Patents

Literature

731results about How to "Reduce heat exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

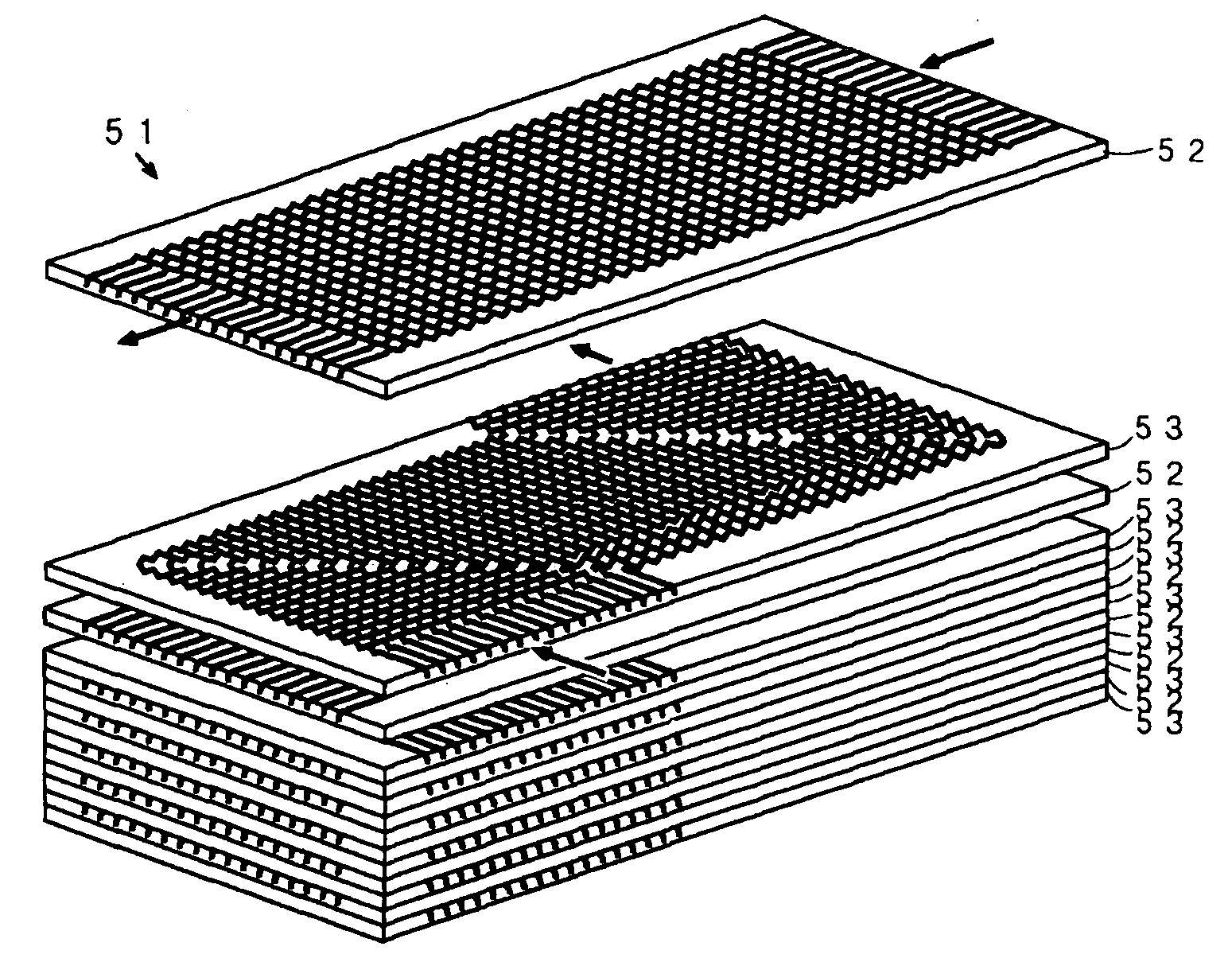

Heat exchanger

InactiveUS7334631B2Without impairment of heat transfer characteristicIncreased pressure lossHeat transfer modificationLaminated elementsThin metalPlate heat exchanger

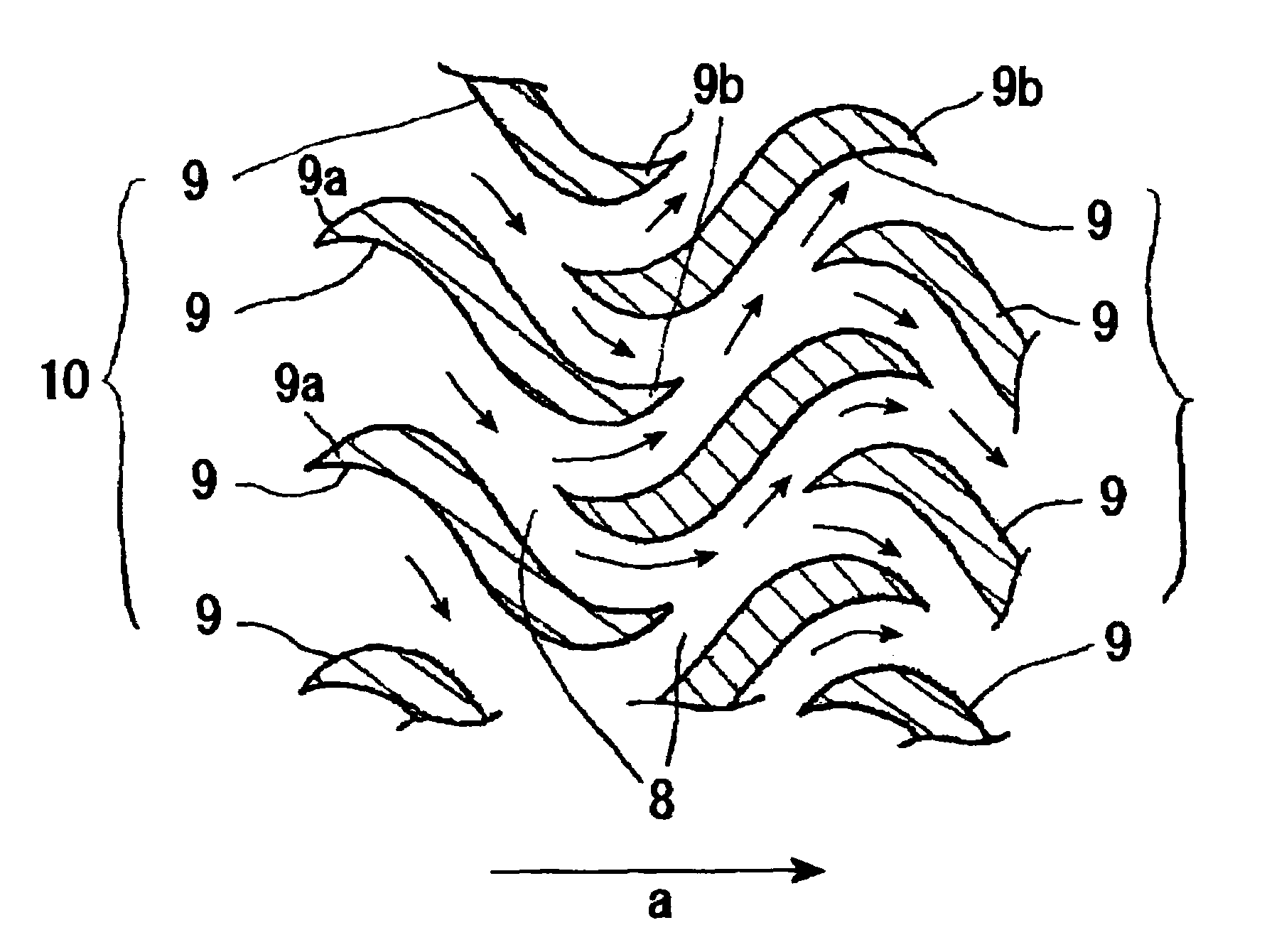

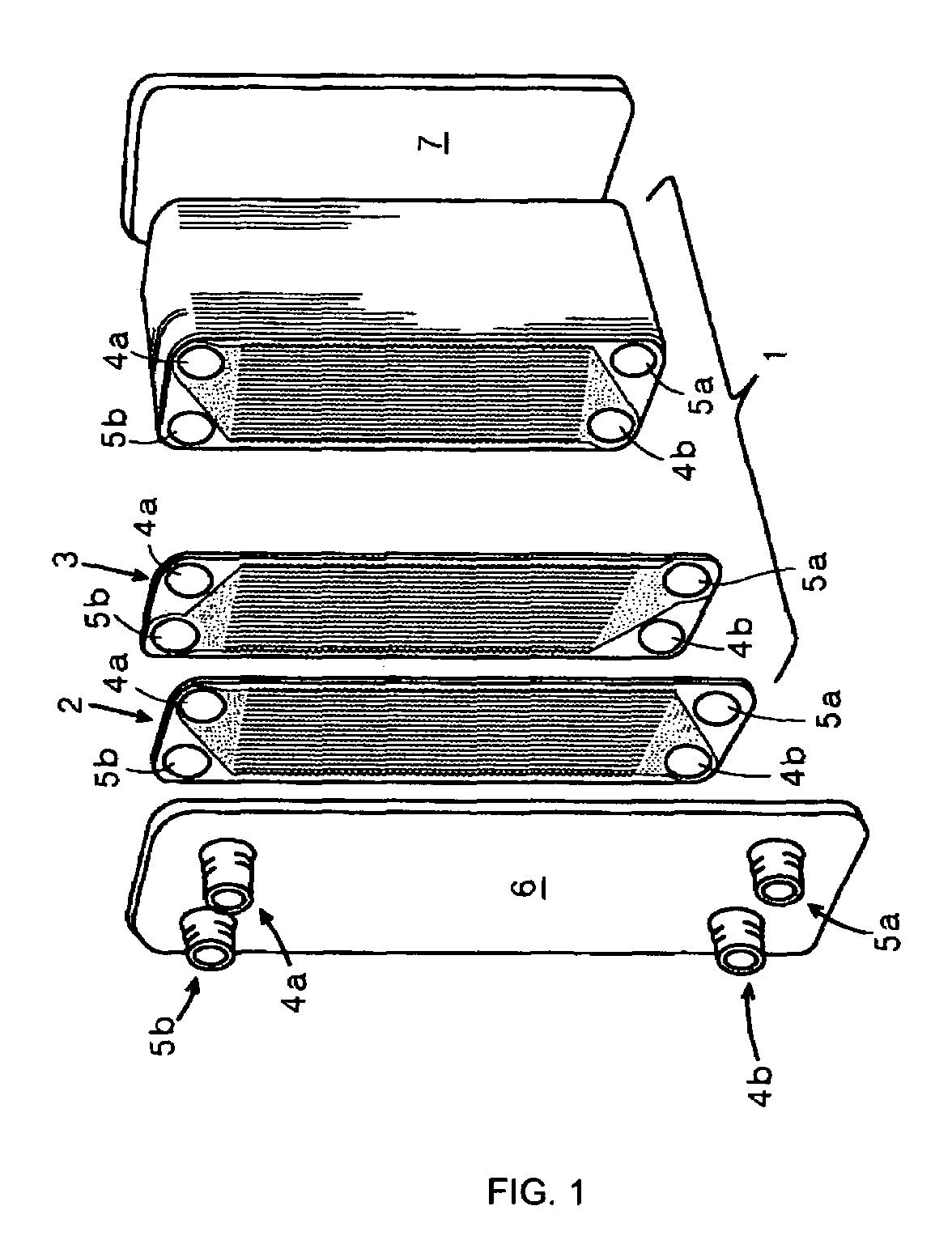

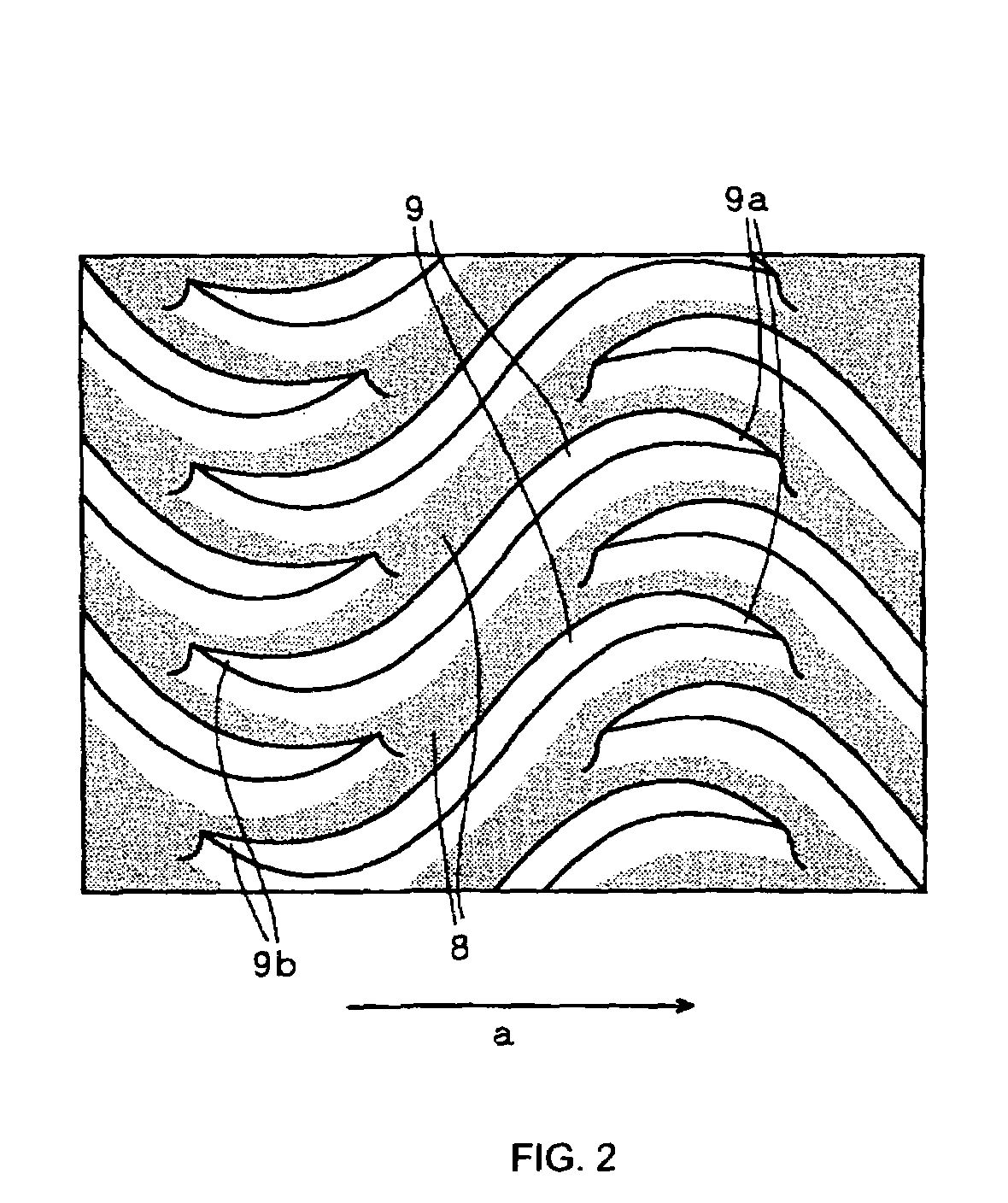

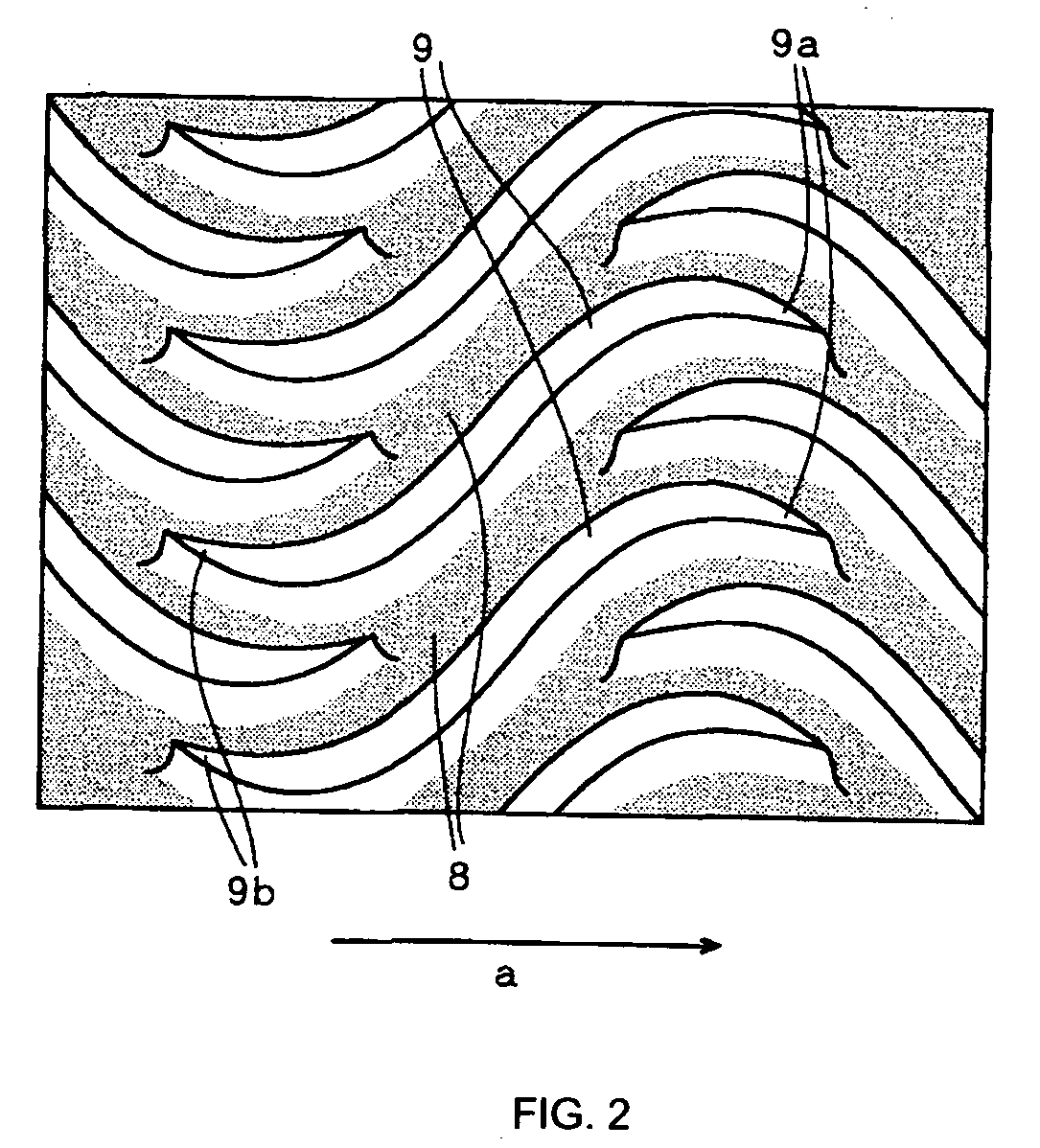

To reduce pressure loss on a heat-exchanger fluid while downsizing a heat exchange and reducing the production cost of the heat exchanger without impairment of the heat transfer performance of the heat exchanger by forming a fluid channel in surfaces of thin metal plates such as stainless steel plates through the use of an etching technique or the like and by improving the shape of the fluid channel. In a heat exchanger in which a plurality of heat exchanger fins are provided in thin metal plates by using an etching technique or the like and a fluid channel for a heat-exchanger fluid is formed between the two opposed thin metal plates by alternately stacking the thin metal plates, the area of the fluid channel, through which the fluid flows between the heat exchanger fins, is made substantially uniform by forming the heat exchanger fins so as to have a curved cross-sectional shape from the front end thereof to the rear end.

