Patents

Literature

94results about How to "Change type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Function integrated numerically controlled automatic leather cutting method

InactiveCN1986835AQuick responseChange typeLeather clicking/perforating/clickingNumerical controlPattern recognitionSystem identification

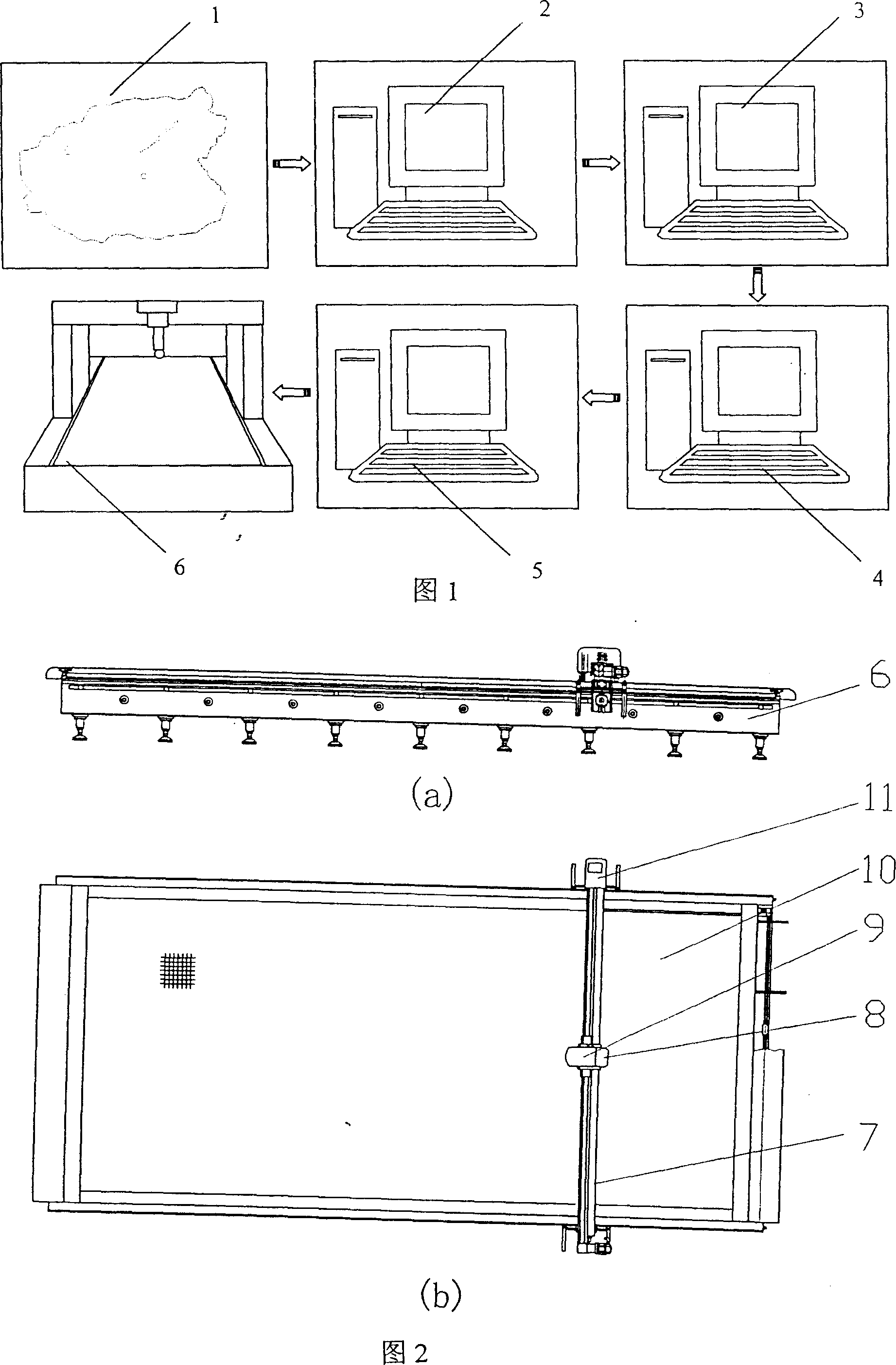

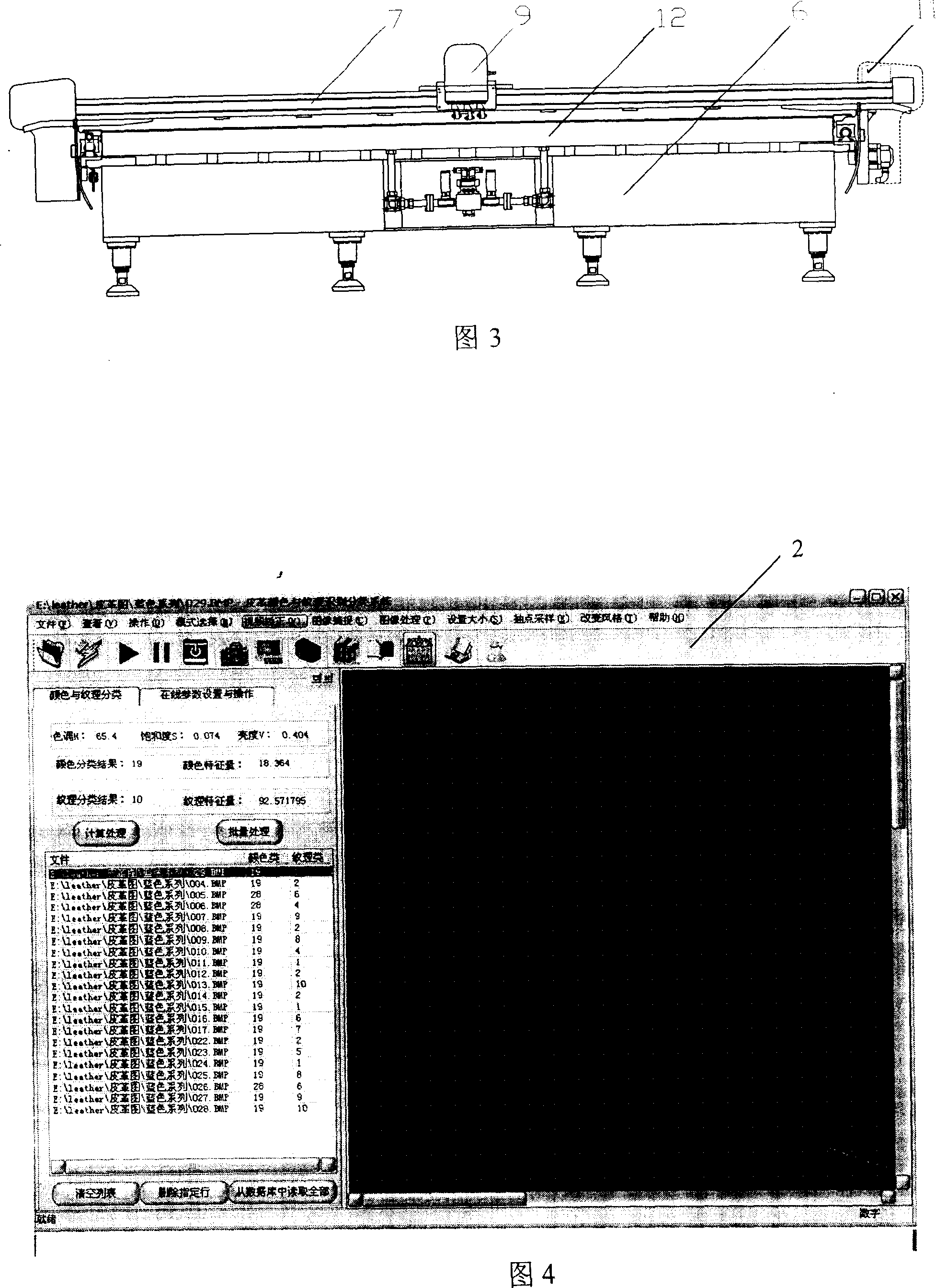

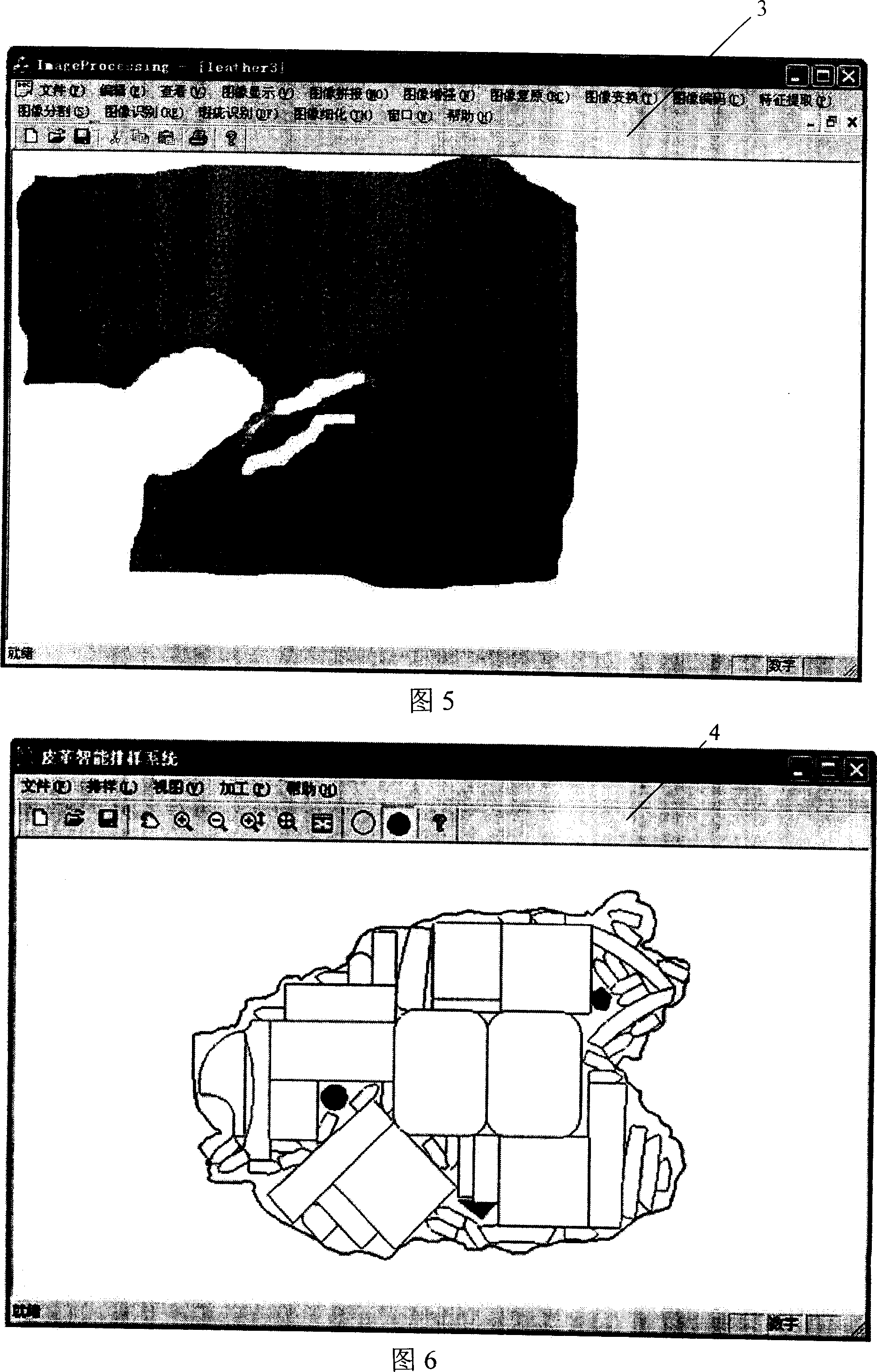

The function integrated numerically controlled automatic leather cutting method includes four parts, automatic leather color and grain identification and classification, automatic leather flaw detection and boundary recognition, automatic optimized template layout and numerically controlled cutting. The automatic leather color and grain identification subsystem completes the leather color and grain matching, the automatic leather flaw detection and boundary recognition subsystem provides the available region information of the leather, the automatic optimized template layout subsystem arranges the optimized cutting template on the available region of the leather to reach maximum leather material utilization rate, and the numerically controlled cutting subsystem completes leather cutting automatically.

Owner:ZHEJIANG UNIV

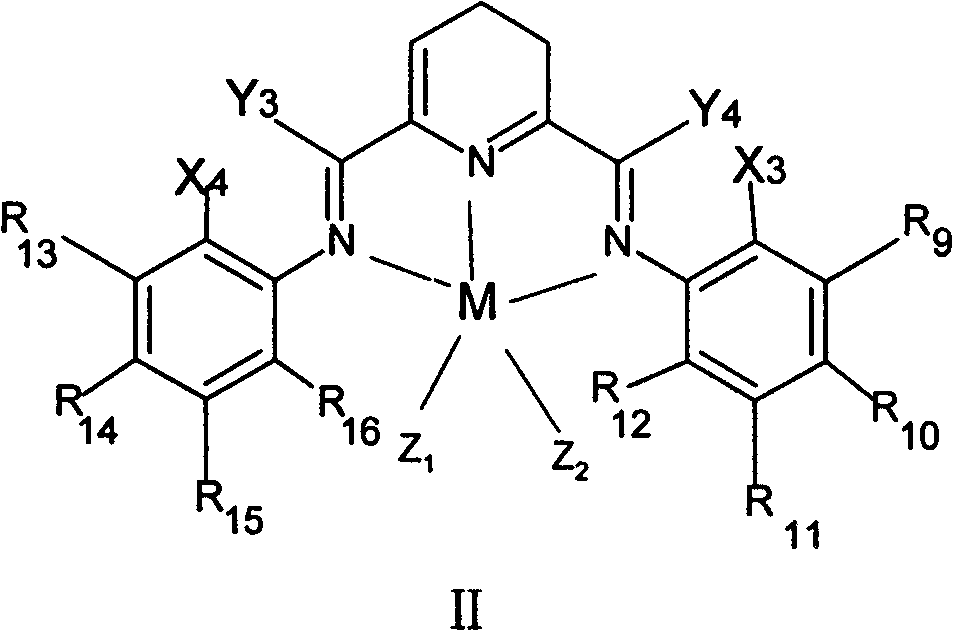

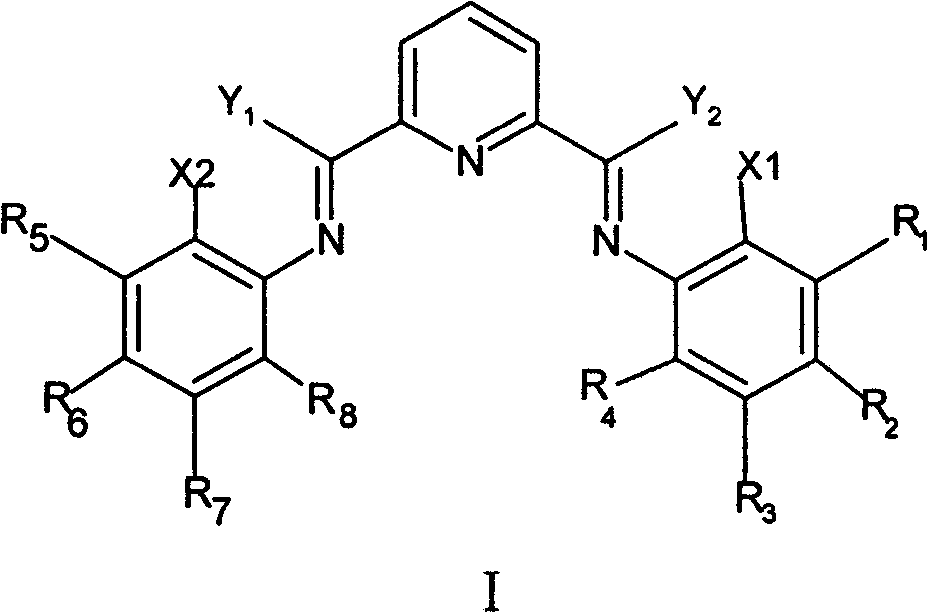

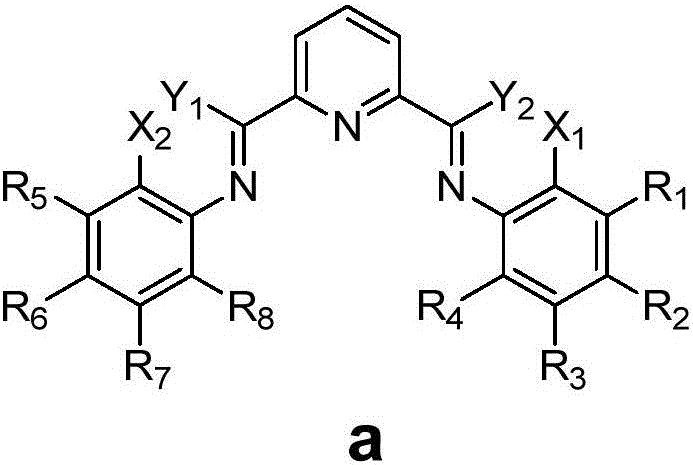

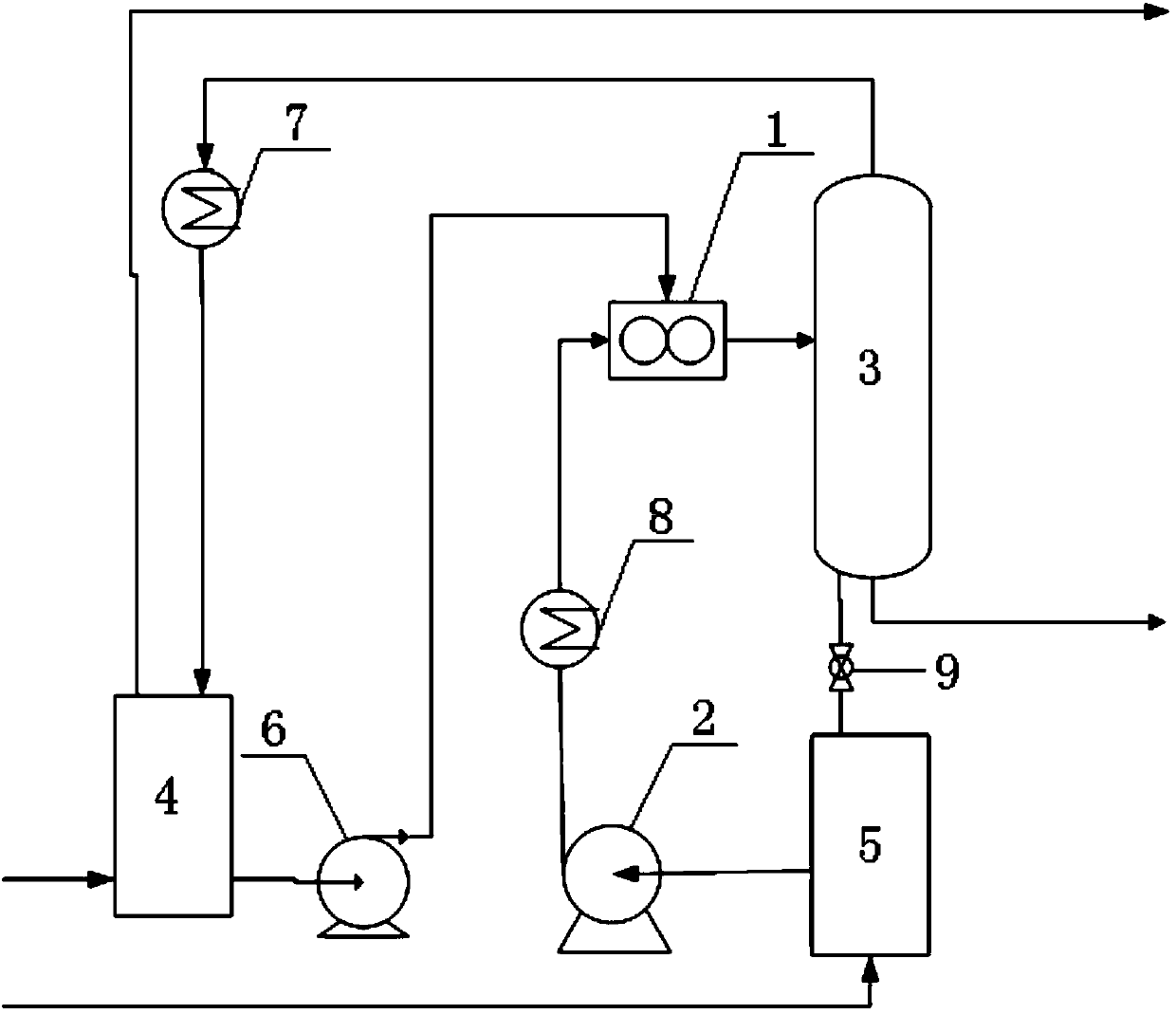

Method for preparing linear alpha-olefin

InactiveCN101906009AEasy to adjustChange typeHydrocarbonsHydrocarbon preparationDistillationMixed materials

The invention discloses a method for preparing linear alpha-olefin. The method comprises the following steps of: introducing catalytic solution and ethylene into a first reactor and reacting at the temperature of between 30 and 120 DEG C and under the pressure of 0.1 to 3 MPa for 1 to 40 min to prepare a first mixed material flow of first linear alpha-olefin, the ethylene and the catalytic solution; introducing the first mixed material flow and the ethylene into a second reactor and reacting at the temperature of between 40 and 90 DEG C and under the pressure of 0.5 to 4 MPa for 5 to 120 min to prepare a second mixed material flow of second linear alpha-olefin, the ethylene and the catalytic solution; performing gas-liquid separation on the second mixed material flow to obtain the ethylene and a liquid-phase product; cycling the separated ethylene to the first reactor or the second reactor for continuous reaction; and performing distillation separation on the liquid-phase product to prepare the linear alpha-olefin. The method has the advantages of mild reaction condition, simple operation and suitability for industrialized production.

Owner:ZHEJIANG UNIV

Grinding roller manufacturing/remanufacturing abrasion-resistant material and preparation method thereof

InactiveCN106238709AWide adjustment of hardnessWidth adjustment toughnessFurnace typesWelding/cutting media/materialsCouplingBoron containing

The invention discloses a grinding roller manufacturing / remanufacturing abrasion-resistant material and a preparation method thereof. A grinding roller is formed by a core roller body, a substrate abrasion-resistant layer, a transition layer and a roller face abrasion-resistant shape layer in a coupling mode. A core material is provided with the highly-abrasion-resistant modified boron-containing high-chromium cast iron substrate abrasion-resistant layer through casting and compounding. The substrate abrasion-resistant layer comprises, by mass, 1.75%-3.0% of C, 12.0%-18.0% of Cr, 0.2%-2.0% of B, 0.4%-0.8% of Mn, 0.4%-1.2% of Si, 0.30%-0.80% of Ni, 0.02%-0.04% of Mg, 0.03%-0.05% of Ce, 0.05%-0.10% of Ti, 0.006%-0.015% of N, 0-0.04% of S, 0-0.04% of P, and the balance Fe. Then surfacing of materials of the roller face abrasion-resistant shape layer is conducted on the surface of the transition layer. The roller face abrasion-resistant shape layer is formed by flux-cored wires through surfacing. The flux-cored wires comprises, by mass, 2.3%-3.5% of C, 14.0%-26.0% of Cr, 1.5%-2.0% of Ni, 0.8%-2.0% of Nb, 1.3%-2.0% of Mo, 1.2%-2.3% of Si, 1.0%-1.7% of Ti, 0.3%-1.0% of V, 0.2%-1.5% of B, 0-<0.007% of S, 0-0. 015% of P, and the balance Fe.

