High strength ductility plugging agent

A ductile and plugging agent technology, applied in the field of high-strength ductile plugging agents, can solve the problems of low leakage plugging pressure capacity, poor plugging ability, and low leakage plugging aging effect, and achieve the compressive strength and ductility. High, high acid solubility, product non-toxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

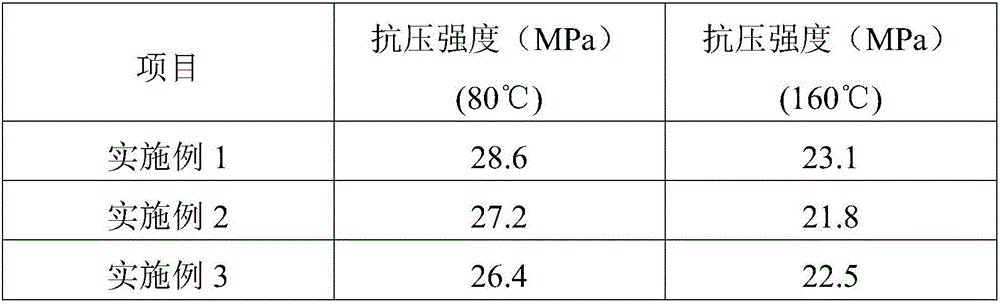

Embodiment 1

[0043] (1) Prepare raw materials:

[0044] Aluminum powder 55g; expandable graphite 12g; silicon carbide 3g; calcium oxide 10g; floating beads 10g; barium carbonate 3g; and manganese dioxide 0.5g;

[0045] Wherein, the particle size of the aluminum powder is 200-400 μm.

[0046] (2) Add aluminum powder into the crucible and heat to 720°C to completely melt the raw material.

[0047] (3) expandable graphite and silicon carbide are pulverized to an average particle size of 150-300 μm with a ball mill; then the pulverized expandable graphite and silicon carbide are added to the aluminum melt of step (2) to make the expandable graphite and silicon carbide The silicon carbide powder is evenly distributed in the melt and kept at 700°C for 10 minutes.

[0048] (4) Calcium oxide, floating beads, barium carbonate, and manganese dioxide are pulverized and mixed evenly. The average particle diameter of calcium oxide, floating beads, barium carbonate, and manganese dioxide is 50-200 μm....

Embodiment 2

[0052] (1) Prepare raw materials:

[0053] 60g of aluminum powder; 15g of expandable graphite; 5g of silicon carbide; 10g of calcium oxide; 10g of floating beads; 3g of barium carbonate; and 0.6g of manganese dioxide;

[0054] Wherein, the particle size of the aluminum powder is 200-400 μm.

[0055] (2) Add aluminum powder into the crucible and heat to 750°C to completely melt the raw material.

[0056] (3) expandable graphite and silicon carbide are pulverized to an average particle size of 150-300 μm with a ball mill; then the pulverized expandable graphite and silicon carbide are added to the aluminum melt of step (2) to make the expandable graphite and silicon carbide The silicon carbide powder is evenly distributed in the melt, and kept at 710°C for 10 minutes.

[0057] (4) Calcium oxide, floating beads, barium carbonate, and manganese dioxide are pulverized and mixed evenly. The average particle diameter of calcium oxide, floating beads, barium carbonate, and manganese...

Embodiment 3

[0061] (1) Prepare raw materials:

[0062] 45g of aluminum-magnesium alloy powder; 10g of expandable graphite; 2g of silicon carbide; 8g of calcium oxide; 8g of floating beads; 3g of barium carbonate; and 0.5g of manganese dioxide;

[0063] Wherein, the particle size of the aluminum-magnesium alloy powder is 200-400 μm.

[0064] (2) Add aluminum powder into the crucible and heat to 710°C to completely melt the raw material.

[0065] (3) expandable graphite and silicon carbide are pulverized to an average particle size of 150-300 μm with a ball mill; then the pulverized expandable graphite and silicon carbide are added to the aluminum melt of step (2) to make the expandable graphite and silicon carbide The silicon carbide powder is evenly distributed in the melt and kept at 700°C for 10 minutes.

[0066] (4) Calcium oxide, floating beads, barium carbonate, and manganese dioxide are pulverized and mixed evenly. The average particle diameter of calcium oxide, floating beads, ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com