Patents

Literature

48results about How to "High lateral compressive strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

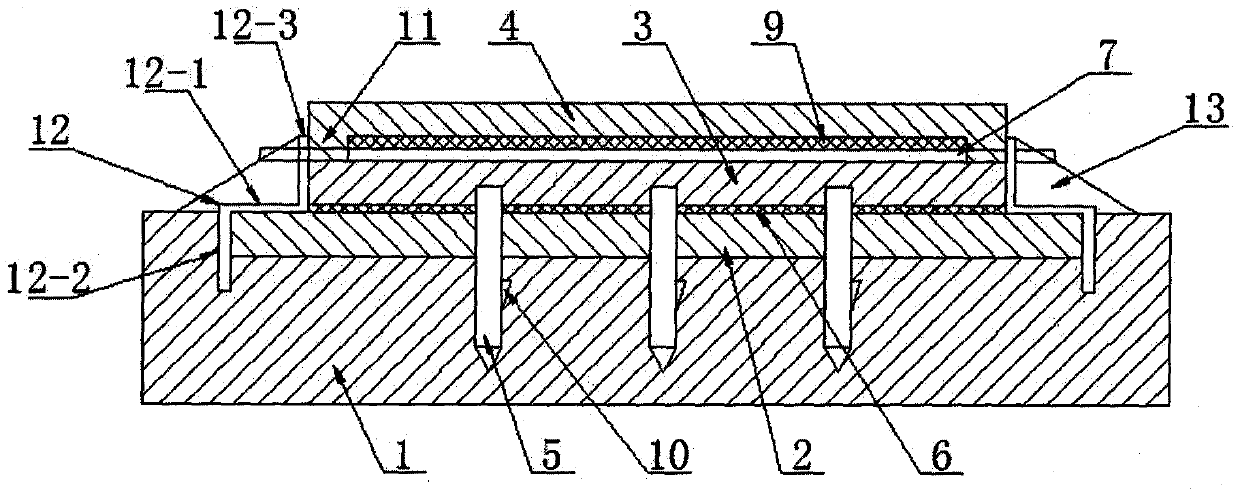

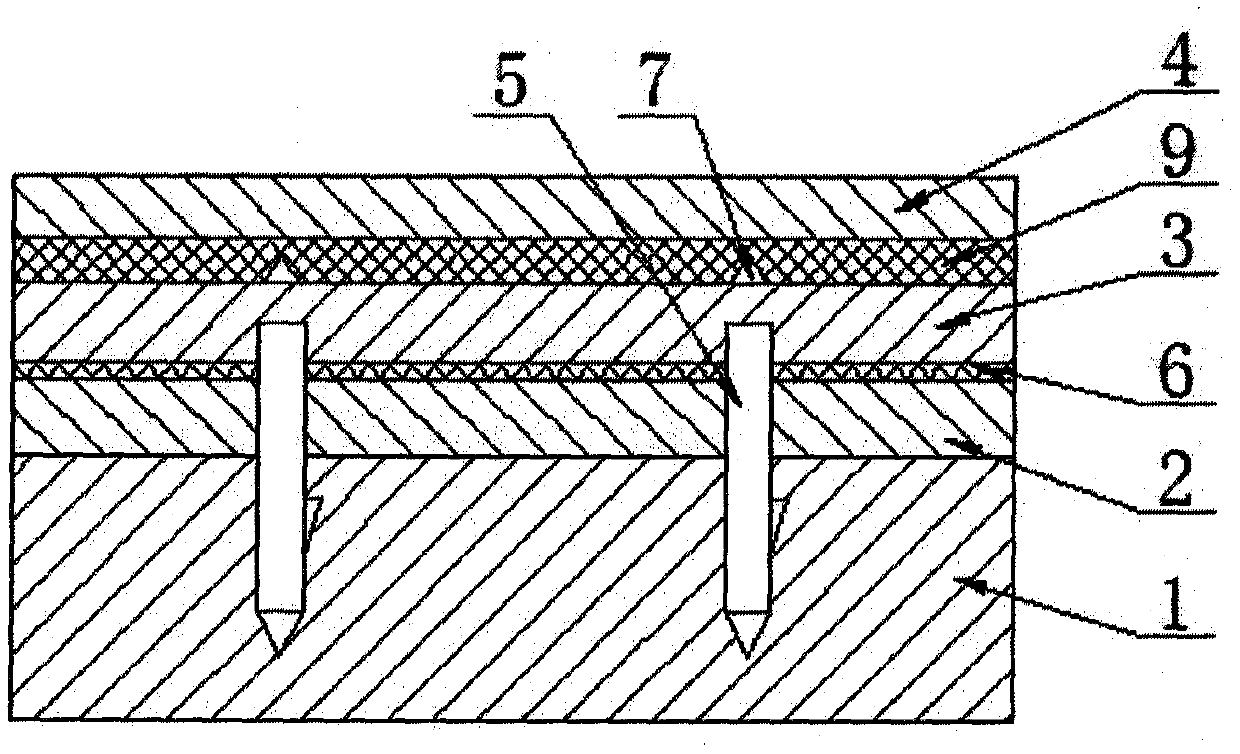

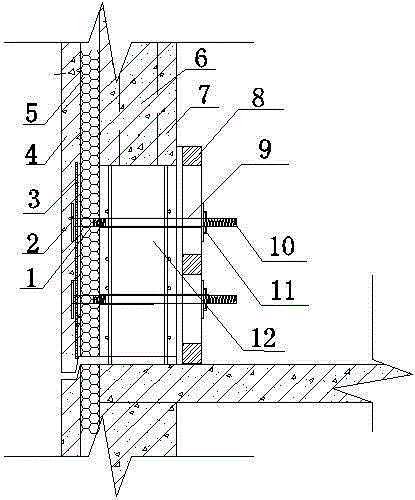

Cast-in-place section concrete construction method of assembling-type concrete structure

ActiveCN103422674AHigh lateral compressive strengthAvoid crackingBuilding material handlingStructural engineeringUltimate tensile strength

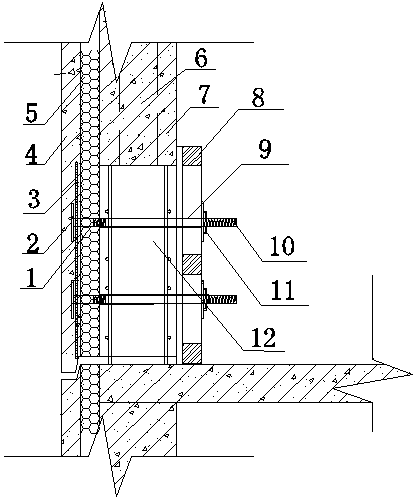

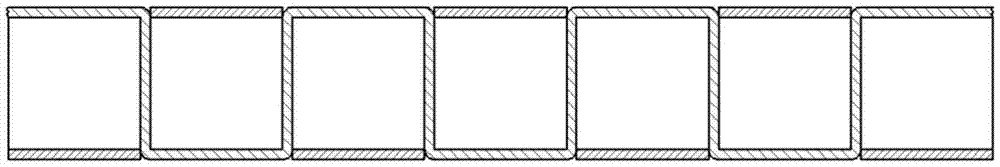

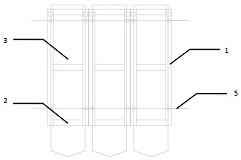

The invention relates to construction methods of assembling-type concrete structures, in particular to a cast-in-place section concrete construction method of an assembling-type concrete structure. The cast-in-place section concrete construction method comprises the steps that when an outer wall body is prefabricated, embedded parts and steel bar meshes are buried and additionally arranged inside an outer wall protective layer of a cast-in-place section correspondingly; a cast-in-place section formwork is connected to the inner side of a wall body structural layer through mutual-pulling screws and buckling pieces, wherein one end of each mutual-pulling screw is connected with a sleeve and the other end of each mutual-pulling screw penetrates out through a reserved hole in the cast-in-place section formwork, and the mutual-pulling screws are sleeved with PVC casing pipes. Cast-in-place section concrete is poured in grouting holes reserved inside the wall body structural layer. After the cast-in-place concrete reaches designed strength, the buckling pieces can be loosened, the cast-in-place section formwork can be disassembled, the mutual-pulling screws are rotated to enable the mutual-pulling screws to be separated from the sleeves, and then the mutual-pulling screws are drawn out from the PVC casing pipes. The cast-in-place section concrete construction method of the assembling-type concrete structure solves the problems that the surface of a warm-keeping protection layer cracks and deforms due to the through-wall screws and water seepage occurs in an outer wall, reduces the workload of outer wall face repairmen, and improves the pouring efficiency of the cast-in-place section concrete.

Owner:CHINA 22MCC GROUP CORP

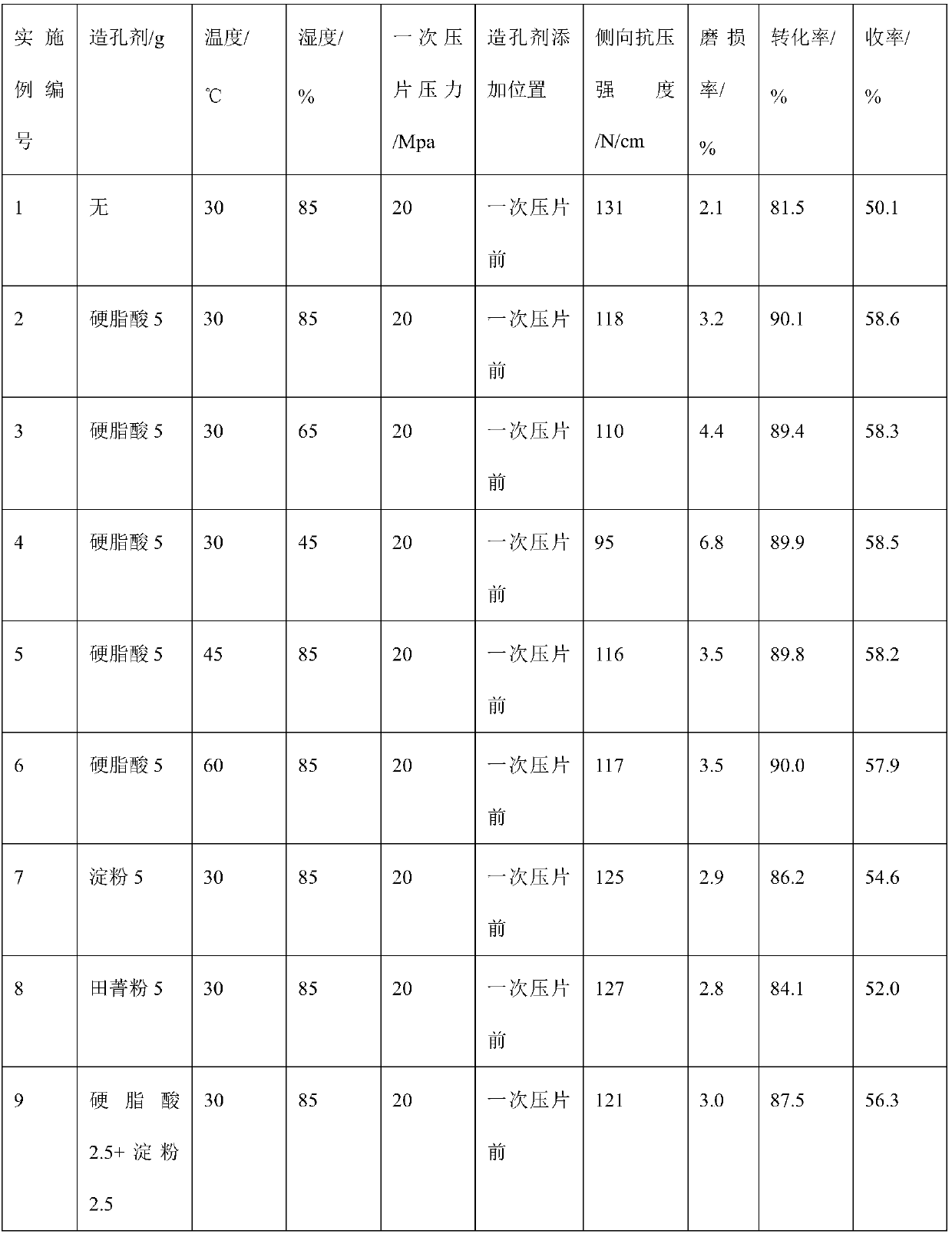

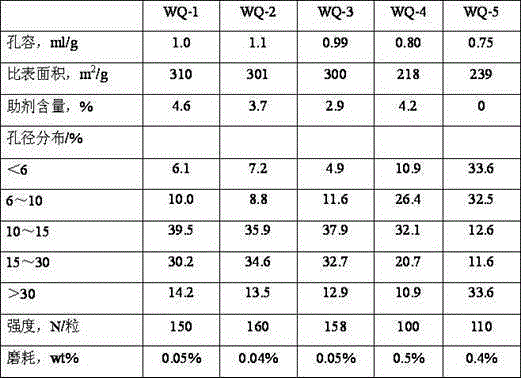

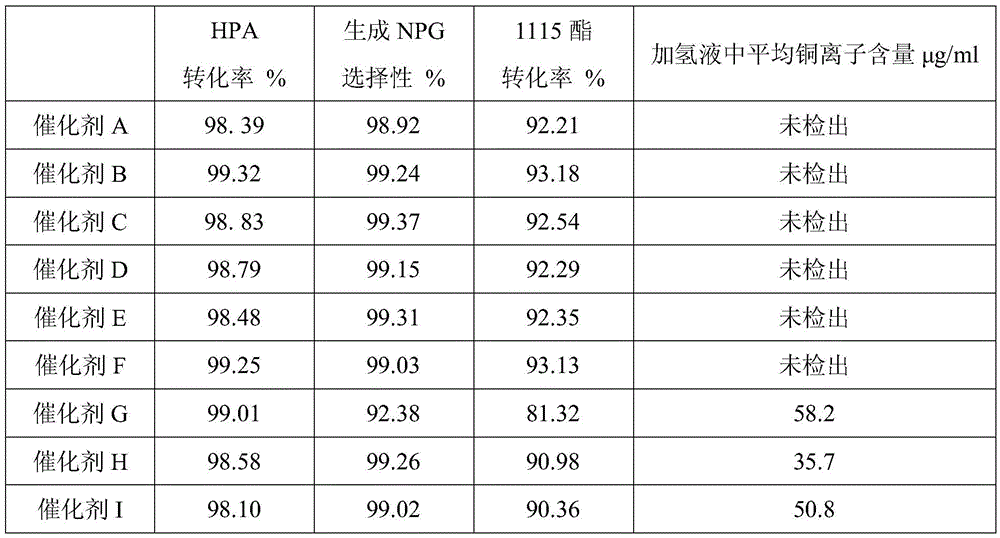

Catalyst for preparing maleic anhydride from n-butane through oxidation and preparation method thereof

