Measuring cup device of molecular sieve assembly device

An assembly device and molecular sieve technology, which is applied in the direction of drying solid materials, drying solid materials without heating, lighting and heating equipment, etc., can solve the problems of increasing equipment investment of producers and reducing the production efficiency of molecular sieves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

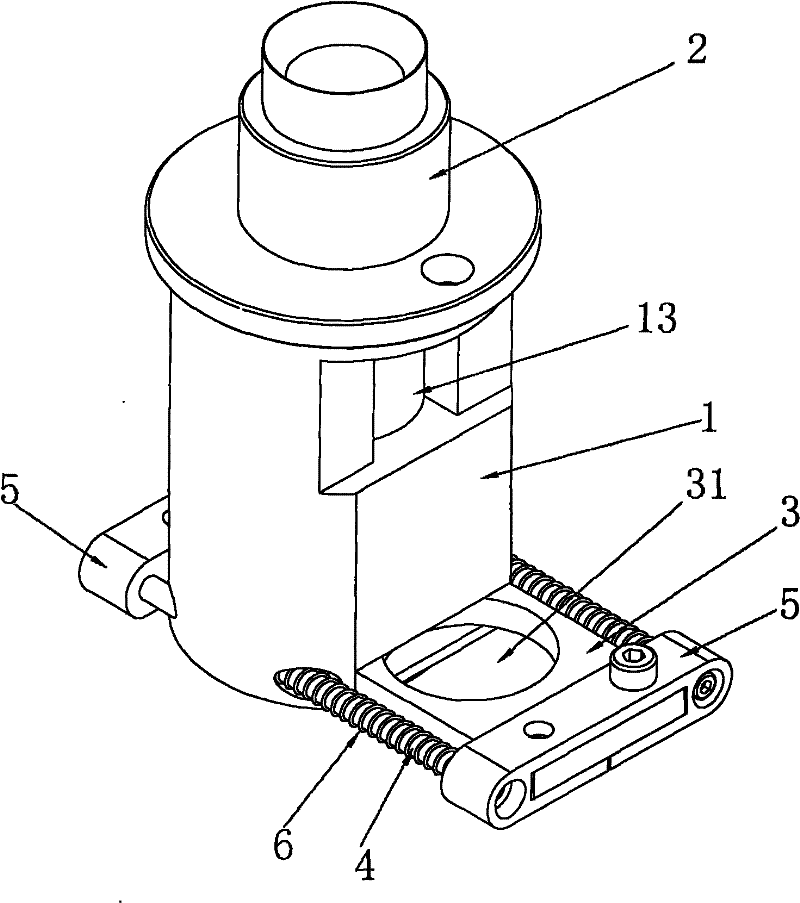

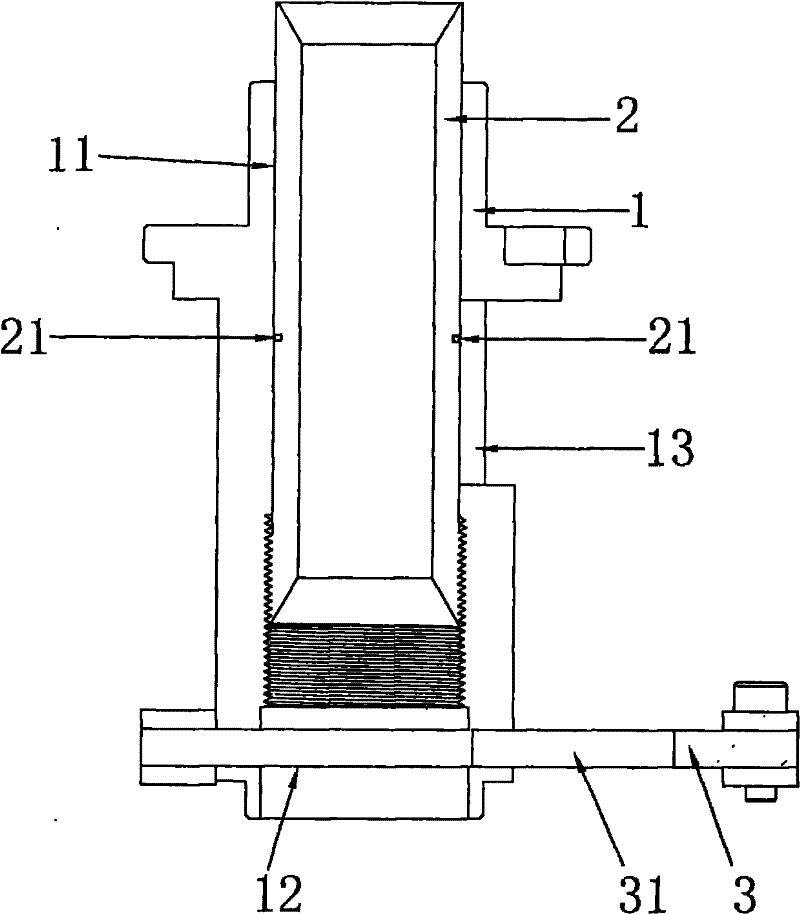

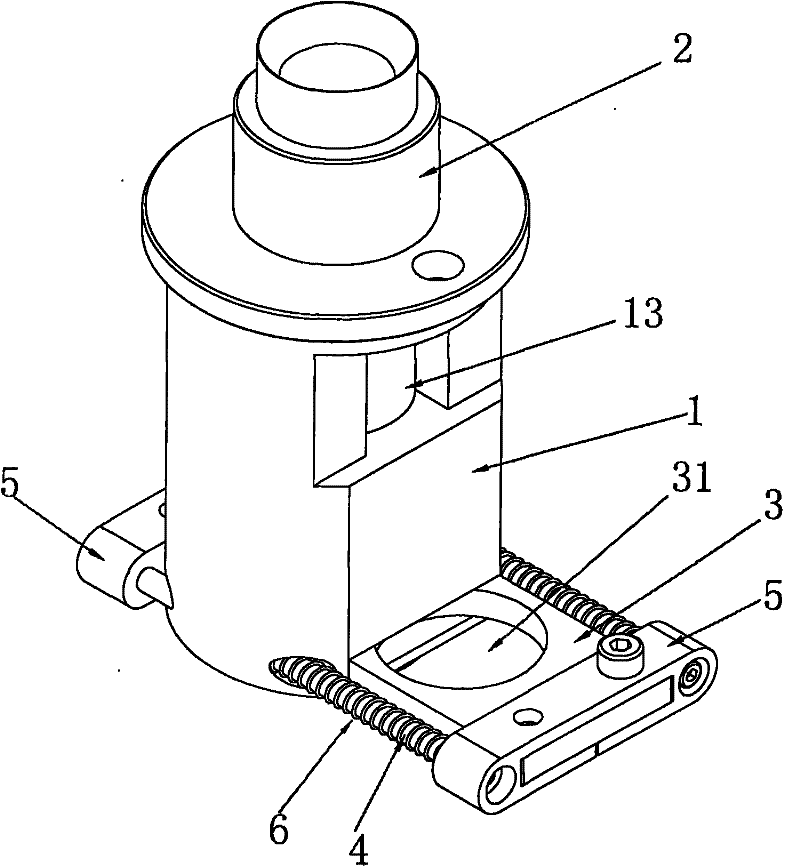

[0012] refer to figure 1 , figure 2 , a measuring cup device for a molecular sieve assembly device disclosed in the present invention includes a cup body 1, a through hole 11 is arranged axially in the cup body 1, a measuring cup 2 is installed in the through hole 11, and a through hole 11 is arranged at the bottom of the cup body 1. Hole 11 is orthogonal to the installation hole 12 of the unloading pumping plate. The unloading pumping plate 3 is installed in the unloading pumping plate installation hole 12. The unloading pumping plate 3 can reciprocate along the unloading pumping plate installation hole. The unloading pumping plate 3 There is a discharge hole 31 corresponding to the through hole 11. When filling the copper tube with desiccant, put the desiccant in the measuring cup in advance, and then push the discharge pump to make the discharge hole and the cup through. The holes are opposite, so that the desiccant falls into the copper tube, so as to achieve the purpose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com