Patents

Literature

161 results about "Mud tank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mud tank is an open-top container, typically made of square steel tube and steel plate, to store drilling fluid on a drilling rig. They are also called mud pits, as they were once simple pits in the earth.

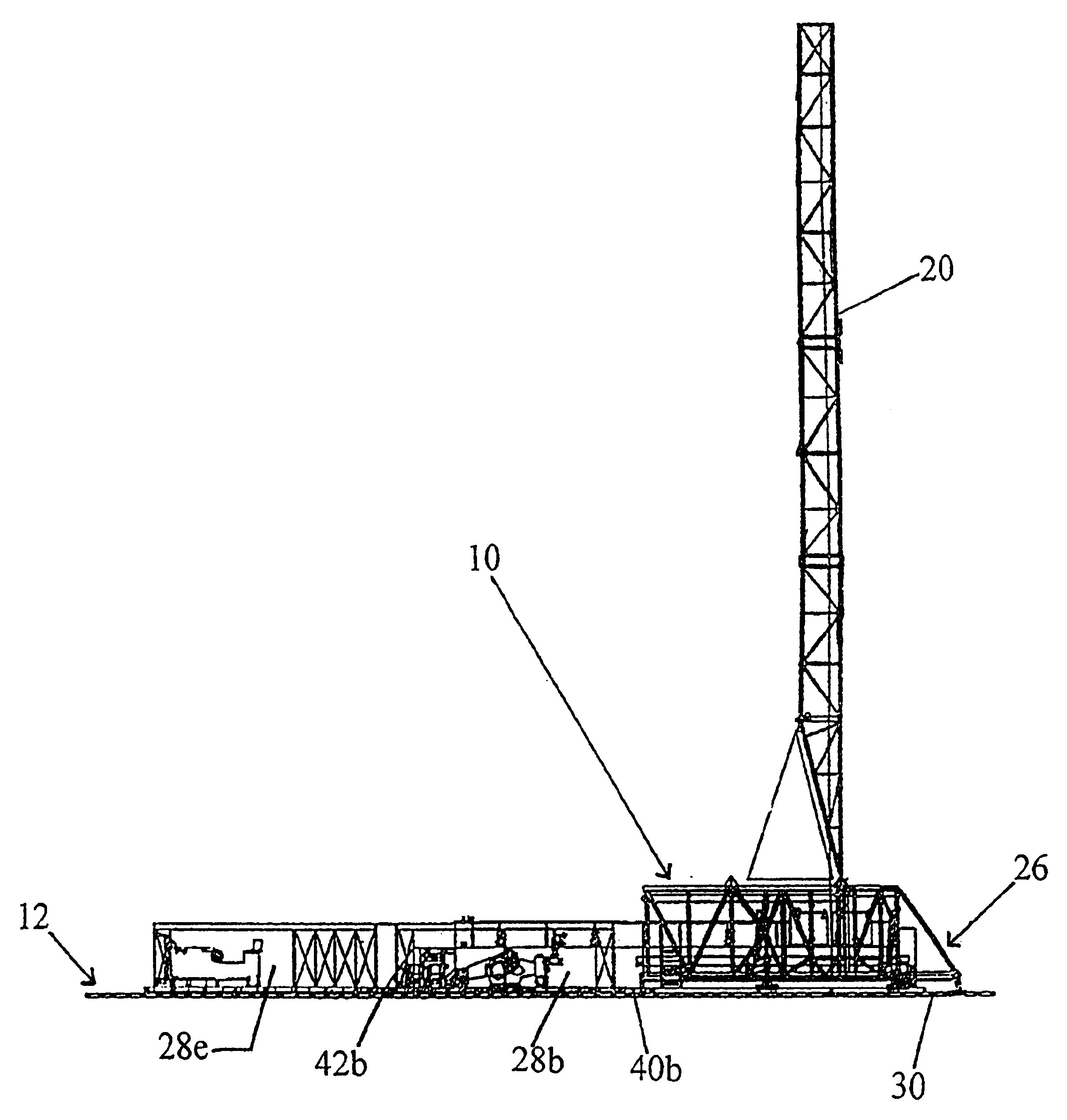

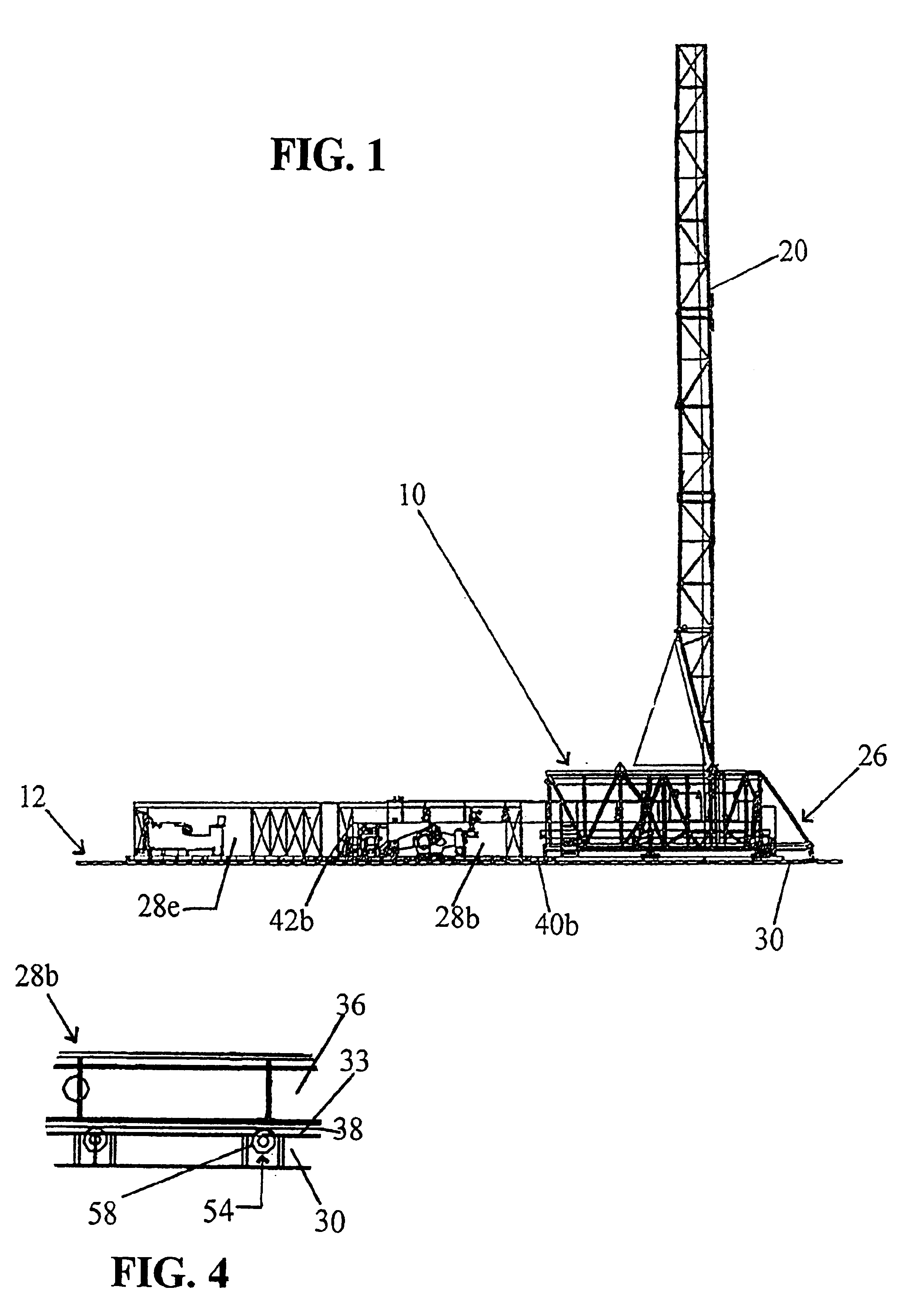

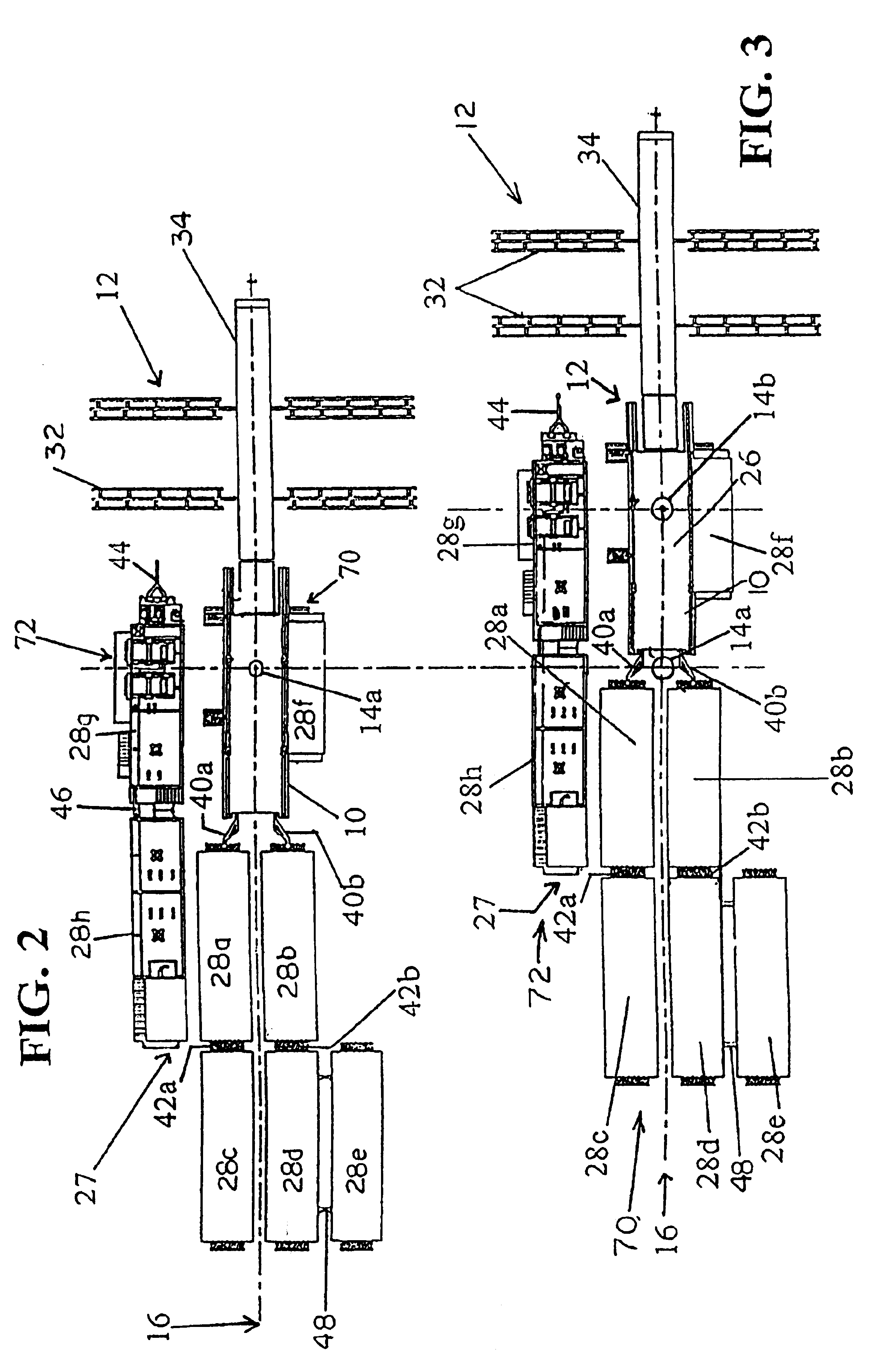

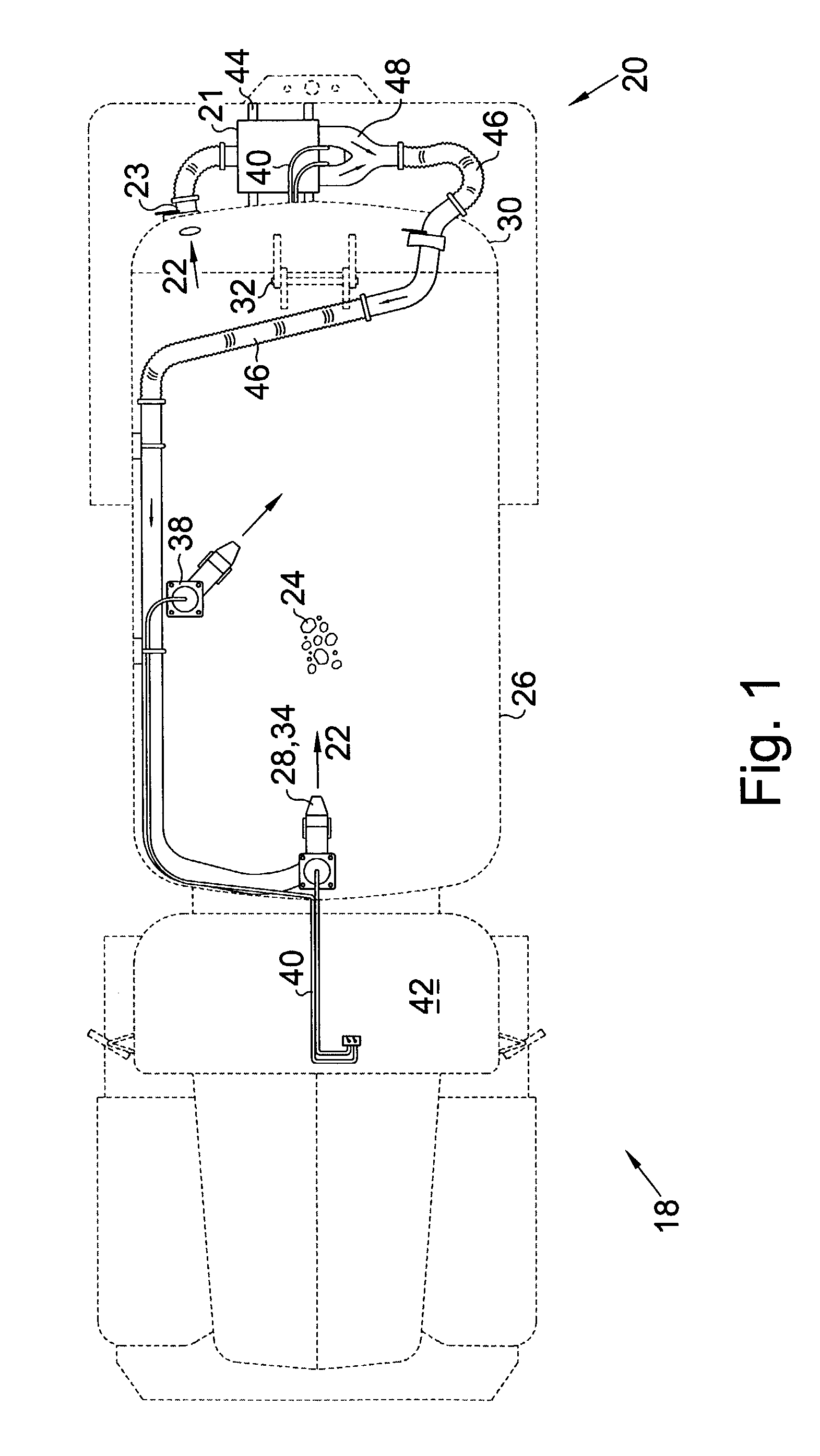

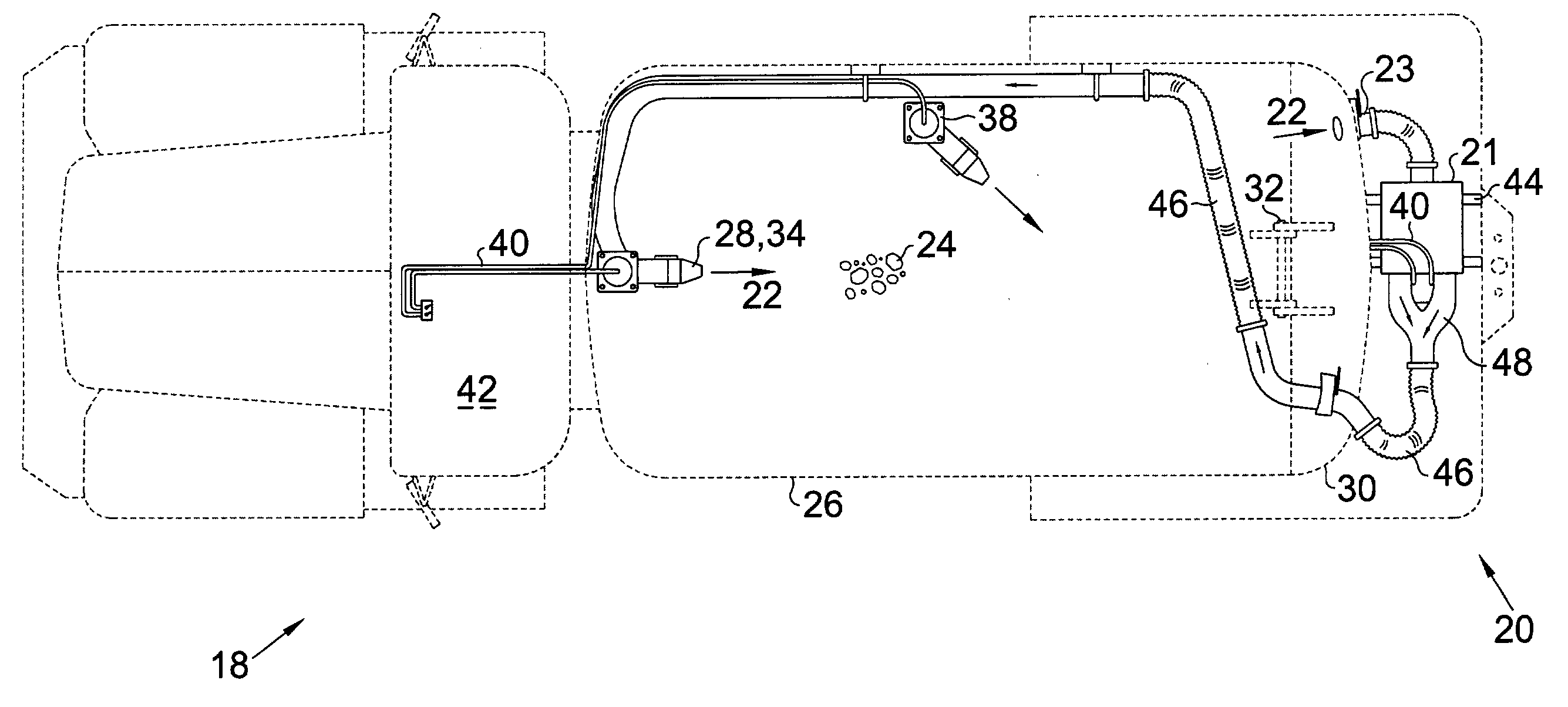

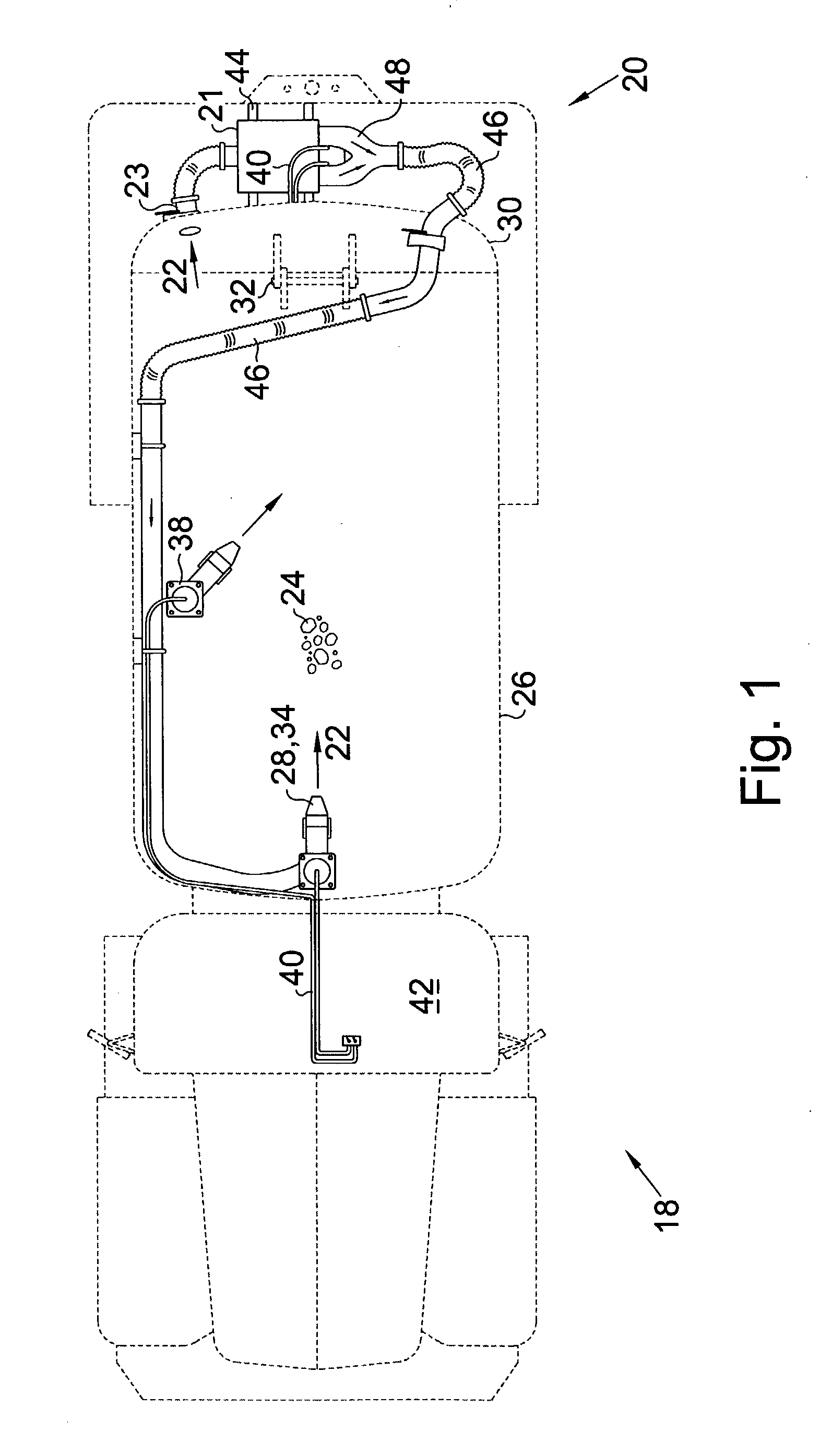

Method and apparatus for interconnected, rolling rig and oilfield building(s)

A conventional land drilling rig is interconnected to the substructure for an oilfield pad location. The interconnected drilling rig is placed on top of matting. The matting has embedded rollers to facilitate movement of the drilling rig as a “convoy” across the mat from one wellhead to another wellhead. The buildings in the mud tank system may also be interconnected and move in a separate convoy but in tandem with the first convoy.

Owner:WEATHERFORD CANADA

Efficient anti-pollution isolation liquid for well cementation and preparation method thereof

ActiveCN102337108AWide temperature rangeFlexible control of rheologyDrilling compositionDry mixingEngineering

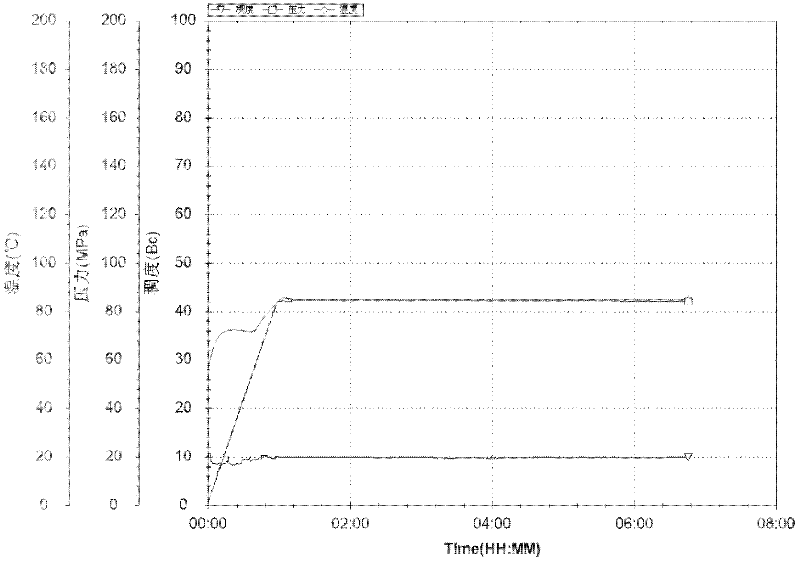

The invention relates to an efficient anti-pollution isolation liquid for well cementation and a preparation method thereof, belonging to the technical field of well cementation. The isolation liquid comprises the following components in parts by weight: 100 parts of clear water, 4-29 parts of suspending stabilizer, 0.5-5 parts of fluid loss additive, 0.3-2 parts of tackifier, 0.1-5 parts of diluting agent, 0-5 parts of viscosity and shearing force increasing agent, 30-350 parts of weighting agent, 1-25 parts of pH value regulating agent and 0.1-0.5 part of defoamer. The isolation liquid provided by the invention has wide density regulation range, large temperature resisting range, strong anti-pollution capacity, wide applicability and strong maneuverability, can be conveniently subjected to in-situ preparation, can be prepared by using a mud tank equipment base fluid method or cement vehicle equipment dry-mixing method, and can apply effective abrasion, scraping and carrying effects to attachments on an interface of a well wall; and by using the isolation liquid, the problems that in the well cementation operation, pollution is generated by fluid displacement, the adhering quality of a well cementation interface is poor and the like are effectively solved.