Owner:KATO YASUYOSHI

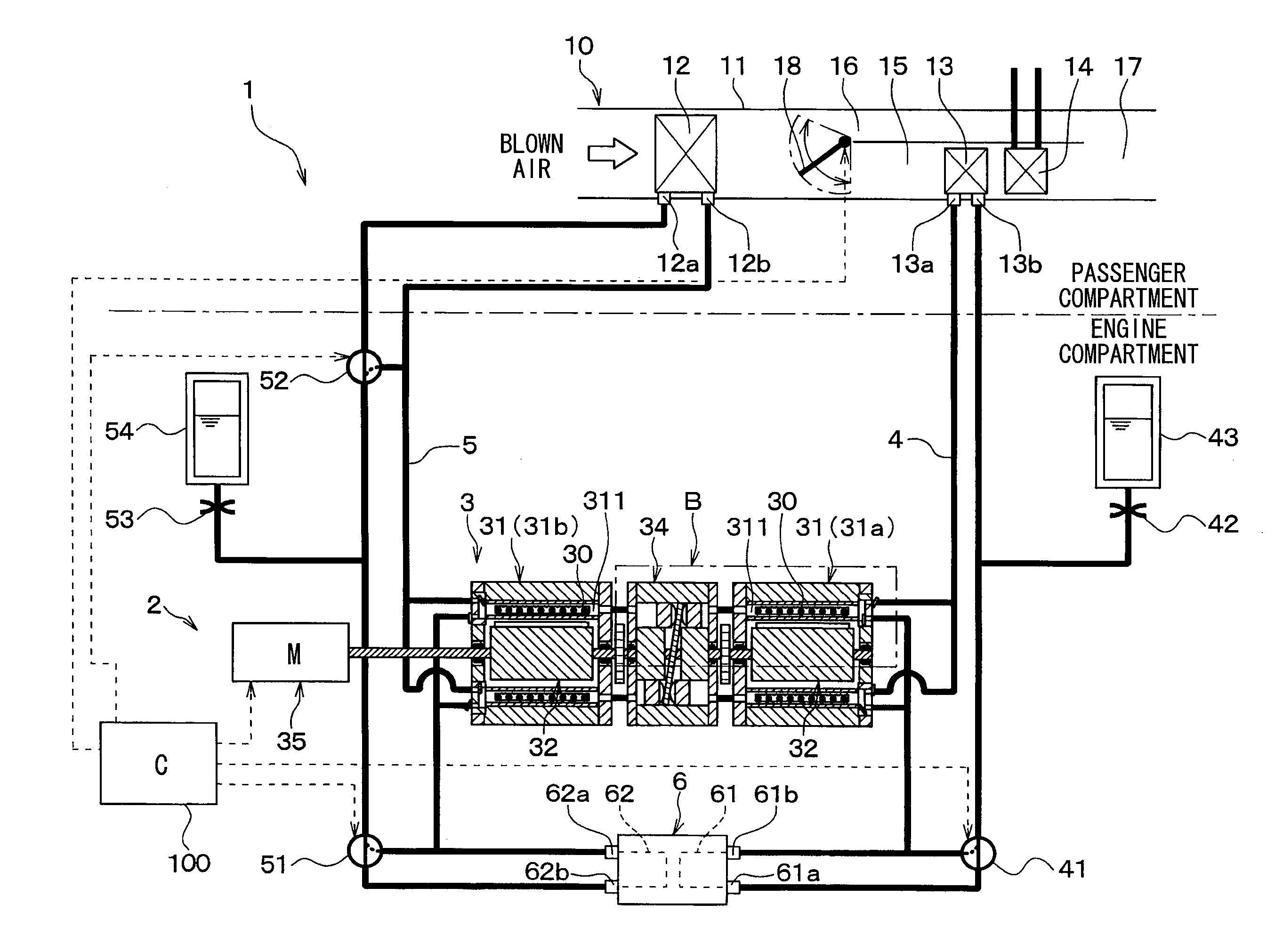

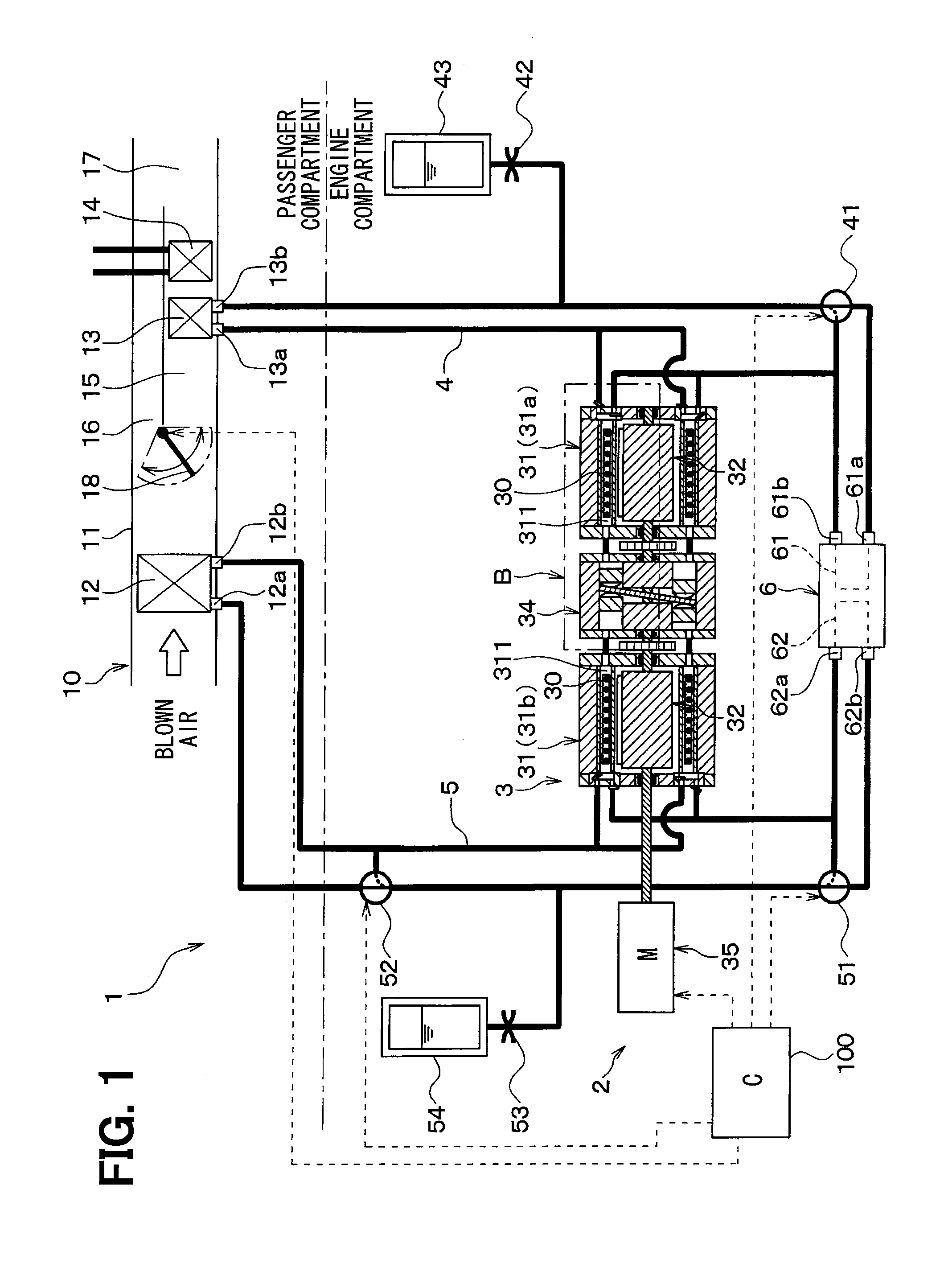

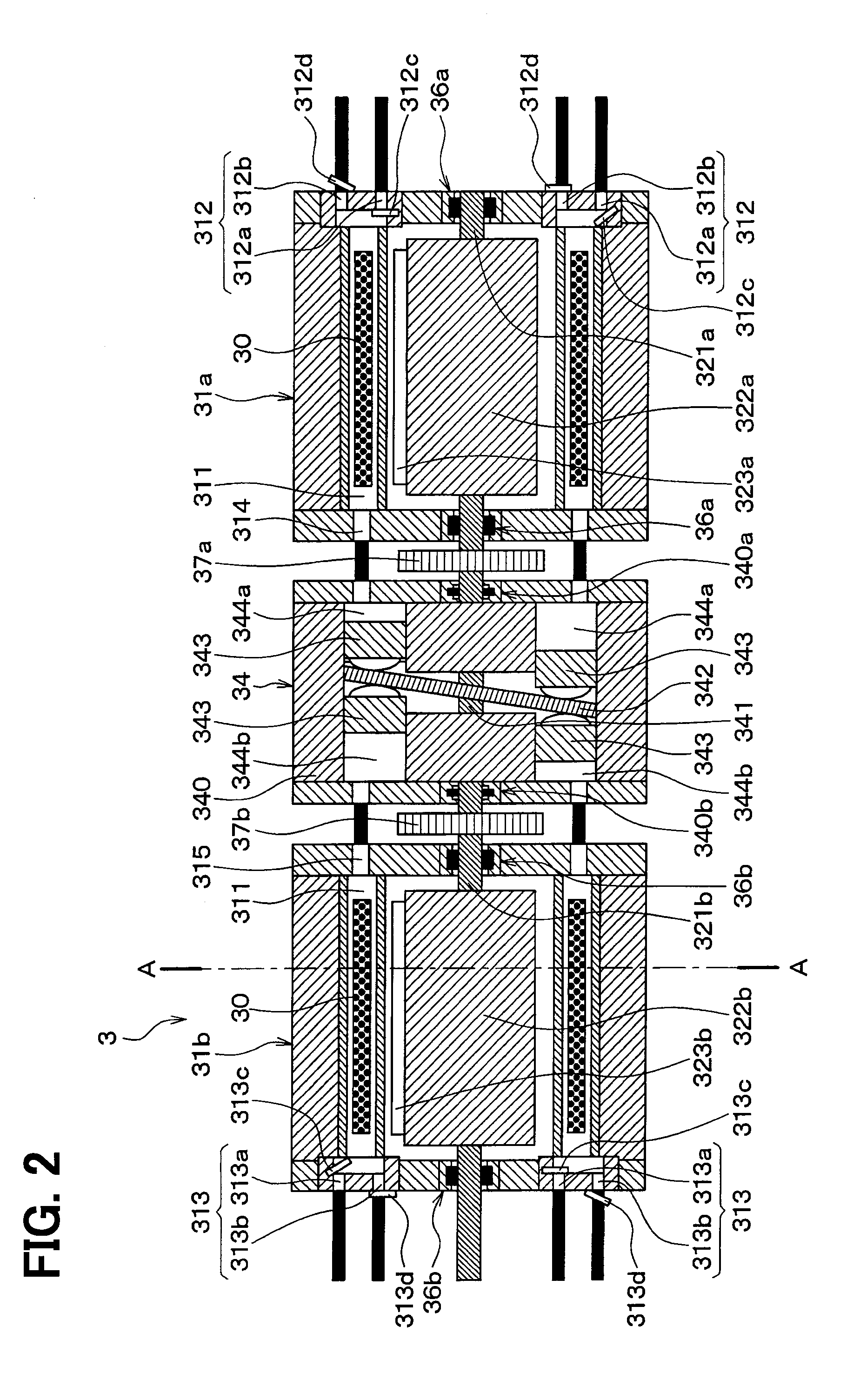

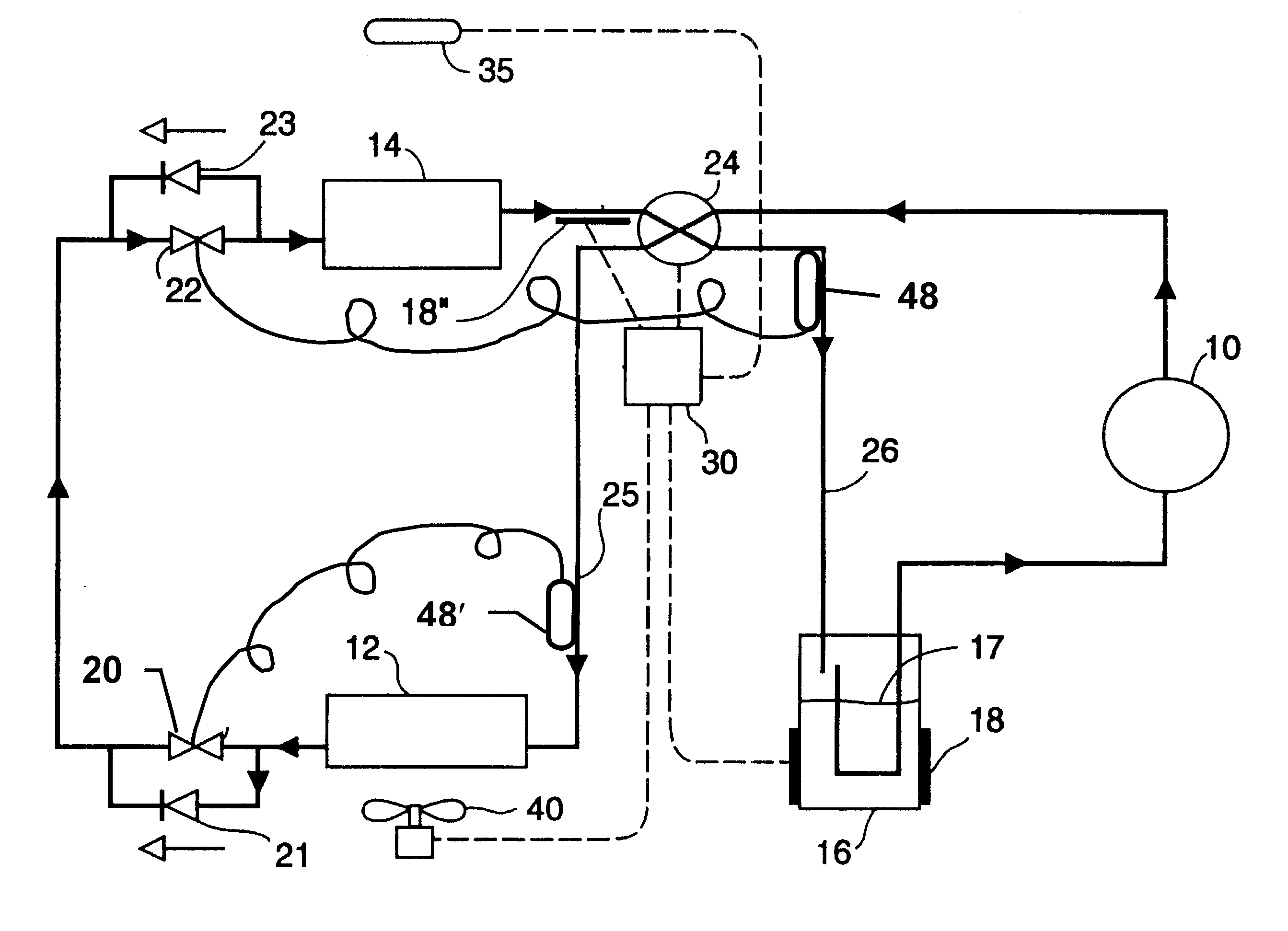

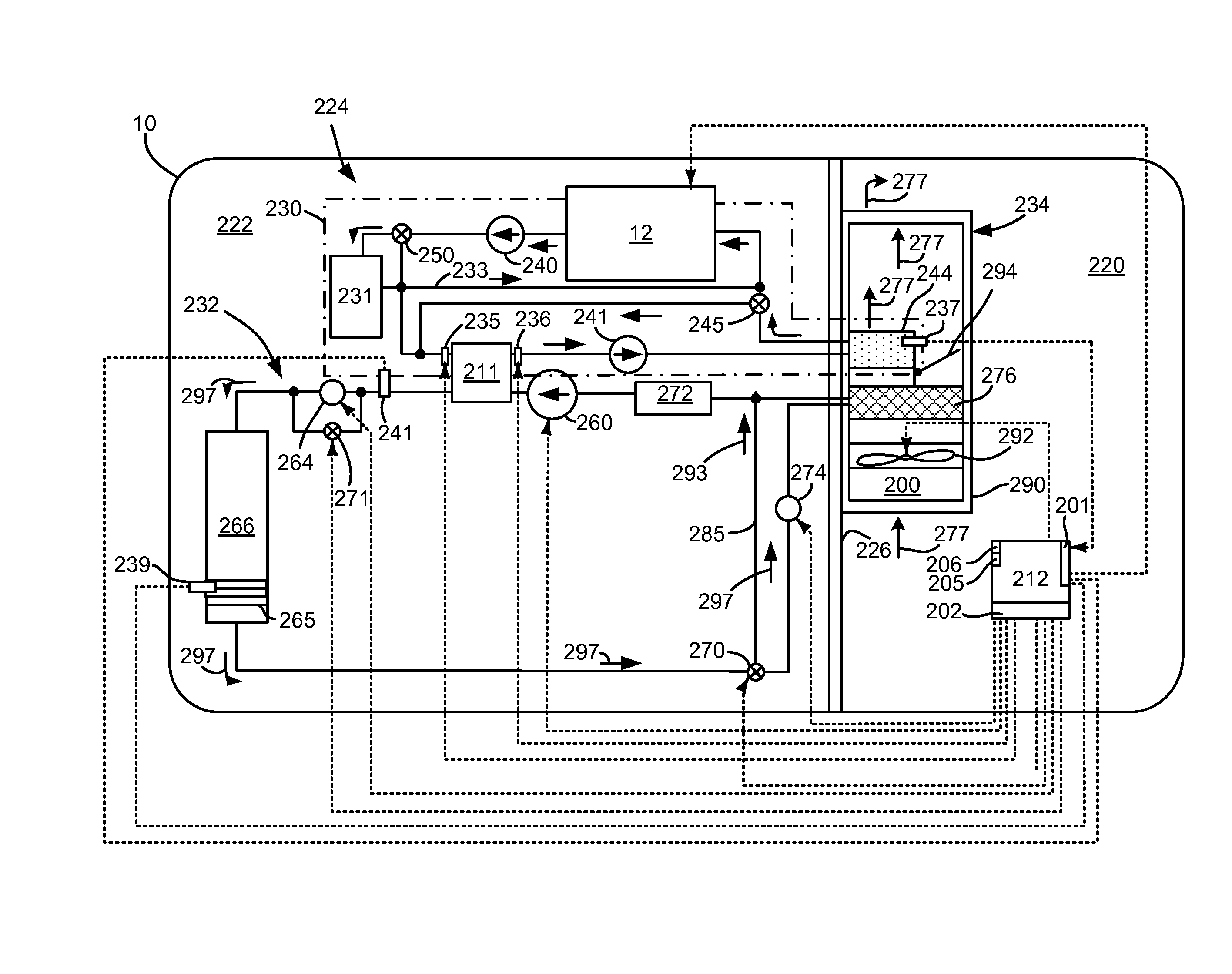

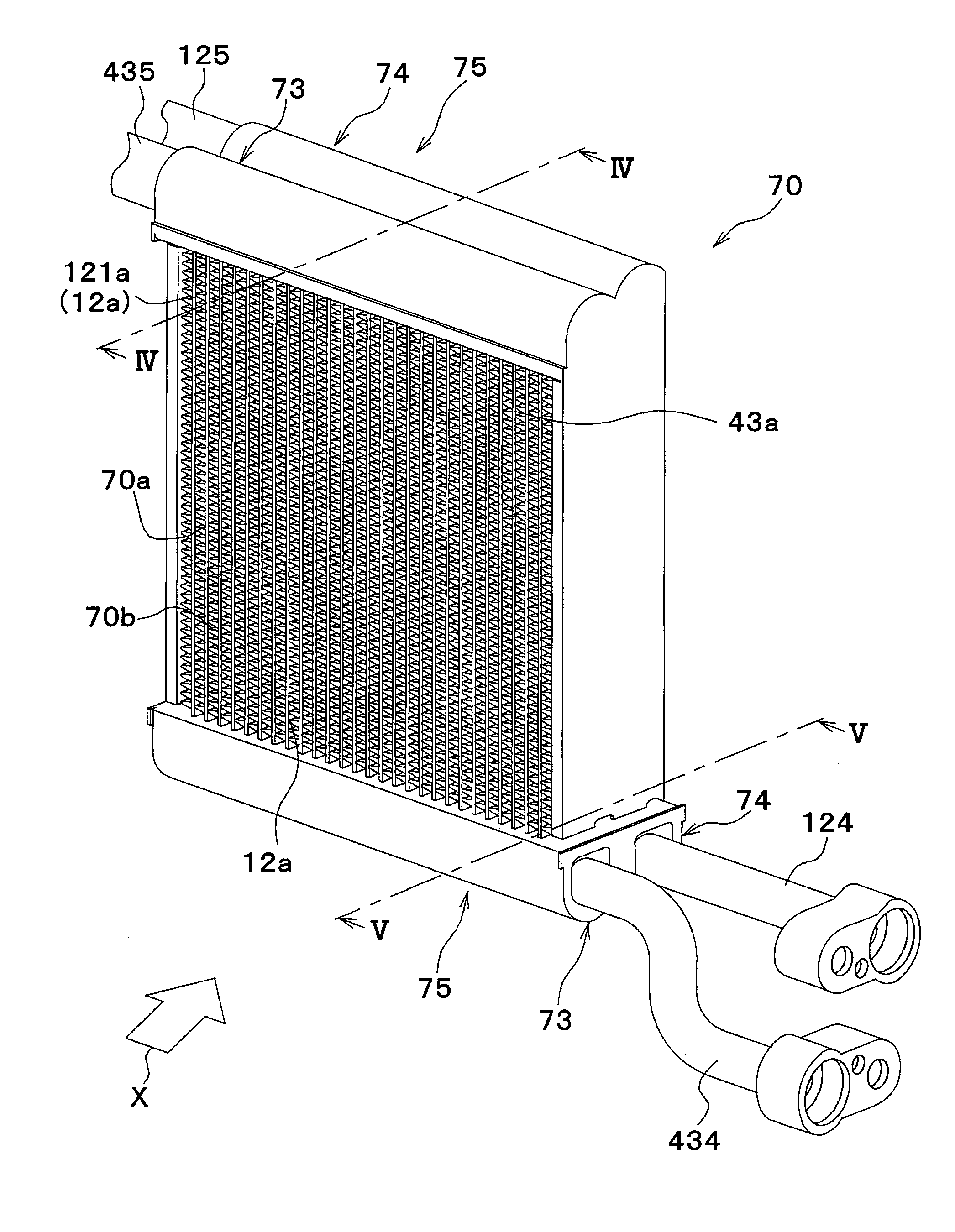

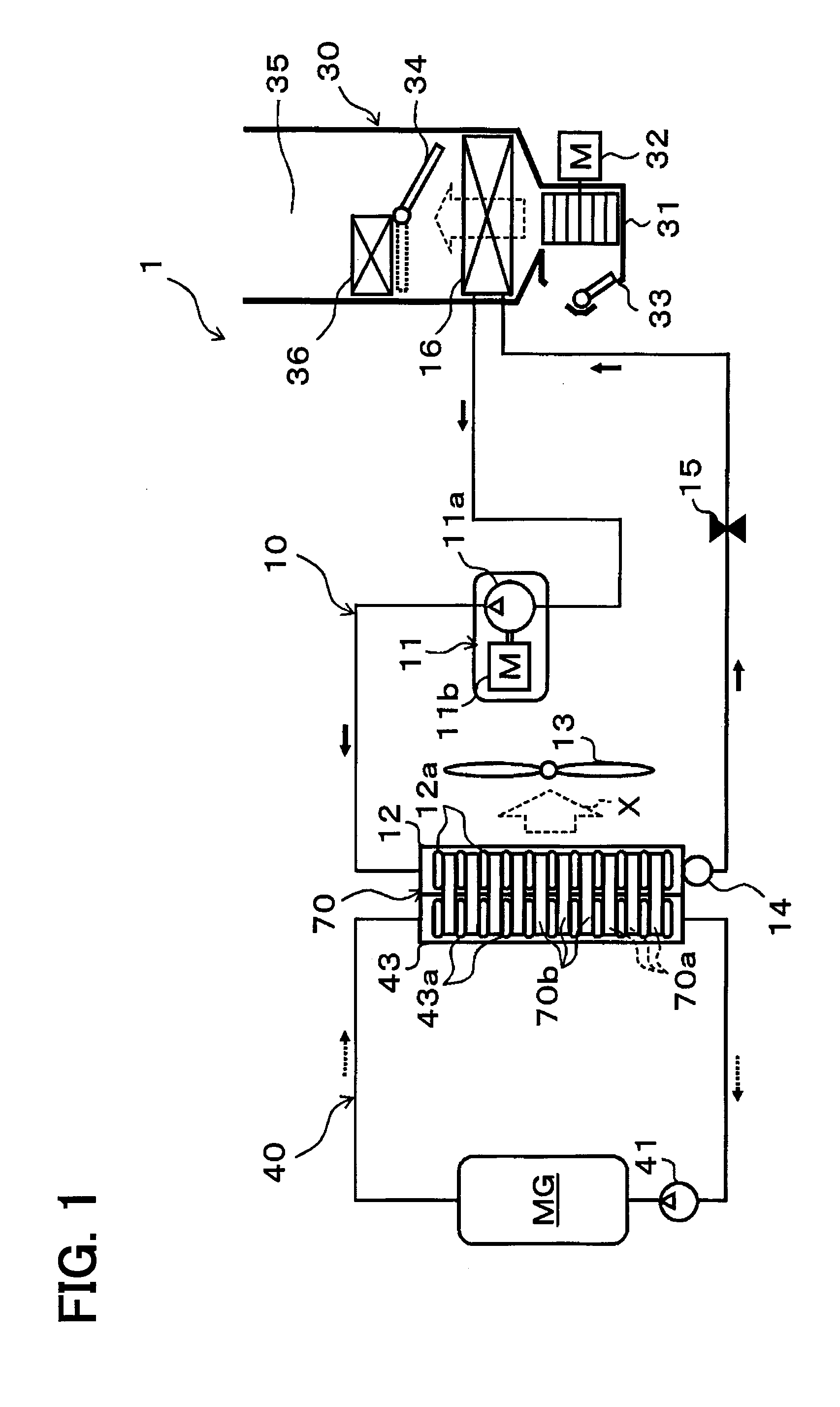

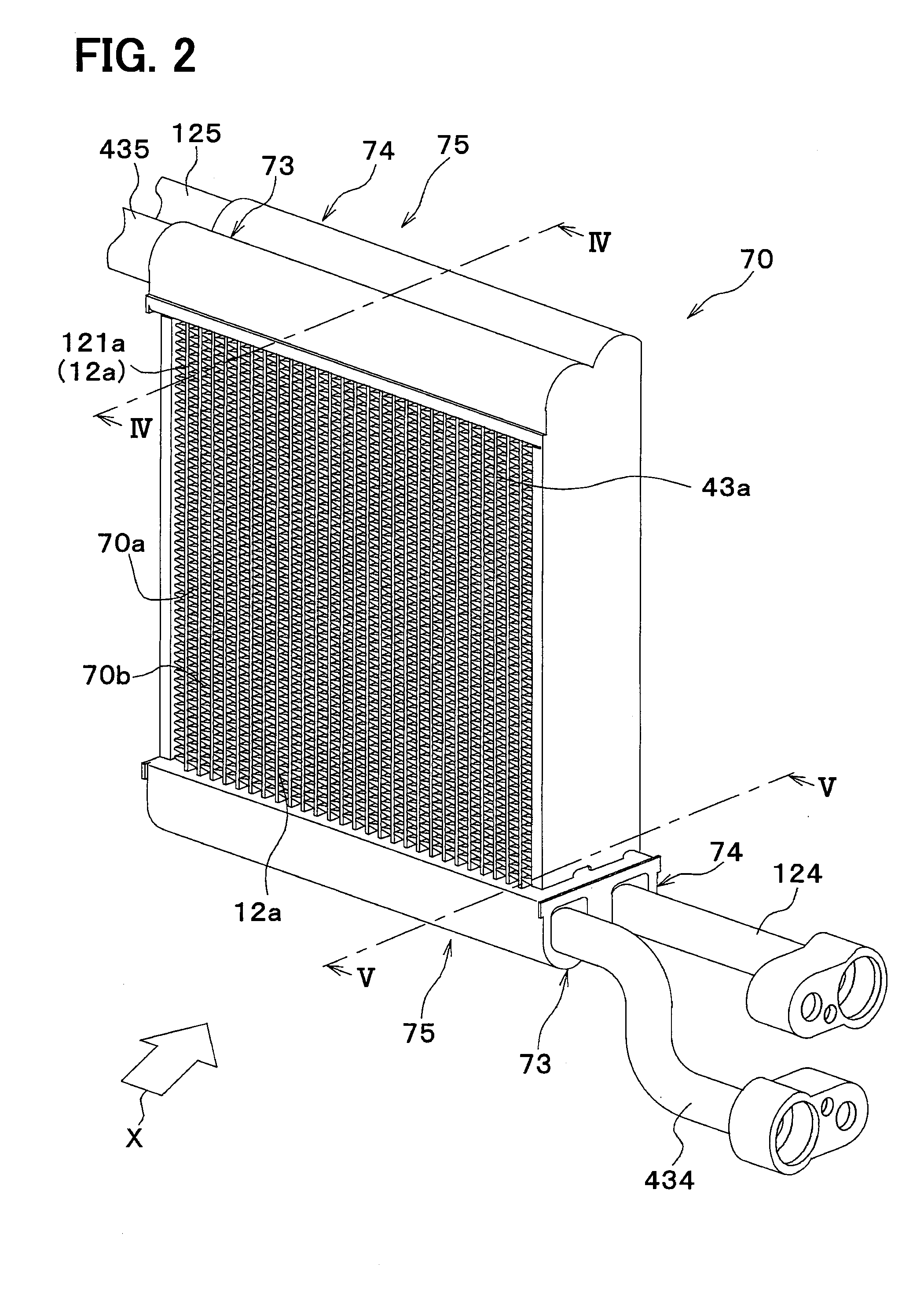

Magnetic refrigeration system and vehicle air conditioning device

InactiveUS20130298571A1Reduce heat exchangeImprove COPVehicle heating/cooling devicesMachines using electric/magnetic effectsAir conditioningRefrigerant

A magnetic refrigeration system constructed in such a way that a refrigerant transfer part transfers refrigerant from a first refrigerant discharge part of one refrigerant port to a first refrigerant circulation circuit after a magnetic field is applied to a magnetic working material by a magnetic field applying and removing part and that the refrigerant transfer part transfers refrigerant from a second refrigerant discharge part of other refrigerant port to a second refrigerant circulation circuit after the magnetic field is removed from the magnetic working material by the magnetic field applying and removing part.

Owner:DENSO CORP

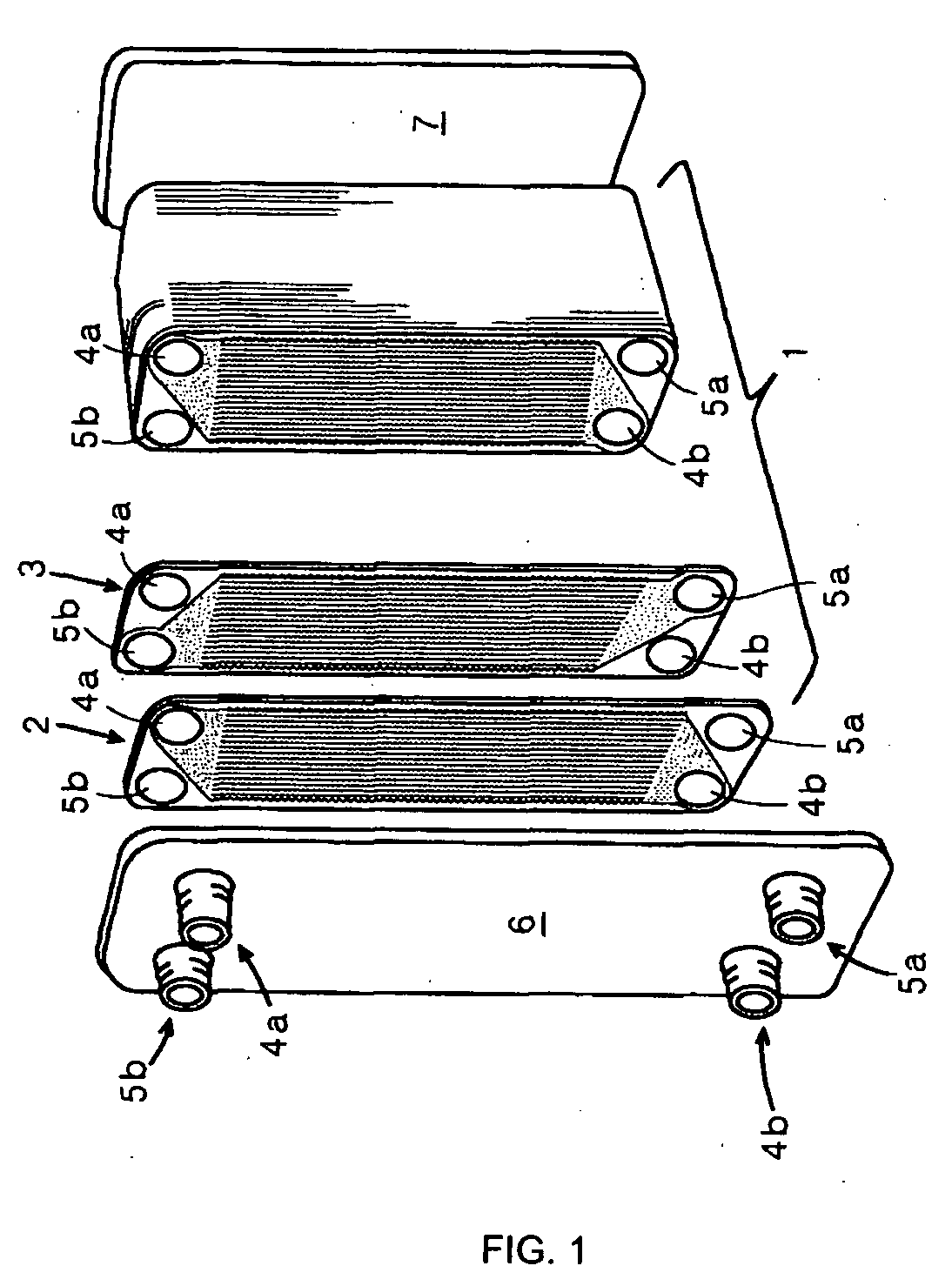

Heat exchanger

InactiveUS20060090887A1Reduce total pressure lossReduce maintenanceHeat transfer modificationLaminated elementsThin metalEngineering

To reduce pressure loss on a heat-exchanger fluid while downsizing a heat exchange and reducing the production cost of the heat exchanger without impairment of the heat transfer performance of the heat exchanger by forming a fluid channel in surfaces of thin metal plates such as stainless steel plates through the use of an etching technique or the like and by improving the shape of the fluid channel. In a heat exchanger in which a plurality of heat exchanger fins are provided in thin metal plates by using an etching technique or the like and a fluid channel for a heat-exchanger fluid is formed between the two opposed thin metal plates by alternately stacking the thin metal plates, the area of the fluid channel, through which the fluid flows between the heat exchanger fins, is made substantially uniform by forming the heat exchanger fins so as to have a curved cross-sectional shape from the front end thereof to the rear end.

Owner:KATO YASUYOSHI

Low-temperature refrigerating control method of air conditioner and air conditioner

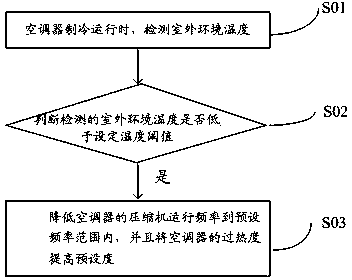

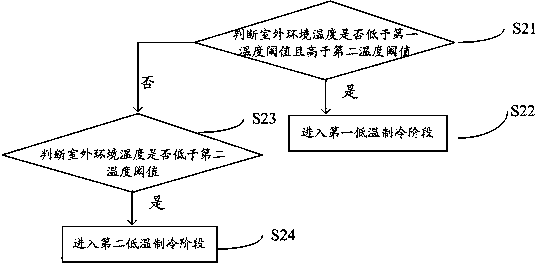

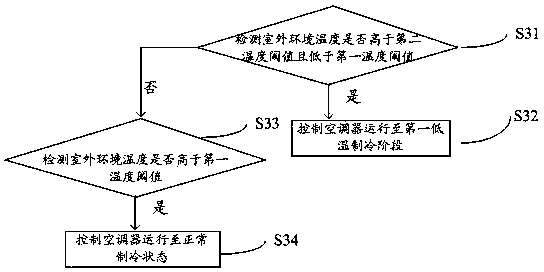

InactiveCN105627496AImprove cooling capacityImprove cooling performanceSpace heating and ventilation safety systemsLighting and heating apparatusContinuous operationThermal threshold

The invention provides a low-temperature refrigerating control method of an air conditioner and the air conditioner. By the adoption of the low-temperature refrigerating control method of the air conditioner and the air conditioner, the technical problem that an air conditioner cannot conduct refrigeration continuously under a low-temperature condition is solved. The control method comprises the following steps that when the air conditioner conducts refrigeration, the outdoor environment temperature is detected; whether the detected outdoor environment temperature is lower than a set temperature threshold value or not is judged; and if so, the operation frequency of a compressor of the air conditioner is lowered to be within a preset frequency range, and the superheat degree of the air conditioner is increased by preset degrees. According to the air conditioner adopting the control method, the effect that an indoor heat exchanger cannot enter a freeze protection mode at the low temperature is guaranteed, the indoor heat exchange capacity is improved, and then the refrigerating capacity is improved; in addition, continuous operation of the compressor is achieved, and the technical effect of continuous refrigeration is achieved at the low temperature.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

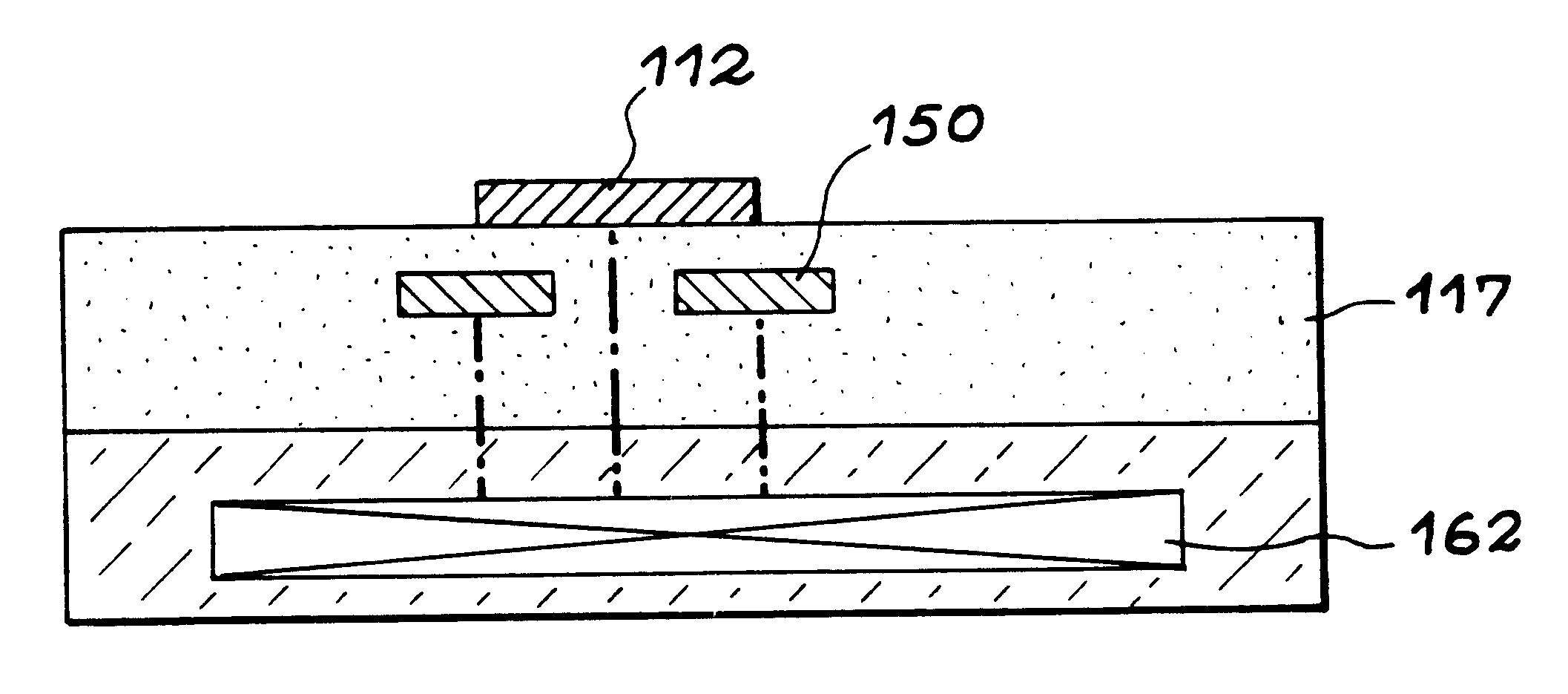

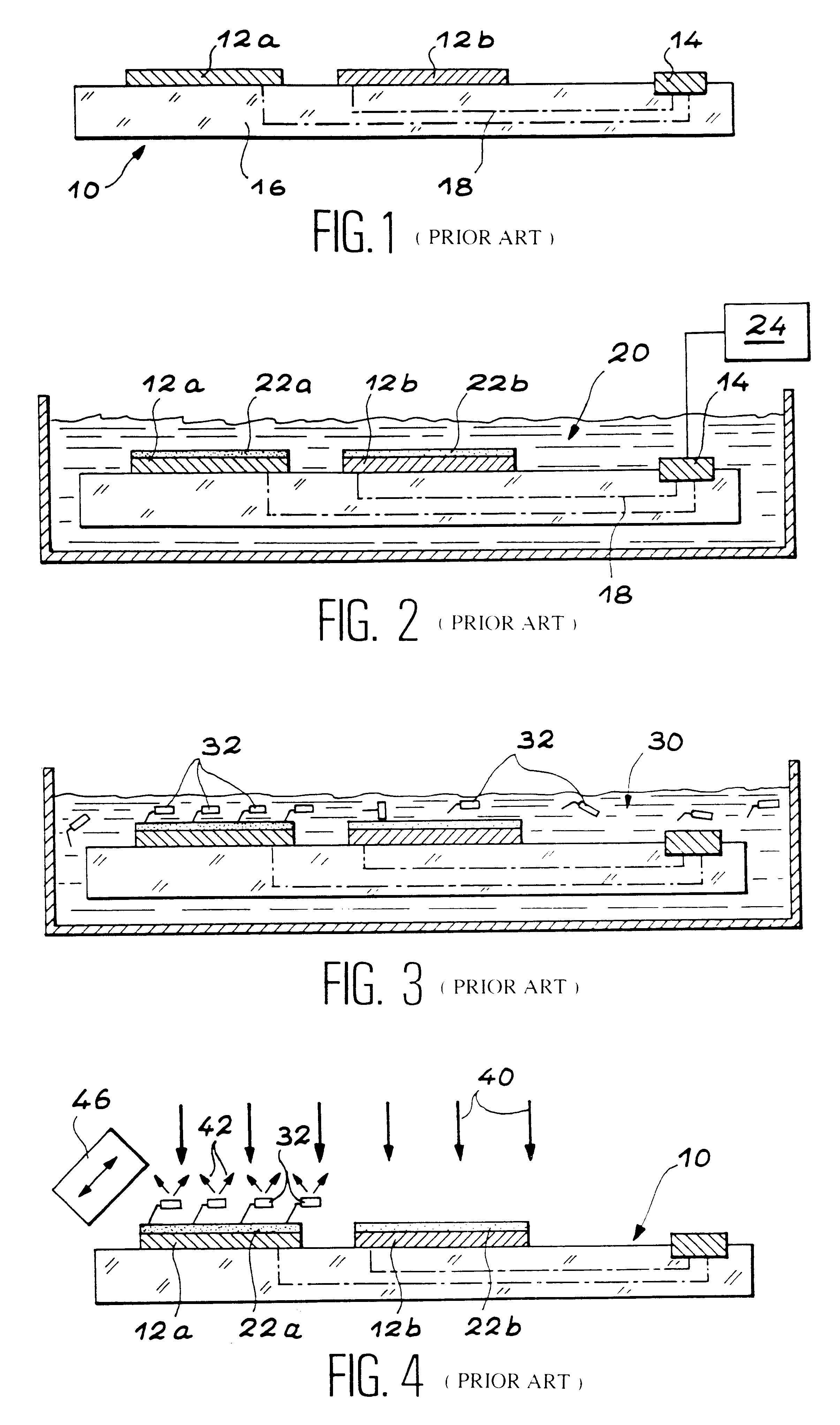

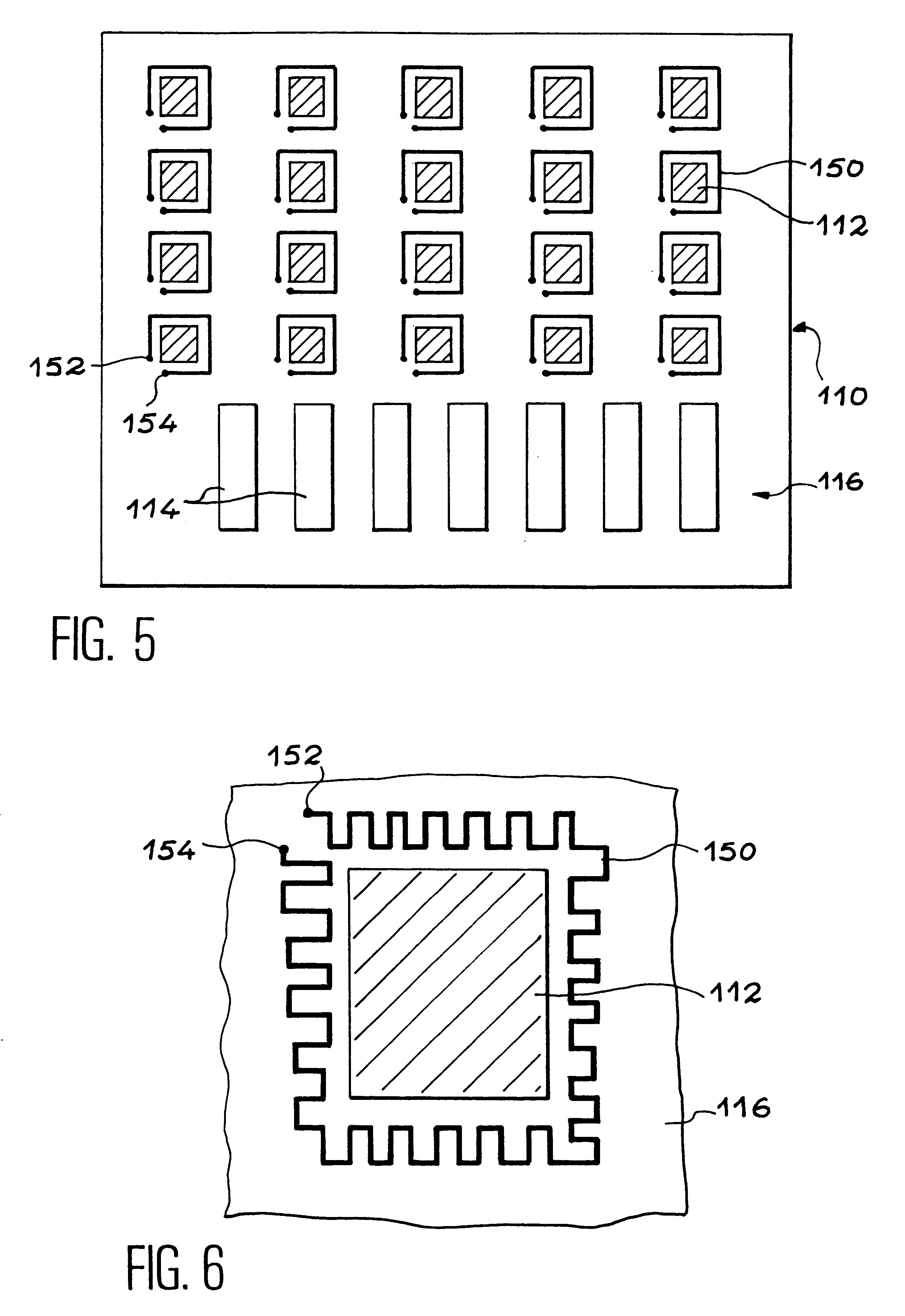

Chip-based analysis device comprising electrodes with localized heating

InactiveUS6255677B1Reduce thermal exchangeSmall sizeBioreactor/fermenter combinationsBiological substance pretreatmentsAntigenAntibody

