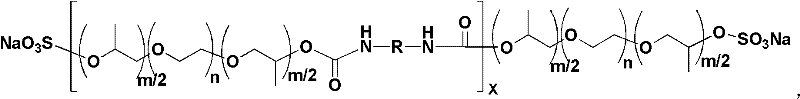

Polyether polyurethane sulfate anionic macromolecular surfactant and preparation method and application thereof

A polyether polyurethane and surfactant technology, applied in textile and papermaking, fiber processing, carbon fiber, etc., can solve the problems of emulsification process influence and limited application scope, and achieve high emulsification efficiency, abundant raw material sources, and easy large-scale production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

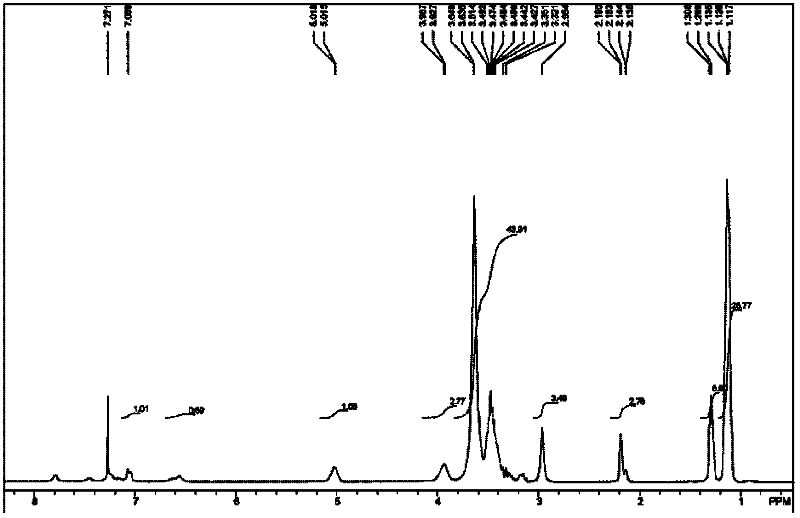

[0050] 81.80 g (0.1 mol) of homemade triblock PPG 4 -PEG 8 -PPG 4 (P 4 E. 8 P 4 ) polyether was added into a 500ml four-neck flask, the temperature was raised to 90°C, and residual moisture was removed by vacuuming. Then the temperature was lowered to below 50° C., and 8.71 g (0.05 mol) of toluene diisocyanate (2,4-TDI) was slowly added dropwise under a flowing high-purity nitrogen atmosphere. After the isocyanate component is added dropwise, the reaction system is heated to 60°C and stirred, and the isocyanate functional group content W is measured by sampling once every 20 minutes. NCO titration analysis. When W NCO When approaching half of the initial value, the temperature of the reaction system was raised to 90°C, and the sampling and W NCO titration analysis. at W NCO When it is close to 0, the reaction system continues to heat up to 130°C, and 5.82 grams (0.06mol) of sulfamic acid and 0.53 grams (0.006mol) of catalyzer N, N'-dimethylurea, which are carefully g...

Embodiment 2

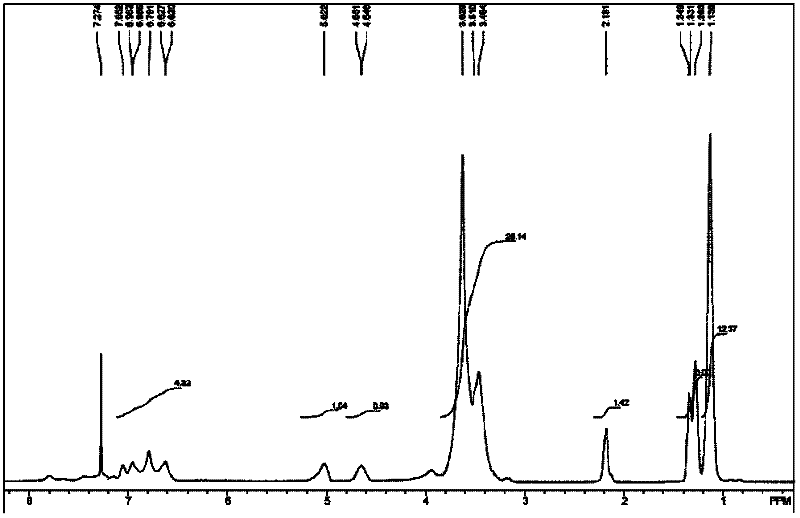

[0052] 81.80 g (0.1 mol) of homemade triblock PPG 4 -PEG 8 -PPG 4 (P 4 E. 8 P 4 ) polyether was added into a 500ml four-neck flask, the temperature was raised to 90°C, and the residual moisture was removed by vacuuming. Then the temperature was lowered to below 50° C., and 10.08 g (0.06 mol) of hexamethylene diisocyanate (HDI) was slowly added dropwise under a flowing high-purity nitrogen atmosphere. After the isocyanate component is added dropwise, the reaction system is heated to 60°C and stirred, and the isocyanate functional group content W is measured by sampling once every 20 minutes. NCO titration analysis. When W NCO When approaching half of the initial value, the temperature of the reaction system was raised to 90°C, and the sampling and W NCO titration analysis. at W NCO When it is close to 0, continue to heat up the reaction system to 130°C, and add 7.76 grams (0.08mol) of sulfamic acid and 0.72 grams (0.012mol) of catalyst urea that have been ground and t...

Embodiment 3

[0054] 49.80 g (0.1 mol) of homemade triblock PPG 2 -PEG 6 -PPG 2 (P 2 E. 6 P 2 ) polyether was added into a 500ml four-neck flask, the temperature was raised to 90°C, and the residual moisture was removed by vacuuming. Then the temperature was lowered to below 50° C., and 8.71 g (0.05 mol) of toluene diisocyanate (2,6-TDI) was slowly added dropwise under a flowing high-purity nitrogen atmosphere. After the isocyanate component is added dropwise, the reaction system is heated to 60°C and stirred, and the isocyanate functional group content W is measured by sampling once every 20 minutes. NCO titration analysis. When W NCO When approaching half of the initial value, the temperature of the reaction system was raised to 90°C, and the sampling and W NCO titration analysis. at W NCO When it is close to 0, continue to heat up the reaction system to 130°C, and add 4.85 grams (0.05mol) of sulfamic acid and 0.30 grams (0.005mol) of catalyst urea that have been ground and thor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| rotational viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com