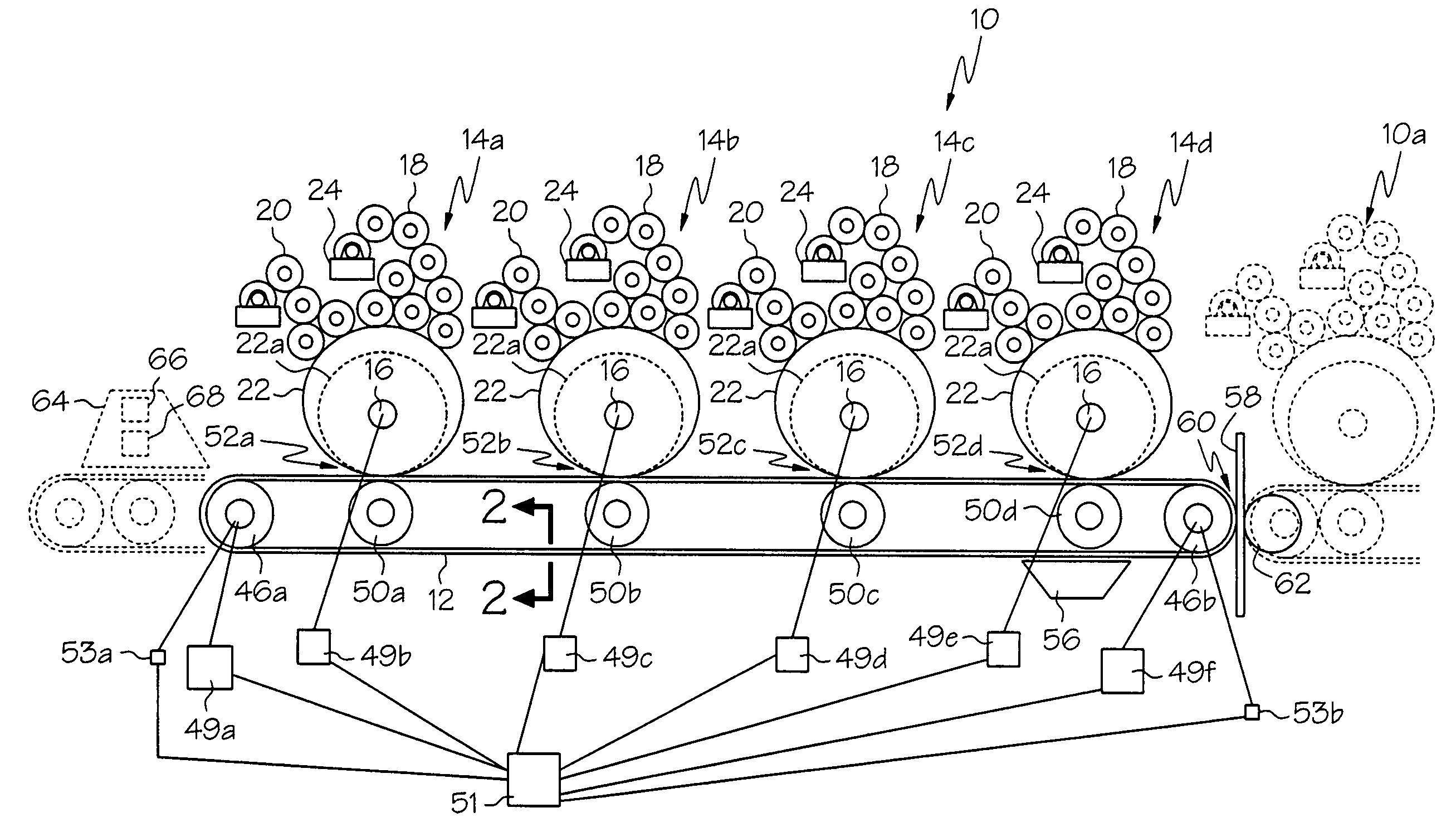

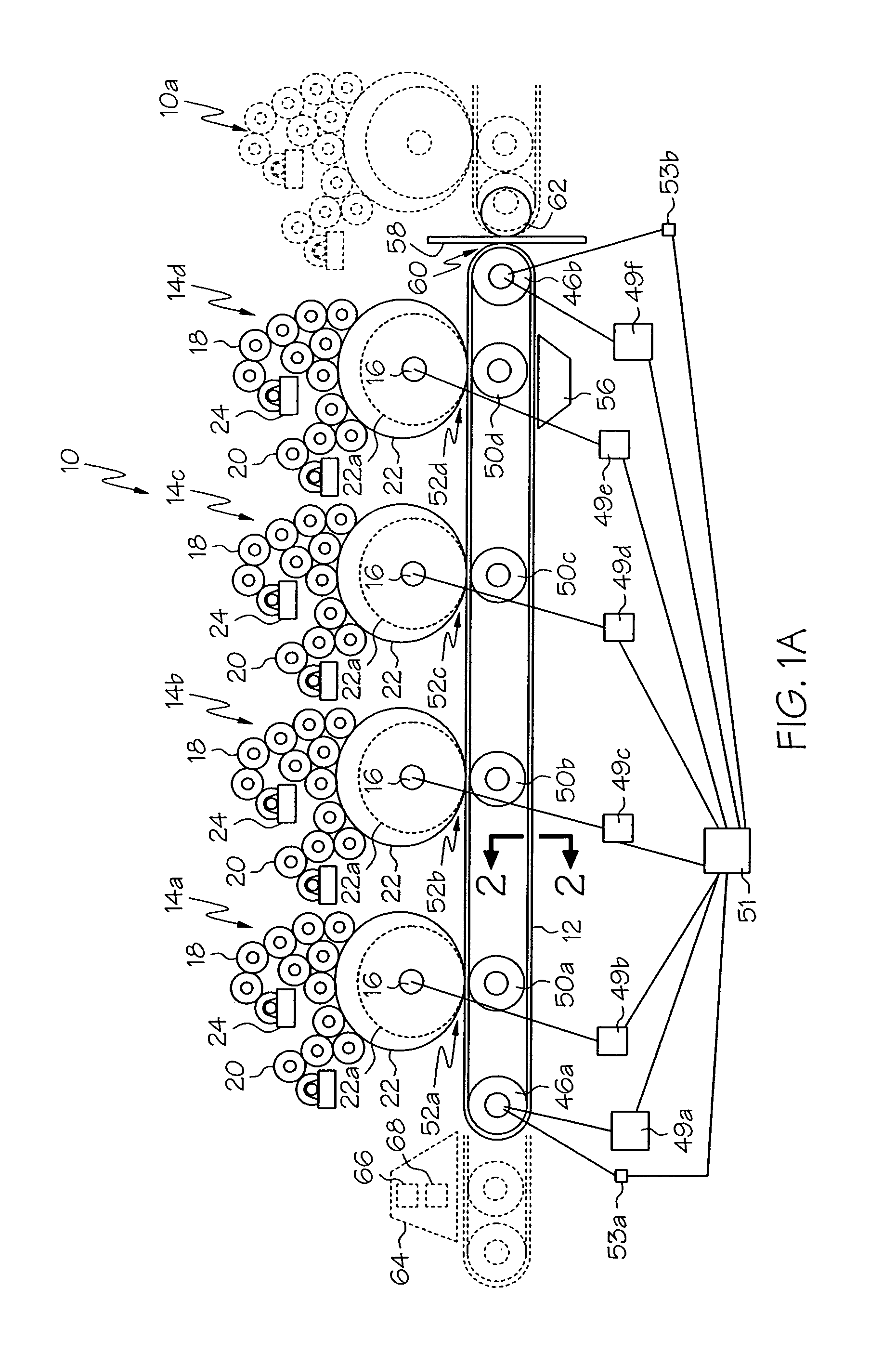

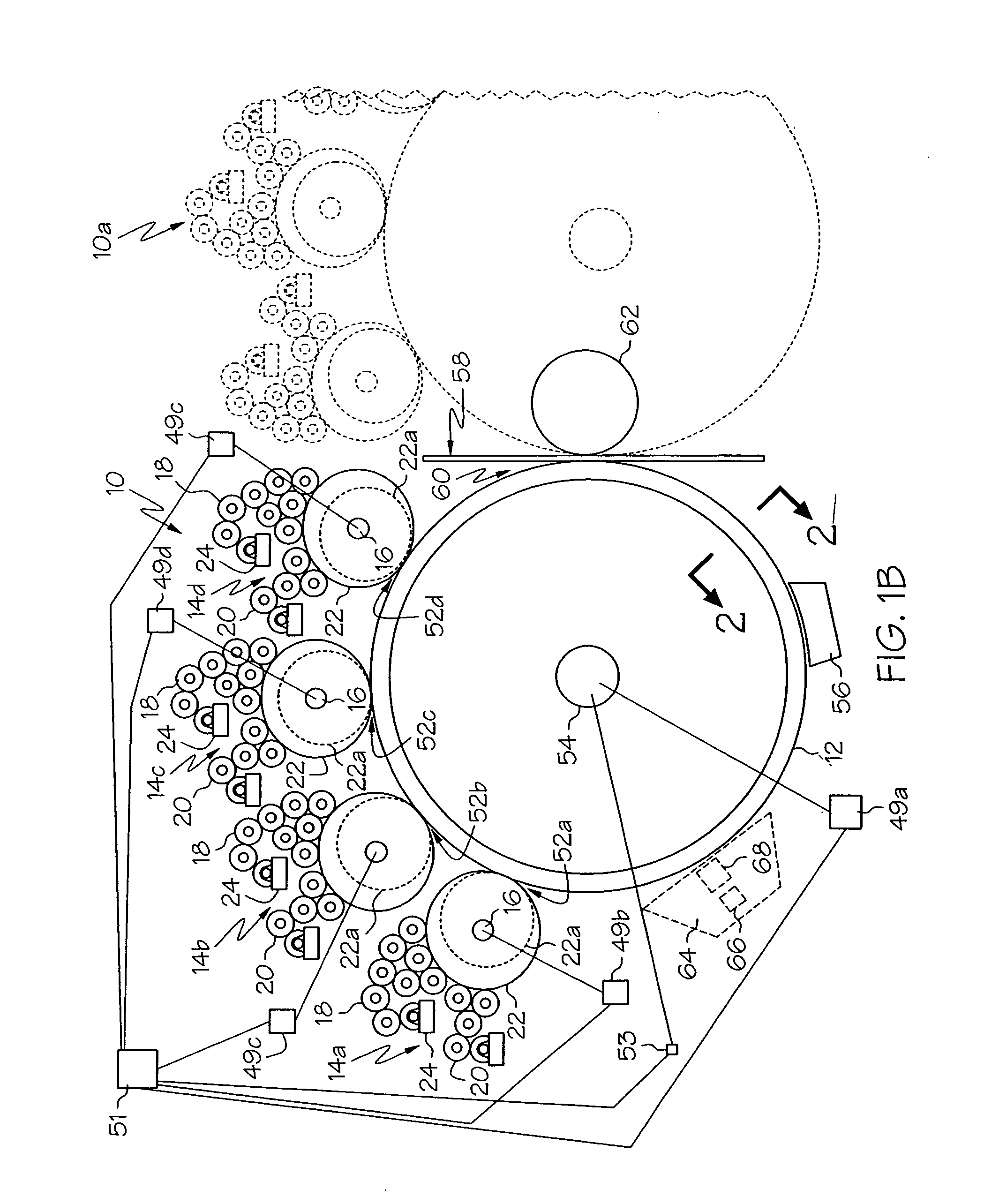

A variable cut-off offset press system and method of operation which utilizes a continuous image transfer belt is provided. The offset printing system comprises at least two plate cylinders adapted to have thereon respective printing sleeves. Each of the printing sleeves is adapted to receive colored ink from a respective ink source. An optional coating source may be provided to fully or partially coat the image transfer belt before inking. The system further comprises at least a impression cylinder, wherein the image transfer belt is positioned to contact each of the printing sleeves at respective nips formed between respective ones of the plate cylinders and the at least one impression cylinder. An image belt cleaning station adapted to remove residual ink or coating from the surface of the image transfer belt after image transfer of a multicolored image from the image transfer belt to a substrate is also provided.