Owner:SOUTHWEST PETROLEUM UNIV

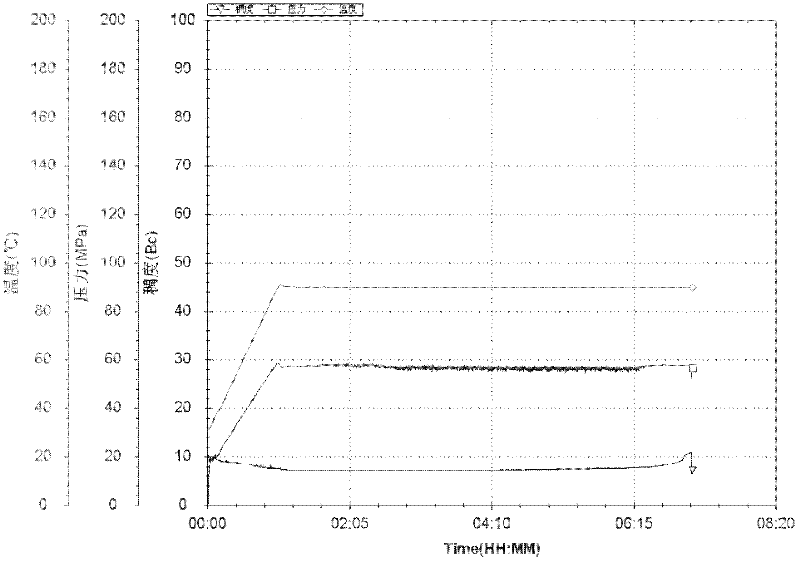

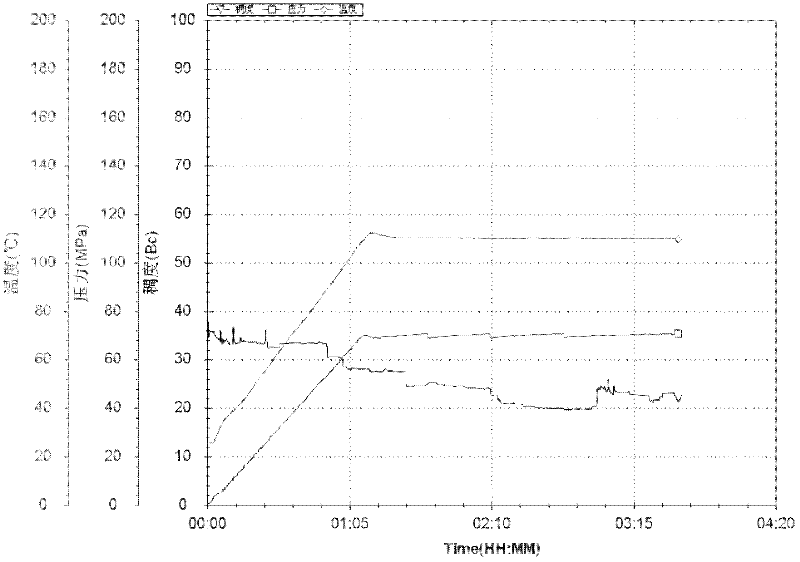

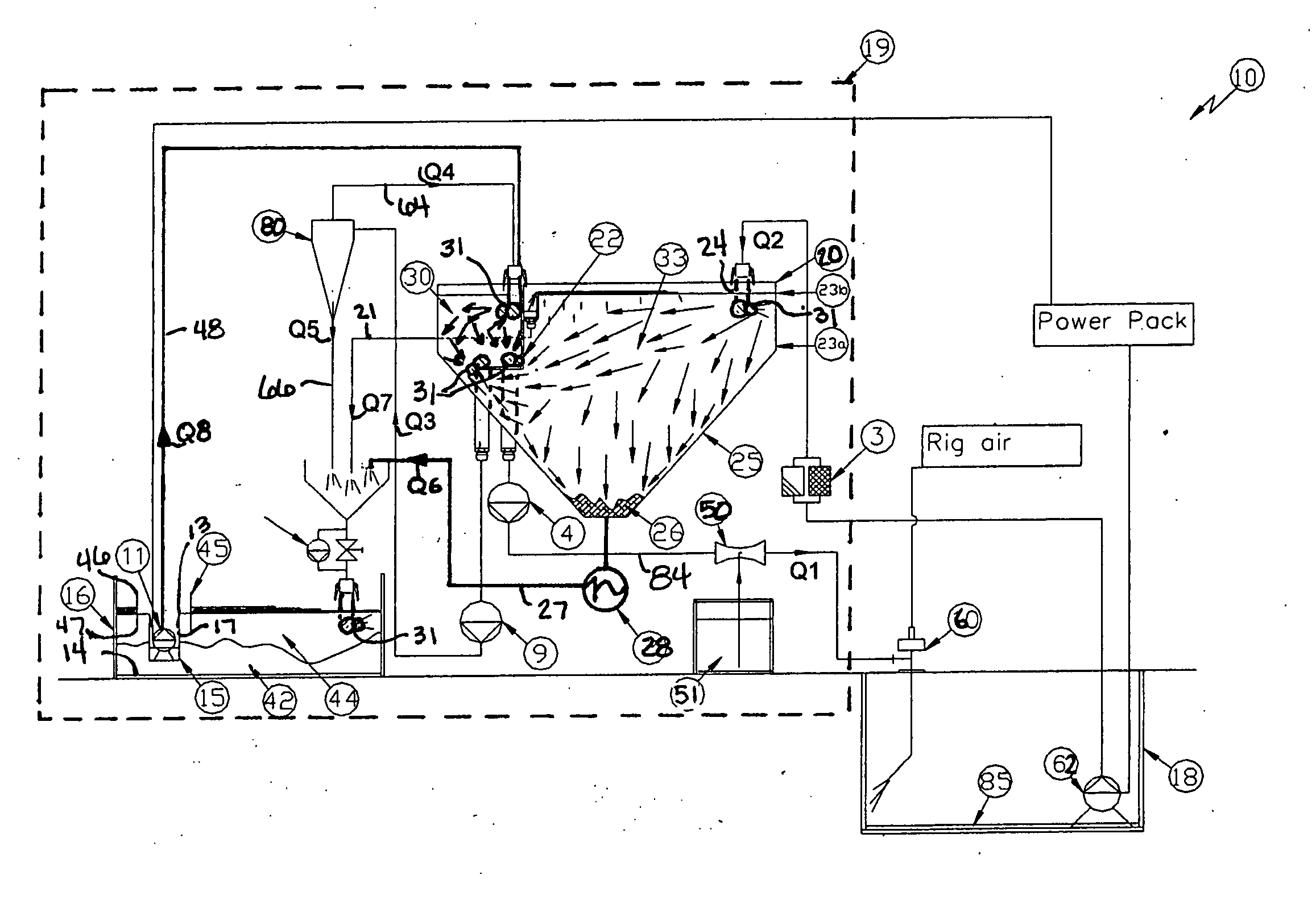

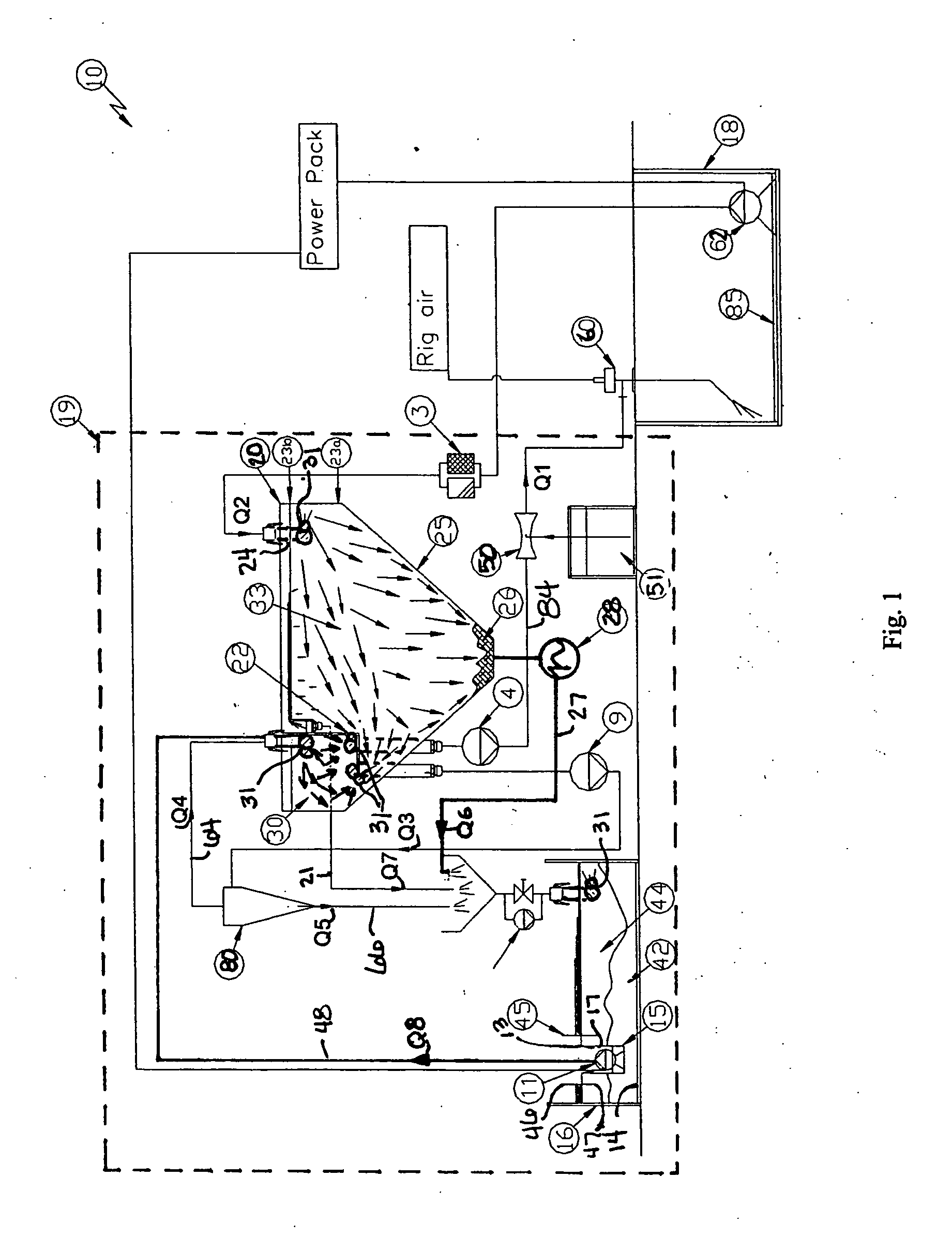

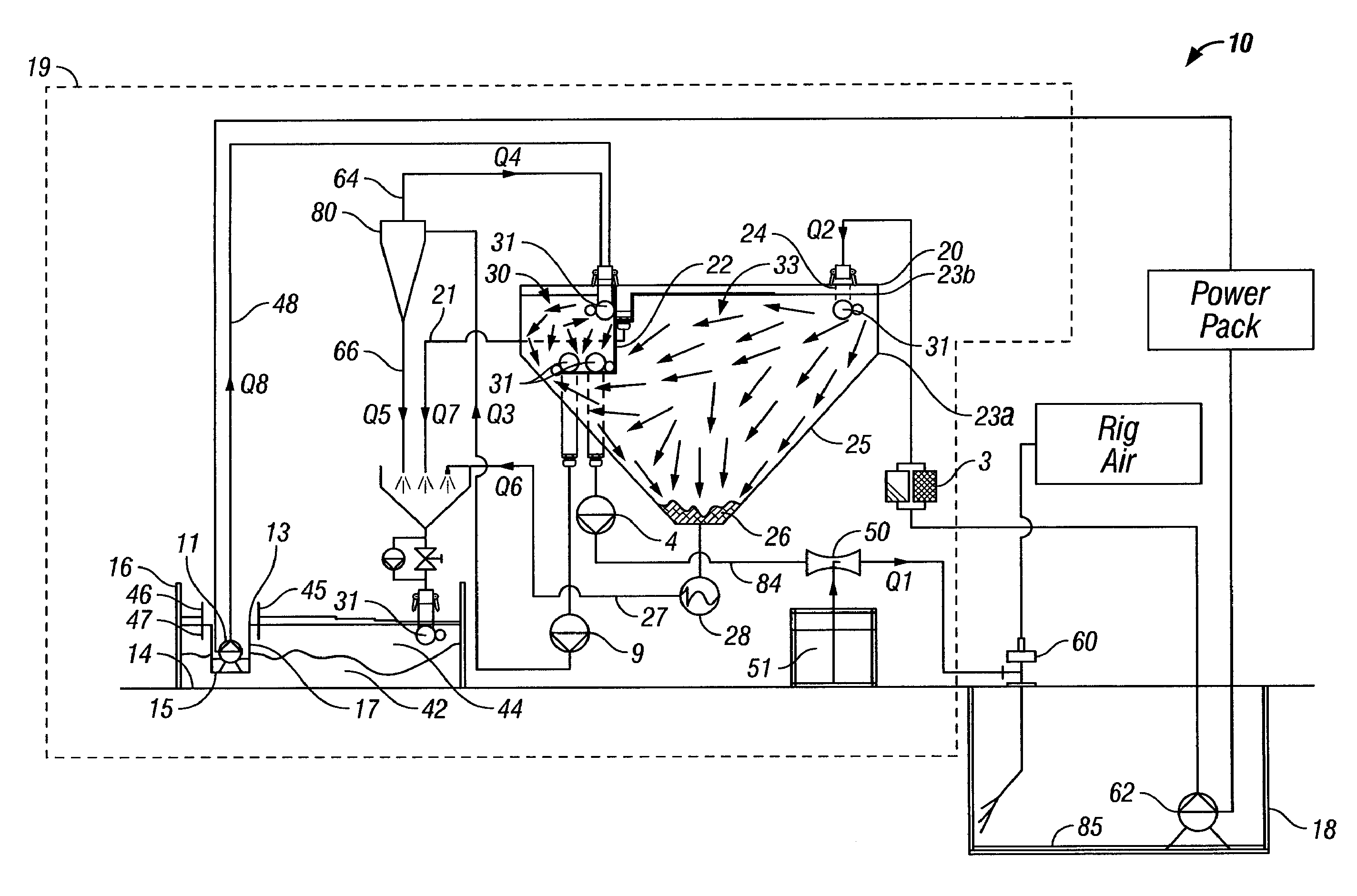

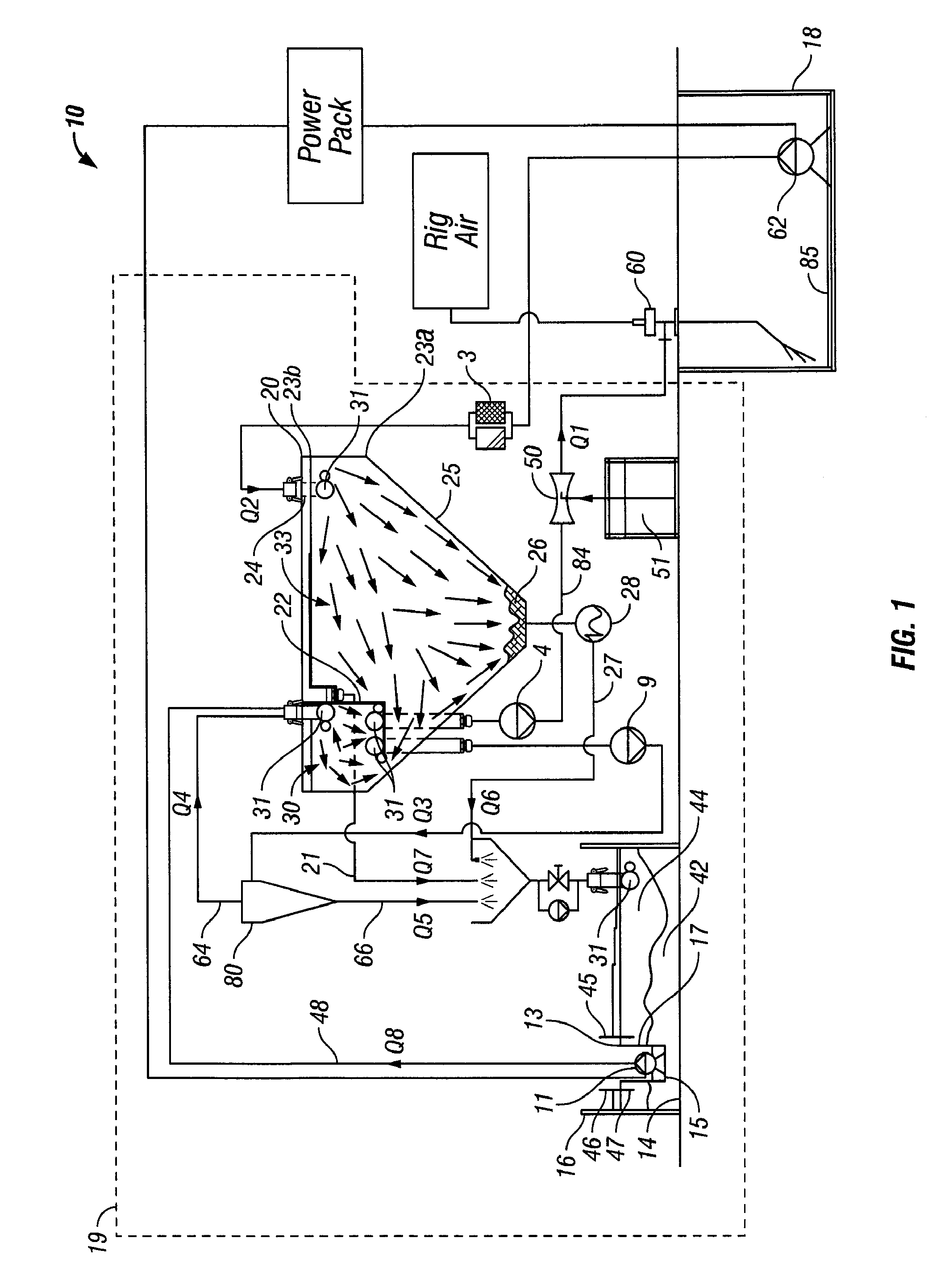

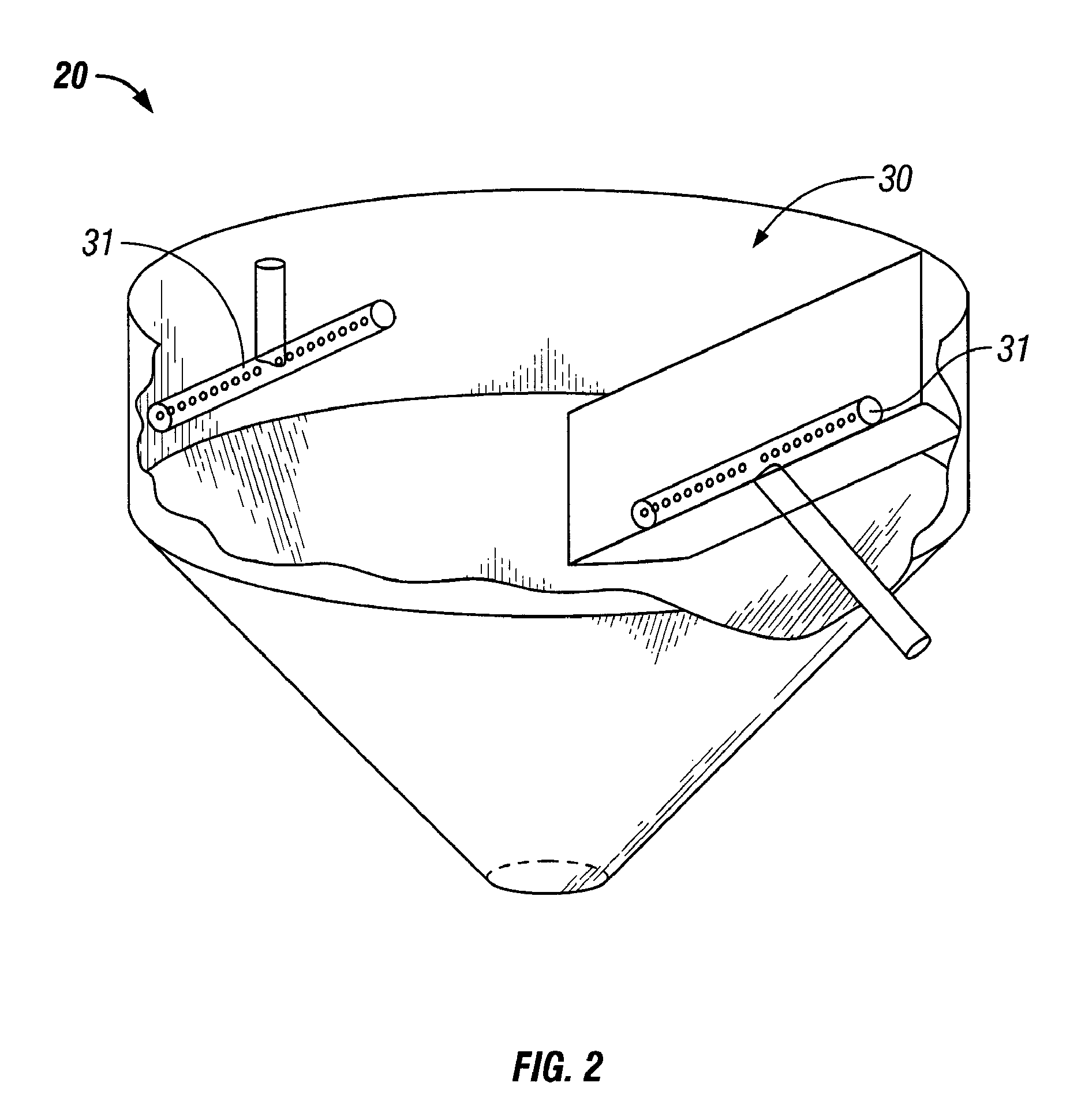

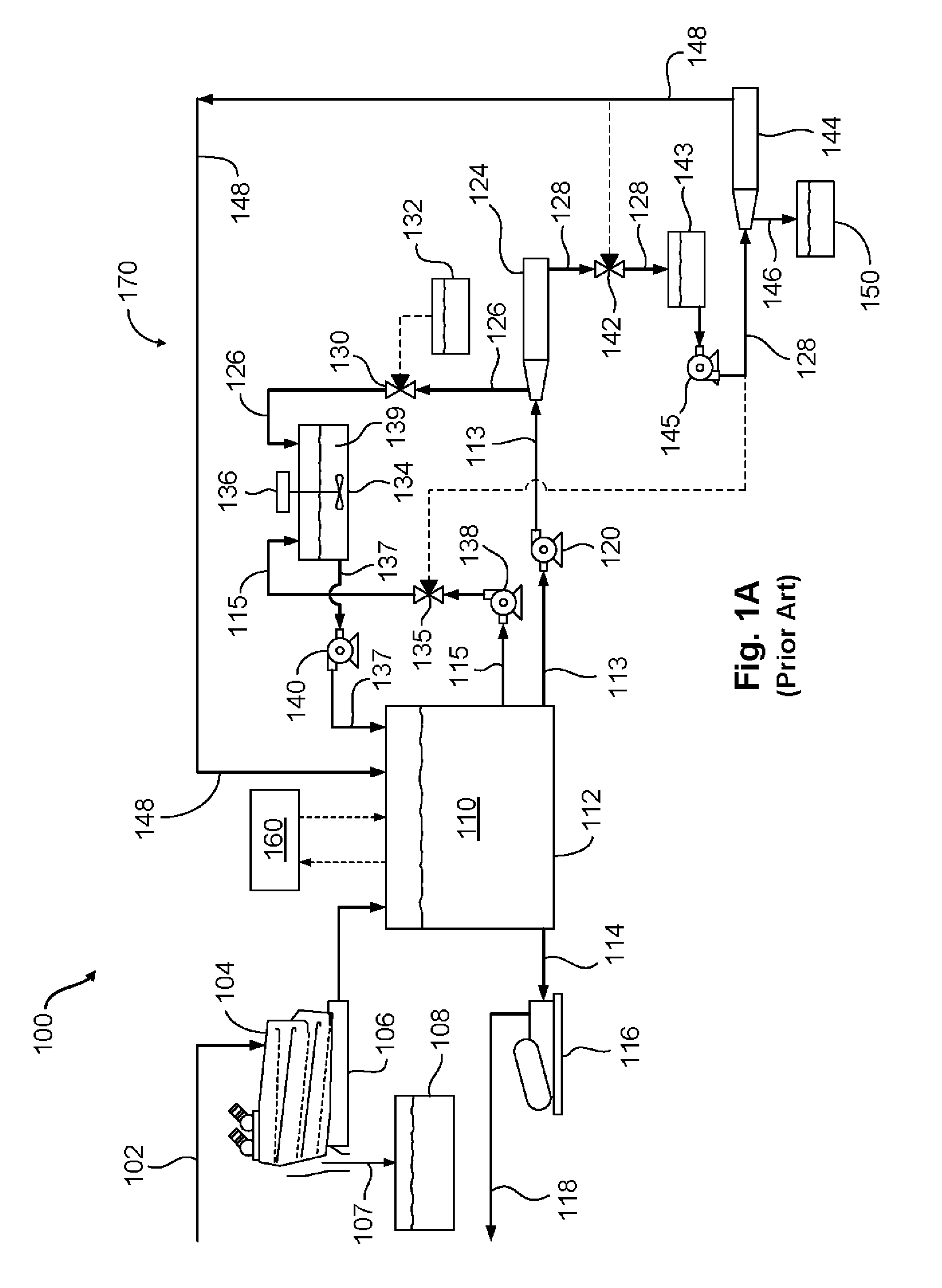

Automatic tank cleaning system

ActiveUS20050205477A1Waste water treatment from quariesLiquid separation auxillary apparatusCompound (substance)Water cycling

An automatic tank cleaning system includes a water recycling unit having a weir therein and a conically-shaped bottom, a cutting box having a portable weir therein, a hydrocyclonic separator, and a mud tank. Tank slop is pumped from the mud tank to the water recycling unit where solids collect at the bottom. The solids are removed and collected in the cutting box. Water in the recycling unit may be pumped through the hydrocyclonic separator. Solids removed by the separator are collected in the cutting box and the water is directed into a clean water compartment defined by the weir within the recycling unit. Water in the cutting box is collected by the portable weir therein and pumped to the clean water compartment. Water from the clean water compartment is pumped to one or more rotary jet heads within the mud tank. Overflow from the water recycling unit may be directed to the cutting box. A chemical inductor may be used to add cleaning chemicals to the water prior to being directed through the wash nozzle. Turbulence preventers may be included at the inlet of each flow line to prevent turbulence from occurring in the tank to which the fluid is directed.

