Method for preparing nanofiber containing pore structure

A nanofiber and pore structure technology, which is applied in fiber treatment, fiber chemical characteristics, spinning solution preparation, etc., can solve the problems of nanofibers with no pore structure, etc., and achieve the effect of simple and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

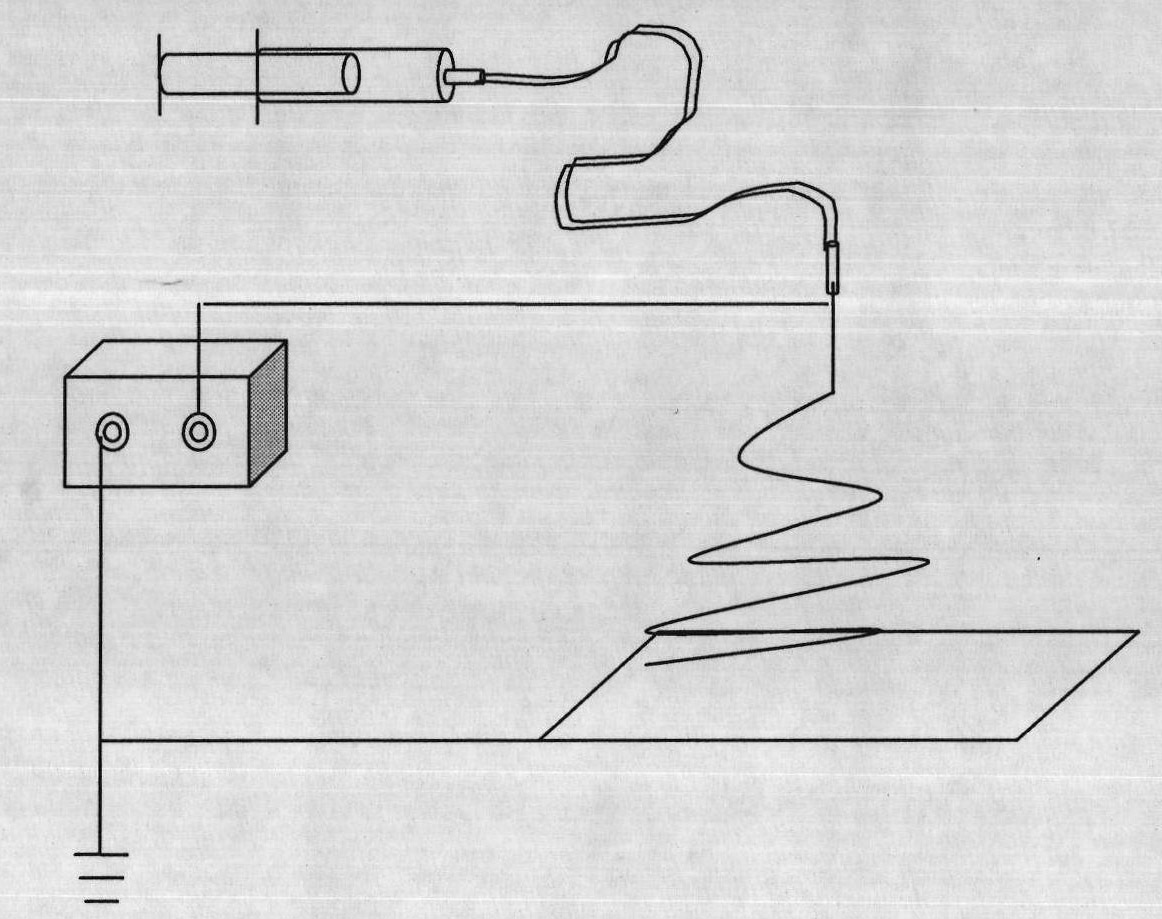

[0020] (1) prepare the DMF solution of 10wt% PAN, get the NaHCO of 2wt% of polymer content 3 Disperse in the polymer solution, stir vigorously, stand still, and spin after the air bubbles are eliminated;

[0021] (2) Add the spinning solution prepared in step 1 into the syringe, adjust the voltage to 25kV, and the distance from the nozzle to the receiver is 10cm. Turn on the spinning device to obtain ultra-fine nanofibers on the collecting device;

