Polyimide fiber and preparation method thereof

A technology of polyimide fiber and polyamic acid, applied in the field of fibers, can solve the problem of insufficient mechanical properties, and achieve the effects of orderly molecular chain structure, good mechanical properties, good high temperature resistance and chemical corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a kind of preparation method of polyimide fiber described in above-mentioned technical scheme, comprises the following steps:

[0039] Mix p-phenylenediamine, 4,4'-diaminodiphenyl ether and 3,3',4,4'-biphenyltetraacid dianhydride in an organic solvent, and perform polycondensation reaction to obtain polyamic acid spinning stock solution , the ratio of the moles of p-phenylenediamine to the total moles of p-phenylenediamine and 4,4'-diaminodiphenyl ether is 0.8-0.95;

[0040] Spinning the polyamic acid spinning stock solution to obtain a polyamic acid precursor;

[0041] Carrying out imidization treatment to the polyamic acid precursor to obtain polyimide spun fibers;

[0042] The polyimide primary fiber is subjected to thermal drawing treatment to obtain polyimide fiber.

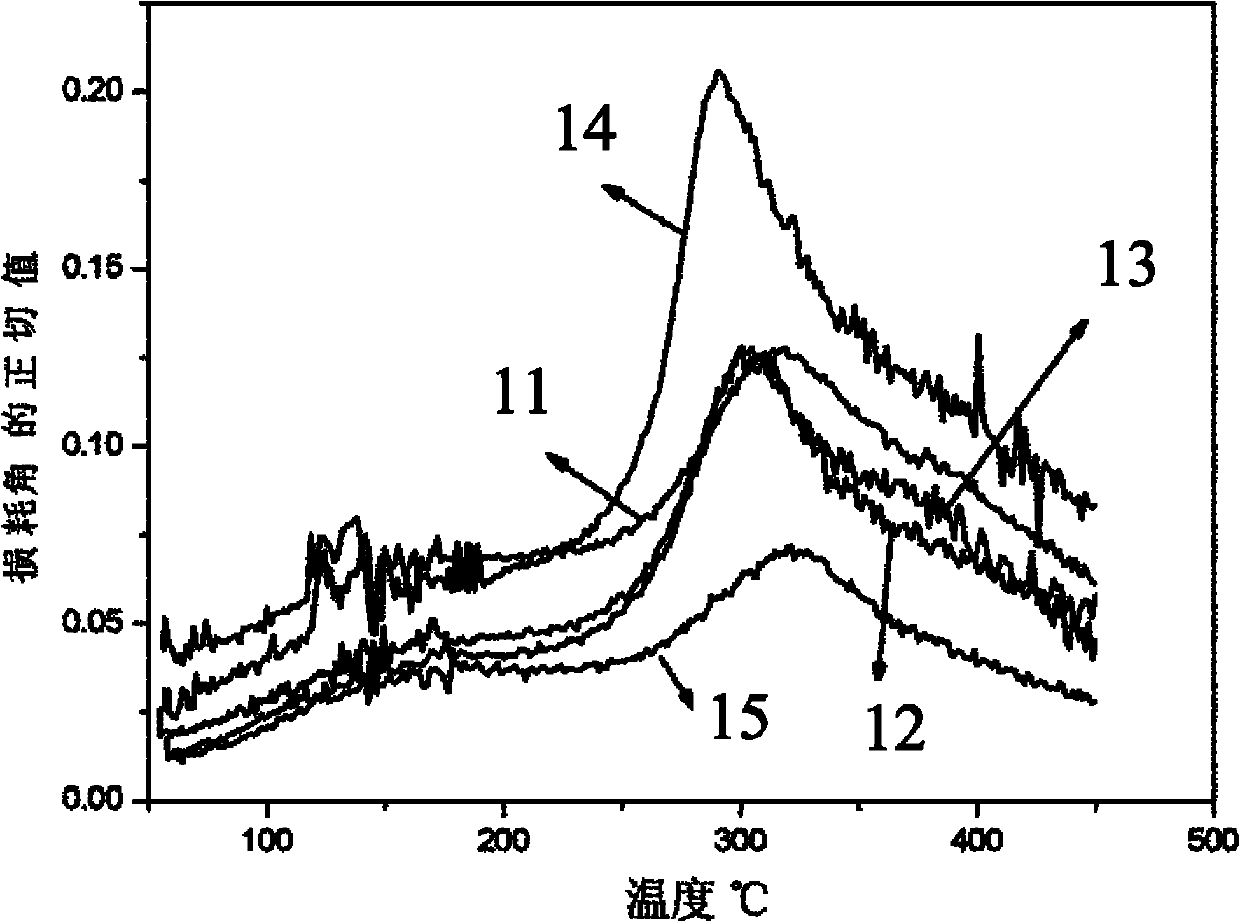

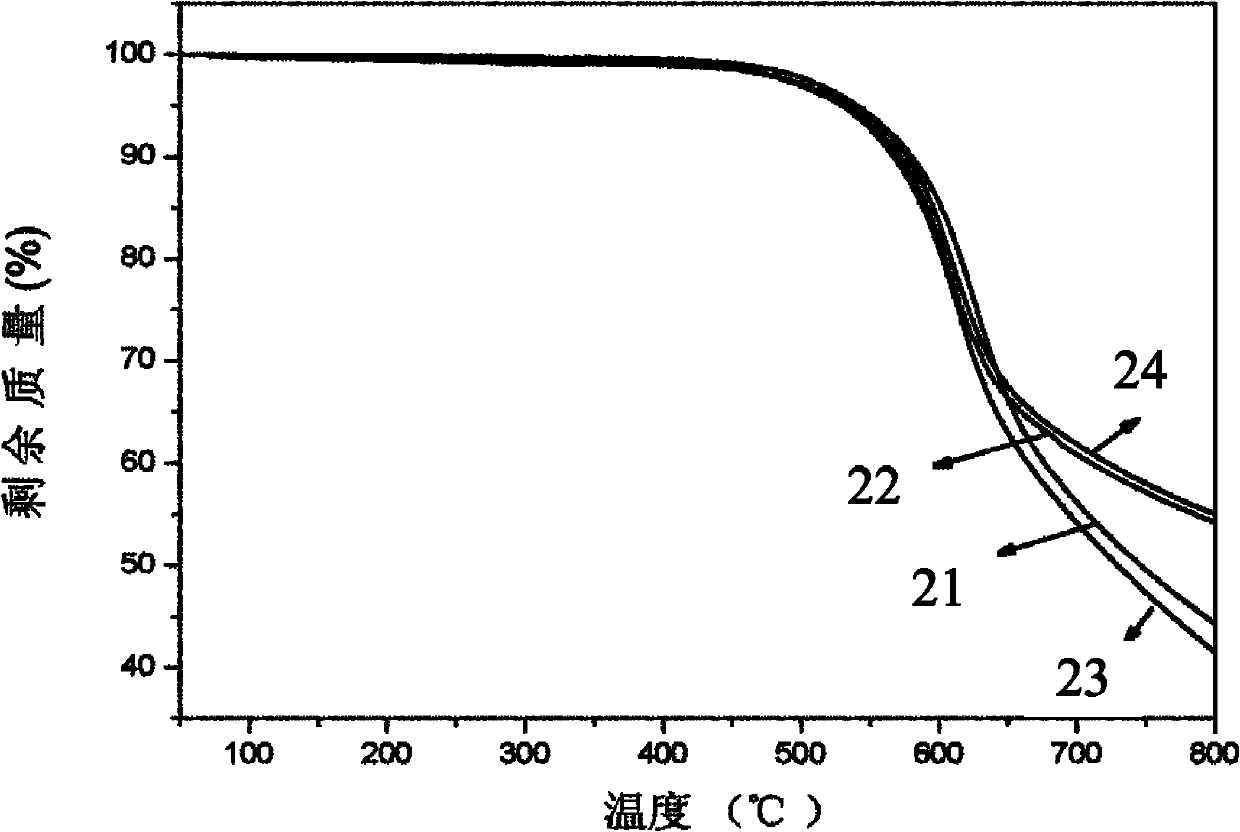

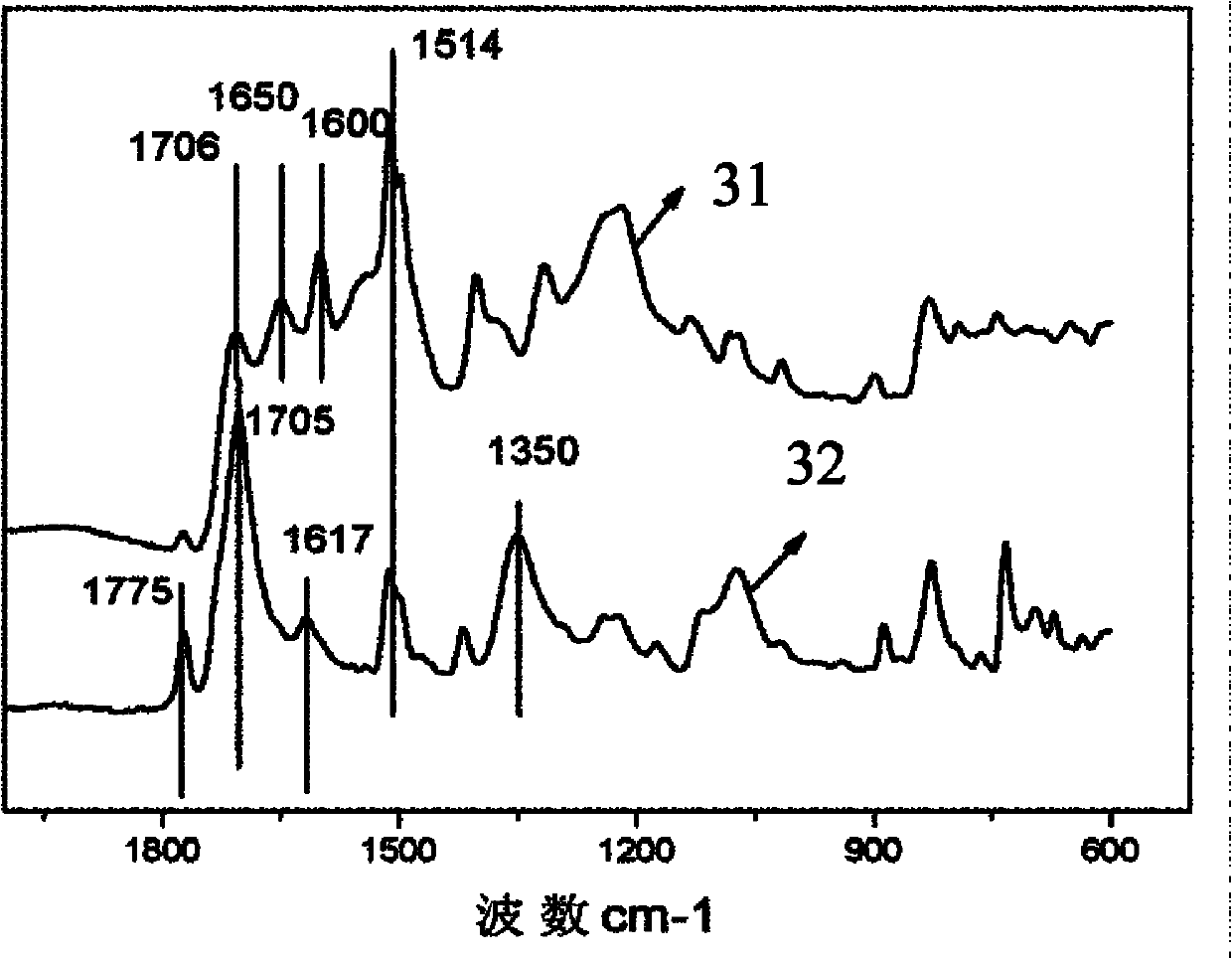

[0043]The invention uses p-phenylenediamine, 4,4'-diaminodiphenyl ether and 3,3',4,4'-biphenyltetraacid dianhydride as raw materials, and adopts a two-step method...

Embodiment 1

[0065] Dissolve 51.33g (0.475mol) of p-phenylenediamine and 5.00g (0.025mol) of 4,4'-diaminodiphenyl ether in 1000mL of N, N'-dimethylacetamide, and add 152.90g (0.520 mol) 3,3',4,4'-biphenyltetraacid dianhydride, after reacting at -5°C to 30°C for 5 hours, a viscous polyamic acid spinning stock solution is obtained, and the mass concentration of the polyamic acid is about 18.2%;

[0066] After the polyamic acid spinning stock solution is filtered, vacuum degassed, extruded from the spinneret, it enters the solidification process composed of N,N'-dimethylacetamide and water with a volume ratio of 40:60 through the air layer. coagulated in a bath, and then washed and dried to obtain polyamic acid precursors. The spinneret of the spinneret is 30 holes, the aperture is 0.12mm, the spray draw ratio is 3.0 times, the spinneret speed is 30m / min, and the air layer height is 70mm;

[0067] The polyamic acid precursor is sent into a gradient heating heat treatment furnace for thermal...

Embodiment 2

[0073] Dissolve 48.63g (0.45mol) of p-phenylenediamine and 10.00g (0.05mol) of 4,4'-diaminodiphenyl ether in 1000mL of N,N'-dimethylacetamide, and add 152.90g (0.520 mol) 3,3',4,4'-biphenyltetraacid dianhydride, after reacting at -5°C to 40°C for 8 hours, a viscous polyamic acid spinning stock solution is obtained, and the mass concentration of the polyamic acid is about 17.9%;

[0074] After the polyamic acid spinning stock solution is filtered and vacuum degassed, it is extruded from the spinneret and enters the solidification process composed of N,N'-dimethylacetamide and water with a volume ratio of 1:1 through the air layer. coagulated in a bath, and then washed and dried to obtain polyamic acid precursors. The spinneret of the spinneret is 150 holes, the aperture is 0.1mm, the spray draw ratio is 4.0 times, the spinneret speed is 100m / min, and the air layer height is 50mm;

[0075]The polyamic acid precursor is sent into a gradient heating heat treatment furnace for th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com