Owner:DAY INT

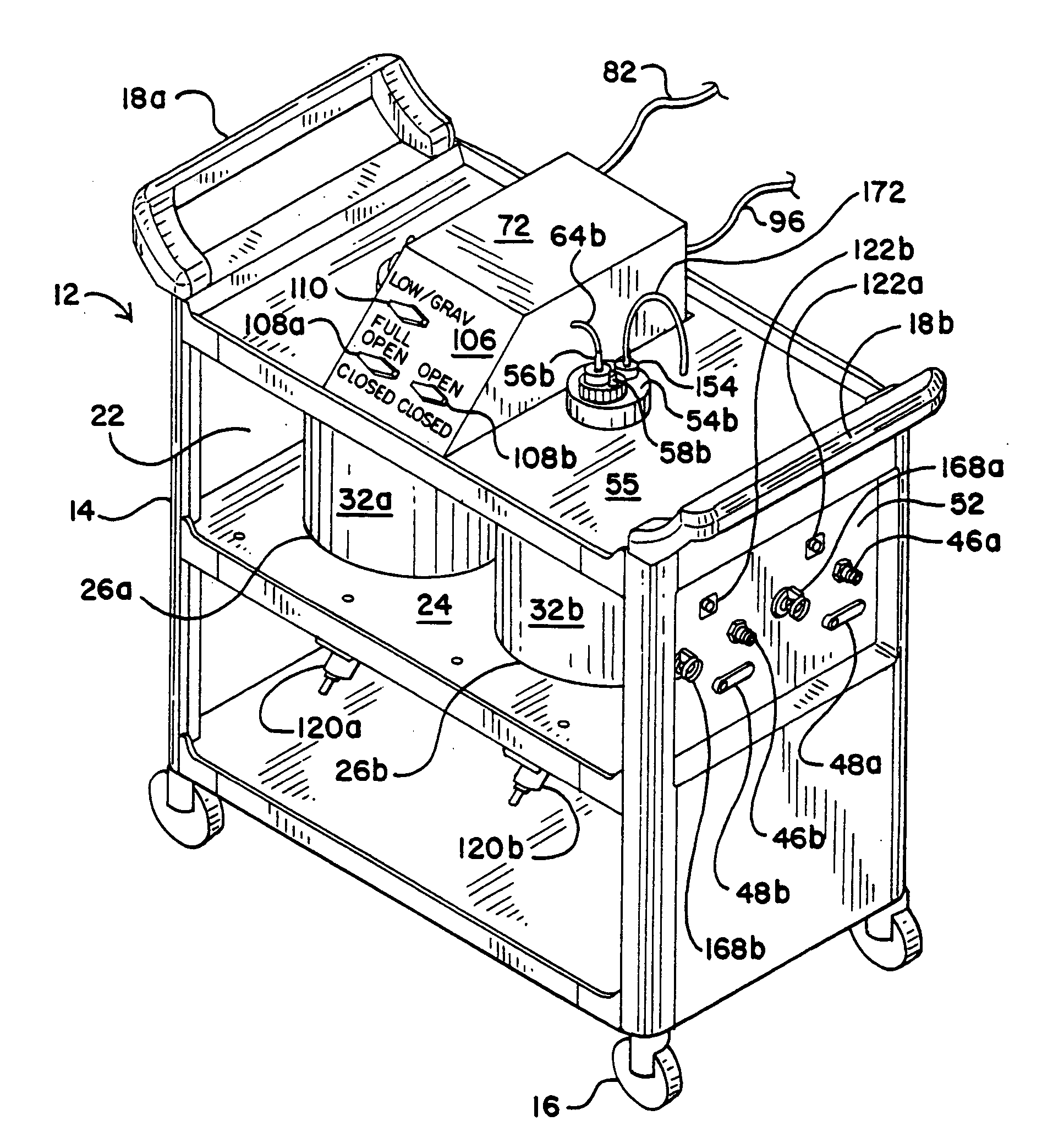

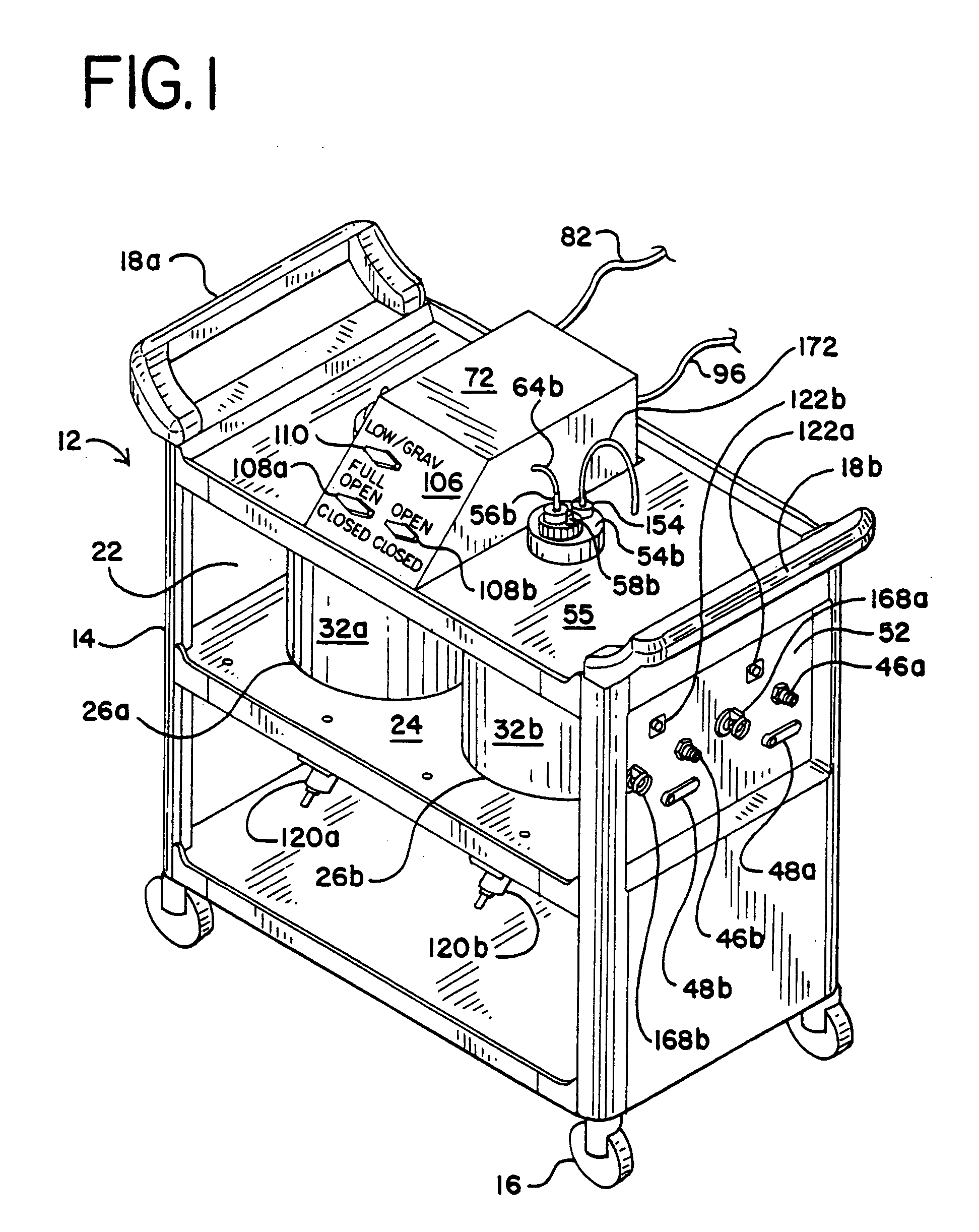

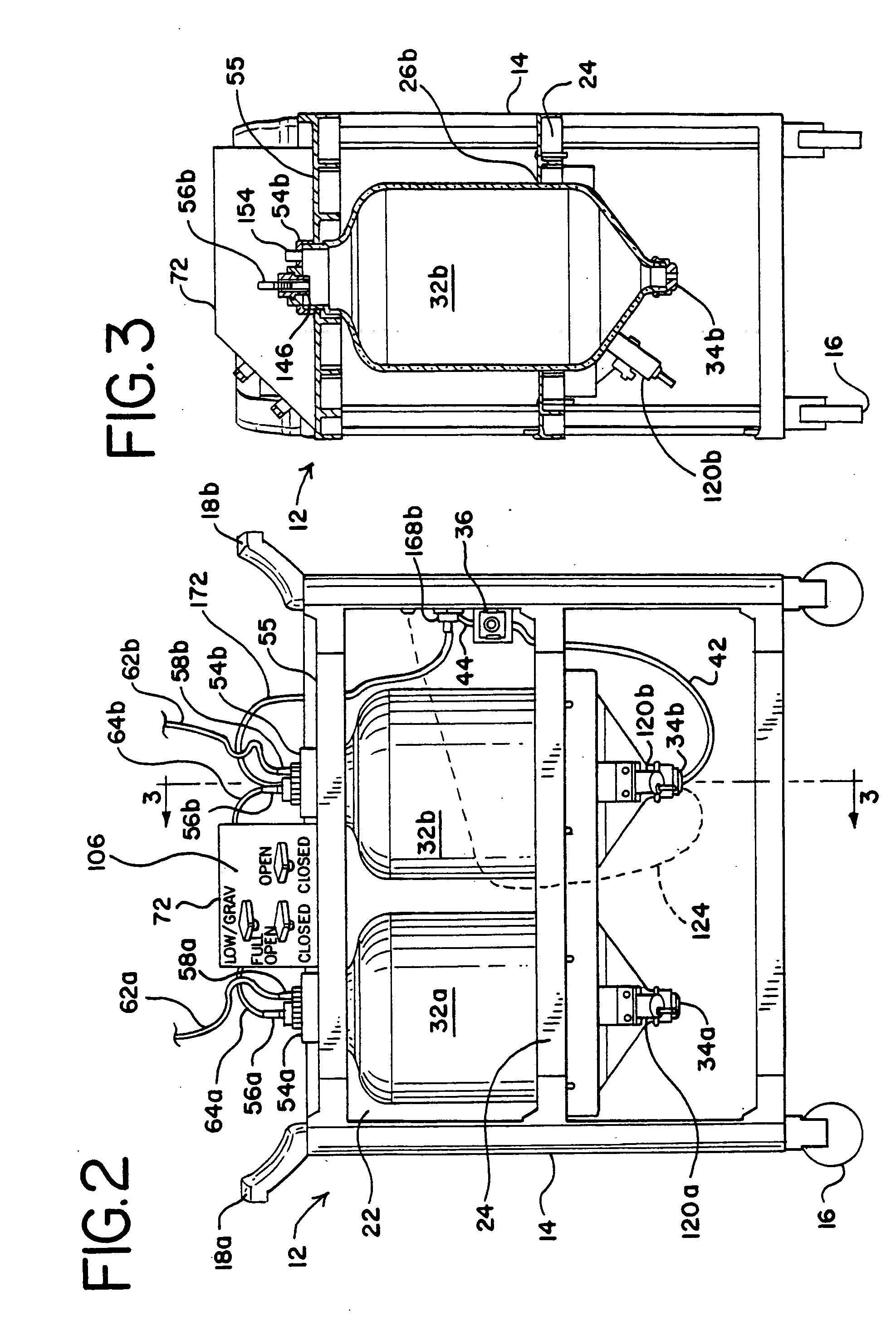

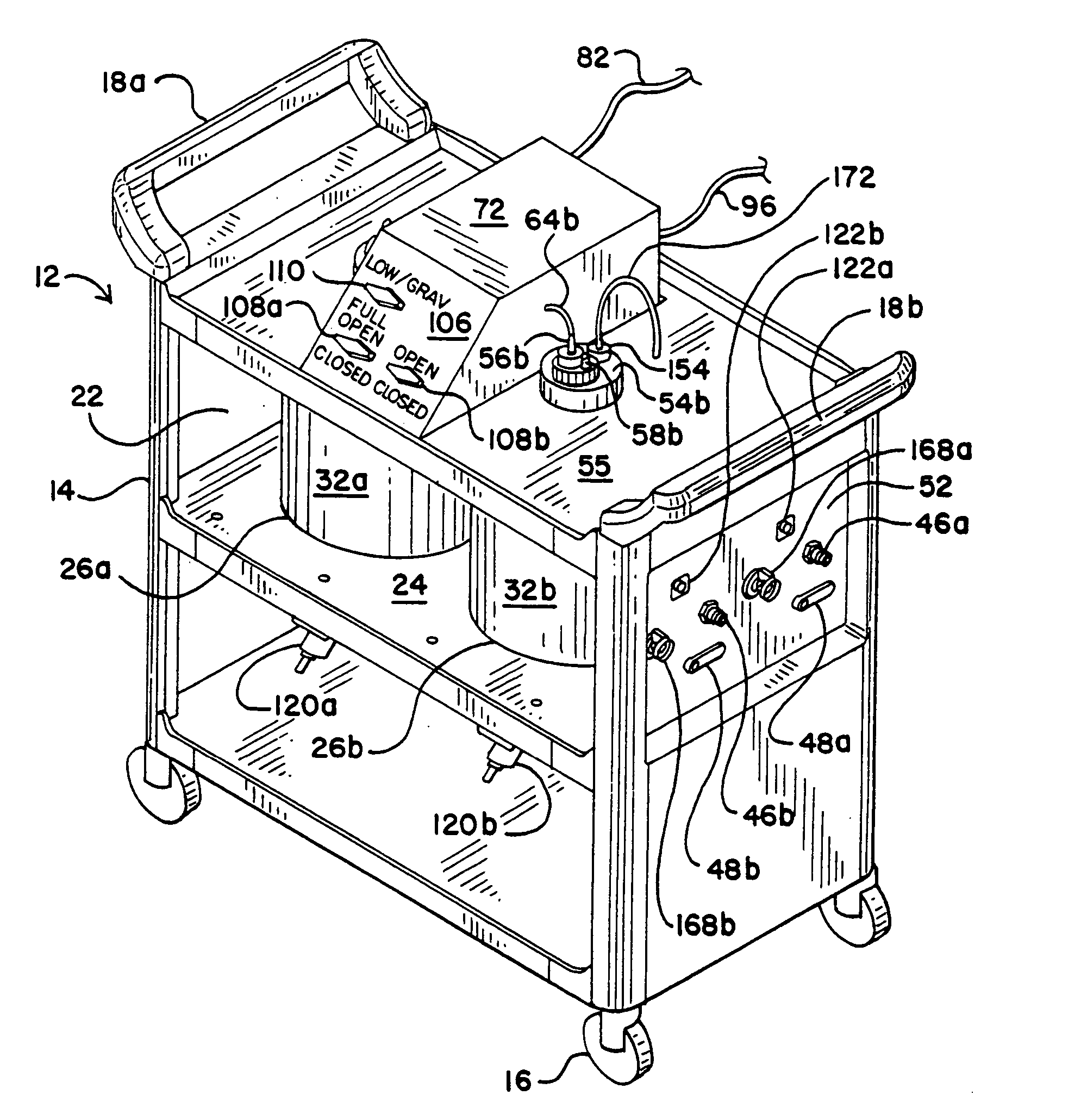

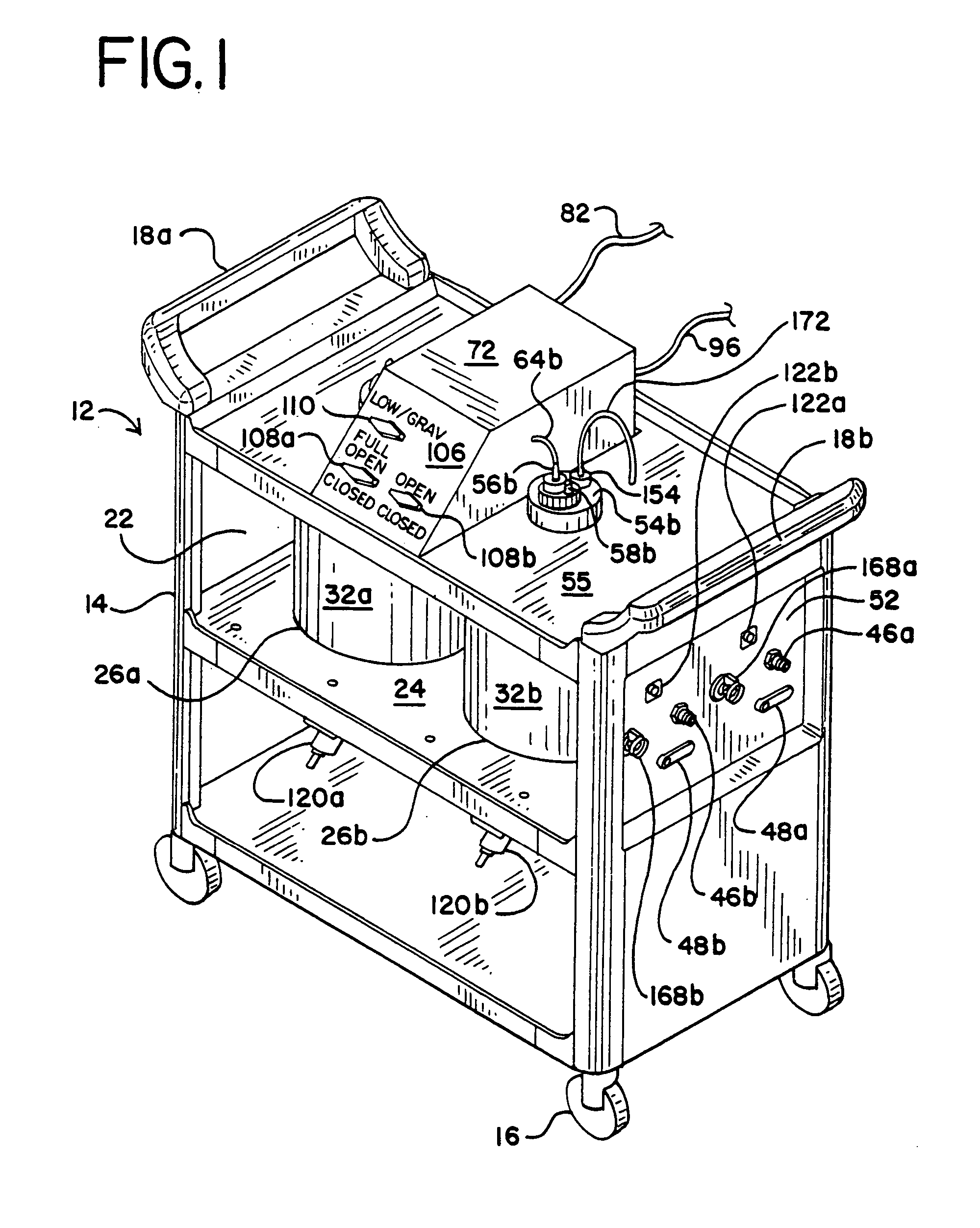

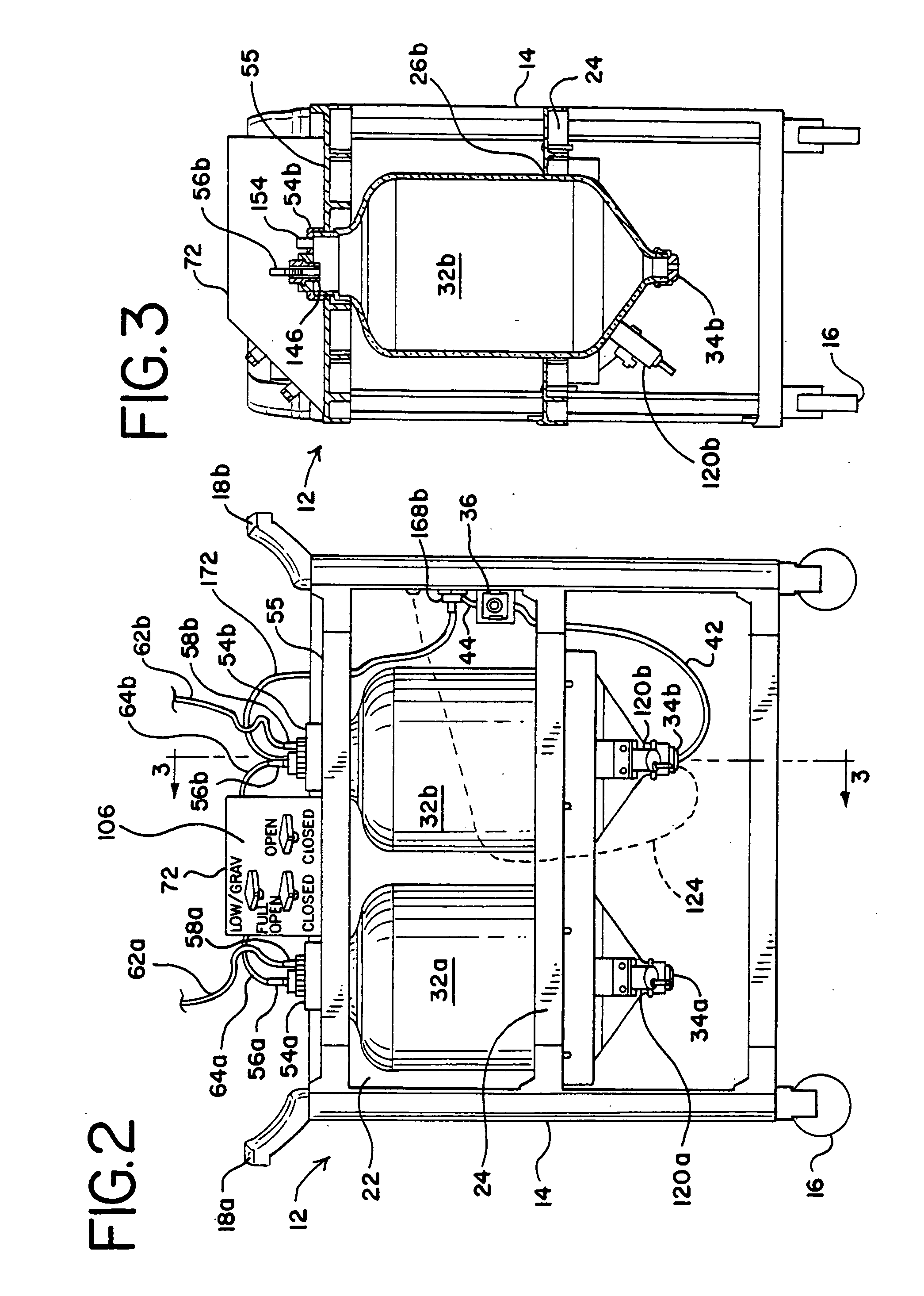

High volume liquid waste collection and disposal system

A system for collecting and disposing of liquid medical waste includes a fluid collection cart and a draining and cleaning station. The fluid collection cart includes a pair of containers, each of which includes a draining port and a cap. Each cap includes an outer portion having a flushing port and a bore formed therein and an inner portion having vacuum and patient ports formed therein. The inner cap portion is disposable and removably positioned within the bore of the outer cap portion. Liquid level detectors also communicate with each container. The cart also includes a regulator so a low vacuum level may be pulled on one of the containers while a full vacuum level is pulled on the other container. Fluids are collected in the containers via suction tubes connected to the patient ports. The flushing and drain ports of the containers are connected to corresponding flushing and drain connectors on the station when the containers are full so that they may be drained and flushed. The cart liquid level detectors communicate with the station microprocessor so that the draining and flushing cycles may be properly sequenced. The station may also clean suction canisters.

