Patents

Literature

94results about How to "Reduce total pressure drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

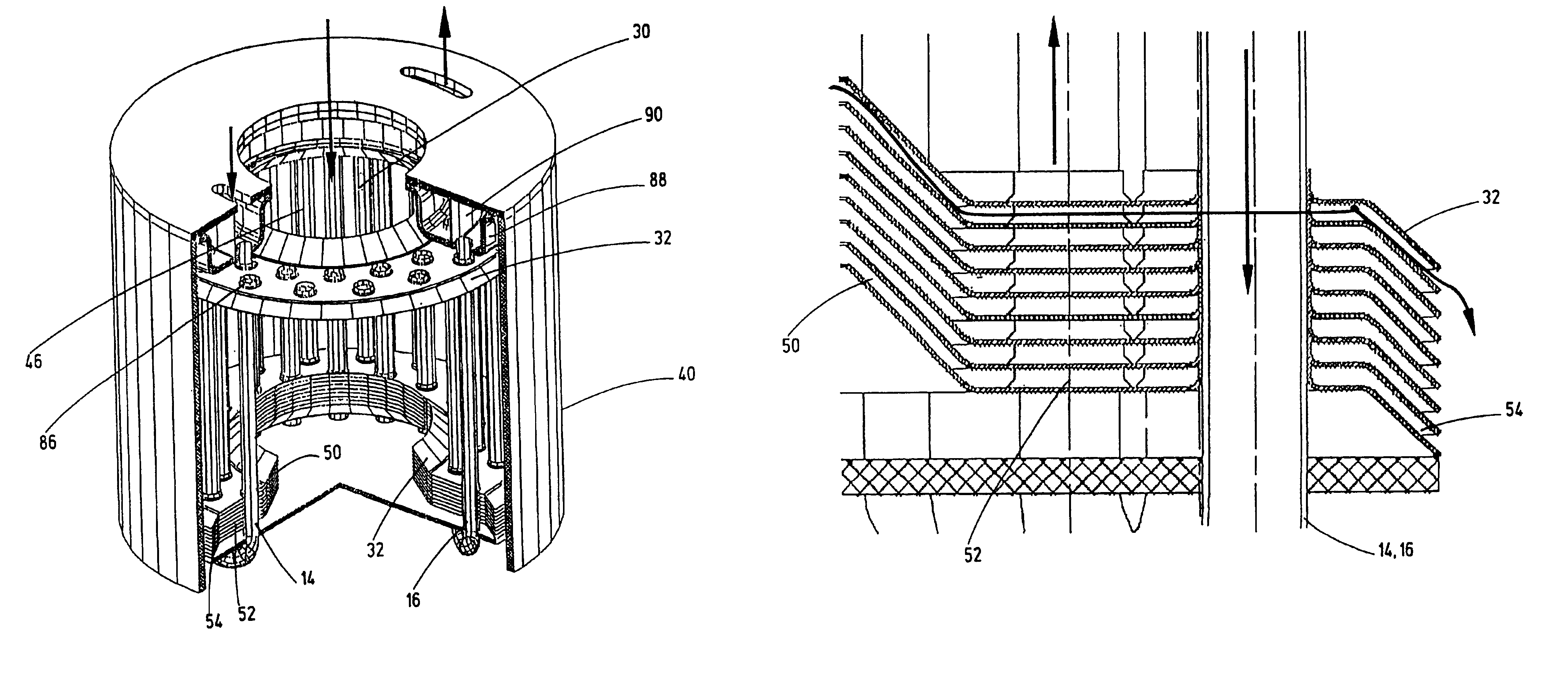

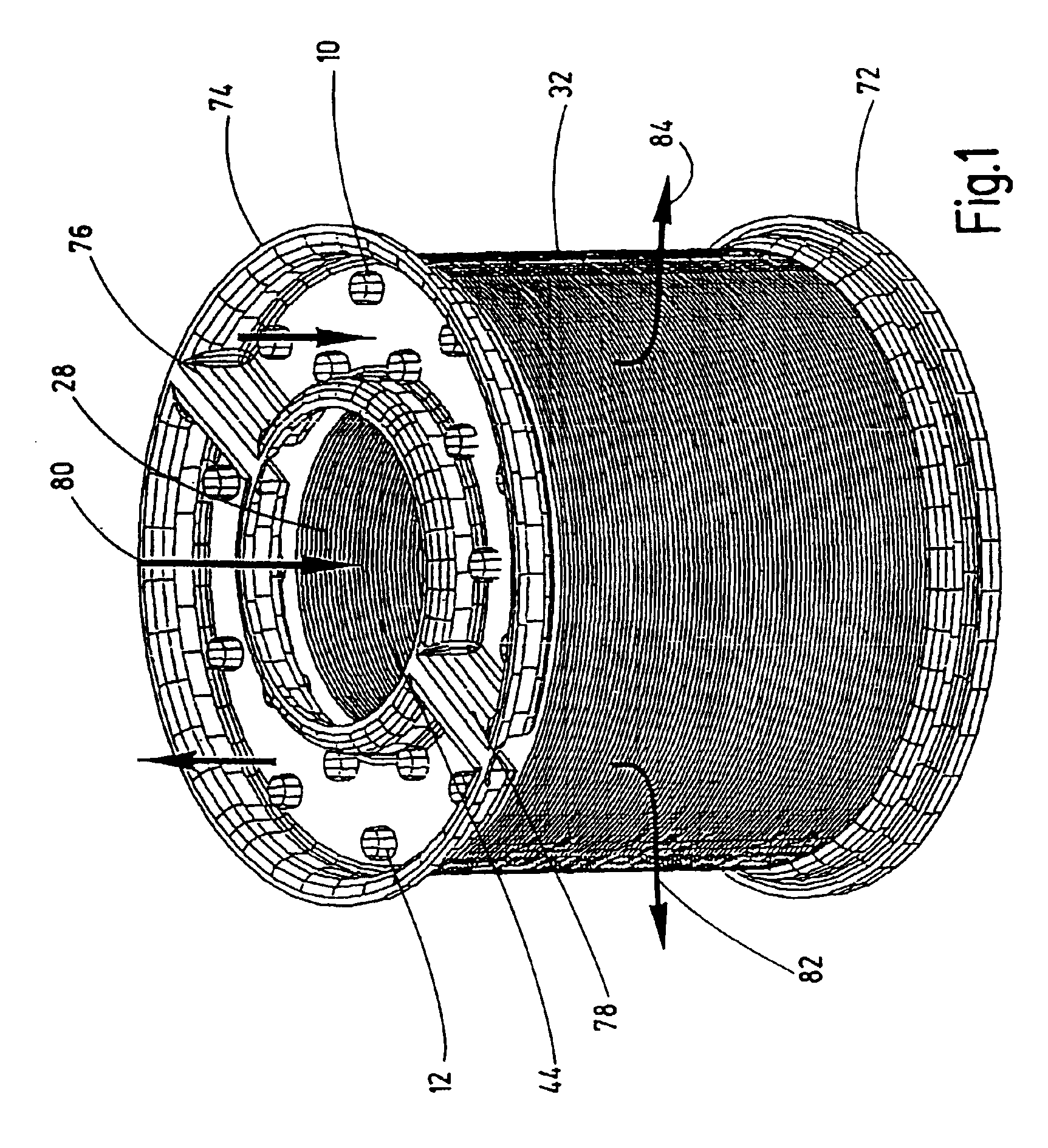

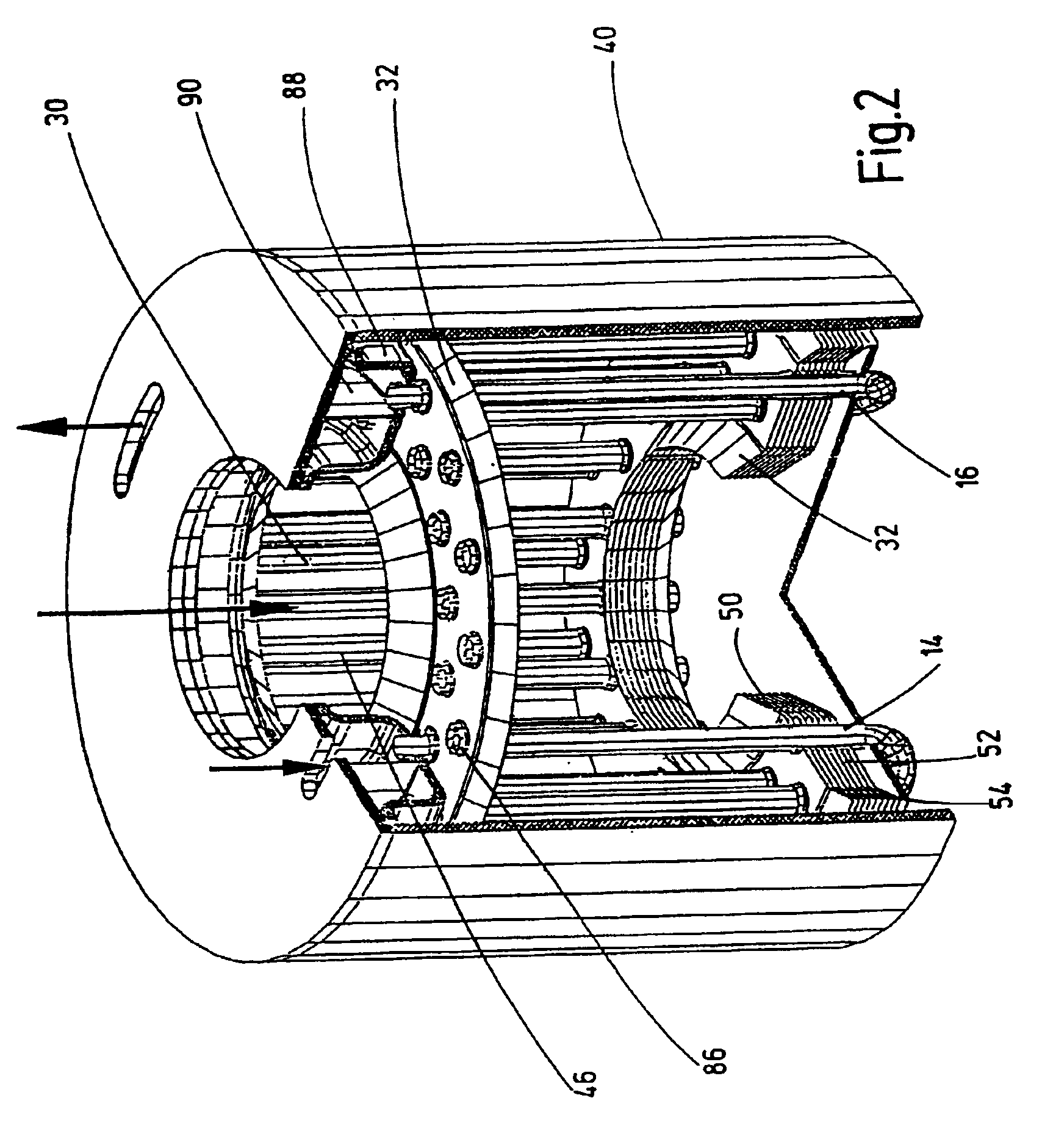

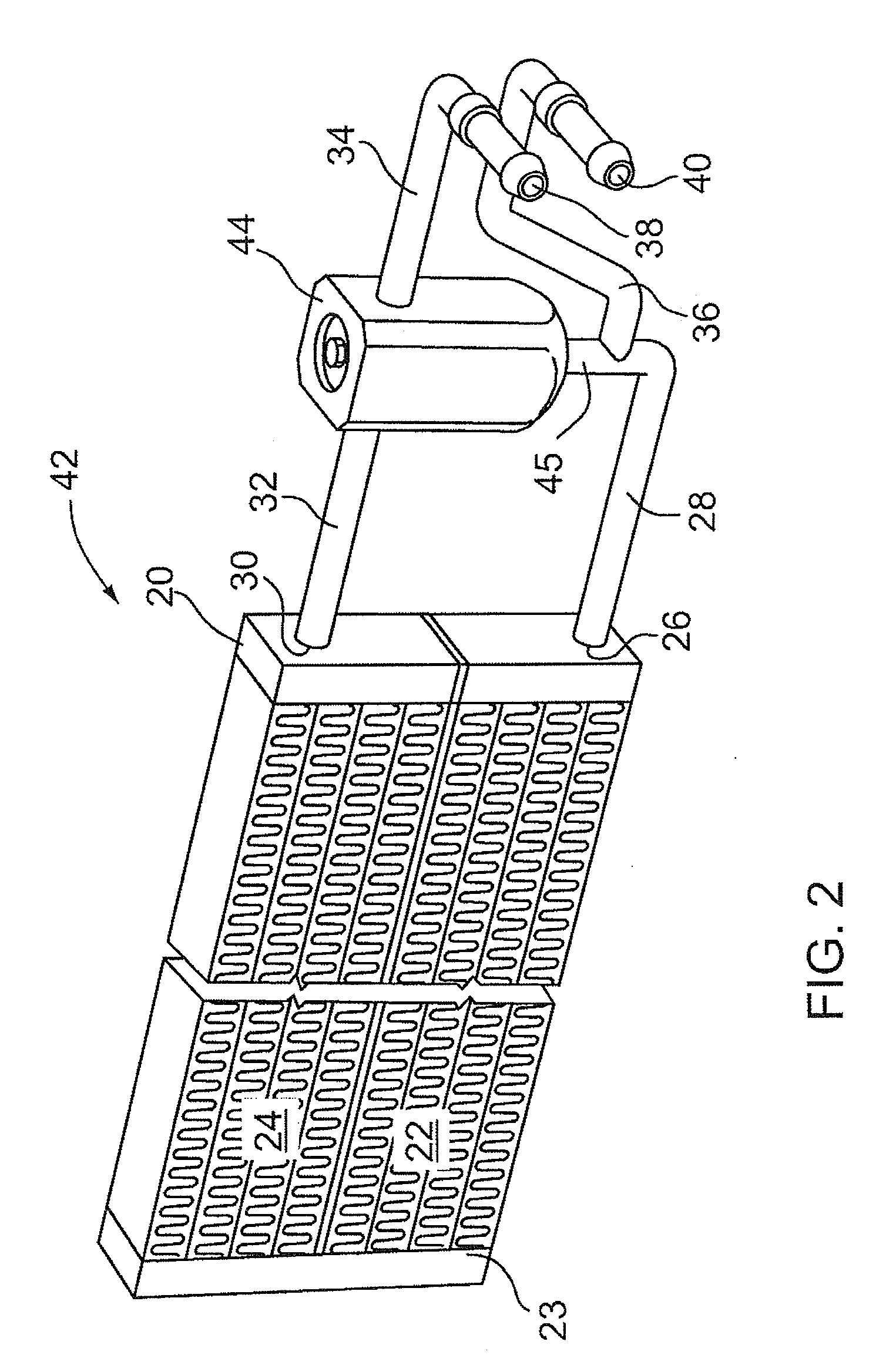

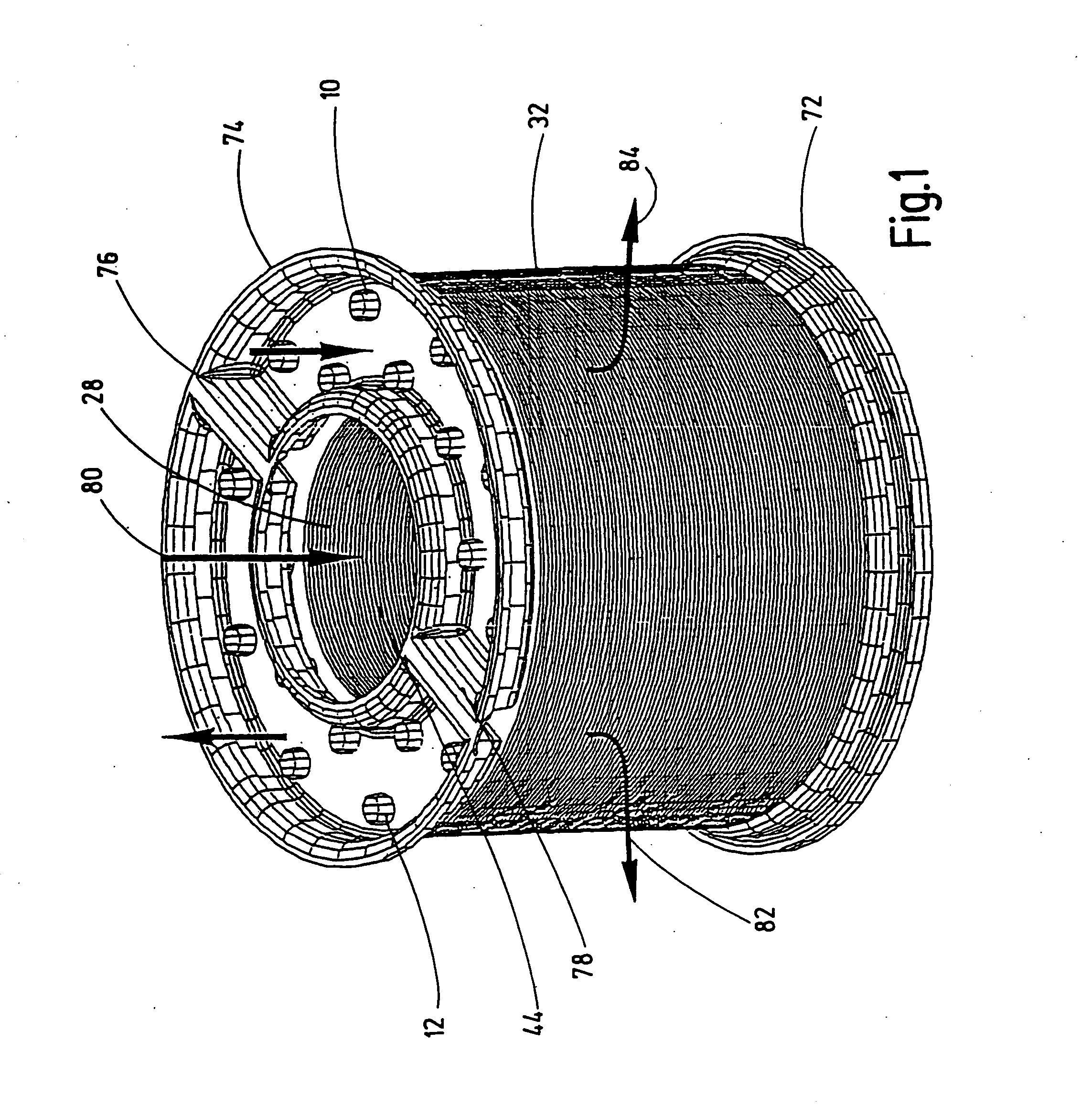

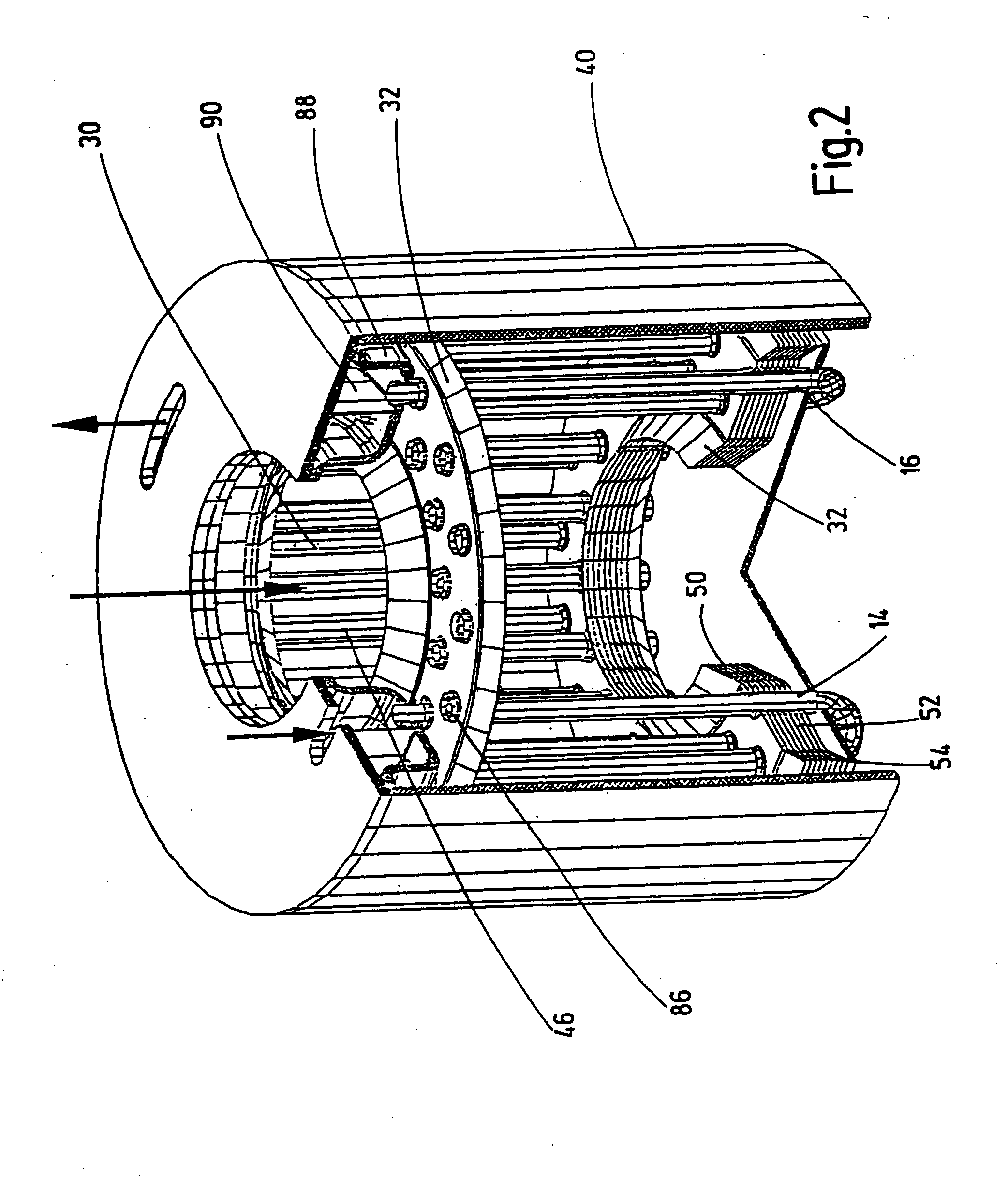

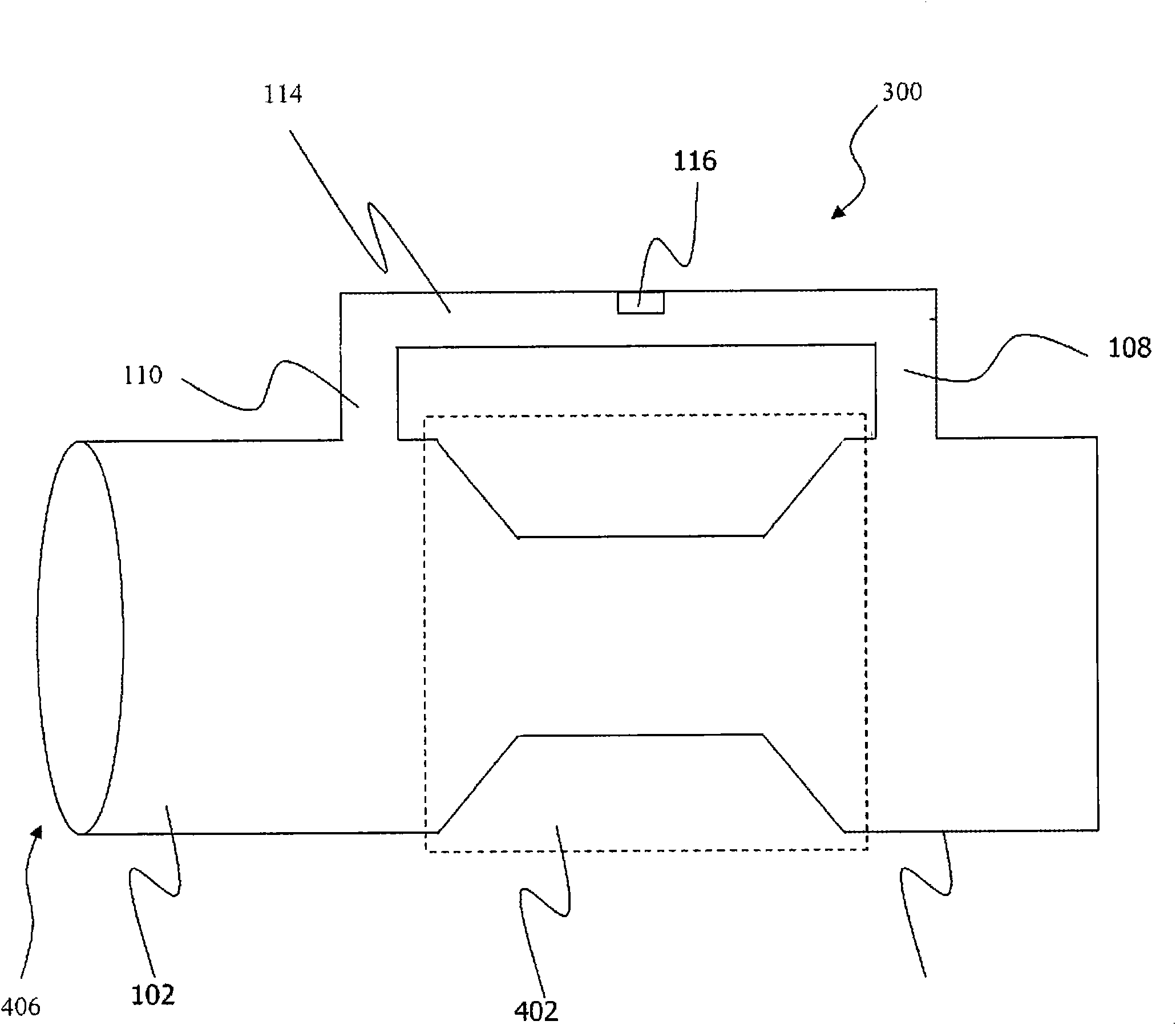

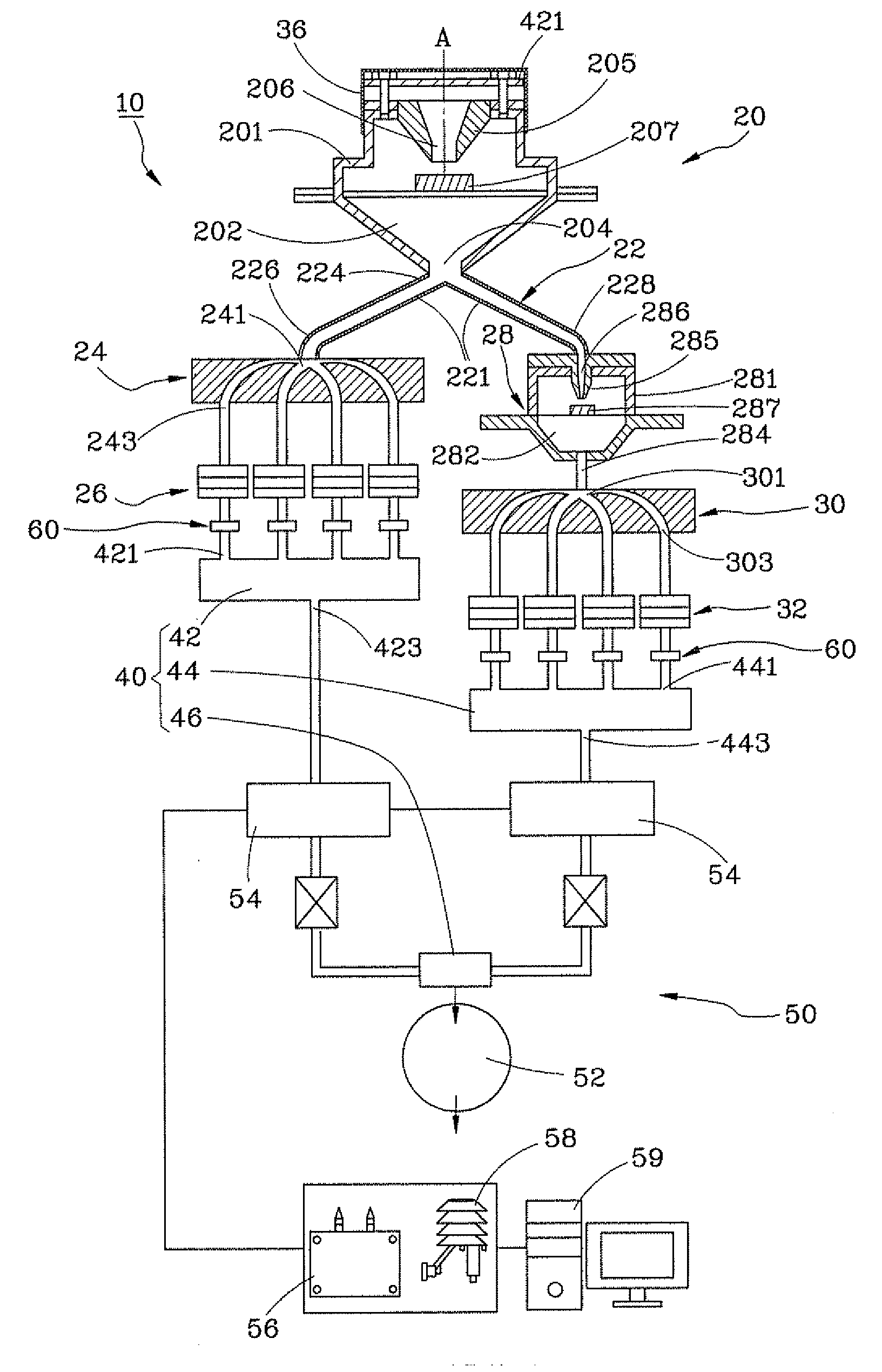

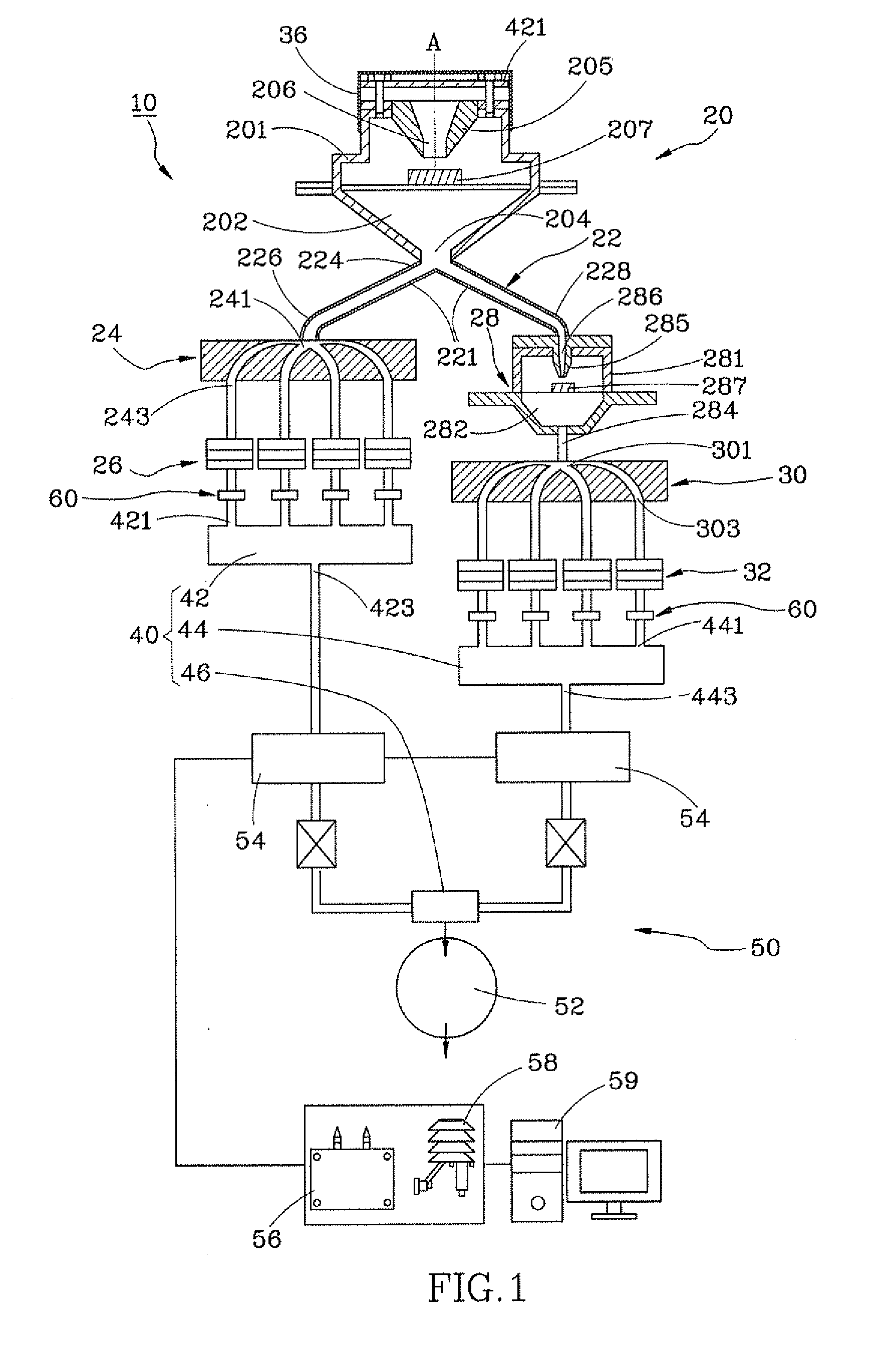

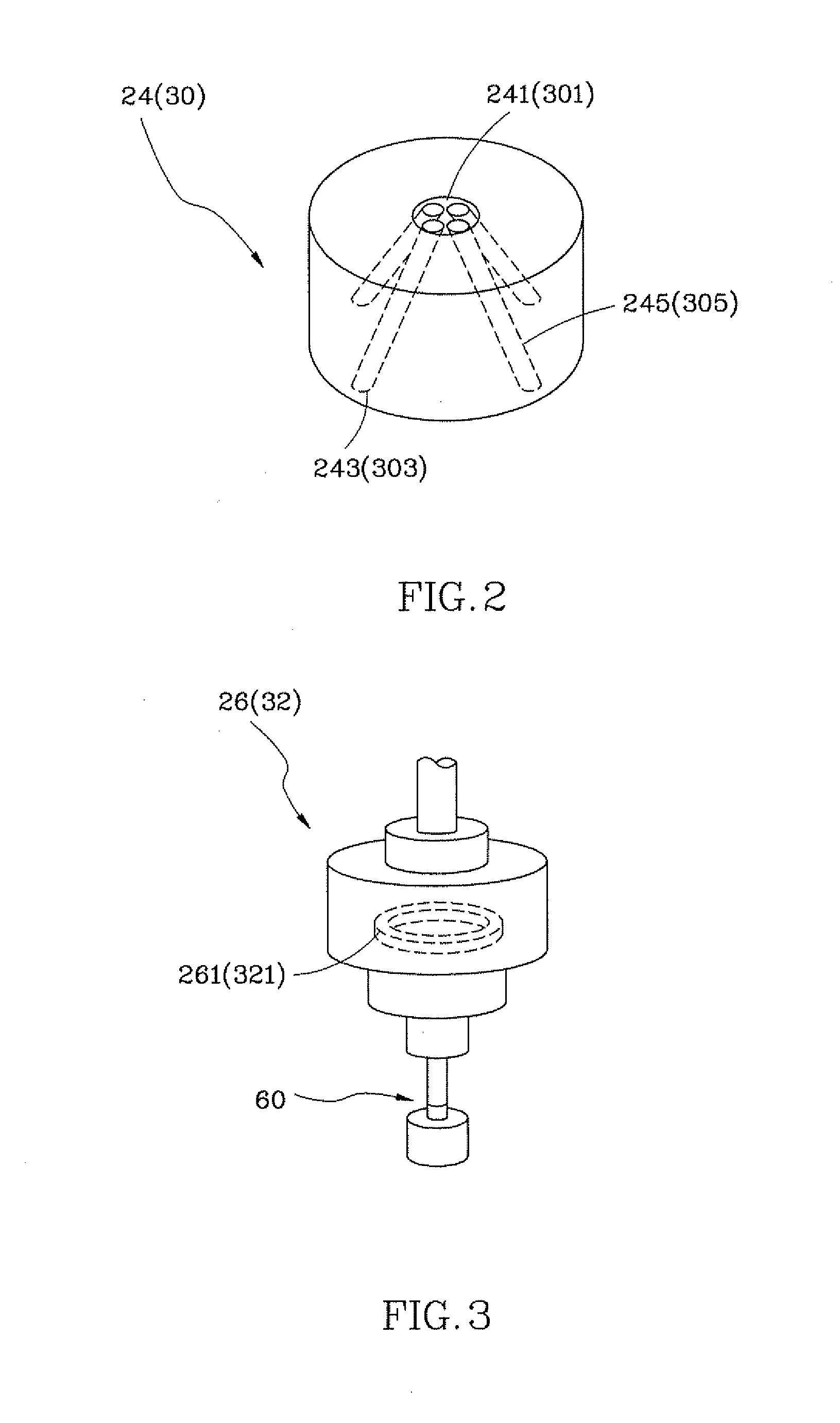

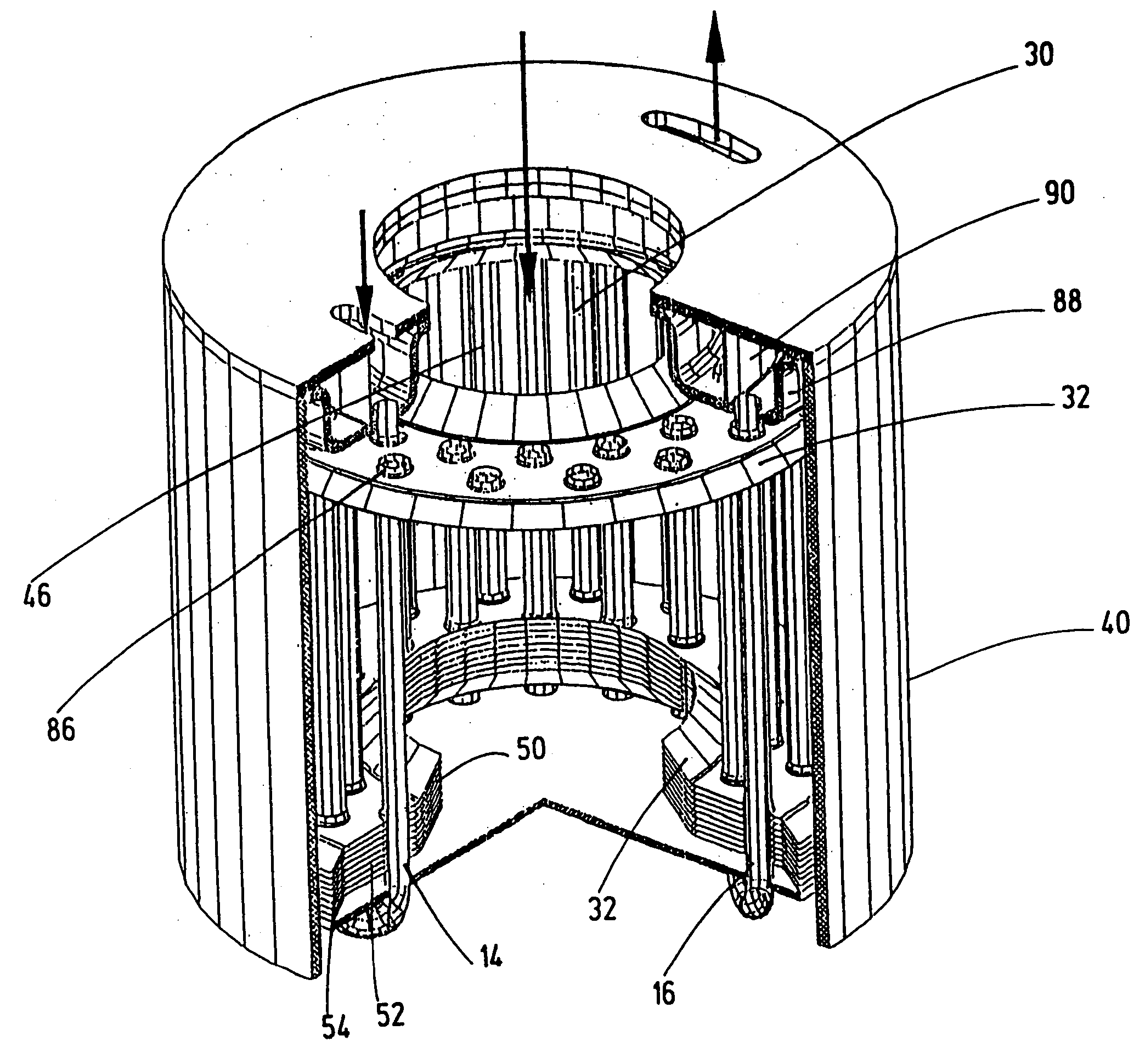

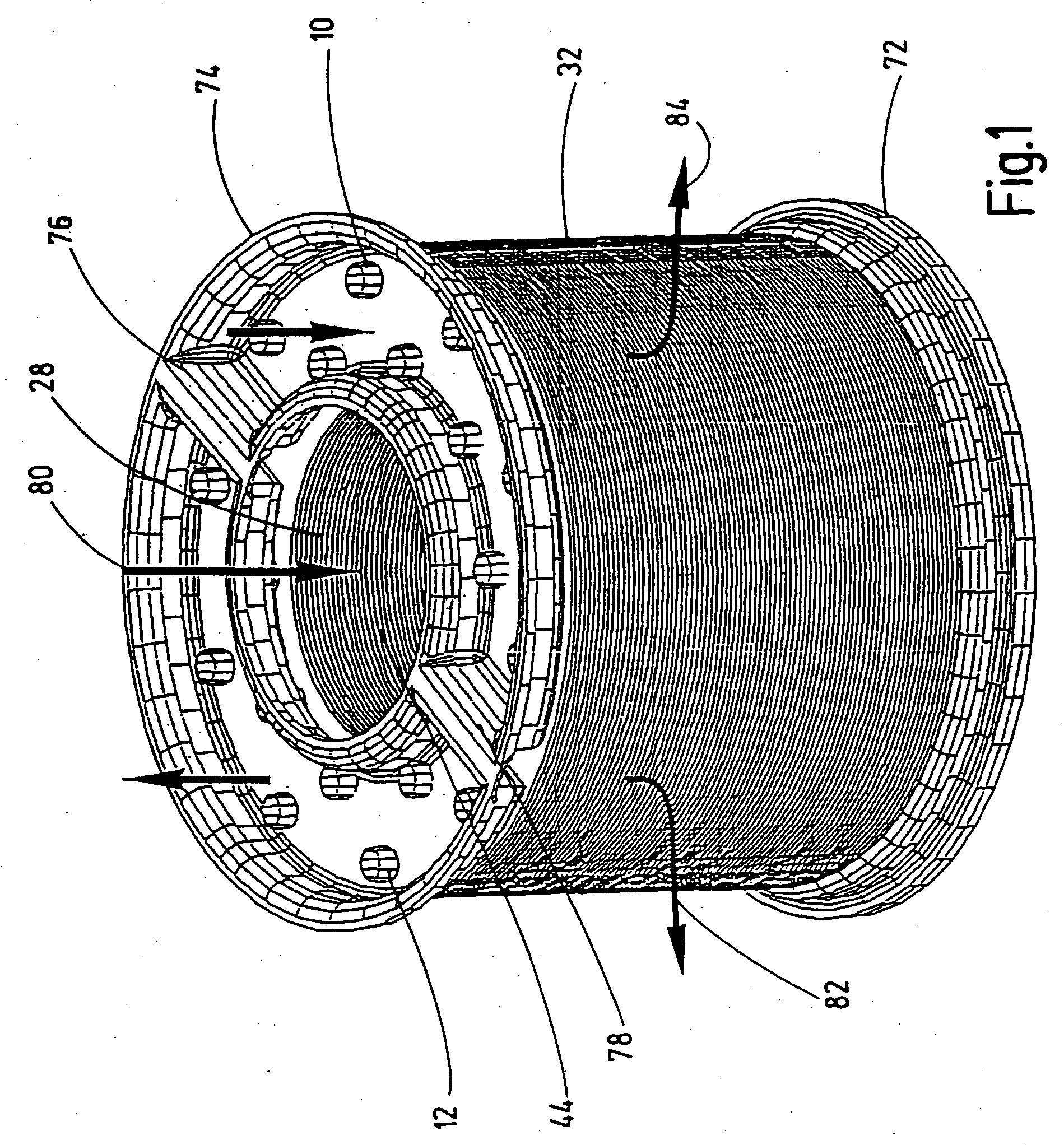

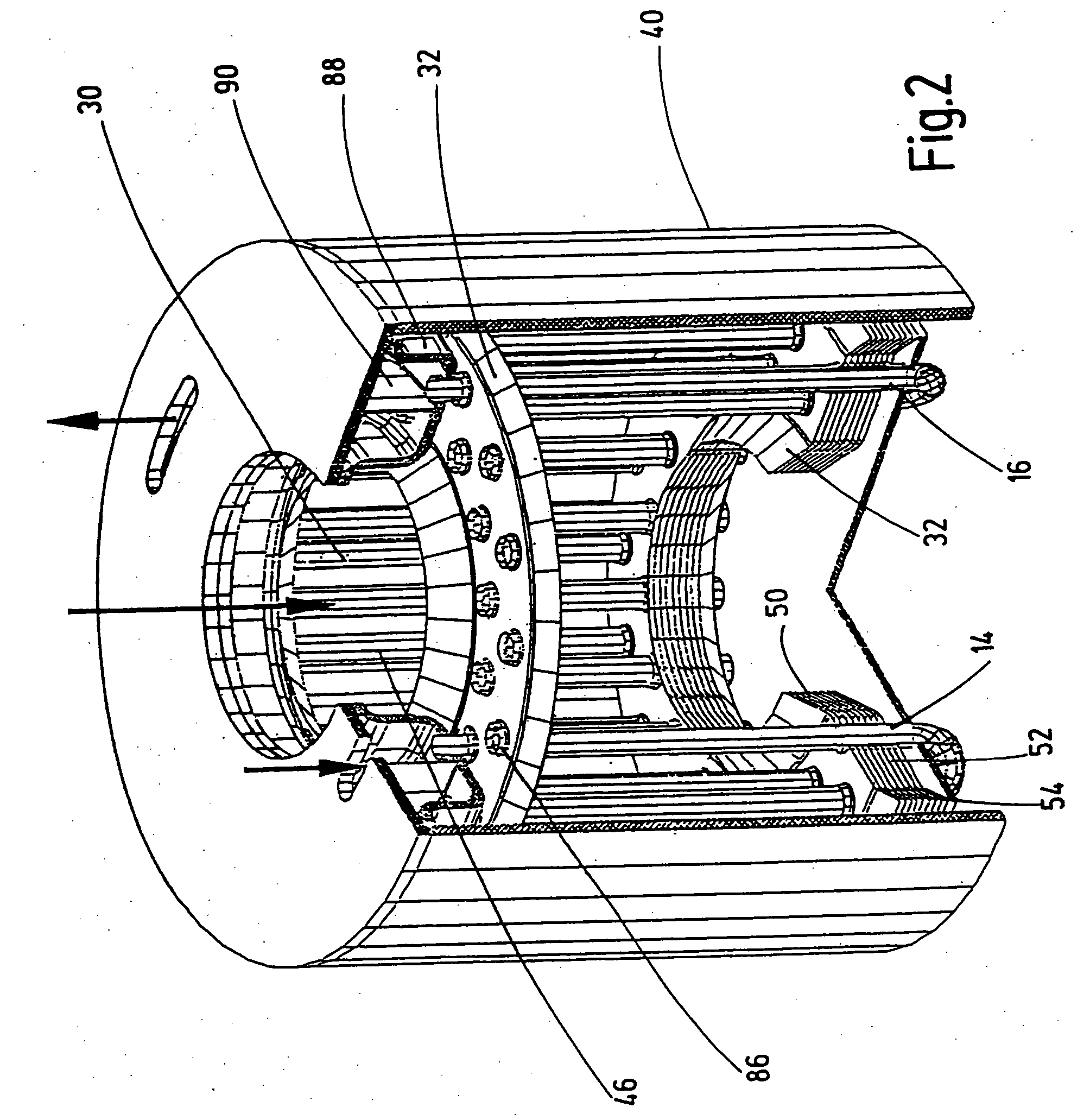

Cooler and method of cooling a medium

InactiveUS6857468B2Reduce pressure dropReduce adverse effectsDomestic stoves or rangesInternal combustion piston enginesEngineeringChiller

The invention relates to a cooler having means for directing a cooling medium, means for directing a medium to be cooled, and an essentially axially symmetrical housing. The means for directing the medium to be cooled is arranged in such a way that the medium to be cooled, in at least one first region, flows in an essentially axial direction, and the medium to be cooled, in at least one second region, flows in a direction having a radial component. The invention also relates to a method of cooling a medium and to various uses of a cooler according to the invention.

