Patents

Literature

159results about How to "Improve emulsification efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stable-protein high-internal-phase oil-in-water emulsion and preparation method thereof

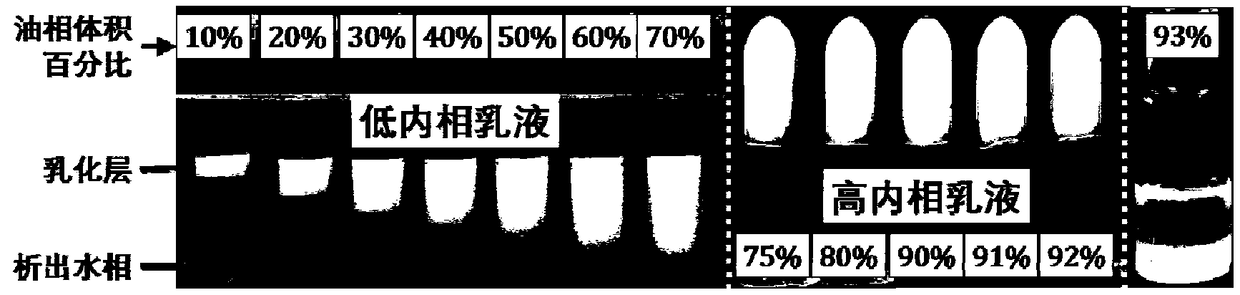

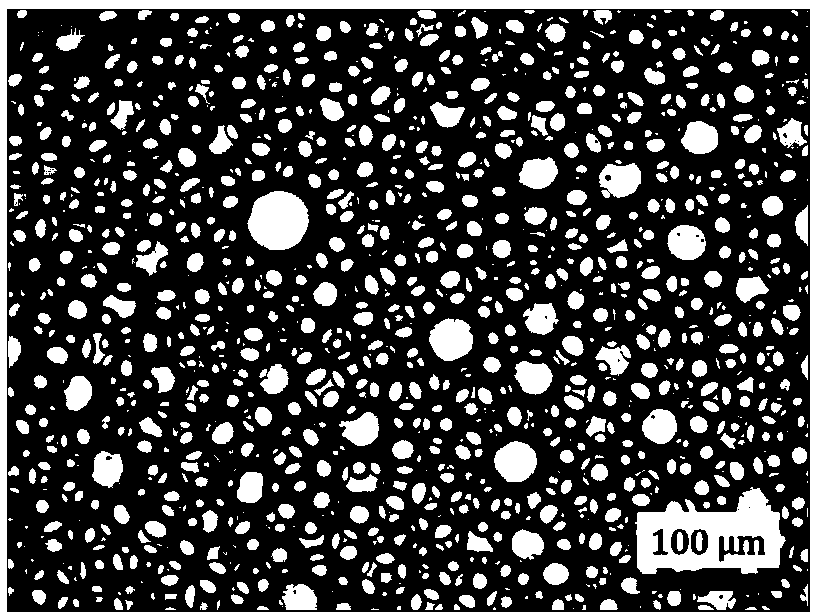

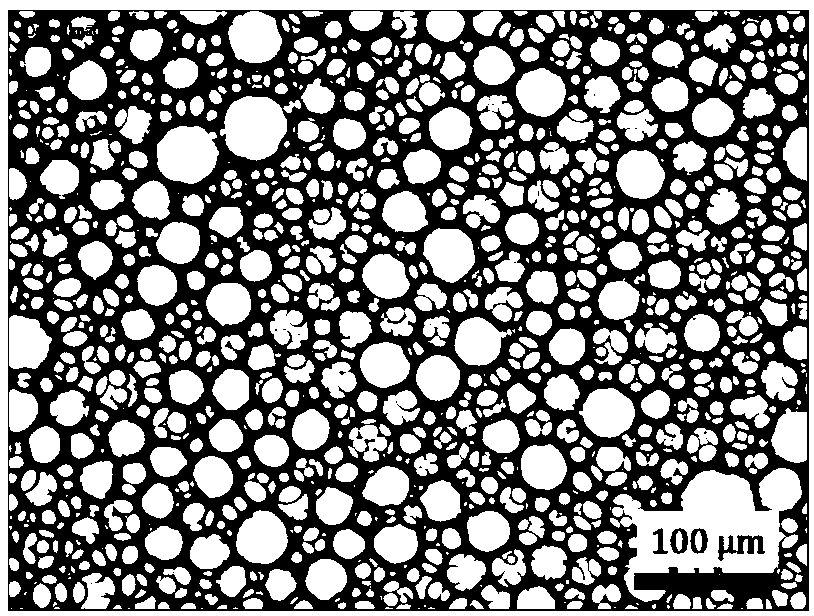

The invention belongs to the technical field of emulsion preparation, and discloses a stable-protein high-internal-phase oil-in-water emulsion and a preparation method thereof. The method comprises the following steps: a protein is dispersed into water, after the protein is fully hydrated, an aqueous phase protein solution is obtained, an oil phase is added, emulsification is performed, and therefore the stable-protein high-internal-phase oil-in-water emulsion is obtained. The method disclosed by the invention does not need any coagulants or surfactants, and the obtained high-internal-phase oil-in-water emulsion has good viscoelasticity, high heat stability and storage stability, and an excellent protection or controlled release effect on the oil phase; and the emulsion has good gelling performance, strong plasticity and remoldability, facilitates further processing, and has good application prospects in the fields of chemical products, daily chemicals, pharmaceuticals, food and healthcare products.

Owner:SOUTH CHINA UNIV OF TECH

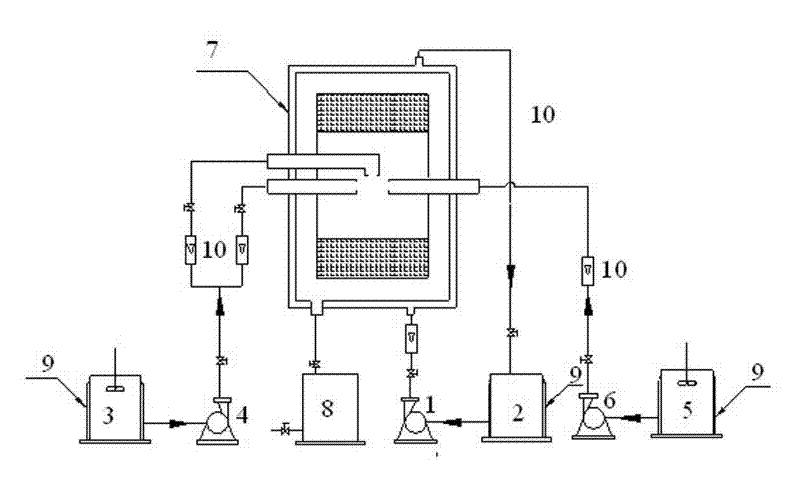

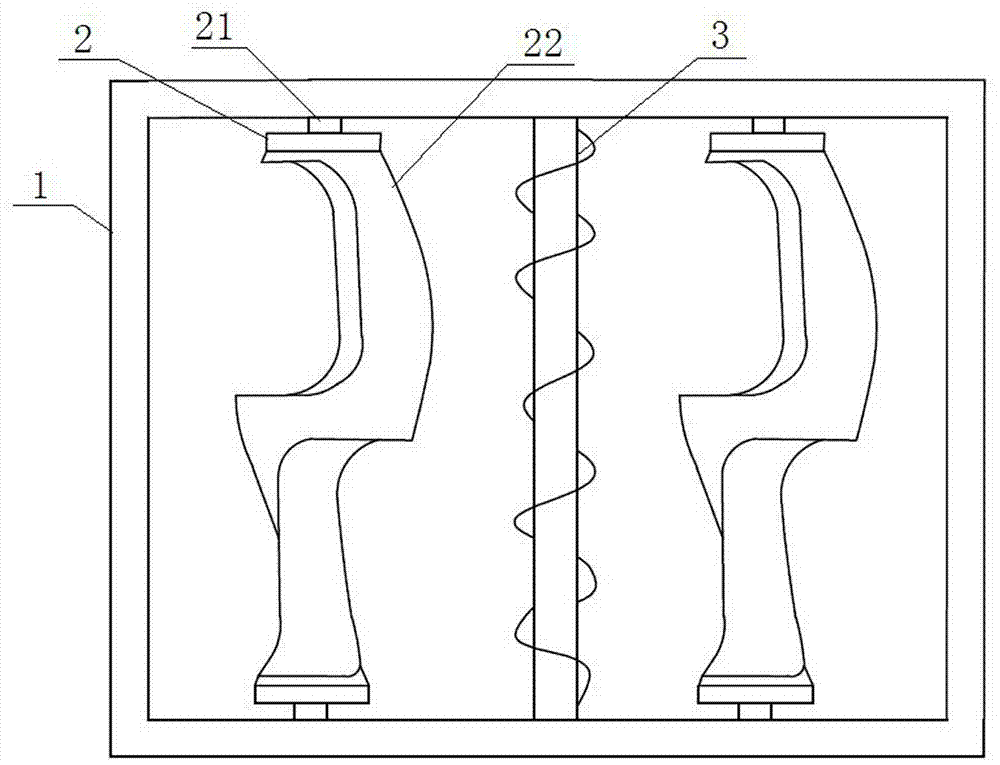

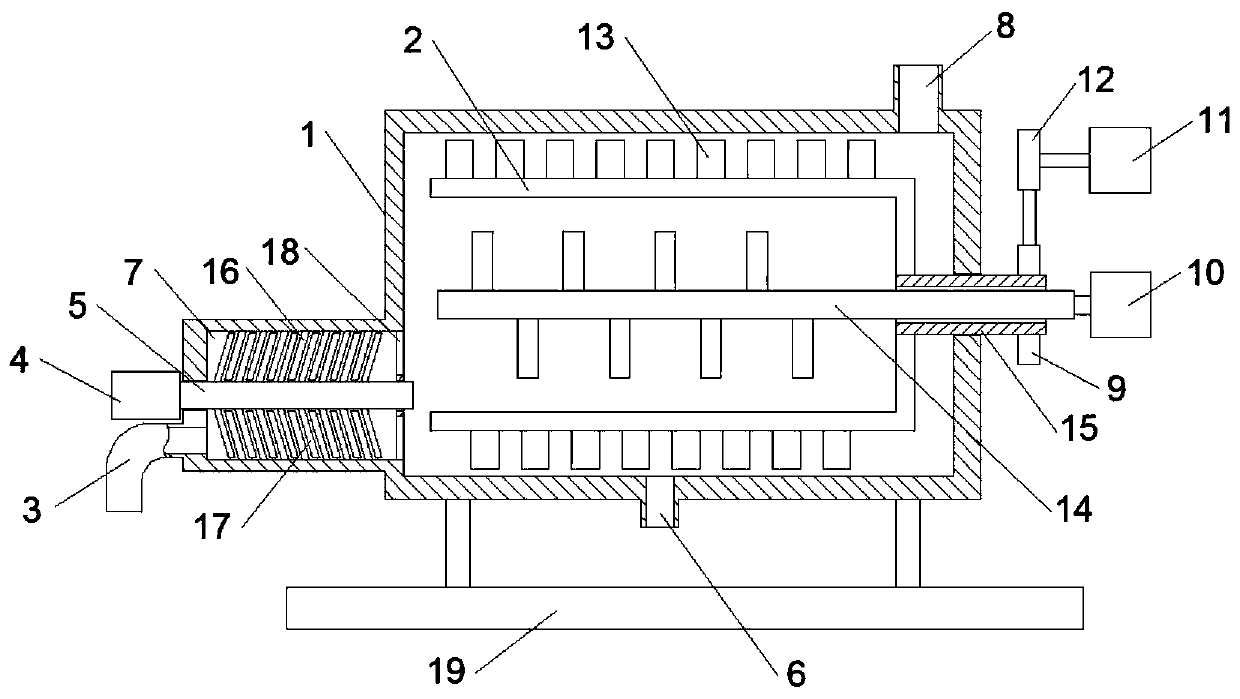

Process for continuously preparing emulsified paraffin and device thereof

The invention belongs to the technical field of emulsified paraffin preparation, and specifically relates to a process and device for continuously preparing emulsified paraffin, which solves the problems of intermittent operation, poor stability, high cost and high energy consumption in the current emulsified paraffin preparation. The method comprises the following steps: adding water in a hydrophilic emulsifier to form a water phase, adding paraffin in a lipophilic emulsifier to form an oil phase, dividing the water phase into two streams, taking oil phase as one stream for entering into an emulsifier, primarily emulsifying, then entering in an annular filling material with high speed rotation to form an oil-in-water emulsified paraffin solution. The device comprises a paraffin emulsifier and a heating and insulating device, the paraffin emulsifier comprises a shell, the netted annular filling material and a liquid distributor; the liquid distributor comprises a water phase nozzle I,a water phase nozzle II and an oil phase nozzle. The device of the invention has the advantages of simple structure, easy operation and low energy consumption, and is capable of preparing the emulsified paraffin with good stability, uniform particle size and high quality.

Owner:ZHONGBEI UNIV

Single-component water-based epoxy resin emulsion and preparation method thereof

InactiveCN102675861ASmall particle sizeEvenly distributedPolyurea/polyurethane coatingsWater basedEpoxy

The invention discloses a single-component water-based epoxy resin emulsion, which comprises the following components in percentage by weight: 100 percent of a modified epoxy resin, 5-35 percent of an efficient emulsifier, 0-1 percent of a surfactant, 0-70 percent of a cosolvent and an appropriate amount of water, wherein the modified epoxy resin comprises an epoxy resin, polyglycol ether, isocyanate, a sealing agent and a catalyst; the efficient emulsifier consists of an epoxy resin, polyether, organic silicon and a catalyst; the surfactant is one or a mixture of more than two of sodium dodecylbenzene sulfonate, sodium lauryl sulfate and potassium dodecyl sulfate; the cosolvent is one or a mixture of more than two of propylene glycol methyl ether, glycol ethylene ether, ethylene glycol monomethyl ether and diacetone; the sealing agent is one or a mixture of more than two of caprolactam, phenol and methyl ethyl ketoxime; and the catalyst is one or a mixture of more than two of 2-ethyl-4-methylimidazole, triphenylphosphine, triphenylhydrogen phosphide or benzyl dimethylamine.

Owner:上海富朗化工科技发展有限公司

Emulsifying agent for emulsion explosive and preparation method of emulsifying agent

ActiveCN103553852AImprove antistatic performanceGood emulsifying effectNon-explosive/non-thermic compositionsButanedioic acidExplosive Agents

The invention relates to an emulsifying agent mainly used for emulsion explosive and a preparation method of the emulsifying agent. The preparation method comprises the following steps: esterifying and modifying polyisobutene succinate by using boric acid, and then blocking by adopting a Span emulsifying agent and a fatty alcohol compound, thus obtaining the emulsifying agent. The emulsifying agent has good anti-static property and emulsifying property, is capable of effectively reducing the diameters of emulsifying molecules and improving the dispersibility of an emulsion, the emulsifying efficiency and the storage stability of the emulsion explosive.