Owner:DORNOCH MEDICAL SYST

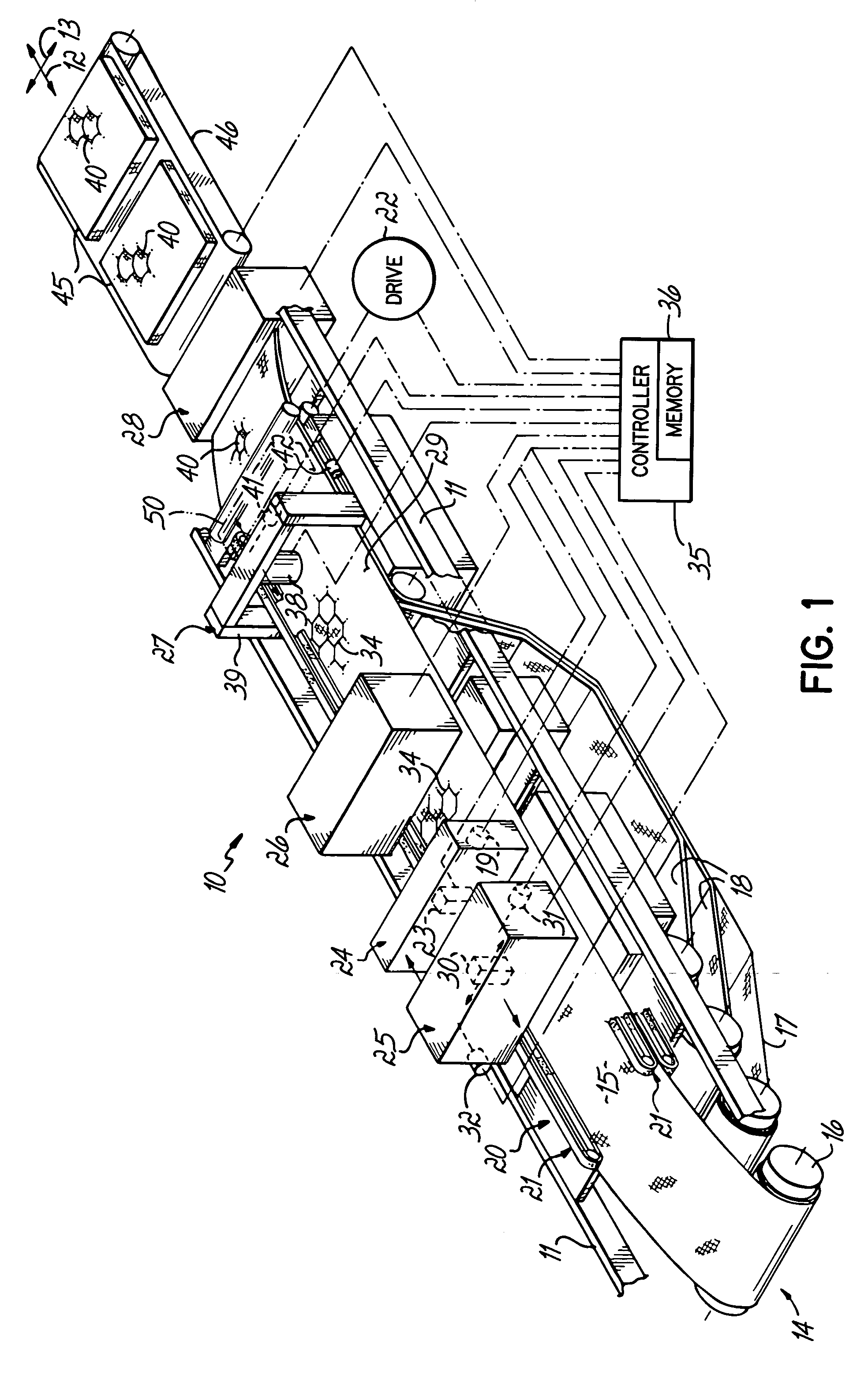

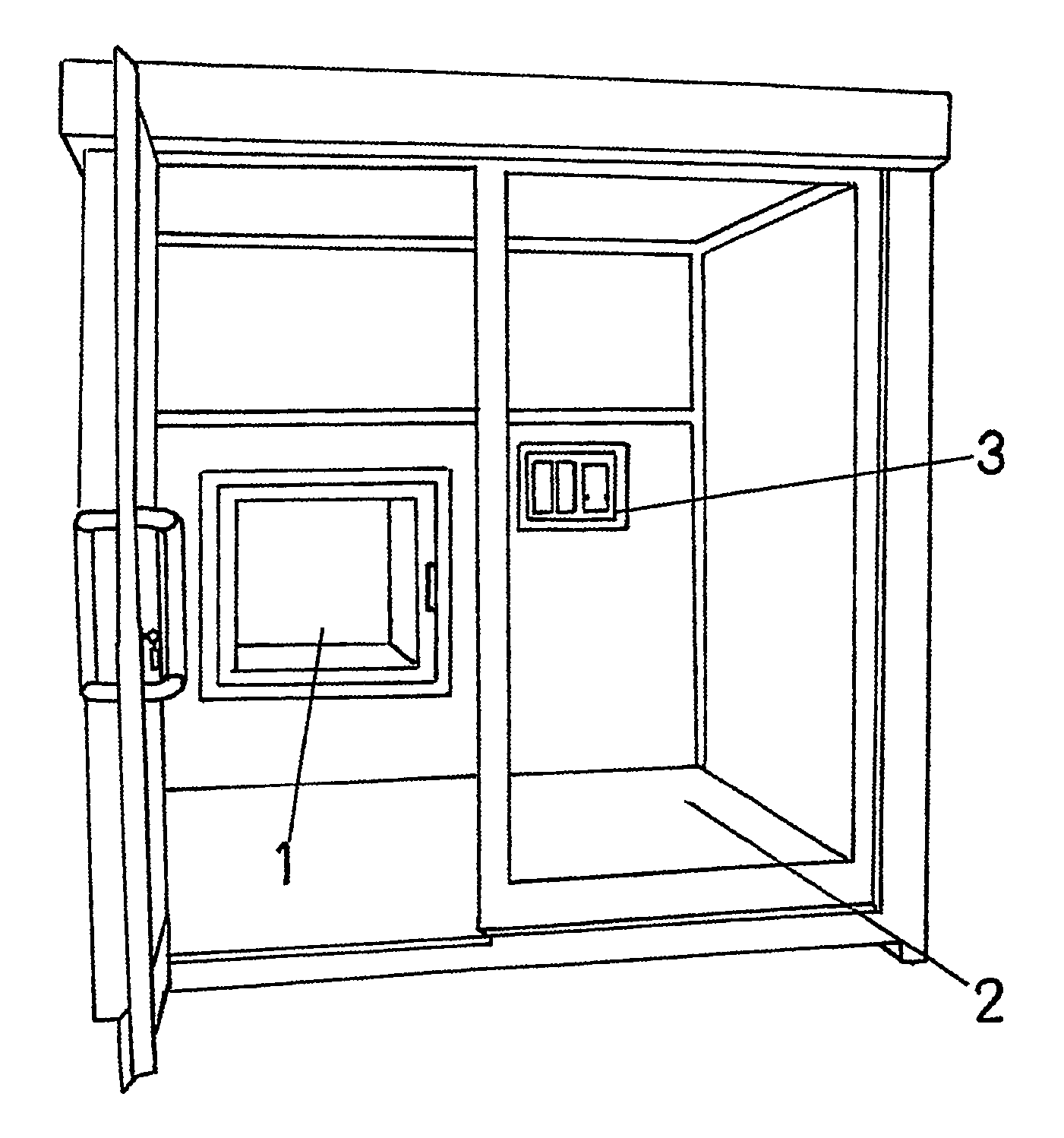

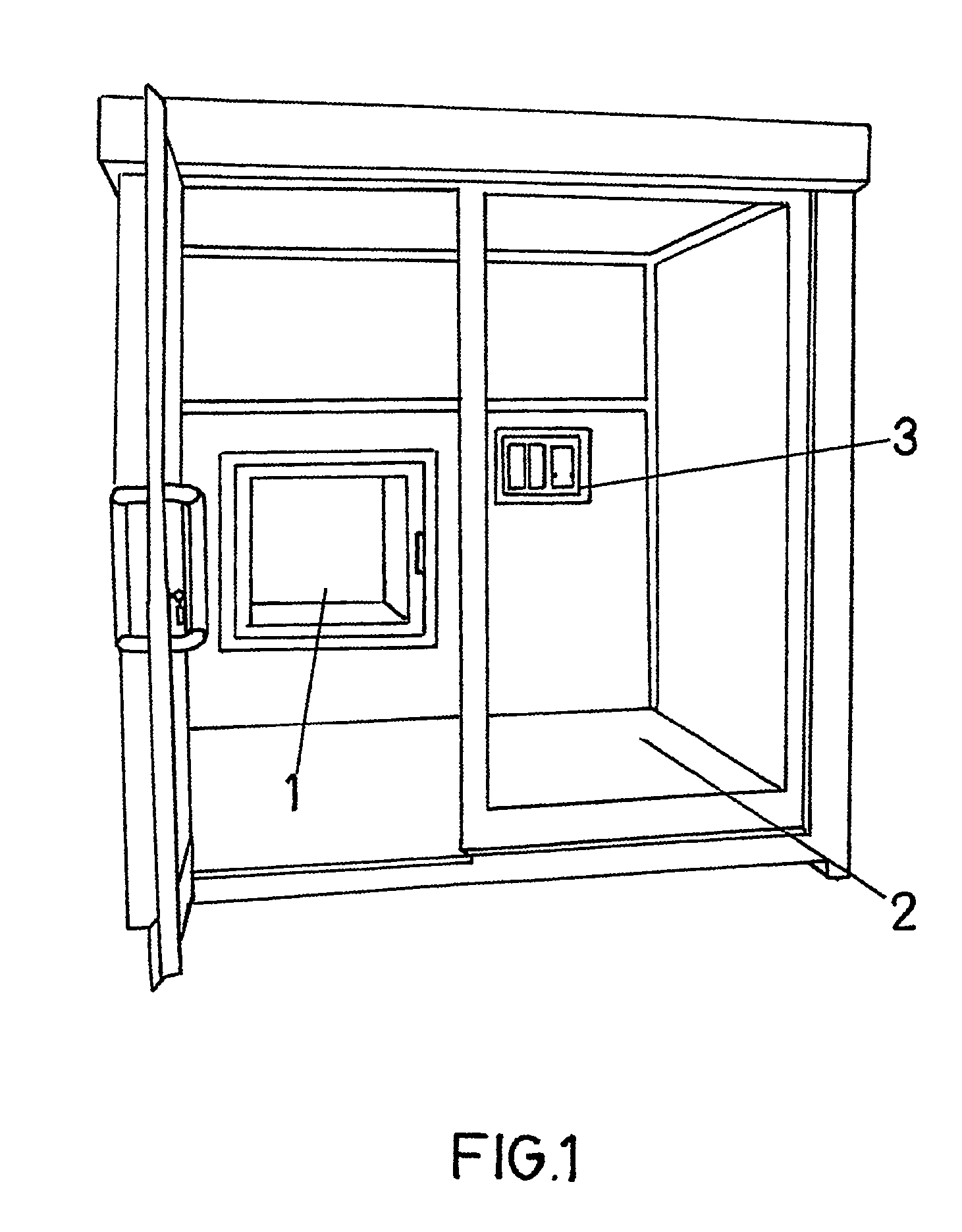

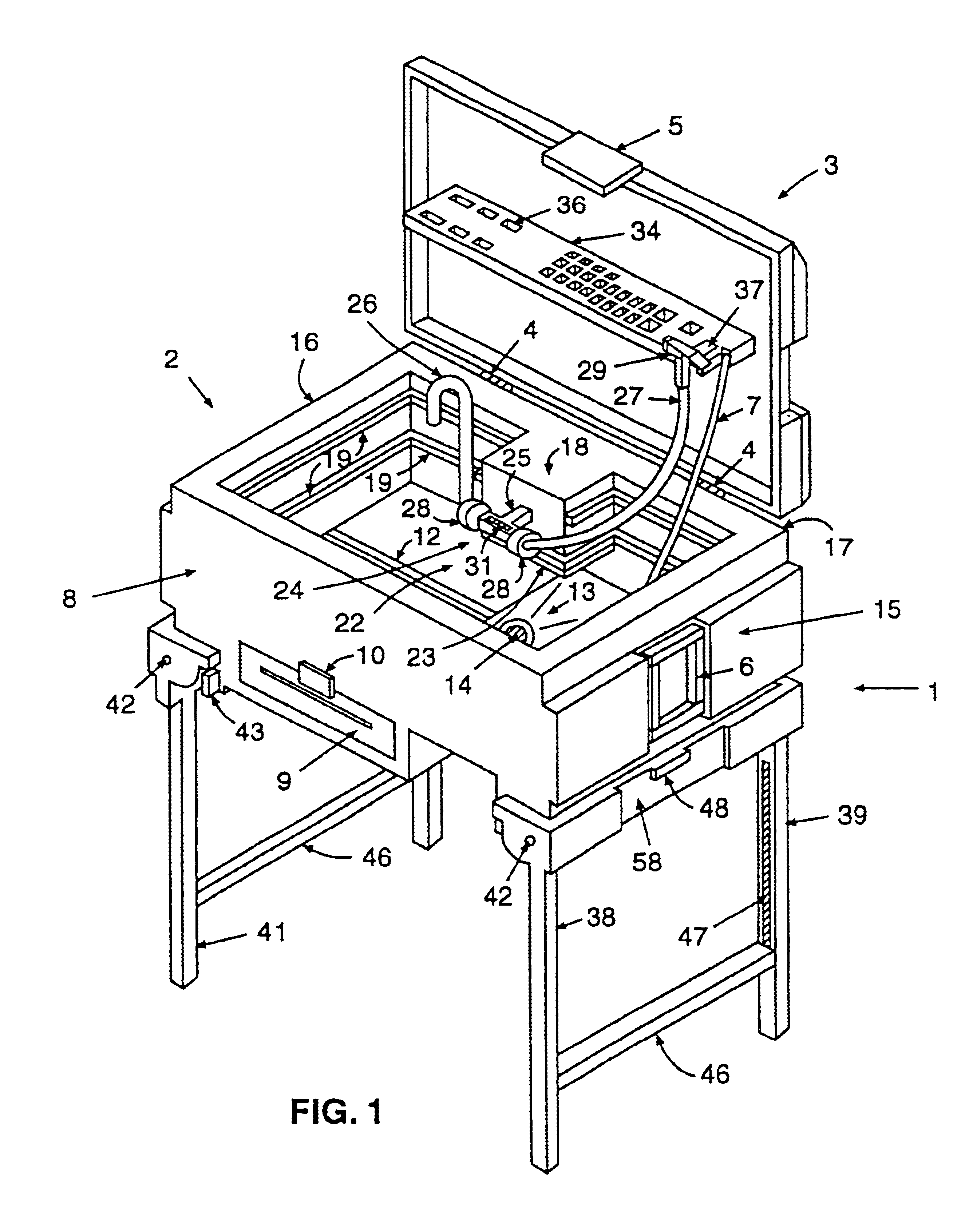

Station for preparing cleaning disinfecting delousing and hydromassaging animals

InactiveUS7011044B2Improve performancePreventing lime deposits on the circuit elementsOther apparatusGrooming devicesHydraulic circuitCleaning station