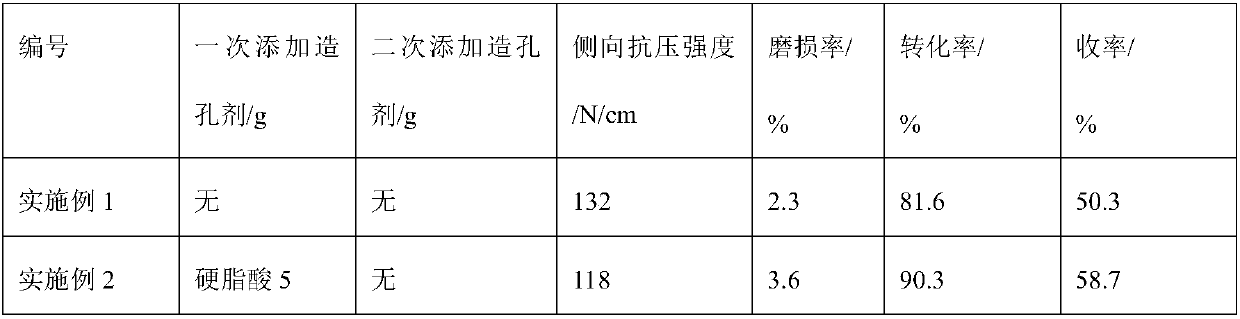

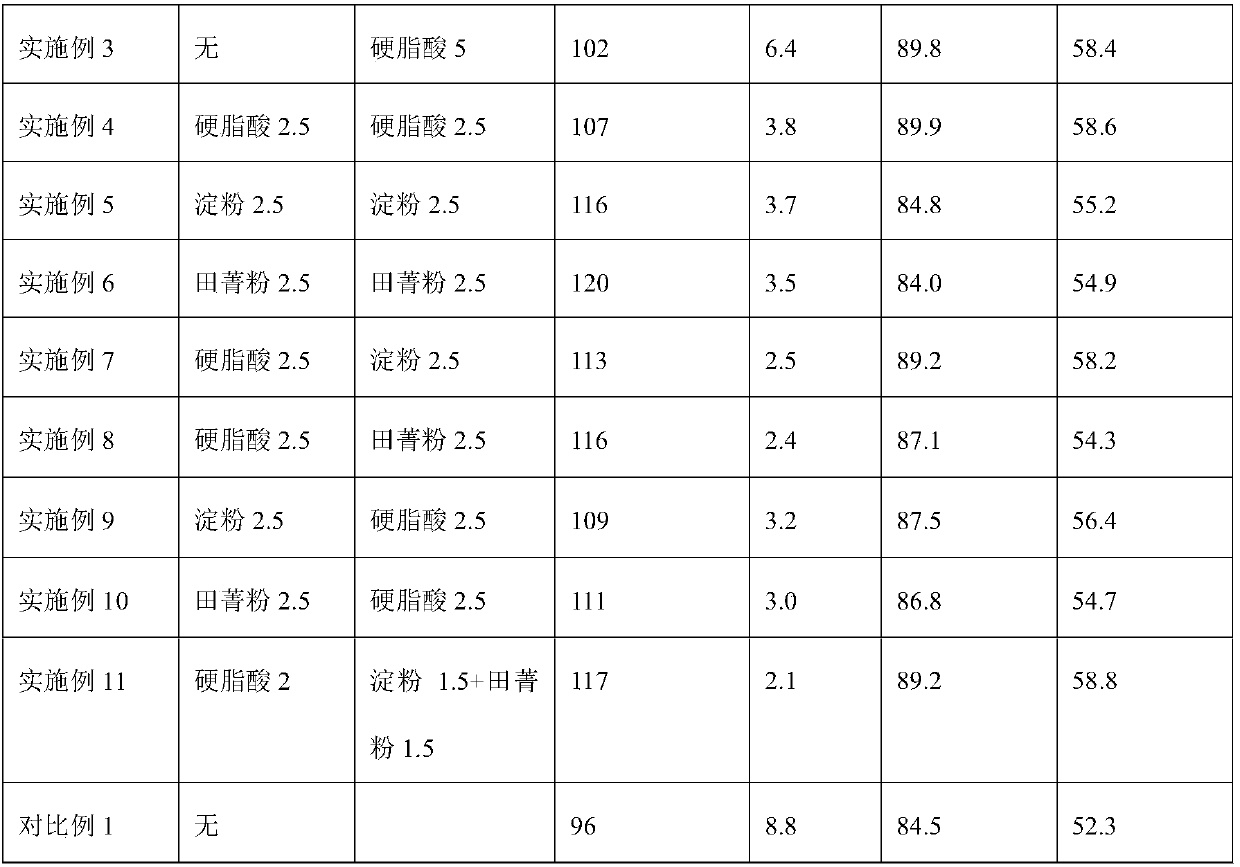

ActiveCN107866245AHigh lateral compressive strengthReduce wear rateOrganic compound preparationCatalyst activation/preparationButaneMaleic anhydride

The invention relates to a catalyst for preparing maleic anhydride from n-butane through oxidation. The catalyst mainly overcomes the problem of low catalytic activity in the prior art. According to the invention, three elements consisting of vanadium, phosphorus and oxygen are used as the main body of the catalyst, and a certain amount of a metal additive is cooperatively used. The catalyst comprises, by weight, 26 to 35% of elemental vanadium, 14 to 20% of elemental phosphorus, 30 to 50% of elemental oxygen and 0.02 to 7% of the metal additive. The catalyst is subjected to constant-temperature constant-humidity treatment, doping of a pore forming agent and secondary molding, so the catalysis performance and strength of the catalyst are improved, and the catalyst is applicable to the field of preparation of maleic anhydride from n-butane through oxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation technology of catalyst used for high temperature catalytic decomposition of N2O

ActiveCN106391037AGood dispersionImprove heat resistanceNitrous oxide captureGas treatmentCooking & bakingCerium nitrate

The invention discloses a preparation technology of a catalyst used for high temperature catalytic decomposition of N2O. The preparation technology comprises the following steps: dissolving magnesium nitrate, cobalt nitrate, lanthanum nitrate, cerium nitrate, nickel nitrate and zirconium nitrate in water to form a mixed nitrate solution; adding ammonia water and aluminum hydroxide, and carrying out compacting, dehydrating, drying and baking to obtain a powder material; and uniformly rolling the powder material, desalinized water and a bonding agent, drying the rolled materials to obtain a granulation material, compacting the granulation material to form a porous cylinder, and calcining the porous cylinder to obtain the catalyst. The preparation technology has the following advantages: a co-precipitation method is selected, an active component reacts with a carrier substance precursor and a precipitating agent to realize co-precipitation, and the active component interacts with the carrier, so the active component is well and stably dispersed; and the active component and the carrier precipitate are commonly calcined at a high temperature of 1000-1300 DEG C, so the active component of the catalyst has good heat tolerance and difficulty loses, thereby the catalyst has the advantages of high efficiency, good stability and long service life.

Owner:四川蜀泰化工科技有限公司

Dephosphorization agent and preparation method thereof

ActiveCN103316624AHigh lateral compressive strengthHigh strengthOther chemical processesDispersed particle separationSodium bicarbonateAlkali metal oxide

The present invention relates to a dephophorization agent and a preparation method thereof. According to the invention, inorganic bentonite is used as a carrier, and one of metallic oxides such as iron, nickel, manganese, zinc, copper, and cerium is used as an active component with alkali metal oxide and alkaline earth metal oxide as auxiliary components, wherein the mass percentage of each component is as following: 5 to 20 percent of active component, 10 to 40 percent of alkaline earth metal oxide, 10 to 25 percent of alkali metal oxide, and the balance of inorganic bentonite. The preparation method provided by the invention includes the following steps: first, adding ammonia water to the active component of soluble metal salt for deposition, and a suspension liquid of the metal is obtained through pulping by adding water; then, adding proportional amounts of calcium oxide, sodium carbonate or sodium bicarbonate as well as bentonite and grinding the mix into a paste, leaving the paste for four hours; drying the paste after molding the paste into a bar, and roasting the same for two hours at the temperature of 300 DEG C to 400 DEG C, then a dephosphorization agent is obtained. The dephosphorization agent is of high strength, and is applicable for desorption of PH3 with low temperature and high phosphorus capacity.

Owner:HAISO TECH

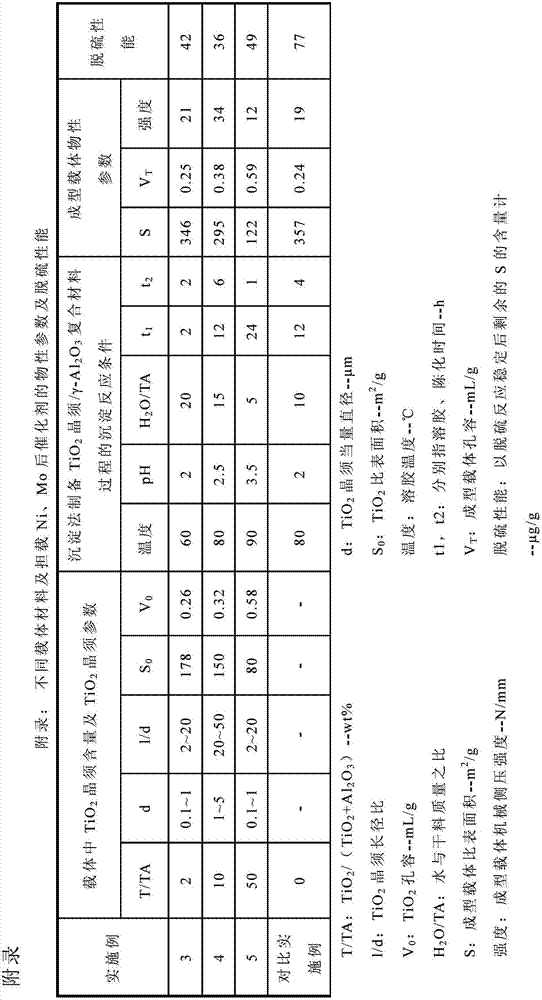

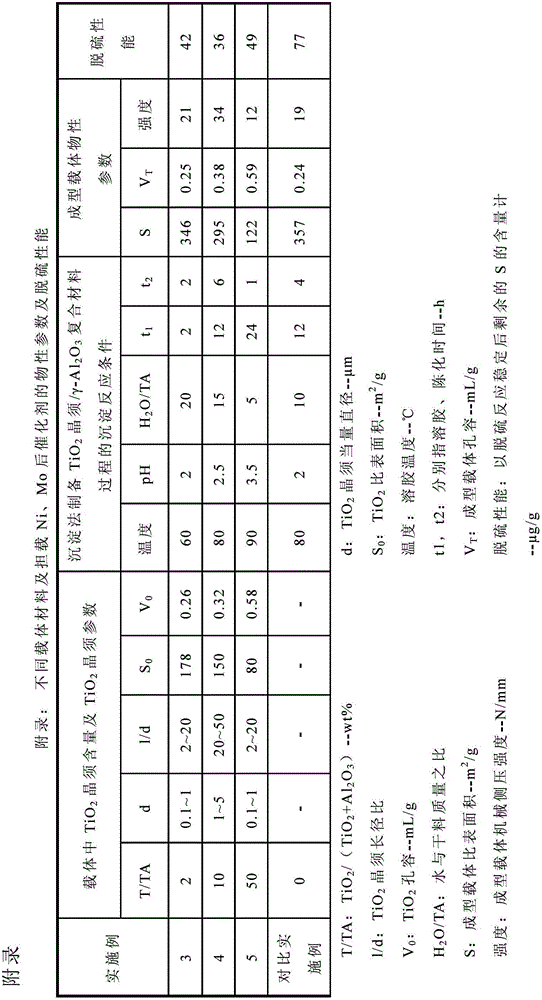

Preparation method of TiO2/gamma-Al2O3 composite carrier material

ActiveCN103706405ALarge specific surface areaLarge hole volumeCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsNickel catalystHydrodesulfurization

The invention relates to a preparation method of a TiO2 / gamma-Al2O3 composite carrier material. The method includes uniformly mixing mesoporous TiO2 crystal whisker and alumina sol, with the weight percent of the mesoporous TiO2 crystal whisker being 2-50 wt% and the weight ratio of dry mixing materials to water being 1:5-20; heating the material mixture to 60-90 DEG C, adding dropwise an inorganic acid to adjust the pH to be 2-3.5 and maintaining for 2-24 h; adding dropwise an alkaline solution to adjust the pH to be 9 to form Ti-Al-H2O composite jelly; ageing for 1-6 h, washing with deionized water to be neutral, filtering and drying in air; and calcining at 500-800 DEG C to obtain the TiO2 / gamma-Al2O3 composite carrier material. The method is simple in operation and low in cost. A molybdenum-nickel catalyst prepared from the carrier has excellent deep hydrodesulfurization performance, and is capable of reducing the sulfur content from 5000 [mu]g / g in inferior diesel oil to below 50 [mu]g / g, thus achieving the Europe IV diesel oil standard.

Owner:PETROCHINA CO LTD

Diesel hydro-refining catalyst and preparation method thereof

ActiveCN104923244ALarge specific surface areaLow bulk densityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsDecompositionSilicon dioxide

The invention relates to a diesel hydro-refining catalyst and a preparation method thereof. The catalyst is composed of an active component nickel-molybdenum metal oxide, a composite dispersion medium silicon dioxide and aluminum trioxide, and an organic salt mixture. The method is a deposition sedimentation method. According to the method, metal salts of nickel, molybdenum, silicon and aluminum are added into water according to a certain ratio, and a homogenous transparent SiO2-gamma-Al2O3 gel is formed through a sol-gel process; with the decomposition of urea, the pH value increases; a reaction of Ni and Mo is carried out under an alkaline condition, such that an Ni-Mo composition is produced and is deposited on the surface of SiO2-gamma-Al2O3; and steps such as filtering, drying, roasting are carried out, such that the bulk catalyst with relatively high dispersion activity is obtained. The catalyst has the advantages of high active component content, uniform active component dispersion, large specific surface area, and high catalytic activity. The catalyst can be used for producing clean diesel with ultralow sulfur content.