Owner:BEHR GMBH & CO KG

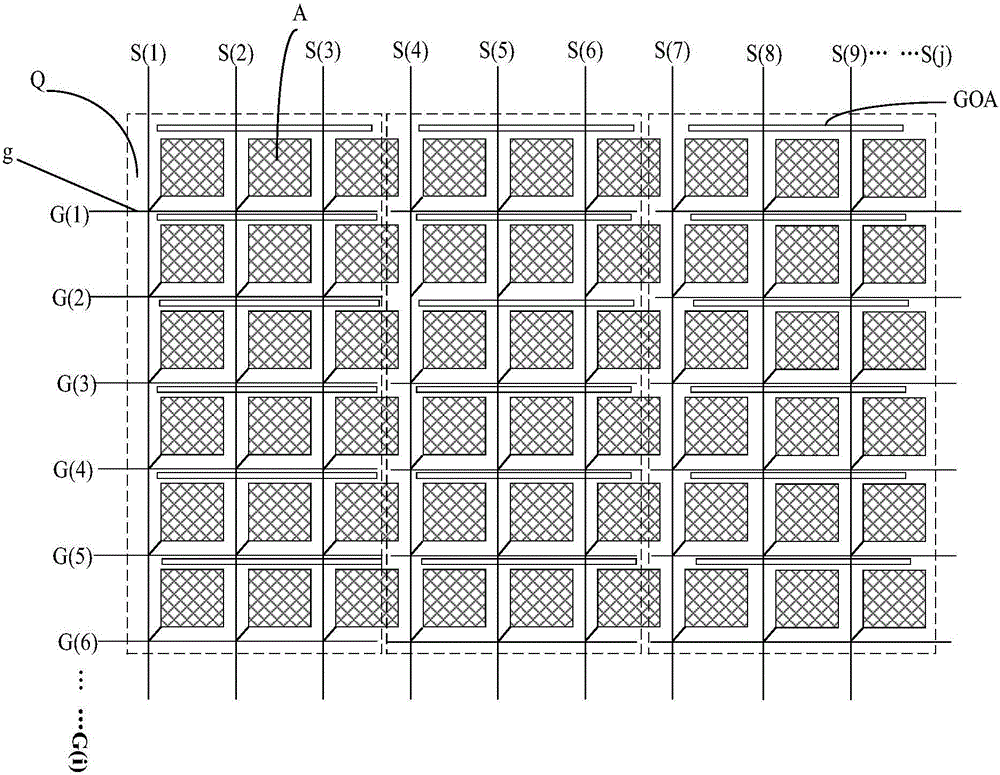

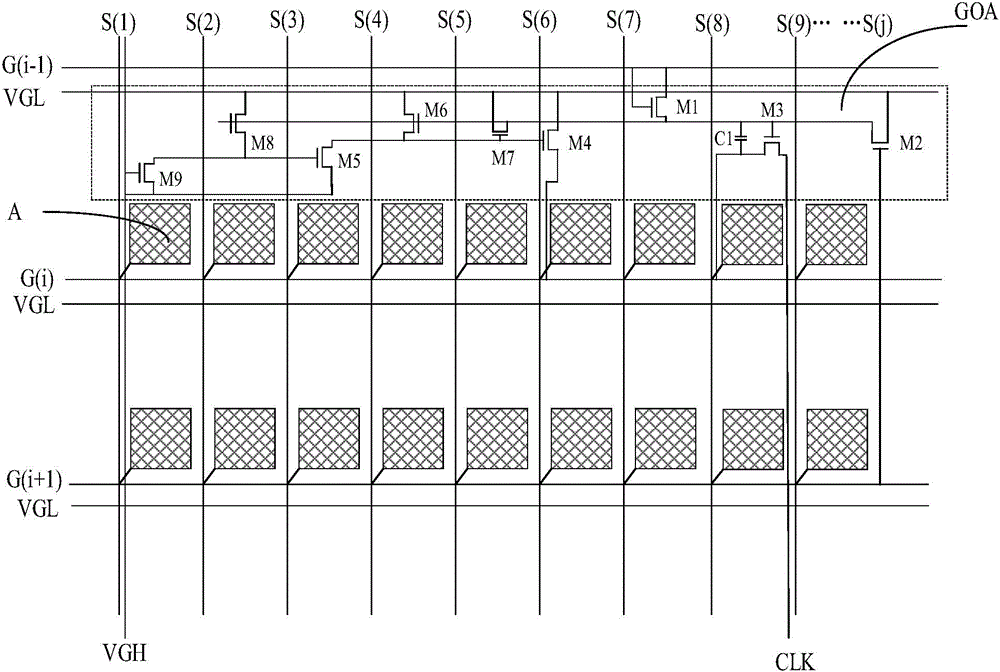

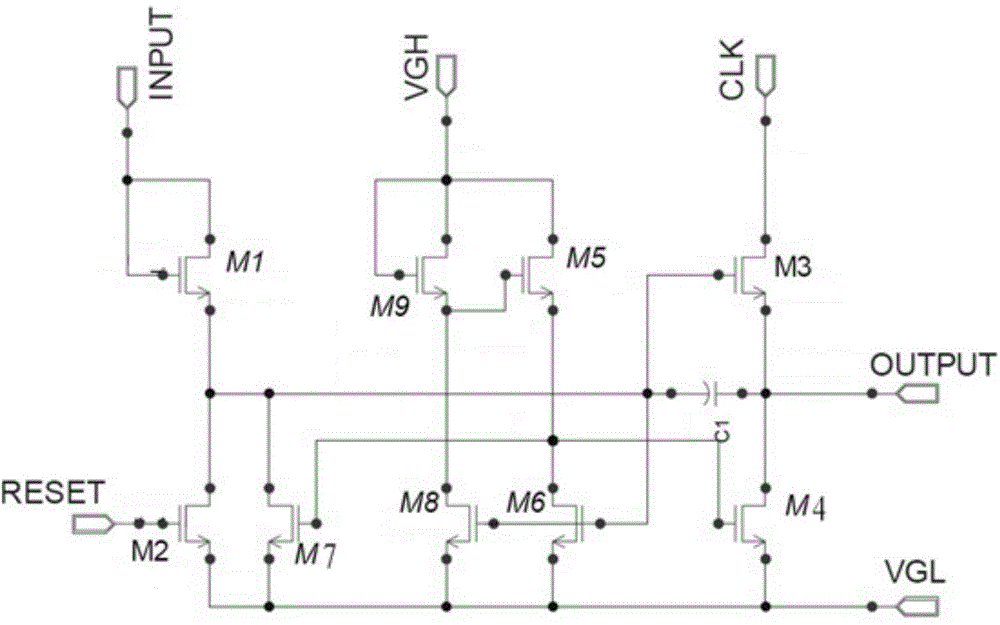

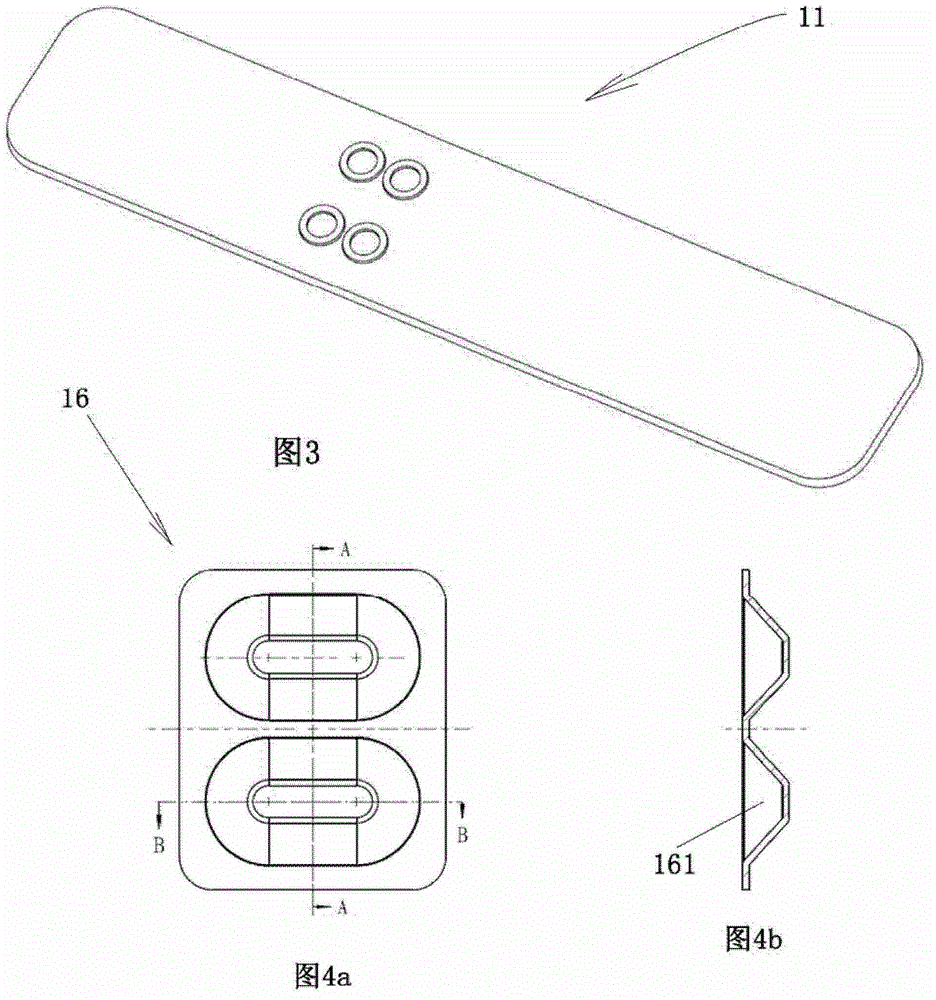

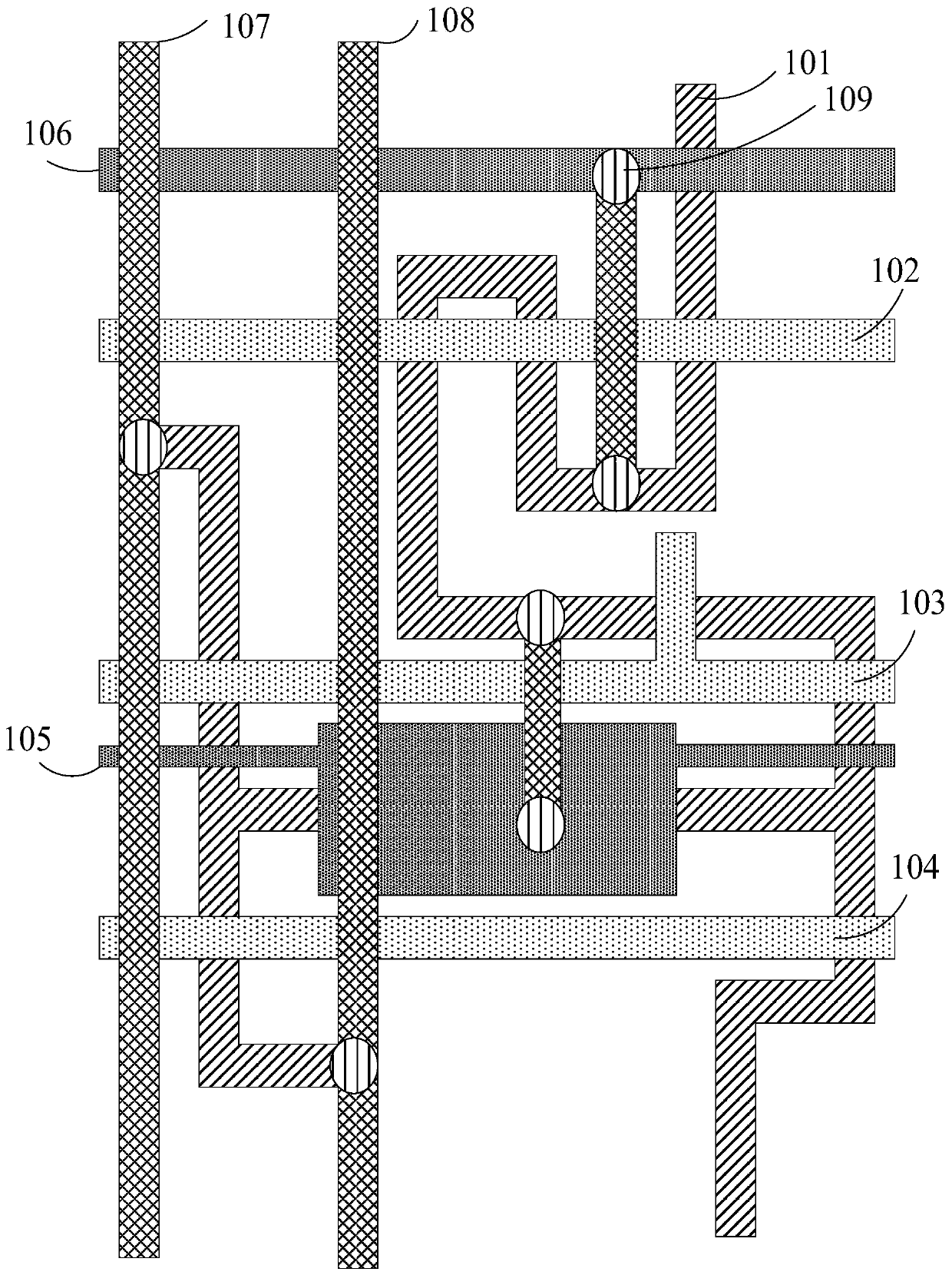

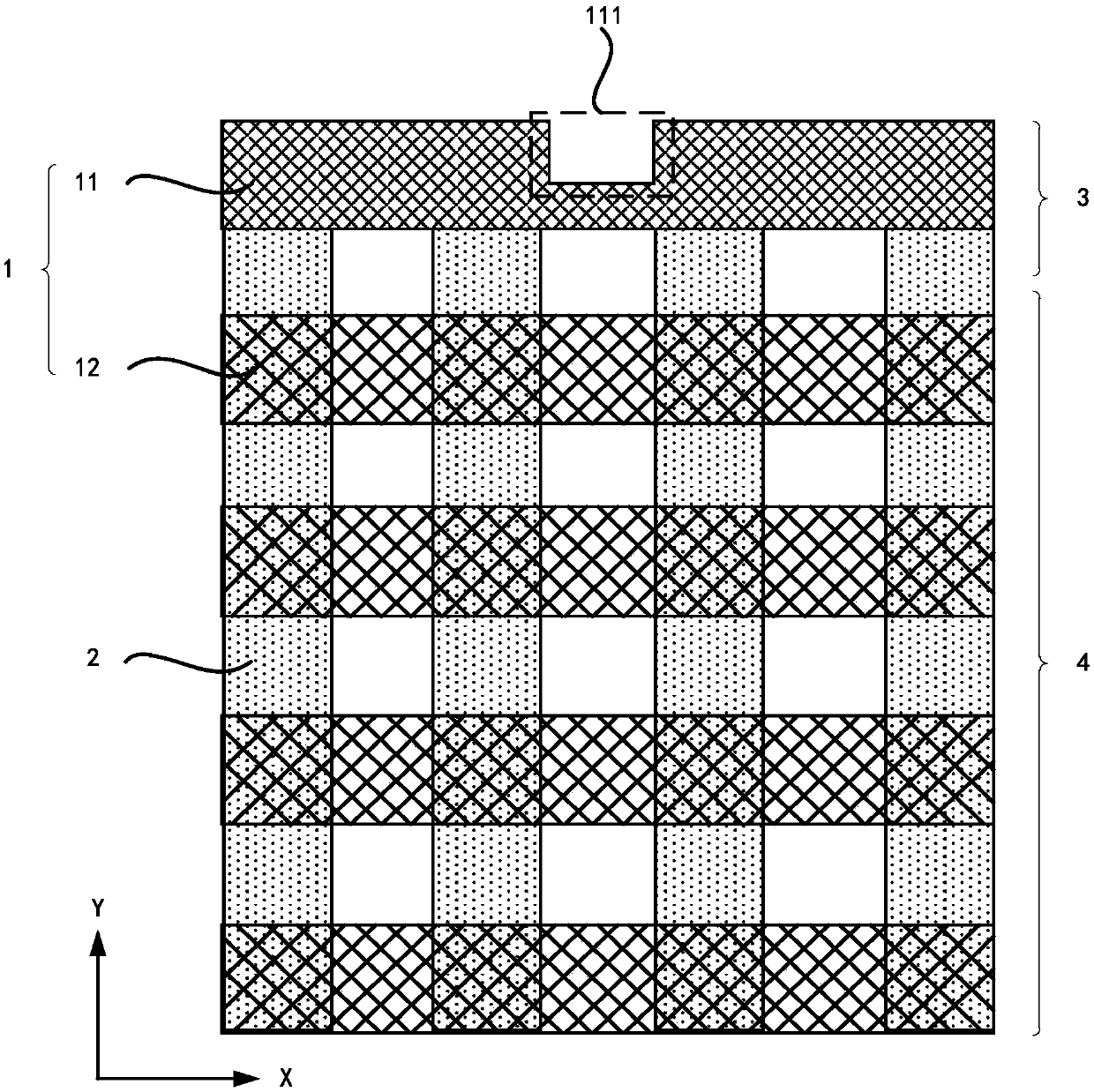

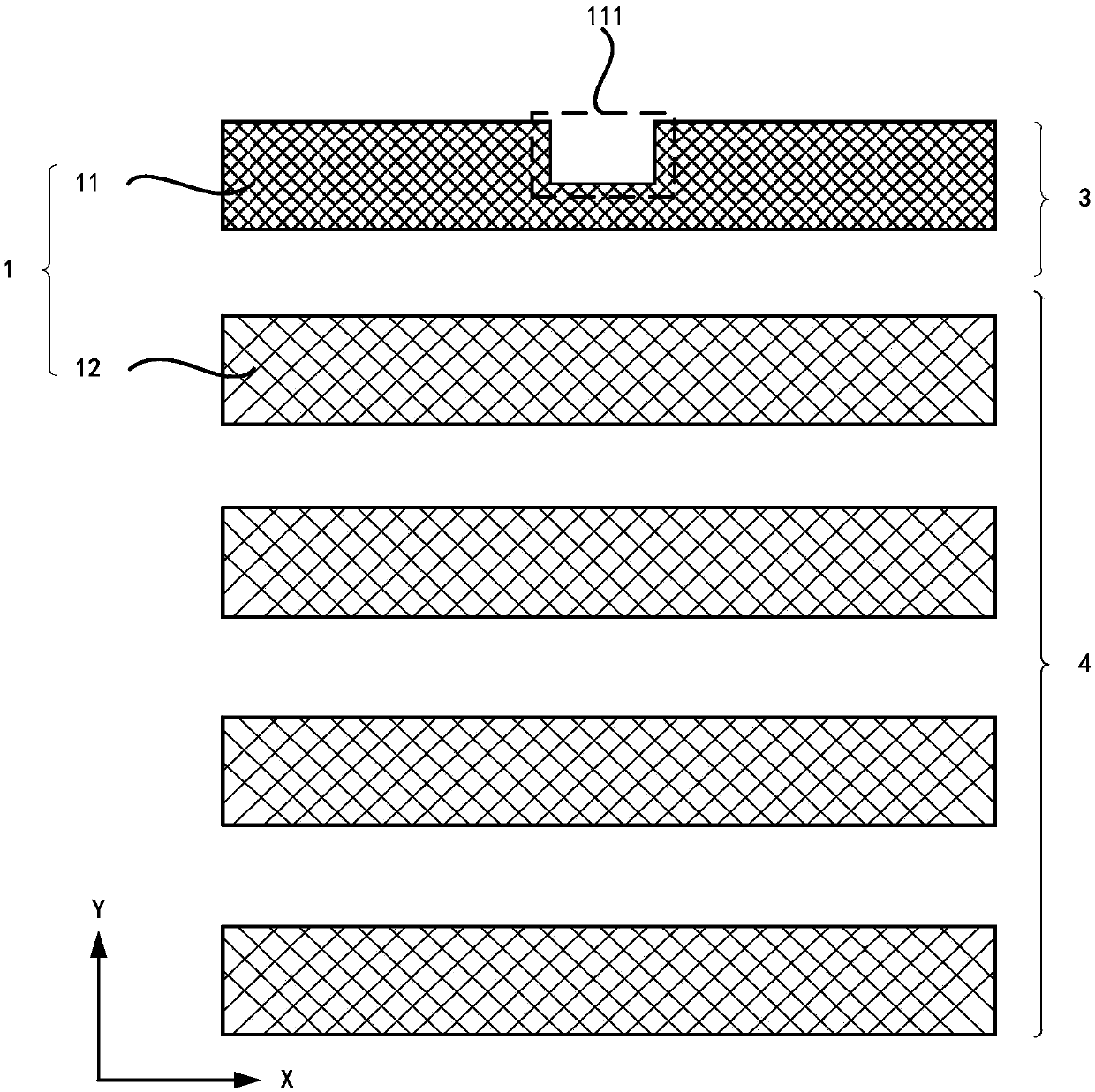

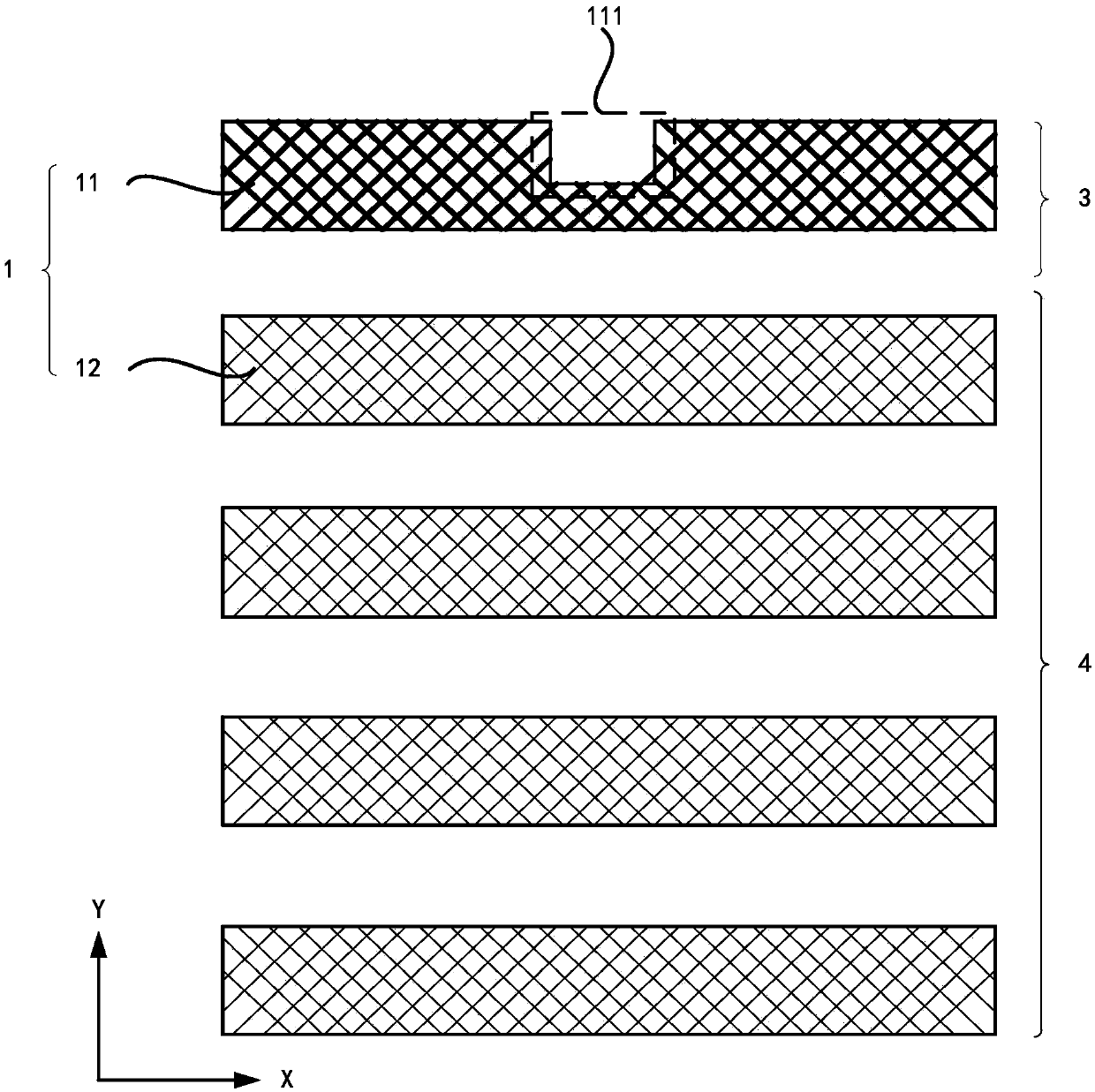

Display panel and display device

The invention provides a display panel and a display device, belongs to the display technology field, and helps to solve the problem that the frame of a conventional display panel is wide. The display panel comprises a display area and surrounding areas. The display area includes multiple grid lines and multiple data lines, the grid lines and the data lines crossing each other. The grid lines and the data lines cross each other to define multiple pixel units. At least one grid line includes at least two grid line segments that are disconnected from each other, and each grid line segment correspondingly controls at least one pixel unit. The display area is divided into at least two sub-display areas according to the disconnection positions of the grid line segments. A shift register unit connected to the grid line segments is arranged in at least one sub-display area, and is used for providing grid scan signals to the grid line segments connected to the shift register unit. At least part of the shift register units are arranged in the display area, so the frame of the display panel is narrow.

Owner:BOE TECH GRP CO LTD

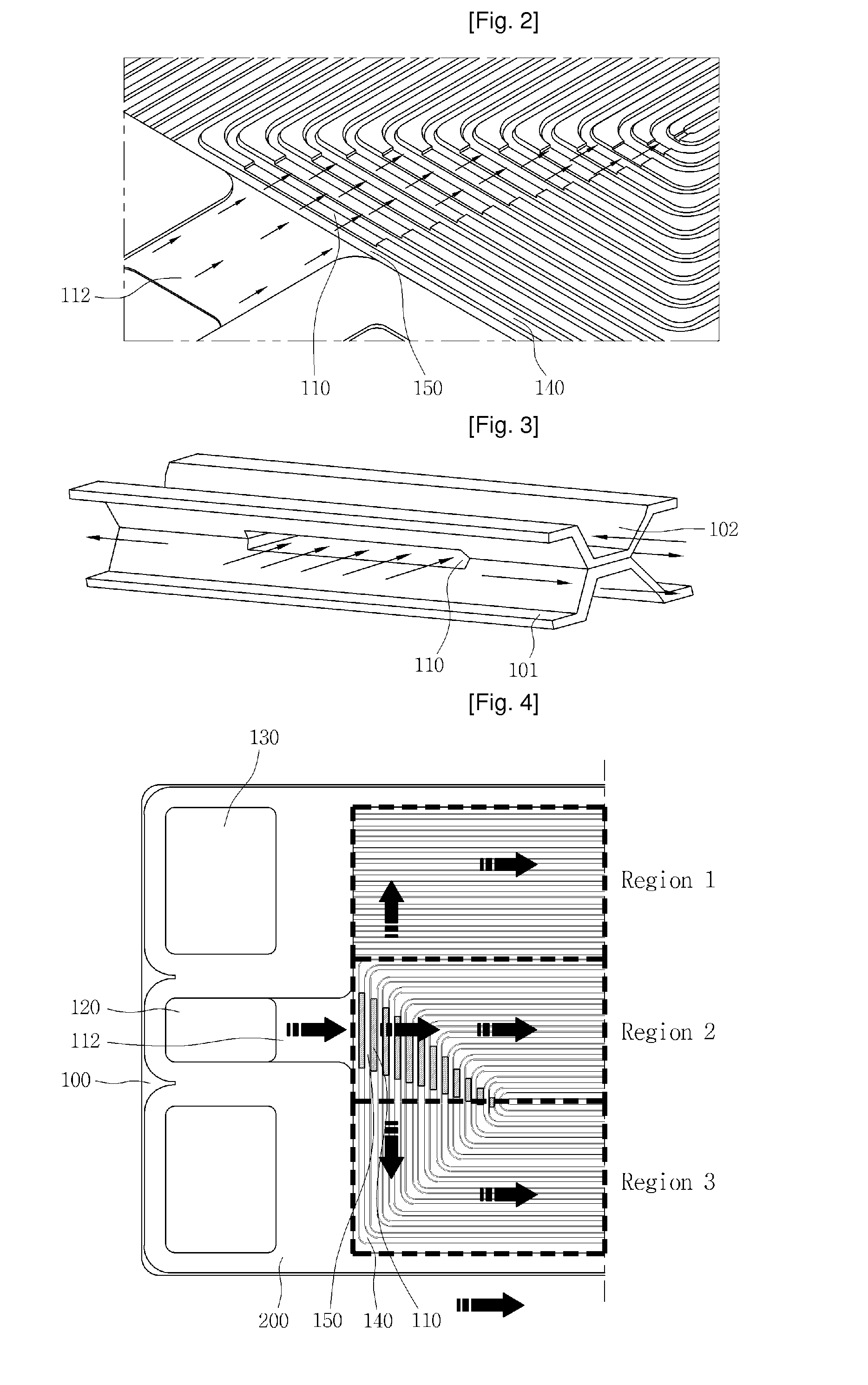

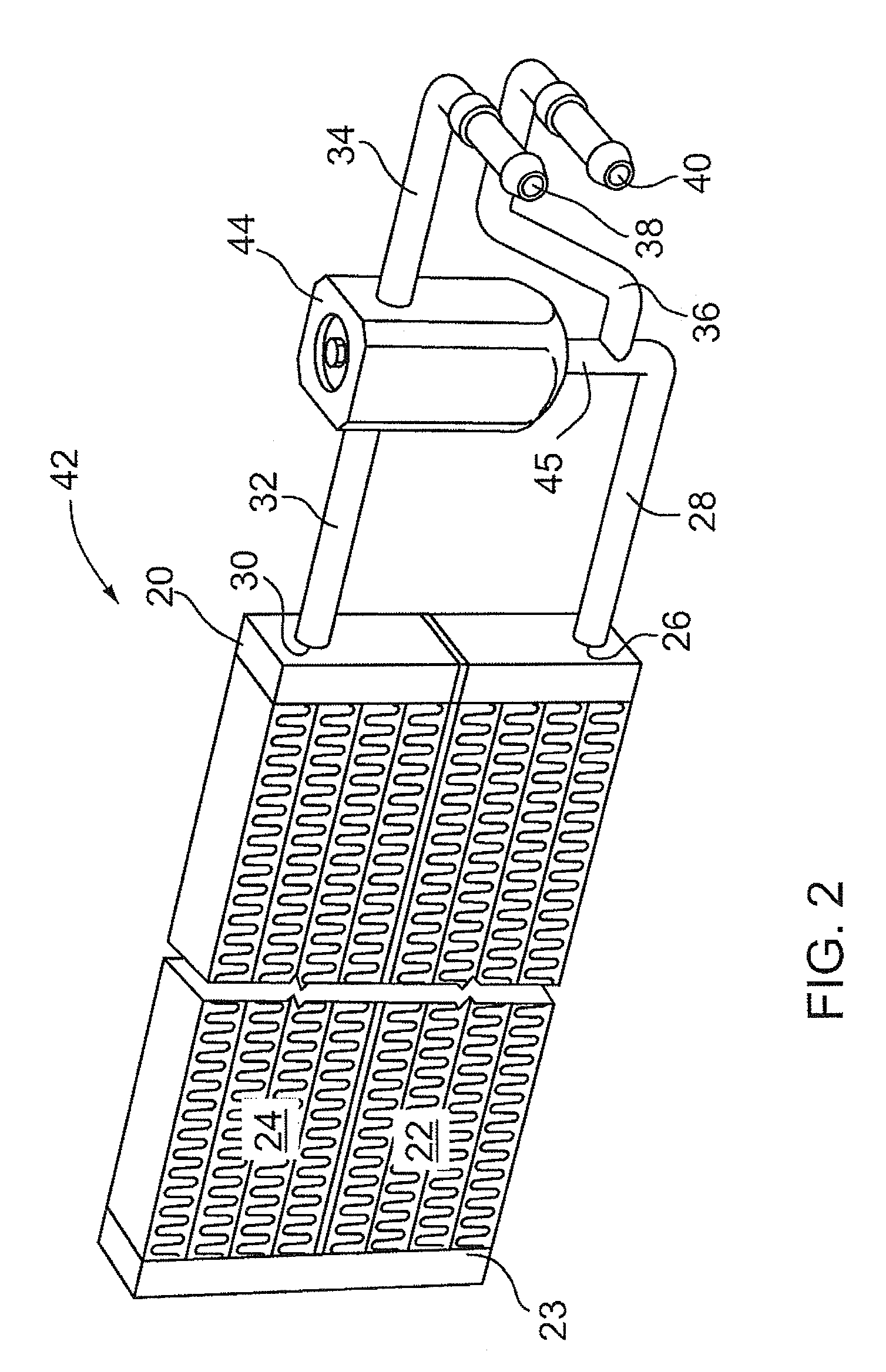

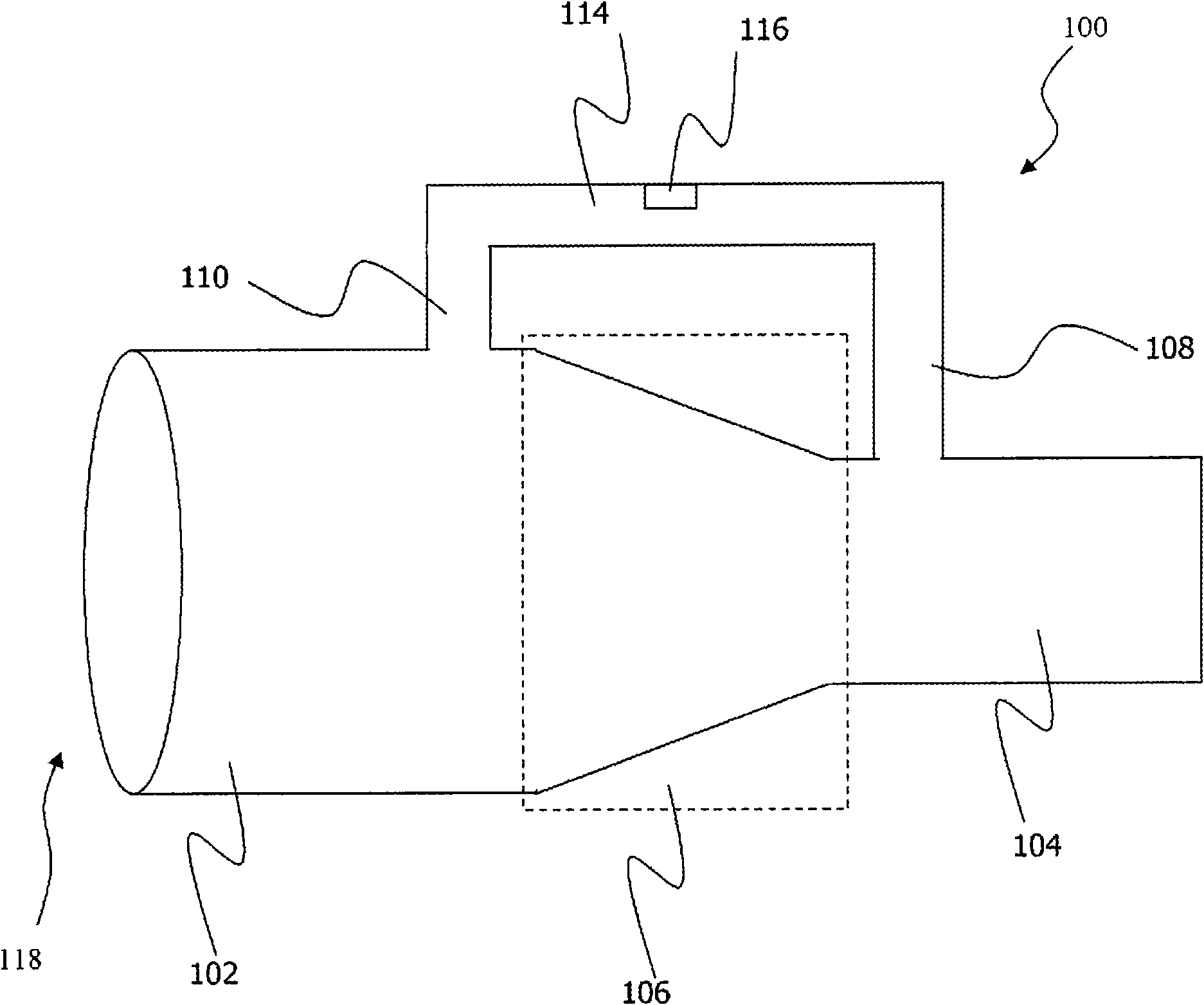

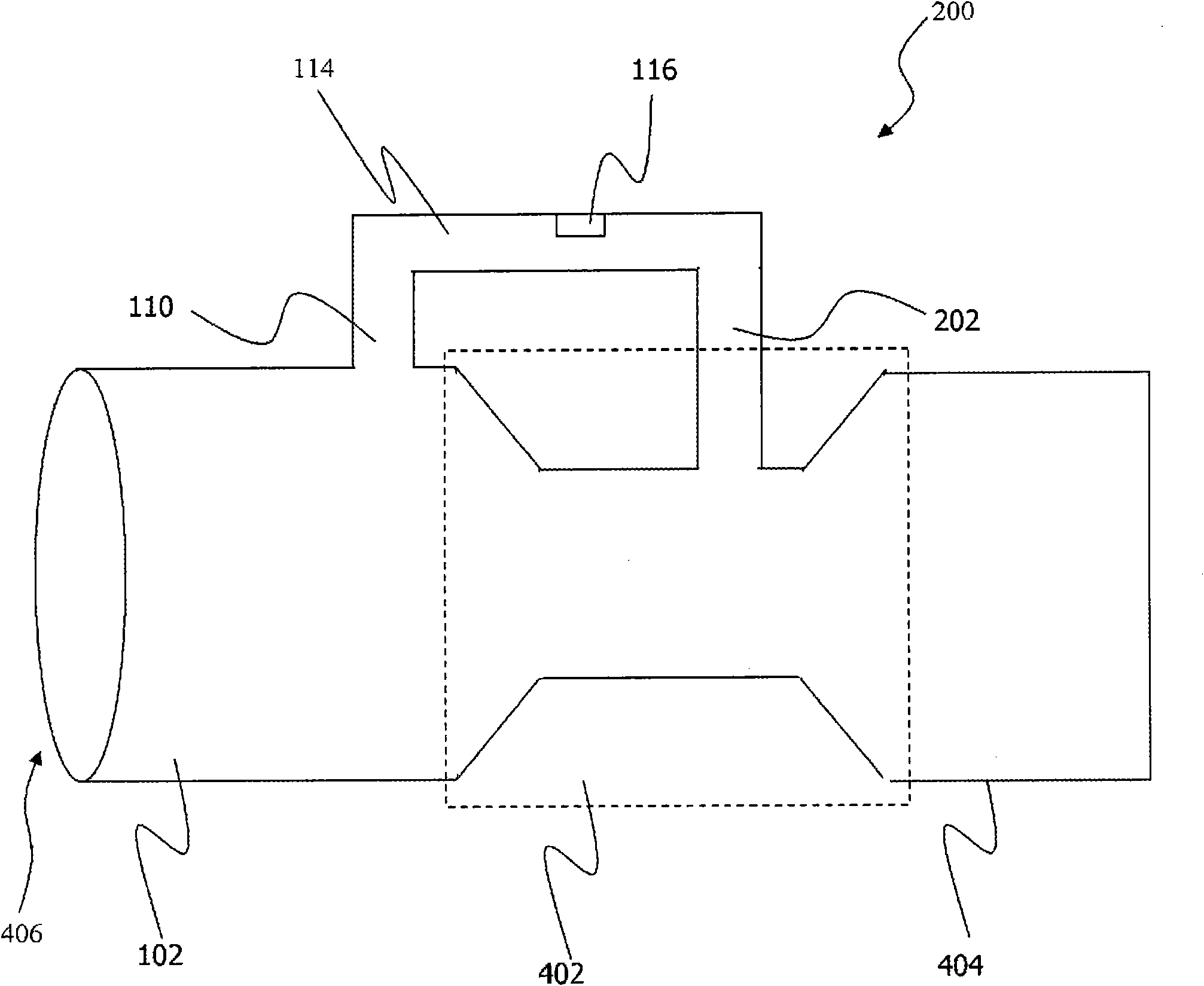

Low Pressure Drop Thermal By-Pass Valve

InactiveUS20110005741A1Readily apparentEasy to operateTemperature control without auxillary powerMachines/enginesActuatorPiston

