Patents

Literature

1373results about "Synthetic polymer filament chemical after-treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

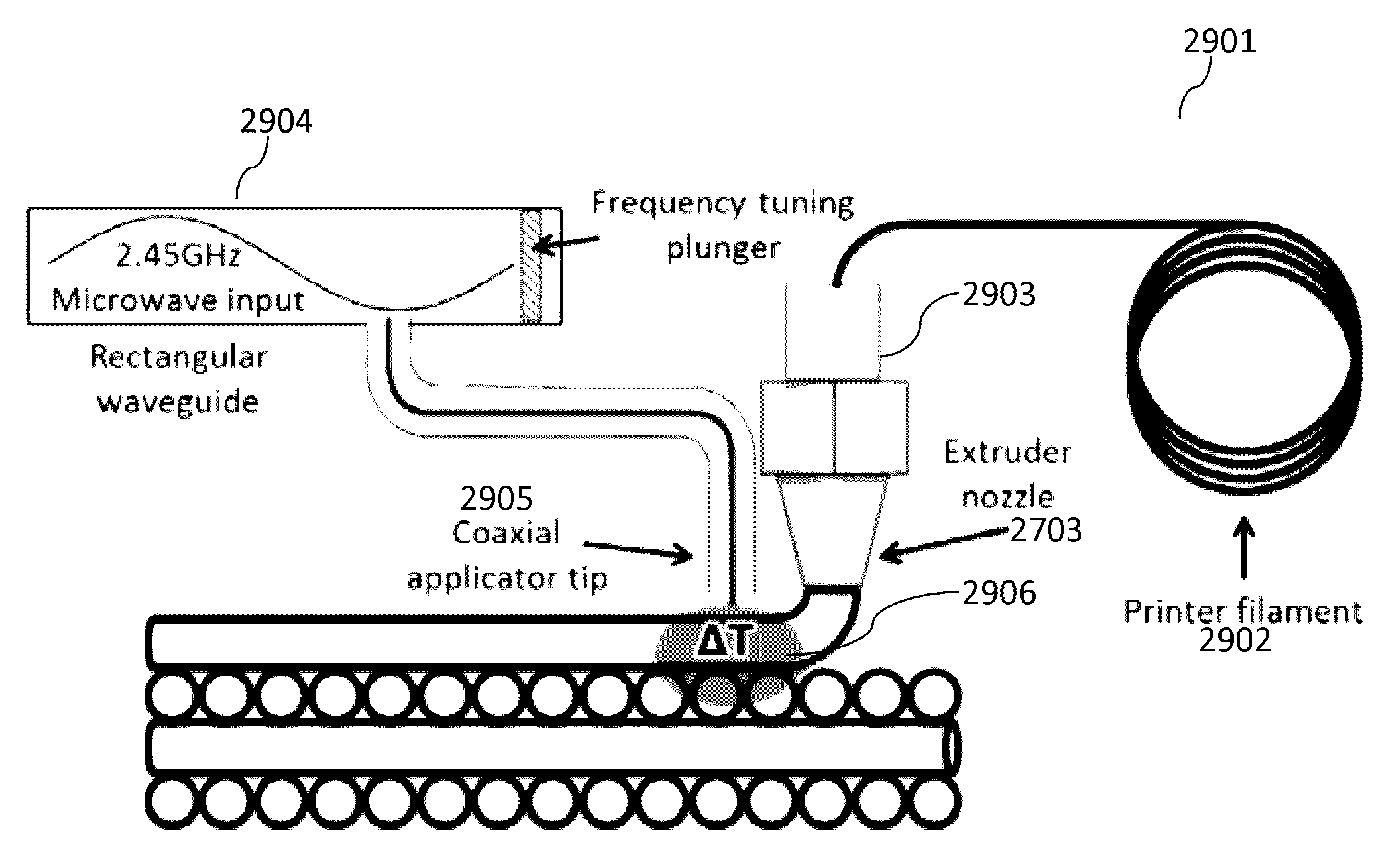

Microwave-induced localized heating of cnt filled polymer composites for enhanced inter-bead diffusive bonding of fused filament fabricated parts

ActiveUS20160325491A1Increase inter-bead bond strengthImprove mechanical propertiesMaterial nanotechnologyElectroconductive/antistatic filament manufacture3d printCarbon nanotube

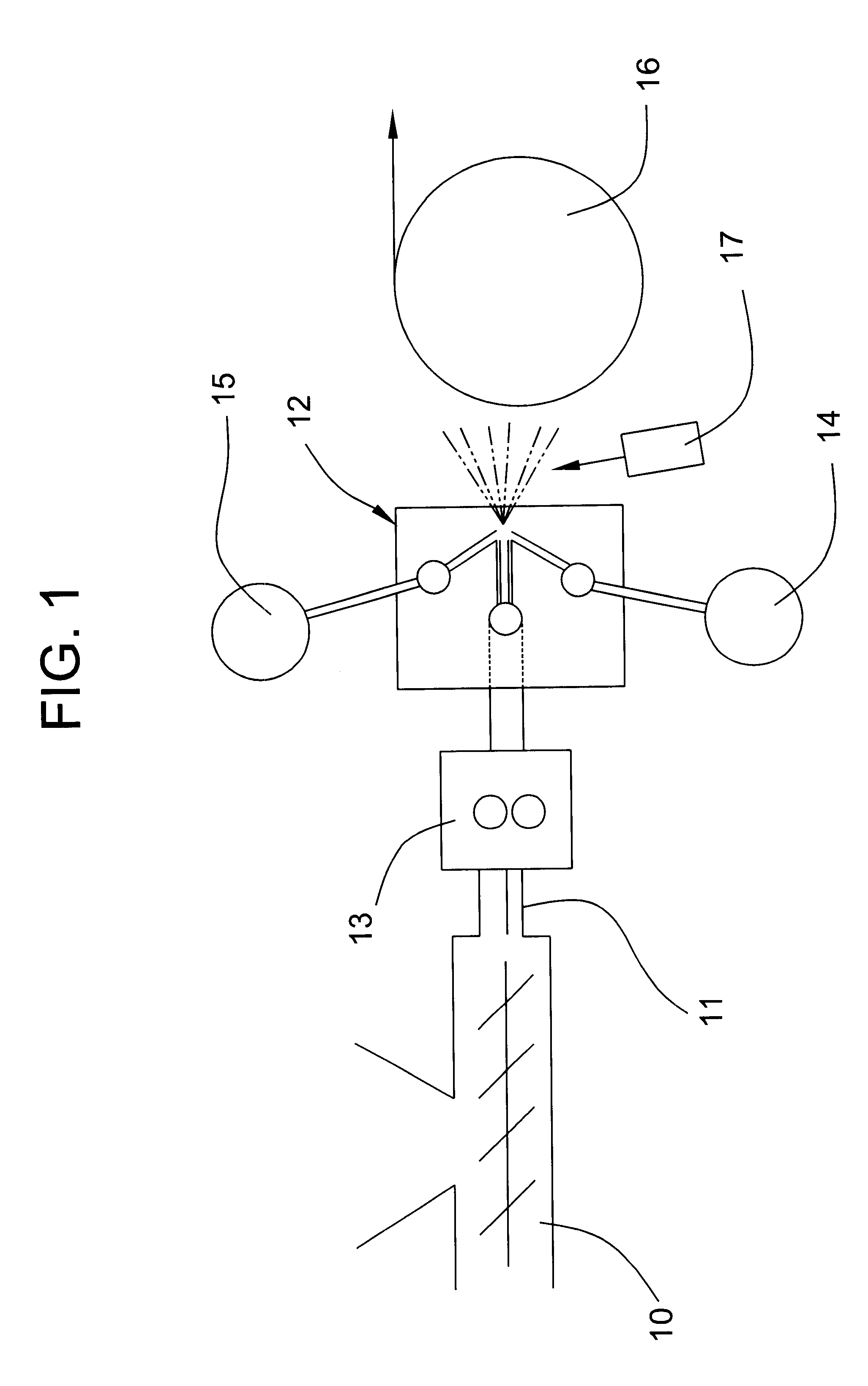

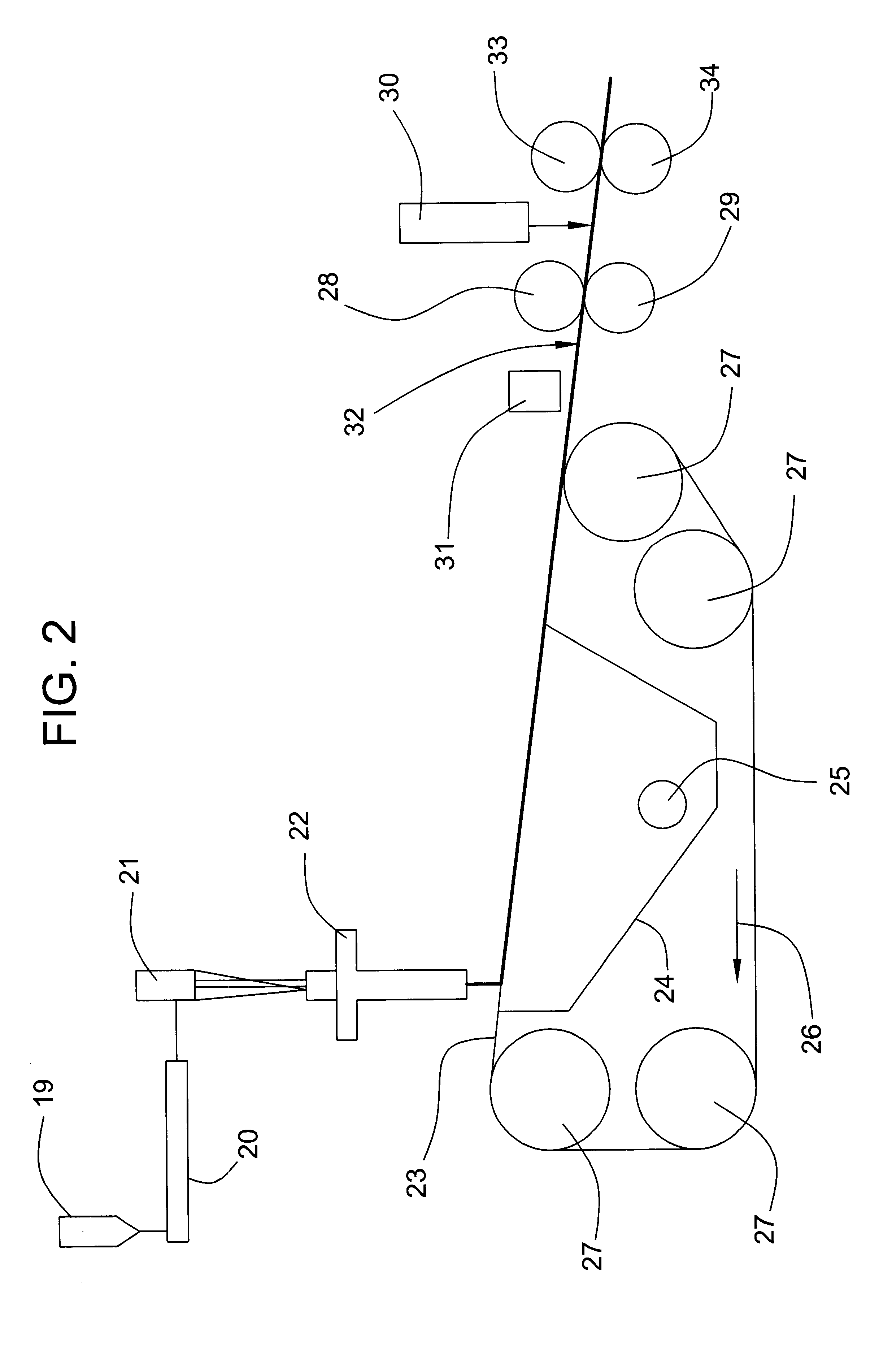

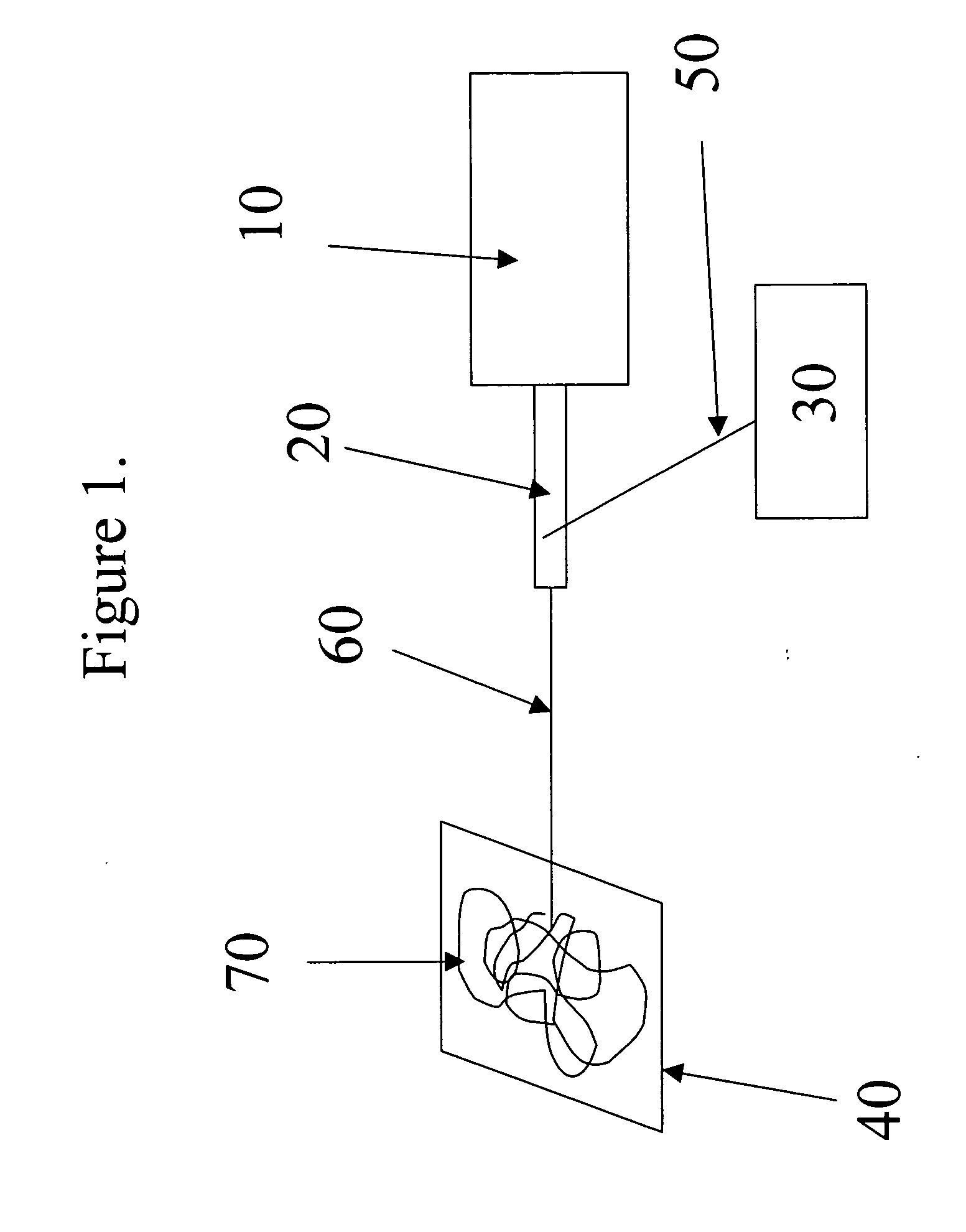

A microwave-induced heating of CNT filled (or coated) polymer composites for enhancing inter-bead diffusive bonding of fused filament fabricated parts. The technique incorporates microwave absorbing nanomaterials (carbon nanotubes (CNTs)) onto the surface or throughout the volume of 3D printer polymer filament to increase the inter-bead bond strength following a post microwave irradiation treatment and / or in-situ focused microwave beam during printing. The overall strength of the final 3D printed part will be dramatically increased and the isotropic mechanical properties of fused filament part will approach or exceed conventionally manufactured counterparts.