Owner:镇江富华轧辊有限公司

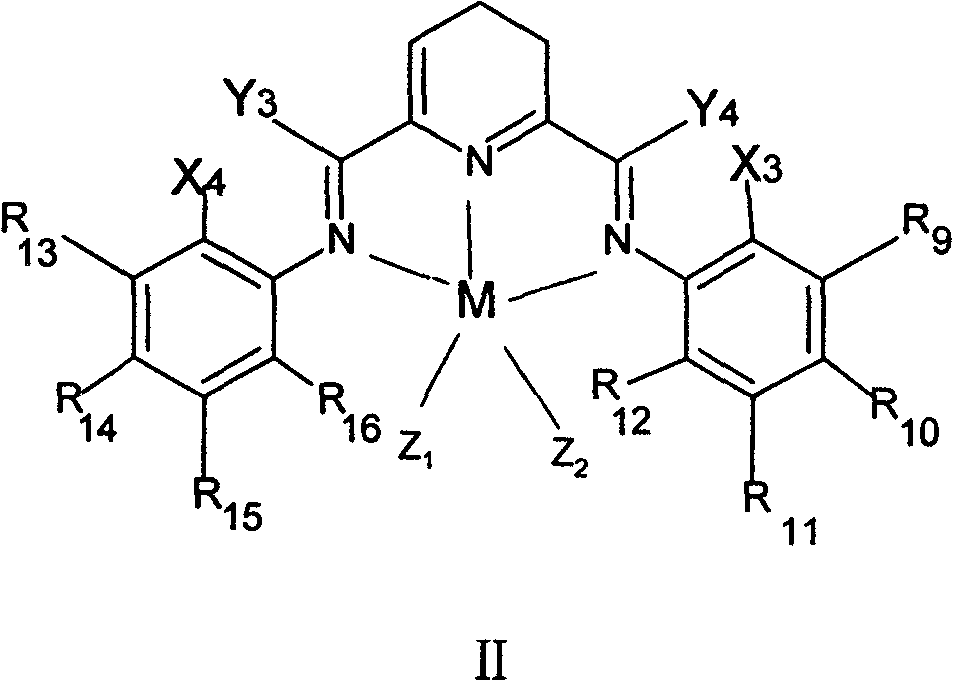

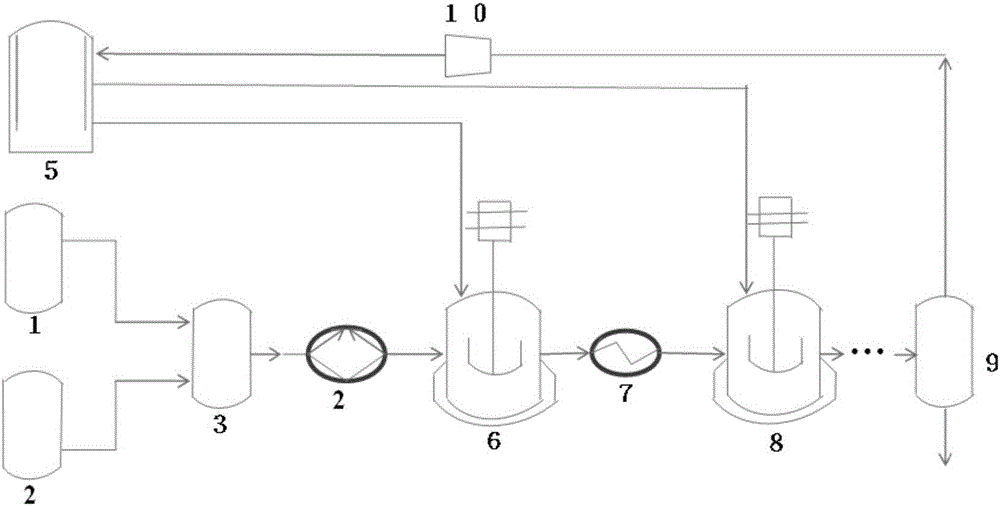

Ethylene oligomerization tanks-in-series technology

ActiveCN105693448ASolve the problem that the activity is too high and easy to overheatSmooth transitionHydrocarbon purification/separationCatalystsReaction temperatureEconomic benefits

The invention discloses an ethylene oligomerization tanks-in-series technology. A reaction medium, a promoter, an iron-based catalyst and a polyethylene wax inhibitor are introduced into a first reactor for pre-reaction at a low temperature, and the reaction materials are introduced into a second reactor after activity starts to be reduced; reaction temperature is increased to maintain high reaction activity for a long time; the reaction materials are sequentially introduced into an n reactor, and the temperature of the reactor is kept high (Tn-Tn-1>=10 DEG C); gas-liquid-solid separation and analysis are conducted on a product after reaction ends. By the adoption of the ethylene oligomerization tanks-in-series technology, catalyst deactivation due to temperature runaway caused by high reaction activity in the early stage of reaction can be effectively avoided, high catalyst activity is maintained for a long time, the catalysis efficiency of the catalyst is improved, and the yield of liquid-phase alpha-olefin is increased remarkably. The reaction technology is good for safety and stable operation of devices so that high economic benefits can be obtained.

Owner:ZHEJIANG UNIV

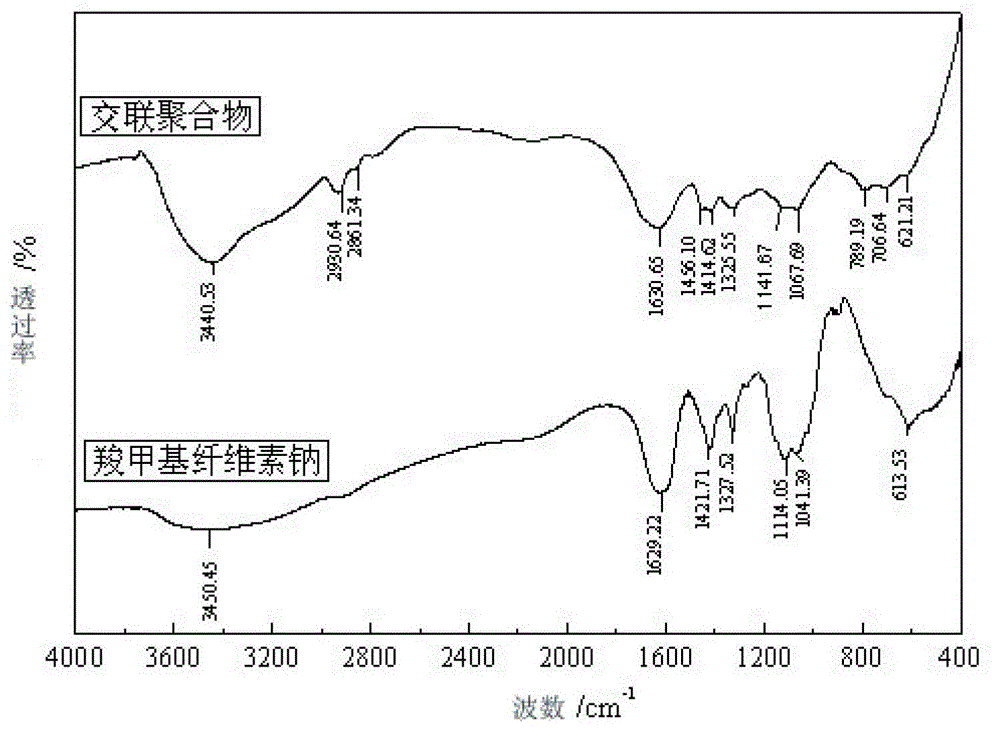

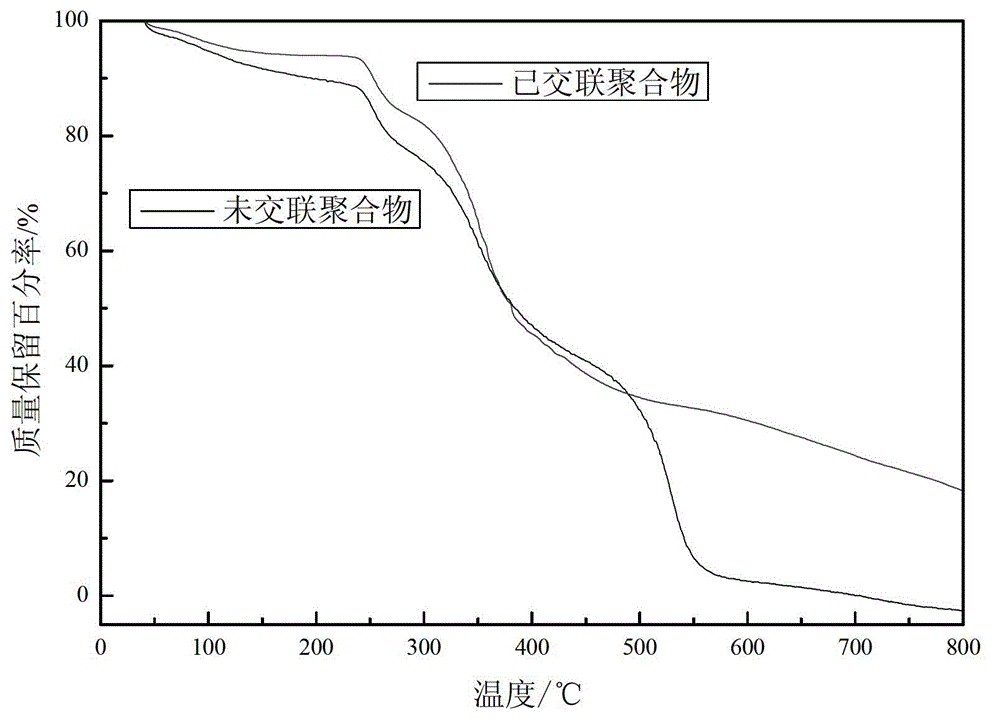

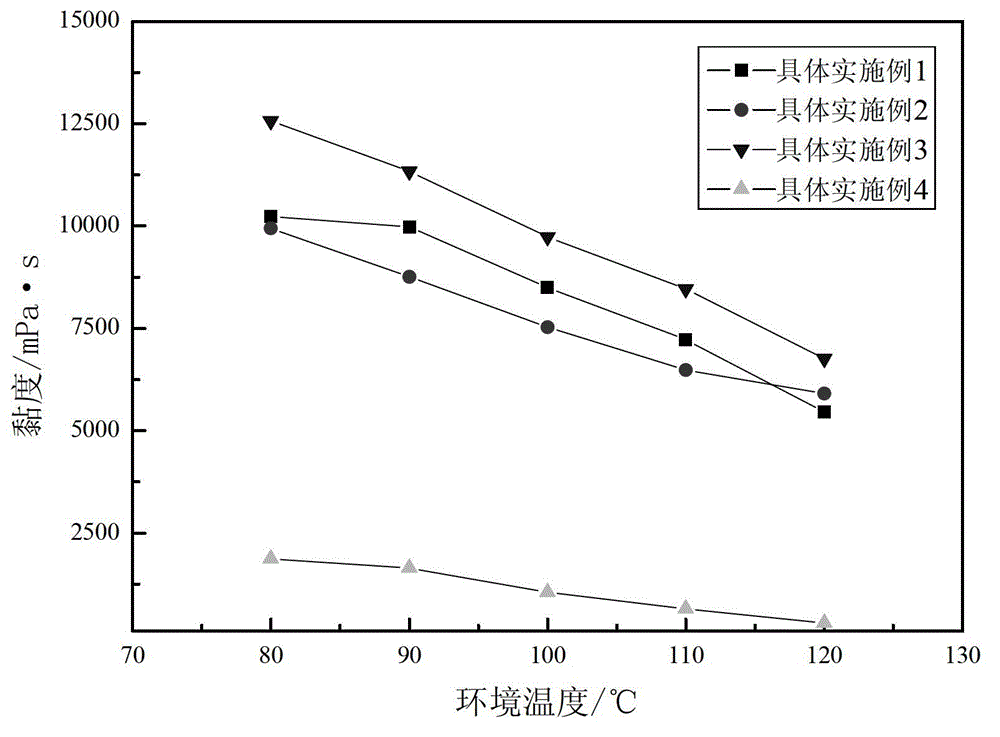

Preparation method of polymer weak gel deep profile control agent

InactiveCN103333669APlay a role in thickeningRich sourcesDrilling compositionCross-linkCarboxymethyl cellulose

The invention relates to a preparation method of a polymer weak gel deep profile control agent. The preparation method comprises the following steps of preparing sodium carboxymethyl cellulose and distilled water into sodium carboxymethyl cellulose water solution of which the mass percentage is 1%-2%; adding acrylamide of which the mass is 2-8 times as great as that of the sodium carboxymethyl cellulose into the sodium carboxymethyl cellulose water solution, and then adding a cross-linking agent which accounts for 0.01%-2% of the total weight of the sodium carboxymethyl cellulose and the acrylamide; enabling nitrogen to enter into a closed system and isolating the air, and adding an initiating agent which accounts for 1%-2% of the total mass of the sodium carboxymethyl cellulose and the acrylamide; and discharging after carrying out constant-temperature reaction for 4-12 hours under the temperature of 30-60 DEG C. According to the preparation method disclosed by the invention, the acrylamide is grafted to the sodium carboxymethyl cellulose, polymer weal gel with a mesh structure is formed under the action of the initiating agent and the cross-linking agent, and a polymer weak gel system integrates the advantages of the sodium carboxymethyl cellulose and the acrylamide.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

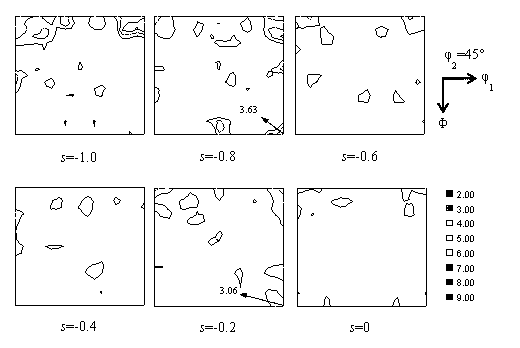

Method for enhancing hot-rolled Gaussian texture of double-roller ribbon continuous casting oriented silicon steel

InactiveCN103255338AEnhanced Hot Rolled Gaussian TextureSimple processMetal rolling arrangementsMetallurgyMolten steel

The invention belongs to the field of oriented silicon steel manufacturing, and in particular relates to a method for enhancing a hot-rolled Gaussian texture of double-roller ribbon continuous casting oriented silicon steel. Steel liquid is smelted by adopting a medium-frequency vacuum induction furnace and forms an oriented silicon steel ribbon which is 1-10 mm thick through double-roller continuous casting; the ribbon is cooled by air to the temperature of 850-1,200 DEG C for performing asynchronous rolling; the differentiate speed ratio is 1.10-1.50; the ribbon is rolled by one gate or two gates; the total press-down rate is controlled to be 10-50 percent; a hot-rolled plate is cooled to the temperature of 500-700 DEG C and then is coiled; and therefore, an oriented silicon steel hot-rolled plate with the enhanced Gaussian texture is obtained. By the method, the hot-rolled Gaussian texture of the double-roller ribbon continuous casting oriented silicon steel can be obviously enhanced by effectively controlling three technical parameters, namely the rolling temperature, the differentiate speed ratio and the total press-down rate. The technology adopted by the invention is simple and stable and can be used for a production flow of the double-roller ribbon continuous casting oriented silicon steel.

Owner:NORTHEASTERN UNIV

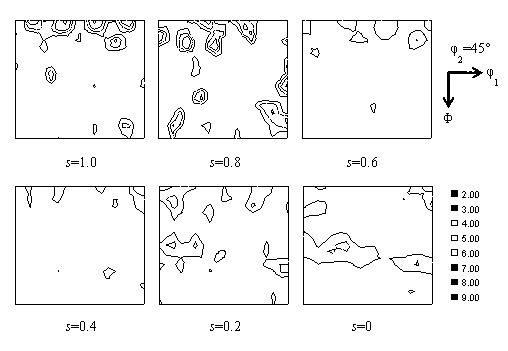

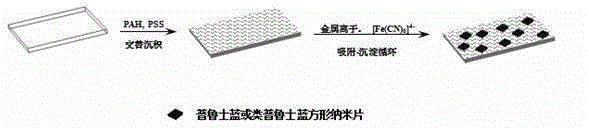

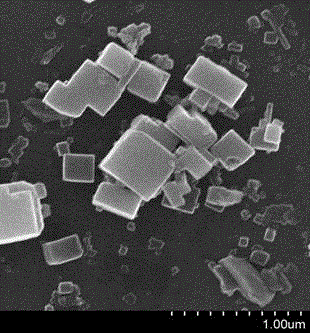

Prussian blue and Prussian blue analogue nanosheet film materials and in-situ preparation method thereof

The invention discloses Prussian blue and Prussian blue analogue nanosheet film materials and an in-situ preparation method thereof. A substrate is modified with two high-molecular polymers with opposite charges, namely PAH (poly allylamine hydrochloride) and PSS (sodium polystyrene sulfonate), and Prussian blue or Prussian blue analogue square nanosheets are synthesized in situ on the modified substrate with metal ionic salt and potassium ferrocyanide as raw materials. A test of a prepared nanosheet film through ultraviolet-visible spectroscopy, a scanning electron microscope and a transmission electron microscope proves that the nanosheets have controllable size and are uniformly dispersed. The growth direction of the nanosheets is limited by the porous network of the high-molecular polymers, so that the nanosheets are square or rectangular, water is used as a solvent in the whole preparation process of the film and is harmless to the environment, the preparation process is simple and feasible, the cost is low, equipment is simple, the film materials with different kinds of functionality are obtained by changing the variety of simple ions, and the in-situ preparation method has important application value in the field of material preparation.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