Owner:NORTH HUAJIN CHEM IND CO LTD

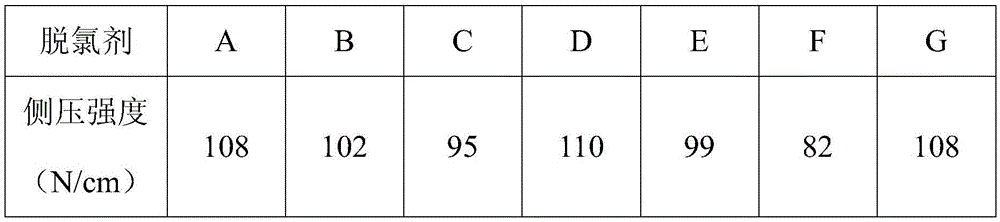

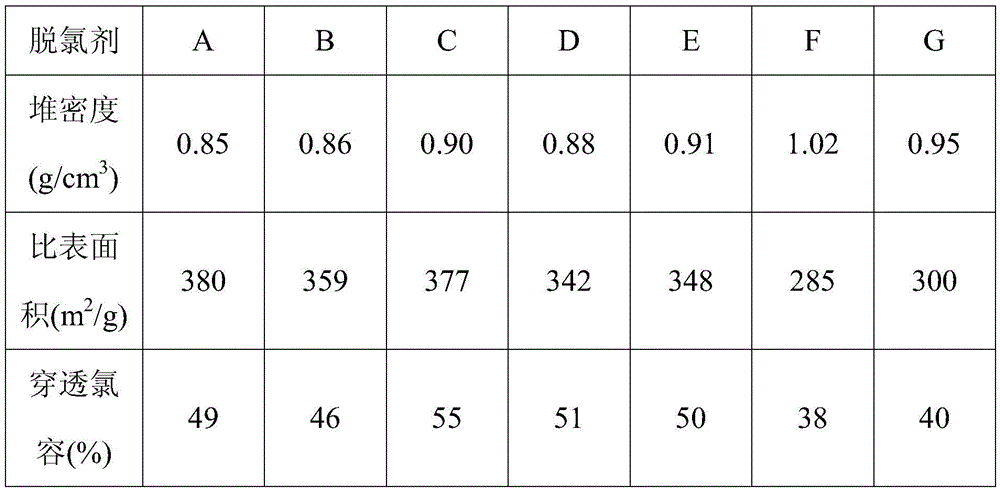

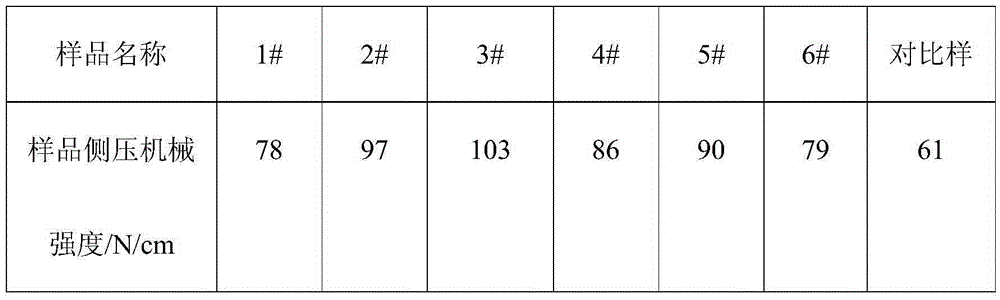

Gaseous phase dechlorinating agent and preparation method thereof

ActiveCN105617853AImprove dechlorination activityHigh strengthGas treatmentDispersed particle separationDesorptionNuclear chemistry

The invention provides a gaseous phase dechlorinating agent. The gaseous phase dechlorinating agent is prepared from the following components in percentage by weight: 15 to 30 weight percent of calcium carbonate, 10 to 35 weight percent of magnesium carbonate, 7.2 to 10.8 weight percent of calcium oxide and 48 to 65 weight percent of aluminate cement. According to the dechlorinating agent provided by the invention, by using the characteristic that the calcium carbonate and the magnesium carbonate are used to generate a regular sandwich structure, chlorine is adsorbed more favorably, the dechlorinating activity is improved, and the breakthrough chlorine content of the dechlorinating agent at 300DEG C is as high as 55 percent; in addition, the strength can be improved, and the side pressure strength of the dechlorinating agent when clay is not used is as high as 110N / cm, so that the clay is prevented from being used and further the sintering of the dechlorinating agent is effectively prevented; meanwhile, by using high hygroscopicity of calcium oxide, the calcium oxide absorbs water and is converted into calcium hydroxide with higher alkalinity, so that the absorbing ability for hydrogen chloride is promoted, the dechlorinating precision is improved, the desorption of chlorine from the dechlorinating agent is hindered, the condition that water and metal chloride generated by chlorine absorption of the dechlorinating agent generate a coordination reaction is prevented, the damage to a dechlorinating agent structure and the blockage of an internal pore canal are avoided, and the chlorine capacity of the dechlorinating agent is effectively improved.