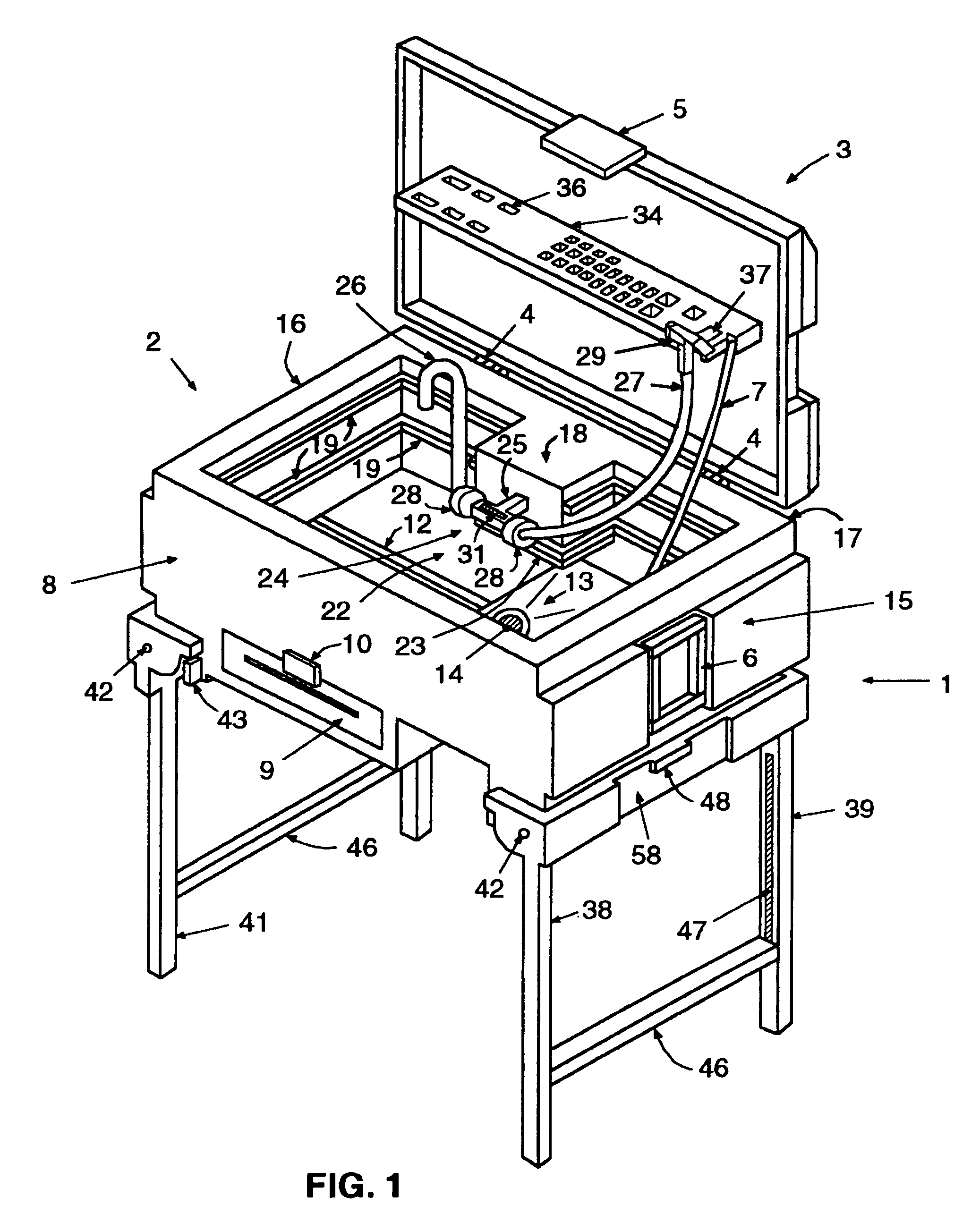

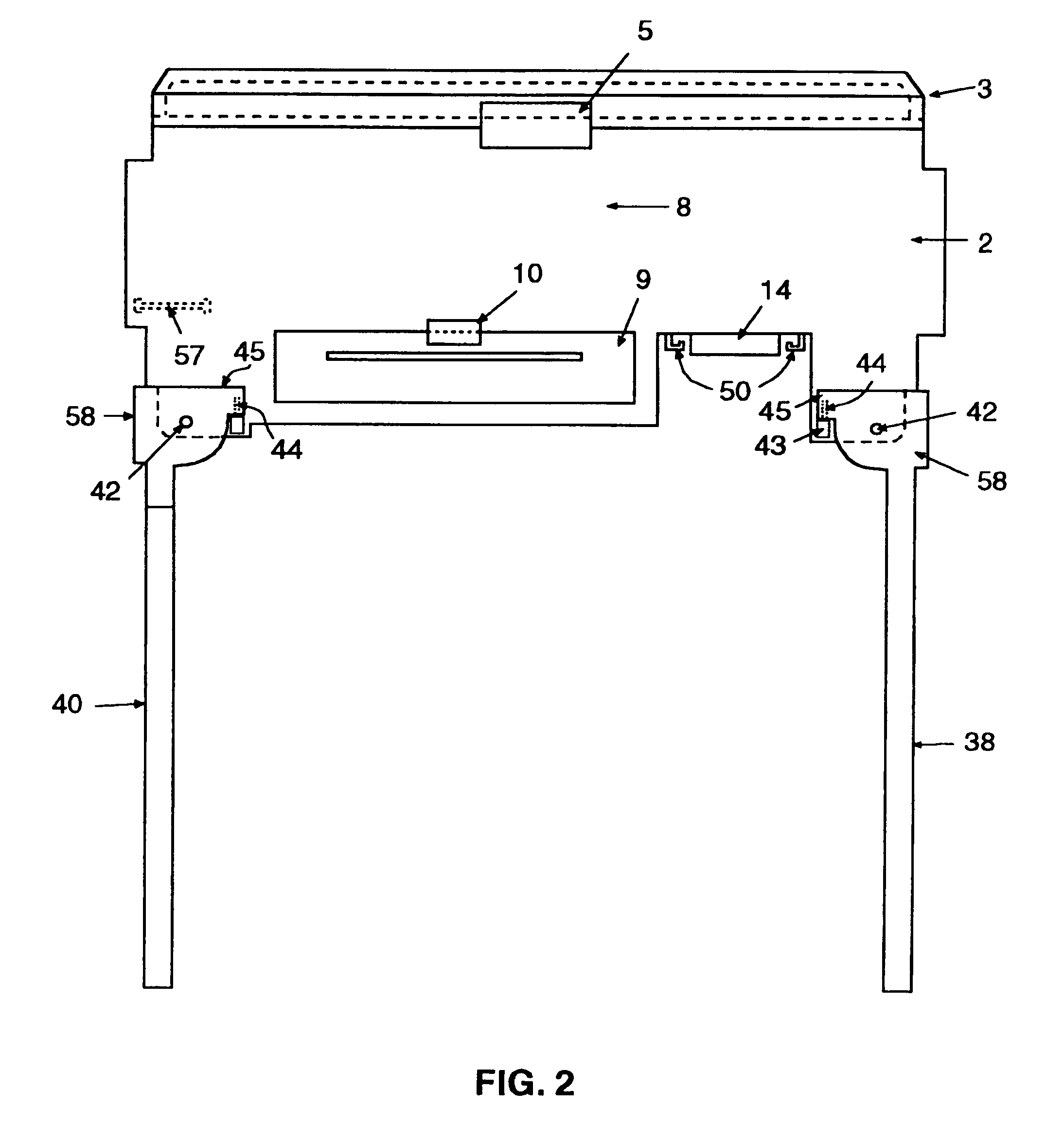

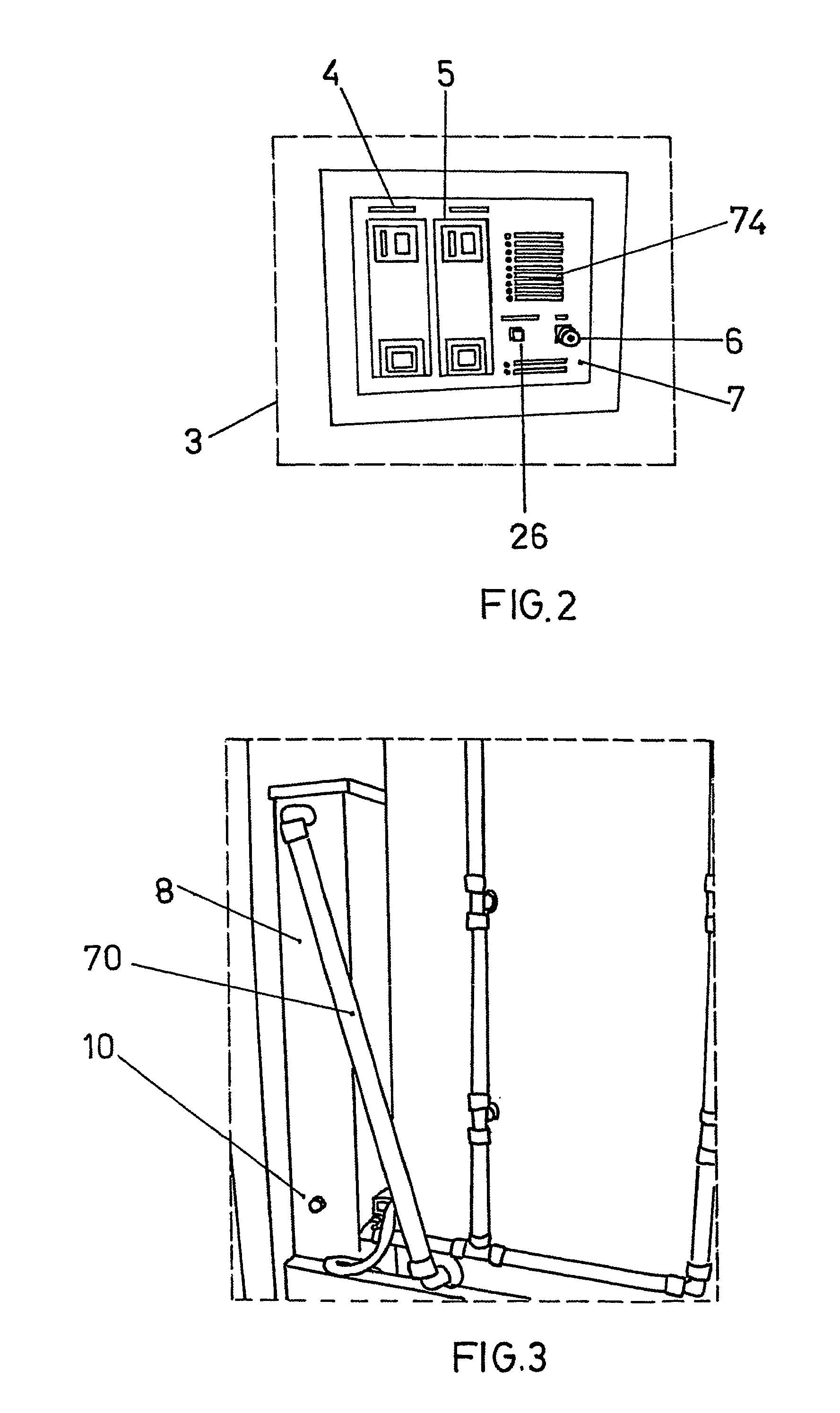

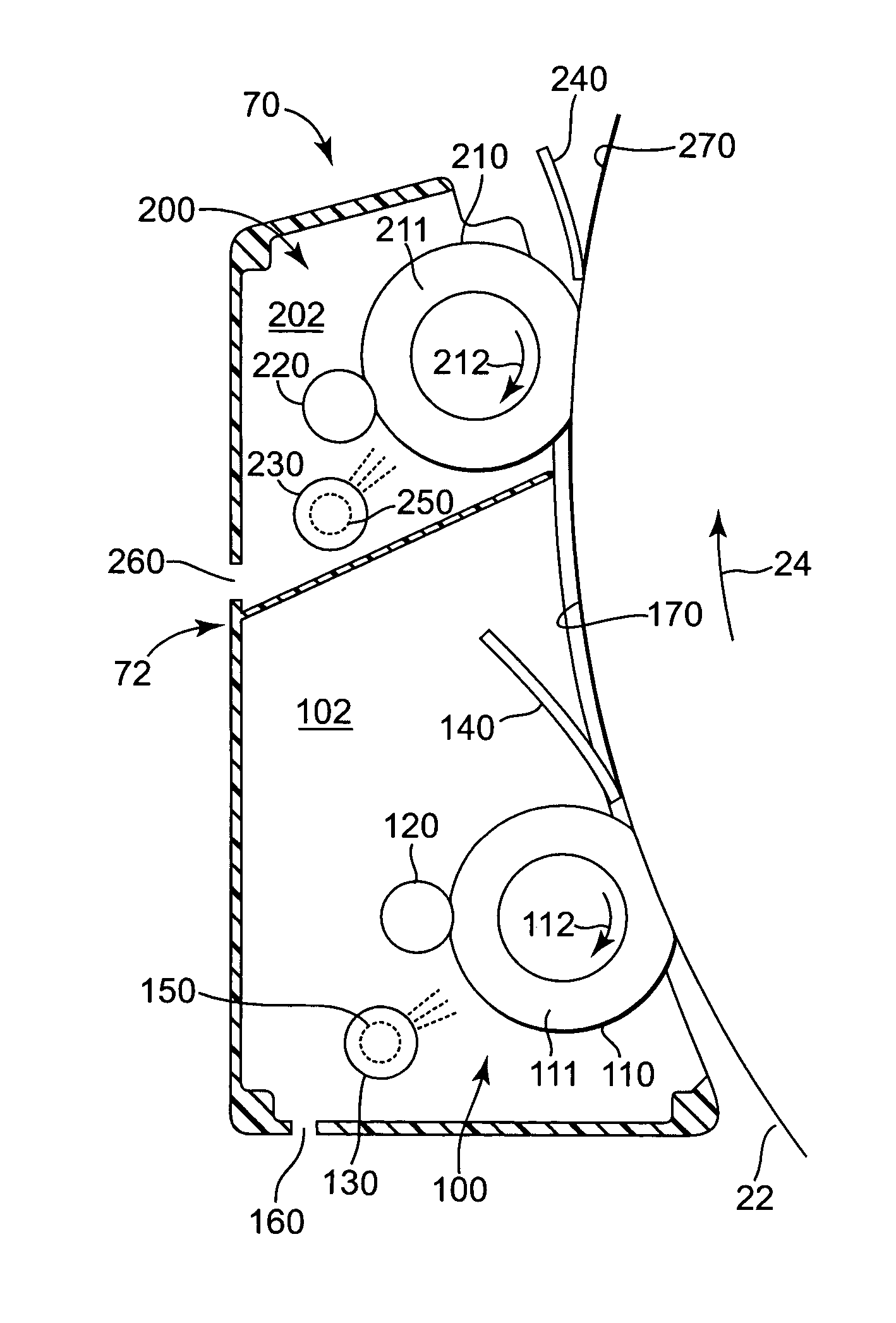

The invention relates to a cleaning station comprising a glass enclosure (2) in which the animals are prepared before and after washing. The glass enclosure (2) comprises the actual washing enclosure (1) and a control panel (3) which are controlled by a controller or PLC. According to the invention, the interior of the enclosure (1) is disinfected with each washing procedure. Moreover, the invention comprises: safety a mechanism for the hydraulic circuit and the electronics which are actuated when the door (72) of the enclosure (1) or the switchboard is opened, a frequency variator / converter which can be used to adjust the flow of air and water, and moisture and unpleasant odour extractors.

Owner:SEGURA JOBAL EDUARDO

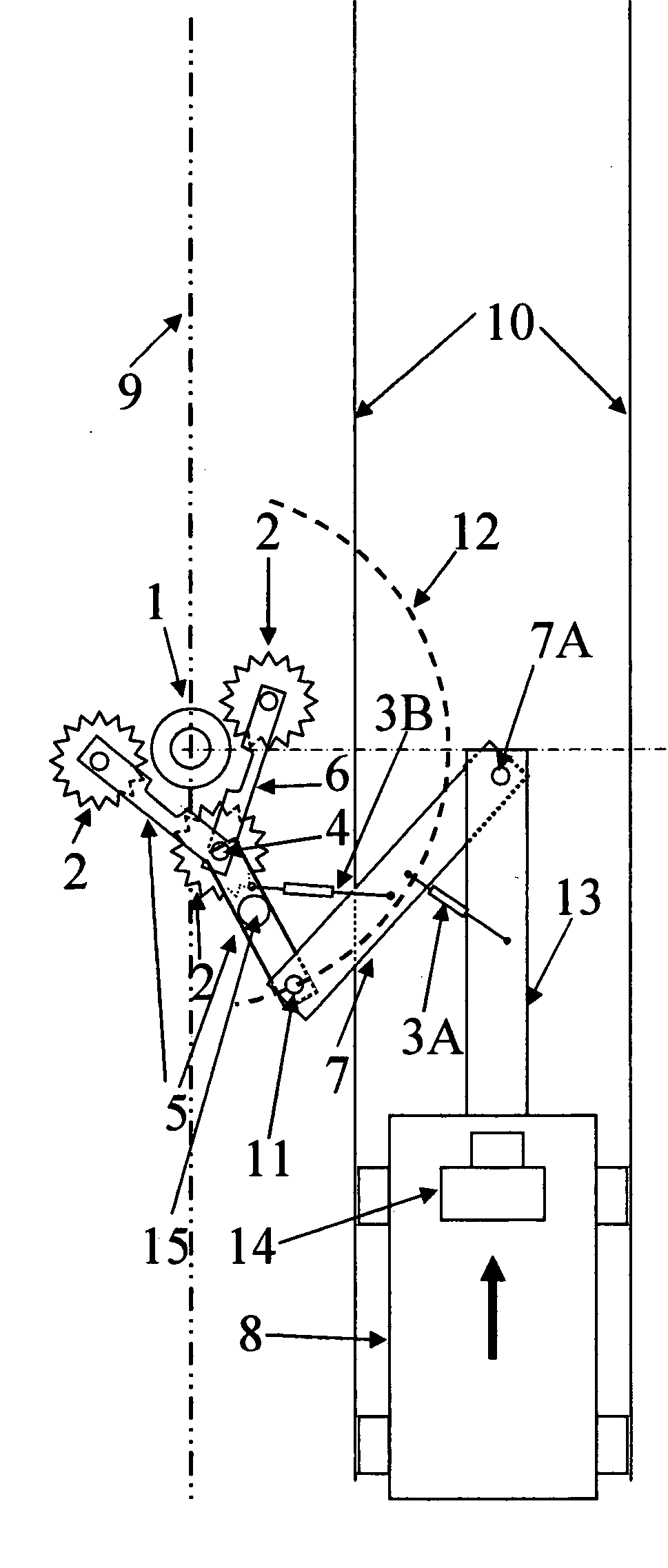

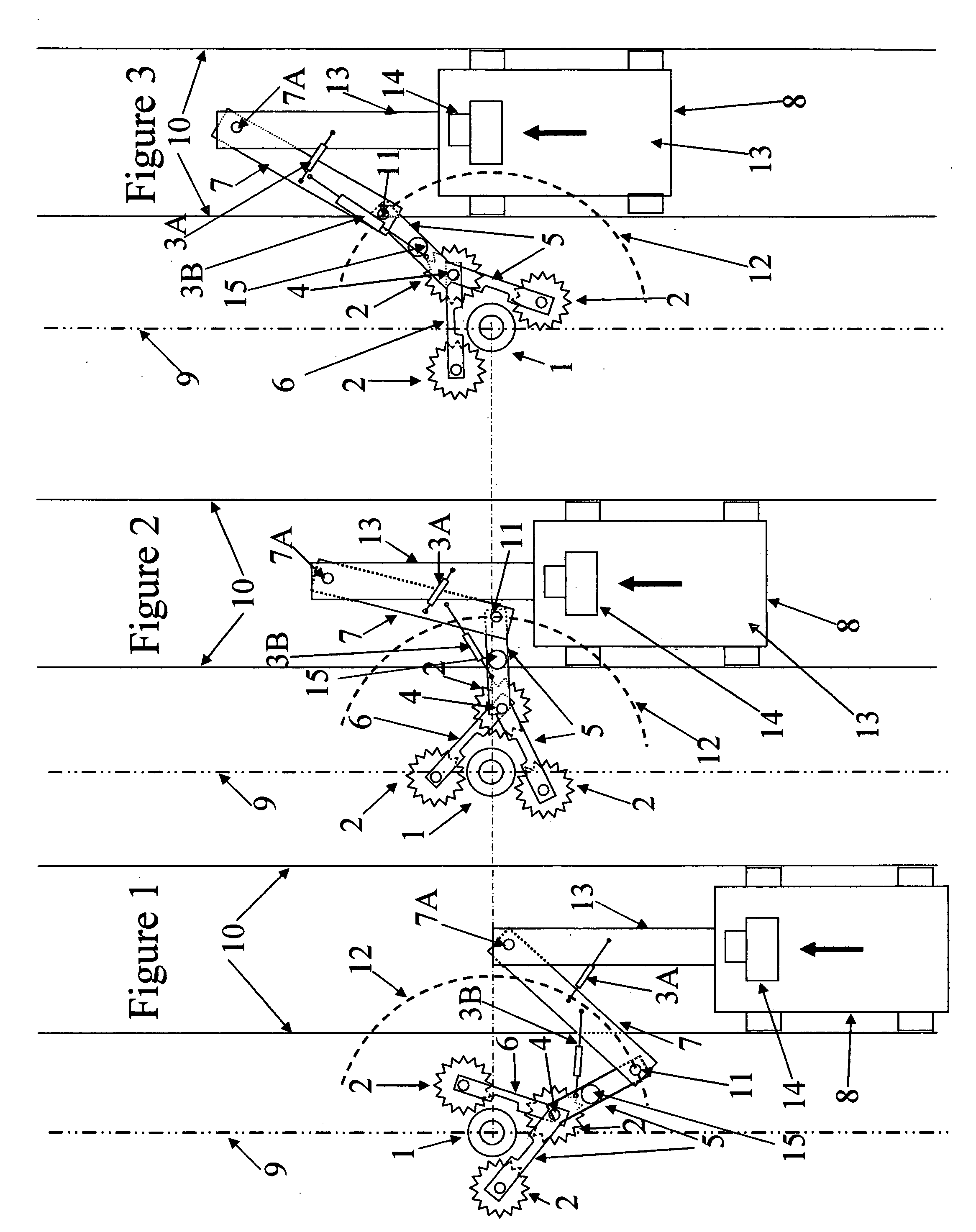

Device and process for cleaning electrified contact rail insulators for rail rapid transit systems

InactiveUS20050268940A1Fast and low-cost cleaningBrush bodiesVehicle cleaning apparatusCleaning stationAcoustic wave

A device and process for cleaning electrical insulators mounted under an electrified contact rail parallel to a rail track comprises positioning arm(s) attached to a vehicle that travels on the track and a cleaning station with fixed or moveable fingers. The fingers have attached cleaning tools and engage, operate on, partly rotate around the circumference of the insulator, and disengage, as the vehicle passes by the insulator. The cleaning station can also ride on the contact rail and have moveable vertical members with cleaning tools attached to L-shaped tool holders that rotate around a portion of the circumference of the insulator. Cleaning tools include powered rotating, reciprocating, vibrating, oscillating and / or linear brushes, wrap-around cleaning belts, sonic horns, ultrasonic vibrating guns, lasers, pressure washing and / or water jetting nozzles on stationary, rotating or oscillating spray bars and spinning heads using steam, tap or deionized water, and pneumatic polishing nozzles.

Owner:VOHRA ARUN

Apparatus for electroless deposition of metals onto semiconductor substrates

An electroless deposition system and electroless deposition stations are provided. The system includes a processing mainframe, at least one substrate cleaning station positioned on the mainframe, and an electroless deposition station positioned on the mainframe. The electroless deposition station includes an environmentally controlled processing enclosure, a first processing station configured to clean and activate a surface of a substrate, a second processing station configured to electrolessly deposit a layer onto the surface of the substrate, and a substrate shuttle positioned to transfer substrates between the first and second processing stations. The electroless deposition station also includes various fluid delivery and substrate temperature controlling devices to perform a contamination free and uniform electroless deposition process.