A thermal by-pass valve for a heat exchange circuit includes a housing forming a chamber and a by-pass valve port surrounded by a valve seat. The valve port is located between first and second sections of the chamber. First and second oil ports open into the first section. At least a third port opens into the second section. A thermally sensitive actuator is mounted in the first section and has a body and a piston located at one end. The body is movable in the chamber in response to extension of the piston. A valve member is operably mounted on the body and is movable by extension of the piston. A spacer projects from and is connected to the body and forms a passage through which the piston extends. The spacer acts to maintain the adjacent end of the actuator body at least the length of the passage away from an end of the chamber. The spacer can have a valve portion to close a further valve port.

Owner:DANA CANADA CORP

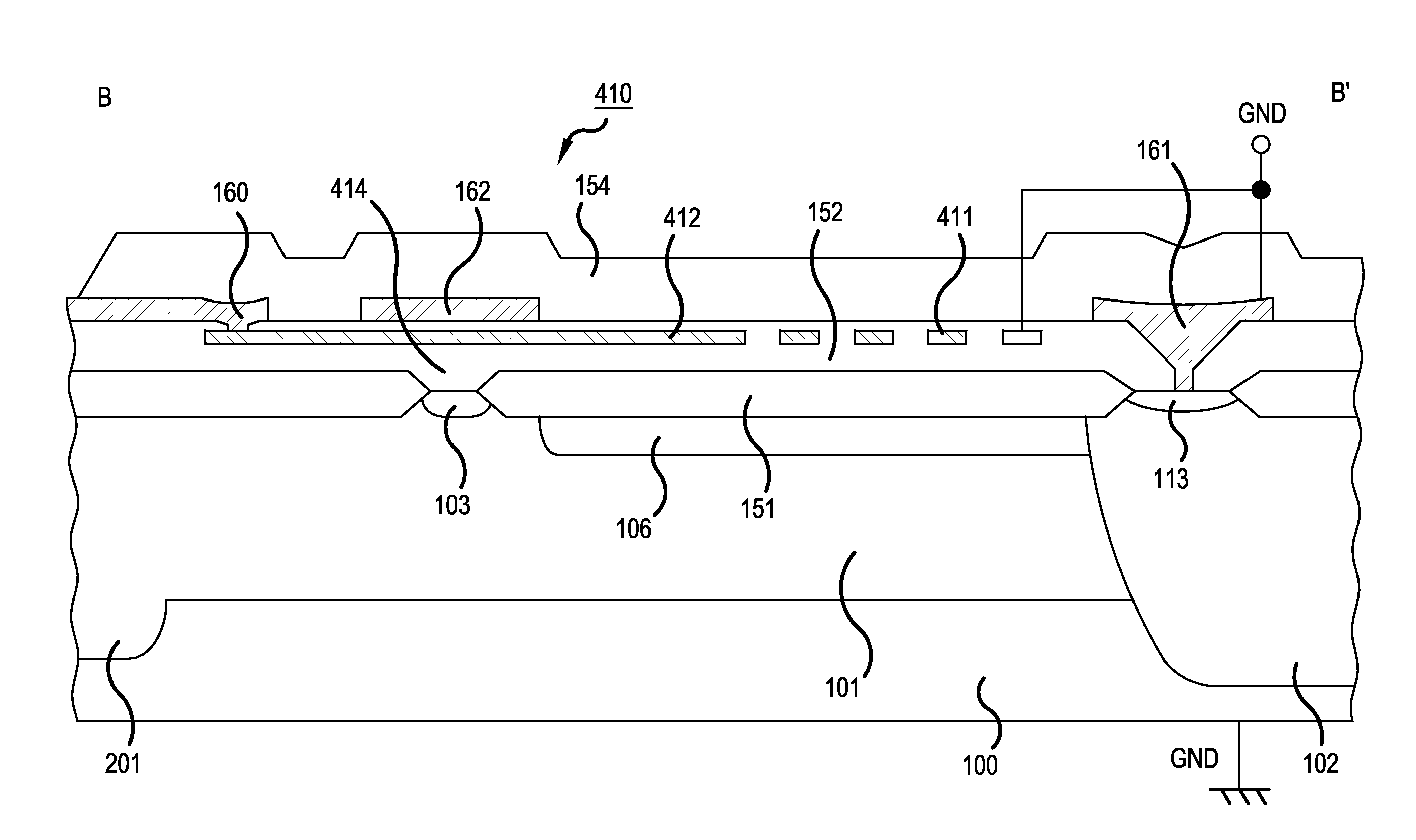

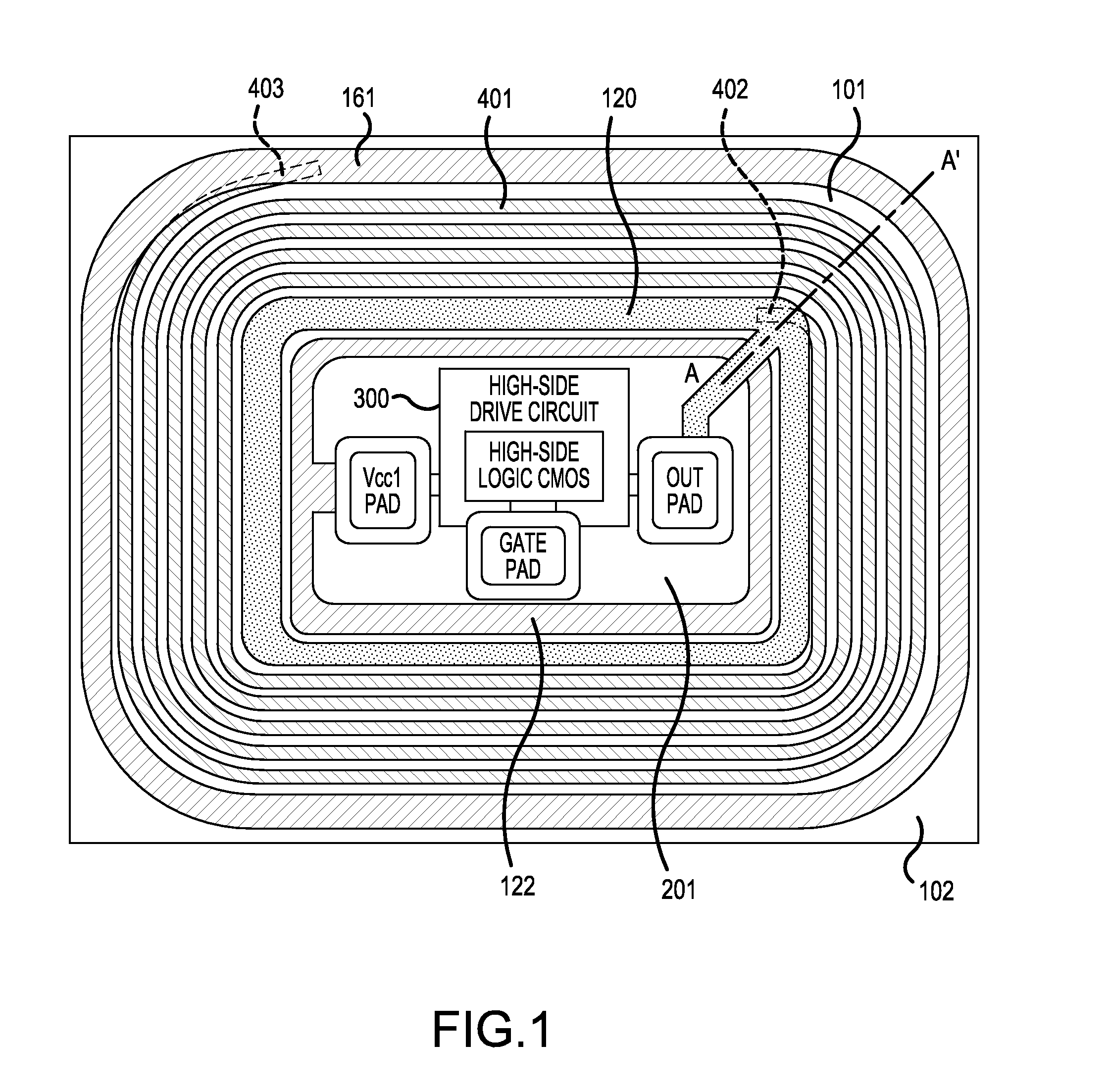

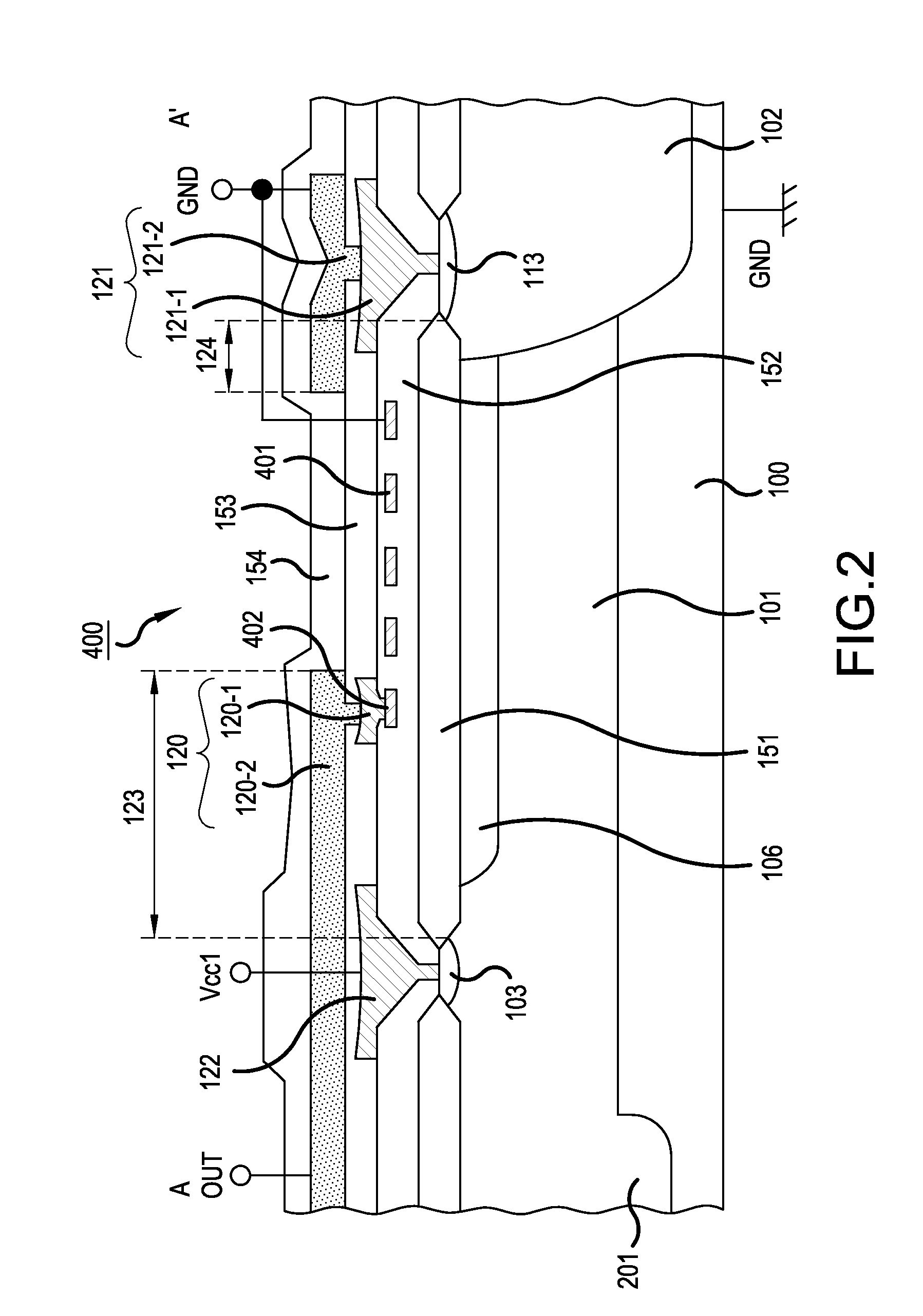

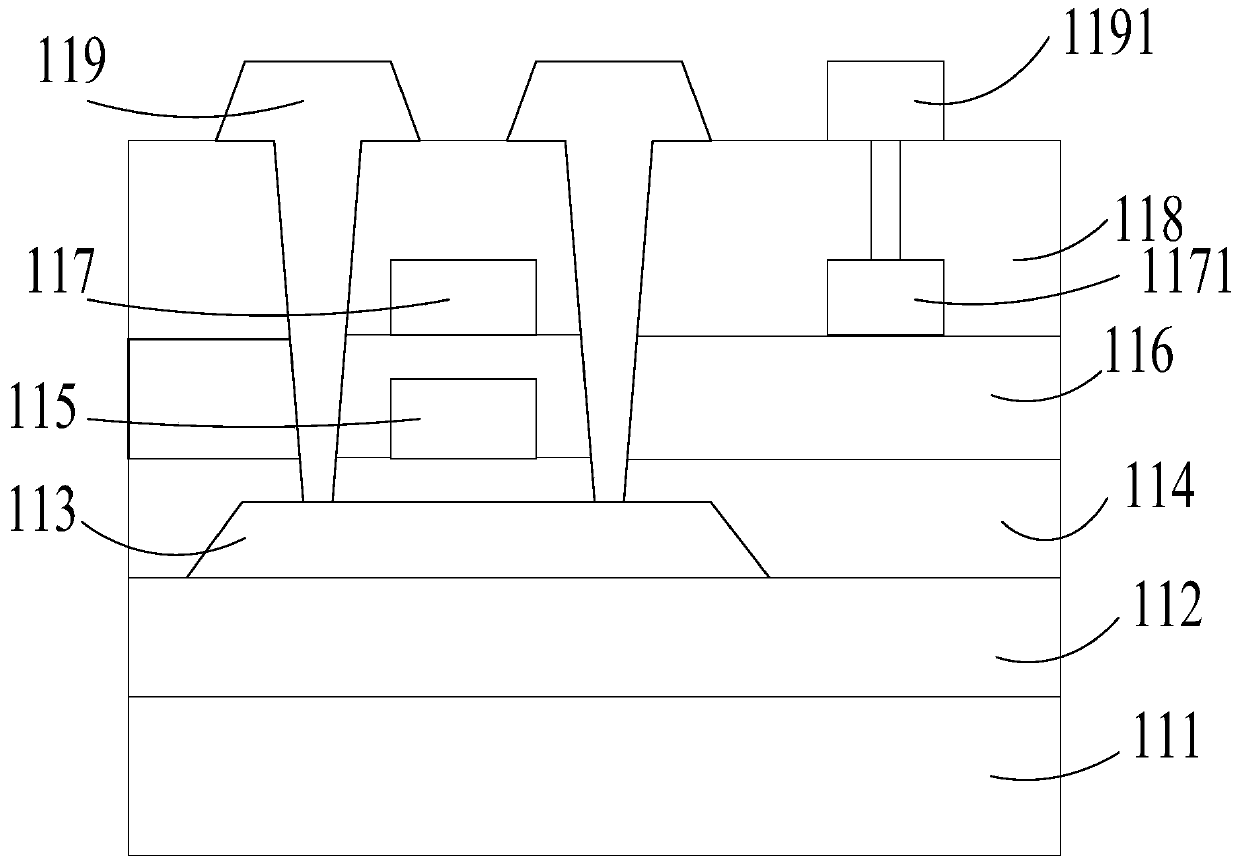

Semiconductor device

ActiveUS20140217466A1Suppress voltage drop amountReduce capacitySolid-state devicesSemiconductor/solid-state device manufacturingHigh resistanceEngineering

An n-type region encloses an n-type well region is disclosed in which is disposed a high-side drive circuit. A high resistance polysilicon thin film configuring a resistive field plate structure of a high breakdown voltage junction termination region is disposed in spiral form on the n-type region. An OUT electrode, a ground electrode, and a Vcc1 electrode are disposed on the n-type region. The Vcc1 electrode is connected to the positive electrode of an auxiliary direct current power supply (a bootstrap capacitor). The OUT electrode is connected to the negative electrode of the auxiliary direct current power supply. One end portion (a second contact portion) of the high resistance polysilicon thin film is connected to the ground electrode, and the other end portion (a first contact portion) of the high resistance polysilicon thin film is connected to the OUT electrode.