Owner:湖北同一科技有限公司

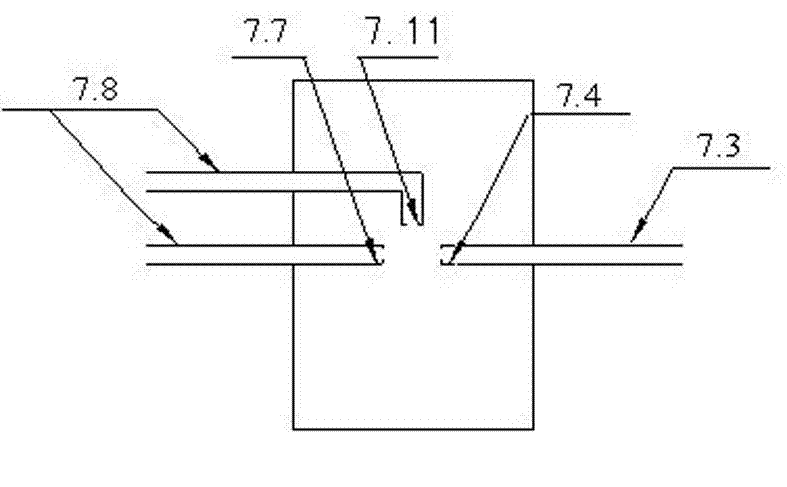

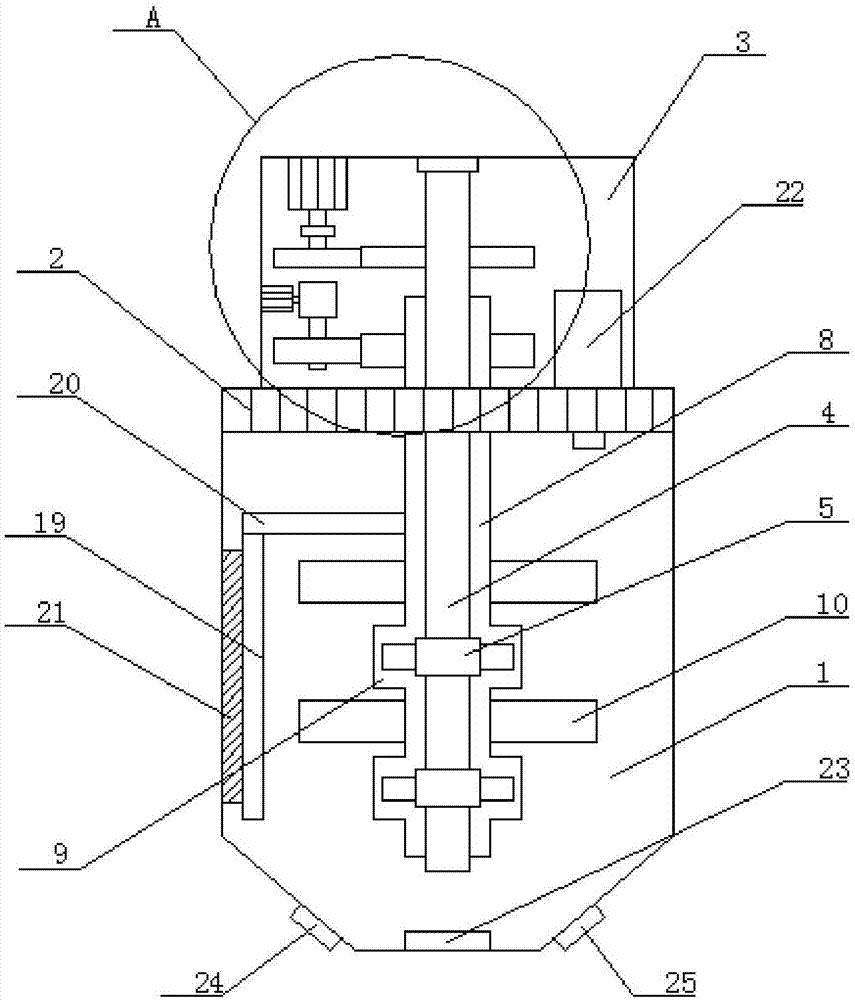

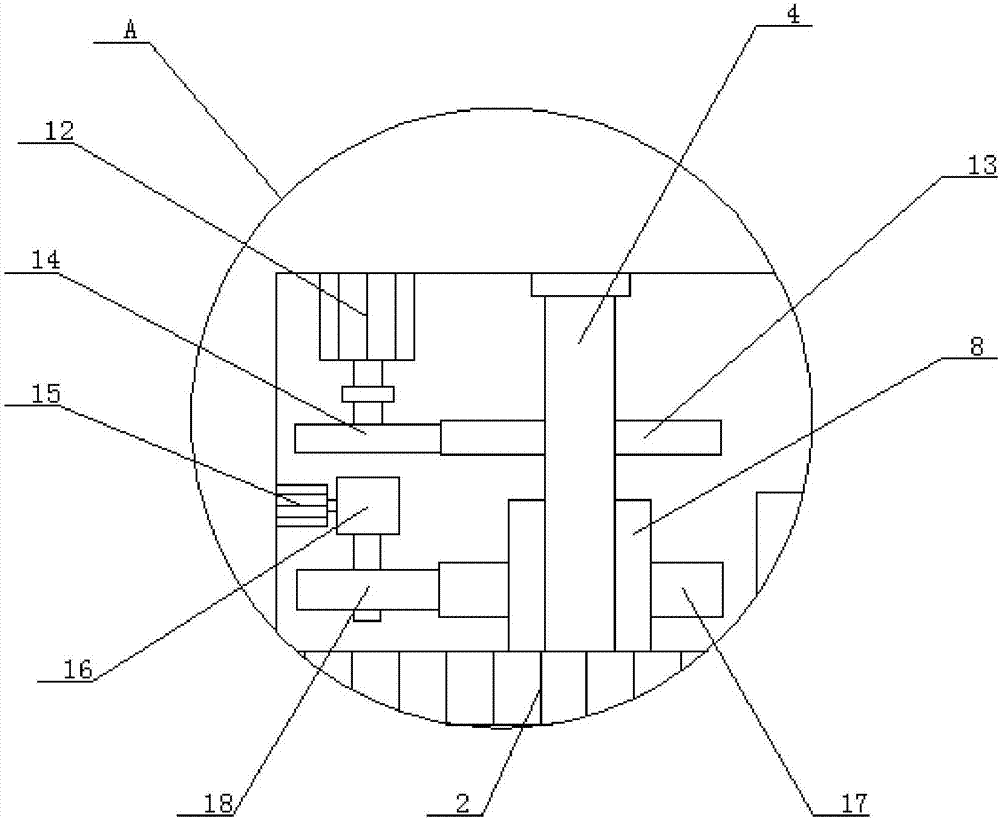

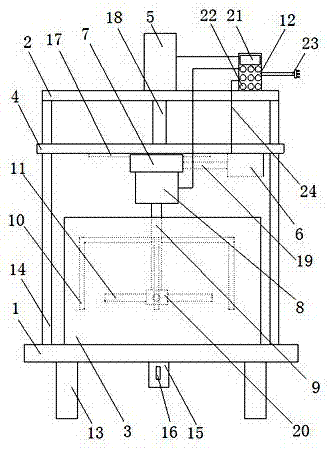

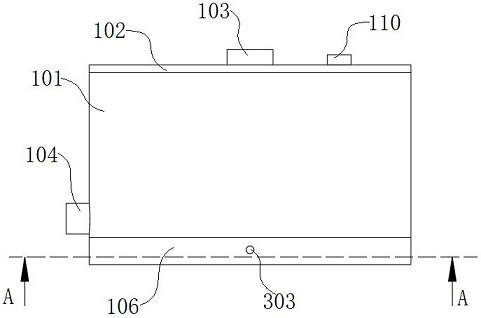

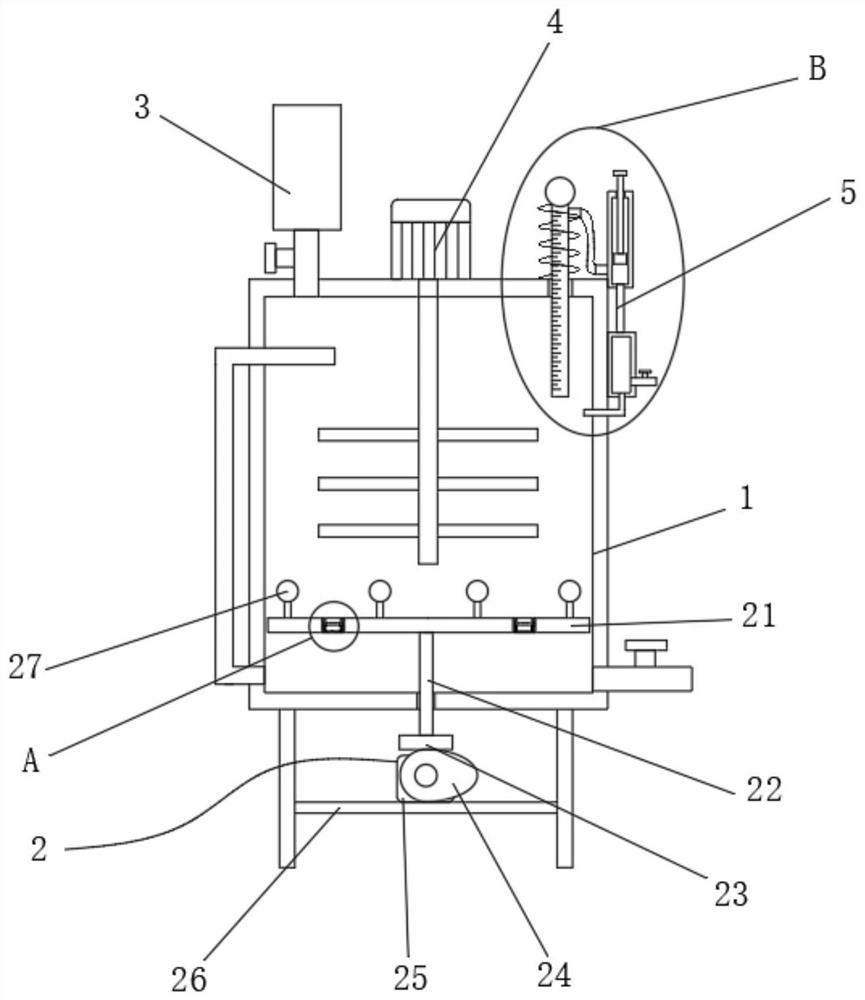

Coating processing emulsifying device and using method of device

InactiveCN107433144AImprove emulsification efficiencyQuality improvementMixing methodsTransportation and packagingDrive shaftPiston rod

The invention discloses a coating processing emulsifying device. The device comprises a bottom board, a top board, an emulsifying barrel, a regulating board, a first cylinder, a second cylinder, a regulating block, an electric motor, a transmission shaft, first stirring bars, second stirring bars and a controller. The device is characterized in that the bottom board are equipped with bottom feet and upright columns; the top board is arranged on the upright columns; the emulsifying barrel is arranged on the bottom board; the regulating board is arranged at the upright columns; the first cylinder is arranged on the top board; the transmission shaft is arrange on the electric motor; and the first stirring bars are arranged on the transmission shaft. A guide rail is arranged on the regulating board in the device provided by the invention; the electric motor is arranged on the regulating block of the guide rail; and the regulating board is connected with a first piston rod of the first cylinder, so that the regulating board can go up or down along the upright columns with the first piston rod, and the transmission shaft on the electric motor can go up or down in the emulsifying barrel. The emulsifying efficiency and emulsifying quality of a coating in the emulsifying barrel are increased, and the labor intensity is decreased at the same time.

Owner:WUHU SANSHAN LONGCHENG NEW MATERIALS

Stearic acid soap paper coating lubricant

ActiveCN101532267ASmall particle sizeLow viscosityNon-fibrous pulp additionLubricant compositionStearic acidStearate

The invention discloses a stearic acid soap paper coating lubricant, which is composed of, based on weight percent, the following ingredients of: 44.5%-51.5% of the stearic acid soap, 2%-2.5% of an oleic acid, 2%-3% of an emulsifier, 0.3%-0.4% of a pH value regulator, 1%-2.2% of an antifreezing agent and 41%-50% of water. The stearic acid soap paper coating lubricant prepared by the invention has the viscosity of 50-150 MPa.s, the solid content of 50%-57% and the pH value of 9-12; compared with the present product, the inventive lubricant has the advantages of small particle diameter, low viscosity, high content of stearate, therefore, the invention is good in stability, high in emulsifying efficiency of the emulsifier, low in production cost, easy in being dispersed in the process of the use, and suitable for high-speed coating technology.

Owner:宁波汇臻新材料有限公司

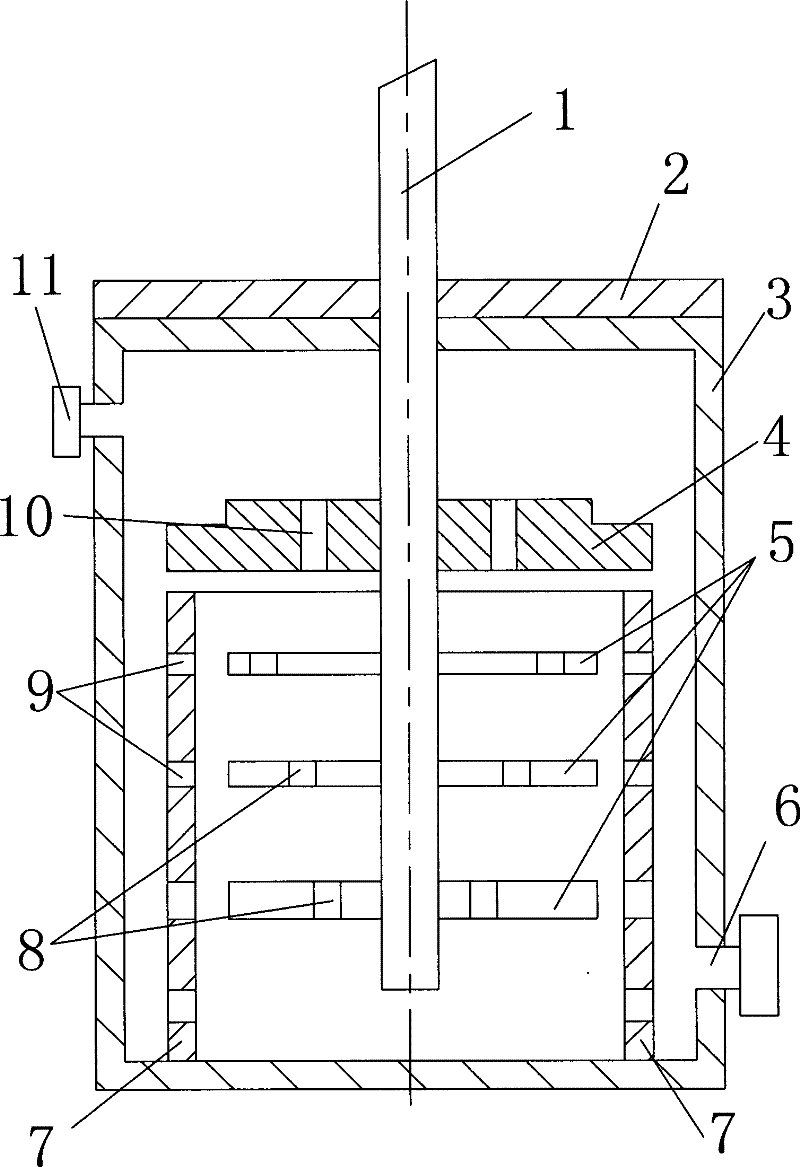

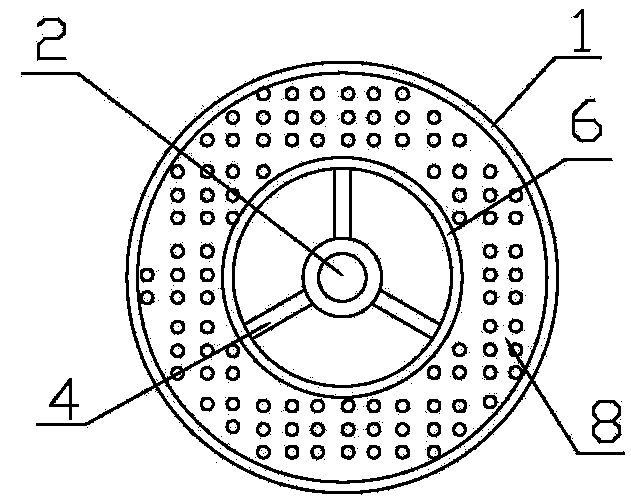

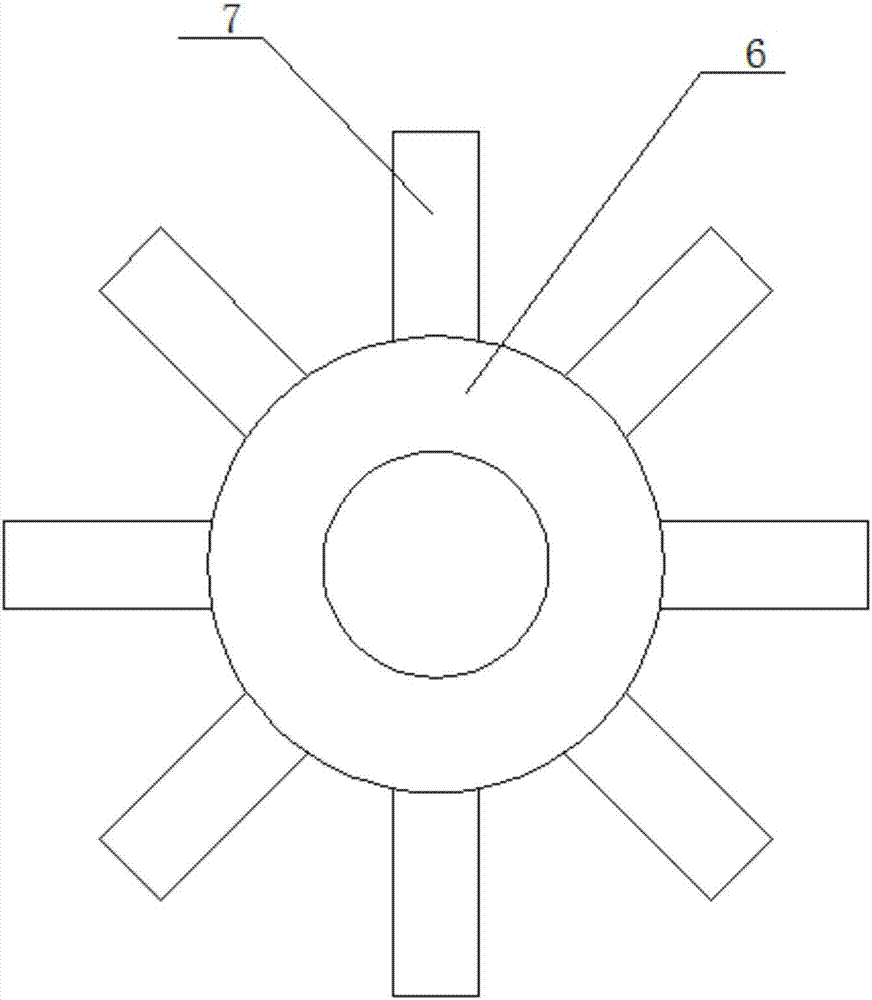

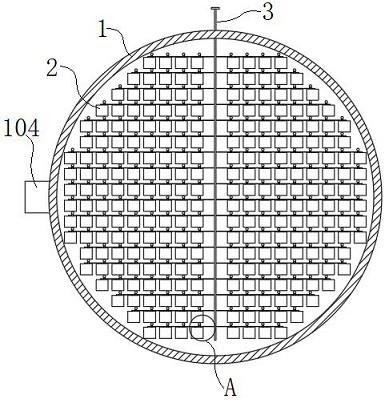

Mulser

InactiveCN102489200AEasy to crushImprove emulsification efficiencyTransportation and packagingRotary stirring mixersImpellerEngineering

The invention discloses a mulser. A stirring shaft vertically extends into an emulsification can from the outside of the top portion of the emulsification can through a can cover, an impeller is fixedly arranged on the stirring shaft in the emulsification can, and the impeller is horizontally arranged and provided with a plurality of third holes. A dispersing barrel with an upper opening communicated with a lower opening and coaxial with the stirring shaft are arranged right below the impeller, the dispersing barrel is perpendicularly and fixedly connected with the bottom of the emulsification can, the top portion of the dispersing barrel is close to the impeller, and a gap is reserved between the top portion of the dispersing barrel and the impeller. A gap is reserved between the outer wall of the dispersing barrel and the inner wall of the emulsification can. The lateral wall of the dispersing barrel is provided with a plurality of second holes, multi-layer blades horizontally arranged and fixedly connected with the stirring shaft are arranged in the dispersing barrel at intervals along the axial direction of the stirring shaft. Each layer of blades is composed of a plurality of straight rods evenly distributed along the circumferential direction of the stirring shaft, and a plurality of first holes are arranged on each straight rod. The mulser is applied to continuous dispersing and emulsification for materials with high viscosity and can finely and evenly crush emulsification medium particles.