Owner:TEXAS TECH UNIV SYST

Activated carbon fibers, methods of their preparation, and devices comprising activated carbon fibers

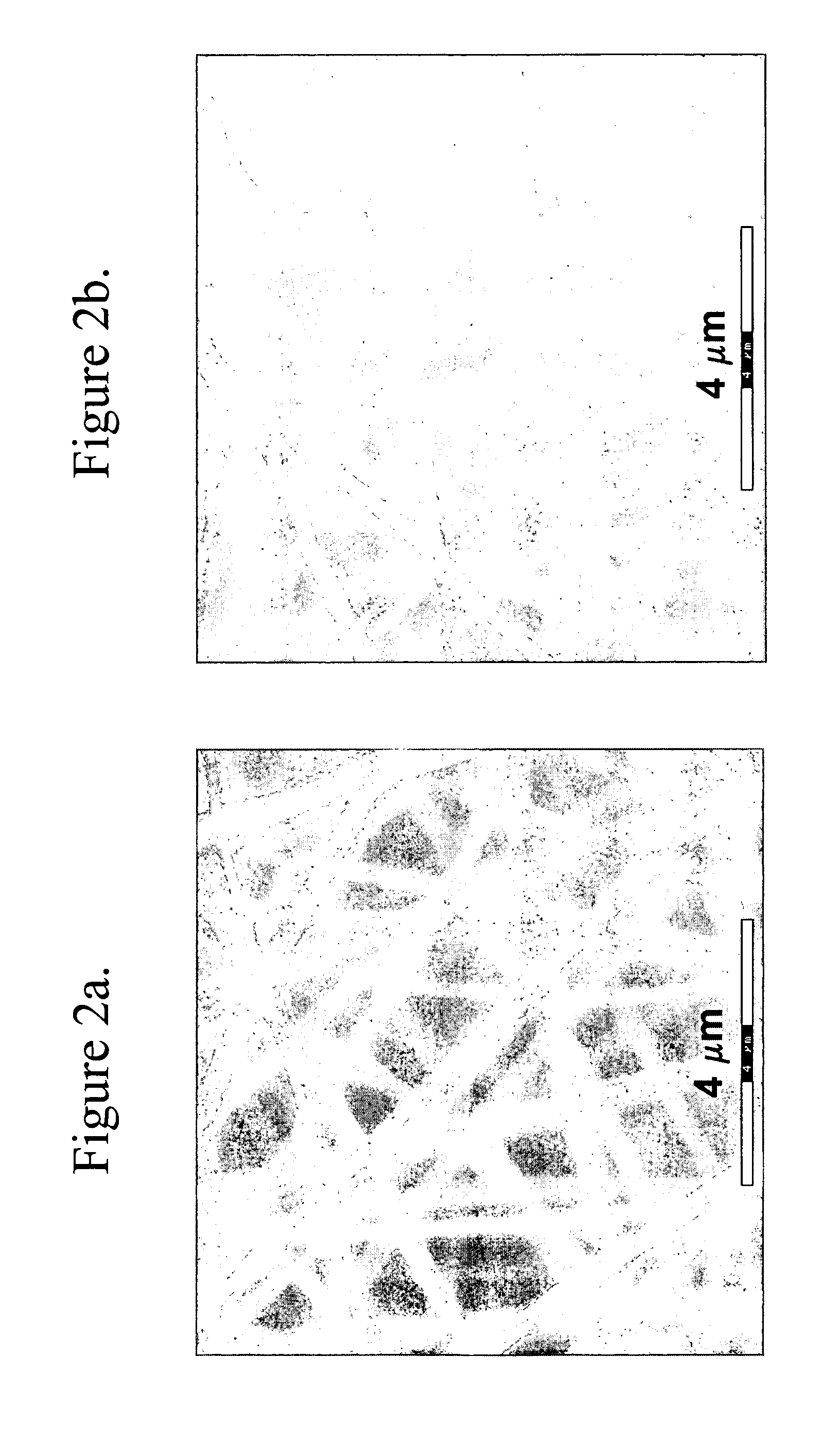

Catalytically activated carbon fibers and methods for their preparation are described. The activated carbon fibers are engineered to have a controlled porosity distribution that is readily optimized for specific applications using metal-containing nanoparticles as activation catalysts. The activated carbon fibers may be used in all manner of devices that contain carbon materials, including but not limited to various electrochemical devices (e.g., capacitors, batteries, fuel cells, and the like), hydrogen storage devices, filtration devices, catalytic substrates, and the like.

Owner:NANOCARBONS LLC

Process for preparing a non-woven fibrous web

Disclosed is a process for preparing a fibrous web. The fibrous web includes a microencapsulated material, such as a microencapsulated phase change material, adhered to the web. Preferably, the web is prepared in a melt-blowing or spun-bonding process. In the melt-blowing process, cooling water containing the microcapsules is used to cool melt blown fibers prior to collection on a collector. In the spun-bonding process, microcapsules are applied in liquid suspension or in dry form to a heated web, for instance, after the web has been calendared. The fibrous webs thus prepared have numerous uses, and are particularly suited to the manufacture of clothing.

Owner:ENCAPSYS LLC

Polyester DTY fiber and preparation method thereof

ActiveCN108385186AHigh molecular weightNarrow molecular weightSpinning head liquid feederFilament/thread formingFiberThermal insulation

The invention relates to polyester DTY fiber and a preparation method thereof. The preparation method comprises: metering a modified polyester melt, extruding, cooling, oiling, and winding to preparethe polyester POY fiber. According to the present invention, during the cooling, the longitudinal height is maintained, and the cross section area of the slow cooling chamber is increased while the plate surface temperature of the spinning plate is maintained by using the thermal insulation method; the material of the fiber is the modified polyester, the molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the structure formula of the diol chain segment having the branched chain is defined in the specification, R1 and R2 are respectively and independently selected from straight chain alkylidene with a carbon atom number of 1-3, R3 is selected from alkyl with a carbon atomnumber of 1-5, and R4 is selected from alkyl with a carbon atom number of 2-5; the chromatic aberration [delta]E of the prepared fiber is less than 0.200; and the preparation process is simple and reasonable, and the obtained fiber has excellent performance.

Owner:JIANGSU HENGLI CHEM FIBER

Sulfopolyester binders

Owner:EASTMAN CHEM CO

Method for preparing polyacrylonitrile carbon fiber protofilament by dry and wet methods

InactiveCN102146595AGive full play to the advantages of dry and wet methodsGive full play to the advantagesArtificial filament washing/dryingFilament/thread formingPolymer scienceCarbon fibers

The invention discloses a method for preparing polyacrylonitrile carbon fiber protofilament by dry and wet methods. The method comprises the steps of polymerization, demonomerization and defoaming, filtration, coagulation, washing and drafting, oiling densification, steam drafting, heat setting and drying. Three-level coagulating baths at the temperature of between 10 DEG C below zero and 70 DEG C and with dimethyl sulfoxide with concentration of 10 to 60 mass percent are adopted in the coagulation step, and the first coagulating bath contains aqueous ammonia accounting for 0.05 to 1 percent of the mass of the first coagulating bath; and a spinning head is subjected to 1.5 to 5 times positive drafting in the first coagulating bath, and the drafting is 0 in the second and third coagulatingbathes. According to the method for preparing the polyacrylonitrile carbon fiber protofilament, the spinning process is stable, the broken filament is little, the spinning speed is high, the spinningis stable, the prepared protofilament has few defects, the density is not less than 1.180g / cm<3>, and the tensile strength is not less than 7cN / dtex. The protofilament can be prepared into a high-performance carbon fiber with tensile strength of more than 4.9GPa and elastic modulus of between 260 and 280GPa by high-temperature carbonization.

Owner:KINGFA SCI & TECH CO LTD +1

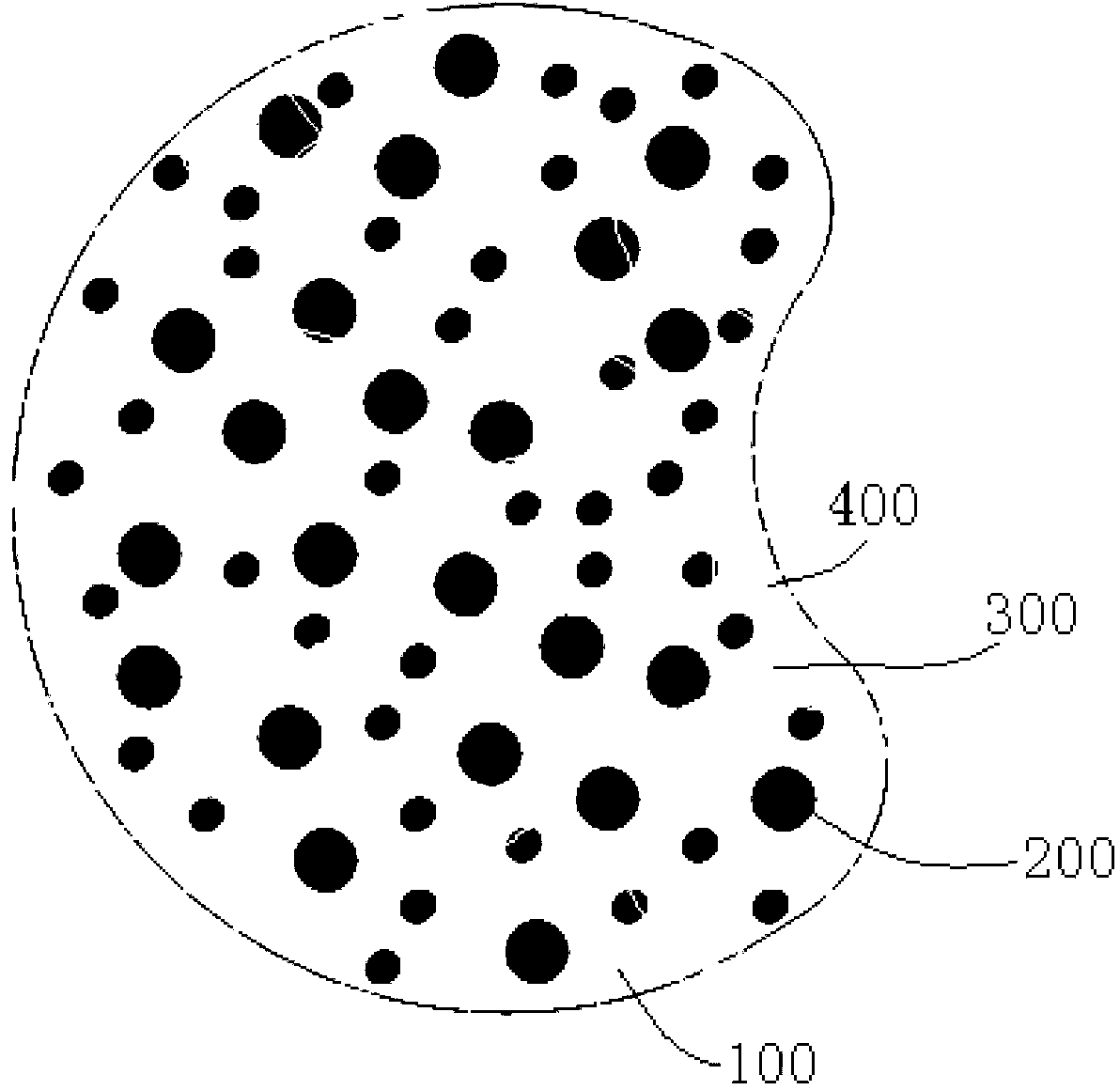

Silicon-carbon composite material with nano micropores and preparation method as well as application thereof

ActiveCN103305965AImprove lithium storage performanceImprove electrochemical performanceCell electrodesFilament/thread formingCarbon compositesCarbon fibers

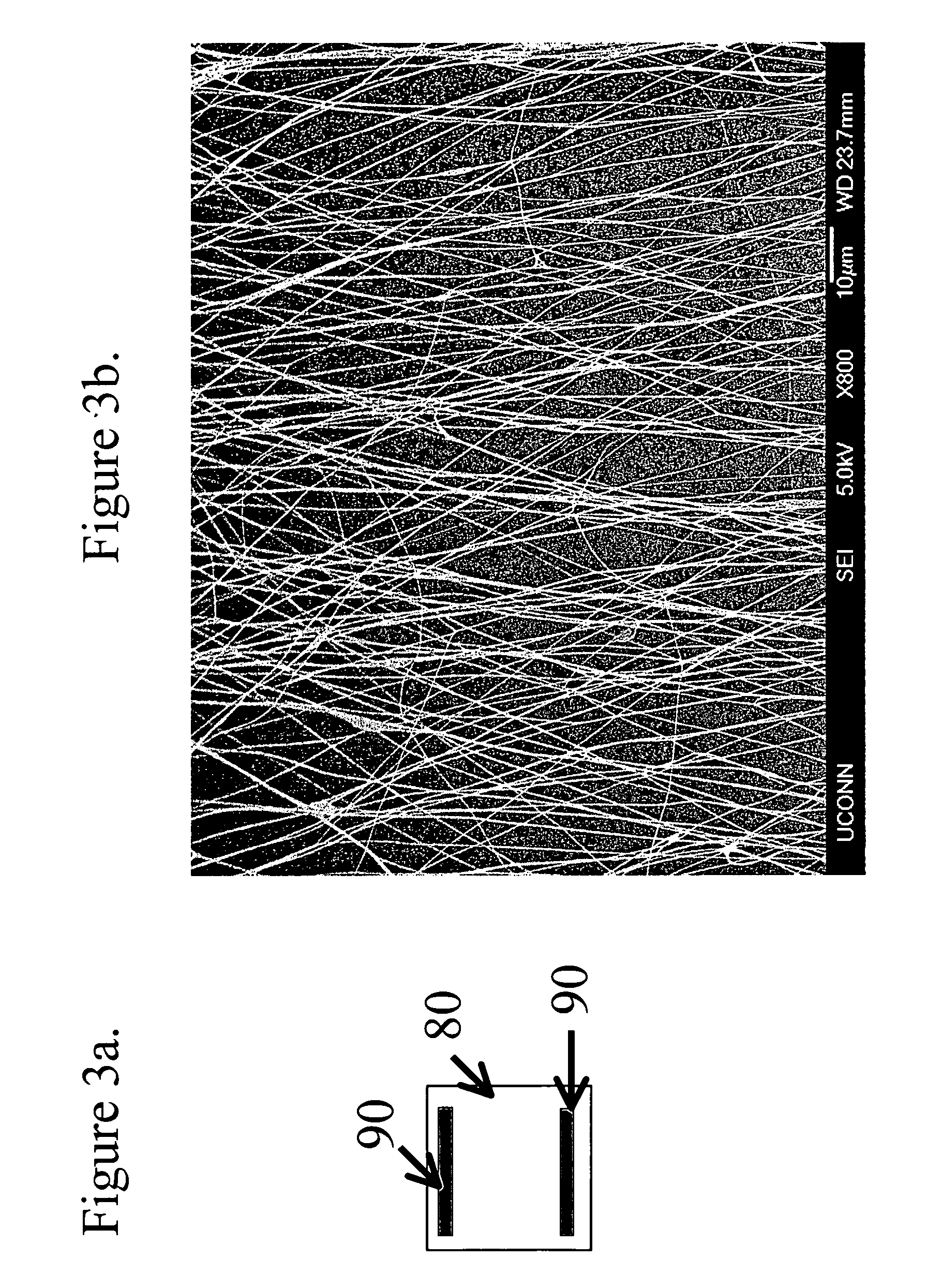

The invention discloses a silicon-carbon composite material with nano micropores and a preparation method as well as application thereof. The material comprises nano-silicon (Si) particles and a carbon nanofiber matrix, wherein the nano-silicon particles are dispersed in the carbon nanofiber matrix; and nano pores and micropores communicated with the nano pores are distributed in the carbon nanofiber matrix. The method comprises the steps of dissolving the nano-Si particles and polyacrylonitrile (PAN) in a solvent to prepare a mixed spinning solution, then carrying out electrostatic spinning on the mixed spinning solution, and curing spinning trickles in a coagulating bath to obtain a porous PAN-Si composite nanofiber; and then carrying out oxidation and carbonization treatment in sequence to obtain the silicon-carbon composite material with a nano micropore structure. The silicon-carbon composite material is applied to preparation of lithium ion battery cathode materials. Compared with the prior art, the silicon-carbon composite material ensures the overall electron transport capacity of the material while reserving buffer space for expansion of the nano-Si particles.

