Sludge discharge equipment comprising vacuum pump and sludge discharge tank

A technology of vacuum pump and sludge discharge tank, applied in mining equipment, drainage, safety devices, etc., can solve the problem of easy damage of water pump, and achieve the effect of long service life, long conveying distance, convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

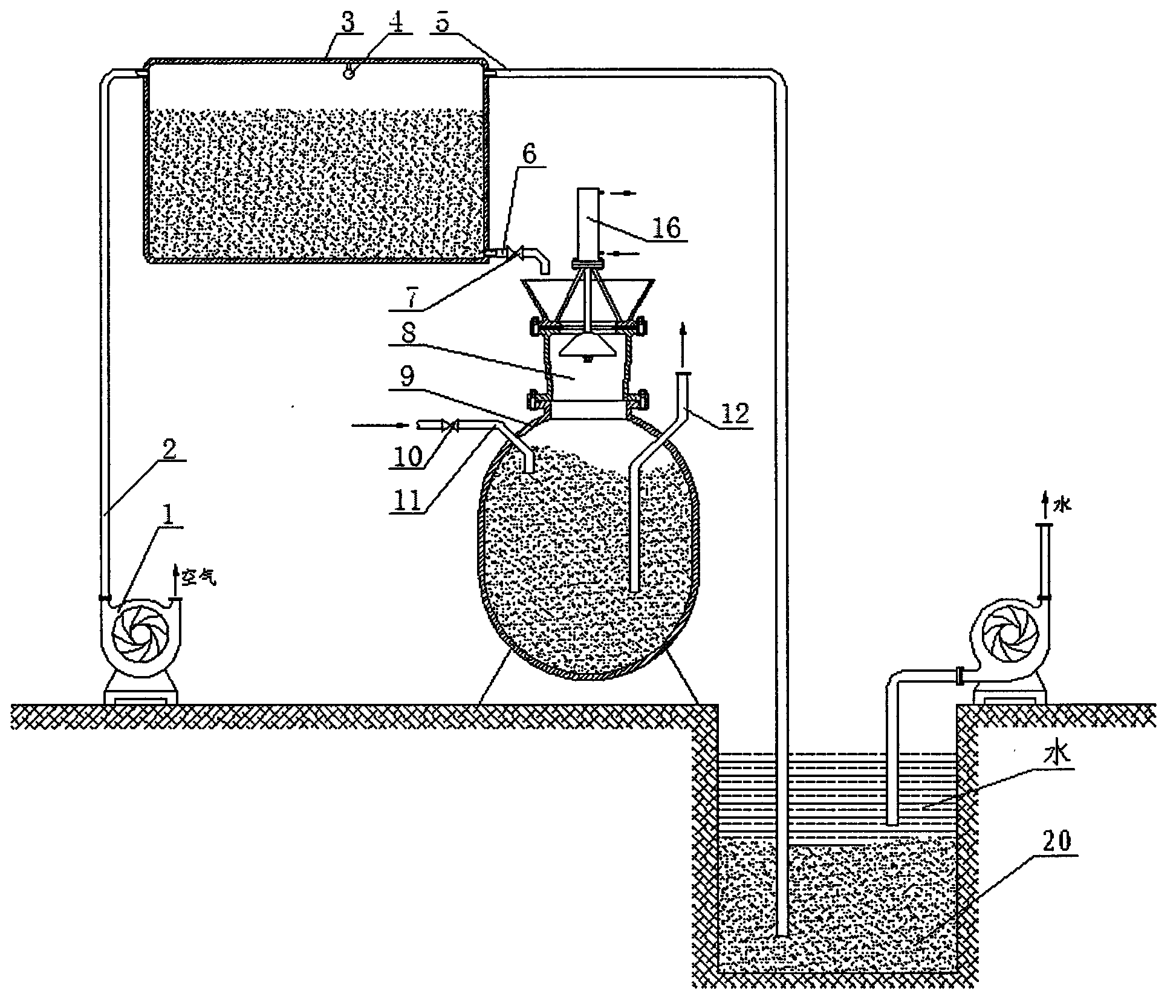

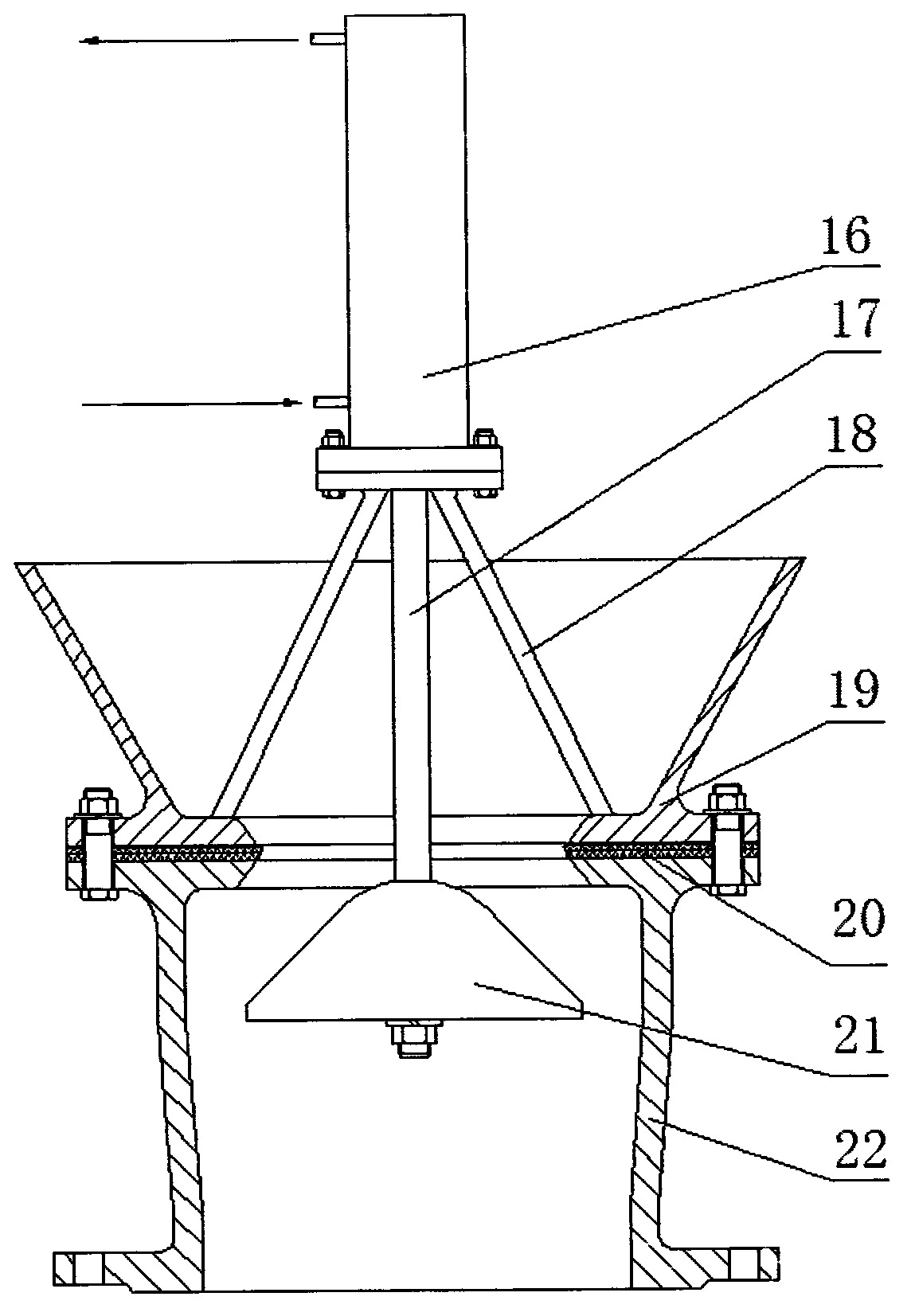

[0016] figure 1 Middle, 1. Vacuum pump, 2. Suction pipe, 3. Mud storage tank, 4. Liquid level gauge, 5. Suction mud pipe, 6. Mud discharge pipe, 7. Mud discharge valve, 8. Bell valve, 9. Discharge Clay pot, 10, air intake valve, 11, air intake pipe, 12, delivery pipe.

[0017] exist figure 1 Among them, the mud storage tank (3) is placed under the mud discharge tank (9), and a suction pipe (2) is arranged above the left end to connect with the vacuum pump (1), and a liquid level gauge (4) is installed above the tank, A mud suction pipe (5) is provided above the right end and goes deep into the silt of the water tank, and a mud discharge pipe (6) and a mud discharge valve (7) are provided below the right end, and the mud is discharged from the water tank under the action of the vacuum pump (1). It is sucked into the mud storage tank (3), and put into the mud discharge tank (9) through the mud discharge valve (7). The mud discharge tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com