Owner:APPLIED MATERIALS INC

Hand cleaning station

Owner:ENFORC HYGIENE

Advanced mask cleaning and handling

InactiveUS6829035B2Facilitates high levelGood removal effectInvestigating moving sheetsSemiconductor/solid-state device manufacturingLithographic artistEngineering

Owner:APPL MATERIALS ISRAEL LTD

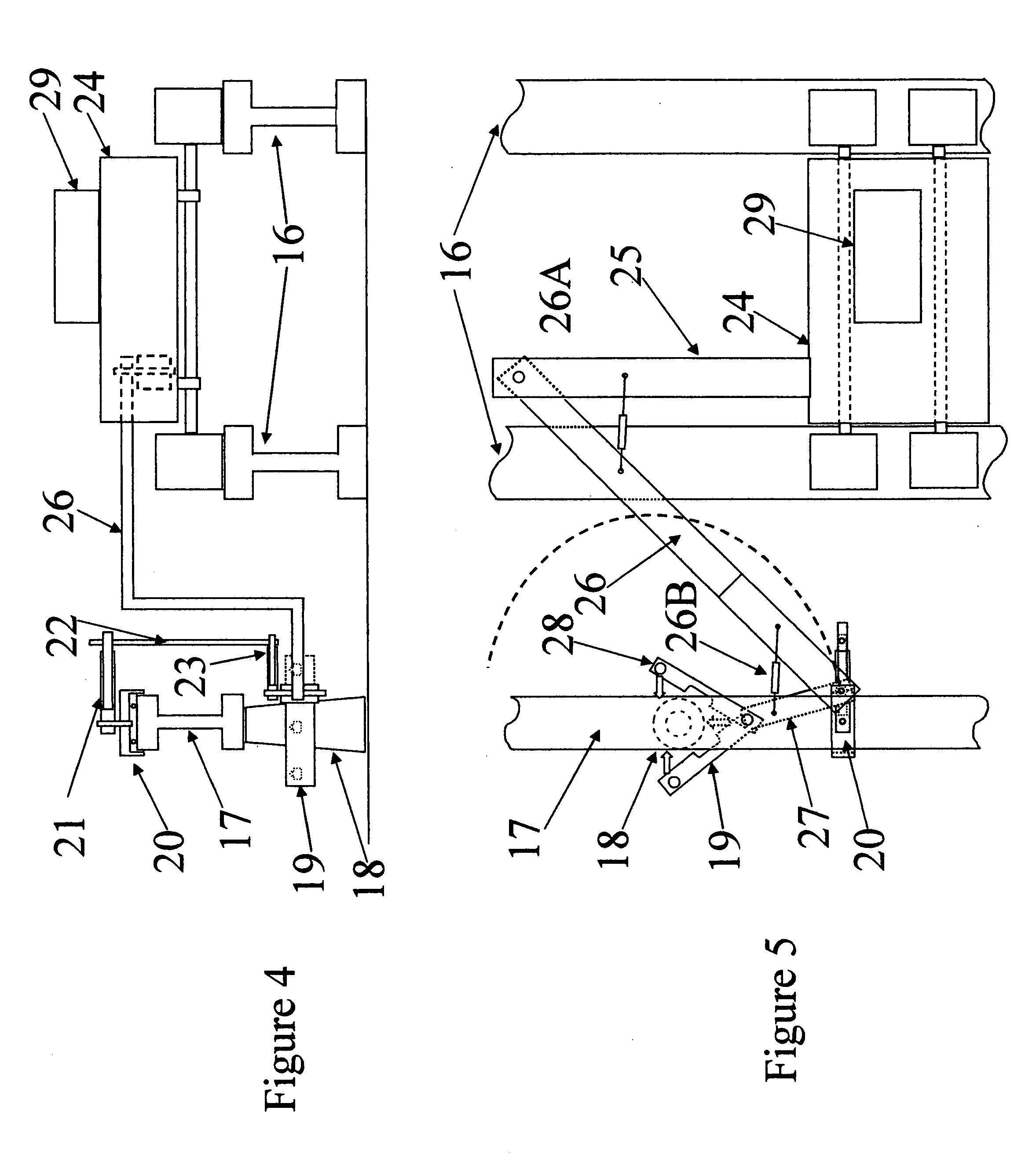

Automatic fiber preparation unit for splicing

InactiveUS20020064355A1Efficient arrangementSimple designFlexible article cleaningCoupling light guidesFiberEngineering

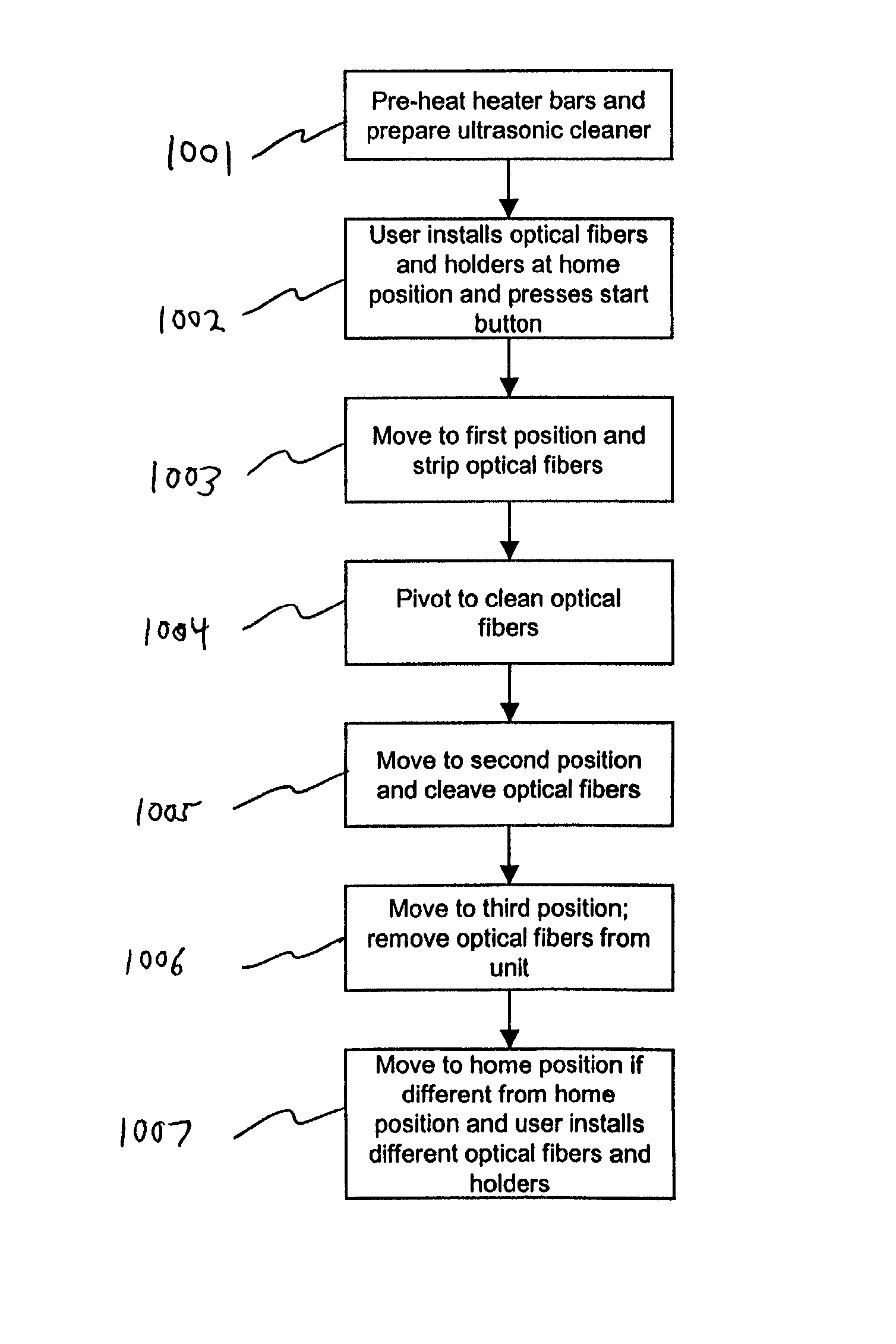

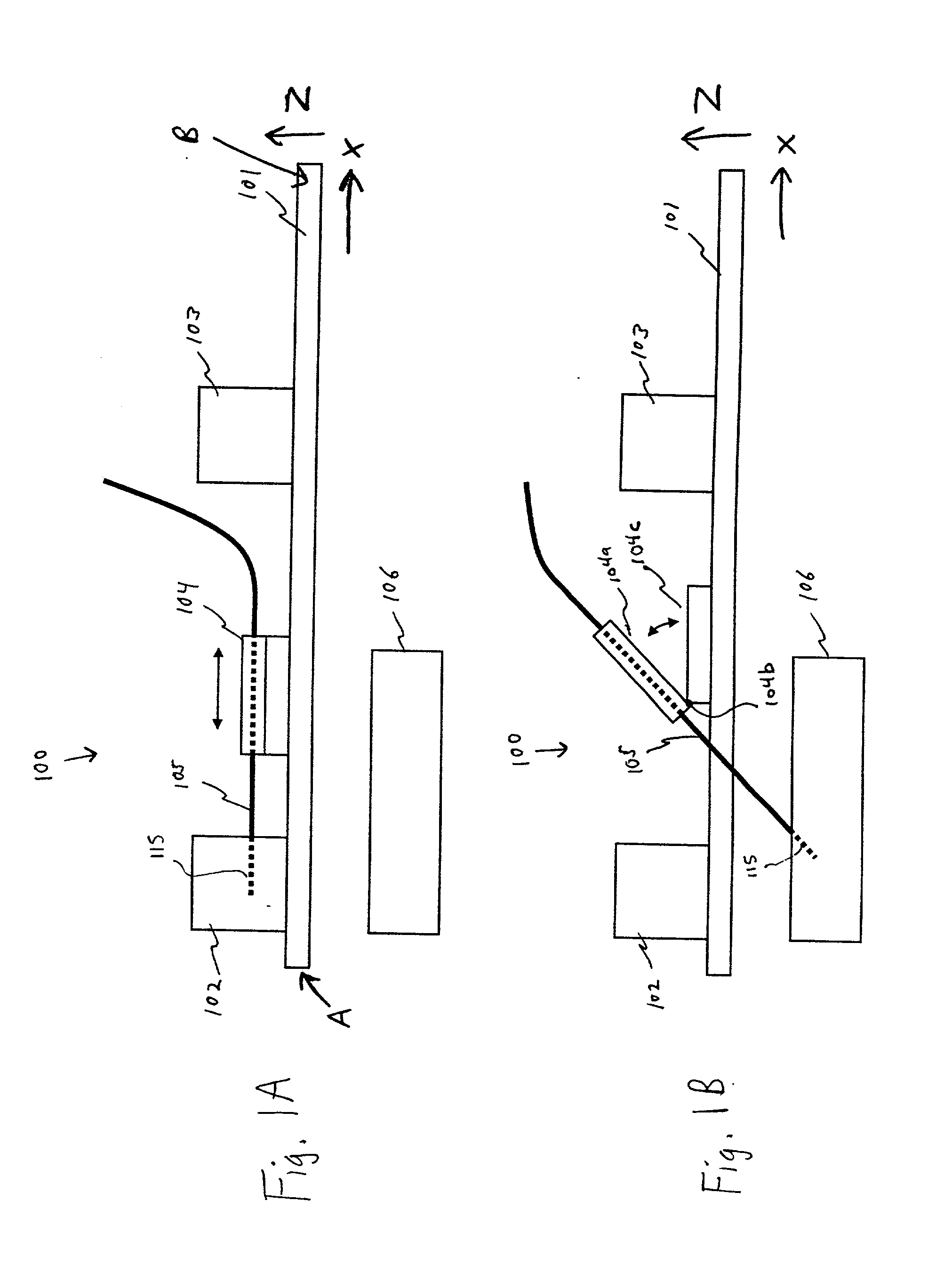

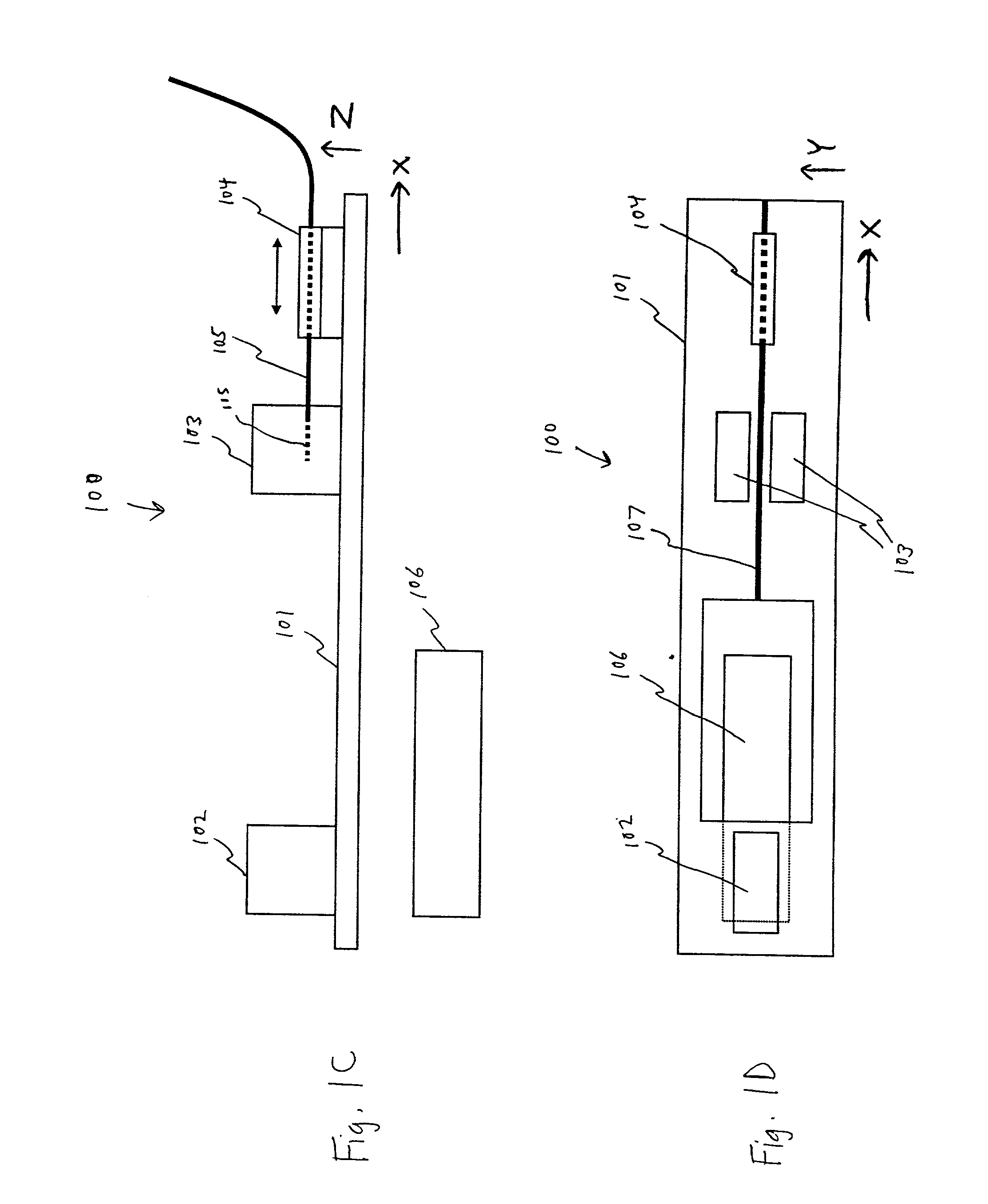

Apparatuses and methods for automatically preparing optical fibers for splicing (or for attachment to a connector or an optical component) by automatically positioning a stripping station, a cleaning station, and a cleaving station to process one or more optical fibers substantially simultaneously. The optical fiber may be held at a fixed position during processing. A vacuum system may further be used to automatically collect scrap produced by the cleaving process.