Owner:深圳石墨烯创新中心有限公司

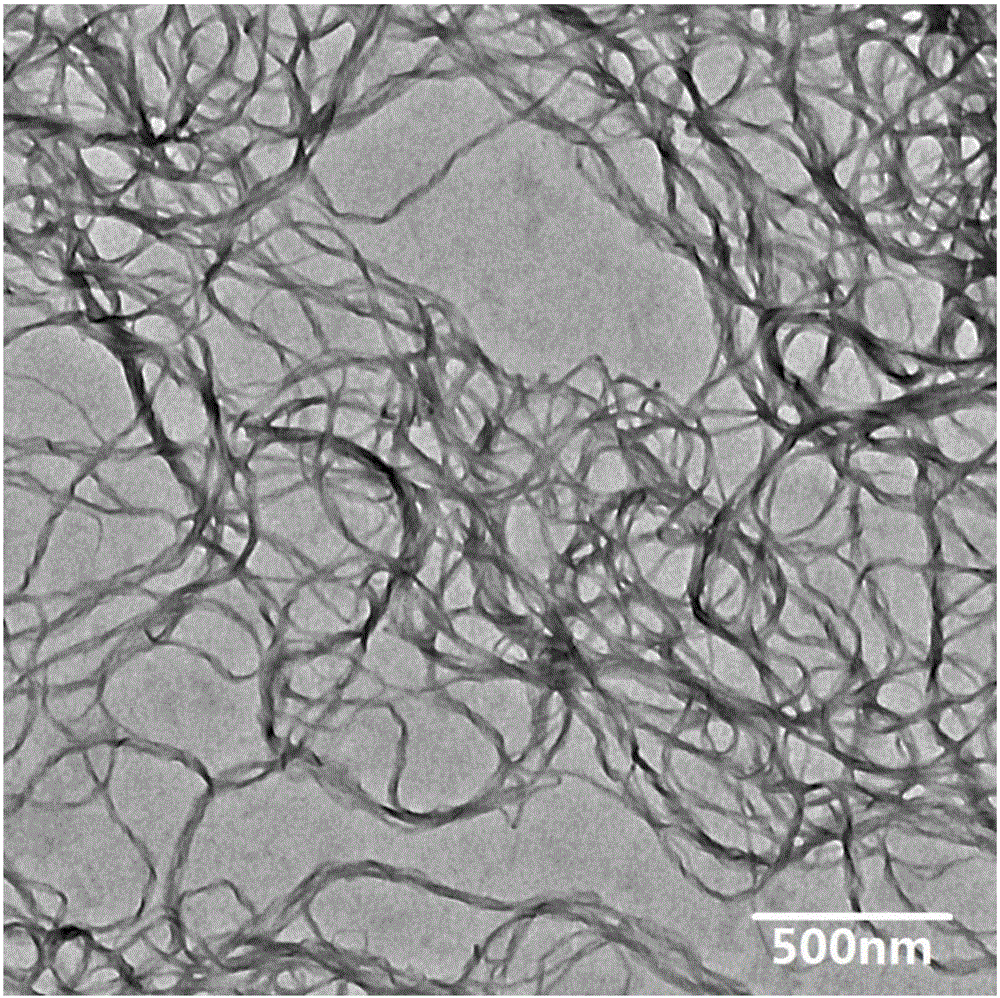

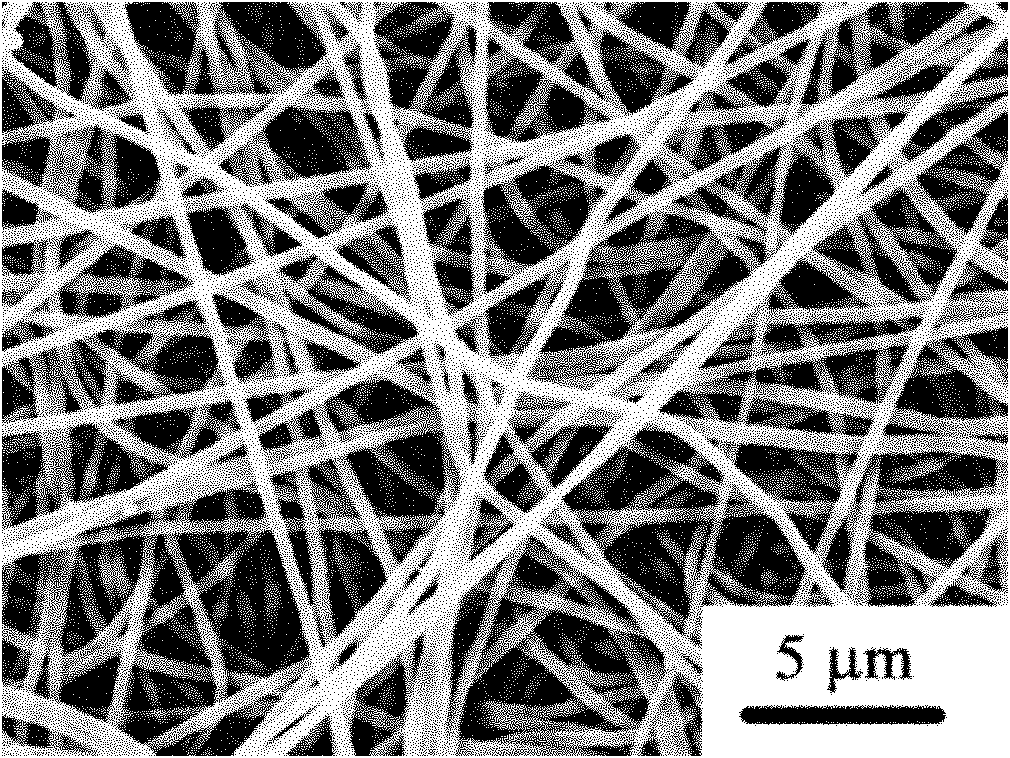

Preparation method of p-aramid nanofiber

ActiveCN105153413AReduce usageSimple processArtificial filament recoveryArtificial filament washing/dryingMicrometerNanofiber

The invention relates to a preparation method of p-aramid nanofiber, and belongs to the technical field of polymer new materials. The diameter of the prepared p-aramid nanofiber ranges from tens of nanometers to hundreds of nanometers, and the length of the prepared p-aramid nanofiber ranges from hundreds of nanometers to tens of micrometers. According to the preparation method, a certain amount of surface active agents are added in the PPTA low-temperature polymerization process, aggregation of PPTA molecules is controlled while PPTA molecule chains are lengthened, and the p-aramid nanofiber which is uniform in size and has the diameter capable of being regulated within the range between nanometer and submicron can be prepared under the auxiliary effect of other means (for example, precipitator and high-speed shearing and dispersing). The preparation method is short in production flow, devices are simple, batched and stable production can be achieved, and therefore the requirement for industrially producing the p-aramid nanofiber on a large scale is met; the preparation method has wide application prospects and can be used for preparing lithium-ion battery separators and high-performance composites.

