System and method for deep nitrogen and phosphorus removal and resource recovery of AAO-BCO process

A technology of AAO-BCO and deep denitrification, which is applied in the field of AAO-BCO deep denitrification and phosphorus removal and resource recovery system to achieve the effects of saving carbon sources, convenient management and reducing sludge treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

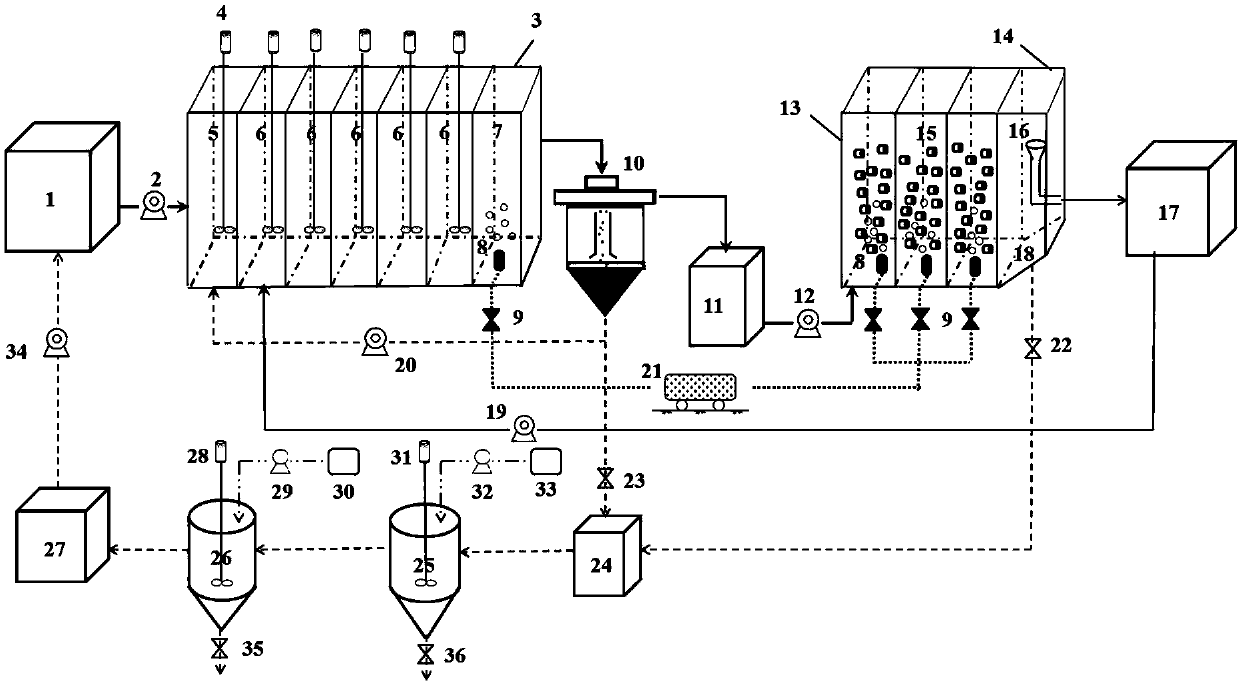

[0040] see figure 1, a deep nitrogen and phosphorus removal and resource recovery system for the AAO-BCO process, including an AAO-BCO system, the AAO-BCO system consists of a raw water tank 1, an inlet pump 2, an AAO reactor 3, an intermediate sedimentation tank 10, The intermediate water tank 11, the intermediate water inlet pump 12, the biological contact oxidation tank 13 and the sedimentation area 14 are sequentially connected.

[0041] Wherein, described AAO reactor 3 comprises anaerobic zone 5, anoxic zone 6 and aerobic zone 7 arranged and connected according to the order of water inflow, agitator 4 is arranged in anaerobic zone 5 and anox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com