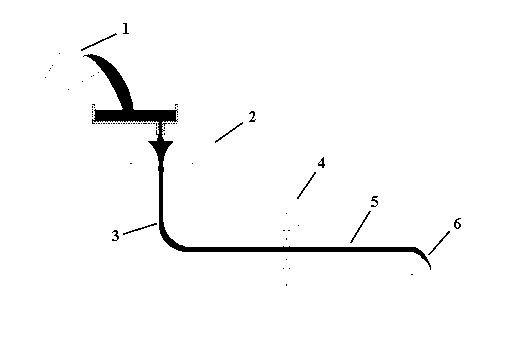

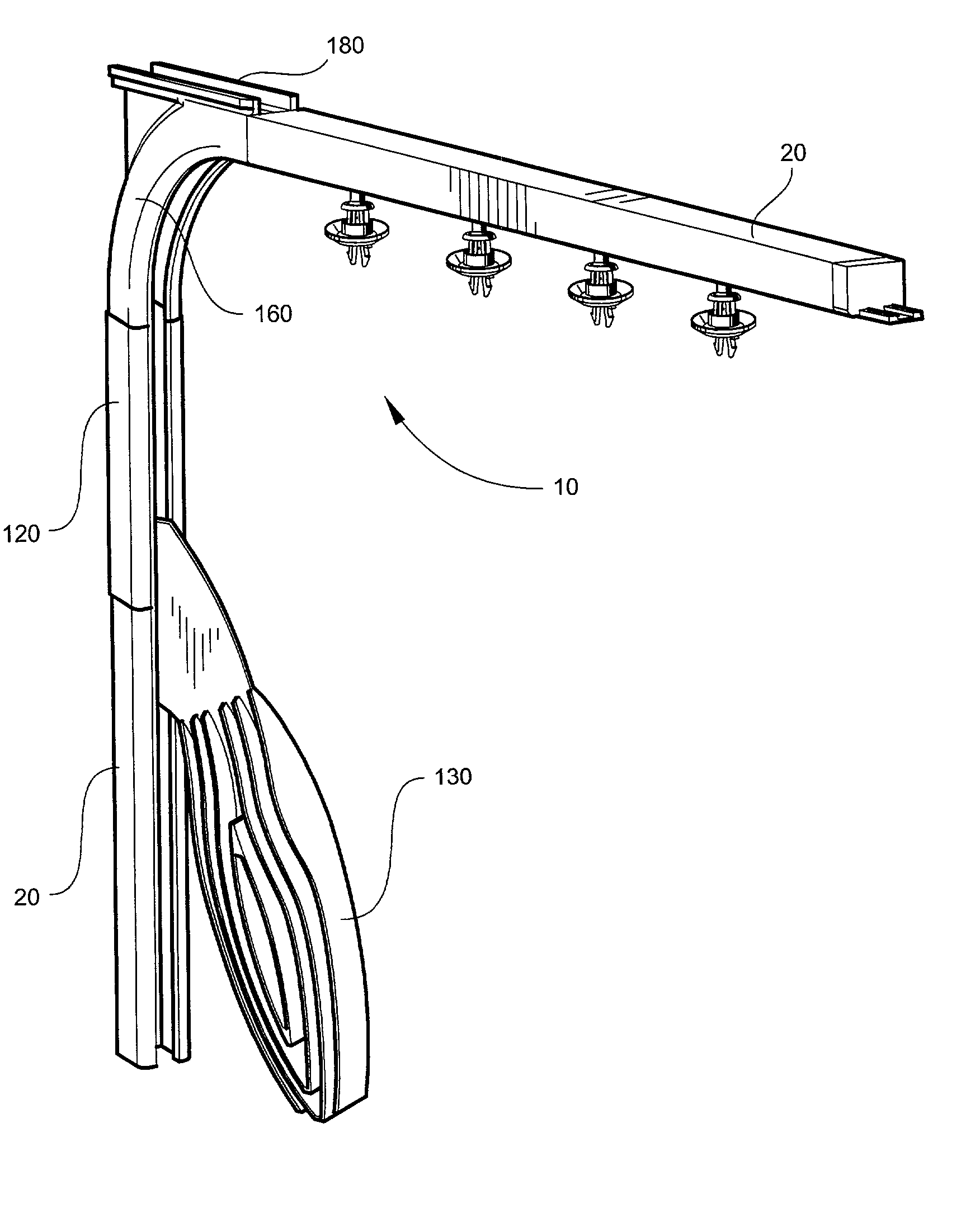

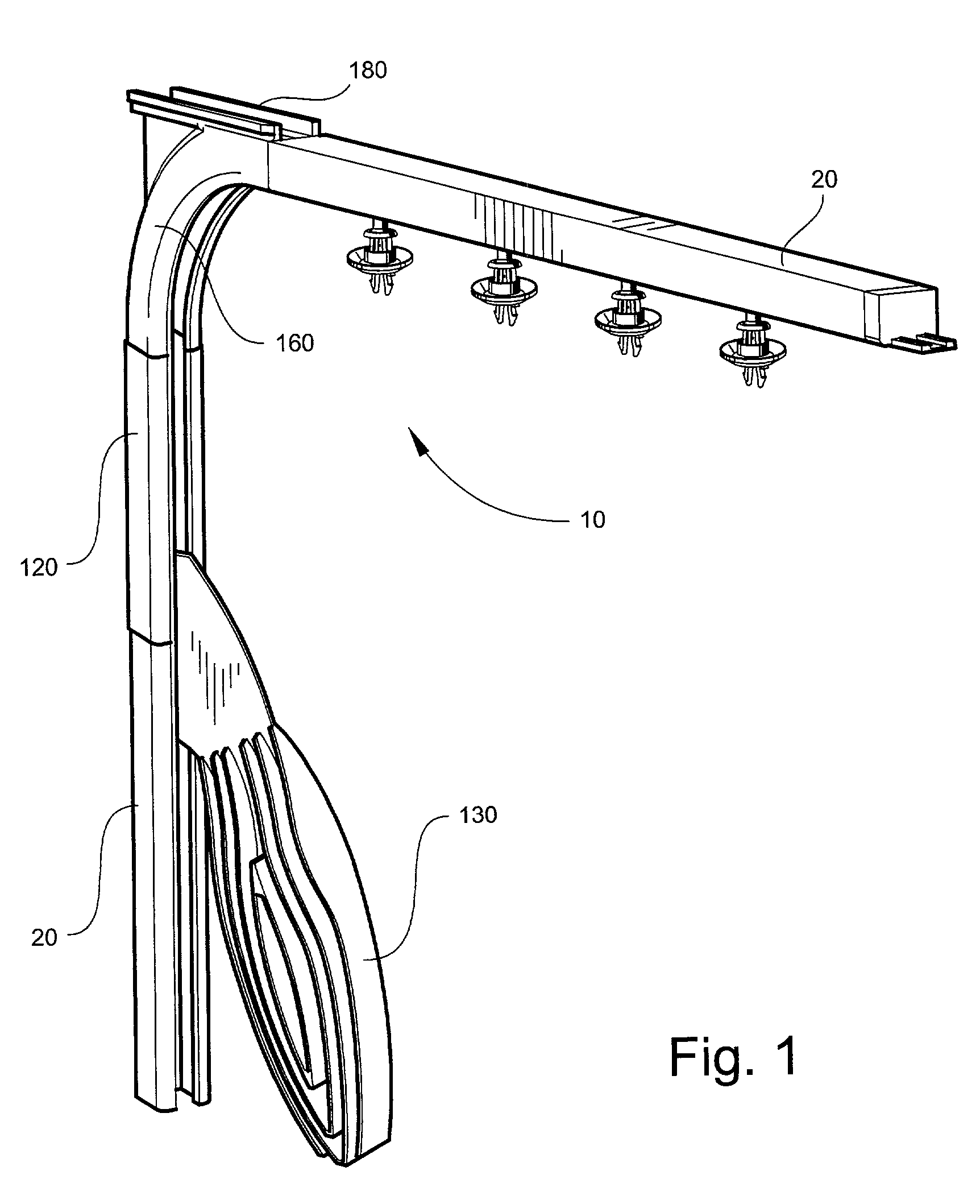

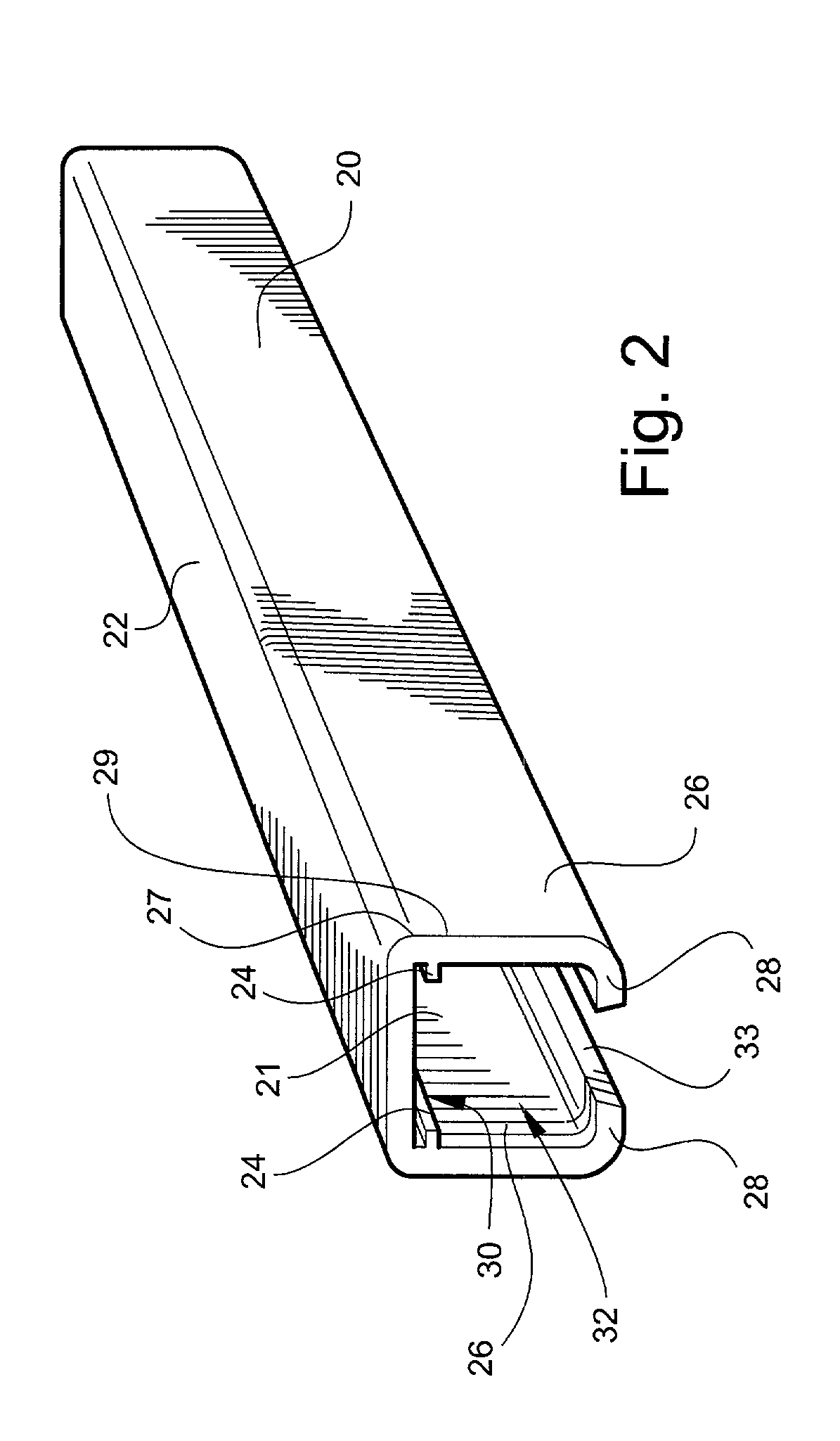

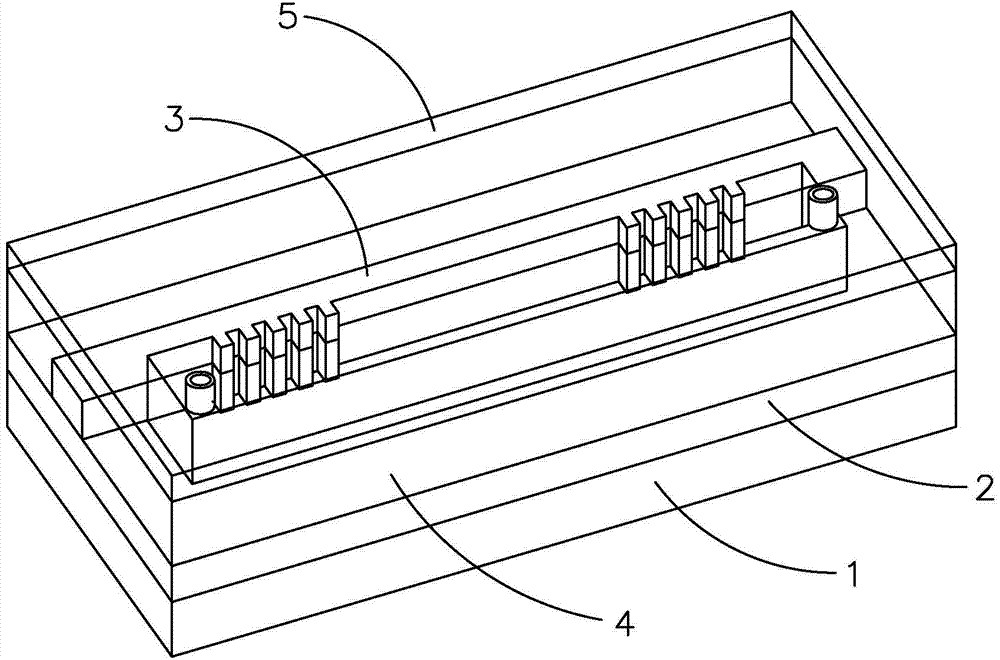

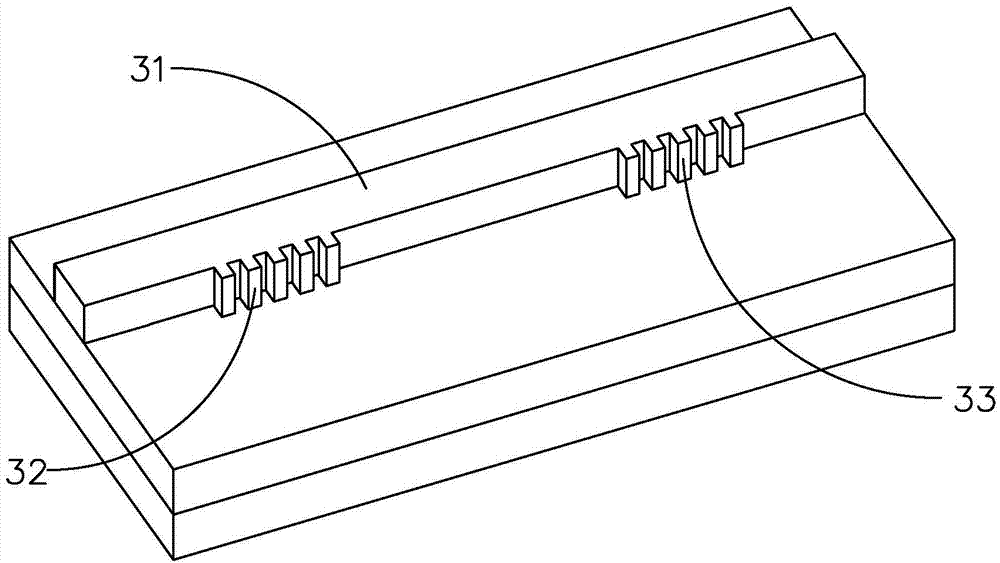

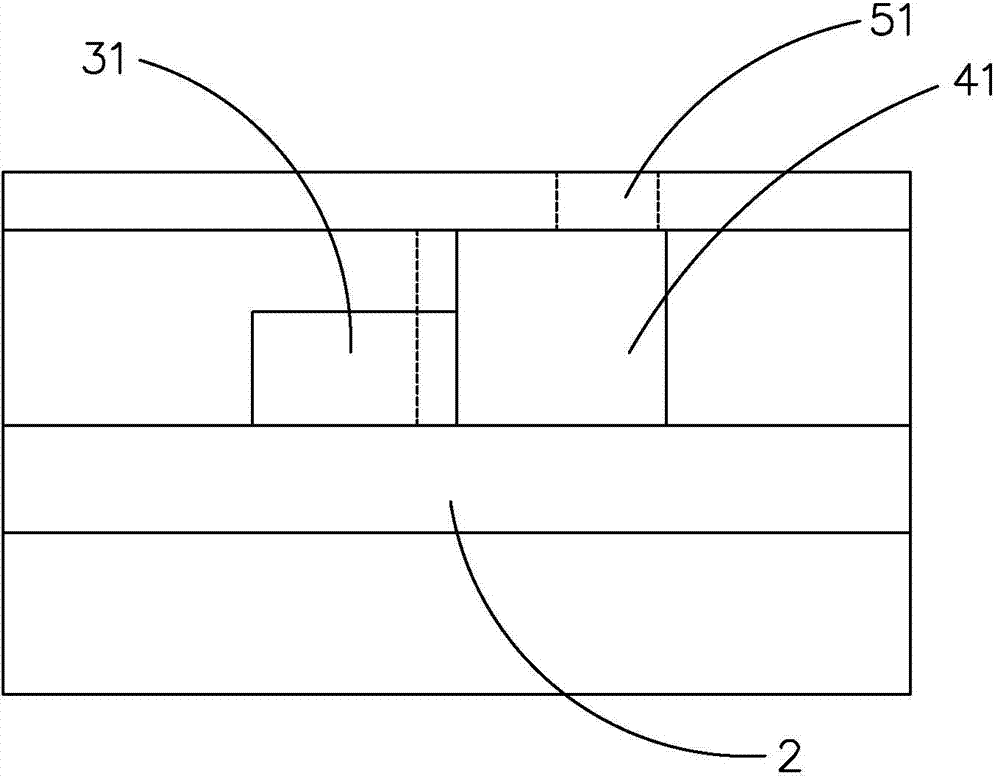

Channel system for light strings

InactiveUS20030185008A1Shorten the timeReduce usagePoint-like light sourceLighting support devicesDisplay deviceEngineering

The present invention is a kit or a channel system useful for the removable mounting (installation and removal) of ornamental light strings onto buildings such as houses, offices, stores, and the like. The system according to the present invention has at least one, preferably a series of, display channel pieces, or tracks, that are attached to a surface of a building, such as a house, store, office, or the like. The channel pieces are coupled together with coupling tabs. Slide mounts moveably fit within, and work with, channels within the channel pieces and are used to moveably secure ornamental light strings to the system when in use. Beveled edges located on distal ends of projections on the channel pieces allow for variable positioning of light strings using the channels system of the present invention. A slide mount guide is used to urge the mounted light string from a storage channel piece to the display channel pieces.