Owner:SHENYANG SANJUKAITE CATALYST

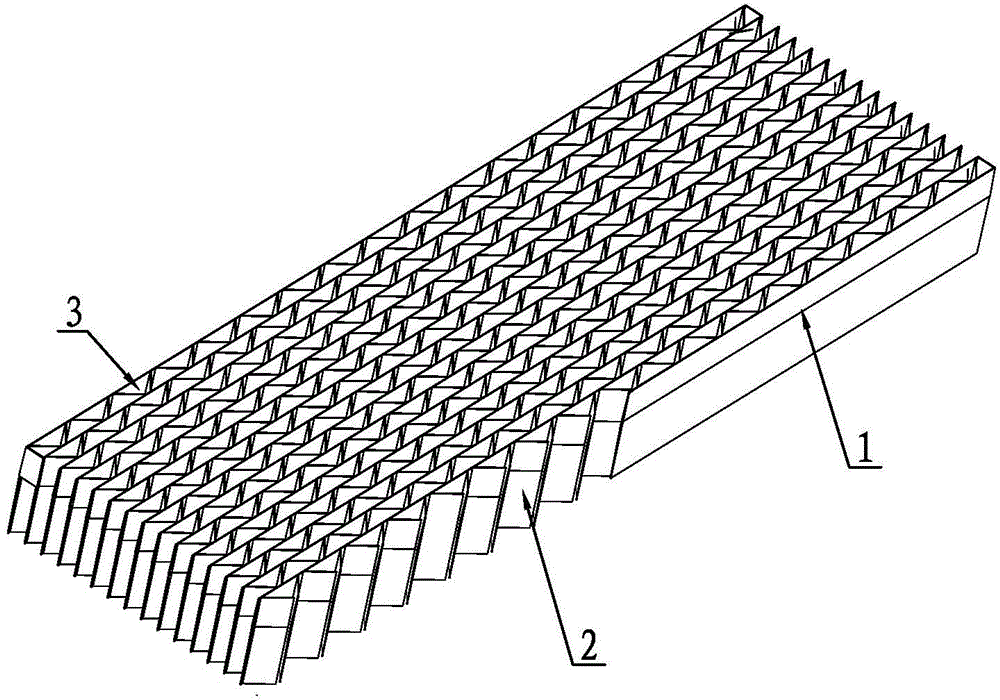

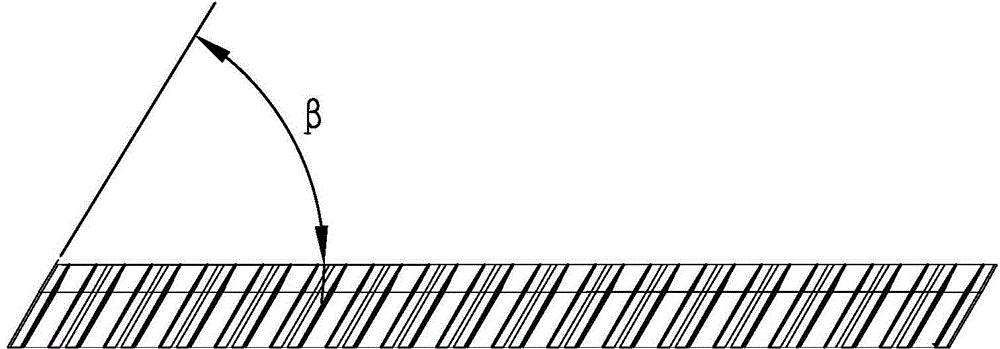

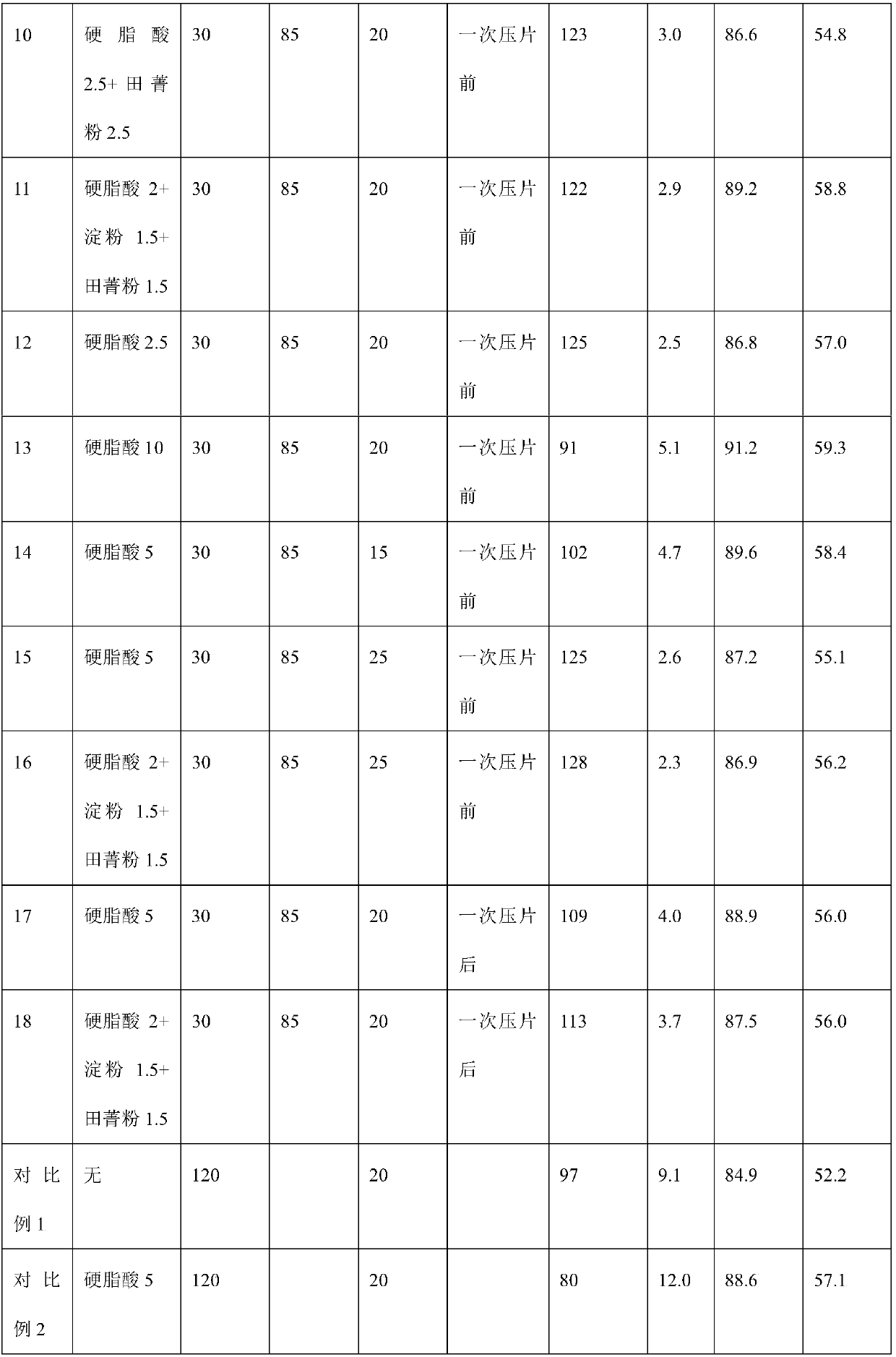

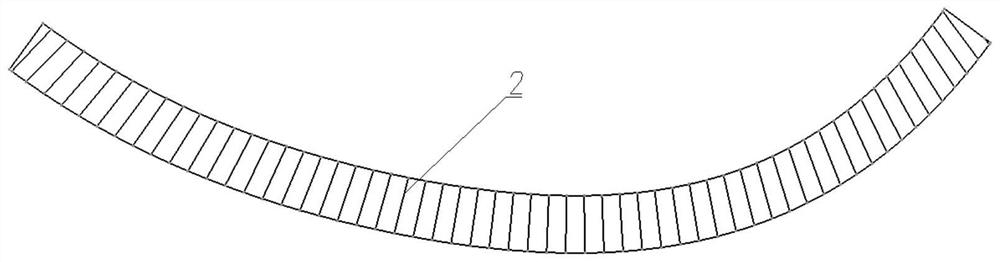

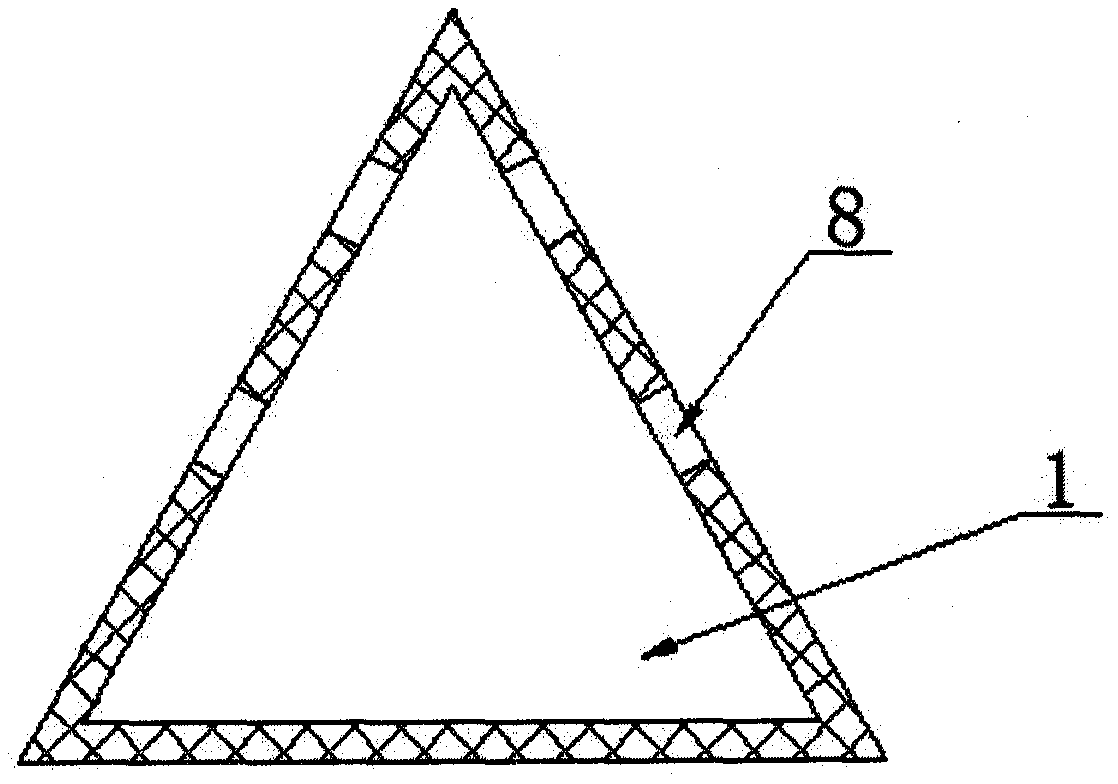

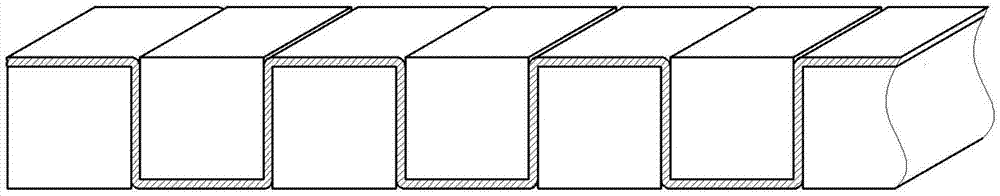

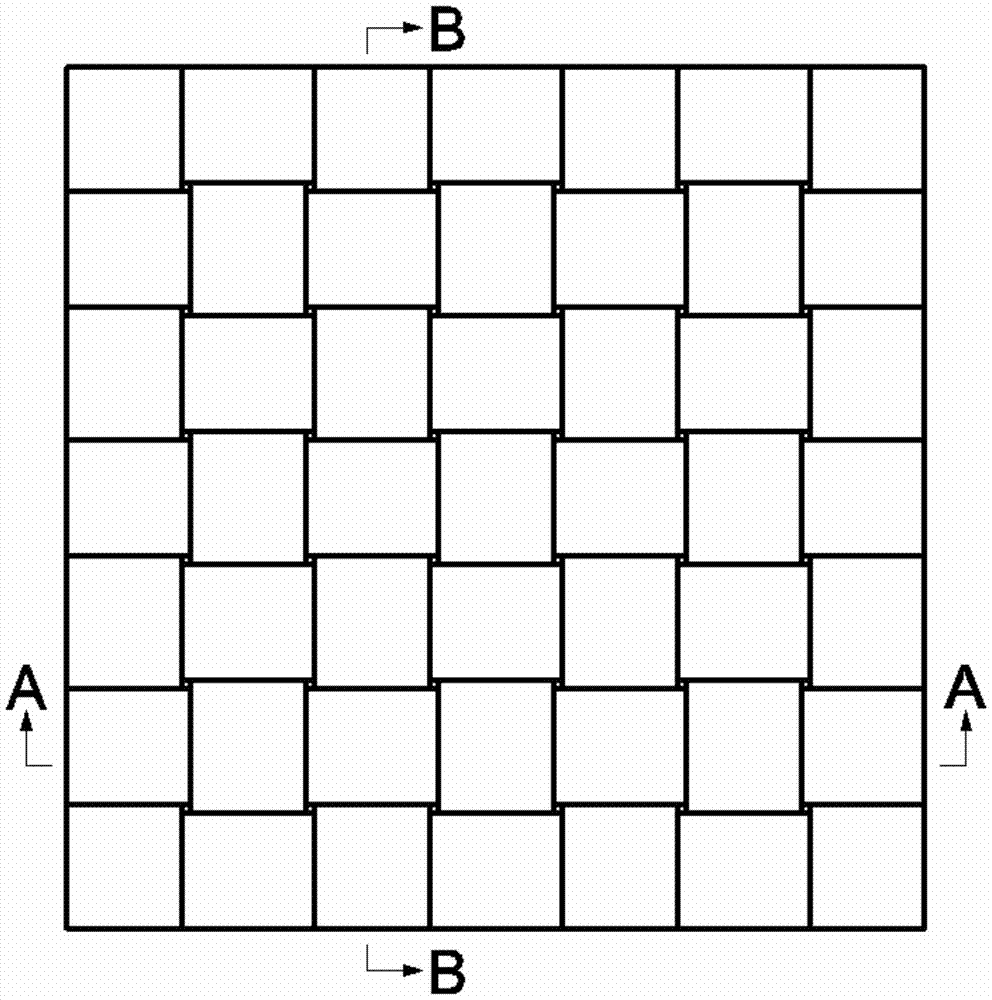

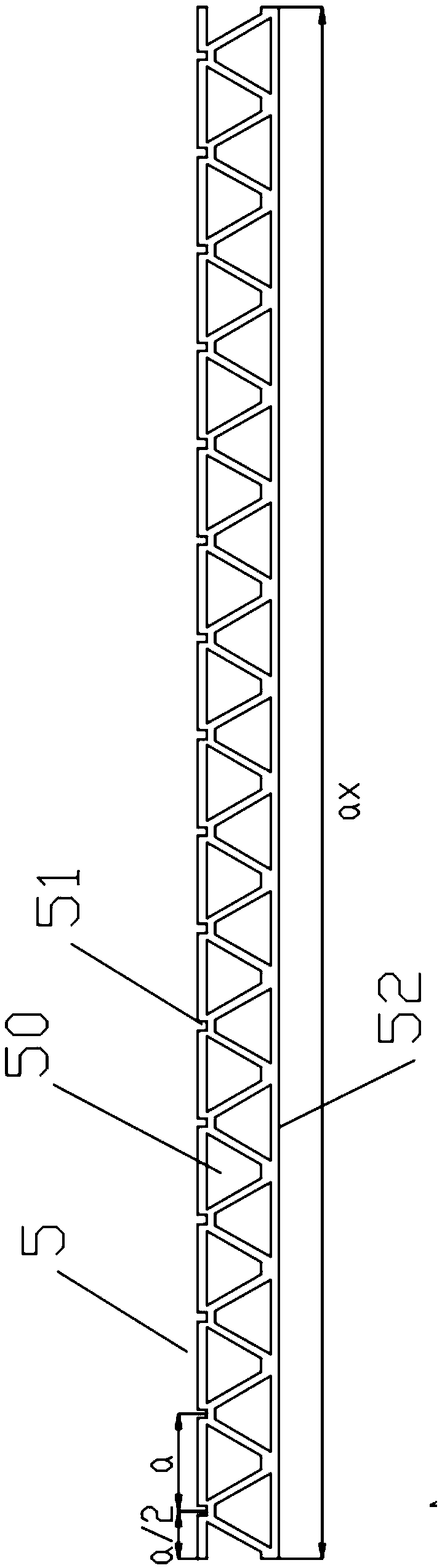

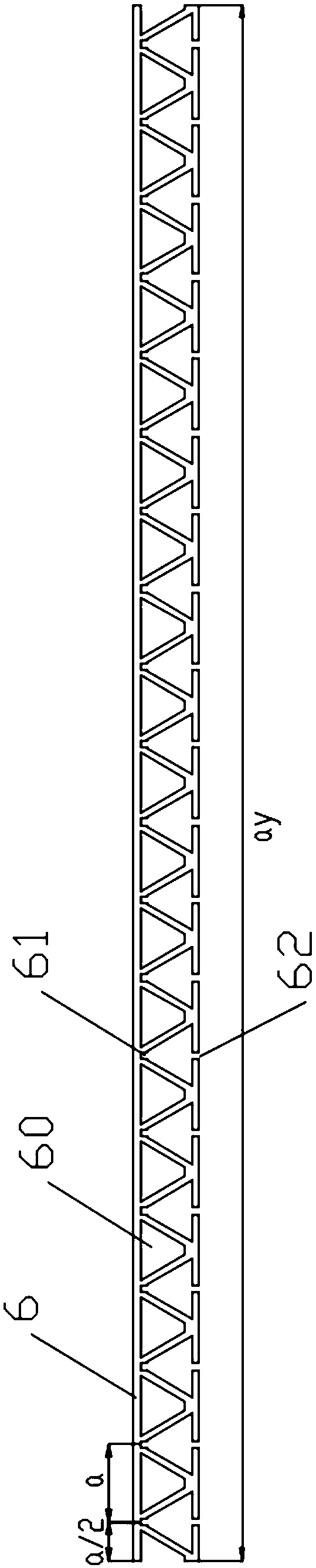

Triangular oblique surface type splash-proof denoising device

PendingCN104634156AHigh lateral compressive strengthEliminate slipping and handover defectsSound producing devicesTrickle coolersCompression moldingCooling tower

Disclosed is a triangular oblique surface type splash-proof denoising device. A partition board and a triangular corrugated plate are arranged in a spaced mode, triangular water cavities are evenly distributed between the partition board and the triangular corrugated plate, the inclination angle between the mass axis of each triangular water cavity and the horizontal plane is 45-75 degrees, and pattern drafts exist at the two ends of each triangular water cavity, so that bidirectional core pulling compression molding is facilitated. The design of the triangular water cavities enables lateral compressive strength to be improved, and denoising during water drop falling is facilitated. Compared with the prior art, the device has the advantages that lateral compressive strength is high, deformation is avoided in use, the splash-proof effect is unchanged, and noise can be reduced by 12-13 decibels. Compared with the sheet type partition board and triangular corrugated plate bonding scheme, the device has the advantages that manufacturing efficiency is improved by 35 times, product quality is stable, reliability is high, the device can be installed and detached conveniently in a cooling tower, installation is stable and reliable, and sliding and falling of a repeatedly bent type stacked splash-proof denoising device during installation and use are avoided.

