Chromium-contaminated soil different-position leaching repairing technology and device

A chromium-contaminated soil and leaching technology, applied in the field of contaminated soil remediation, can solve problems such as soil chromium pollution, high chromium toxicity and carcinogenicity, and achieve the effects of reducing the content of heavy metals, increasing the collision probability and strength, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

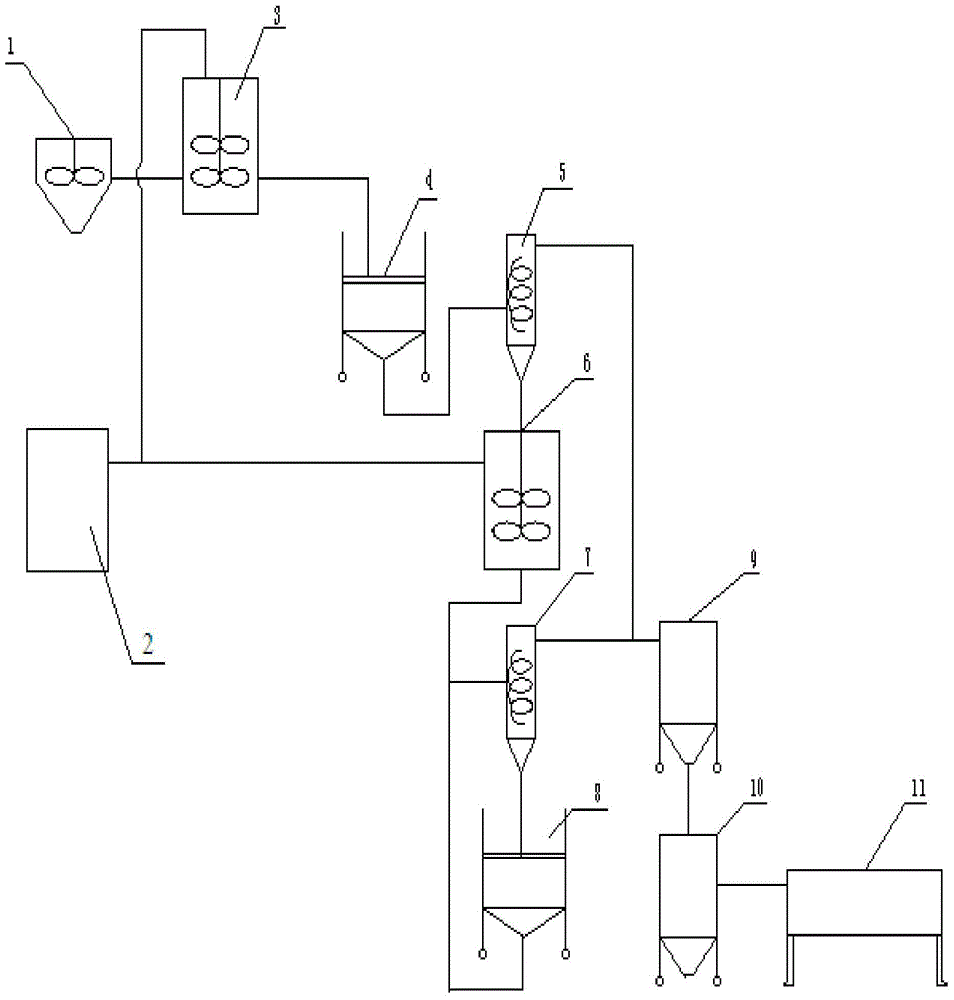

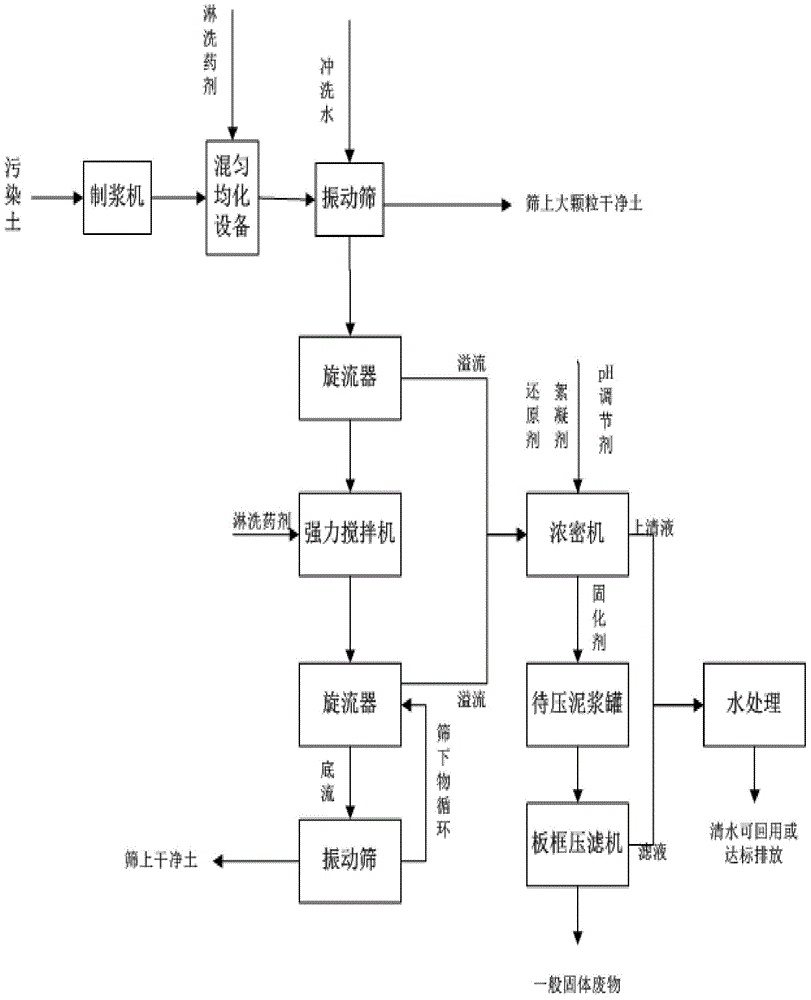

[0046] The contaminated soil was taken from the abandoned site of a chemical plant, with a moisture content of about 25%. The above-mentioned chromium-contaminated soil ectopic leaching and repairing device was used for leaching and repairing, including the following steps:

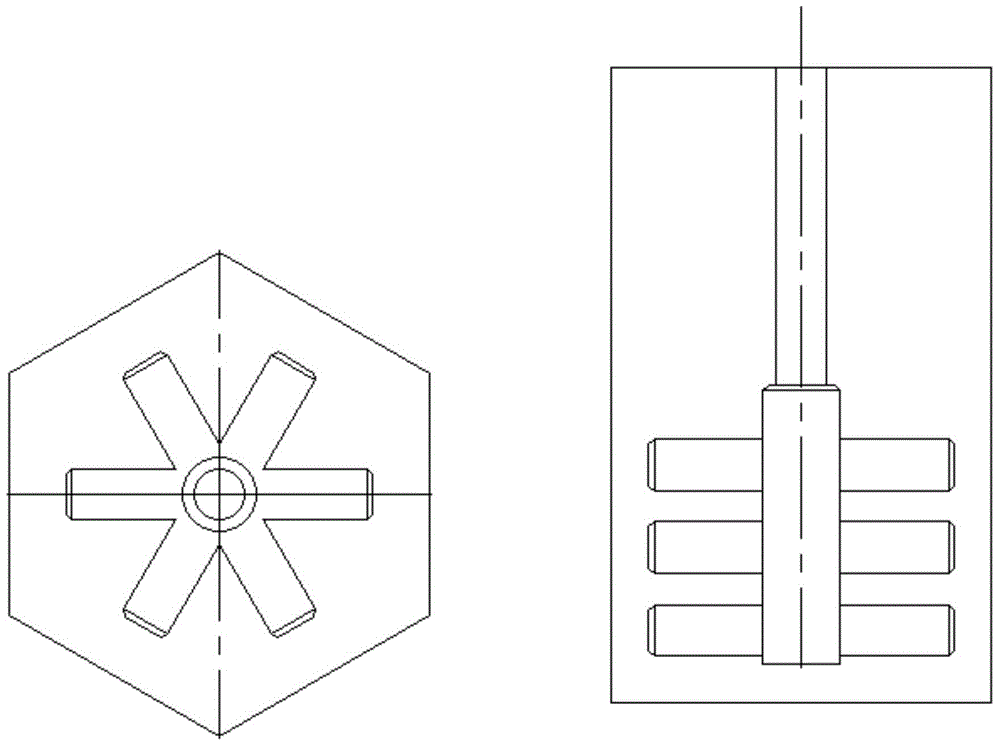

[0047] (1) First-level leaching: After adding water to the contaminated soil, it is made into a slurry with a solid concentration of 500g / L in the pulper, and then pumped to the mixing and homogenizing equipment, and at the same time added to the mixing and homogenizing equipment 60g / kg soil leaching agent ferrous sulfate (FeSO 4 ), turn on the mixing and homogenizing equipment for the first rinsing, the rinsing time is 40min, after the rinsing is over, the slurry is pumped to the first-level vibrating screen for screening and rinsed with a certain amount of flushing water, the screen surface is in the motor Under the action of the generated exciting force, it moves longitudinally, and the large-grained m...

Embodiment 2

[0052] The contaminated soil was taken from the abandoned site of the electroplating workshop of a machinery factory, with a moisture content of about 30%. The above-mentioned chromium-contaminated soil ectopic leaching and repairing device was used for leaching and repairing, including the following steps:

[0053] (1) Primary leaching: After adding water to the contaminated soil, it is made into a slurry with a solid concentration of 600g / L in the pulper, and then pumped to the mixing and homogenizing equipment, and at the same time added to the mixing and homogenizing equipment 40g / kg soil leaching agent ferrous sulfate (FeSO 4 ), turn on the mixing and homogenizing equipment for the first rinsing, the rinsing time is 30min, after the rinsing, the slurry is pumped to the first-level vibrating screen for screening and rinsed with a certain amount of flushing water, the screen surface is in the motor Under the action of the generated exciting force, it moves longitudinally, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com