Owner:SHANDONG JUFANG NEW MATERIAL CO LTD

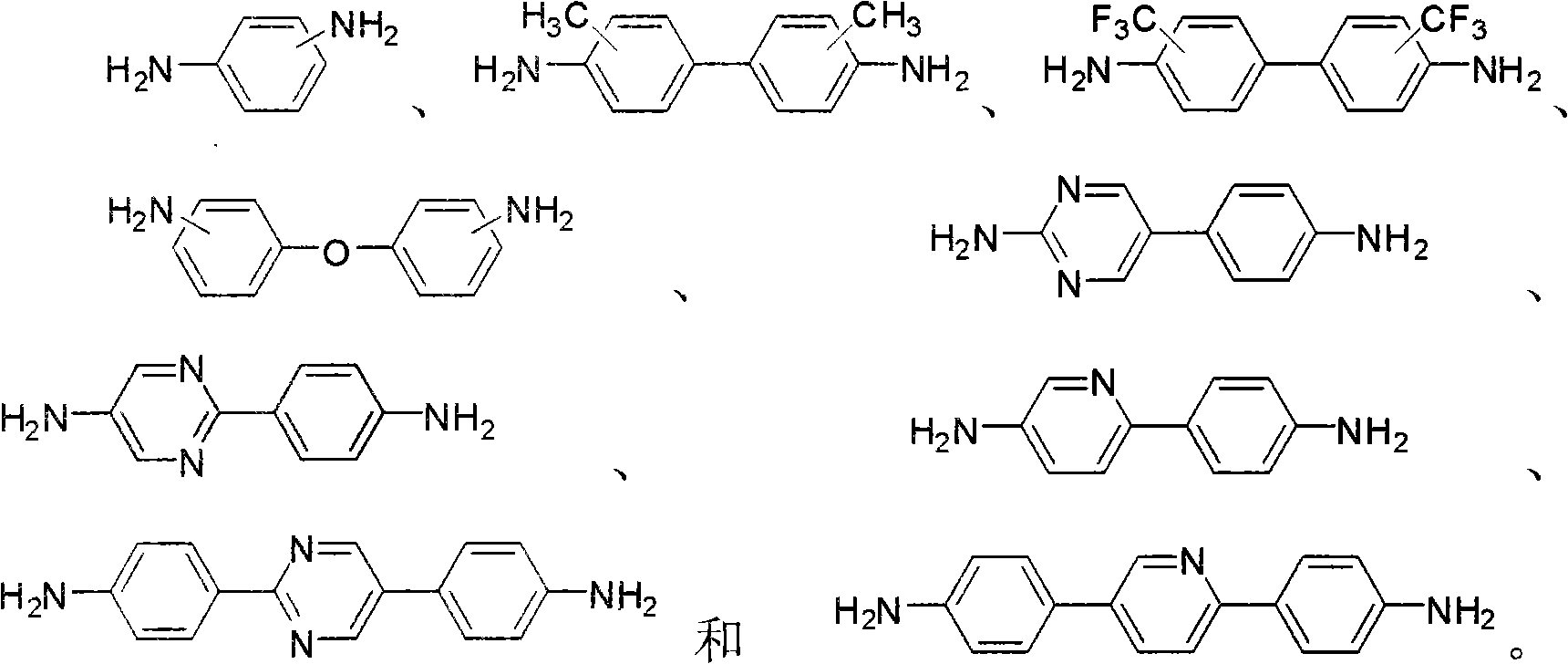

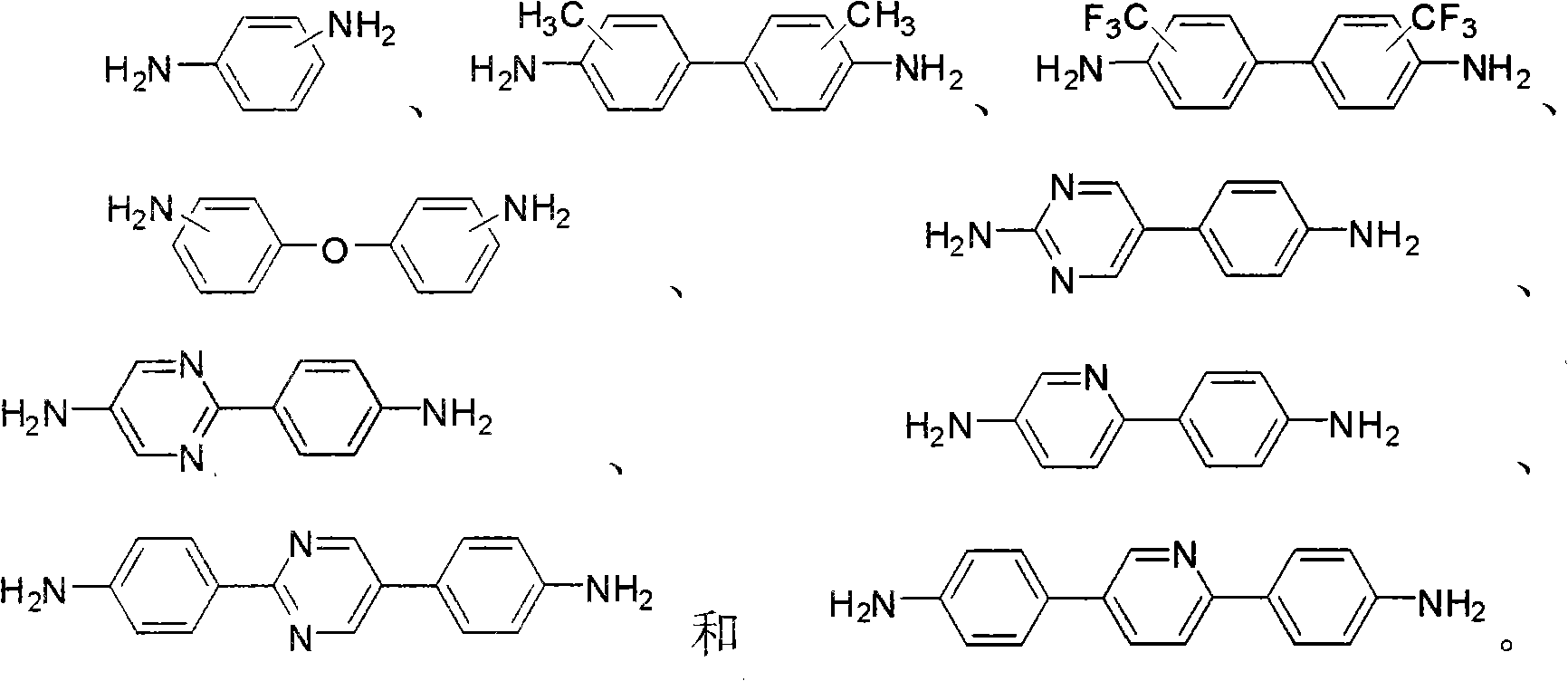

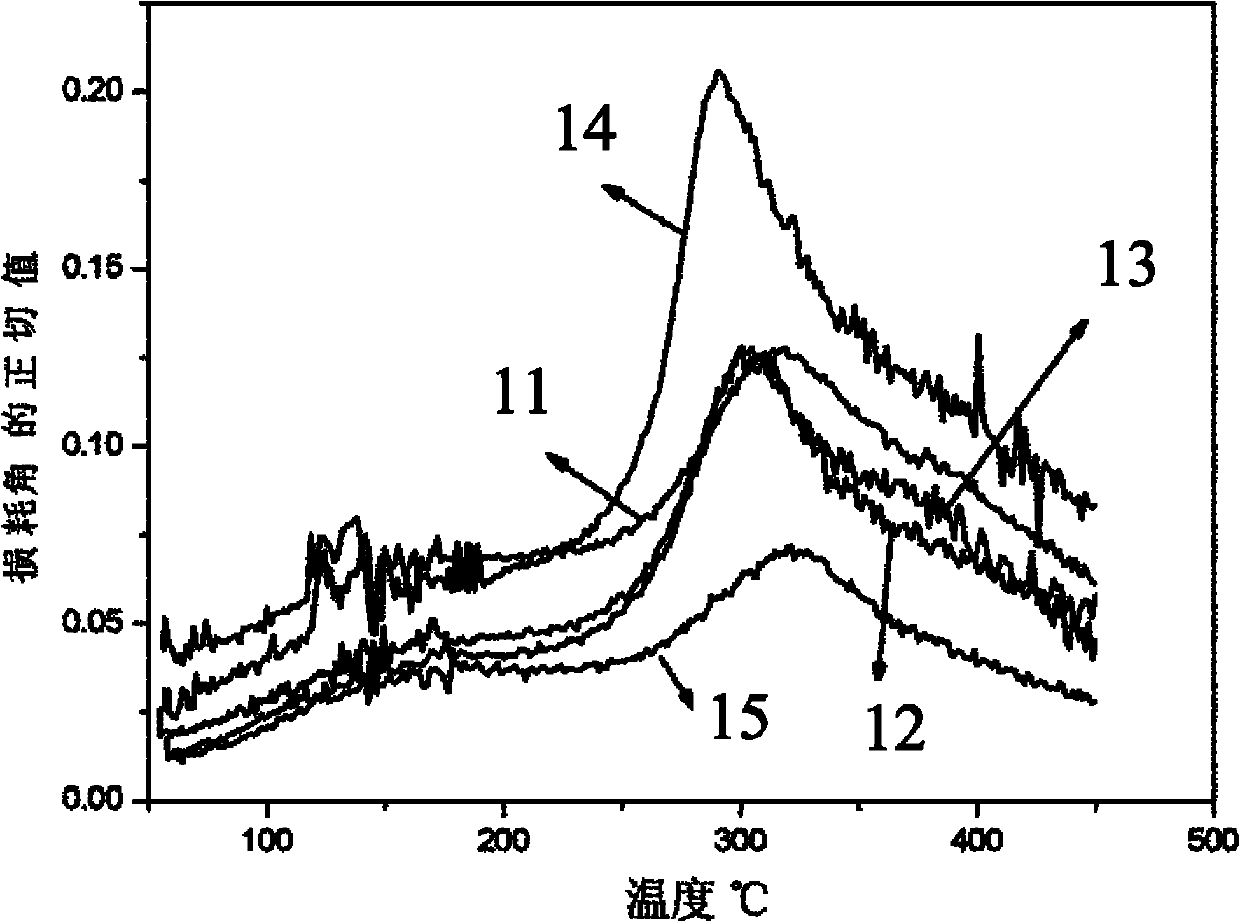

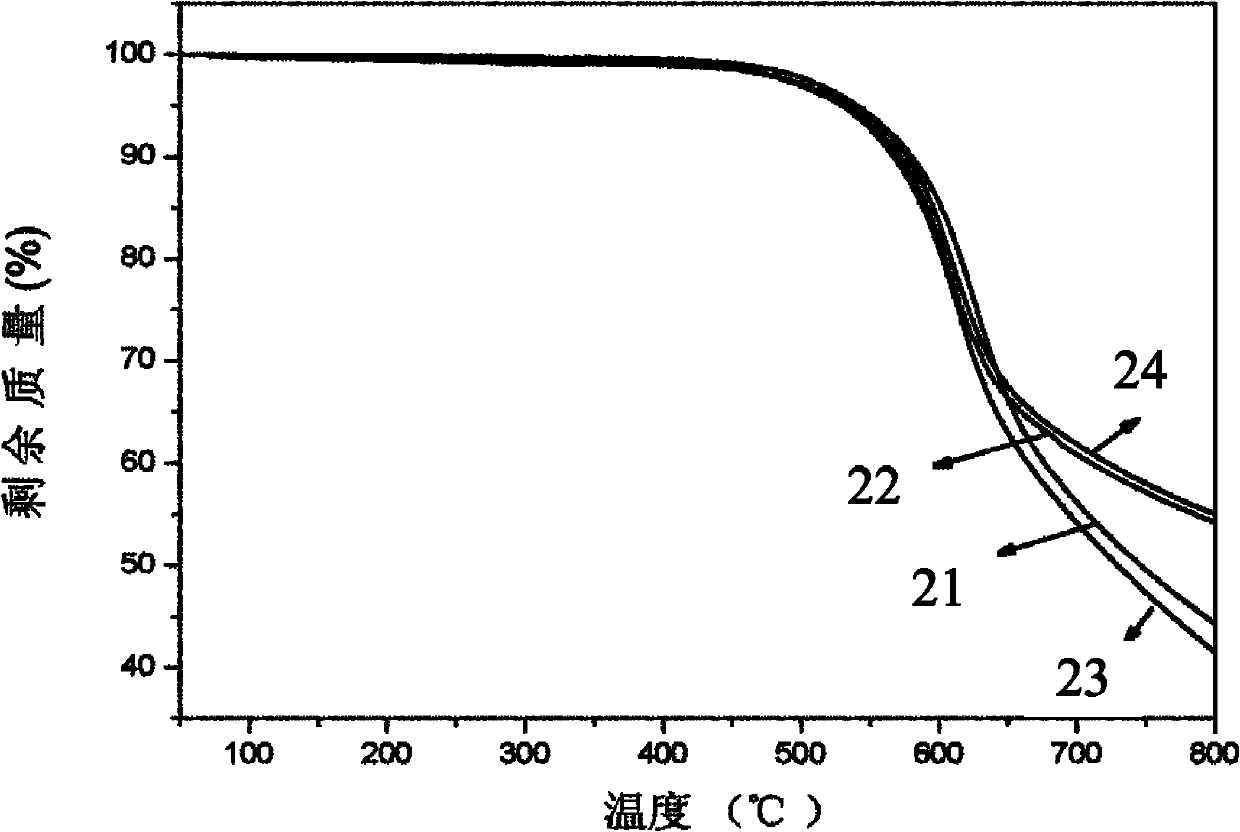

Method for preparing polyimide fiber

ActiveCN101338462AHigh strengthHigh modulusSynthetic polymer filament chemical after-treatmentMonocomponent polyamides artificial filamentFiberTemperature control

The invention relates to a preparation method of polyimide fiber. The procedures and conditions of the preparation method are as follows: (1) precursor acid polyamine solution used for spinning is made by fasculating diamine and dianhydride monomer; (2) the preparation of the polyimide fiber adopts dry-wet spinning process; (3) the polyimide fiber is imidized; and (4) the polyimide fiber undergoes the heat drawing under the temperature of 300 to 500 DEG C, and the drawing multiple of the fiber is 1 to 7 times. Imide process adopts a gradient heating-up thermal treatment furnace so as to overcome the defects of the inaccurate temperature control and the non-feasibility of the prior double thermal furnace process. The preparation method has simple process and is easy for continuous production. The prepared polyimide fiber has stronger strength and high modulus and can be used under the temperature of over 300 DEG C. In addition, the polyimide fiber has UV irradiating resistance property, a higher limited oxygen index and corrosion resistance, so the polyimide fiber can be widely applicable for the reinforced fiber of composite materials, a cable sheath, a cable reinforcing core, the mooring rope of vehicle and vessel and the filtering materials of high temperature or radioactive substance, etc.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Carbon fibers, acrylic fibers, and production processes thereof

InactiveUS6103211AMonocomponent synthetic polymer artificial filamentThin material handlingCarbon fibersTurbine

PCT No. PCT / JP97 / 01716 Sec. 371 Date Jan. 20, 1998 Sec. 102(e) Date Jan. 20, 1998 PCT Filed May 22, 1997 PCT Pub. No. WO97 / 45576 PCT Pub. Date Dec. 4, 1997The object of the present invention is to provide carbon fibers with high tensile strength as a resin impregnated strand even if the single filaments constituting the carbon fibers are thick. The carbon fibers of the present invention consisting of a plurality of single filaments are characterized by satisfying the following relation: sigma > / =11.1-0.75dwhere sigma is the tensile strength of the carbon fibers as a resin impregnated strand (in GPa) and d is the average diameter of the single filaments (in mu m). The carbon fibers can be preferably used as a material for forming energy-related apparatuses such as CNG tanks, fly wheels, wind mills and turbine blades, a material for reinforcing structural members of roads, bridge piers, etc., and also a material for forming or reinforcing architectural members such as timber and curtain walls.

Owner:TORAY IND INC

Preparation method of polyacrylonitrile/graphene composite-based carbon fiber

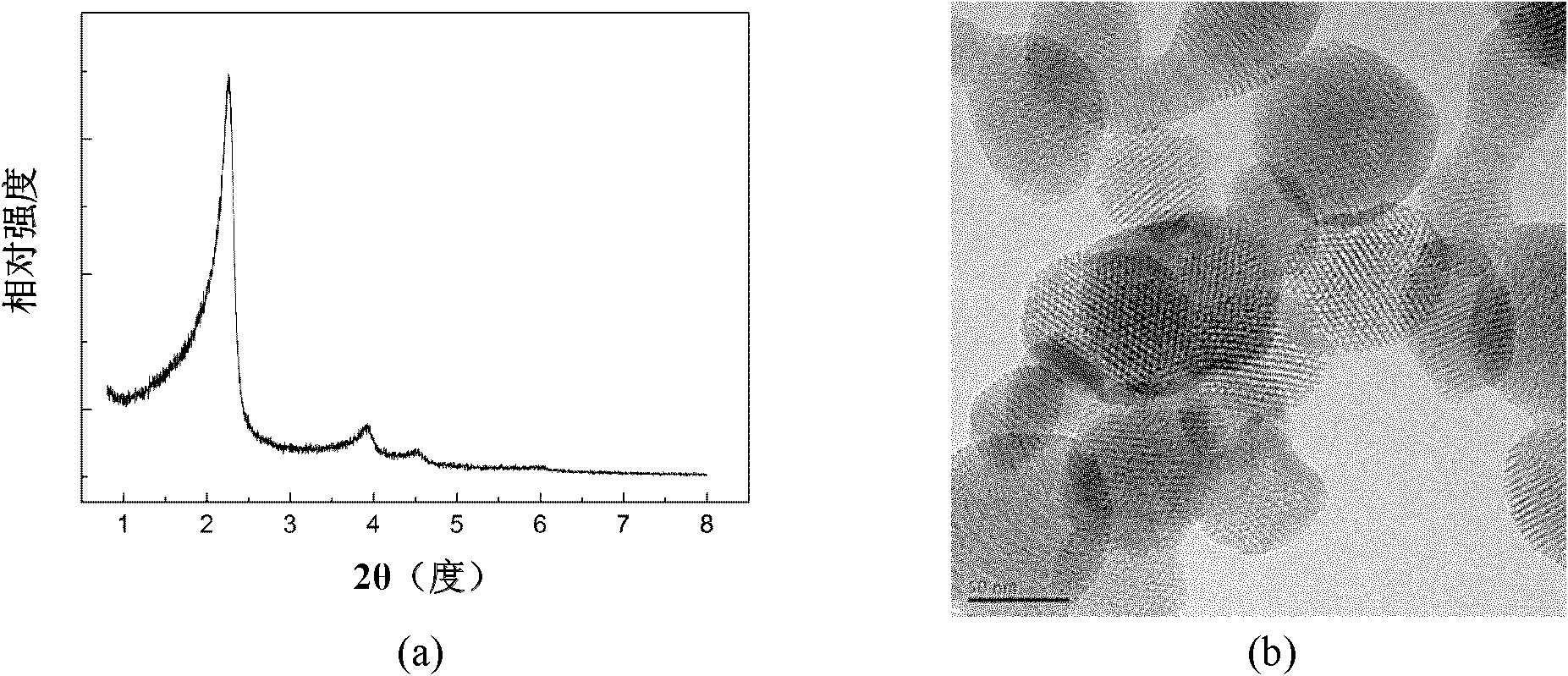

ActiveCN102560746AImprove thermal conductivityUniform deliveryElectroconductive/antistatic filament manufactureSynthetic polymer filament chemical after-treatmentCarbon fibersIn situ polymerization

The invention discloses a preparation method of polyacrylonitrile / graphene composite-based carbon fiber, which comprises the following steps: firstly preparing a polyacrylonitrile mixed solution uniformly dispersed with graphene through an in-situ polymerization method, and then employing the mixed solution as a spinning solution and obtaining a polyacrylonitrile / graphene composite protofilament by a wet spinning or dry-jet wet spinning process, and finally making the protofilament subject to a pre-oxidation treatment and a carbonization treatment to obtain the polyacrylonitrile / graphene composite-based carbon fiber. Compared with the existing polyacrylonitrile-based carbon fiber, the carbon fiber prepared by the method of the invention has a significantly increased mechanical property, and the carbonation yield in the preparation process is improved, therefore, the preparation method is an efficient and reliable preparation method with good application prospects.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Oil agent for carbon fiber precursor fiber, carbon fiber and method for producing carbon fiber

InactiveCN101091010AInhibit thermal bondingInhibit adhesionMonocomponent synthetic polymer artificial filamentSynthetic polymer filament chemical after-treatmentFiberCarbon fibers

By using an oil agent for precursor fiber of carbon fiber containing a base compound and a liquid fine particle, and said liquid fine particle contains a liquid of which kinematic viscosity at 150 DEG C is 15000 cSt or more, it is possible to suppress an uneven stabilization in stabilizing process, and it becomes possible to provide a carbon fiber of high performance and uniform quality.

Owner:TORAY IND INC

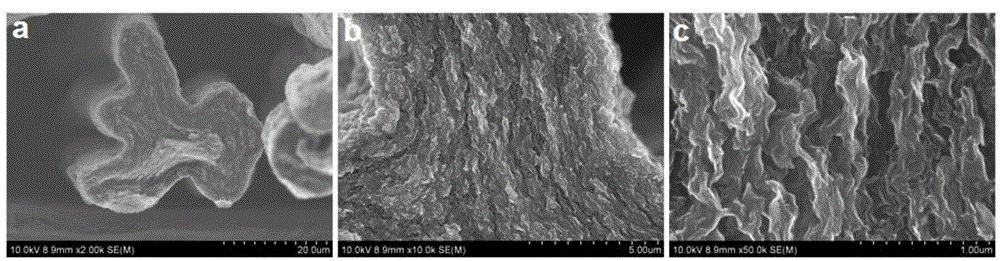

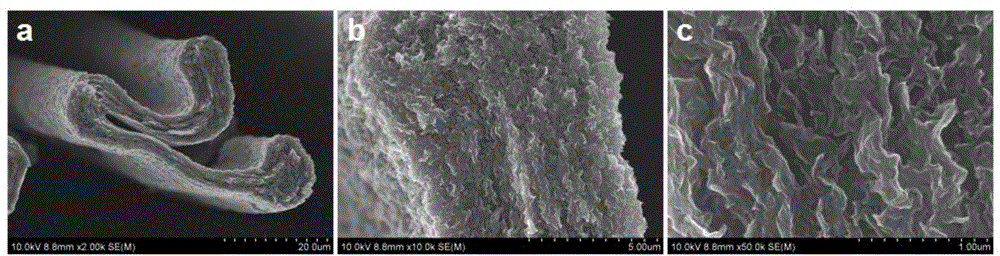

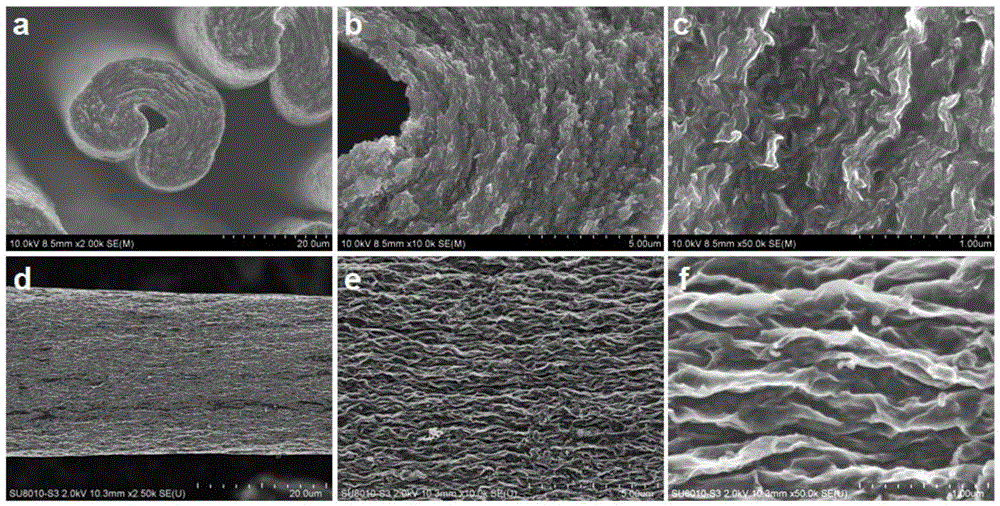

Water-soluble polymer/graphene composite fiber as well as preparation method and application thereof

ActiveCN104451925AHigh strengthImprove toughnessElectroconductive/antistatic filament manufactureElectrode carriers/collectorsFiberMicro structure

The invention relates to water-soluble polymer / graphene composite fiber as well as a preparation method and application thereof. The cross section of the fiber is special-shaped, the surface of the fiber is of an orientated micro-fiber-shaped structure, the strength of the fiber is greater than 100 MPa, the elongation at break is greater than 2%, and the conductivity of the fiber is greater than 0.1 S / cm. The preparation method comprises the following steps: preparing a composite spinning liquid, extruding into a coagulating bath for curing, drafting, leading out of the coagulating bath, drying, and coiling, thereby obtaining the water-soluble polymer / graphene composite fiber; and finally reducing by using a chemical or physical method, thereby obtaining the water-soluble polymer / graphene composite fiber. The cross section of the composite fiber provided by the invention is of a special-shaped structure, the surface of the fiber is of a rich groove micro structure, the strength and the toughness of the fiber are greatly improved when being compared with those of pure graphene fiber, and good conductivity is still maintained, so that the water-soluble polymer / graphene composite fiber has a wide application prospect in the fields such as anti-electrostatic and conductive fabrics, electromagnetic wave absorption and shielding fabrics, energy storage devices, sensors and water treatment.

