Patents

Literature

66results about How to "Improve flowback rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

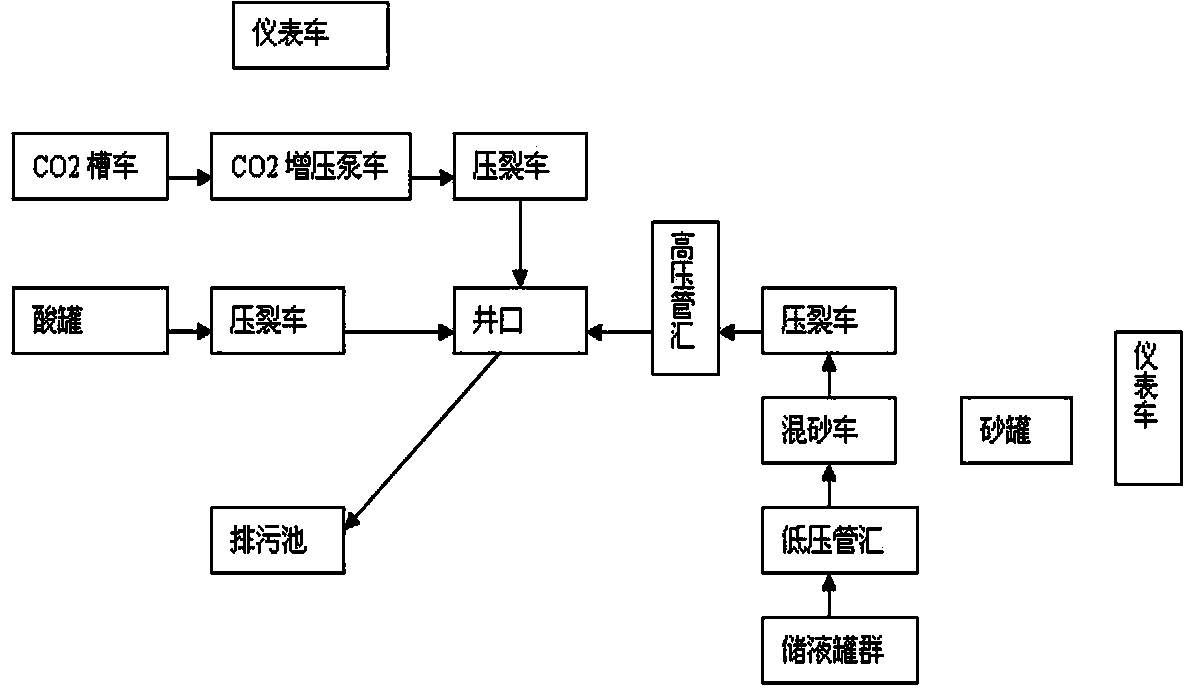

Shale gas well CO2 and slickwater mixing fracturing technology

The invention discloses a shale gas well CO2 and slickwater mixing fracturing technology, and relates to the technical field of shale gas exploiting, in particular to the mixing fracturing technology by adopting CO2 and slickwater. In the construction process, a fracturing truck, a fracturing blender truck, a CO2 tank truck, a CO2 pump truck, a measuring truck, a fracturing manifold truck, an acid tank, propping agents and a liquid storage pot group need to be prepared, the fracturing manifold truck is provided with a low-pressure manifold and a high-pressure manifold, and the measuring truck is provided with a monitoring instrument, and the technology is characterized by comprising seven steps of doing well site planning, pressure testing, acid liquid processing, CO2 fracturing construction, slickwater fracturing construction, well closing after fracturing, and flow opening and flowback after fracturing. The shale gas well CO2 and slickwater mixing fracturing technology has the advantage that the shale gas exploiting method which is low in cost, low in relative construction difficulty, small in damage to a shale gas reservoir stratum and efficient is achieved.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

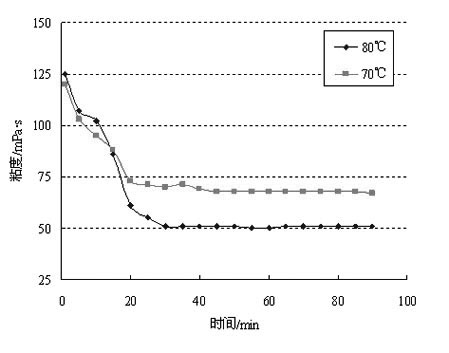

Fracturing fluid system of CO2 cleaning foam

The invention relates to a fracturing fluid system used in an oil and gas field, in particular to a fracturing fluid system of CO2 cleaning foam. The fracturing fluid system comprises the following components in percentage by weight: 0.3-0.8 percent of water-soluble hydrophobic association polymer, 0.25-0.55 percent of rheological auxiliary agent, 0.5-3.0 percent of clay stabilizer, 0.1-0.5 percent of foaming agent, 0.01-0.2 percent of gel breaker, 30.0-80.0 percent of liquid CO2 and the balance of water. Compared with the prior art, in the fracturing fluid system of the CO2 cleaning foam, a cross-linking agent is not needed, the foamability is good, the foam stability is high, the sand-carrying capability is strong, gel breaking is easy to control, no residue is generated after gel breaking, the superficial / interfacial tension of gel-breaking liquid is low, and the damage to the formation is less, and therefore, the fracturing fluid system can be used for fracturing modification of hypoisotonic, low-pressure and water-sensitive storage layers at the temperature of 60-140 DEG C.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

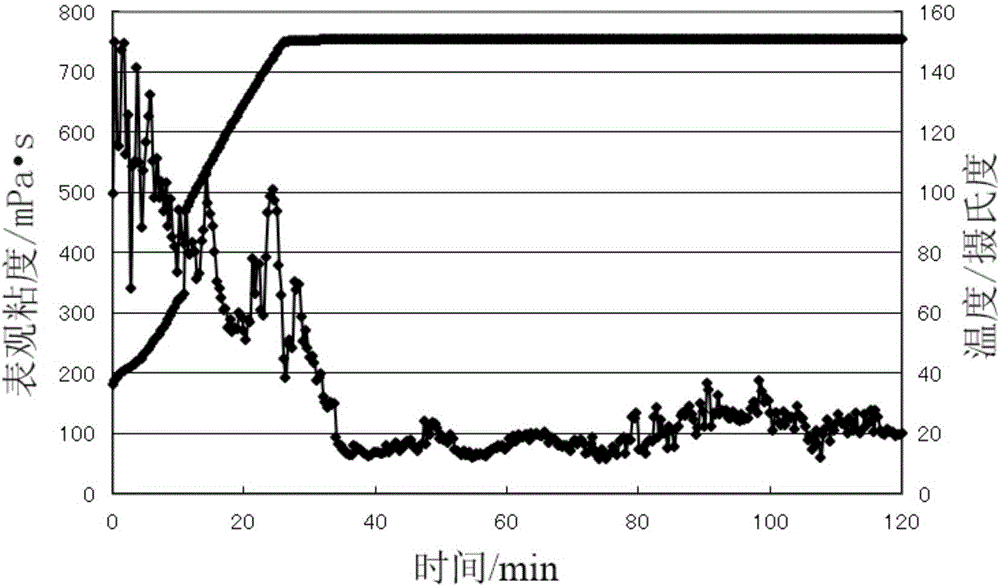

High-temperature resistant CO2 foam cleaning and associated fracturing fluid and preparation method and application thereof

ActiveCN106675546AFast water solubilityEasy to prepareFluid removalDrilling compositionCross-linkPolymer science

The invention provides high-temperature resistant CO2 foam cleaning and associated fracturing fluid and a preparation method and application thereof. The high-temperature resistant CO2 foam cleaning and associated fracturing fluid comprises a fracturing fluid base solution, a cross-linking agent, a gel breaker and liquid CO2, wherein the cross-linking agent and the gel breaker account for 0.3%-0.8% and 0-0.05% of the fracturing fluid base solution in parts by weight separately; and the liquid CO2 accounts for 30%-70% of total volume of the CO2 foam cleaning and associated fracturing fluid. The high-temperature resistant CO2 foam cleaning and associated fracturing fluid provided by the invention has the characteristics of being few in additive types, simple in preparation, controllable in crosslinking, low in residue, low in damage, low in friction, high in foaming efficiency, high in flowback rate and resistant to high temperature.

Owner:PETROCHINA CO LTD

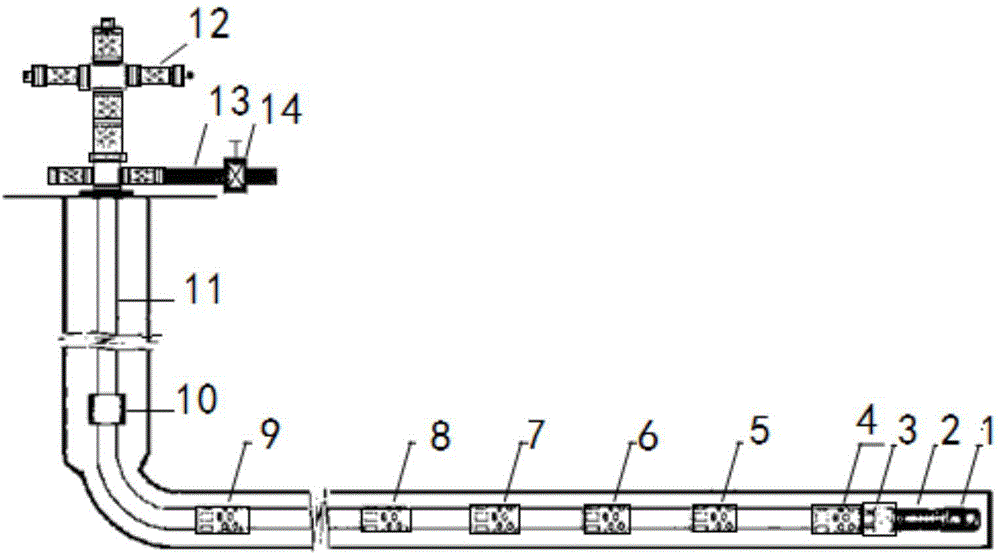

Immovable string hydraulic sandblasting fracture annulus pressure control method for gas field horizontal well

InactiveCN104632172AEnsure wellbore stabilityReduced risk of borehole collapseFluid removalFlushingConstruction designWellhead

The invention provides an immovable string hydraulic sandblasting fracture annulus pressure control method for a gas field horizontal well, and belongs to the technical field of gas field horizontal well sectional improvement. An immovable string hydraulic sandblasting fracture technique string of the gas field horizontal well is laid in the gas field horizontal well, and ejectors are aligned to planned improvement positions; a throttle valve is installed at a wellhead sleeving and releasing outlet, and a sleeving and releasing pipeline is connected into a slurry pond; sandblasting and perforation are carried out on target sections according to construction design, an annulus is opened during sandblasting and perforation, and annulus pressure is controlled through the throttle valve; after perforation, displacement is increased, jet flow pressurization is improved, the annulus pressure is adjusted through the throttle valve, a stratum is pressed open and then a sleeve gate is closed for main fracture construction, and liquid nitrogen is injected in the whole process of main fracture construction of each section; a next layer hydraulic sandblasting fracture tool is opened in a ball throwing mode for next layer perforation and fracture construction; after pressing, the aims that liquid is quickly discharged, the flowback rate is increased, and construction risk is lowered are achieved.