Owner:KMOR INNOVATIONS

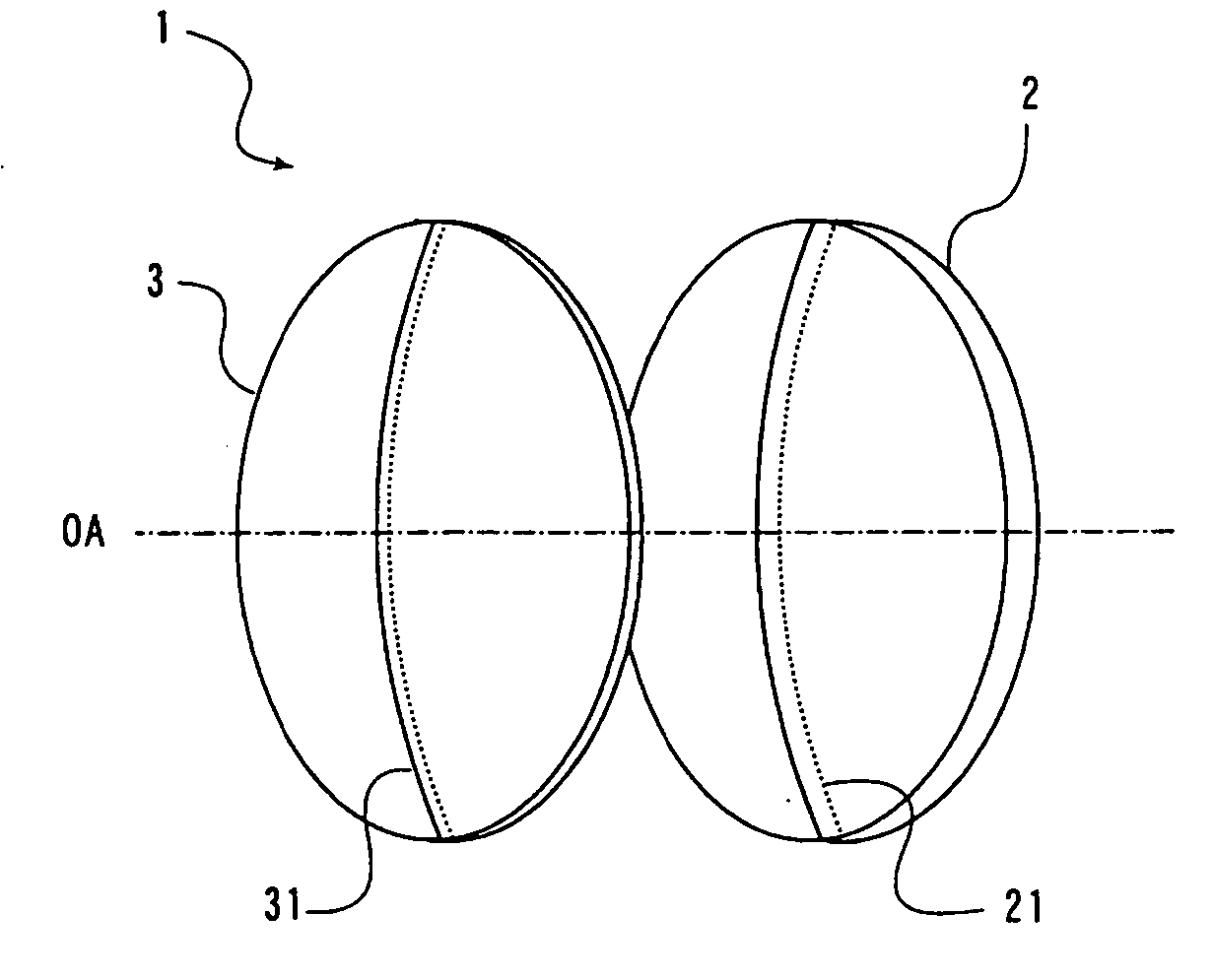

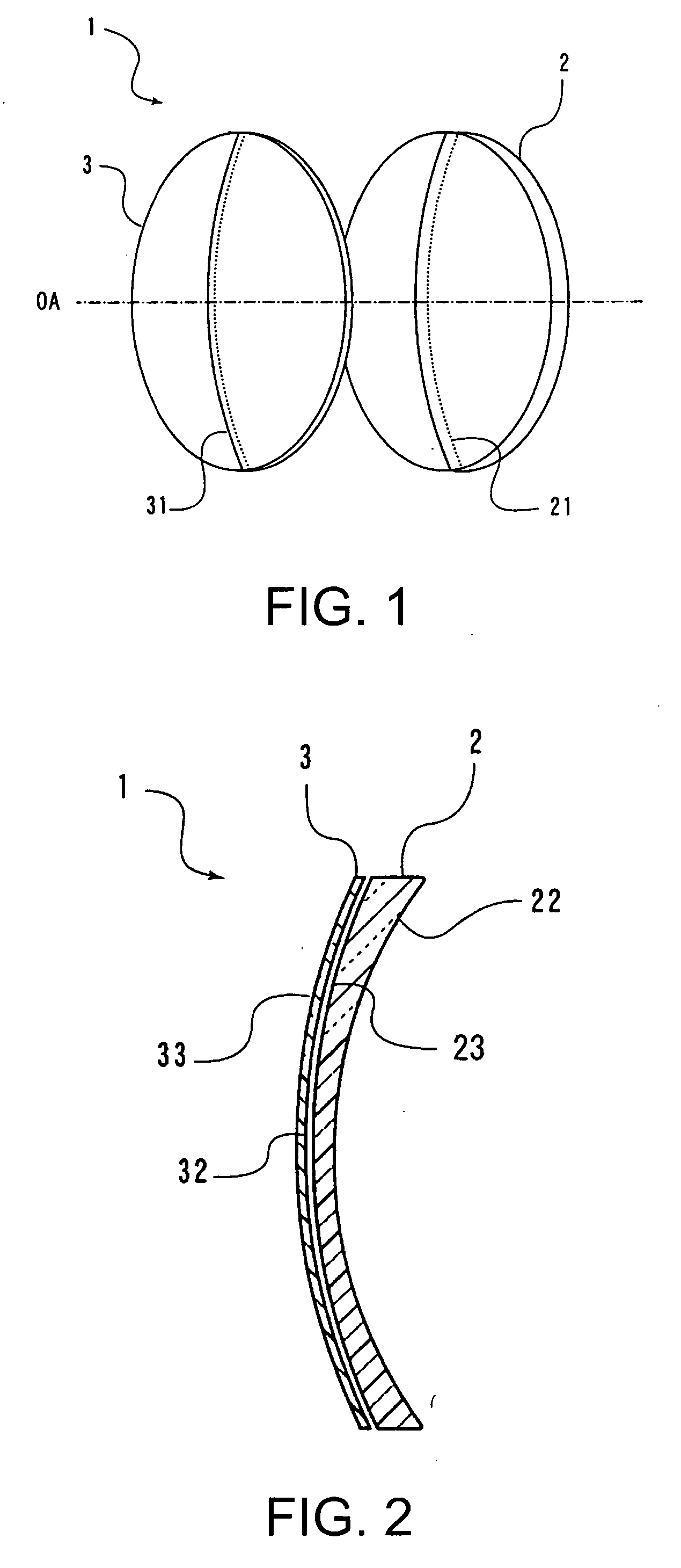

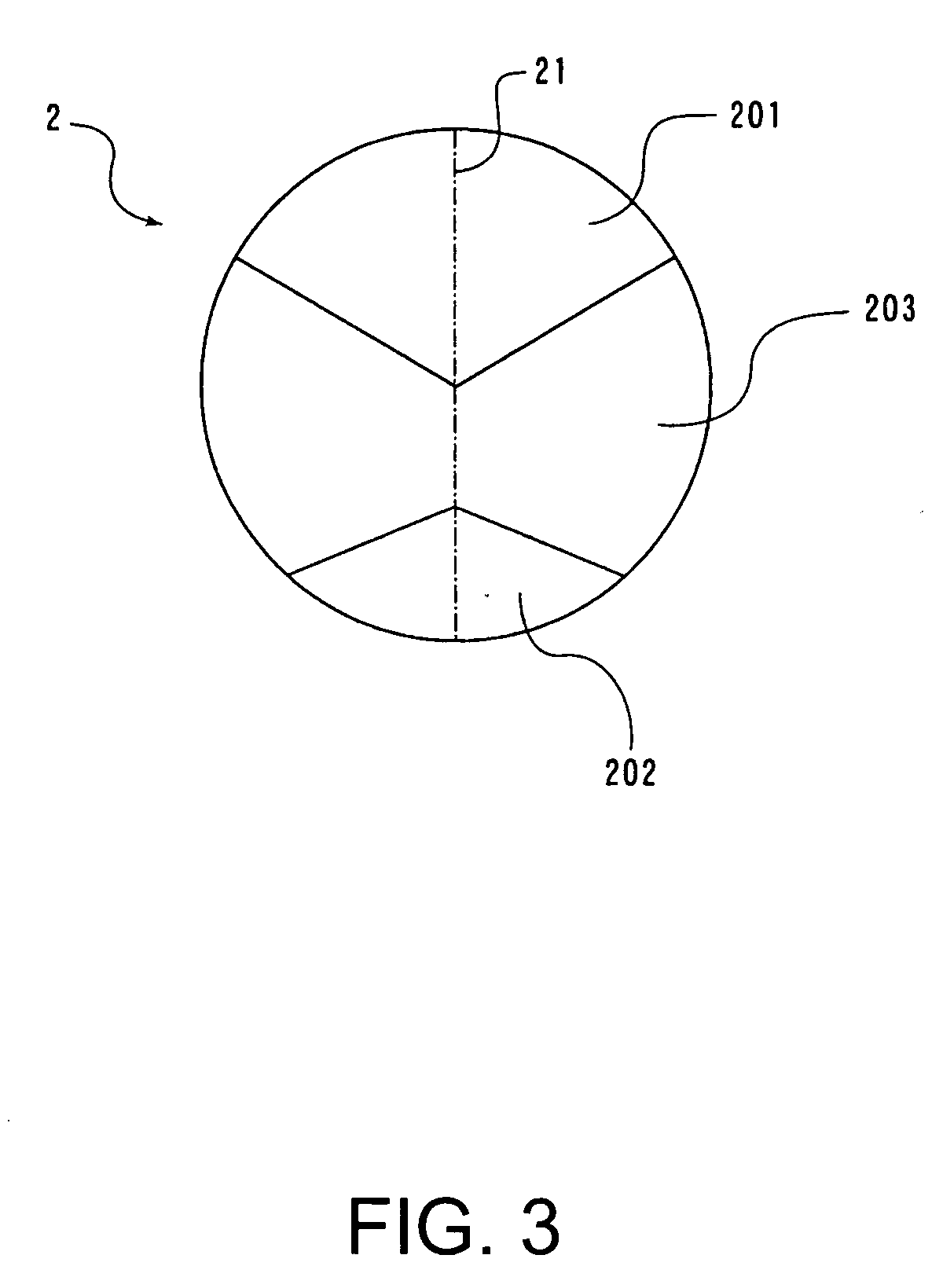

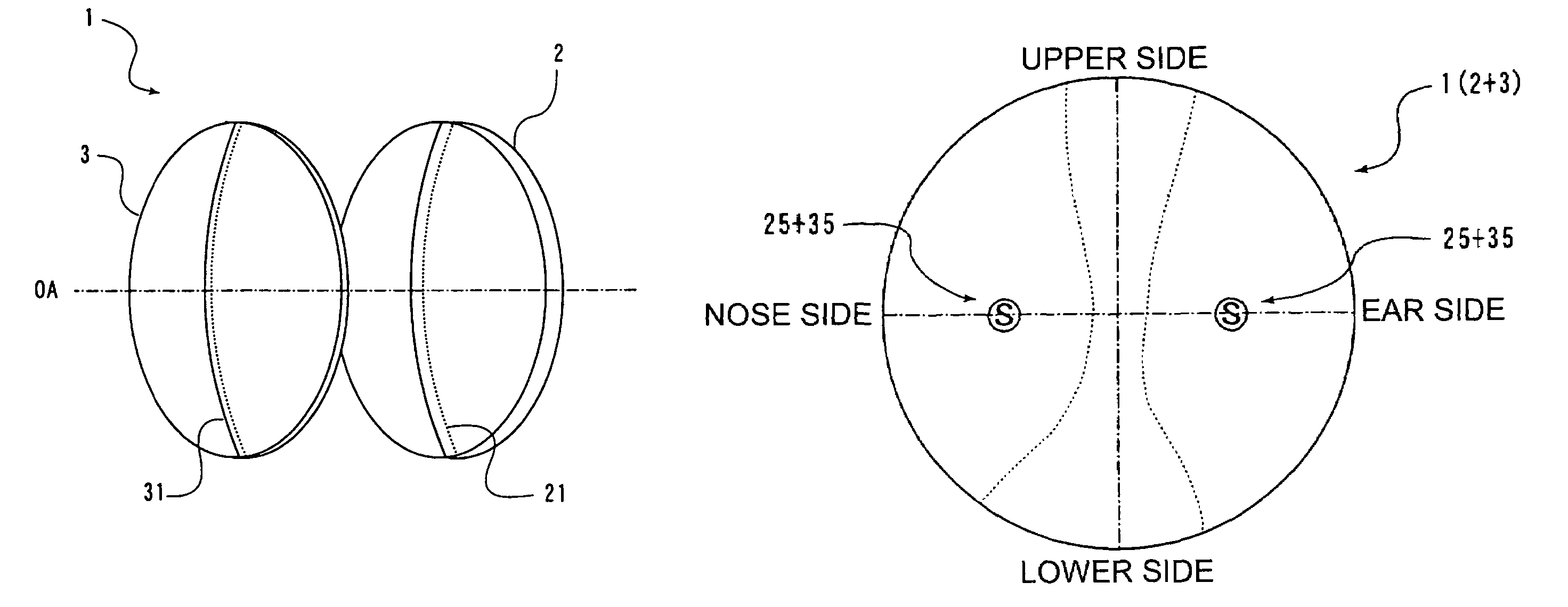

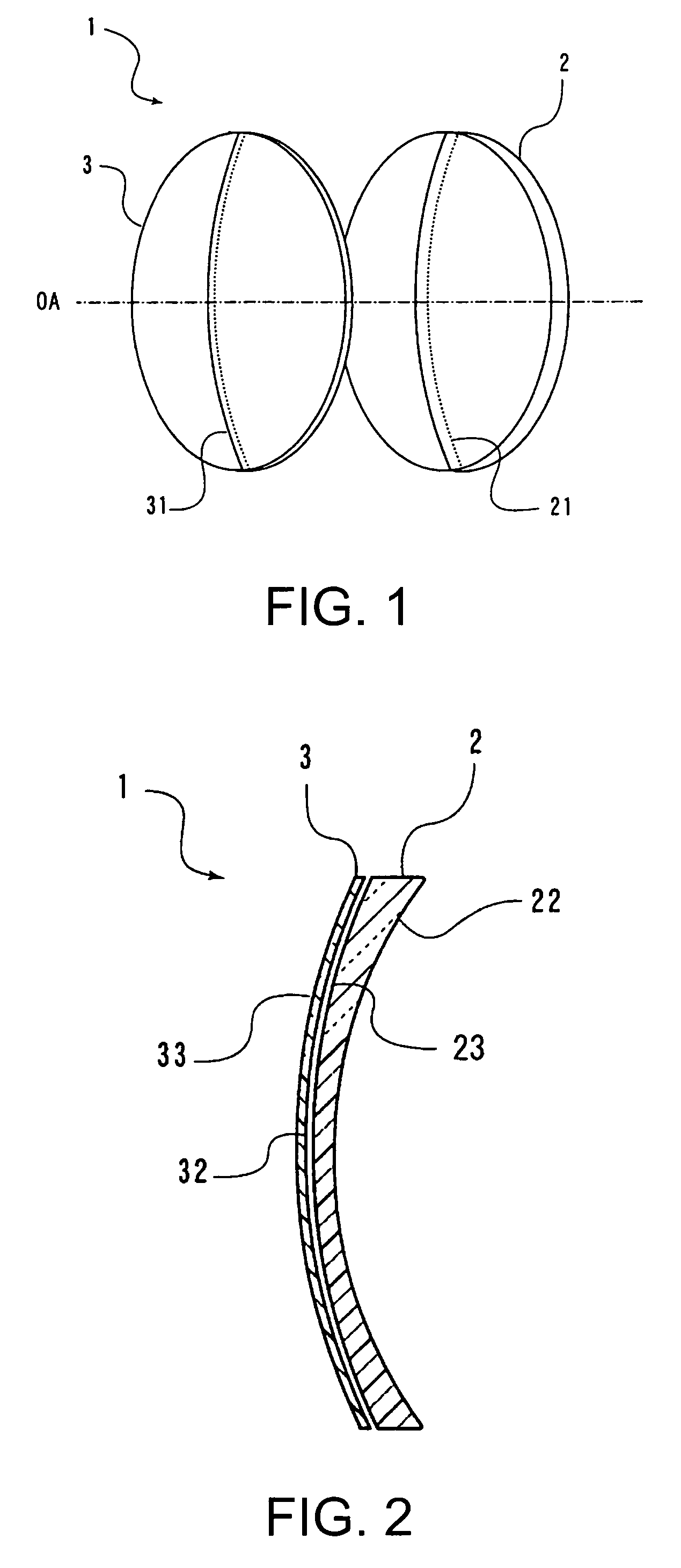

Combined spectacle lens, auxiliary lens, and method of edging lenses

InactiveUS20060176445A1Easily changeSecure assembly accuracySpectales/gogglesOptical partsEngineeringEyeglass lenses

A combined spectacle lens including a combination of a basic lens and an auxiliary lens, the basic lens formed with a progressive-power surface having a first power portion having a power for viewing an object at a predetermined distance, a second power portion having a power different from that in the first power portion, and a progressive portion in which the power is progressively changed from the first power portion to the second power portion on either one or both of refractive surfaces on an object side and an eyeball side, wherein a resultant power obtained by combining a basic lens power of the basic lens and an auxiliary lens power of the auxiliary lens is partly or entirely different from that of the basic lens power.

Owner:HOYA LENS MFG PHILIPPINES

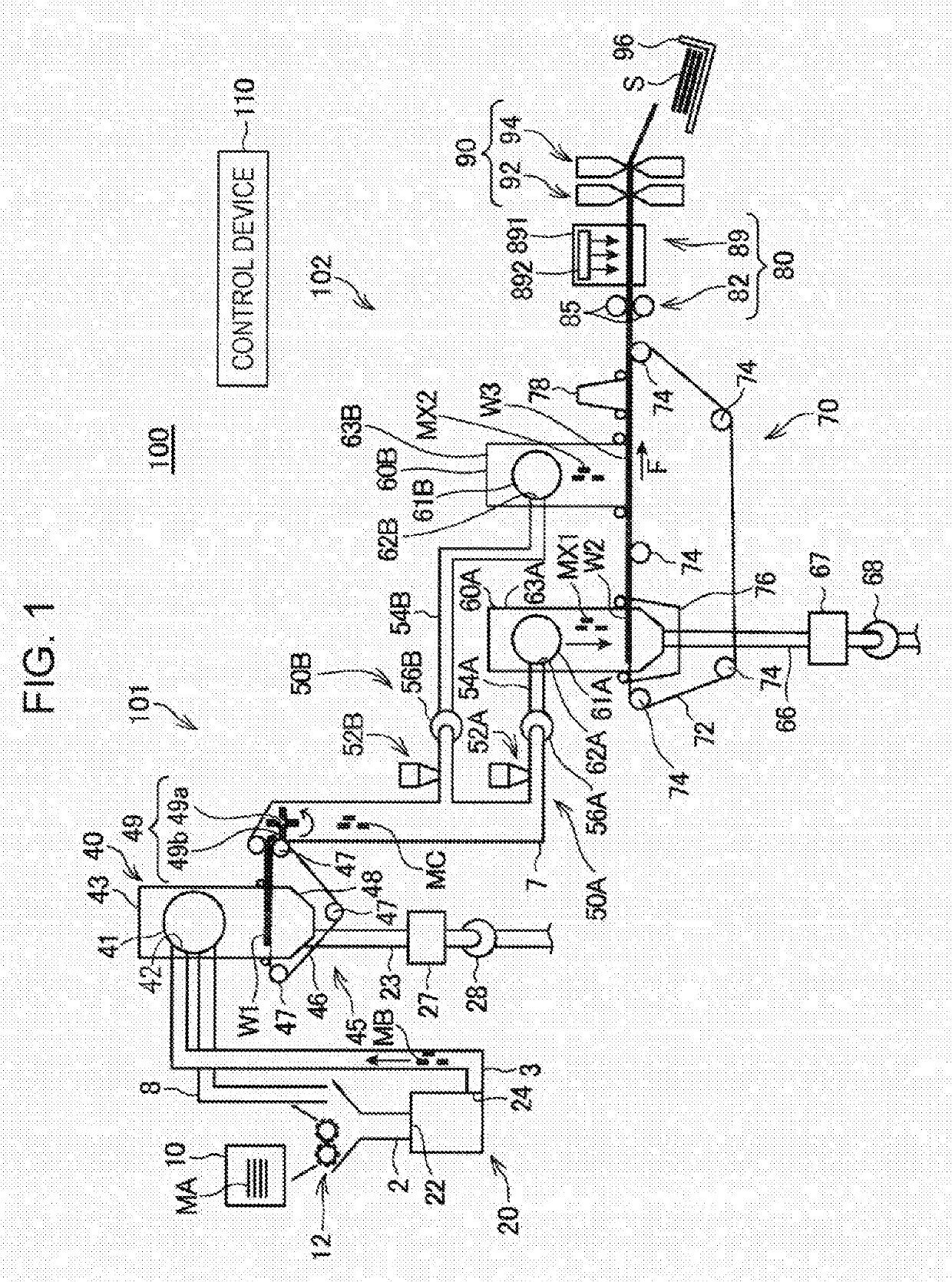

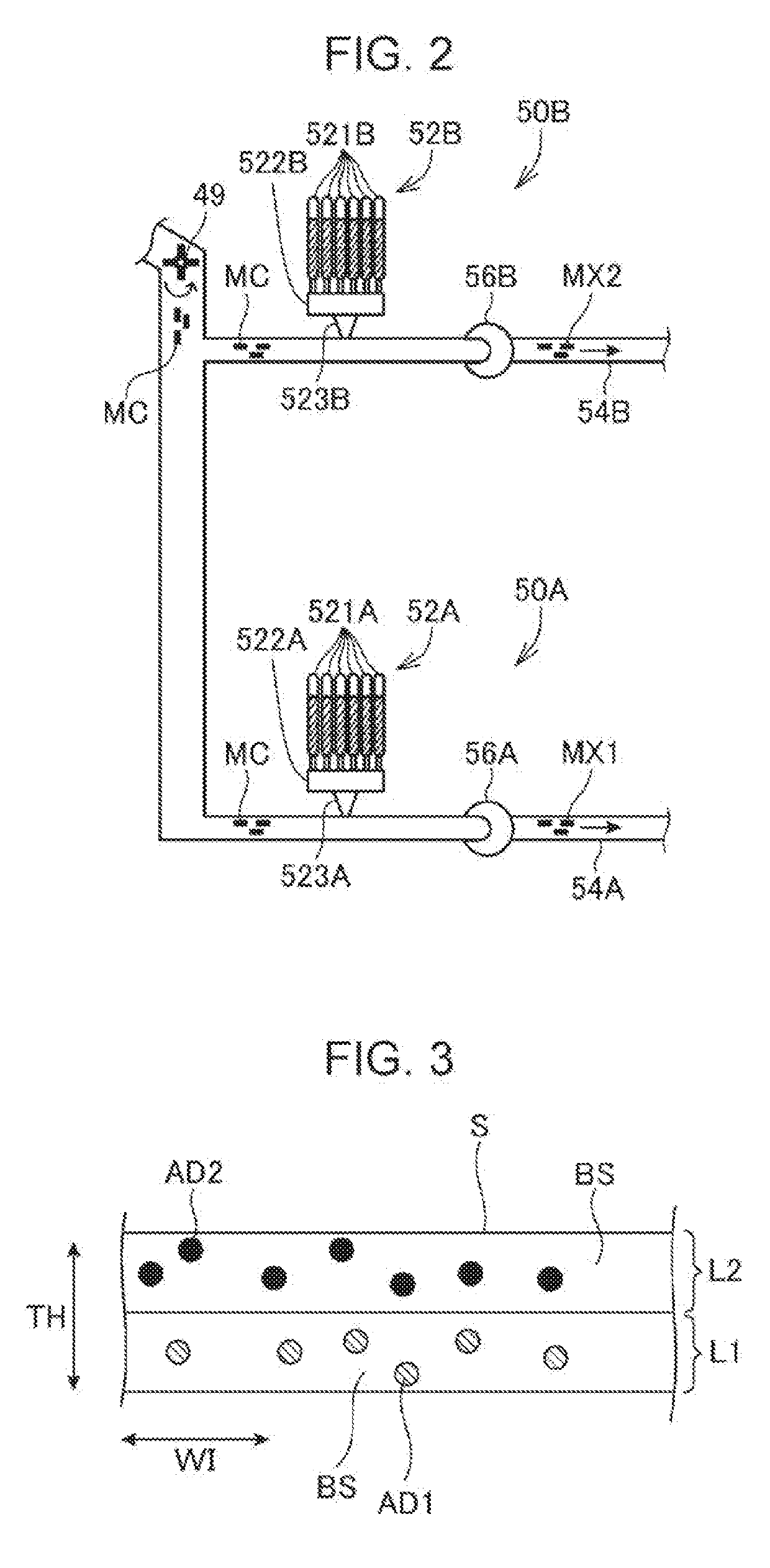

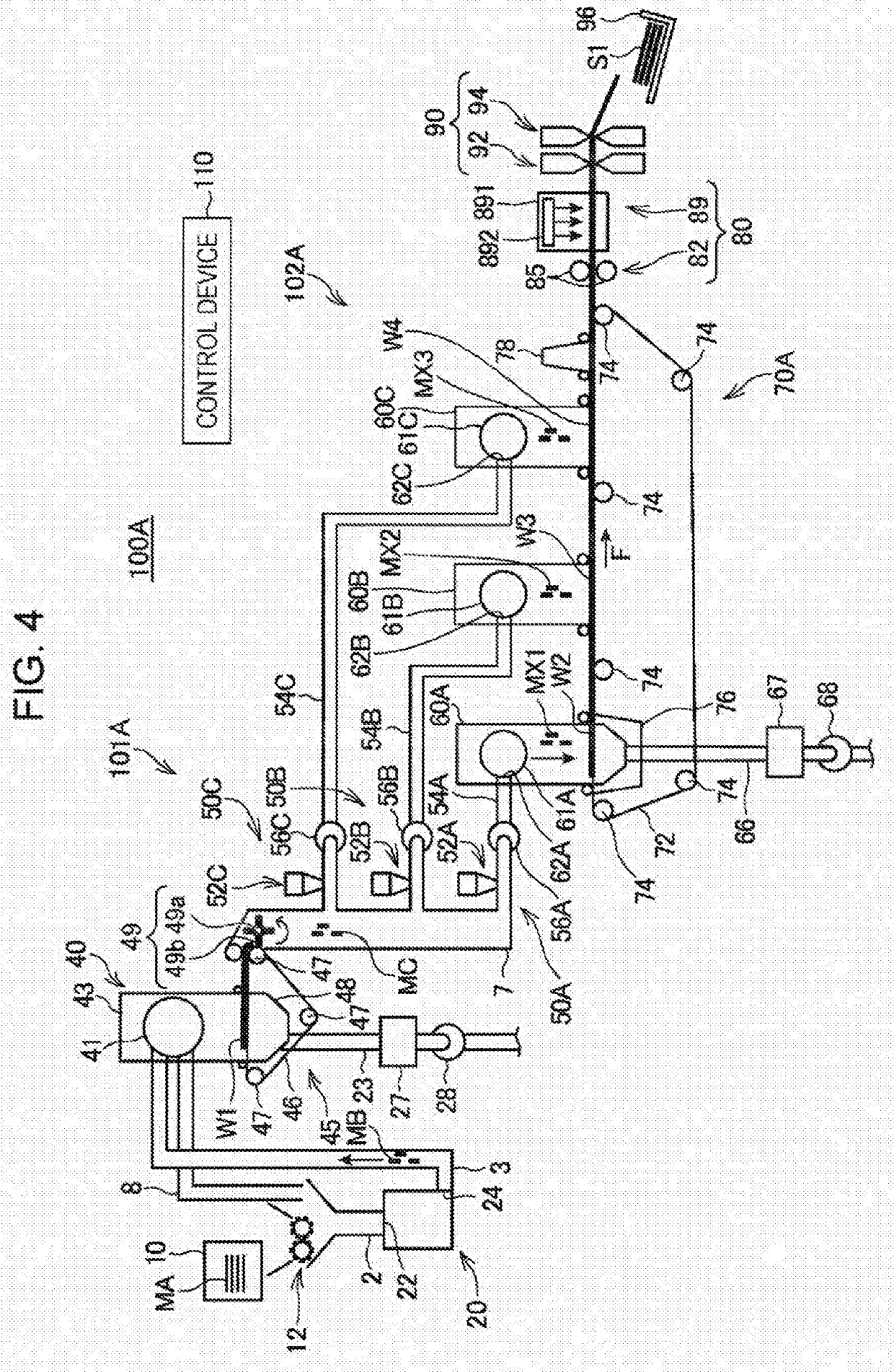

Sheet manufacturing apparatus and sheet manufacturing method

InactiveUS20190232606A1Change in stateAdjustable densityBiocideNon-fibrous pulp additionBiomedical engineeringFiber

A sheet manufacturing apparatus includes: a web forming unit that includes a first depositing unit which forms a first web by depositing a first mixture containing fibers and a second depositing unit which forms a second web by depositing a second mixture containing fibers on the first web, and that forms a web for processing; and a processing unit that manufactures a sheet by performing processing including heating with respect to the web for processing formed by the web forming unit.