Owner:MI

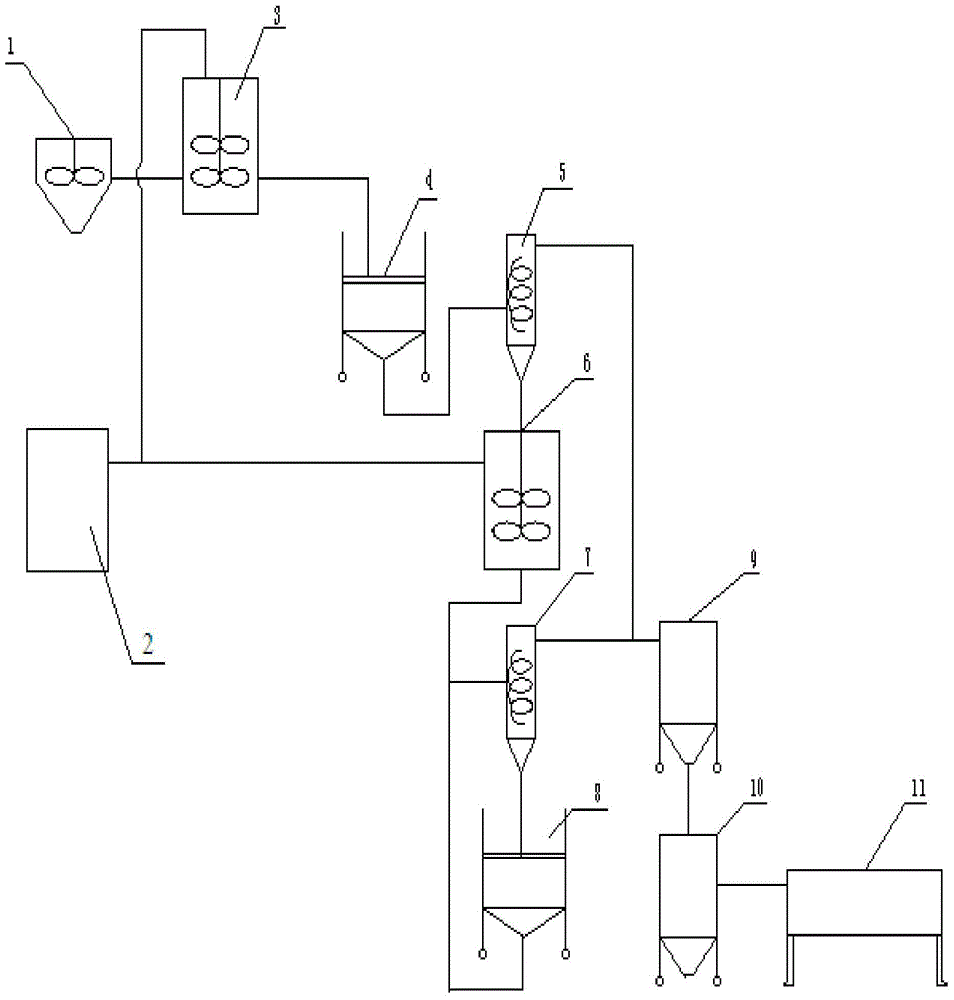

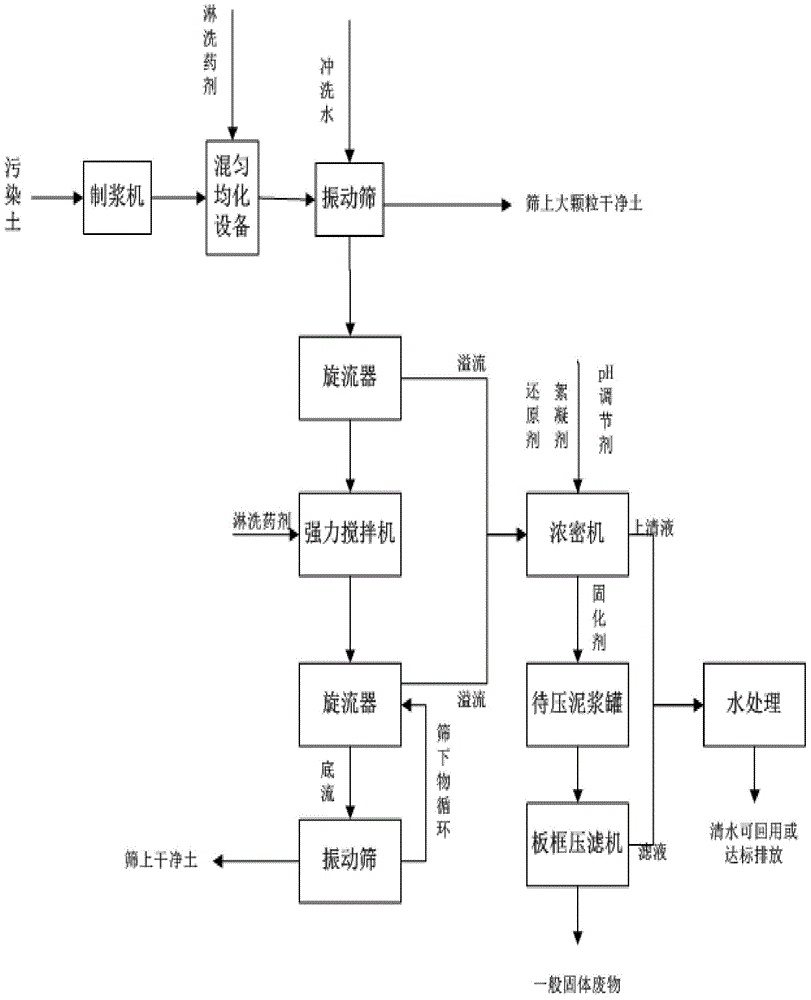

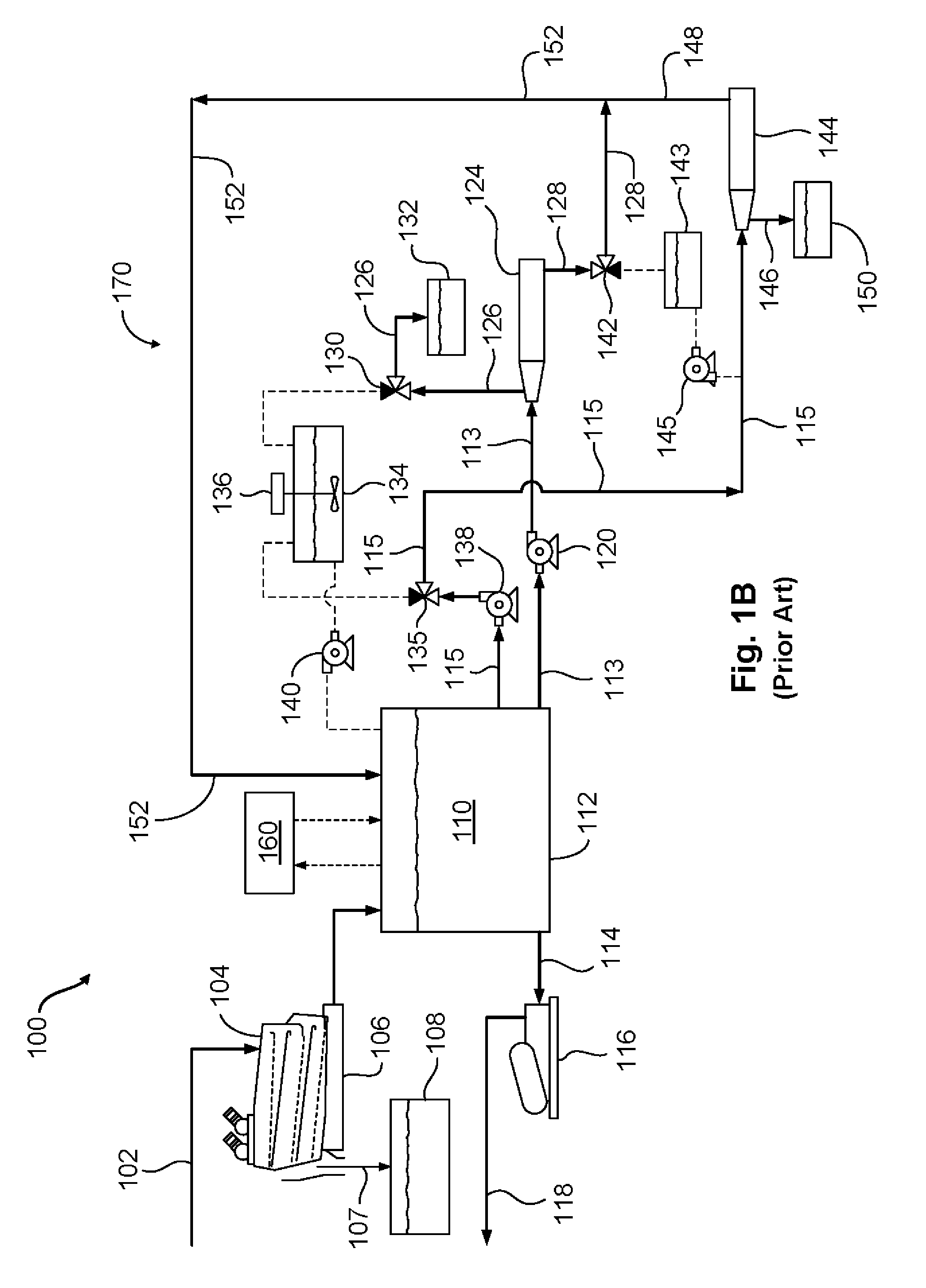

Chromium-contaminated soil different-position leaching repairing technology and device

ActiveCN105057340AGood removal effectIncreased chance of collisionContaminated soil reclamationCycloneFilter press

The invention belongs to the technical field of contaminated soil repairing treatment, and particularly relates to a heavy metal (chromium VI)-contaminated soil different-position chemical leaching repairing technology and device. The chromium-contaminated soil different-position leaching repairing device comprises a one-level scrubbing unit, a two-level scrubbing unit, a waste liquid treatment unit and a medicament adding unit. The one-level scrubbing unit comprises a pulper, an even mixing and homogenizing device, a one-level vibration screen and a one-level cyclone. The two-level scrubbing unit comprises a strong stirrer, a two-level cyclone and a two-level vibration screen. The waste liquid treatment unit comprises a thickener, a to-be-pressed mud tank and a plate-and-frame filter press. The medicament adding unit comprises a medicament tank. The chromium contaminated soil different-position leaching repairing technology comprises one-level leaching, two-level leaching and waste liquid treatment. The different-position leaching repairing technology can be flexibly adjusted according to the situation of soil or bottom mud containing various pollutants. The different-position leaching repairing technology device can be moved to a next project site to be used again after the project is over, and therefore the equipment utilization rate can be increased, and cost can be reduced.

Owner:SAFECLEEN TECH

Automatic tank cleaning system

ActiveUS7232525B2Waste water treatment from quariesLiquid separation auxillary apparatusInductorCistern

An automatic tank cleaning system includes a water recycling unit having a weir therein and a conically-shaped bottom, a cutting box having a portable weir therein, a hydrocyclonic separator, and a mud tank. Tank slop is pumped from the mud tank to the water recycling unit where solids collect at the bottom. The solids are removed and collected in the cutting box. Water in the recycling unit may be pumped through the hydrocyclonic separator. Solids removed by the separator are collected in the cutting box and the water is directed into a clean water compartment defined by the weir within the recycling unit. Water in the cutting box is collected by the portable weir therein and pumped to the clean water compartment. Water from the clean water compartment is pumped to one or more rotary jet heads within the mud tank. Overflow from the water recycling unit may be directed to the cutting box. A chemical inductor may be used to add cleaning chemicals to the water prior to being directed through the wash nozzle. Turbulence preventers may be included at the inlet of each flow line to prevent turbulence from occurring in the tank to which the fluid is directed.