Owner:DONGHUA UNIV

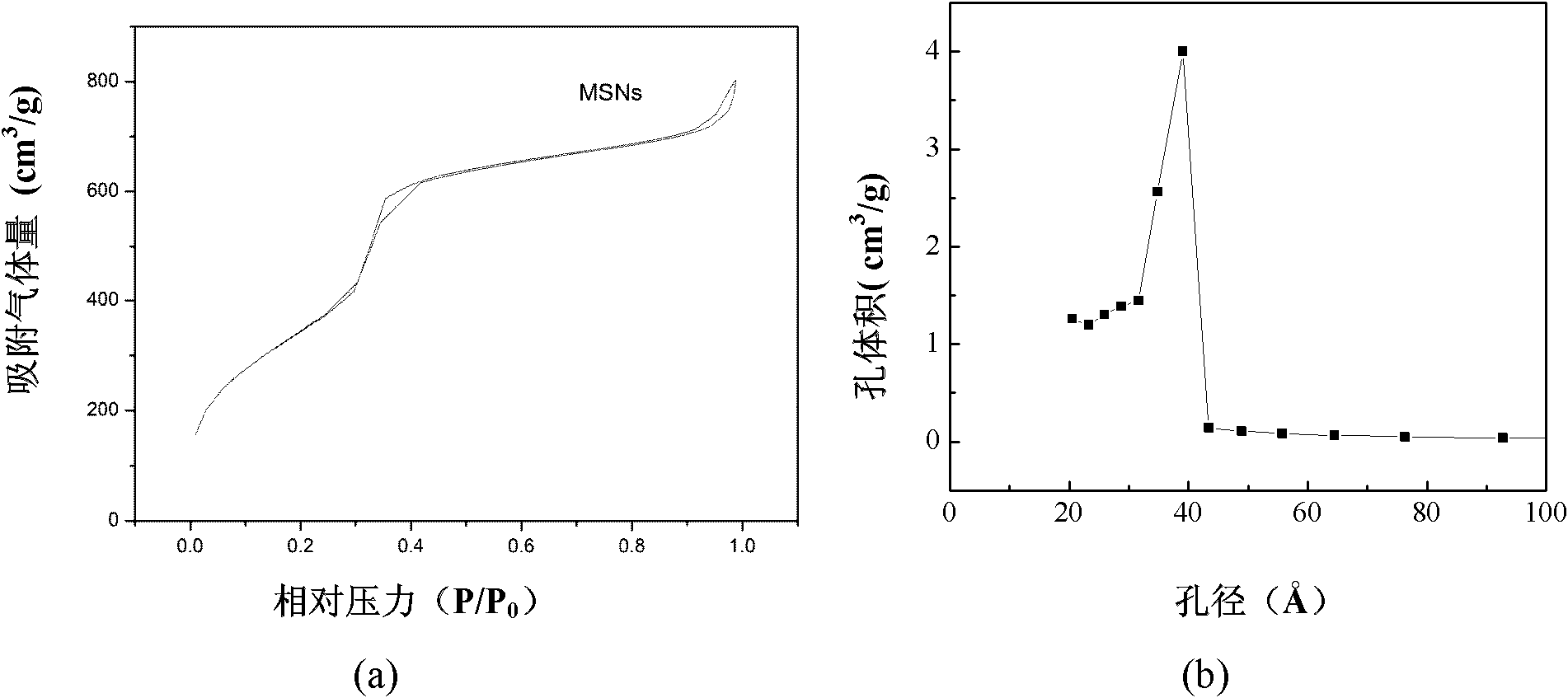

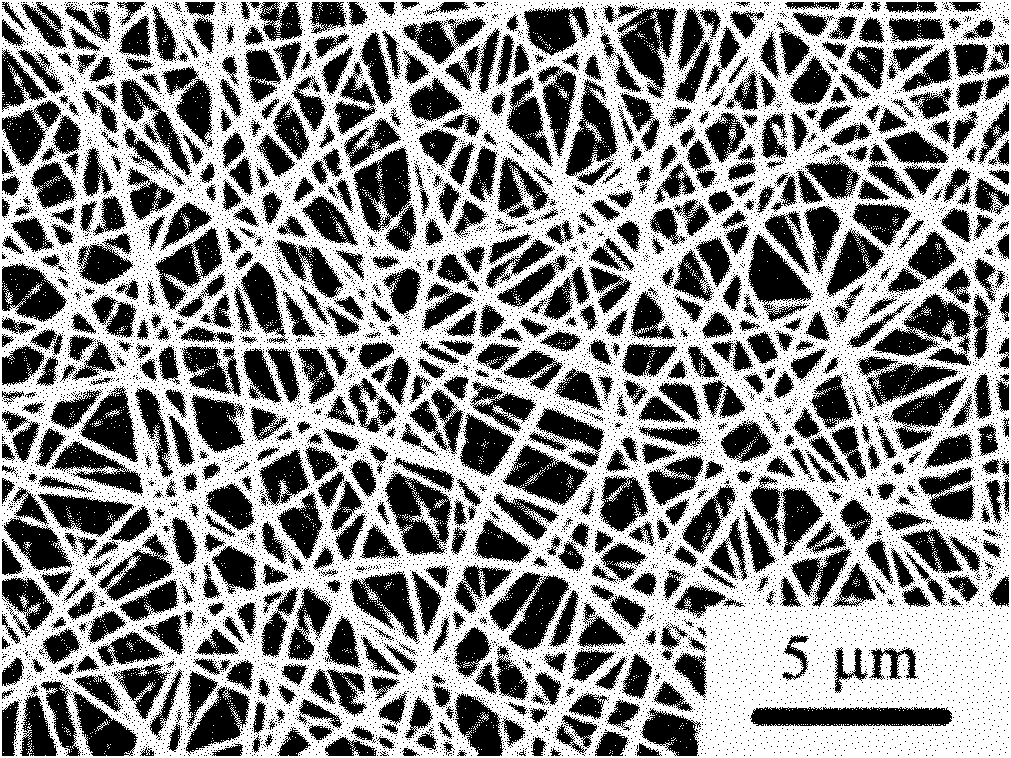

Mesoporous silicon oxide particle/degradable polymer nano composite fiber, preparation method and application thereof

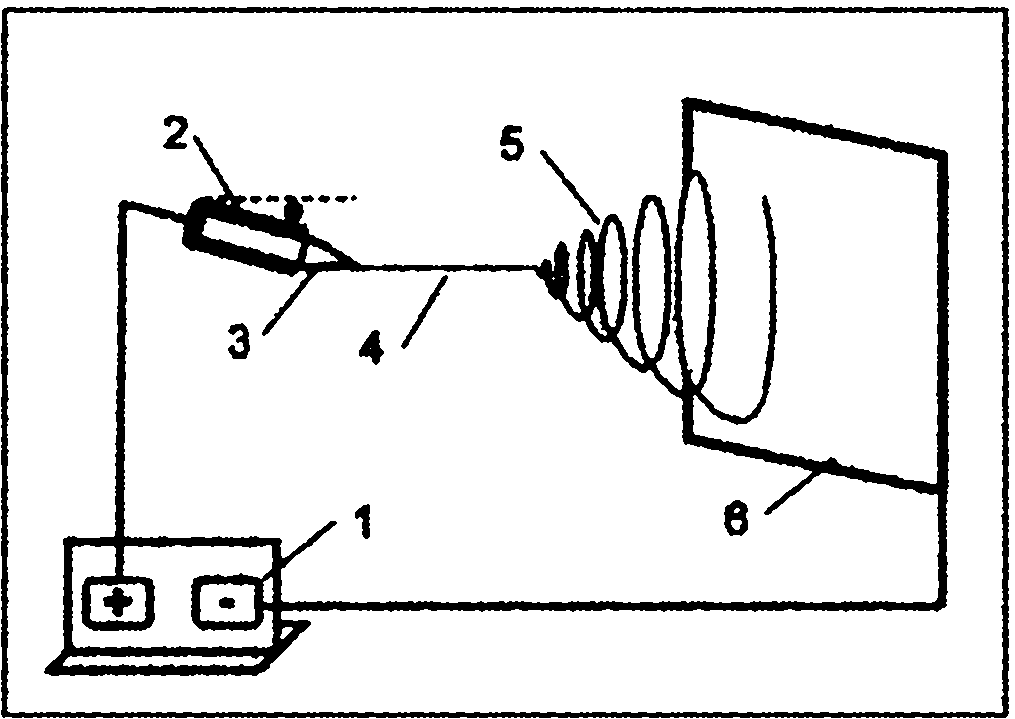

InactiveCN102051702ARetain performanceImprove throughputMonocomponent protein artificial filamentFilament/thread formingFiberElectrospinning

The invention discloses a mesoporous silicon oxide particle / degradable polymer nano composite fiber, a preparation method and application thereof. The method comprises the following steps of: uniformly dispersing mesoporous silicon oxide particles into a solution of degradable polymers; and then preparing nano composite fibers by adopting an electrostatic spinning process, wherein the mesoporous silicon oxide particles are uniformly distributed in the degradable polymer fibers. Compared with traditional polymer fibers, the nano composite fiber can be used for better controlling the release ofdrugs and has quicker biodegradability and higher mechanical strength, and meanwhile, the fiber has better cellular compatibility. The nano composite fiber can be used as a tissue engineering support, a drug release vector, a wound coating material or a functional membrane.

Owner:EAST CHINA UNIV OF SCI & TECH

Production technique of three-dimensional curly hollow polyester staple fibers

InactiveCN102517675AQuality assuranceLow costFilament forming substance formingHollow filament manufacturePolyesterDrum drying

The invention discloses a production technique of three-dimensional curly hollow polyester staple fibers, wherein the production technique comprises the steps of: utilizing regenerative PET material as raw material; sequentially performing the following procedures to obtain a finished product: pre-treating, drum drying, melting spinning, cooling forming, winding, stretching, curling, oiling, cutting and heat setting, wherein the drum drying duration is 9.5-10.5 h, a spinneret plate in the melting spinning procedure is three-dimensional hollow helical, the cross section of a spinneret orifice is a sealed space formed by sealing the circular arcs of two concentric circles, the temperatures of the threaded rod of a threaded rod extruding machine and the box body of a spinning box are 265-275 DEG C; a circular air blowing asymmetrical cooling forming mode is utilized, the circular blowing blast temperature is 20-24 DEG C, and the circular blowing wind speed is 4.7-5.7 m / s; the total stretching fold is 2.5-2.7 folds, the main curling pressure of a curling wheel is 0.05-0.1 MPa, and no backpressure exists; the heat setting temperature is 175-180 DEG C, and the heat setting duration is 10-14 min. The production technique of the invention has the advantages of saving the cost and protecting the environment, and the prepared finished product not only has good three-dimensional configuration and bulkiness, but also has better thermal stability.

Owner:HANGZHOU BEST CHEM FIBER

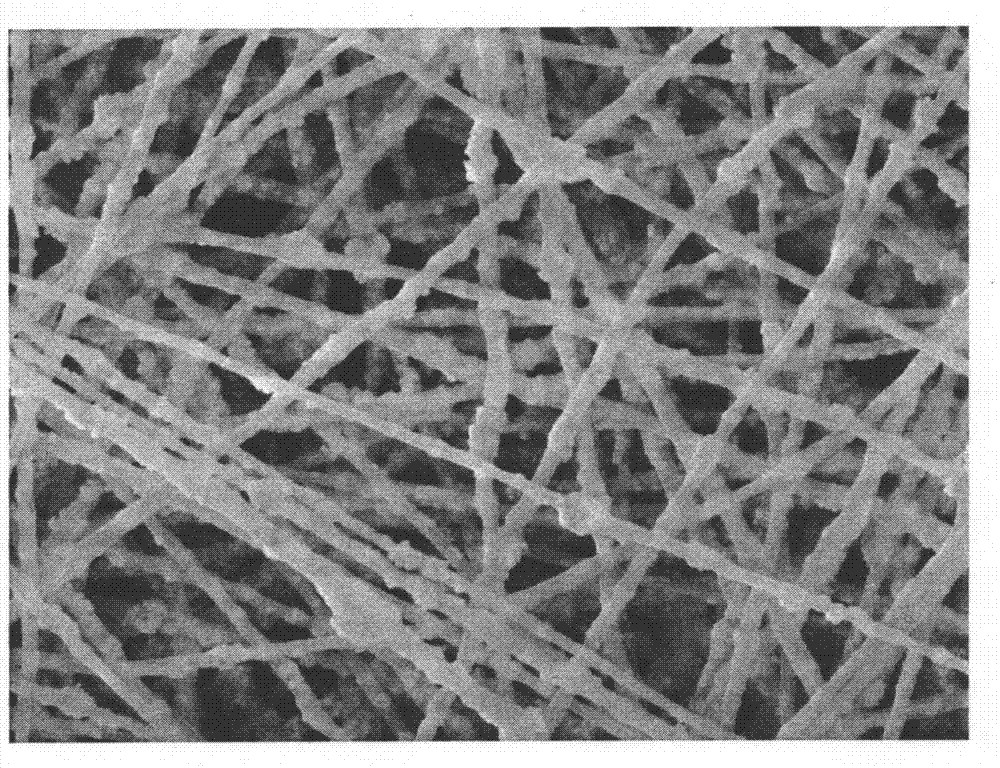

Composite nano fiber filtration material with photocatalysis/anti-bacterial functions and preparation method of filtration material

ActiveCN107497182AIncrease spinning speedSolve problems such as easy blockageDispersed particle separationElectro-spinningFiberSpinning

The invention relates to a composite nano fiber filtration material with photocatalysis / anti-bacterial functions and a preparation method of the filtration material. The filtration material comprises a supporting layer and a nano fiber filtration layer which adheres to the surface of the supporting layer, the nano fiber layer is uniformly filled with an photocatalyst and an antibacterial agent, and the preparation method comprises the following steps: 1, preparing a spinning liquid: dispersing a certain amount of the photocatalyst and the antibacterial agent into a solution uniformly to form a dispersion liquid, performing ultrasonic treatment, and adding a high polymer to form a stable and uniform electrostatic spinning solution; 2, performing electrostatic spinning: setting up electrostatic spinning parameters, and performing stretching on the spinning polymer solution at solid metal wire tips for wire production by utilizing an assembled needle head; and 3, performing slight dissolving treatment on the surface of the composite nano fiber filtration material by adopting solvent vapour recovery at a certain releasing speed to obtain the final composite nano fiber filtration material with the photocatalysis / the anti-bacterial functions. The composite nano fiber filtration material effectively solves a problem that the liquid outlet end of a current needle head / spray nozzle used for the electrostatic spinning is easy to block, can be directly used for decomposition of organic pollutants, inactivation of microorganism pathogenes and the like under visible light, and has excellent filtration performance at the same time.

