Low-quantitation super-hydrophobic filter paper and preparation method thereof

A low-quantity, super-hydrophobic technology, used in filter paper, separation methods, chemical instruments and methods, etc., can solve the problems of short service life, unevenness, easy to fall off, etc., and achieve the effect of easy dispersion, good stability and strong bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

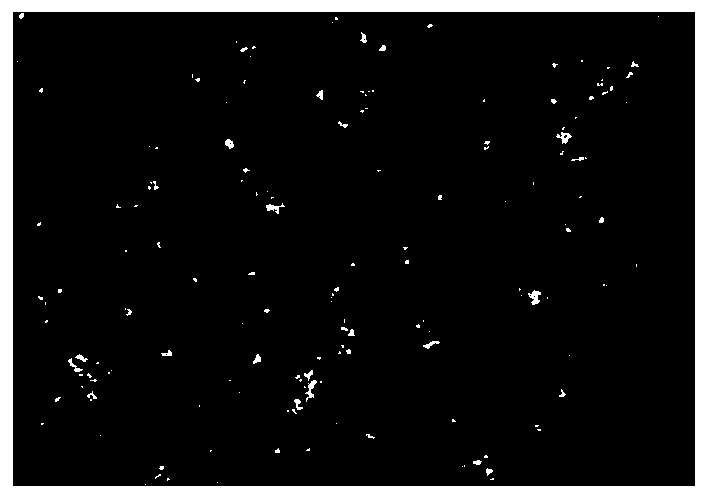

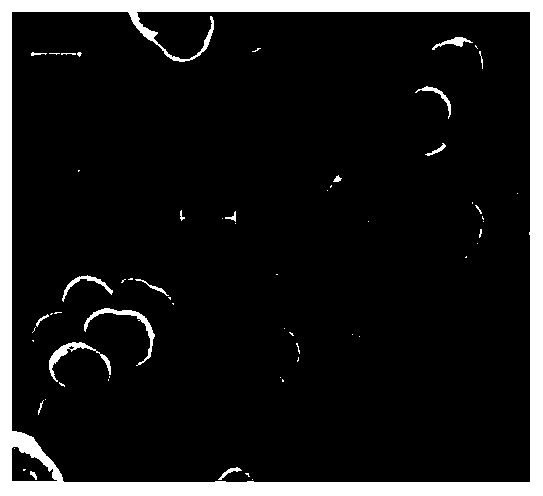

Image

Examples

Embodiment 1

[0028] A low-weight ultra-hydrophobic filter paper, including modified filter paper and a coating applied to its surface; the coating includes a microcrystalline cellulose / modified nano-silica mixed layer and a hydrophobic film layer; two coating quality The ratio is 3:1, the coating weight is 3g / m 2 .

[0029] The preparation method of above-mentioned low quantitative ultra-hydrophobic filter paper is:

[0030] 1) Clean the filter paper with ethanol ultrasonically for 3 times, dry at 60°C for 30 minutes, and set aside;

[0031] 2) Soak the filter paper treated in step 1) in a 65% zinc chloride solution at 75°C for 3 minutes, take it out and ultrasonically clean it with ethanol for 3 times, dry it at 60°C for 30 minutes, and set aside;

[0032] 3) Micro-nano structure coating preparation: 20 μm microcrystalline cellulose preparation concentration is 5% solution, at a stirring speed of 100r / min, add 2% modified silica solution, the volume ratio of the two is 3:1, and the mixe...

Embodiment 2

[0041] A low-weight ultra-hydrophobic filter paper, including modified filter paper and a coating applied to its surface; the coating includes a microcrystalline cellulose / modified nano-silica mixed layer and a hydrophobic film layer; two coating quality The ratio is 5:1, the coating weight is 5g / m 2 .

[0042] The preparation method of above-mentioned low quantitative ultra-hydrophobic filter paper is:

[0043] 1) Clean the filter paper with ethanol ultrasonically for 3 times, dry it at 30°C for 10 minutes, and set aside;

[0044] 2) Soak the filter paper treated in step 1) in a 65% zinc chloride solution at 75°C for 3 minutes, take it out and ultrasonically clean it with ethanol for 3 times, dry it at 30°C for 10 minutes, and set aside;

[0045] 3) Micro-nano structure coating preparation: 50 μm microcrystalline cellulose preparation concentration is 5% solution, at a stirring speed of 150r / min, add 2% modified silica solution, the volume ratio of the two is 3:1, and the m...

Embodiment 3

[0054] A low-weight ultra-hydrophobic filter paper, including modified filter paper and a coating applied to its surface; the coating includes a microcrystalline cellulose / modified nano-silica mixed layer and a hydrophobic film layer; two coating quality The ratio is 4:1, the coating weight is 4g / m 2 .

[0055] The preparation method of above-mentioned low quantitative ultra-hydrophobic filter paper is:

[0056] 1) Clean the filter paper with ethanol ultrasonically for 3 times, dry it at 45°C for 20 minutes, and set aside;

[0057] 2) Soak the filter paper treated in step 1) in a 65% zinc chloride solution at 75°C for 2 minutes, take it out and ultrasonically clean it with ethanol for 3 times, dry it at 45°C for 20 minutes, and set aside;

[0058] 3) Micro-nano structure coating preparation: 40 μm microcrystalline cellulose preparation concentration is 5% solution, at a stirring speed of 200r / min, add 2% modified silica solution, the volume ratio of the two is 1:3, and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com