Owner:JIANGSU HUANNENGTONG ENVIRONMENTAL PROTECTION TECH

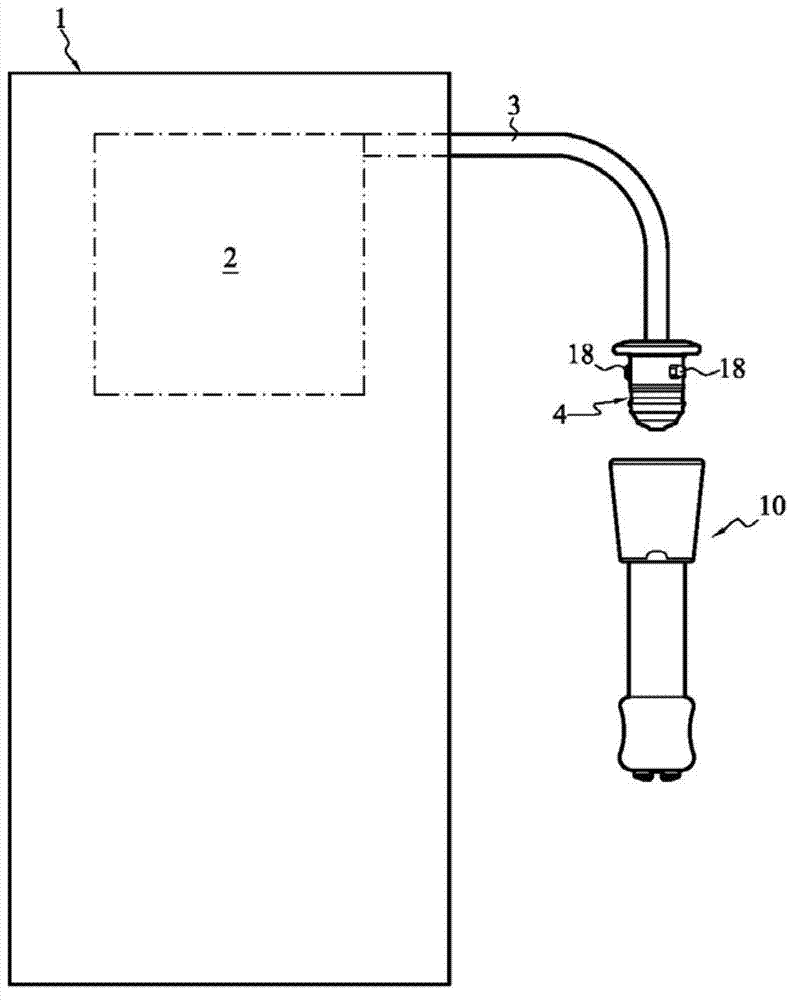

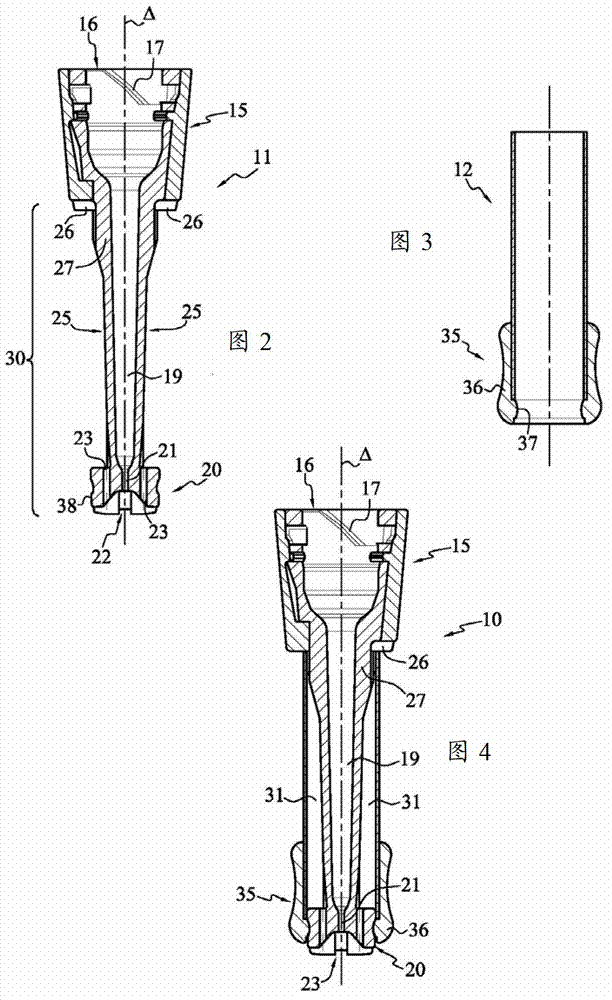

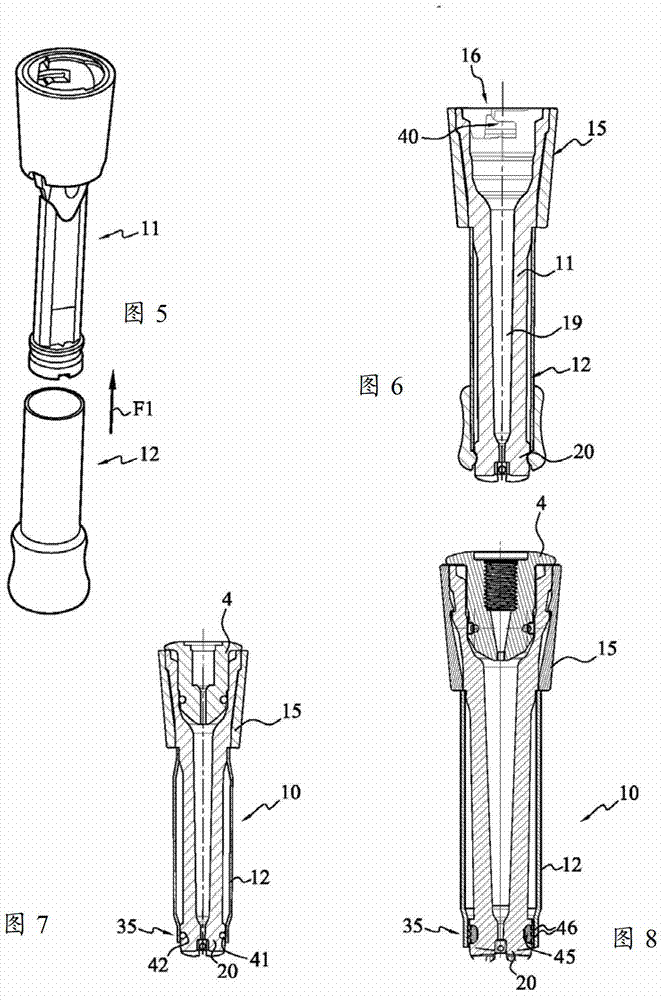

Removable device for reheating and emulsifying a liquid and machine provided with such a device

The invention relates to a device for reheating and emulsifying a liquid. The device has an elongated body that includes a connection head and an internal channel for supplying vapor, where the channel connects the connection head to an ejector nozzle. A rigid, removable, tubular outer sleeve surrounds a tubular core. A suction pipe is defined by the sleeve in cooperation with a longitudinal recess. A sealing unit is provided between the sleeve and the nozzle that are made of a separate flexible material that is distinct from sleeve material for assembling / disassembling of the sleeve.

Owner:SEB SA

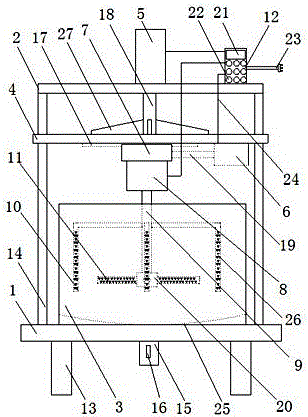

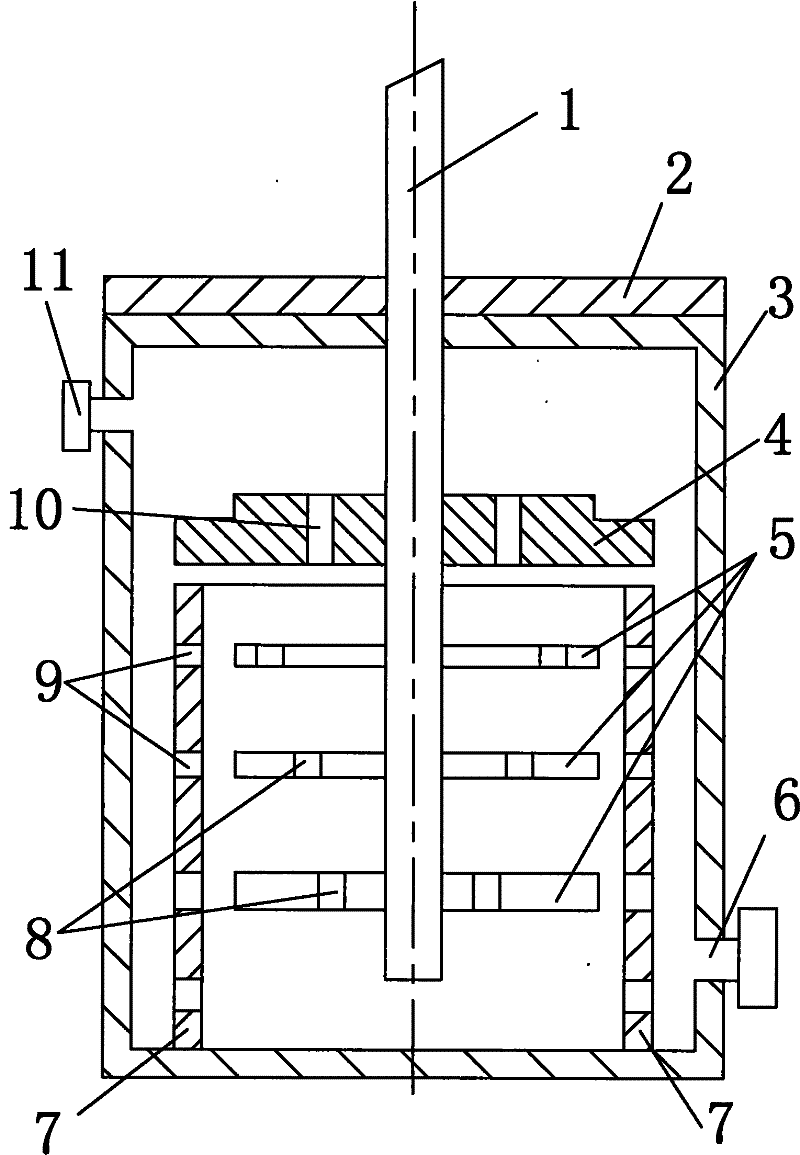

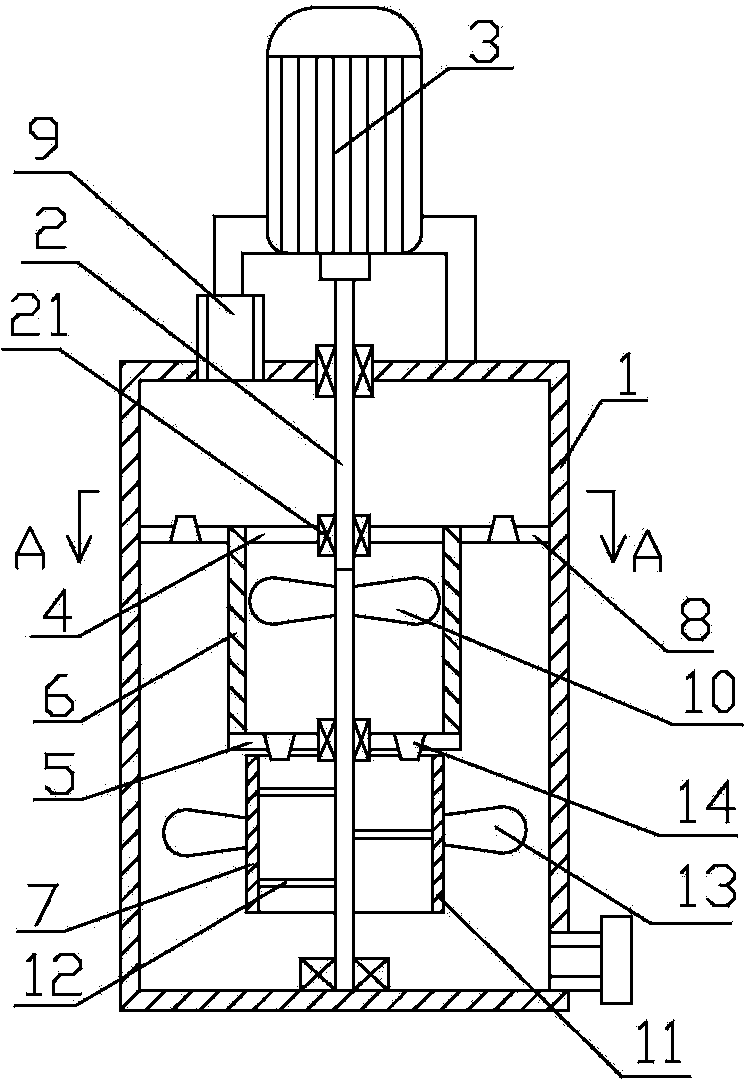

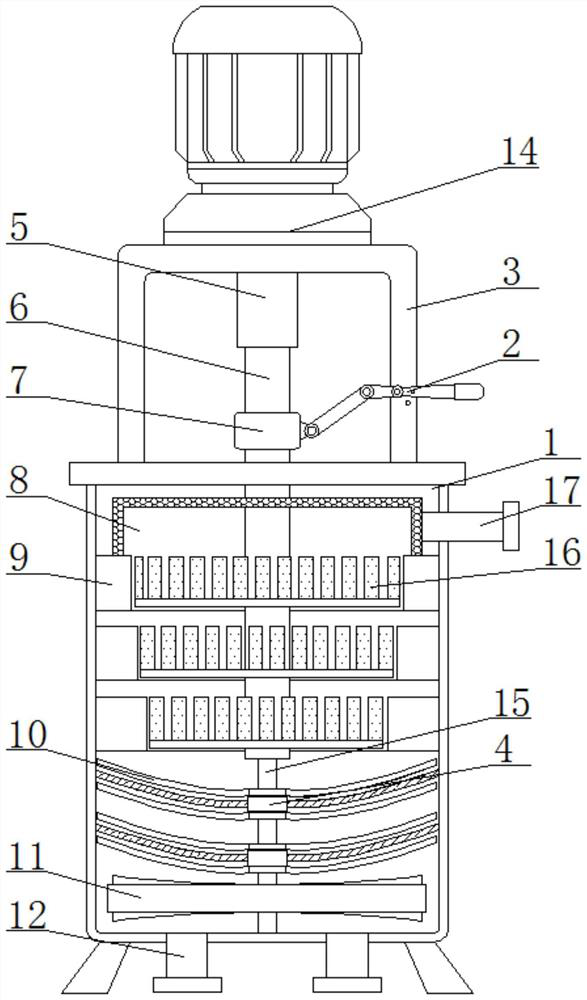

Emulgator for producing nitro-sulfenyl slow-release fertilizer

InactiveCN103861507AImprove product qualityWell mixedRotary stirring mixersMixing methodsEngineeringTower

The invention relates to fertilizer production equipment, and in particular relates to an emulgator for producing a nitro-sulfenyl slow-release fertilizer. The emulgator comprises a shell and a stirring shaft arranged inside the shell, wherein the upper end of the stirring shaft stretches to the outer side of the shell and is in transmission connection with a motor; the inner cavity of the shell is internally provided with a fixed barrel; the fixed barrel and the stirring shaft are coaxially arranged; the upper end of the fixed barrel is provided with a connecting spoke, and the lower end of the barrel is provided with a circular bushing; the connecting spoke is fixedly connected between the fixed barrel and an upper shaft sleeve; the upper shaft sleeve sleeves the stirring shaft; the circular bushing sleeves the stirring shaft through a bearing; an annular bushing is fixedly connected between the outer wall of the fixed barrel and the inner wall of the shell; a plurality of through holes are formed in the circular bushing and the annular bushing; the stirring shaft between the connecting spoke and the circular bushing is provided with a main fin. The emulgator can push materials to move vertically while stirring, so that the materials with different specific gravities are mixed more uniformly, the emulsifying efficiency is improved, and thus the emulgator is beneficial for improving the product quality of a nitro-sulfenyl high tower slow-release fertilizer.