Owner:PETROCHINA CO LTD

CO2 refracturing process technology for low-permeability gas well

The invention belongs to the technical field of oil exploitation, and relates to a refracturing modification process for a low-permeability and low-yield gas well, in particular to a CO2 refracturing process technology for a low-permeability gas well. The CO2 refracturing process technology is used for performing secondary fracturing construction for an implemented well, comprises analysis and optimization before fracturing and fracturing construction, and is characterized in that the analysis and optimization before fracturing comprises fracturing failure analysis, fracturing material optimization and construction parameter optimization, and the specific process technology is implemented according to steps of fracturing failure analysis, fracturing material optimization, construction parameter optimization and refracturing construction. According to the CO2 refracturing process technology for the low-permeability gas well, a CO2 foam fracturing technology and low-damage cleaning fracturing liquid are used for performing a modification test for a low-yield gas well by analyzing a reservoir, the flowback rate of the fracturing liquid and the yield of the low-yield gas well are increased effectively, and damage to the reservoir is effectively reduced.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

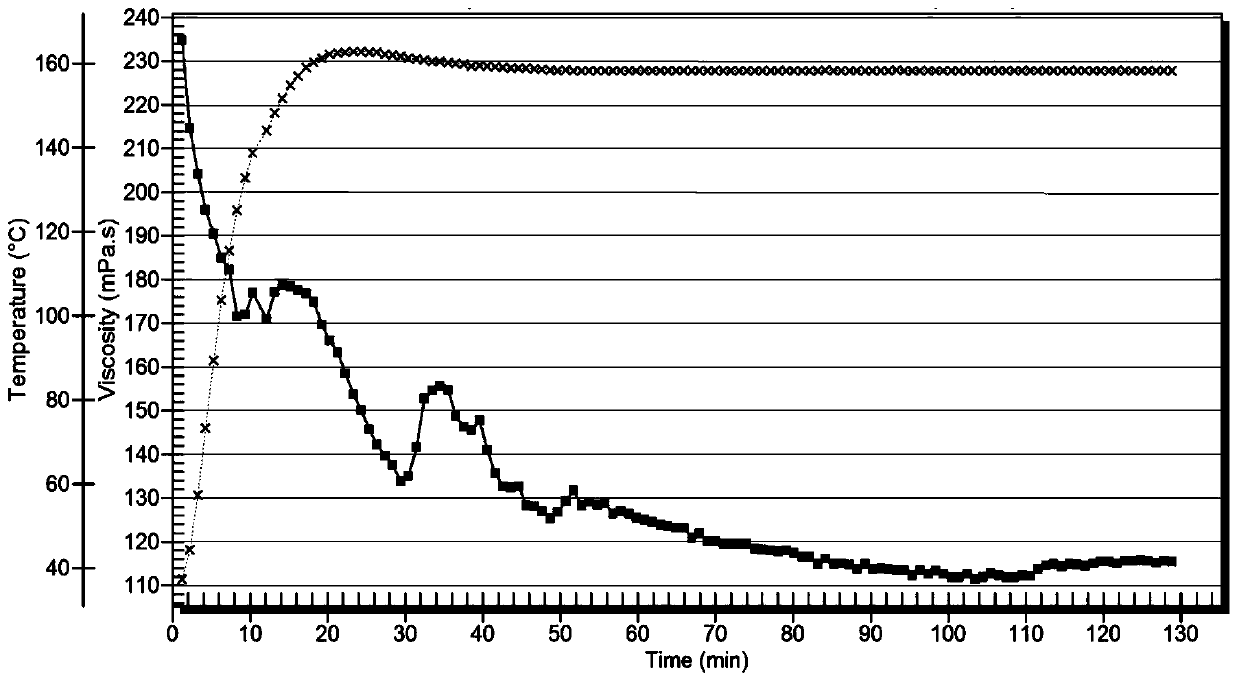

Oil-based liquid-state fracturing fluid thickening agent, and preparation method thereof

ActiveCN103911136ADoes not affect outputDoes not affect structureDrilling compositionLiquid stateFracturing fluid

The invention discloses an oil-based liquid-state fracturing fluid thickening agent, and preparation method thereof. Density of the oil-based liquid-state fracturing fluid thickening agent ranges from 0.9 to 1.2g / cm<3>; gelling time is 20s or less; and viscosity of 1.2% of the oil-based liquid-state fracturing fluid thickening agent after dissolving is 30mPa.s or more. The invention also discloses a preparation method of the oil-based liquid-state fracturing fluid thickening agent.

Owner:北京爱普聚合科技有限公司

Method for preparing residue free fracturing fluid

InactiveCN1285700CMeet the needs of fracturing constructionAvoid harmFluid removalDrilling compositionFluid viscosityFracturing fluid

The present invention relates to a kind of fracturing fluid used in oil and gas field development process, fracturing stimulation measures, the present invention provides an effective method, that is to use unsaturated fatty acid salt with 18 carbon atoms mixed with brine or 18 A fatty acid with 2 carbon atoms, an inorganic base, and brine are mixed. In the brine, the fatty acid salt increases the fluid viscosity and viscoelasticity due to the formation of highly entangled rod-shaped micelles, so as to meet the viscosity requirements of the fracturing fluid. The viscosity of this fracturing fluid depends on the nature of the micelles, which can be disrupted by changing the structure of the micelles. When the fracturing fluid encounters hydrocarbons or is diluted by formation water, it will break the gel without residue, so as to solve the problem of vegetable glue fracturing fluid residues and reduce the impact of residues on the permeability of the fracturing fracture support zone and the formation The damage caused by permeability can improve the stimulation effect of fracturing. At the same time, it provides a new way for fracturing fluid preparation.

Owner:DAGANG OIL FIELD GRP +2

Surfactant complex-based high temperature-resistant solvent

InactiveCN103992783AImprove liquidityImprove permeabilityDrilling compositionInorganic saltsThermodynamics

The invention discloses a surfactant complex-based high temperature-resistant solvent. The surfactant complex-based high temperature-resistant solvent is used for unconventional energy thickened oil steam-injection thermal recovery and through the surfactant complex-based high temperature-resistant solvent, a steam-chemical assistant combined exploitation method is formed. The surfactant complex-based high temperature-resistant solvent comprises a dispersant, a surfactant complex and an inorganic salt, and concretely, the surfactant complex-based high temperature-resistant solvent comprises, by mass, 5-10 parts of the dispersant, 10-30 parts of the surfactant complex, 5-10 parts of the inorganic salt and 80-50 parts of water. Through compounding of a fluorocarbon surfactant and a hydrocarbon surfactant, the surfactant complex-based high temperature-resistant solvent can resist a temperature of 300 DEG C and can improve steam transmission efficiency and stripping, viscosity reduction and displacement effects on thickened oil in thickened oil steam-injection recovery and especially in thickened oil steam assisted gravity drainage (SAGD).

Owner:KARAMAY XINRONG TECH

Quick gel breaking process for intermediate and low temperate oil gas well fracturing fluid

InactiveCN102562021ACompletely broken glueImprove flowback rateFluid removalDrilling compositionGuar gumCrosslinking reagent

The invention discloses a quick gel breaking process for intermediate and low temperate oil gas well fracturing fluid, and the process at least comprises the following steps: 1) adding a sufficient amount of gel breaking agent in a pre-loading liquid stage; 2) lowering the use concentration of a crosslinking agent in the construction field to form weak crosslinking or under crosslinking fracturing fluid gel; and 3) in the later stage of a sand-carrying agent step, i.e., when a sand adding step is about to finish, adding a gel breaking agent into well fracturing fluid in a tail chase wedge shape. The quick gel breaking process has the following advantages: (1) the water base fracturing fluid is quick, the gel is thoroughly broken, and the flowback rate is high; (2) the gel breaking process is simple, is easy to master and is convenient to operate on site; (3) the gel breaking process is wide in applicable range, is suitable for the common guar gum fracturing fluid system and is also suitable for the water base polymer fracturing fluid system of other gel breaking agents; and (4) the gel breaking process can be used for intermediate and low temperate oil gas well fracturing at the temperature of 20-60DEG C.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

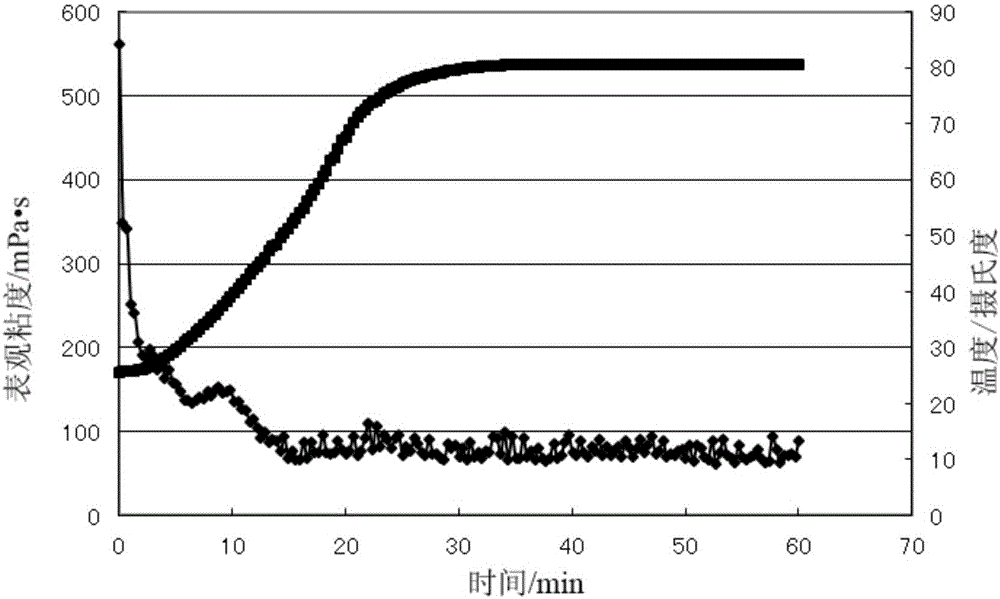

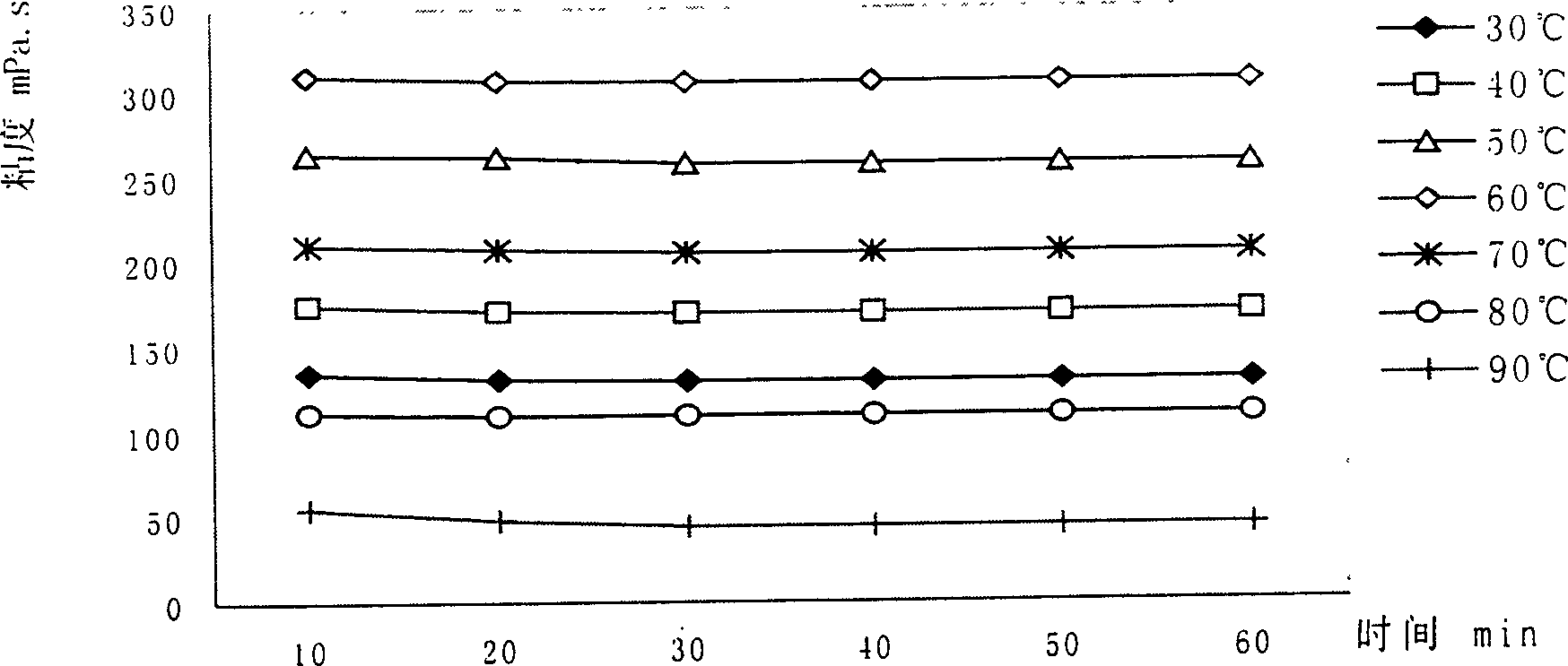

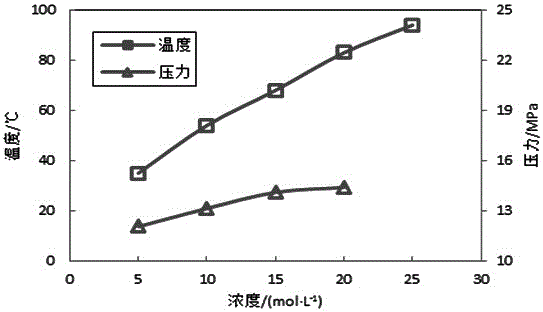

Development of ultra-low temperature (0-30 DEG C) fracturing fluid system

InactiveCN103074048AGood dispersionFast dissolutionDrilling compositionFracturing fluidEnvironmental geology