Owner:常州金坛塑料厂

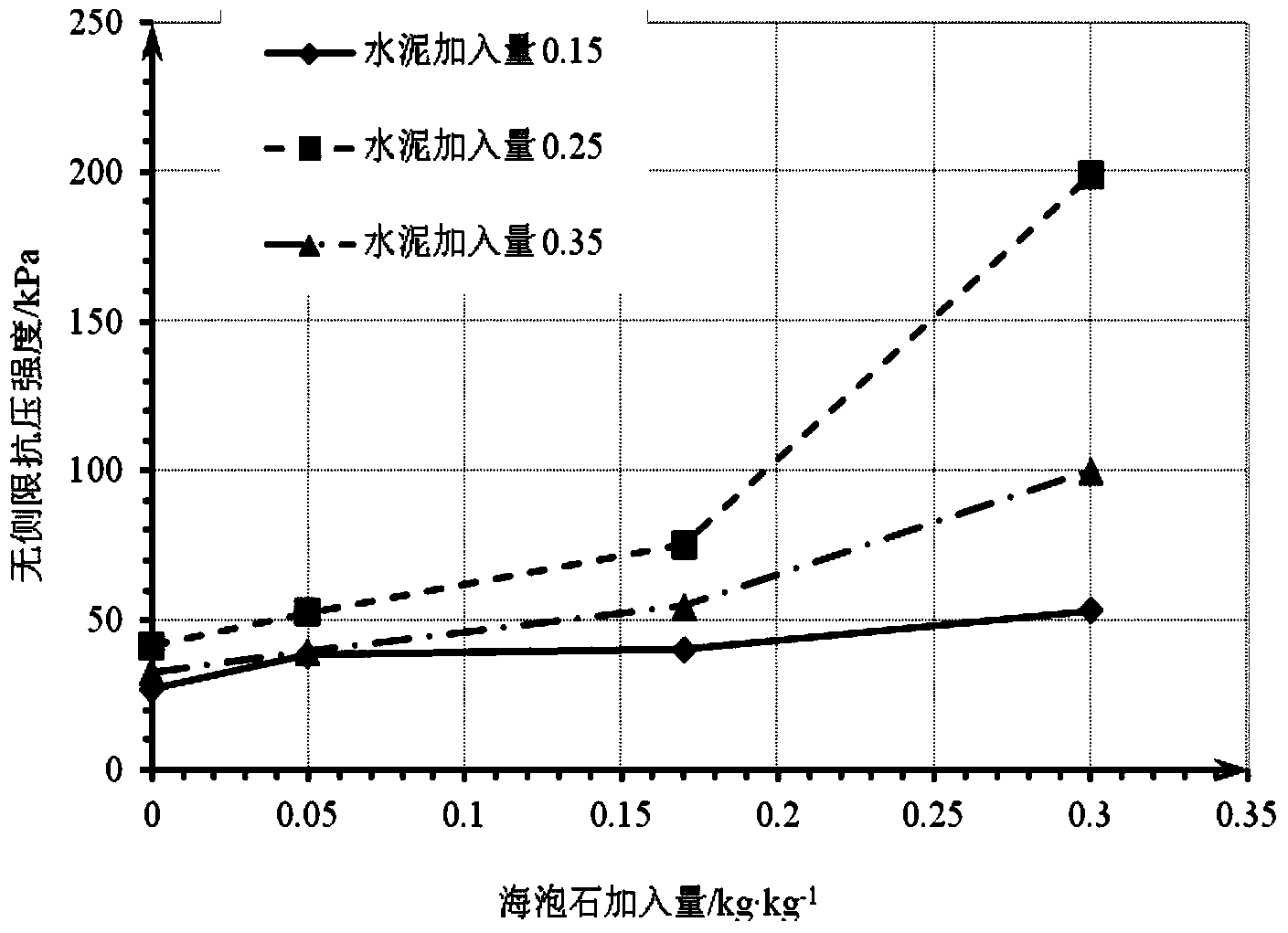

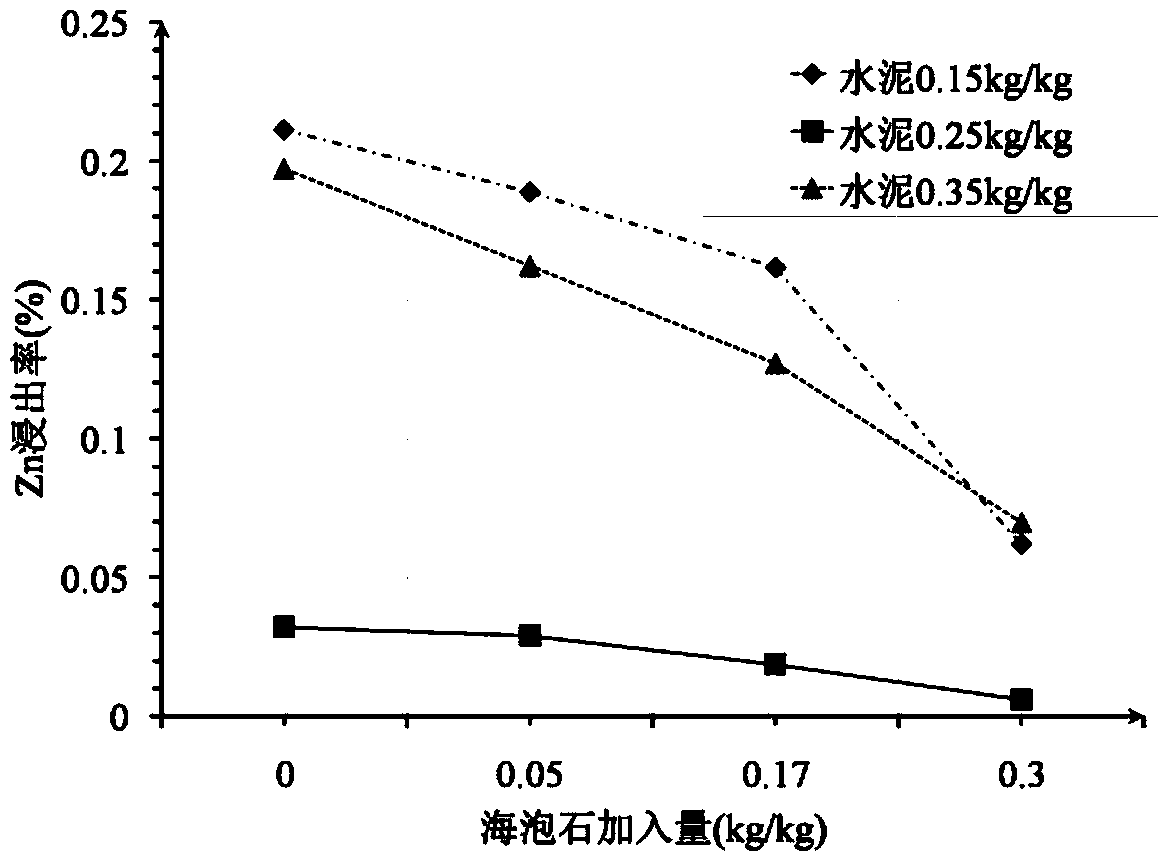

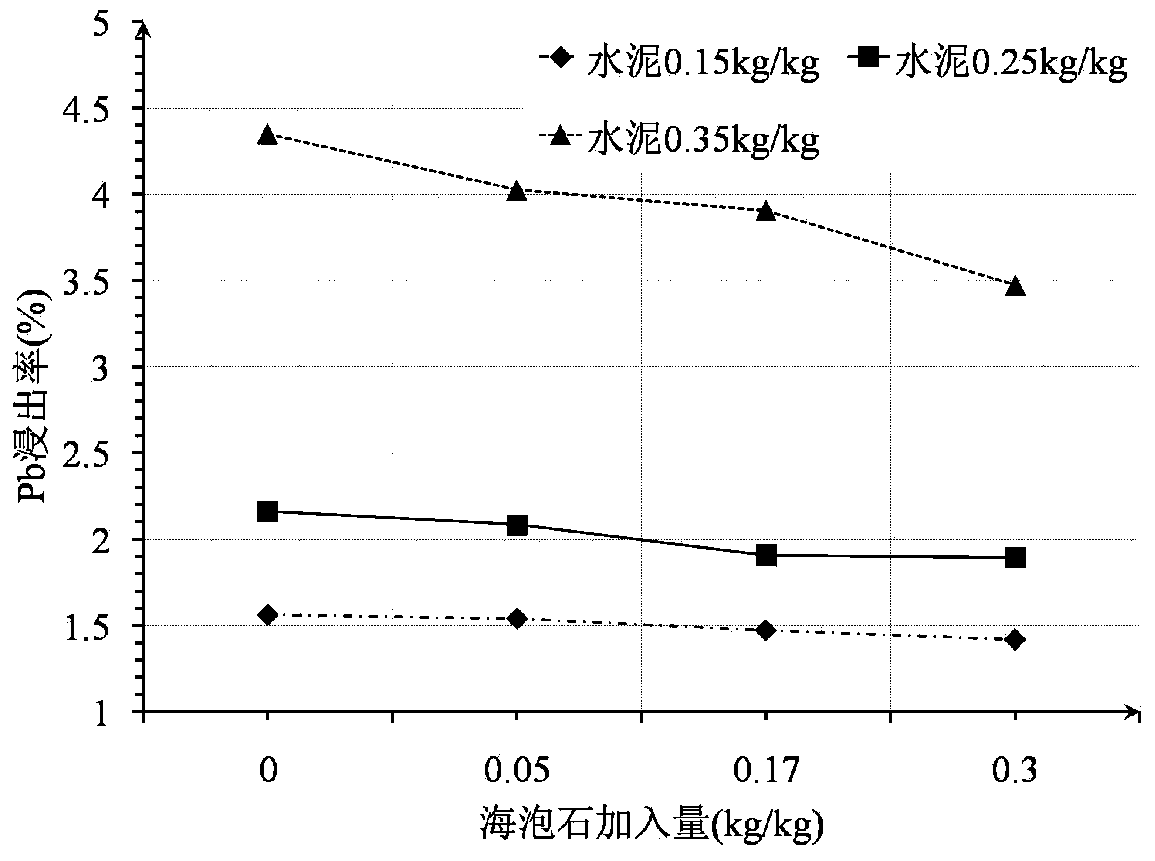

Method for solidifying and stabilizing sludge

InactiveCN103449692AEnhanced lateral compressive strengthLow leaching rateSludge treatment by de-watering/drying/thickeningLeaching rateSepiolite

The invention relates to a method for solidifying and stabilizing sludge. The ratio of the added amount of cement to the mass of sludge is 0.25, and the ratio of the added amount of sepiolite to the mass of sludge is 0.05-0.30; the sepiolite, cement and sludge are mixed and stirred uniformly and conserved for 28 days. According to the method, sepiolite is used as an additive which is uniformly mixed with residual sludge and cement after mechanical dehydration at certain proportion so as to solidify and stabilize the sludge. Experiments indicate that after adding the sepiolite and conserving the sludge solidified body based on cement solidification for 28 days, the no-lateral confinement compressive strength is greater than or equal to 50-100kPa, the lateral pressure resistance is greatly enhanced, the leaching rate of harmful substances in the sludge is greatly reduced, the sludge solidifying and stabilizing cost is greatly lowered, and the capacity increasing ratio is greatly reduced.

Owner:HUNAN UNIV

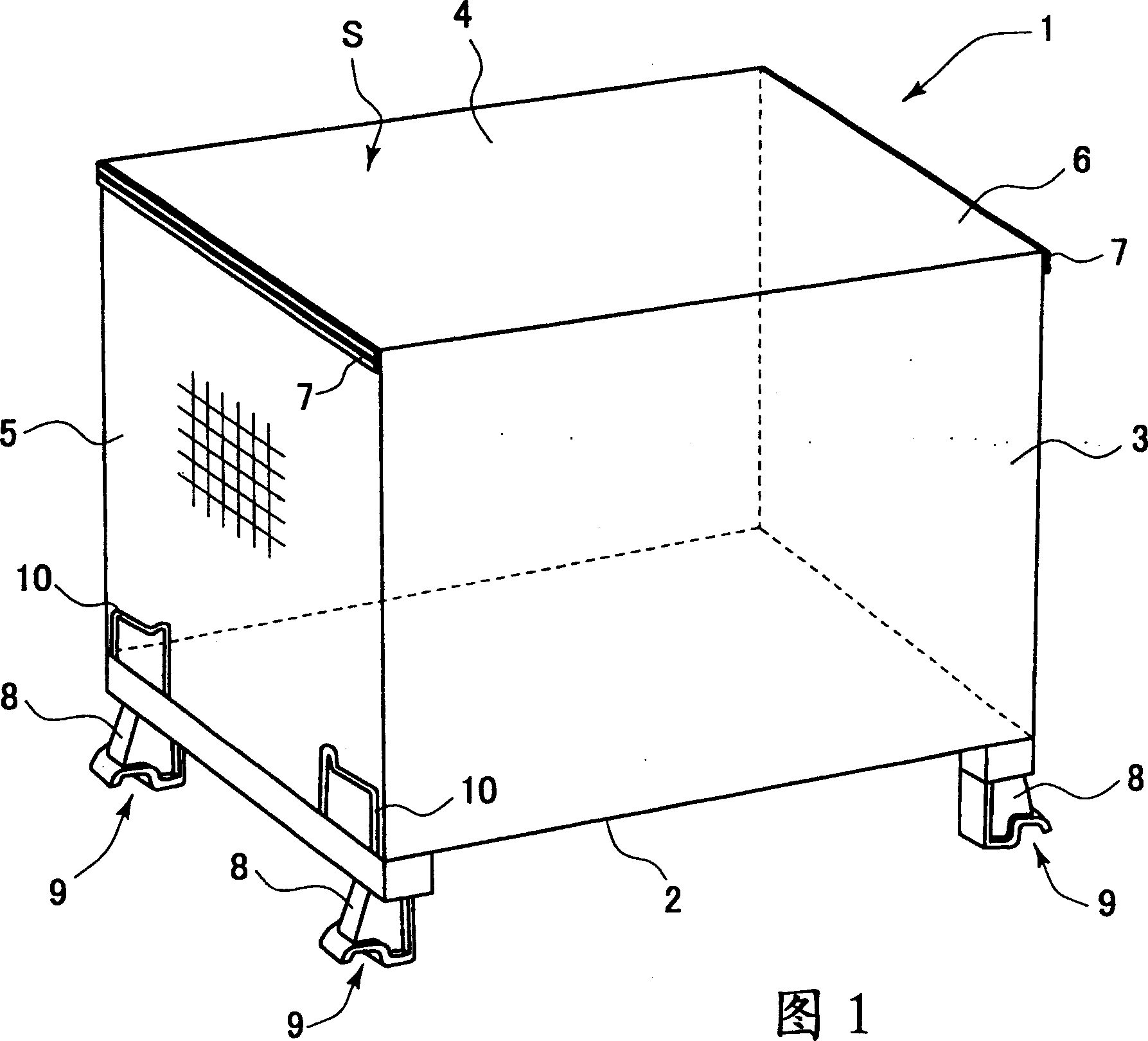

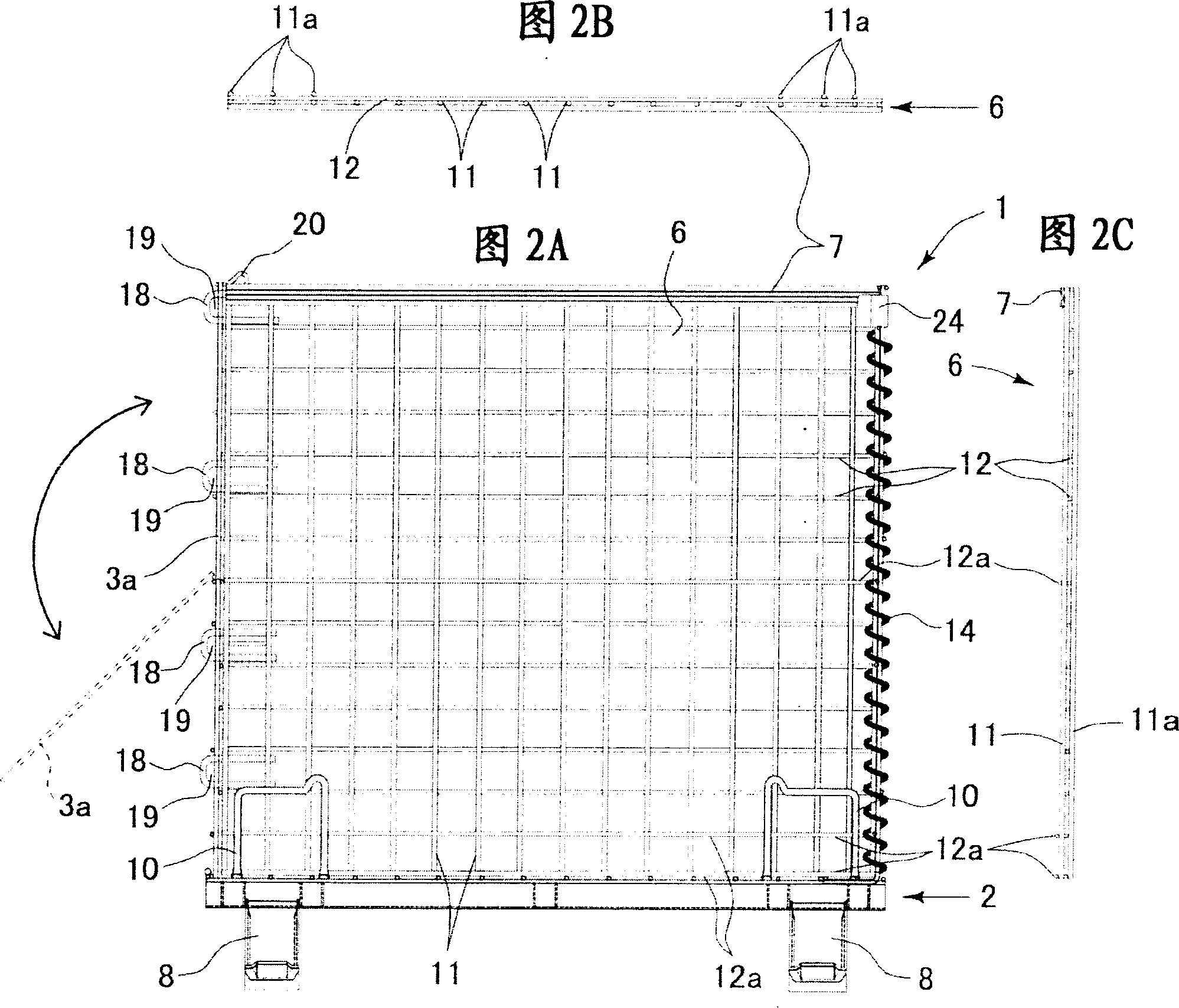

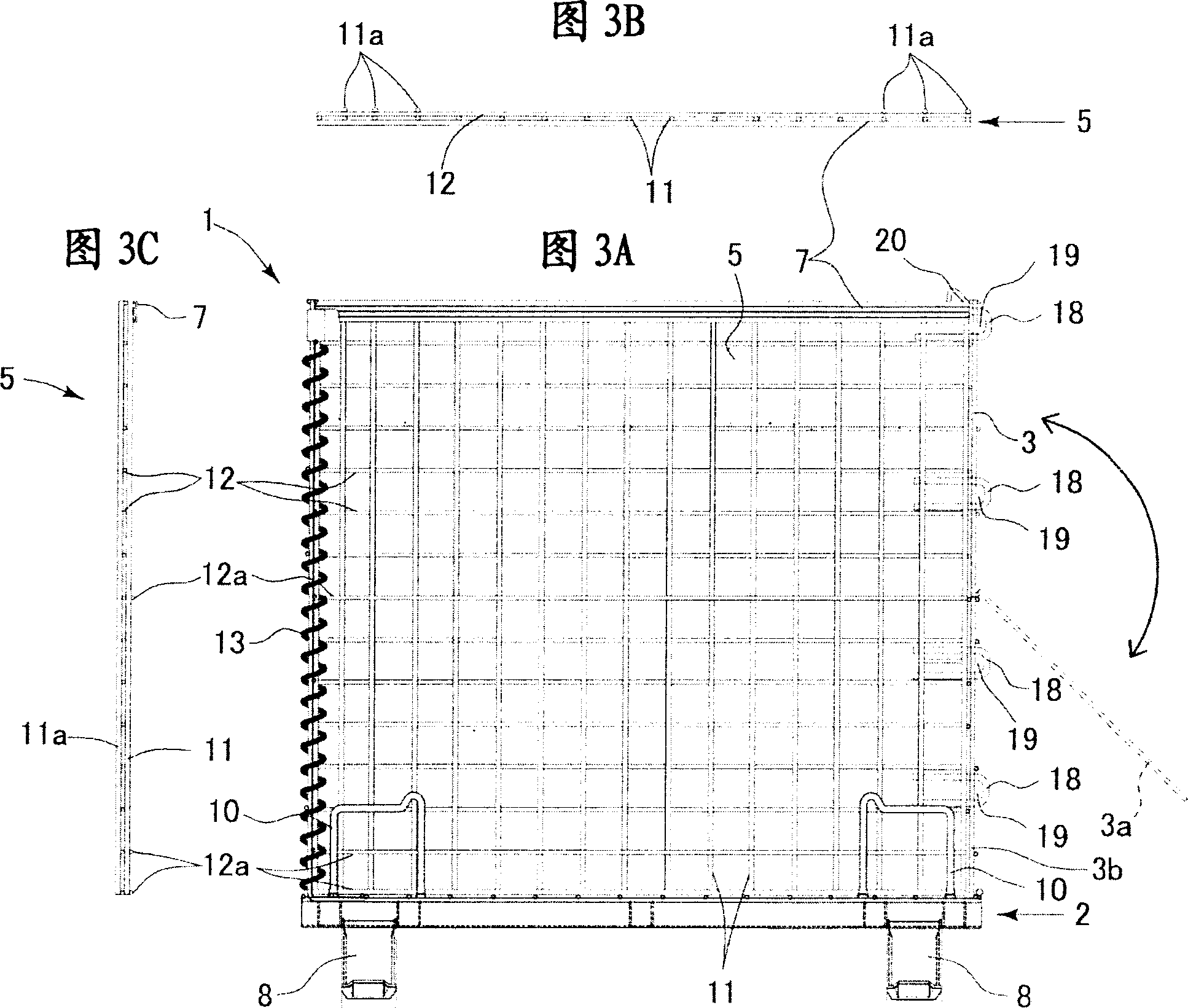

Article storage apparatus

InactiveCN1810587AIncrease the number ofReduce weightRigid containersUltimate tensile strengthMechanical engineering

Owner:MAKITECH

Catalyst for preparing maleic anhydride from n-butane through oxidation and preparation method thereof

ActiveCN107866248AHigh lateral compressive strengthReduce wear rateOrganic compound preparationCatalyst activation/preparationUltimate tensile strengthButane

The invention relates to a catalyst for preparing maleic anhydride from n-butane through oxidation. The catalyst mainly overcomes the problem of low catalytic activity in the prior art. According to the invention, three elements consisting of vanadium, phosphorus and oxygen are used as the main body of the catalyst, and a certain amount of a metal additive is cooperatively used. The catalyst comprises, by weight, 22 to 35% of elemental vanadium, 12 to 22% of elemental phosphorus, 35 to 55% of elemental oxygen and 0.01 to 8% of the metal additive. The catalyst is subjected to constant-temperature constant-humidity treatment, doping of a pore forming agent and secondary molding, so the catalysis performance and strength of the catalyst are improved, and the catalyst is applicable to the field of preparation of maleic anhydride from n-butane through oxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation technology for the catalyst of high temperature catalytic decomposition of N2O

ActiveCN106391037BGood dispersionImprove heat resistanceNitrous oxide captureDispersed particle separationCerium nitrateAluminium hydroxide

Owner:四川蜀泰化工科技有限公司

Honeycomb stabilization method for forming large-thickness large-size honeycomb sandwich structure

The invention belongs to the technical field of aviation composite material manufacturing, and discloses a honeycomb stabilization method for forming a large-thickness and large-size honeycomb sandwich structure, for a large-thickness honeycomb, when a local stabilization process is adopted, the lateral pressure resistance of the large-thickness honeycomb is enhanced, the overall rigidity is reduced, the stabilized honeycomb keeps certain deformation capacity, and the stability of the large-thickness honeycomb is improved. When a large-thickness honeycomb sandwich structure is formed, the deviation between a honeycomb and a theoretical molded surface of the honeycomb is reduced through honeycomb deformation, so that enough forming pressure is applied to a mold surface skin of the honeycomb sandwich structure. The method solves the problems that the rigidity of a large-thickness and large-size honeycomb is increased after the side pressure resistance of the large-thickness and large-size honeycomb is increased, the edge of the formed honeycomb sandwich structure is whitened due to edge upwarp, namely the porosity is increased due to insufficient pressurization of the film pasting surface of the area, the preparation process level of the large-thickness and large-size honeycomb sandwich structure is improved, and a large practical application value is achieved.

