Preparation method of polymer weak gel deep profile control agent

A deep profile control and weak gel technology, which is applied in the direction of drilling compositions, chemical instruments and methods, can solve the problems of narrow range of temperature and salt resistance, short gelation time, high cost, etc., to reduce production costs, The ratio of solid content is low and the gelling performance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

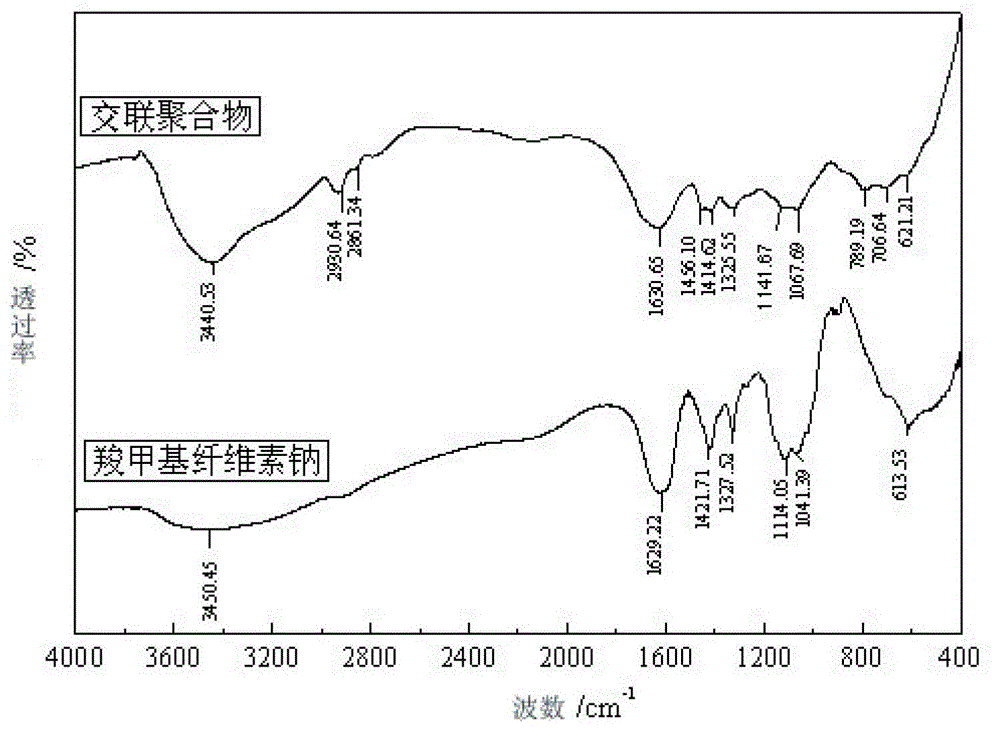

[0032] Prepare 2.50 g of sodium carboxymethylcellulose (CMC) with a viscosity of 800-1200 mPa·s into a 1% solution with distilled water and stir evenly, then add 10.00 g of acrylamide and 0.0075 g of N,N'-methylene Base bisacrylamide, pass nitrogen into the system, add Na in turn 2 SO 3 0.0566g, (NH 4 ) 2 S 2 o 8 0.1065g, stir well and react in a constant temperature water bath at 40°C for 8 hours to form a gel.

[0033] Precipitate and separate the prepared polymer weak gel with ethanol solvent, dry to obtain a crude cross-linked polymer, extract the crude cross-linked polymer with acetone in a Soxhlet extractor for 10 hours to remove the homopolymer, and dry it in a vacuum to obtain Pure cross-linked polymer. Take the dried raw material of sodium carboxymethyl cellulose and purified polymer weak gel 2~3mg and 200~300mg of dry KBr powder and mix them in an agate mortar, fully grind until the particle diameter is less than 2μm, and use stainless steel Scoop 70-90mg into...

Embodiment 2

[0039] Prepare 2.50 g of sodium carboxymethylcellulose (CMC) with a viscosity of 800-1200 mPa·s into a 1% solution with distilled water and stir evenly, then add 10.00 g of acrylamide and 0.0063 g of N,N'-methylene Base bisacrylamide, pass nitrogen into the system, add Na in turn 2 SO 3 0.0666g, (NH 4 ) 2 S 2 o 8 0.1209g, stirred evenly and reacted in a constant temperature water bath at 30°C for 8 hours to form a gel.

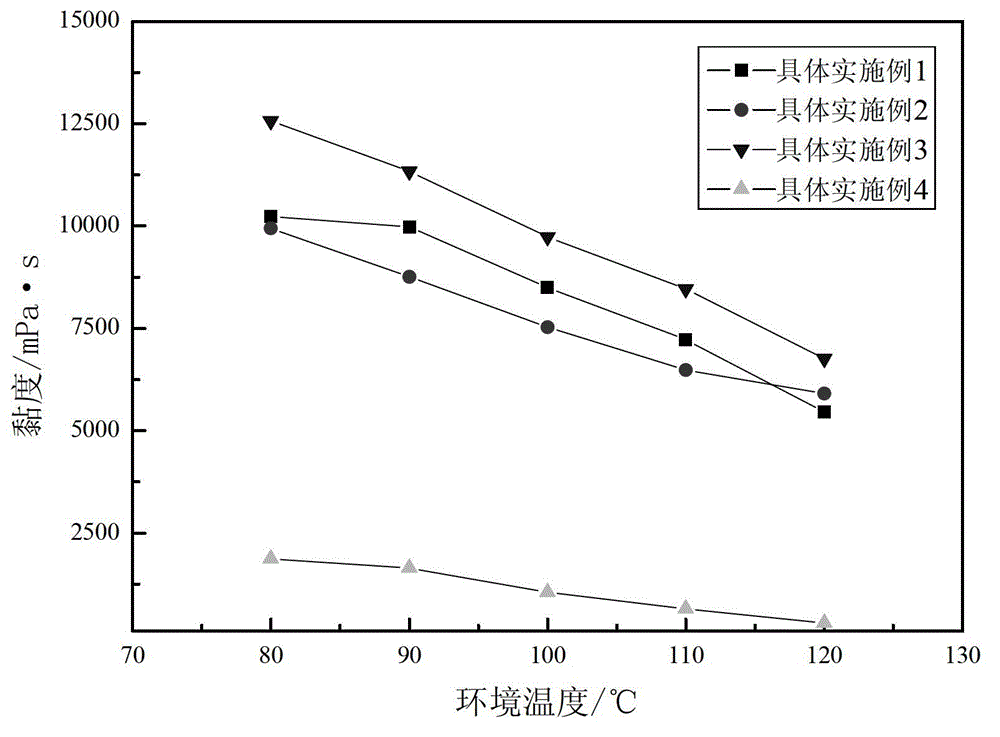

[0040] The viscosity of the gel measured by NDJ-8S viscometer is 10520mPa·s, and the temperature and salt resistance properties are shown in the attached image 3 And attached Figure 5 shown.

Embodiment 3

[0042] Prepare 2.50 g of sodium carboxymethylcellulose (CMC) with a viscosity of 800-1200 mPa·s into a 2% solution with distilled water and stir evenly, then add 12.50 g of acrylamide and 0.0075 g of N,N'-methylene Base bisacrylamide, pass nitrogen into the system, add Na in turn 2 SO 3 0.0694g, (NH 4 ) 2 S 2 o 8 0.1255g, stir well and react in a constant temperature water bath at 40°C for 8 hours to form a gel.

[0043] The viscosity of the gel measured by NDJ-8S viscometer is 13280mPa·s, and the temperature and salt resistance properties are as follows: image 3 And attached Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com