Owner:AMHERST HLDG

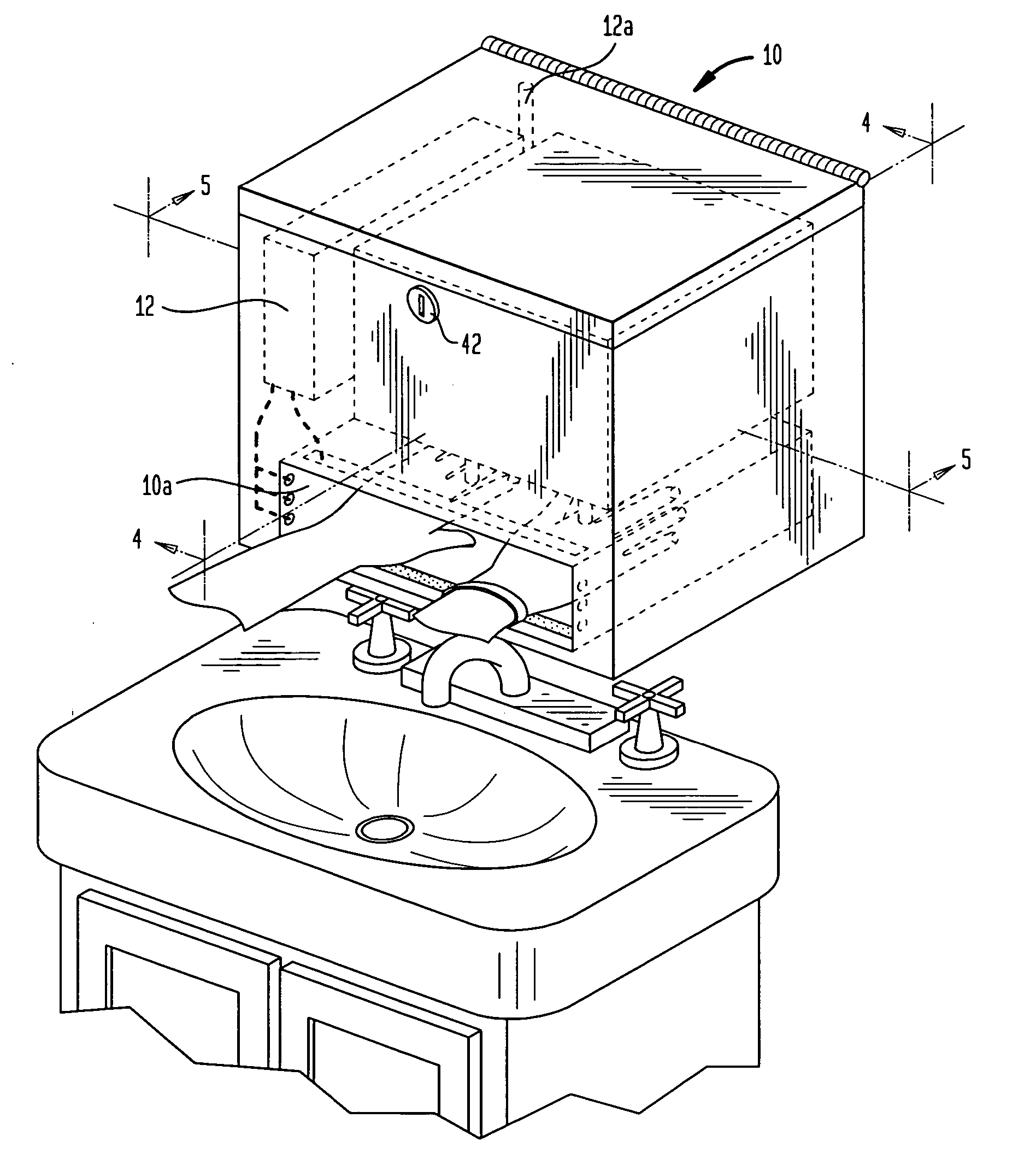

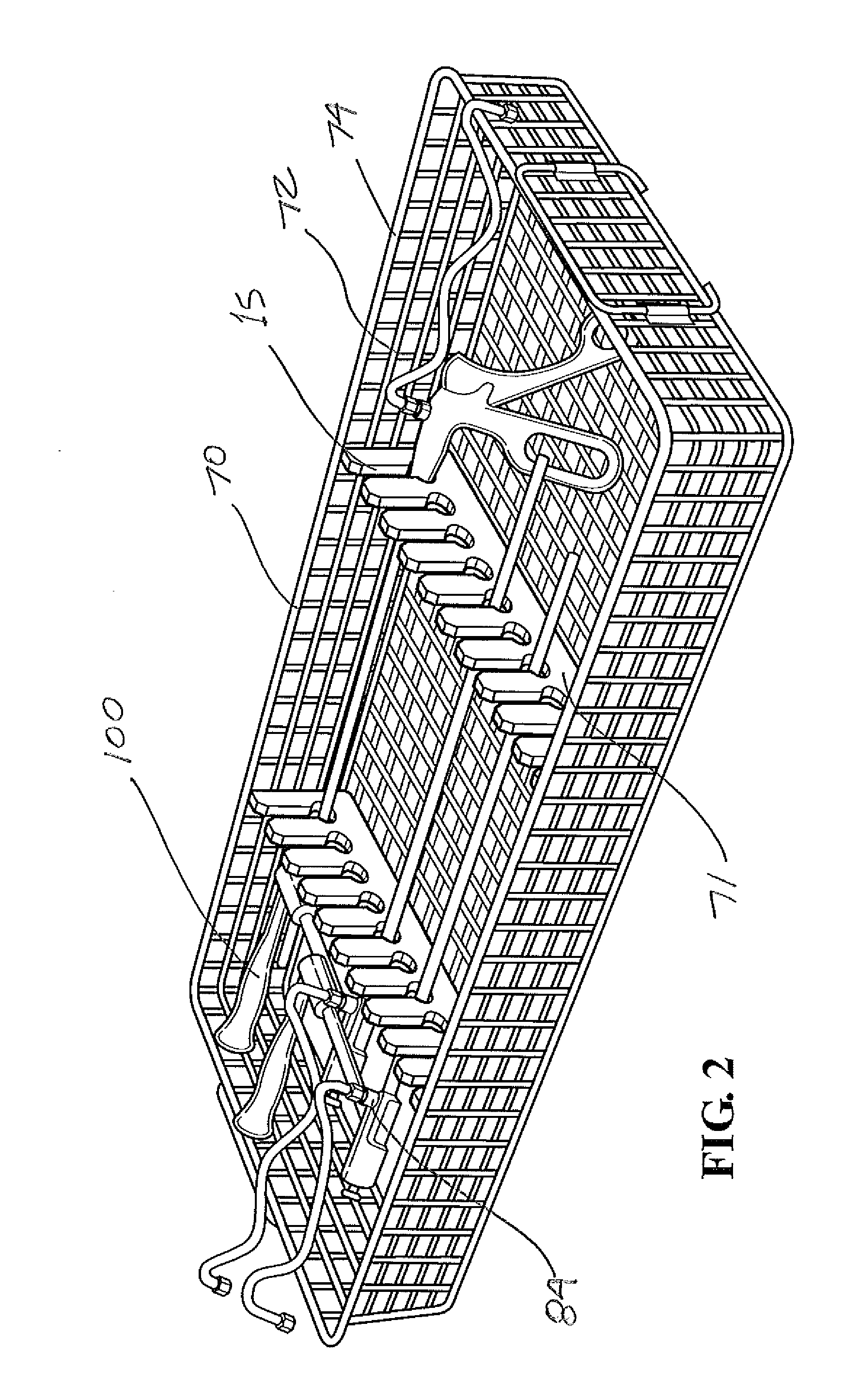

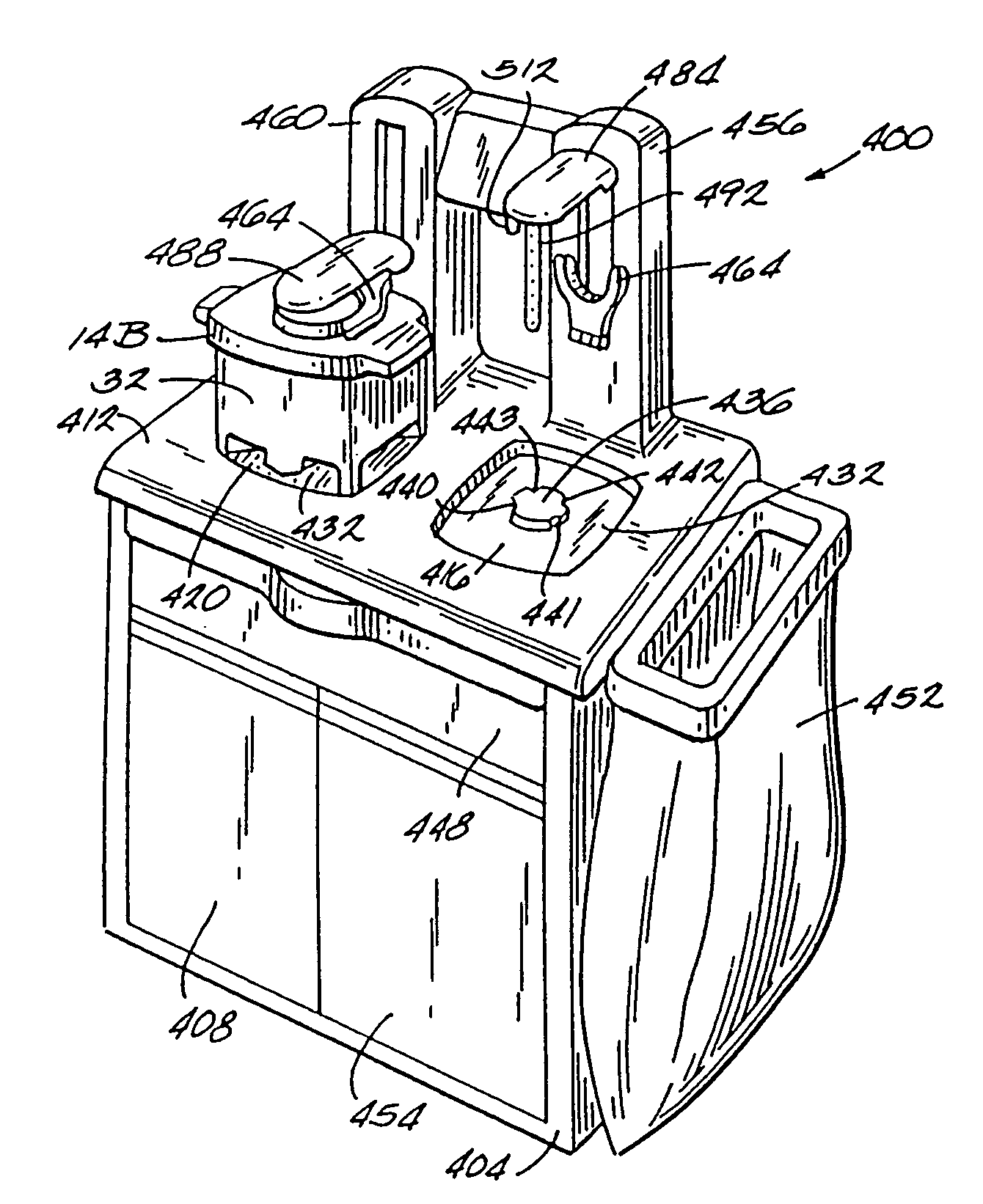

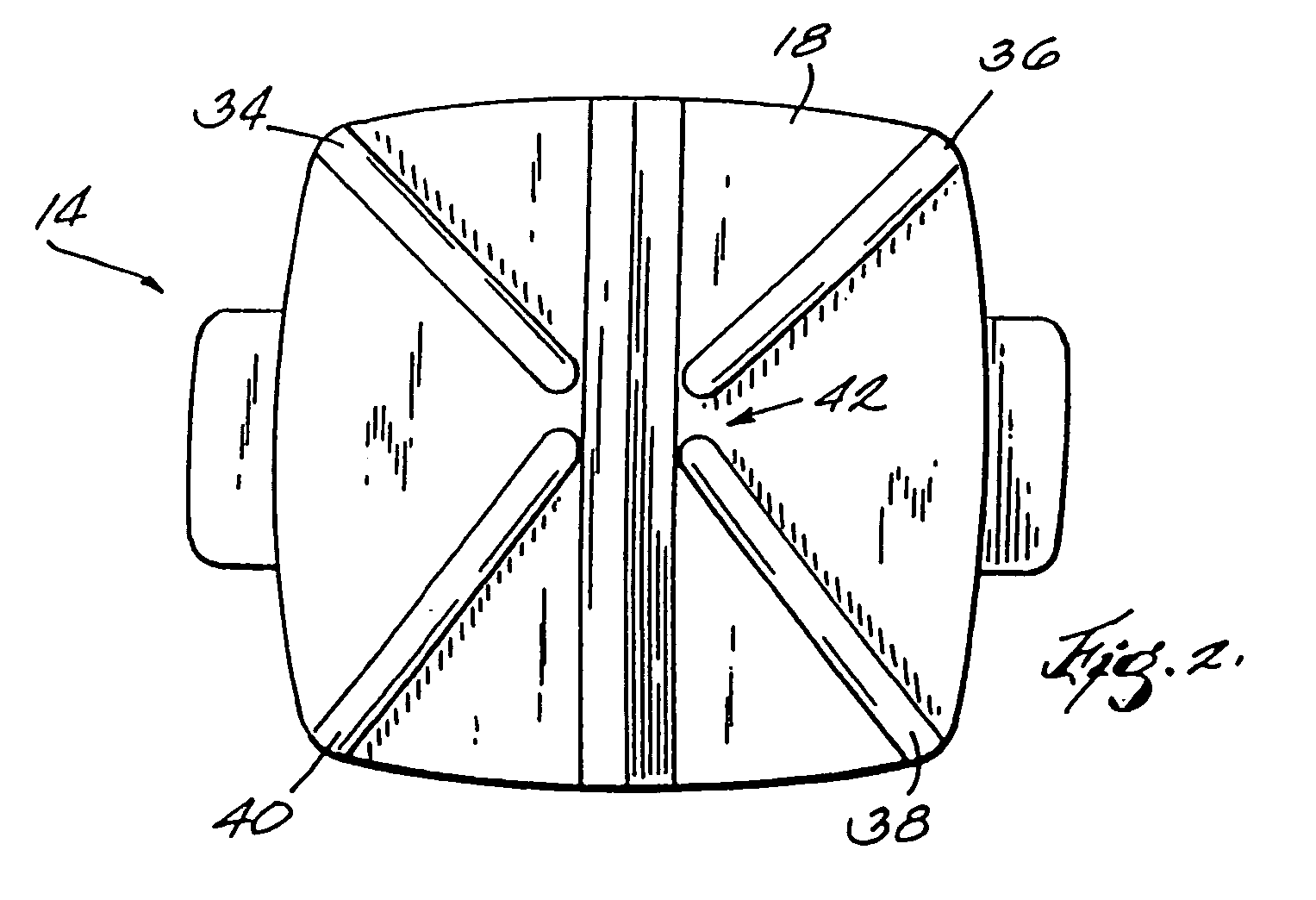

Combination game cleaning station, portable sink and ice chest

The portable sink is capable of being connected to an existing water supply, such as an outdoor hose or faucet, such that running water can be provided inside the sink in an outdoor environment. The sink preferably has features that make it easy to use in any outdoor environment, such as folding legs, an adjustable spigot, a spray nozzle, a storage drawer, a shelf, a large drain, a funnel, a strainer for the drain, cutting boards, baskets, etc. The lid also enables the sink to be used as a container for storing items during travel. In this respect, the sink can be made of an insulating material so that it can double as an ice chest when desired. A pressurized water tank can be provided which is preferably sized to fit inside the sink and adapted to supply water where no other water supply is available.

Owner:CAWTHON ENTERPRISES

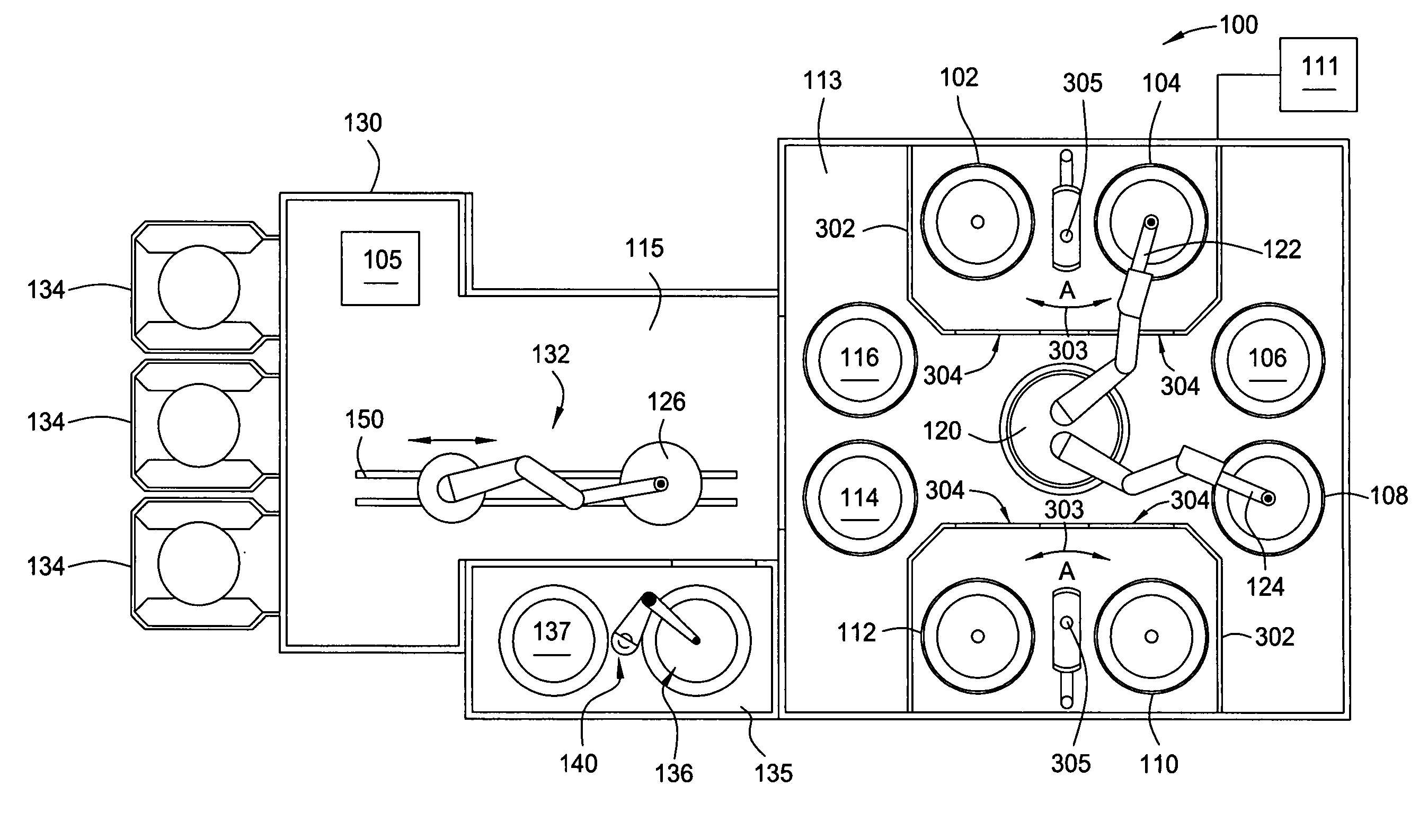

Apparatus for electroless deposition of metals onto semiconductor substrates

ActiveUS20050160990A1Efficient depositionMinimal defectCellsLiquid surface applicatorsRobot positionEngineering

An electroless deposition system is provided. The system includes a processing mainframe, at least one substrate cleaning station positioned on the mainframe, and an electroless deposition station positioned on the mainframe. The electroless deposition station includes an environmentally controlled processing enclosure, a first processing station configured to clean and activate a surface of a substrate, a second processing station configured to electrolessly deposit a layer onto the surface of the substrate, and a substrate transfer shuttle positioned to transfer substrates between the first and second processing stations. The system also includes a substrate transfer robot positioned on the mainframe and configured to access an interior of the processing enclosure.

Owner:APPLIED MATERIALS INC

Management method for collecting and calculating garbage

InactiveCN101872428AImplement job managementCo-operative working arrangementsRefuse transferringRefuse collectionApproaches of management

The invention relates to a management method for collecting and calculating garbage, which comprises the following steps of: firstly, classifying and coding garbage cans in each residential area, and sticking RFID cards which comprise garbage codes on each garbage can; secondly, reading information in the RFID cards in the garbage codes through a hand GPRS card reading and writing device, recombining into a set of new codes to write back to the RFID cards by combining with positioning information, and transmitting the new codes to a sealing type cleaning station; and thirdly, transmitting information in the hand GPRS card reading and writing device into a calculating and weighing mechanism of movable compressing equipment or directly putting the garbage cans on the calculating and weighing mechanism, and distinguishing from the source of the can of the garbage, and weighing and calculating the garbage by the calculating and weighing mechanism. The management method has the beneficial effects that source of each can of the garbage and the amount of the garbage in the sealing type cleaning station can be calculated, and the calculation of the amount of the garbage can be corrected to the residential area or the social unit, thereby providing a calculating and clearing basis for the garbage measurement charge.

