Quick coring drilling system without marine riser and method based on circulating drilling fluid

A technology for circulating drilling fluid and riser, which is used in drilling equipment, undisturbed core extraction devices, and driving devices for drilling in wellbore. The effect of core drilling and the effect of solving core blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

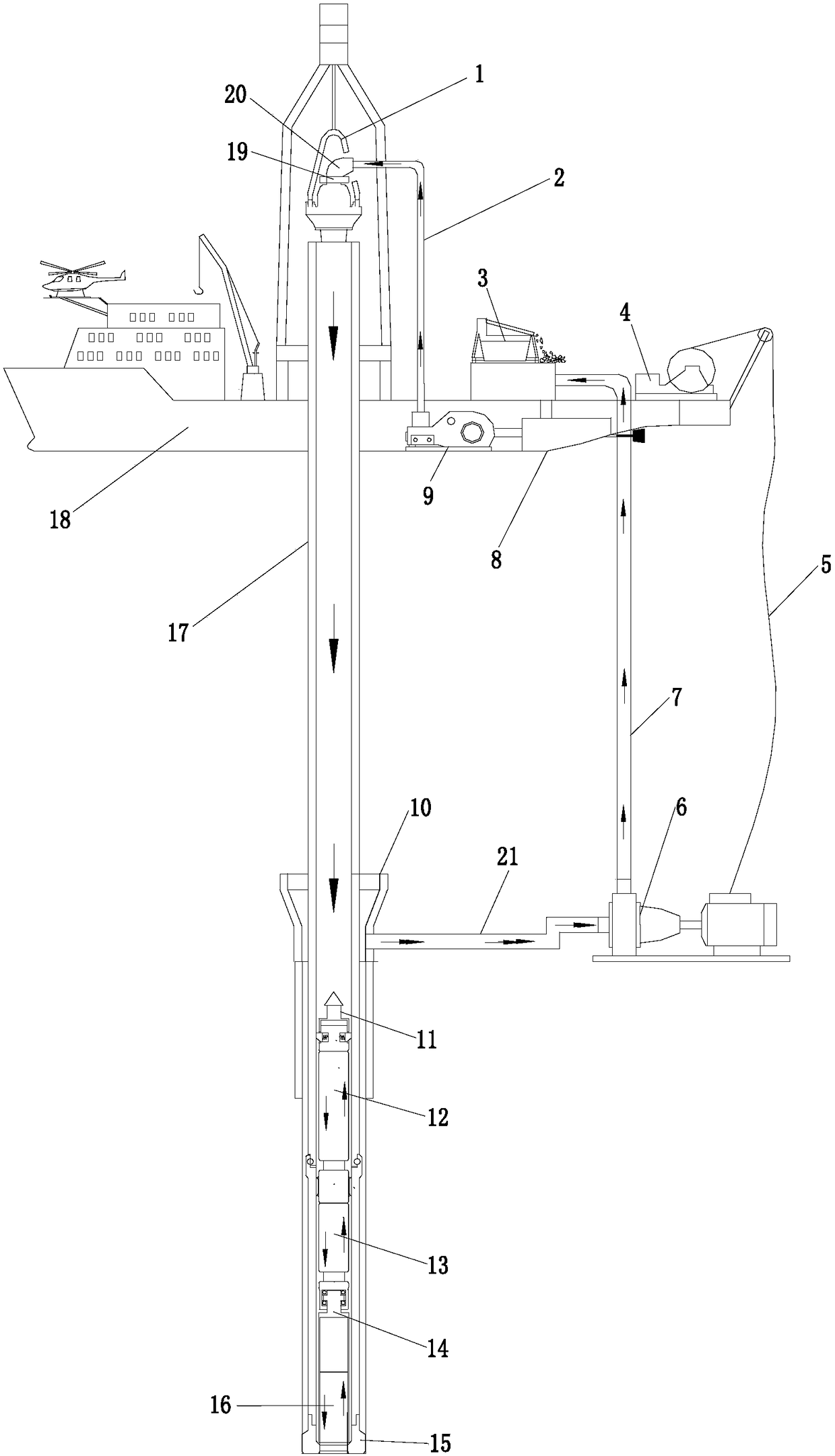

[0019] Such as figure 1 As shown, a riser-free rapid coring drilling system based on circulating drilling fluid includes a mud circulation system and a coring drilling system; the core drilling system includes a drill pipe 17 and a The salvage spear head 11, the driving device 12, the hydraulic down-the-hole hammer 13, the core pipe 14 and the drill bit 15 are connected in sequence; the mud circulation system includes the return cone 10, the recovery pump 6, the umbilical cable winch 4, and the umbilical cable 5 , solid control equipment 3, mud tank 8, mud pump 9 and delivery pipeline group; Described delivery pipeline group comprises the first delivery pipeline 2, the second delivery pipeline 7 and the 3rd delivery pipeline 21; The umbilical winch 4 is connected to the recovery pump 6 located in the seabed through the umbilical cable 5, the umbilical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com