Coke oven coaling hole sealing device and sealing method thereof

A technology of coal charging hole and coal charging hole cover is applied in the door/closure of coke oven, coke oven, heating of coke oven, etc. It is convenient for long-distance operation, and the effect of sealing mud is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment is realized on the device embodiment.

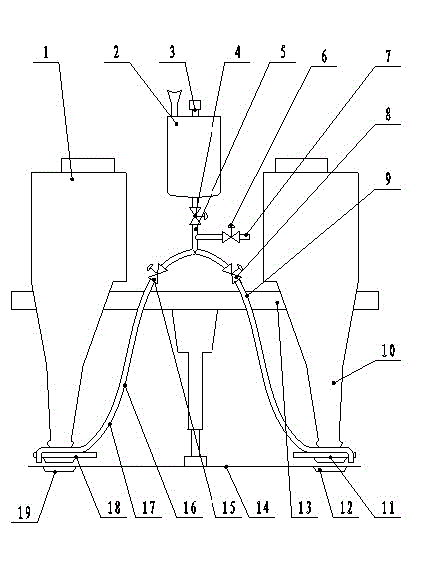

[0032] The embodiment of this coke oven coal charging hole sealing method can be found in figure 1 , which includes the following sequential steps:

[0033] 1. Open the agitator 3 installed in the mud tank 2 to make the mud stir evenly; the ratio of ash and water in the present embodiment is 1:7;

[0034] 2. The opening and closing device 18 of the first coal charging hole cover sends the first coal charging hole cover 19 into the coal charging hole, and closes the coal charging hole;

[0035] 3 Open the mud tank solenoid valve 4 and the first slurry inlet solenoid valve 15, close the second slurry inlet solenoid valve 8, the mud flows from the first mud pipe hose 16 to the opening and closing device 18 of the first coal charging hole cover by its own weight, and injects To the sealing groove between the first coal charging hole cover 19 and the seat;

[0036] 4 After 16 seconds, close the mud tank solenoid valv...

Embodiment 2

[0041] This embodiment is realized on the device embodiment.

[0042] The embodiment of this coke oven coal charging hole sealing method can be found in figure 1 , which includes the following sequential steps:

[0043] 1. Open the agitator 3 installed in the mud tank 2 to make the mud stir evenly; the ratio of ash and water in the present embodiment is 1:7;

[0044]When the sealing operation of the second coal hole cover 12 and the first coal hole cover 19 is carried out continuously, the present embodiment is directly carried out by the following step 2, and the step 1 of the present embodiment is not needed.

[0045] 2. The second coal charging hole cover opening and closing device 11 sends the second coal charging hole cover 12 into the coal charging hole, and closes the coal charging hole;

[0046] 3 Open the mud tank electromagnetic valve 4 and the second slurry inlet electromagnetic valve 8, close the first slurry inlet electromagnetic valve 15, the mud flows from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com