Owner:FUJI ELECTRIC CO LTD

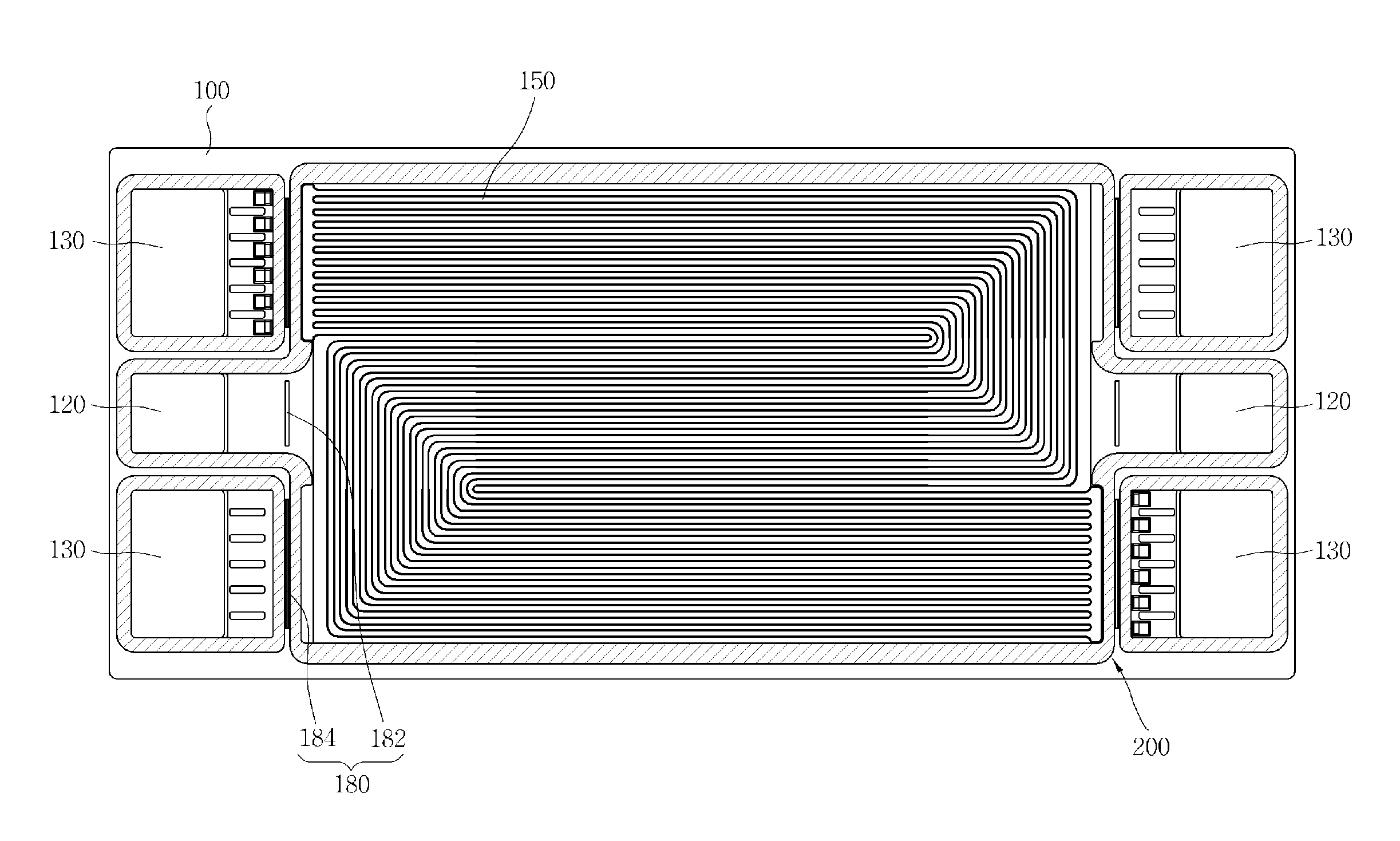

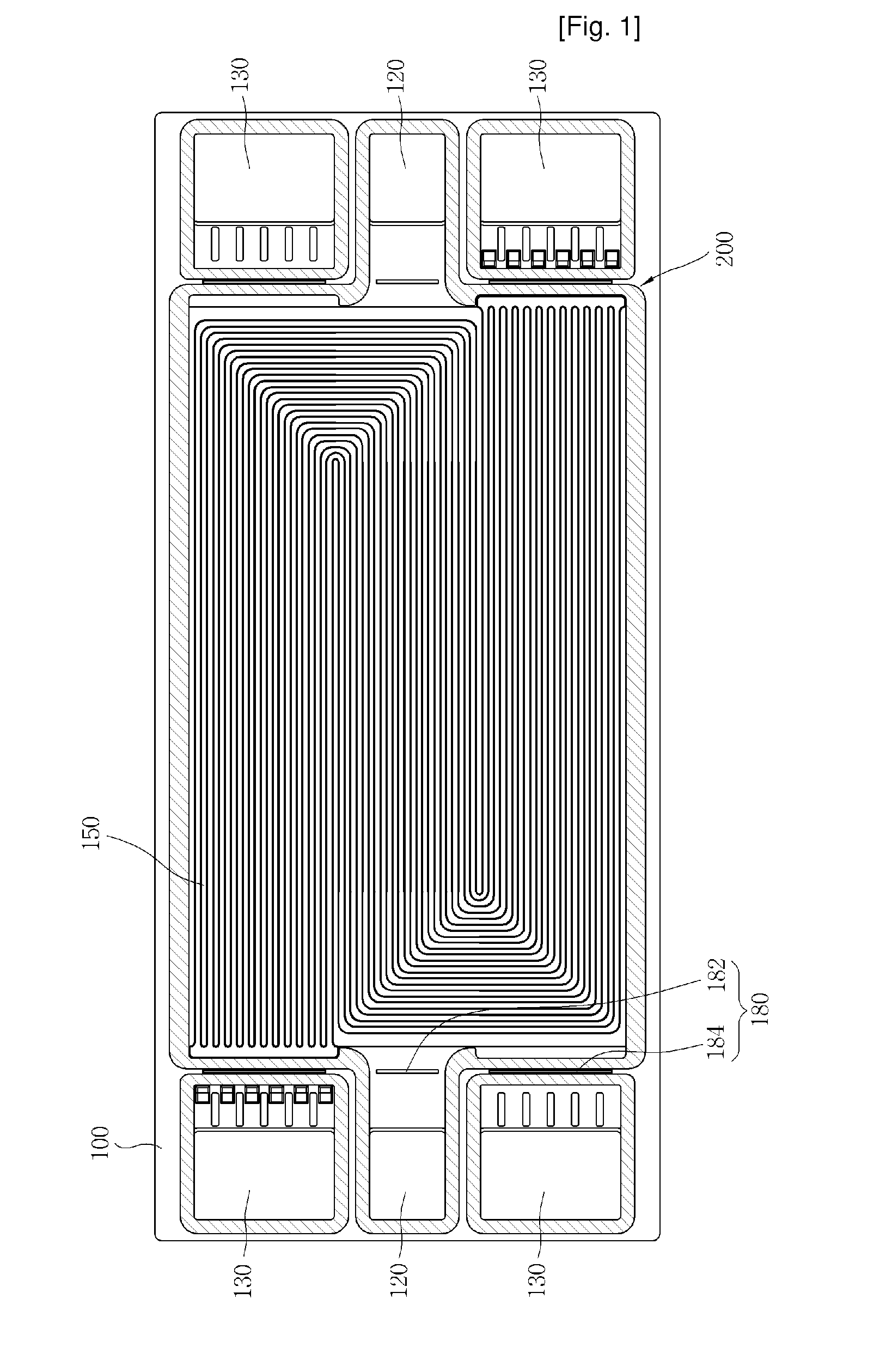

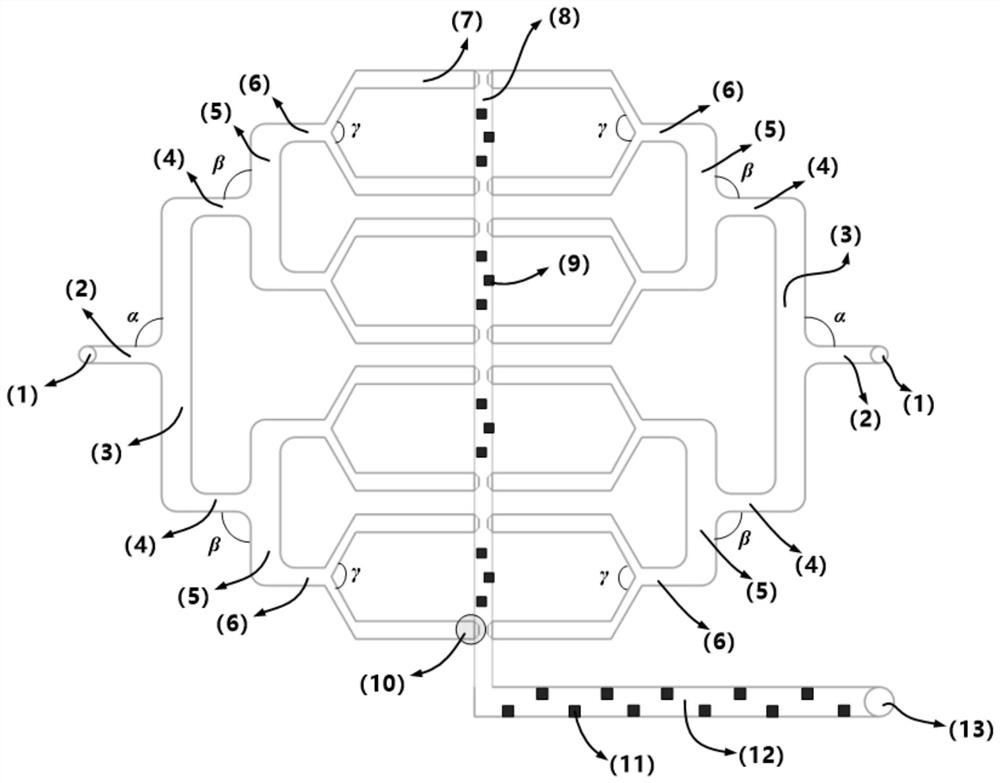

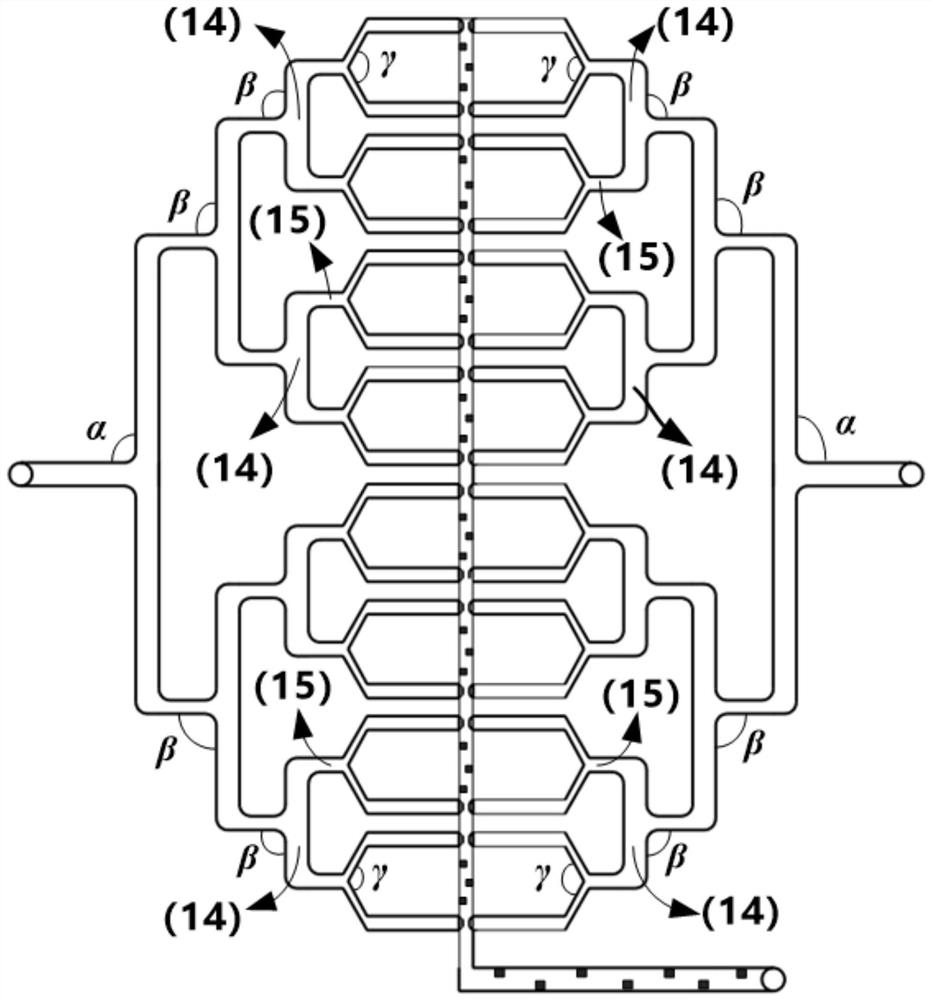

Metal separator for fuel cell and fuel cell stack having the same

ActiveUS20100028742A1Improve cooling effectShorten manufacturing timeFuel cells groupingFinal product manufactureFuel cellsCoolant flow

The present invention discloses a metal separator for a fuel cell including a reaction gas channel formed to protrude from a first face of the metal separator to a second face thereof, a coolant channel formed between the reaction gas channels protruding from the second face of the metal separator, a reaction gas manifold opened to introduce a reaction gas into the metal separator, a coolant manifold opened to introduce a coolant into the metal separator, and a stepped portion positioned at any one of the space between the reaction gas channel and the reaction gas manifold, and the reaction gas channel. This configuration serves to widen the reaction gas flowing portion and the coolant flowing portion on the metal separator, and prevent deformation of the reaction gas flowing portion and the coolant flowing portion, thereby improving efficiency of the fuel cell.

Owner:HYUNDAE STEEL CO LTD

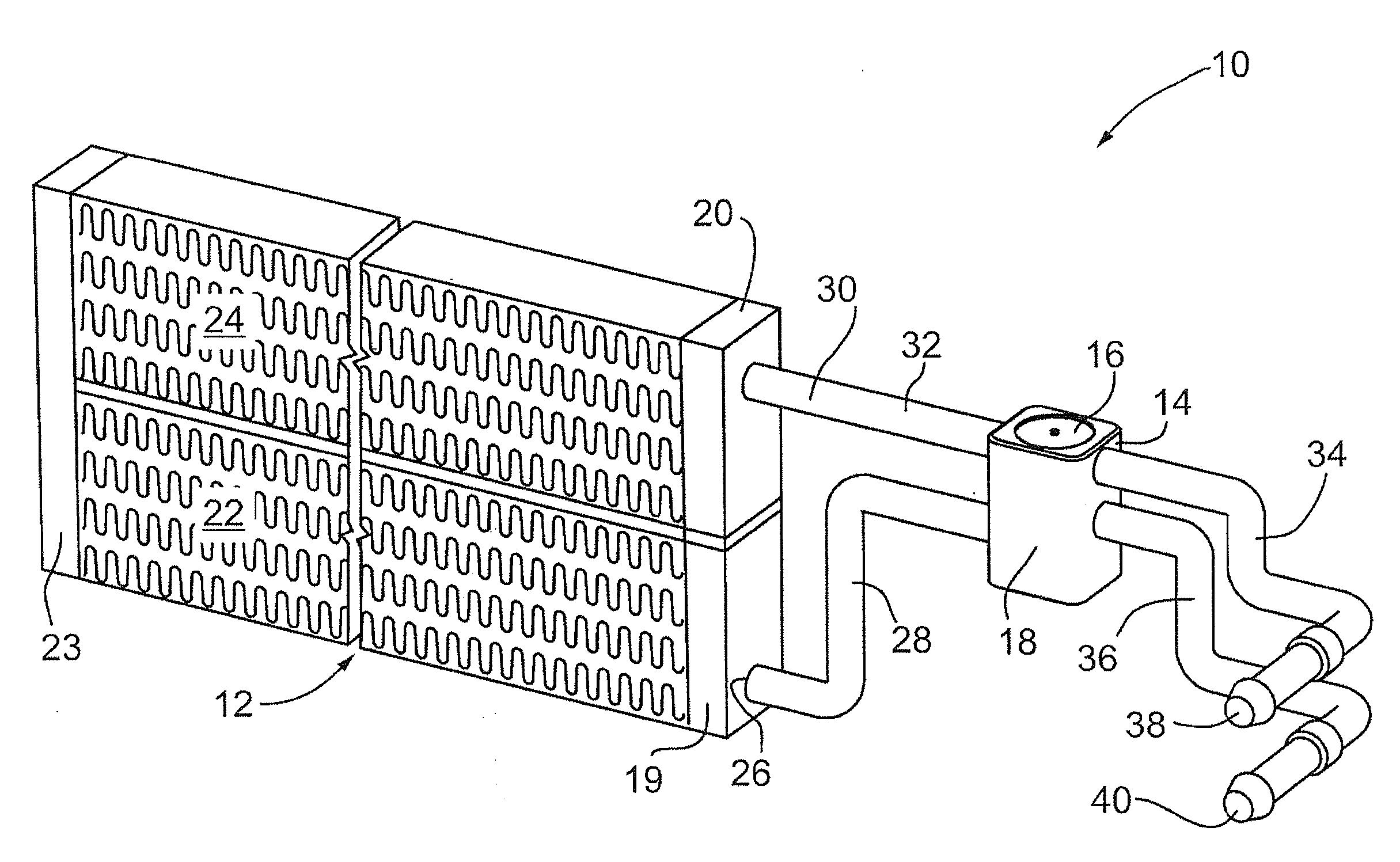

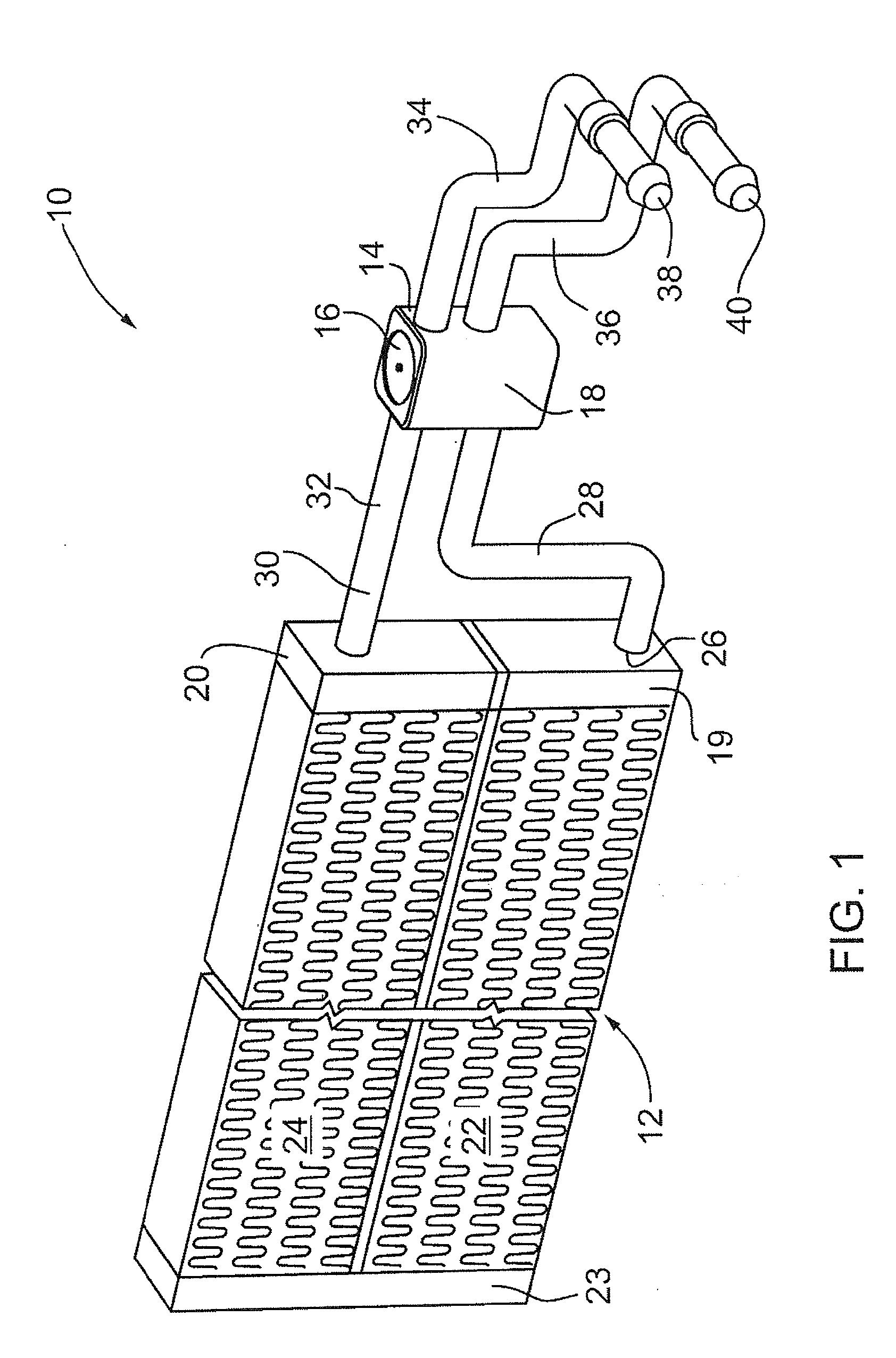

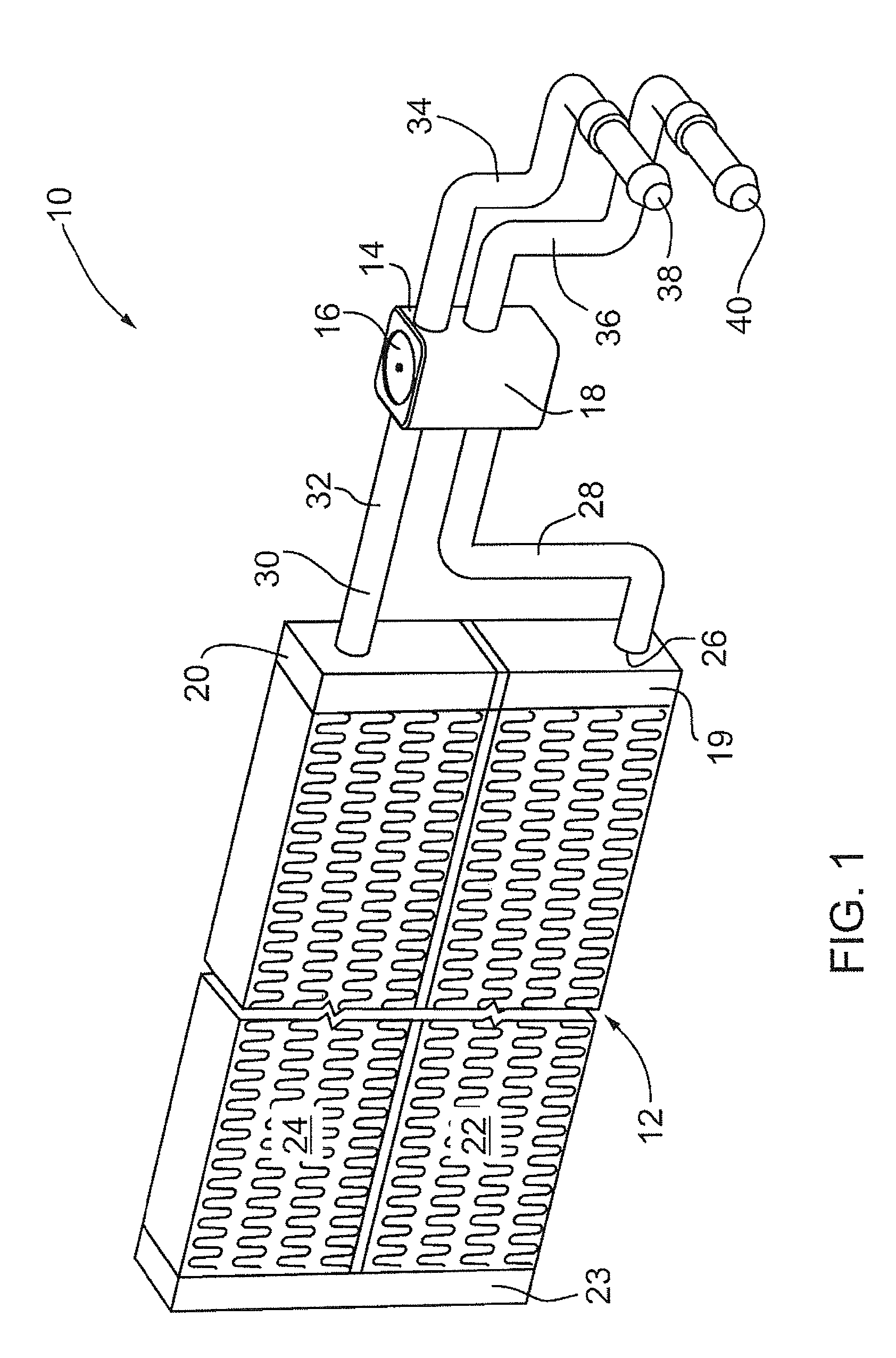

Low pressure drop thermal by-pass valve

InactiveUS8991719B2Easy to operateReduce total pressure dropTemperature control without auxillary powerCoolant flow controlEngineeringActuator

A thermal by-pass valve for a heat exchange circuit includes a housing forming a chamber and a by-pass valve port surrounded by a valve seat. The valve port is located between first and second sections of the chamber. First and second oil ports open into the first section. At least a third port opens into the second section. A thermally sensitive actuator is mounted in the first section and has a body and a piston located at one end. The body is movable in the chamber in response to extension of the piston. A valve member is operably mounted on the body and is movable by extension of the piston. A spacer projects from and is connected to the body and forms a passage through which the piston extends. The spacer acts to maintain the adjacent end of the actuator body at least the length of the passage away from an end of the chamber. The spacer can have a valve portion to close a further valve port.

Owner:DANA CANADA CORP

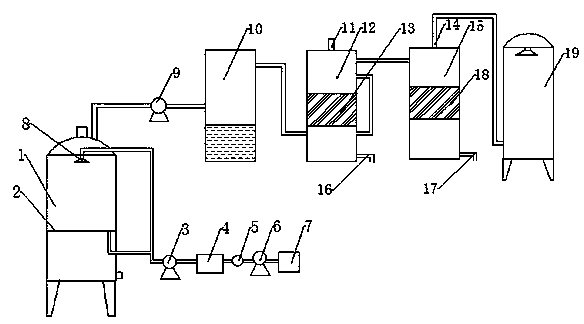

Method and device for treating waste gas generated by printing and dyeing wastewater

InactiveCN103691268ALow running costReduce total pressure dropDispersed particle separationAir quality improvementDyeing wastewaterChemical agent

The invention belongs to the technical field of waste gas treatment and particularly relates to a method for treating waste gas generated by printing and dyeing wastewater. The method comprises the following steps of: firstly, treating the waste gas; and then carrying out primary biological treatment and secondary biological treatment on the waste gas. When the method disclosed by the invention is adopted to treat the waste gas generated by the wastewater in the printing and dyeing process, by removing dust in odor and preventing the dust from entering a subsequent biotrickling filter to cause increase of a pressure drop, increase of operating cost and even failure of operation are avoided. The method has another advantage that the method is low in investment, is low in operating cost, has low power consumption, does not consume chemical agents, does not generate secondary pollutants, is convenient to manage and operate, has good impact resistance, is rapidly recovered after shutdown, can reach a full load only in 2 to 3 days, is the most natural and green environmental-friendly process and is suitable for places in which the gas volume is large, concentration is low and pollutant ingredients can be biodegraded.