The invention relates to an ultra-low temperature (0-30 DEG C) fracturing system which is used for yield increase and modification of shallow gas fields. According to the invention, a fracturing fluid comprises the following main components: 0.3-0.4 percent of ultra-low temperature fracturing fluid thickening agent, 0.4-0.6 percent of cross-linking agent, 0.2-0.4 percent of main gel breaker, 0.1-0.2 percent of auxiliary gel breaker, and the balance of water. The ultra-low temperature fracturing fluid system has the main characteristics of wide application range (beyond the range of 0-30 DEG C), high dissolving speed, capability of solution under the temperature of 0-30 DEG C within 60 min, good gel elasticity, convenience in sand carrying, complete gel breaking, high flowback rate and no environment harm.

Owner:NANTONG KEYI CHEM

A high-efficiency fluoride-free acidizing aid

The invention relates to a fluoride-free cleanup additive used for acidifying, which is composed of a main agent, a reinforcing agent, a cosolvent and water. the main agent is alkyl trimethyl ammonium bromide or alkyl bromid pyridine, wherein the alkyl can be dodecyl, cetyl or octadecyl, the main agent accounts for 20-50% of the cleanup additive by weight percentage, the reinforcing agent is fatty alcohol polyoxyethylene ether, dihydroxyethyl dodecyl amide or cocamidopropyl dimethyl betaine, the reinforcing agent accounts for 1-10% of the cleanup additive by weight percentage, the cosolvent is a mixture of one or more of methanol, ethanol or glycol, the cosolvent accounts for 5-25% of the cleanup additive by weight percentage, and the balance is water. The cleanup additive is capable of effectively reducing the capillary force in stratum, rapidly discharging the residual acid liquid out of the stratum and reducing the damage to the stratum.

Owner:SOUTHWEST PETROLEUM UNIV

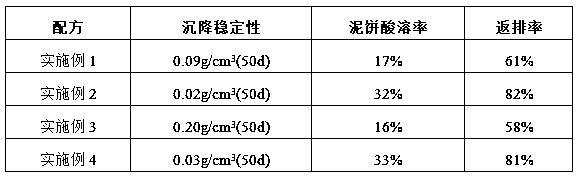

High-temperature gas well and horizontal well drilling fluid and completion fluid containing same

InactiveCN103351853AHigh acid solubilityImprove flowback rateDrilling compositionSolubilityDrilling fluid

The invention discloses a high-temperature gas well and horizontal well drilling fluid and a completion fluid containing the same. On the basis of an original polymer sulfonated water-base drilling fluid, an acid soluble material is added to achieving weighing so as to serve as the completion fluid, the completion fluid is higher in mud-cake acid solubility and flowback rate and good in reservoir bed protective capability. The phenomena that in the later period of well completion test process, the continuous high-temperature resistant stability is poor and the probability of high-temperature degradation is high are avoided, and the problems that the later-period test result accuracy and the productivity discovery are seriously influenced, and tool blockage and accidents are easily caused are solved. The high-temperature gas well and horizontal well drilling fluid consists of a base fluid and a heavy weight additive, wherein the base fluid comprises water, a thickening agent, drilling Bentonite, an inhibiter, a plugging agent, a fluid loss reducer and a lubricant; the heavy weight additive is barite. The high-temperature gas well and horizontal well completion fluid comprises the base fluid and the heavy weight additive, wherein the base fluid is the original drilling fluid; the heavy weight additive is an acid soluble material.

Owner:SICHUAN RENZHI PETROCHEMICAL TECHNOLOGY CO LTD

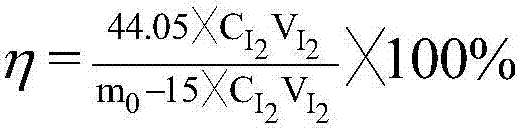

Oil and gas field fracturing fluid, oil and gas field well cementation agent and oil and gas field fracturing temporary plugging agent

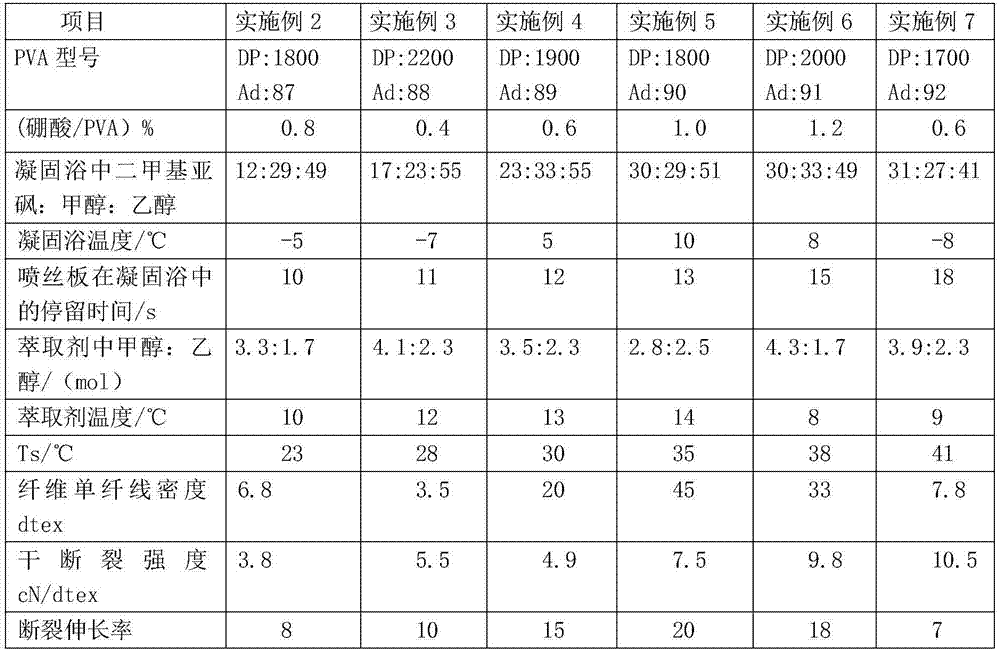

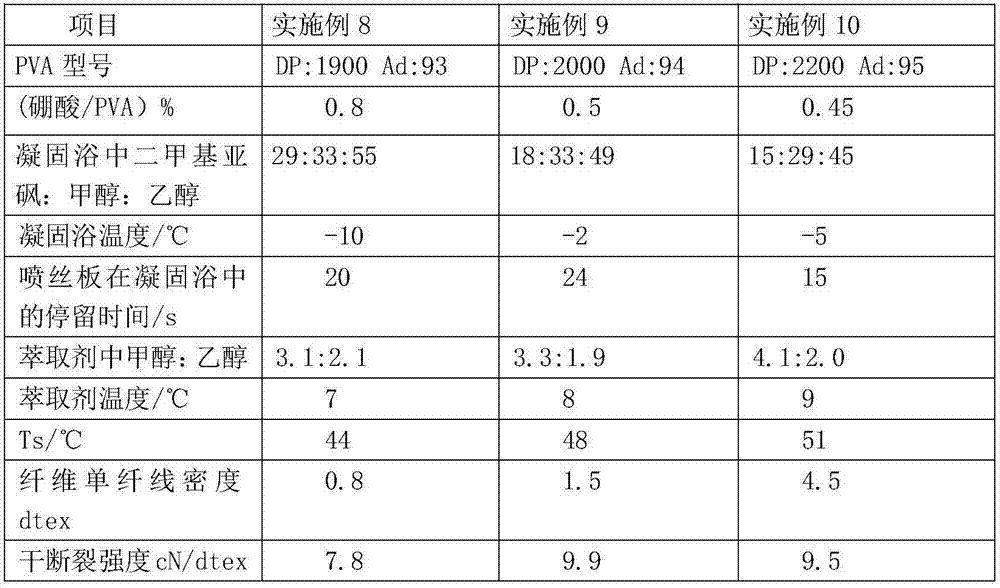

InactiveCN107286923AAdequate mechanical propertiesLow mass lossDrilling compositionConjugated synthetic polymer artificial filamentsFiberPolyvinyl alcohol

The invention provides oil and gas field fracturing fluid, an oil and gas field well cementation agent and an oil and gas field fracturing temporary plugging agent, which contain PVA (Polyvinyl Alcohol) fibers. The PVA fibers are papered from polyvinyl alcohol with the polymerization degree of 1000 to 3000 and the alcoholysis degree of 80 mole percent to 99.5 mole percent through spinning; the hydroformylation degree eta of the PVA fibers is 25 percent to 35 percent and Rp is 120 DEG C to 180 DEG C. The PVA fibers have the monofilament density of 1.0dtex to 1.8dtex at normal temperature and have the elongation at break of 10 percent to 25 percent; the slenderness ratio of the fibers is 200 to 600 and the real density of the fibers is 0.8g / cm<3> to 1.4g / cm<3>. The yield increasing range of the oil and gas field can reach 30 percent to 50 percent; the strength and toughness of the well cementation agent are remarkably improved and the well cementation agent can also have an anti-leakage effect; when being used in the fractured oil and gas field, the oil and gas field fracturing temporary plugging agent aims at plugging old cracks and breaking new cracks; when the fracturing temporary plugging agent is used, the pressure is raised by 6MPA or above and the yield of the oil and gas field is improved by two times or above.