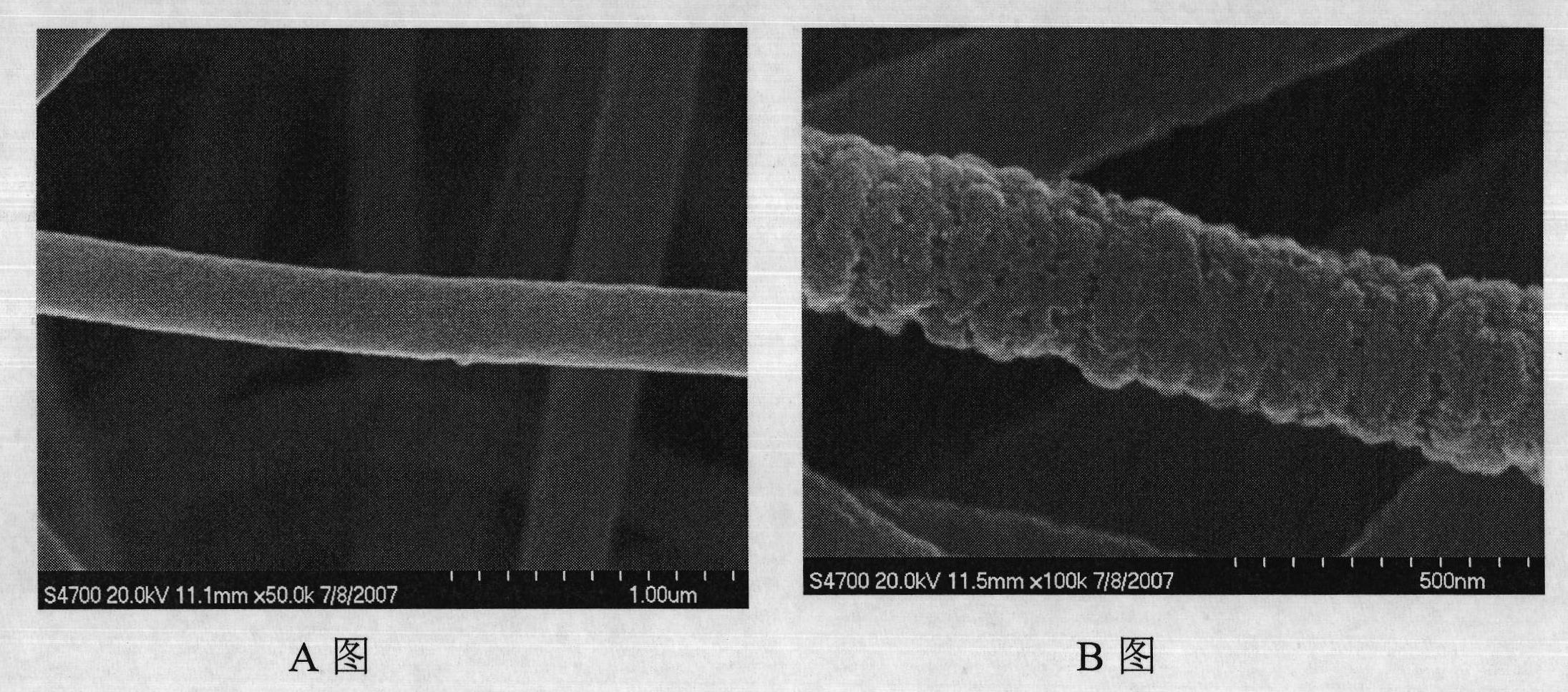

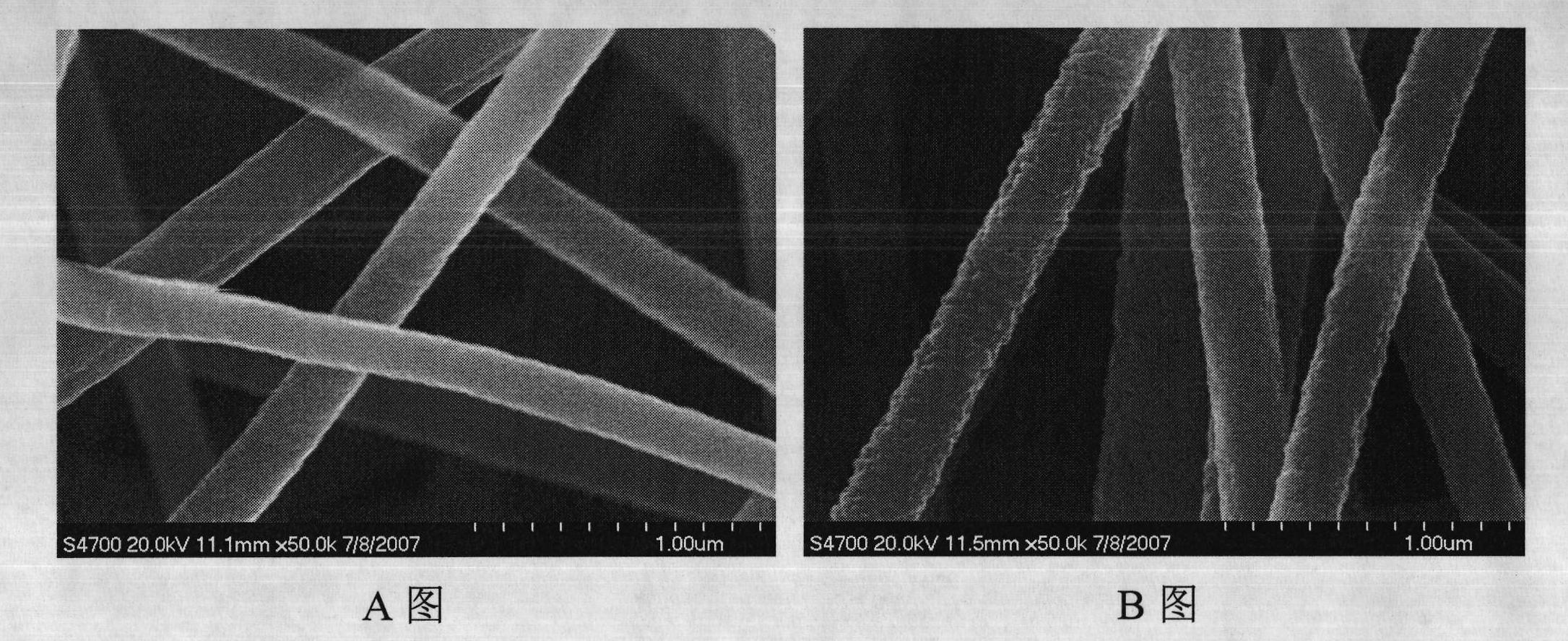

[0022] (3) Immerse the nanofiber prepared in step 2 in 5% dilute hydrochloric acid, take it out after 24 hours, dry it in an oven, and observe the fiber morphology with a scanning electron microscope.

Embodiment 2

[0024] (1) prepare the DMF solution of 15wt% PAN, get the 5wt% (NH 4 )HCO 3 Disperse in the polymer solution, stir vigorously, stand still, and spin after the air bubbles are eliminated;

[0025] (2) Add the spinning solution prepared in step 1 into the syringe, adjust the voltage to 25kV, and the distance from the nozzle to the receiver is 10cm. Turn on the spinning device to obtain ultra-fine nanofibers on the collecting device;

[0026] (3) Immerse the nanofiber prepared in step 2 in 2% acetic acid, take it out after 24 hours, dry it in an oven, and observe the fiber morphology with a scanning electron microscope.

Embodiment 3

[0028] (1) prepare the DMF solution of the PS of 20wt%, get the NaHCO of 1wt% of polymer content 3 Disperse in the polymer solution, stir vigorously, stand still, and spin after the air bubbles are eliminated;

[0029] (2) Add the spinning solution prepared in step 1 into the syringe, adjust the voltage to 25kV, and the distance from the nozzle to the receiver is 10cm. Turn on the spinning device to obtain ultra-fine nanofibers on the collecting device;

[0030] (3) Immerse the nanofiber prepared in step 2 in 8% dilute hydrochloric acid, take it out after 24 hours, dry it in an oven, and observe the fiber morphology with a scanning electron microscope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com