Owner:HUAFANG

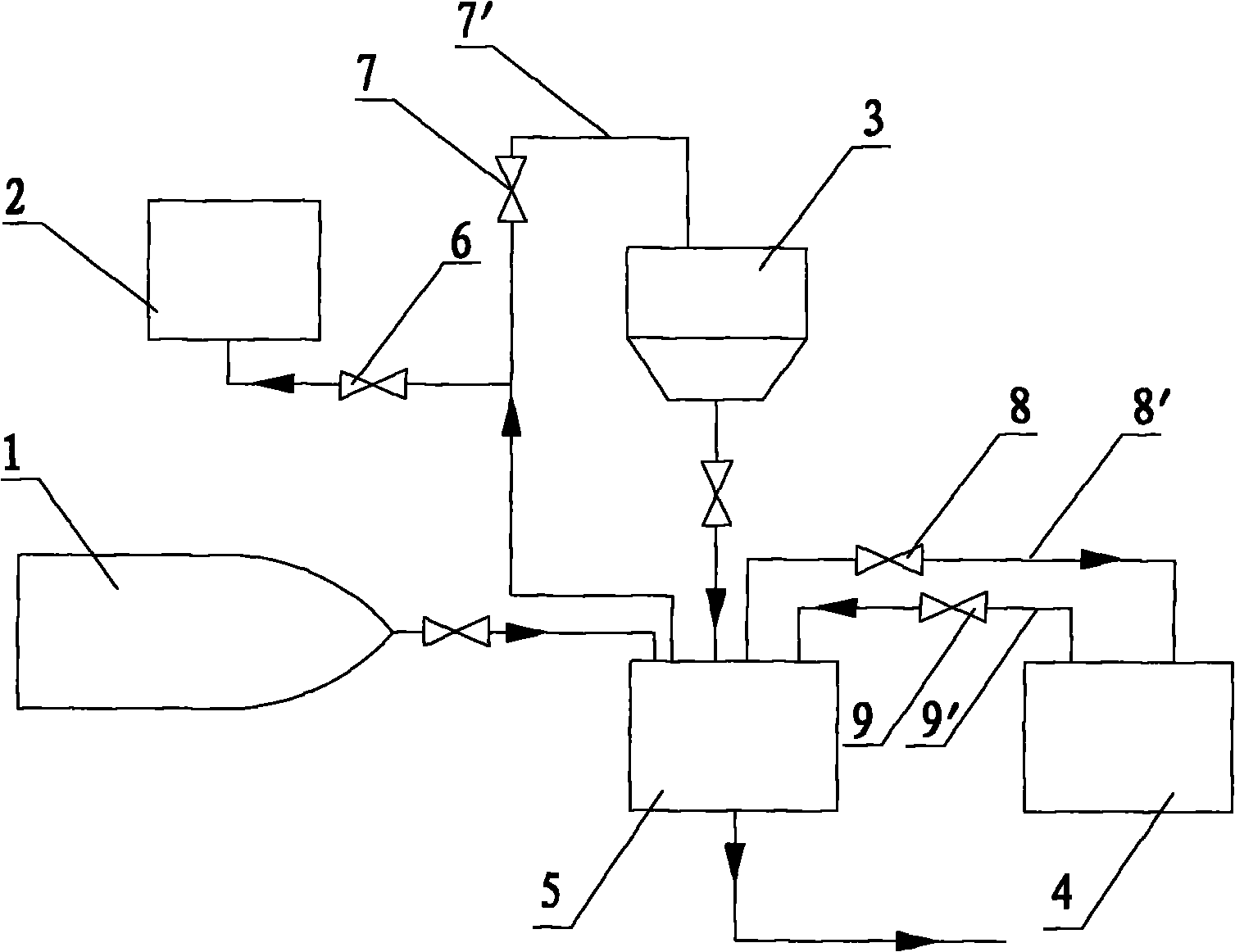

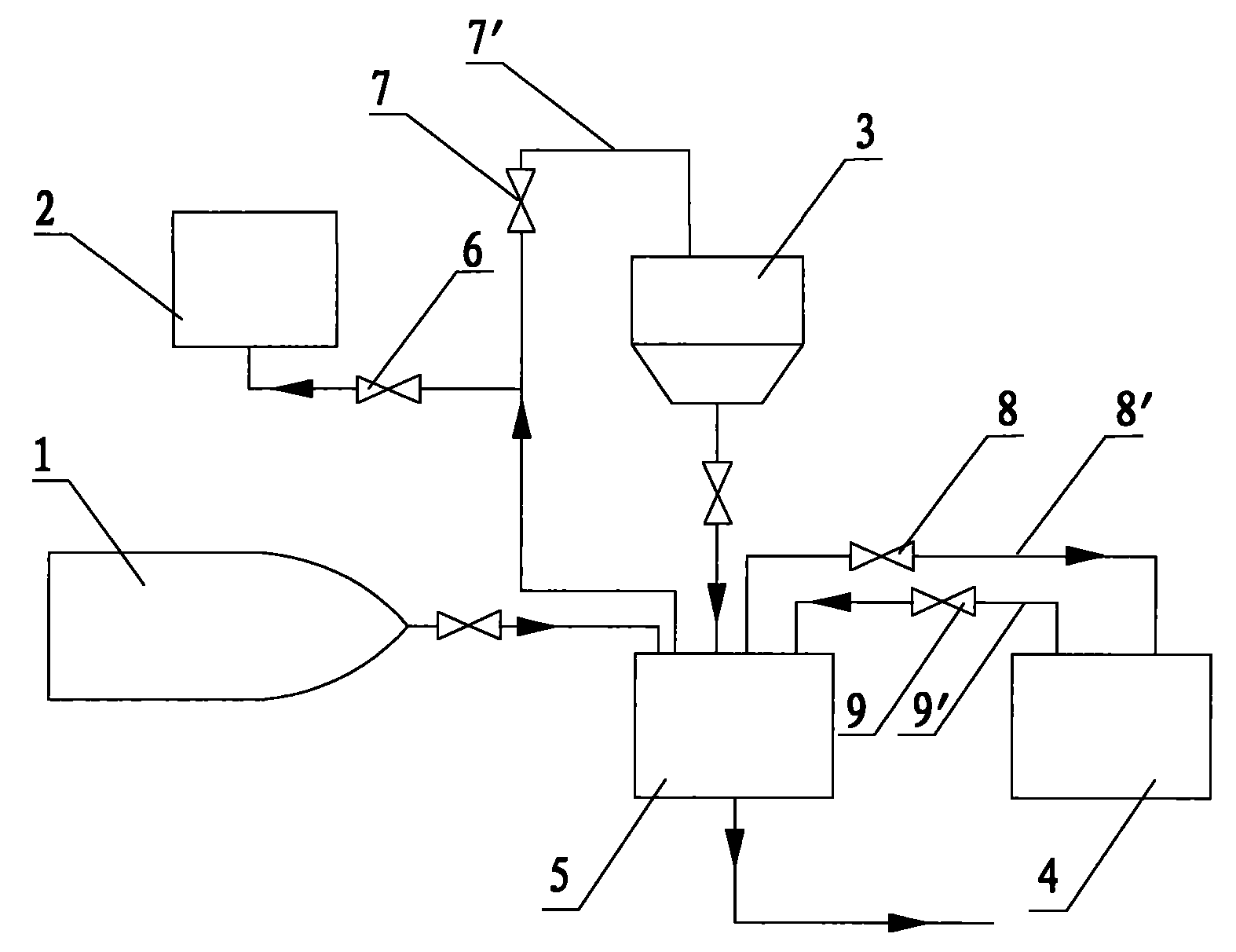

Blast-furnace coal powder injection method and system thereof

The invention discloses a blast-furnace coal powder injection method and a system thereof. The method comprises the following steps: A, arranging coal powder stored in a coal powder bin in an injecting tank of an injecting tank group; B, pressurizing the injecting tank by using the high pressure gas obtained from a factory-supplied gas system, and injecting the coal powder into a blast furnace; and C, depressurizing the high pressure gas in the injecting tank, and then directly discharging into the coal powder bin, wherein a step C' needs to be done before the step C, and a step B' needs to be done before the step B. The step C' comprises the following steps: communicating the injecting tank with a gas container, and depressurizing the gas container by using the injecting tank. The step B' comprises the following steps: communicating the injecting tank with the gas container, and pressurizing the injecting tank by using the gas container. The invention can realize the effective recycle of the gas depressurized by the injecting tank, reduce the gas consumption of the powder making and injecting system, save the production cost, reduce the depressurized pressure difference of the depressurization system, decrease the maximum instant depressurized gas flow, reduce the impact on pipelines in the depressurization process, improve the operation stability of the system, and achieve high gas recovery rate.

Owner:CISDI ENG CO LTD

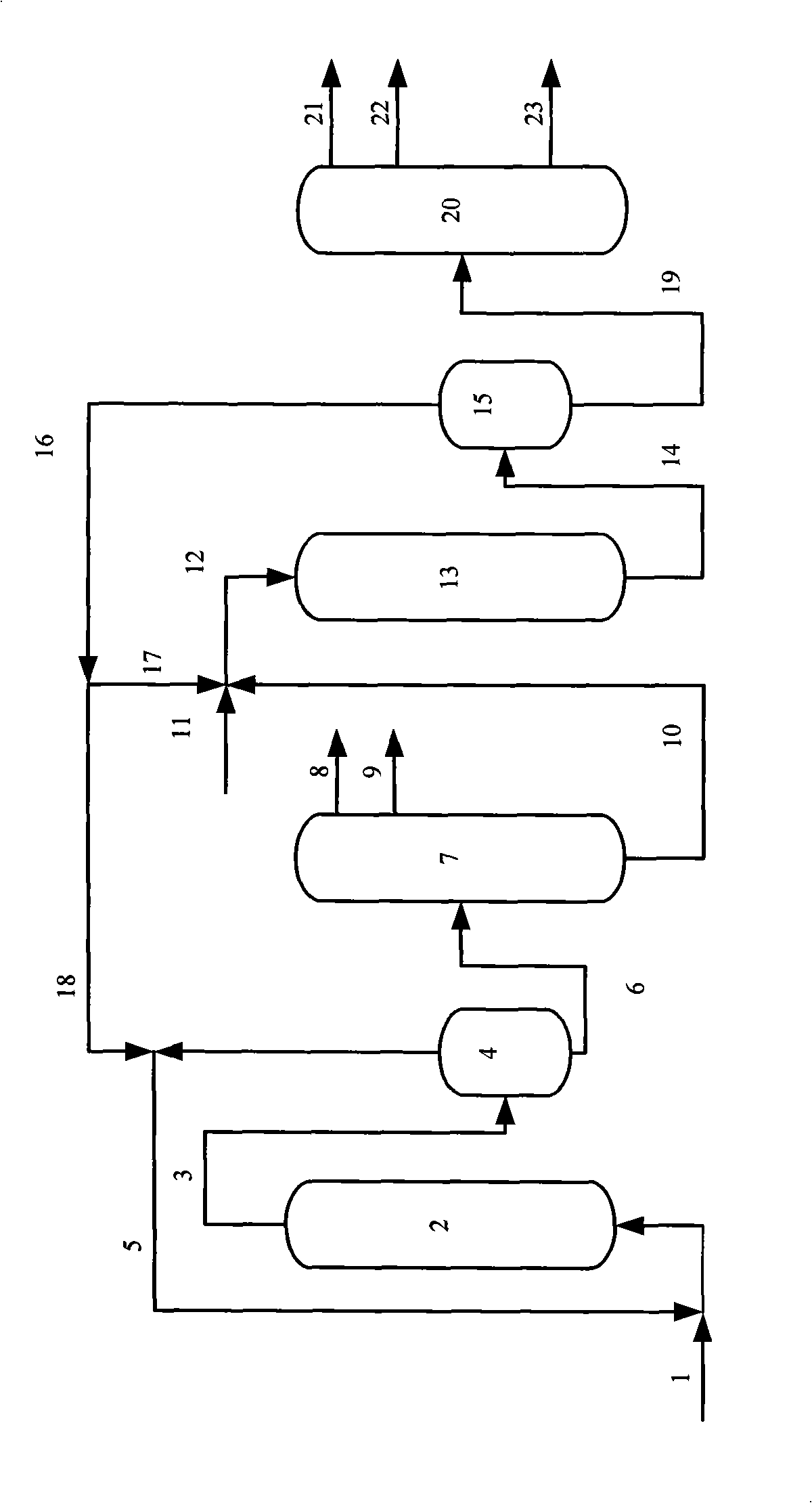

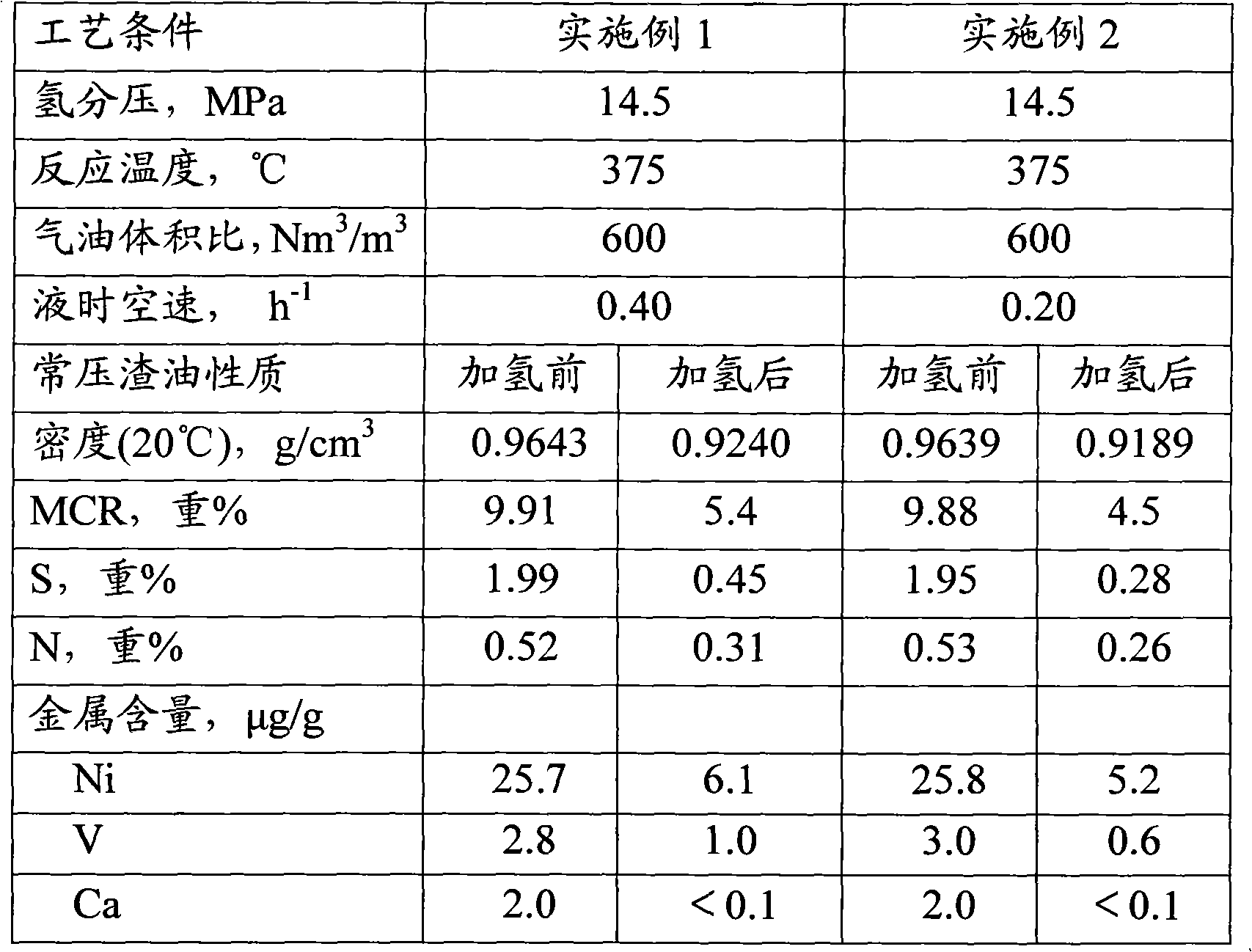

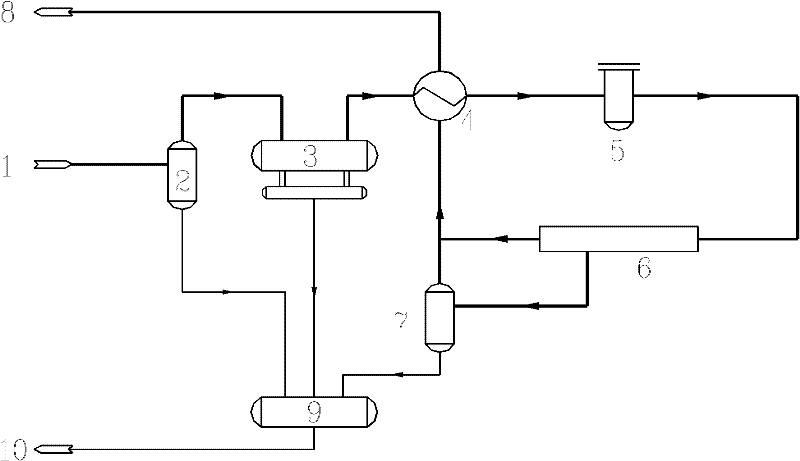

Hydrotreating method of high-acid and high-calcium crude oil

ActiveCN101684414ALow costReduce hydrogen consumptionRefining to eliminate hetero atomsNaphthaHydrogenation reaction

The invention relates to a hydrotreating method of high-acid and high-calcium crude oil. The high-acid and high-calcium crude oil carries out hydrogenation reaction in a crude oil hydrogenation reaction area; obtained hydrogenation crude oil enters a normal-pressure tower and is fractionated to obtain normal-pressure naphtha, normal-pressure diesel and normal-pressure residue oil, wherein the normal-pressure residue oil and hydrogen gas enter a residue oil hydrogenation reaction area together to carry out the hydrogenation reaction; and reaction products are separated to obtain hydrogenationnaphtha, hydrogenation diesel and hydrogenation residue oil, wherein the hydrogenation residue oil is qualified catalytic cracking feeds. Through the method, after the high-acid and high-calcium crude oil is in hydrotreatment in the crude oil hydrogenation reaction area, acid materials and calcium in the crude oil can be efficiently removed, and therefore, corrosion of the acid materials to the normal-pressure tower can be avoided, and increase of pressure drop of a residue oil hydrogenation catalyst bed caused by calcium deposition can be avoided, and long-period safety operation of the normal-pressure tower and a residue oil hydrogenation reactor can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

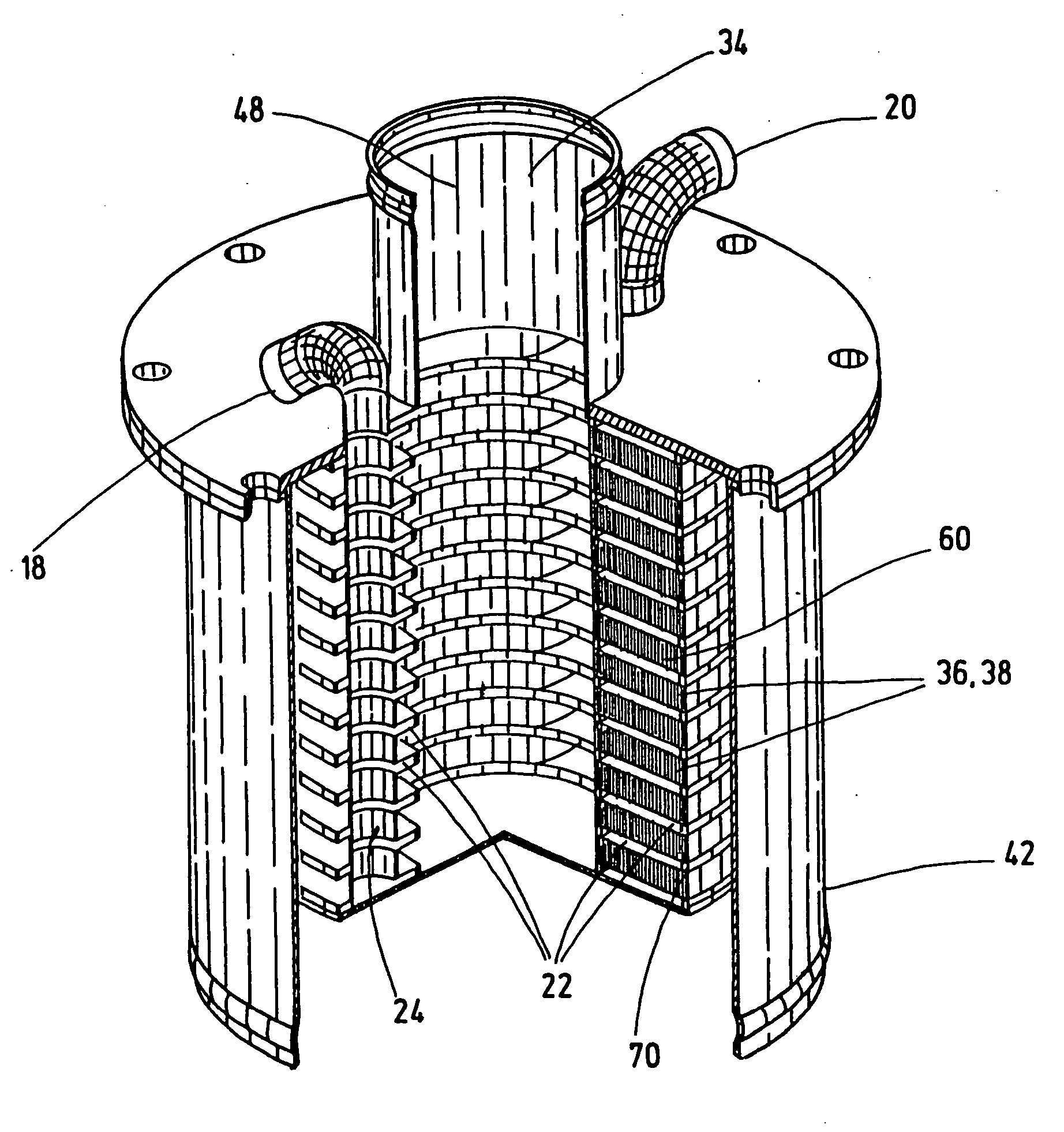

Cooler and method of cooling a medium

InactiveUS20070199683A1Reduce total pressure dropReduce adverse effectsDomestic stoves or rangesInternal combustion piston enginesEngineeringChiller

The invention relates to a cooler having means for directing a cooling medium, means for directing a medium to be cooled, and an essentially axially symmetrical housing. The means for directing the medium to be cooled is arranged in such a way that the medium to be cooled, in at least one first region, flows in an essentially axial direction, and the medium to be cooled, in at least one second region, flows in a direction having a radial component. The invention also relates to a method of cooling a medium and to various uses of a cooler according to the invention.

Owner:BEHR GMBH & CO KG

Venturi flow sensor

ActiveCN101910801AReduce total pressure dropVolume flow proportion measurementVolume/mass flow by differential pressureEngineeringStreamflow

A venturi flow sensing method, system, and apparatus. A tube or chamber may be tapered from a larger to smaller diameter to create a venturi region within the tube or chamber. The venturi region causes a local increase in flow velocity. The change in velocity creates a local change in pressure which is, in turn, used to drive flow through a parallel bypass tube or chamber. Inside this bypass, a flow sensor can be located, and in some cases, a pressure sensor as well. The flow is then either exhausted back into the original tube or the bypass tube may alternatively dead end. In either case, flow can be measured without causing a significant overall pressure drop in the system.

Owner:HONEYWELL INT INC

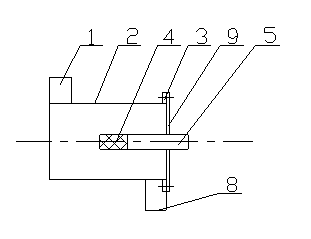

Multi-layer structure micro-channel mixer and fluid mixing method thereof

ActiveCN112206695ASpeed up the flowEfficient mixingFlow mixersTransportation and packagingEngineeringMixing effect

The invention relates to a multi-layer structure micro-channel mixer, which comprises a base plate and a sealing plate, wherein two sample injection liquid storage chambers, two inlet channels, two groups of fluid distribution channel nets, two groups of process fluid channels, a fluid collision mixing cavity, a fluid reinforced mixing channel and an outlet buffer chamber are arranged on the baseplate in a bilateral symmetry manner and are arranged on the two sides of the fluid collision mixing cavity. Two fluids to be mixed are respectively conveyed to two sample injection liquid storage chambers, respectively enter an inlet channel through the sample injection liquid storage chambers, enter a process fluid channel after being distributed through a multi-stage fluid distribution channel,and form two opposite impinging streams after flowing out of the process fluid channel,and after mixing, vortex or secondary flow is generated under the action that the fluid collides with a bafflingbaffle or an inner component in the mixing cavity, and finally the mixed fluid mixture flows out of the mixer through the outlet buffer chamber. The multi-layer structure micro-channel mixer has theadvantages of wide operation condition range, good mixing effect, high mass transfer coefficient, small pressure drop and low energy consumption.

Owner:FUDAN UNIV

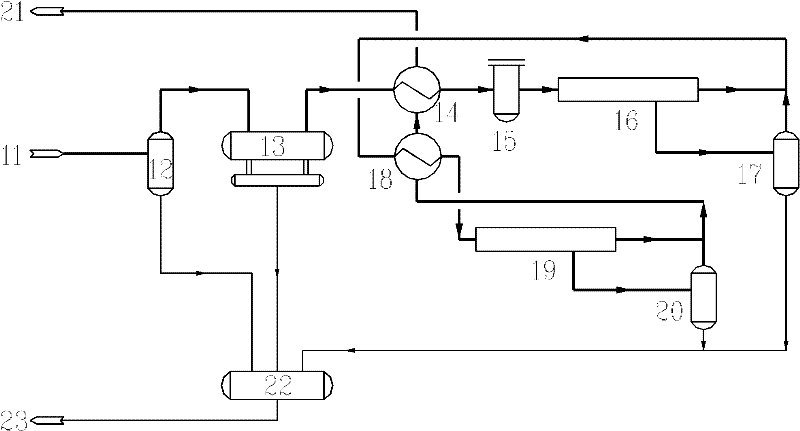

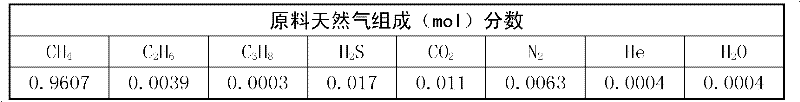

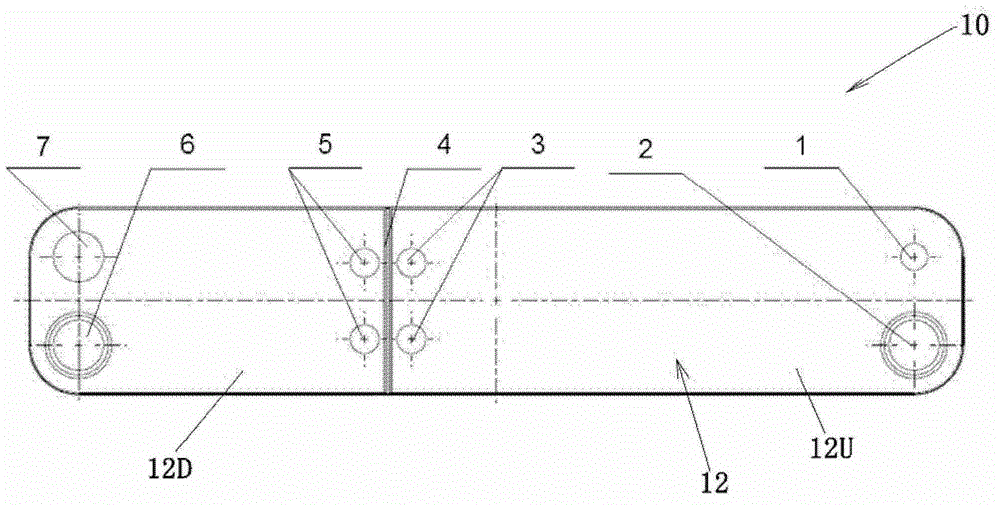

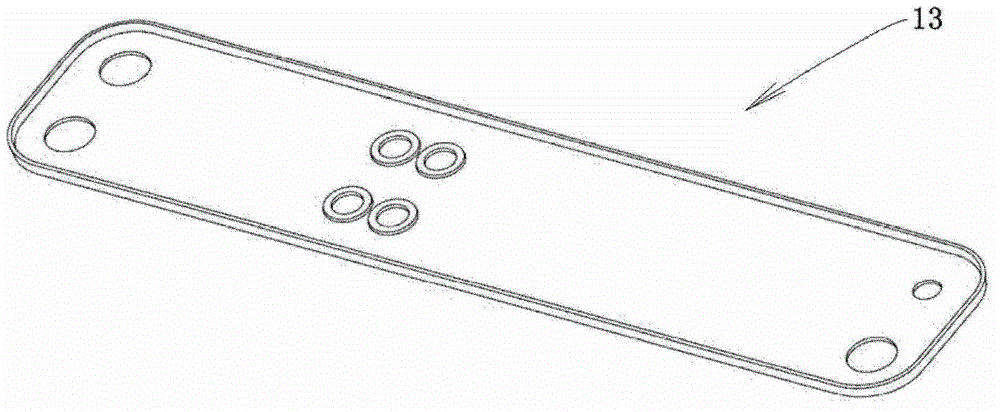

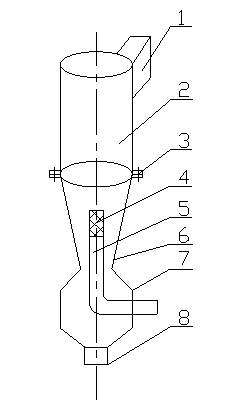

Gas dehydration and dealkylation method for supersonic vortex tube

ActiveCN102389690AAvoid cloggingLow hydrocarbon dew pointCombination devicesGaseous fuelsProcess engineeringDry gas

The invention relates to a gas dehydration and dealkylation method for a supersonic vortex tube, wherein the feed gas enters a separator and a filter separator to separate large particles out, the filtering separated feed gas and a dry gas are cooled in a first level gas-to-gas heat exchanger, and enter a first level prewhirling pre-nucleation supersonic vortex tube to be dehydrated after fine and small solid particles are separated out through a fine filter, and are separated into a first level dry gas and a gas-liquid mixture; the gas-liquid mixture enters a first level gas-liquid separatorto be separated; the separated gas phase flows into the first level dry gas to enter a second level gas-to-gas heat exchanger; the cooled first level dry gas enters a second level prewhirling pre-nucleation supersonic vortex tube to be dehydrated, and is separated into a second level dry gas and the gas-liquid mixture; the gas-liquid mixture enters a second level gas-liquid separator to be separated; the separated gas phase is interflowed with the second level dry gas to enter the second level gas-to-gas heat exchanger and the first level gas-to-gas heat exchanger for exchanging heat with thefirst level dry gas and the feed gas for temperature rise, and the heated dry gas is exported; and the high water dew point and blockage problems of hydrocarbon are solved, the dehydration and the dealkylation of the feed gas are realized, and a purification device is ensured to stably operate.

Owner:PETROCHINA CO LTD

Plate type heat exchanger

ActiveCN102980328AEvenly distributedImprove heat transfer performanceIce productionEvaporators/condensersRefrigerant distributionEvaporation

The invention provides a plate type heat exchanger. The plate type heat exchanger comprises heat exchange plates defining first fluid passages and second fluid passages, and moreover, the first fluid passage is provided with an upstream fluid passage part and a downstream fluid passage part, which communicate with each other through a fluid communicator. The plate type heat exchanger can uniformly distribute refrigerant without depending on a distributor, and moreover, based on the related heat transfer mechanism of refrigerant evaporation, different heat exchange areas are arranged in the passage in order to enhance heat transfer. Not only is the difficulty in the production and machining of the distributor-less heat exchanger based on the invention decreased, but also the practical application range and conditions of the product are broadened. In addition, since the heat exchanger does not have the distributor, the overall pressure drop of the refrigerant flow path of the heat exchanger is lower than the overall pressure drops of the refrigerant flow paths of other products, and thereby therefore more space can be reserved for the model selectionchoice of expansion valves.

Owner:DANFOSS HANGZHOU PLATE HEAT EXCHANGER

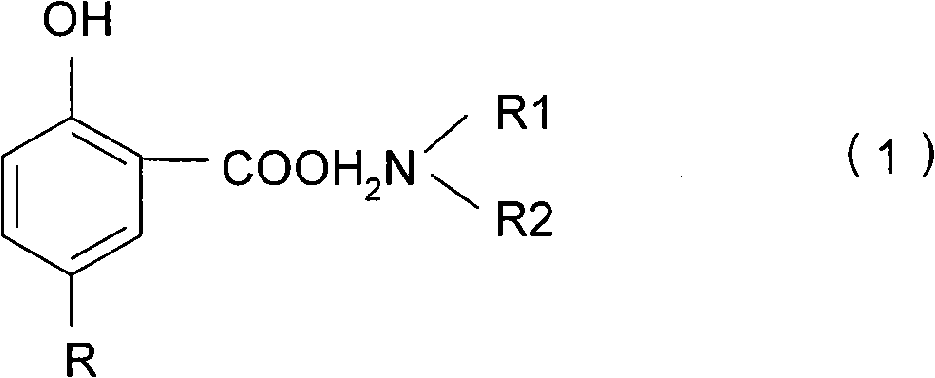

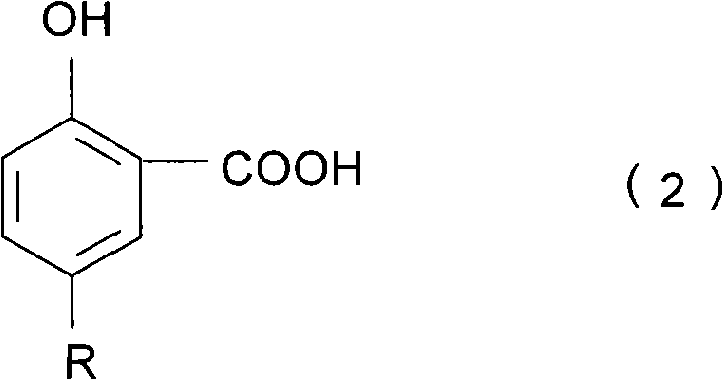

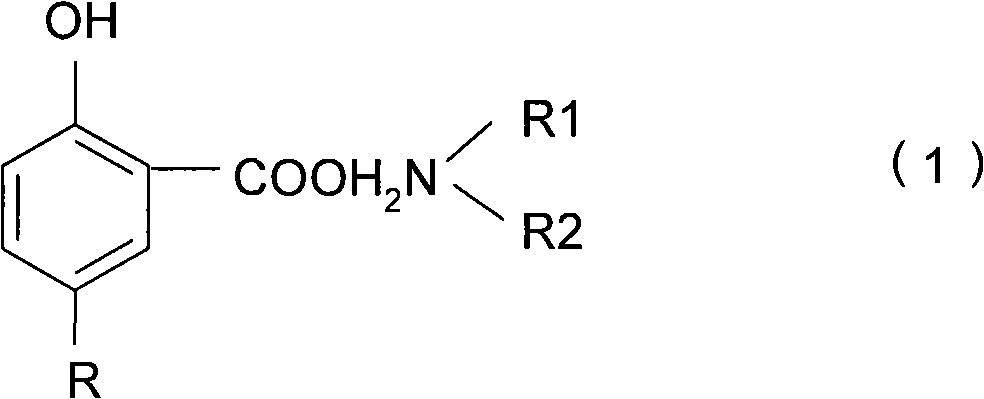

Anti-scaling agent used for hydrogenation plant and its preparation method and application

ActiveCN101265418AInhibition formationLarge poresTreatment apparatus corrosion/fouling inhibitionRefining to eliminate hetero atomsArylHeating furnace

The invention discloses a descaling agent used for a hydrogenation device and the preparation method and the application thereof, and solves the coking and scale deposition of the relevant equipment during the petroleum refining process, such as a hydrogenation device reactor, a heating furnace, and a heat exchanger. The general formula of the hydrogenation descaling agent is shown as the formula (1), wherein, R is C8-C20 alkyl; R2 is H, R1 is C1-C24 alkyl, alkoxy or aryl; or both of the R1 and the R2 are C1-C15 alkyl, alkoxy or aryl. Through adopting the descaling agent of the invention, not only the coking and scale deposition can be inhibited, but also the production is simple and easy, and the descaling agent is harmless to the environment.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

Multi-filter pm 10-pm 2.5 sampler

InactiveUS20130036837A1Improve accuracyReduce total pressure dropWithdrawing sample devicesVena contracta diameterEngineering

A multi-filter PM 10-PM 2.5 sampler which enable the simultaneous collection of four PM 10 and four PM 2.5 samples is disclosed. The sampler is provided with a PM 10 impactor to remove coarse particles and operates at 33.4 L / min. After the PM 10 impactor, the aerosol flow is divided by half by a branch pipe. Half of the flow is directed into four PM 10 cassettes, while the other half is directed into four PM 2.5 cassettes after the aerosols are further classified by a PM 2.5 impactor. To ensure the aerosol flow uniformly passes through each of the four PM 10 or four PM 2.5 cassettes, an orifice plate is assembled behind each of the filter cassettes to increase the pressure drop, such that the flow rates of eight sampling lines are nearly equal.