Owner:CHINA PETROCHEMICAL CORP +1

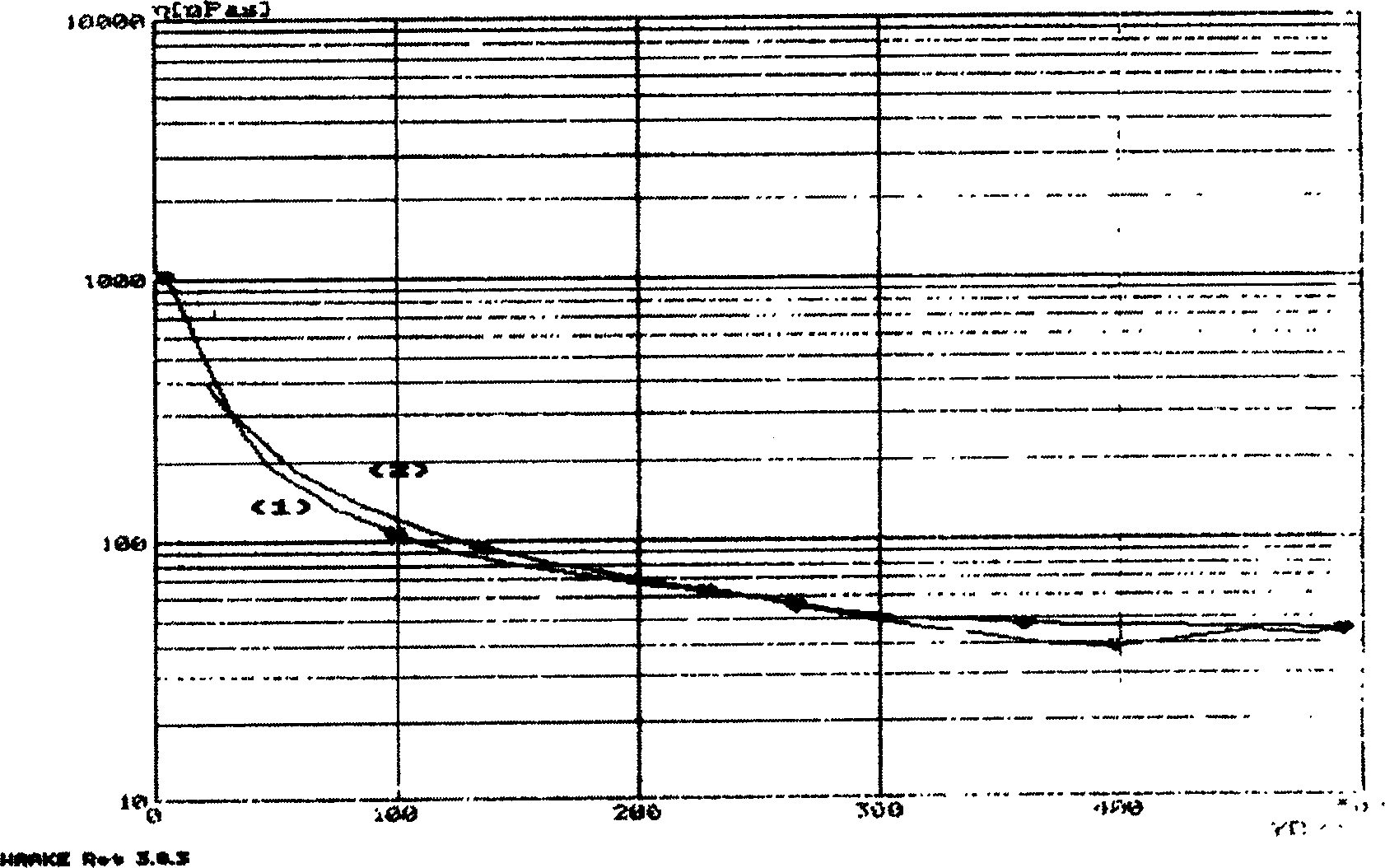

Low-injury clean fracturing fluid of oilfield oil well and application of fracturing fluid

InactiveCN103881688AReduce harmHigh yieldFluid removalDrilling compositionFracturing fluidSodium salicylate

The invention provides low-injury clean fracturing fluid of an oilfield oil well, which comprises the following components in percentage by mass: 0.7-1.8 wt% of hexadecyl trimethyl ammonium bromide, 0.7-0.9 wt% of additive sodium salicylate, and the balance of water. The low-injury clean fracturing fluid of the oilfield oil well has the advantages that the fracturing fluid can thoroughly perform gel breaking, flowback rate is high, the problems that gel breaking is not thorough and crack pore channels are blocked by residues after gel of the fracturing fluid is broken in a stratum in the oil layer fracturing improvement process can be solved, injury of the fracturing fluid to an oil layer is reduced, and the low-permeability reservoir producing reserve, the recovery efficiency and the yield are increased.

Owner:PETROCHINA CO LTD

Gas-producing system capable of improving permeability of tight oil reservoir and application thereof

ActiveCN105838347AImprove flowback rateImprove seepage capacityFluid removalDrilling compositionChemical reactionHigh pressure

The invention provides a gas-producing system capable of improving permeability of a tight oil reservoir and application thereof, belonging to the technical field of oilfield development. The gas-producing system comprises a microcapsule and hydrochloric acid; the microcapsule uses a mixture of urea and sodium nitrite as a core material and a mixture of azodiisobutyronitrile, styrene, methyl methacrylate and methacrylic acid as a capsule dressing. In operation, nitrite and the microcapsule are injected into a stratum to a predetermined depth; and the microcapsule undergoes corrosion under stratum conditions and chemically reacts with hydrochloric acid to produce a great amount of gas and release a great amount of heat, so local high pressure is formed in a predetermined part. According to the invention, effective seepage channels of difficult-to-produce reserves such as an ultralow-permeability oil reservoir and the tight oil reservoir are increased so as to improve permeability, increase local energy of reservoirs and the flowback rate of raffinate, and reduce reservoir contamination, so the purpose of improving the recovery efficiency of the difficult-to-produce reserves is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

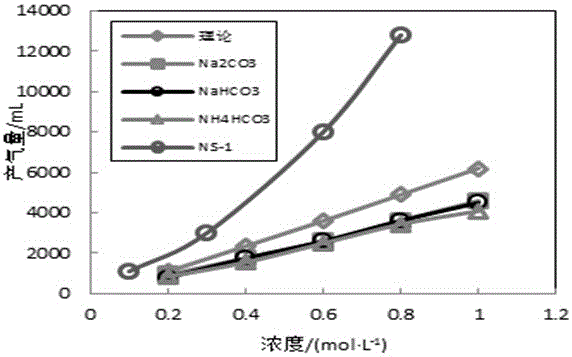

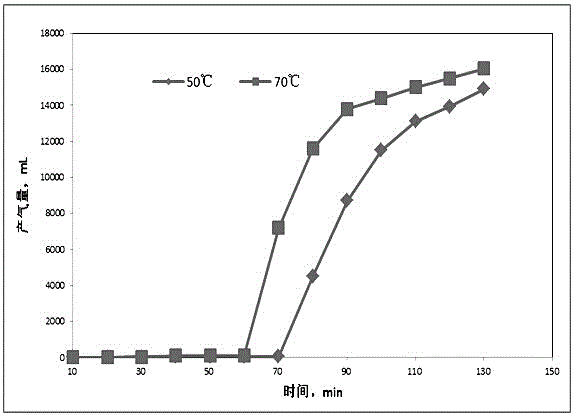

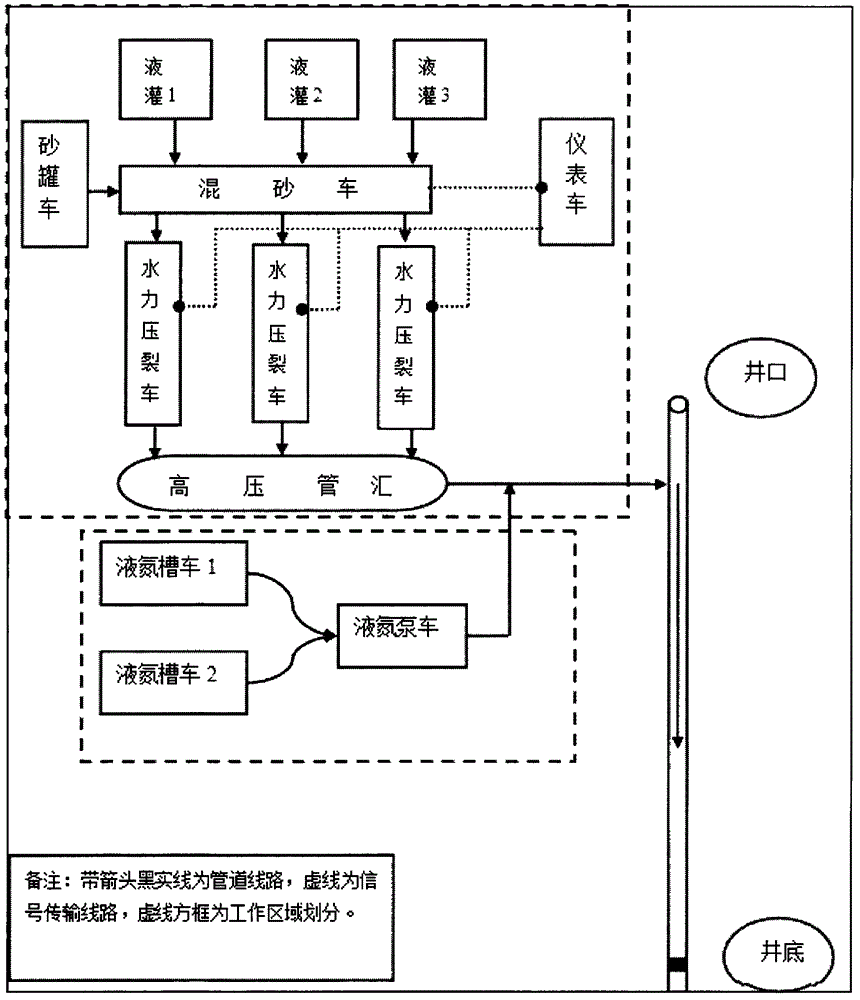

Active water-nitrogen injection combination fracturing fast flow-back production increase method for coal-bed gas well

InactiveCN104533374AReduce pollutionIncrease gas productionFluid removalHydraulic fracturingNitrogen gas

The invention relates to the technical field of coal-bed gas exploration and development, in particular to an active water-nitrogen injection combination fracturing fast flow-back production increase method for a coal-bed gas well. The active water-nitrogen injection combination fracturing fast flow-back production increase method for the coal-bed gas well includes steps that using a liquid nitrogen pump truck to fill nitrogen when performing low-pressure low-permeability coal reservoir fracturing improvement, using a hydraulic fracturing truck to fill active water, and immediately opening flow to flow back after ending fracturing. The active water-nitrogen injection combination fracturing fast flow-back production increase method for the coal-bed gas well solves the problems of low even zero flow-back rate of flow opening, large pollution to the coal reservoir and low permeability after the active water fracturing improvement for the low-permeability coal reservoir of the coal-bed gas well. The active water-nitrogen injection combination fracturing fast flow-back production increase method for the coal-bed gas well can realize 80% flow-back rate, the pollution to the coal reservoir is small, and meanwhile, the nitrogen is capable of lowering the partial pressure of methane and improving the permeability of the oil reservoir and good for quickly desorbing the gas of the coal-bed gas well and improving the gas output.

