Well-drilling safety intelligent monitoring method and well-drilling safety monitoring alarming device

An intelligent monitoring and drilling technology, applied in wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve problems affecting accurate measurement, flow meter failure, alarm, etc., to increase safety and stability, increase stability , Guarantee the effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

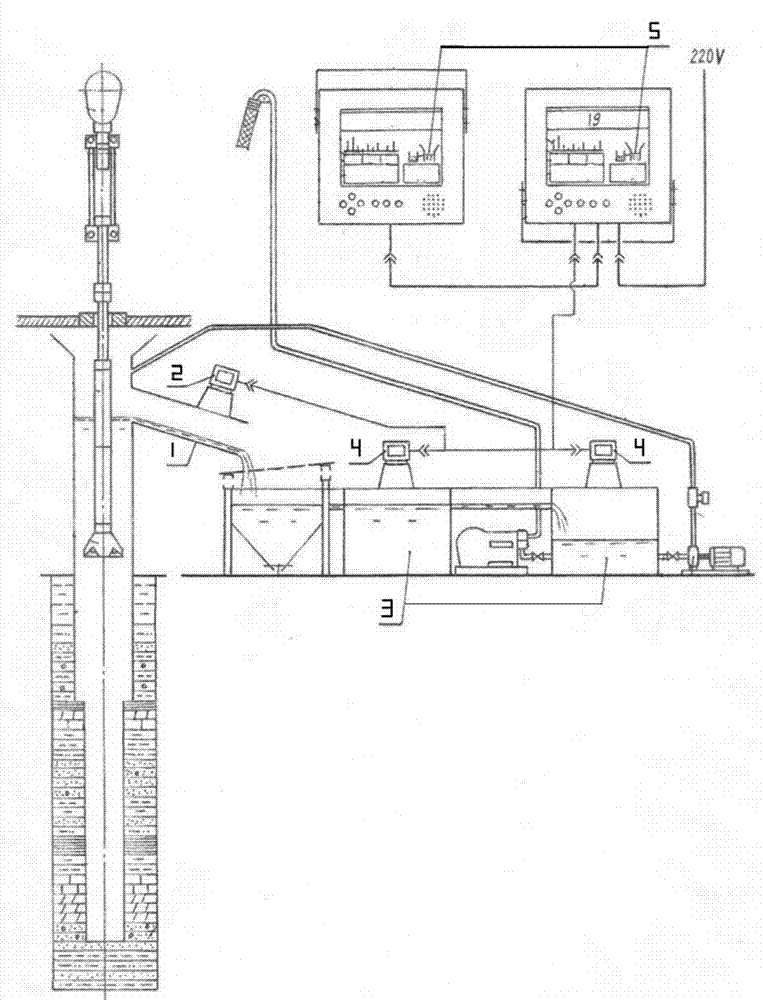

[0026] A drilling safety intelligent monitoring method mainly consists of the following steps:

[0027] S1: Measurement step: measure the liquid flow velocity and liquid temperature at the outlet of the overflow pipe; measure the liquid volume in the mud tank;

[0028] S2: Early warning step: if the liquid flow velocity variation reaches the first velocity increment warning value, such as 1L / s, a well kick warning is performed; if the fluid flow velocity variation reaches the second velocity increment warning value, For example, 2L / s, a well kick alarm will be issued; if the liquid flow velocity change reaches the third speed increment warning value, such as 3L / s, an emergency well kick alarm will be issued;

[0029] At the same time, if the liquid flow velocity variation reaches the first velocity decrement early warning value, such as -1L / s, a lost circulation warning is performed; if the fluid flow velocity variation reaches the second velocity decrement early warning value...