Owner:黄庭梁

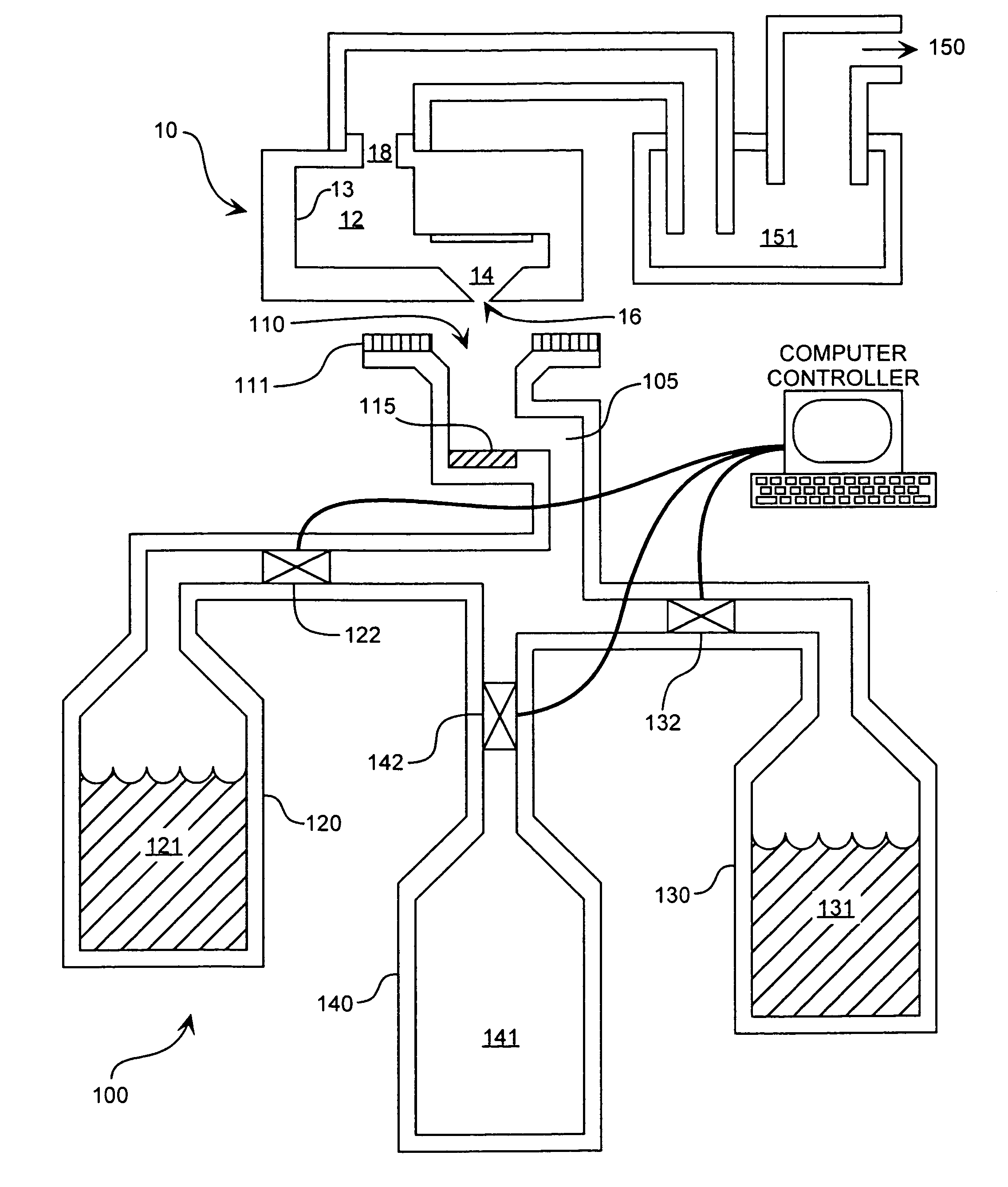

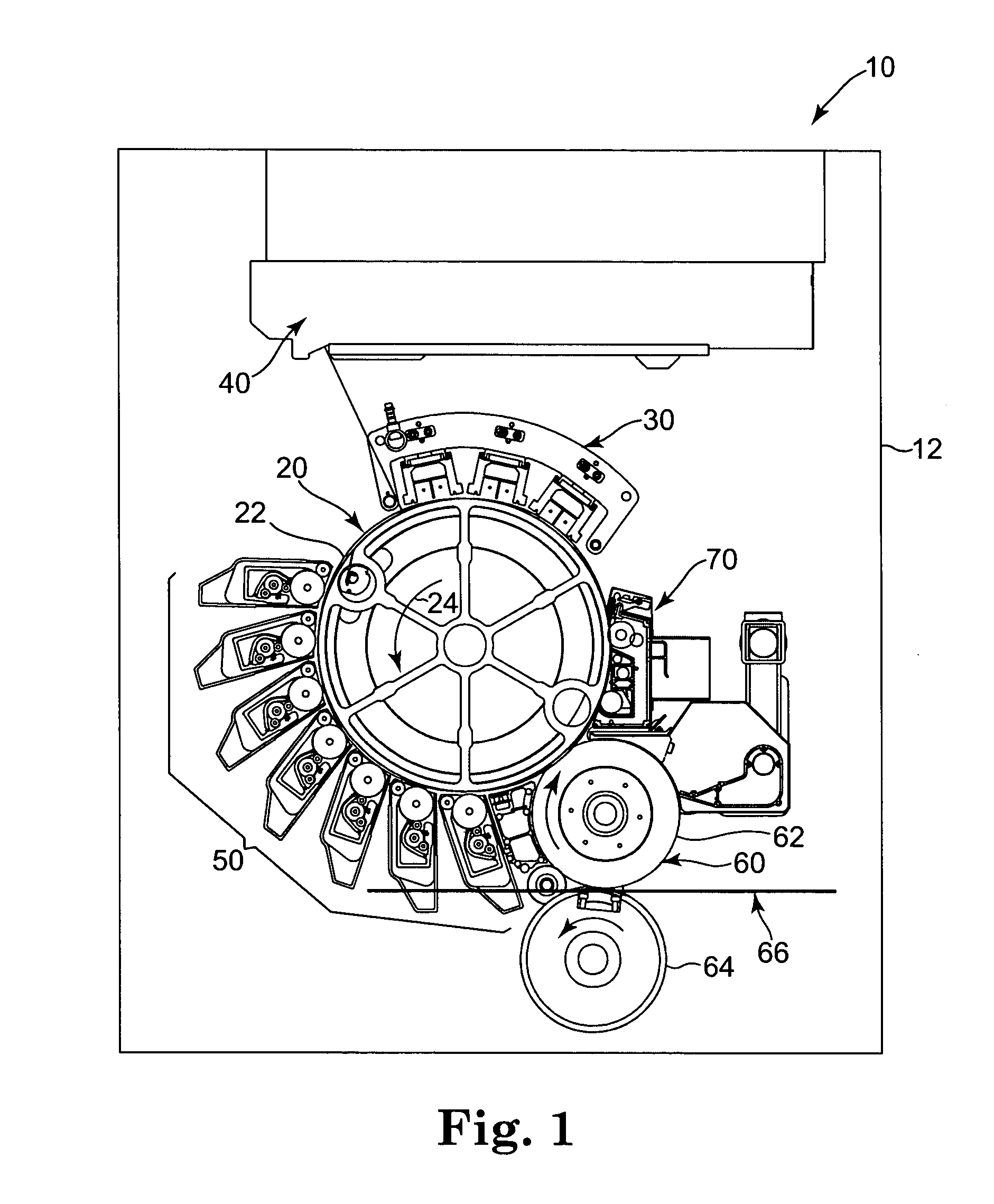

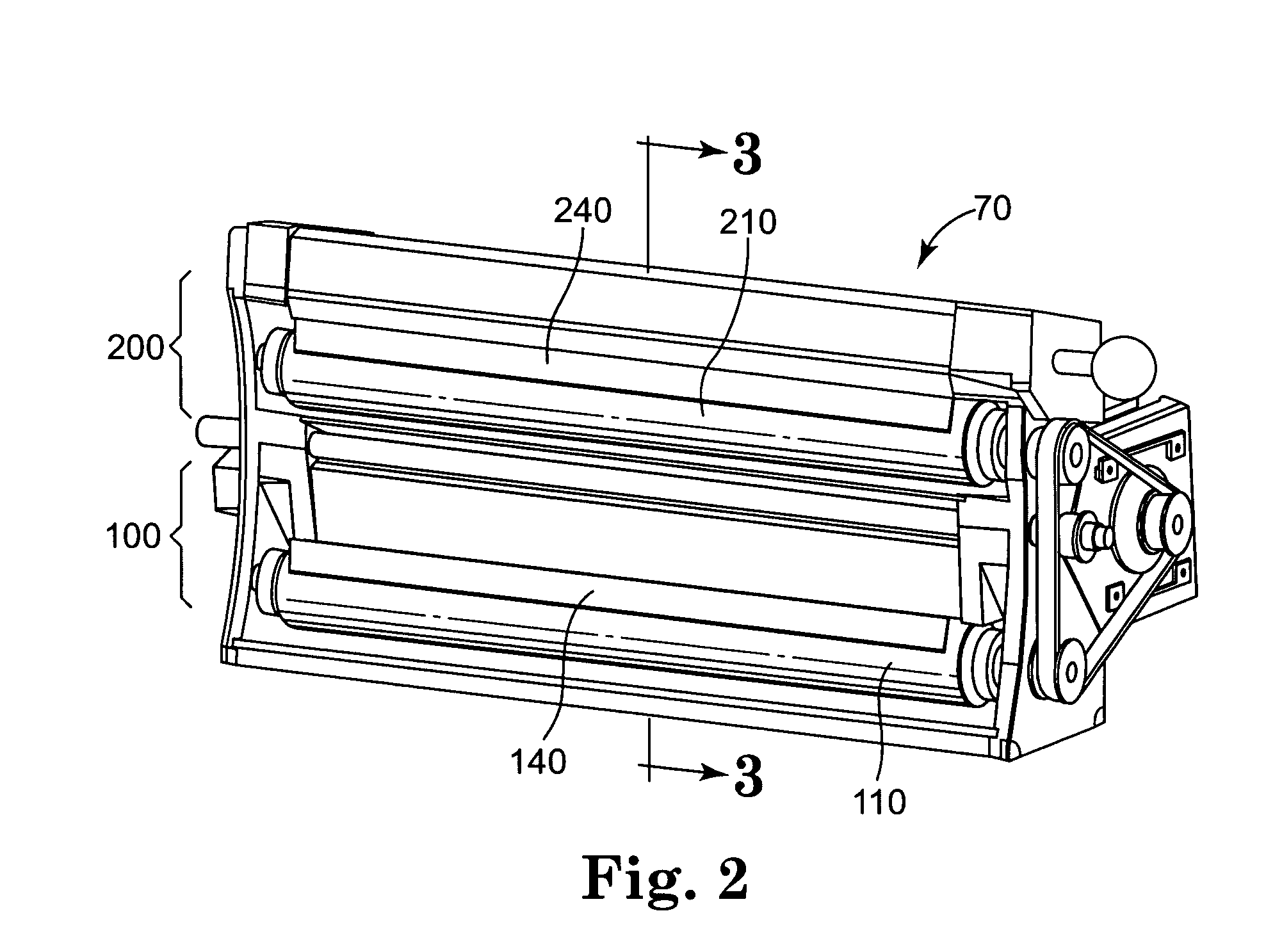

Apparatus and method for cleaning an image transfer device

An apparatus and method for cleaning an image transfer surface in an image transfer device. The cleaning apparatus includes a first cleaning station and a second cleaning station positioned to consecutively clean the image transfer surface. The first and second cleaning stations apply cleaning fluid to the image transfer surface and remove cleaning fluid with residual material from the image transfer surface. A first tank supplies cleaning fluid to, and receives cleaning fluid with residual material from, the first cleaning station. A second tank supplies cleaning fluid to, and receives cleaning fluid with residual material from, the second cleaning station. The second tank also supplies cleaning fluid to the first tank.

Owner:HEWLETT PACKARD DEV CO LP

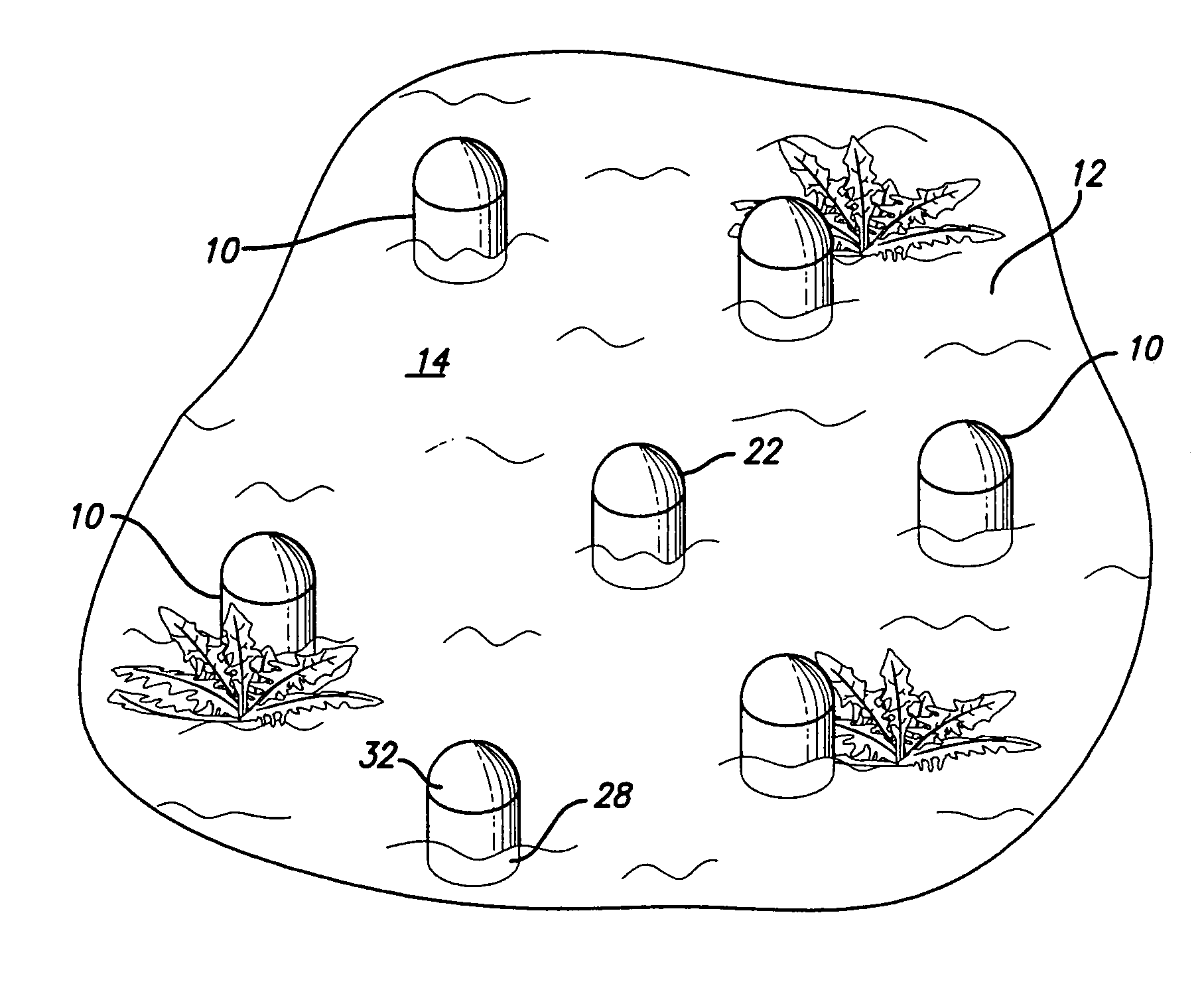

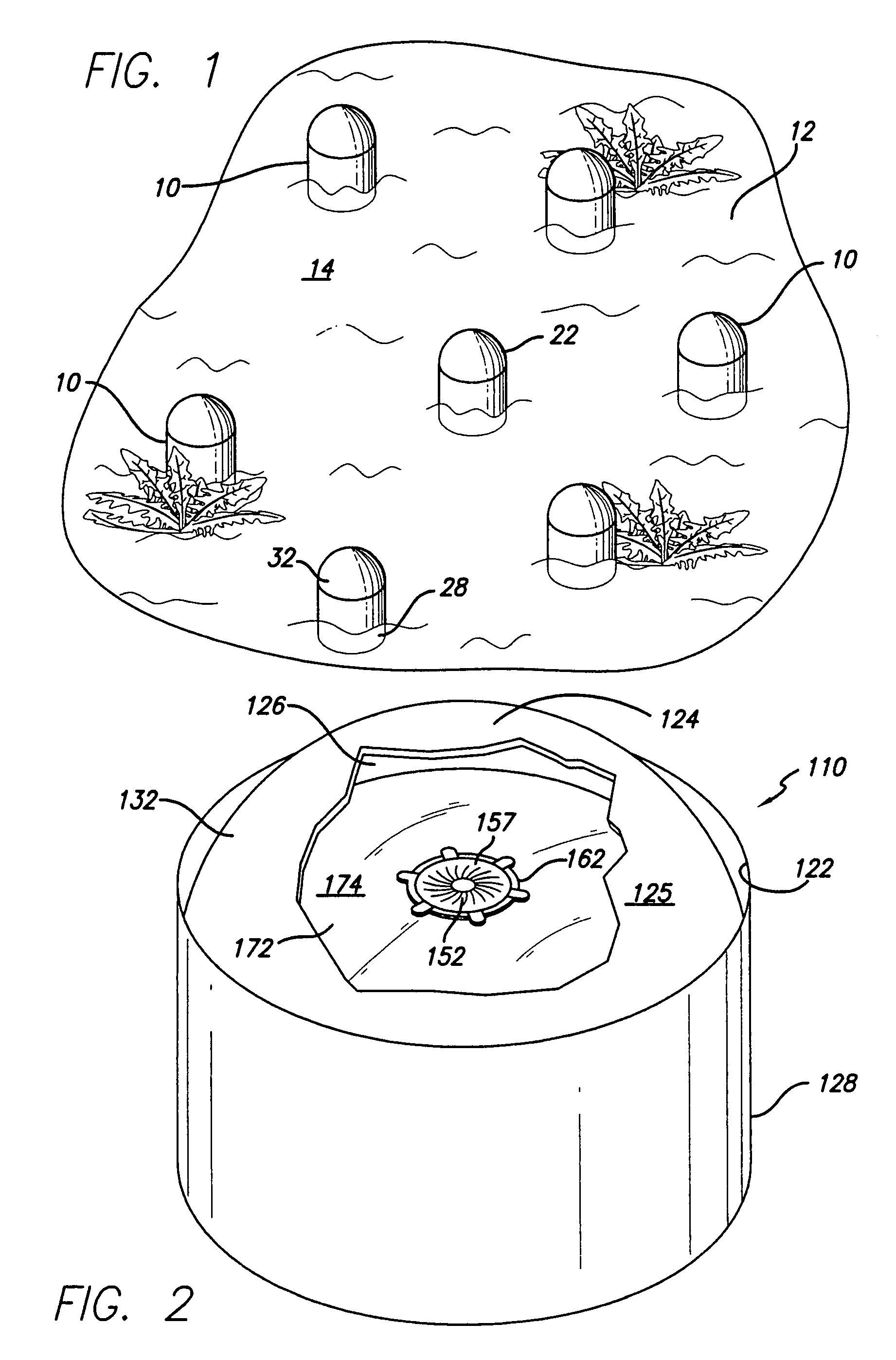

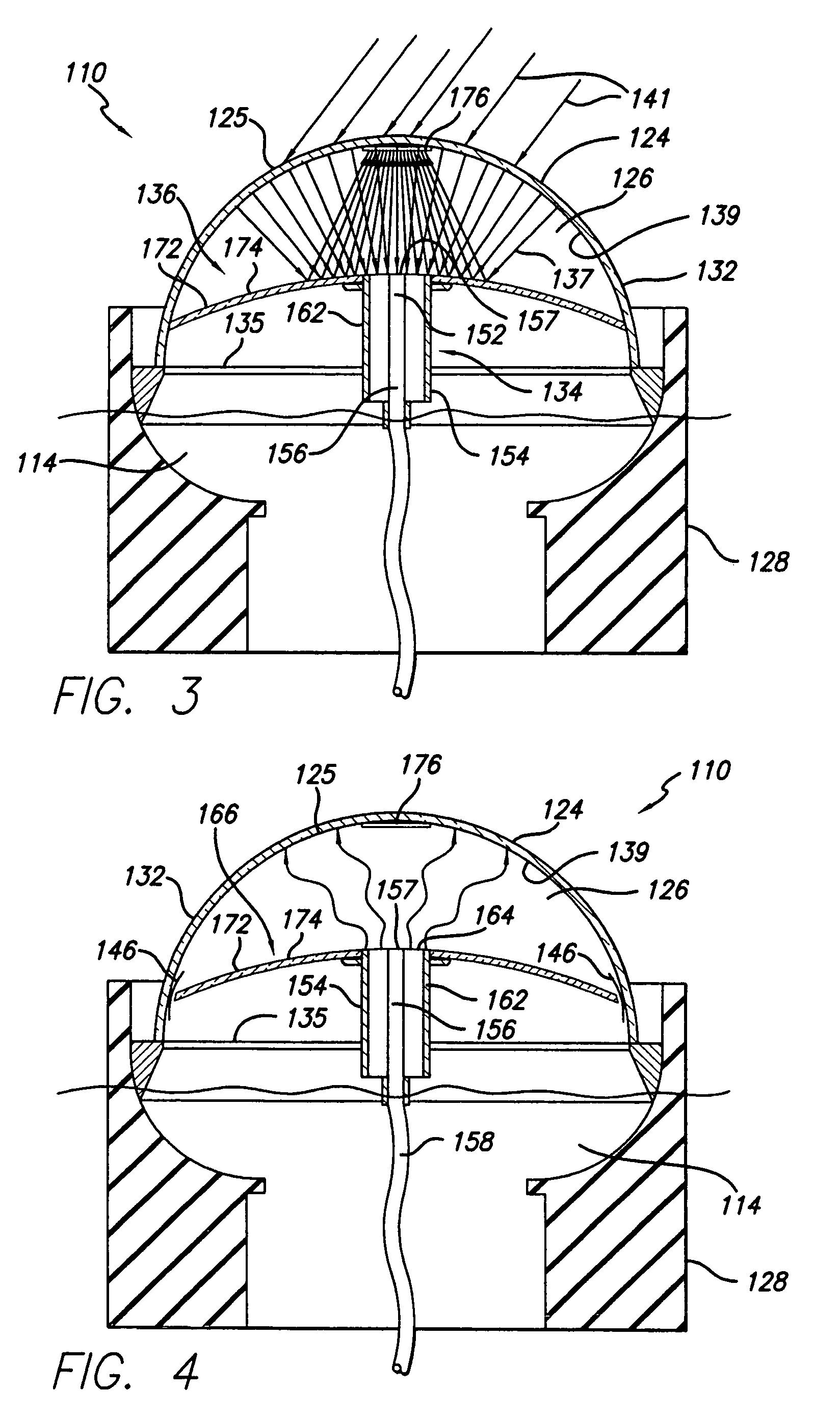

Multi-unit, distributive, regenerable, in situ desalination method

Cultivated field water is desalinated by a series of independent units that float on the water surface, taking up the saline water with a wick, evaporating the water from the wick in desalinating relation by concentrating incident solar radiation with a combination of a lenses and cooperating mirrors onto the upper end portion of the wick while the wick lower end portion is immersed in the field water, capturing the desalinated vapor resulting by condensing within the unit and returning the condensed, desalinated water to the field, and periodically renewing the wick by rinsing the salt from it at a cleaning station beyond the field.