Owner:THE RES INST FOR SPECIAL STRUCTURES OF AERONAUTICAL COMPOSITE AVIC

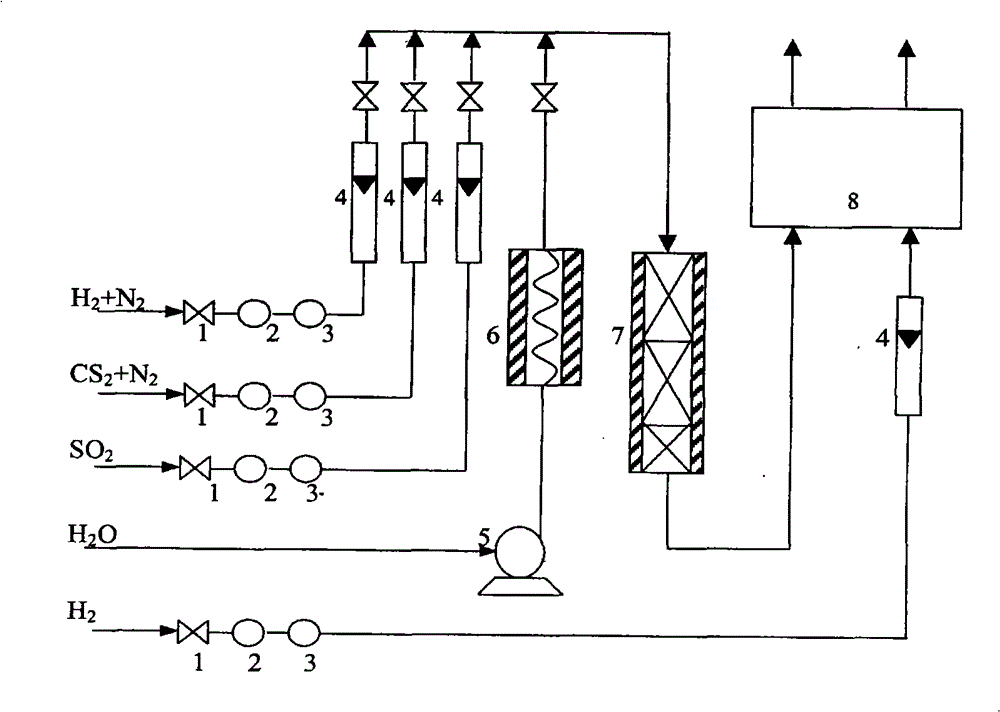

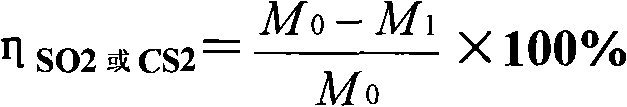

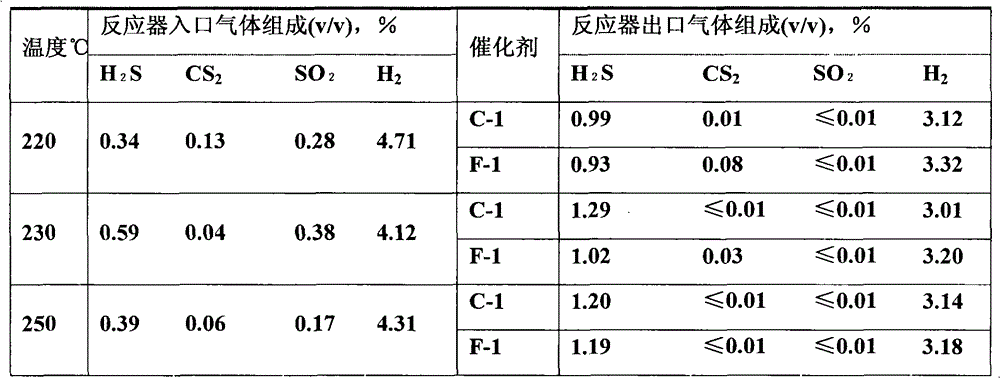

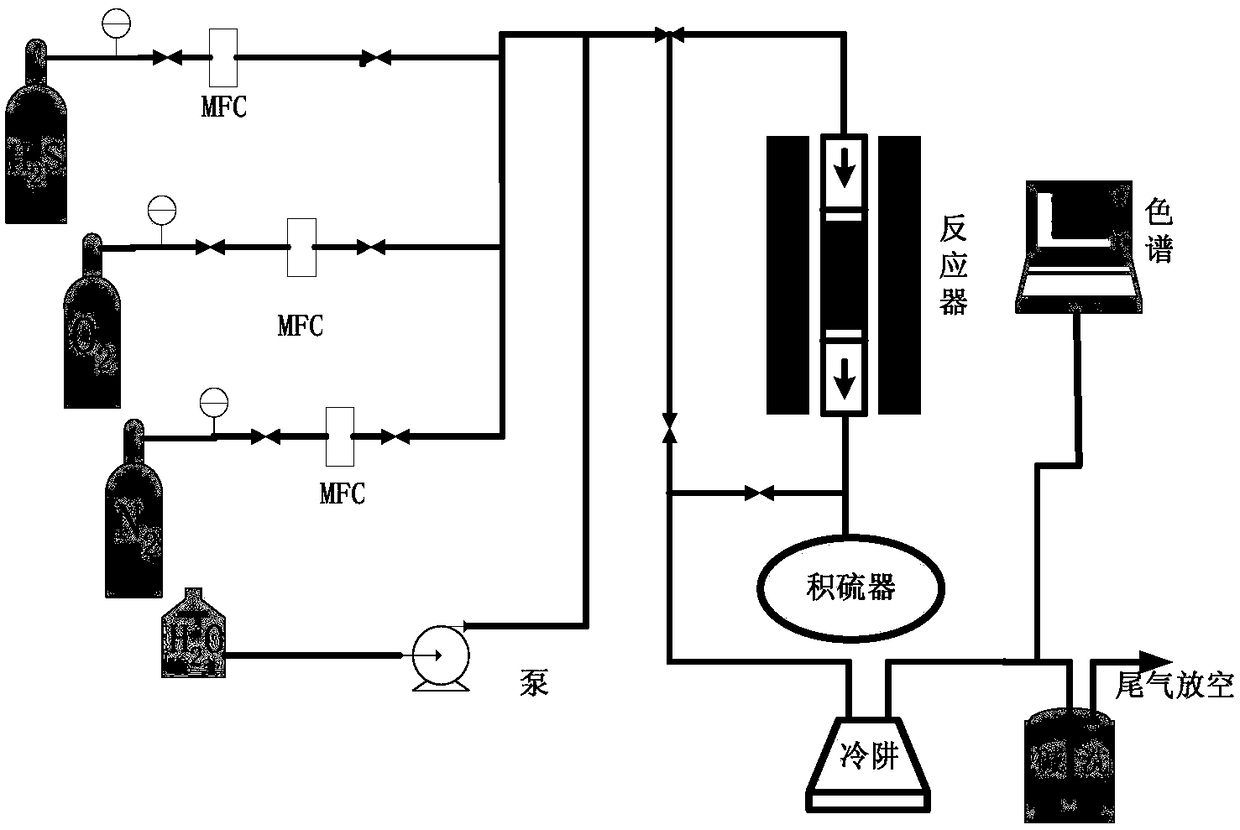

Low-temperature Claus tail-gas hydrogenation catalyst and preparation method thereof

ActiveCN101879451BReduce resistanceReduce wearDispersed particle separationCatalyst activation/preparationCobaltHydrolysis

The invention relates to a Claus tail-gas hydrogenation catalyst and a preparation method thereof. The Claus tail-gas hydrogenation catalyst is mainly characterized in that a carrier of the catalyst is made of silicon modified titanium and aluminum composite dry glue, a cementing agent, a chambering agent and an auxiliary agent, wherein the auxiliary agent is one or more of zinc oxide, iron oxide, magnesium oxide or salts thereof; and an active component is a ternary active component consisting of molybdenum or tungsten and cobalt as well as nickel. The Claus tail-gas hydrogenation catalyst is prepared by adopting an immersion method preparation process. The catalyst has the characteristics of no pollution in the preparation process, low temperature SO2 hydrogenation activity, hydrogenolysis activity of organic sulfurs of CS2, COS and the like and good hydrolysis activity, can be used in a Claus tail gas hydrogenation process, and has remarkable energy-saving and consumption-reducing effects because the use temperature of the Claus tail-gas hydrogenation catalyst is lower than over 60 DEG C as comparison with the common Claus tail-gas hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP

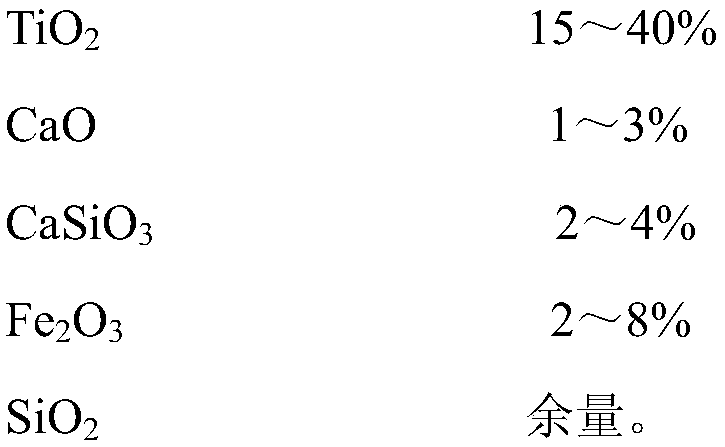

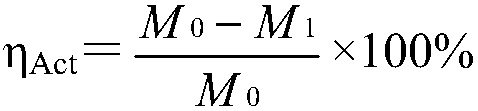

Hydrogen sulfide selective oxidation catalyst and preparation method thereof

ActiveCN109382105APore structure is suitableAvoid Claus Reverse ReactionHeterogenous catalyst chemical elementsSulfur preparation/purificationCalcium silicateWater vapor

The invention belongs to the technical field of sulfur recovery, and particularly relates to a hydrogen sulfide selective oxidation catalyst and a preparation method thereof, wherein the raw materialsof the carrier comprise metatitanic acid, silica powder and calcium silicate, iron oxide and calcium oxide are used as active components, and the silica powder is fumed silica powder having a specific surface area of 40-60 m<2> / g. According to the present invention, by using the carrier of the invention, the catalyst can have a suitable pore structure, the Claus reverse reaction of the catalyst at the selective oxidation stage can be avoided, and the sensitivity of the catalyst to water vapor and the oxygen content can be reduced; the catalyst has characteristics of high activity, insensitivity to water vapor and oxygen content in the process gas, high side pressure and high H2S conversion rate; and by using the catalyst, the hydrogen sulfide conversion rate can reach more than 95%, the sulfur yield can reach more than 90%, and the side pressure strength can reach more than 120 N / cm so as to improve the sulfur recovery rate of the sulfur recovery device and achieve the significant economic and social benefits.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of aluminum oxide carrier

ActiveCN106669852AImprove performanceImprove desulfurizationCatalyst carriersEnergy based chemical/physical/physico-chemical processesAluminateIonic liquid

The invention discloses a preparation method of an aluminum oxide carrier. The method comprises the following steps: (1) bottom water is added into a pressure zone and a reaction zone of a reactor, ionic liquid I is added, and gelling temperature is adjusted; (2) an aqueous solution of alkaline aluminate is added into the reactor, at the same time CO2 enters the reaction zone from the lower part of the reaction zone, CO2 and the aqueous solution of alkaline aluminate are neutralized for carrying out a sol forming reaction, when water in the pressure zone enters the reaction zone through a semi-permeable membrane, the sol concentration is kept in a concentration range, and the reaction is continuously carried out; (3) after the reaction ends, ultrasonic vibration at the bottom is started, and after aging, washing and drying are carried out, pseudo-boehmite is obtained. (4) mixing and kneading, moulding, drying and calcination of the pseudo-boehmite prepared in the step (3), an adhesive and ionic liquid II are carried out, and the aluminum oxide carrier is obtained. The aluminum oxide carrier has the advantages of high specific surface area, large aperture and pore volume, high lateral compressive strength, and low abrasion; and the product is adapted to be the carrier of boiling bed wax oil, residual oil hydrogenation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Road roadbed structure

ActiveCN110130169AHigh lateral compressive strengthHigh bonding strengthRoadwaysClimate change adaptationSurface layerRoad engineering

The invention relates to a road roadbed structure, and relates to the technical field of road engineering. A first lime-soil layer is laid on a foundation, a second lime-soil layer is laid on the first lime-soil layer, a gravel stabilization layer is laid on the second lime-soil layer, and a surface layer is laid on the gravel stabilization layer; a bearing pile is arranged in the first lime-soillayer in an inserted mode, and the lower end of the bearing pile is arranged in the foundation in an inserted mode after penetrating through the first lime-soil layer; a reinforcing net is arranged between the first lime-soil layer and the second lime-soil layer, and the reinforcing net is arranged on the bearing pile in a sleeving mode; a triangular pipeline is fixedly arranged on the upper surface of the second lime-soil layer, the bottom side of the triangular pipeline abuts against the upper surface of the second lime-soil layer, and a water seepage hole is formed in the side edge of the triangular pipeline; and the upper surface of the second lime-soil layer is paved with a leveling layer, and the triangular pipeline is buried in the leveling layer. According to the road roadbed structure, the bearing pile is arranged so that the connection strength between the first lime-soil layer and the foundation is strengthened, the lateral load-resisting strength of a roadbed is strengthened; and the reinforcing net is arranged, so that the connection strength between the lime-soil layers is strengthened, and layering is avoided.