Owner:山东天山丰耘生态肥业有限公司

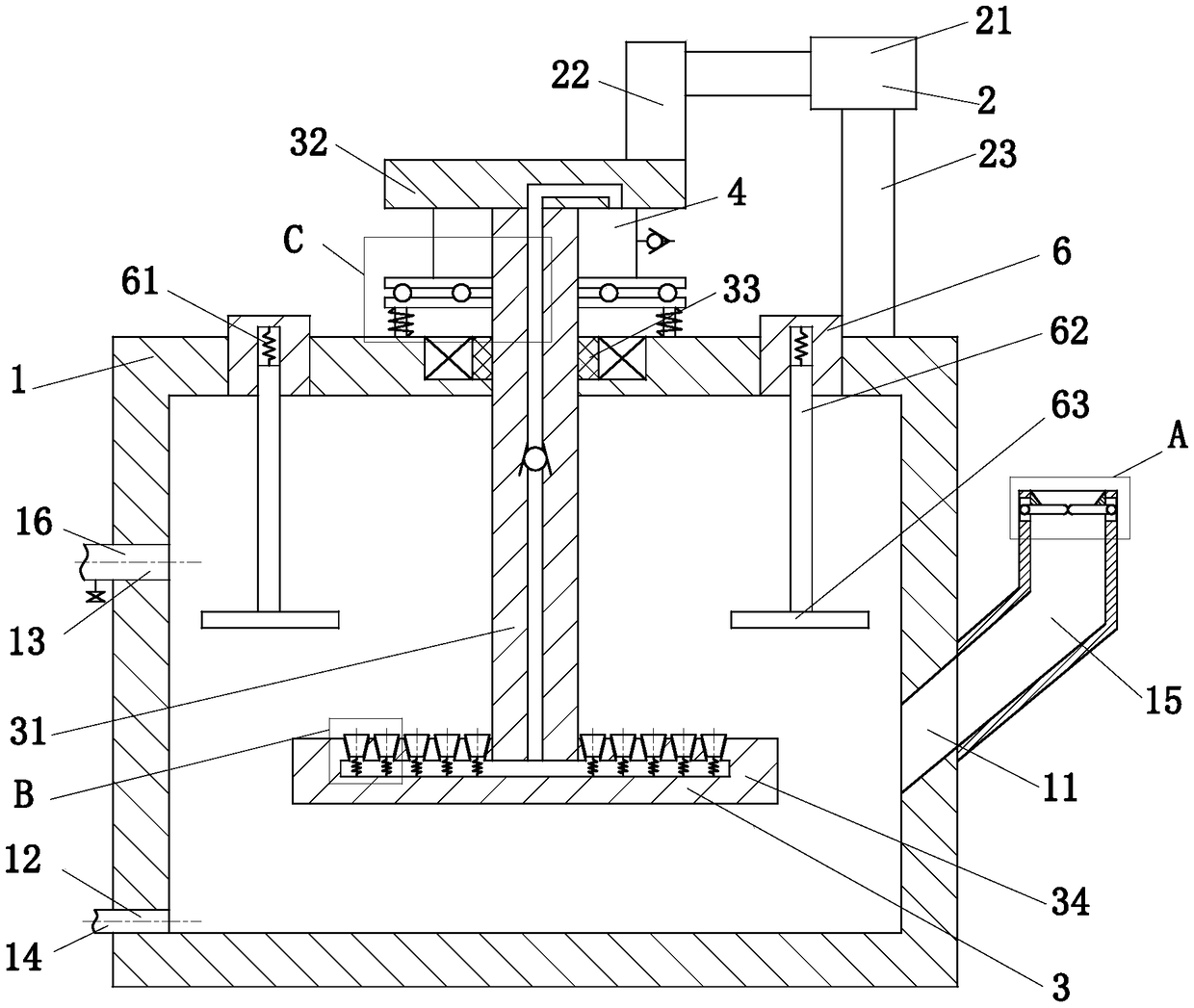

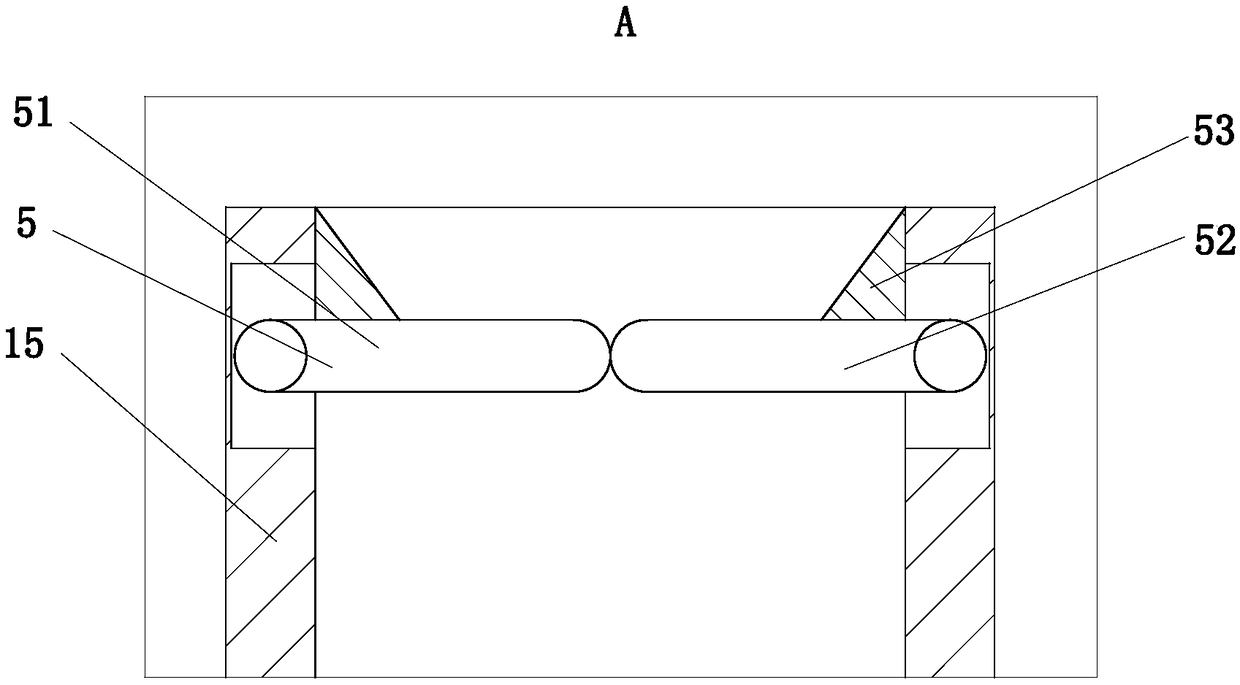

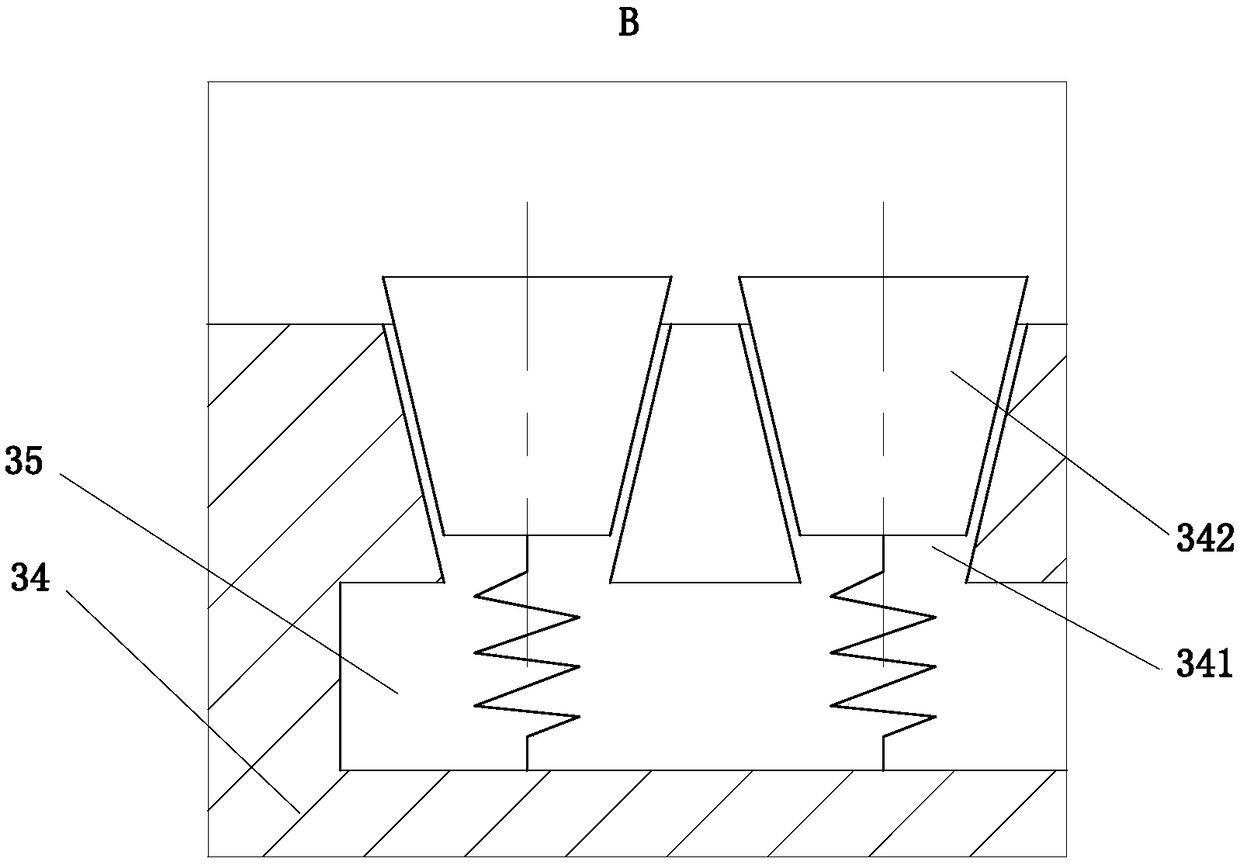

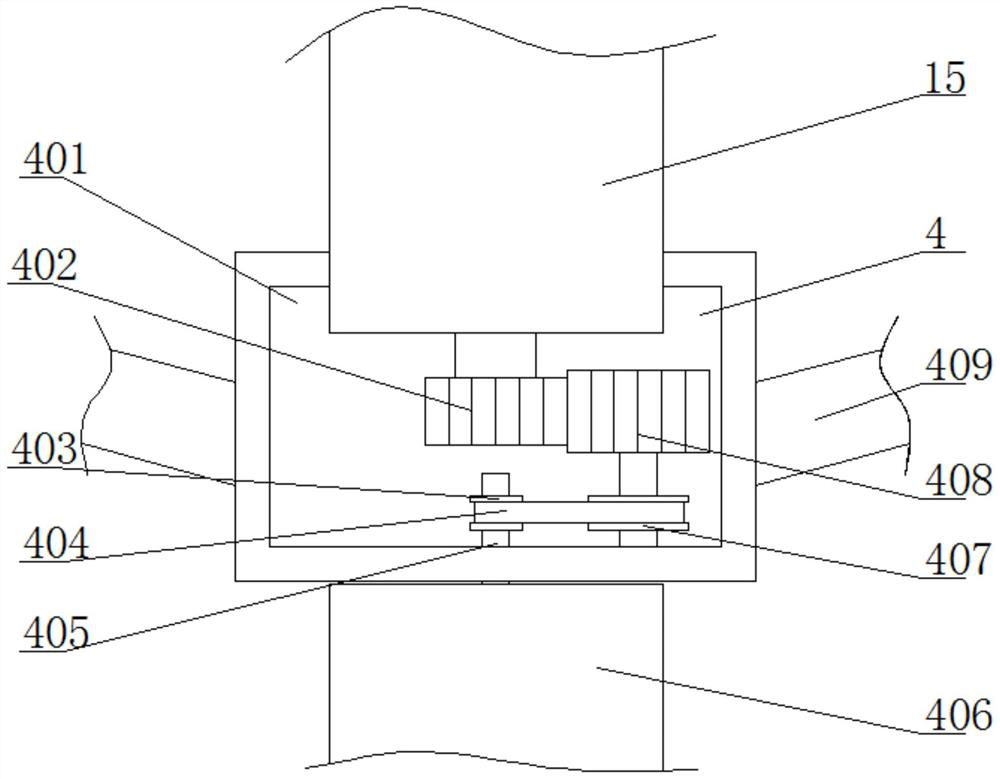

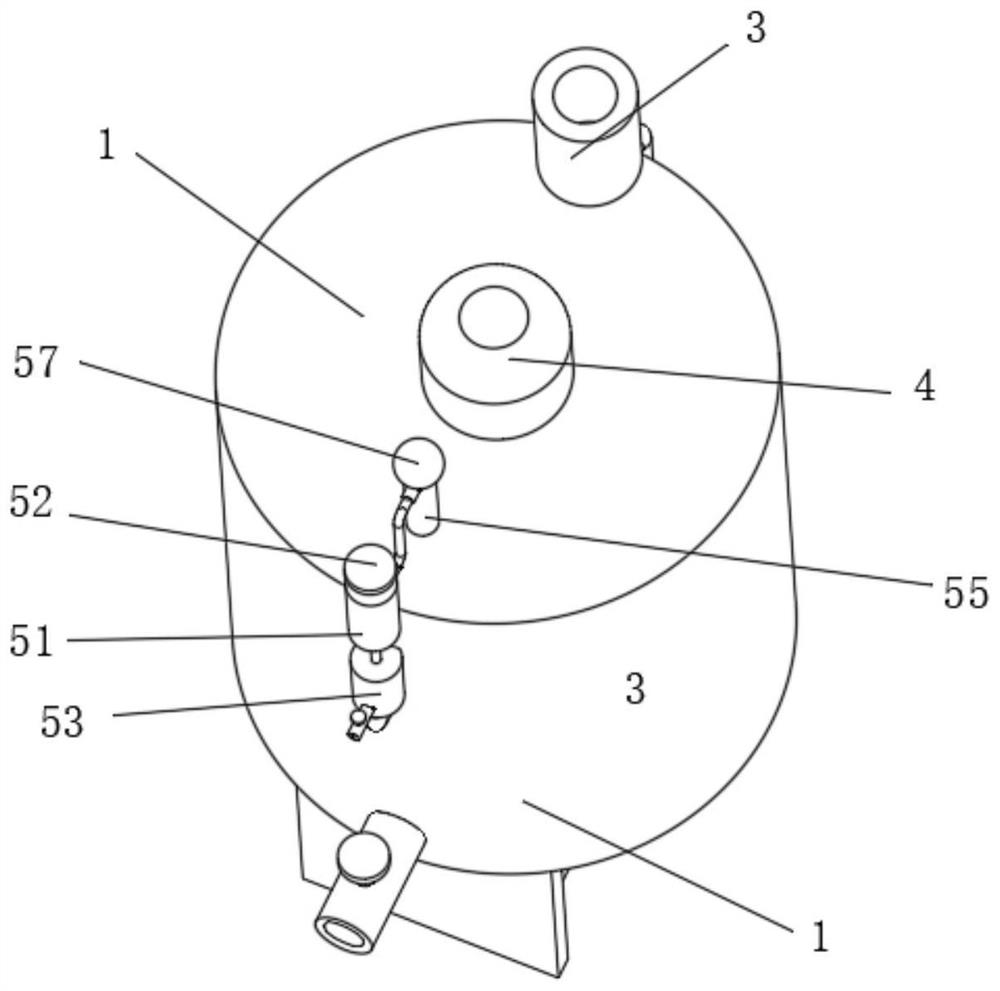

Polyurethane coating emulsifying device

ActiveCN108939967AStir wellImprove emulsification efficiencyShaking/oscillating/vibrating mixersTransportation and packagingReciprocating motionEngineering

The invention belongs to the technical field of emulsifying machinery equipment and in particular relates to a polyurethane coating emulsifying device. The polyurethane coating emulsifying device comprises an emulsifying tank and further comprises a drive unit, a stirring unit and a telescopic unit, wherein the stirring unit is used for achieving a coating emulsifying effect; the drive unit is used for driving the stirring unit to stir; and the telescopic unit is used for realizing the motion of the stirring unit in the vertical direction. Through mutual match of a driving motor, an eccentricwheel, a rotating disc and the telescopic unit, the stirring disc can reciprocate in the vertical direction and can also rotate in the horizontal direction. On one hand, the contact area between the stirring disc and the coating is enlarged, so that the stirring efficiency of the coating by the stirring disc is improved, and the coating emulsifying efficiency is further improved; on the other hand, the coating is uniformly stirred by the stirring disc, so that the coating emulsifying effect is improved.

Owner:骏能化工(龙南)有限公司

Method for preparing aluminum alloy material through electrophoresis

ActiveCN103805816AImprove toughnessImprove corrosion resistanceAnodisationElectrophoretic coatingsElectrophoresisMaterials processing

The invention relates to aluminum alloy material processing and concretely relates to a method for preparing an aluminum alloy material through electrophoresis. The method comprises the steps of delivering raw material components into an electric melting furnace according to a certain ratio, and heating to form a molten mass; mixing and emulsifying the molten mass to form a uniform mixture; carrying out cast rolling on the mixture to form a blank; carrying out annealing treatment on the blank; extruding the annealed blank to form an aluminum alloy profile; degreasing the profile, and then, washing; anodizing after washing, and then, washing; electrolytically coloring and washing with hot water; electrophoretically coating the washed profile, washing with water, and leaching; curing and packaging. According to the invention, all the components are mixed by using an emulsifying machine, so that the components are relatively uniformly mixed, the quality of the formed material is high, and the emulsifying efficiency is high; the profile is electrophoretically coated to form a layer of paint film on the surface, so that the profile can be prevented from being soaked by water, mud, mortar and acid rain, and the coating effect of the profile is improved.