Owner:MI

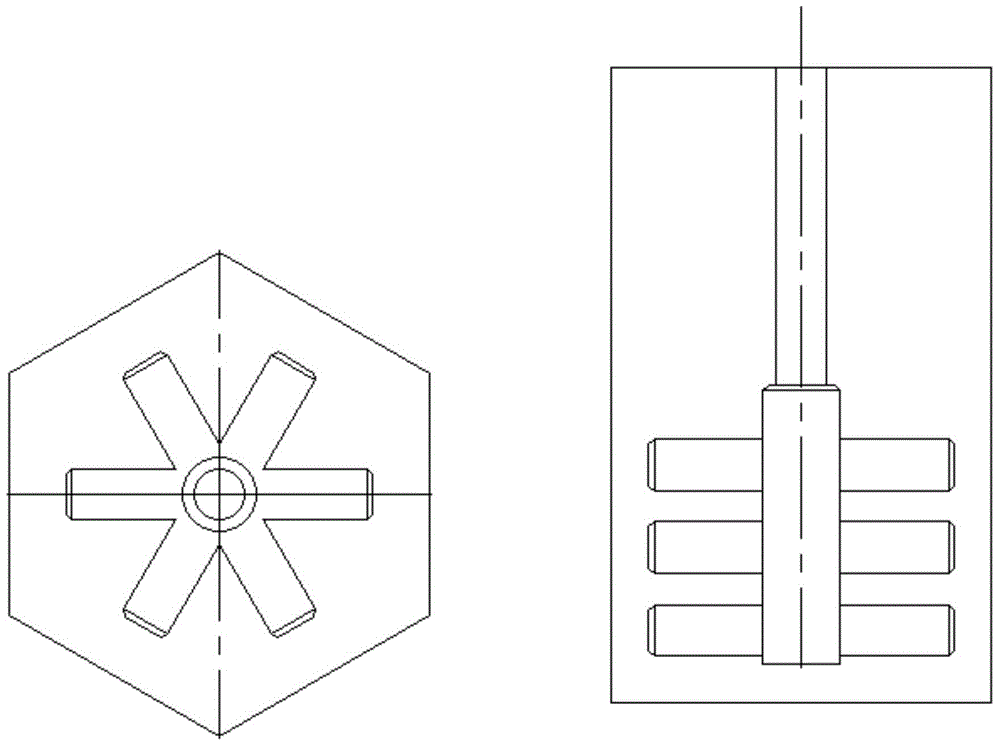

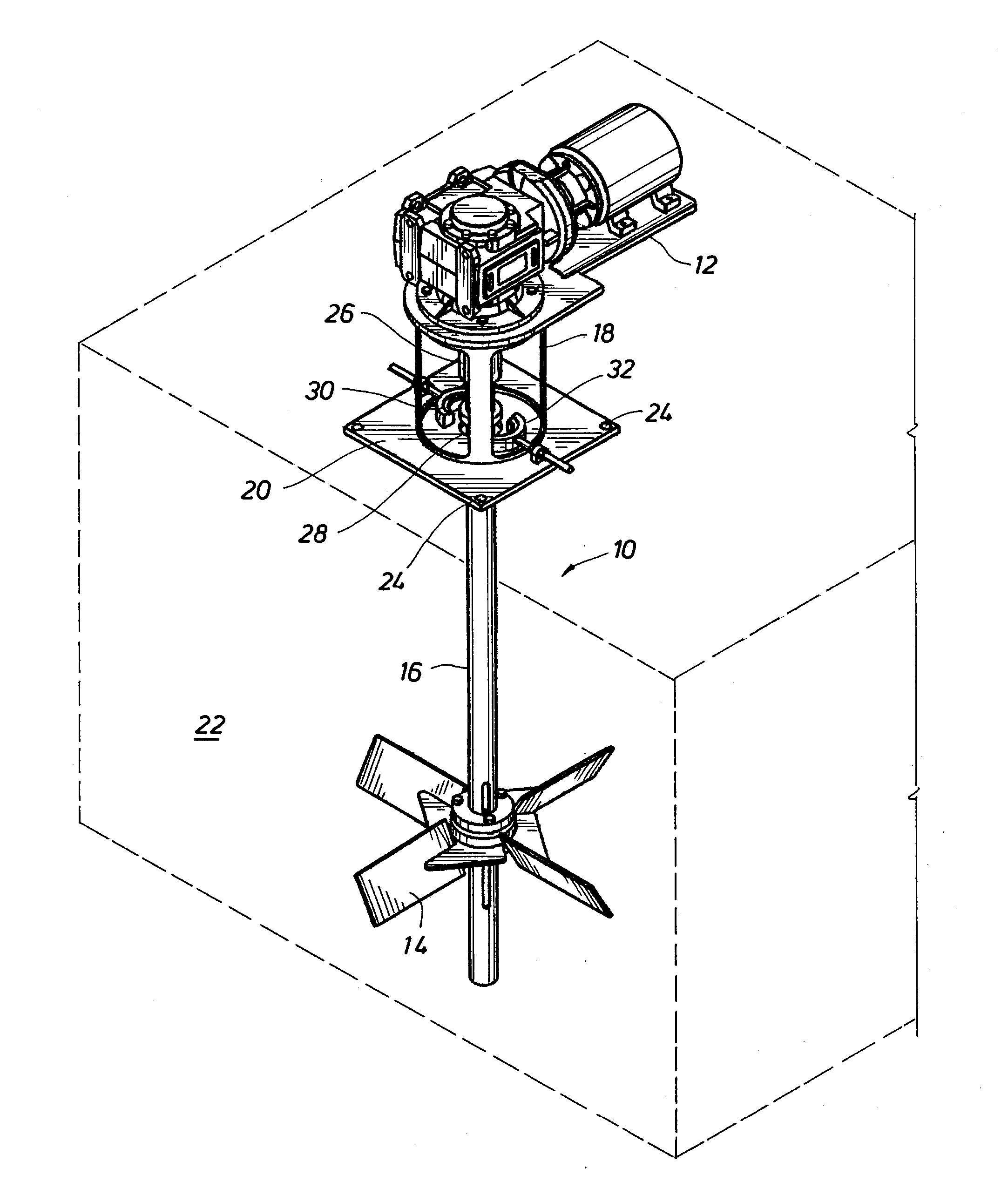

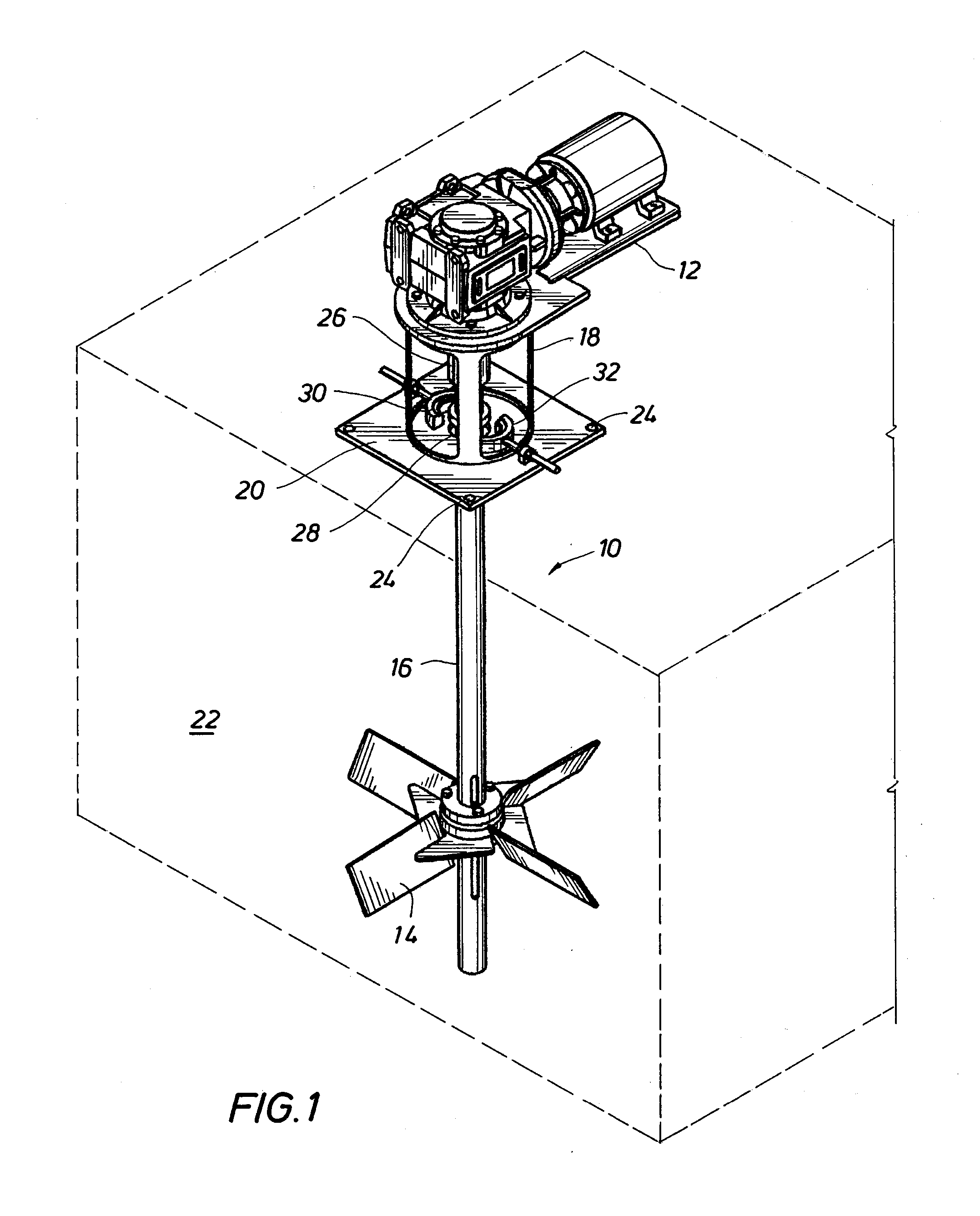

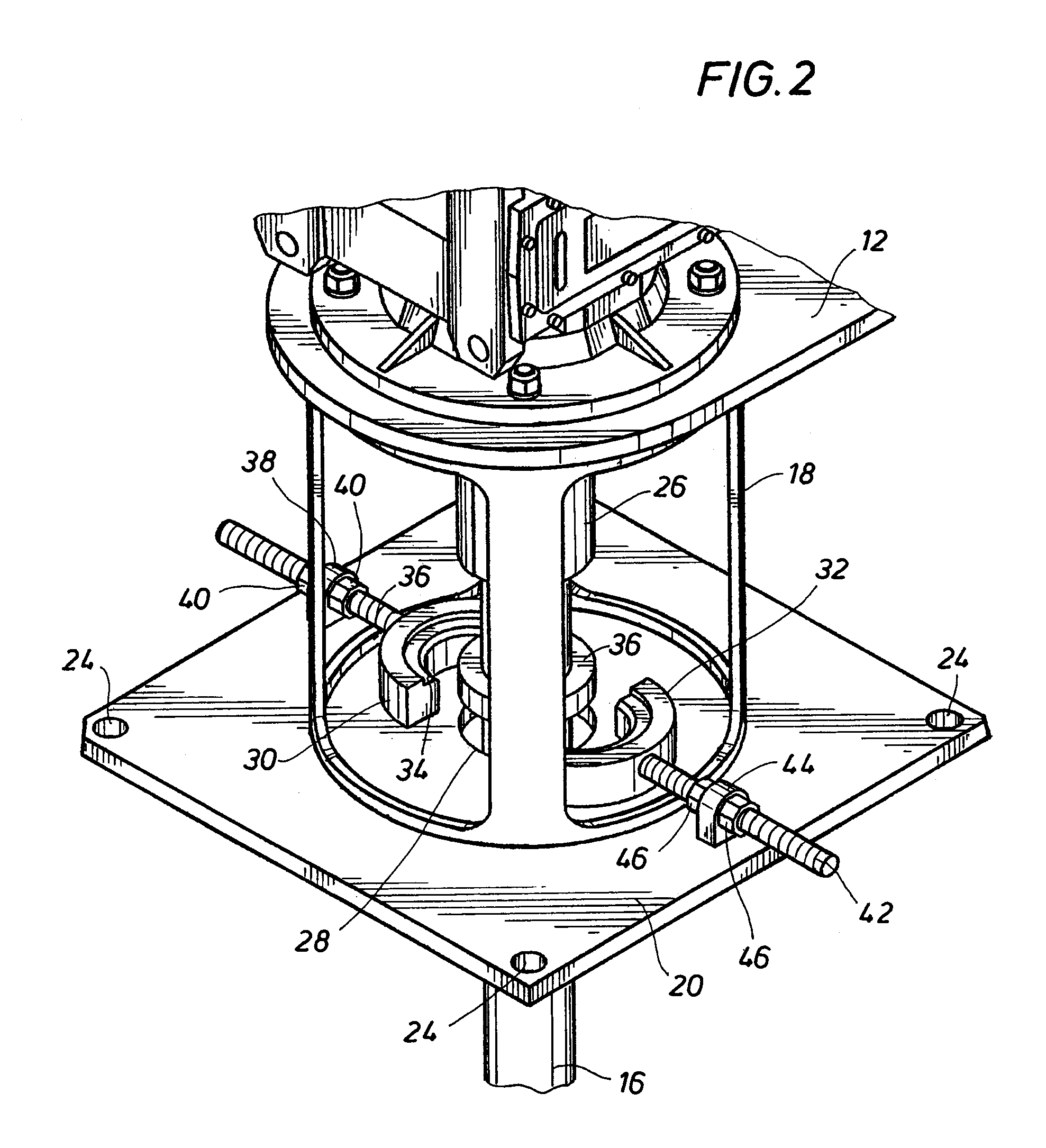

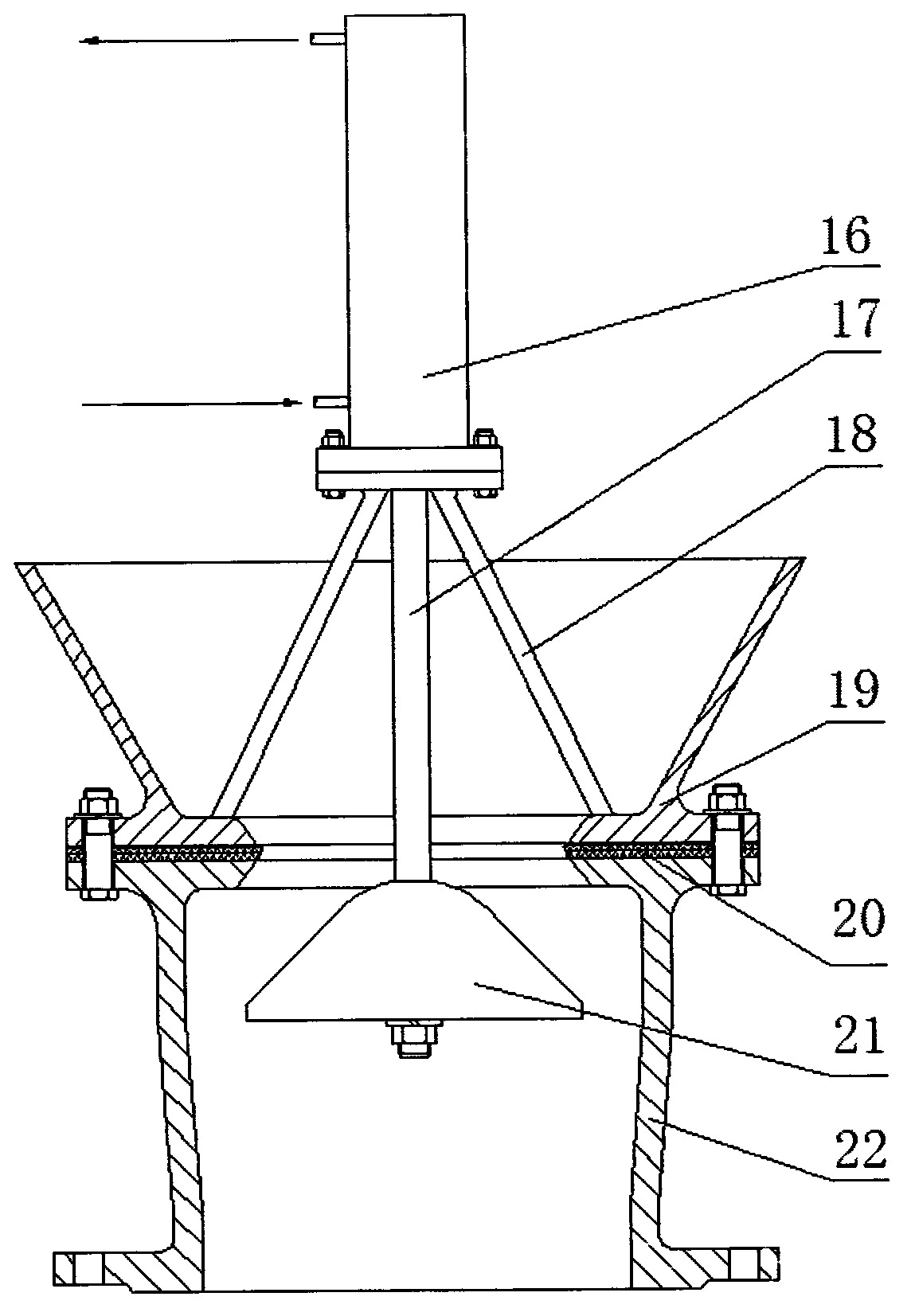

Drilling Mud Agitator With Shaft Retainer

InactiveUS20130088934A1Quickly and easily removedRotary stirring mixersTransportation and packagingMechanical engineeringCoupling

A mechanism secures a mud agitator motor on top of a man-way cover on a mud tank. The mechanism includes a retractable shaft retainer element arranged to engage a retainer block affixed to the agitator shaft. A pair of hemi-cylindrical coupling halves couple the agitator motor shaft to the agitator shaft. The retractable shaft retainer element, once engaged with the retainer block, secures the agitator shaft. The coupling halves can then be quickly and easily removed, and the motor can then be removed for repair or replacement.

Owner:PROCESS SOLUTIONS INT

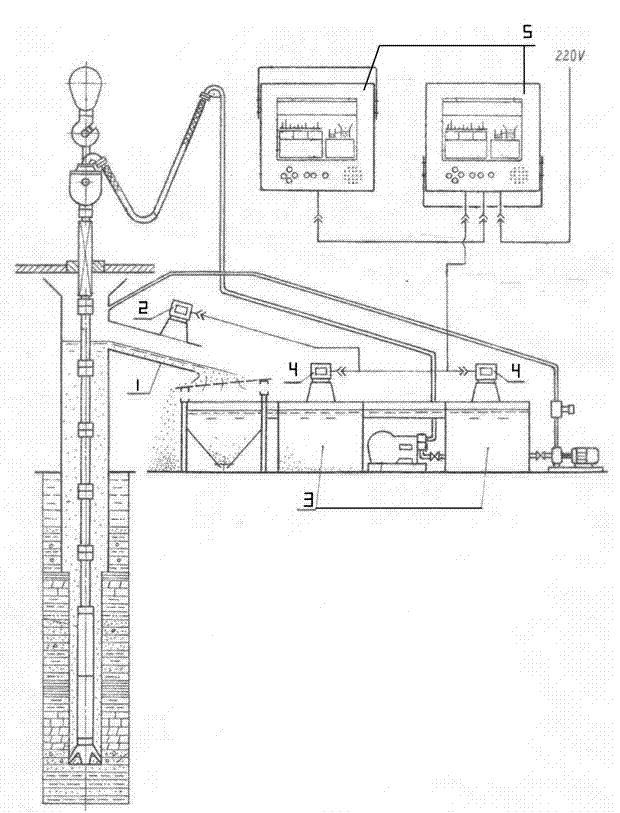

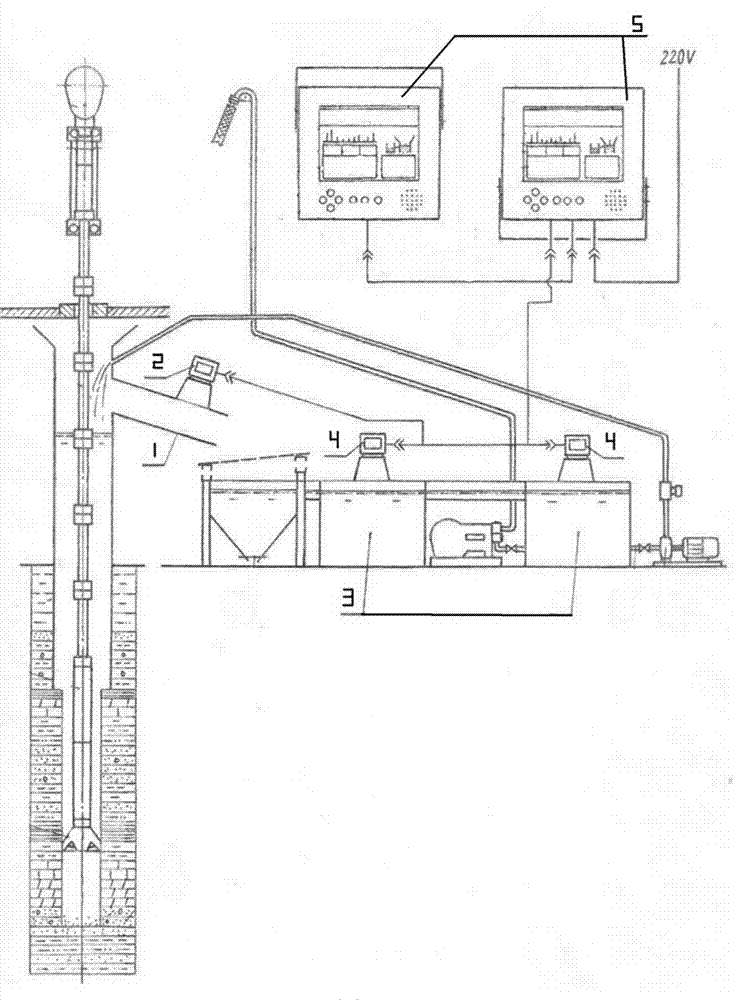

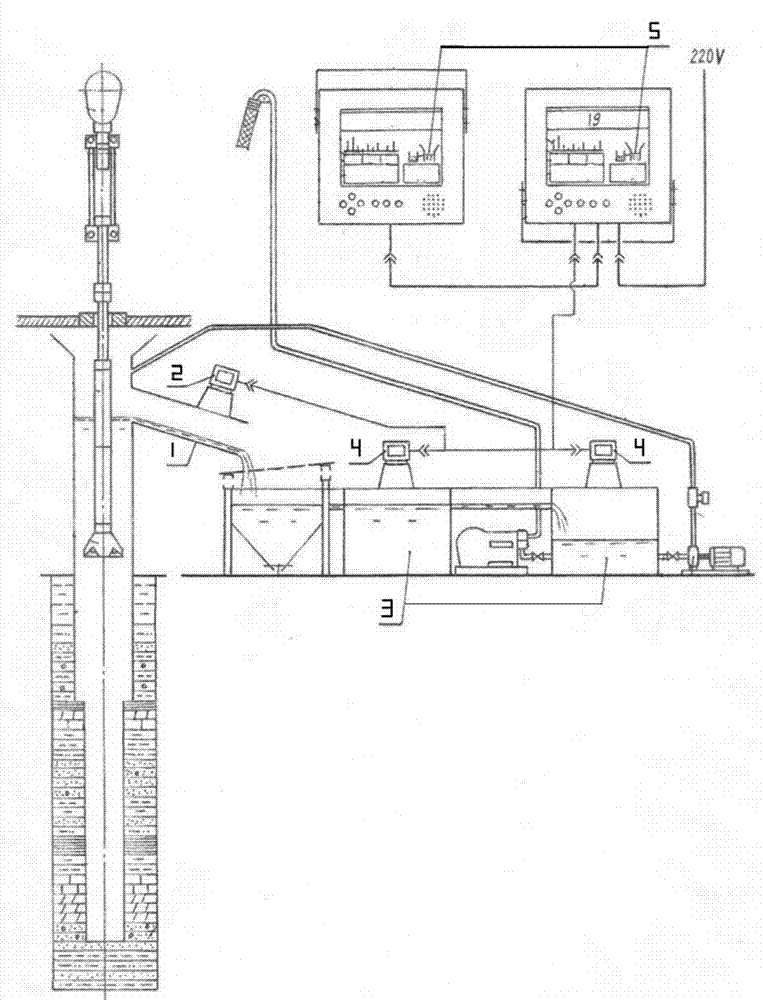

Waste drilling mud recycling water shut-off and profile control technique

ActiveCN104153731AHigh degree of motorizationMove at any timeSludge treatmentFluid removalWell drillingOil water

The invention relates to a waste drilling mud recycling water shut-off and profile control technique. The waste drilling mud recycling water shut-off and profile control technique comprises the following steps of scattering waste mud in a waste mud pond by using a high-pressure sewage gun; descending a submerged mud pump to the waste mud pond by using a small crane and stirring the waste mud by using the submerged mud pump; carrying recycled mud to a water shut-off and profile control field by using a mud tank truck; adding chemicals in the waste mud and blending the waste mud into water shut-off and profile control plugging agents; pumping the water shut-off and profile control plugging agents into a stirring tank; sufficiently stirring and curing the mud by using a stirrer; and injecting the mud into an oil-water well by using an intelligent profile control injection pump according to the amount of design in three slugs comprising an early strength slug, a main body slug and a sealing slug and performing a water shut-off and profile control process. The waste drilling mud recycling water shut-off and profile control technique has the advantages that environmental pollution of the waste mud is eliminated when the waste mud is not solidified; the recycled mud pond is not required to be solidified; a large amount of mud solidifying cost is saved; the recycled waste mud serves as inorganic plugging agents after being blended; remote plugging in deep positions of a stratum is realized; and the whole water shut-off and profile control effect is improved.