Owner:HENAN POLYTECHNIC UNIV +1

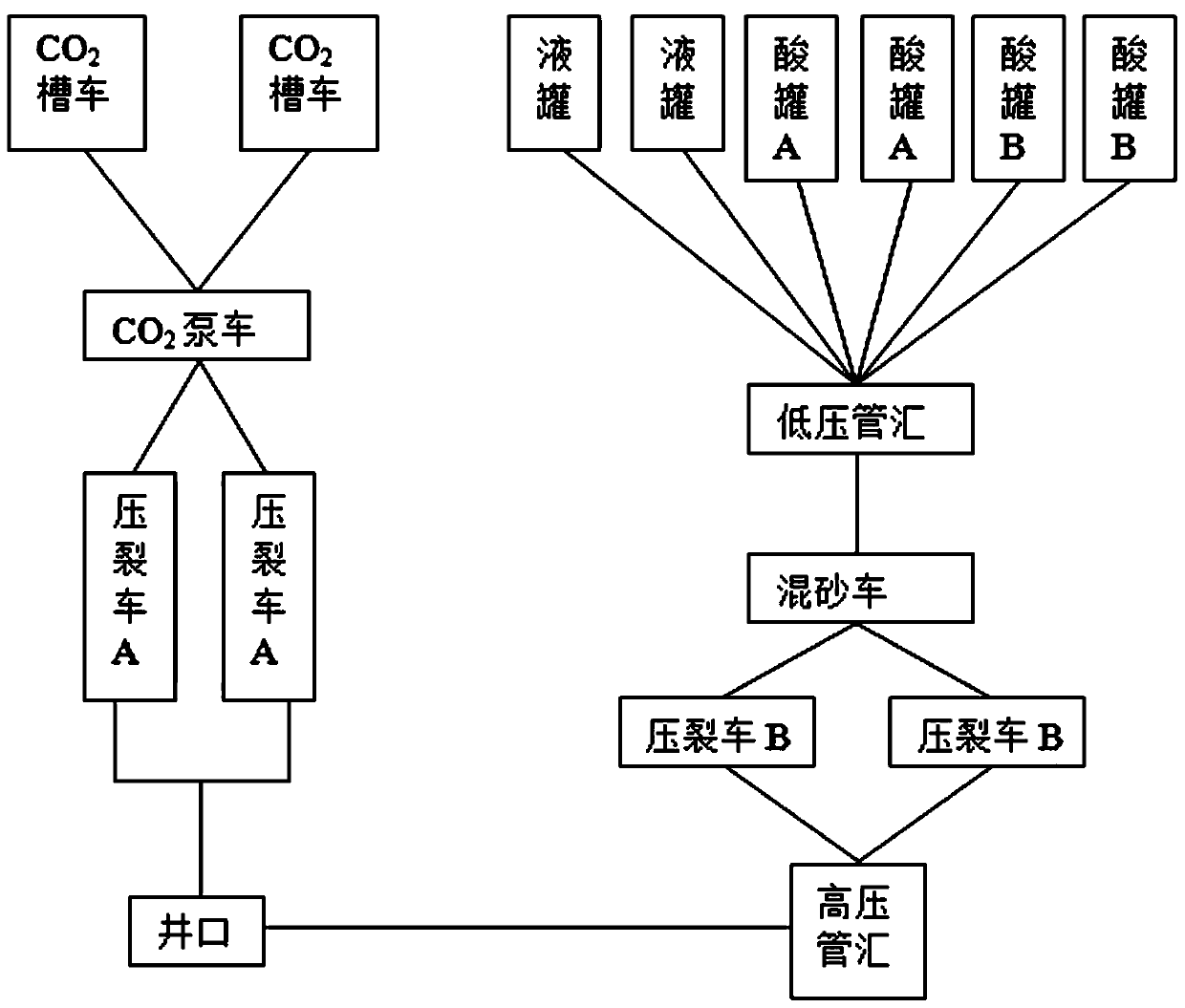

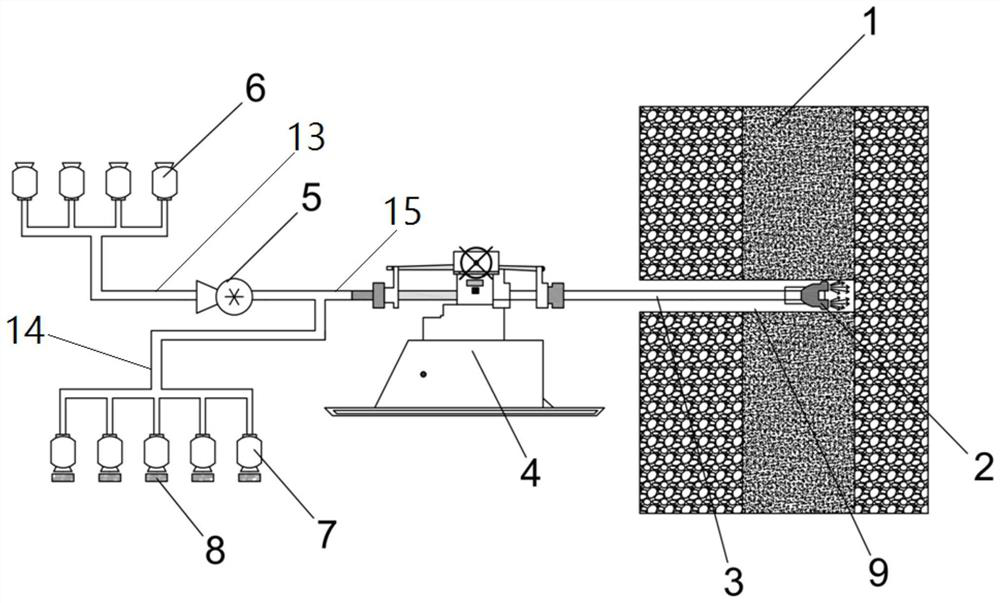

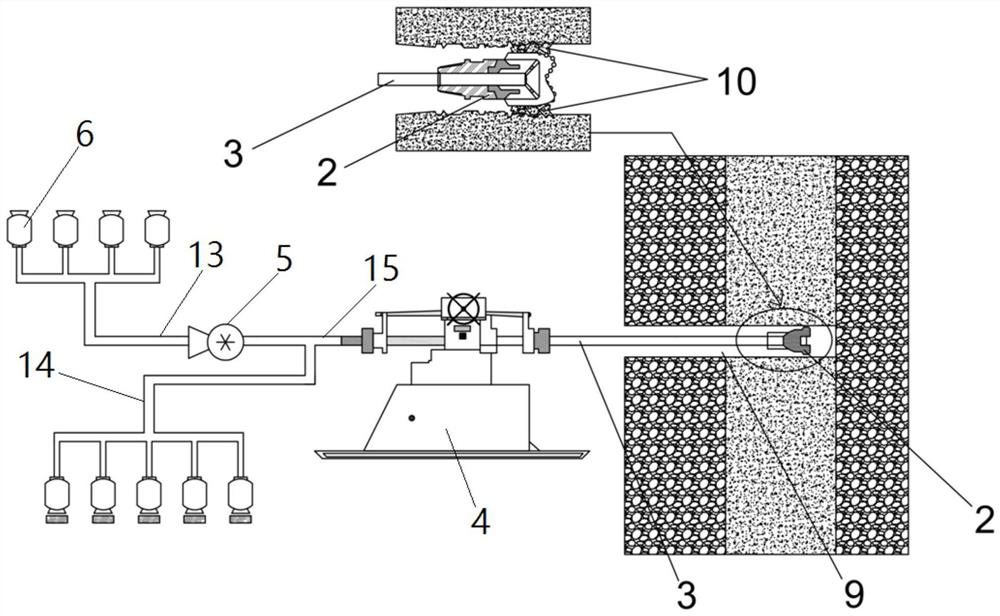

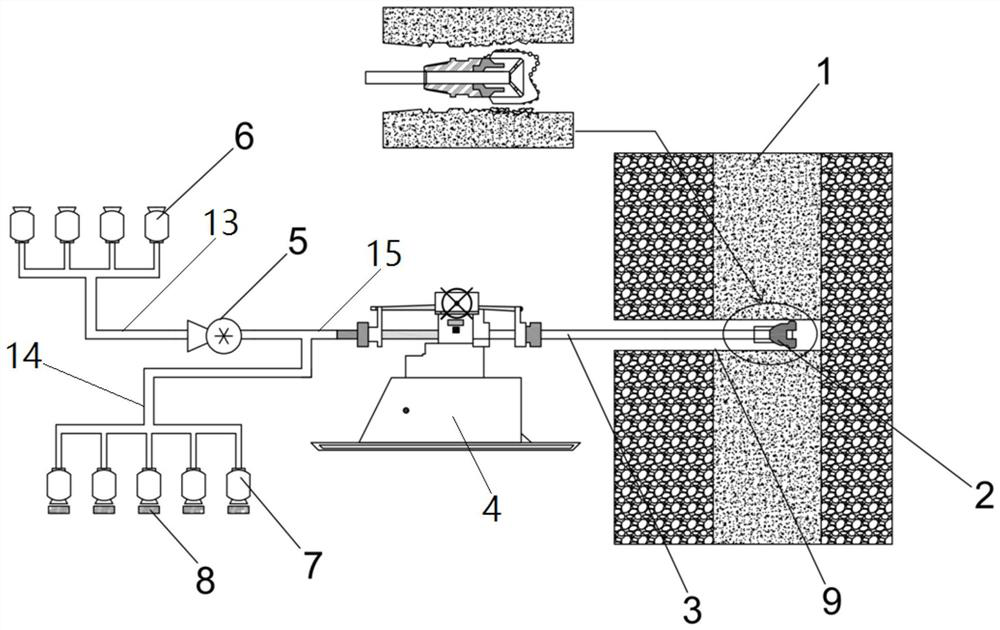

Carbon dioxide acid fracturing method for low permeability heterogeneous carbonate gas reservoir

The invention discloses a carbon dioxide acid fracturing method for a low permeability heterogeneous carbonate gas reservoir. The carbon dioxide acid fracturing method comprises the following steps that (1) CO2 tank trucks, a CO2 pump truck and fracturing trucks A are connected into a wellhead in series; (2) liquid tanks, acid tanks A and acid tanks B are directly connected with a low pressure manifold; (3) the low pressure manifold, a sand mixing truck, fracturing trucks B and a high pressure manifold are connected into the wellhead in series; (4) resistance reducing acid is subjected to pumpinjection with the displacement of 1.0-1.5m<3> / min; (5) CO2 is subjected to pump injection with the displacement of 1.5-3.0m<3> / min; (6) slickwater is subjected to pump injection with the displacement of 3.0-8.0m<3> / min; (7) the resistance reducing acid is subjected to pump injection with the displacement of 3.0-8.0m<3> / min; (8) steering acid is subjected to pump injection with the displacement of 2.0-6.0m<3> / min; (9) the steps (6)-(8) are repeated for 0-2 times, and the steps(6)-(7) are repeated for 1 time; and (10) the slickwater is subjected to pump injection. According to the carbon dioxide acid fracturing method, the acid fracturing effect can be improved, and the daily gas production quantity is increased.

Owner:SHAANXI YANCHANG PETROLEUM GRP +1

Chemical-heat-generation efficient gel breaking method used in oil-gas well fracturing process

InactiveCN108373913APromotes oxidative chain scission of macromoleculesImprove flowback rateFluid removalDrilling compositionChemistryPetroleum

The invention provides a chemical-heat-generation efficient gel breaking method used in an oil-gas well fracturing process and belongs to the field of oil exploitation. The method includes: in a hydrofracturing pumping process, adding a heat-generation chemical agent into a mixture of fracturing fluid and a gel breaking agent which are on the way of being pumped in; when sand adding is completed for replacement, continuing adding the heat-generation chemical agent. Temperature of gel breaking reaction between the gel breaking agent and a thickener can be increased, the fracturing fluid can bepromoted to realize efficient gel breaking, and viscous damage of the fracturing fluid can be reduced.