The invention concerns an analysis device including at least one chip (110) equipped with a plurality of analysis electrodes (112). In accordance with the invention, the device also includes means of individual heating (150) of the analysis electrodes.The invention can be used for the analysis of chemical or biological products, for example in an antigen / antibody recognition or DNA / DNA analysis.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

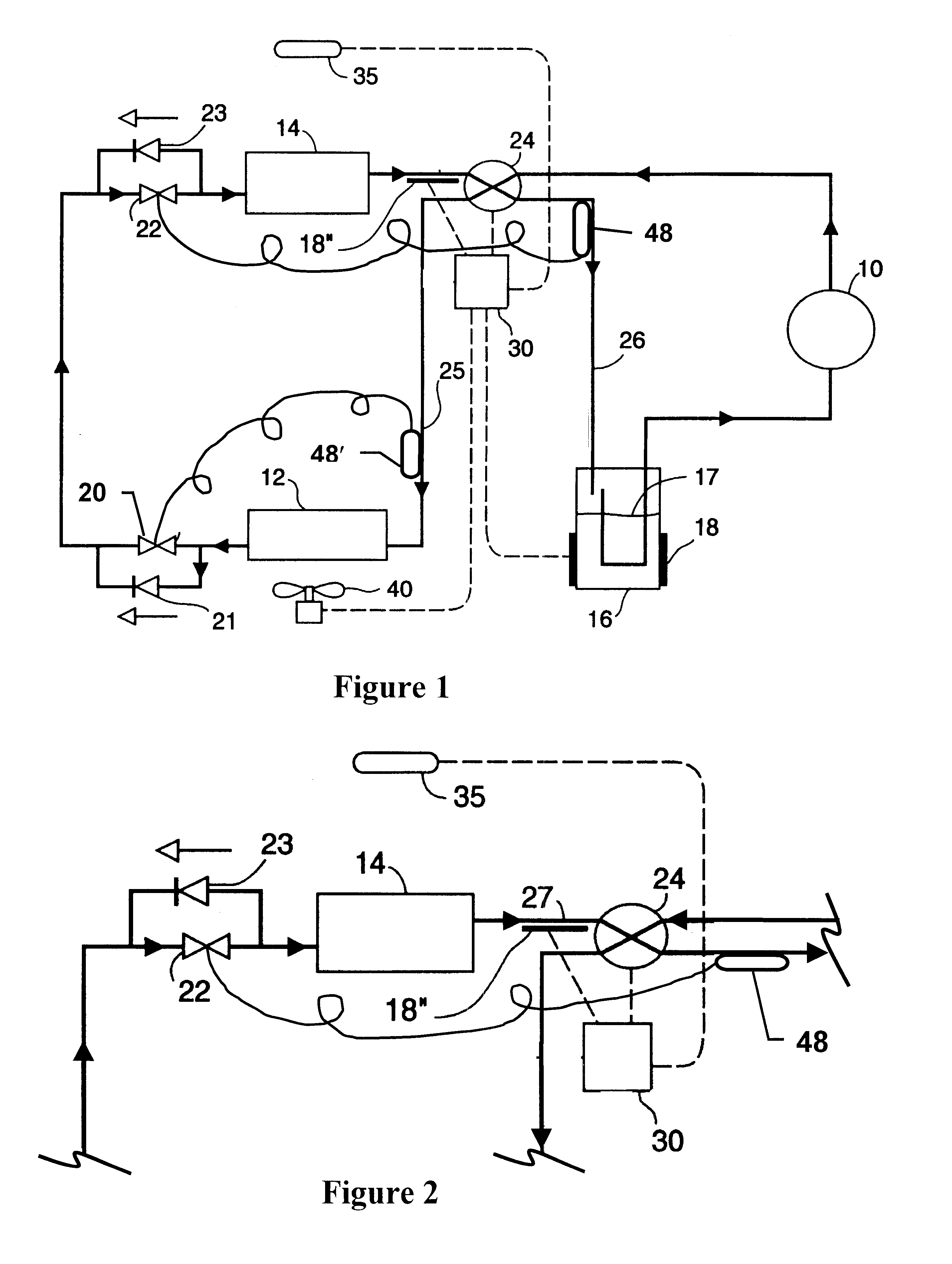

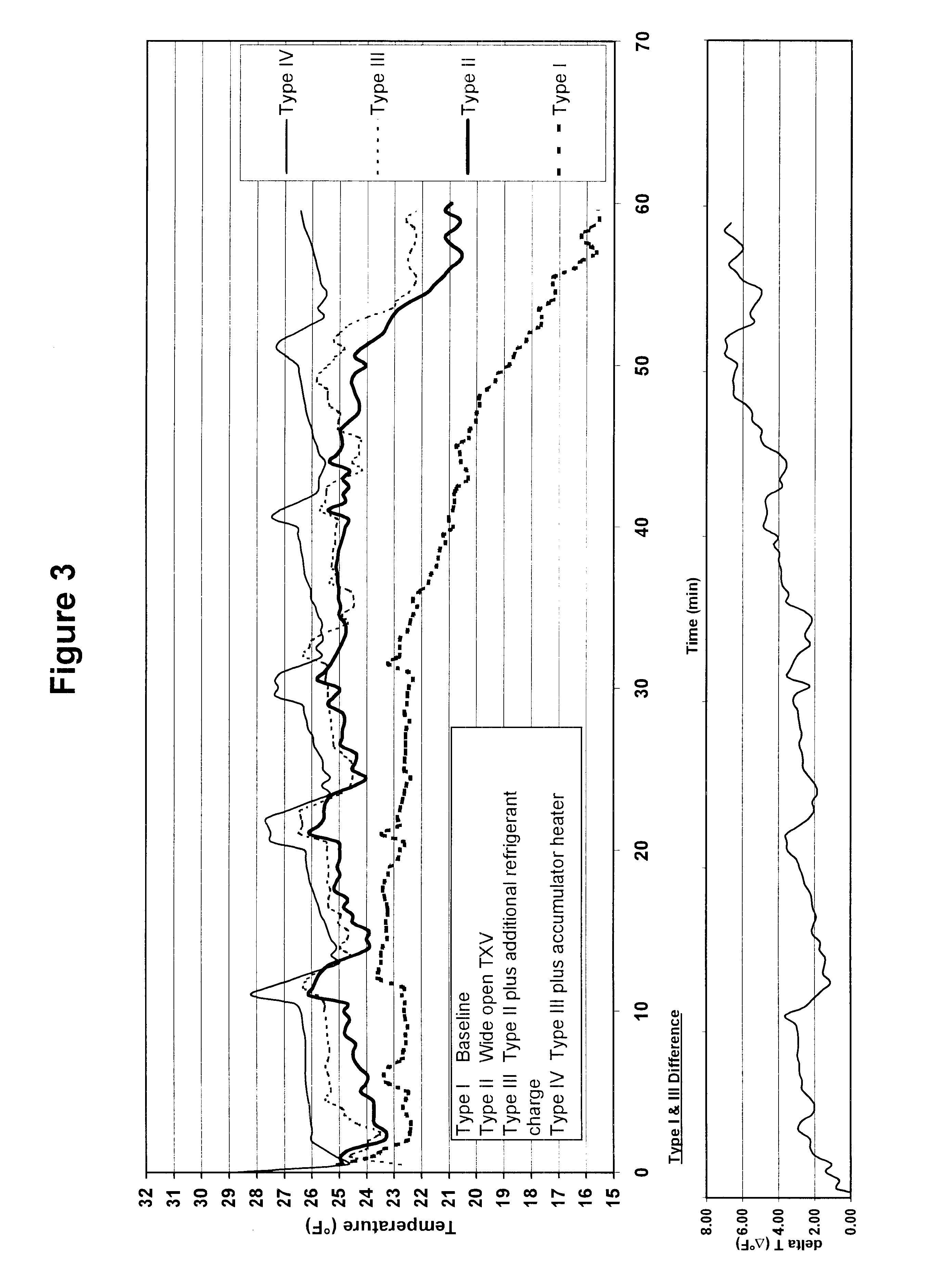

Frostless heat pump having thermal expansion valves

InactiveUS6467284B1Increased mass flow rateIncrease heating efficiencyCorrosion preventionCompression machines with reversible cyclePipingOutdoor temperature

A heat pump system having an operable relationship for transferring heat between an exterior atmosphere and an interior atmosphere via a fluid refrigerant and further having a compressor, an interior heat exchanger, an exterior heat exchanger, a heat pump reversing valve, an accumulator, a thermal expansion valve having a remote sensing bulb disposed in heat transferable contact with the refrigerant piping section between said accumulator and said reversing valve, an outdoor temperature sensor, and a first means for heating said remote sensing bulb in response to said outdoor temperature sensor thereby opening said thermal expansion valve to raise suction pressure in order to mitigate defrosting of said exterior heat exchanger wherein said heat pump continues to operate in a heating mode.

Owner:UT BATTELLE LLC

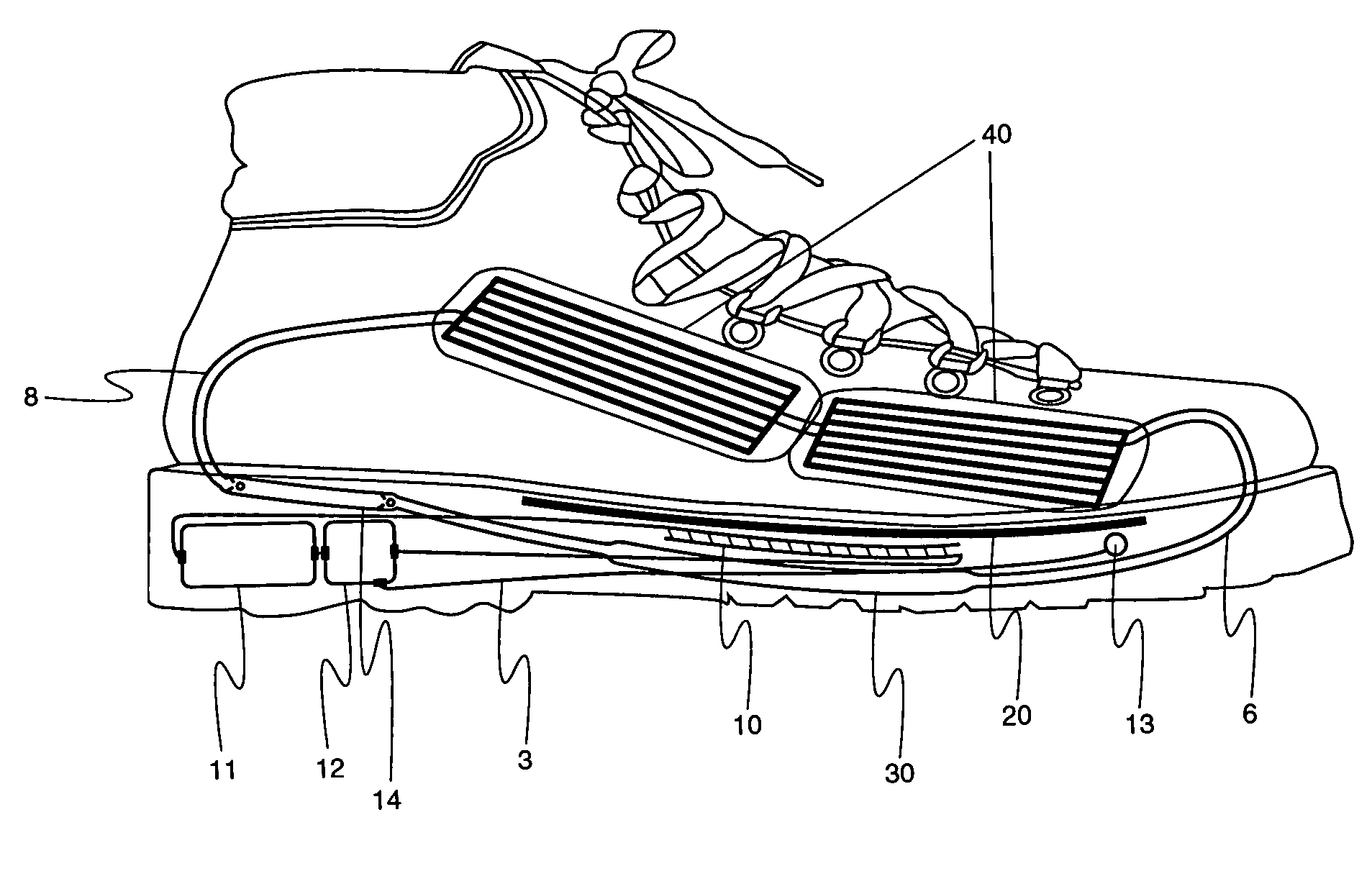

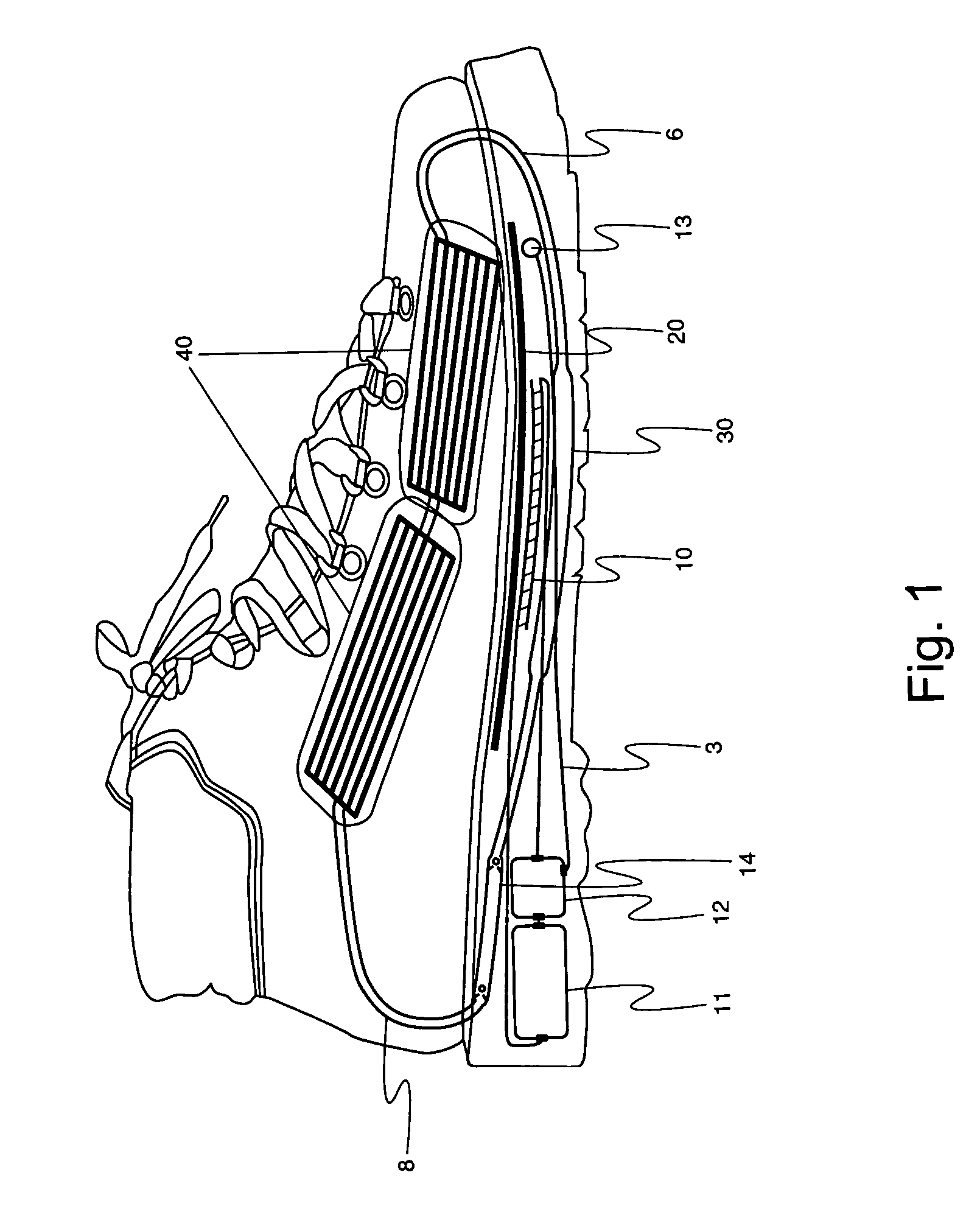

Temperature regulated clothing

InactiveUS7186957B2Reduce heat exchangeHeat dissipationGlovesHeater elementsControl systemEngineering

Temperature regulated clothing with a thermo-electric module that can be configured to transfer heat to or from the inside of the clothing. The clothing can include, e.g., a control system to maintain a desired internal clothing temperature. The clothing can have, e.g., a circulating coolant system to enhance the rate and / or efficiency of heat transfer.

Owner:PHOENIX CONSULTANTS

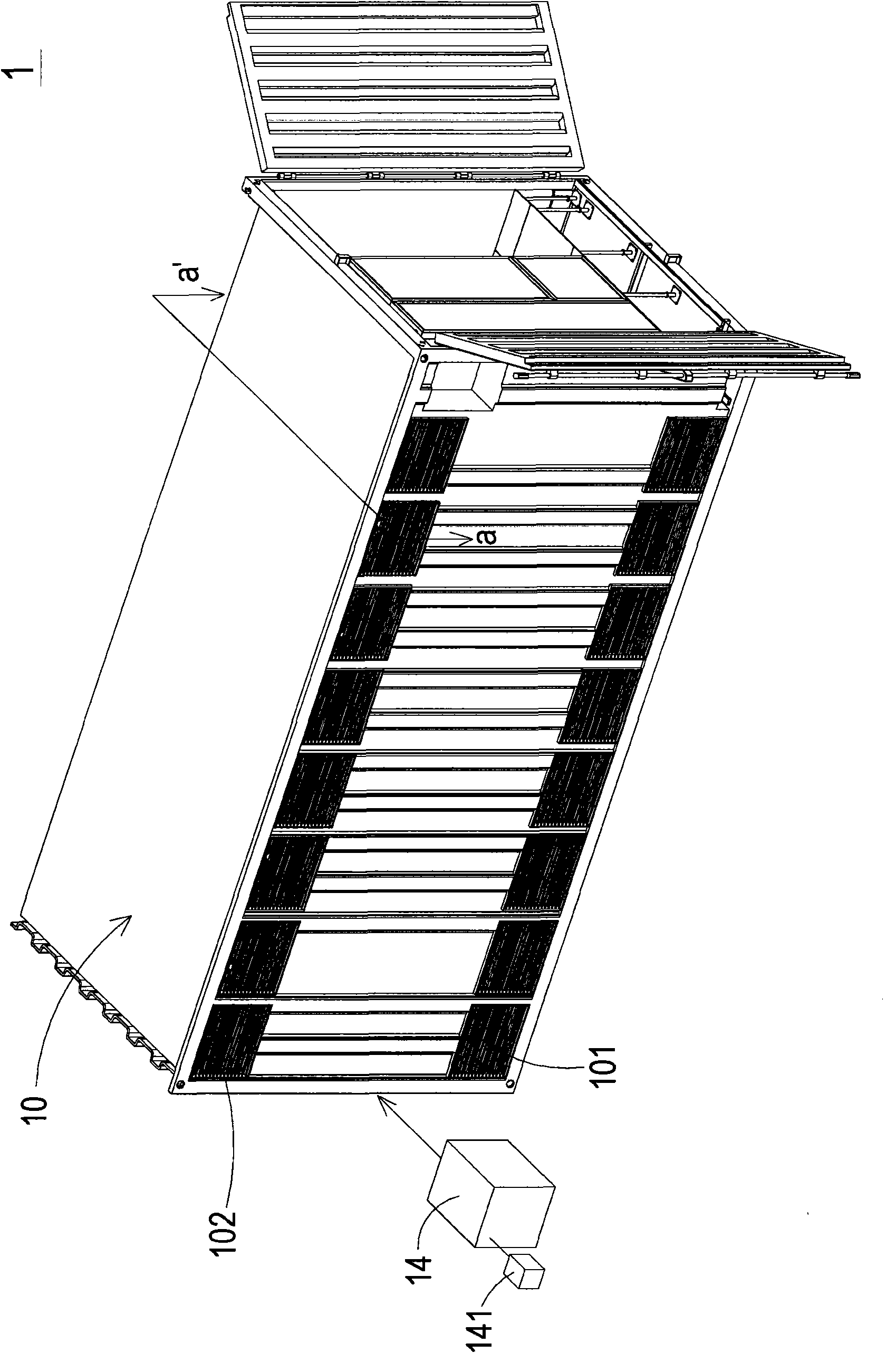

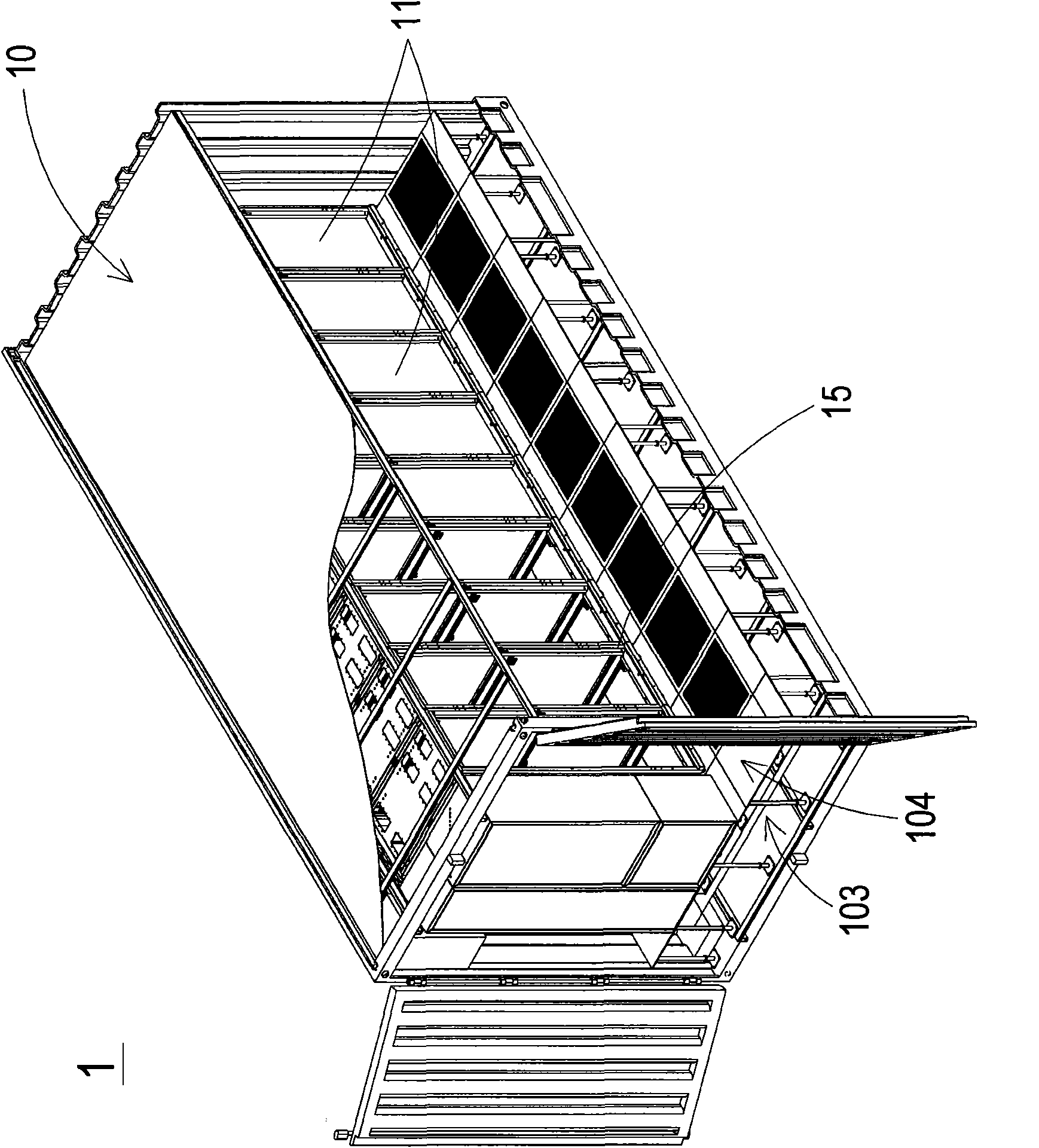

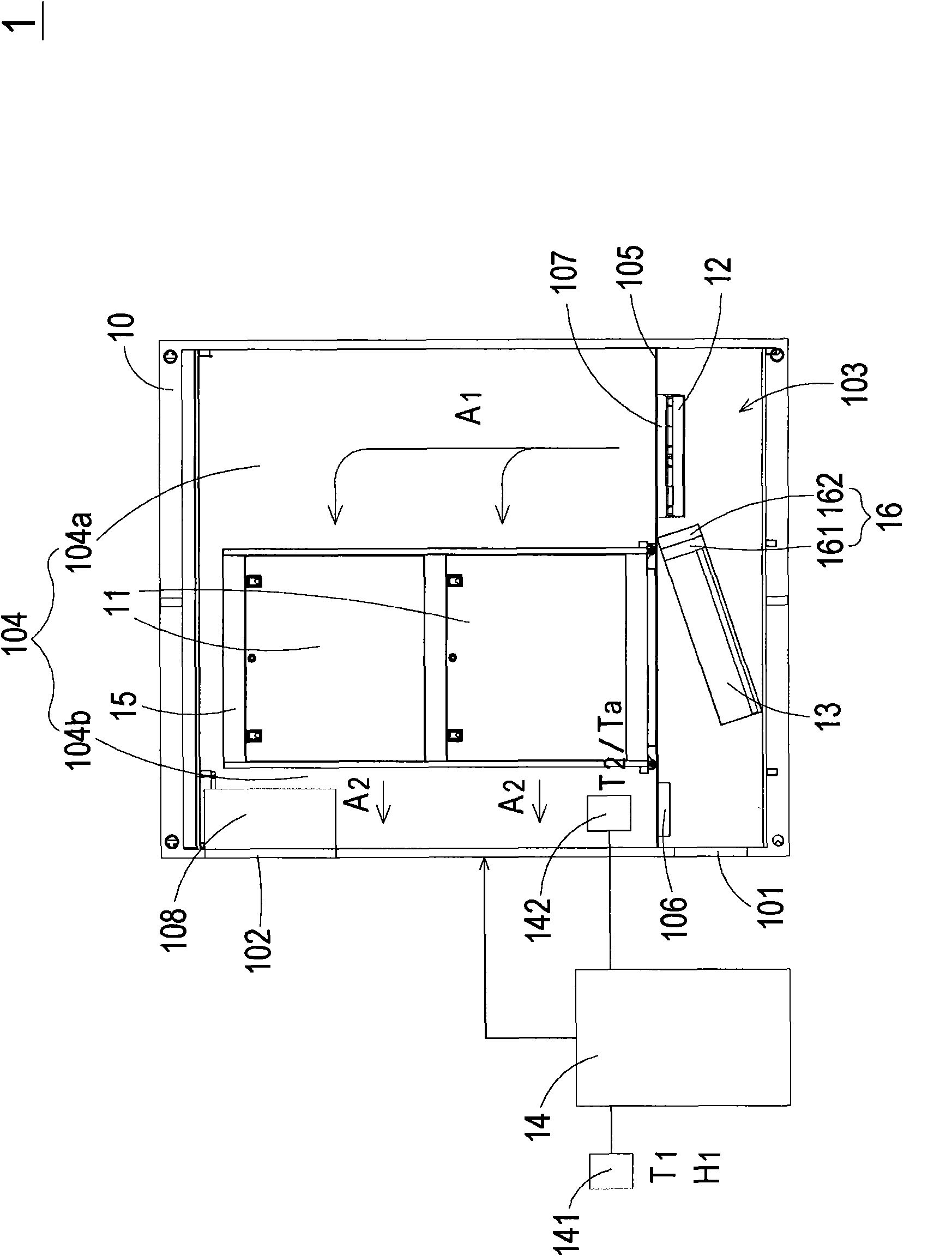

System and method for adjusting environment of portable data center

ActiveCN102105033AReduce heat exchangeReduce lossServersTemperature control with auxillary non-electric powerData centerControl unit

The invention discloses a system and a method for adjusting environment of a portable data center. The system comprises a computer room, a plurality of computer cabinets, a blowing device, a control unit and a first sensor, wherein the computer room comprises a first opening and a second opening; the plurality of computer cabinets are accommodated in the computer room and generate a second air flow after heat exchange with the first air flow; the blowing device is arranged in the computer room and guides the first air flow towards the computer cabinets; the control unit controls the first andsecond openings of the computer room; the first sensor detects the first temperature of the outside air of the computer room and is electrically connected with the control unit; wherein the control unit controls the on and off of the first and second openings by comparing the first temperature with the second temperature. By the invention, the heat exchange amount of the heat exchanger can be reduced so as to reduce the electric energy consumption of the heat exchanger, avoid the waste of energy and save the operation cost.

