Method and device for continuously preparing methanol emulsified diesel

A technology for emulsification of diesel and methanol, applied in chemical instruments and methods, mixing methods, petroleum industry, etc., can solve the problems of intermittent production, high device cost, poor product stability, etc., and achieve uniform particle size distribution, dosage saving, stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

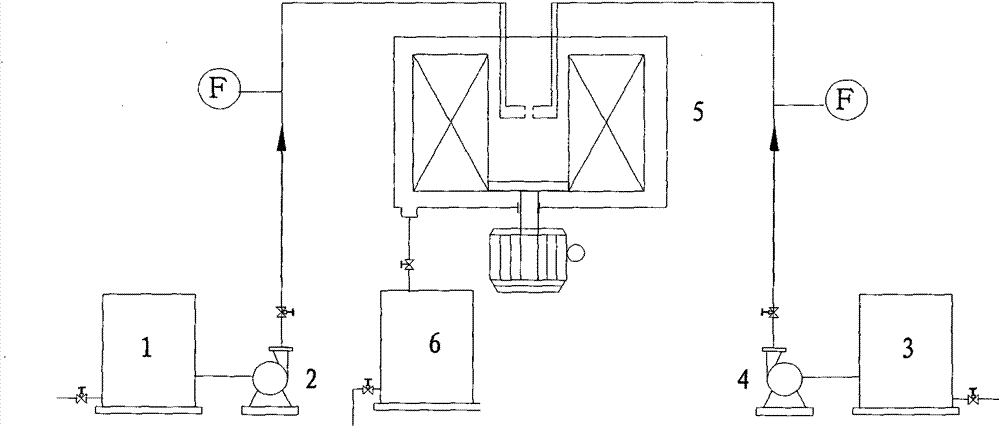

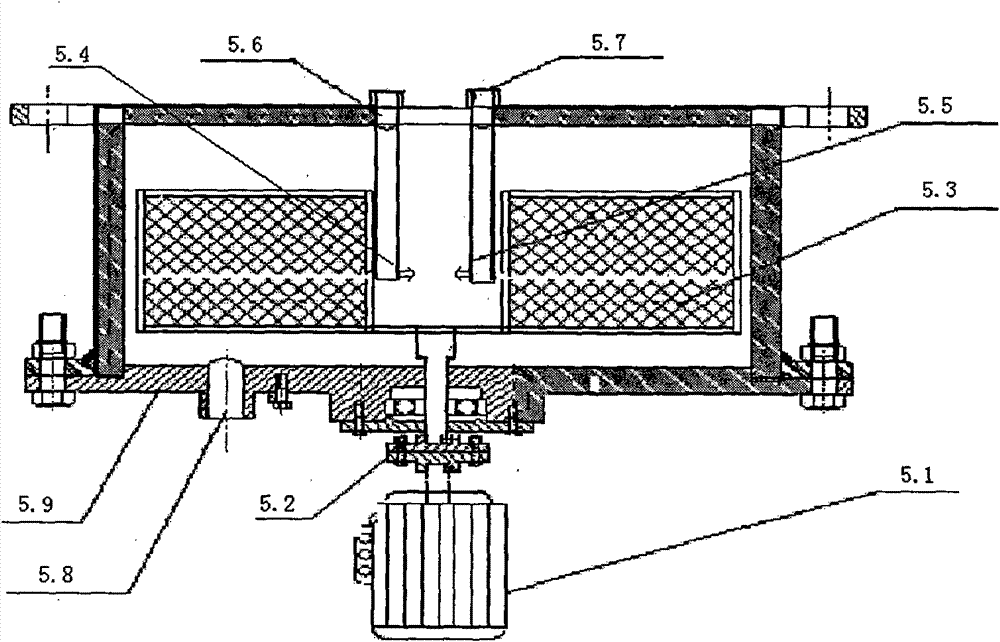

Method used

Image

Examples

Embodiment 1

[0028] A methanol solution containing a hydrophilic emulsifier is prepared in the methanol storage tank 1, and a diesel solution containing a lipophilic emulsifier is prepared in the diesel storage tank 3. Enter the emulsifier according to the ratio of water phase: oil phase = 10:90, the opening diameter of the nozzle is 0.5mm, which is a long hole, the filler is plastic mesh, and the initial impact velocity of the water phase and oil phase is 1m / s , the rotational speed of the annular filler is 300rpm, the emulsifier is a compound of Span60 and Tween80, the HLB value is 5.2, and the content of the emulsifier is 0.1% of the total mass of methanol and diesel. The average particle size of the prepared methanol-emulsified diesel is 30 μm, and it does not separate water for 10 days at room temperature, and the appearance of the methanol-emulsified diesel is clear and bright.

Embodiment 2

[0030] A methanol solution containing a hydrophilic emulsifier is prepared in the methanol storage tank 1, and a diesel solution containing a lipophilic emulsifier is prepared in the diesel storage tank 2. Enter the emulsifier according to the ratio of water phase: oil phase=15:85, the opening diameter of the nozzle is 2mm, which is a round hole, the filler is a stainless steel wire mesh, the initial impact velocity of the feed is 5m / s, the rotating speed is 800rpm, and the emulsifier is Span80 and Tween60 are compounded, the HLB value is 5.0, and the emulsifier content is 0.5% of the total mass of methanol and diesel. The prepared methanol-emulsified diesel has an average particle size of 15 μm, and remains free of stratification for 20 days at room temperature. The appearance of the methanol-emulsified diesel is clear and bright.

Embodiment 3

[0032] A methanol solution containing a hydrophilic emulsifier is prepared in the methanol storage tank 1, and a diesel solution containing a lipophilic emulsifier is prepared in the diesel storage tank 2. Enter the emulsifier according to the ratio of water phase: oil phase = 20:80. The opening diameter of the nozzle is 3mm, which is a long hole. The filler is plastic mesh. The agent is a compound of oleic acid and Tween60, the HLB value is 4.0, and the emulsifier content is 2% of the total mass of methanol and diesel. The prepared methanol-emulsified diesel has an average particle size of 10 μm, and remains free of stratification for 40 days at room temperature. The appearance of the methanol-emulsified diesel is clear and translucent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com