Owner:SEIKO EPSON CORP

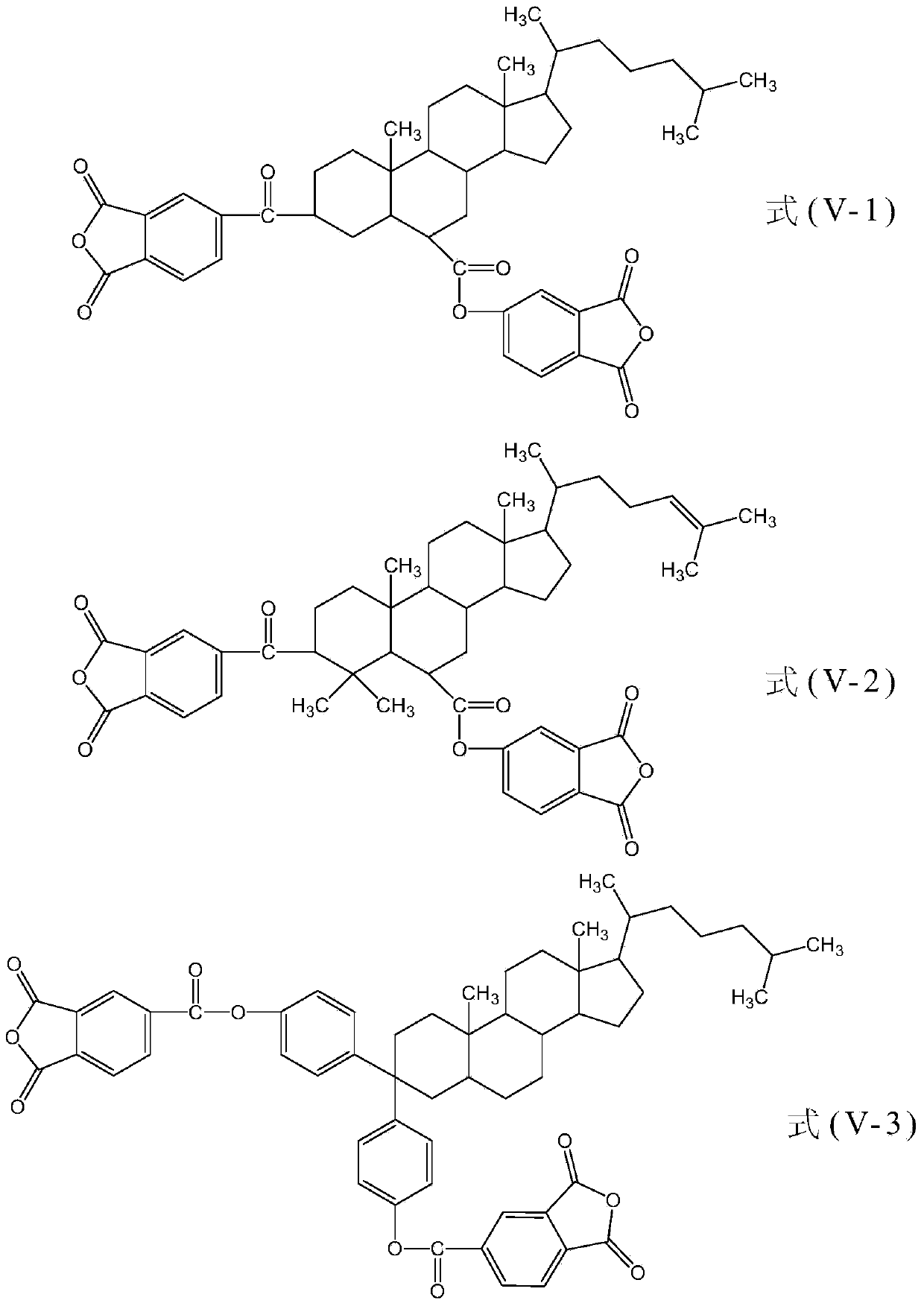

Liquid crystal alignment agent, liquid crystal alignment film and liquid crystal display element

InactiveCN104178181AGood spreadabilityGood adhesionLiquid crystal compositionsNon-linear opticsCrystallographyLiquid-crystal display

The present invention relates to a liquid crystal alignment agent, a liquid crystal alignment film made by the liquid crystal alignment agent and a liquid crystal display element having the liquid crystal alignment film. The liquid crystal alignment agent includes a polymer composition (A) and a solvent (B). The polymer composition (A) is synthesized by reacting a mixture that includes a tetracarboxylic dianhydride component (a) and a diamine component (b). The aforementioned liquid crystal alignment agent has a better long-term printability.

Owner:CHI MEI CORP

Preparation method and application of surface molecular imprinting solid-phase adsorbent for psychiatric drugs

InactiveCN103554374AUnique methodReduce "entrapment" phenomenonOther chemical processesChromatographic separationFunctional monomer

The invention relates to a molecular imprinting solid-phase extraction adsorbent and a chromatographic separation solid phase, and relates to a preparation method of a surface molecular imprinting solid-phase adsorbent for psychiatric drugs, which has specific recognition performance for the psychiatric drugs. The method comprises the following steps: preparing a macroinitiator on the surface of styrene resin through chloromethylation; initiating the functional monomer polymerization by use of the initiator, eluting a template molecule, washing and testing the adsorption property of the adsorbent. By adopting the technology, the influence of nonspecific adsorption on selectivity can be reduced, the embedding phenomenon of the existing molecular imprinting is greatly reduced, the imprinting efficiency and adsorption / desorption rate can be improved, the variety of the reaction monomer is changed, and the product has the characteristics of multiple functional groups and the like and can be widely applied to solid-phase extraction adsorbents.

Owner:NINGXIA UNIVERSITY

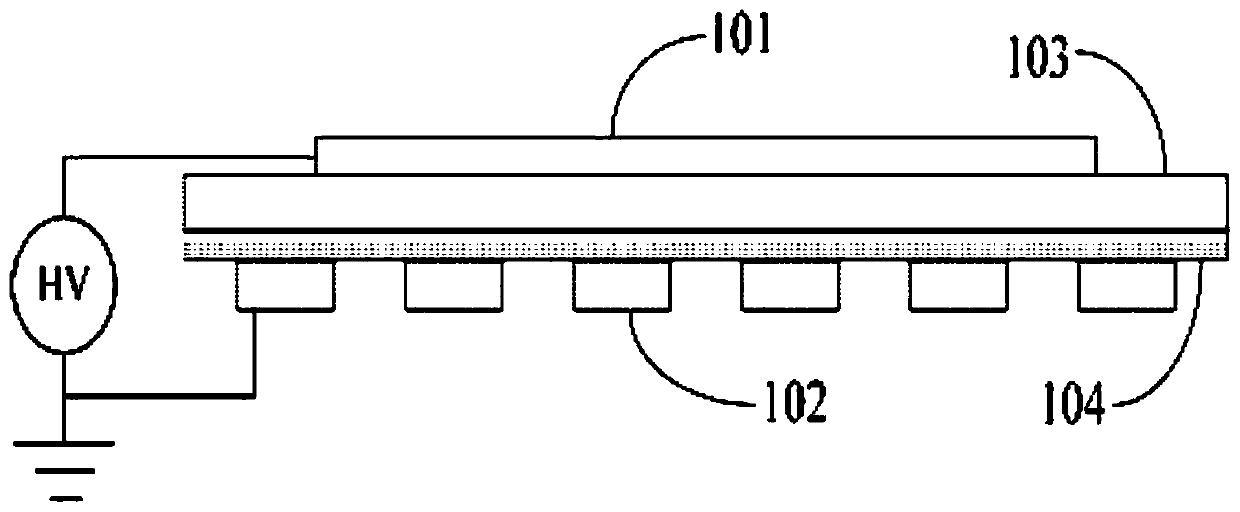

Surface discharge plasma device

The invention discloses a surface discharge plasma device formed by a combined dielectric material. The surface discharge plasma device comprises a high-voltage electrode, a ground electrode and a combined dielectric layer, wherein the high-voltage electrode is of a flat-plate structure; the ground electrode is of a strip-shaped structure; the combined dielectric layer comprises an aluminum oxideceramic layer and a polytetrafluoroethylene layer which are stacked; the high-voltage electrode is tightly attached to the aluminum oxide ceramic layer; the ground electrode is tightly attached to thepolytetrafluoroethylene layer; and when the high-voltage electrode is excited by a high-voltage power supply, the ground electrode generates a discharge plasma distributed along the surface of the ground electrode.

Owner:XI AN JIAOTONG UNIV

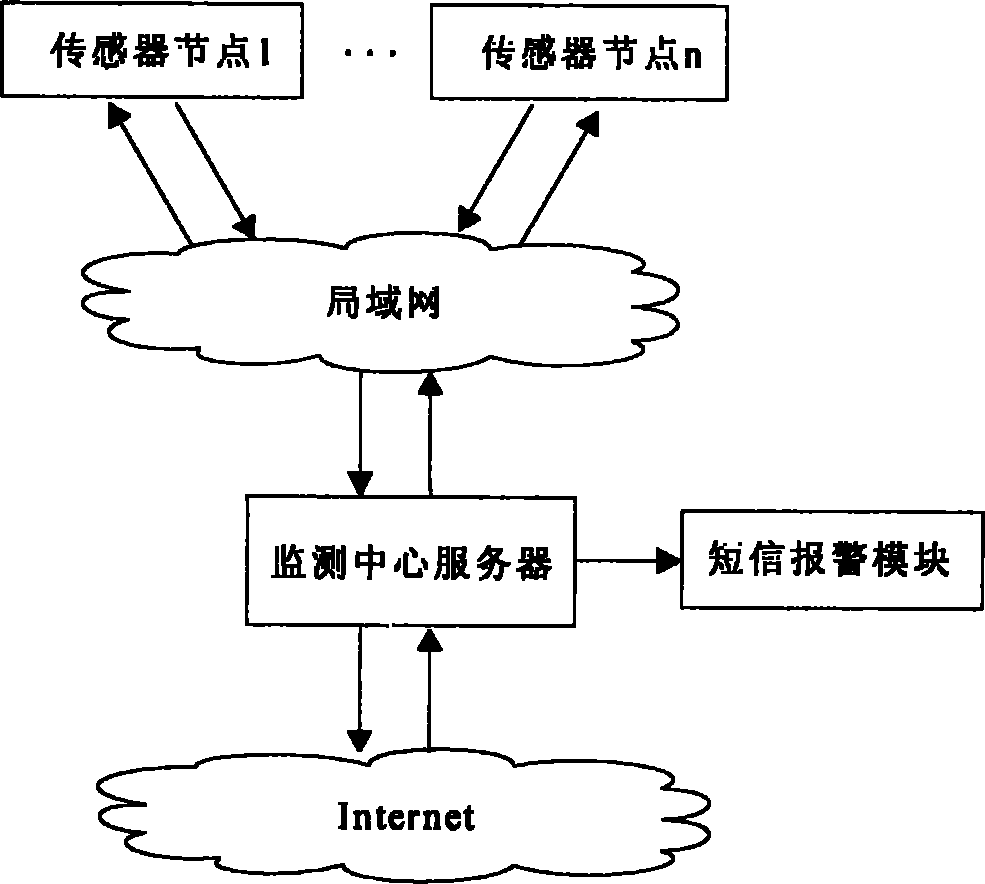

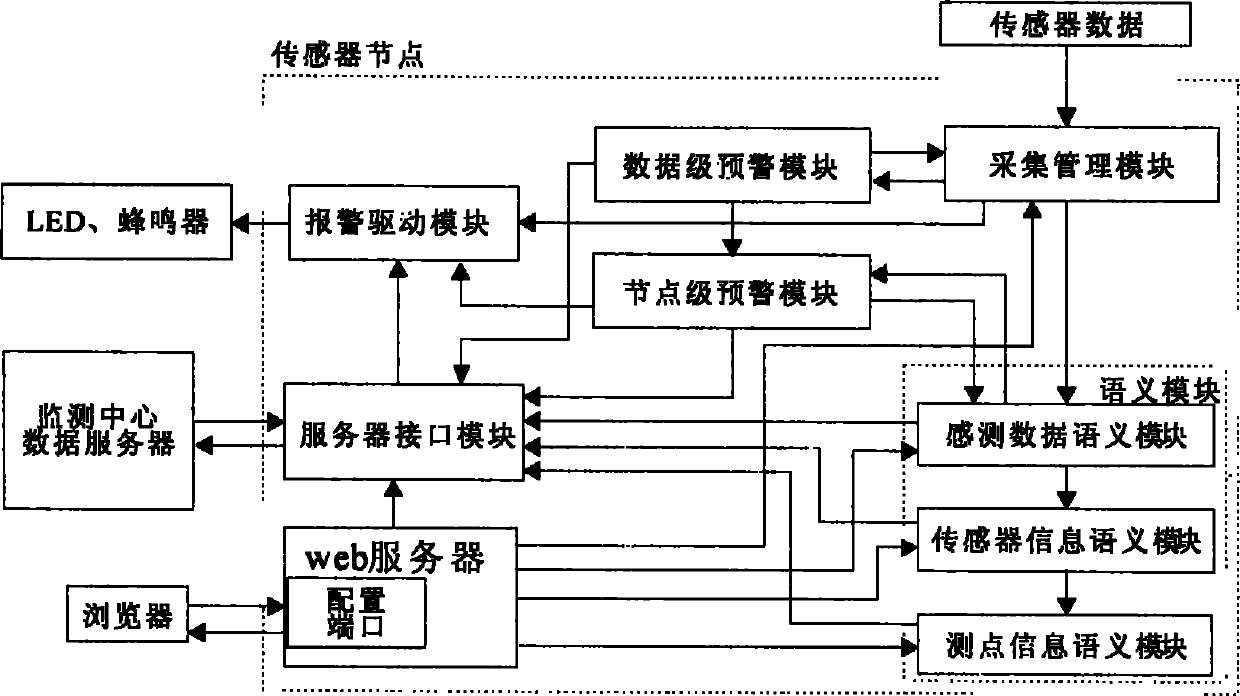

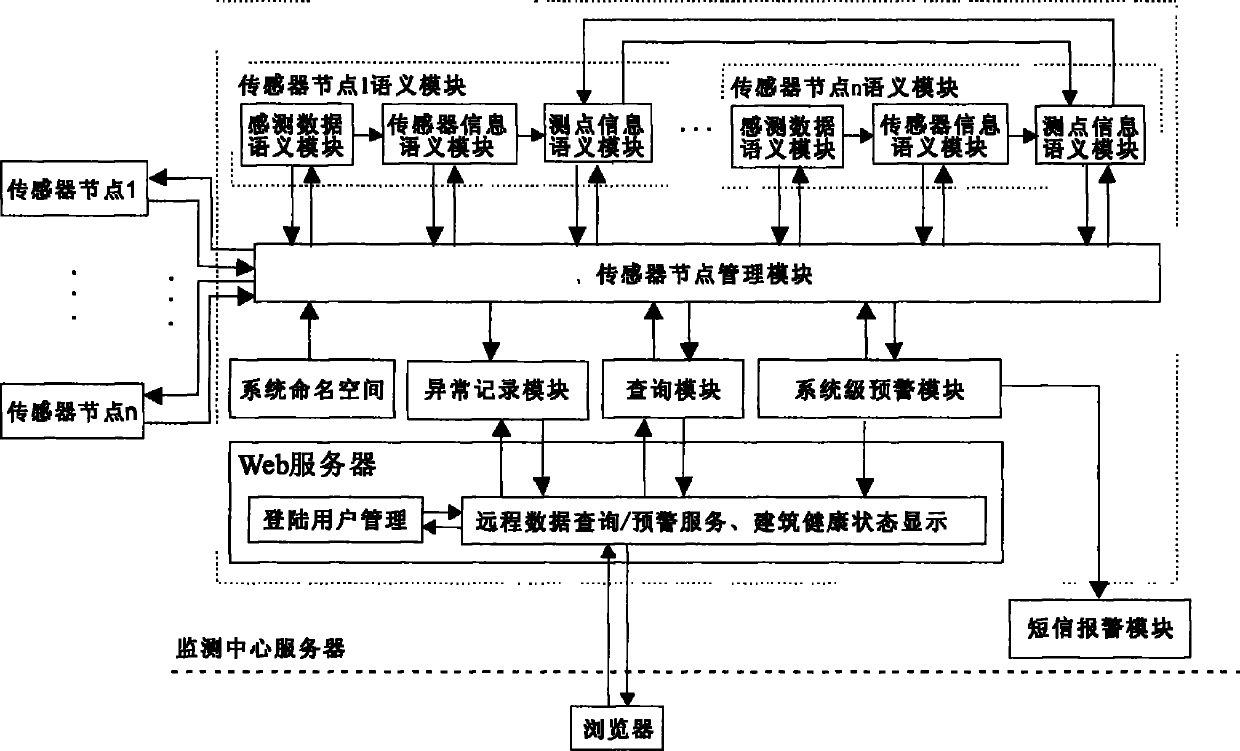

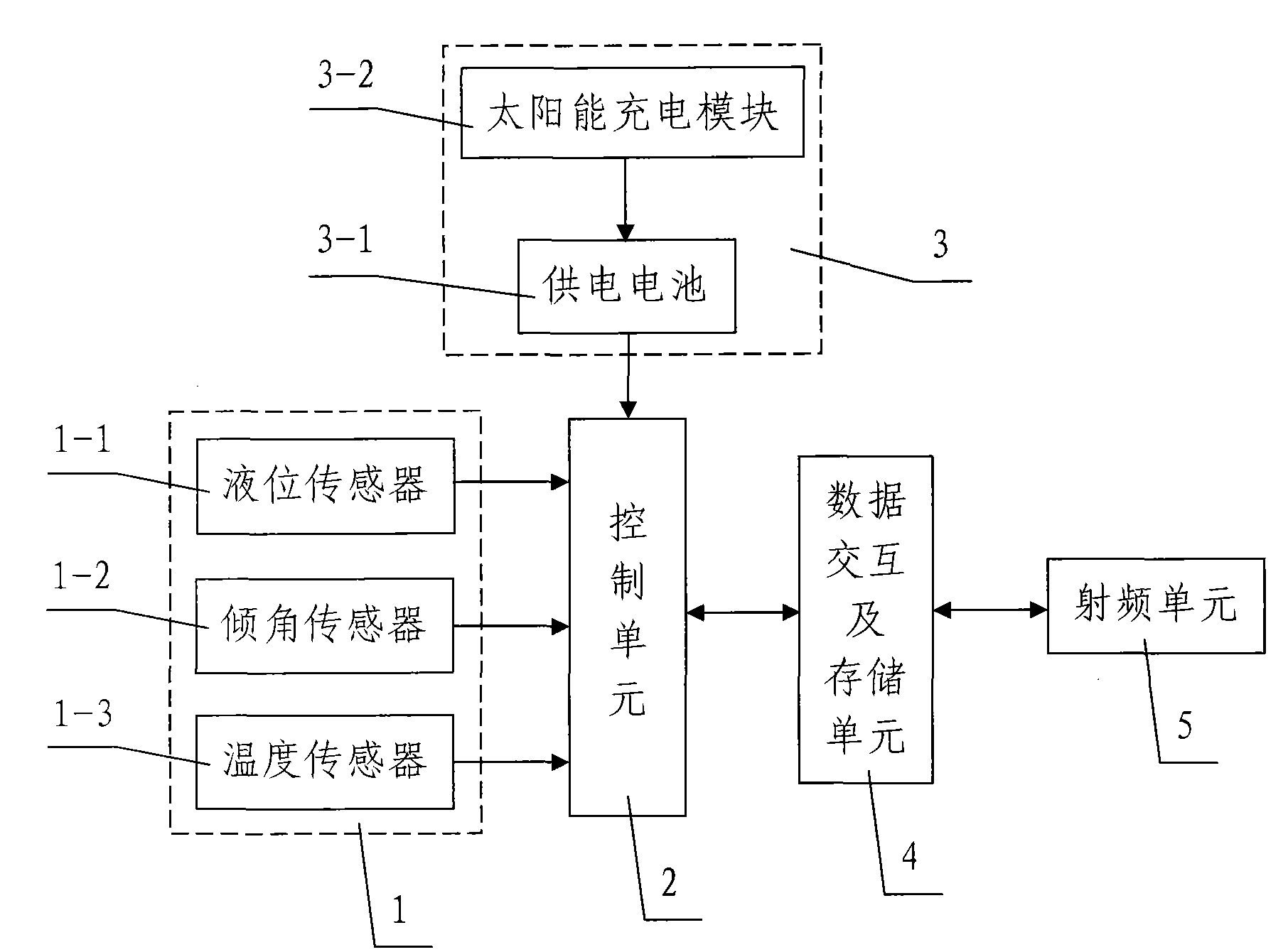

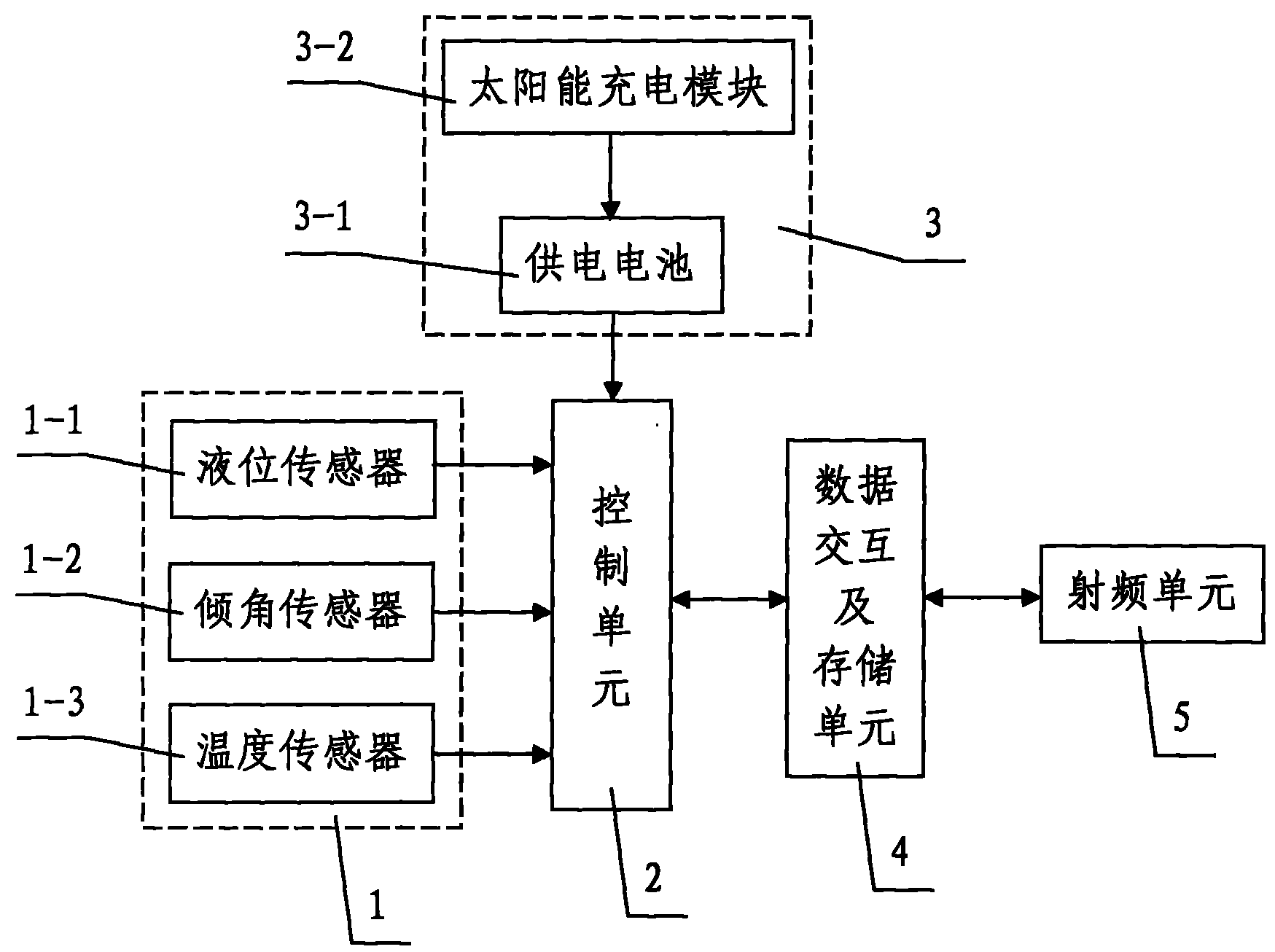

Sensor system used for building-structure safety monitoring

The invention proposes a sensor semantic system including sensor nodes, a local-area network, a monitoring-center server, the Internet and a text-message alarm module. The sensor nodes are arranged on parts to be detected and connected with the monitoring-center server through the local-area network. A built-in web server of the monitoring-center server provides data services or sends forewarning information to remote users through the Internet and forewarning text messages can also be sent through the text-message alarm module. The system is characterized in that the sensor nodes include a sensor information semantic module, a detected-point information semantic module and a sensed-data semantic module and the three semantic modules are associated through attributes and add a semantic background for data output by the sensor. An RDF (Resource Description Framework) is used to describe the three semantic modules and sensor information, detected-point information and sensed data are defined as resources on networks through a URI (Universal Resource Identifier). The sensed-data semantic module carries out semantic annotation on data so that semantic data are formed and then stored. When a storage space exceeds a limit, data saved at earliest time are covered automatically and at the same time, the semantic data are submitted to the monitoring-center server through a server interface module.

