Automatic assembling and detecting device for automobile front grille

A detection device and front grille technology, applied in the direction of measuring device, geophysical measurement, radio wave measurement system, etc., can solve the problems of hidden dangers in operation safety, low degree of automation, unreliable assembly, etc., to achieve firm and reliable assembly, mobile The effect of high degree of automation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

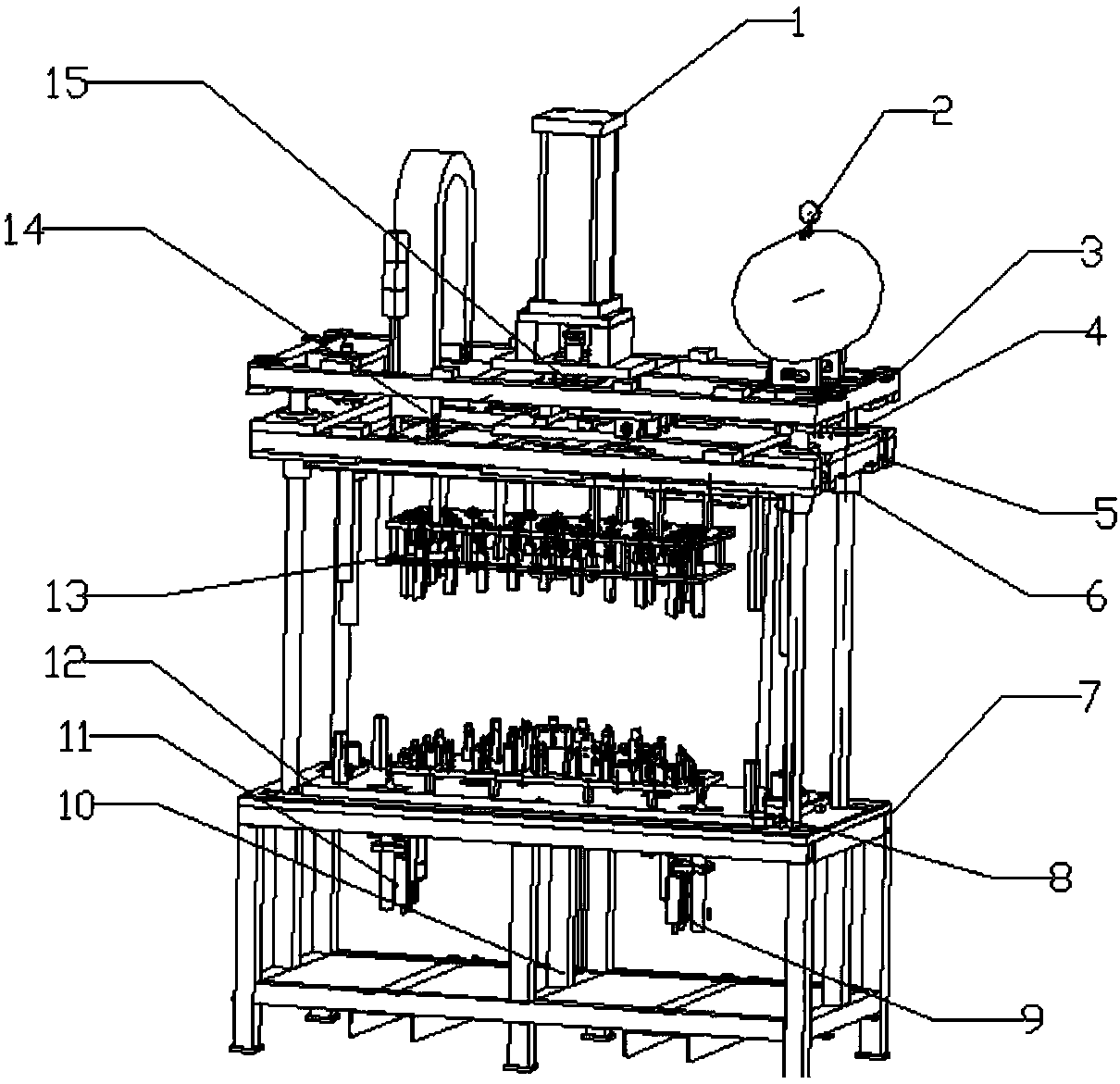

[0044] This embodiment provides an automatic assembly and detection device for the front grille of an automobile, which is used for assembling the front grille of an automobile, such as figure 1 , comprising: a frame 7; a workbench, arranged at the bottom of the frame 7, for placing the front grille of the automobile; a top plate 3, which is horizontally arranged on the top of the frame; a master cylinder 1 and an air storage tank 2, The main cylinder 1 and the gas storage tank 2 are all arranged on the top plate 3; the floating plate 5, the floating plate 5 is horizontally arranged on the frame, and the floating plate 5 is located under the top plate 3, the floating plate 5 and the top plate 3 movable connection, the floating plate 5 can move up and down in the vertical direction; the upper die 13, the upper die 13 is movably connected with the bottom surface of the floating plate 5; the lower die 12, the lower die 12 is set horizontally On the workbench; the lower die 12 is ...

