Waste drilling mud recycling water shut-off and profile control technique

A technology of waste mud, water plugging and profile control, applied in chemical instruments and methods, water/sludge/sewage treatment, earth square drilling and mining, etc., can solve the problems of failure to meet the plugging and adjusting process requirements, unstable accumulation volume, and clay dispersion and other problems, to achieve the effect of reducing the cost of the blockage adjustment process, improving the effect of the blockage adjustment process, and simplifying the recovery process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: A kind of drilling waste mud reuse water plugging and profile control process method mentioned in the present invention comprises the following steps:

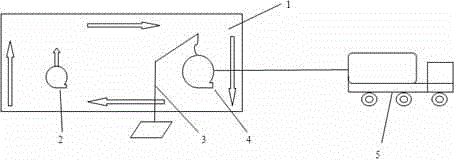

[0026] (a) Use the high-pressure sewage gun 2 to disperse the waste mud in the waste mud pool 1 to make it have a certain fluidity and suspension, and establish a circulation inside the waste mud pool 1. When the mud density in the waste mud pool 1 When it is relatively uniform and the suspension is good, enter the next step;

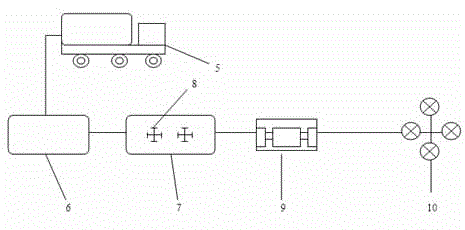

[0027] (b) Use a small crane 3 to lower the submersible mud pump 4 into the bottom of the abandoned mud pool 1, use the impeller of the pump body to fully stir, connect the outlet of the submersible mud pump 4 to the mud tanker 5, and the mud tanker 5 will transport the recovered mud Go to the water plugging and profile control site; repeat pumping in this way until the waste mud in the waste mud pool 1 is pumped clean, and the clean waste mud pool 1 can be backfilled directly with ...

Embodiment 2

[0035] Embodiment 2: A process method for recycling waste drilling mud for water plugging and profile control mentioned in the present invention, wherein the agents prepared at the scene of water plugging and profile control are divided into three types according to their uses: mud early-strength water reducer, mud Stabilizer and mud strengthening agent, the mud early-strength superplasticizer is composed of sodium aluminate, calcium sulfate, and calcium oxide, the proportion is 0.5:1.5:0.5, and the use concentration is 2% of the mud mass fraction; The mud stabilizer is composed of sodium carbonate, sodium sulfite, sodium lignosulfonate, and phenolic resin, the ratio of which is 1.5:2.5:0.5:1.5, and the use concentration is 5‰ of the mud mass fraction; the strengthening agent is composed of silicic acid It is composed of sodium, diethanolamine and ammonium chloride. The ratio is 2.5:0.5:1.5, and the concentration used is 2% of the mud mass fraction.

Embodiment 3

[0036] Embodiment 3: A process method for recycling waste drilling mud for water plugging and profile control mentioned in the present invention, wherein the agents prepared at the scene of water plugging and profile control are divided into three types according to their uses: mud early strength water reducer, mud Stabilizer and mud strengthening agent, the mud early-strength superplasticizer is composed of sodium aluminate, calcium sulfate, and calcium oxide, and its proportion is 1.5:0.5:1.5, and the use concentration is 3% of the mud mass fraction; The mud stabilizer is composed of sodium carbonate, sodium sulfite, sodium lignosulfonate, and phenolic resin, the ratio of which is 2.5:1.5:1.5:0.5, and the use concentration is 6‰ of the mud mass fraction; the strengthening agent is composed of silicic acid Sodium, diethanolamine, ammonium chloride, the ratio is 1.5:1.5:0.5, the concentration used is 3% of the mud mass fraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com