Owner:山东华曦石油技术服务有限公司

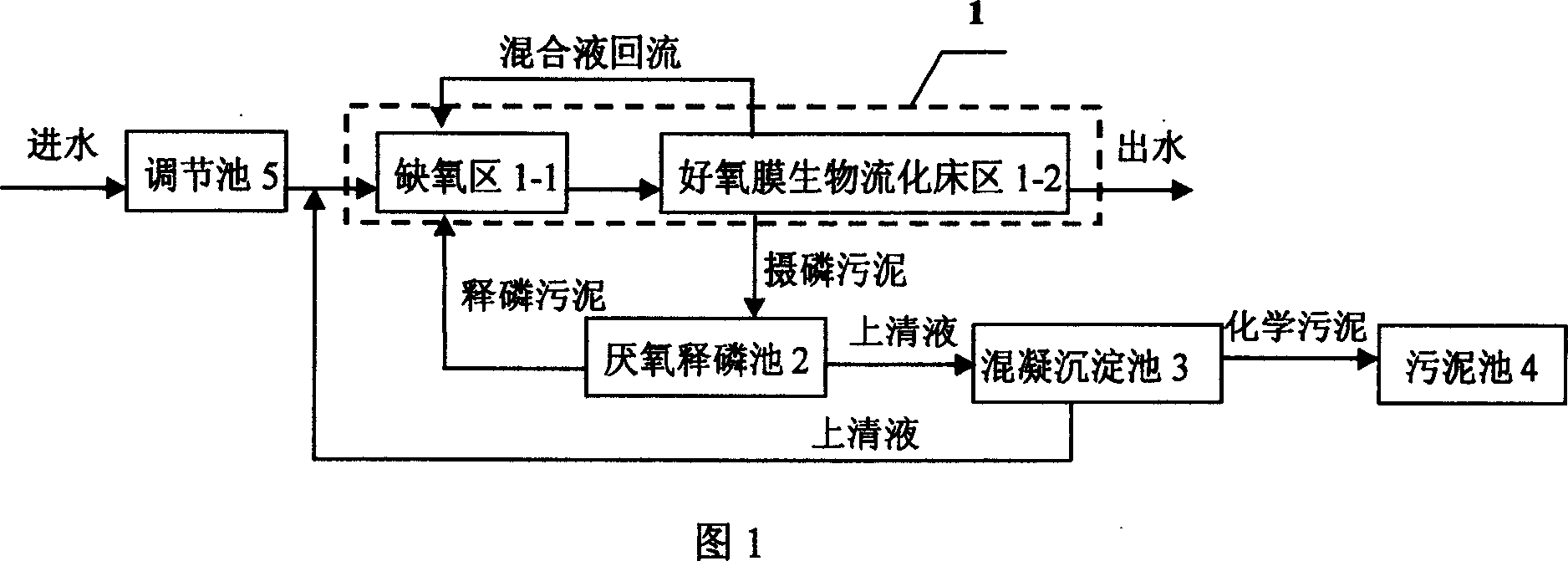

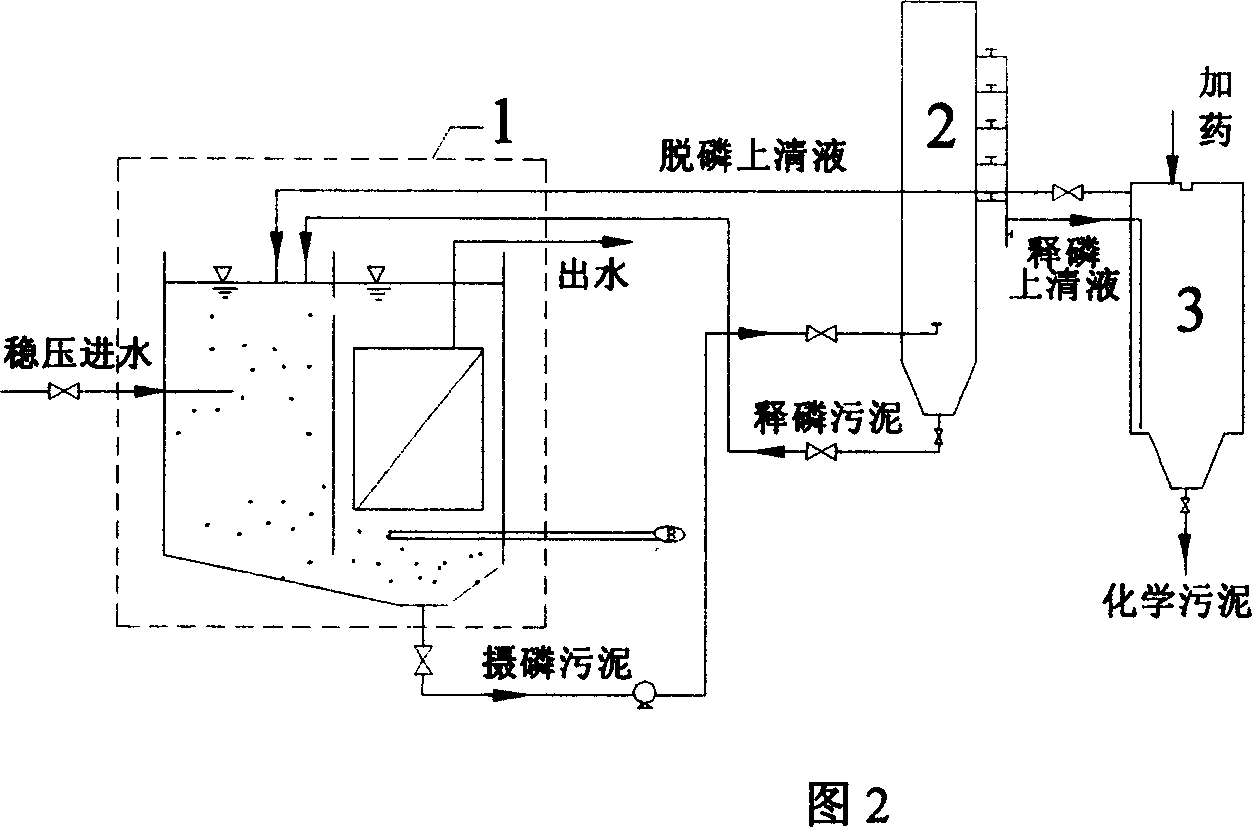

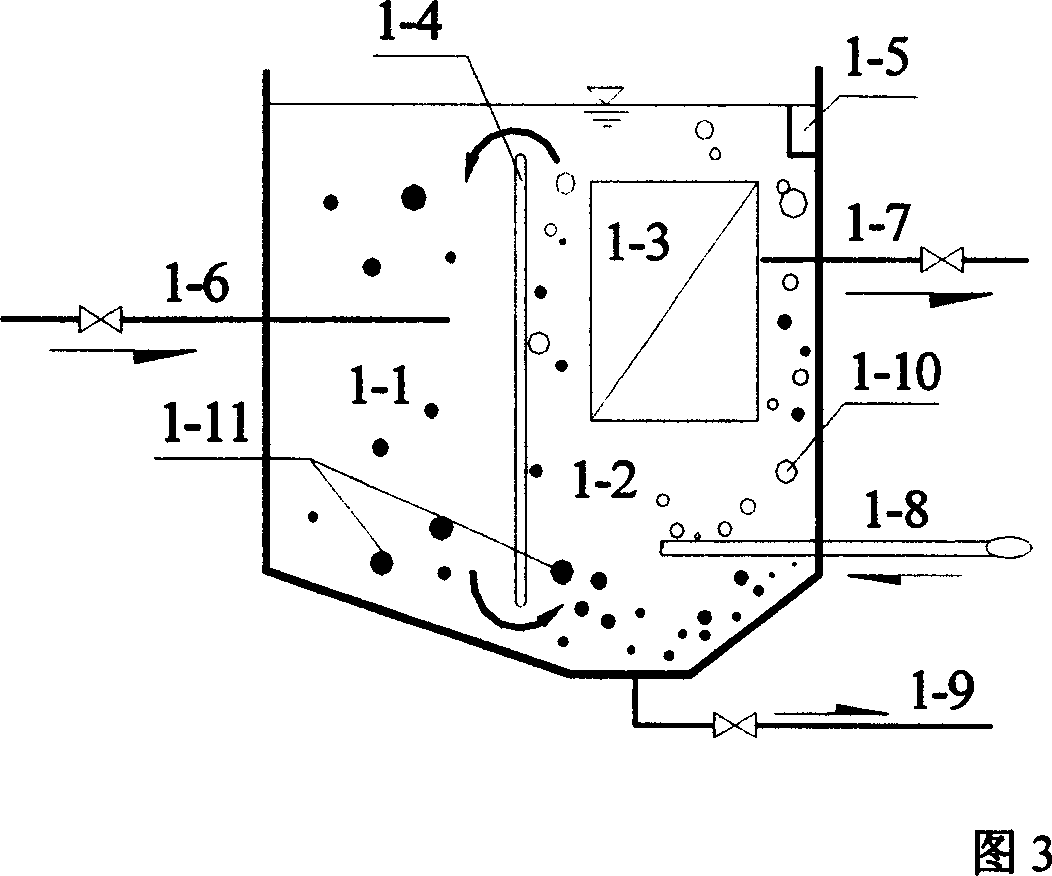

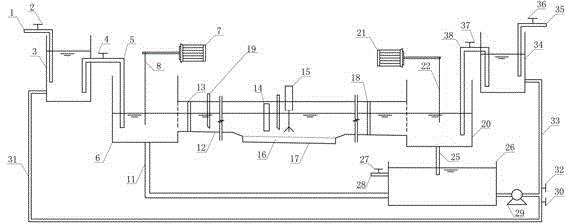

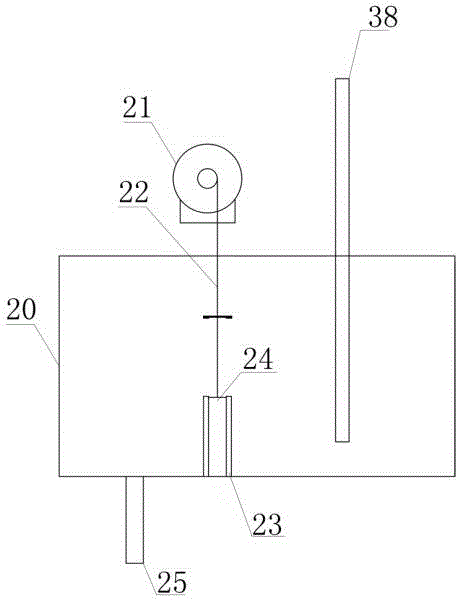

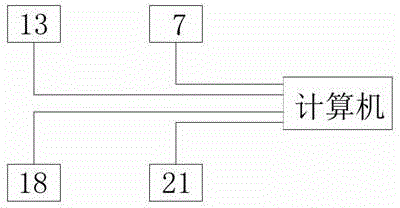

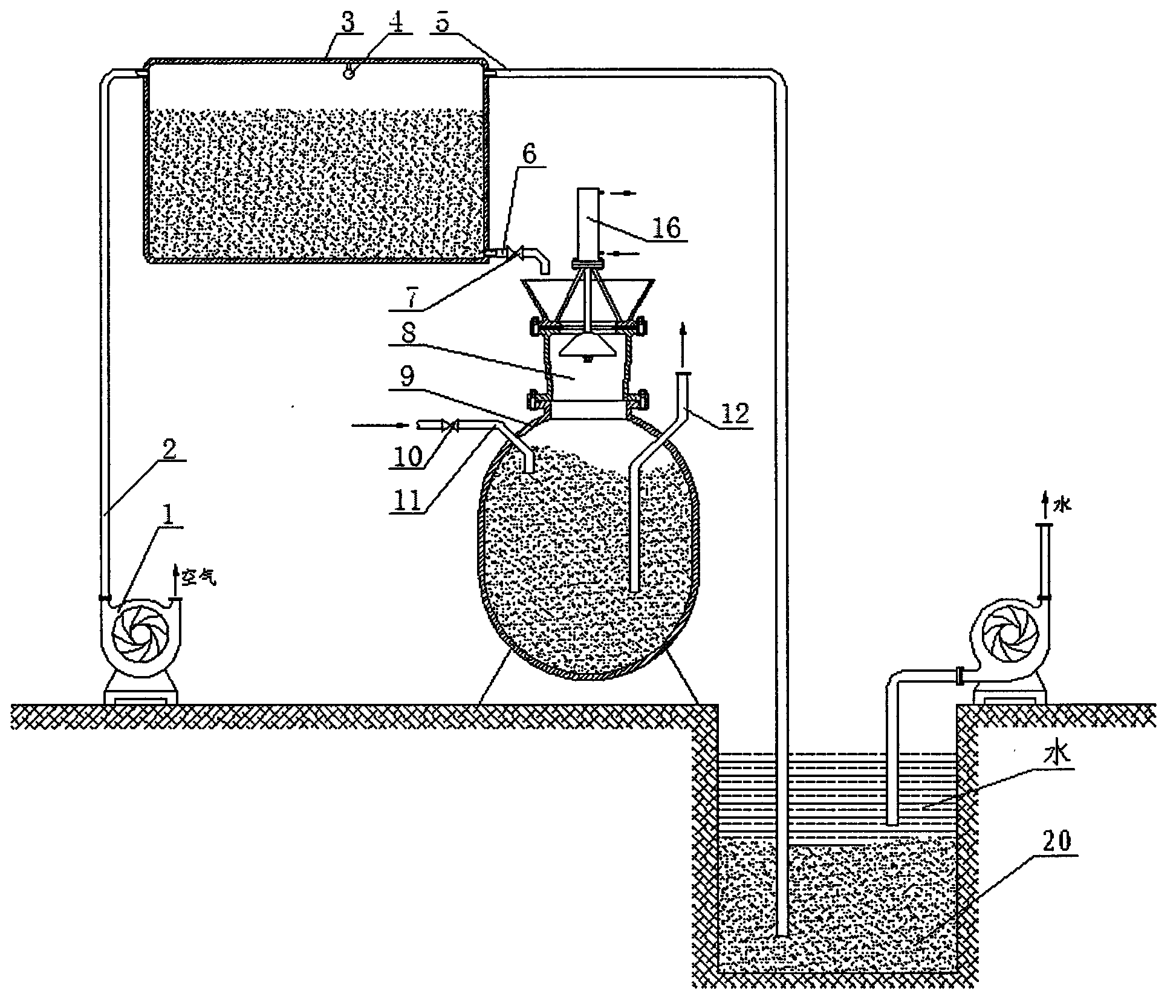

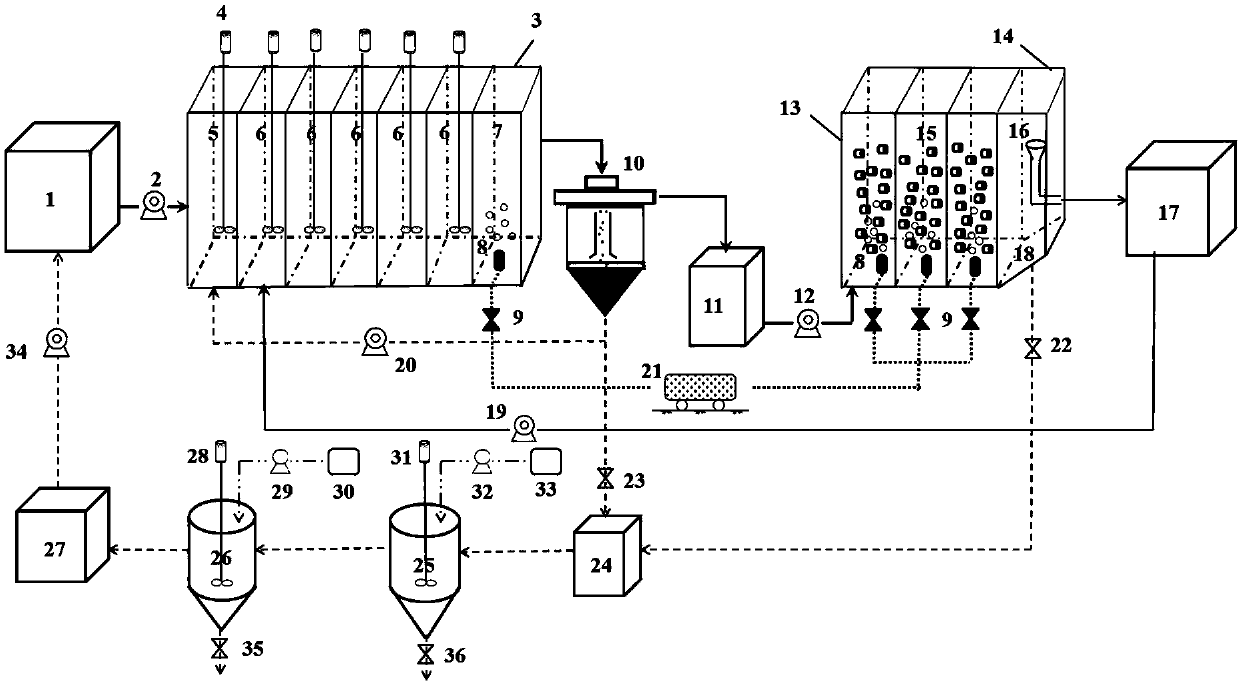

Integrated membrane biological fluidized bed sewage treating method and apparatus

InactiveCN1935697AExtended service lifeImprove operating flowTreatment with aerobic and anaerobic processesFluidized bedSludge

The invention is an integrated membrance biofluidized bed sewage treating method and device, a device and method for organic sewage (waste) water treatment, where the method: feeding sewage water through regulating tank into an oxygen-starved area, then feeding the pretreated sewage water into an aerobic membrane biofluidized bed area for treatment, then making membrane separation to output clean water and discharging P-carrying mud into an anaerobic P releasing tank for treatment, then returning the P-released mud into the oxygen-starved area and discharging supernatant into a mixing coagulation settling tank, and finally returning the supernatant into the oxygen-starved area and discharging chemical mud into a mud tank. And the device mainly comprises integrated membrane biofluidized bed sewage treater, anaerobic P releasing tank, and mixing coagulation settling tank.

Owner:SOUTHEAST UNIV

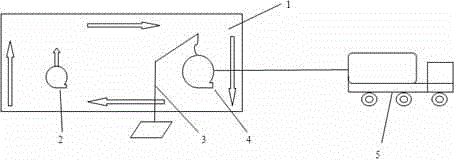

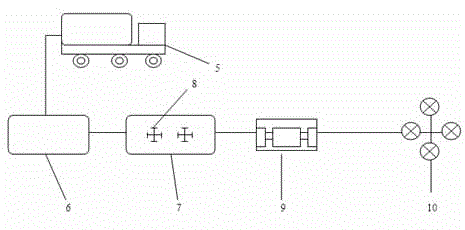

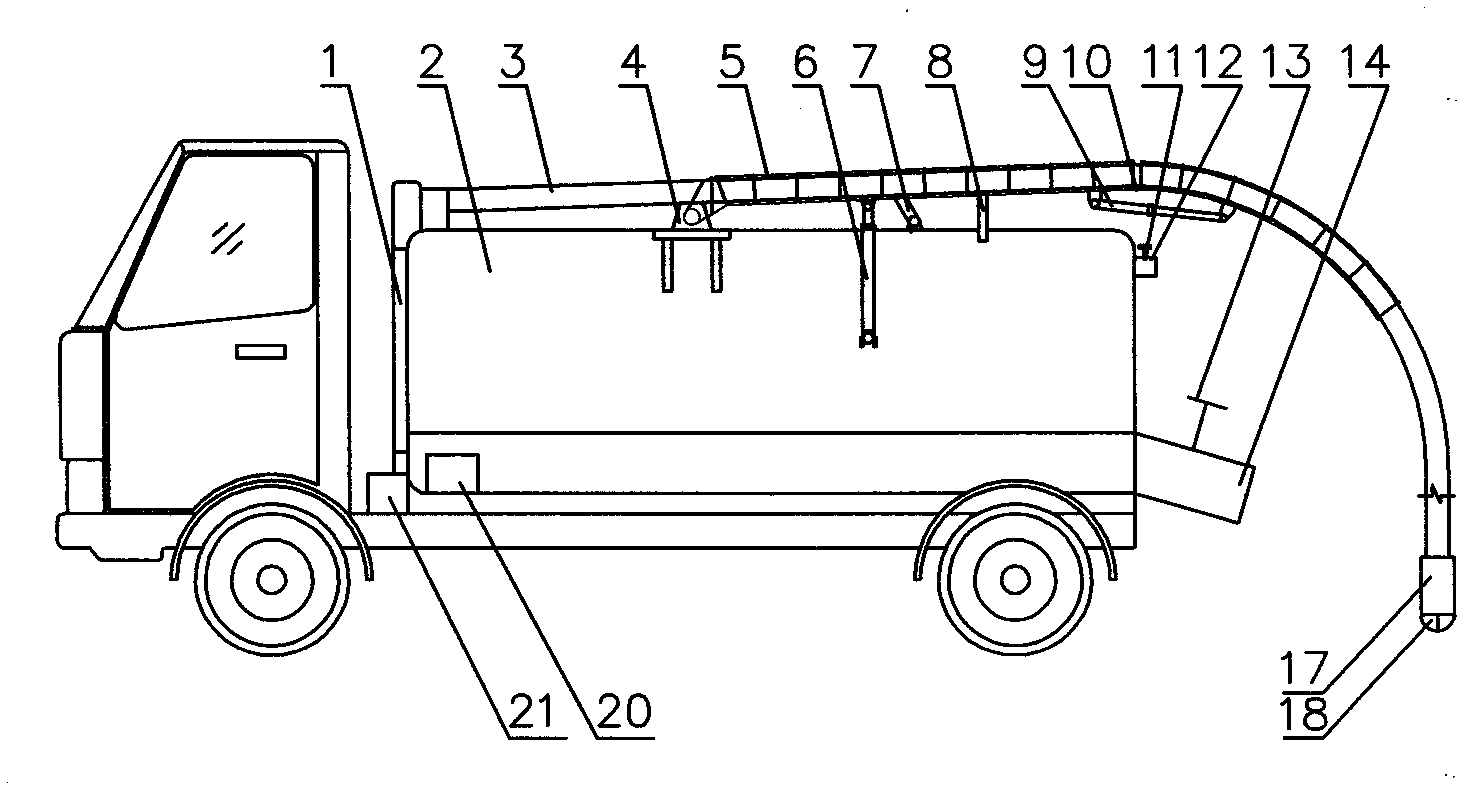

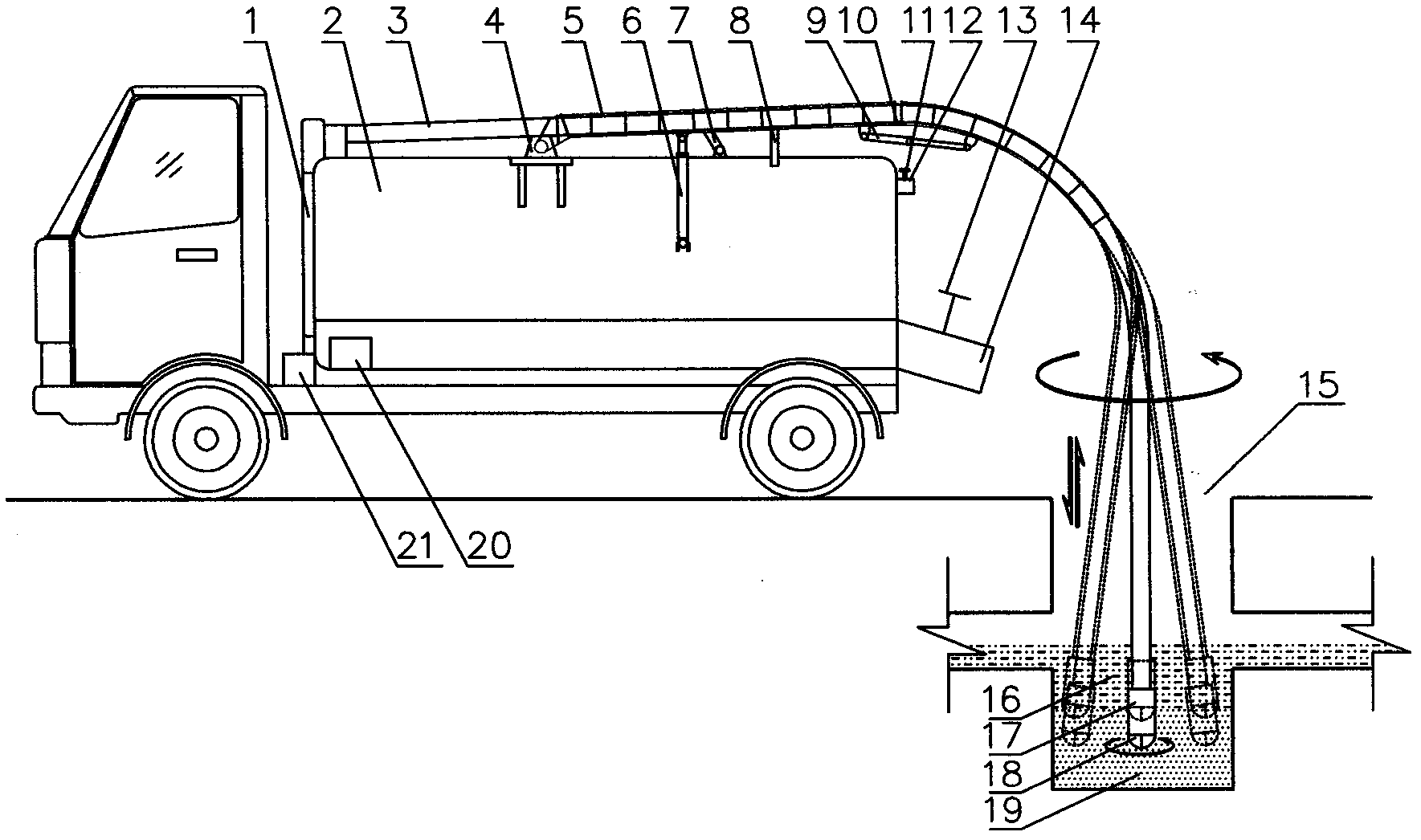

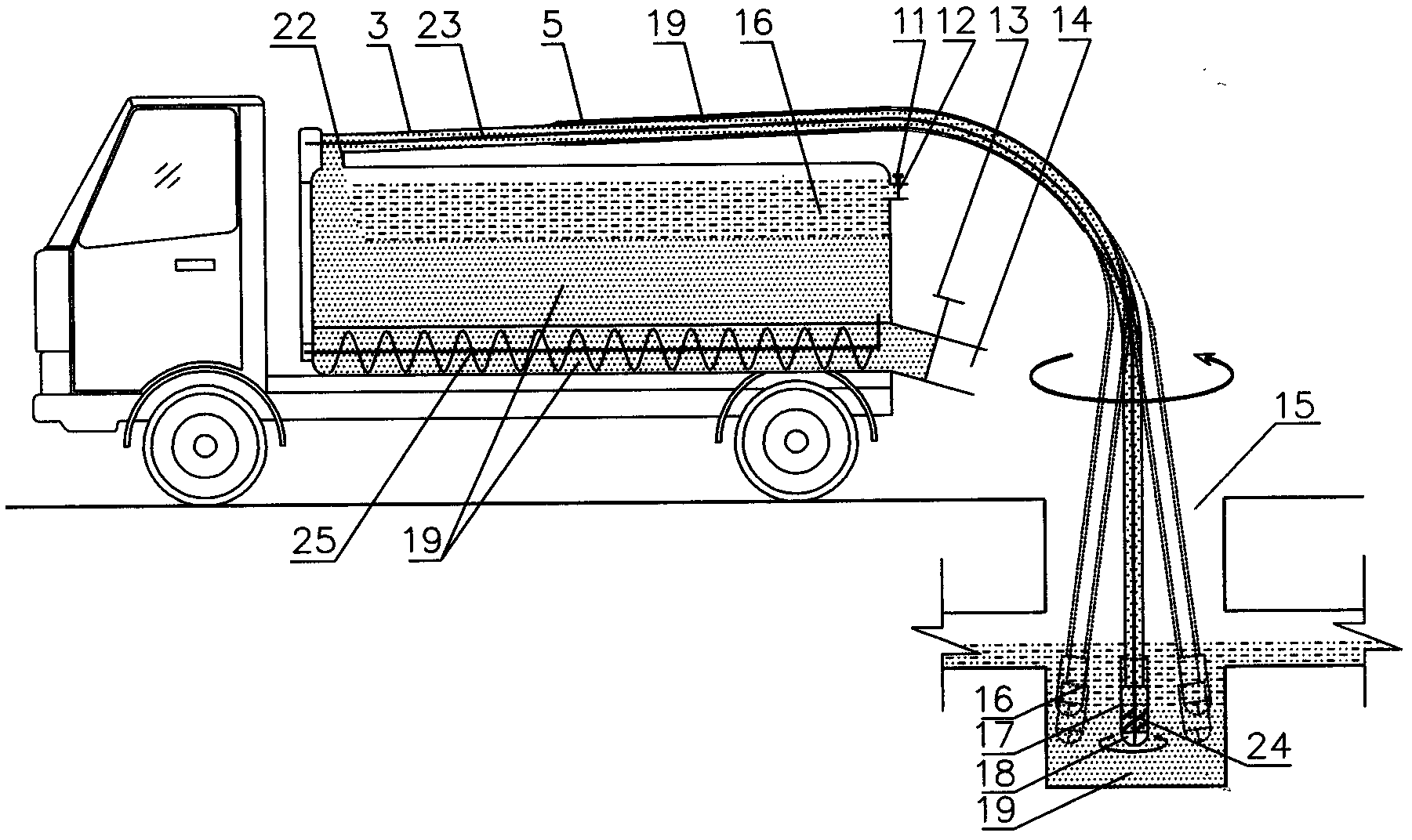

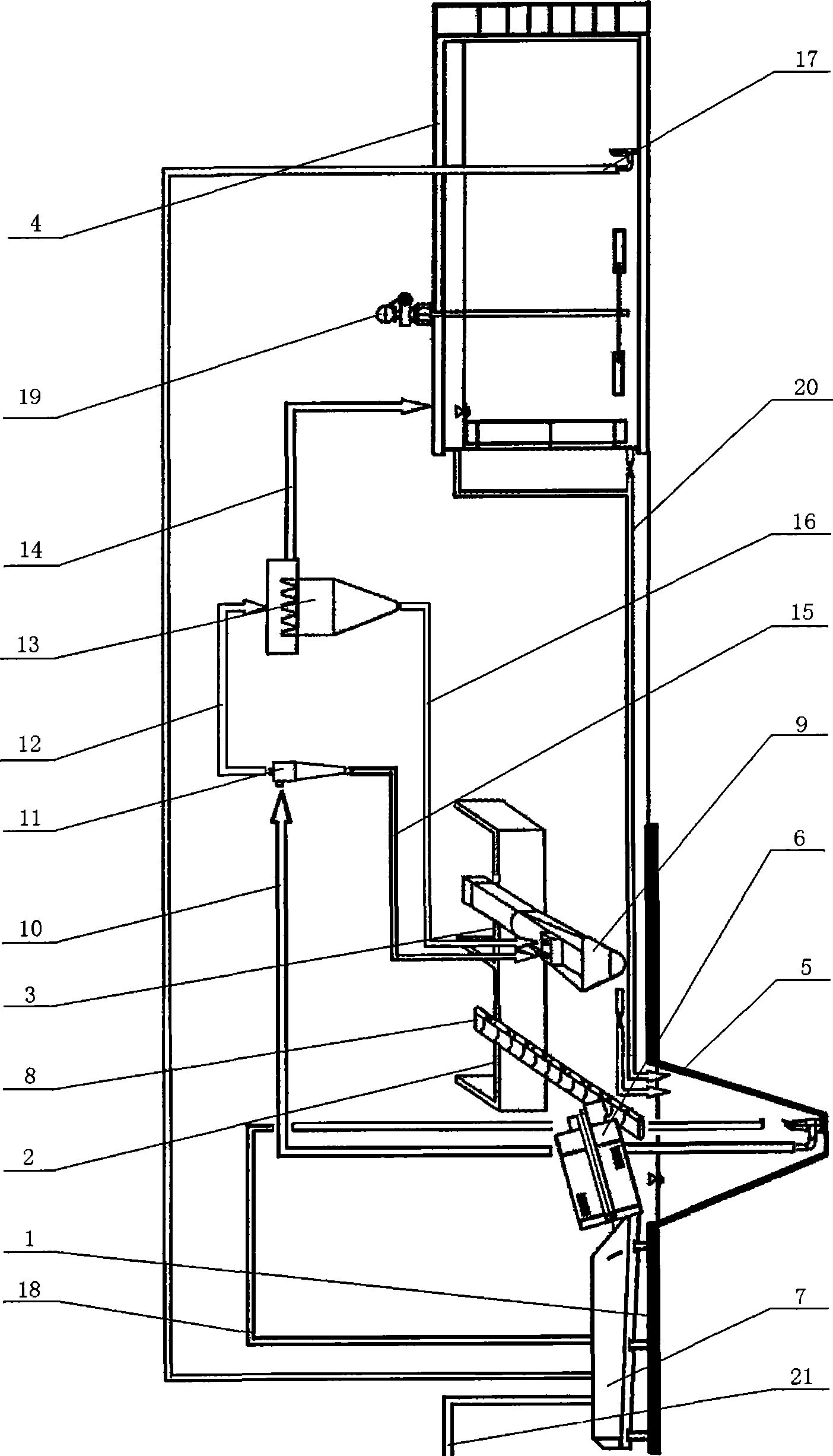

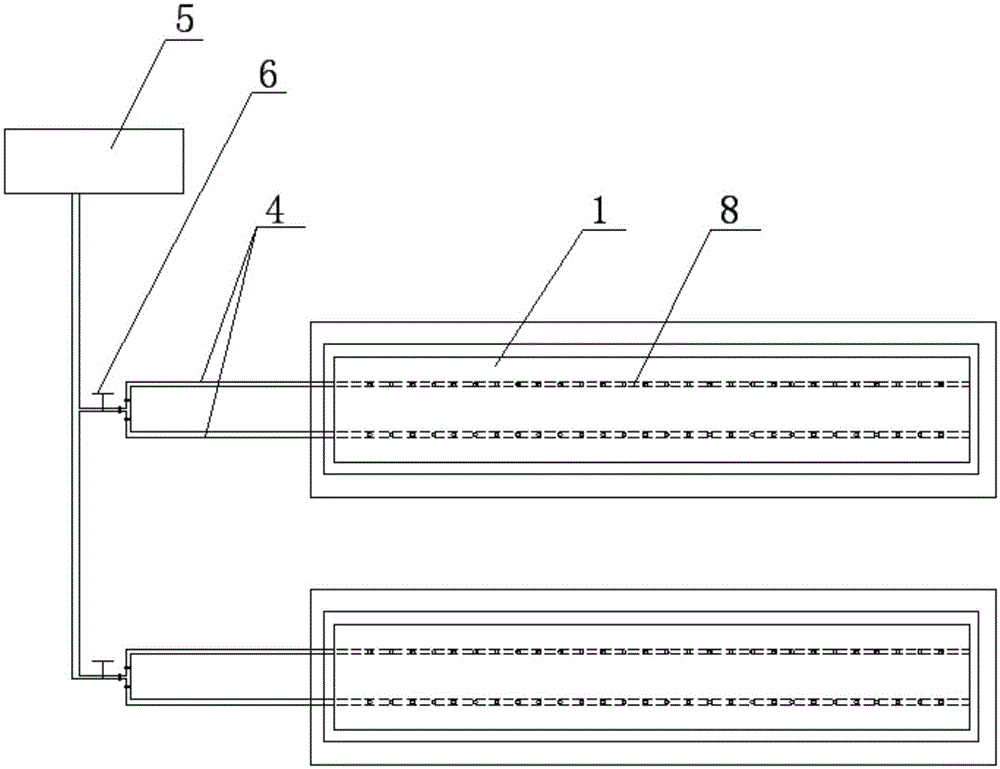

Intelligent multifunction combined suction sewage truck

The invention relates to the manufacturing field of the sewage pipeline dredging machine, and in particular to an intelligent multifunction combined suction sewage truck, which mainly comprises a vacuum device (4), a high-pressure flushing device (5) and a sewage circulating device (6), wherein the sewage circulating device (6) comprises a clean water tank (7), a mud tank (8), a rotation suspension arm (9), a filter plate assembly (15), a physical filter (16), a whirlwind filter cylinder (17) and a whirlwind filter (19). When swage is sucked into the mud tank (8), the sewage is blocked by the filter plate assembly (15) on the rear end of the mud tank (18), then sewage enters the rotation filter cylinder (17), so the sewage and the mud are further separated with a centrifugal way, and finally the sewage enters the physical filter (16) to be finally filtered with a precipitation filtering way. The intelligent multifunction combined suction sewage truck can simultaneously carry out the vacuum sewage suction, high-pressure flushing and sewage circulation, can continuously work for long time, and has high working efficiency.

