Water-soluble PVA (polyvinyl alcohol) fiber as well as preparation method and application thereof

A fiber and dissolution temperature technology, applied in the directions of spinning solution preparation, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problems of formation pollution, use restrictions, etc., and achieve the effect of reducing damage, reducing dosage, and achieving good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

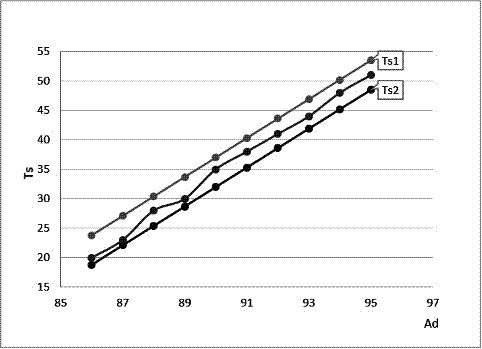

Image

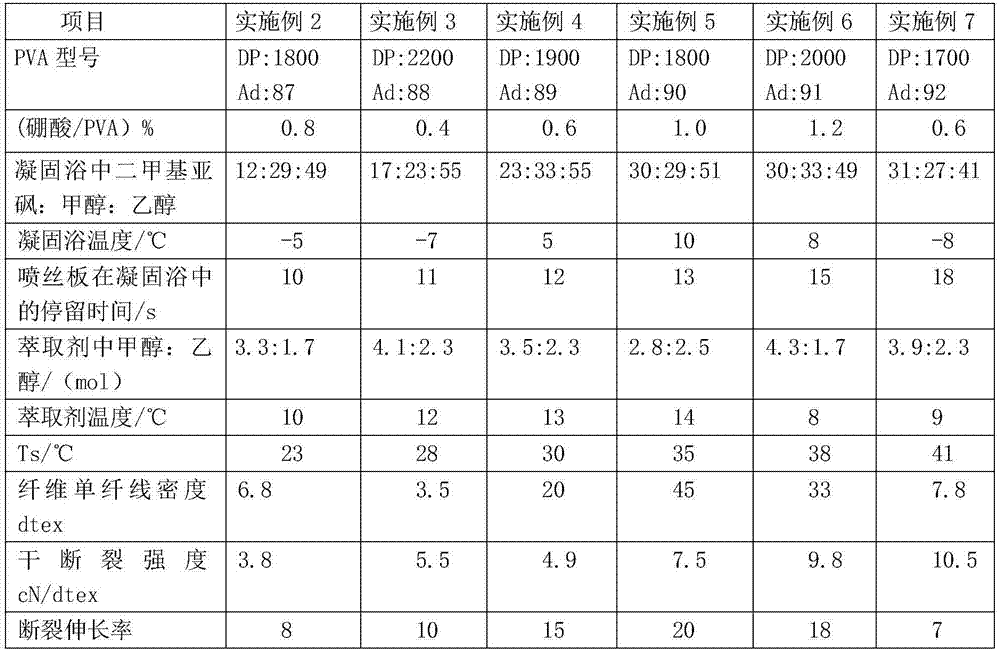

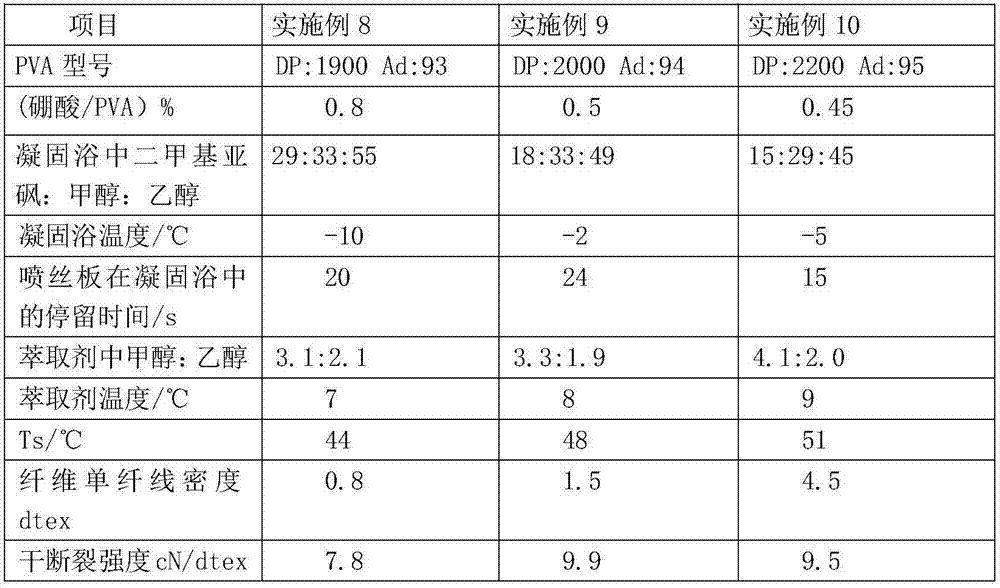

Examples

Embodiment 1

[0039] Embodiment 1: prepare water-soluble PVA fiber, main steps are as follows:

[0040] (1) Preparation of spinning stock solution: the degree of polymerization is 1600, the degree of alcoholysis is 86.0 (mol)% PVA and boric acid are dissolved in water and made into spinning stock solution, the mass concentration of PVA in stock solution is 15%, boric acid is added The amount is 0.5% of the PVA mass, the stock solution is heated up to 105 ° C, and the pressure is maintained at 0.08 MPa, dissolved for 12 hours, then filtered, defoamed, and then enters the spinning process.

[0041] (2) Spinning: The PVA stock solution is sent to the spinning assembly by a metering pump, and the PVA stock solution is sprayed into the coagulation bath from the small hole of the spinneret. The composition of the coagulation bath is dimethyl sulfoxide, methanol and ethanol, the mass ratio of dimethyl sulfoxide, methanol and ethanol is 13:25:41, the temperature of the coagulation bath is -5°C, and...

Embodiment 11

[0051] This embodiment provides a fiber-containing guar gum fracturing fluid, the preparation method of which is as follows:

[0052] Step 1: under stirring condition, add 0.2 weight part of thickener hydroxypropyl guar gum (China Petroleum Substances Kunshan Company), 0.12 weight part of sodium carbonate, 0.1 weight part of potassium chloride to 100 weight parts of water, then stir for 20min, Obtain guar thickener aqueous solution;

[0053] Step 2: under stirring conditions, add 0.2 parts by weight of crosslinking agent aluminum nitrate to the above-mentioned thickener aqueous solution to obtain guar gum fracturing fluid (excluding fiber guar gum fracturing fluid);

[0054] Step 3: Add 0.5 parts by weight of the PVA fiber prepared in Example 1 to the above-mentioned guar gum fracturing fluid, cut the fiber to a length of 10 mm, add it to the oil and gas field fracturing fluid and disperse evenly, and obtain the fiber-containing guar gum fracturing fluid.

[0055] Step 4: Add...

Embodiment 12

[0057] Referring to Example 11, cut the high-strength and high-modulus PVA fibers obtained in Example 2 to a length of 6 mm, add them to the oil and gas field fracturing fluid, and disperse evenly. In the final stage, PVA fibers are added to the fracturing fluid in three steps. Guar gum and crosslinking agent are also added to the fracturing fluid of oil and gas fields. The mass content of PVA fibers in the fracturing fluid of oil and gas fields is 1.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com