Owner:柳州增程材料科技有限公司

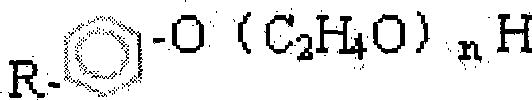

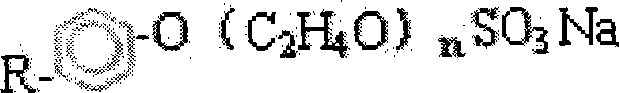

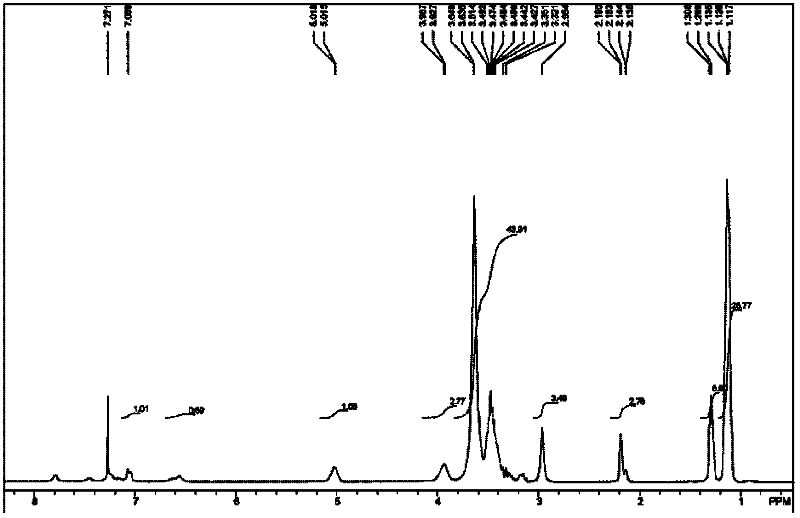

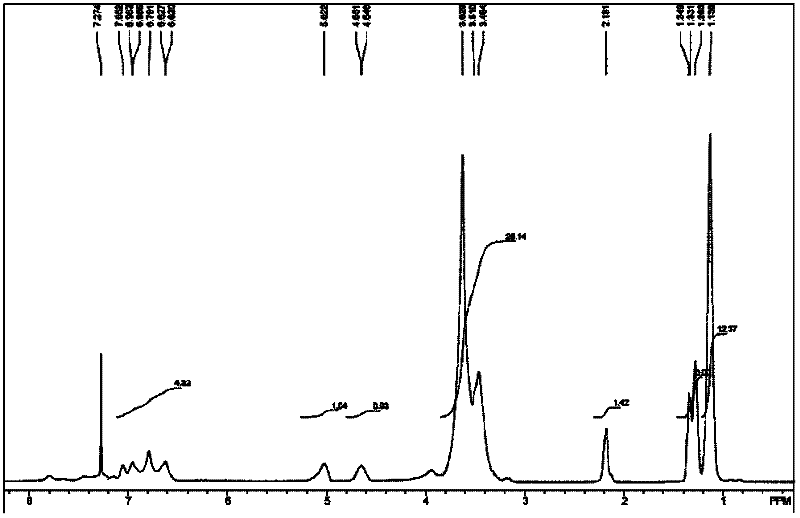

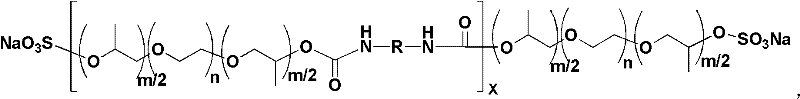

Polyether polyurethane sulfate anionic macromolecular surfactant and preparation method and application thereof

The invention provides a polyether polyurethane sulfate anionic macromolecular surfactant and a preparation method and application thereof. The preparation method disclosed by the invention has the advantages that the total percent conversion is higher than 80%, the process is mild and controllable, raw materials can be prepared easily, the cost is low, generated byproducts and industrial three wastes are less. The prepared polyether polyurethane sulfate anionic macromolecular surfactant can be used as an emulsifier for emulsifying bisphenol A type epoxy resin to prepare water-based epoxy resin emulsion, and also can be used as a carbon fiber sizing agent in the manufacture engineering of carbon fiber. Compared with the traditional polyether sulfate anionic macromolecular surfactant, the polyether polyurethane sulfate anionic macromolecular surfactant has the advantage that, due to the introduction of carbamic acid ester groups in the molecular structure of polyether polyurethane sulfate, the abrasive resistance, water tolerance, heat resistance and formed film elasticity of seized carbon fiber can be improved, which is favorable to the preparation of a high-performance fiber reinforced resin based composite material.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

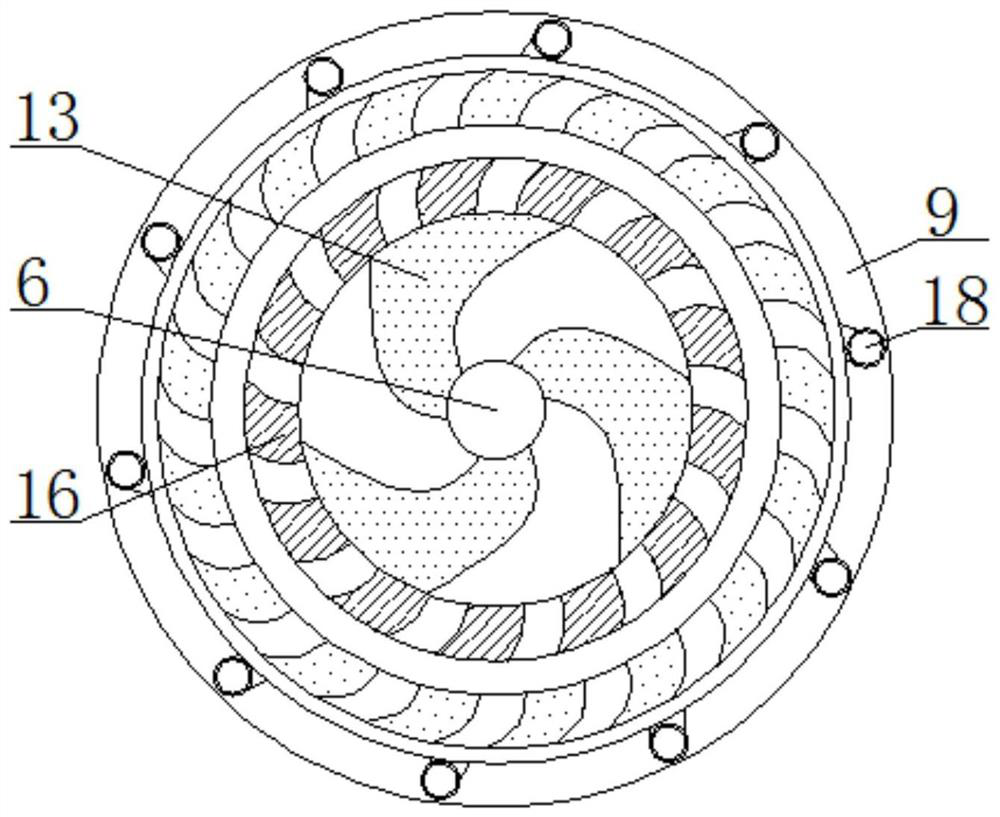

High-efficiency emulsifying equipment for cosmetic production

InactiveCN106943921AIngenious designAvoid stickingMixing methodsTransportation and packagingMechanical engineeringRaw material

The invention relates to high-efficiency emulsifying equipment for cosmetic production. The high-efficiency emulsifying equipment comprises a kettle body, a drive mechanism, a first rotating mechanism and a second rotating mechanism, wherein the drive mechanism, the first rotating mechanism and the second rotating mechanism are arranged on the kettle body; the first rotating mechanism comprises a first rotating shaft and a rotor sleeving the first rotating shaft; the second rotating mechanism comprises a sleeve, a stator and a stirring blade; the drive mechanism comprises a first drive assembly and a second drive assembly; the first drive assembly drives the first rotating mechanism to rotate; and the second drive assembly drives the second rotating mechanism to rotate. According to the high-efficiency emulsifying equipment for cosmetic production, combined effects such as intense reciprocating hydraulic shearing, friction, centrifugal extrusion and liquid flow collision can be formed between a high-speed rotating rotor in the first rotating mechanism and the stator in the second rotating mechanism; the stirring blade on the second rotating mechanism is capable of stirring and mixing raw materials in the kettle body to improve the emulsifying efficiency; and a scraping assembly arranged on the second rotating mechanism is capable of preventing the raw materials from being attached to the inner wall of the kettle body.