Embodiment 2

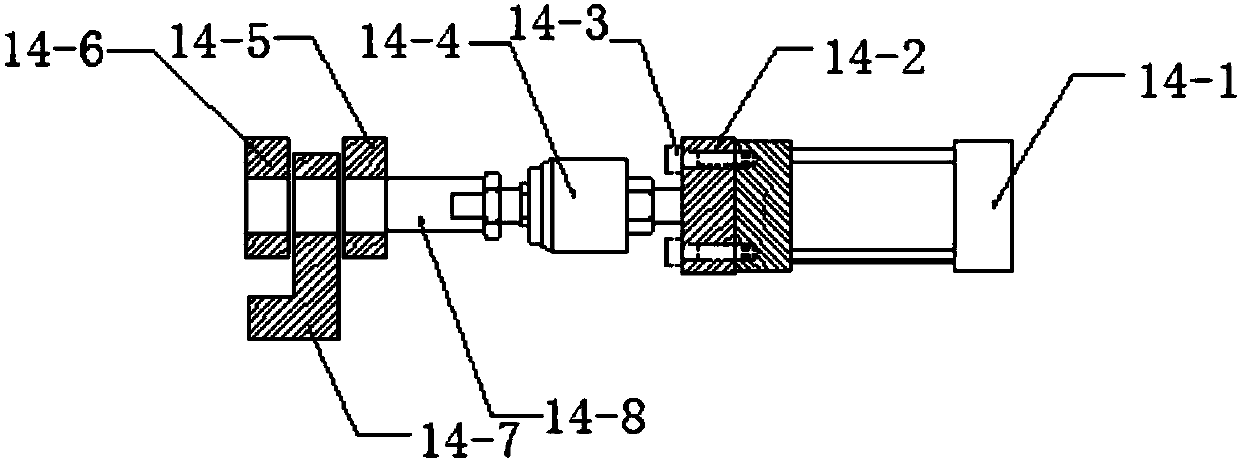

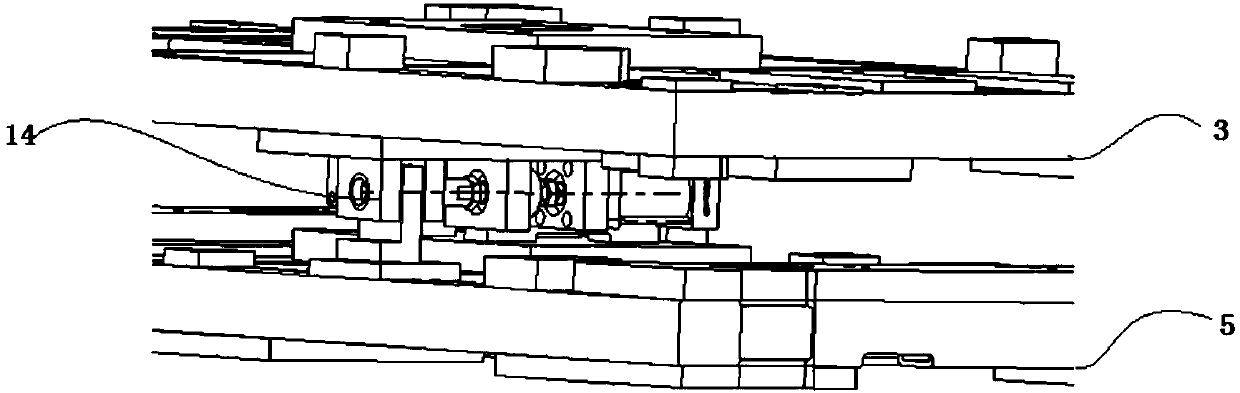

[0047] On the basis of Embodiment 1, this embodiment provides a way to realize the movable connection between the upper die 13 and the bottom surface of the floating plate 5, as shown in Figure 2, the floating plate 5 and the top plate 3 are movable through the safety locking mechanism 14 connection, the safety locking mechanism 14 includes a cylinder 14-1, a first positioning plate 14-2, a cylinder piston rod 14-4, a first connecting plate 14-5, a second connecting plate 14-6, and a third connecting plate 14-7, safety locking pin 14-8, the cylinder 14-1 is connected with the first positioning plate 14-2, the first positioning plate 14-2 is provided with a through hole, the cylinder piston rod 14-4 passes through The through hole on the first positioning plate 14-2 is connected with the safety locking pin 14-8, and the safety locking pin 14-8 is successively connected with the first connecting plate 14-5, the third connecting plate 14-7, and the second connecting plate. The pl...

Embodiment 3

[0051] On the basis of Embodiment 1, this embodiment provides the specific structure of the upper die, as shown in Figure 3 (a), the upper die 13 includes a first fixed plate 13-1, a second positioning plate 13-2 and a plurality of Guide rail 13-3, the first fixing plate 13-1 is parallel to the second positioning plate 13-2, and the first fixing plate 13-1 is located below the second positioning plate 13-2, the first fixing plate It is connected with the second positioning plate 13-2 through a plurality of guide rails 13-3.

[0052] As shown in Figure 3 (b), each guide rail 13-3 includes a linear bearing 13-4, a spring 13-5 and an upper tire mold 13-6 coaxially connected, and the linear bearing 13-4 is connected to the first fixed plate 13-6. 1, and the upper tire mold 13-6 is connected with the second positioning plate 13-2. The upper die in this embodiment is equipped with a spring, which can realize flexible pressing of the front grille of the automobile during processing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com