Owner:HUAIAN SPECIAL PURPOSE VEHICLE MFG

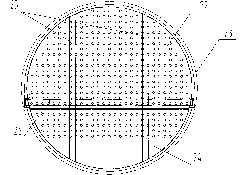

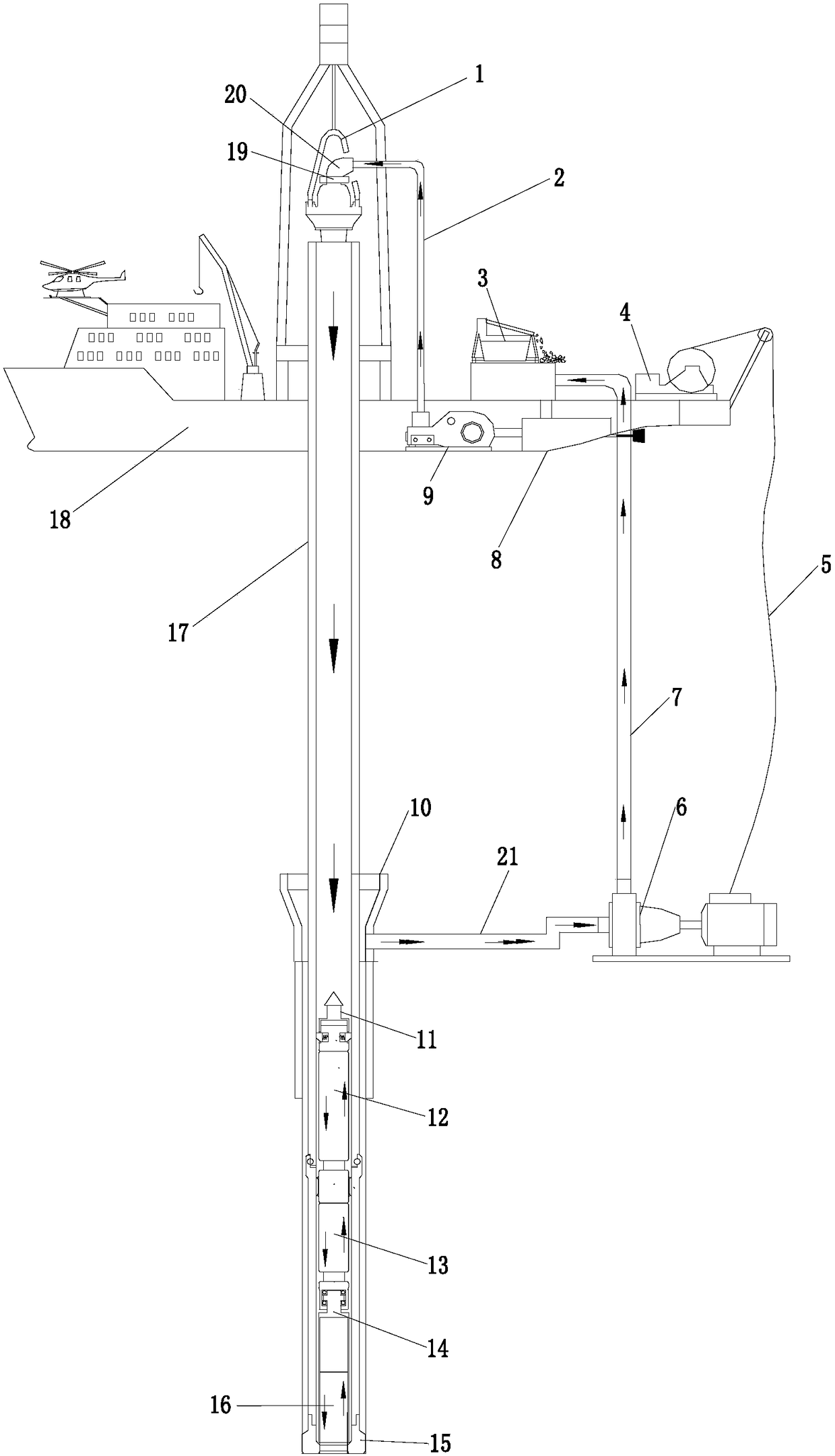

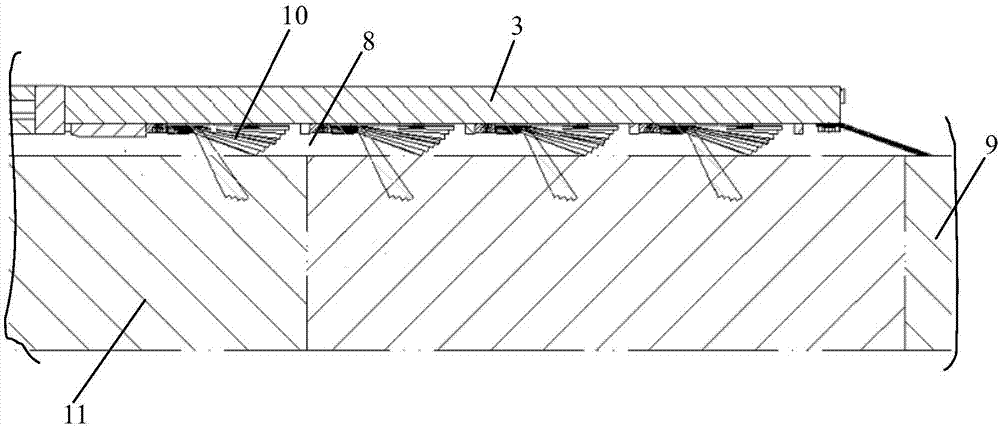

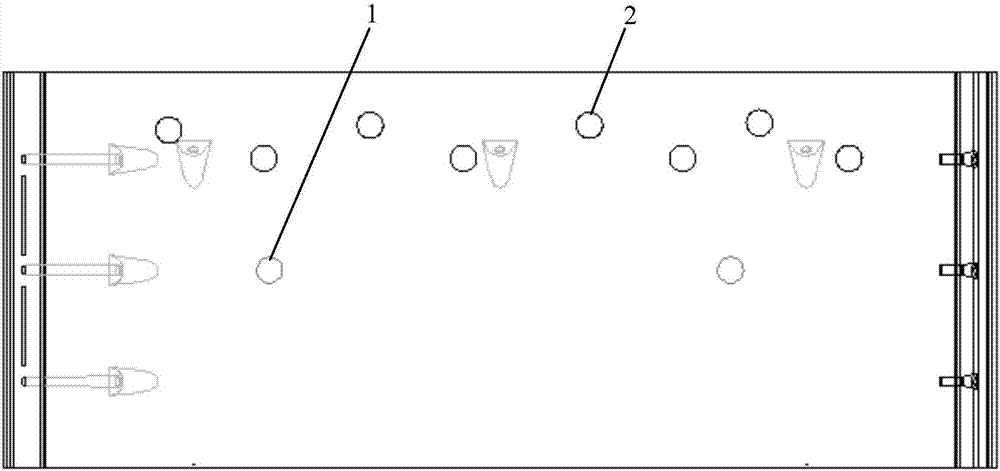

Quick coring drilling system without marine riser and method based on circulating drilling fluid

PendingCN108547587AImprove mobilityReduce the risk of instabilityBorehole drivesCore removalLine tubingInstability

The invention relates to a quick coring drilling system without a marine riser and method based on circulating drilling fluid. The quick coring drilling system comprises a mud circulation system and acoring drilling system body, wherein the coring drilling system body comprises a drill pipe, a spearhead, a driving device, a hydraulic down-hole hammer, a core pipe and a drill bit which are sequentially connected from top to bottom inside the drill pipe; the mud circulation system comprises a return cone, a recovery pump, a mud tank, a mud pump and a conveying pipeline group; the conveying pipeline group comprises a first conveying pipeline, a second conveying pipeline and a third conveying pipeline; and the mud tank, mud pump, the drill pipe, the return cone and the conveying pipeline group are in communication with each other to form a mud circulation channel. The quick coring drilling system does not use the marine riser, the time for lowering a pipe column is reduced, the emergencyrelease speed is accelerated, the connection can be quickly performed through the return cone, time and cost are saved, and the risk of wellhead instability is reduced.

Owner:GUANGZHOU MARINE GEOLOGICAL SURVEY

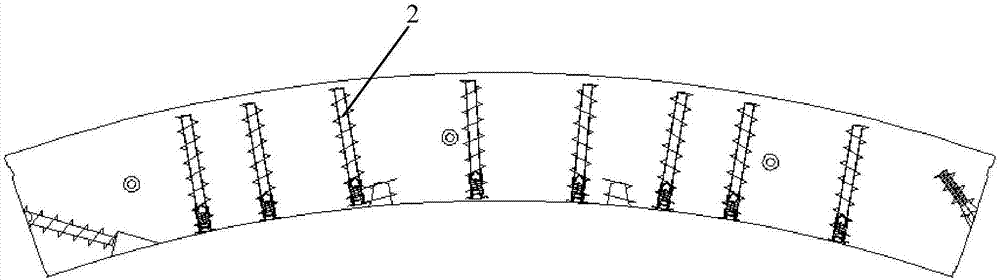

Replacing method of shield tail brushes of super-large-diameter shield machine under high water pressure condition

ActiveCN107035378AEasy to replace, safe, stable and efficientSolve the difficulty of replacementUnderground chambersTunnel liningSlurryEngineering

The invention provides a replacing method of shield tail brushes of a super-large-diameter shield machine under a high water pressure condition. In the propelling process of last ring pipe pieces before shutdown, in addition to the last ring pipe piece before shutdown, gaps between a shield tail and the pipe pieces is filled with elastic water absorbing materials or elastic waterproof materials; in the propelling process of the last ring pipe pieces before shutdown, ordinary grease is injected into a grease cavity of the shield tail brushes in a pressure mode, and the other grease cavities of other shield tail brushes of the super-large-diameter shield machine are injected with waterproof grease in a pressure mode; in the replacement position, a mud tank of the super-large-diameter shield machine is subjected to new slurry replacement; and in the replacement position, a shield shell hoop of the super-large-diameter shield machine is injected with filling slurry body in a pressure mode. Preferably, the shield tail brushes are detachable. According to the replacing method of the shield tail brushes of the super-large-diameter shield machine under the high water pressure condition, replacement of the shield tail brushes under the high water pressure condition is easy, safe, stable and efficient, the problem that replacement of the shield tail brushes of the super-large-diameter shield machine under the high water pressure condition is difficult can be solved, design is ingenious, construction is simple, convenient, safe and efficient, and large-scale application and promotion is adaptable.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

Truck for removing sludge from inspection well

The invention relates to a truck for removing sludge from an inspection well, which belongs to the technique of mechanically removing the sludge from the inspection well for the urban pipe network. When the sludge in the inspection well is removed, an inspection well cover is opened. The truck power is started by a microcontroller to start an oil pump and drive a soft shaft. Meanwhile, a sludge conveying flexible pipe is driven to move an oil cylinder upwards, downwards, leftwards, rightwards, frontwards and backwards, and the soft shaft, the sludge conveying flexible pipe, a sludge pump and a stirring head are correctly conveyed in the inspection well. According to size of the inspection well, a program that has been set by the microcomputer controller is selected. Under the control of the program, the sludge deposited in the inspection well is stirred in a flowing shape by the stirring head spirally from top down, and the sludge in the flowing shape is conveyed into a sludge storage tank by effect of an impeller of the sludge pump. The waste water in the sludge storage tank is discharged through a waste water outlet after continuous operation and sludge deposition, so that the sludge storage tank can store the sludge maximally. After the sludge is stored in the whole sludge storage tank, the sludge storage tank is conveyed to a named place where the sludge is discharged. Finally the sludge deposited on the bottom of the sludge storage tank is pushed out from a sludge discharge outlet by a sludge discharge spiral rod.

Owner:宋兰芳 +2

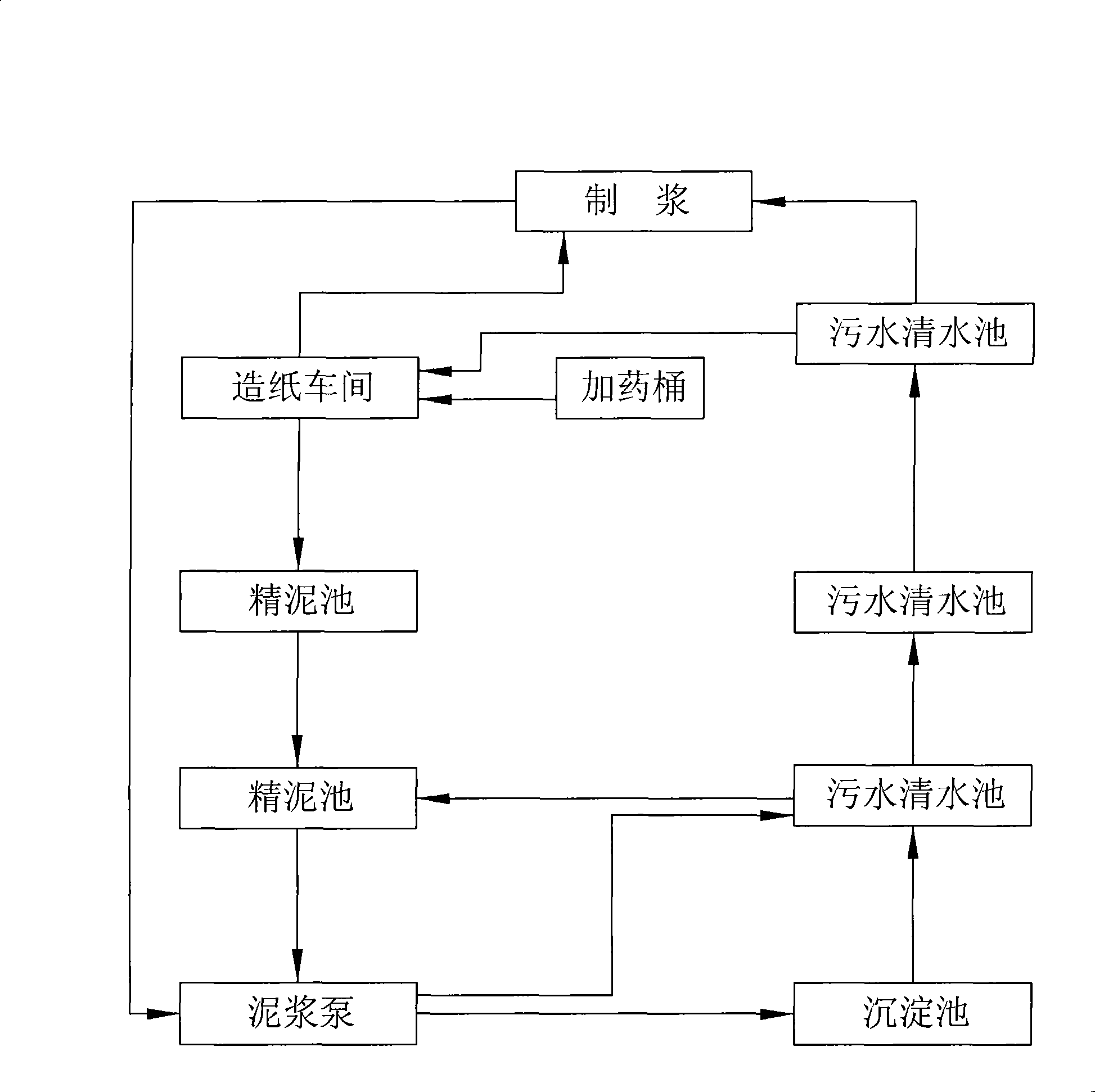

Zero discharge technology of paper making sewage disposal

InactiveCN101381135AReduce meshSave waterWater/sewage treatment by flocculation/precipitationFiberAfter treatment

Owner:许金平

Device for simulating reciprocating flow riverway in-situ bottom mud resuspension and simulation technology thereof

InactiveCN104863084AAffects the effect of resuspensionMaintain propertiesHydraulic modelsBrushless motorsSiphon

The invention relates to a device for simulating reciprocating flow riverway in-situ bottom mud resuspension and a simulation technology thereof. According to the device for simulating the reciprocating flow riverway in-situ bottom mud resuspension, an upstream flow water level control device comprises a first water inlet pipe, an upstream water level control water tank, an upstream backflow simulation water tank, a first siphon backflow pipe and a first water outlet pipe; a water tank device comprises a water tank body, a bottom mud tank, a flow velocity gauge, a turbidity meter and at least two sampling ports; a downstream tide simulation control device comprises a tide water level control tank, a second siphon backflow pipe, a tide backflow simulation water tank, a backflow water tank, an overflow pipe, a variable frequency water pump and a second water outlet pipe; an experiment platform automatic control device comprises a first resistance-type liquid level meter, a second resistance-type liquid level meter, a first pulling line, a second pulling line, a first direct current brushless motor, a second direct current brushless motor, a first movable pulling plate and a second movable pulling plate. The simulation technology comprises the steps of bottom mud preparing, overlying water preparing, flow velocity gauge and turbidity meter installing, unidirectional flow simulating, tide reciprocating flow simulating and water sample measuring. The simulation accuracy is high, and the device for simulating the reciprocating flow riverway in-situ bottom mud resuspension and the simulation technology thereof can be popularized.

Owner:HOHAI UNIV

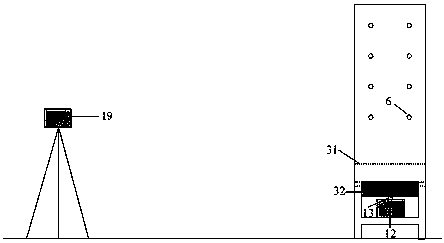

Well-drilling safety intelligent monitoring method and well-drilling safety monitoring alarming device

The invention discloses a well-drilling safety intelligent monitoring method for monitoring liquid flow speed at an outlet of an overflow pipe and alarming while achieving an alarming condition. According to the well-drilling safety intelligent monitoring method, the well kick or well leakage dangerous case can be timely detected in the early days. The monitoring on the liquid flow speed is in real time, so that the misinformation situation as a mud tank is avoided and the safety stability is increased. The invention also discloses a well-drilling safety monitoring alarming device which comprises an outlet flow meter utilizing a sonar sensor to monitor the liquid flow speed at the outlet. Due to the non-contact property of the sonar sensor, the stability of the work of the outlet flow meter is ensured, the conditions, such as fault operation, caused by the blocking of the mud slurry are avoided, and the stability of the well-drilling safety monitoring alarming device is increased.

Owner:SICHUAN GUANGHAN HENGSHENG PETROLEUM EQUIP

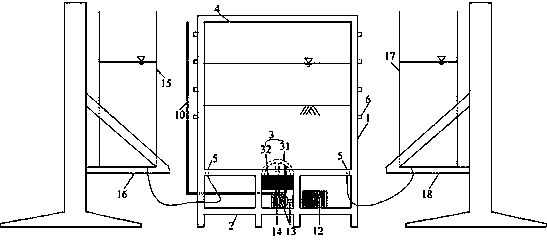

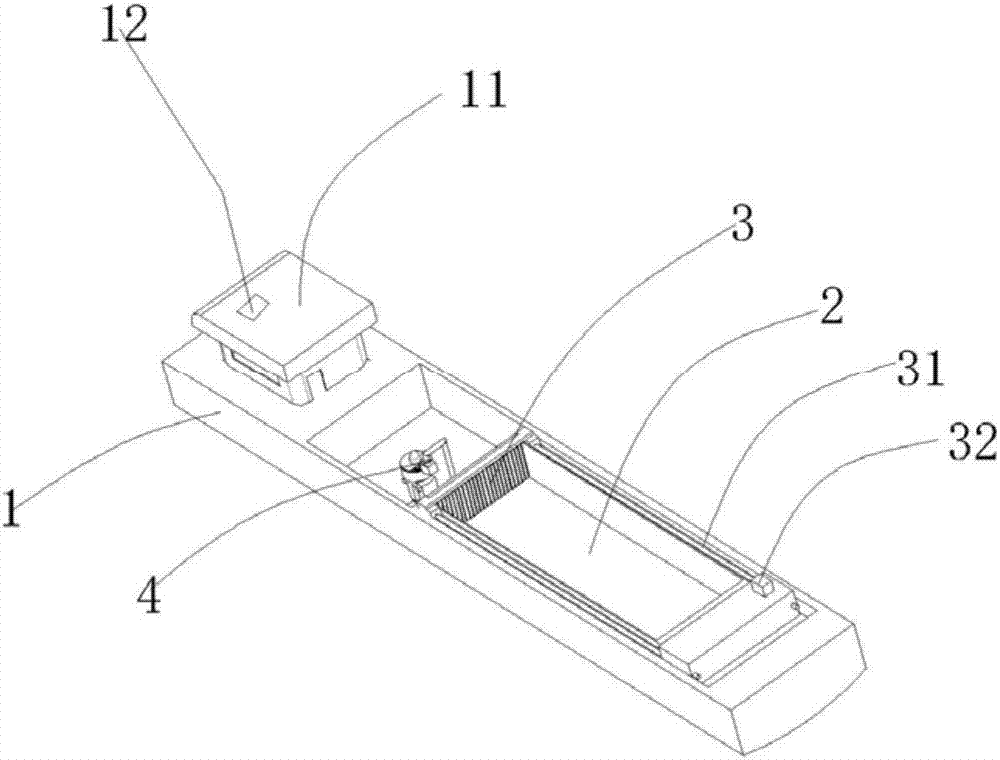

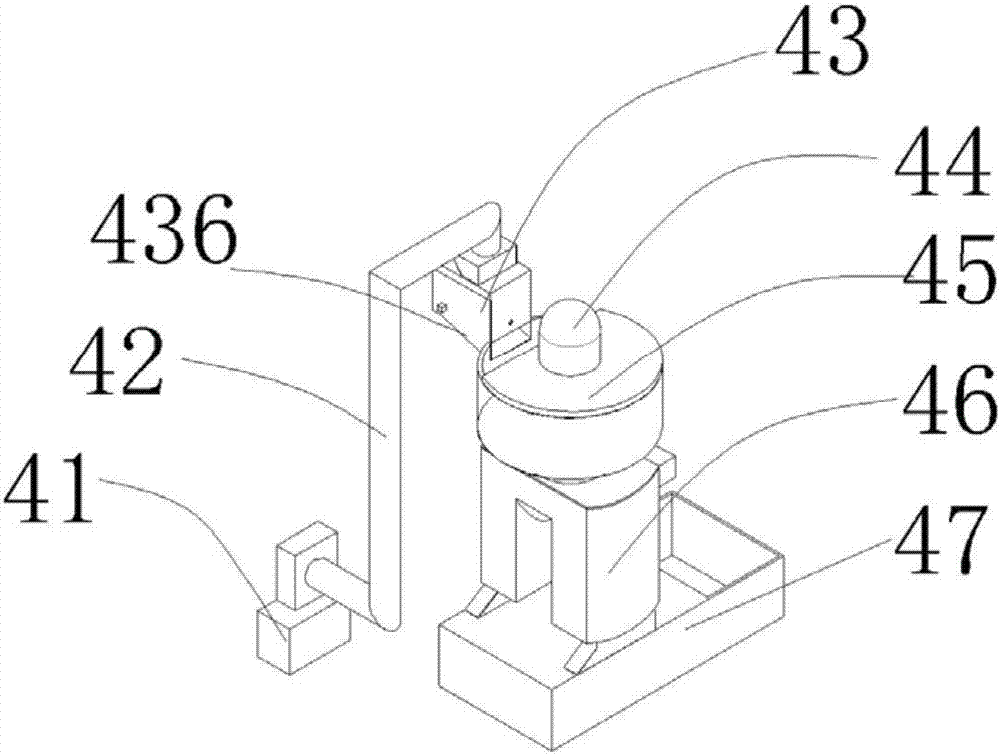

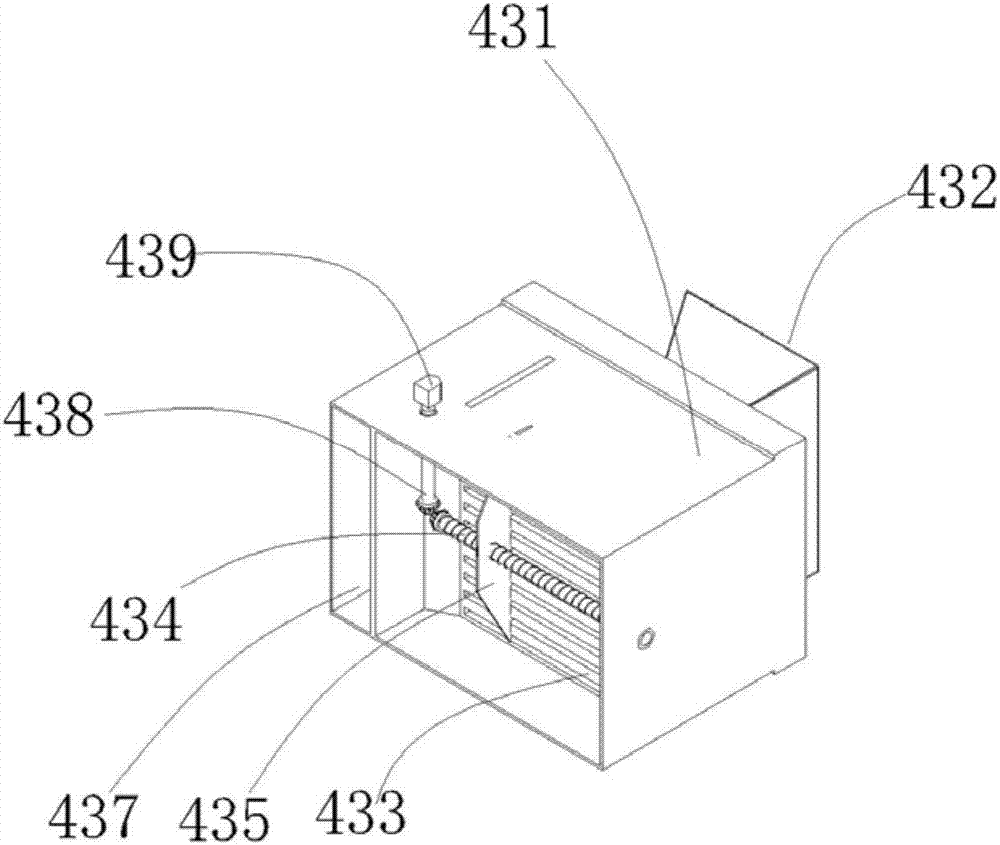

Seabed shield tunnel excavation testing device under seepage condition and method

