A kind of hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst, a first-class technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of separate preparation or purchase of alumina fibers, and achieve improved peptization and good The effect of high mechanical properties and lateral compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

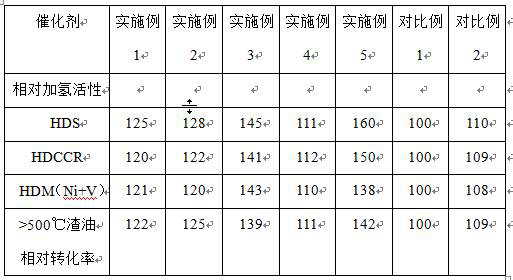

Examples

Embodiment 1

[0040] (1) Preparation of pseudo-boehmite filter cake

[0041] In the primary reactor, add the bottom water of 1 / 5 of the reactor volume, and then add the caustic ratio of 1.35 and the concentration of 100gAl in cocurrent. 2 O 3 / L sodium metaaluminate solution and 50gAl 2 O 3 / L of aluminum sulfate solution is reacted, the pH value of the control system is 4.0, and the reaction temperature is controlled to be 60 ° C. The reaction effluent is divided into two streams, which are the first stream and the second stream respectively, and the first stream accounts for the reaction outflow. The bottom water was added to the secondary reaction kettle, the first material stream and 5.0wt% sodium carbonate solution entered the secondary reaction kettle, the pH value of the control system was 10.0, and the temperature was 90 ° C; the secondary reaction kettle obtained The reaction product was aged at 100°C for 0.5h, and filtered to obtain primary filtrate and primary filter cake; the...

Embodiment 2

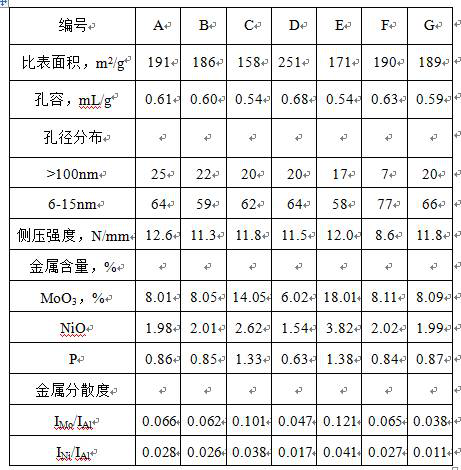

[0047] Other conditions are the same as in Example 1, only the bottom water of the primary reactor is adjusted to 1 / 4 of the volume of the reactor, the pH value of the secondary reactor is adjusted to 7.0, the aging temperature of the secondary aging device is adjusted to 80 ° C, and the wet The dry basis of the filter cake material was adjusted to 28wt%, and the solid weight of polyethylene glycol 200 was changed to 7.99g to obtain catalyst B. The physicochemical properties of the obtained catalyst are listed in Table 1.

Embodiment 3

[0049] Other conditions are the same as in Example 1, except that the bottom water of the primary reactor is adjusted to 1 / 3 of the volume of the reactor, the aging temperature of the primary aging device is adjusted to 60°C, and the aging time is adjusted to 2.0h. The amount taken was changed to 850g, the weight of industrial pseudo-boehmite raw materials was changed to 150g, the weight of polyethylene glycol 200 was changed to polyethylene glycol 400, the mass of molybdenum oxide was changed to 100.95g, and the quality of basic nickel carbonate was changed to 34.37g , the mass of phosphoric acid was changed to 26.55g, and catalyst C was obtained, and the physicochemical properties of the obtained catalyst were listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com