Owner:NAT CHIAO TUNG UNIV

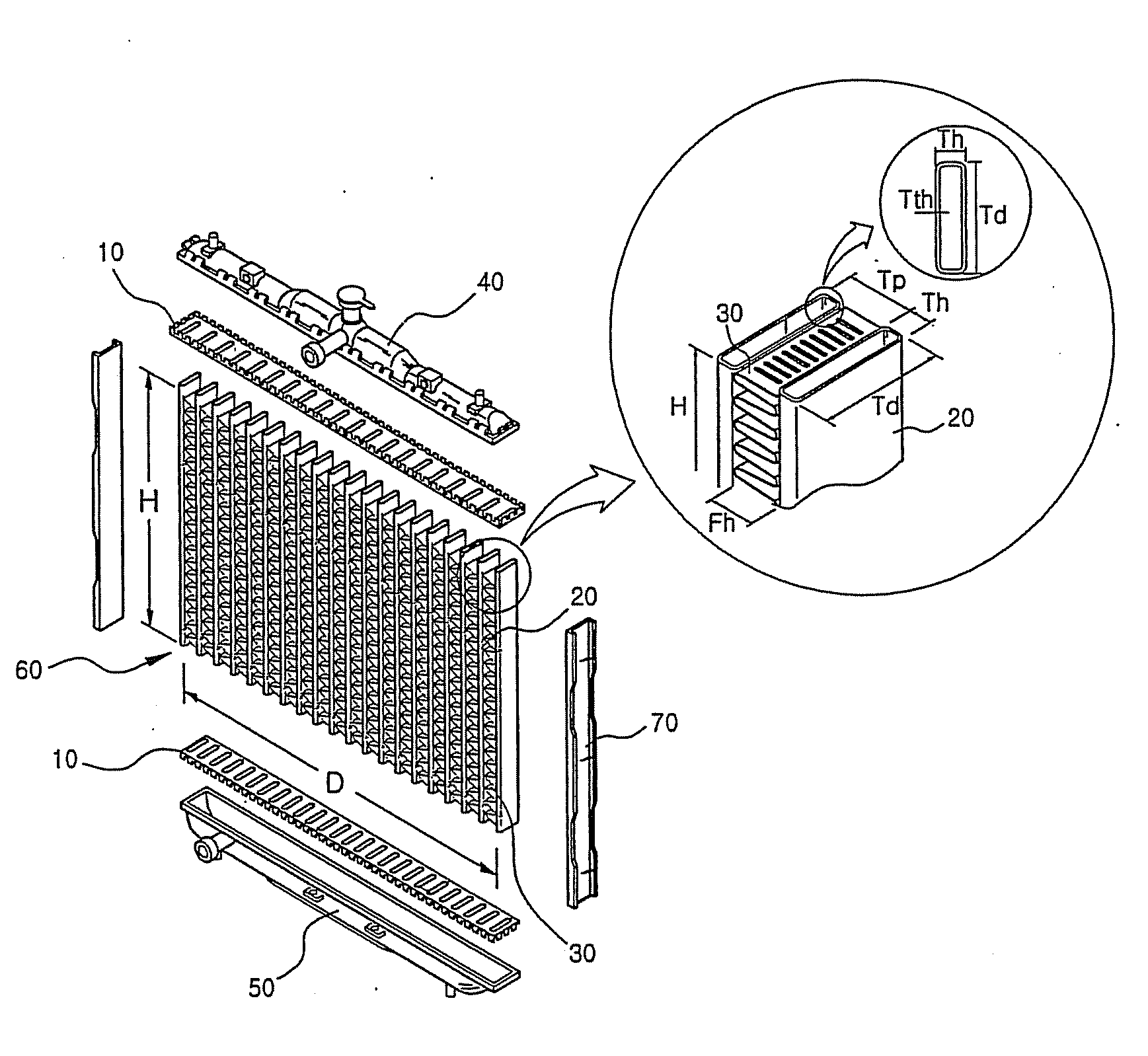

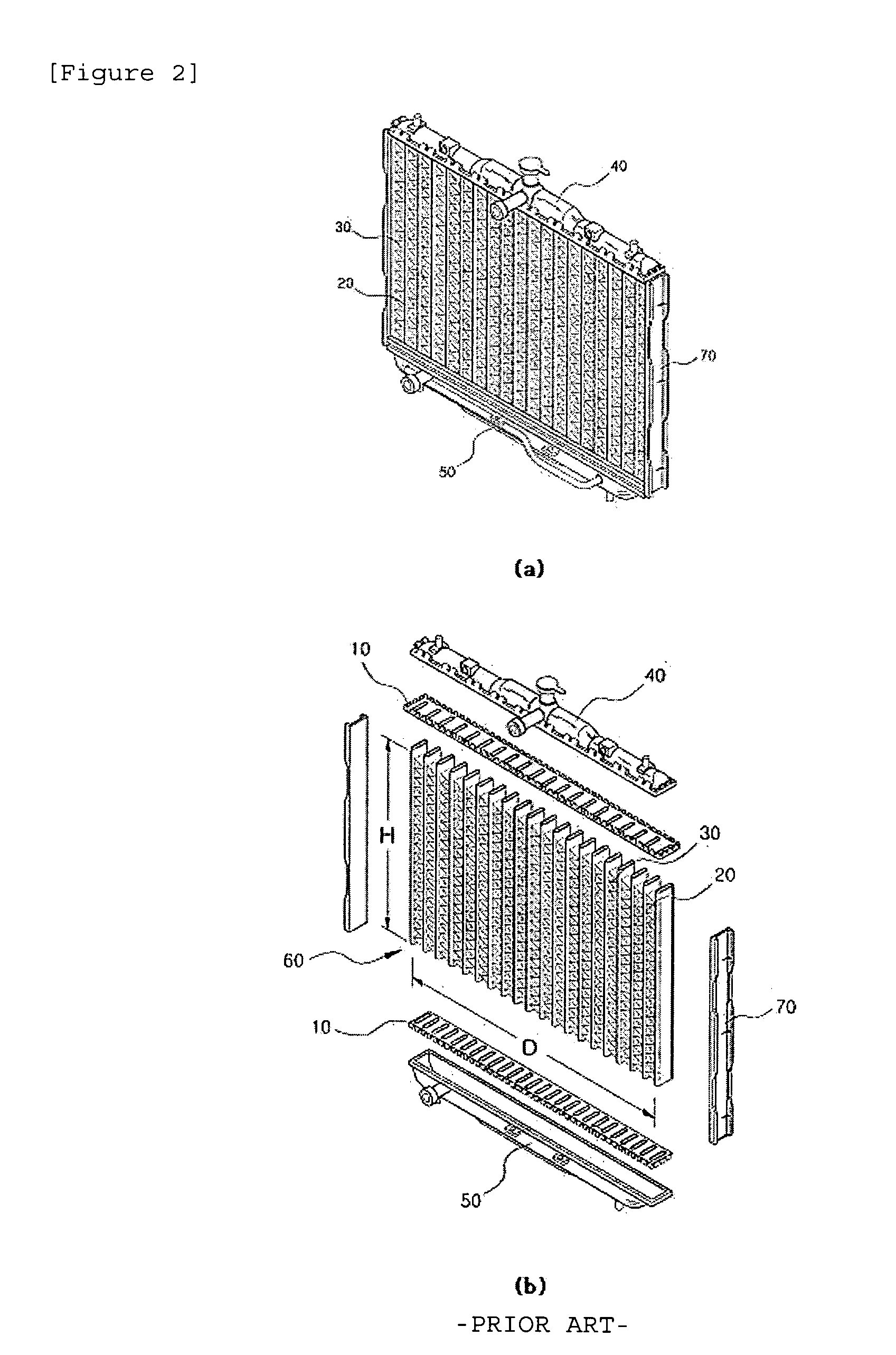

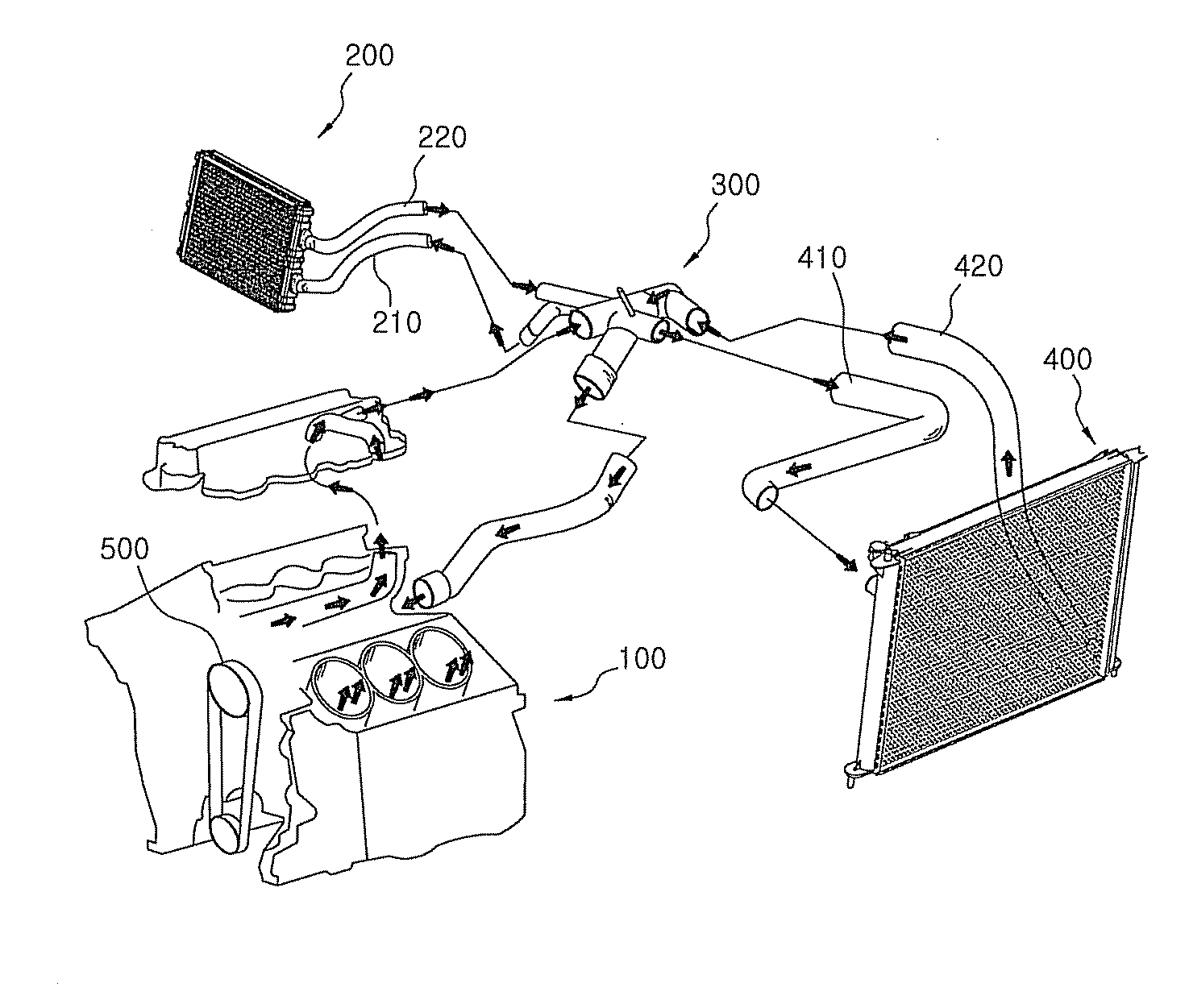

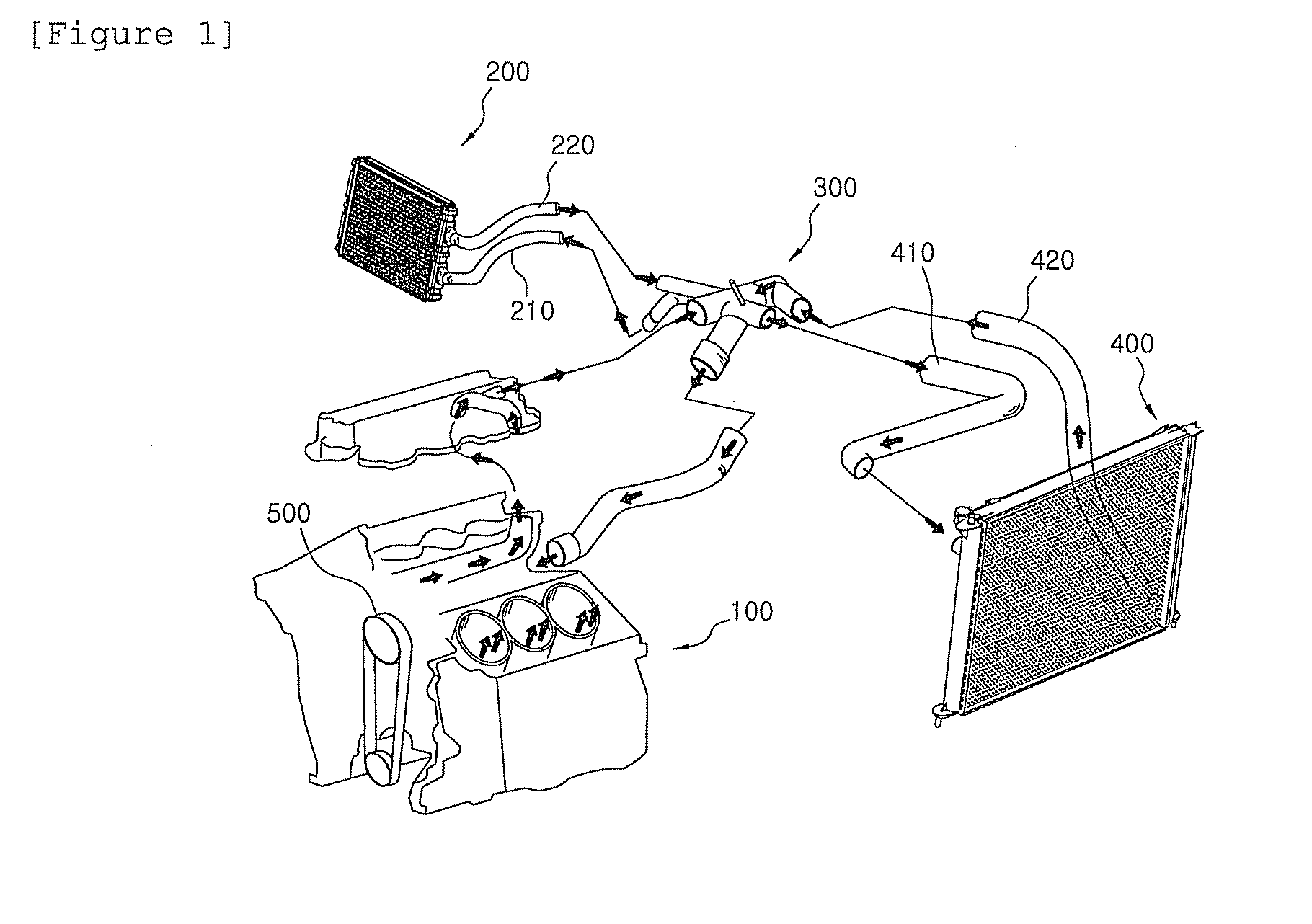

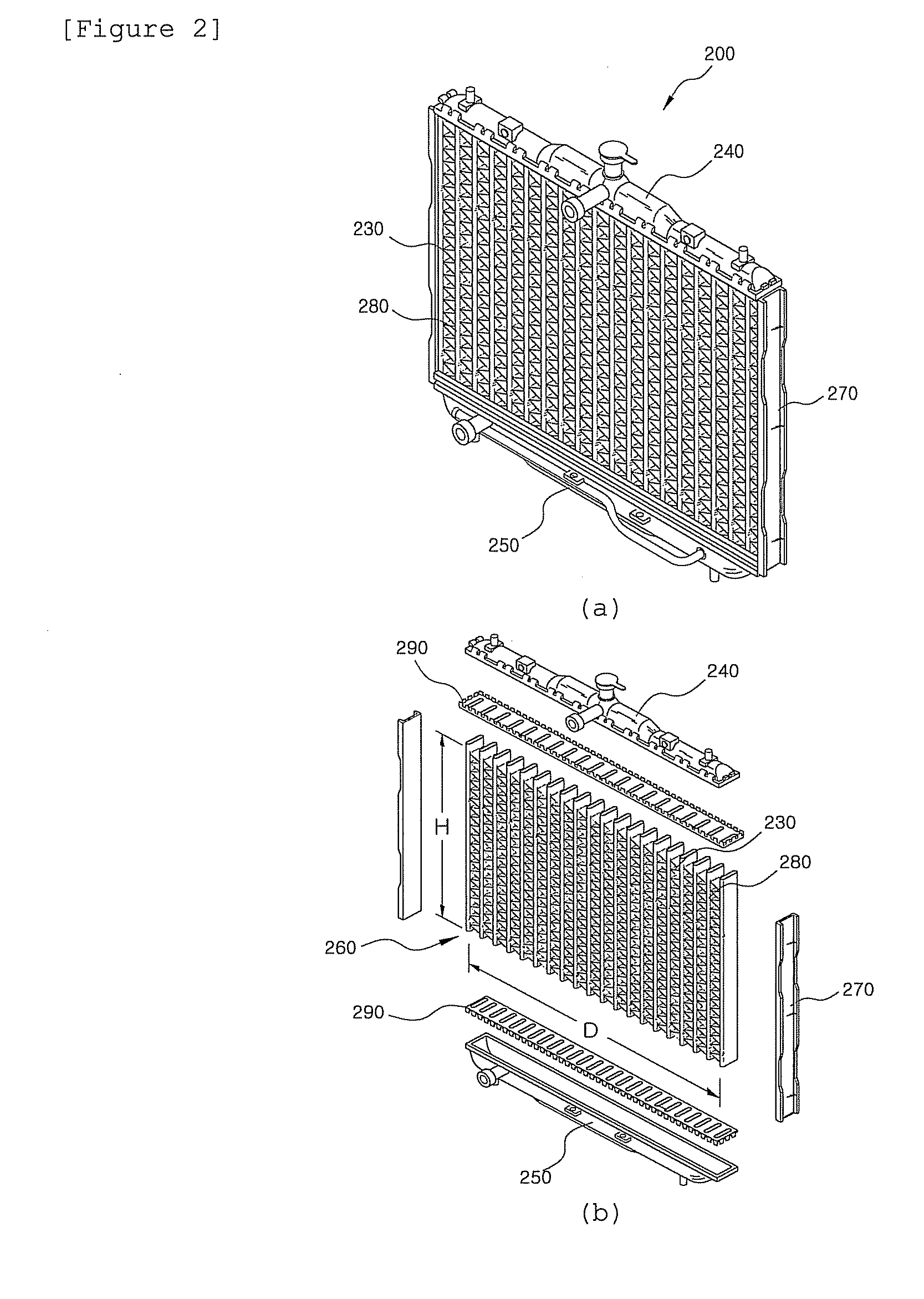

Heat exchanger for a vehicle

InactiveUS20080142190A1Low production costImprove cooling effectLiquid coolingAir-treating devicesPlate heat exchangerThermostat

A heat exchanger for a vehicle engine includes a pair of tanks for supplying a coolant through a thermostat for adjusting opening / shutting depending on the temperature of the coolant and a water pump, and discharging the cooled coolant to an engine side; a header at one side coupled with the tank at one side, to which the coolant is supplied; heat exchange tubes which are structurally fastened to communicate with the heater at one end portion thereof, and arranged in parallel to a direction of driving wind; a header at the other side coupled with the tank at the other side, which is structurally fastened at the other end portion of the heat exchange tube to communicate therewith so as to discharge the coolant into the engine; and a core portion including fins fixedly brazed between the heat exchange tubes.

Owner:HANON SYST

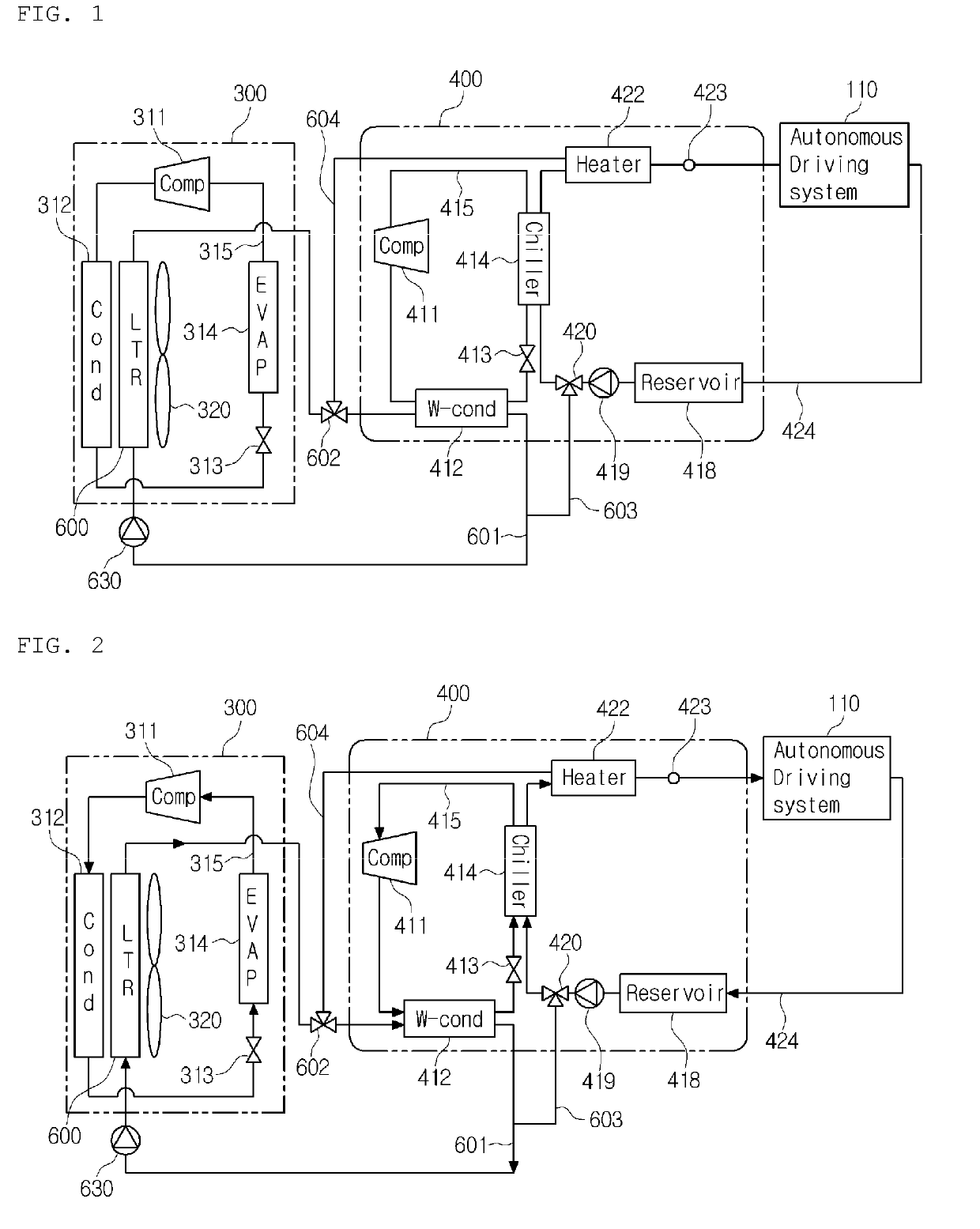

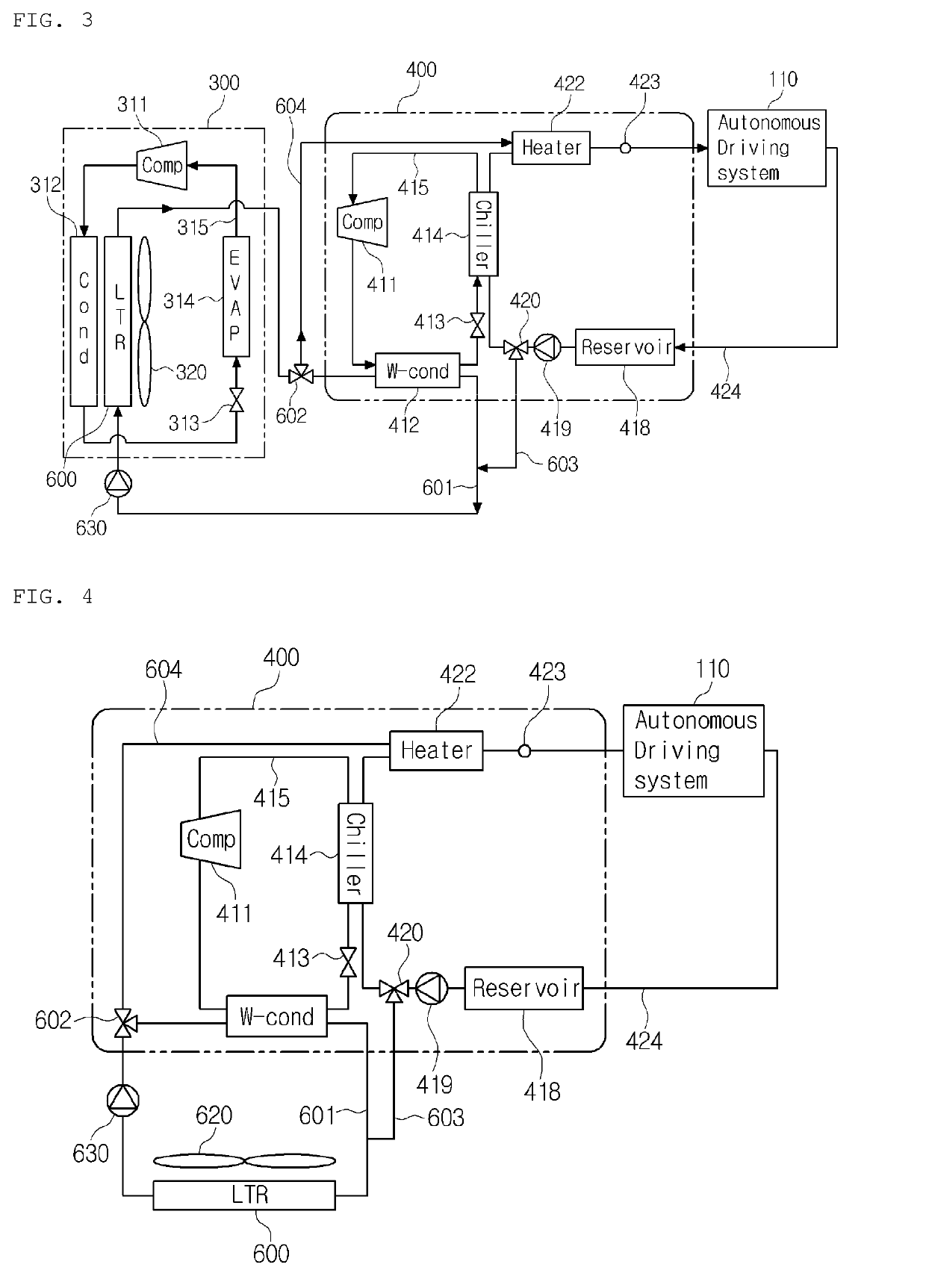

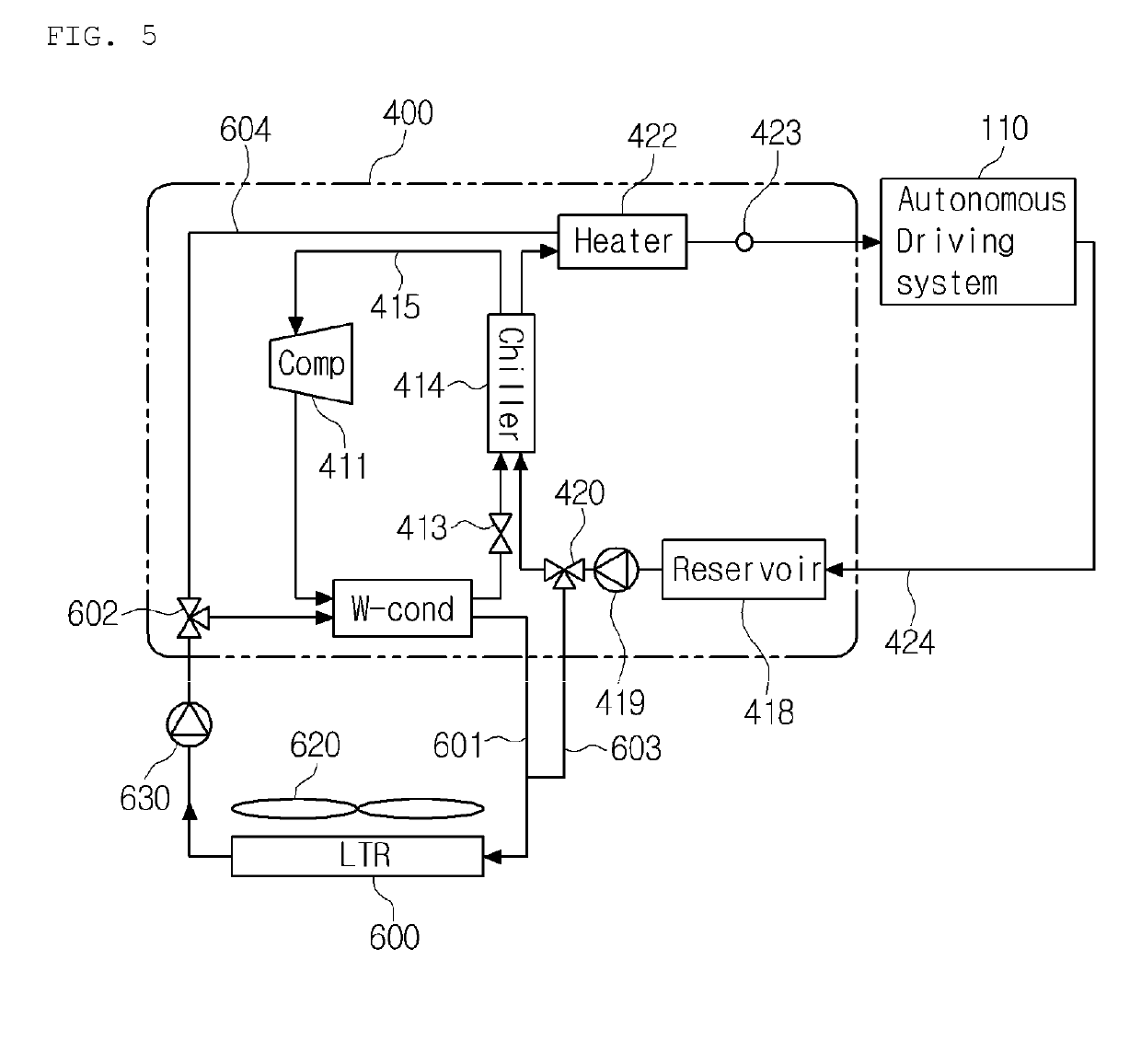

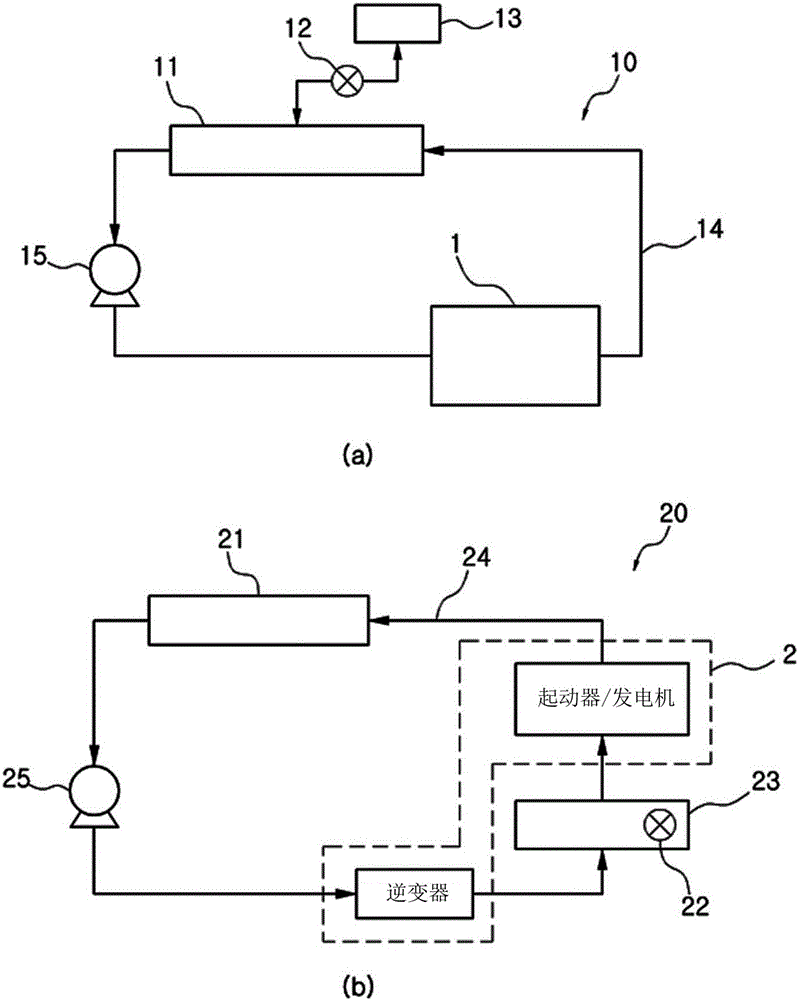

Thermal management system for vehicle

ActiveUS20190168570A1Reduce noiseSmall sizeAir-treating devicesVehicle sub-unit featuresModularityThermal management system

The present invention relates to a vehicle thermal management system which is separately provided with the final heat dissipation unit of a cooling system for cooling electronic components required for the autonomous driving of a vehicle, optimizes the modularization of units, and thereby promotes the reduction of a package.