Owner:DELTA ELECTRONICS INC

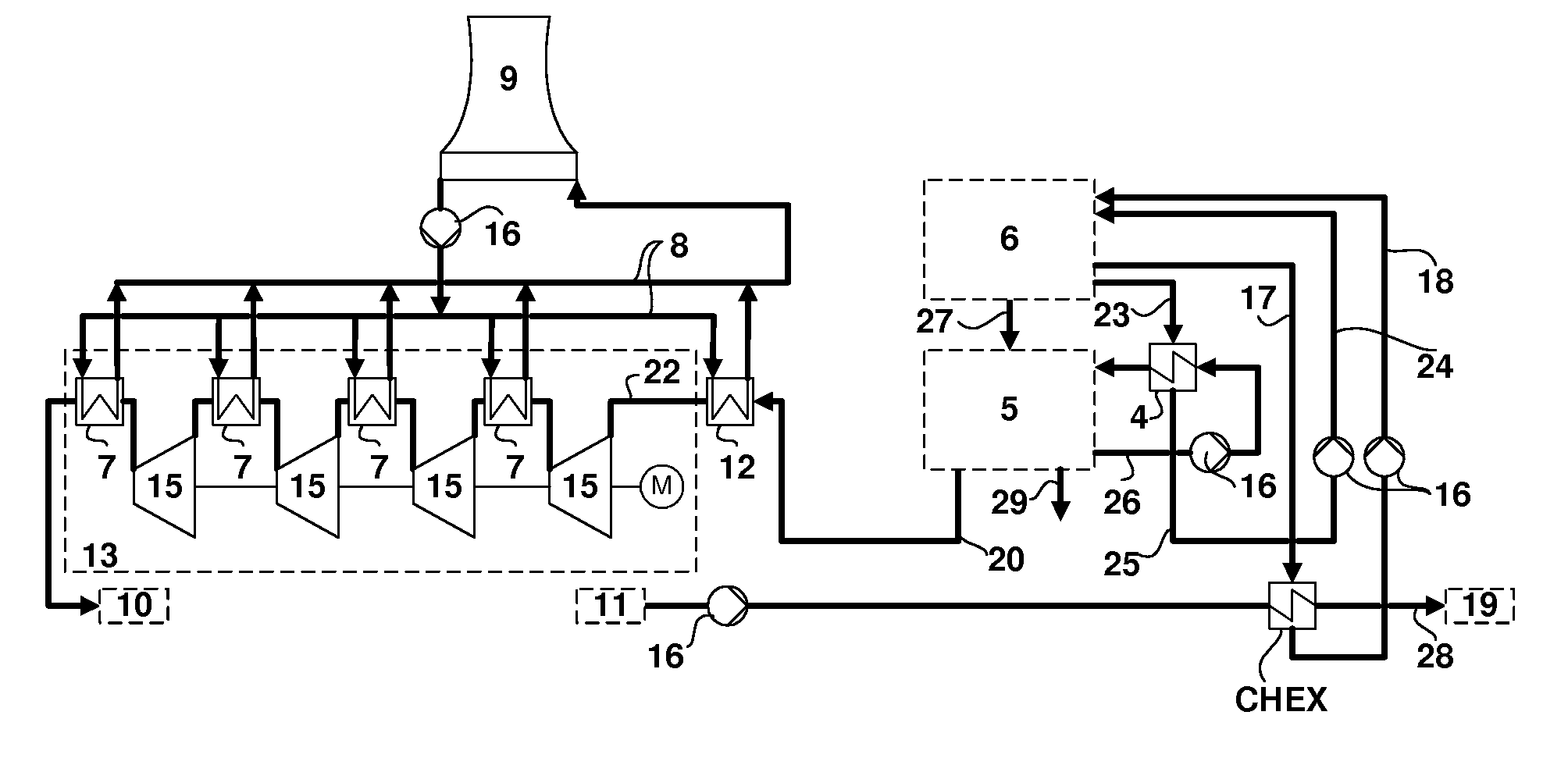

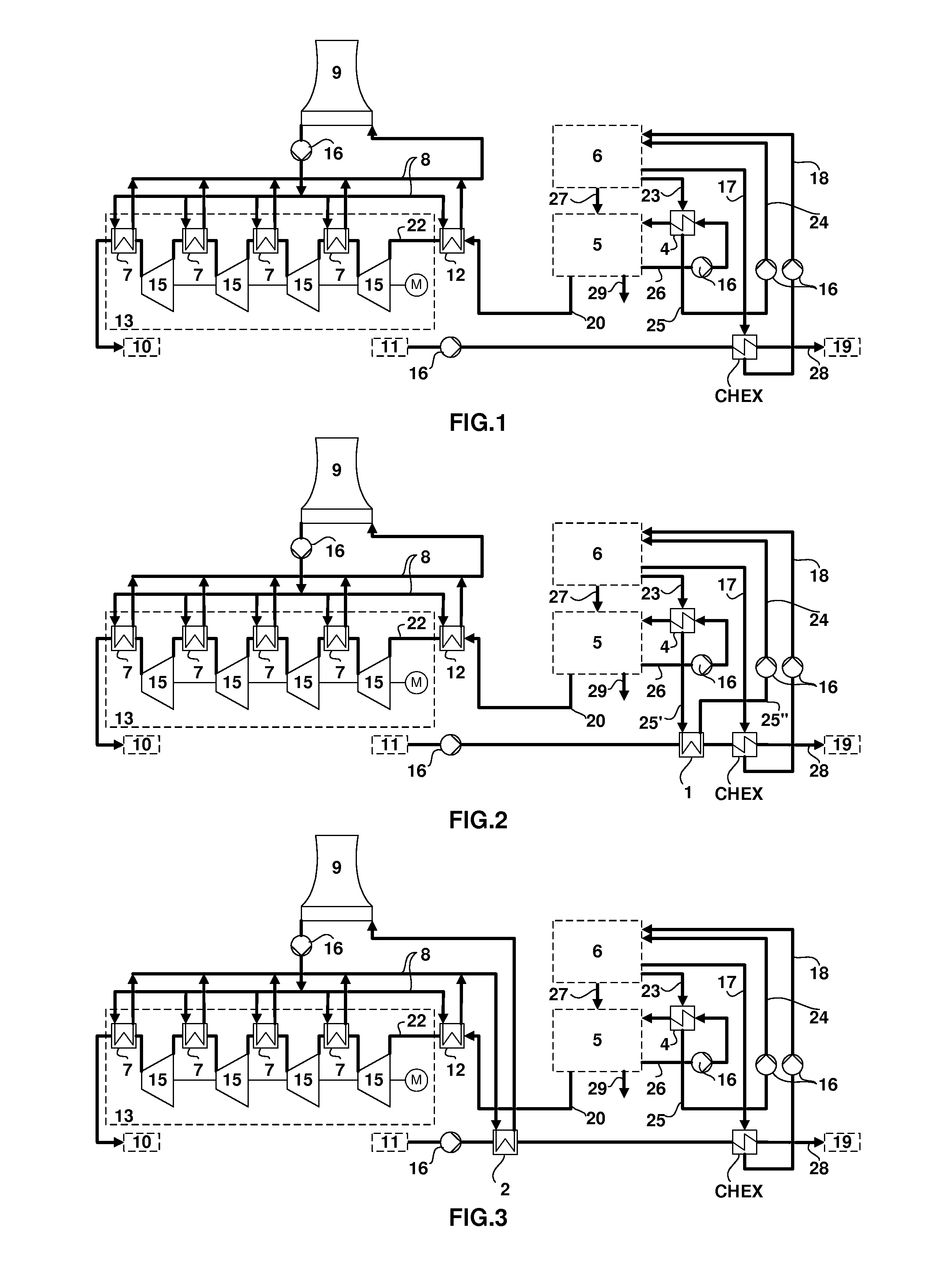

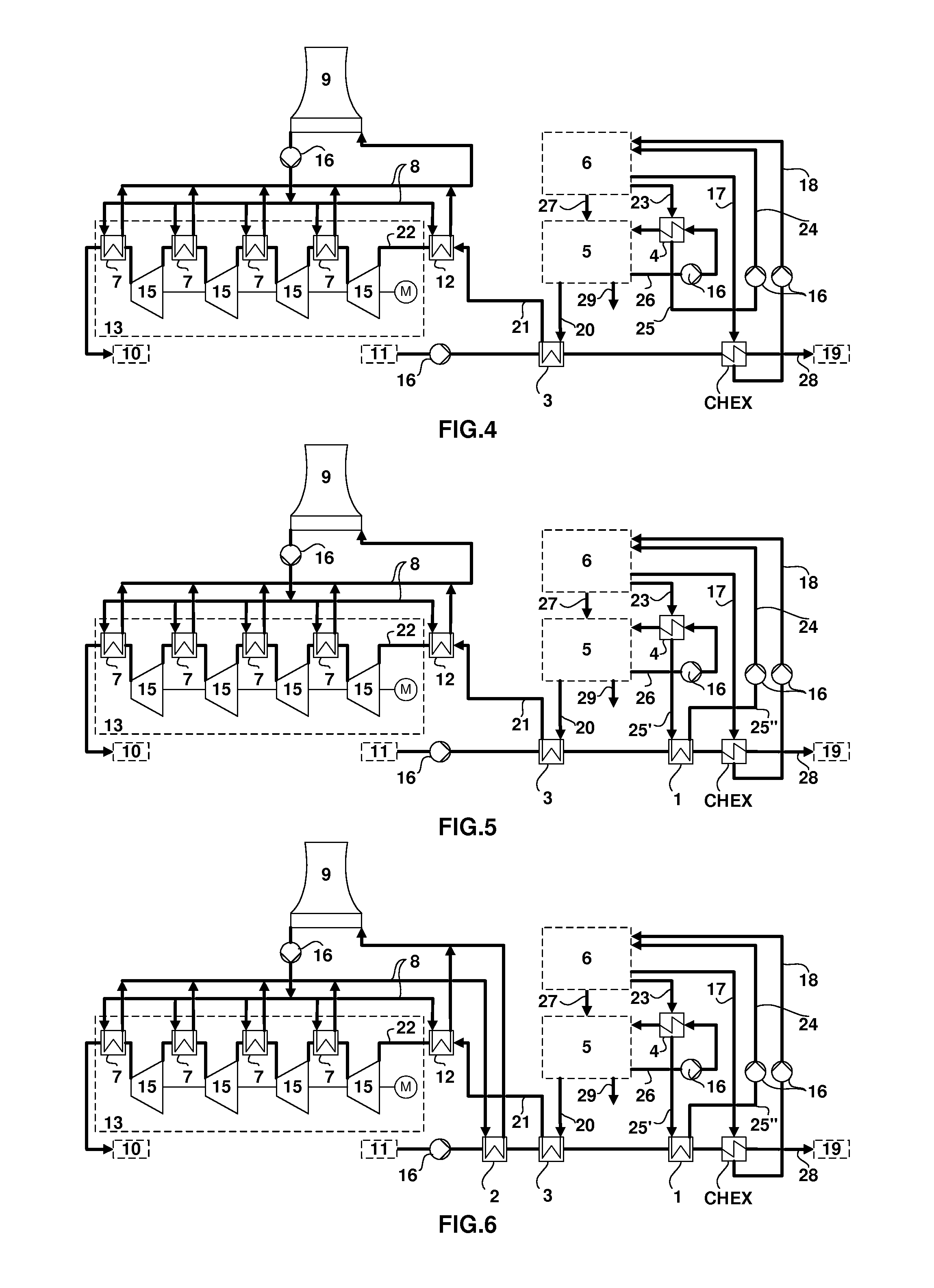

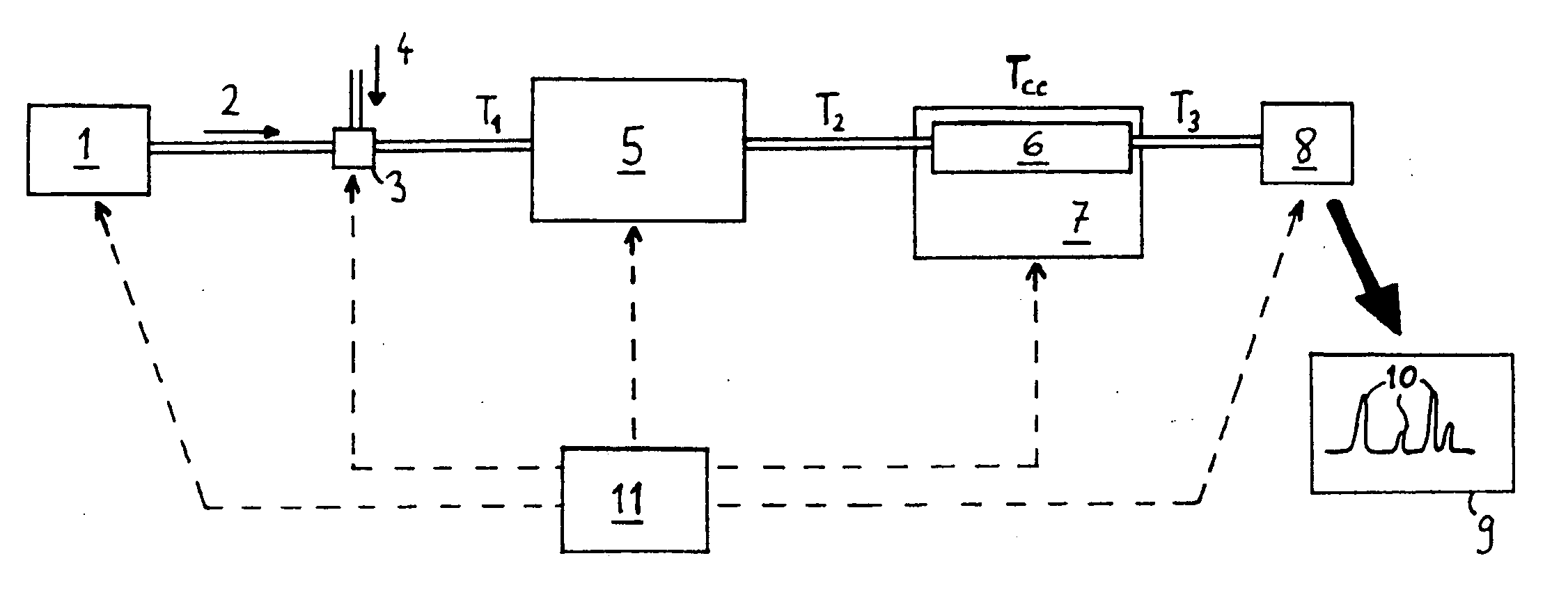

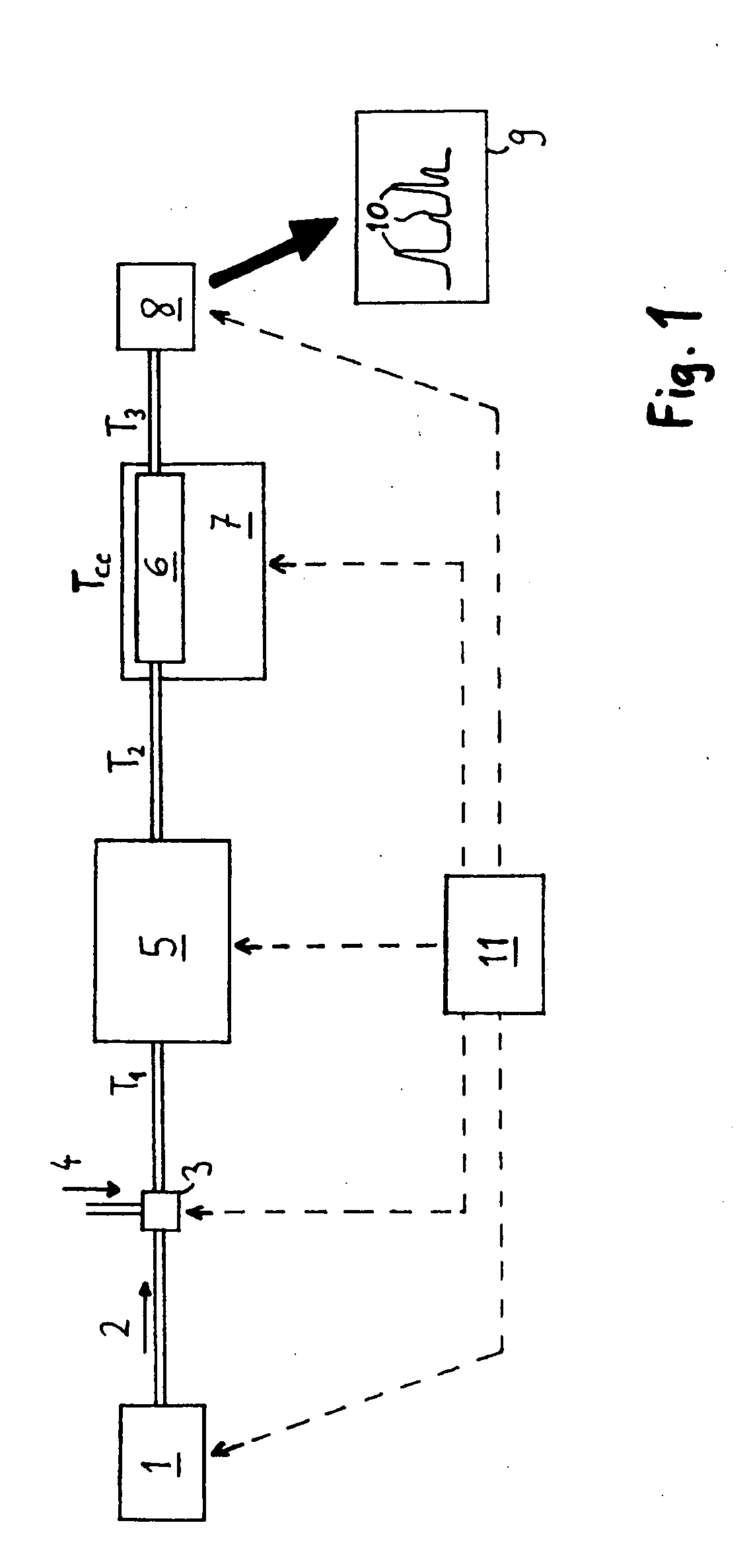

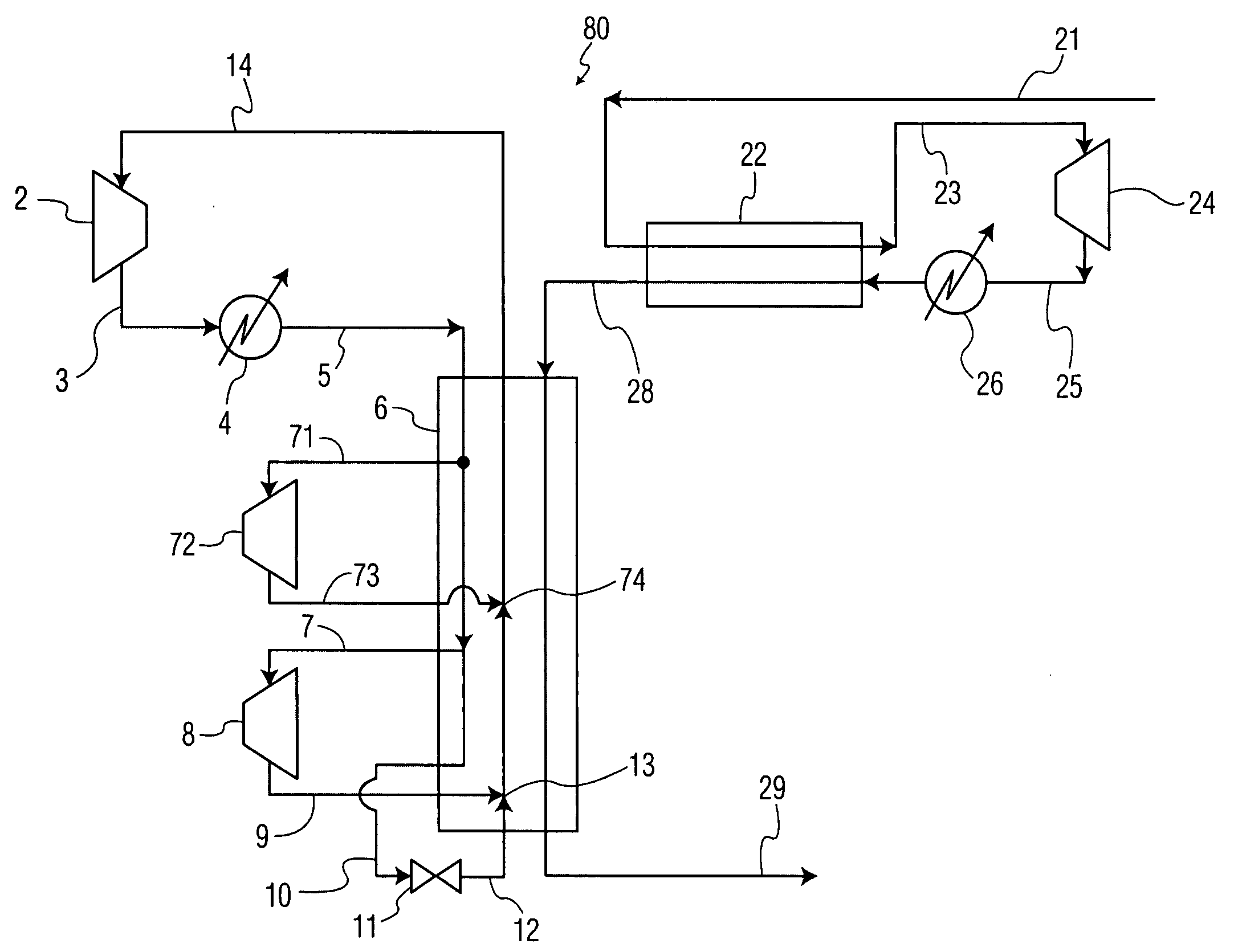

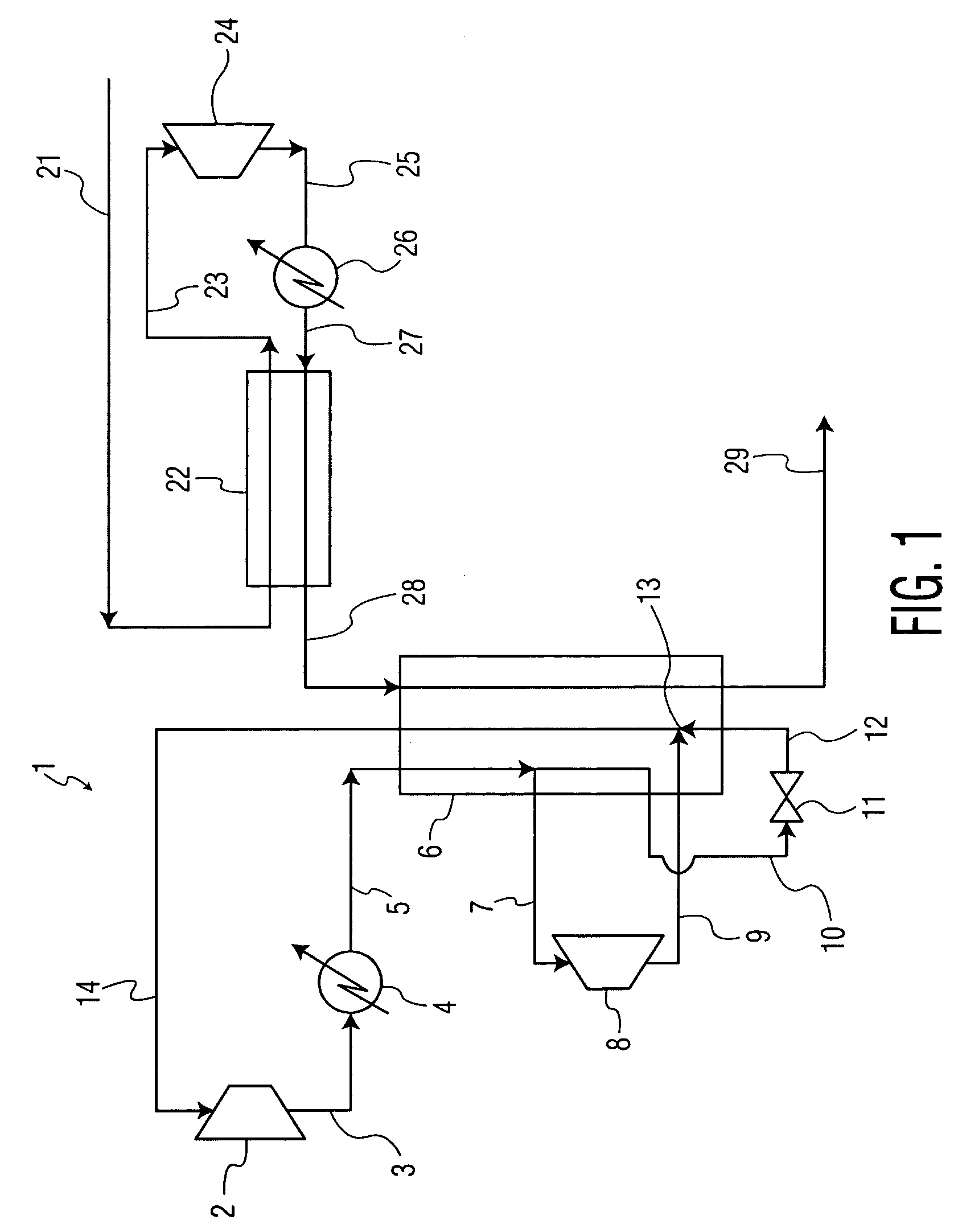

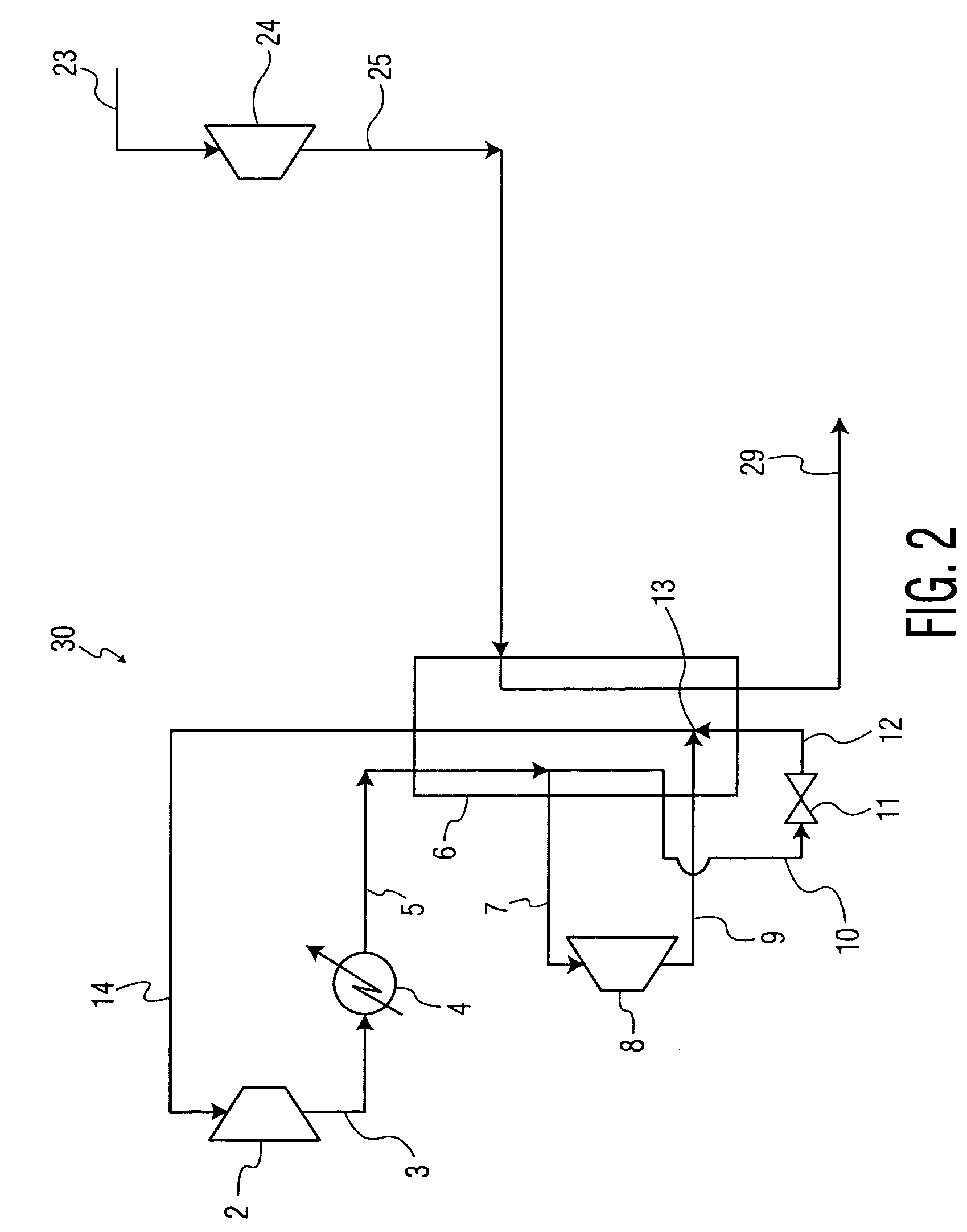

Thermal integration of a carbon dioxide capture and compression unit with a steam or combined cycle plant

ActiveUS20110265477A1Improve power efficiencyReduce extractionGas treatmentCarbon compoundsElectricityHeat flow

A power plant system including a fossil fuel fired power plant (6) for the generation of electricity, a carbon dioxide capture and compression system (5, 13), and an external heat cycle system has at least one heat exchanger (1,2,3) for the heating of the flow medium of the external heat cycle system. The heat exchanger (1,2,3) is connected to a heat flow from the CO2 capture plant (5) or a CO2 compression unit (13). A return flow from the heat exchanger (1,2,3) is led to the CO2 capture and compression system (5,13) or to the power plant (6). The power plant system allows an increase in overall efficiency of the system.

Owner:GENERAL ELECTRIC TECH GMBH

System and method for de-icing a heat pump

InactiveUS20160332504A1Increasing rate of de-icingReduce the possibilityMechanical apparatusAir-treating devicesEngineeringHeat pump

Methods and system for providing de-icing a heat pump heat exchanger and heating a vehicle passenger cabin are presented. In one example, a heat pump that experiences icing of exterior heat exchanger fins may be operated in a cooling mode where a passenger cabin heat exchanger operates as an evaporator to improve de-icing of the exterior heat exchanger fins.

Owner:FORD GLOBAL TECH LLC

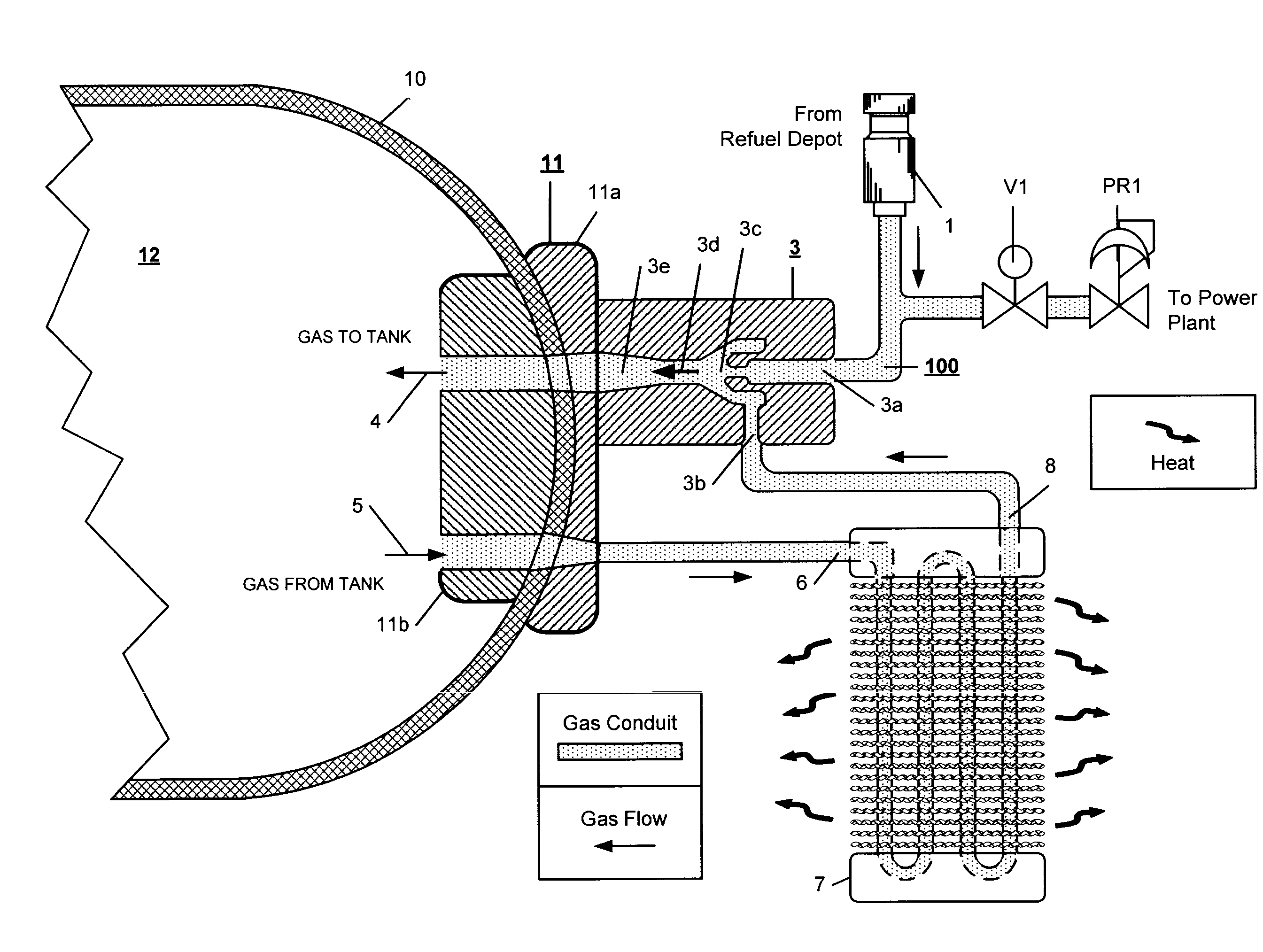

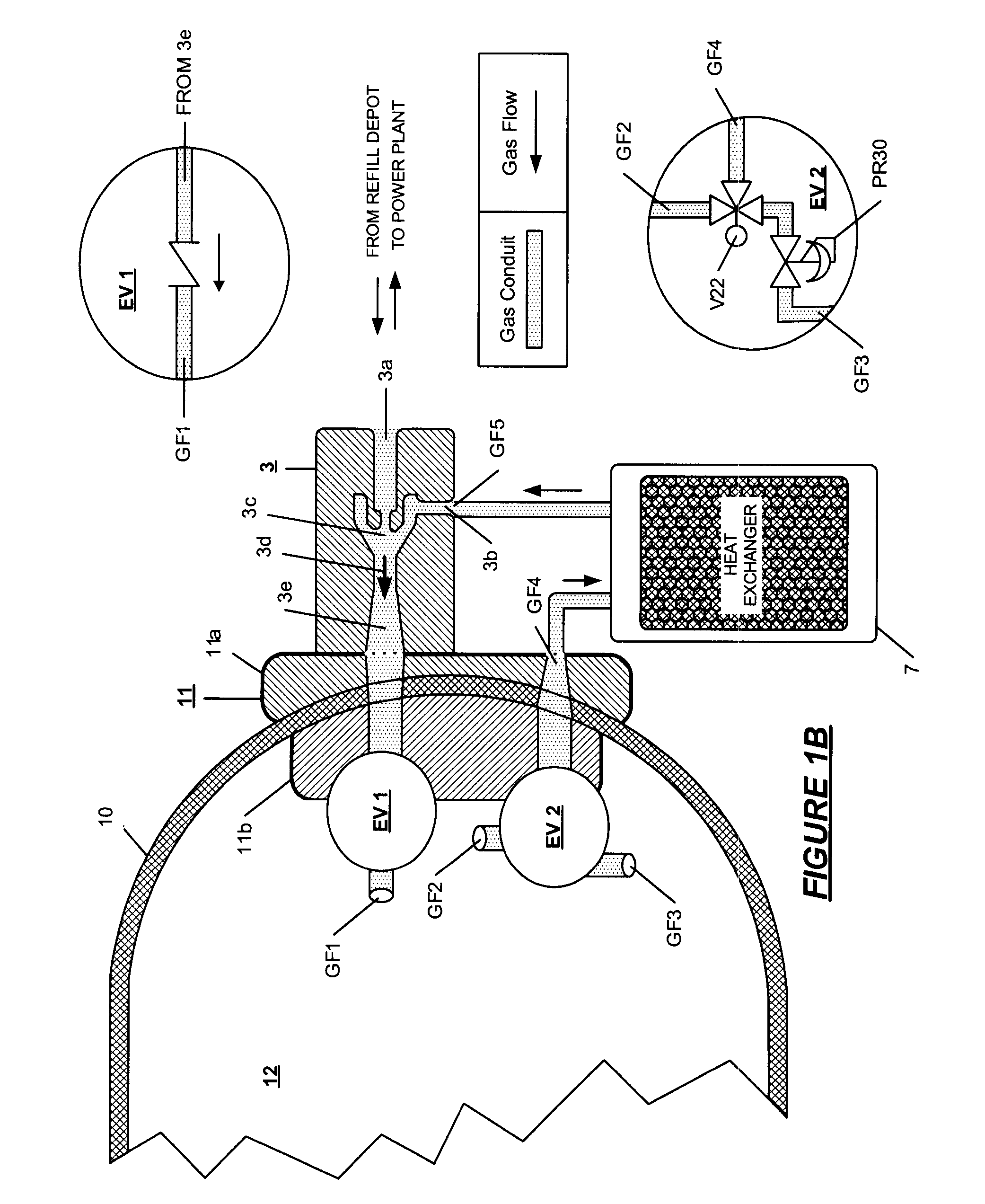

Supplemental heat exchange for high pressure gas tank

ActiveUS7938149B2Increase efficiency and refueling capacityRemove heatGas handling applicationsSolid materialProduct gasEngineering

Apparatus for heat exchange in a high pressure gas storage tank wherein a heat absorbent gas media circulates within the tank and absorbs or radiates the heat resulting from compression and expansion of gas stored in the on board tank depending upon the mode of operation of the vehicle, the gas media is circulated through a heat exchange unit external to the tank whereby heat is radiated to or absorbed from an environment external to the tank, and an in situ heat exchange device installed within the tank absorbs or radiates the heat from or to the gas stored in the tank as a result of heat exchange through a unit external to the tank.