ActiveCN108489892ARich water and soil loadEarth material testingUsing mechanical meansOcean bottomEngineering

The invention discloses a seabed shield tunnel excavation testing device under a seepage condition and a method. The device comprises a mold tank, a lifting device and a testing auxiliary device, wherein the mold tank comprises a filling tank (1), a steel bracket (2) and an excavation module (3); the filling tank (1) is mounted above the steel bracket; the excavation module is arranged in the middle of the steel bracket; the lifting device comprises a speed reduction motor (12), a screw rod (13) and a gear train (14); the testing auxiliary device comprises a first external water tank (15), a second external water tank (17), a first lifting rack (16) and a second lifting rack (18); the excavation module (3) consists of a moveable baffle plate (31) and a fixing sleeve (32). The method comprises the following steps: flattening a field, arranging equipment, preparing a soil sample, saturating a soil body, adjusting a water level, forming seepage, carrying out tests, recording data, cleaning the filing tank, and repeating the tests.

Owner:EAST CHINA JIAOTONG UNIVERSITY

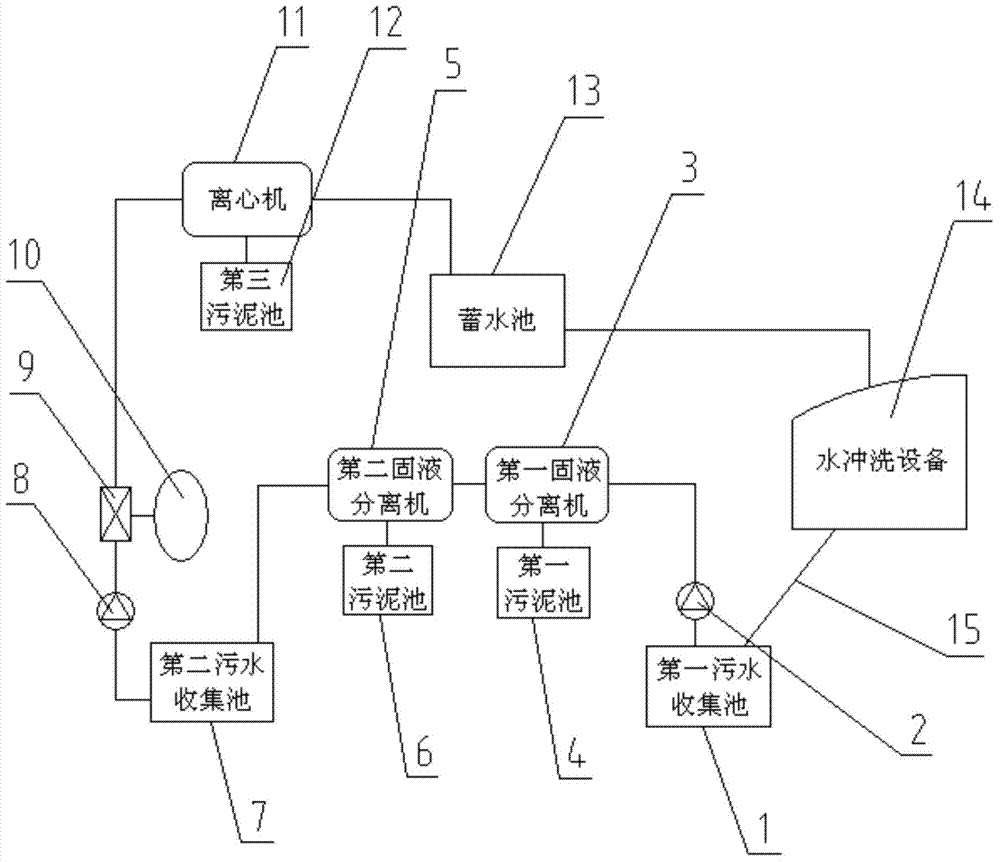

Mud sewage treatment recycling system

The present invention provides a mud sewage treatment recycling system, which is characterized by comprising: a first sewage collection tank; at least a solid-liquid separator connected with the first sewage collection tank, wherein the middle is provided with a first water pump, and the solid-liquid separator is connected with a mud tank; a second sewage collection tank connected with the solid-liquid separator; a centrifuge connected with the second sewage collection tank, wherein the middle is provided with a second water pump and a mixer, the mixer is connected to an agent adding device, and the centrifuge is connected with a mud tank; and a water storage tank connected with the centrifuge. According to the invention, with the multi-stage solid-liquid separation, the mud and the water in the mud water can be separated and recycled so as to achieve the pollution-free emission and the water recycling.

Owner:开阳县鱼上建安硅矿(普通合伙)

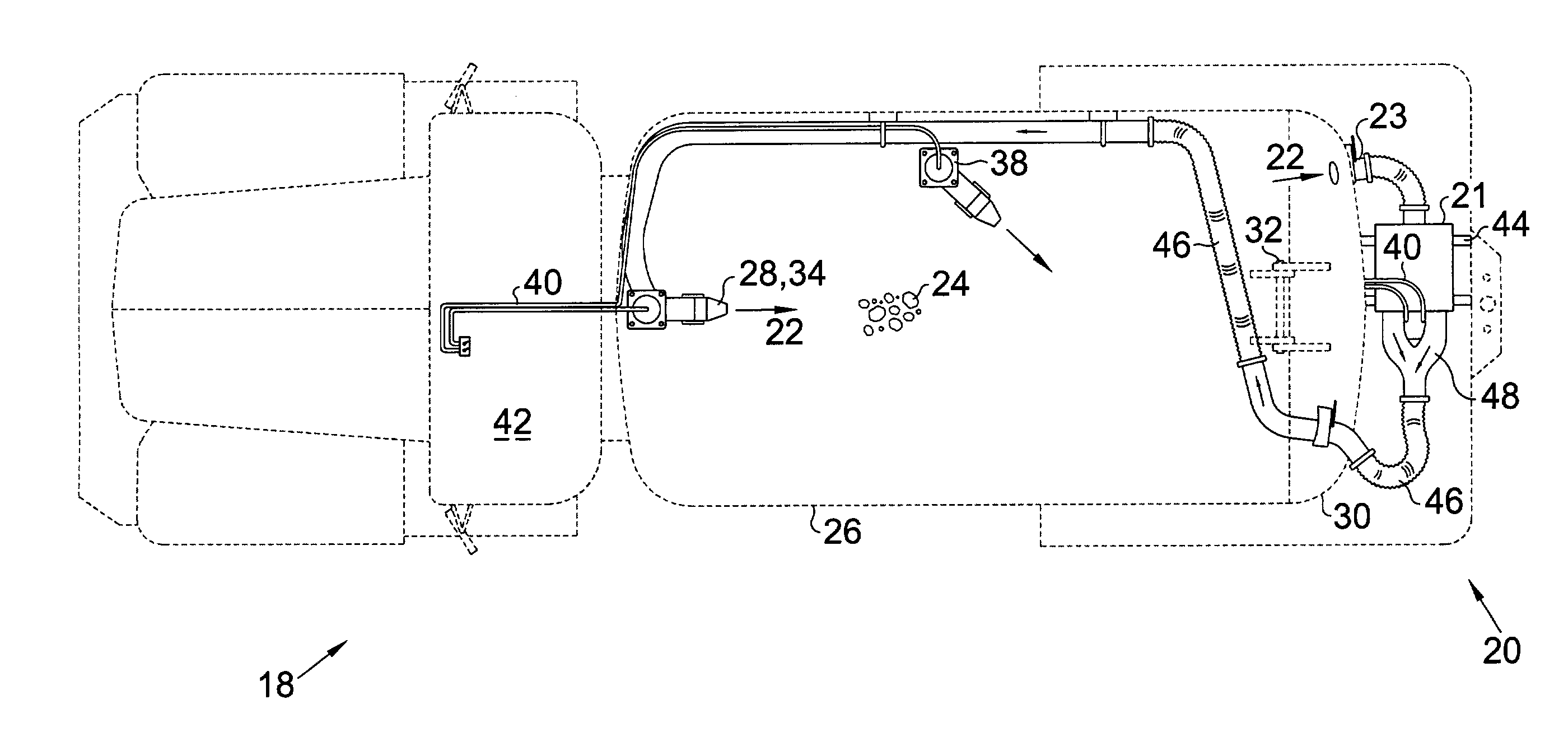

Waste mud agitation system

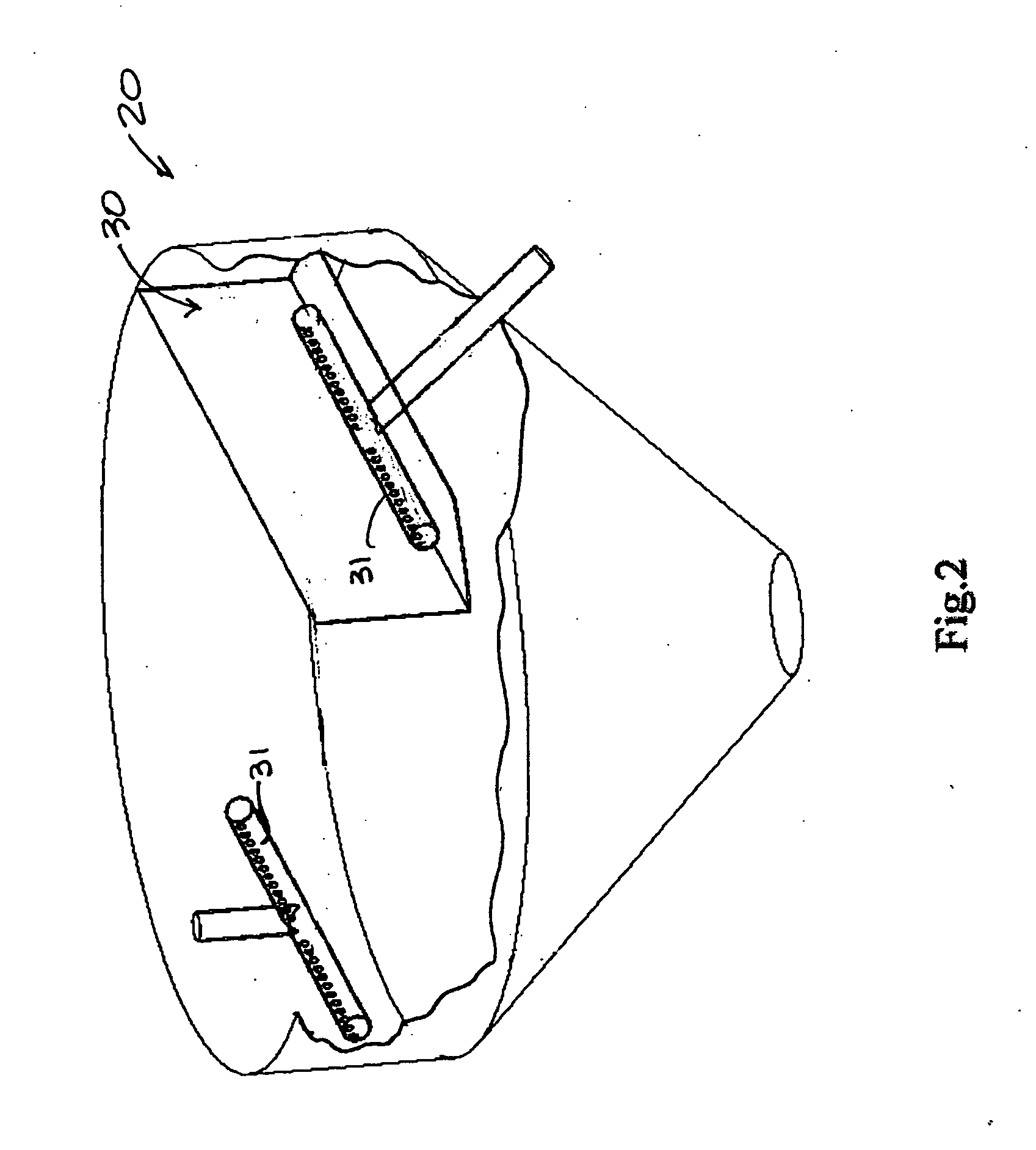

InactiveUS6997599B2Eliminate heavy and messyPromote efficient dumpingFlow mixersTransportation and packagingSludgeTruck

An agitation system for a mud tank to prevent core material initially suspended in the drilling mud, from settling. The method agitates sludge and eliminates the need to hand shovel sludge from the tank after dumping. The method comprises the step of pumping mud taken from within the tank through a permanently mounted rubber nozzle directed at mud on a bottom portion of the tank. In a preferred aspect of this invention the tank is a cylindrical and longitudinally mounted on a truck for waste mud hauling, and has a rear end cap hinged to a top portion of the tank, so that when a front portion of the tank is marginally elevated and the end cap is hinged opened, mud dumps from a rear end portion of the tank.

Owner:GALLUP GORDON LEROY

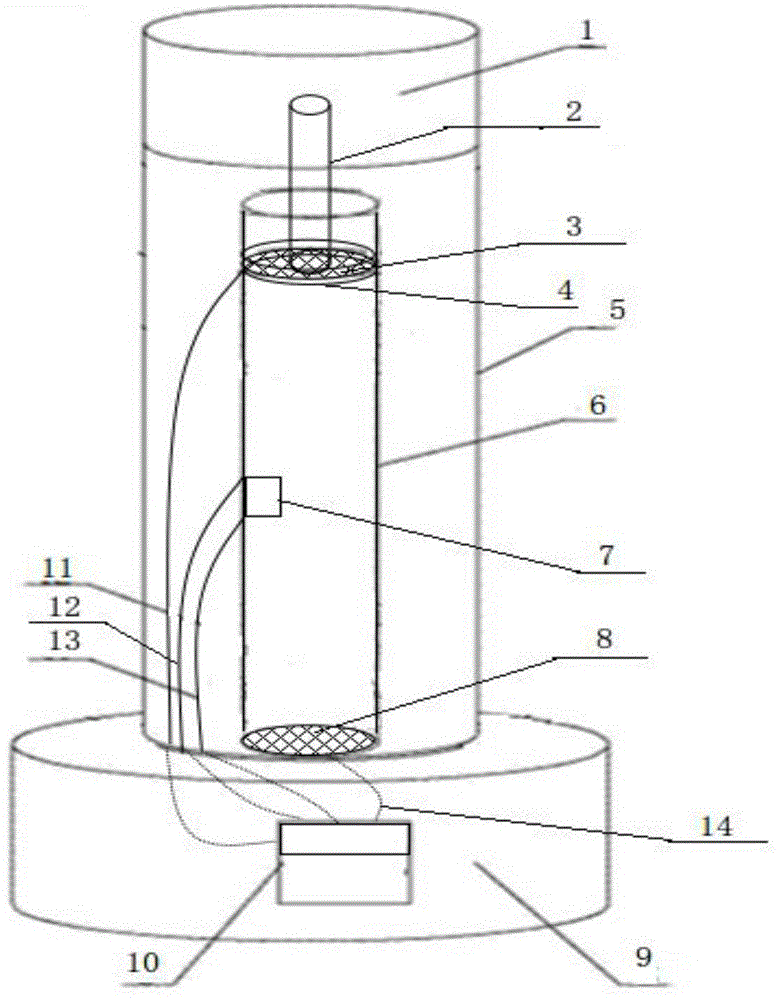

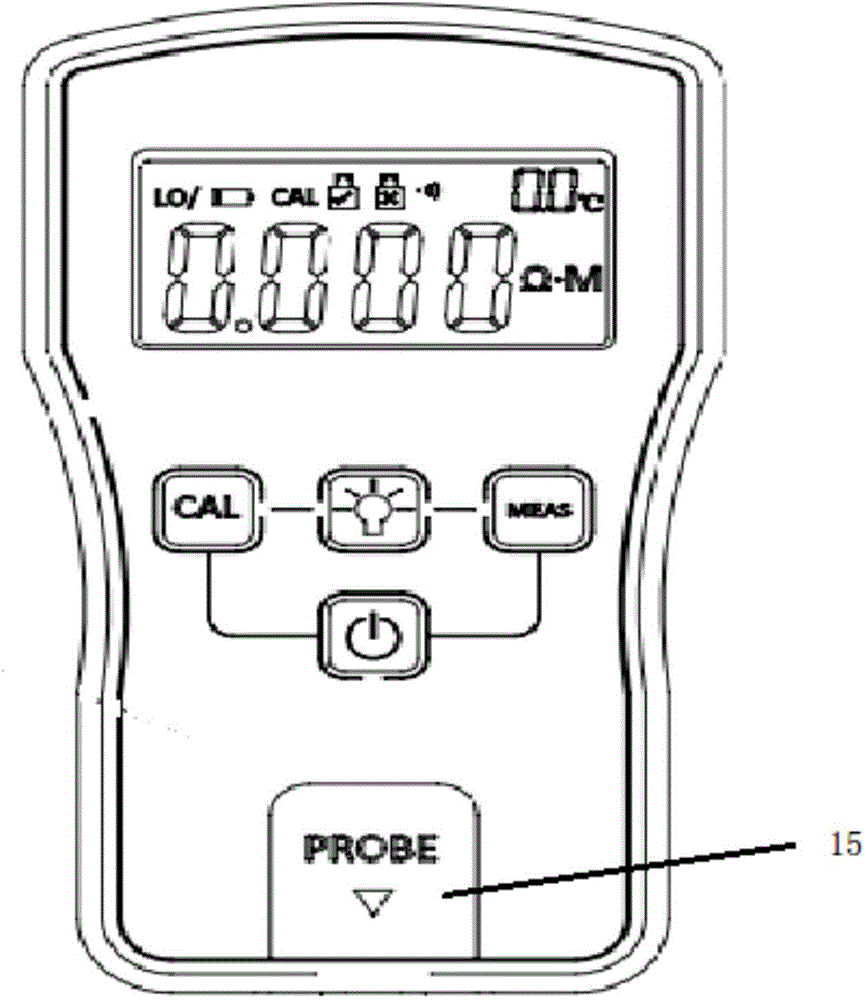

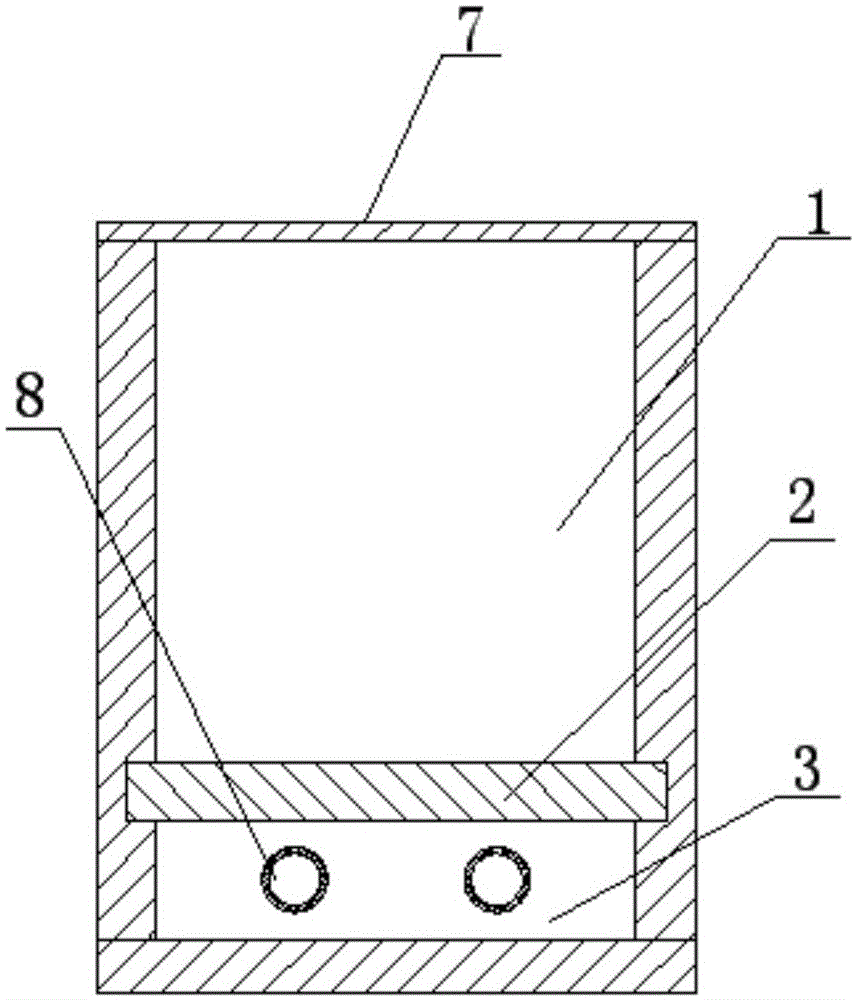

Power grid pole mud resistivity measurement system

InactiveCN104407227AImprove portabilityReduce distractionsFluid resistance measurementsMaterial resistanceWell loggingUSB

The invention relates to the well logging field and discloses a power grid pole mud resistivity measurement system. The power grid pole mud resistivity measurement system of the invention comprises a mud tank and a handheld device; the handheld device comprises a resistance measurement module, a temperature measurement module, a resistivity calculation module and a USB interface; the mud tank comprises a mud tank body, a sealing cover and a USB base; an upper power grid electrode is arranged in the sealing cover; a lower power grid electrode is arranged in the mud tank; the USB base is provided with a USB connector; and the handheld device is connected with the mud tank through a USB. The power grid pole mud resistivity measurement system can provide a uniform electric field for mud in measurement, so that the accuracy of mud resistivity measurement can be improved; the USB communication interface is adopted, so that wiring is not required, and therefore, convenient operation and little possibility of making mistakes can be realized; two grounding ends are arranged in a circuit, and therefore, circuit interference can be can effectively reduced. With the power grid pole mud resistivity measurement system of the invention adopted, the size of a mud resistivity measurement instrument can be effectively decreased, and the portability of the instrument can be enhanced. According to the power grid pole mud resistivity measurement system, resistivity measurement and temperature measurement are combined together, and therefore, measuring precision can be ensured, and workload of measurement work can be decreased.