Embodiment 2

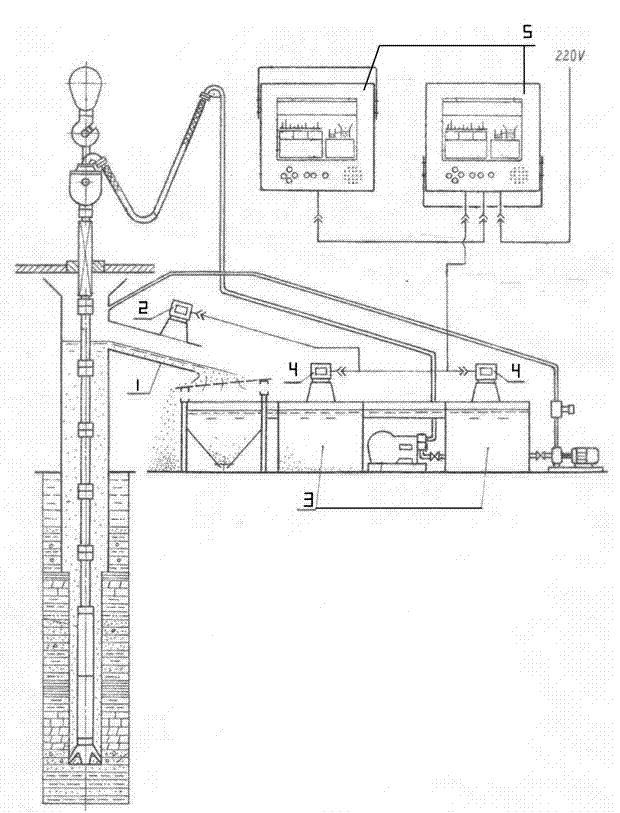

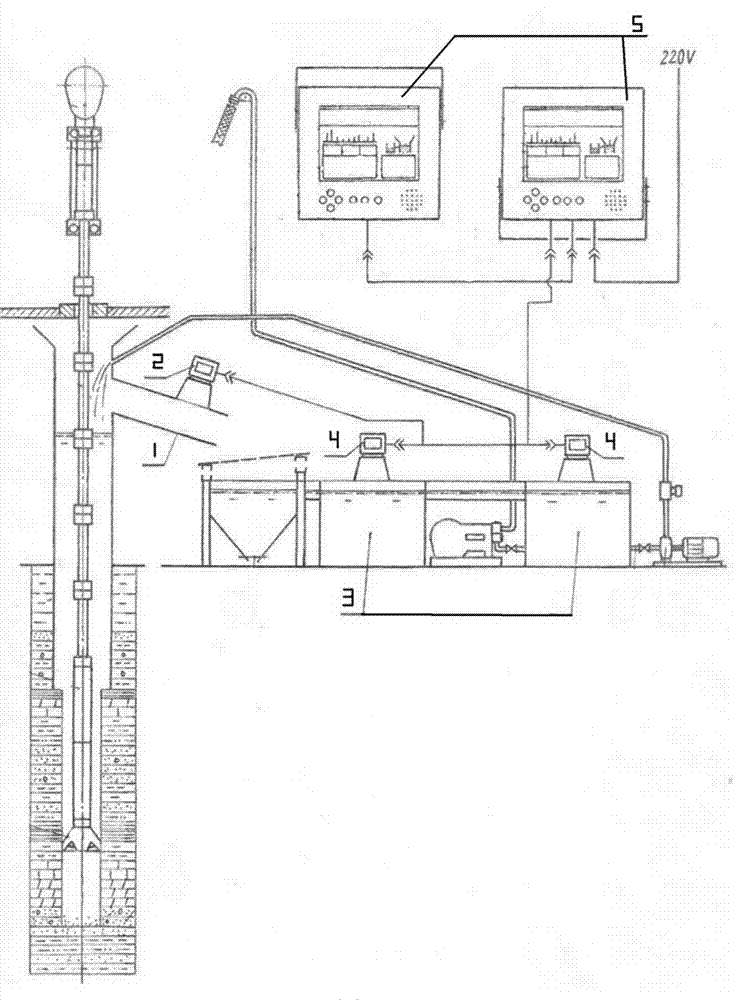

[0036] A drilling safety monitoring and alarming device is composed of an outlet flowmeter, a liquid level transmitter, a sound alarm and at least two monitoring terminals.

[0037] The outlet flowmeter includes a flowmeter bracket, a flowmeter casing, a flowmeter sonar sensor, a flowmeter main control board, a flowmeter digital tube and a flowmeter temperature sensor; the flowmeter casing is a cubic steel with a transparent tempered glass window. Shell; the flowmeter bracket bolts are connected to the lower part of the flowmeter casing in the direction of gravity; the flowmeter sonar sensor is installed on the side of the flowmeter casing connected to the flowmeter bracket, and is connected to the flowmeter main control board through wires; the flowmeter main control board The board is installed inside the flowmeter housing and connected to the digital tube of the flowmeter through wires; the digital tube of the flowmeter is installed on the side of the flowmeter housing with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com