Owner:HONDA MOTOR CO LTD

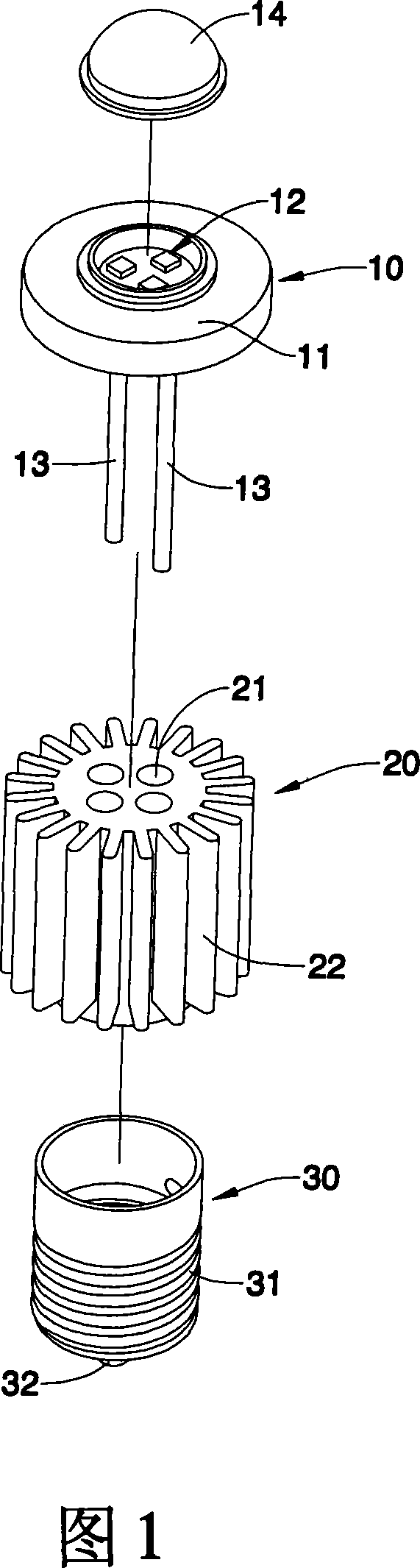

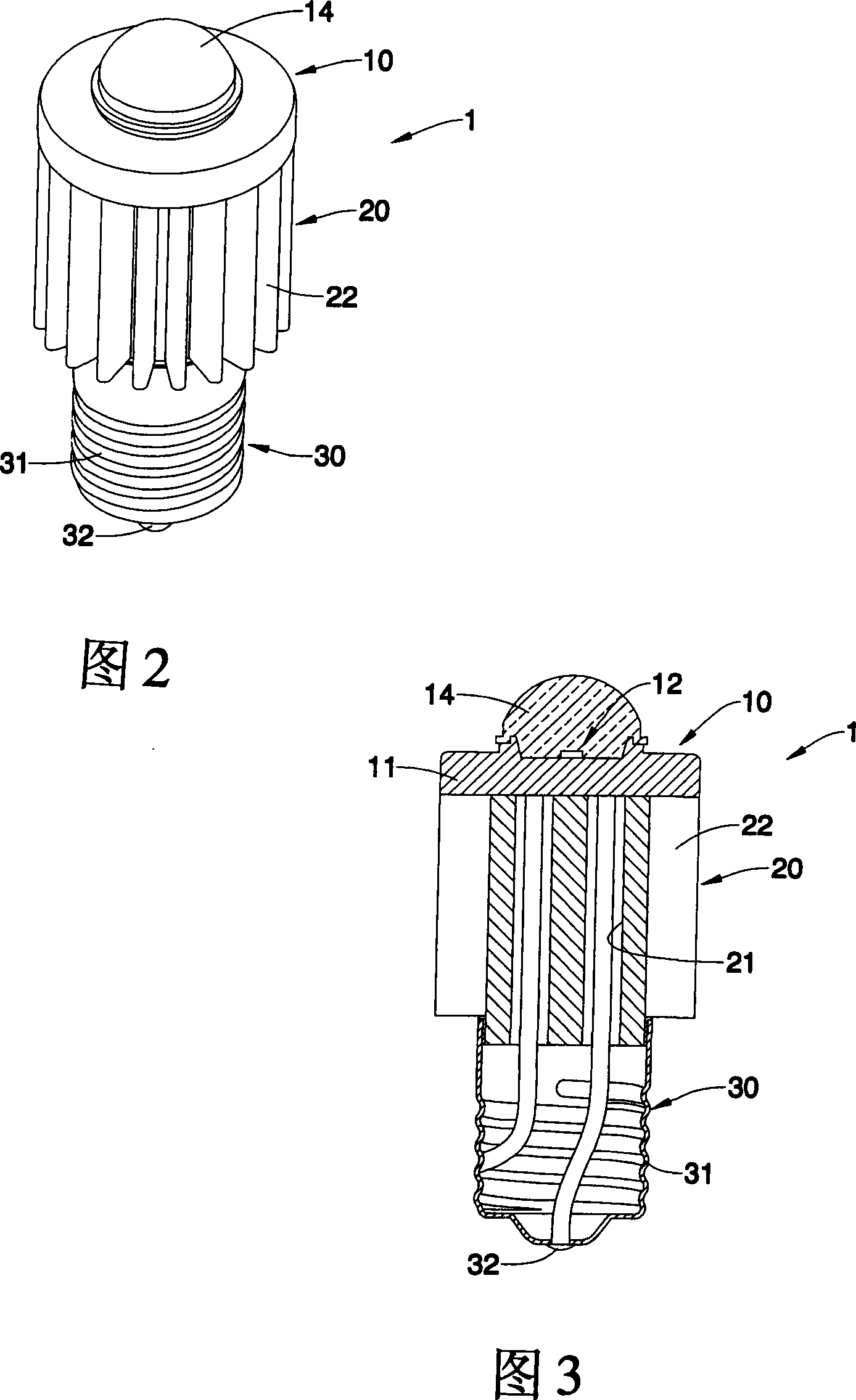

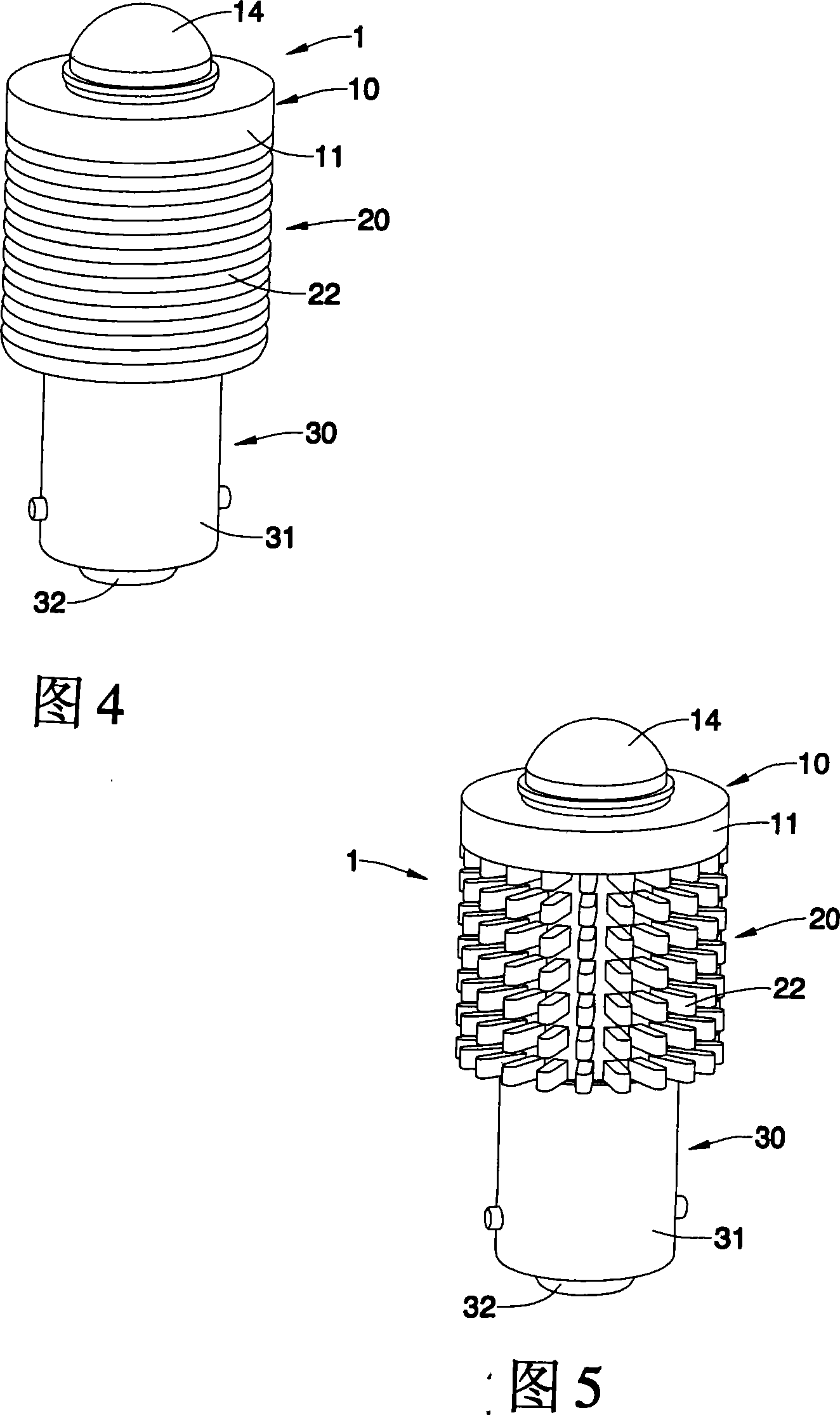

Twist type LED module and LED device

InactiveCN101089461AAvoid burnsExtended service lifePoint-like light sourceElectric circuit arrangementsEngineeringLight-emitting diode

The present invention relates a screw-plug LED module and LED device. Said screw-plug LED module is characterized by that the rear end of metal base seat of LED component is equipped with a radiating base seat by adopting surface contact mode. Said invention also provides the LED device composed of several screw LED modules, and also provides the concrete structure of said LED device.

Owner:ANTEYA TECH CORP +1

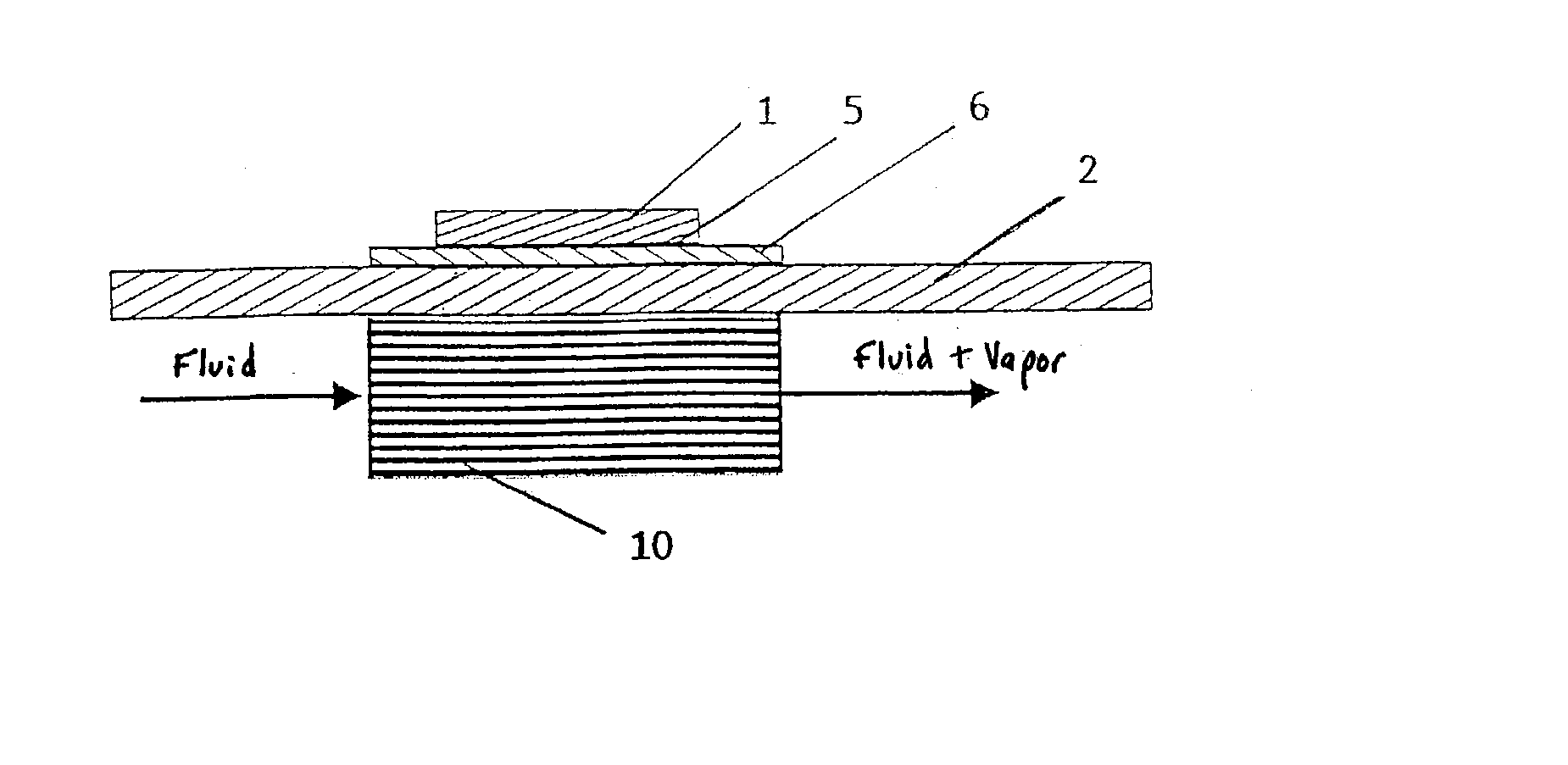

Cooling device for cooling components of the power electronics, said device comprising a micro heat exchanger

InactiveUS20030178178A1Large heat transfer surfaceLarge heat flowDomestic cooling apparatusSemiconductor/solid-state device detailsNuclear engineeringCooling power

The present invention relates to a cooling device, in particular for cooling of components of power electronics, using a coolant which flows through a micro heat exchanger (10) having a good heat contact with the component (1), and wherein the coolant is selected in such a way that it evaporates in the micro heat exchanger (10) at the desired component temperature.

Owner:ROBERT BOSCH GMBH

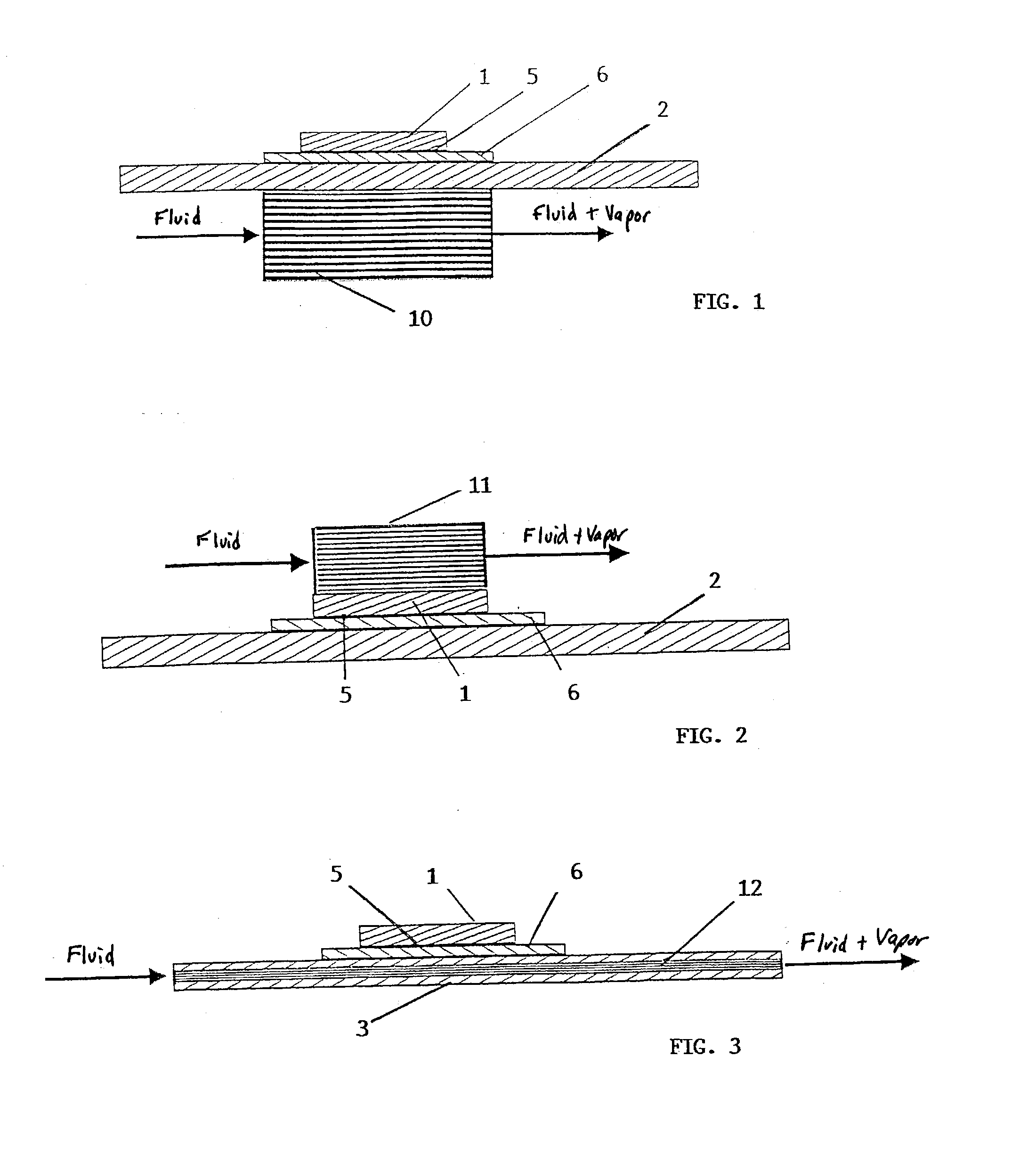

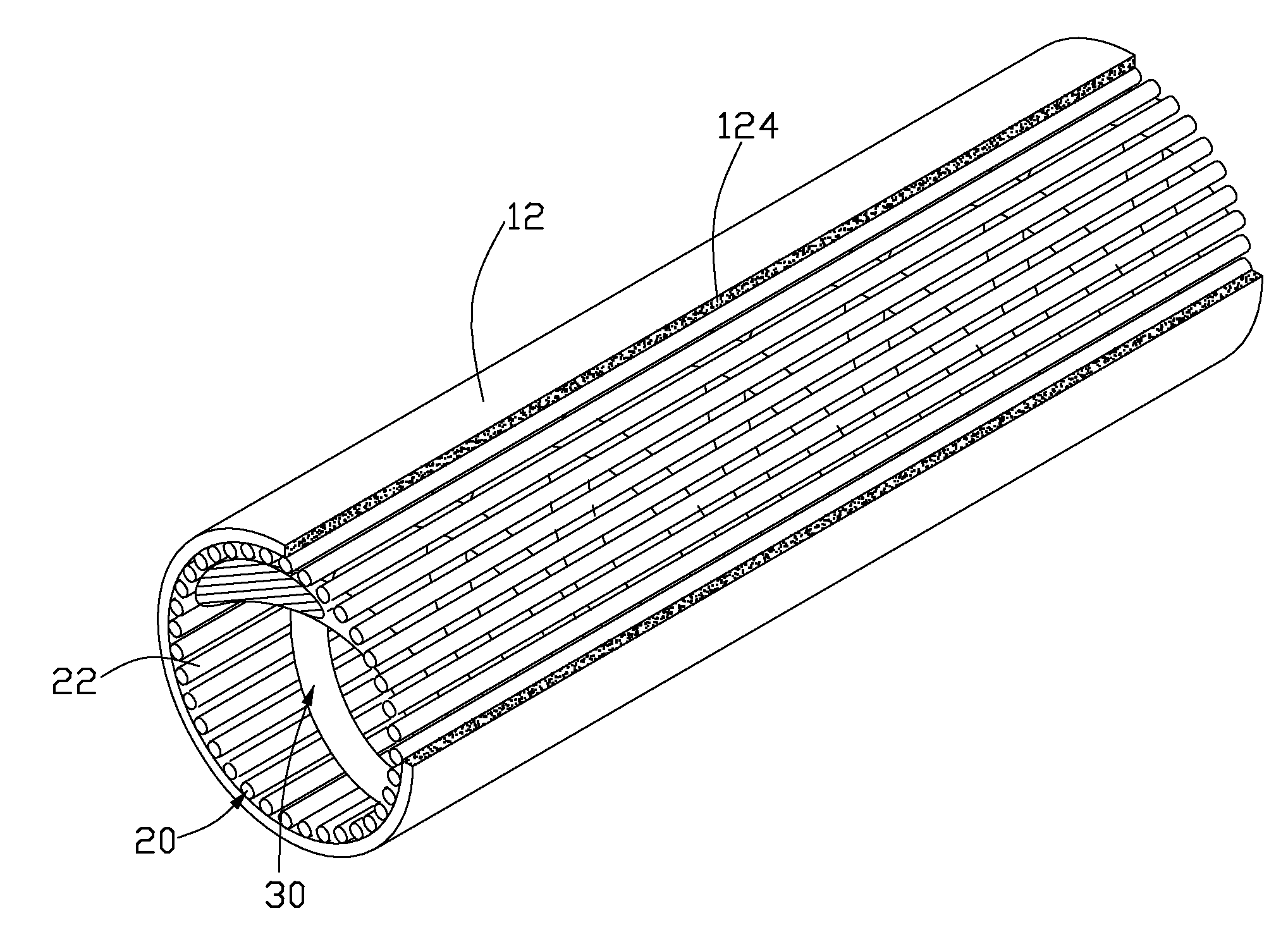

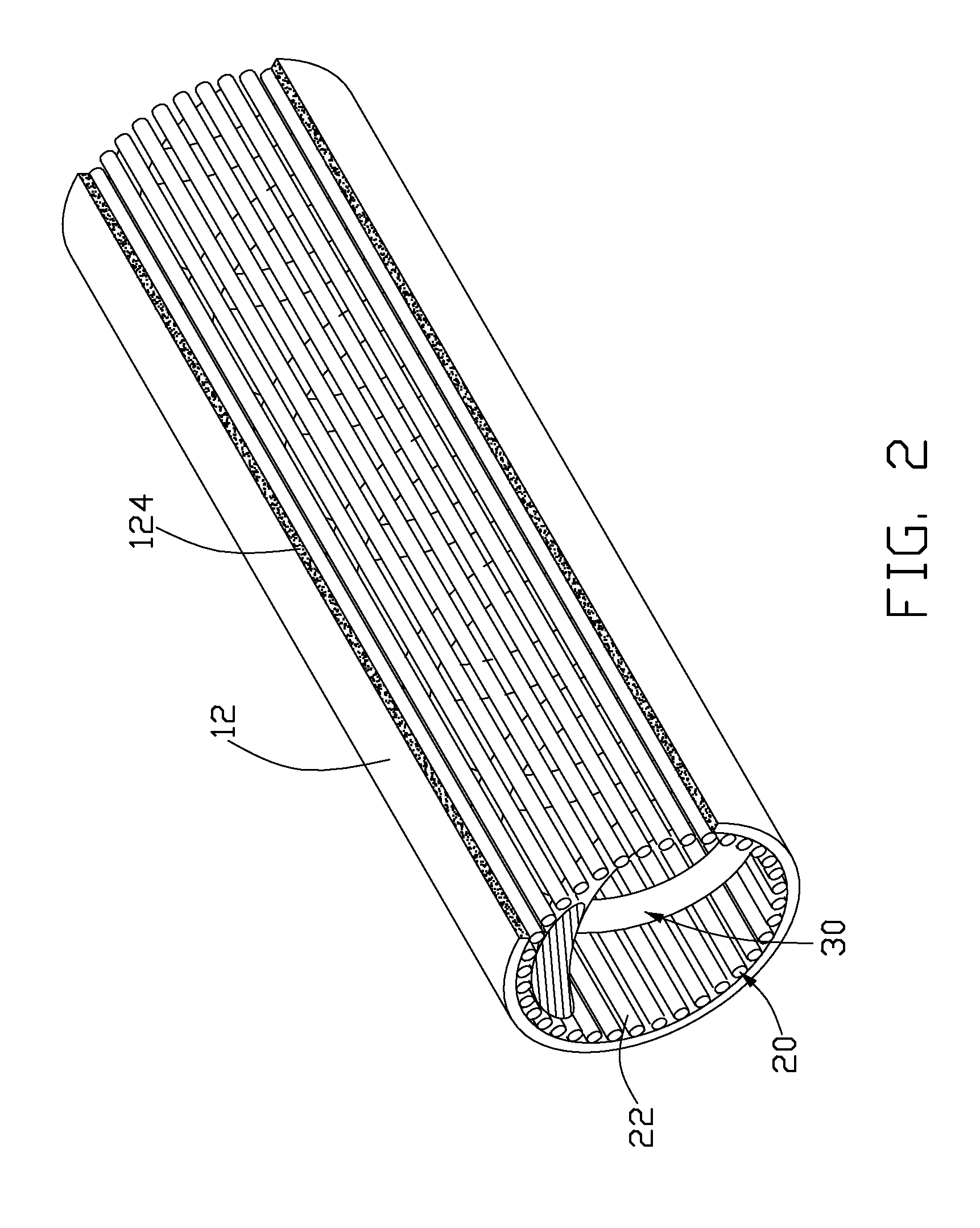

Flexible heat pipe

InactiveUS20080099186A1Different coefficientReduce heat exchangeSolid-state devicesIndirect heat exchangersEvaporationMechanical engineering

A flexible heat pipe (10) includes a casing (12), a wick structure (20) arranged in the casing, and a working medium saturated in the wick structure. The casing includes an evaporation section (122), a condensation section (126), and a flexible adiabatic section (124) connecting the evaporation section with the condensation section. The wick structure includes a first portion (21), a second portion (23) and a third portion respectively disposed in the evaporation, the condensation and the adiabatic sections of the casing. The adiabatic section of the casing further accommodates a supporting member (30) therein for supporting the third portion of the wick structure to have an intimate contact with an inner surface of the adiabatic section.