Owner:BITSWAVE SUZHOU

Concrete classifying and reclaiming system

The invention discloses a classified recovery system of concrete, which is characterized in that gravel, sand, mud and water are separated from concrete by a gravel separation device and a sand separation device. A fluid reservoir is arranged at the bottom of the worktable of the gravel separation device while a separator at the top. The feed port of the separator is connected with a tilting chute, and the separator outlet is connected with one end of a conveyor, while the other end of the conveyor is connected with a gravel tank. One end of the sand separation device, which is a fluid conveying pipe, is arranged in the fluid reservoir while the other end is connected with the inlet of a primary cyclone. The fluid outlet of the primary cyclone is connected with the inlet of a secondary cyclone through the fluid conveying pipe while the fluid outlet of the secondary cyclone is connected with a mud tank also through the fluid conveying pipe; the discharge ports of the primary and secondary cyclones are respectively connected with a spiral conveyor located on the top of the worktable through the fluid conveying pipe, and the delivery end of the spiral conveyor is connected with a sand tank. The invention has the advantages of waste reclamation, raw materials saving and environmental pollutions preventing.

Owner:尹钟喆

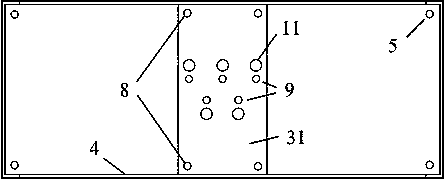

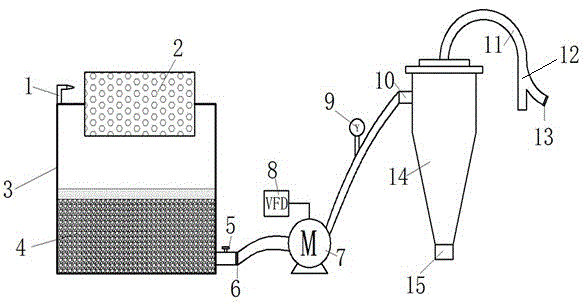

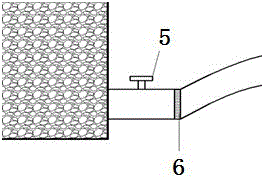

Sorting method and device for contaminated soil particles with different particle sizes

ActiveCN105618281ARealize sortingControl pressureVortex flow apparatusContaminated soil reclamationSoil scienceEnvironmental engineering

The invention discloses a sorting method and device for contaminated soil particles with different particle sizes. The sorting device comprises a water spraying pipe 1, a drum screen 2, a mud tank 3, a filter screen 6, a mud pump 7, a hydrocyclone feed port 10, an overflow pipe 11, a filter screen 13, a hydrocyclone 14 and a desilting port 15, wherein the water spraying pipe 1 and the drum screen 2 are both fixedly installed on the mud tank 3; the mud pump 7 is connected with the mud tank 3 and the hydrocyclone feed port 10 through mud pipelines correspondingly, and the filter screen 6 is arranged in the mud pipeline between the mud pump 7 and the mud tank 3; the overflow pipe 11 is installed on the hydrocyclone 14, and the filter screen 13 is installed at the end of the overflow pipe 11; the desilting port 15 is formed in the bottom of the hydrocyclone 14. The sorting method and device have the advantages that the technique is simple, the sorting effect is good, the device is suitable for various weather environments, the application range is wide, and subsequent drip washing cost can be reduced; the method and device have extremely good application prospects.

Owner:SUN YAT SEN UNIV

Waste mud agitation system

InactiveUS20040231891A1Eliminate heavy and messyPromote efficient dumpingFlow mixersTransportation and packagingSludgeTruck

An agitation system for a mud tank to prevent core material initially suspended in the drilling mud, from settling. The method agitates sludge and eliminates the need to hand shovel sludge from the tank after dumping. The method comprises the step of pumping mud taken from within the tank through a permanently mounted rubber nozzle directed at mud on a bottom portion of the tank. In a preferred aspect of this invention the tank is a cylindrical and longitudinally mounted on a truck for waste mud hauling, and has a rear end cap hinged to a top portion of the tank, so that when a front portion of the tank is marginally elevated and the end cap is hinged opened, mud dumps from a rear end portion of the tank.

Owner:GALLUP GORDON LEROY

Sludge discharge equipment comprising vacuum pump and sludge discharge tank

Sludge discharge equipment comprising a vacuum pump and a sludge discharge tank consists of the vacuum pump, an air suction pipe, a sludge storage tank, a liquid level meter, a sludge suction pipe, sludge discharge pipe, a sludge discharge valve, a bell-type valve, the sludge discharge tank, an air inlet valve, an air inlet pipe and a delivery pipe. The sludge storage tank is arranged above the sludge discharge tank, the air suction pipe is arranged on the left end of the sludge storage tank and is connected with the vacuum pump, the liquid level meter is installed at the inner upper part of the sludge storage tank, the sludge suction pipe is arranged on the right end of the sludge storage tank and extends into sludge in a water sump, the sludge discharge pipe is arranged below the right end of the sludge storage tank and is provided with the sludge discharge valve, and the sludge in the water sump is sucked into the sludge storage tank from the water sump under the action of the vacuum pump. The sludge discharge tank is arranged below the sludge storage tank, a feed port is formed in the upper end of the sludge discharge tank and is connected with the bell-type valve for controlling slurry to flow into, the air inlet pipe and the air inlet valve are arranged on the left upper end of the sludge discharge tank for controlling high pressure air to flow into the sludge discharge valve, and the delivery pipe is installed on the right upper end of the sludge discharge tank for delivering the slurry. The sludge discharge equipment has the advantages of simple equipment, convenience in maintenance, large delivery capacity, long service life, long delivery distance and less investment.

Owner:CENT SOUTH UNIV

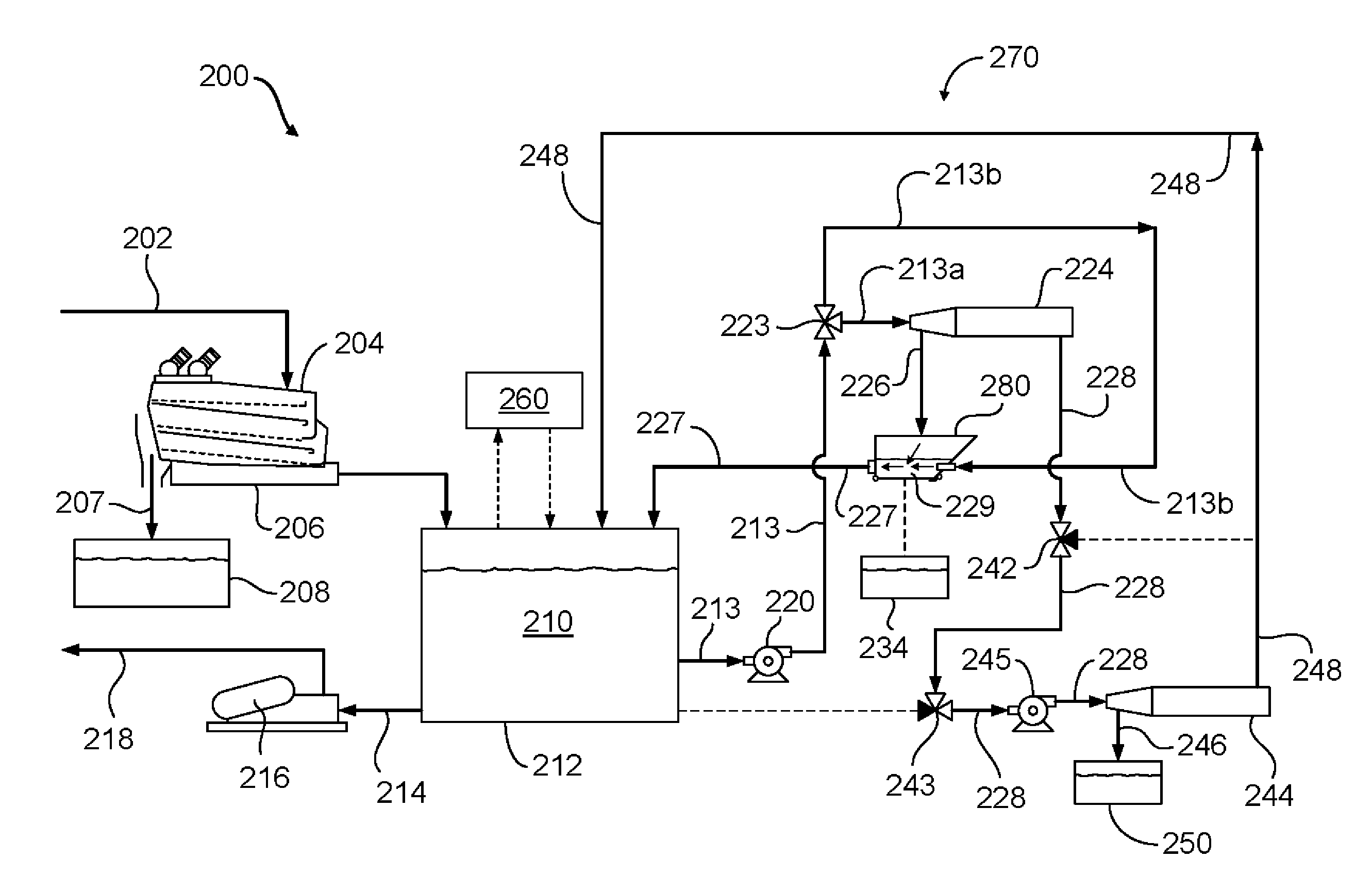

System, apparatus, and method for recovering barite from drilling fluid

A barite recovery hopper includes a shell having an open top, wherein the barite recovery hopper is adapted to receive a flow of recovered barite particles from a solids discharge chute of a decanter centrifuge through the open top of the shell. An inlet is adapted to receive a flow of drilling mud from a mud tank. A hopper bypass gate is adapted to seal a bottom opening of the shell when the hopper bypass gate is in a closed position during a barite recovery operation, and to allow collection of at least a portion of the recovered barite particles for mixture, inside of the barite recovery hopper, with the flow of drilling mud received through the inlet when the hopper bypass gate is in the closed position. An outlet is adapted to discharge a flow of the recovered barite particle / drilling mud mixture to the mud tank.

Owner:VARCO CANADA ULC

System and method for deep nitrogen and phosphorus removal and resource recovery of AAO-BCO process

PendingCN107758866AAchieve reductionImplement resourcesTreatment using aerobic processesWater contaminantsSludgeMagnesium salt

The invention discloses a system and method for deep nitrogen and phosphorus removal and resource recovery of an AAO-BCO process. The system comprises an AAO-BCO system which is formed by sequentiallyconnecting a raw water tank, a water inlet pump, an AAO reactor, a middle settling tank, a middle water tank, a middle water inlet pump, a biological contact oxidation tank and a settling region, wherein a mud discharging pipe at the bottom of the middle settling tank and the bottom of the settling region are connected with a mud storage tank through a mud discharging valve I and a mud discharging valve II, respectively, the mud storage tank is sequentially connected with a fermentation tank, a nitrogen and phosphorus recycling tank and a liquid storage tank, the top of the fermentation tankis connected with an alkali liquid dosing tank through a lifting pump II, and a mud discharging valve IV is arranged at the bottom of the fermentation tank; and the top of the nitrogen and phosphorusrecycling tank is connected with a magnesium salt solution dosing tank through a lifting pump I, a mud discharging valve III is arranged at the bottom of the nitrogen and phosphorus recycling tank, and the liquid storage tank is connected with the raw water tank through a lifting pump III. According to the system and the method, the deep nitrogen and phosphorus removal and the resource utilizationof sludge of the AAO-BCO process are realized under a low C / N sewage condition.

Owner:YANGZHOU JIEYUAN DISCHARGE WATER CO LTD

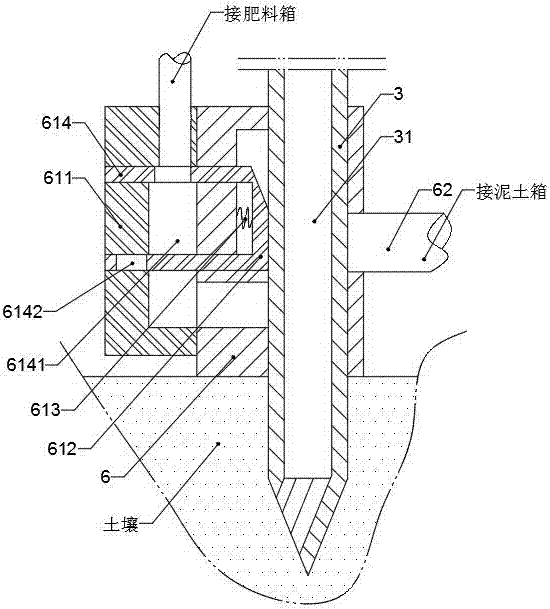

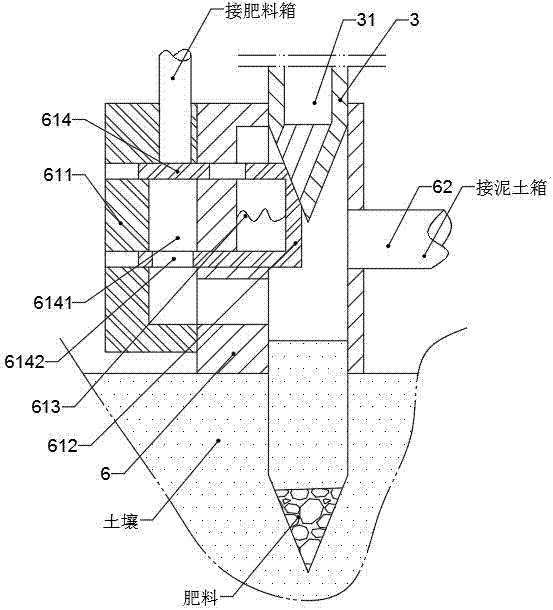

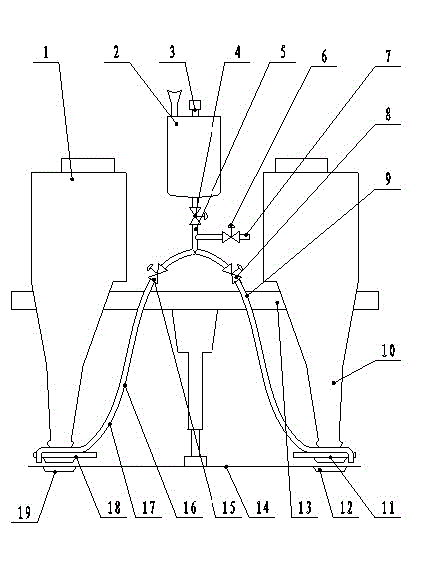

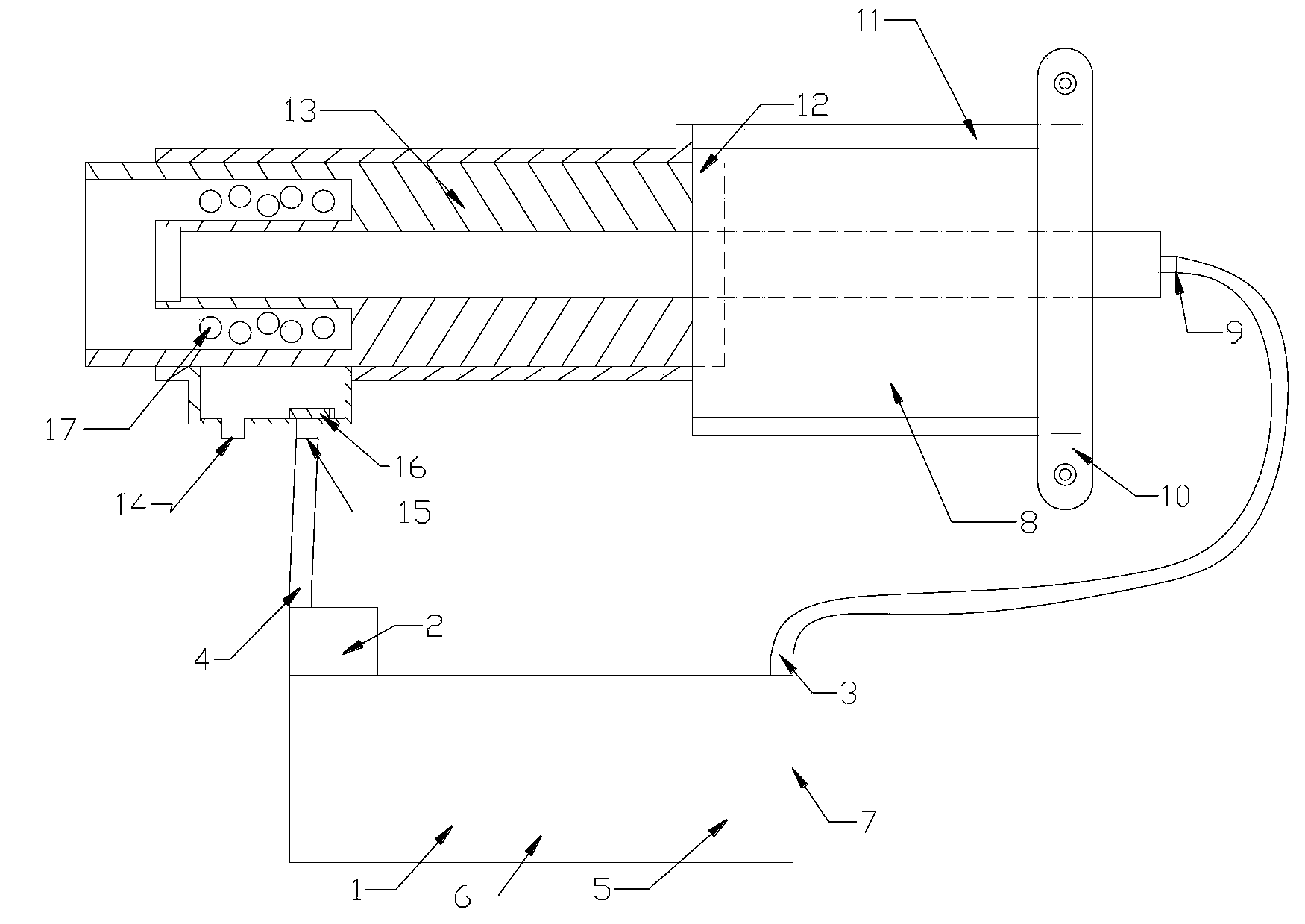

Crop fertilizer applying device

PendingCN107535123APrevent washout lossReduce wastePlantingFertiliser distributersFertilizerAgricultural engineering

The invention provides a crop fertilizer applying device. The crop fertilizer applying device comprises a rack, a vacuum pump and a conical drill bit; a mud tank and a fertilizer tank are mounted at the top part of the rack, a sleeve is mounted at the bottom part of the rack; a fertilizer filling valve and a mud filling valve are arranged on the inner wall of the sleeve; the fertilizer filling valve and the mud filling valve are respectively communicated with the fertilizer tank and the mud tank; the vacuum pump is communicated with the fertilizer tank; a hollow cavity is arranged in the conical drill bit, a plurality of spiral cutting knives are mounted on the peripheral surface; a gap communicated with the hollow cavity is formed between the two adjacent spiral cutting knives; the conical drill bit penetrates through the sleeve and is rotatably connected with the rack; the conical drill bit is connected with the sleeve in a sliding manner; and the hollow cavity is communicated with the mud tank. According to the provided crop fertilizer applying device, a fertilizer is buried under the soil to prevent the soil from being washed by rainwater and getting lost, the waste is reduced,and the fertilization efficiency is improved.

Owner:重庆市老君利源农业开发有限公司

Coke oven coaling hole sealing device and sealing method thereof

The invention relates to a coke oven coaling hole sealing device and a sealing method of the coaling hole. The device comprises two coal car hoppers, a mud tank, a mud hard pipe and two mud flexible pipes. A tilt angle of each mud flexible pipe is not less that 60 degrees in a horizontal direction, a compressed air control solenoid valve is installed on the mud hard pipe, and the other end of the compressed air control solenoid valve is connected with a compressed air pipe. The sealing method of the coaling hole comprises a step of opening a stirrer installed inside the mud tank; a step of sending a coal-charging hole cover to the coal-charging hole through one of an off-and-on device of the coal-charging hole cover and opening the coal-charging hole; a step of opening the solenoid valve of the mud tank and a mud-entering solenoid valve, closing another mud-entering valve and injecting the mud into sealing grooves of the coal-charging hole cover and a coal-charging base; a step of closing the solenoid valve of the mud tank, opening a control solenoid valve used for compressing air and emptying the mud soft pipe; a step of packing up the sealing device of the off-and-on device of the coal hole cover. The sealing device and the sealing method enable sealing mud of the sealing grooves of coal-charging hole cover and the coal-charging base to be uniform.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

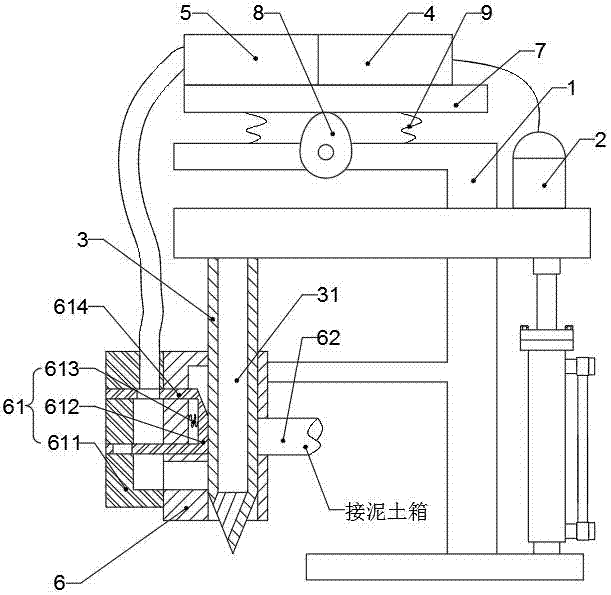

Drilling head separating floor anchoring drill

The invention discloses a drilling head separating floor anchoring drill which comprises a water-rock separating circulator, a hydraulic pump, a motor, a silencer, a velometer, a soil pickup outlet and a hollow transmission shaft. Water inlet holes are formed in the hollow transmission shaft, water is injected into the bottom of a drilled hole through the water inlet holes, the temperature of a drill bit is reduced, and dust is removed. The water-rock separating circulator is divided into a clear water tank and a mud tank by a filter screen, the hydraulic pump is mounted on the upper portion of the water-rock separating circulator, mud (rock powder and water mixture) in the drilled hole is pumped into the mud tank by the hydraulic pump, clear water enters the clear water tank after the mud is filtered, and the clear water is pumped into a water inlet tank by the hydraulic pump and recycled through a clear water inlet hole. Waste of water resources is avoided, rock powder generated in drilling is collected, sticking in drilling of the drill is prevented, the dust is prevented from harming health of workers, the water and the rock powder in the drilled hole are timely pumped out, the water is prevented from weakening floor lithology, and support efficiency is improved. Operation is facilitated, and construction is easily performed.

Owner:CHINA UNIV OF MINING & TECH

Channel integration dredging mud making structure and construction method thereof

InactiveCN107119738AEasy to transportImprove comfortSludge treatment by de-watering/drying/thickeningSoil-shifting machines/dredgersReciprocating motionSludge

The invention discloses an integrated channel dredging and mud-making structure, which includes a barge, a deck house is installed on the deck of the barge, and a control room is arranged under the deck house, and the control room is respectively connected with a GPS positioning device and an AIS system The device is connected with the tide reporting system device, and there is still a mud tank on the barge, and screw guide rails are installed on both sides of the mud tank, and a filter net is installed on the screw guide rail, and the filter net is controlled by a motor It reciprocates on the guide rail of the screw rod to conduct preliminary separation of the sludge. One side of the filter screen is provided with a dredging mud making device. The invention adopts the integrated granulation equipment to process the dredging mud into soil particles on the spot, which makes the dredging mud easy to transport in one step, reduces the cost input, simplifies the working procedure, improves the efficiency, and greatly improves the comfort of the ship operation and security.

Owner:成荣鹏

Indoor fresh ginger germination-accelerating device and using method thereof

The invention discloses an indoor fresh ginger germination-accelerating device. The device comprises mud tanks used for stacking fresh gingers, the mud tanks are formed by piling up bricks and stones, steel plates are arranged at the bottoms of the mud tanks, water tanks are formed below the steel plates, the steel plates are erected above the water tanks, two through long water pipes with small holes are arranged inside the water tanks below the steel plates and connected with external water pipes, the other ends of the external water pipes are connected with a steam boiler, the tops of the mud tanks are covered with seal cloth with small ventilation holes, and a thermometer and a hydrometer are arranged at the portions, on the two steel plates of the water tanks, inside the mud tanks respectively. The thermometer and the hydrometer master germination acceleration of the fresh gingers through the device, in this way, the temperature difference inside the mud tanks is small, the temperature inside the mud tanks is basically kept balanced, then germination acceleration of the fresh gingers succeeds in a one-off mode, and the germination rate of the fresh gingers is increased.

Owner:铜陵南门姜业专业合作社

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com