Owner:泉州惠安长圣生物科技有限公司

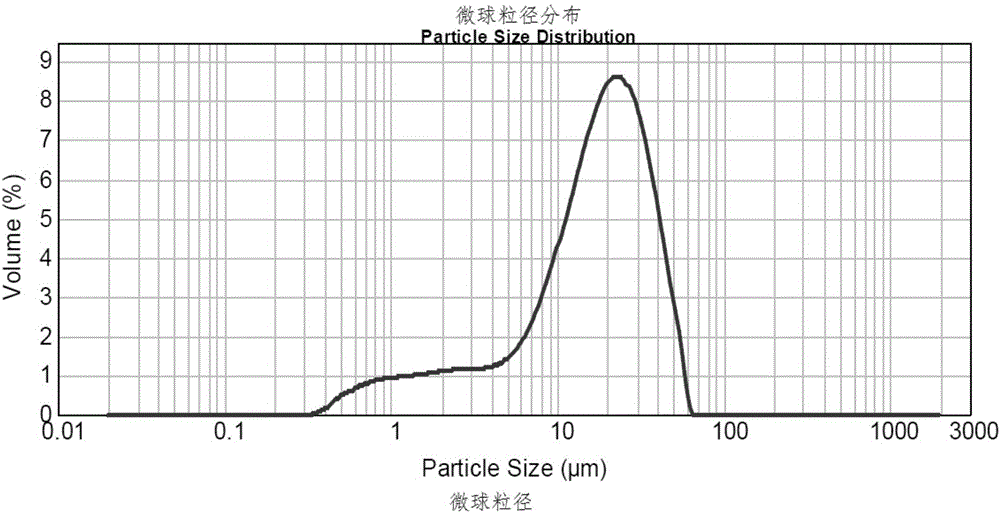

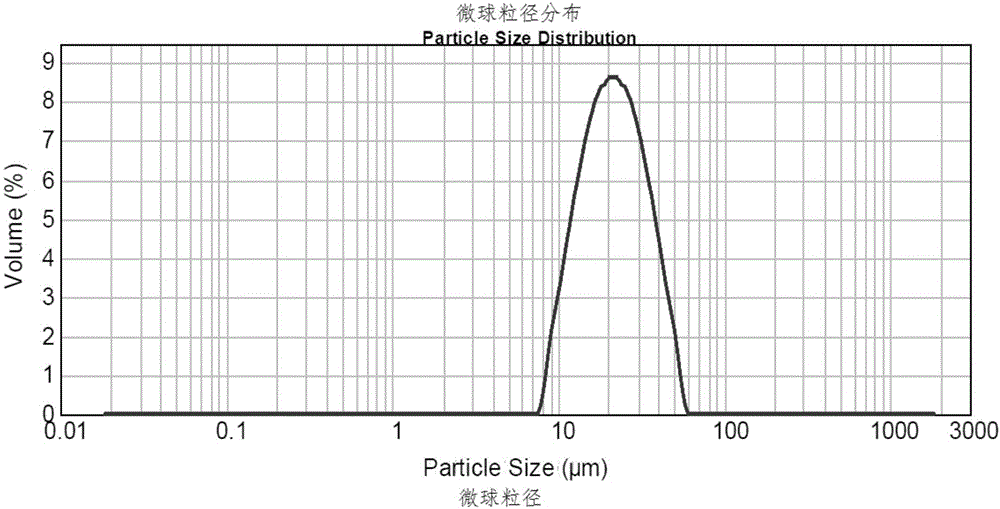

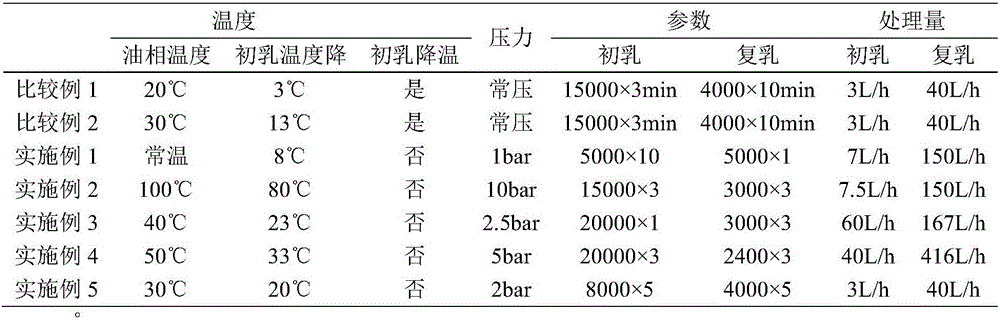

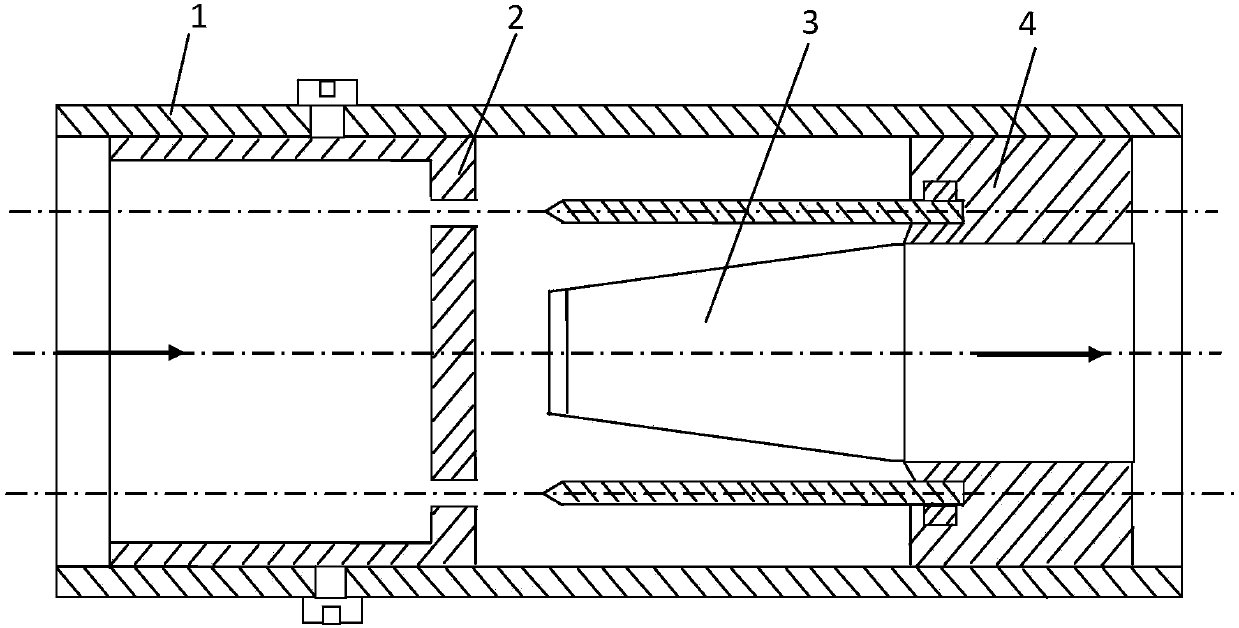

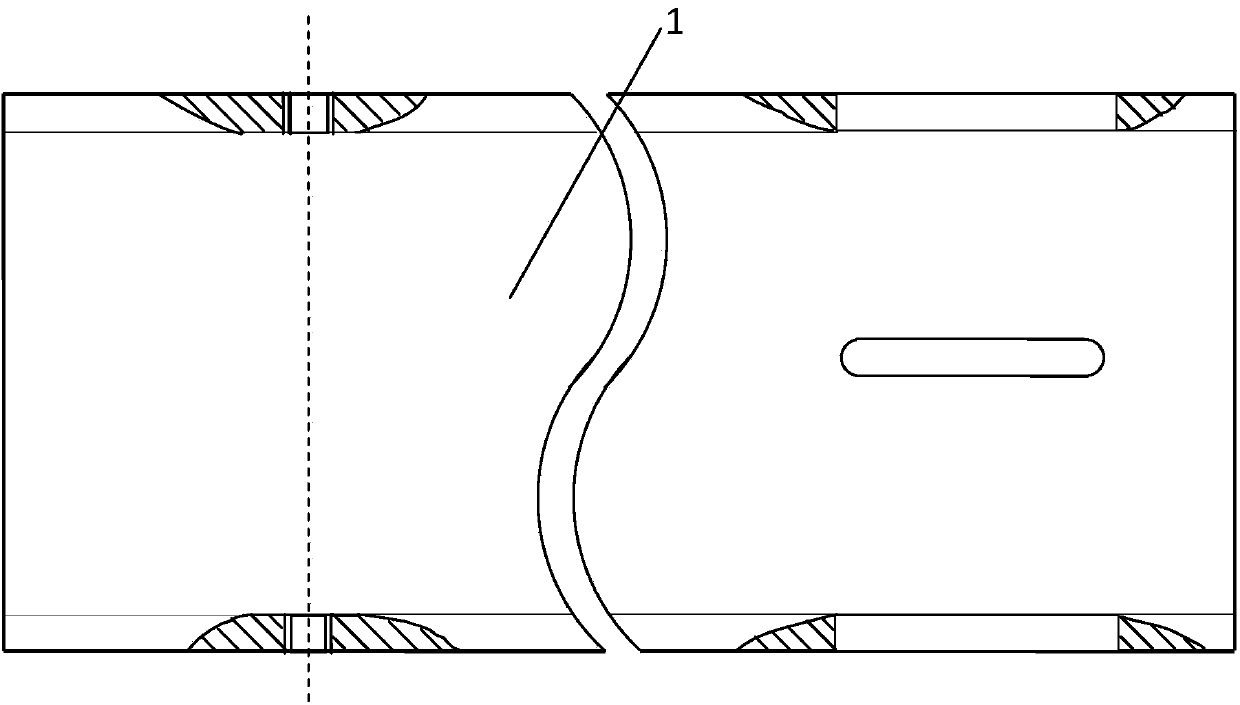

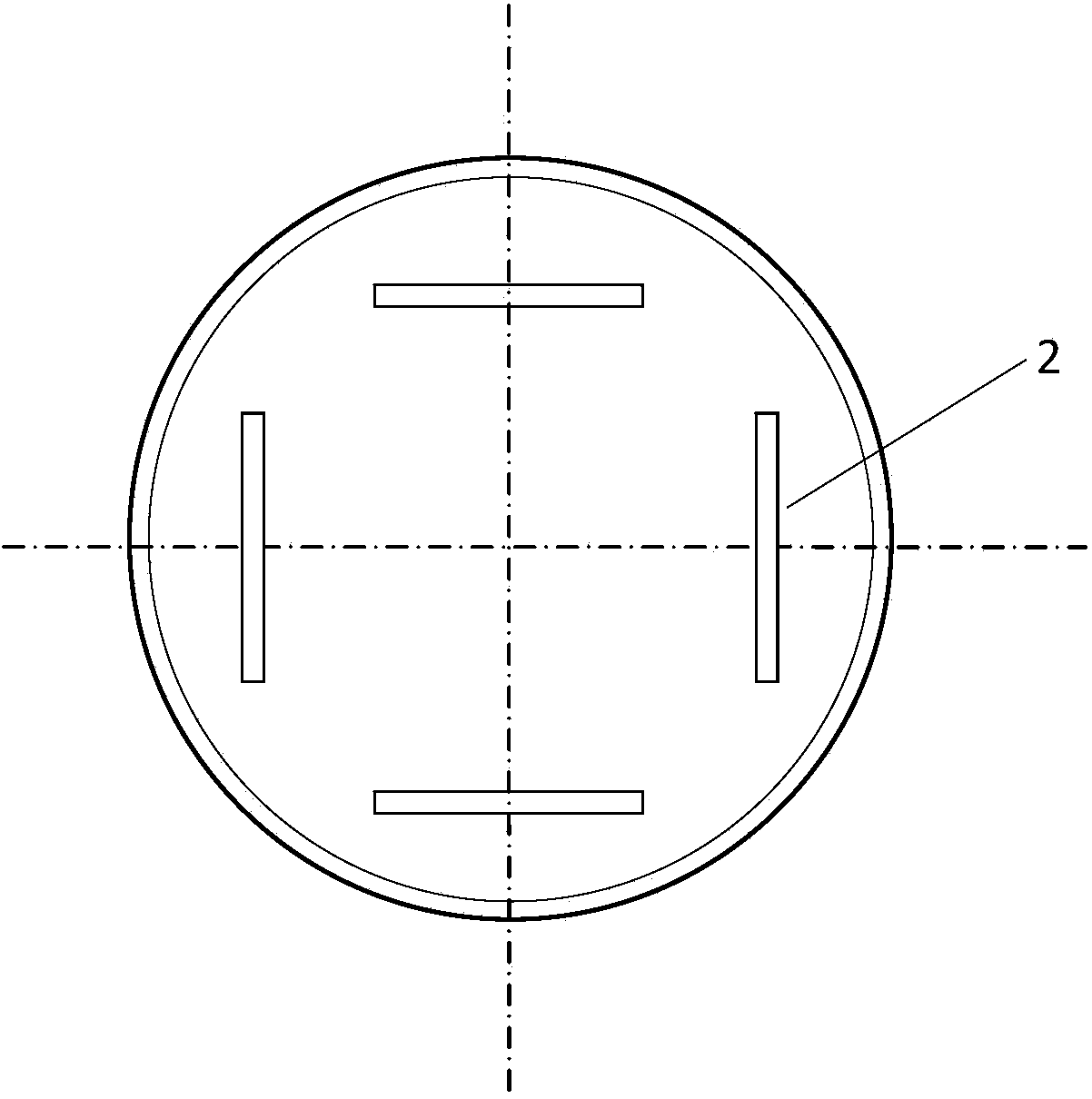

Preparation method of leuprorelin microspheres

ActiveCN106668831ACancel the cooling stepThe process steps are simplePeptide/protein ingredientsGranular deliveryLeuprorelinMicrosphere

The invention discloses a preparation method of leuprorelin microspheres. The method comprises steps of preparation of an oil phase, preparation of an inner water phase, preparation of an outer water phase, preparation of a primary emulsion, preparation of a compound emulsion, drying in a liquid and the like. A total-closed online emulsification and separate tank drying mode is adopted, and the problems of high probability of evaporation and boiling of DCM in the emulsification process are effectively solved by accurately controlling temperatures and pressure; through reduction of the viscosity of the oil phase, the emulsification efficiency is improved, residues of the primary emulsion in tanks are reduced, and the overall yield of a product is increased. Besides, batch production of the leuprorelin microspheres is changed into continuous production, transition from a lab-scale test to a pilot plant test to production is smoother, and room for improvement of the productivity of a workshop is larger.

Owner:ZHEJIANG SUNDOC PHARMA SCI & TECH CO LTD

Complex frequency emulsified fluid power sounding device

InactiveCN103990409AImprove vibrationAvoid breakingShaking/oscillating/vibrating mixersWork periodJet flow

The invention relates to a complex frequency emulsified fluid power sounding device. A spraying nozzle is arranged on one side in a sleeve; a bracket opposite to the spraying nozzle is arranged on the other side of the sleeve; at least two spraying openings are machined in the spraying nozzle; an overflowing hole is machined in the middle of the bracket; reeds which are in one-to-one correspondence with the spraying openings are arranged on the periphery of the overflowing hole; each reed faces the jet direction of the corresponding spray opening; the length or / and the thickness of each reed is different from the length or / and the thickness of the adjacent reed. The complex frequency emulsified fluid power sounding device can produce a plurality of different sound wave frequencies, is favorable for the emulsifying and the mixing of liquid; the reeds start to oscillate more easily, and are not easily broken within a long working time; the complex frequency emulsified fluid power sounding device can be directly connected between pipelines, and is high in emulsifying and mixing efficiency, stable in operation, simple in structure, low in cost, and suitable for engineering application.

Owner:SHAANXI NORMAL UNIV

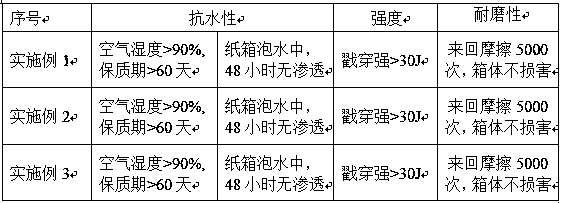

Production technology of waterproof wax-impregnated corrugated paper box

InactiveCN108277694AImprove anti-wear performanceImprove wear resistanceSpecial paperPaper coatingParaffin waxGroup control

The invention discloses a production technology of a waterproof wax-impregnated corrugated paper box. The production technology comprises six steps of putting a paper box on a hanging frame, pre-heating in a pre-heating drying channel, impregnating wax in a wax groove, leveling wax liquid in a leveling drying channel, drying wax and sizing, and taking off a wax box from the hanging frame, and is characterized in that the wax liquid for the waterproof wax-impregnated corrugated paper box is prepared from microcrystalline paraffin wax, oxidized polyethylene wax, amide wax, silicon dioxide nano powder, rosin, a surfactant and water. According to the production technology of the waterproof wax-impregnated corrugated paper box, disclosed by the invention, the used wax liquid is a wax composition, has excellent performance of water resistance, wear resistance and the like and has a long life cycle and good stability; in the production technology, heat preservation and heat insulation are carried out so that an energy-saving effect is realized; based on a PLC (Programmable Logic Controller) group control system, automatic flow line production can be realized and the production efficiencyis improved.

Owner:重庆融康彩印包装有限公司

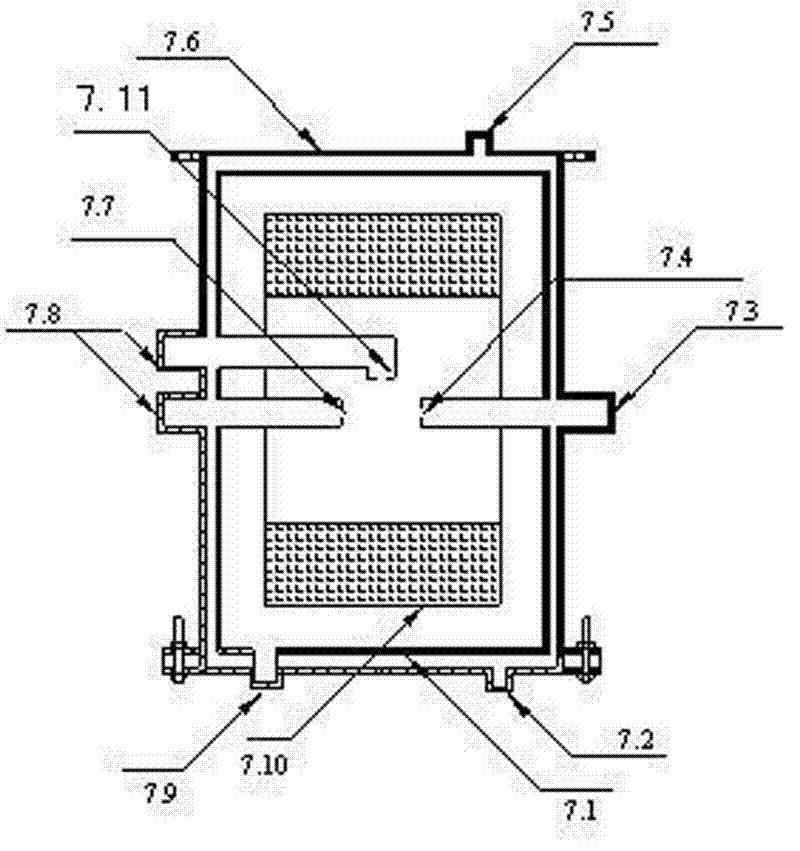

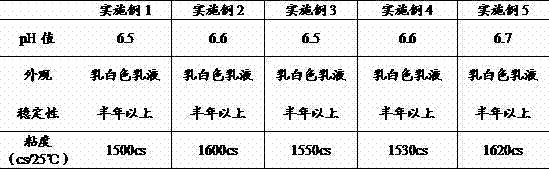

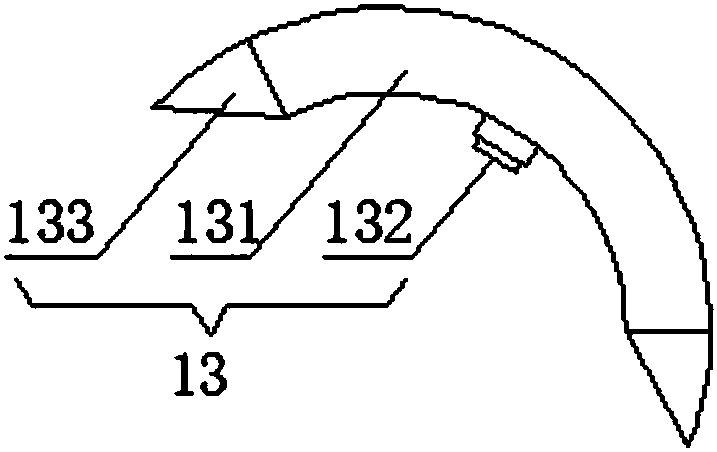

Ultra-high molecular weight polysiloxane emulsion, preparation method and special equipment thereof

InactiveCN103589163AReasonable compositionImprove emulsification efficiencyRotary stirring mixersCoatingsPolymer sciencePolyethylene oxide

Belonging to the technical field of chemical finishing materials, the invention relates to an ultra-high molecular weight polysiloxane emulsion, a preparation method and special equipment thereof. The ultra-high molecular weight polysiloxane emulsion comprises the following components by mass: 100 parts of polysiloxane with viscosity of 150000-200000cs, 20-50 parts of a composite emulsifier, and 150-300 parts of deionized water. The composite emulsifier is composed of, by weight: 15-25 parts of fatty alcohol polyethylene oxide, 2-8 parts of fatty alcohol polyoxyethylene ether, 3-7 parts of sodium dodecyl sulfate, and 2-6 parts of polyol. The composite emulsifier provided by the invention has the characteristics of reasonable compatibility of components and a HLB value in a reasonable range, and can achieve a good emulsification effect and high emulsification efficiency when used for ultra-high molecular weight polysiloxane emulsification. The ultra-high molecular weight polysiloxane emulsion prepared by the invention has high molecular weight and high viscosity. Application of the ultra-high molecular weight polysiloxane emulsion in leather surface finishing can endow the leather surface with lubricant and smooth handfeel, and can remain for a long time on the leather surface.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-speed shearing, homogenizing and emulsifying device

ActiveCN111644089AAvoid reprocessingOrderly feeding emulsificationTransportation and packagingMixing methodsElectric machineryEngineering

The invention relates to the technical field of emulsifying equipment, and discloses a high-speed shearing, homogenizing and emulsifying device. The device includes an outer cartridge, a supporting seat is fixedly mounted at the top of the outer cylinder, a high-speed motor is fixedly mounted at the top of the supporting seat, and the output end of the high-speed motor extends into the supportingbase and is fixedly connected to a hollow connecting shaft, a rotating shaft is movably clamped to the bottom of the hollow connecting shaft, a lifting apparatus is movably installed on the outer surface of the rotating shaft, the bottom of the rotating shaft extends into the outer cylinder, and the outer surface of the rotating shaft is fixedly sleeved with rotors. When the high-speed shearing, homogenizing and emulsifying device is used, the situation that a traditional emulsifying machine needs to be placed in a charging barrel, so that materials in the charging barrel flow into the emulsifying device disorderly is changed, repeated processing of the materials by the emulsifying device is prevented, with the device, materials can be fed and emulsified orderly and then flow out, and theemulsifying efficiency is improved.

Owner:浙江巨邦高新技术有限公司

Wax-containing composition used for water resistance and viscidity increasing of table tennis bats

ActiveCN103773238AImprove water resistanceGood sweat resistanceWax coatingsRosin coatingsWaxMicrochiroptera

The invention discloses a wax-containing composition used for water resistance and viscidity increasing of table tennis bats. The wax-containing composition mainly comprises petroleum wax, oxidized polyethlene wax, amide wax, rosin, modified rosin or a derivative of rosin, a surfactant, and water. According to the wax-containing composition, petroleum wax is taken as a basic material so as to increase water resistance and sweat resistance of table tennis bats; oxidized polyethlene wax is used for increasing wear resistance; intersolubility of amide wax with other ingredients is excellent, system uniformity is increased, emulsifying efficiency is increased, and stability is improved. The wax-containing composition is used for rubber surface protection and maintenance of table tennis bats, is safe for using, is friendly to the environment, is convenient for coating, is excellent in water resistance and sweat resistance, long in use cycle, and stable in stability; and influence on the rubber surfaces is less.

Owner:CHINA PETROLEUM & CHEM CORP +1

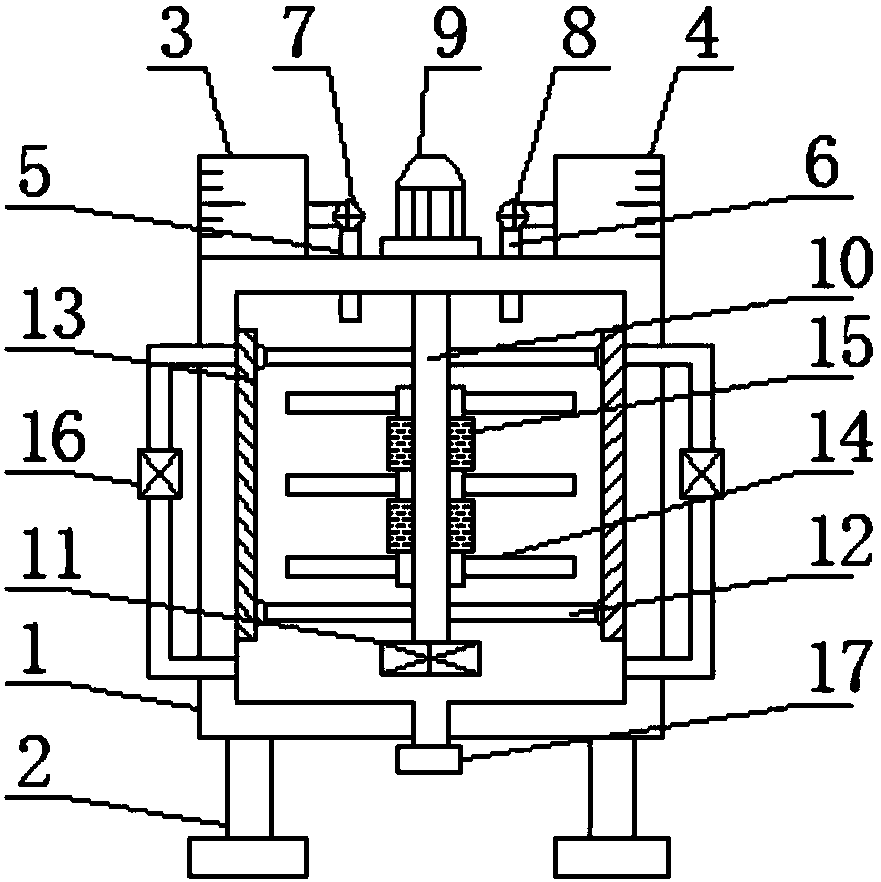

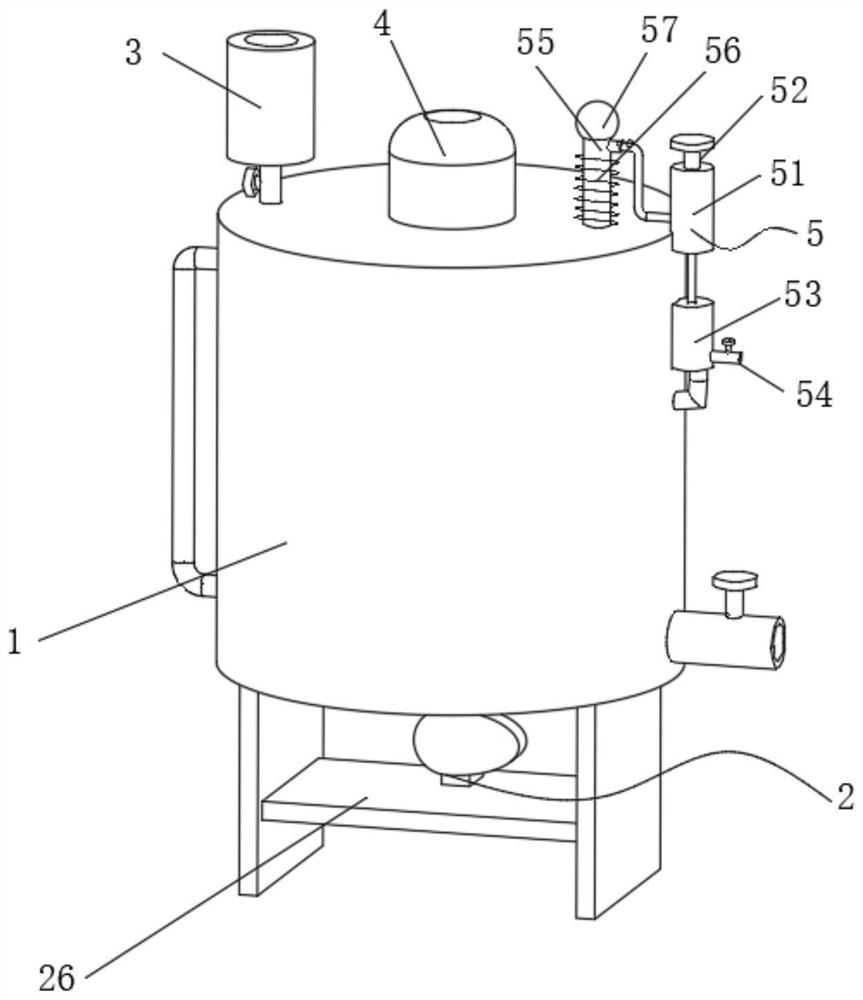

Anti-sticking type vacuum homogeneous emulsifying machine

InactiveCN108246135AWell mixedEasy to removeFlow mixersTransportation and packagingMotor drivePulp and paper industry