Owner:HON HAI PRECISION IND CO LTD

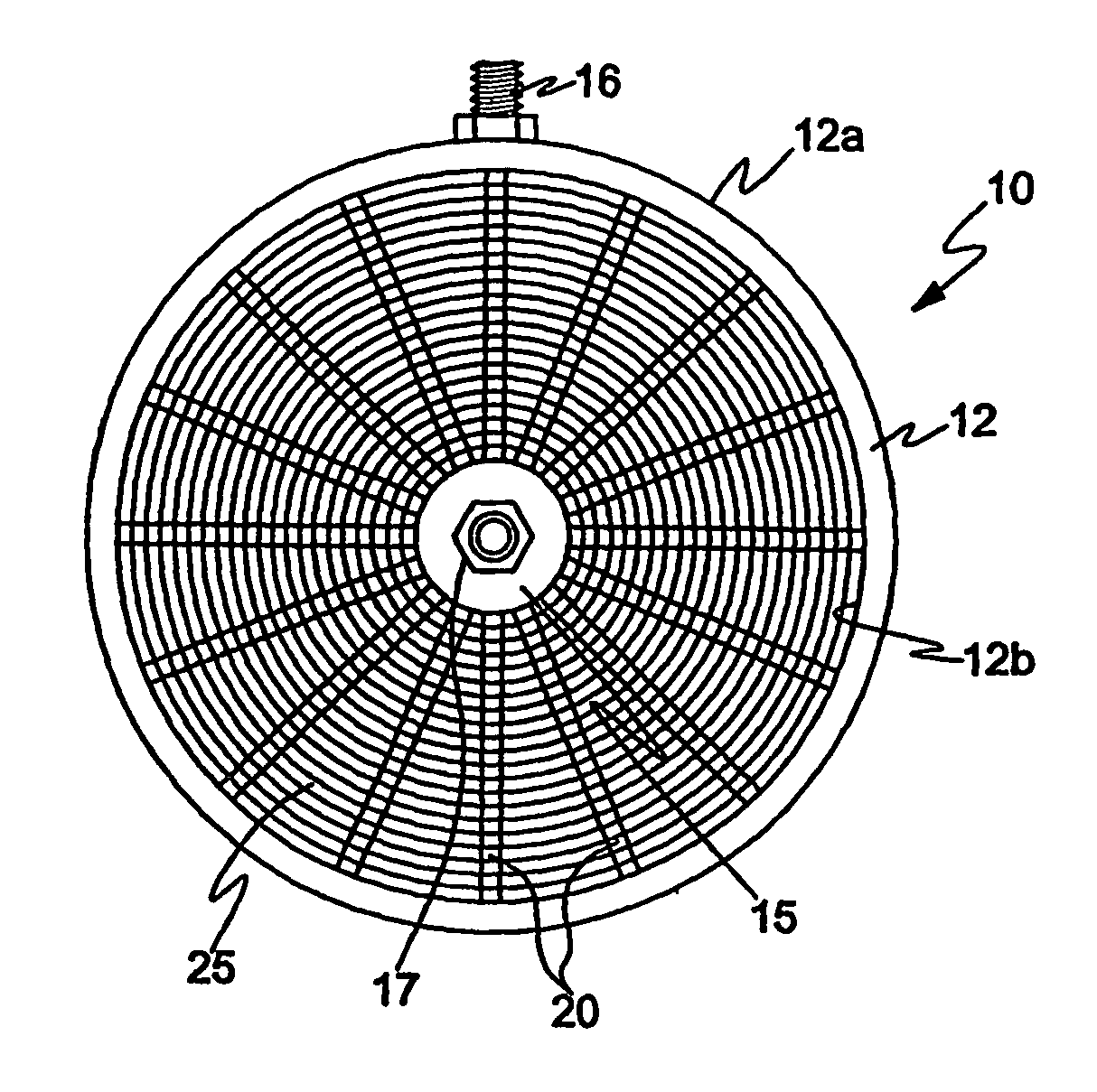

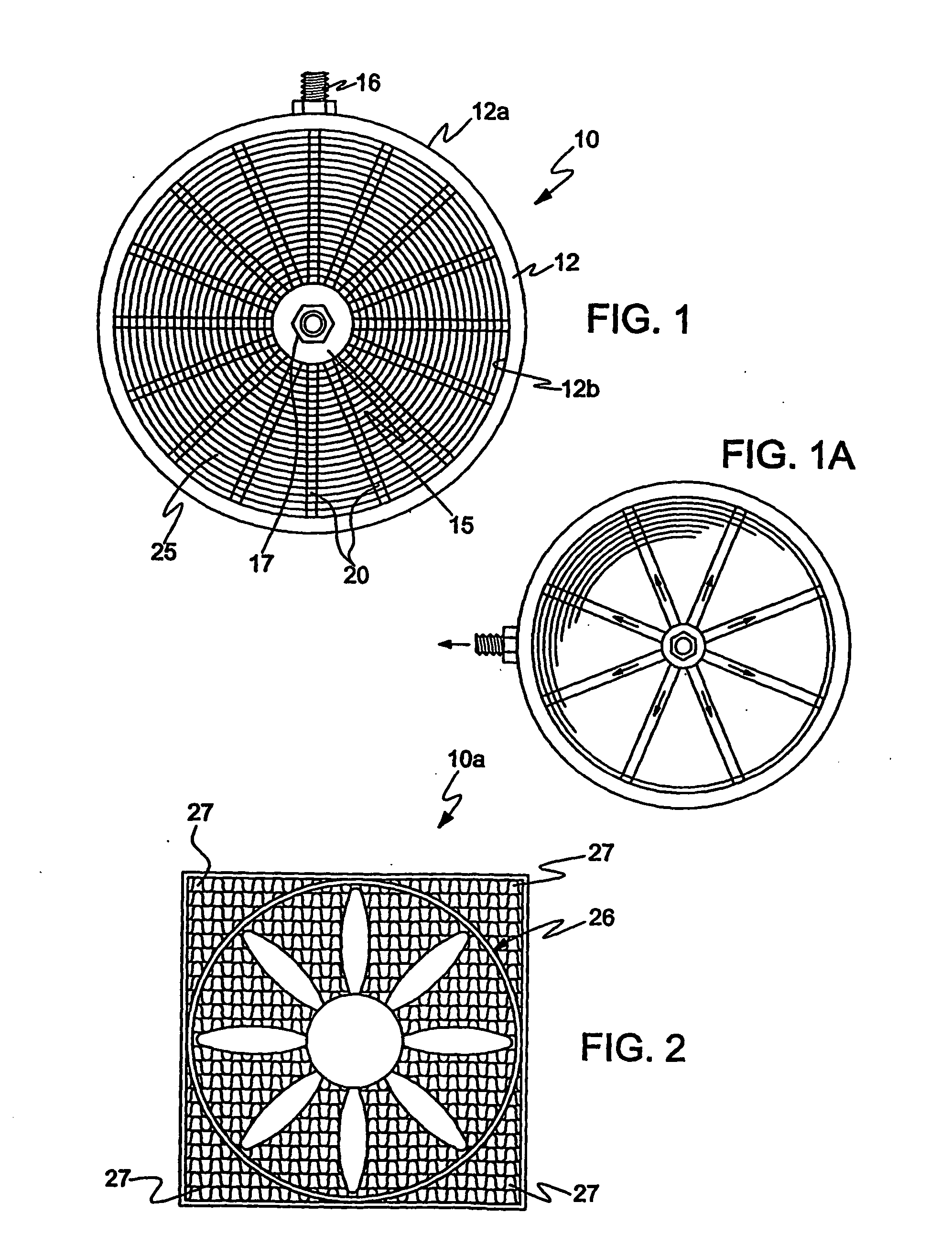

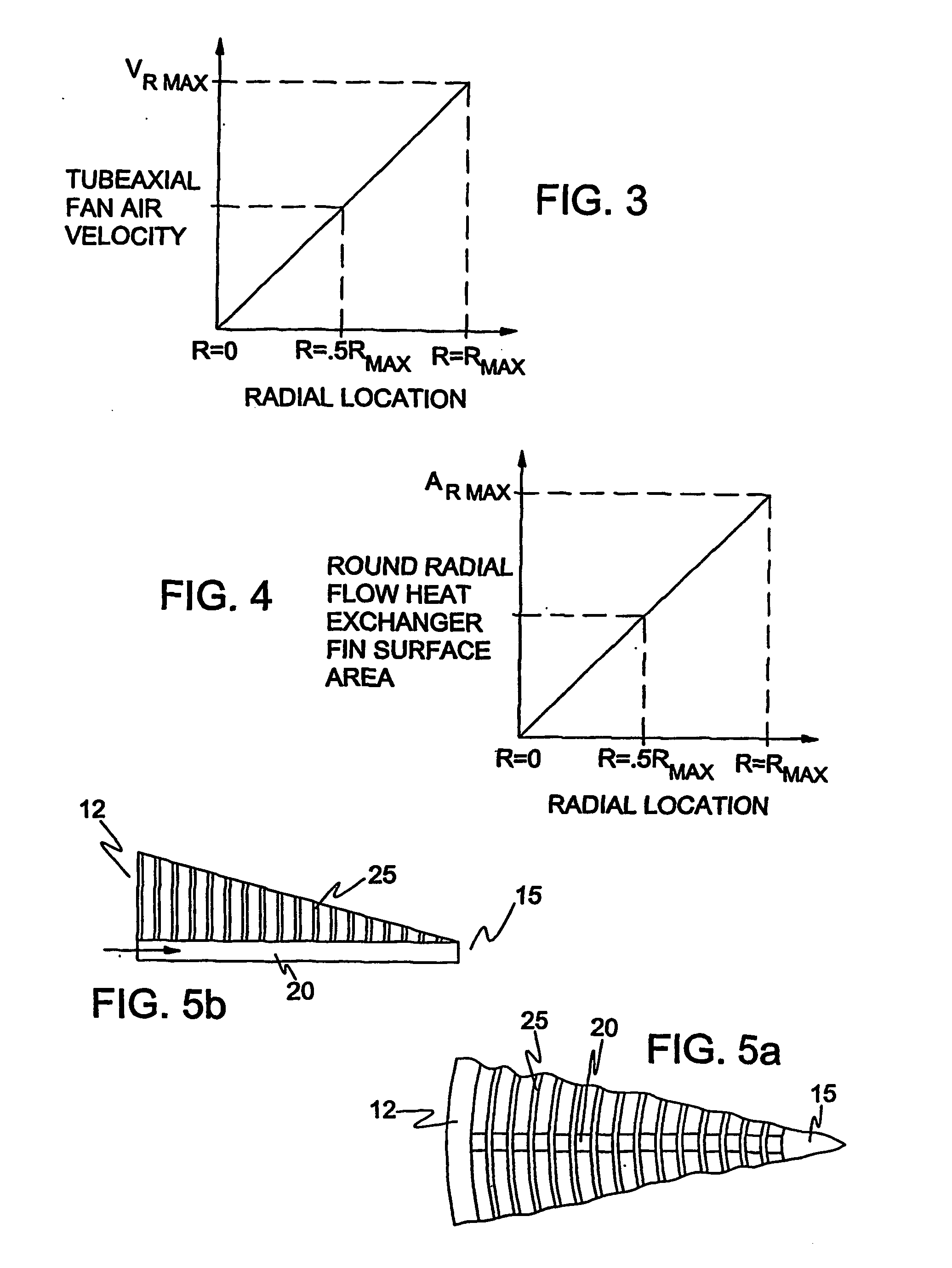

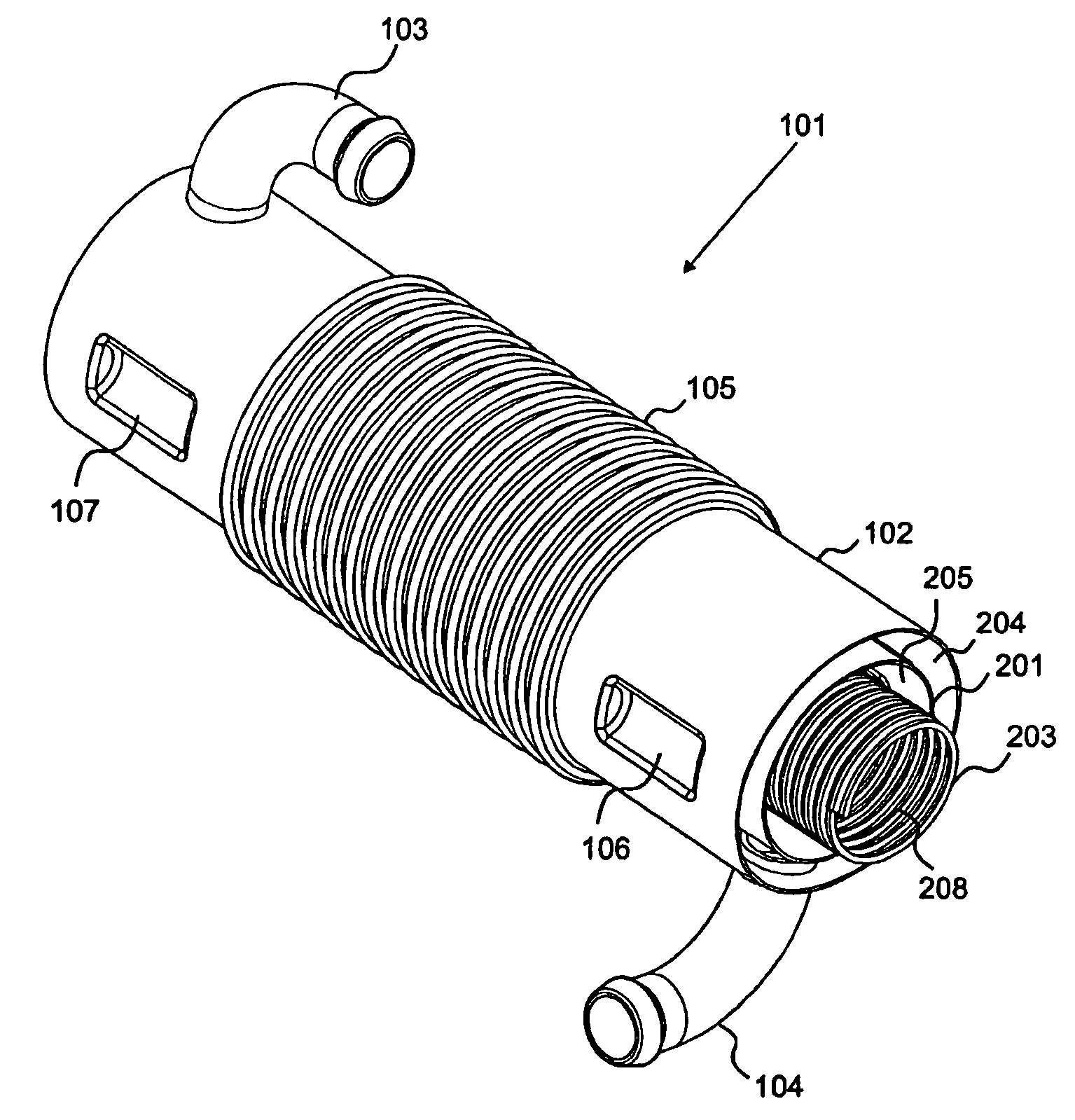

Radial flow heat exchanger

InactiveUS20050056408A1Improve heat transfer performanceEfficient heat transferStationary conduit assembliesHeat exchanger casingsHeat conductingBiomedical engineering

A radial flow heat exchanger for heating or cooling a fluid includes a sealed fluid manifold for passage of fluid. A sealed fluid receiving hub is spaced interiorly of the interior peripheral portion of the manifold and includes a passageway for passage of fluid into or out of the heat exchanger. A plurality of separate and spaced fluid flow tubes are disposed between the manifold and the hub. Each of the tubes are in sealed fluid communication with the manifold at one end and the other end is in sealed fluid communication with the hub. A fin assembly is positioned between the manifold and the hub and includes a heat conducting material arranged at spaced intervals between the manifold and the hub, the heat conducting material including a plurality of spaced apertures through which tubes pass. The heat conducting material is in intimate heat conducting contact with the tubes whereby fluid flowing between the manifold and the hub flows into each of the tubes in a radial direction between the manifold and the hub and wherein the heat conducting material of the fin assembly operates to give up or pick up heat from the fluid through the wall of the tubes.

Owner:GREGORY CHRISTIAN T

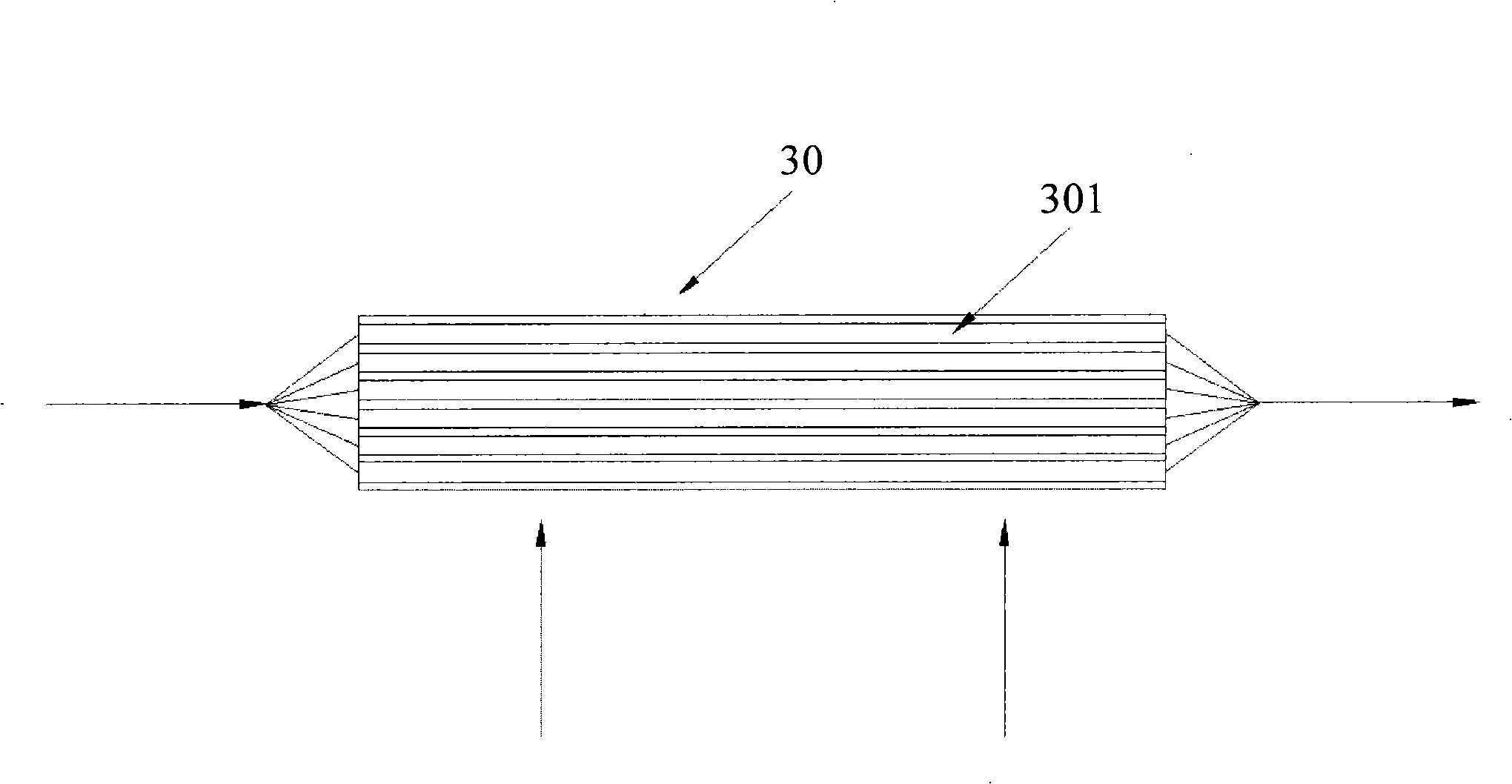

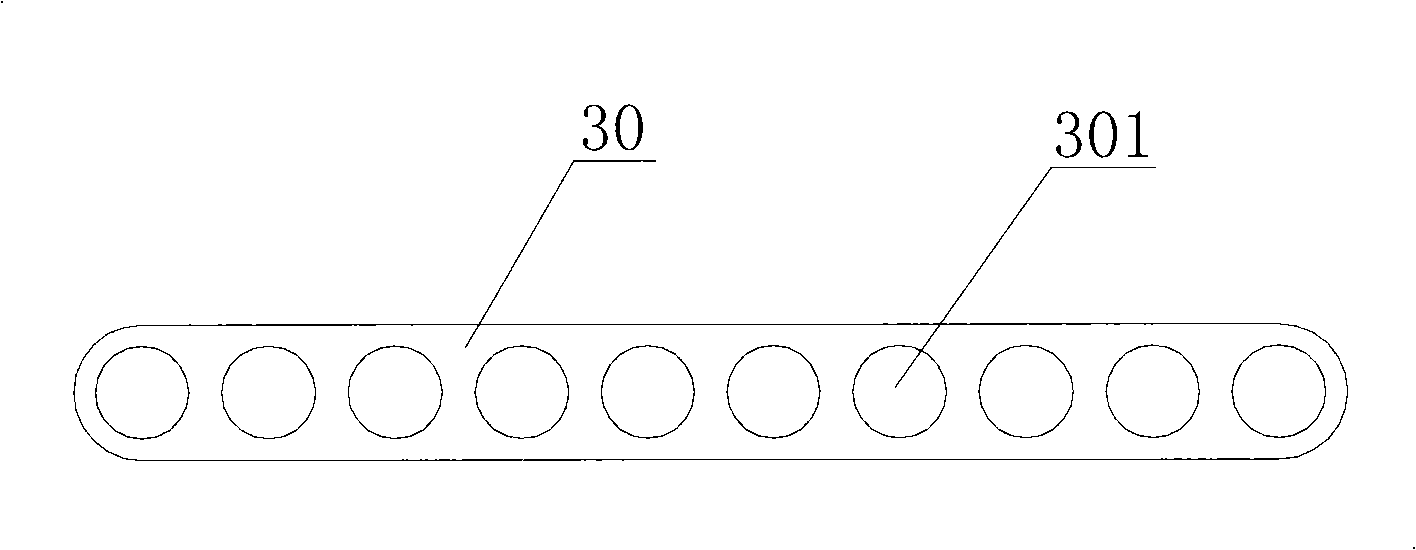

Flat pipe and heat exchanger

InactiveCN101526322AGive full play to the heat transfer performanceUniform stateStationary conduit assembliesTubular elementsPlate heat exchangerHeat transmission

The invention relates to the technical field of heat exchanger, in particular to a flat pipe which comprises not less than two through holes which extend along the lengthwise direction of the flat pipe. The through holes are arranged side by side along the width direction of the flat pipe. Two ends of the flat pipe along the width direction respectively form an external air influx entrance end and an external air outflux end. The section sizes of the through holes are reduced gradually along the direction from the external air influx entrance end of the flat pipe to the external air outflux end of the flat pipe. The through hole near the external air influx entrance end of the flat pipe has larger section size, larger heat transmission temperature difference, large heat exchange volume and larger mass flow. The through hole near the external air outflux end of the flat pipe has smaller section size, lower heat transmission temperature difference, less heat exchange volume and less mass flow. The invention brings the heat exchange performance of the flat pipe into play completely and improves the heat exchange efficiency of the heat exchanger further. The invention also provides a heat exchanger.

Owner:SANHUA(HANGZHOU) MICRO CHANNEL HEAT EXCHANGER CO LTD

Coating material with biocide microcapsules

The invention relates to a coating material for protection against microorganism invasion on surfaces which are exposed to the effects of damp or water. The coating material has either a pH-value of at least 11.0 or is provide with a base material for the coating whereby the pH-value is at least 11. The coating material is characterized in that it contains a biocide which bonds to solid particles in a carrier material and is released in a delayed manner therefrom.

Owner:THOR GMBH

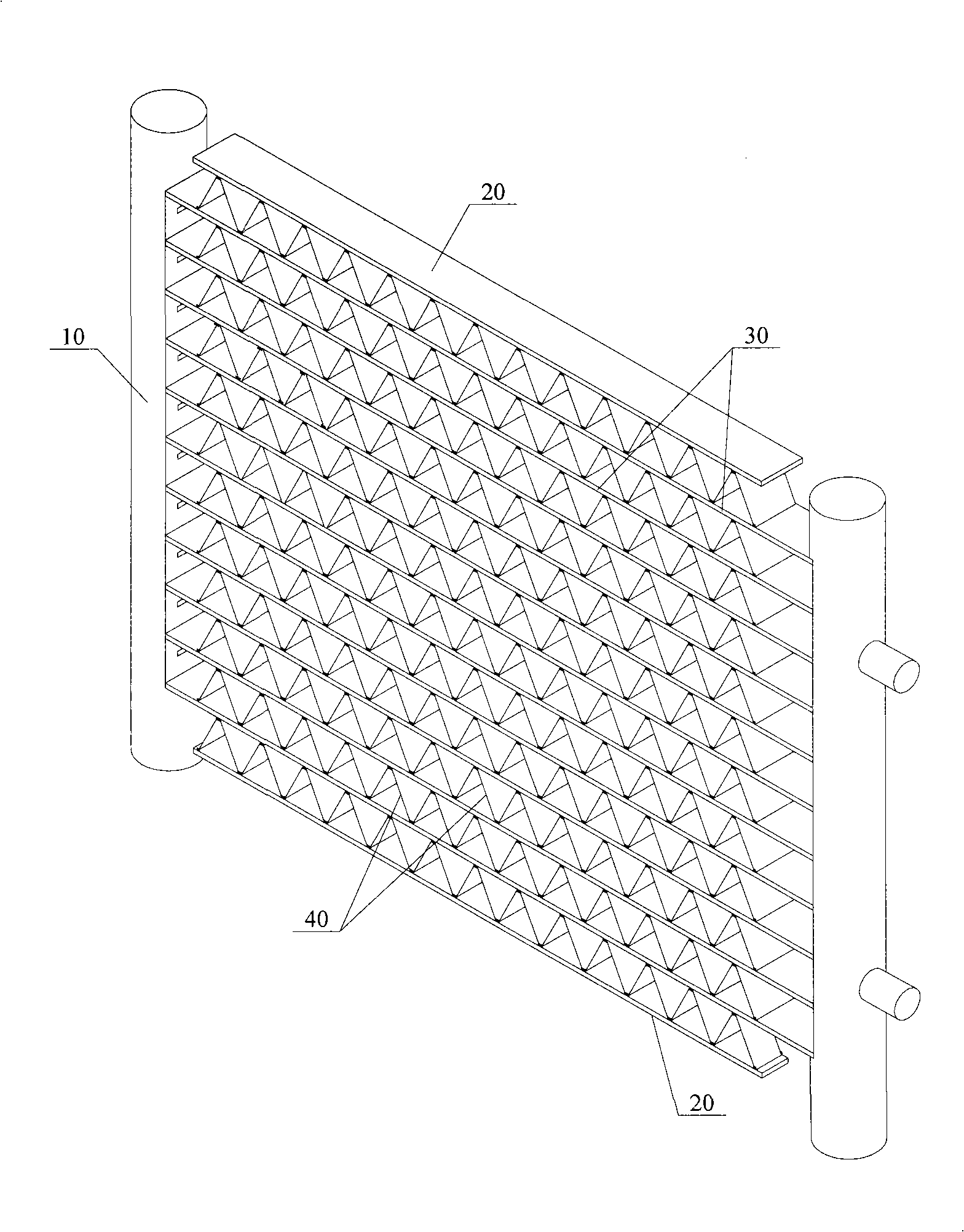

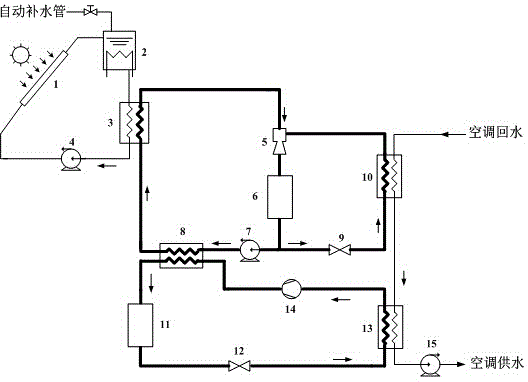

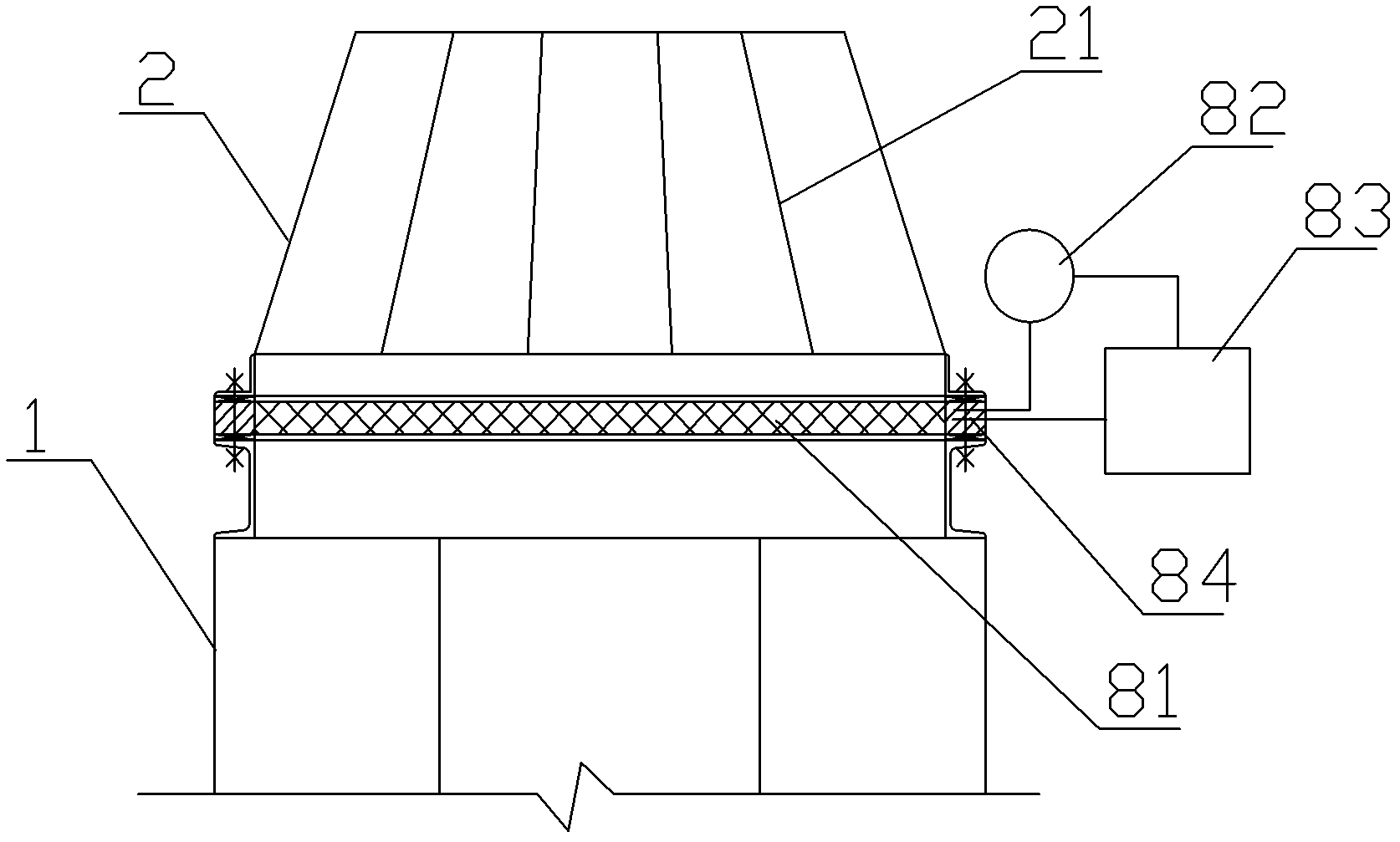

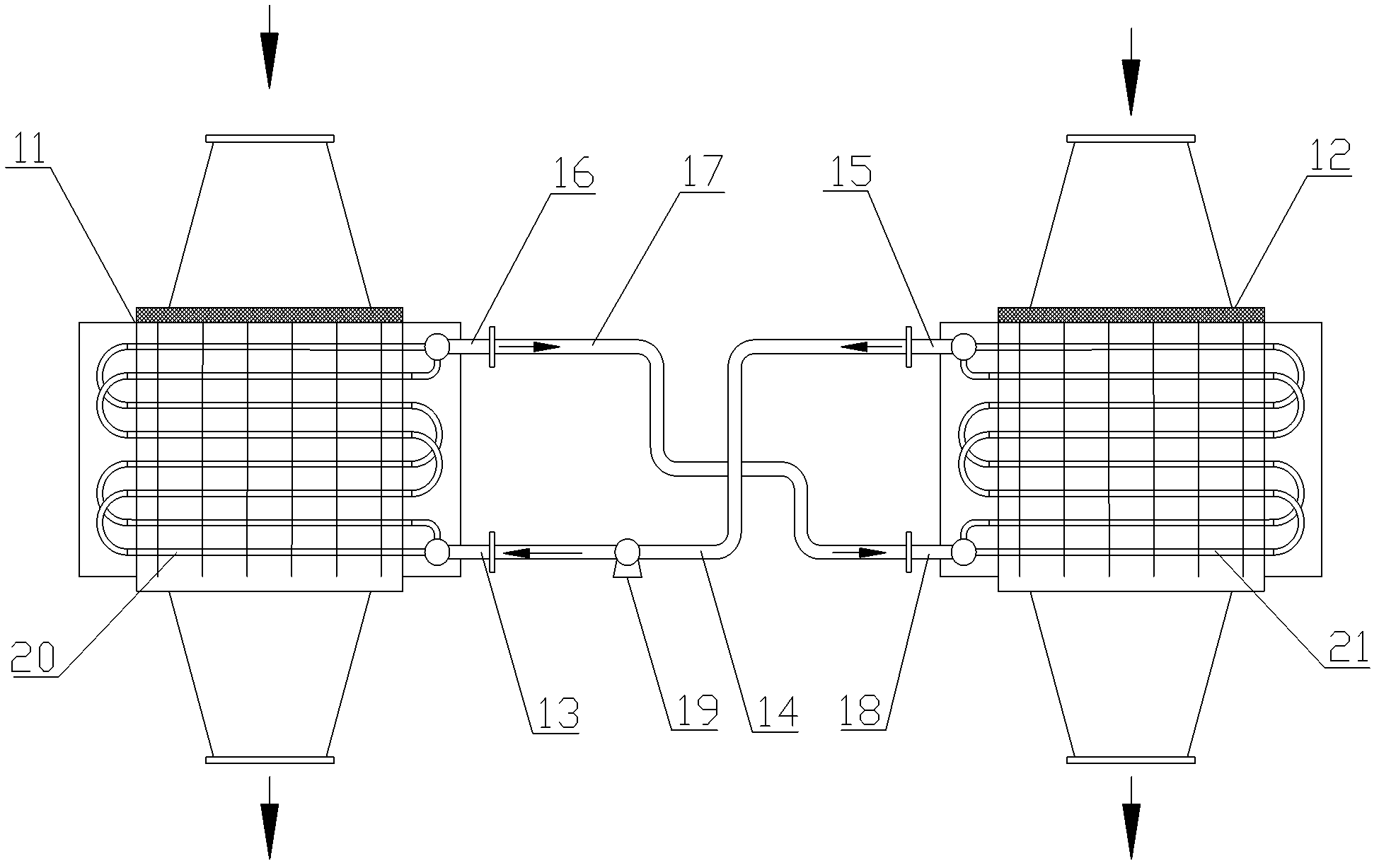

Preheating type solar ejection-compression combined refrigerating system

ActiveCN104132477ASmall design areaReduce heat exchangeMechanical apparatusCompression machines with non-reversible cycleElectricityEngineering

A preheating type solar ejection-compression combined refrigerating system comprises a solar hot-water loop, an ejection refrigerating fluid loop, an electric compression refrigerating fluid loop and an air conditioning water loop. The ejection refrigerating fluid loop is connected with the electric compression refrigerating fluid loop through a preheater. The ejection refrigerating fluid loop is formed by a generator, an ejector, a jet condenser, a jet evaporator, a work medium pump, a preheater and a second pipeline in a series connection mode. The electric compression refrigerating fluid loop is formed by a preheater, a compressing condenser, a throttle mechanism, a compressing evaporator, a compressor and a third pipeline in a series connection mode. According to the preheating type solar ejection-compression combined refrigerating system, heat of condensation of refrigerating fluid in exhaust gas of the compressor in the electric compression refrigerating fluid loop is recycled and used for preheating the refrigerating fluid entering the generator, the design heat exchange area of the generator of an ejection refrigerating system and the condenser of a compression refrigerating system can be decreased, and the system refrigerating capacity of the solar unit heat collection area is improved. The preheating type solar ejection-compression combined refrigerating system is suitable for air conditioning systems of radiant cooling, fan coils and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

