Catalyst carrier

A catalyst support and integrated technology, which is applied in the direction of catalyst support, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems affecting the use efficiency of catalysts and devices, large bed resistance, low lateral pressure strength, etc., to reduce Effects of pressure drop, increased load capacity, and increased lateral pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in detail as follows:

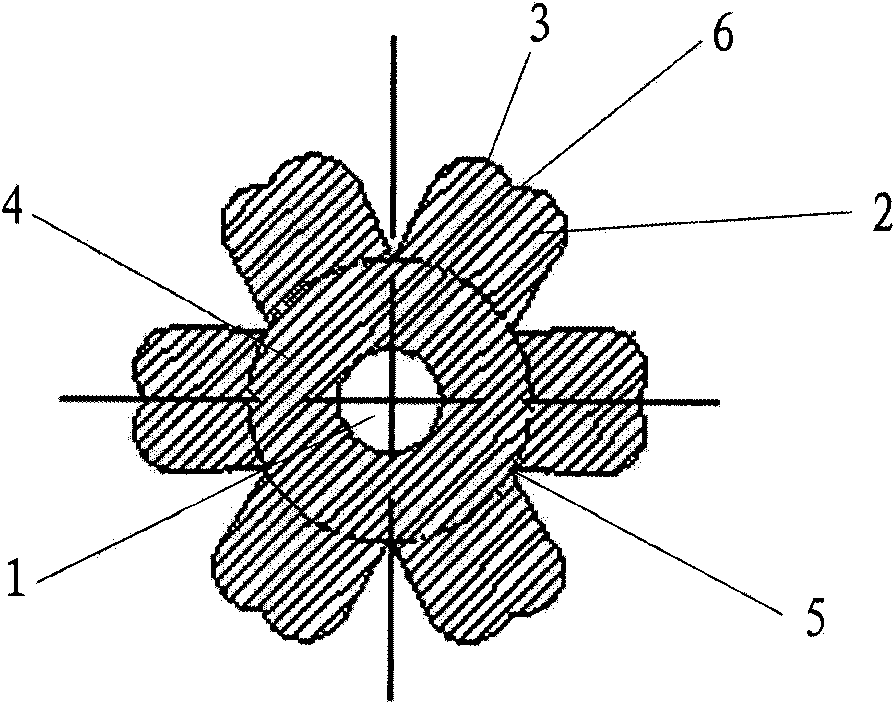

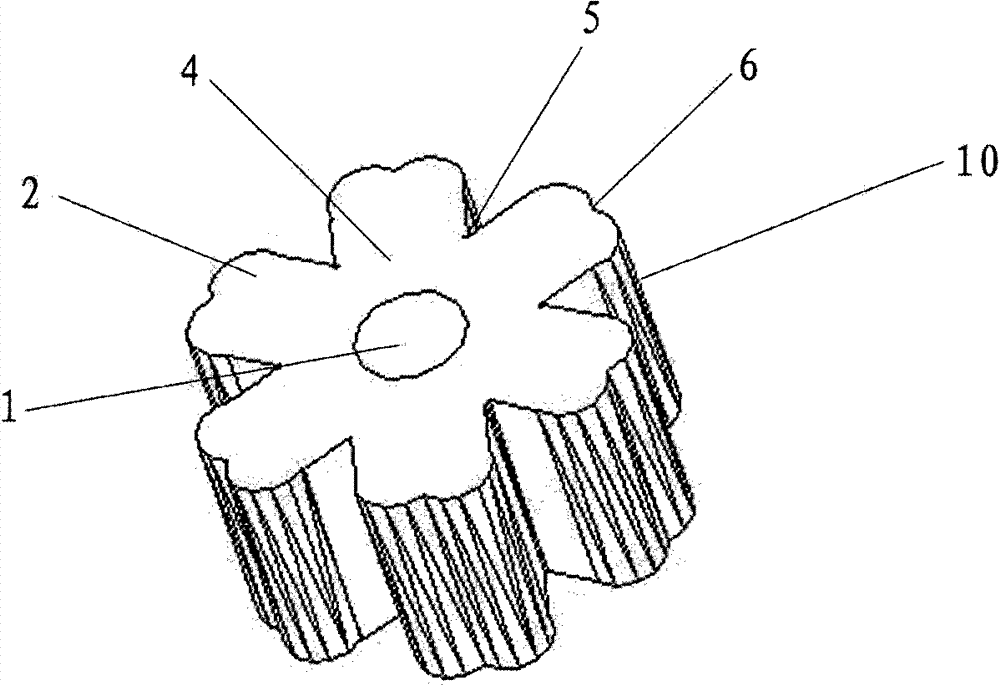

[0020] figure 1 , figure 2 It is a schematic view of the end face structure and a schematic view of the three-dimensional structure of the present invention. Such as figure 1 , figure 2 A catalyst carrier of the present invention is shown, comprising: a central hole 1 , a raised portion 2 , a top 3 , a column 4 , a concave portion 5 , a groove 6 and a body 10 . The body 10 is integrally formed by a cylinder 4 and at least one protrusion 2 arranged around it; the cylinder 4 is a cylindrical solid structure, and a through-hole center hole 1 is arranged in the axial direction, and the center hole 1 is best The diameter is 7 mm; at least one protruding part 2 is a leaf-column, tooth-shaped or arc-column-shaped solid structure, and two adjacent protruding parts 2 are connected to form a V-shaped concave part 5; the at least one protruding part 2 protrudes At leas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com