Owner:PETROCHINA CO LTD

Efficient mining method for coal bed gas short horizontal well group of broken low-permeability coal seam

ActiveCN112593910ARealize commercial miningImprove flowback rateFluid removalDirectional drillingMining engineeringWell drilling

The invention discloses an efficient mining method for a coal bed gas short horizontal well group of a broken low-permeability coal seam, and belongs to the technical field of coal and coal bed gas co-mining. The efficient mining method can solve the problems that an existing broken soft low-permeability coal seam coal bed gas development method is poor in extraction effect and difficult to commercialize and popularize. According to the efficient mining method, the modes that a conventional U-shaped horizontal well drainage well and an engineering well are in butt joint and conduct drainage and drilling correspondingly are changed, the short horizontal well group is creatively used for fracturing the coal seam roof, the drainage vertical well is arranged in an L-shaped short horizontal well group well field, the drainage vertical well fractures the coal seam, well roof fracturing cracks of the short horizontal well are in communication, the mining cost is effectively reduced, the fracturing fluid flow-back rate is increased, the continuous high yield of the gas yield of the well group is guaranteed, the high yield duration time is obviously longer than that of the conventional U-shaped well, the cost is reduced by half of that of the conventional U-shaped well, and therefore commercial mining of the broken and soft low-permeability coal reservoir coal bed methane is achieved.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

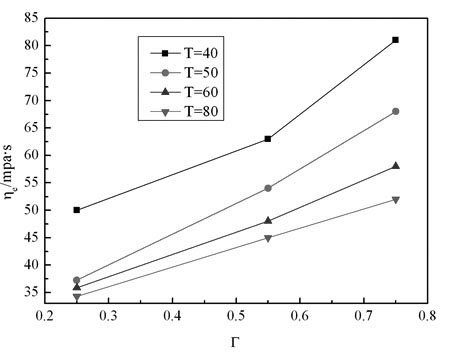

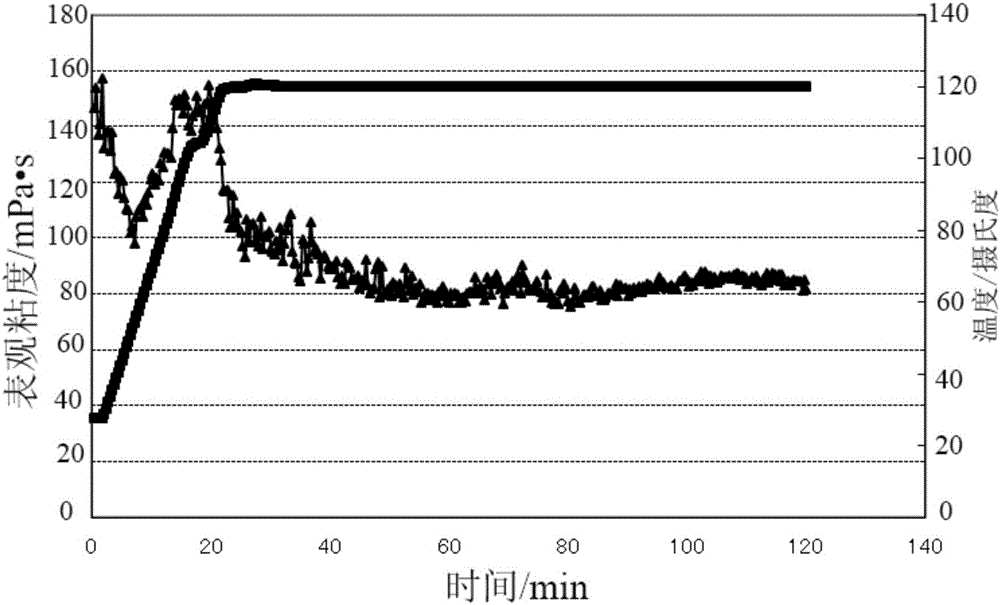

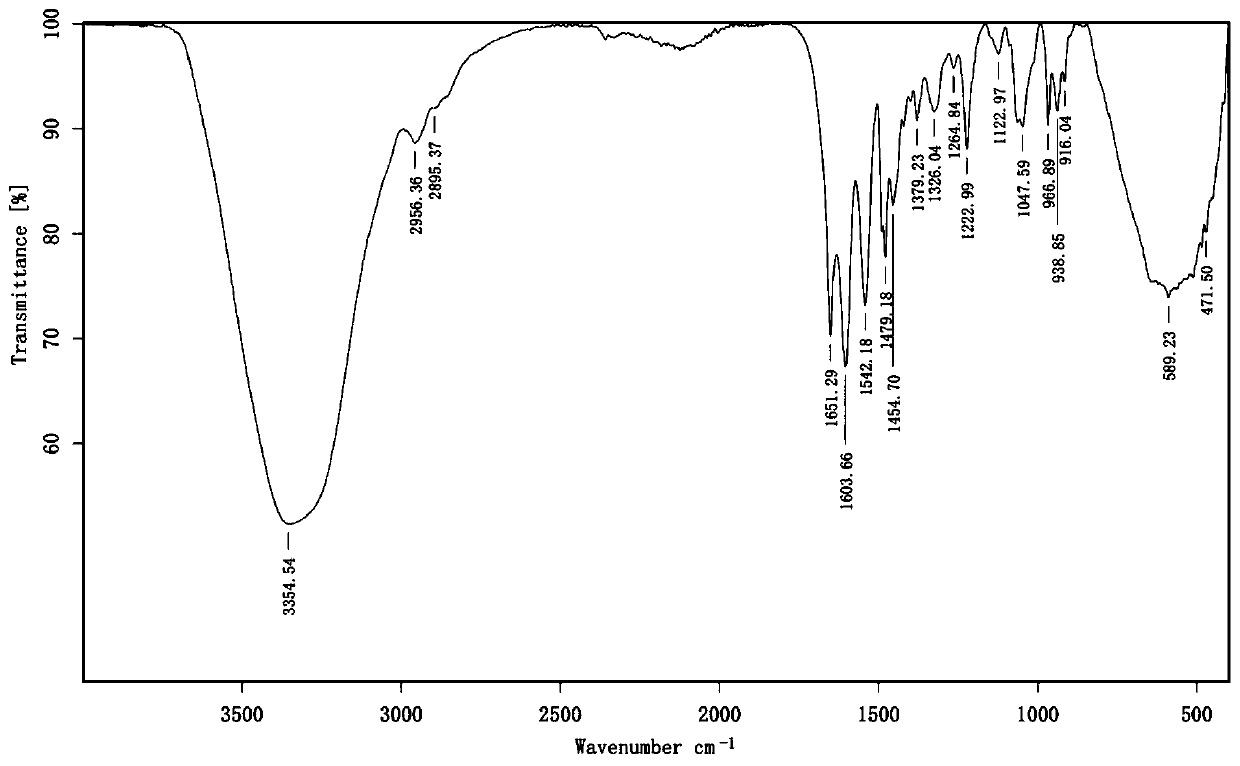

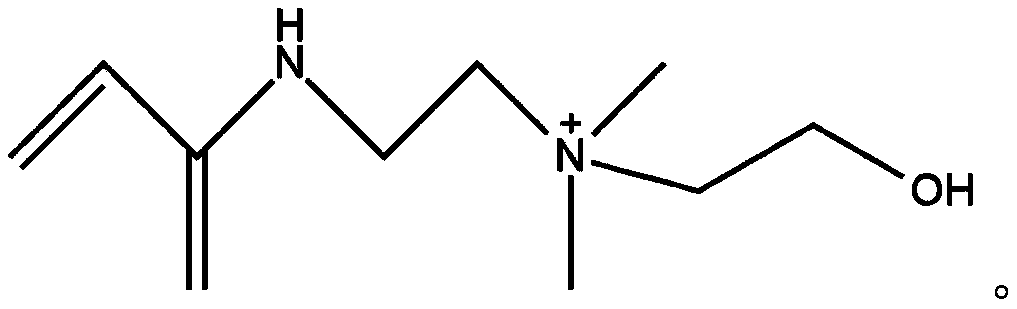

Polyhydroxy thickener, high-temperature-resistant alcohol-based fracturing fluid system and application of high-temperature-resistant alcohol-based fracturing fluid system

ActiveCN111574989AImprove temperature resistanceImprove shear resistanceFluid removalDrilling compositionAlcoholCross linker

The invention discloses a polyhydroxy thickener and a high-temperature-resistant alcohol-based fracturing fluid system. The polyhydroxy thickening agent is formed by copolymerizing three monomers, namely acrylamide, N-vinylpyrrolidone and N-acrylamide propyl-N,N,N-dimethyl hydroxyethyl ammonium chloride, in an aqueous solution; and based on the total mass of the monomers, the mass ratios of acrylamide, N-vinylpyrrolidone and N-acrylamide propyl-N,N,N-dimethyl hydroxyethyl ammonium chloride are 40-85%, 5-35% and 3-25%, respectively. The high-temperature-resistant alcohol-based fracturing fluidsystem is prepared from the following raw materials: the polyhydroxy thickener, a composite cross-linking agent, a regulator, high-flash-point alcohol and water. According to the alcohol-based fracturing fluid system disclosed by the invention, the polyhydroxy thickening agent is introduced, so the alcohol-based fracturing fluid system has relatively high temperature resistance and shearing resistance, and can resist a temperature of 160 DEG C or above; by using the high-flash-point alcohol, the fracturing system is safer; and an alcohol / water ratio can be increased to 60% or above, even an anhydrous system with the alcohol / water ratio of 100% can be realized, so the fracturing fluid system has the advantages of high flowback rate, small stratum damage, safety, environment friendliness andthe like.

Owner:北京九恒质信能源技术有限公司

Filtrate loss reducer and application thereof to non-tackifying pure liquid-state CO2 sand fracturing

ActiveCN106833594AReduce fluid lossHigh viscosityFluid removalDrilling compositionWater basedEcological environment

The invention discloses a filtrate loss reducer. The filtrate loss reducer is prepared from the following raw materials in parts by weight: 10-25 parts of 5# white oil, 0.5-2 parts of NP-1, 0.1-1 part of TX-4, 1-10 parts of n-caprylic acid, 1-10 parts of KCl, 4-15 parts of a carboxymethyl guanidine gum solution with the concentration of 1%. According to the filtrate loss reducer, the sand carrying capability of pure liquid-state CO2 fracturing liquid can be improved and the loss of the fracturing liquid is effectively reduced. Meanwhile, the invention further provides application of the filtrate loss reducer to a pure liquid-state CO2 sand fracturing process; the filtrate loss reducer is pumped into a stratum before pure liquid-state CO2 fracturing is constructed, and the sand fracturing is carried out; the filtrate loss reducer has the advantages of rapid backflow, increased backflow rate, shortened period of putting into production and the like; and water-based fracturing liquid does not need to be prepared in the process and backflow liquid does not need to be treated, so that the environment pollution degree is reduced, and the filtrate loss reducer has relatively good practical significance on regions with lacked water resources and regions with fragile ecological environments.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Gemini type air humidity reversal agent compound as well as preparation method and application thereof

ActiveCN107986981AGood hydrophobic and oleophobic propertiesReduce adsorptionOrganic compound preparationCarboxylic acid amides preparationAqueous solutionAir humidity

The invention relates to a gemini type air humidity reversal agent compound as well as a preparation method and application thereof. The gemini type air humidity reversal agent compound is N,N-di(perfluoro-capryloyl) imine carboxylate. The invention also provides a preparation method of the gemini type air humidity reversal agent compound. The gemini type air humidity reversal agent compound is easy to prepare, relatively high in yield, can be prepared into an aqueous solution with water in any proportion and can change liquid humidity of the surface of a shale reservoir into air humidity, oil-gas recovery ratio is increased, and field application is facilitated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