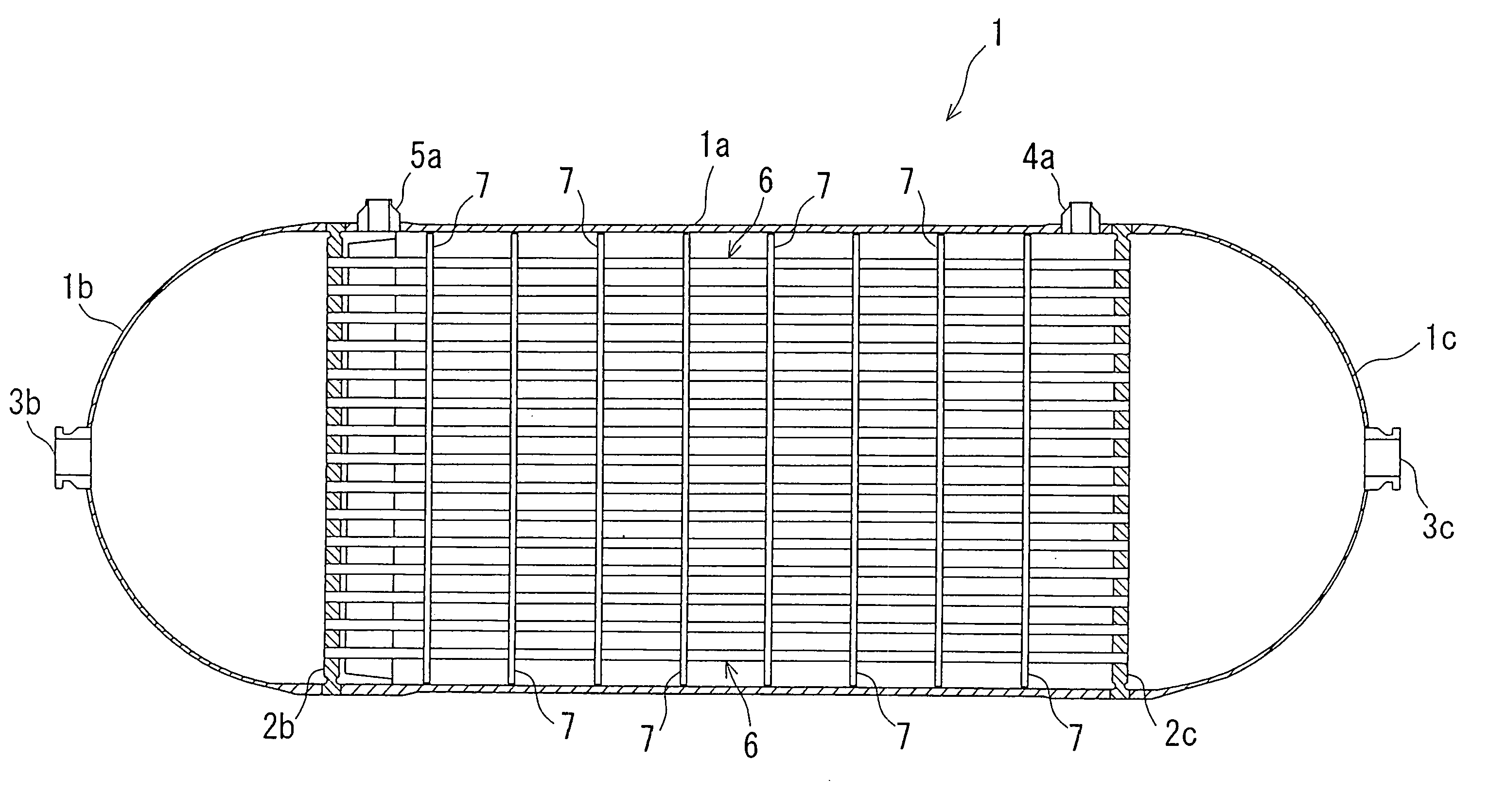

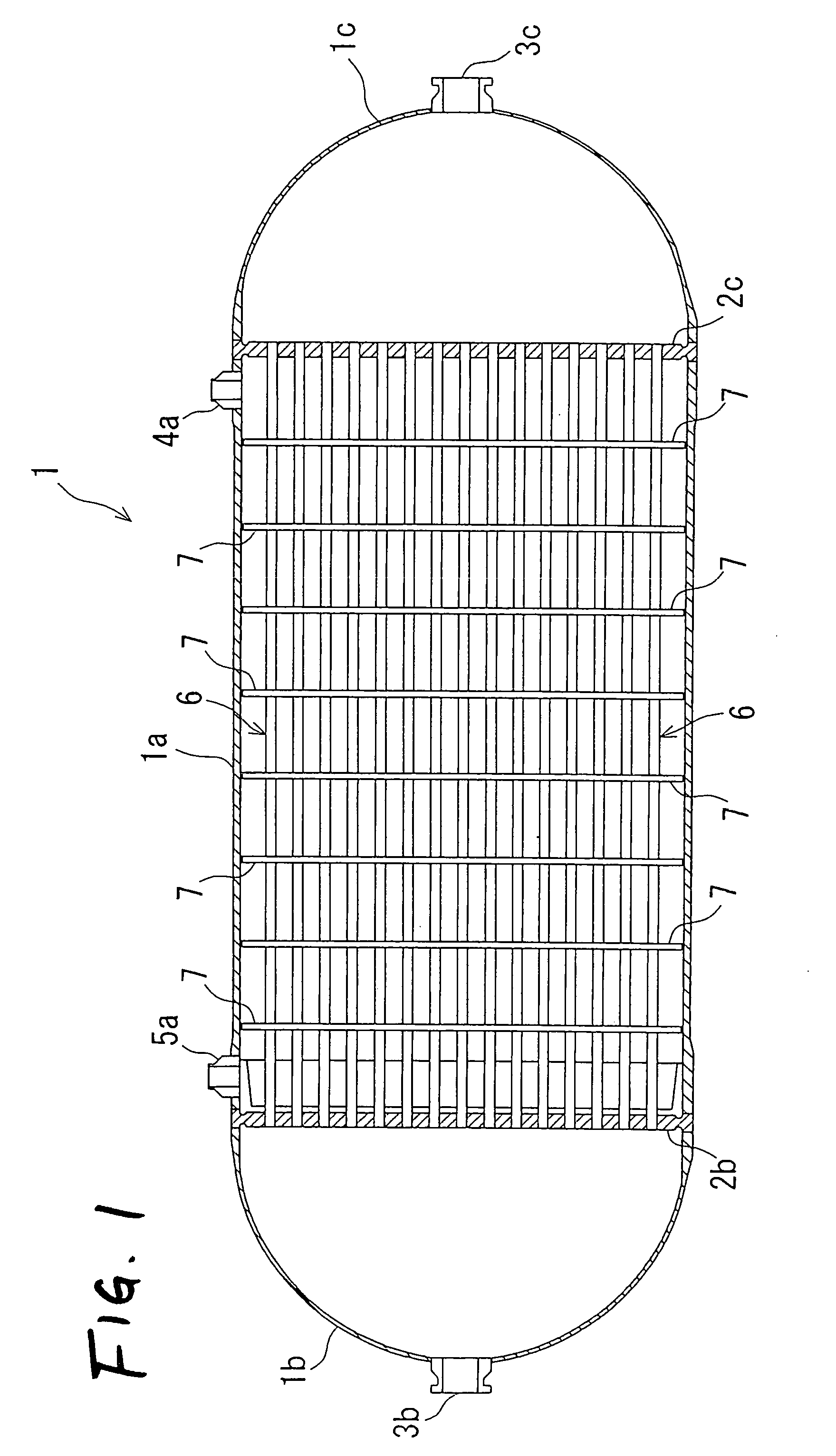

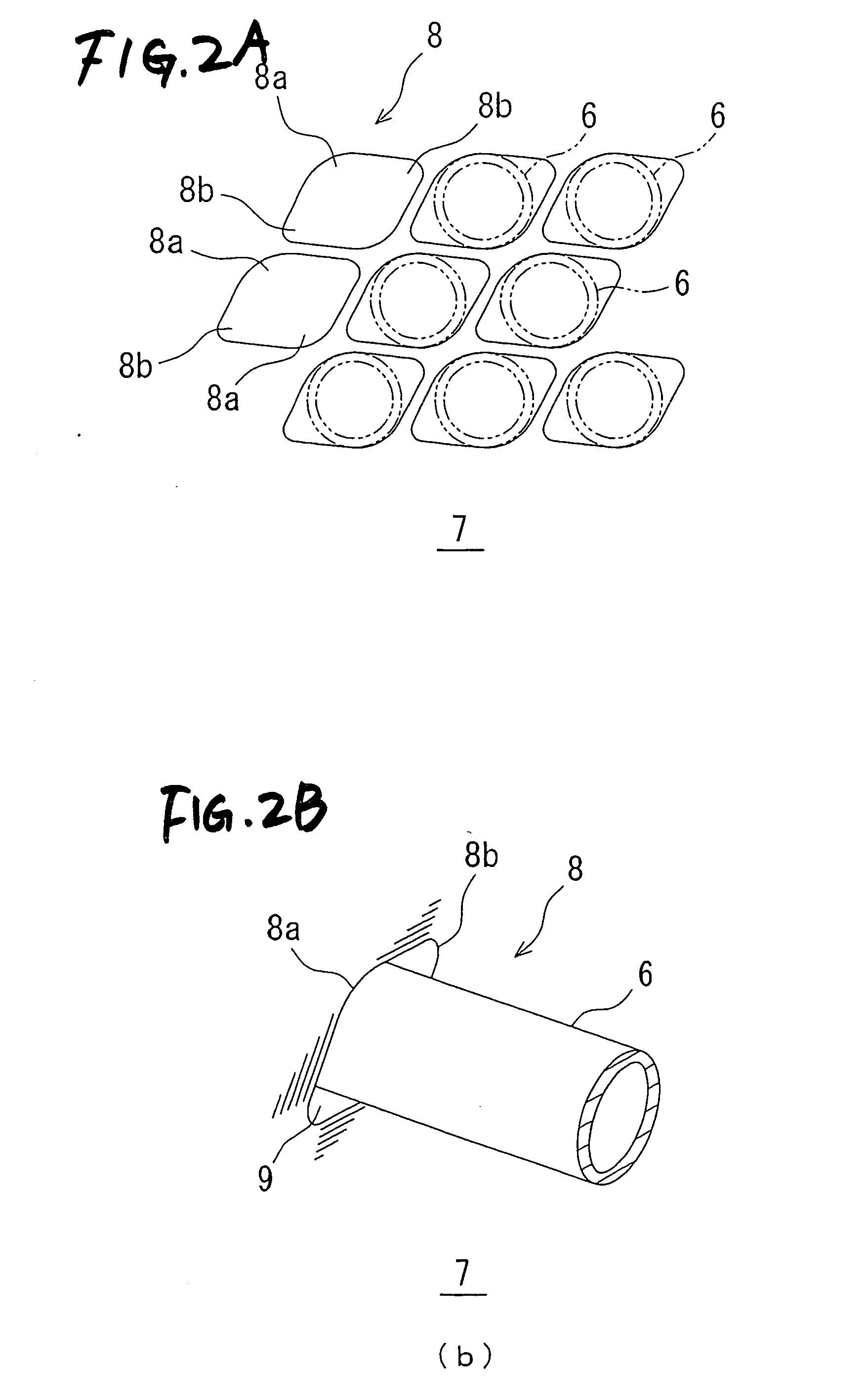

Multi-tube heat exchanger

InactiveUS20050167089A1Decrease heat exchange efficiencyStably fixHeat exchanger casingsStationary tubular conduit assembliesEngineeringHigh dimensional

The multi-tube heat exchanger includes a bundle of tubes which form fluid passages of first heat exchanging fluid, an outer shell which covers the bundle of tubes and form a fluid passage of second heat exchanging fluid, and a baffle plate which is arranged inside the outer shell in a direction intersecting an axial direction of the bundle of tubes and provided with a plurality of through holes through which respective tubes of the bundle are passed. Each of the through holes has such a shape that a portion of an outer peripheral face of the tube comes into contact with a portion of an inner peripheral face of the through hole, and a gap for passing the second heat exchanging fluid is formed between the other portion of the inner peripheral face and the outer peripheral face of the tube. It is possible to support the tubes with high dimensional accuracy, and to enhance heat exchanging efficiency by decreasing fluid resistance. It is also possible to make pitch of the through holes smaller and to make the heat exchanger compact.

Owner:JAPAN STEEL WORKS LTD

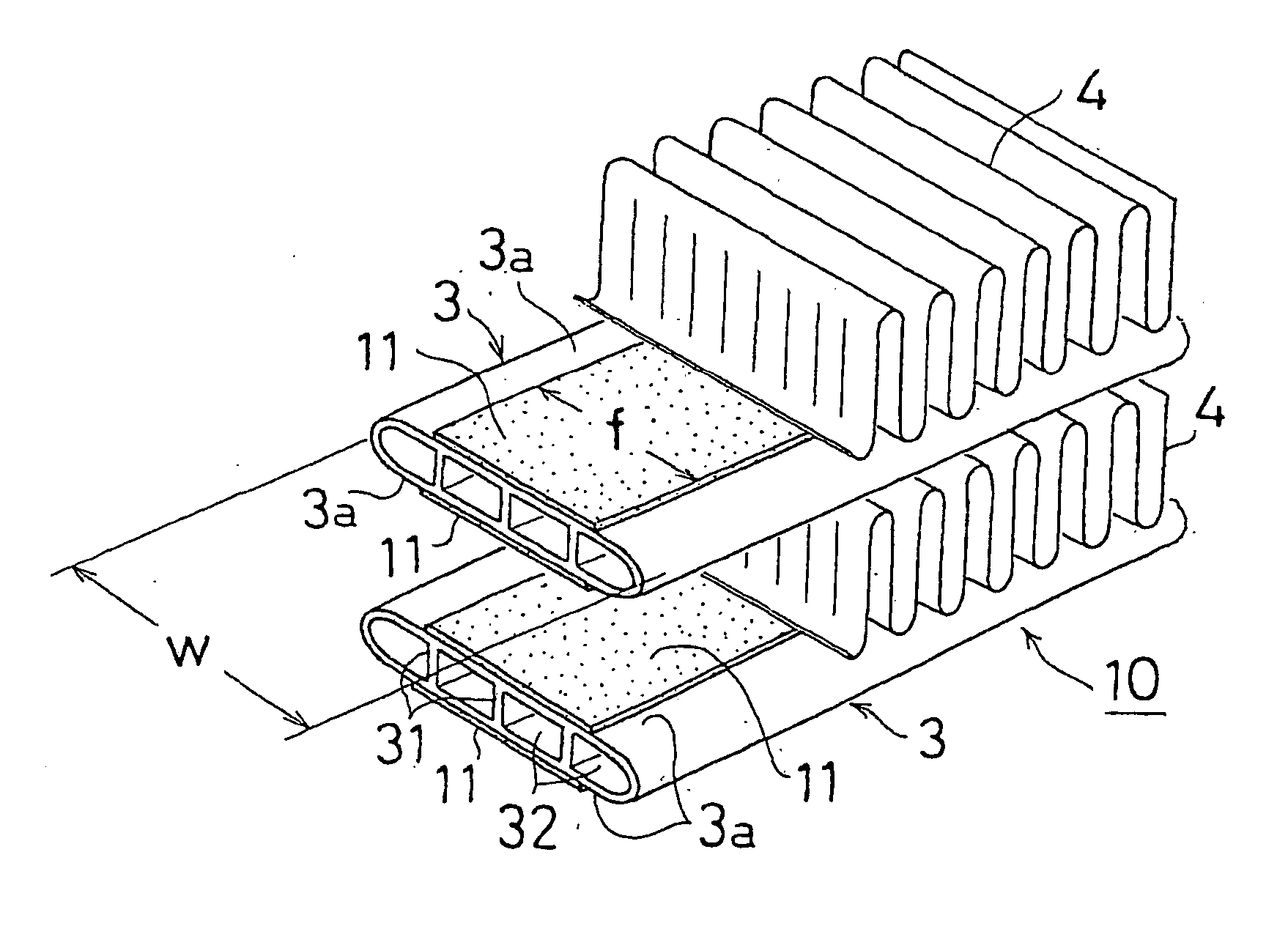

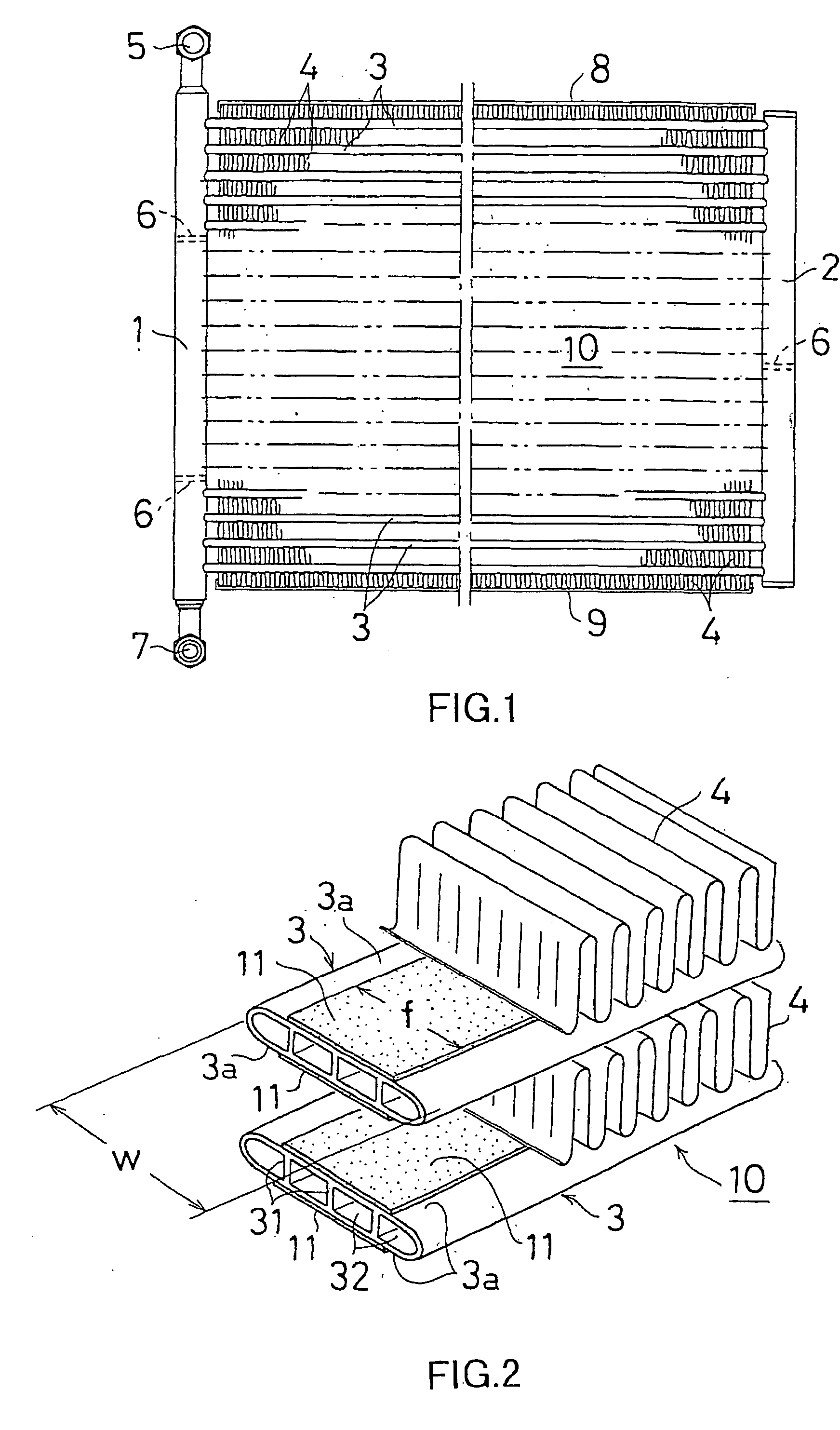

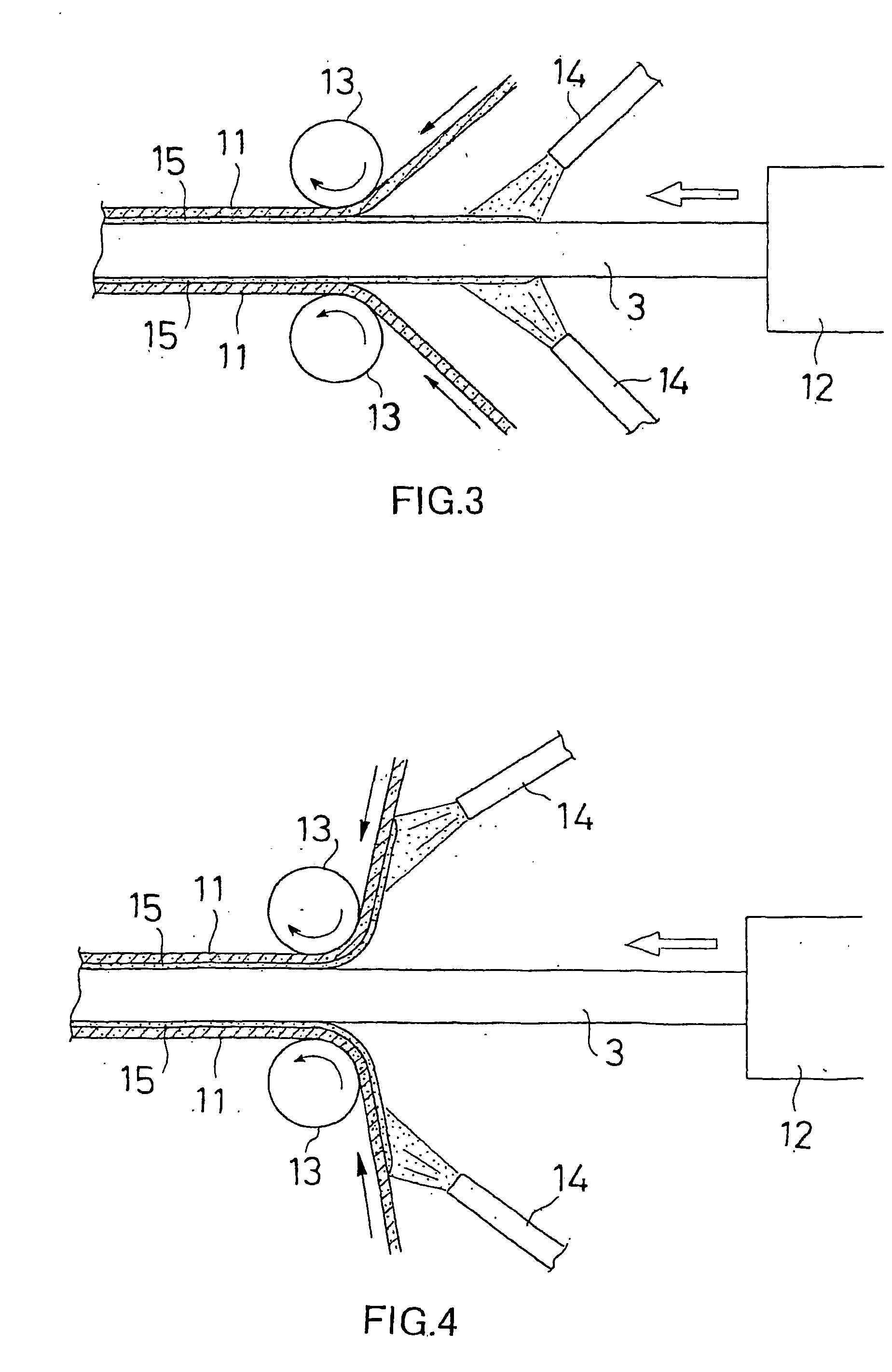

Method for manufacturong heat exchanger

InactiveUS20040040153A1Erosion can be avoided effectivelyLow melting pointWelding/cutting media/materialsWelding/soldering/cutting articlesMetalLow melting point

Low melting point metal such as Zn is sprayed onto a flat surface (3a) of an aluminum flat tube (3) to form a sprayed metal coating (15) thereon inmediately after extrusion of the flat tube. Inmediately thereafter, a brazing foil (11) is integrally adhered onto the sprayed metal coating (15). The obtained flat tube (3) with the brazing foil is combined with a corrugated fin (4) to form a temporary assembly. Then, the temporary assembly is heated at a predetermined temperature to braze the tube (3) and the fin (4) to thereby form a heat exchanger core. The low melting point metal may be sprayed on both the flat surface (3a) of the flat tube and the surface of the brazing foil (11). Thus, it becomes possible to obtain a lightweight thin fin and to decrease material costs.