Owner:COON WARREN

Method and apparatus for cleaning of laparoscopic surgical instruments

InactiveUS20110132404A1Improve cleaning operationsEasy to disassembleLighting and heating apparatusDiagnosticsAbdominal cavityPERITONEOSCOPE

The invention is a method and apparatus for cleaning and disinfecting laparoscopic surgical instruments. The method comprises the introduction into the interior channels of the instruments of cleaning fluid heated at a predetermined temperature, and activated of the fluid by the introduction of sonic energy into the fluid at varying frequencies. The apparatus includes a unitary cleaning station containing receptacles for holding the laparoscopic instruments in a bath, and for directing cleaning fluid from the bath through the interior of the instruments while providing a source of ultrasonic mechanical energy to the cleaning fluid both inside and outside the laparoscopic instruments.

Owner:LUTZ TODD M +1

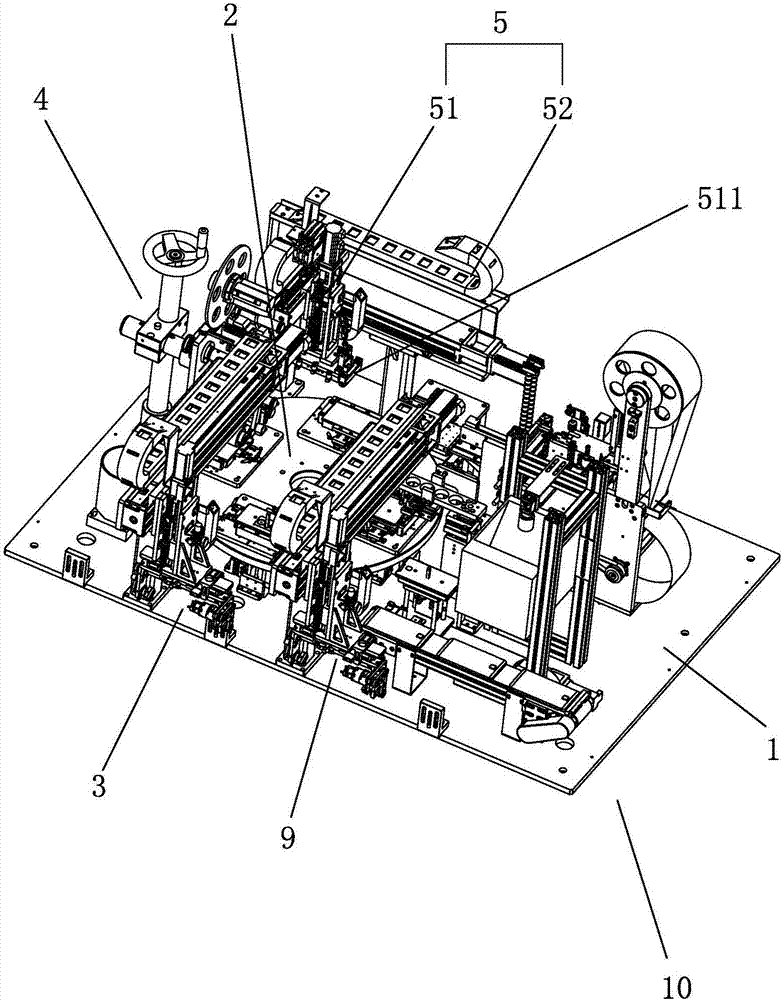

Film pasting equipment for mobile phone screen and film pasting method for mobile phone screen

ActiveCN107336865ASmall footprintReduce labor costsPlastic recyclingPackaging automatic controlProduction rateSmall footprint

The invention relates to film pasting equipment for a mobile phone screen and a film pasting method for the mobile phone screen. The film pasting equipment for the mobile screen comprises a base, a conveying device arranged on the base, a first feeding device arranged on one side of a feeding station, a cleaning device arranged on one side of a cleaning station, a film pasting device arranged on one side of a film pasting station and a detection device arranged on one side of a detection station, wherein the feeding station, the cleaning station, the film pasting station, the detection station and clamps for clamping mobile phones are arranged on the conveying device. The film pasting equipment for the mobile phone screen further comprises a film tearing device arranged on one side of the film pasting device. The whole equipment is small in occupied space, the automatic control is adopted in the full process, the labor cost is saved, the stability of mobile phone film pasting is high, and the efficiency is high; and due to the fact that the mobile phones pasted with films are detected by the detection device, the reject ratio during production can be reduced.

Owner:SHENZHEN GDLASER TECH CO LTD

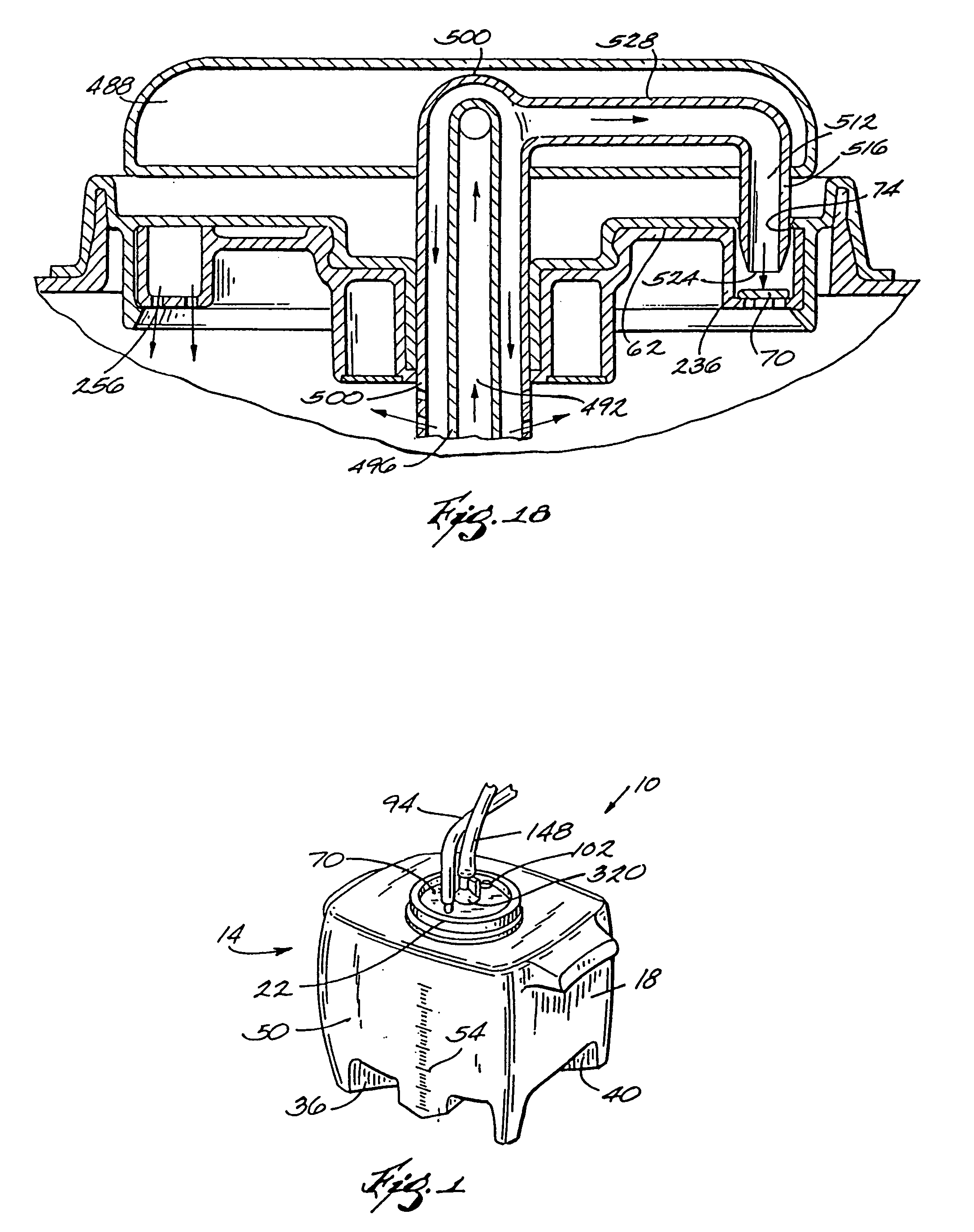

Medical suction system

A medical suction system comprising a medical suction canister used in draining bodily fluid from a patient, and a cleaning station for automatically draining and cleaning the suction canister and for automatically providing a visible indication that the canister has been cleaned.

Owner:BEMIS MANUFACTURING CO

High volume liquid waste collection and disposal system

A system for collecting and disposing of liquid medical waste includes a fluid collection cart and a draining and cleaning station. The fluid collection cart includes a pair of containers, each of which includes a draining port and a cap. Each cap includes an outer portion having a flushing port and a bore formed therein and an inner portion having vacuum and patient ports formed therein. The inner cap portion is disposable and removably positioned within the bore of the outer cap portion. Liquid level detectors also communicate with each container. The cart also includes a regulator so a low vacuum level may be pulled on one of the containers while a full vacuum level is pulled on the other container. Fluids are collected in the containers via suction tubes connected to the patient ports. The flushing and drain ports of the containers are connected to corresponding flushing and drain connectors on the station when the containers are full so that they may be drained and flushed. The cart liquid level detectors communicate with the station microprocessor so that the draining and flushing cycles may be properly sequenced. The station may also clean suction canisters.

Owner:DORNOCH MEDICAL SYST

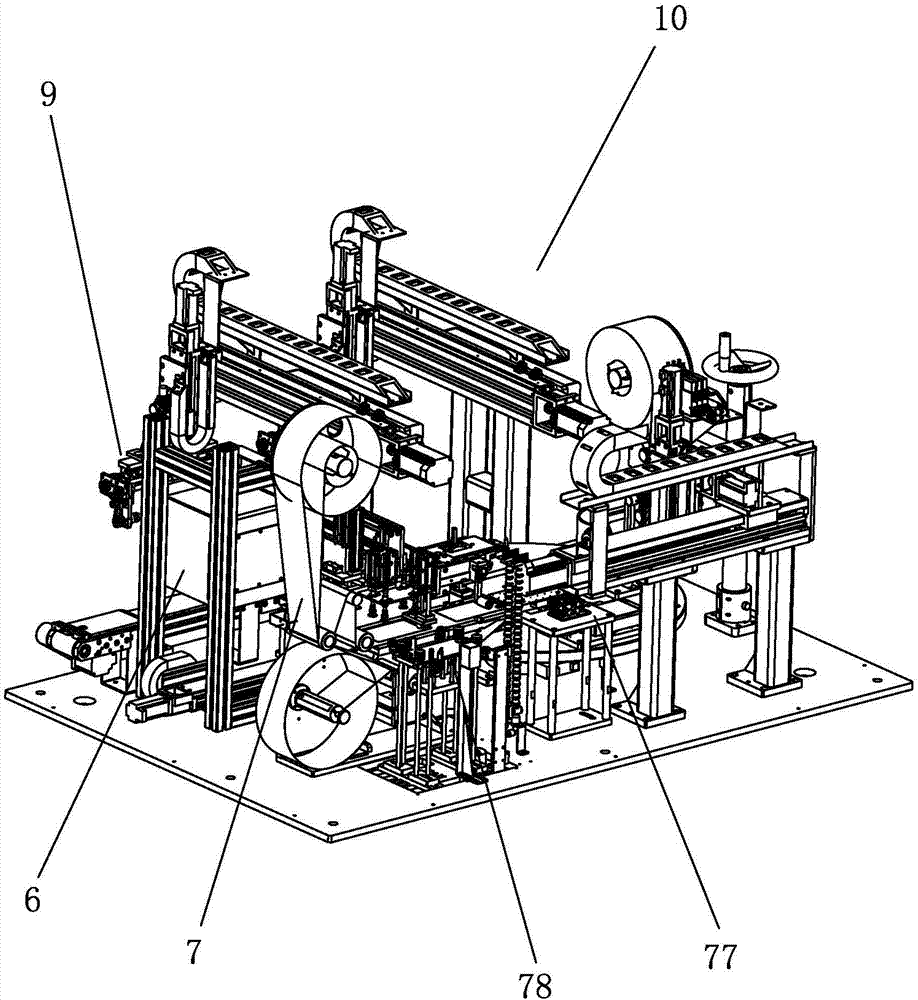

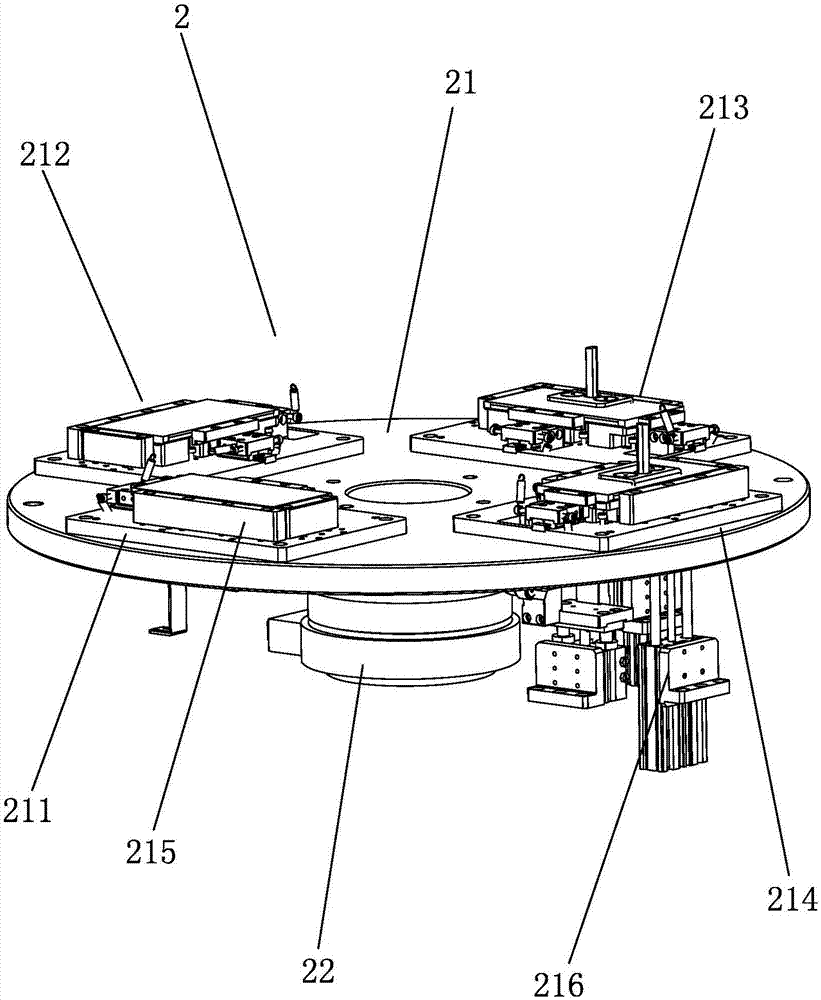

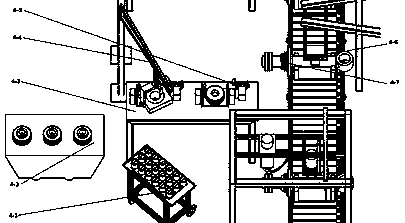

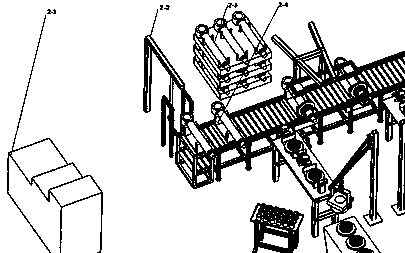

Automated assembly line of horizontal type hydraulic oil cylinder

InactiveCN104175117ARealize semi-automatic productionImprove yieldAssembly machinesAssembly lineEngineering

The invention discloses an assembly line of a hydraulic oil cylinder, which is capable of realizing semi-automated production of the hydraulic oil cylinder in cleaning and assembling. The automated assembly line is formed by eight main stations of a cleaning station, a piston rod material feeding station, a cylinder tube material feeding station, a guiding sleeve installing station, a piston installing station, a piston fastening station, a cylinder tube final assembly station, a guiding sleeve and clamping key fastening station and the like, wherein related stations are provided with a stop dog, a lifting mechanism and a pressing device in a matching way for catching, positioning and pressing a workpiece, a line body is formed by a section material roller double-layer line (a driving device is an electric motor), and the line head and the line tail are provided with elevators for ensuring the cycle use of a tool plate; the guiding sleeve installing station and the piston installing station are equipped with assistant mechanical arms in which are used for manually assisting the installing of a guiding sleeve and a piston, and a sealed installing platform is provided with a workpiece turnover mechanism which is used for overturning the guiding sleeve and the piston and assisting the installing of a sealing piece; a final assembly process of the cylinder tube final assembly station is completed by a horizontal type cylinder installing machine. According to the automated assembly line disclosed by the invention, the labor strength of a worker can be reduced, the production efficiency is increased, meanwhile, the damage to a seal ring in each key position during assembling is effectively avoided, and the finished product rate of the hydraulic oil cylinder is increased.

Owner:王志峰 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com