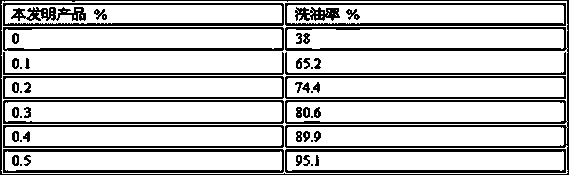

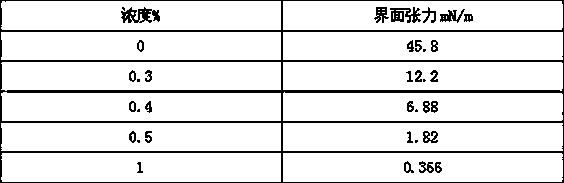

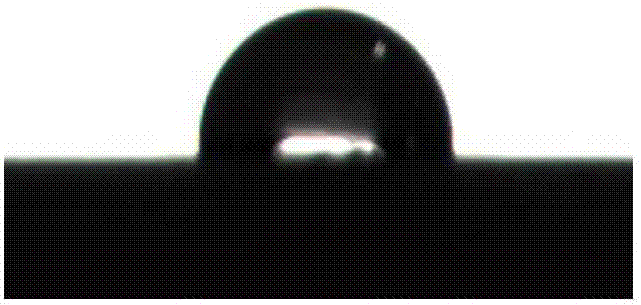

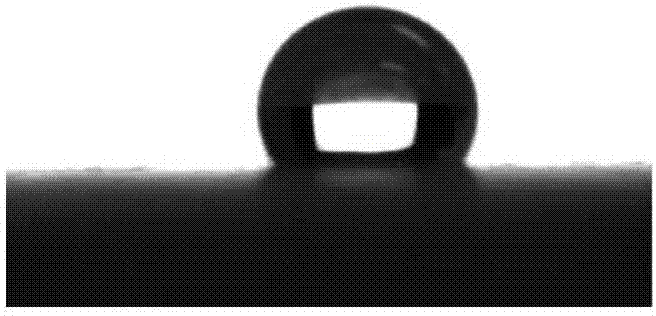

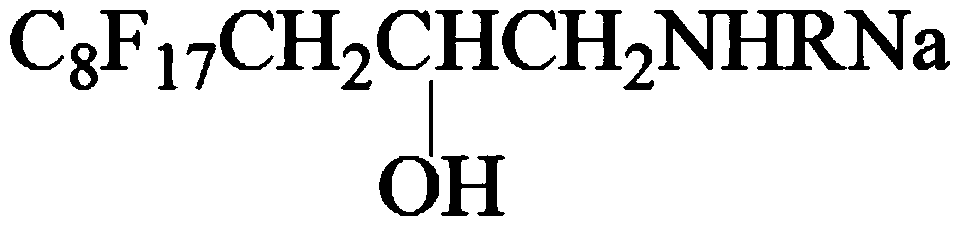

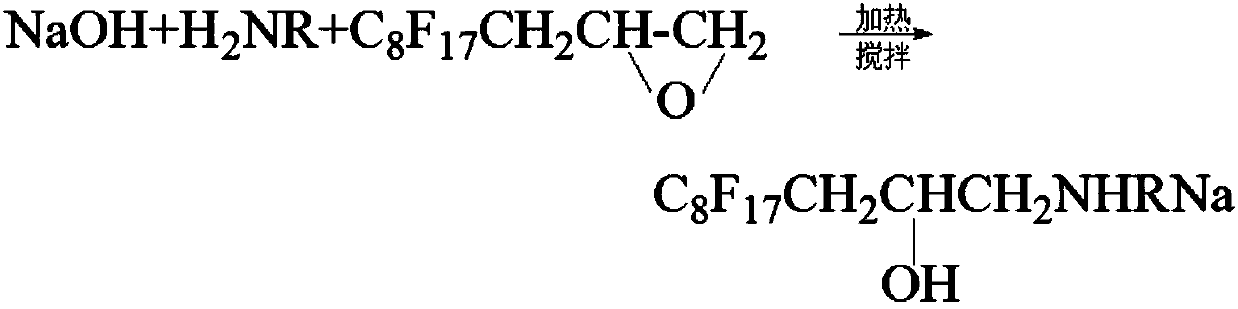

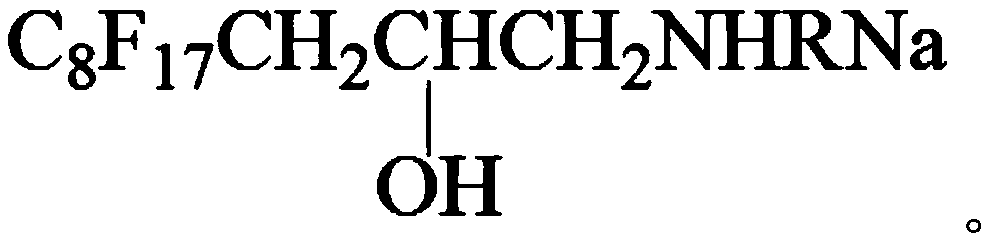

Fluorocarbon surfactant as well as preparation method and application thereof

ActiveCN107759484AImprove surface activityImprove temperature resistanceOrganic compound preparationSulfonic acids salts preparationSolubilityMaterials preparation

The invention discloses a fluorocarbon surfactant as well as a preparation method and application thereof and relates to the technical field of material preparation. The preparation method of the fluorocarbon surfactant comprises the following steps: mixing caustic alkali, amino compounds, 3-perfluorooctyl epoxypropane and a first solvent, and reacting under the temperature condition of 60-90 DEGC for 10-30 hours. Preferably, the reaction temperature is 65-75 DEG C, and the reaction time is 16-24 hours. The preparation method is simple, feasible and convenient for industrialized application.The fluorocarbon surfactant prepared by using the method has the advantages of being high in surface activity, excellent in temperature resistance, excellent in solubility, small in usage amount, mildin synthesis conditions and the like, and the surface tension of an aqueous solution can be effectively reduced. Meanwhile, the fluorocarbon surfactant is capable of effectively reducing the surfaceand interfacial tension of acidizing and fracturing fluid and improving a flowback rate and can be applied to a process of preparing an oilfield acidizing and fracturing assistant.

Owner:克拉玛依市新聚工贸有限责任公司

Fluoride-free cleanup additive used for acidifying

The invention relates to a fluoride-free cleanup additive used for acidifying, which is composed of a main agent, a reinforcing agent, a cosolvent and water. the main agent is alkyl trimethyl ammonium bromide or alkyl bromid pyridine, wherein the alkyl can be dodecyl, cetyl or octadecyl, the main agent accounts for 20-50% of the cleanup additive by weight percentage, the reinforcing agent is fatty alcohol polyoxyethylene ether, dihydroxyethyl dodecyl amide or cocamidopropyl dimethyl betaine, the reinforcing agent accounts for 1-10% of the cleanup additive by weight percentage, the cosolvent is a mixture of one or more of methanol, ethanol or glycol, the cosolvent accounts for 5-25% of the cleanup additive by weight percentage, and the balance is water. The cleanup additive is capable of effectively reducing the capillary force in stratum, rapidly discharging the residual acid liquid out of the stratum and reducing the damage to the stratum.

Owner:SOUTHWEST PETROLEUM UNIV

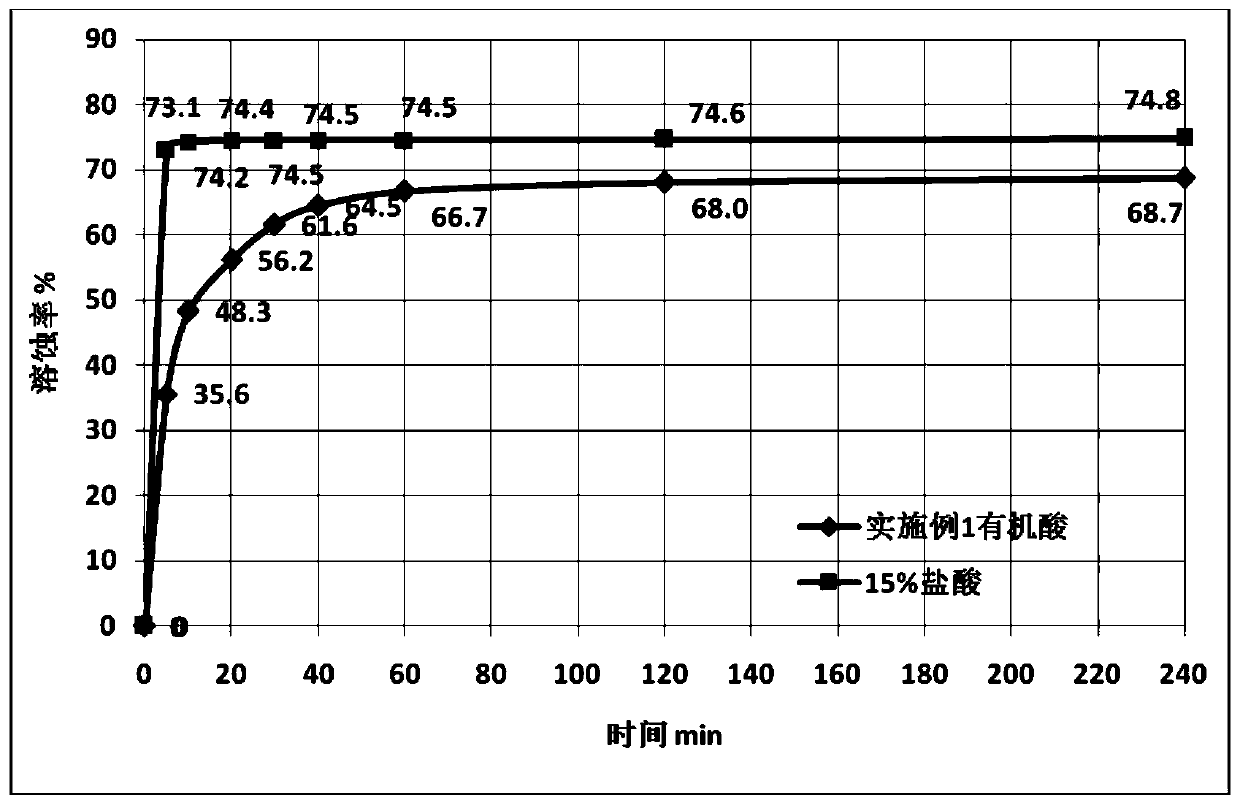

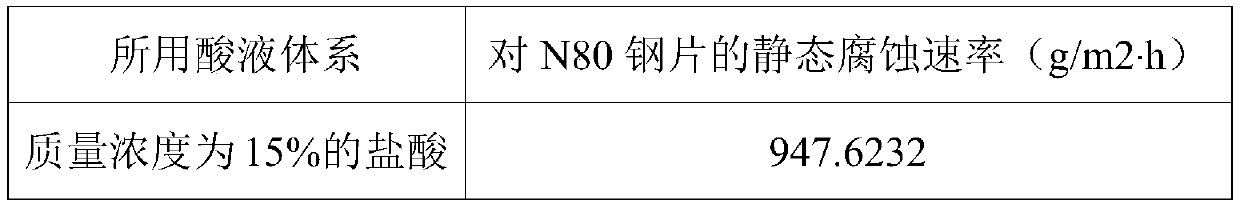

Organic acid system for acidification transformation of carbonate reservoir and preparation method

The invention discloses an organic acid system for acidification transformation of a carbonate reservoir and a preparation method. The organic acid system comprises the following components in percentage by mass: 45-60% of an organic acid liquid, 0.3-2% of a corrosion inhibitor, 0.2-1% of EDTA (ethylene diamine tetraacetic acid), 0.03-1.5% of a slow-speed additive, 0.03-1.5% of an iron ion stabilizer, 0.1-1% of a discharge aiding agent and the balance of water. With the combination of the corrosion inhibitor and other components, the system is capable of preventing corrosion under a strong acid condition, acidification of pipeline equipment can be retarded, corrosion of equipment and tubes can be reduced, the reaction velocity of acidic rock can be reduced, the length of an acid etching crack can be increased, and thus an effect of deep acidification transformation can be achieved.

Owner:PETROCHINA CO LTD

Drilling, jam releasing and fracturing integrated device and method for soft coal seam

ActiveCN114508336AAvoid borehole collapseImprove coal slag flowback rateConstructionsLiquid/gas jet drillingDrill holeSoft Coals

The invention provides a drilling, jam releasing and fracturing integrated device and method for a soft coal seam. According to the device, a drill rod is assembled on a drilling machine, a jet flow drill bit is installed at the outlet end of the drill rod, and the inlet end of the drill rod is connected with an outlet of a low-temperature pump; outlets of a plurality of first liquid nitrogen tanks in the first set of liquid nitrogen tank group are connected with an inlet of a low-temperature pump through a first nitrogen supply pipeline; outlets of a plurality of second liquid nitrogen tanks in the second liquid nitrogen tank group are connected with the main nitrogen supply pipeline through a second nitrogen supply pipeline; a heater is arranged at the bottom of the second liquid nitrogen tank. The method comprises the steps of determining a coal seam drilling position and an anti-reflection transformation area; arranging a drilling, jam releasing and fracturing integrated device in the rock roadway; liquid nitrogen output by the first set of liquid nitrogen tank group is pressurized by a low-temperature pump and then is conveyed into a jet flow drill bit, and formed high-speed liquid nitrogen jet flow acts on a coal seam; and blocking the inlet of the drill hole, fracturing the coal seam by using high-pressure fluid generated by liquid nitrogen phase change, and forming cracks in the coal seam. By means of the device and method, drilling, jam releasing and fracturing operation can be integrally achieved.