Owner:HANON SYST

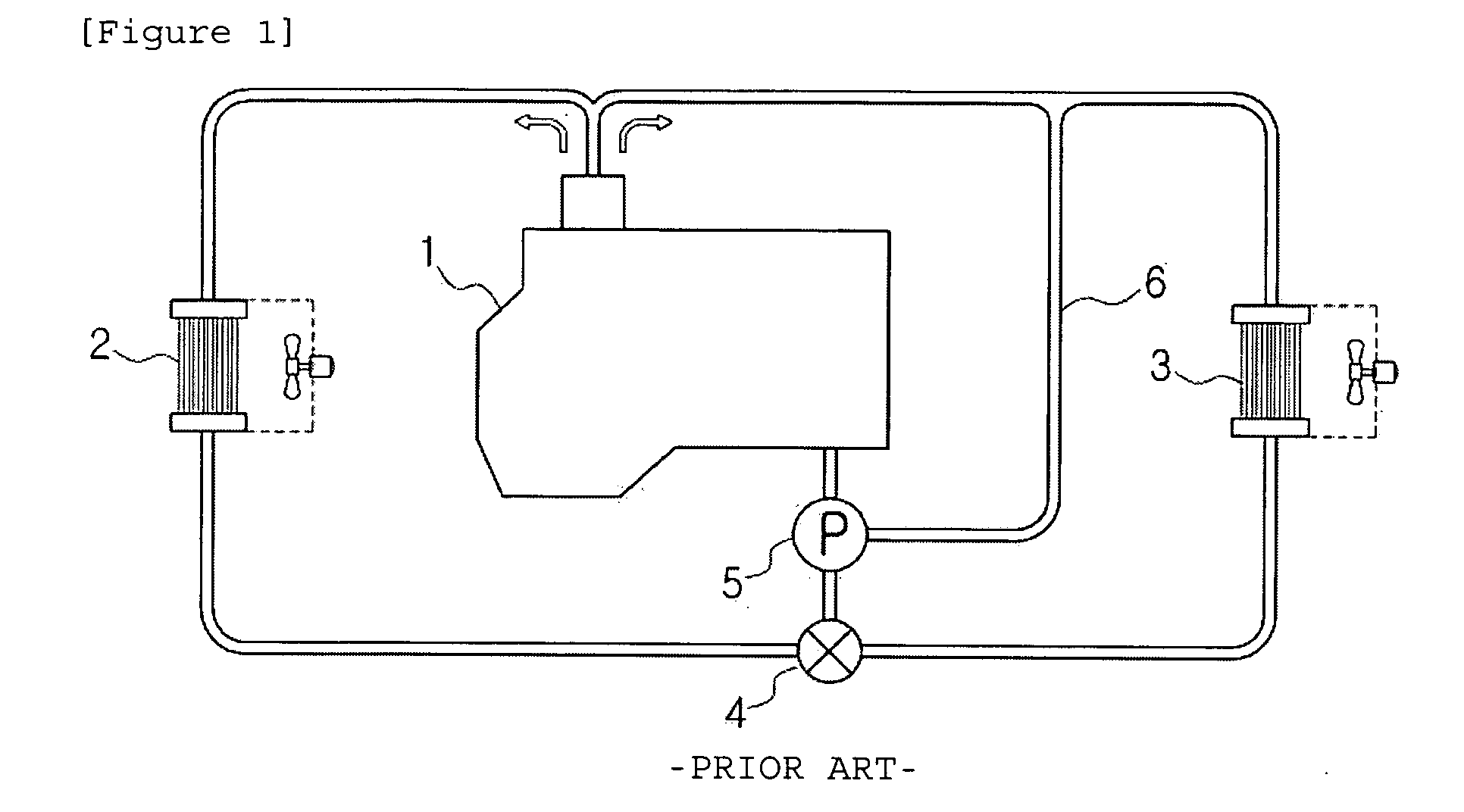

Cooling system for a vehicle

InactiveUS20090038562A1Improve efficiencyLow production costLiquid coolingCoolant flow controlWater flowHill climbing

Disclosed is a cooling system for a vehicle, in which coolant coolant, a blend of an antifreezing solution and water flowed into a radiator generates turbulent flow when a vehicle is in a state of a critical driving mode of a vehicle for example, a hill-climbing mode, thereby enhancing heat radiating performance and reducing pressure drop amount at the same time.

Owner:HALLA CLIMATE CONTROL

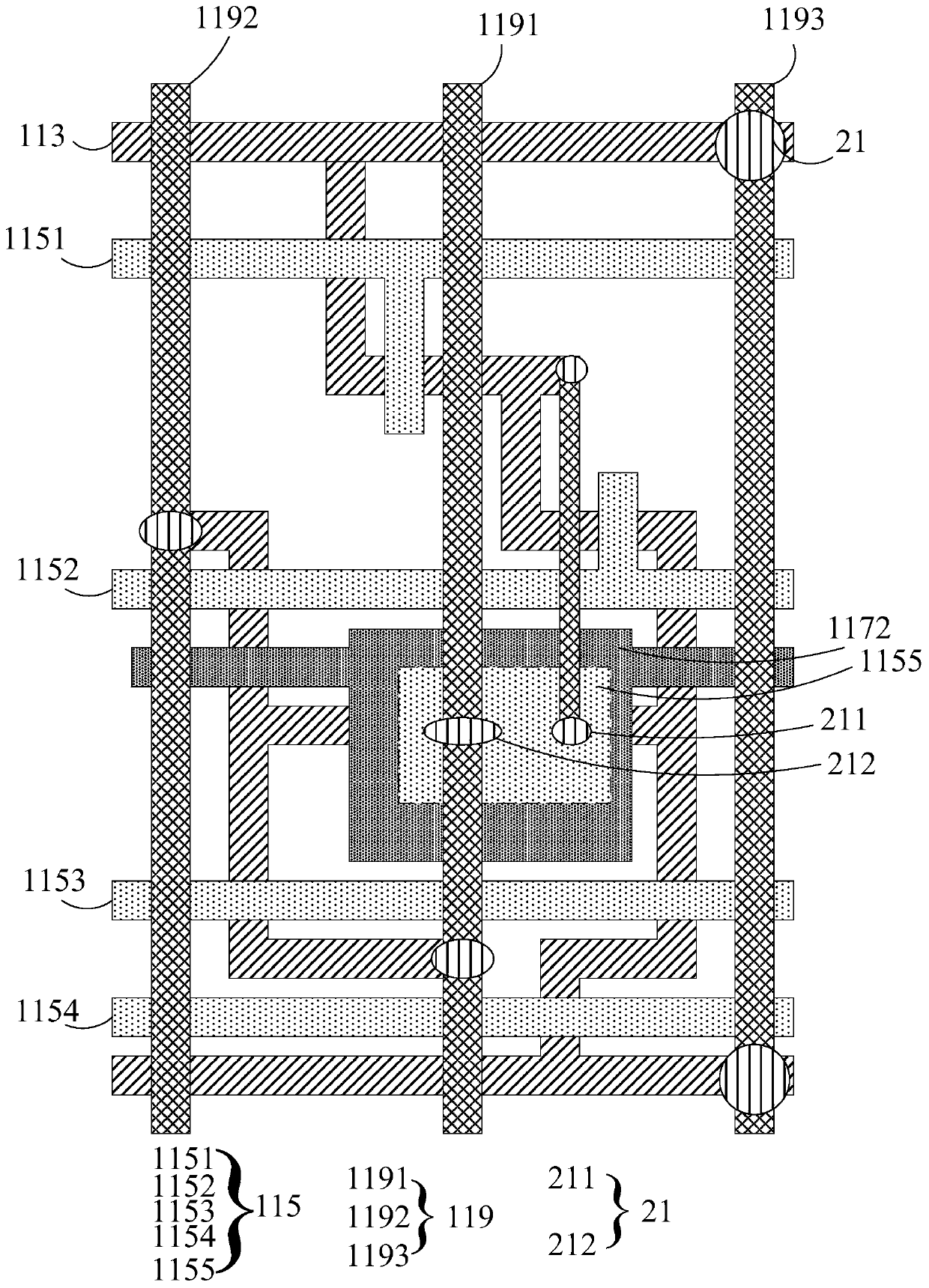

Array substrate and display panel

PendingCN111129093ADoes not affect thicknessAlleviating technical problems of uneven brightnessSolid-state devicesSemiconductor devicesVoltage dropEngineering

The invention provides an array substrate and a display panel. According to the array substrate, a first power supply voltage line is formed on a second metal layer of the array substrate, a first viahole is formed in the interlayer insulating layer, a first power supply voltage line on the second metal layer is connected with a second power supply voltage line of the source-drain electrode layerthrough a first via hole, at least two connections exist between the first power supply voltage line and the second power supply voltage line, parallel connection of the first power supply voltage line and the second power supply voltage line is ensured, therefore, the impedance of the power supply voltage line is reduced, the problem of voltage drop on the power supply voltage line is relieved,a film layer does not need to be added, the thickness of the display panel is not influenced, and the technical problem of uneven brightness of the display panel due to the voltage drop on the power supply voltage signal line of an existing display panel is relieved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

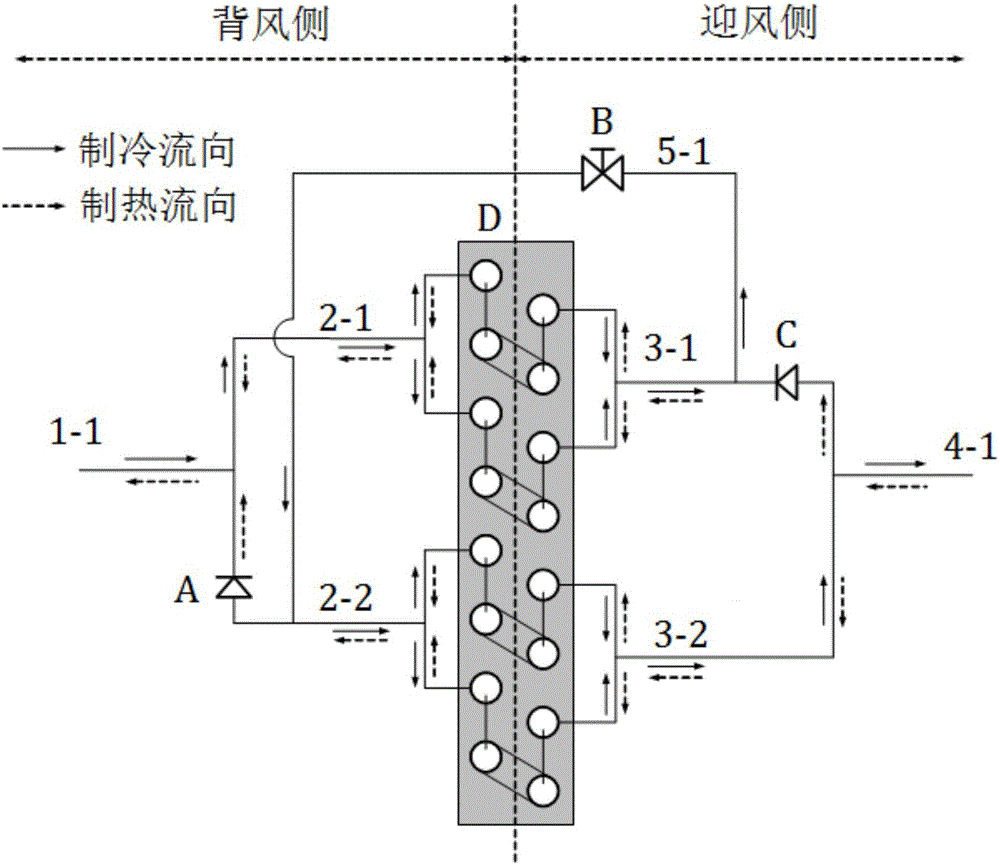

Heat pump type air-conditioning heat exchanger with heat exchange working medium flow direction and flow path number in synchronous change

InactiveCN105865008AImprove reliabilityReduce total pressure dropMechanical apparatusEvaporators/condensersPlate heat exchangerEngineering

The invention discloses a heat pump type air-conditioning heat exchanger with a heat exchange working medium flow direction and a flow path number in synchronous change. The heat pump type air-conditioning heat exchanger comprises a heat exchanger with 2n flow paths, first and second branch pipes at a leeward side, first and second branch pipes at a windward side, a header pipe at the leeward side and a header pipe at the windward side, wherein the header pipe at the leeward side is separately connected with the first branch pipe and the second branch pipe at the leeward side; the header pipe at the windward side is separately connected with the first branch pipe and the second branch pipe at the windward side; the branch pipes at the leeward side and the branch pipes the windward side are correspondingly arranged, and are separately connected with end openings at the leeward side and the windward side of the n flow paths in the heat exchanger; the second branch pipe at the leeward side and the first branch pipe at the windward side are provided with one-way valves; the inlet end of the one-way valve of the second branch pipe at the leeward side and the outlet end of the one-way valve of the first branch pipe at the windward side are connected through a pipeline to form a refrigerating branch pipe; and the refrigerating branch pipe is provided with an electronic valve. The number of the flow paths of the heat exchanger is changed with the switching of a refrigerating working condition and a heating working condition while the flow direction of the heat exchange working medium is changed with the switching of the working condition, so that the performances of an air conditioner are optimal.

Owner:SHANGHAI JIAO TONG UNIV +1

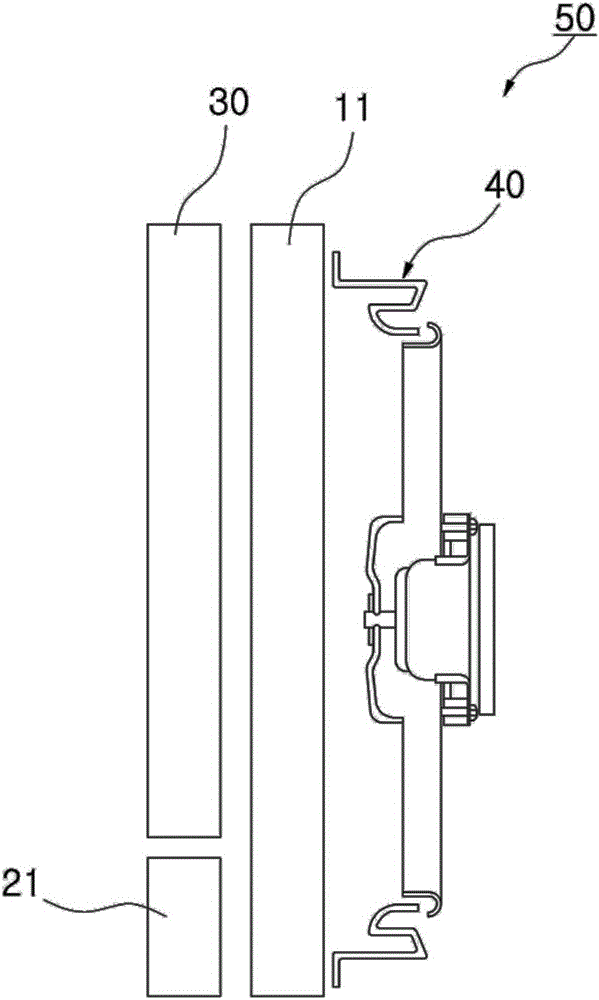

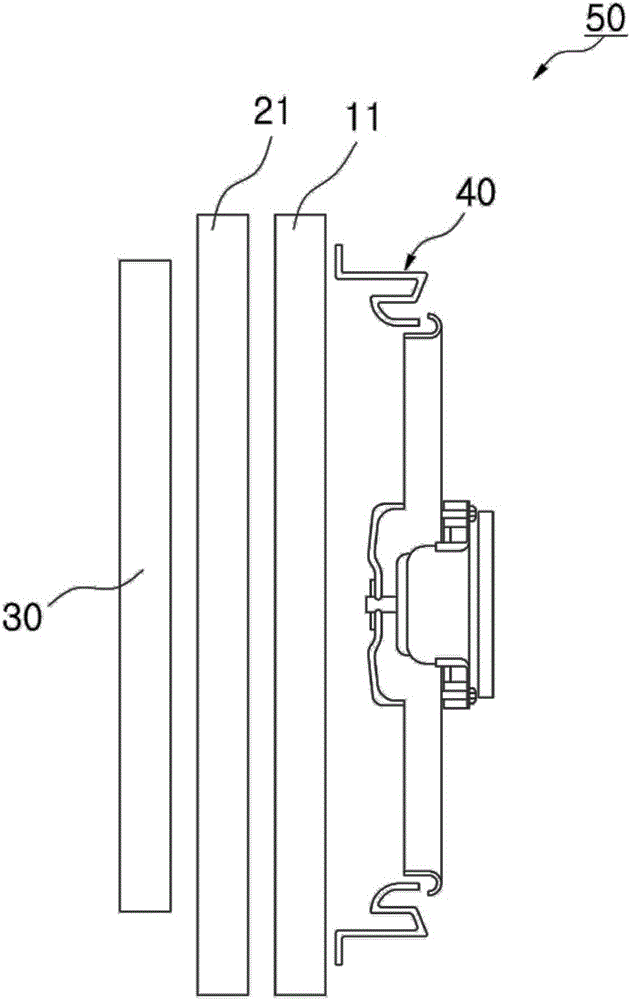

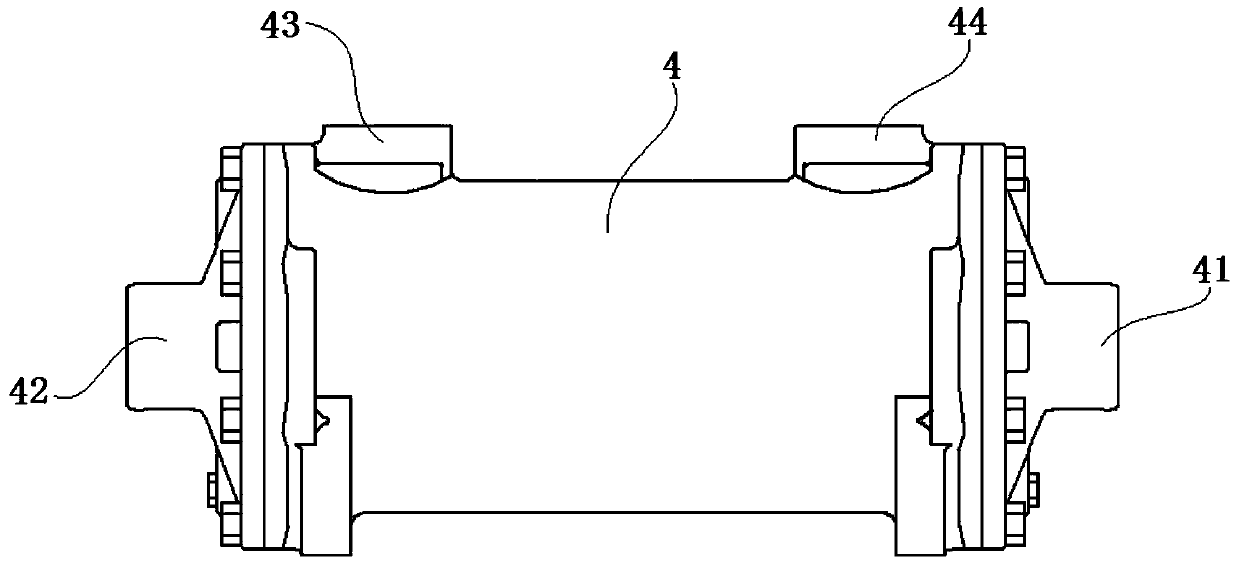

Cooling module

ActiveCN105904960AEnhanced refrigerant condensation performanceSmall sizeStationary conduit assembliesHeat exchanger casingsFuel cellsElectronic component

A cooling module provided by the invention includes a first radiator configured to cool a fuel cell stack. A second radiator is positioned in a predetermined area in front of the first radiator in an air flow direction and configured to cool an electronic component. A first condenser is positioned in the other remaining area in front of the first radiator in the air flow direction and heat-exchanged with ambient air to condense a refrigerant. A second condenser is provided within the second radiator and heat-exchanged with a coolant to condense a refrigerant. The second radiator and the first condenser are positioned alongside each other in front of the first radiator. The second condenser is provided within the second radiator. The condensate performance of the coolant is improved, and the size of the cooling module is reduced.

Owner:HANON SYST

Touch display panel and display device

InactiveCN107831943ASmall pressure dropEnhance touch signalInput/output processes for data processingMesh gridDisplay device

The embodiment of the invention provides a touch display panel and a display device. The touch display device includes a plurality of grid-shaped first touch electrodes and a plurality of grid-shapedsecond touch electrodes. The first touch electrodes include a first sub-touch-electrode and second sub-touch-electrodes. The first sub-touch-electrode is located in a first display region. The secondsub-touch-electrodes are located in a second display region in a first direction. The first sub-touch-electrode is provided with a groove. The second sub-touch-electrodes are not provided with a groove. Any mesh area of a grid on the first sub-touch-electrode is smaller than any mesh area of grids on the second sub-touch-electrodes. After adopting the above-mentioned design, difference between thecross section area of the first sub-touch-electrode and the cross section area of the second sub-touch-electrodes can be reduced, voltage drop difference generated by the first sub-touch-electrode and the second sub-touch-electrodes under the same voltage is enabled to be reduced, and thus sensitivity degrees of the first sub-touch-electrode and the second sub-touch-electrodes are enabled to be roughly the same.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

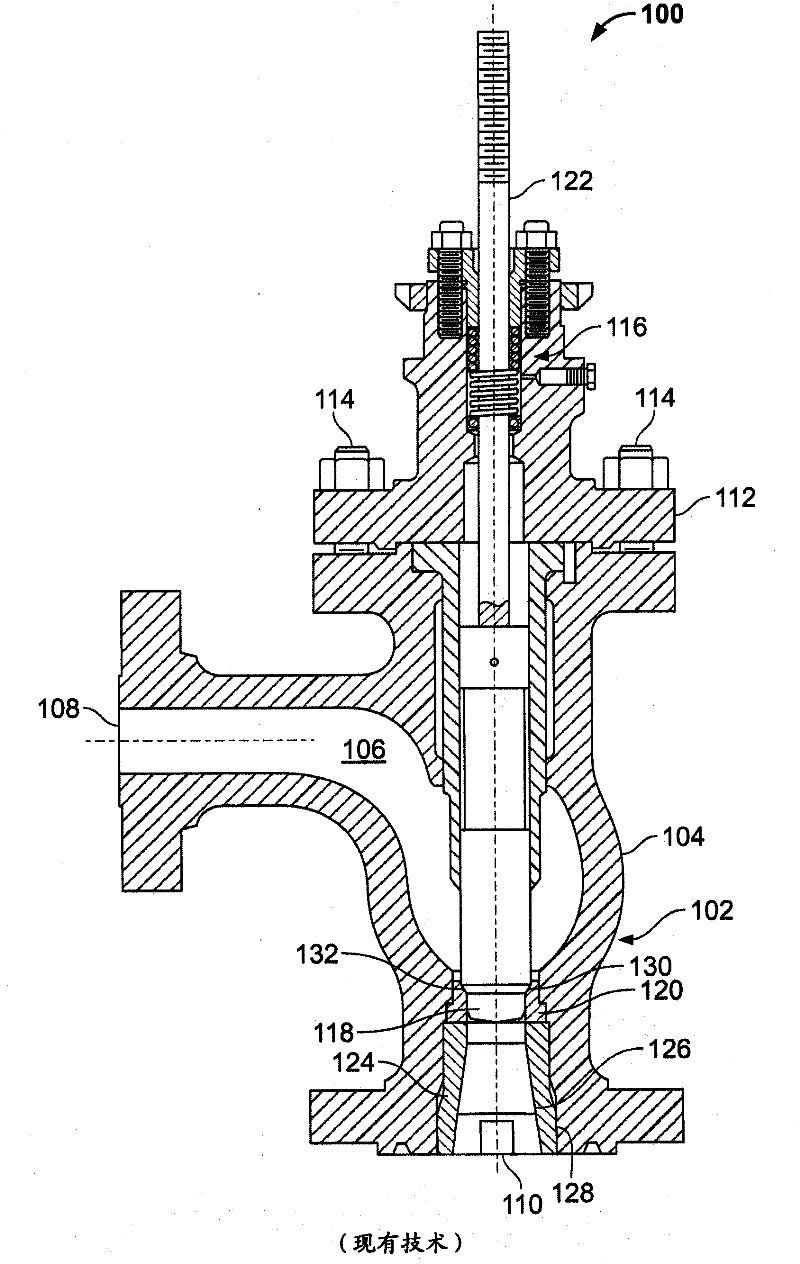

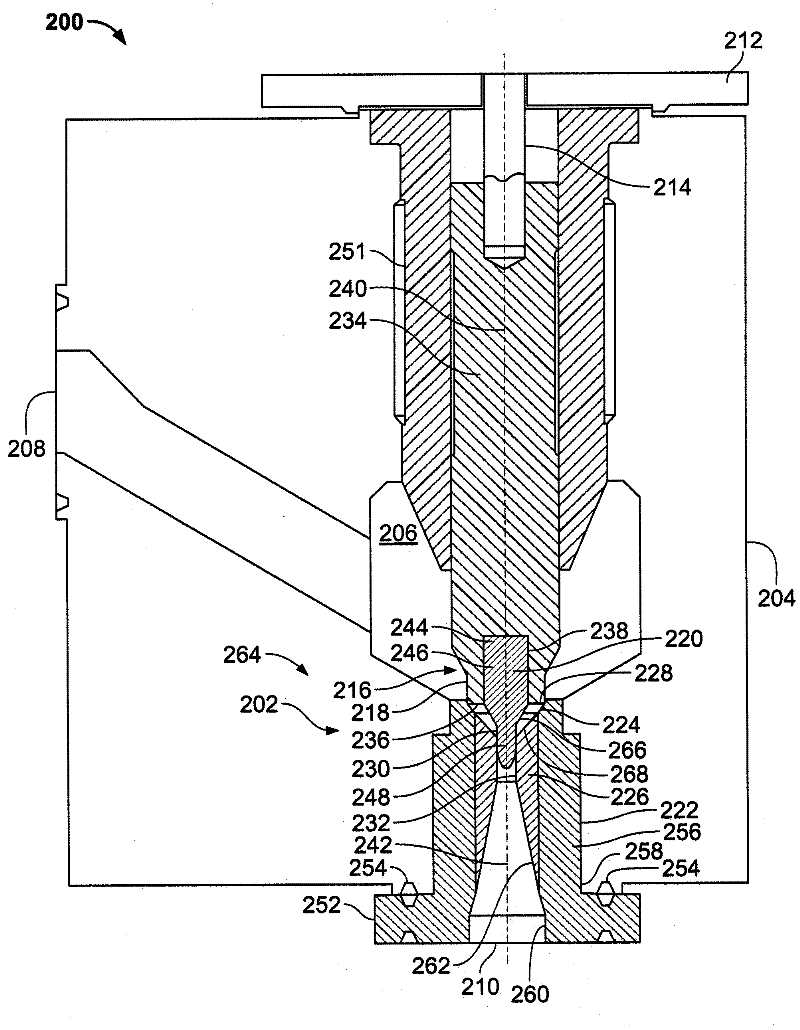

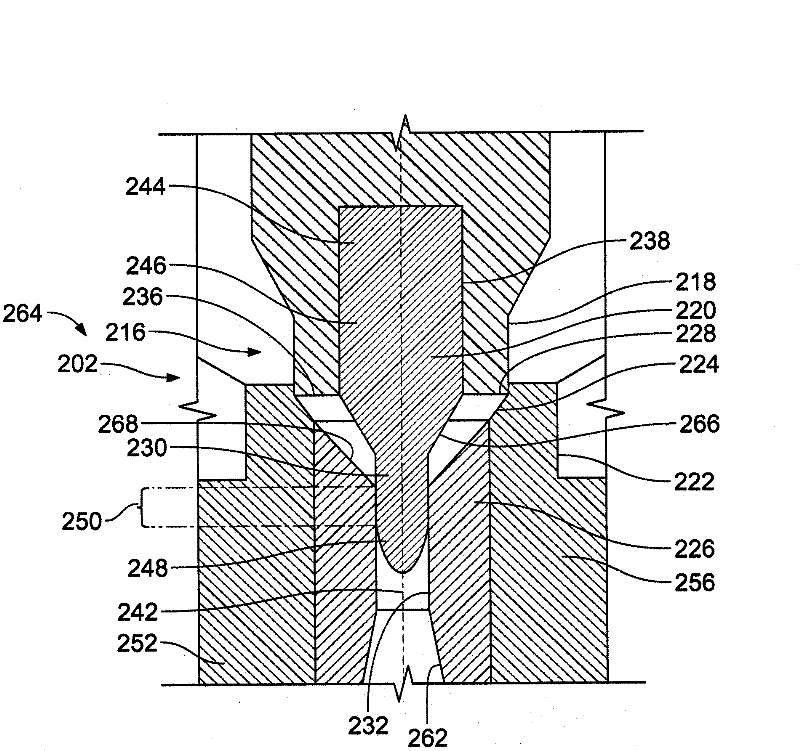

Valves having ceramic trim with protected shut-off surfaces

ActiveCN102365485AReduce total pressure dropValve members for absorbing fluid energyLift valveMaterials scienceValve seat

Valve trim apparatus (202) having ceramic trim (210) with protected shut-off surfaces are described. An example valve trim apparatus includes a valve seat (222) composed of a non- ceramic material and having a sleeve insert (226) composed of a ceramic material. A closure member (216) has a primary flow control member (218) and a secondary flow control member (220). The secondary flow control member is composed of a ceramic material and fitted within a cavity (238) of the closure member (216). The primary flow control member sealingly engages the non- ceramic material of the valve seat and the secondary flow control member moves within an aperture (232) of the sleeve insert to modulate a fluid flow through the valve seat as the primary flow control member disengages from the non -ceramic material of the valve seat.

Owner:FISHER CONTROLS INT LLC

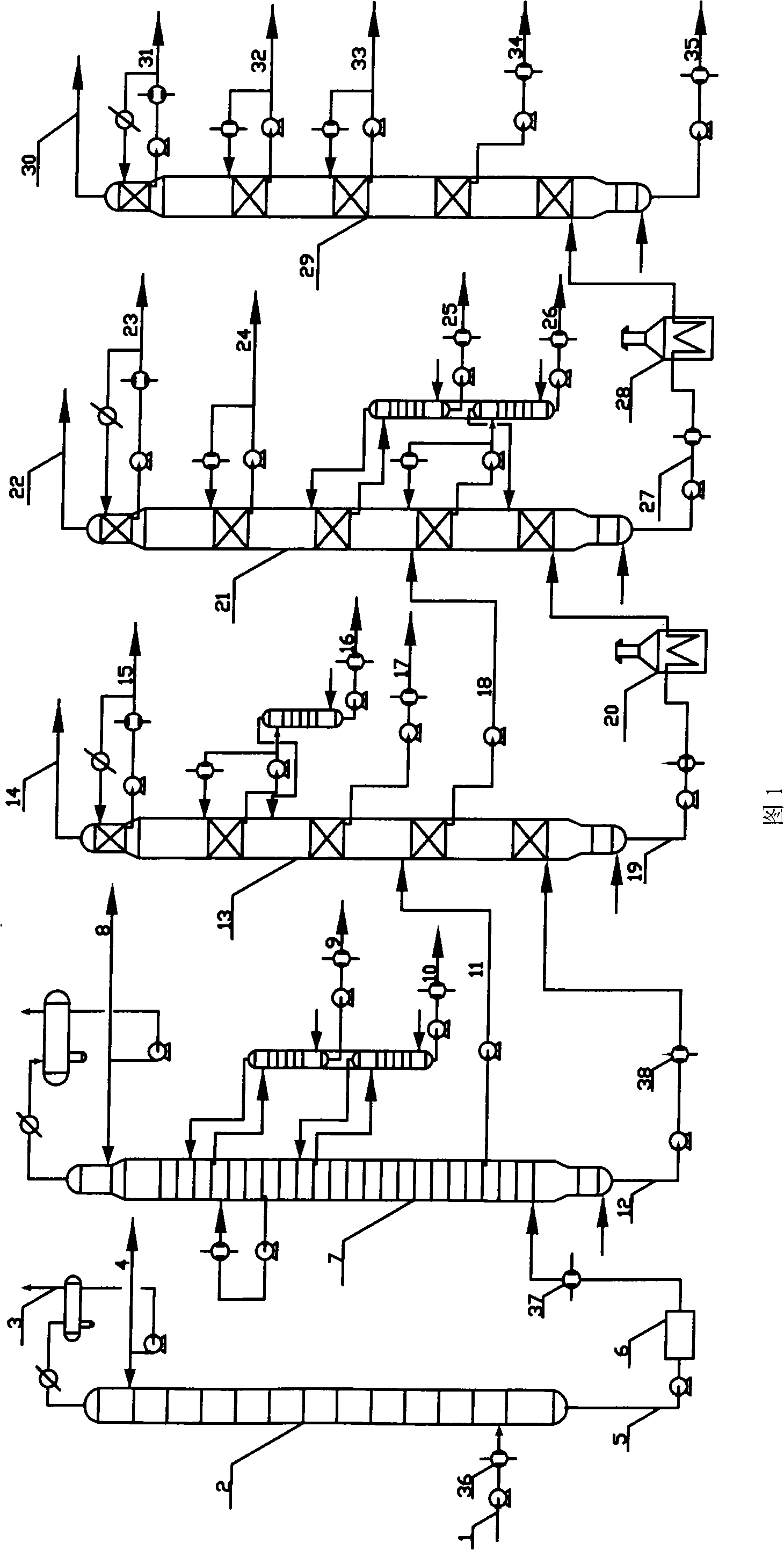

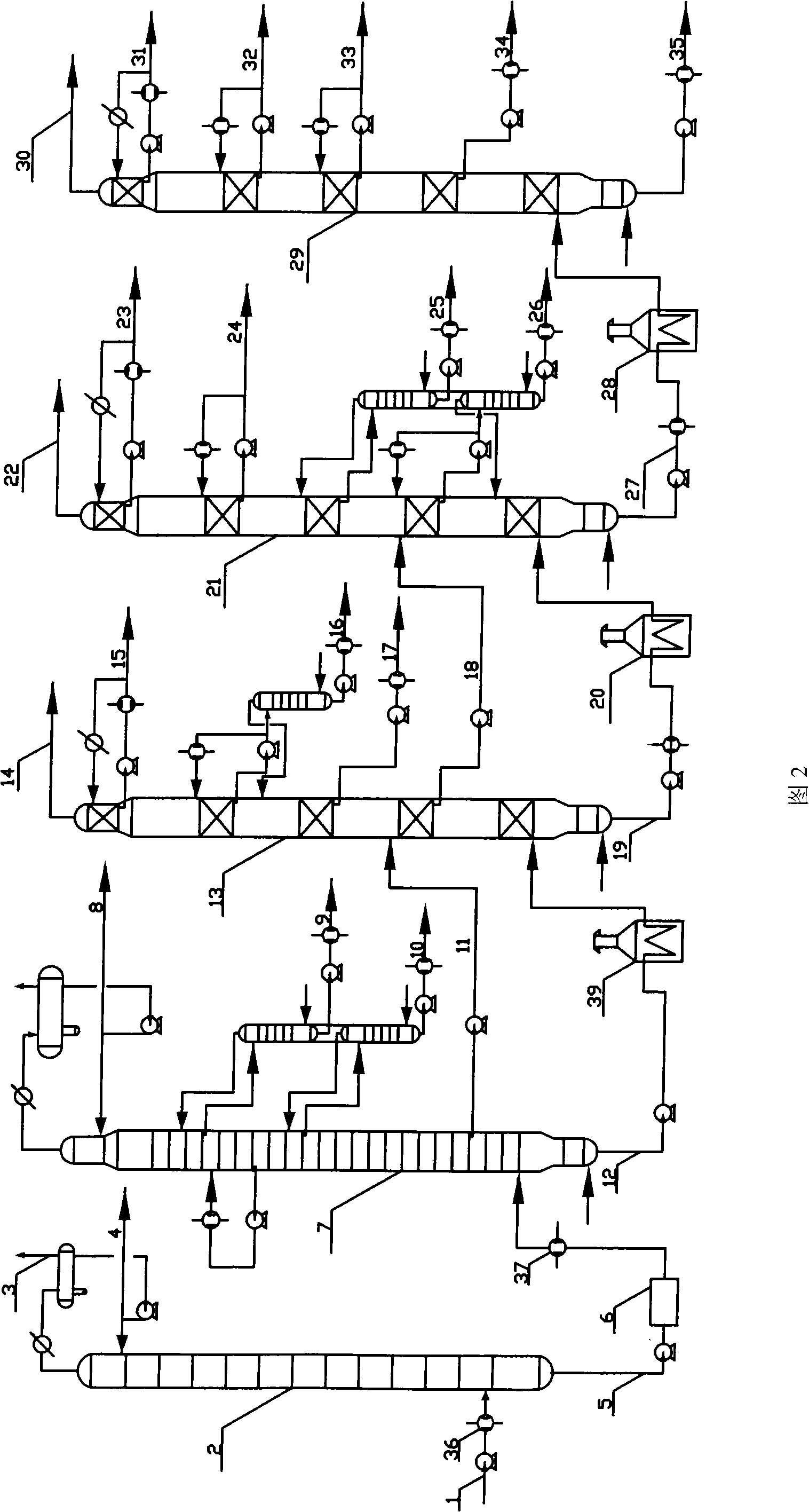

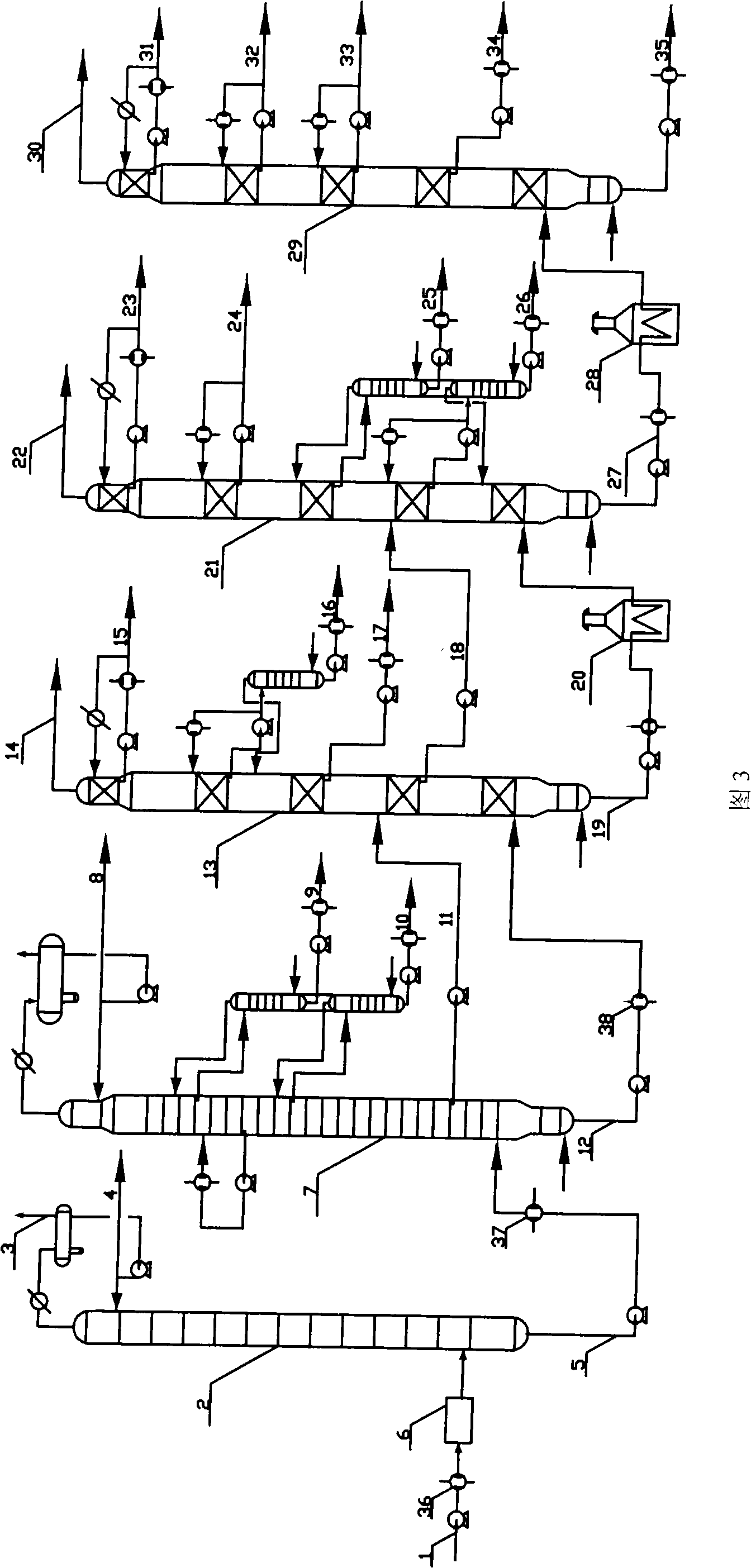

Crude oil gradual distillation energy saving apparatuses and technological process