The invention discloses an anti-sticking type vacuum homogeneous emulsifying machine in the technical field of emulsifying machines. The anti-sticking type vacuum homogeneous emulsifying machine comprises an emulsifying tank, a water-phase tank and an oil-phase tank are mounted on the left side and the right side of the top of the emulsifying tank respectively, a rotating rod is mounted at the output end of a motor, the bottom end of the rotating rod extends into the bottom of a cavity of the emulsifying tank, and a shearing head is mounted at the bottom end of the rotating rod; and the otherend of a cross rod is connected with a material scrapering device, and a discharging port is formed in the bottom of the emulsifying tank. The device is easy to operate, the motor drives the rotatingrod to rotate so that the water phase and the oil phase can be blended uniformly, a heating device can heat the mixture in the emulsifying process so that emulsifying can be conducted more sufficiently, the rotary rotating rod can drive the material scrapering device to move by being stuck to the inner wall of the emulsifying tank, thus raw materials stuck to the inner wall of the emulsifying tankcan be removed conveniently, an inlet of a vacuum pump is communicated with the bottom end of the emulsifying tank through a pipeline, an outlet of the vacuum pump is communicated with the top end ofthe emulsifying tank, the mixed liquid is driven to flow from the upper end of the emulsifying tank to the lower end of the emulsifying tank under the effect of the vacuum pump, and accordingly the emulsifying efficiency is further enhanced.

Owner:扬州市钰翔轻工机械设备厂

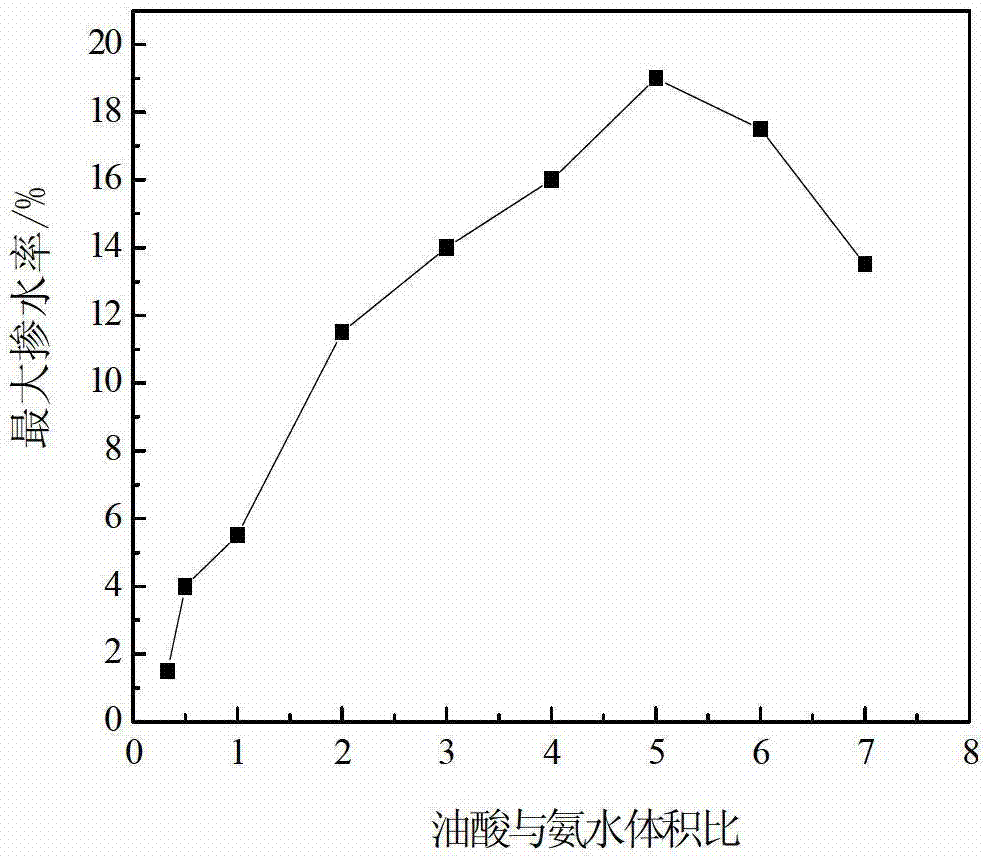

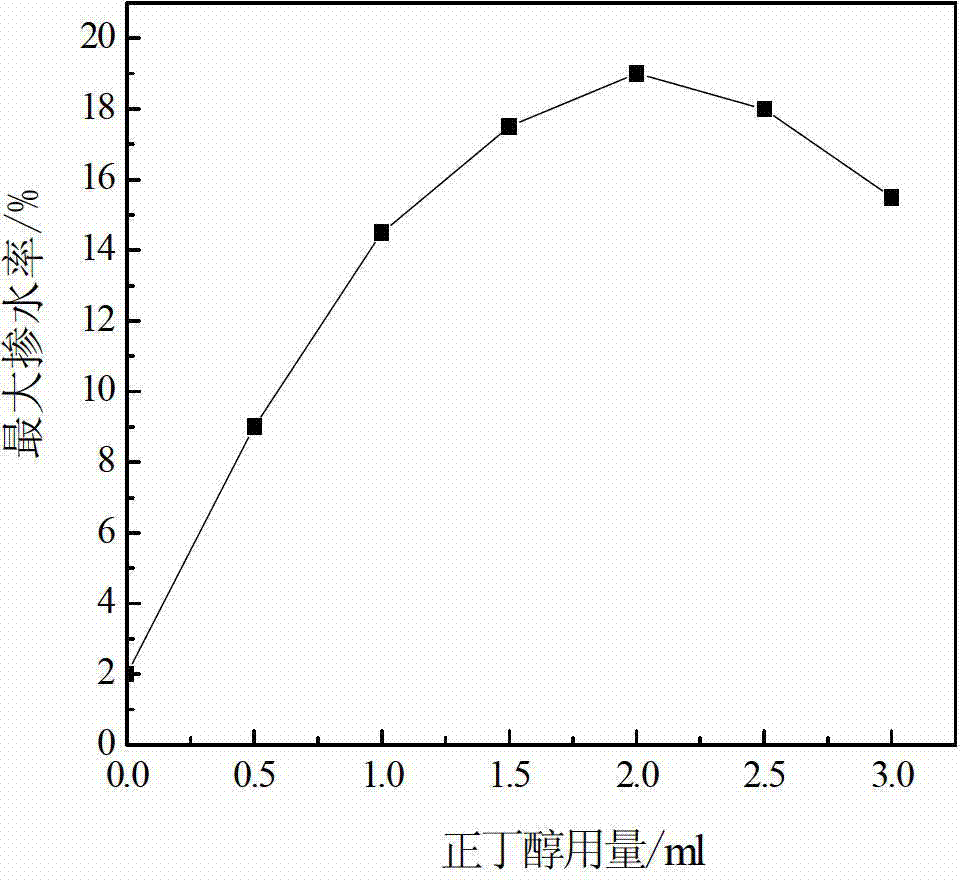

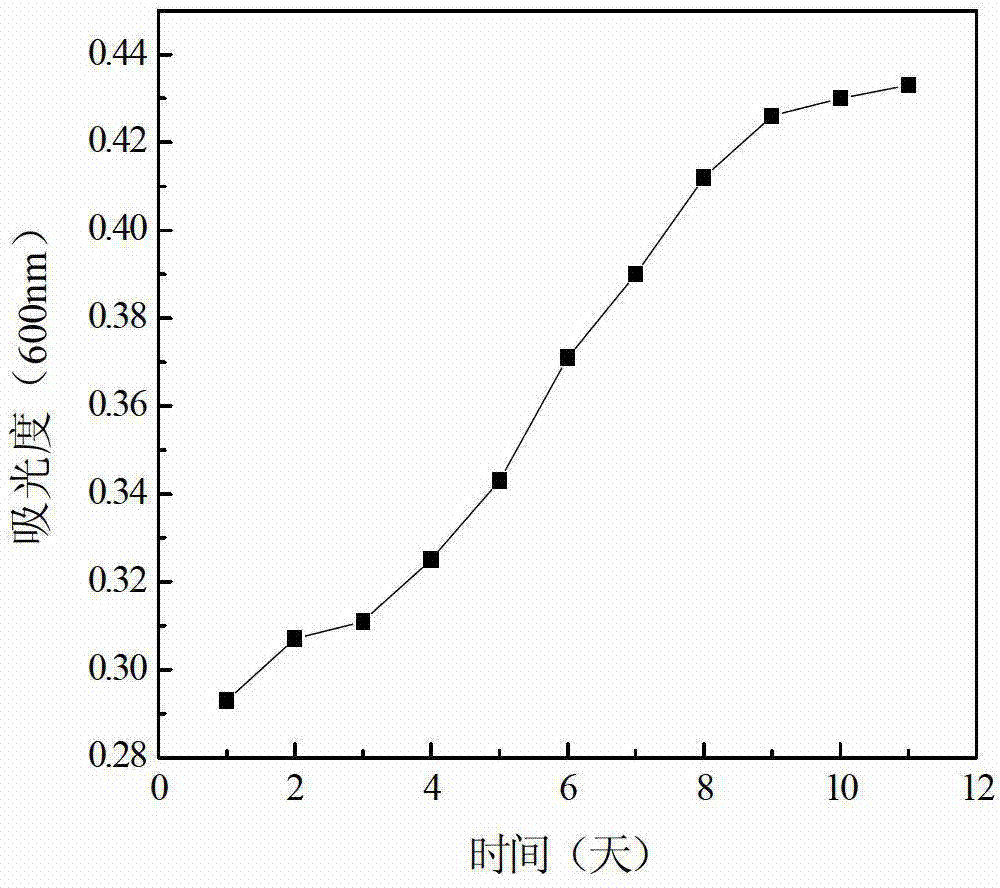

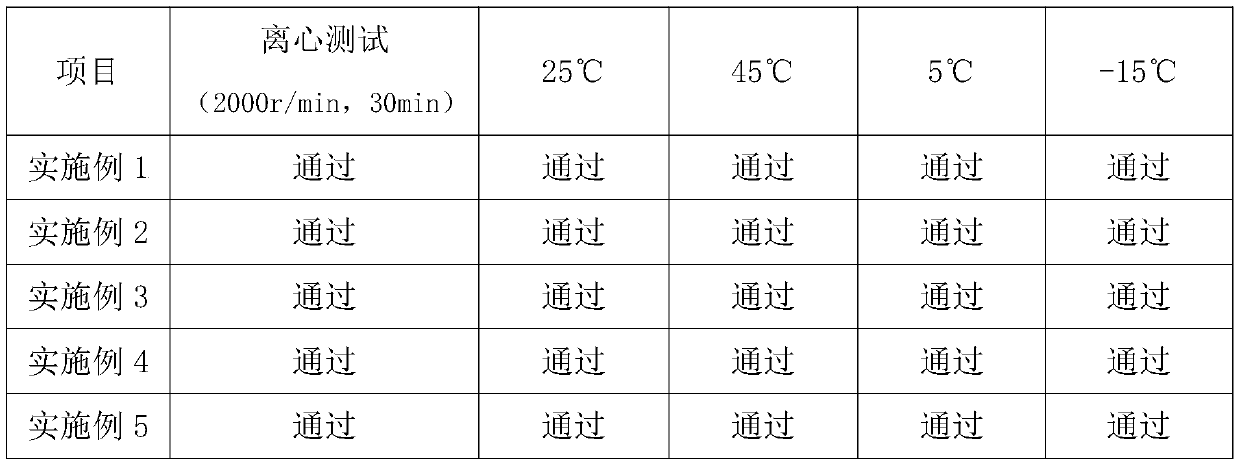

Diesel oil emulsifier and preparation method thereof, and emulsified diesel oil containing same and preparation method thereof

ActiveCN102816617AShort emulsification timeImprove emulsification efficiencyLiquid carbonaceous fuelsAlcoholWater quality

The invention discloses a diesel oil emulsifier and a preparation method thereof, and emulsified diesel oil containing the same and a preparation method thereof. The diesel oil emulsifier comprises ammonium oleate and an alcohols solvent, wherein the content of the ammonium oleate accounts for, by volume percent, 40-90% of the diesel oil emulsifier, and the content of the alcohols solvent accounts for, by volume percent, 10-60% of the diesel oil emulsifier. The obtained emulsified diesel oil is transparent and clear in appearance like pure diesel oil in color, and is stable in performance without layering, and the water mixing ratio can reach 19% to the maximum; and the diesel oil emulsifier has the advantages of being short in emulsification time, high in emulsification efficiency, low in corrosion and abrasion to an internal combustion engine, high in adaptability to water quality, wide in source, low in price and provided with great popularization and application values.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Water-in-oil phase inversion emulsion spray and preparation method thereof

PendingCN110859761AFast absorptionImprove water and sweat resistanceCosmetic preparationsToilet preparationsActive agentSodium silicate

The invention discloses a water-in-oil phase inversion emulsion spray and a preparation method thereof, and aims to provide a water-in-oil phase inversion emulsion spray which has the characteristicsof light skin feeling, water resistance, sweat resistance, skin nourishing, uniform atomization coverage and high stability. The technical scheme of the invention is as follows: the emulsion spray iscomposed of the following components in percentage by mass. 3.0-6.0% of surface active agents; 4.0-8.0 % of isopropyl myristate; 0.5-1.5% of petrolatum; 1.0-5.0% of polydimethylsiloxane; 0.1-0.3% of tocopherol; 0.2-0.6% of preservatives, 4.5-11.0% of humectants, 0.03-0.15% of carbomer, 0.2-1.0% of sodium magnesium lithium silicate, 0.5-1.5% of stabilizers, 0.02-0.1% of a chelating agent, 0.1-0.7%of a pH regulator, 0.01-0.5% of an odorant and the balance of deionized water, totaling 100%. The emulsion spray belongs to the technical field of cosmetics.

