Cooling system for a vehicle

a technology for cooling systems and vehicles, applied in indirect heat exchangers, machines/engines, light and heating apparatus, etc., can solve the problems of limiting the choice of deign objects, and achieve the effects of reducing production costs, high efficiency, and reducing the weight of heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

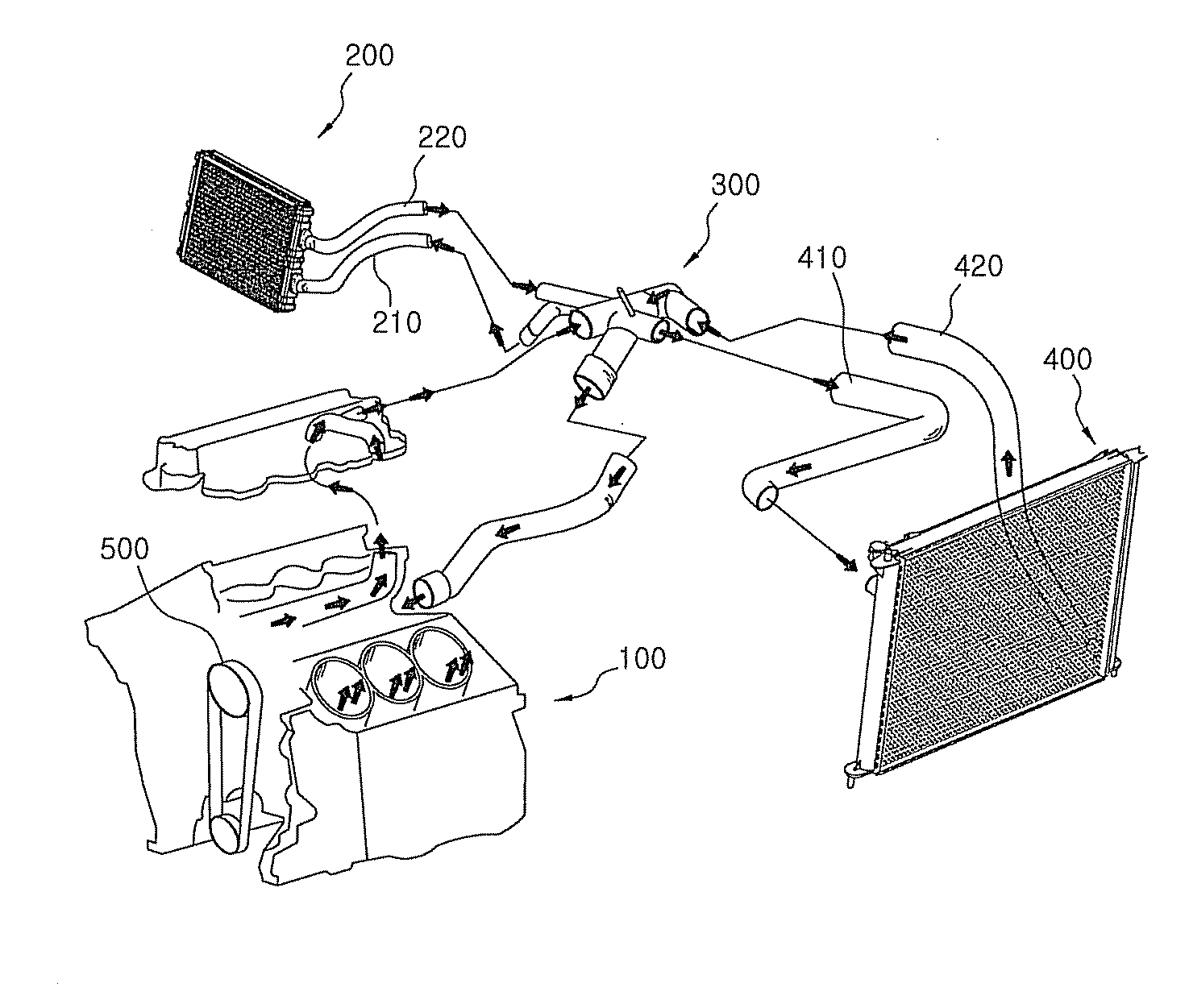

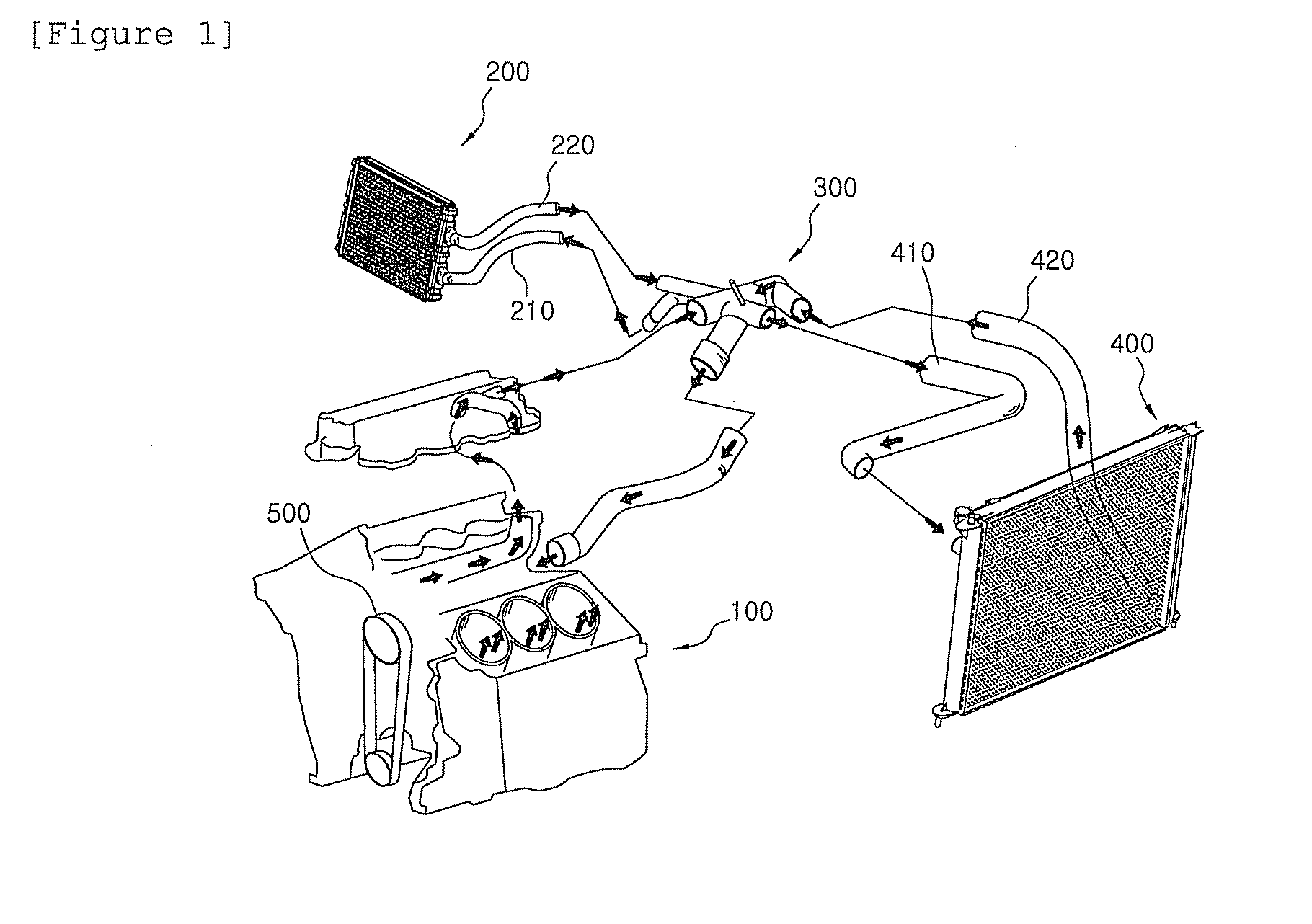

[0023]As shown in FIG. 1, a cooling system for a vehicle according to the present invention includes an engine 100 in which coolant is flowed along a passage formed in outer wall of a cylinder block, a heater core 400 through which high temperature coolant discharged from the engine 100 is flowed, a radiator 200, a thermostat 300 which controls flow direction of the coolant discharged from the engine 100 and a water pump 500 which receives power from a crank shaft (not shown) of the engine 100 to forcedly circulate the coolant.

[0024]In the cooling system for a vehicle, by an action of the water pump 500 operably connected to the crank shaft (not shown), the coolant heated at the engine 100 is cooled by exchanging heat with external air during it passes through the heater core 400 and the radiator 200 and then is flowed again into the engine 100 to perform the heat exchange with the high temperature engine 100.

[0025]Since the engine can maintain an appropriate temperature by the cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com