Owner:BEIJING UNIV OF TECH +1

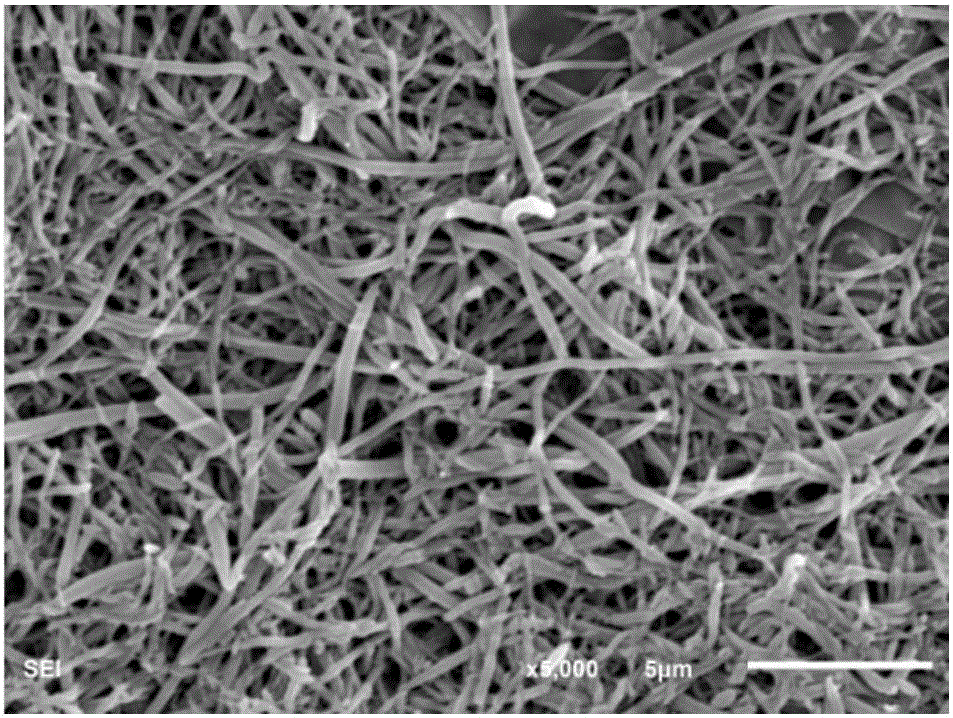

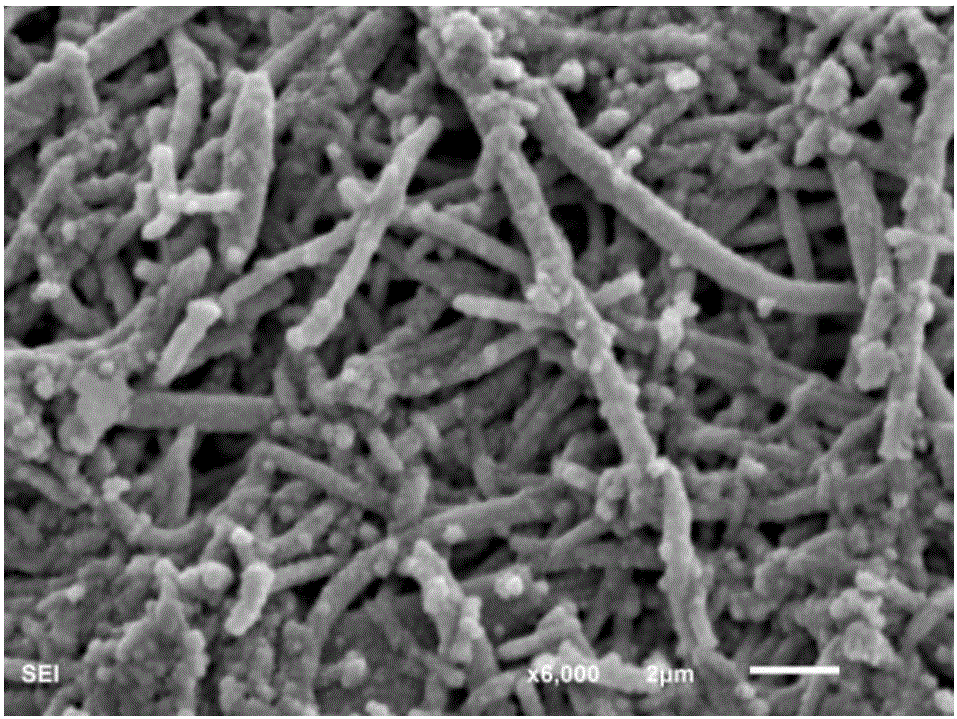

Nickel nanofiber membrane for membrane catalysis and preparation method of nickel nanofiber membrane

ActiveCN105148996APhysically and chemically stableReliable specific surface areaOrganic-compounds/hydrides/coordination-complexes catalystsFibre typesSolventChemistry

The invention relates to a nickel nanofiber membrane for membrane catalysis. The nickel nanofiber membrane is composed of a thermoplastic polymer nanofiber membrane and a nickel nano membrane deposited on the thermoplastic polymer nanofiber surface and comprises components in mass of 14%-75% of the thermoplastic polymer nanofiber membrane and 25%-86% of the nickel nano membrane. A preparation process adopts the method that thermoplastic polymers and cellulose acetate butyrate are subjected to blending melt spinning in proportion, thermoplastic polymer nanofibers are prepared through solvent extraction and dispersed and coated to the surface of a smooth substrate, and the thermoplastic polymer nanofiber membrane is taken down after drying. The nanofiber membrane is placed into a nickel bath with a certain formula for chemical nickel-plating after allergy and activating treatment and dried after taken out to obtain the nickel nanofiber membrane for membrane catalysis. The process is simple, the cost is low, and large scale preparation is easy to implement. The nickel nanofiber membrane for membrane catalysis has the characteristics that the porosity is high, the pore diameter is controllable, the flux is large, the catalytic activity is high, and separation is easy.

Owner:佛山市维晨科技有限公司 +1

Underwater environmental monitoring wireless data acquisition and transmission device

InactiveCN102052917ASimple structureLow costTransmission systemsOpen water surveyRadio frequencyControl unit

Owner:XIAN CENTN TECH

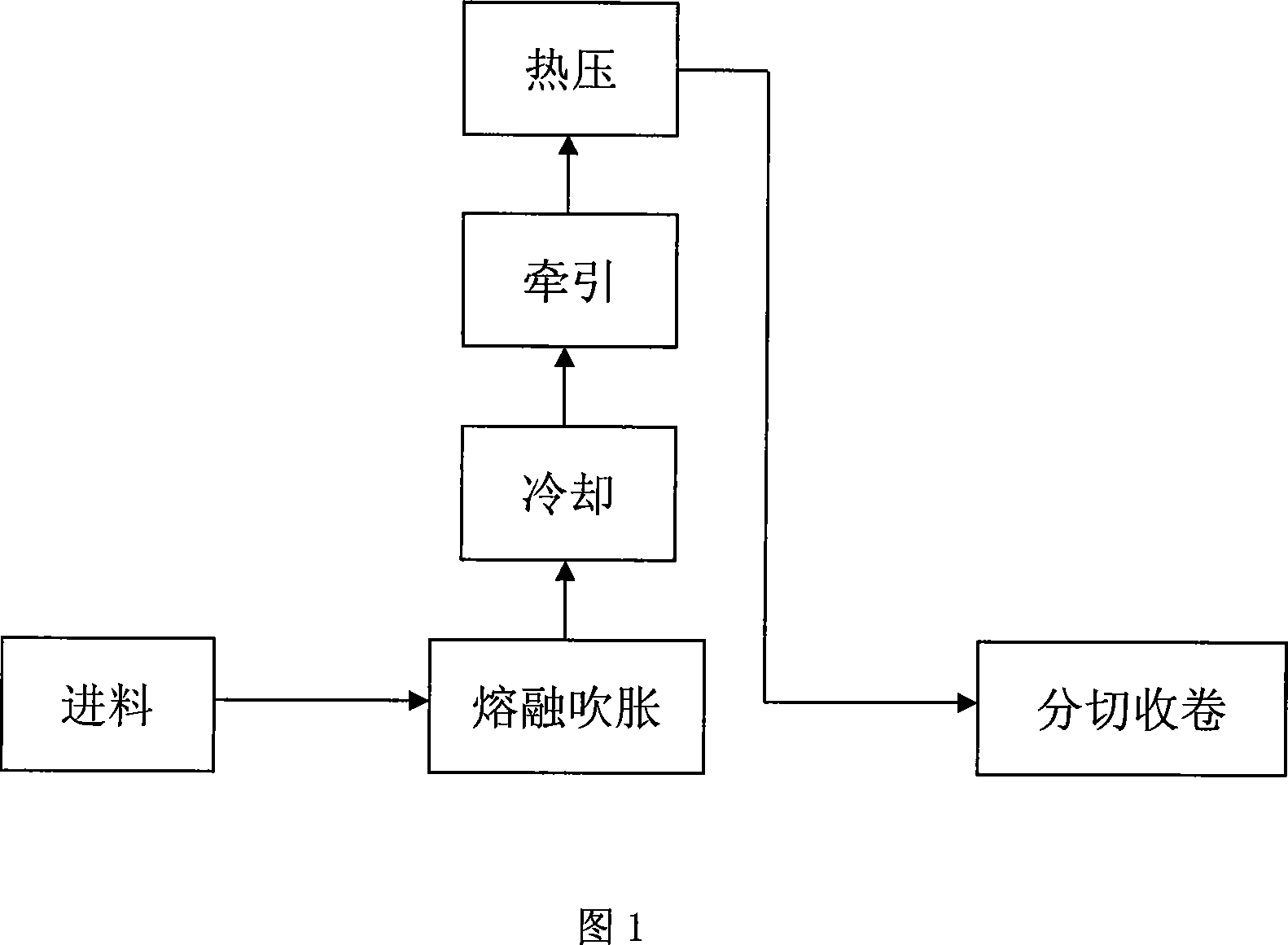

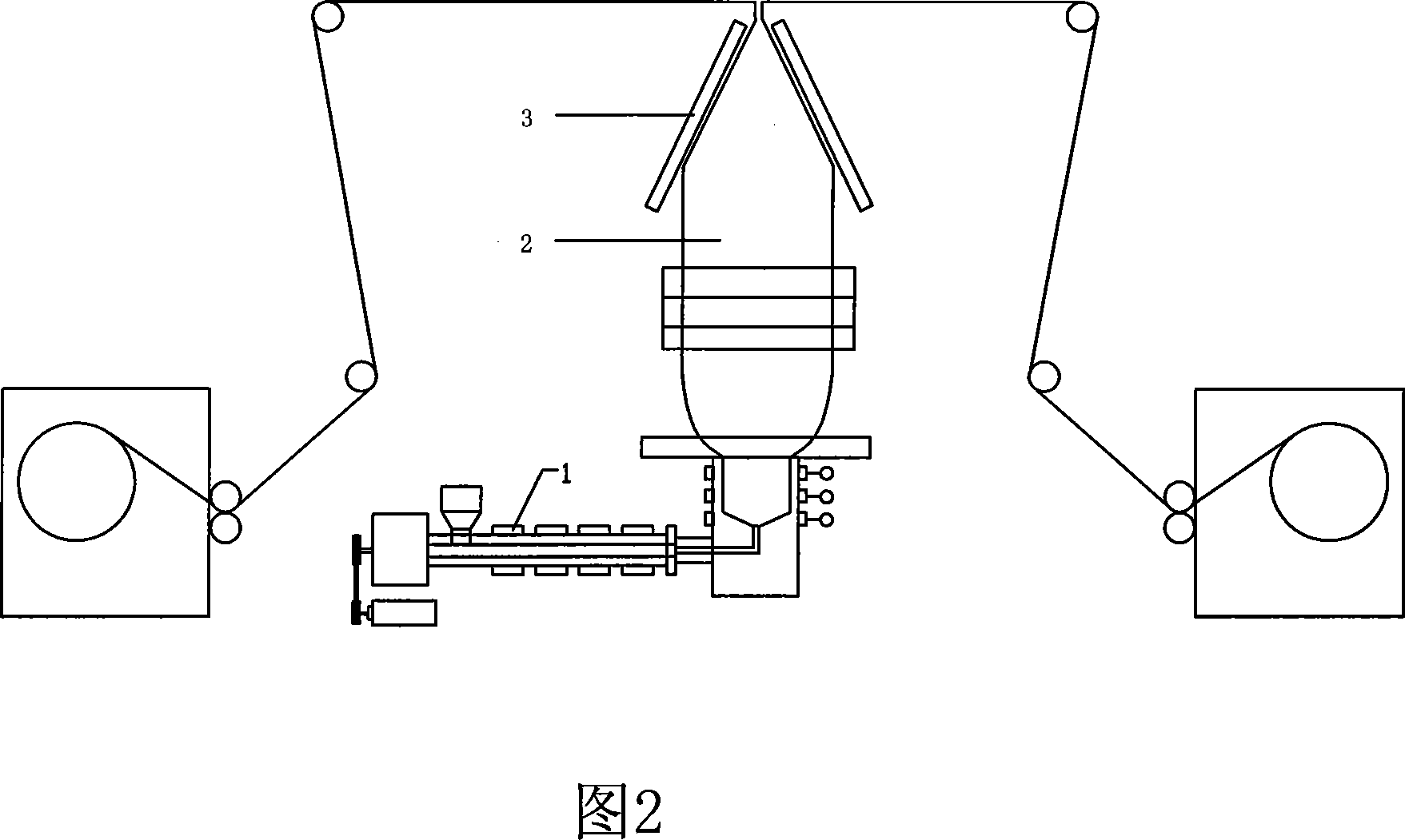

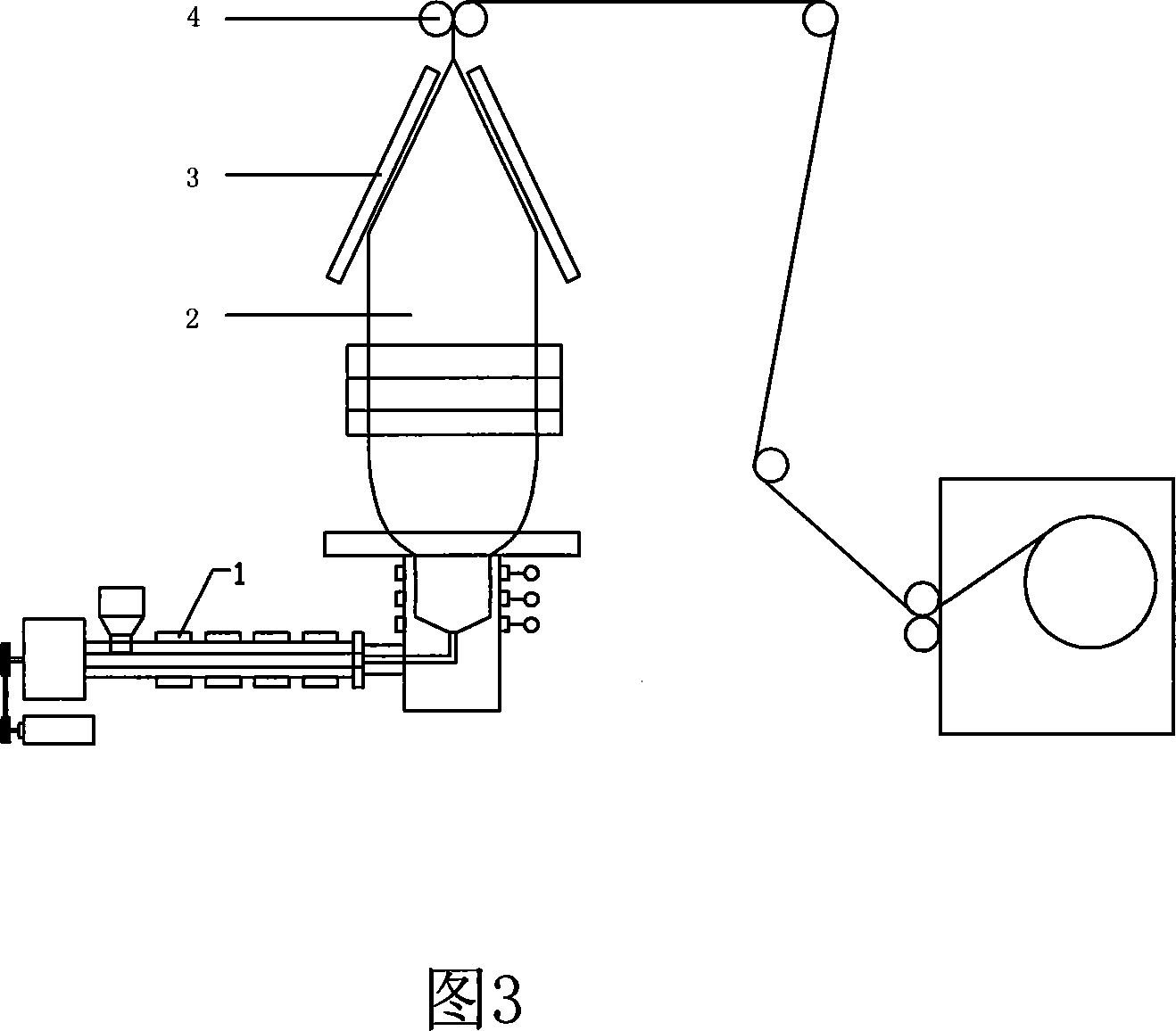

Process and apparatus for producing packing plastic material

The present invention discloses process and apparatus for producing packing plastic material. The process includes the following steps: feeding material through several feed ports including feeding adhesive resin material in the inner layer feed port, melting and blowing to produce film bubble, cooling, drawing to form two sheets of film, hot pressing, and cutting and winding. Compared with available technology, the present invention has the advantages of low production cost, simple produce process, high material homogeneity, high compounding strength and rich colors.

Owner:惠州宝柏包装有限公司

Preparation method for aluminum-plastic composite film

ActiveCN108481863AHigh composite strengthImprove stamping formabilitySynthetic resin layered productsLaminationMolten stateStress concentration

The invention belongs to the technical field of packaging of power lithium battery shells, and specifically provides a preparation method for an aluminum-plastic composite film. The preparation methodcomprises the following steps: preparation of a treatment layer: a step of cleaning the surface of an aluminum foil, carrying out drying, coating a surface treating agent onto the matte surface of the aluminum foil, carrying out a reaction under heating, and carrying out drying; coating a surface film-forming agent onto the other surface of the aluminum foil, and carrying out heating and drying so as to form a special protective layer; coating a polyurethane adhesive onto the treatment layer of the aluminum foil, then carrying out compounding with a film, and carrying out curing; selecting aswelling-resistant polypropylene or polyethylene modified particle material, adding a slipping agent in a certain proportion, carrying out full mixing, then adding an obtained mixture into a feed hopper of a screw extruder, and carrying out extrusion, wherein a thickness is controlled by control of the amount of extrusion and the rate of production, and an extruding and compounding process is adopted; and spraying an obtained material in a molten state onto the surface of the special protective layer of a cured aluminum-plastic composite film semi-finished product so as to complete a manufacturing process. The preparation method provided by the invention has the following effects: the disadvantage of insufficient impact molding performance of the aluminum-plastic composite film is solved;the chemical resistance of the aluminum-plastic composite film is greatly reinforced; and an outer protective layer has improved bonding effect and can bear strong stress concentration.

Owner:CHANGZHOU SVECK PHOTOVOLTAIC NEW MATERIAL

Manufacturing technique for resource utilization of cow dung to manufacture bio-organic fertilizer

InactiveCN106748373AIncrease added valueRich in nutrientsBio-organic fraction processingExcrement fertilisersWater contentChemistry

The invention discloses a manufacturing technique for resource utilization of cow dung to manufacture a bio-organic fertilizer. The method specifically comprises the steps of obtaining a raw material to be fermented which is 35%-40% in water content, (25-35):1 of the ratio of carbon to nitrogen, and 8.0 in pH value by preparing, by weight, 65-68 parts of cow dung and 25-30 parts of dry organic matter; uniformly spraying a prepared microbial bacterial solution A to the raw material to be fermented, conducting piling to obtain a fermentation heap to conduct fermentation, setting one temperature measuring point on the fermentation heap in every 0.5 m <3>, conducting heap turning operation when the temperature of over 75% of the temperature measuring points reaches 58-60 DEG C, and finishing primary fermentation after ten days; conducting secondary fermentation by uniformly spraying a prepared microbial bacterial solution B to the fermentation heap after the fermentation heap is subjected to primary fermentation, and conducting fermentation at the temperature of 40-42 DEG C for eight days; conducting prilling, screening and drying to obtain the product. According to the manufacturing technique for resource utilization of the cow dung to manufacture the bio-organic fertilizer, the problems that the bio-organic fertilizer is low in production and fermentation, insufficient in decomposing, and not high in product viable cont are solved.