Owner:DONGHUA UNIV

Technology for producing poly(p-phenylene benzobisoxazole) (PBO) fibers

ActiveCN102943316AEfficient transferAchieving Scale AggregationWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention relates to a technology for producing poly(p-phenylene benzobisoxazole) (PBO) fibers, and belongs to the field of high performance fiber production. The technology comprises the steps: A, degassing, pre-polymerizing and defoaming; B, post-polymerizing and defoaming; C, spinning and solidifying; D, post-treating; and E, heat-treating and the like. Through optimizing equipment and controlling parameters, a plurality of problems of the prior art are solved. The technological process, equipment cooperation and parameter control of the basic technical scheme are taken as an integral system, are cooperated with each other and are dispensable, materials can be effectively transferred, the scale polymerizing and subsequent scale spinning of the PBO polymer are realized, and a high-quality PBO fiber product is obtained.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

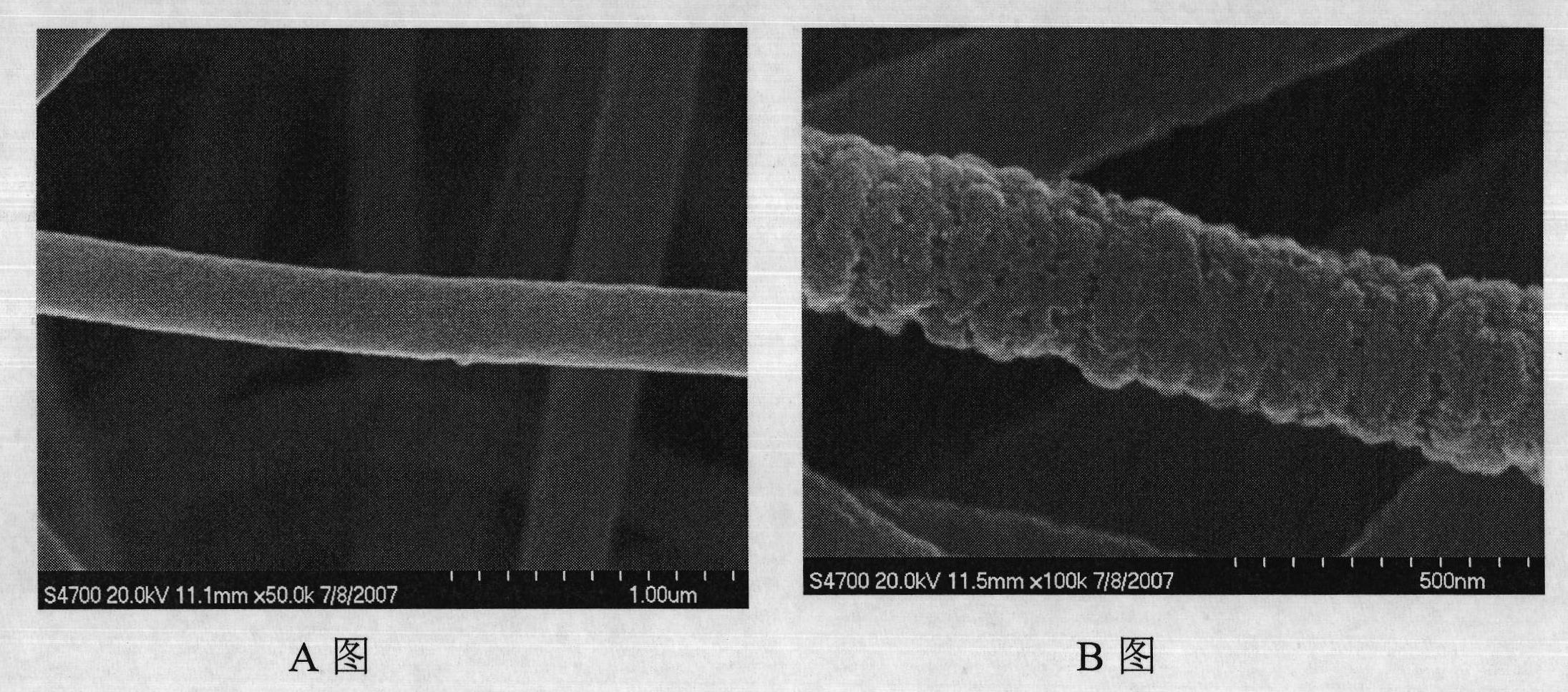

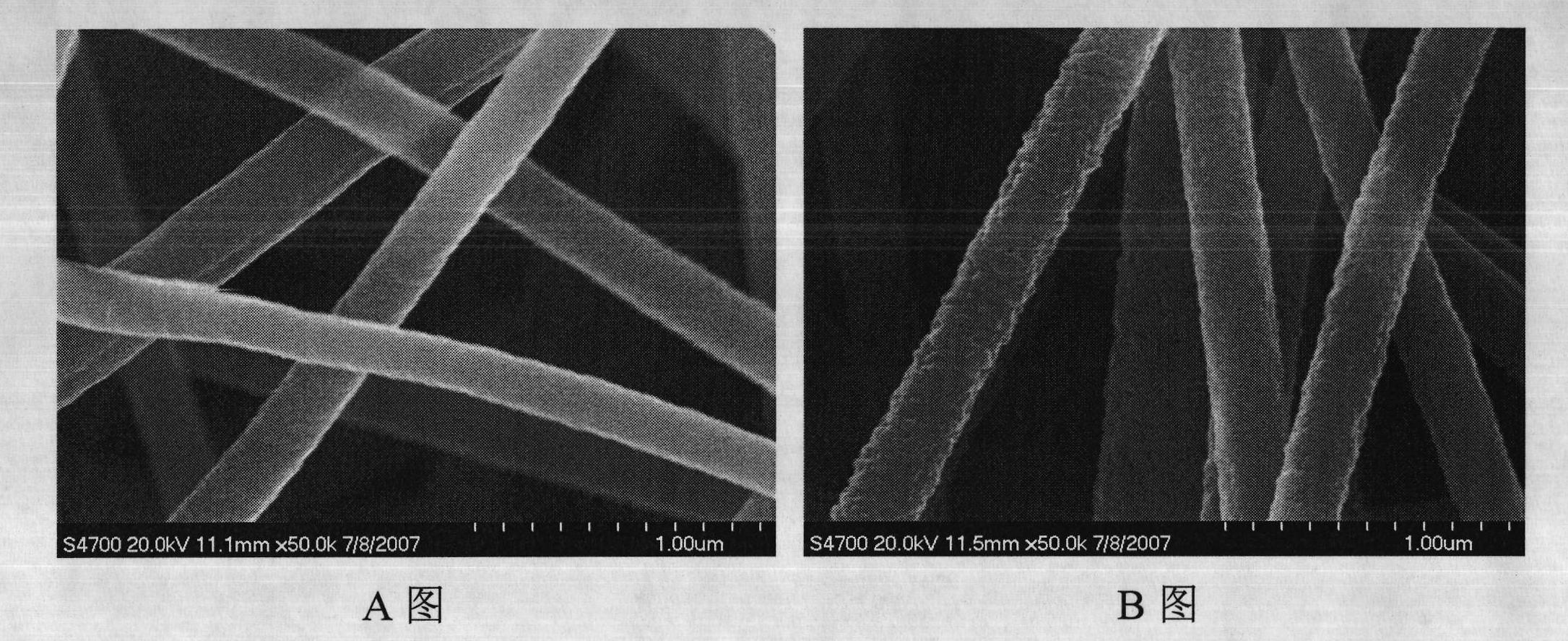

Preparation method of polyacrylonitrile/polyaniline compound micro-nano conductive fiber

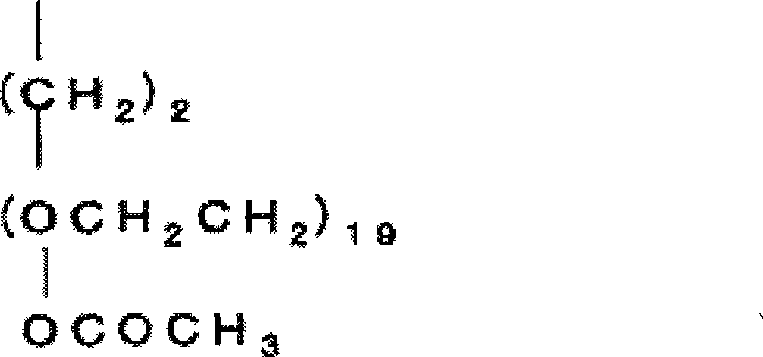

InactiveCN103255634AIncrease contentImprove conductivityFibre typesFilament/thread formingMicro nanoPolyethylene glycol

The invention discloses a preparation method of a polyacrylonitrile / polyaniline compound micro-nano conductive fiber. The preparation method comprises the following steps of: (1) dissolving polyacrylonitrile and polyethylene glycol into dimethylformamide; standing, de-foaming, and spinning a polyacrylonitrile / polyethylene glycol micro-nano fiber in an electrostatic spinning device; (2) placing the polyacrylonitrile / polyethylene glycol micro-nano fiber into water of 40-90 DEG C for 10-60 minutes to obtain a polyacrylonitrile porous micro-nano fiber; and (3) adding an aniline monomer into hydrochloric acid; uniformly agitating and immersing the polyacrylonitrile porous micro-nano fiber in the solution; and adding hydrochloric acid dissolved with ammonium persulfate to react for 0.5-3 hours to obtain the polyacrylonitrile / polyaniline compound micro-nano conductive fiber. The polyethylene glycol used in the preparation method disclosed by the invention is a water-soluble polymer which has a wide application range, has no pollution to an environment, and is cheap and easy to obtain, environment-friendly and low in cost.

Owner:ZHONGYUAN ENGINEERING COLLEGE

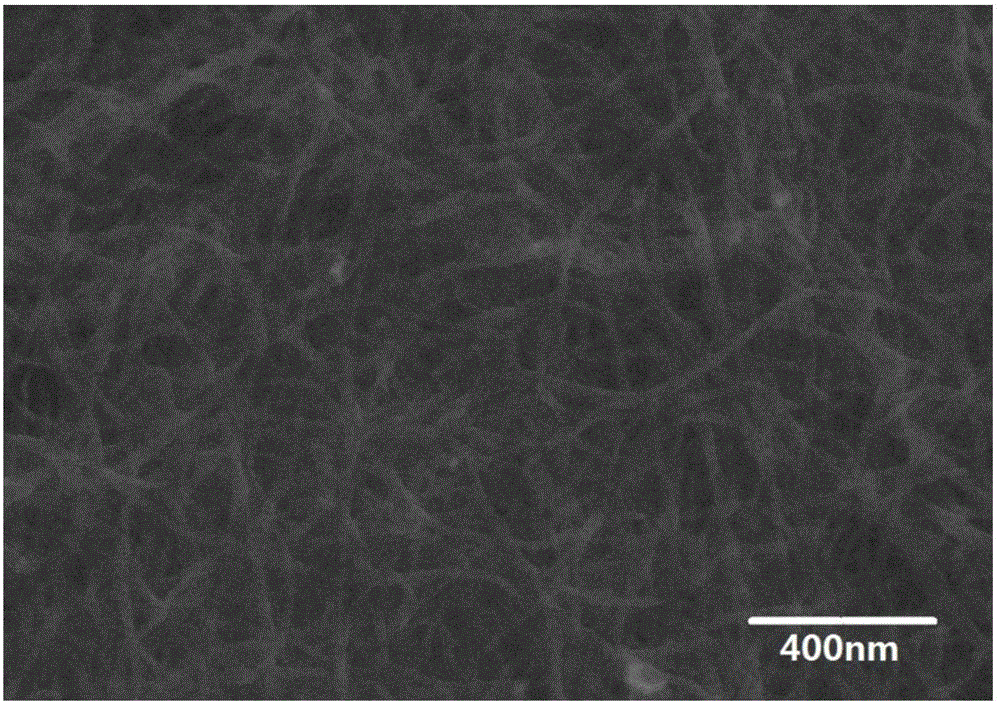

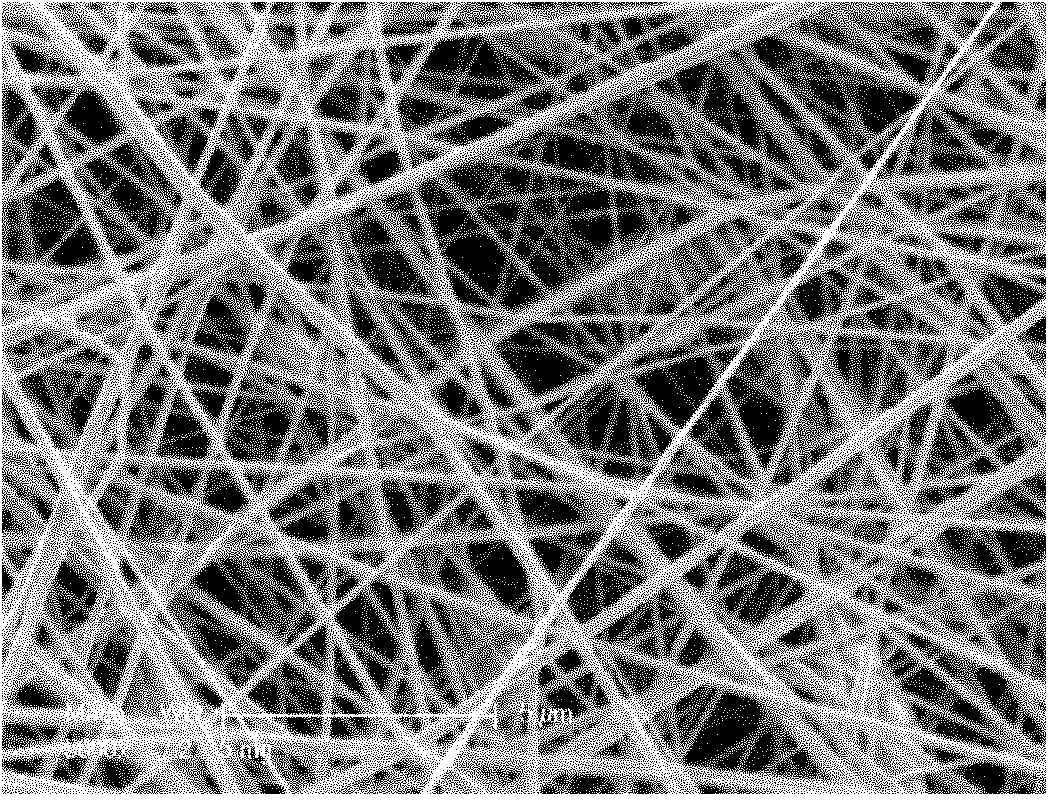

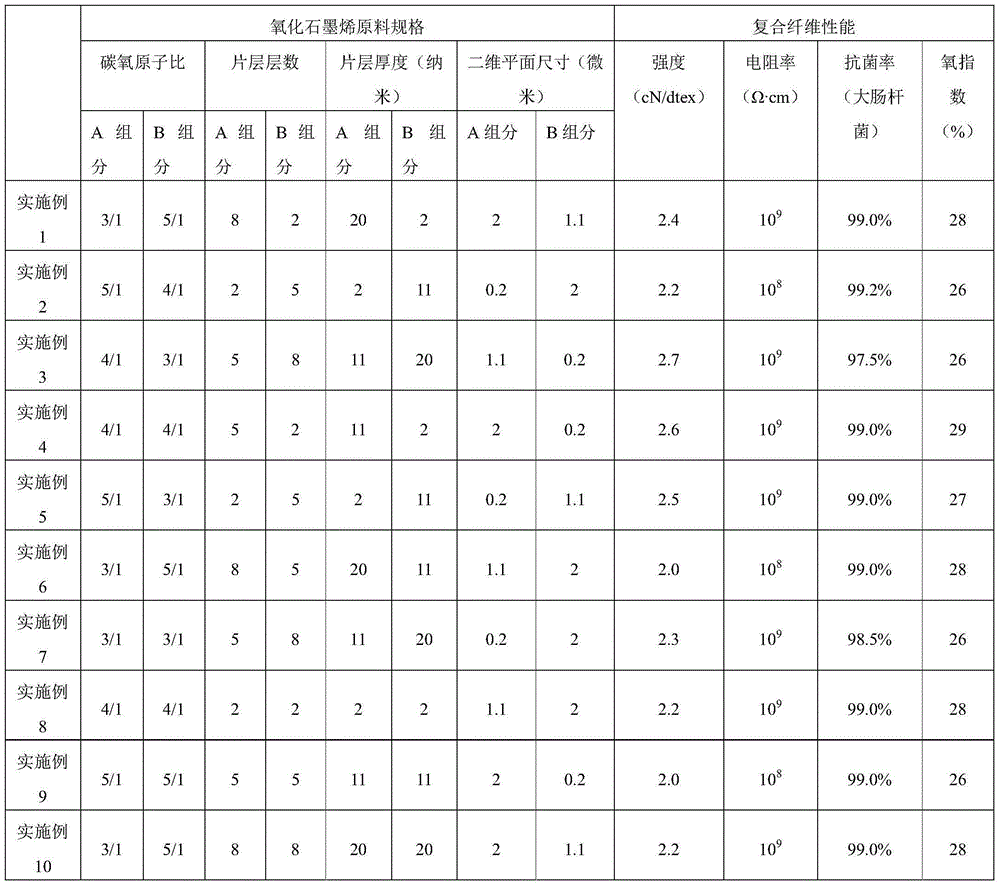

Polymer composite function fibers containing partial graphene, and preparation method thereof

ActiveCN105002595AIncrease productivityHigh strengthElectroconductive/antistatic filament manufactureFlame-proof filament manufacturePolyesterPolymer science

The present invention discloses a polymer composite function fibers containing partial graphene, and a preparation method thereof. The fibers comprise a component A and a component B, wherein the component A and the component B are combined in a partial exposing manner, side-by-side manner or skin-core manner, and 20-100% of the outer area of each fiber is the component B. The method comprises: crystallizing a polyester containing 0.1-1 wt% of partial reducing graphene and a polyester containing 4-20 wt% of a nanometer composite filler containing partial reducing graphene and TiO2, drying, carrying out melt composite spinning, and carrying out drawing and relaxation heat setting at a temperature of 80-160 DEG C, and reducing the partial graphene in the fibers to achieve the carbon / oxygen atom ratio of 9 / 1-15 / 1 through the reducing treatment. According to the present invention, the prepared fibers can be produced at the high spinning speed, and the production efficiency is high; and the fibers have characteristics of low single fineness, high strength and lower resistivity, meets the antistatic requirement, and further has characteristics of anti-bacterial property and flame retardant property so as to provide good application prospects.

