Film pasting equipment for mobile phone screen and film pasting method for mobile phone screen

A technology for laminating equipment and mobile phone screens, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of low degree of automation, high labor intensity of workers, and unstable film quality, so as to reduce the defect rate and save labor costs. , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with schematic diagrams, but is not limited thereto.

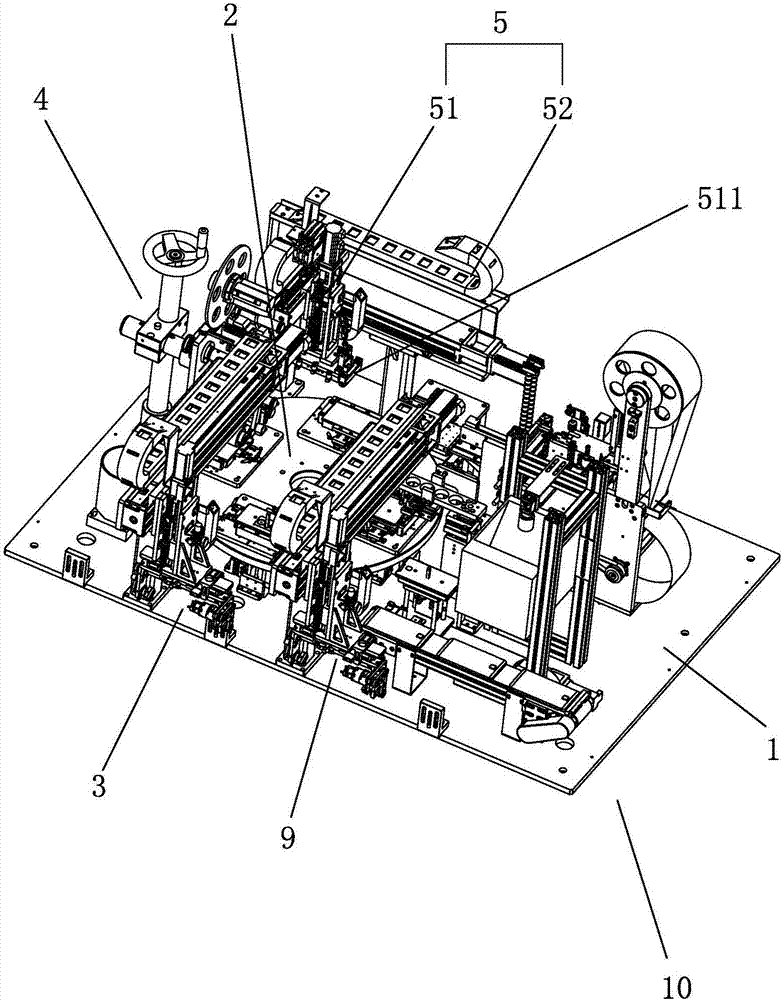

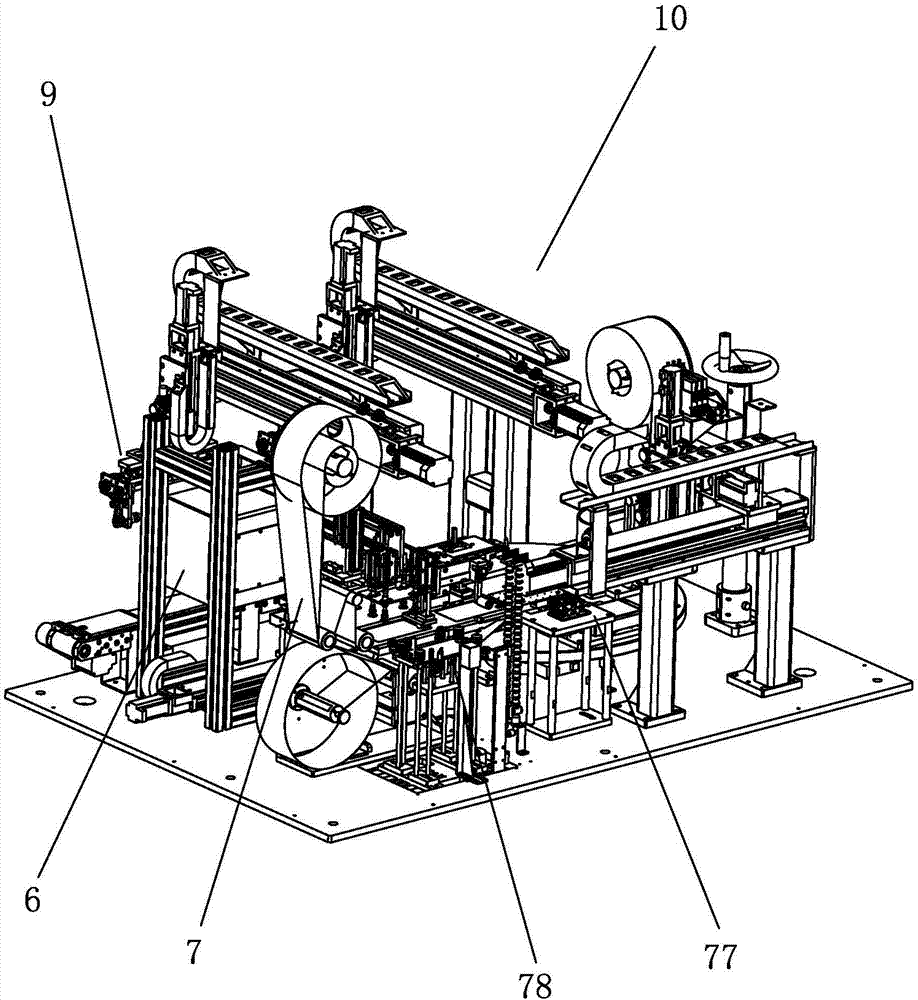

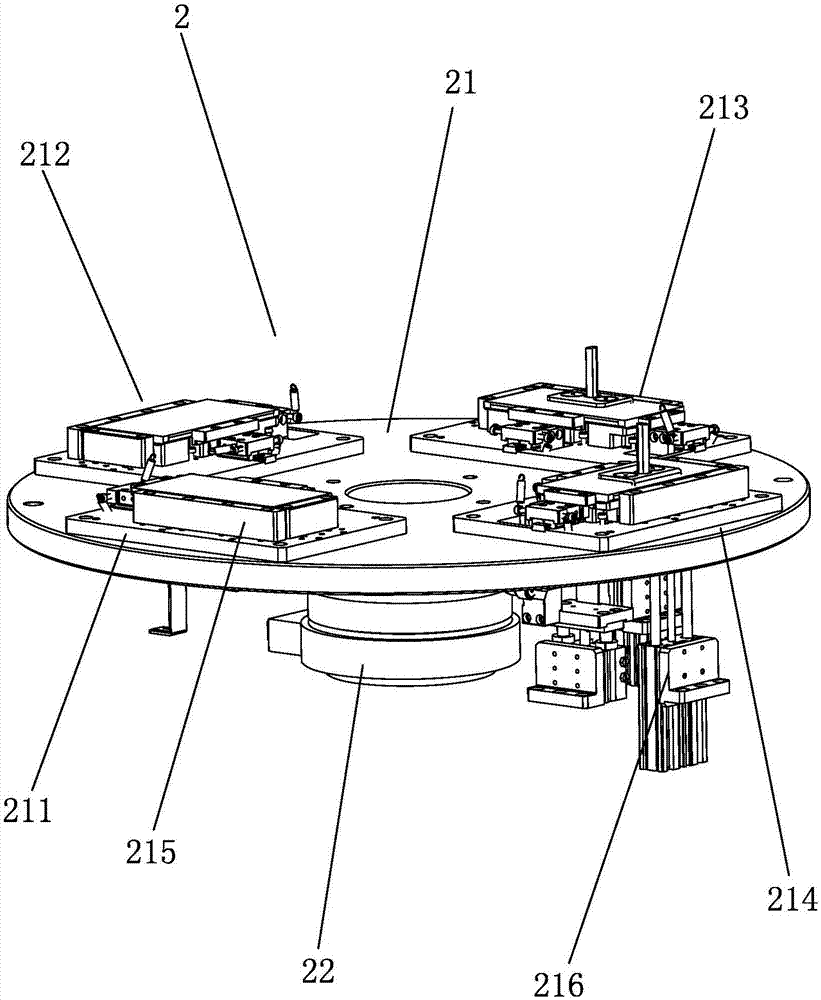

[0074] A mobile phone screen film sticking device, comprising: a base, a transport device arranged on the base, a first feeding device, a cleaning device, a film sticking device, a detection device, a film tearing device set on one side of the film sticking device, and a centering component , Storage membrane components. The transportation device is equipped with a feeding station, a cleaning station, a film pasting station, a testing station, and a fixture for clamping mobile phones. The first feeding device is arranged on one side of the feeding station, the cleaning device is arranged on one side of the cleaning station, the film sticking device is arranged on one side of the film sticking station, and the detection device is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com