Owner:重庆信首科技有限公司

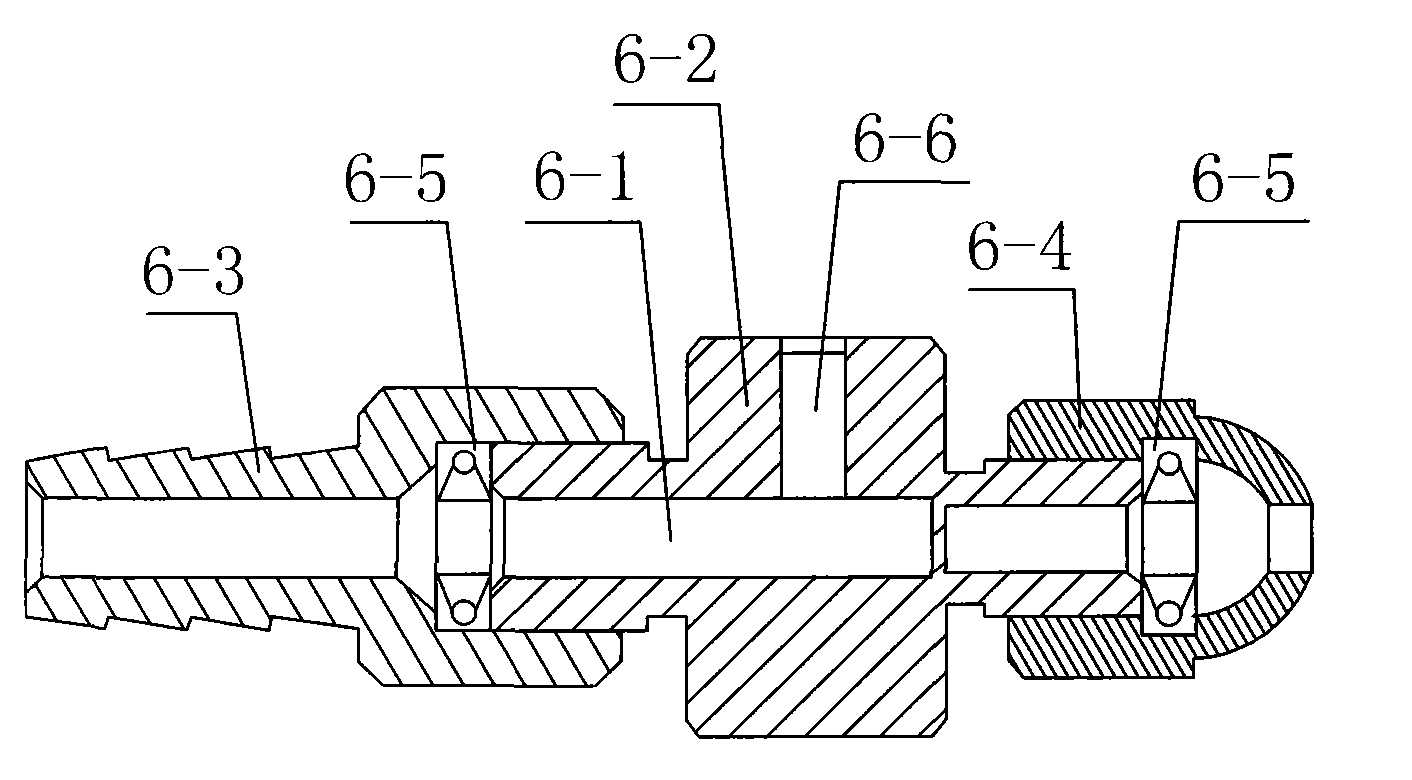

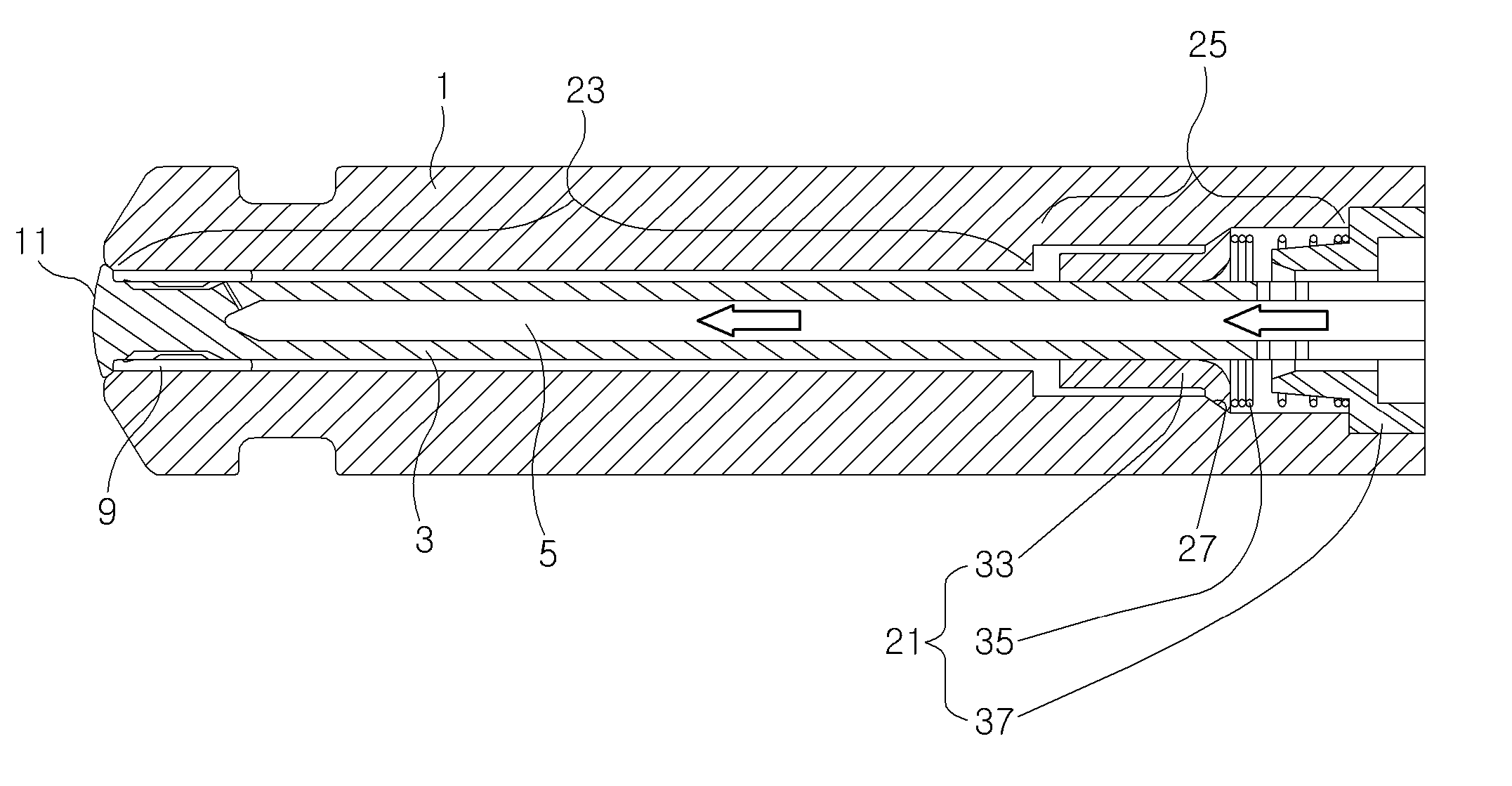

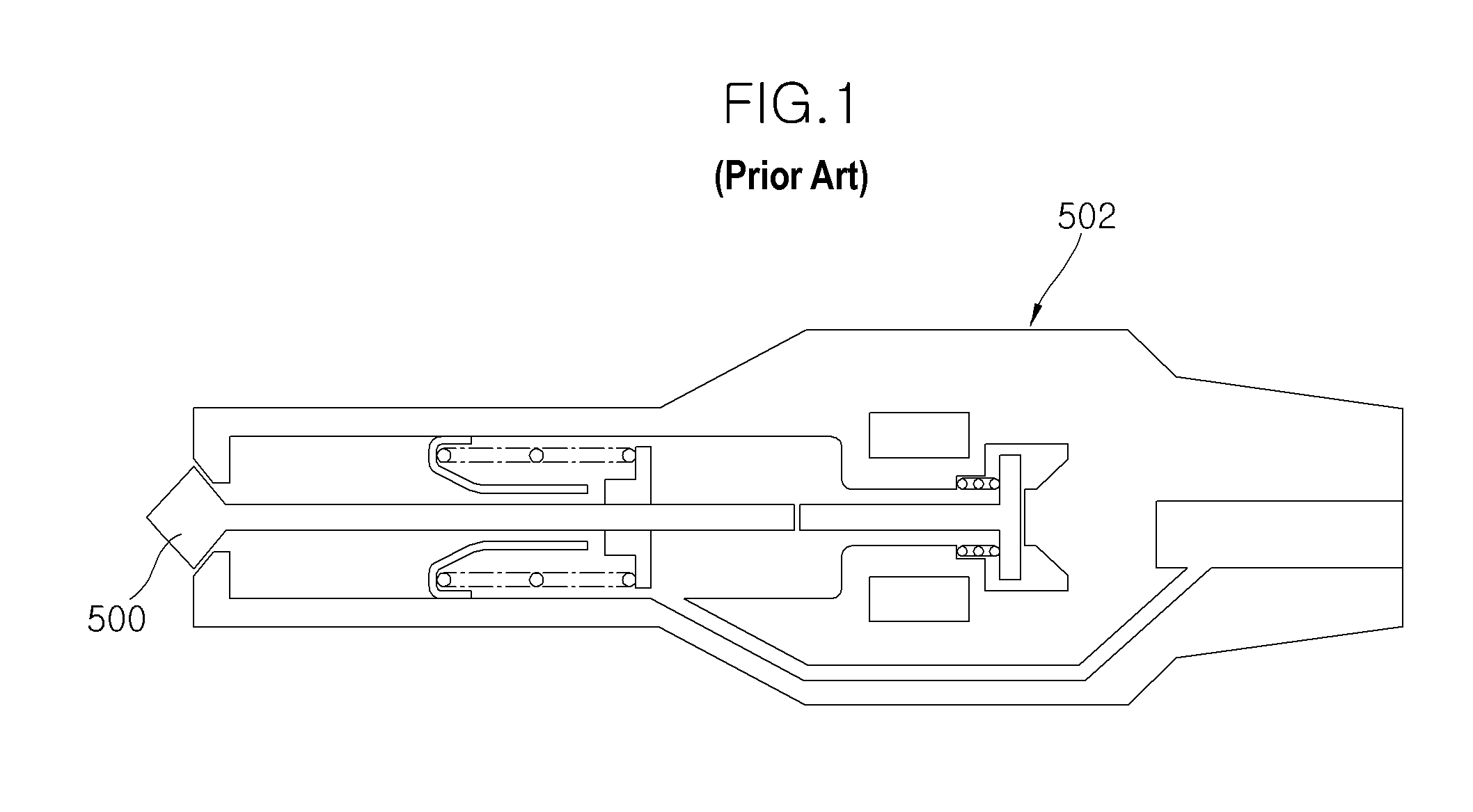

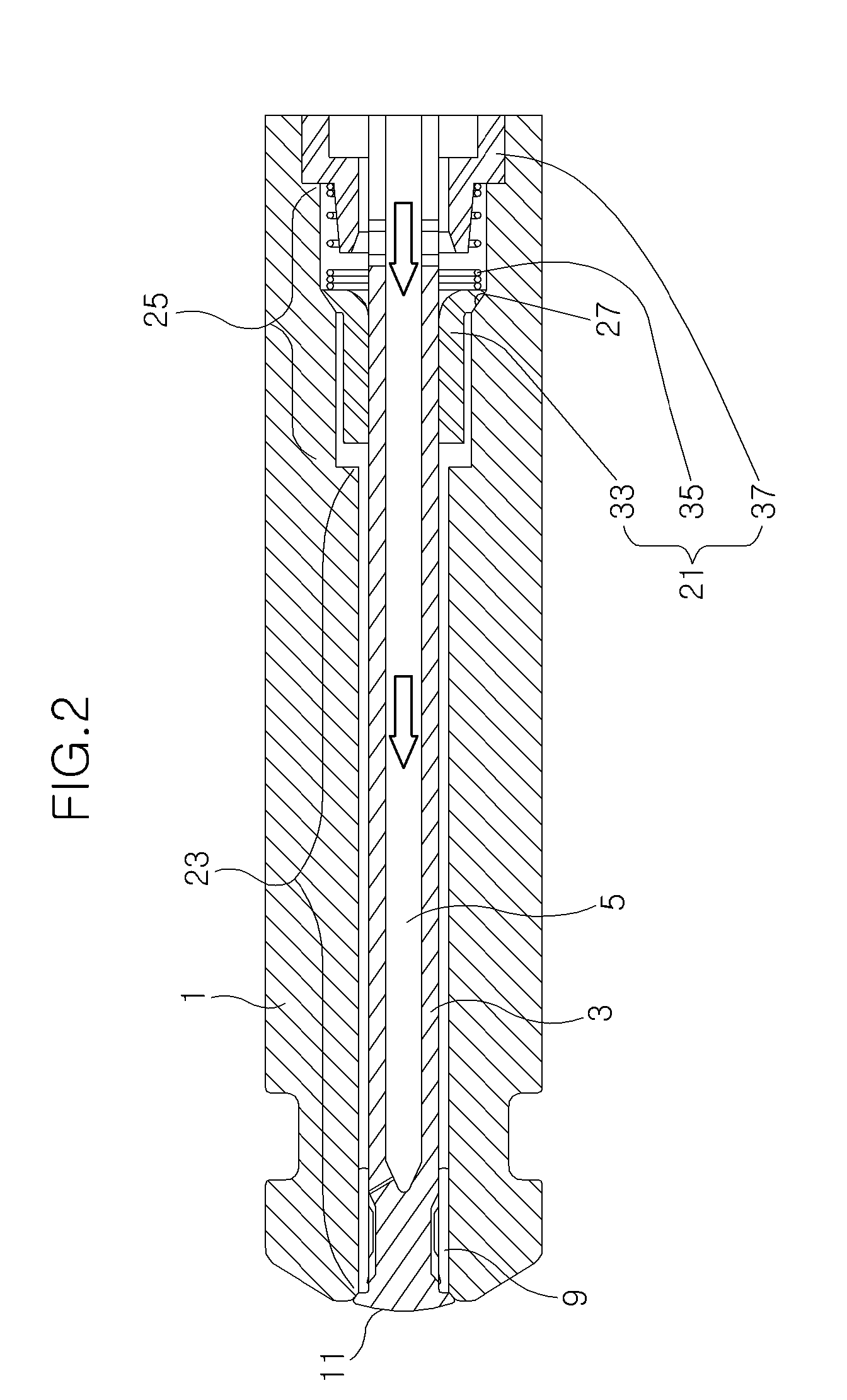

Direct injection injector for engine

A direct injection injector for an engine includes a body forming the outer structure and having a space therein, a needle inserted to slide linearly in the body and having a hole therein forming a fuel channel, and a cylinder nozzle fitted on needle to communicate with hole and having a nozzle hole for injecting fuel, such that it is possible to prevent caulking in which the nozzle of the injector is clogged with soot while injecting fuel at relatively low pressure, change the spray type of the injected engine in various shapes, and sufficiently decrease the size of droplet of the fuel.

Owner:HYUNDAI MOTOR CO LTD

Combined spectacle lens, auxiliary lens, and method of edging lenses

InactiveUS7631969B2Change typeEasy to changeSpectales/gogglesOptical partsEyeglass lensesEngineering

A combined spectacle lens including a combination of a basic lens and an auxiliary lens, the basic lens formed with a progressive-power surface having a first power portion having a power for viewing an object at a predetermined distance, a second power portion having a power different from that in the first power portion, and a progressive portion in which the power is progressively changed from the first power portion to the second power portion on either one or both of refractive surfaces on an object side and an eyeball side, wherein a resultant power obtained by combining a basic lens power of the basic lens and an auxiliary lens power of the auxiliary lens is partly or entirely different from that of the basic lens power.

Owner:HOYA LENS MFG PHILIPPINES

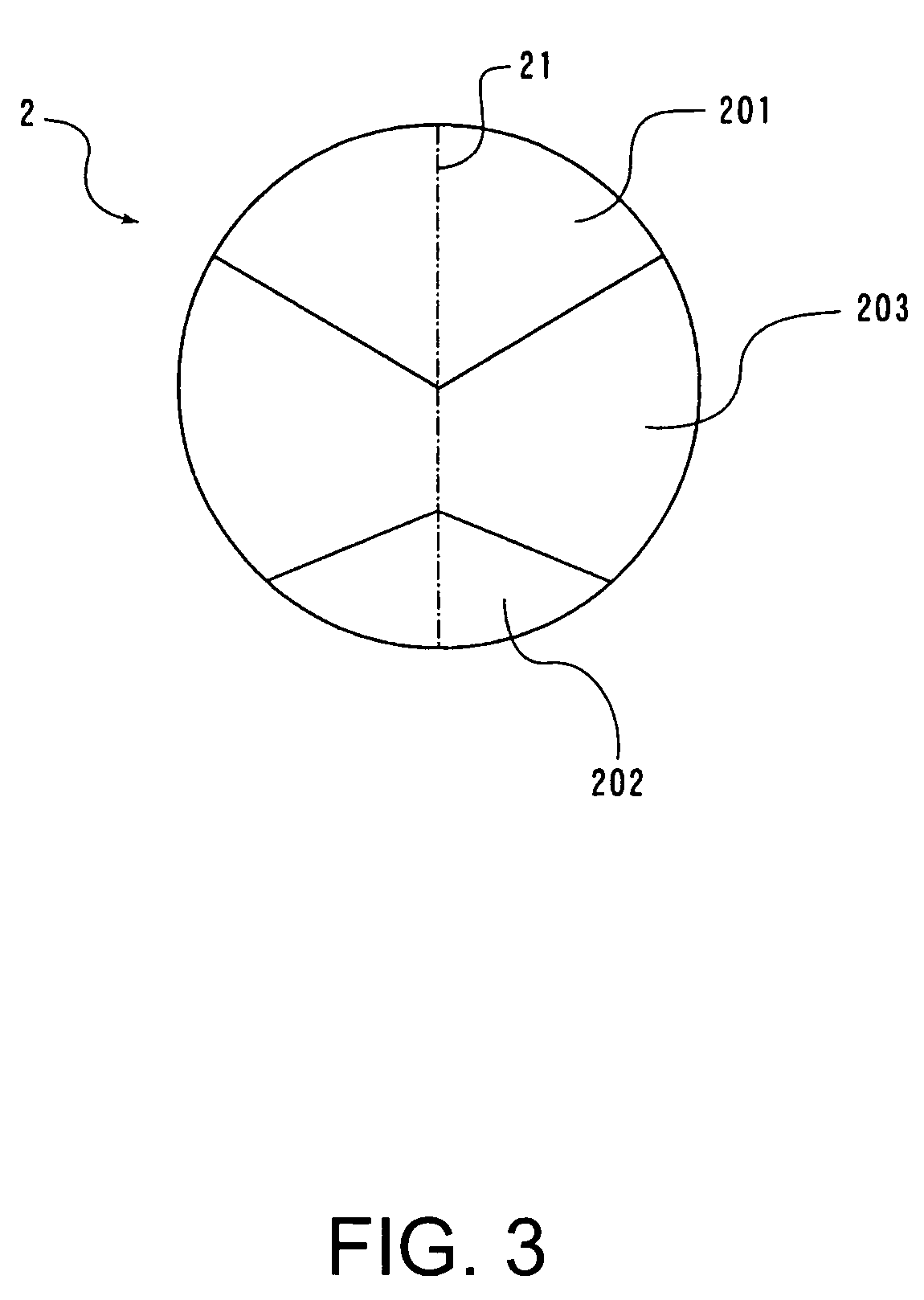

Preparation method, product and application of low-temperature phosphorus-doped carbon nitride loaded high-dispersion palladium hydrogen evolution catalyst

ActiveCN111774083AThe synthesis method is simpleImprove electron concentrationMaterial nanotechnologyCatalyst activation/preparationNano catalystSchottky barrier

The invention provides a preparation method of a low-temperature phosphorus-doped carbon nitride loaded high-dispersion palladium hydrogen evolution catalyst and a product and application thereof. Thepreparation method of the phosphorus-doped carbon nitride loaded high-dispersion metal Pd particle hydrogen evolution catalyst is relatively simple in synthesis method, low in cost and capable of reacting at a low temperature. According to the invention, phosphorus is doped into a carbon nitride substrate, so that the Schottky barrier of the heterojunction is improved, meanwhile, by means of theaction of lone pair electrons of nitrogen and metal Pd, the dispersity of Pd nano particles is improved to a great extent, and loss of Pd is reduced. By improving the Schottky heterojunction barrier,more free electrons can flow to the Pd nano particles from the phosphorus-doped carbon nitride substrate, so that the electron aggregation of the Pd nano particles is greatly improved. The prepared phosphorus-doped carbon nitride loaded Pd metal nano-catalyst can be used in borane ammonia hydrogen evolution reaction, and the catalyst shows very high catalytic activity under visible light irradiation.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Method for preparing MOF nanofiltration membrane by adopting thermal annealing post-synthesis technology

ActiveCN111672330AEffective size controlEffective regulation of adhesionSemi-permeable membranesNanoparticleNanofiltration

The invention provides a method for preparing an MOF nanofiltration membrane by adopting a synthesis technology after thermal annealing, and belongs to the field of membrane separation, wherein the method comprises the following steps: carrying out ultrasonic pretreatment on a porous ceramic substrate, activating and cleaning the surface of the ceramic substrate; firstly, coating the surface of the ceramic substrate with metal gel, then placing the ceramic substrate in a solution containing organic ligands, and enabling MOF nanoparticles to grow on the ceramic substrate in situ to form a continuous defect-free MOF separation layer; carrying out high-temperature post-synthesis modification on the synthesized MOF composite membrane, and activating the internal microstructure of the MOF particles and regulating and controlling the thickness and morphology of an MOF separation layer by regulating and controlling the annealing temperature, the annealing time, the heating rate, the cooling rate and the like. The MOF separation membrane prepared by the method disclosed by the invention is good in binding force with a substrate, and the mass transfer rate in the separation process can be effectively improved, so that the flux of the separation membrane is improved under the condition of not sacrificing the rejection rate.

Owner:BEIJING UNIV OF TECH

Bottom material surface processing technology enabling surface to have crystal flower lines

InactiveCN103721915ABest Drying ProcessSolve the problem of unsatisfactory drynessPretreated surfacesCoatingsPhoto irradiationMetallurgy

A bottom material surface processing technology enabling a surface to have crystal flower lines comprises the following steps of (1) bottom material preprocessing, wherein bottom material surface oil stain and dust are cleared, and drying is carried out; (2) crystallization paint coating, wherein the clean bottom material surface is coated with crystallization paint of a crystallization type; (3) solidification and crystallization, wherein standing in room temperature is carried out for 30-40 minutes for solidification and crystallization; (4) paint film drying, wherein bottom materials are placed in a drying oven with the preset temperature of 70-100 DEG C for drying for 30-90 minutes; (5) vacuum coating, wherein a metal film is arranged on a crystallization paint film in a vacuum-evaporation mode; (6) finishing paint coating, wherein ultraviolet light curing finishing paint is arranged in the metal film in a coating mode; and (7) finishing paint solidification, wherein the paint film is solidified through ultraviolet irradiation for 5-10s. According to the technology, the metal film is arranged on the crystallization paint film in a vacuum-evaporation mode successfully, the crystal flower lines high in glossiness are obtained, the finishing paint is arranged on the metal film in a coating mode to be used as a protecting layer and a coloring layer, and the obtained paint film is bright in color, high in strength and good in solvent resistance.