Owner:NINGBO MYBABY BABY & CHILDREN PROD MFG

Wet-Laid process to produce a bound nonwoven article

Owner:EASTMAN CHEM CO

Method for preparing nanofiber containing pore structure

InactiveCN102071485AAdjust dosageAdjust sizeFilament/thread formingMonocomponent synthetic polymer artificial filamentFiberChemical reaction

The invention belongs to the technical field of high polymer material, relating to a method for preparing nanofiber containing a polymer pore structure, wherein the pore structure is formed on the fiber by a chemical reaction foaming method. The method comprises the following steps of: dispersing the inorganic salt, capable of discharging gas by reaction, in polymer solution, preparing super fine nanofiber by a high pressure static spinning method, immerging the obtained fiber in reaction solution, reacting the inorganic salt in the fiber, discharging the gas, and forming the pore structure on the fiber. The method has the advantages of obtaining the pore structure-containing nanofiber with controllable aperture number and uniform distribution, greatly increasing the specific surface area of the nanofiber and widening the application range of the nanofiber prepared by the electric spinning method. The prepared fiber has high application value in releasing medicine, carrier of catalyst, filtering absorbing material and the like. The method of the invention is wide in application range and can be directly applied to preparing the pore structure-containing nanofiber of a plurality of materials such as PS (polystyrene), PMMA (polymethyl methacrylate), PU (polyurethane), etc.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

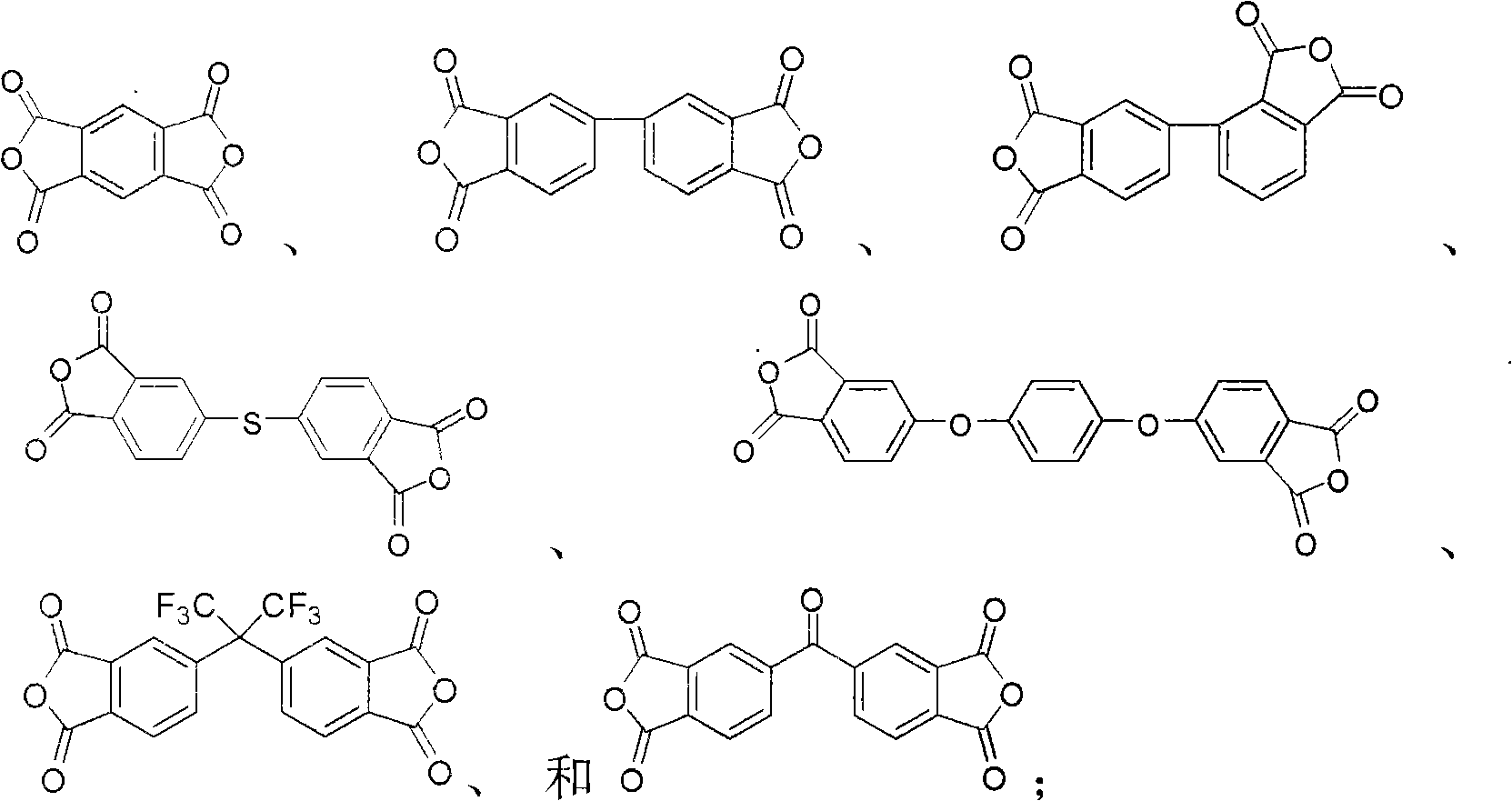

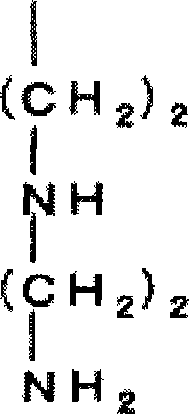

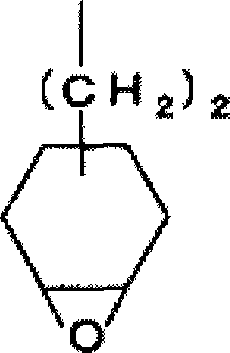

Polyimide fiber and preparation method thereof

ActiveCN102041577AImprove mechanical propertiesGood mechanical propertiesArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberOrganic solvent

The invention provides a polyimide fiber comprising a polymer with a structure shown in a formula (I) in the specification, wherein m is the proportion of a repeat unit with a structure shown in a formula (II), in the structure of the polymer, and is more than and equal to 0.8 and less than and equal to 0.95. The invention also provides a preparation method of the polyimide fiber, comprising the following steps of: mixing p-phenylenediamine, 4,4'-diaminodiphenyl ether and 3,3',4,4-biphenyltetracarboxylic dianhydride in an organic solvent to carry out condensation polymerization so as to obtain a polyamic acid spinning solution, wherein proportion of the mole number of the p-phenylenediamine to the total mole number of the p-phenylenediamine and the 4,4'-diaminodiphenyl ether is 0.8-0.95; spinning to obtain polyamic acid protofilaments by using the polyamic acid spinning solution; carrying out imidization processing on the polyamic acid protofilaments to obtain polyimide nascent fibers; and carrying out hot stretching processing on the polyimide nascent fibers to obtain the polyimide fiber.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Super-soft superfine polyester fiber and preparation method thereof

ActiveCN105019059ASoft lusterConvenient careArtificial thread manufacturing machinesFibre typesPolyesterPolymer science

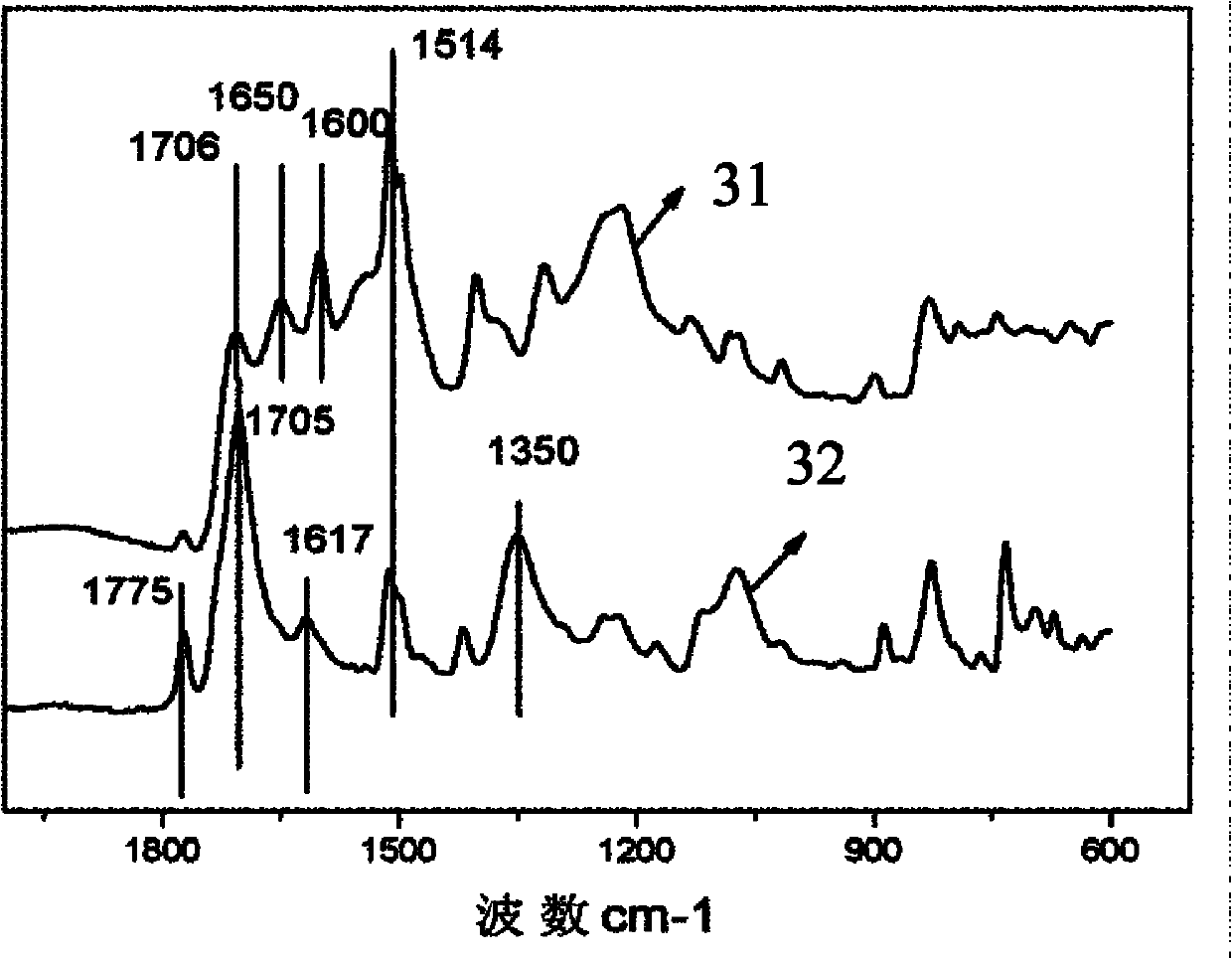

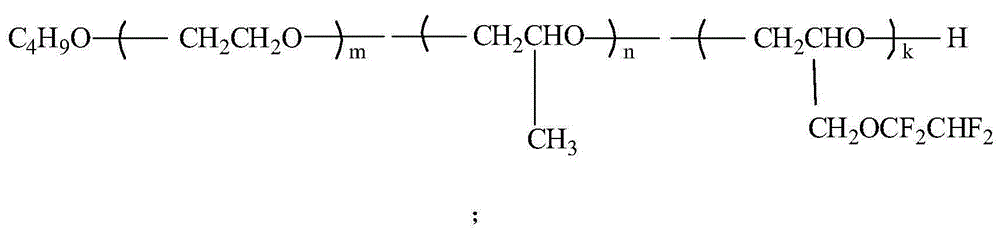

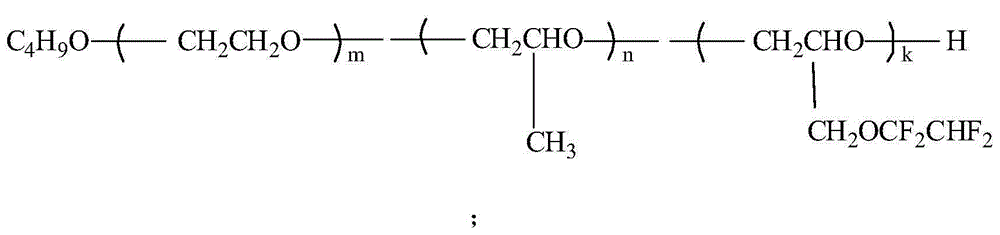

The invention relates to a super-soft superfine polyester fiber and a preparation method thereof. The super-soft superfine polyester fiber is mainly prepared by the steps of melt spinning of polyester through spinneret holes, application of an oiling agent and high-speed winding, wherein the oiling agent at least comprises fluorine-containing polyether, the mass of which is more than or equal to 45% of that of the oiling agent, the fluorine-containing polyether is a random copolymer of ethylene oxide, [(1,1,2,2-tetrafluoroethoxy) methyl] oxirane and propylene oxide, and the structural formula of the random copolymer is shown in the specification. The preparation method comprises the steps of metering, extruding, cooling, oiling, stretching, heat setting and high-speed winding of polyester, thereby obtaining the super-soft superfine polyester fiber. As the filament fineness of the super-soft superfine polyester fiber is very high, a fabric has advantages of specially soft and fine hand feeling, soft luster, comfortableness, breathability and good appearance texture and is easy to care, thus being popular with users more and more.