Owner:广州欧正化妆品技术研究院有限公司

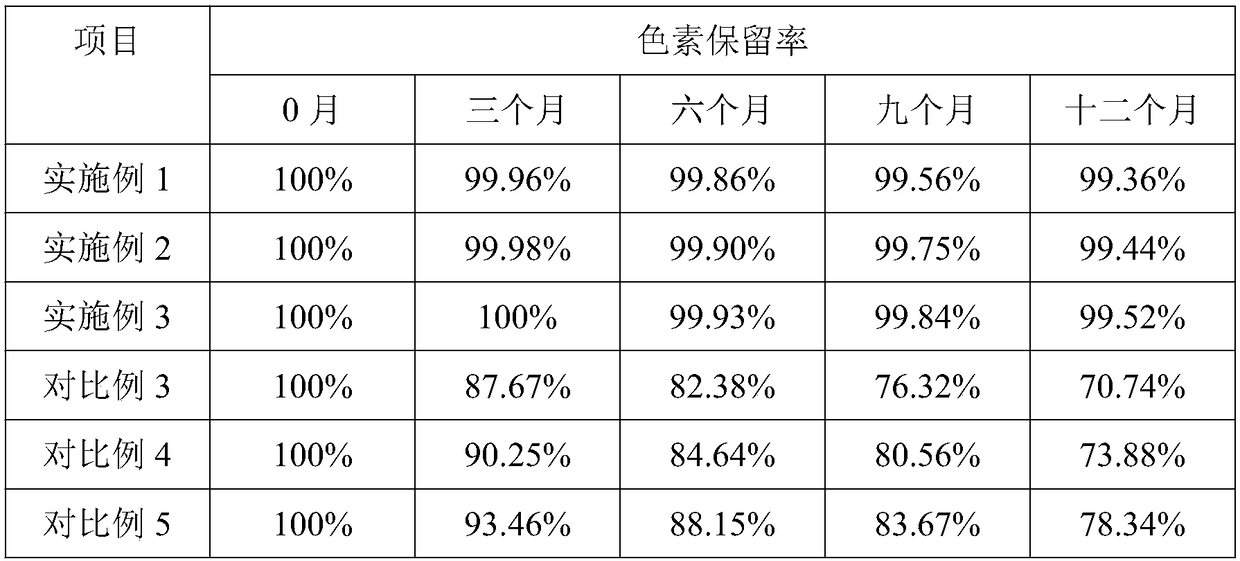

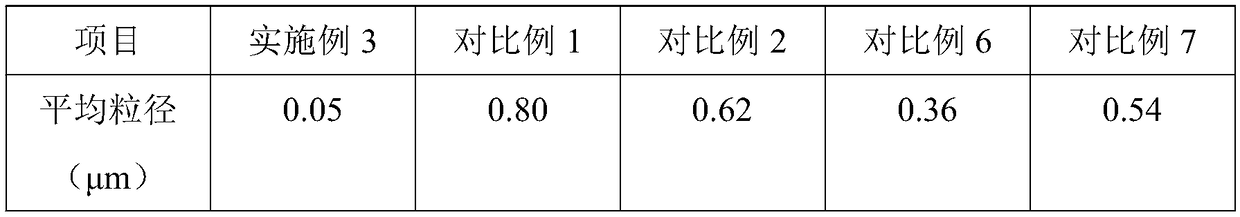

Preparation method of natural carotene preparation

ActiveCN108433013AProtectiveHas a color enhancing effectFood shapingFood ingredient as emulsifierWater solubleOil phase

The invention belongs to the technical field of natural pigment, and particularly relates to a preparation method of a natural carotene preparation. The preparation method of a natural carotene preparation provided by the invention comprises the following steps of taking natural carotene, adding a composite emulsifying agent, and performing uniform mixing so as to obtain an oil phase; taking deionized water, adding water soluble polymer materials to the taken deionized water, and performing stirring until the water soluble polymer materials completely dissolve to obtain an aqueous phase; adding the obtained oil phase to the obtained aqueous phase, and performing shearing and emulsifying twice so as to obtain emulsion; and homogenizing the obtained emulsion, wherein the homogenizing pressure is 50-100MPa, and the homogenizing time is 2-4min. The preparation method of a natural carotene preparation provided by the invention is simple, the natural carotene preparation prepared by the method provided by the invention is good in moisture disperse, excellent in stability and convenient to use. In addition, the natural carotene preparation prepared by the method is small in particle diameter, and the bioavailability of the natural carotene preparation can be significantly improved.

Owner:AAFUD IND ZHUHAI

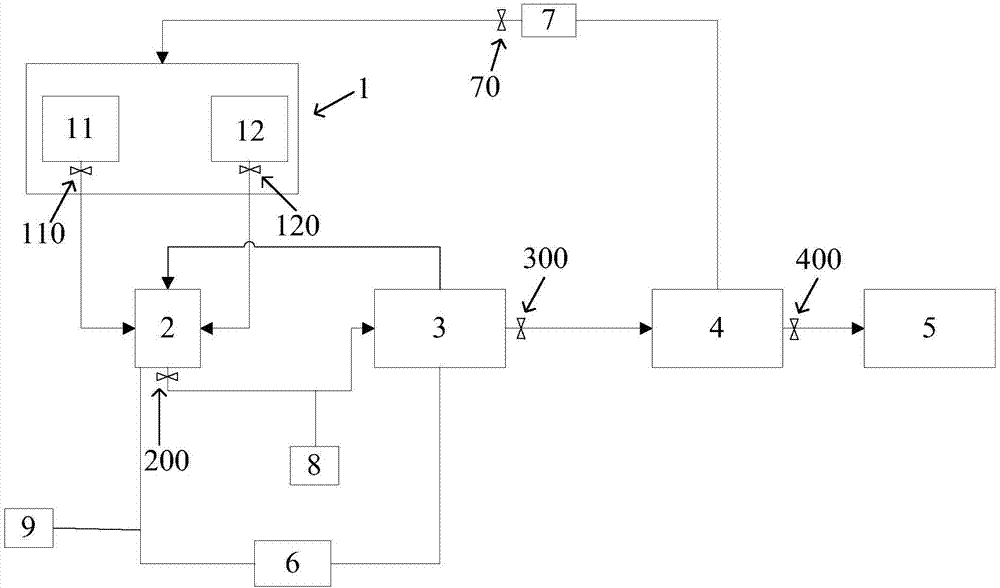

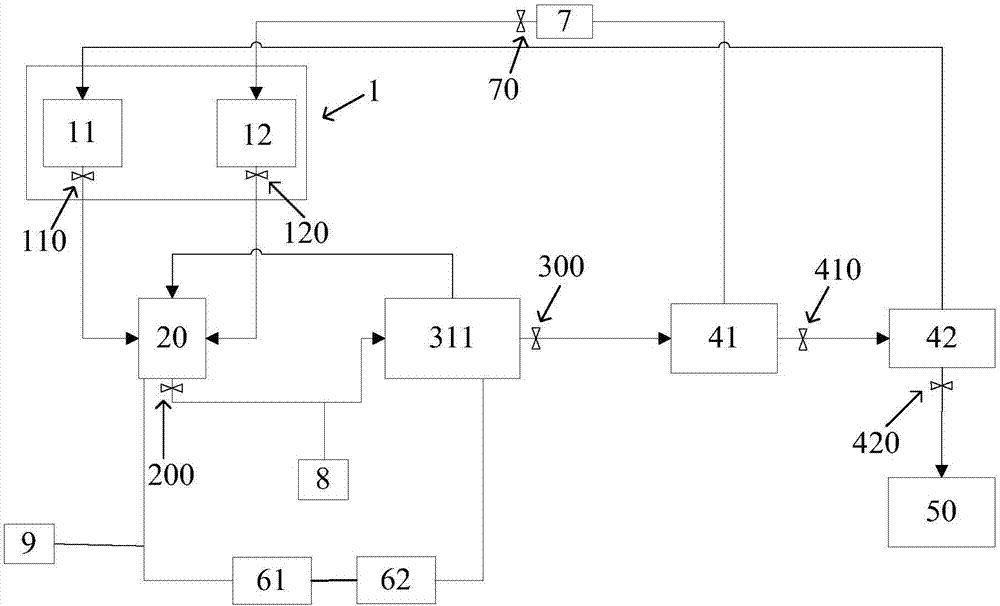

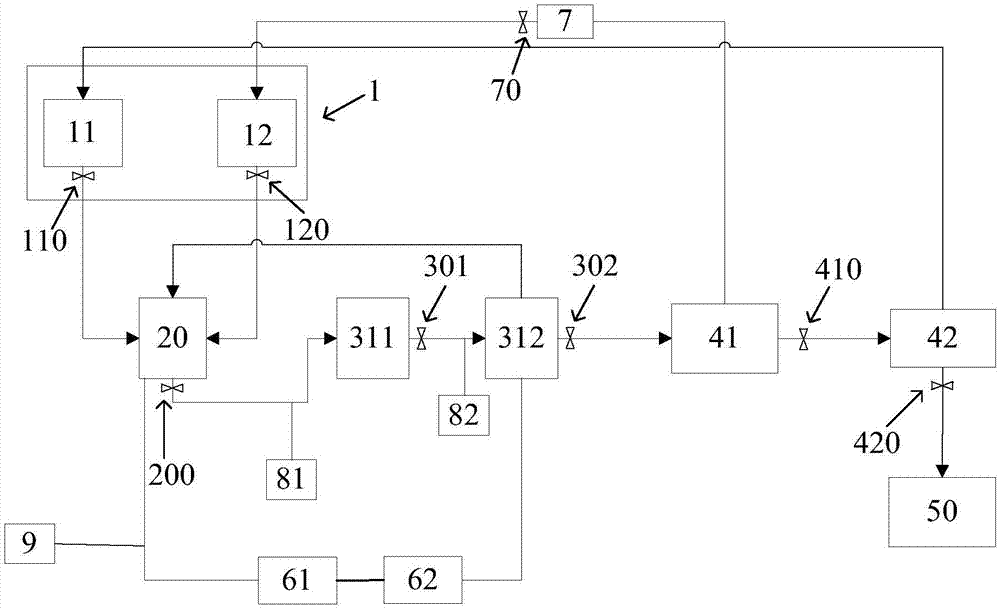

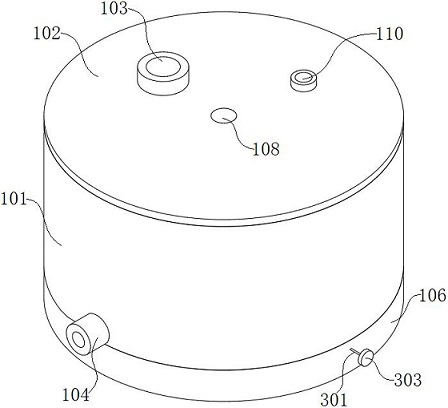

Automatic continuous production device for nanocapsules and method for preparing nanocapsules

PendingCN107961746ASmall particle sizeGood particle dispersionTransportation and packagingMixersMaterials preparationEmulsion

The invention relates to the field of nano material preparation, and in particular, relates to an automatic continuous production device for nanocapsules and a method for preparing the nanocapsules byusing the device. The device includes a storage tank, a shearing device, an emulsifying homogenizing device and a solvent recovery device which are connected in series in sequence through a pipeline,wherein the storage tank includes a dispersed phase storage tank for storing a dispersed phase material and a continuous phase storage tank for storing a continuous phase material; the emulsifying homogenizing device preferably includes a multistage emulsifier, a membrane emulsifier or a high pressure homogenizer or a combination thereof. The method for preparing the nanocapsules by using the device includes the steps: preparing the dispersed phase material and the continuous phase material respectively, mixing, carrying out high-speed shearing, emulsifying and homogenizing to obtain a fine emulsion, and then recovering to obtain the nanocapsules by a solvent. The device can prepare the nanocapsules with uniform and controllable particle size, the process is simple, the energy consumptionof the preparation process is low, and the large-scale automatic continuous production of the nanocapsules can be realized.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

Emulsifying unit for coating production and operation method thereof

InactiveCN107413235AImprove emulsification efficiencyQuality improvementMixing methodsTransportation and packagingDrive shaftAgricultural engineering

The invention discloses an emulsifying unit for coating production. The emulsifying unit comprises a bottom plate, a top plate, an emulsifying barrel, an adjustment plate, an air cylinder I, an air cylinder II, an adjustment block, a motor, a transmission shaft, a stirring rod I, a stirring rod II and a controller and is characterized in that bottom legs and vertical columns are arranged on the bottom plate; the top plate is arranged on the vertical columns; the emulsifying barrel is arranged on the bottom plate; the adjustment plate is arranged on the vertical columns; the air cylinder I is arranged on the top plate; the transmission shaft is arranged on the motor; the stirring rod I is arranged on the transmission shaft; the stirring rod II is arranged on a connection block; the controller is arranged on the top plate. A guide rail is arranged on the adjustment plate, the motor is arranged on the adjustment block of the guide rail, the adjustment plate is connected with a piston rod I of the air cylinder I, so that the adjustment plate can ascend or descend on the vertical columns along with the piston rod I, the transmission shaft on the motor can ascend or descend in the emulsifying barrel, and the emulsification efficiency of a coating in the emulsifying barrel is improved.

Owner:WUHU SANSHAN LONGCHENG NEW MATERIALS

Low-quantitation super-hydrophobic filter paper and preparation method thereof

ActiveCN111021143AIncrease surface hydroxylImprove bindingPaper/cardboardPhysical paper treatmentSuperhydrophobeAqueous droplet

The invention relates to the technical field of super-hydrophobic materials, particularly to low-quantitation super-hydrophobic filter paper and a preparation method thereof. According to the invention, the bonding strength and the effective bonding capacity between a coating and paper can be improved, so that the filtering function can be effectively played for a long time; the preparation methodis simple, convenient, easy to implement, environmentally friendly, easy to operate, free of expensive instruments and equipment and suitable for industrialization; and 20-200 nm modified nano silicon dioxide, a 20-50 [mu]m microcrystalline cellulose micro-nano coating and a hydrophobic layer are constructed on the surface of modified filter paper to form the super-hydrophobic filter paper, wherein the water contact angle of the surface of the paper is greater than 150 DEG, and the rolling angle of the water drops on the surface of the paper is less than 10 DEG.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Emulsion explosive and preparation method thereof

ActiveCN110981662AImprove stabilityHigh degree of polymerizationNon-explosive/non-thermic compositionsExplosive ingredient compoundingExplosive AgentsGear drive

The invention discloses an emulsion explosive and a preparation method thereof. An emulsifying device comprises a bracket; a shell is fixedly arranged at the upper end of the support, and the shell isprovided with a feeding port and a second discharging port; a second motor is arranged on one side of the shell; a second stirring shaft is fixedly arranged on an output shaft of the second motor; the second stirring shaft penetrates through the side wall of the shell and is positioned in an inner cavity of the shell; the outer side of the second stirring shaft is also sleeved with a shaft sleeve; the shaft sleeve penetrates through the side wall of the shell and is rotatably connected with the shell; a second gear is fixedly arranged at one end, located outside the shell, of the shaft sleeve, and the second gear is in transmission connection with a first gear fixed to an output shaft of a first motor, and a first stirring shaft is fixedly arranged at one end, located in the shell, of theshaft sleeve; a scraping plate is arranged on the outer side of the first stirring shaft, and an emulsifying cavity is further formed in one side, away from the second motor, of the shell. The emulsion explosive has the advantages of low production cost, good emulsion explosive stability and the like.

Owner:SICHUAN MIANZHU XINGYUAN SPECIAL CHEM

Emulsification accelerating device for mixed liquid

ActiveCN114011295AFast emulsificationDoes not affect fluid propertiesRotary stirring mixersTransportation and packagingElectric machineAir pump

The invention discloses an emulsification accelerating device for mixed liquid, and relates to the technical field of mixed liquid emulsification. The device comprises an emulsifying barrel, airflow control devices and a reset rod, the emulsifying barrel comprises a material barrel and a barrel seat, the barrel seat is mounted under the material barrel, the reset rod and the airflow control devices are mounted in the material barrel, the reset rod is matched with the airflow control devices, a rotating motor is mounted on the emulsifying barrel, and the airflow control devices are communicated with a pressurizing air pump through a barometer. Stirring blades and the airflow control device are arranged to exert positive and negative influences on mixed liquid in the emulsifying barrel, the emulsifying speed of the mixed liquid can be further increased under the condition that the fluid characteristics of target liquid are not affected, and the emulsifying efficiency of a product is improved.

Owner:烟台金能机械有限公司

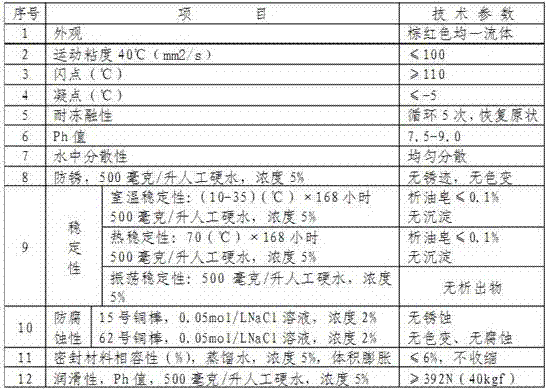

Emulsion for hydraulic support

InactiveCN107513456AHas an antioxidant effectReduce dependenceLubricant compositionWear resistantSuccinic acid

The invention relates to an emulsion for a hydraulic support. The emulsion comprises the following components in percentage by weight: 40 to 50% of water soluble castor oil, 20 to 30% of barium dinonyl naphthalene sulfonate, 15 to 20% of compound additive, 0.5 to 2% of nonionic surfactant, 1 to 2% of zinc naphthenate, 1 to 3% of dodecenyl succinic acid, 1 to 3% of borax, 0.2 to 1% of zinc dialkyl dithiophosphate, and 4 to 8% of water. The compound additive is prepared by reactions among the following components in parts by weight: 35 to 45 parts of boric acid, 35 to 45 parts of triethanolamine, and 3 to 8 parts of sodium hydroxide. The emulsion has the advantages of excellent extreme pressure lubricating performance, wear resistant property, cooling property, antirust function, cleaning property, good stability, and resistance to corruption and deterioration.

Owner:江苏捷达油品有限公司

Color paste formula for water-based paint and production process thereof

InactiveCN112409848AAchieve circular flowGood dispersionShaking/oscillating/vibrating mixersTransportation and packagingCarboxylic acidDetackifier

The invention discloses a color paste formula for a water-based paint. The color paste is prepared from the following raw materials in percentage by weight: 30-40% of color paste resin, 10-20% of toner, 2-4% of dispersing agent, 10-20% of titanium dioxide, 20-30% of deionized water, 5-8% of emulsifying agent, 2-3% of anti-sticking agent, 2-3% of thickening agent, 2-5% of carboxylic acid and 1-2% of defoaming agent. Deionized water is used as a solvent to play a role in dissolving all components, the emulsifying agent plays a role in emulsifying and providing a carrier, toner plays a role in coloring, the dispersing agent contributes to particle crushing of all the components, dispersion stability is guaranteed, all the components are evenly dispersed in a system, and the defoaming agent isused for preventing the foaming phenomenon in the stirring process. The color paste is high in coloring capacity, can be placed for a long time without mildewing, can keep stable rheological property, and is wide in application range, non-toxic and high in compatibility.

Owner:JIANGMEN SINOBLE TECH SHARES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com