The invention belongs to crude oil gradual distillation energy-saving equipment and a process method. According to a connecting mode of crude oil gradual distillation, the equipment comprises a flash distillation tower, a primary distillation tower, a primary decompression tower, a shallow decompression tower and a deep decompression tower; an electrical desalting device and a heat exchange network are arranged between the flash distillation tower and the primary distillation tower; a heat exchange network or a primary decompression furnace is arranged between the primary distillation tower and the primary decompression tower; a shallow decompression furnace is arranged between the primary decompression tower and the shallow decompression tower; and a deep decompression furnace is arranged between the shallow decompression tower and the deep decompression tower. Through gradual heating, crude oil is gradually heated to be close to the condensed temperature and vaporized so as to substantially reduce the nonreversibility of heating and cooling; simultaneously, as light components are gradually drawn out, the residual materials can realize vaporization under the lower pressure; therefore, the materials can enter the decompression and distillation stage after passing through the primary distillation tower; the gradual decompression technology of primary decompression, shallow decompression and deep decompression is adopted to reduce the heating temperature of raw materials, lighten the load of a heating furnace and remarkably improve the processing capacity of the system.

Owner:TIANJIN UNIV

Cooler and method of cooling a medium

InactiveUS20050121176A1Reduce total pressure dropReduce adverse effectsDomestic stoves or rangesInternal combustion piston enginesEngineeringChiller

The invention relates to a cooler having means for directing a cooling medium, means for directing a medium to be cooled, and an essentially axially symmetrical housing. The means for directing the medium to be cooled is arranged in such a way that the medium to be cooled, in at least one first region, flows in an essentially axial direction, and the medium to be cooled, in at least one second region, flows in a direction having a radial component. The invention also relates to a method of cooling a medium and to various uses of a cooler according to the invention.

Owner:BEHR GMBH & CO KG

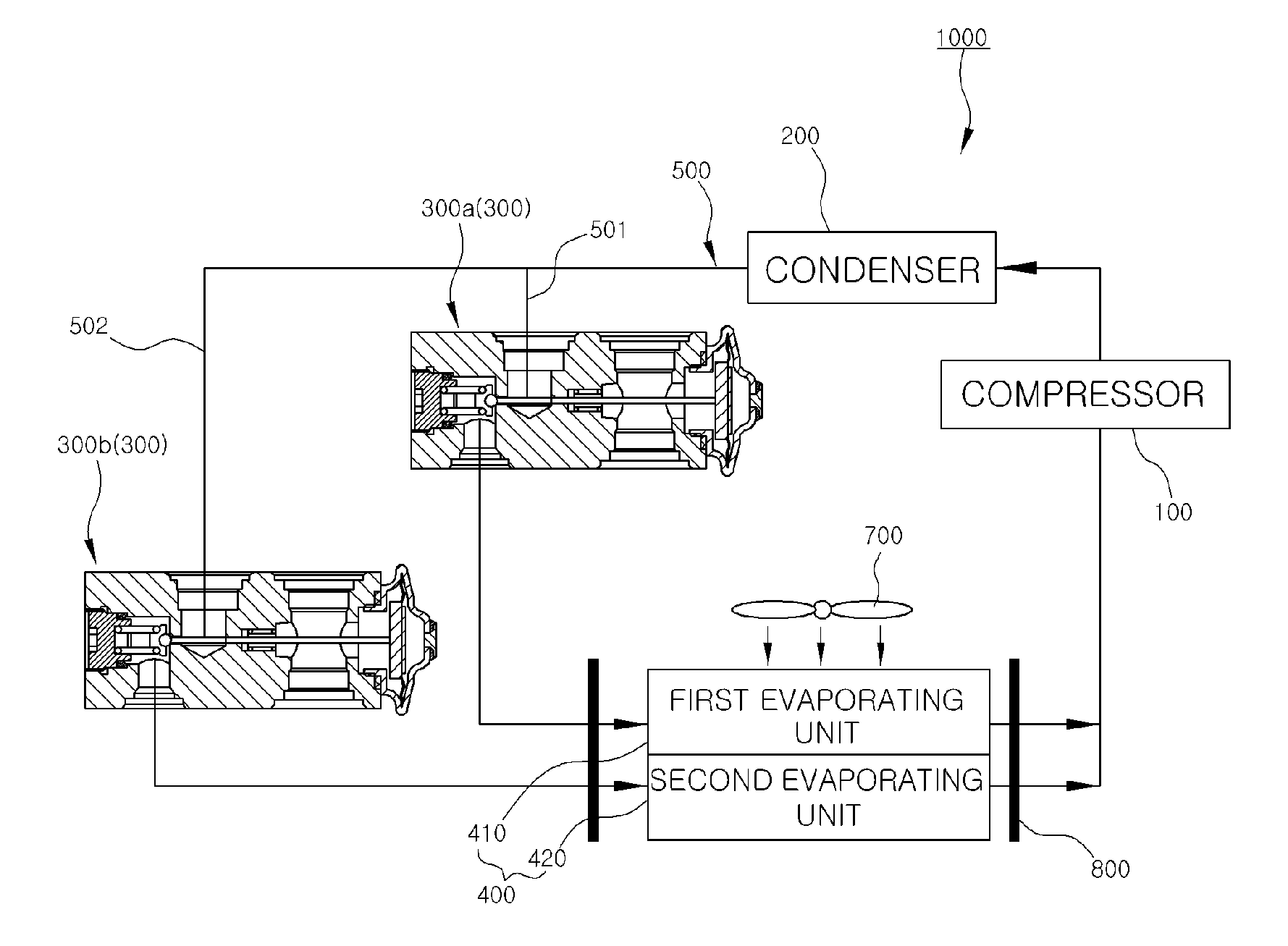

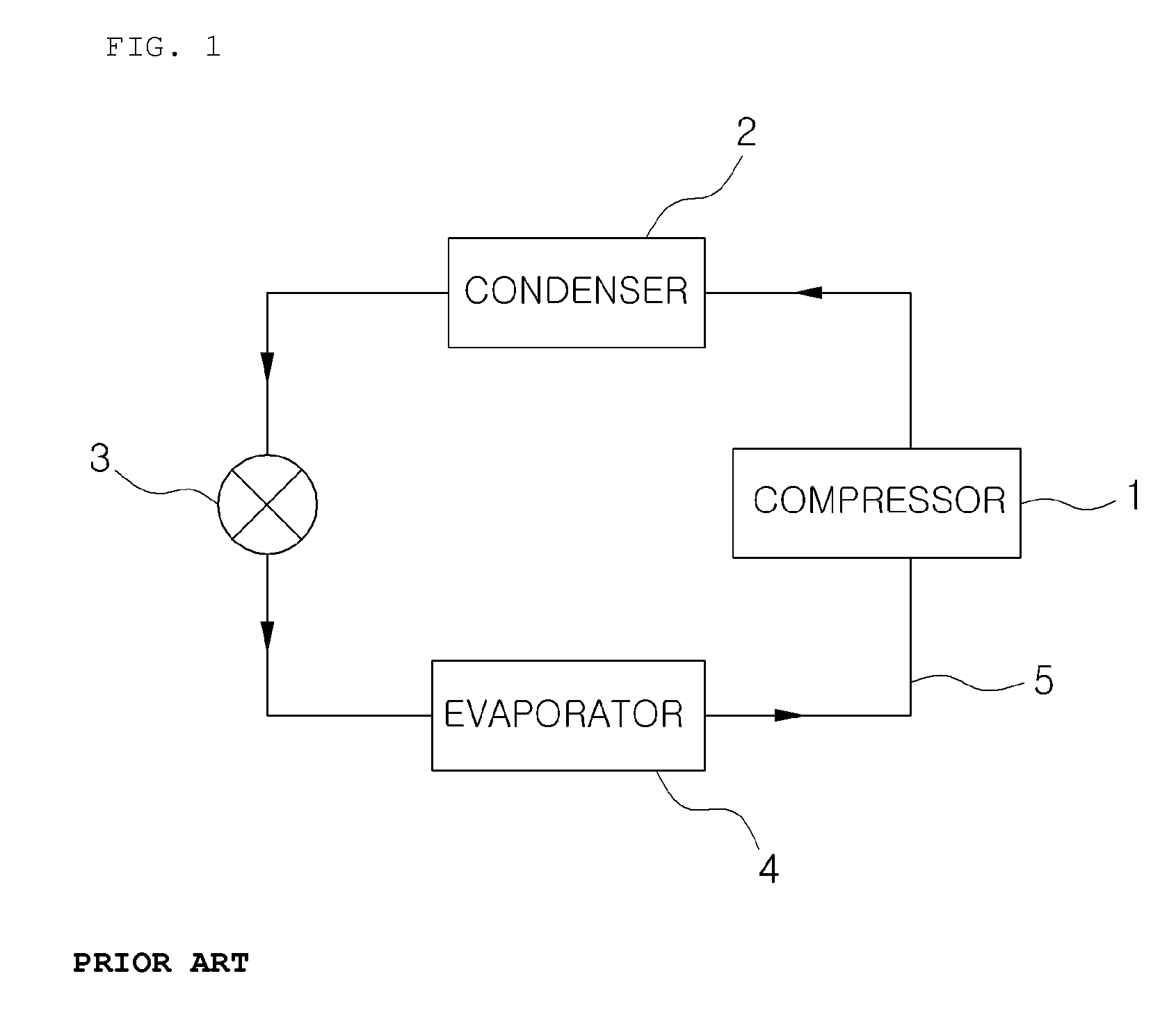

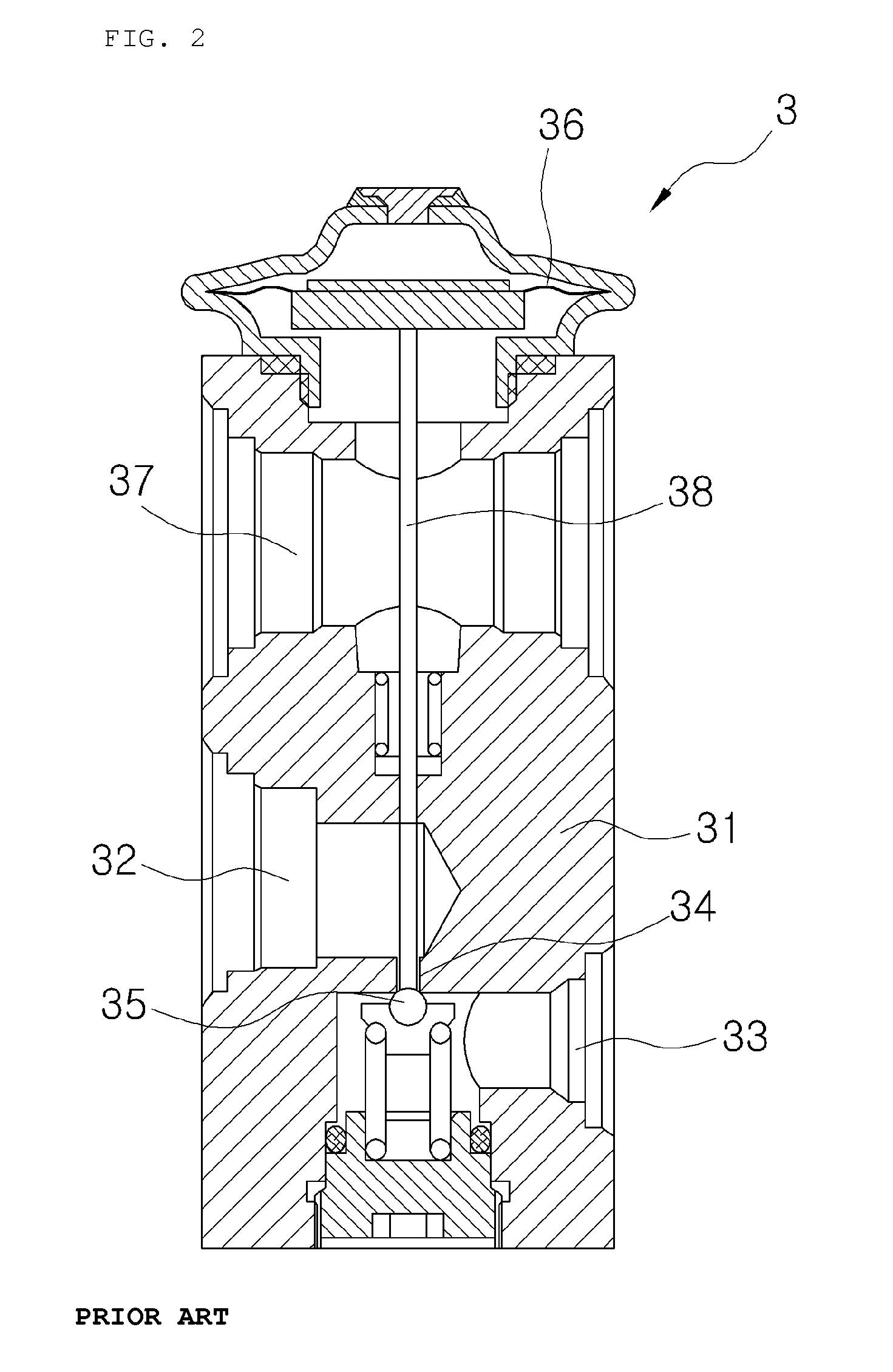

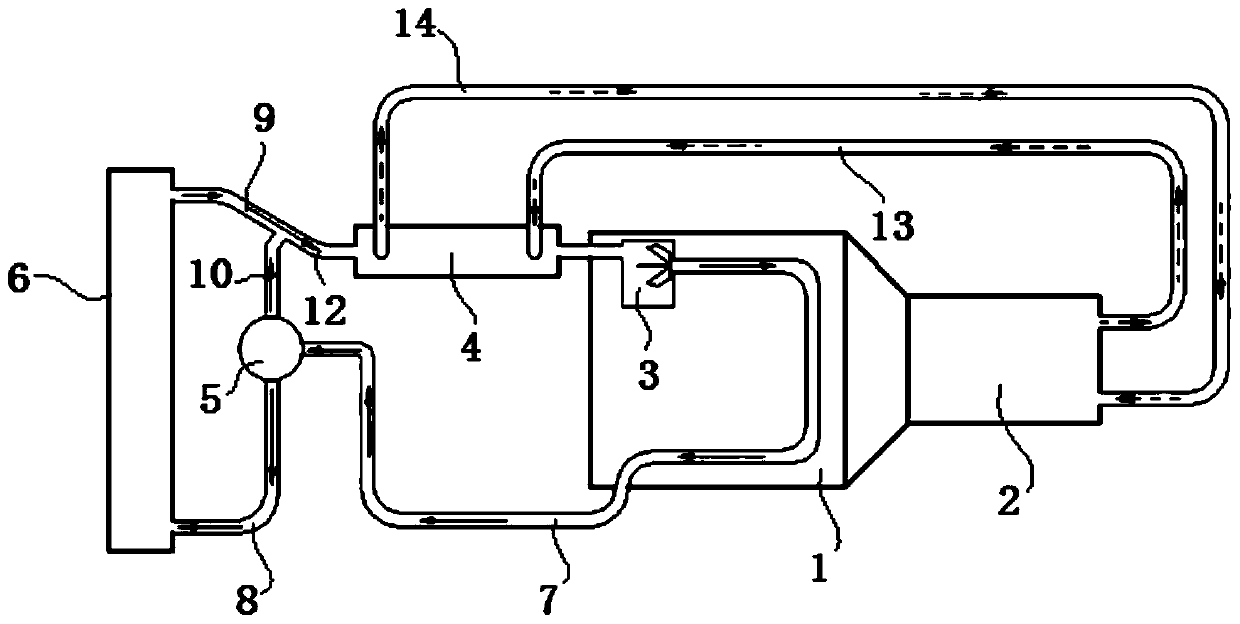

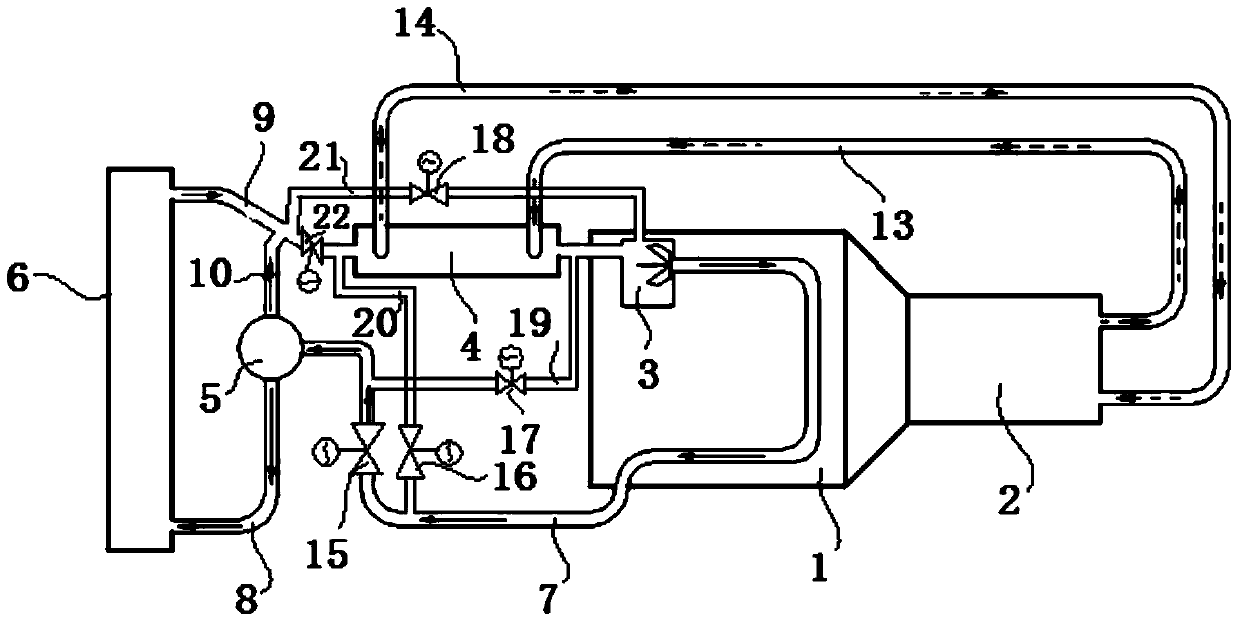

Air conditioner for vehicles

ActiveUS8978412B2Improve efficiencyImprove performanceMechanical apparatusAir-treating devicesEngineeringRefrigerant

Provided is a refrigerant cycle of an air conditioner for vehicles, and more particularly, a refrigerant cycle of an air conditioner for vehicles having a first evaporating unit and a second evaporating unit disposed upstream and downstream in a direction in which air blown from a single blower flows to control an amount of the refrigerant supplied to each evaporating unit, thereby making it possible to obtain optimal radiating performance (cooling performance) and cooling efficiency (COP) through the design of the optimal refrigerant flow ratio depending on the cooling load.

Owner:HANON SYST

Oil cooling system

ActiveCN104196990ASimple structureAvoid pressure dropGear lubrication/coolingTransmission elementsCooling fluidThermodynamics

The invention provides an oil cooling system. The oil cooling system comprises a cooling liquid circulating loop of an engine and an oil circulating loop of a hydraulic execution mechanism and further comprises an oil cooler, and heat exchange is carried out on cooling liquid in the cooling liquid circulating loop of the engine and oil in the oil circulating loop of the hydraulic execution mechanism in the oil cooler. The oil cooling system is simple in structure, and pressure is reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

High-efficiency and low-resistance dust remover for gas separation and purification

ActiveCN103285701AImprove purification efficiencySmall filter resistanceCombination devicesCycloneBiochemical engineering

The invention discloses a high-efficiency and low-resistance dust remover for gas separation and purification. The high-efficiency and low-resistance dust remover comprises a direct current type cyclone separator, and is characterized in that a filter element (4) is arranged at an inlet of a gas exhaust pipe (5) of the direct current type cyclone separator and is made of a low-resistance and high-efficiency ultramicropore paper filter barrel. According to the high-efficiency and low-resistance dust remover, the filter element is arranged in the direct current type cyclone separator, so that the characteristics of the separator and the characteristics of the filter are organically combined; the higher separation efficiency can be guaranteed, the total pressure drop can be reduced, and the energy consumption and the cost are reduced; moreover, the pressure drop of the selected direct current type cyclone separator is smaller, and the low-resistance and high-efficiency filter element made of the ultramicropore paper filter barrel is low in initial filter resistance which is less than 200 Pa and high in purification efficiency; for micro dust particles of which the particle size is more than 0.5 microns, the purification efficiency is up to 99.9 percent; and the filter element which is convenient to mount, dismount, replace and clean and the detachably connected direct current type cyclone separator are more suitable for drilling work with higher flowability.

Owner:JIANGSU NANFANG COATING & ENVIRONMENT PROTECTION EQUIP

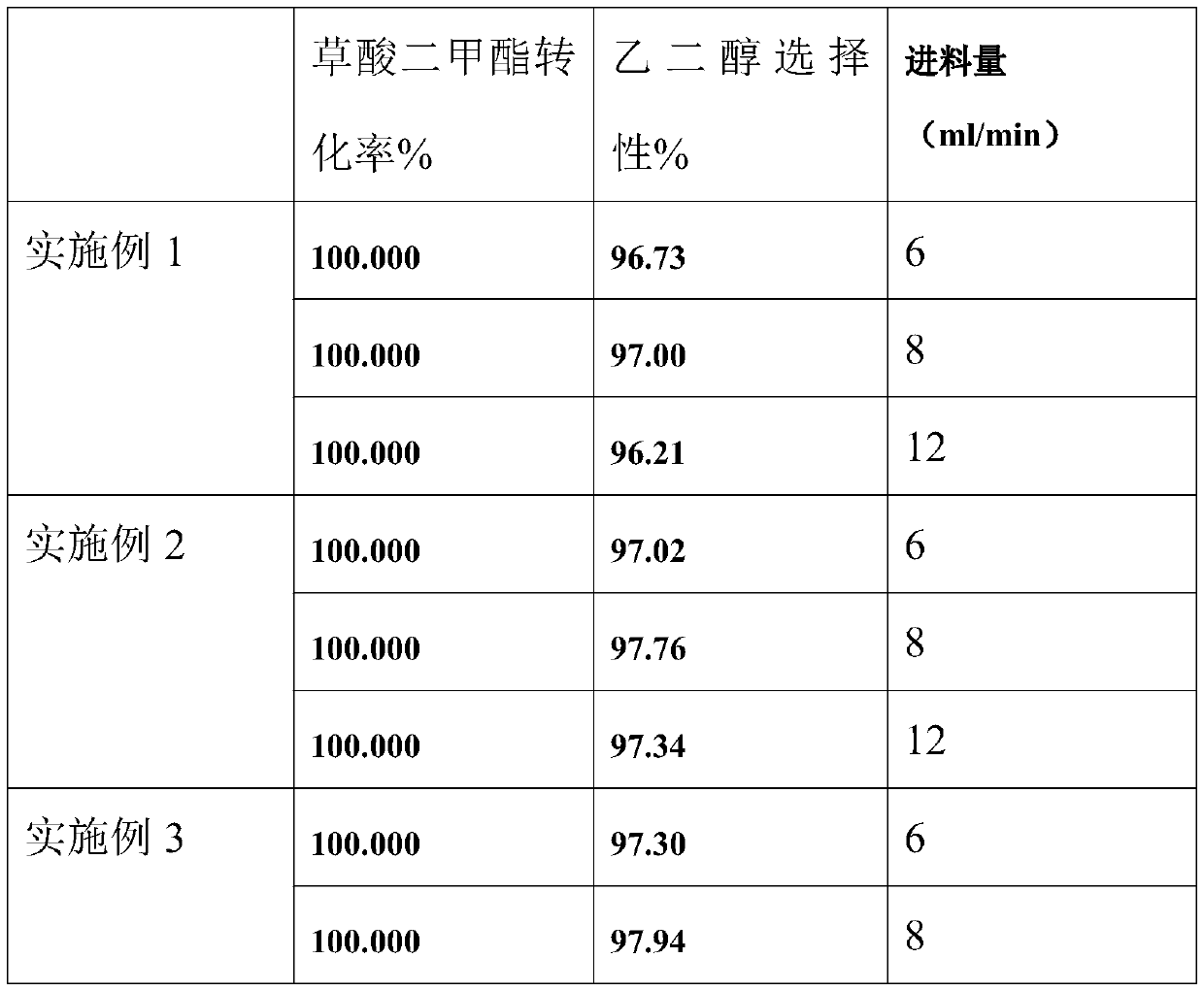

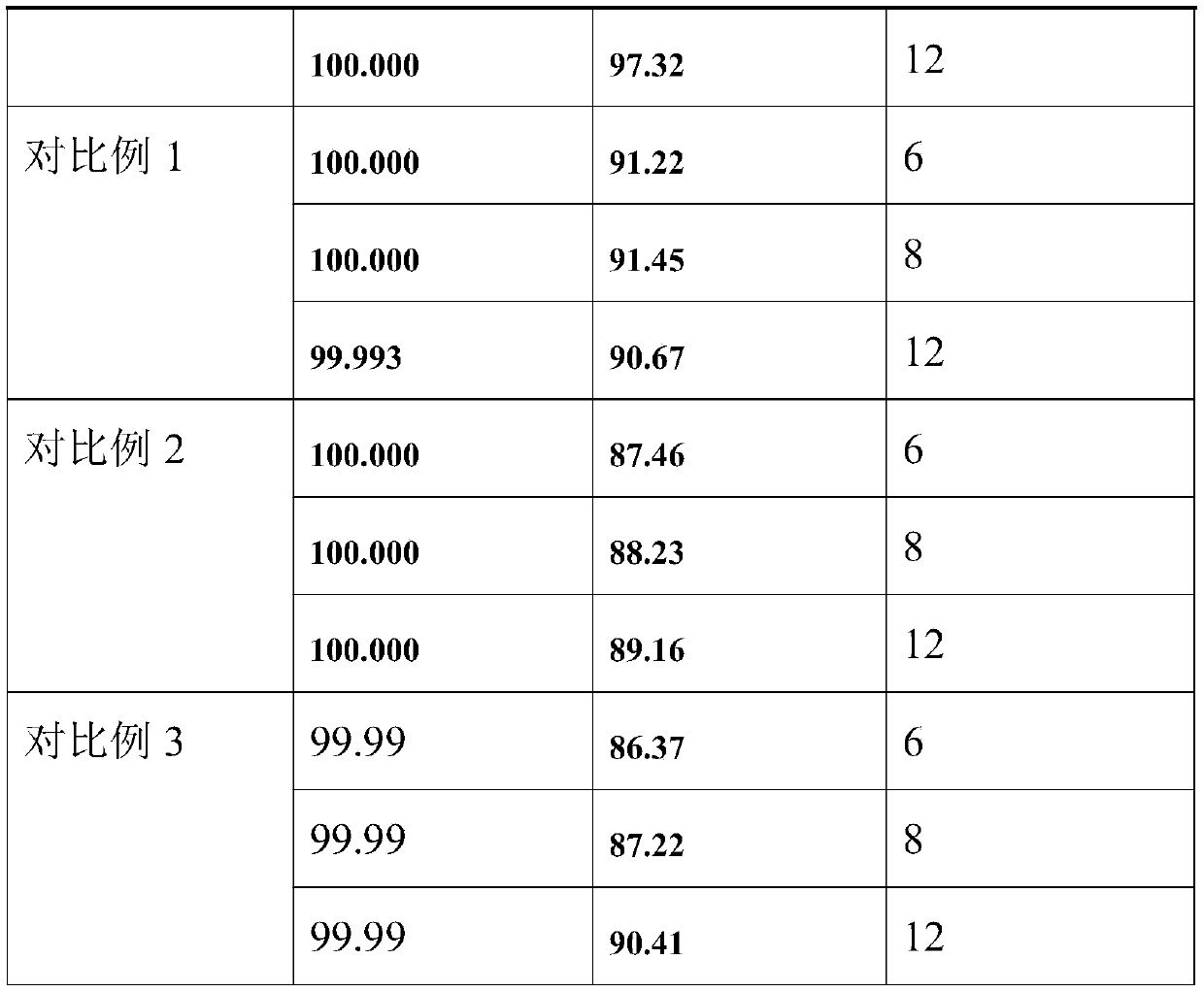

Catalyst for preparing ethylene glycol through dimethyl oxalate hydrogenation and preparation method and application of catalyst

ActiveCN110624561AHigh activityGood stabilityMolecular sieve catalystsOrganic compound preparationActivated carbonCarbon nanotube

The invention discloses a catalyst for preparing ethylene glycol through dimethyl oxalate hydrogenation. The catalyst is of a hollow cyclic structure and comprises the following components in parts byweight: 1-50 parts of an active component, 0-10 parts of a metal aid and 30-90 parts of a carrier, wherein the active component is at least one of copper, silver, nickel, cobalt, gold and iron; the carrier is at least one of SiO2, carbon nanotubes, activated carbon, graphene, mesoporous carbon, ZrO2, Al2O3, ZnO, SBA-15, HMS, ZSM-5, MCM-41 and MCM-48. The catalyst for preparing ethylene glycol through dimethyl oxalate hydrogenation, which is disclosed by the invention, is high in activity, good in stability and high in selectivity, the conversion rate of dimethyl oxalate is greater than 99.9%,the selectivity of ethylene glycol is greater than 96%, the reaction has a small amount of byproducts, target products are easy to separate, and the catalyst is stable in reaction and free of conspicuous deactivation phenomena after long-term single tube operation of 1000 hours.

Owner:高化学(江苏)化工新材料有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com