Owner:江苏轩达高分子材料有限公司

Sulfopolyester binders

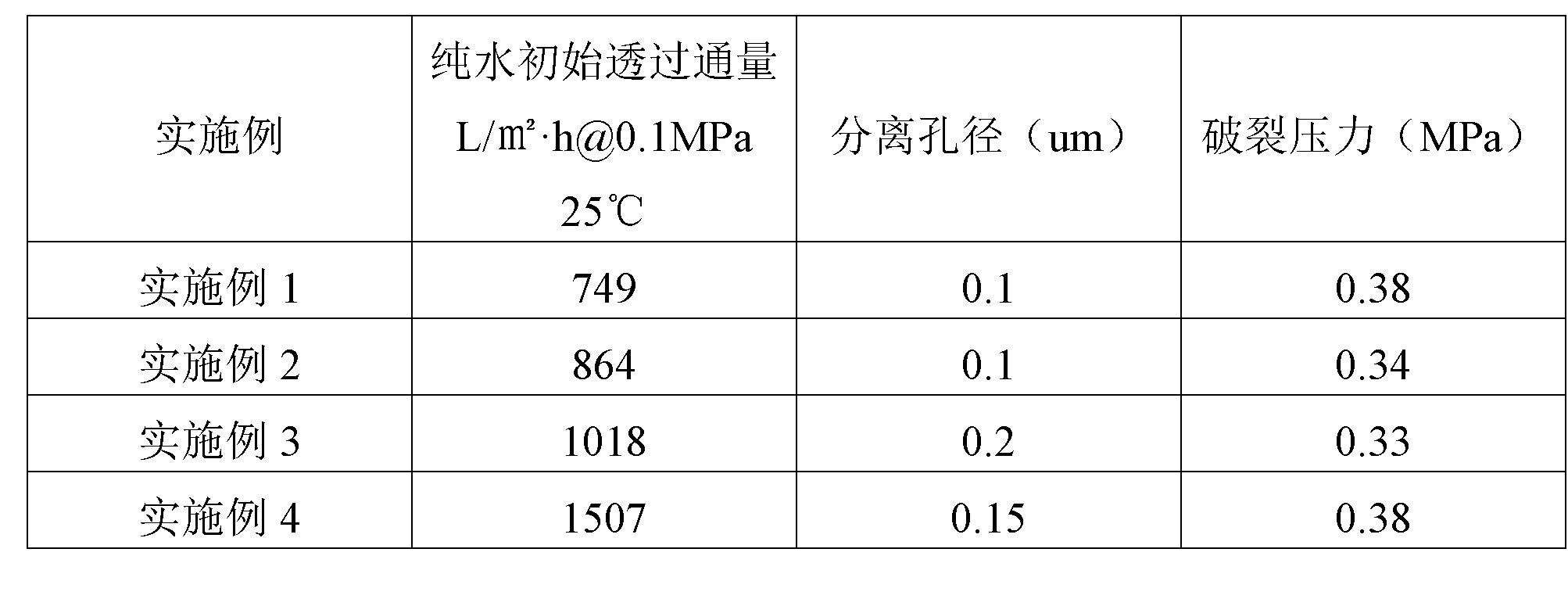

ActiveUS20120181720A1Filament/thread formingReinforcing agents additionBursting strengthPolymer science

Owner:EASTMAN CHEM CO

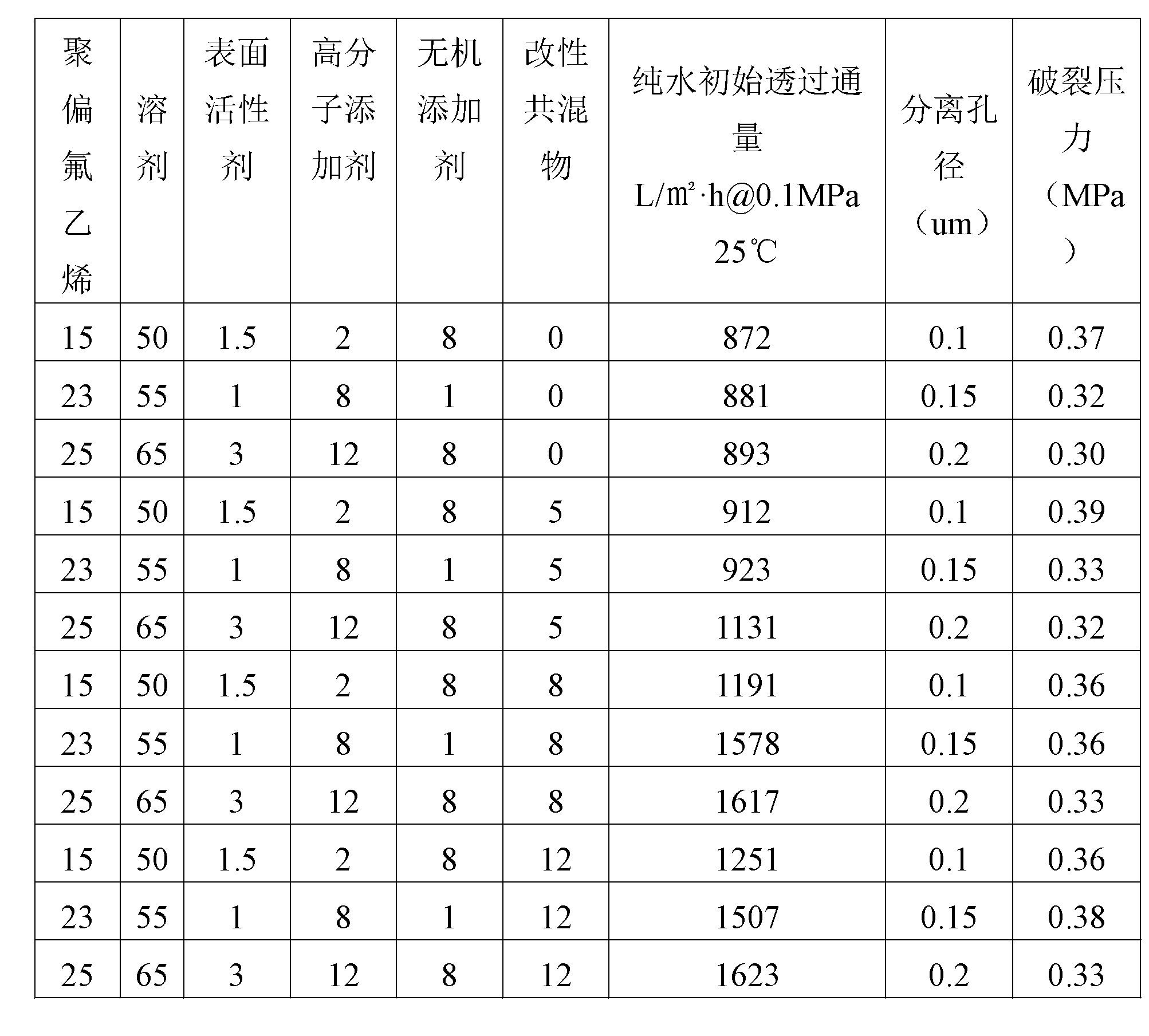

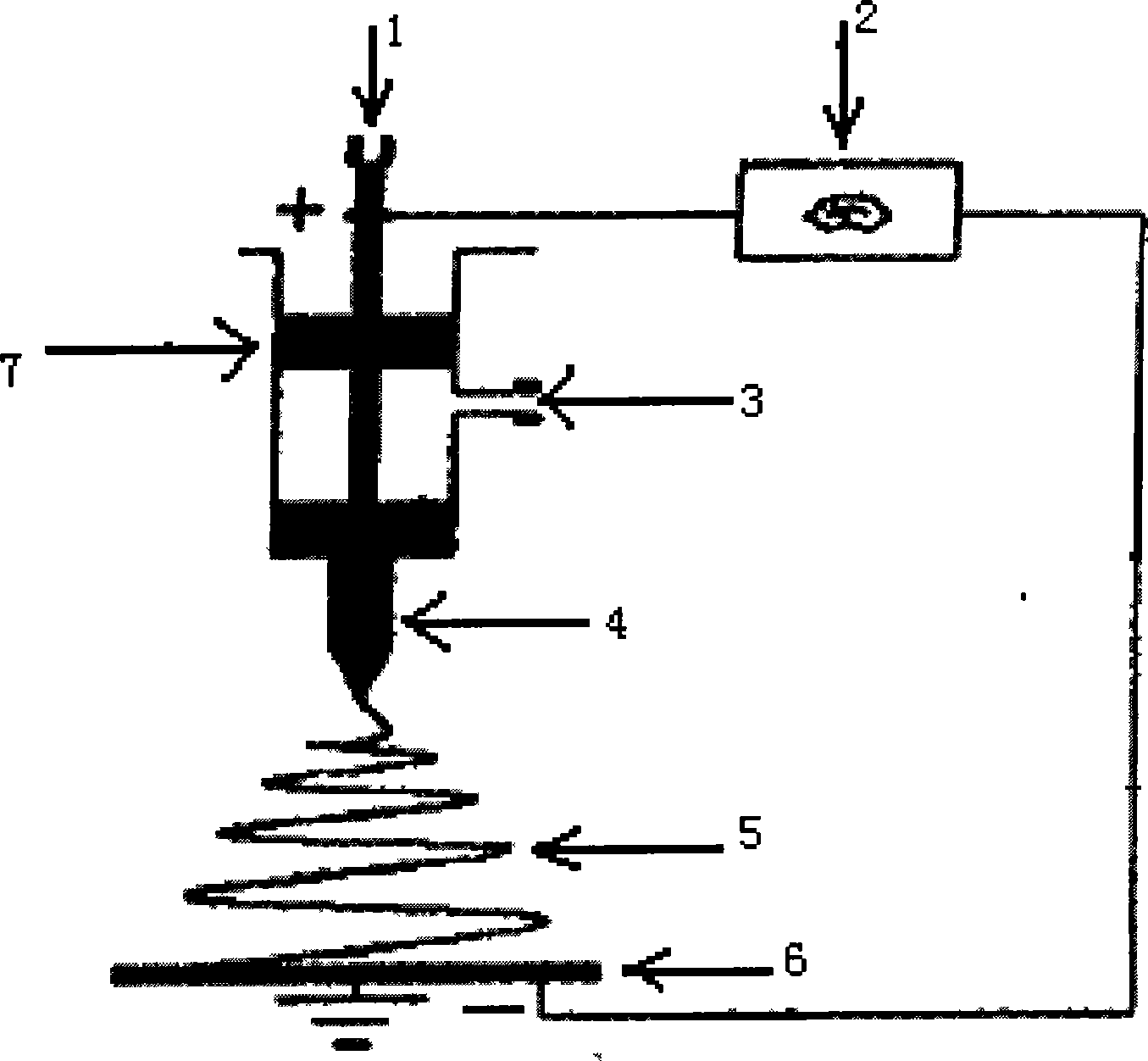

Polyvinylidene-fluoride hollow fibre membrane and preparation method thereof

InactiveCN102836645AEasy extractionPrevent shrinkage deformationSemi-permeable membranesHollow filament manufactureFiberHollow fibre membrane

The invention discloses a polyvinylidene-fluoride hollow fibre membrane and a preparation method thereof. Calculated according to parts by weight, the polyvinylidene-fluoride hollow fibre membrane is mainly prepared by the following components: 15 to 25 parts of polyvinylidene fluoride, 50 to 80 parts of solvent, 1 to 3 parts of surfactant, 2 to 12 parts of polymeric additive, 1 to 8 parts of inorganic additive and 1 to 12 parts of modified blend. By utilizing the simultaneous action of two modes of organic blending and inorganic adding according to the polyvinylidene-fluoride hollow fibre membrane and the preparation method thereof, the hydrophilcity of the polyvinylidene-fluoride hollow fibre membrane is obviously improved, and the pollution resistance can be obviously reinforced; and the pure water flux of the polyvinylidene-fluoride hollow fibre membrane is further enhanced by selecting and regulating the raw materials and the mixture ratio of the modified blend and the inorganic additive so as to obtain the permanently hydrophilic modified polyvinylidene-fluoride hollow fibre membrane.

Owner:CHINA HUADIAN ENG

Preparation of rubber nano fibre

InactiveCN101498057AShape stableResolve continuityFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPolymer science

The invention relates to a method of preparing rubber nanometer fibers. The method adopts a coaxial electrostatic spinning method which uses a rubber as a sandwich layer solution and a water-soluble polymer solution as a casing solution, exerts high-pressure static electricity and then carries out coaxial electrostatic spinning. The preparation method is simple, has good spinning continuity and stability and stable figures of the prepared rubber fibers and is widely applicable to the fields of biomedicine, antibacterium, sterilization, toughened plastics, and the like.

Owner:BEIJING UNIV OF CHEM TECH

Compound protein fiber and preparation method thereof

ActiveCN102174720ASoft touchSoft lusterConjugated cellulose/protein artificial filamentsWet spinning methodsMoisture absorptionPVA - Polyvinyl alcohol

The invention relates to a compound protein fiber and a preparation method thereof. The compound protein fiber comprises the following components in percentage by mass: 10 to 45 percent of collagen, 10 to 45 percent of soybean protein and 10 to 80 percent of polyvinyl alcohol. The preparation method of the compound protein fiber comprises the following steps of: dissolving the collagen and the soybean protein in water, adding the polyvinyl alcohol, dissolving, and performing copolymerization modification to obtain spinning solution; and performing processes such as wet spinning, solidification molding, acetalation treatment and the like to obtain the compound protein fiber. The invention has the characteristics that: the compound protein fiber which has a high mechanical property, a high moisture absorption property, high air permeability, a high dyeing property, smooth handfeel, soft luster, skin intimate performance and health-care performance and is comfortably worn is manufactured by performing blending and copolymerization modification on the polyvinyl alcohol by using the collagen and the soybean protein; and the collagen and the soybean protein have wide raw material resources and low prices, a manufacturing process is relatively simple, and production cost is reduced.

Owner:SHANGHAI QUANYU BIO TECH SUIPING

Method for preparing thioamide-based chelating nanofiber for adsorbing heavy metal ions

InactiveCN102140705AAchieve enrichmentUniform diameterOther chemical processesFilament/thread formingHeat stabilitySolvent

The invention relates to a method for preparing a thioamide-based chelating nanofiber for adsorbing heavy metal ions by combining an electrostatic spinning technology with a chemical grafting technology. The method comprises the following steps of: preparing a nanofiber from polyacrylonitrile which has high chemical stability, is easily subjected to electrospinning and is taken as an initiative raw material of reaction by the electrostatic spinning technology, pre-crosslinking, and performing thioamidation to prepare the chelating nanofiber for adsorbing the heavy metal ions. The fiber membrane of the prepared chelating nanofiber has good appearance, uniform diameter, high mechanical property, heat stability and solvent resistance, and high property of adsorbing the heavy metal ions such as gold, silver, lead, mercury, palladium, cadmium and the like. By the technology, the preparation process is simple, production equipment is low-cost, and the chelating nanofiber has low requirement on production conditions, and high properties, so the chelating nanofiber has high practical value, the content of the heavy metal ions which are produced due to industrial development and harm human health is reduced, and the chelating nanofiber has a wide application prospect for solving the livelihood problem.

Owner:JILIN UNIV

Flame-retardant antibacterial artificial wig hairline

ActiveCN106245156AWith temperature and weather resistanceRich in colorWigsFlame-proof filament manufacturePolyesterMasterbatch

The invention discloses a flame-retardant antibacterial artificial wig hairline, which comprises, by weight, 80-90% of a polyester material, 5-11% of a flame retardant agent, 2.5-6% of an antibacterial agent, 0.3-3% of a dispersing agent, 0.2-0.5% of an antioxidant, and 2-5% of color masterbatch. According to the present invention, the flame-retardant antibacterial artificial wig hairline has characteristics of high simulation degree, flexible hairline, diverse color, flame retardant property, antibacterial property, no fused drop, environmental protection and the like, and can replace the expensive human hairline. The invention further discloses a manufacturing method of the flame-retardant antibacterial artificial wig hairline, wherein the manufacturing method comprises: pre-treating a polyester raw material, carrying out blending granulation on the polyester material, the antibacterial agent, the flame retardant agent, the dispersing agent and the stabilizer by using a double-screw extruder to obtain a flame-retardant antibacterial slice, carrying out melt spinning on the slice, carrying out high-temperature shaping treatment, carrying out washing and drying, and carrying out other steps.

Owner:见喜新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com