Owner:YANGTZE UNIVERSITY

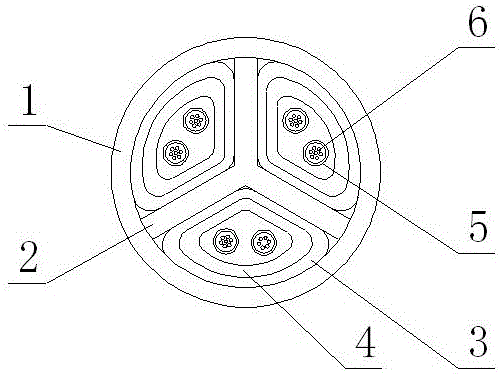

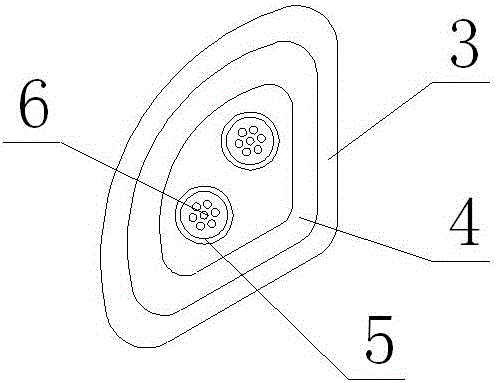

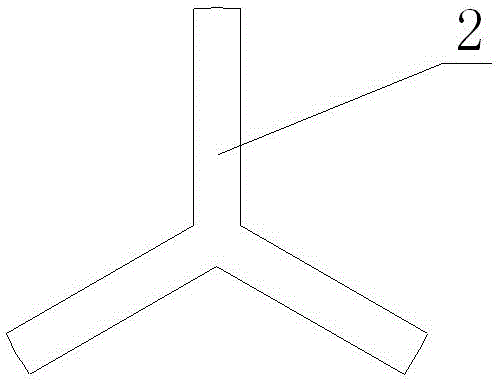

High mechanical strength optical cable

PendingCN106125227AAvoid entanglementConvenient branchFibre mechanical structuresBiomedical engineeringFiber

The invention discloses a high mechanical strength optical cable which comprises an outer sheath (1), an inner support member arranged in the outer sheath (1), an inner sheath (4) arranged between the outer sheath (1) and the support member, a plurality of fiber protection casings (5) arranged in the inner sheath (4), and fibers arranged in the fiber protection casings (5). The outer side of the inner sheath (4) is provided with an armored layer. The high mechanical strength optical cable has the advantages that through arranging the support member in the outer sheath, the sheath is divided with multiple areas to facilitate the installation of multiple groups of cables, thus the cable is easy to be branched, a role of support can be played, the anti-pressing and anti-bending ability of the cable are improved, the mechanical strength of the cable is raised, through arranging the armored layer, the prevention of the deformation of the inner sheath to press the fibers is facilitated, thus the effect of protecting the fibers is achieved, and the anti-pressing ability of the cable can be improved.

Owner:成都威迪斯达科技有限公司

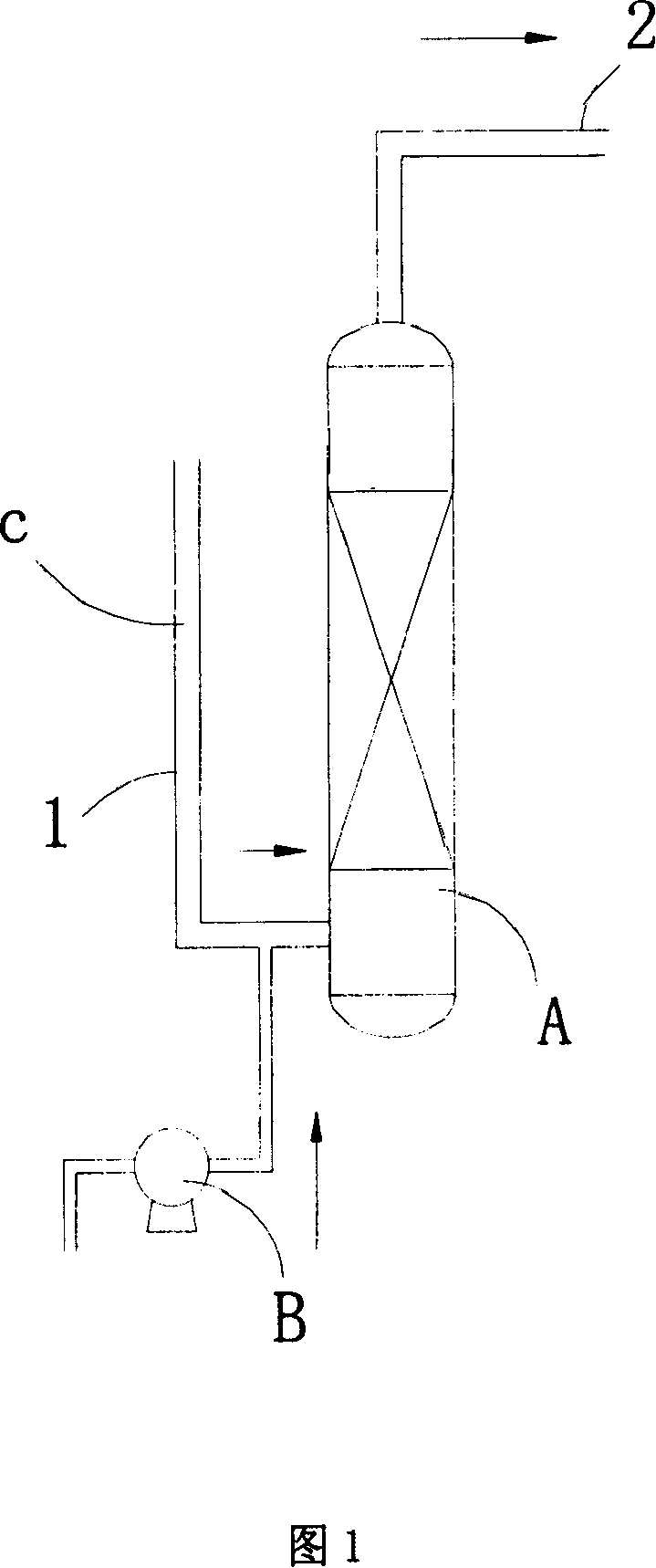

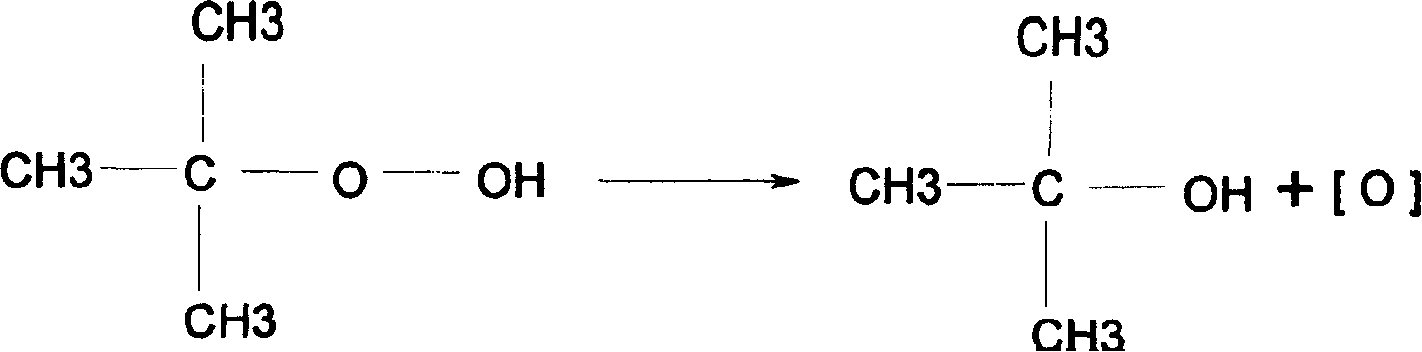

Method for supplying oxygen to hydrocarbon oil

InactiveCN100352894CSimple processEasy to operateRefining with oxygen compoundsLiquid oxygenActive oxygen

The present invention relates to a method for supplementing oxygen into hydrocarbon oil. Said method is characterized by that in the hydrocarbon oil a liquid oxygen-supplementing agent using tert-butyl hydroperoxide as effective component can be added, and in the flowing process the tert-butyl hydroperoxide in the oxygen-supplementing agent can be dissolved in the hydrocarbon oil, and when the hydrocarbon oil in which the tert-butyl hydroperoxide is dissolved in passed through the catalyst bed layer which is placed in the fixed bed reactor and has catalytic property of decomposing tert-butyl hydroperoxide, under the action of catalyst the tert-butyl hydroperoxide in the hydrocarbon oil can be decomposed, and can release out nascent active oxygen. The active component or said catalyst is compound of manganese.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

A quasi-three-dimensional reinforced composite lattice sandwich structure and its manufacturing method

The invention discloses a quasi-three dimensional enhanced composite dot matrix interlayer structure and a manufacturing method thereof. The dot matrix interlayer structure is composed of orthogonally-woven rectangular fabric cloth or a prepreg strip, a three-dimensional foam core and a panel pavement layer. The designability of the composite structure is ingeniously utilized, and a new quasi-three dimensional weaving structure is designed to serve as a dot matrix core and is simultaneously cured and formed with a panel. On the premise that component materials are the same, compared with existing dot matrix interlayer structures (such as a grid interlayer structure, a honeycomb interlayer structure, a foam interlayer structure and a three-dimensional dot matrix interlayer structure), the interface strength between the panel and the core is greatly improved, the problem that fiber in a conventional dot matrix interlayer structure core pavement layer is not continuous is solved, and therefore the bending strength, the shearing strength, the lateral pressure strength and the like of the interlayer structure are improved, and very important significance is achieved for the development of the composite three-dimensional structure enhancing technology.

Owner:NANJING TECH UNIV

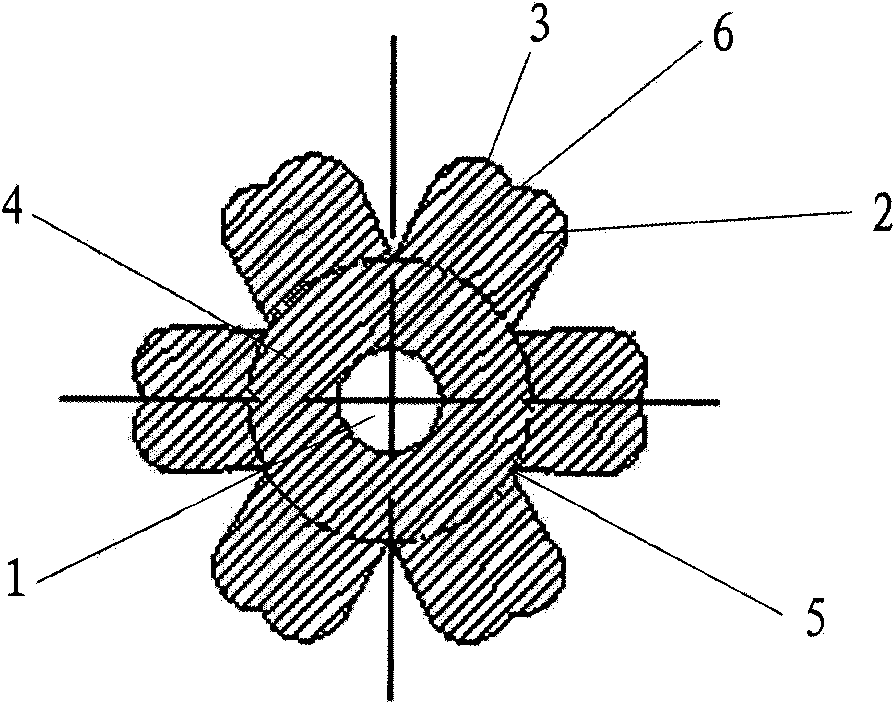

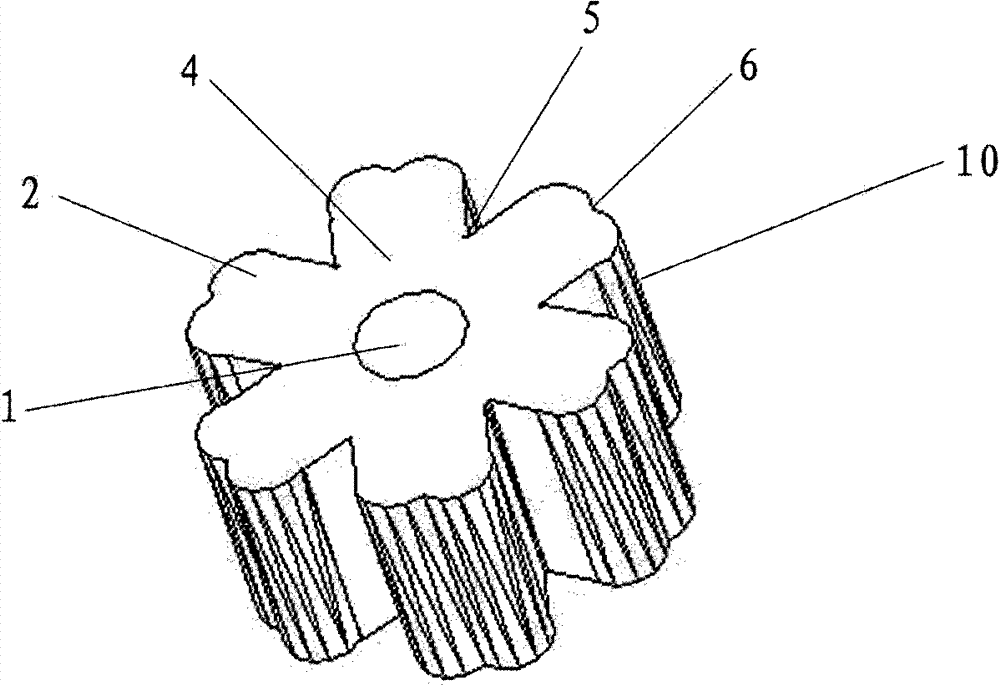

Catalyst carrier

ActiveCN101816953BUniform size designIncrease loading capacityCatalyst carriersSolid structureFixed bed

The invention discloses a catalyst carrier, which belongs to the technical field of the protection and supporting product structure of a fixed bed catalyst which is a solid catalyst product used in industries of oil refining, chemicals, gas processing and the like. The catalyst carrier comprises a central hole, a convex part, a top part, a cylinder, a concave part, a groove and a body, wherein the body comprises the cylinder and at least one convex part arranged around the cylinder, which are formed in one piece; the cylinder has a cylindrical solid structure, and a through central hole is arranged along an axial direction; and the at least convex part has a blade cylinder-shaped, toothed or arch cylinder-shaped solid structure, and the protruding top part of the at least one convex part is provided with at least one groove running through the axial direction. When the technical scheme of the invention is adopted, lateral loading capacity is improved, the intensity of lateral pressureis improved, the voidage of a supporting protective agent is improved, and the pressure drop of the bed of the catalyst is reduced.