Owner:HANGZHOU SANJING ART CRAFT PLASTIC

Urea hydrogen peroxide disinfectant and preparation method thereof

InactiveCN102206174AEasy to manufactureChange typeUrea derivatives preparationOrganic compound preparationChlorine dioxideDisinfectant

The invention discloses a urea hydrogen peroxide disinfectant and a preparation method thereof. The finished urea hydrogen peroxide disinfectant is prepared by stirring and mixing urine, hydrogen peroxide, trisodium phosphate, salicylic acid and sodium silicate in a certain weight ratio at a certain temperature. The preparation process of the urea hydrogen peroxide disinfectant is simple and convenient; in reaction time, the rise of a reaction temperature can be controlled and the type of the stabilizer can be changed effectively; the crystallization temperature is changed; and the chlorine dioxide can be used for disinfection in various industries such as hospitals, schools, drinking water and the like, the application range is wide and the effect is obvious.

Owner:ANHUI HUANGHUAI VETERINARY MEDICINE

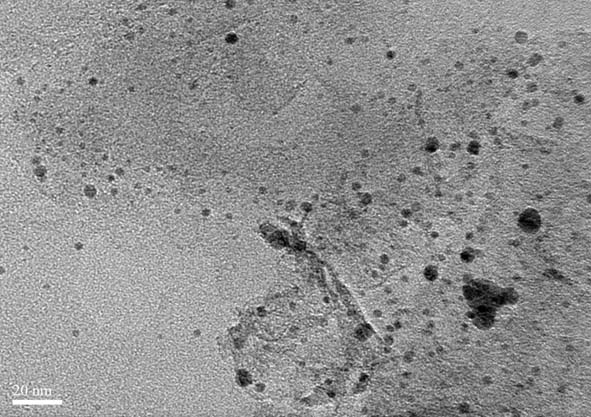

Biochemical sensor based on polymer long-period waveguide optical grating and preparation method thereof

InactiveCN104730007ASmall sizeSimple structureColor/spectral properties measurementsGratingWaveguide

The invention discloses a biochemical sensor based on a polymer long-period waveguide optical grating and a preparation method thereof. The biochemical sensor comprises a silicon substrate layer, a lower covering layer, a core layer and an upper covering layer which are overlapped sequentially from bottom to top, wherein the upper covering layer is provided with a liquid channel; and the core layer comprises a straight waveguide, and a first long-period optical grating and a second long-period optical grating which are connected with one side of the straight waveguide and stretch into the liquid channel. Furthermore, the preparation method adopts a mask plate I and a mask plate II, and combines a magnetron sputtering process, a photoetching process, a wet-process etching process, a dry-process etching process and the like, so that the biochemical sensor can be conveniently and rapidly prepared; and compared with a traditional biochemical sensor, the biochemical sensor disclosed by the invention has the advantages of small size, simple structure, high sensitivity, rapid detection, low cost, convenience for integration and detection diversity.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

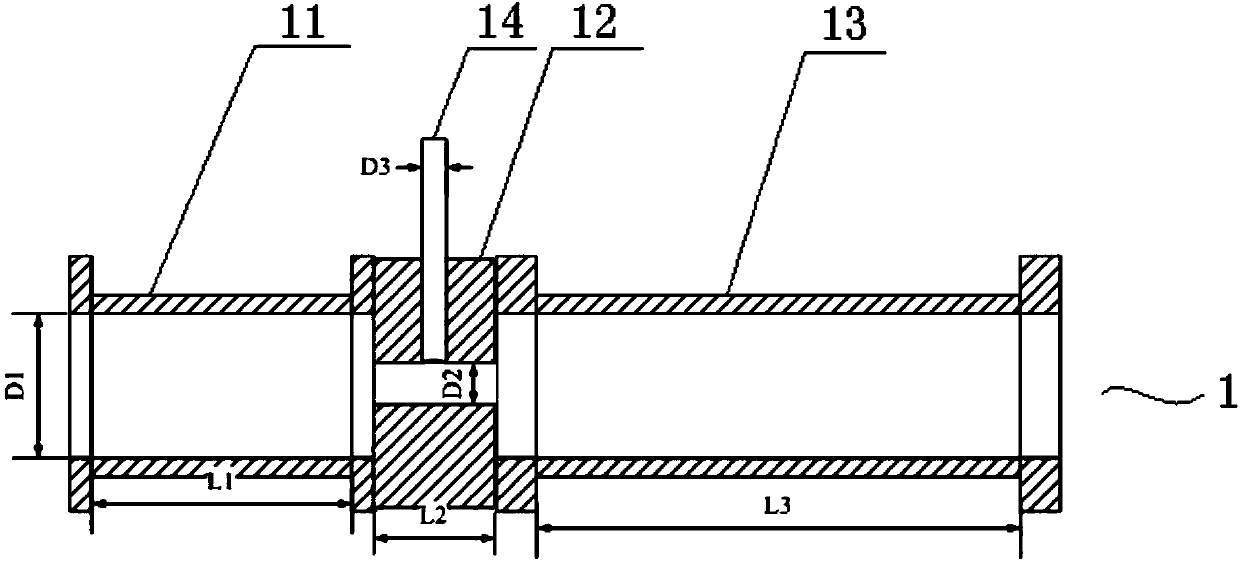

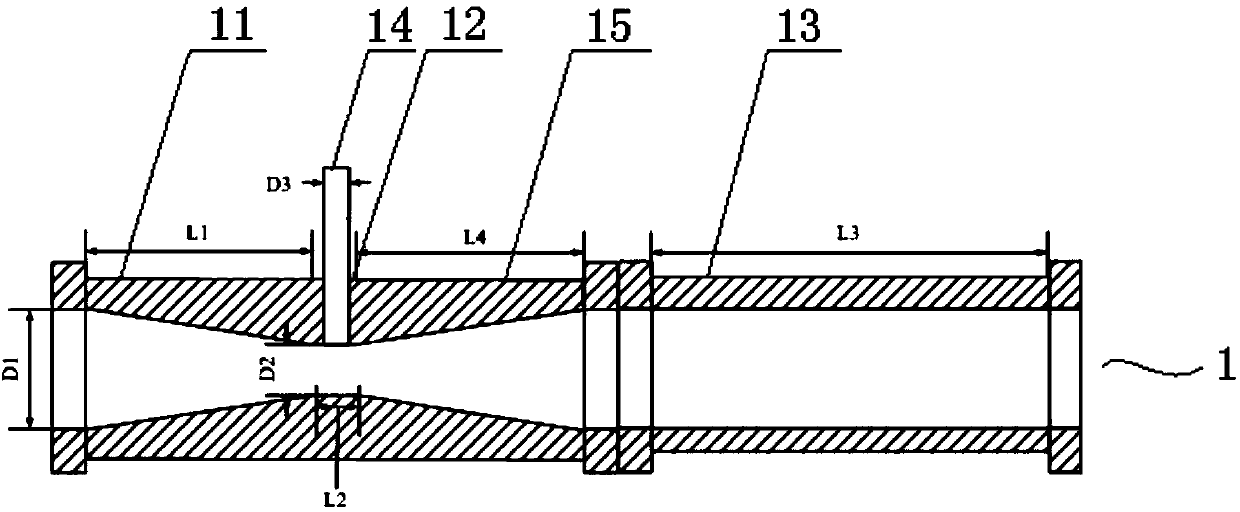

Method and system for modifying heavy oil through hydrodynamic cavitation

ActiveCN105505443AReduce energy consumptionImprove cavitation effectHydrocarbon oils refiningFuel oilEngineering

The invention provides a method and a system for modifying heavy oil through hydrodynamic cavitation. The method is carried out through a hydrodynamic cavitation apparatus including, in a successively manner, a heavy oil inlet section, a throat pipe section and a stable section, wherein the flow area of the throat pipe section is less than those of both the other two sections. The throat pipe section is connected to and axially communicated with the heavy oil inlet section and the stable section. An additive inlet section communicated with the throat pipe section is arranged radially on the throat pipe section. The method includes the steps of: pressurizing heavy oil and feeding the heavy oil into the heavy oil inlet section of the apparatus, sucking a cavitation additive through the additive inlet section when the heavy oil flows through the throat pipe section to perform the hydrodynamic cavitation to the heavy oil and the cavitation additive in the stable section; and feeding a hydrodynamic cavitation reaction to a gas-liquid separation apparatus to perform gas-liquid separation. The method and the system achieve modification on the heavy oil through the hydrodynamic cavitation at a low temperature with excellent modification and viscosity reducing effects achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

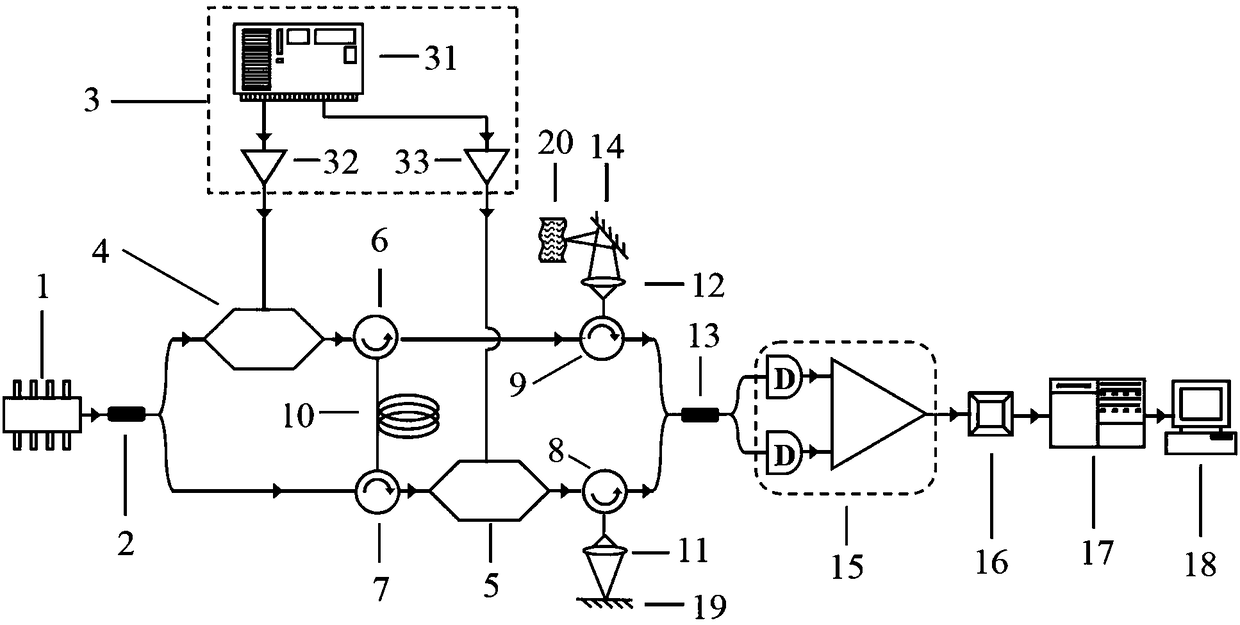

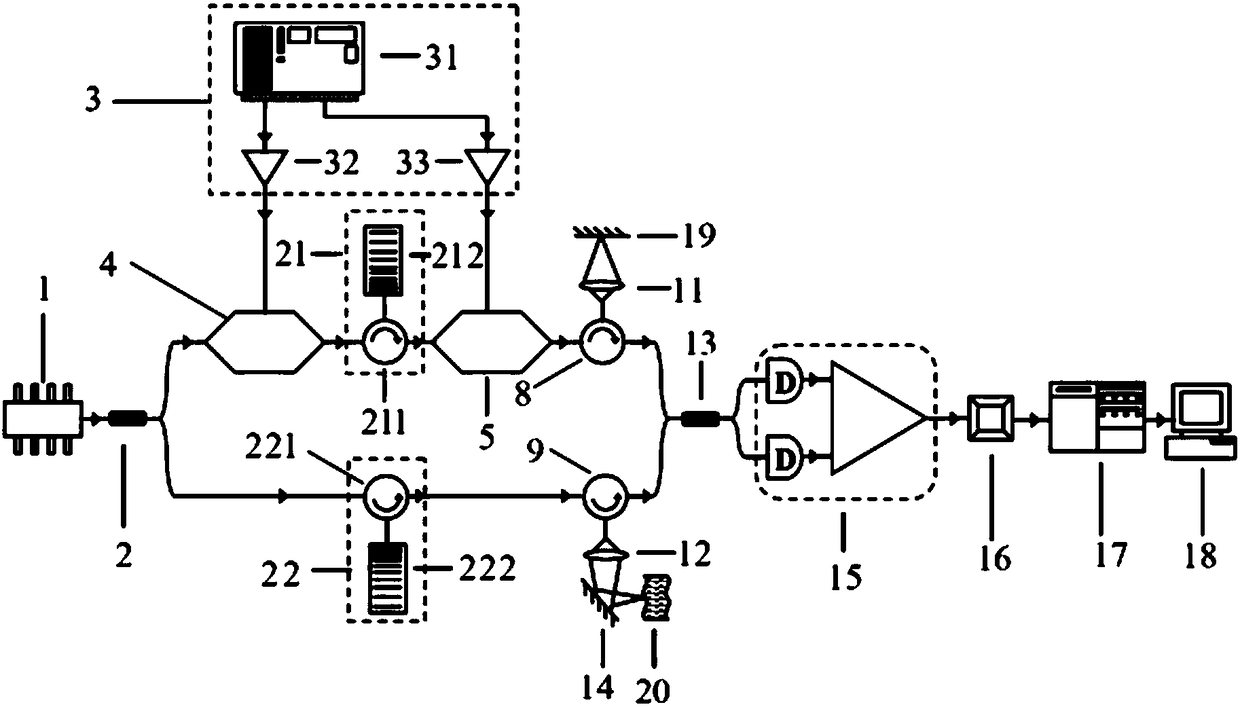

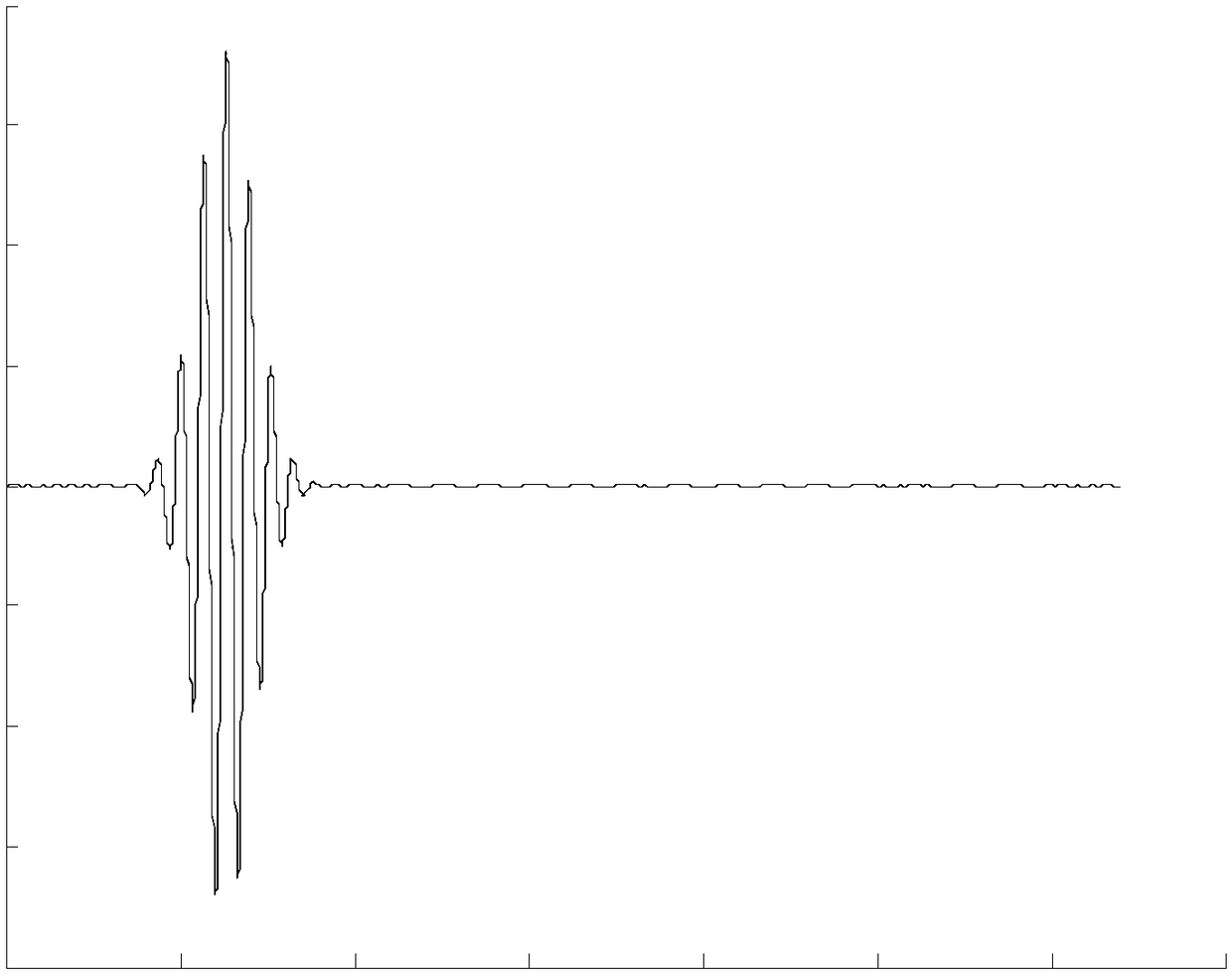

Optical calculation optical coherence imaging system with high signal-to-noise ratio

ActiveCN108572142AReduce lossSimple structureMaterial analysis by optical meansSignal-to-noise ratio (imaging)Test sample

The invention relates to an optical calculation optical coherence imaging system with high signal-to-noise ratio. The optical calculation optical coherence imaging system is characterized in that direct current broadband light emitted by a broadband light source is split into reference light and measurement light by a first coupler; the reference light is emitted to a first optical phase modulation device and is modulated, the modulated light is emitted to a dispersion device, the light passing through the dispersion device is emitted to a second optical phase modulation device and is modulated again, the modulated light is emitted to a reflection mirror by a focusing lens, then returns along the original optical path, and is emitted to a second coupler; the measurement light enters the dispersion device, the light emitted by the dispersion device enters a two-dimensional scanning system through a focusing lens, the two-dimensional scanning system is used for reflecting the measurementlight to different positions of a to-be-tested sample, and the light reflected by the to-be-tested sample at different positions and different depths returns and enters the second coupler along the original optical path, and interferes with the reference light; and the interference light emitted by the second coupler sequentially passes through a balance detector, a wave filter and a demodulator,and is emitted to a computer so as to obtain the structural image of the sample.

Owner:TSINGHUA UNIV

Seasonal influenza-RSV combined vaccine and preparation method and application thereof

ActiveCN107961371AImprove immunityStable structureSsRNA viruses negative-senseViral antigen ingredientsSeasonal influenzaCombined Vaccines

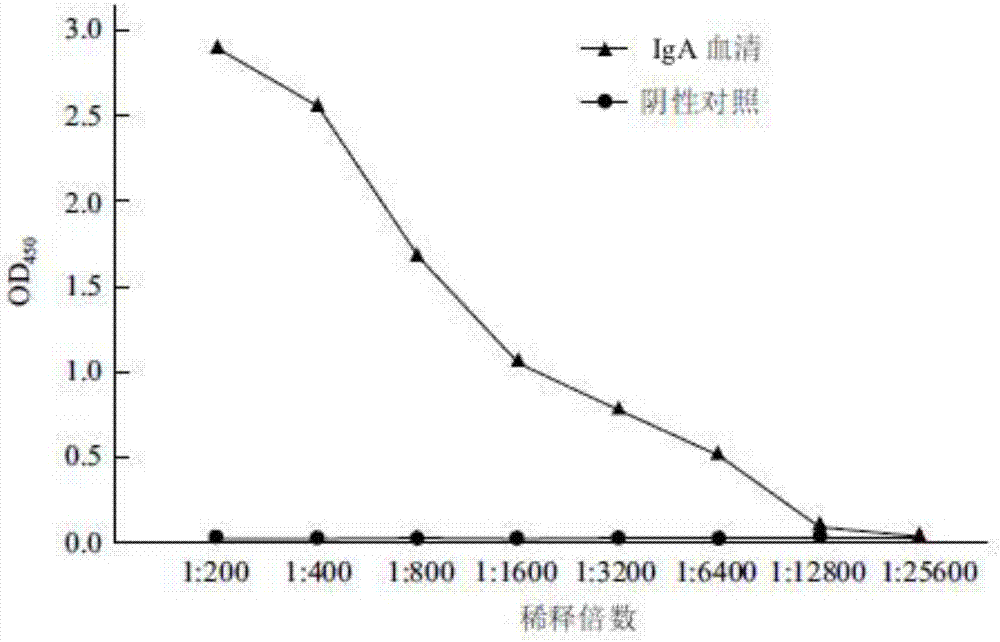

The invention discloses a seasonal influenza-RSV combined vaccine and a preparation method and application thereof. The combined vaccine comprises a seasonal influenza virus protein and respiratory syncytial virus (RSV) fusion protein and an immunologic adjuvant. The fusion protein is a highly conserved protein sequence of seasonal influenza viruses and RSVs. The constructed fusion protein and theimmunologic adjuvant are mixed according to a ratio of (0.5-2): 1 so that the seasonal influenza-RSV combined vaccine is obtained. The recombinant fusion protein is used as a novel antigen and increases serum IgG and mucosal system IgA antibody titer through oral and nasal administration. The combined vaccine can cause common immune response to seasonal influenza viruses and RSVs. Through use ofthe mucosal adjuvant, the mucosal immune is produced and the immune effects are improved.

Owner:BRAVOVAX

Forage suitable for different growing periods of sheep

InactiveCN105341376AFast growthChange typeFood processingAnimal feeding stuffAnimal scienceAnimal Foraging

The invention relates to a forage suitable for different growing periods of sheep. The forage comprises a forage A, a forage B and a forage C. The forage A is employed after sheep wean and when the body weight of sheep is less than 25 kilograms. The forage B is employed when the body weight of sheep is more than 25 kilograms and less than 45 kilograms. The forage C is employed when the body weight of sheep is more than 45 kilograms. The feeding habit is changed according to different growing periods of sheet, the forage kind and dosage are changed, and the growth speed of sheep and the utilization rate of the forage are raised. Through scientific feeding, the stomach disease incidence rate of sheet during the growth process can be lowered greatly, the breeding cost is saved, mutton is delicious and the content of trace elements in mutton is raised.

Owner:马英臣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com