Owner:CHINA UNIV OF MINING & TECH

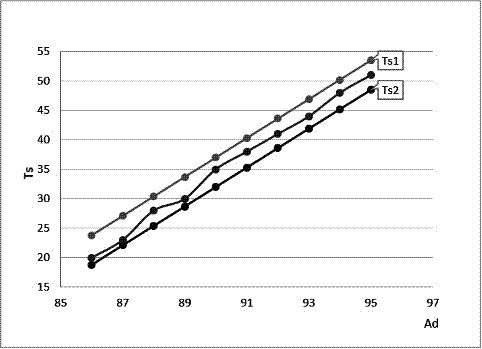

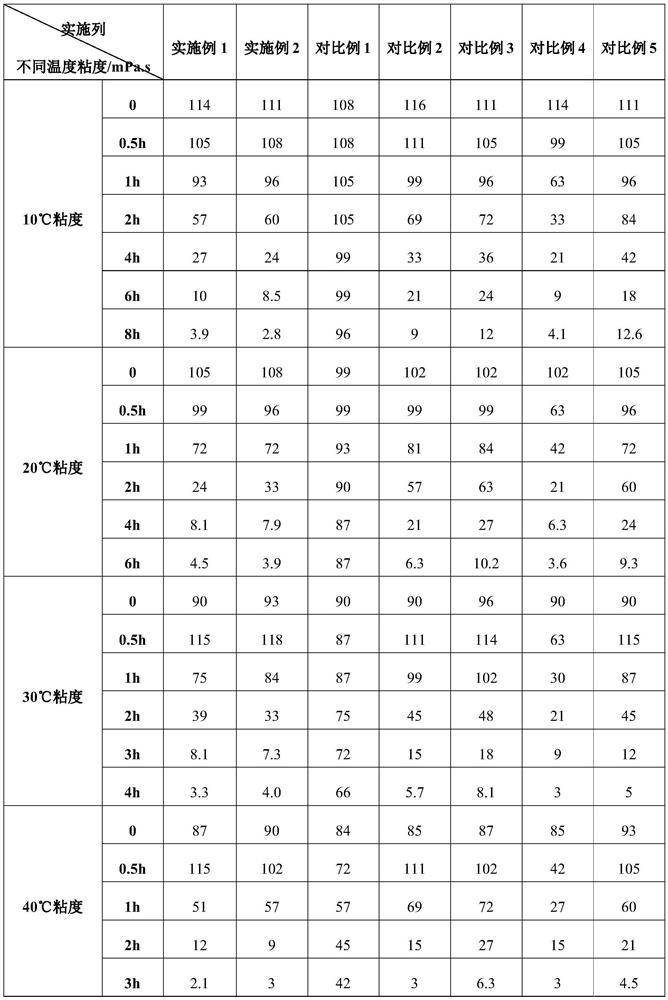

Water-soluble PVA (polyvinyl alcohol) fiber as well as preparation method and application thereof

ActiveCN107268103ASpecial water solubilityPromote production increaseWet spinning methodsMonocomponent synthetic polymer artificial filamentSolubilityFiber

A PVA (polyvinyl alcohol) fiber is prepared, through spinning, from PVA with polymerization degree being 1500-2500 and alcoholysis degree Ad meeting a relation that Ad (mol / mol) is larger than or equal to 86% and smaller than or equal to 95.0%. The PVA fiber has special water solubility, and can improve the sand carrying capacity of fracturing fluid when used in fracturing construction of oil and gas fields; due to the good water solubility, the product can flow back to the ground timely after fracturing construction, and accordingly, production increase of the oil and gas fields is promoted greatly. A preparation method is simple and suitable for industrial production.

Owner:CHINA PETROCHEMICAL CORP +1

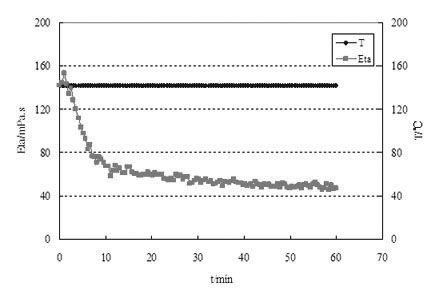

Efficient low-temperature gel breaker for polymer fracturing fluid and preparation method thereof

InactiveCN112745822AViscosity changes smoothlyViscosity change gradient is gentleDrilling compositionPolymer sciencePolyamide

The invention relates to the technical field of gel breakers for fracturing fluids, and particularly discloses an efficient low-temperature gel breaker for a polymer fracturing fluid. The efficient low-temperature gel breaker comprises an agent A and an agent B. The agent A comprises 35-45 parts of a gel breaking main agent, 3-5 parts of a gel breaking main agent stabilizer, 45-65 parts of mineral oil, 1-2 parts of polyamide and 0.3-0.5 part of hydrogenated castor oil, and the gel breaking main agent is peroxide; the agent B comprises the following components in parts by weight: 5-10 parts of a gel breaking activator, 1-2 parts of an activation stabilizer, 15-20 parts of a gel breaking auxiliary agent, 5-10 parts of a gel breaking retarder, 3-5 parts of an emulsifier, 30-40 parts of white oil and 20-30 parts of water. Compared with a conventional gel breaker system, the low-temperature gel breaker has the advantages that the performance of gel breaking liquid is not reduced during construction, gel breaking is rapid and thorough after construction is completed, the low-temperature gel breaker has the dual functions of liquid construction performance protection and efficient gel breaking, and the problem of gel breaking at the low temperature of 0-50 DEG C is solved.

Owner:CHENGDU LEARN PRACTICES TECH CO LTD +1

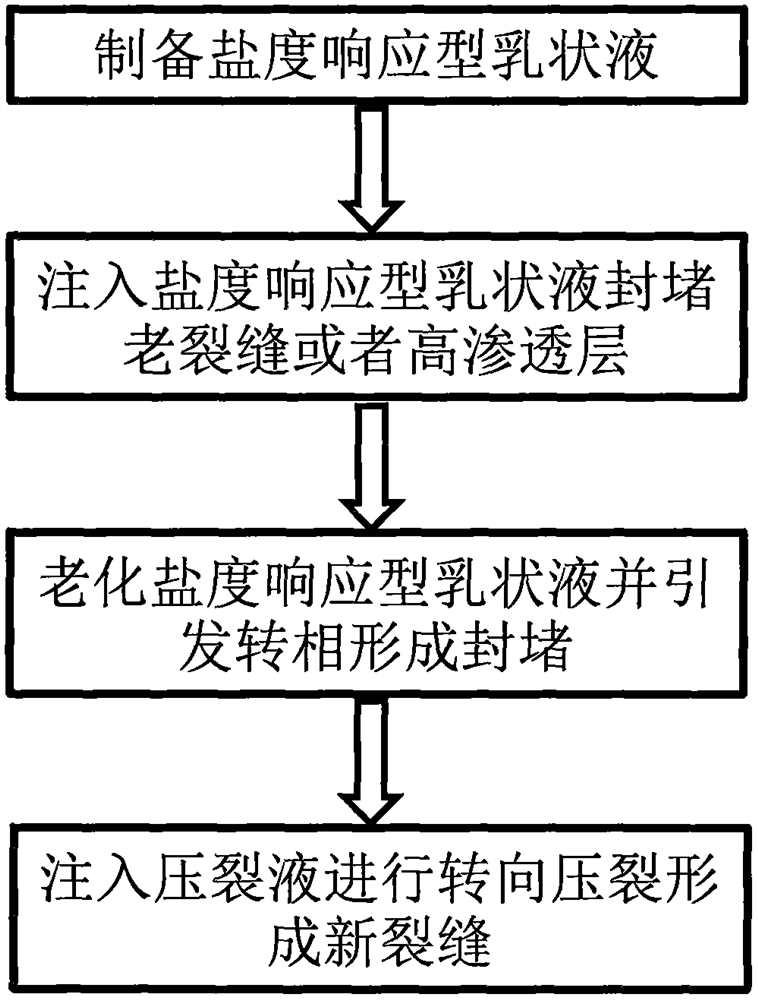

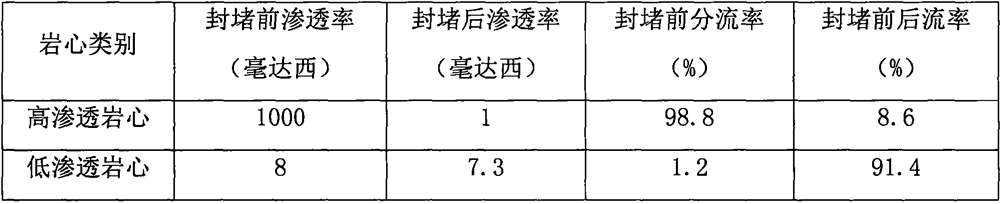

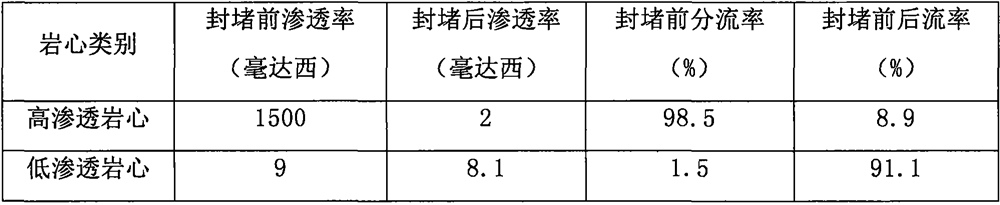

Method for temporarily plugging diversion fracturing by using salinity response type emulsion

PendingCN112901110ALow costEasy to prepareFluid removalDrilling compositionEmulsionEnhanced oil recovery

The invention discloses a method for temporarily plugging diversion fracturing by using a salinity response type emulsion. The method comprises the following steps of 1, preparing the salinity response type emulsion; 2, injecting the salinity response type emulsion to plug old cracks or high-permeability layers; 3, aging the salinity response type emulsion and initiating phase inversion to form plugging; and 4, injecting a fracturing fluid for the diversion fracturing to form new cracks. A salinity response type emulsion-based diverting agent has the advantages of simple preparation, high plugging performance and small formation damage, and solves the problems of low plugging strength, complex use process, difficult gel breaking or degradation, low flowback rate and large formation damage of an existing diverting agent; and the diverting agent can effectively plug the original cracks, and then the new cracks have a certain angle with respect to the original cracks are formed after the diversion fracturing, so that more oil gas seepage channels are formed, the oil drainage area is expanded, the crude oil recovery rate and economic benefits are greatly improved, and the diverting agent is convenient to popularize and use.

Owner:CHANGAN UNIV

Fracturing method of reservoir

InactiveCN112814641AElimination of minimum principal stressGood for flowbackFluid removalOrganic acidFracturing fluid

The invention relates to a fracturing method of a reservoir. The fracturing method comprises the steps that a first agent, a second agent and a third agent are sequentially added into a stratum; the first agent comprises one or a combination of at least two of mud acid, multi-hydrogen acid and organic acid; the second agent is liquid carbon dioxide; the third agent comprises water-based fracturing fluid and a propping agent; by adopting a specific agent treatment mode, treatment of the total wave and the volume of the reservoir is achieved, a fracture network is constructed in a near-wellbore area, and the minimum main stress of the near-wellbore area is eliminated; the water-based fracturing fluid constructs a main fracture with the high flow conductivity in a far-wellbore area, so that the fracture extends to the deep part of the reservoir, the volume of the fracturing wave is further expanded, and a powerful guarantee is provided for continuous high and stable yield of a subsequent oil and gas well; and the liquid carbon dioxide in the middle section plays a role in promoting flowback and supplementing energy.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com