Owner:萍乡市中天化工填料有限公司

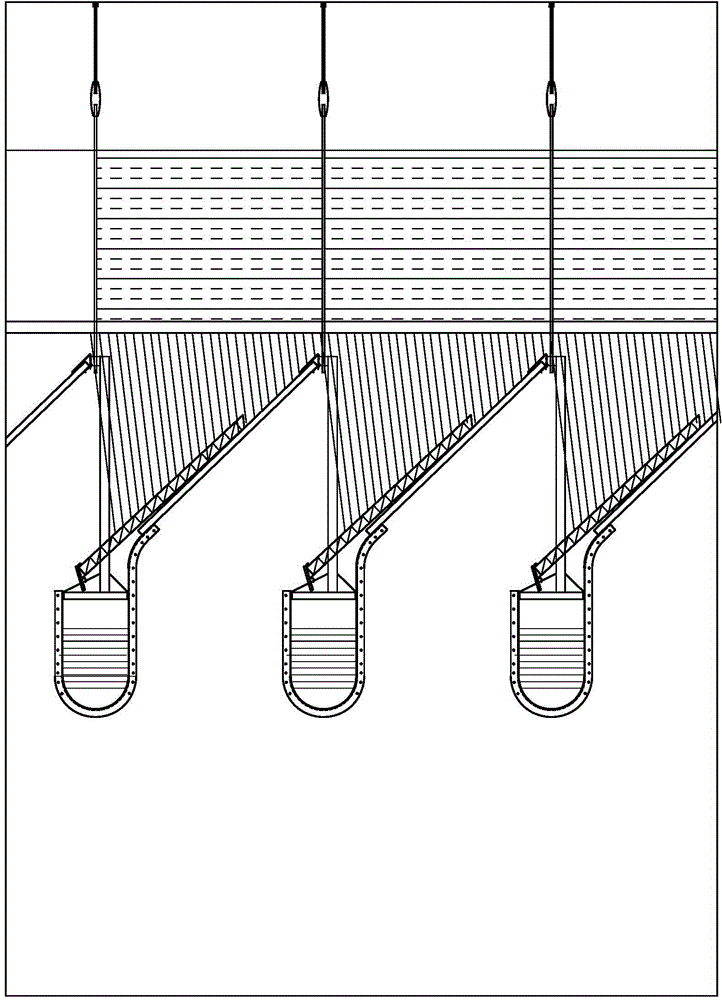

Movable flood-fighting retaining dam

PendingCN114837138ASimple structureSave installation timeBarrages/weirsClimate change adaptationArchitectural engineeringWire rope

The movable flood-fighting retaining dam comprises guide rail protection rods, a guide rail frame, a water baffle, a guide rail support and a steel wire rope, the water baffle is of a V-shaped structure, and the guide rail frame is provided with an insertion opening so that mounting and dismounting can be convenient. The structure is simple, on the basis that flood fighting and water retaining are met, mounting and dismounting are easy and fast, the construction time of the retaining dam is shortened, and life and property losses caused by flood are reduced.

Owner:王飞

Thermal-insulating and fireproof sandwich plate adopting foaming cement as core veneer

InactiveCN108071180AWith thermal insulationWith sound insulationHeat proofingSound proofingFiberSlag

The invention relates to the technical field of research and production of building insulation materials, and discloses a thermal-insulating and fireproof sandwich plate adopting foaming cement as a core veneer. Wood chip fiber is used as a panel, the foaming cement is used as the core veneer, a wood-face foaming cement sandwich plate is formed by pressing adopting a cold pressing preparation technology, and the panel can provide a better protective effect for the foaming cement sandwich plate; the fireproof strength of the foaming cement core veneer is improved, the defects of low strength, easy cracking and slag separation, bad decorating property and the like are solved, and the edgewise compressive strength, the bending strength, the impact toughness and the other mechanical strength of the sandwich plate can be greatly improved; and the advantages of good machining property, inorganic thermal insulation material heat-insulating property, sound insulation property, good flame retardant property and the like can be achieved, and the thermal-insulating and fireproof sandwich plate adopting the foaming cement as the core veneer can be applied to the field of decorative sheets, internal parting walls, fireproof door cores, fireproof wallboard and the like of the industrial and civil constructions.

Owner:ANHUI GUODIAN ENERGY EQUIP ENG

A kind of preparation method of tio2/γ-al2o3 composite carrier material

ActiveCN103706405BLarge specific surface areaLarge hole volumeCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsNickel catalystHydrodesulfurization

The invention relates to a preparation method of a TiO2 / gamma-Al2O3 composite carrier material. The method includes uniformly mixing mesoporous TiO2 crystal whisker and alumina sol, with the weight percent of the mesoporous TiO2 crystal whisker being 2-50 wt% and the weight ratio of dry mixing materials to water being 1:5-20; heating the material mixture to 60-90 DEG C, adding dropwise an inorganic acid to adjust the pH to be 2-3.5 and maintaining for 2-24 h; adding dropwise an alkaline solution to adjust the pH to be 9 to form Ti-Al-H2O composite jelly; ageing for 1-6 h, washing with deionized water to be neutral, filtering and drying in air; and calcining at 500-800 DEG C to obtain the TiO2 / gamma-Al2O3 composite carrier material. The method is simple in operation and low in cost. A molybdenum-nickel catalyst prepared from the carrier has excellent deep hydrodesulfurization performance, and is capable of reducing the sulfur content from 5000 [mu]g / g in inferior diesel oil to below 50 [mu]g / g, thus achieving the Europe IV diesel oil standard.

Owner:PETROCHINA CO LTD

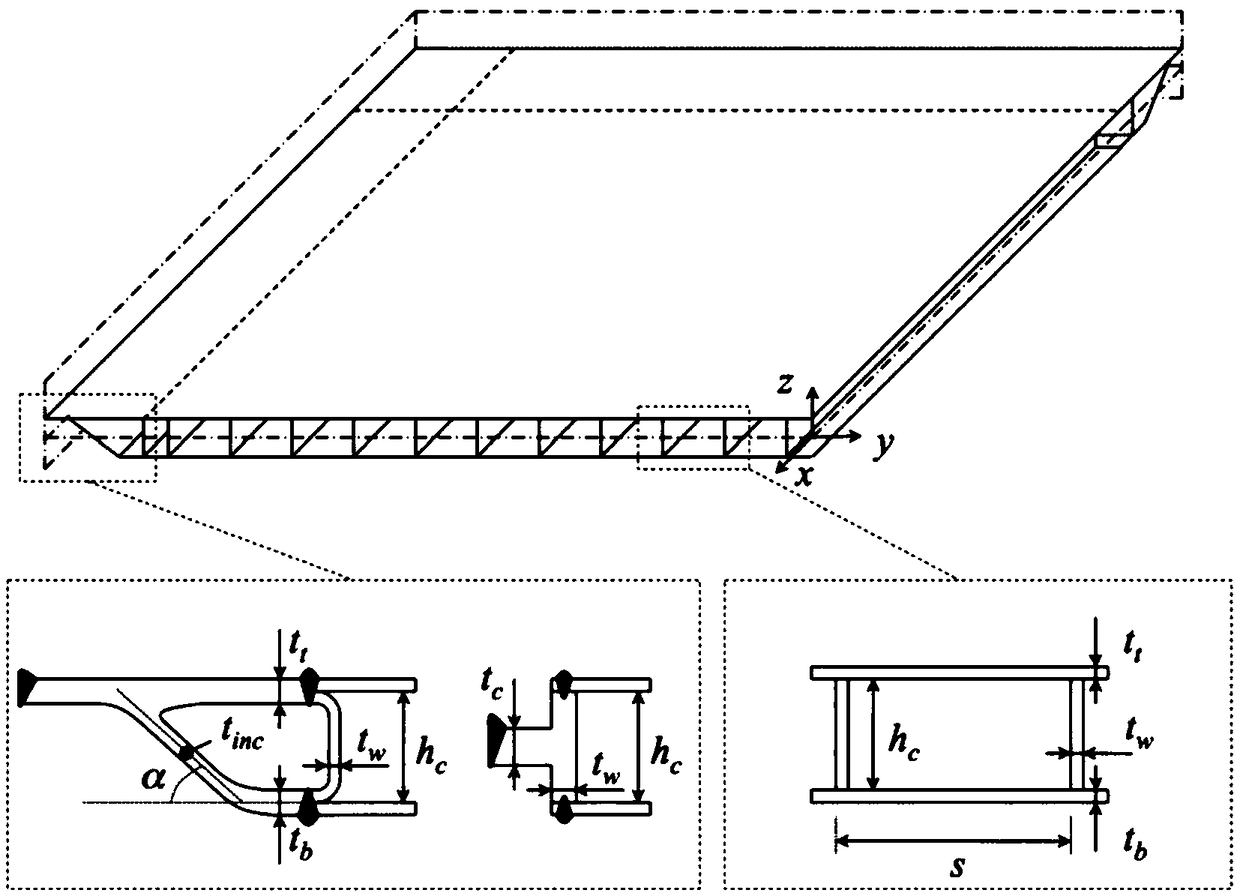

Metal lattice plate and manufacturing method thereof

ActiveCN108943884AImprove shear resistanceAvoid discontinuitiesLaminationLamination apparatusEngineeringMetal lattice

A metal lattice plate is characterized by comprising a lattice plate (1). The lattice plate (1) comprises an upper panel (2) and a lower panel (3), which are integrated by lattice cores (4) comprisinga plurality of vertically arranged warp-wise stringers (6) and horizontally arranged weft-wise stringers (5); and the warp-wise stringers (6) and the weft-wise stringers (5) are clamped and connectedto each other. Compared with a conventional connection mode, the provided metal lattice plate has the advantages that the discontinuity of the core structure in the lattice plate will not appear on asame end face, the anti-shearing performance of the lattice plate in the joints is improved; the joint welds of two lattice plates are all arranged in the cores of two lattice plates, the stability of the connection structure is improved, the core-free weld of a panel is avoided, and the mechanical properties of the lattice plate are improved.

Owner:NANJING UNIV OF TECH

Molding method and application of catalyst

PendingCN114471575AHigh molding strengthHigh lateral compressive strengthHydrocarbon from carbon oxidesCatalyst activation/preparationPtru catalystMolecular adsorption

The invention discloses a forming method and application of a catalyst, and the forming method comprises the following steps: (1) granulating the catalyst to obtain catalyst particles of 0.5-5 mm; (2) crushing and screening the catalyst particles obtained in the step (1) to obtain 30-80-mesh catalyst particles; and (3) mixing the catalyst particles obtained in the step (2) with a binder with a particle size of 30-80 meshes, and carrying out tabletting molding to obtain the molded catalyst, the catalyst comprises an active component; the active component comprises an iron element. According to the invention, the binder and the active component of the catalyst form strong interaction, the raw material molecule adsorption and catalysis process in the specific reaction process of carbon dioxide hydrogenation is enhanced, the reaction efficiency is greatly improved, and the stability of the strength and performance of the catalyst particles under the long-time high-temperature reaction condition is ensured.

Owner:珠海市福沺能源科技有限公司 +1

A kind of hydrogenation catalyst and preparation method thereof

ActiveCN112742425BImprove mechanical propertiesHigh lateral compressive strengthCatalyst activation/preparationBulk chemical productionPtru catalystFluidized bed

The invention discloses a hydrogenation catalyst and a preparation method thereof. The catalyst preparation method first prepares a wet filter cake material, then mixes it with an industrial pseudo-boehmite raw material, adds an extrusion aid and kneads it, and then it is dried and roasted to obtain hydrogenation Catalyst carrier; after further supporting active metal components, drying and calcining to obtain a hydrogenation catalyst. The hydrogenation catalyst prepared by the method of the invention has good mechanical properties, high strength and good wear resistance, and is especially suitable for the fluidized bed hydrogenation process. The preparation method of the hydrogenation catalyst has simple process and low energy consumption, and is suitable for large-scale production of the fluidized bed catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Concrete construction method for cast-in-place section of prefabricated concrete structure

ActiveCN103422674BHigh lateral compressive strengthAvoid crackingBuilding material handlingSteel barEngineering

The invention relates to construction methods of assembling-type concrete structures, in particular to a cast-in-place section concrete construction method of an assembling-type concrete structure. The cast-in-place section concrete construction method comprises the steps that when an outer wall body is prefabricated, embedded parts and steel bar meshes are buried and additionally arranged inside an outer wall protective layer of a cast-in-place section correspondingly; a cast-in-place section formwork is connected to the inner side of a wall body structural layer through mutual-pulling screws and buckling pieces, wherein one end of each mutual-pulling screw is connected with a sleeve and the other end of each mutual-pulling screw penetrates out through a reserved hole in the cast-in-place section formwork, and the mutual-pulling screws are sleeved with PVC casing pipes. Cast-in-place section concrete is poured in grouting holes reserved inside the wall body structural layer. After the cast-in-place concrete reaches designed strength, the buckling pieces can be loosened, the cast-in-place section formwork can be disassembled, the mutual-pulling screws are rotated to enable the mutual-pulling screws to be separated from the sleeves, and then the mutual-pulling screws are drawn out from the PVC casing pipes. The cast-in-place section concrete construction method of the assembling-type concrete structure solves the problems that the surface of a warm-keeping protection layer cracks and deforms due to the through-wall screws and water seepage occurs in an outer wall, reduces the workload of outer wall face repairmen, and improves the pouring efficiency of the cast-in-place section concrete.

Owner:CHINA 22MCC GROUP CORP

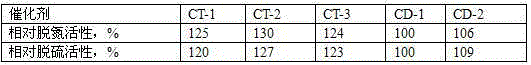

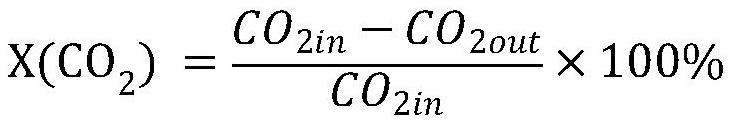

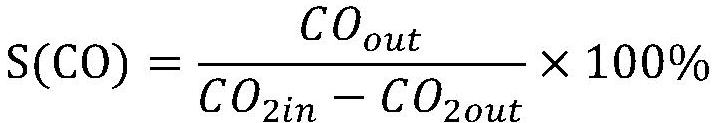

Catalyst for high temperature catalytic decomposition of N2O and preparation method thereof

ActiveCN103949264BUniform appearanceHigh lateral compressive strengthNitrous oxide captureDispersed particle separationAdditive ingredientCerium

The invention discloses a catalyst for performing high-temperature catalytic decomposition of N2O and a preparation method of the catalyst and belongs to the technical field of environment-friendly catalytic materials and atmospheric pollution treatment. The catalyst for performing high-temperature catalytic decomposition of N2O is prepared by taking a solid solution containing titanium, magnesium, zirconium and cerium as a carrier, taking transition metal oxides supported by the carrier as active components of the catalyst, and adding a suitable quantity of accessory ingredients, wherein the transition metal oxides account for 1-15% of the total mass of the catalyst; the accessory ingredients account for 1-5% of the total mass of the catalyst; the accessory ingredients are selected from one or several of scandium oxide, ferric oxide, sodium oxide, chromic oxide, yttrium oxide and rare earth oxide. Compared with the foreign mainstream products, the catalyst for performing high-temperature catalytic decomposition of N2O is uniform in appearance, high in edgewise compressive strength, large in specific surface area and low in shrinking ratio. The activity detection shows that the activity of the catalyst of our company is equivalent to the activities of the foreign mainstream products at the temperature of about 860 DEG C; the catalyst disclosed by the invention is excellent in activity at high and low temperatures, wide in temperature zones of activity and excellent in high-temperature activity stability.

Owner:四川蜀泰化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com