Owner:SHOWA DENKO KK

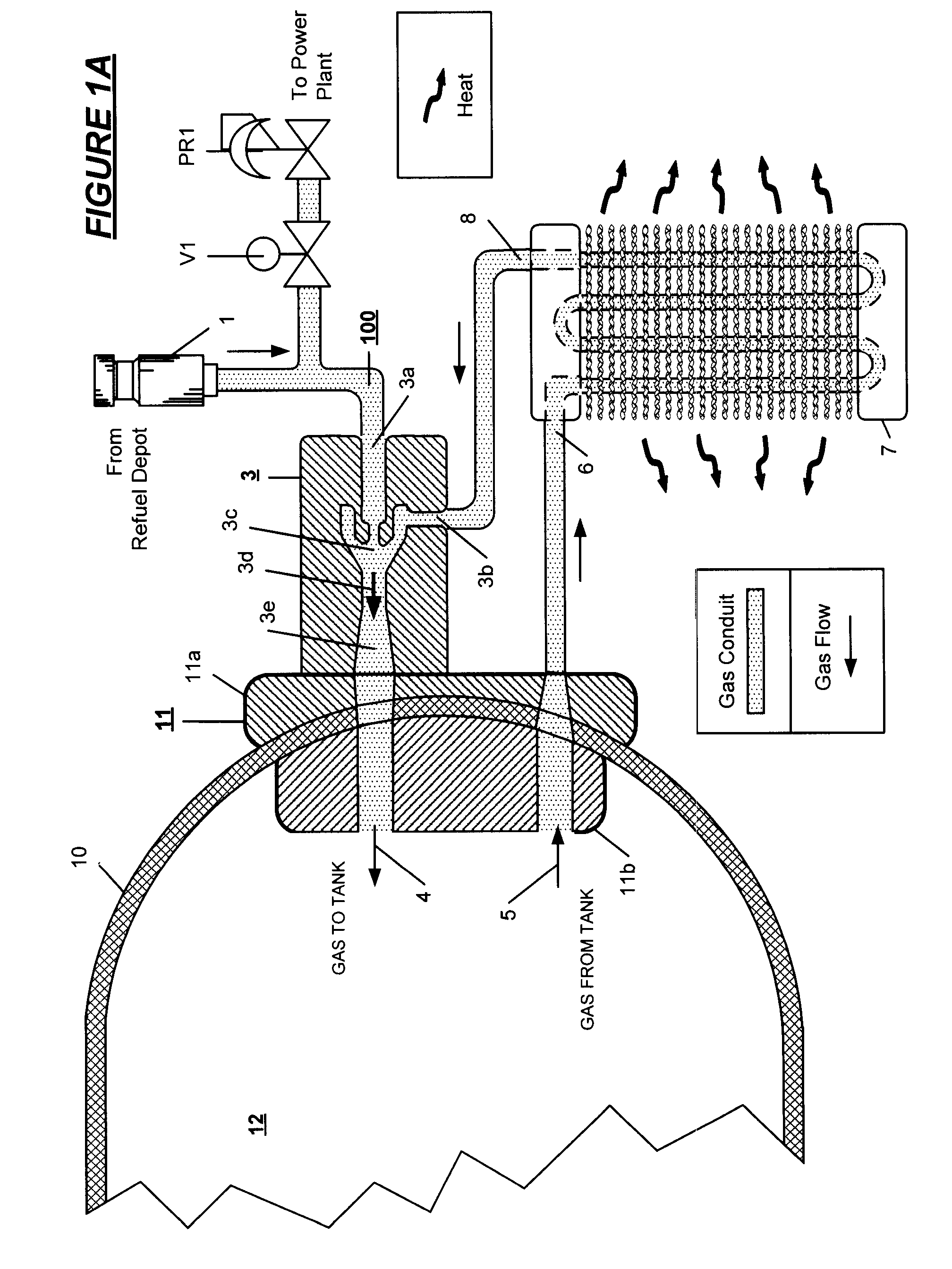

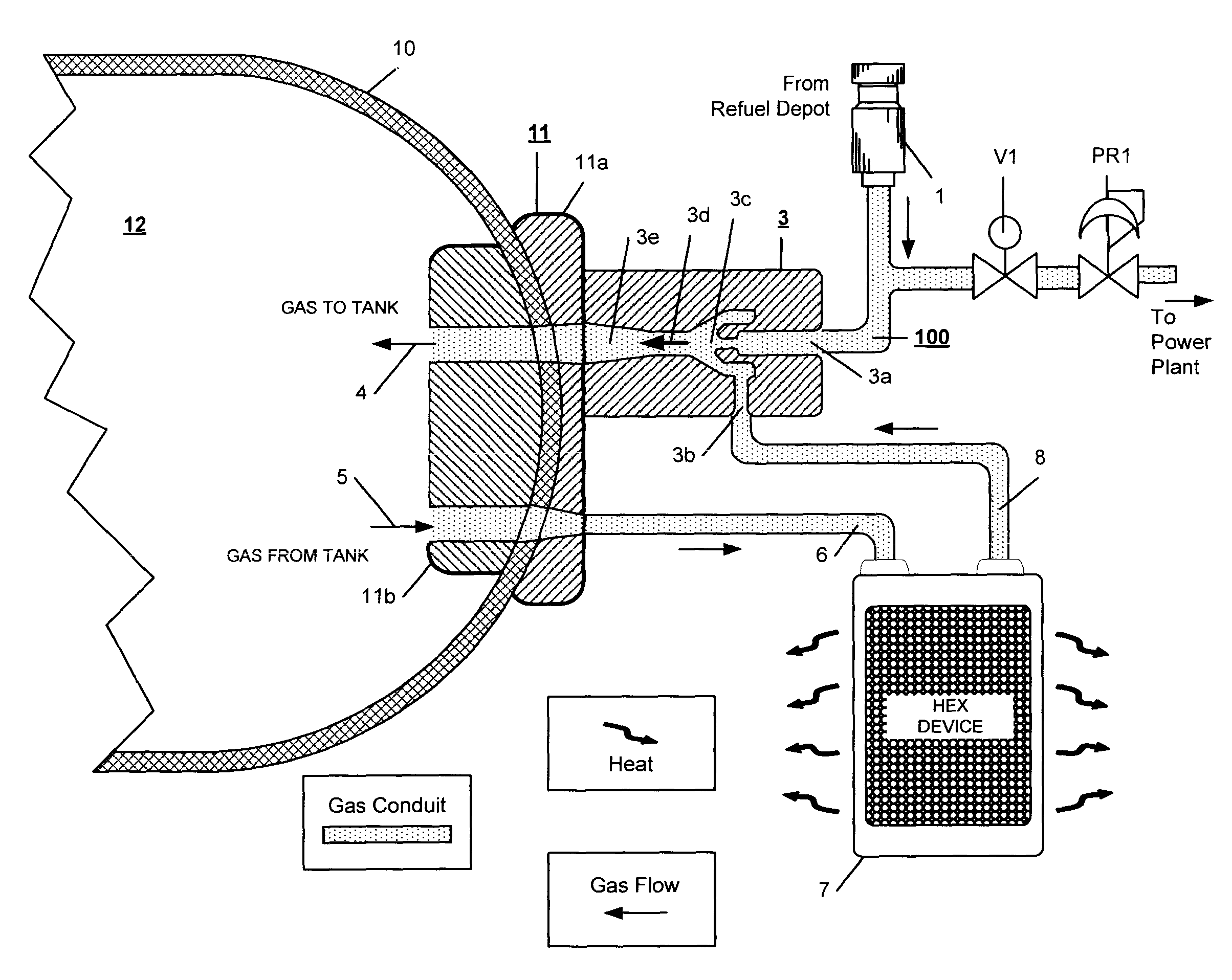

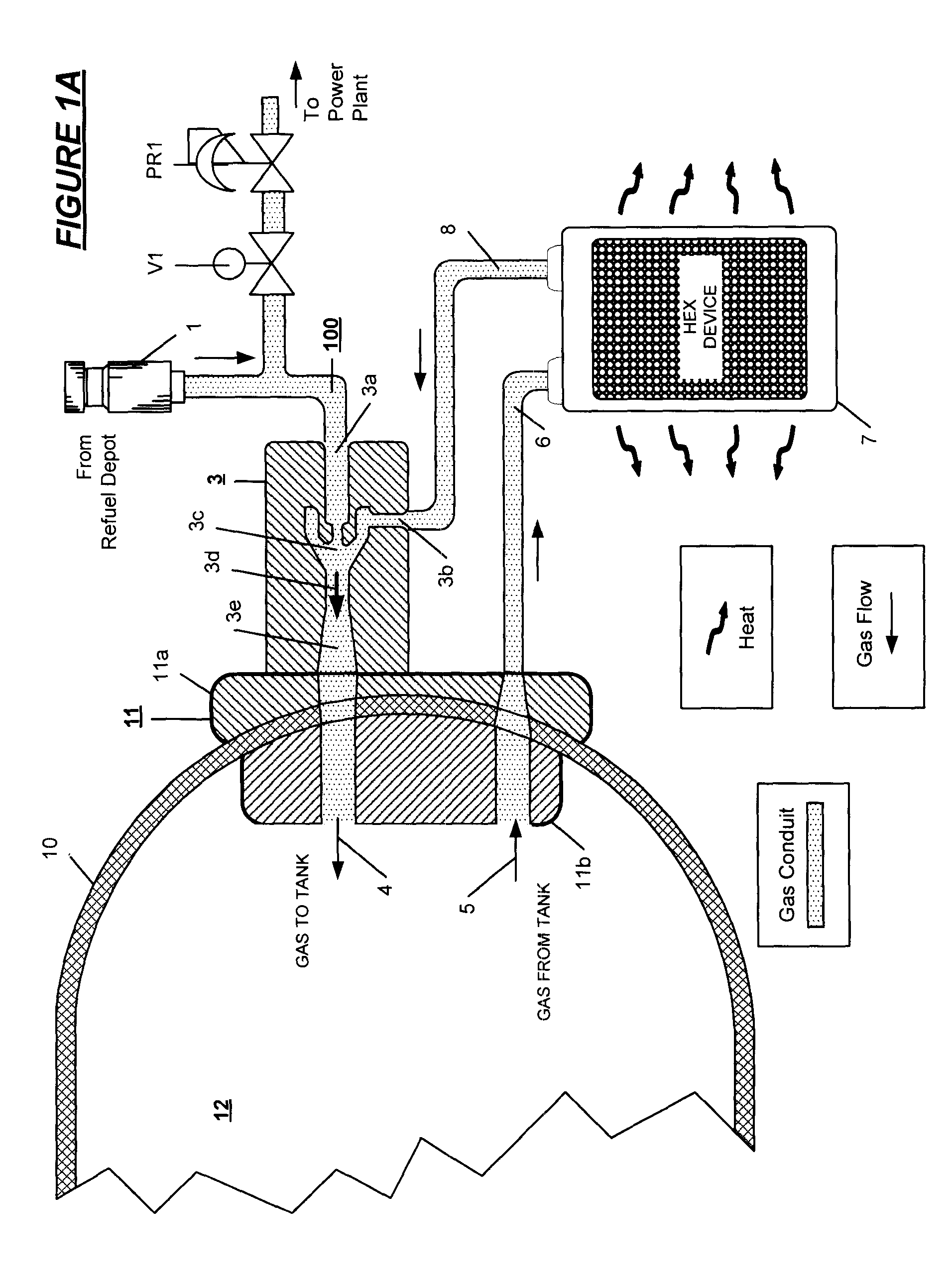

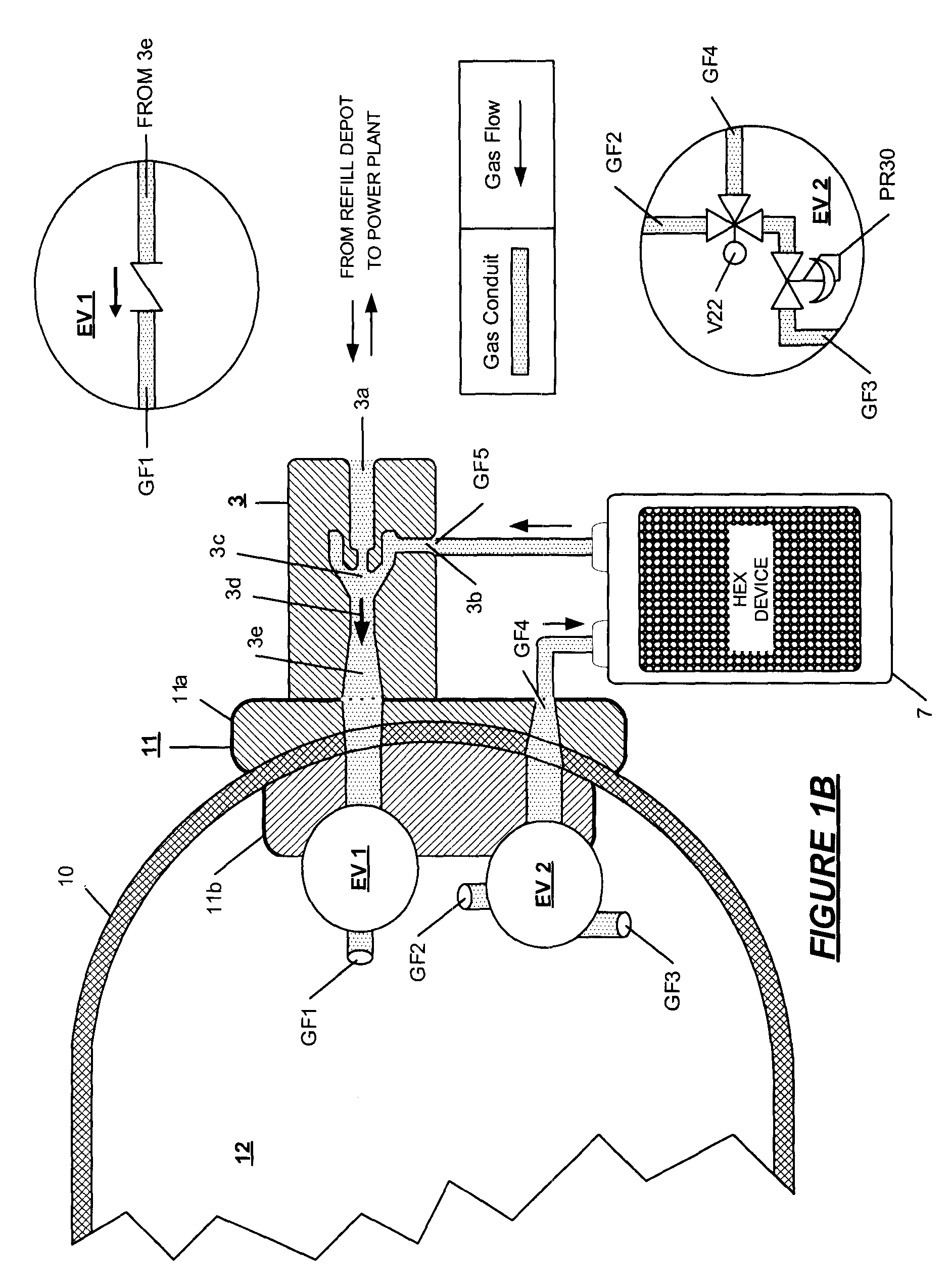

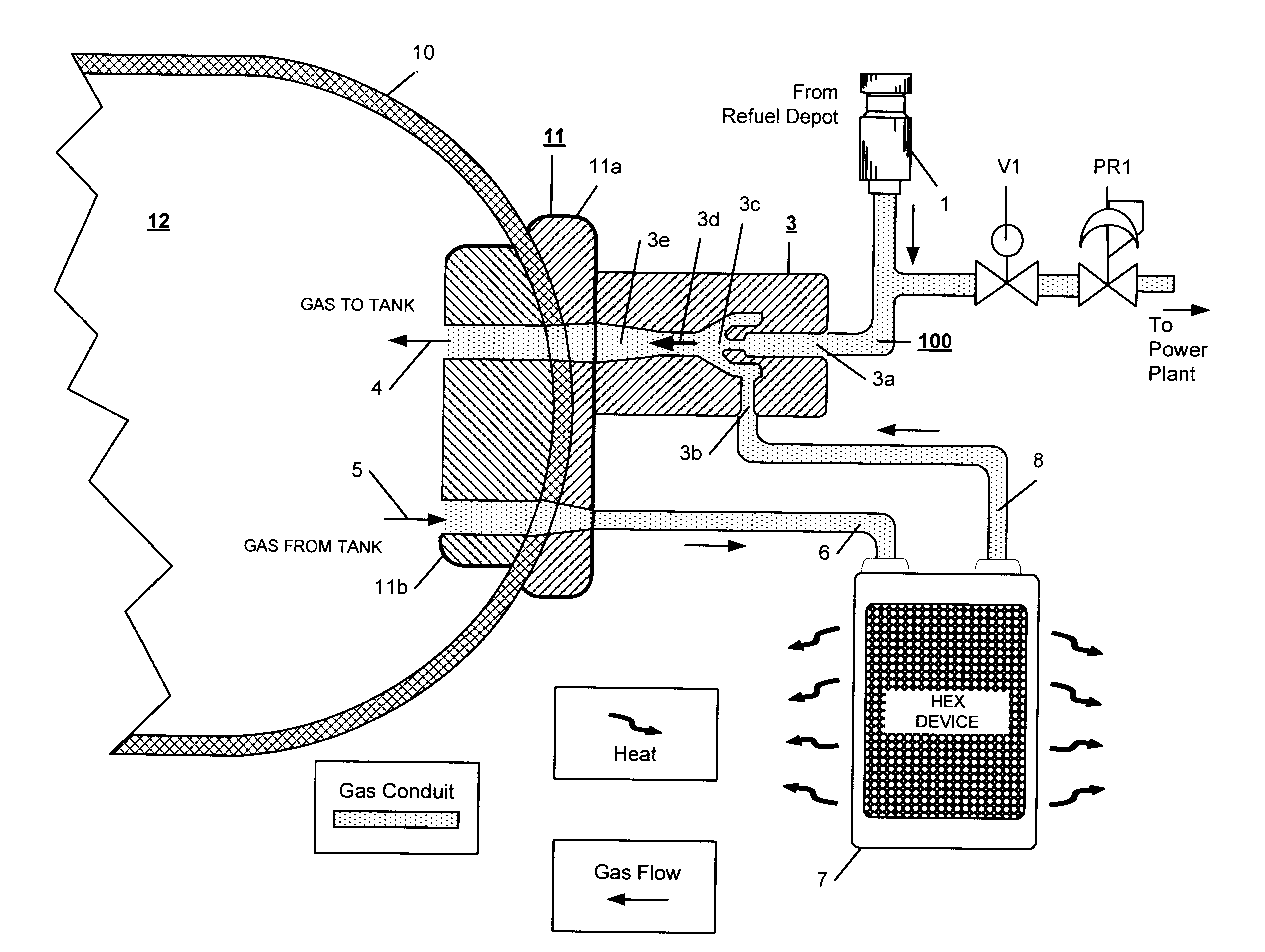

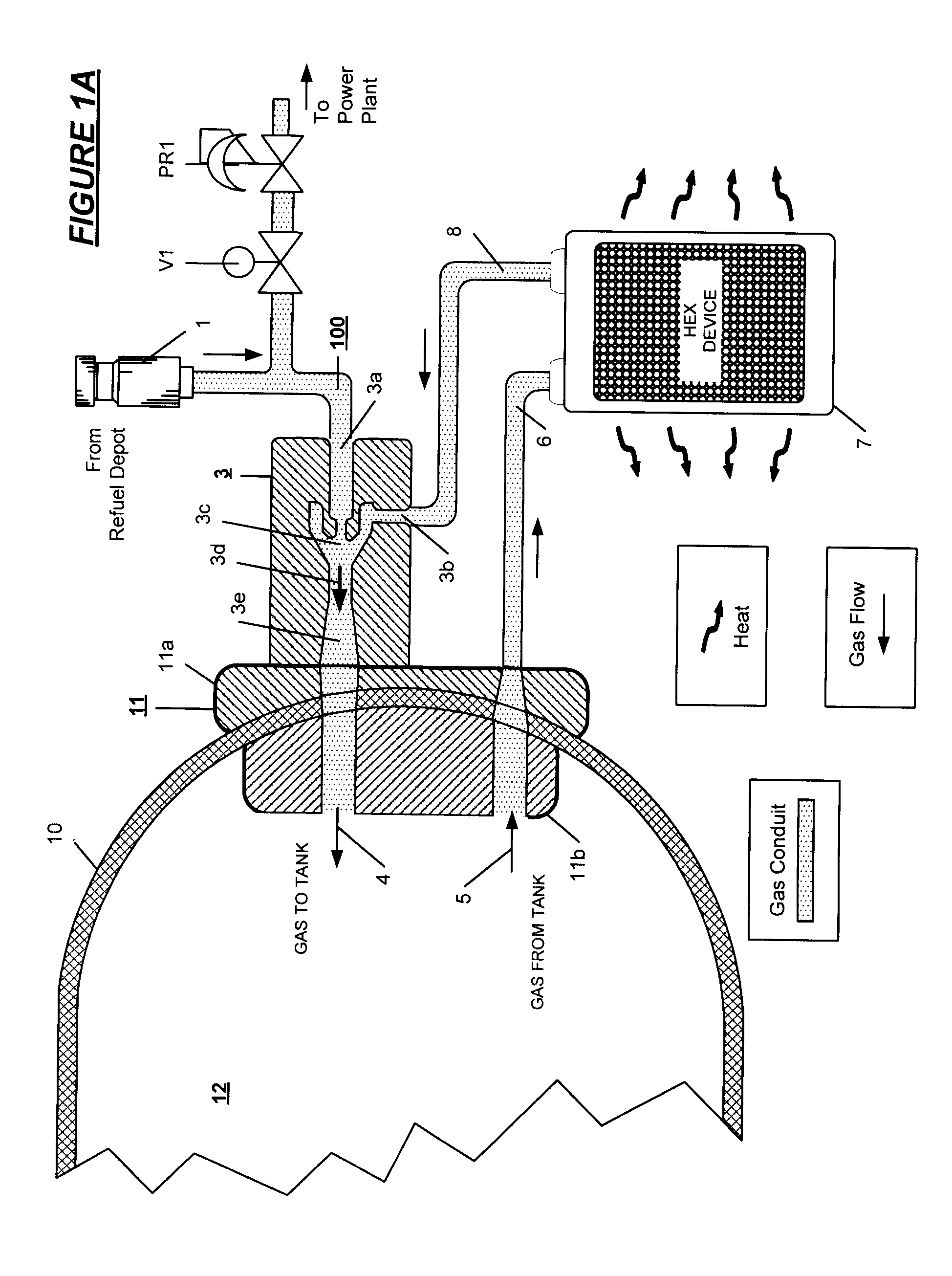

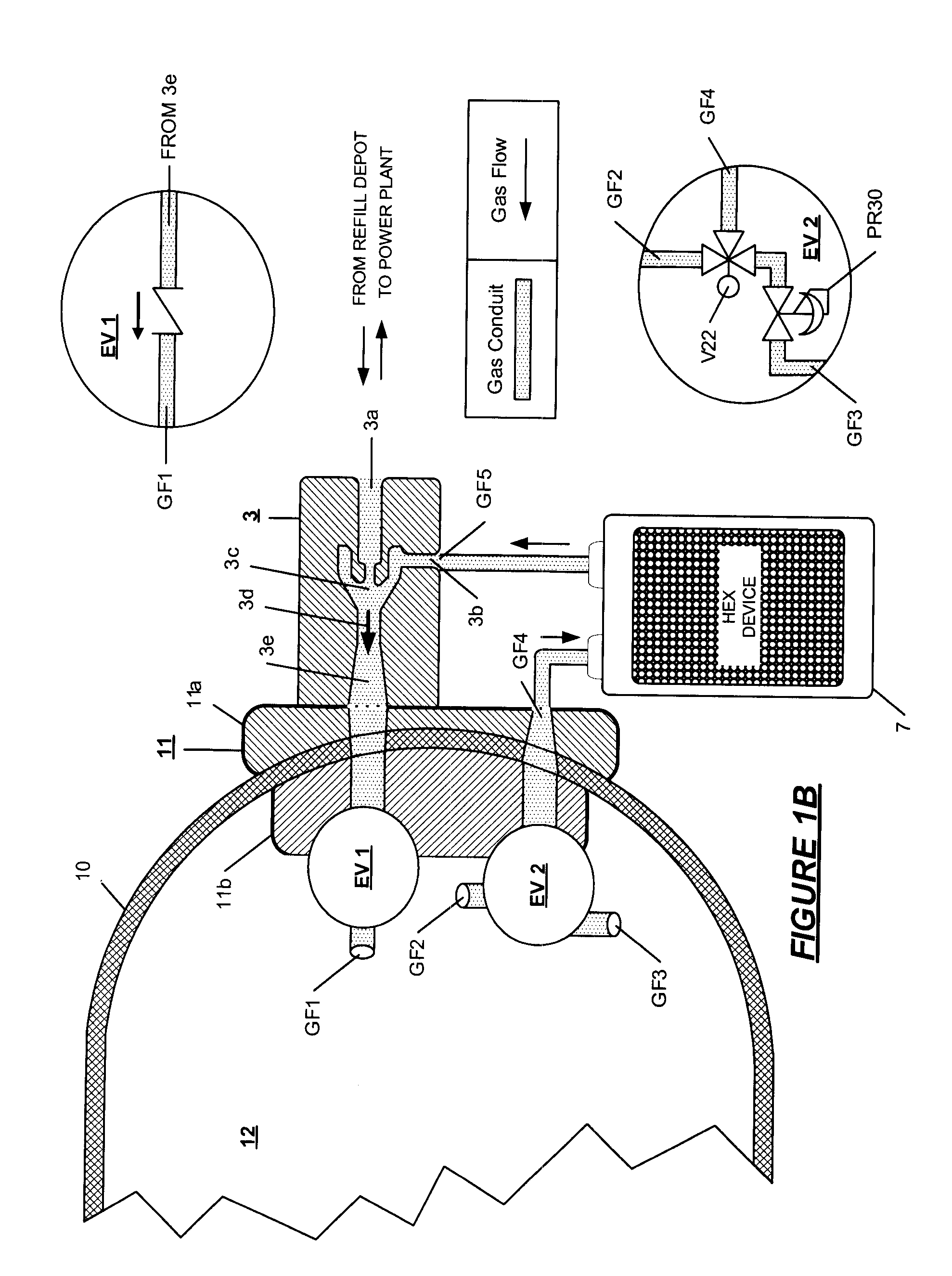

Thermal management for high pressure storage tanks

InactiveUS7891386B2Increase efficiency and refueling capacityRemove heatVessel mounting detailsGas handling applicationsHeat managementProcess engineering

Apparatus for the thermal management of high pressure gas storage tanks wherein the compression heat of refueling the tank is evacuated from the interior of the tank in which a gas circulates within the tank powered by a pump powered and as the gas traverses from the high pressure refuel depot to the storage tank, the circulating gas absorbs the refueling heat and carries the heat to a cooling system having a supplemental heat exchange device before the gas is introduced into the tank. The apparatus may be operated in reverse to transfer heat from a source to the tank interior to provide more complete exhaustion of the tank during vehicle operation.

Owner:HONDA MOTOR CO LTD

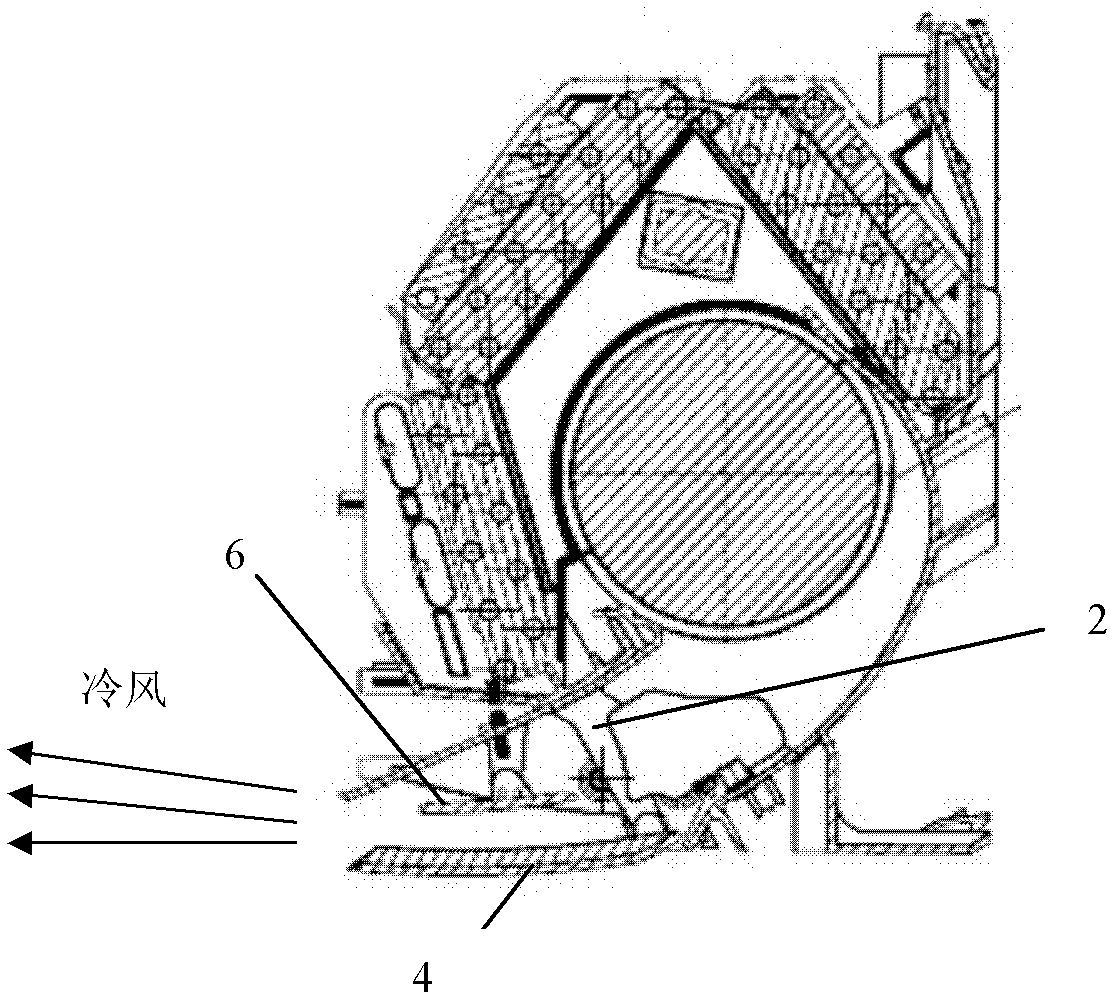

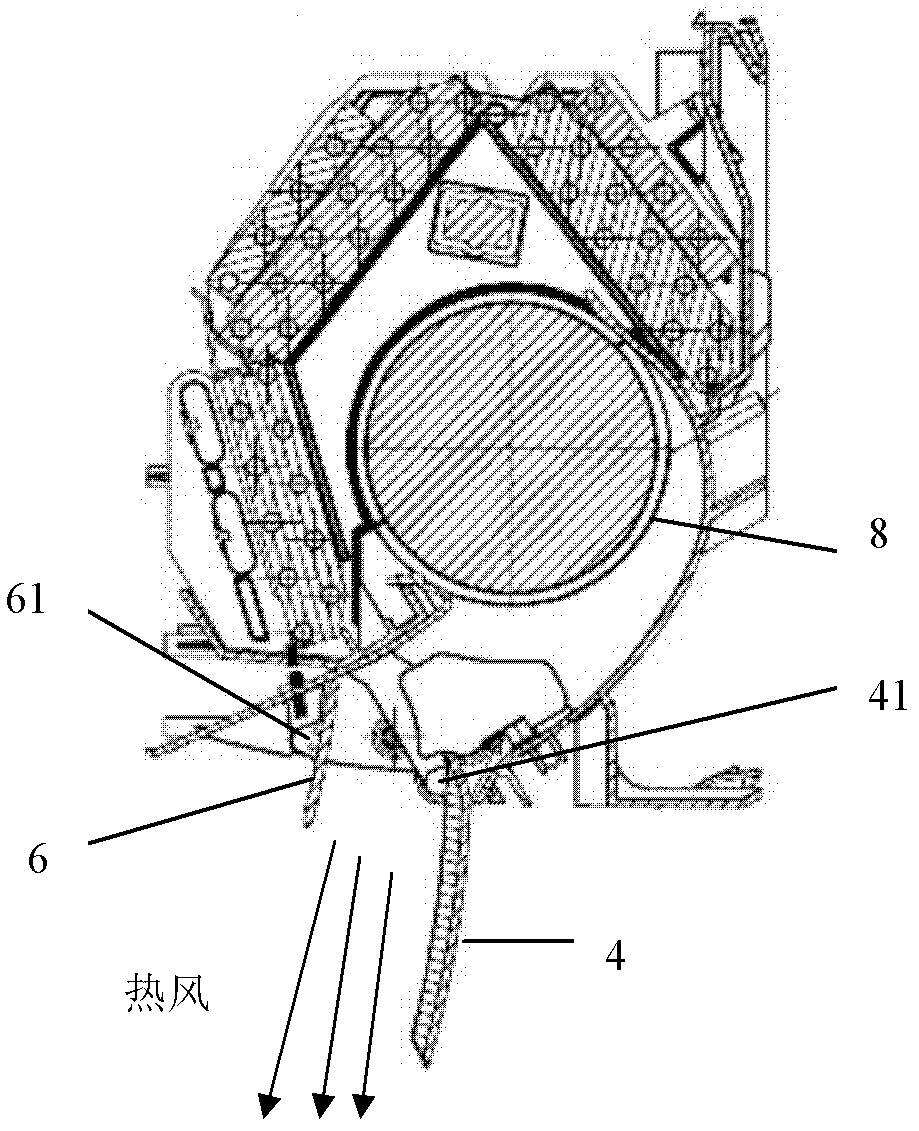

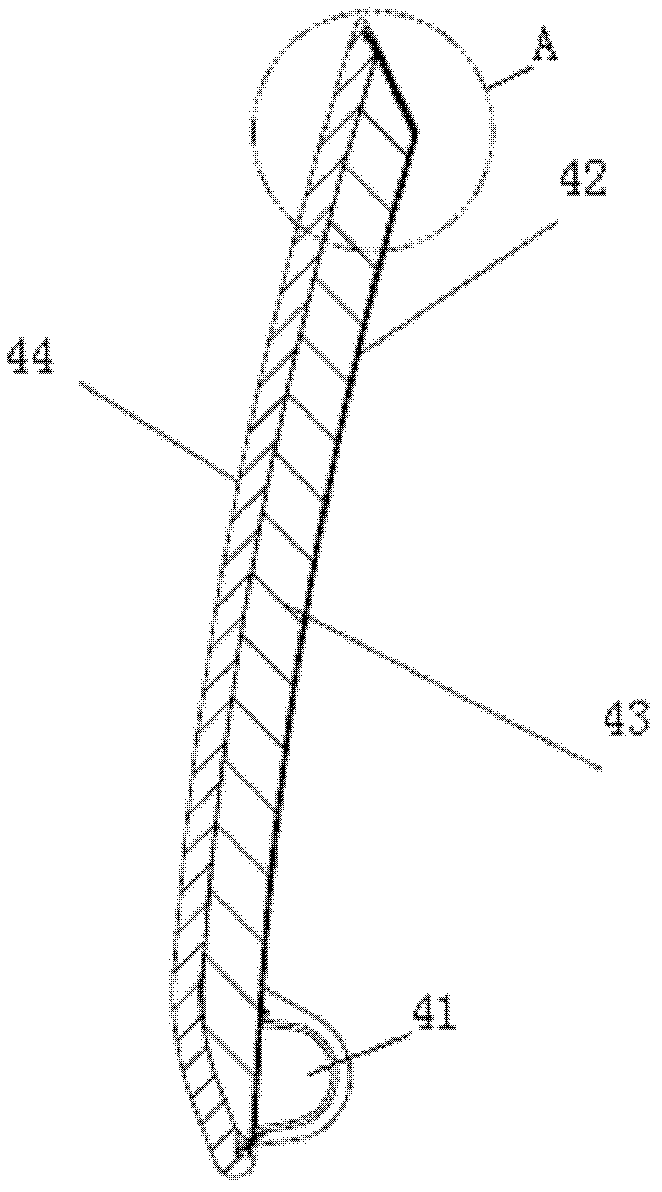

Hanging air conditioner

InactiveCN102384536APromote circulationAvoid hot and cold uneven phenomenonLighting and heating apparatusAir conditioning systemsCold airEngineering

The invention provides a hanging air conditioner which is provided with a frame (2) on which an air outlet is formed. The frame (2) is in pivoted connection with an outer air guiding plate (4) which is matched with the air outlet in shape, and is taken as a cover plate of the air outlet in the closing position, the frame (2) is also in pivoted connection with an inner air guiding plate (6) which is covered by the outer air guiding plate (4) in the closing position, and the outer air guiding plate (4) and the inner air guiding plate (6) are matched to form an air guiding channel on which air guiding ports are alternated in the horizontal direction and the vertical downward direction. The hanging air conditioner can make hot air and cold air balanced rapidly in a room in refrigerating and heating.

Owner:HEFEI HAIER AIR CONDITIONER +2

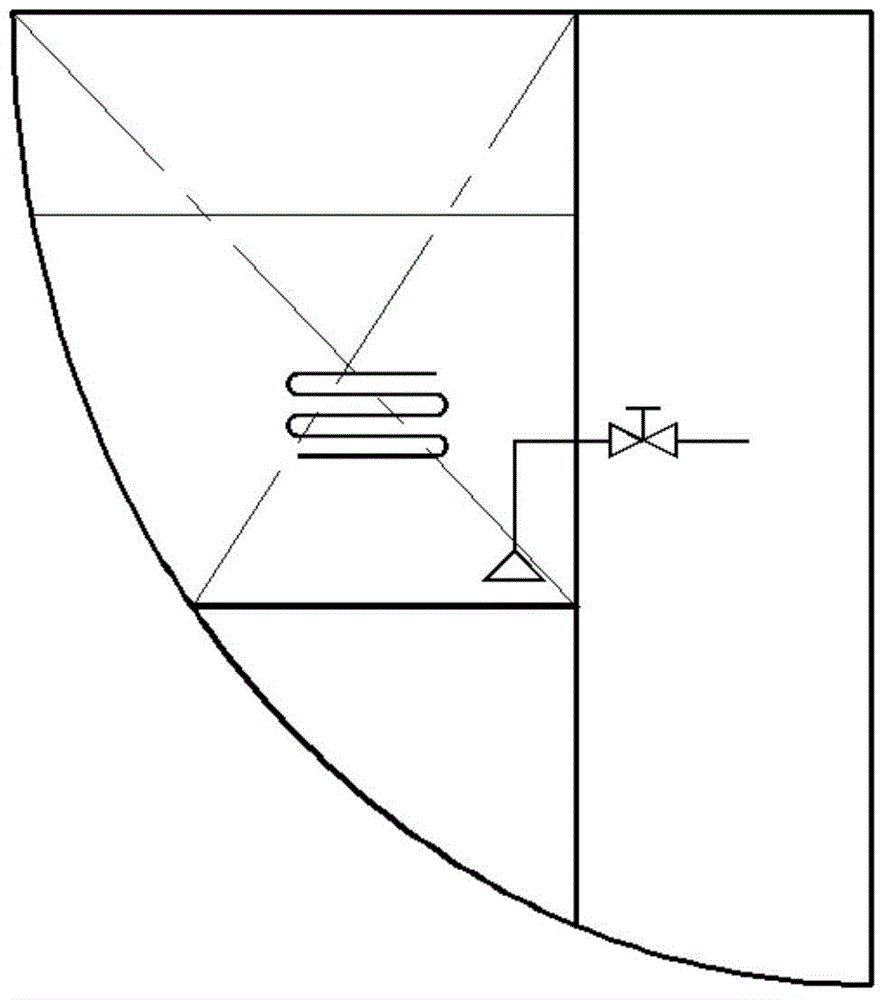

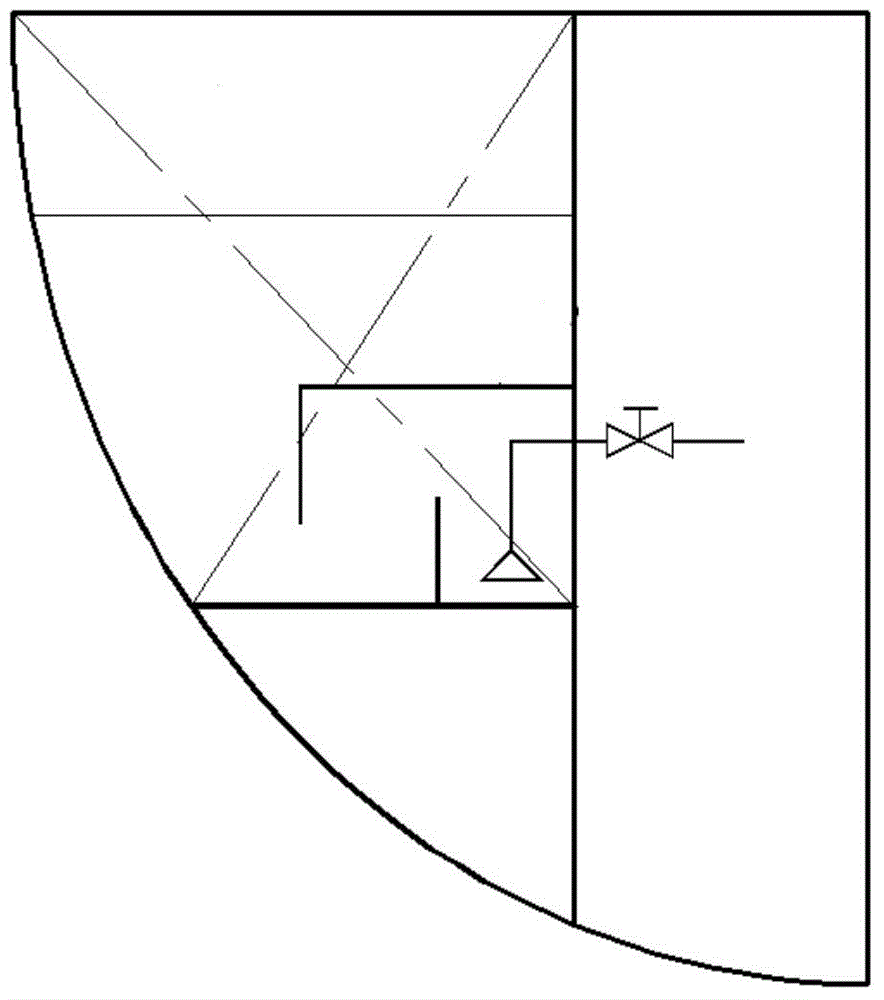

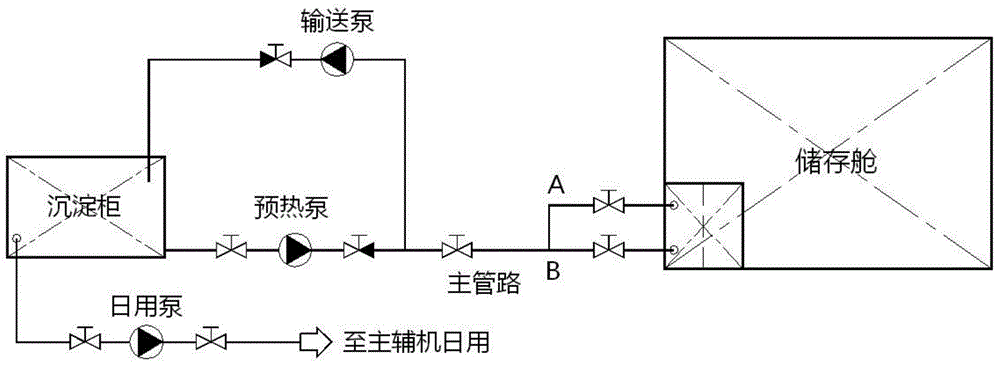

Ship fuel preheating system and preheating method

ActiveCN104819080AReduce operating costsEfficient use ofHull interior subdivisionElectrical controlFuel oilEngineering

The invention relates to a ship fuel preheating system. The ship fuel preheating system is characterized in that a fuel preheating branch pipeline and a fuel conveying branch pipeline are arranged between a storage bin and a sedimentation cabinet. A main pipeline is shared and is divided into two branches near the sedimentation cabinet, a preheating pump is arranged on one branch and provides high temperature fuel for the storage bin, a transfer pump is arranged on the other branch and conveys heated heavy oil to the sedimentation cabinet, and the two branches are provided with stop check valves in the corresponding directions so as to avoid pipeline direction malposition. A small compartment is arranged at one corner of the storage bin, and a first partition plate is arranged in the middle of the small compartment and divides the compartment into two parts in the X direction. A pipe A and a pipe B are arranged in a first sub-compartment, the upper right corner of the first partition plate is provided with a hole, the lower left corner of a second partition plate is provided with a hole, and the two holes are in opposite angle arrangement. Small holes are formed at the bottoms of partition plates to be used for sweeping. An upper plate of the compartment is provided with a plurality of air holes, so as to guarantee timely overflow of generated steam. The pipe A and the pipe B are communicated with the main pipeline and provided with regulating valves respectively.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

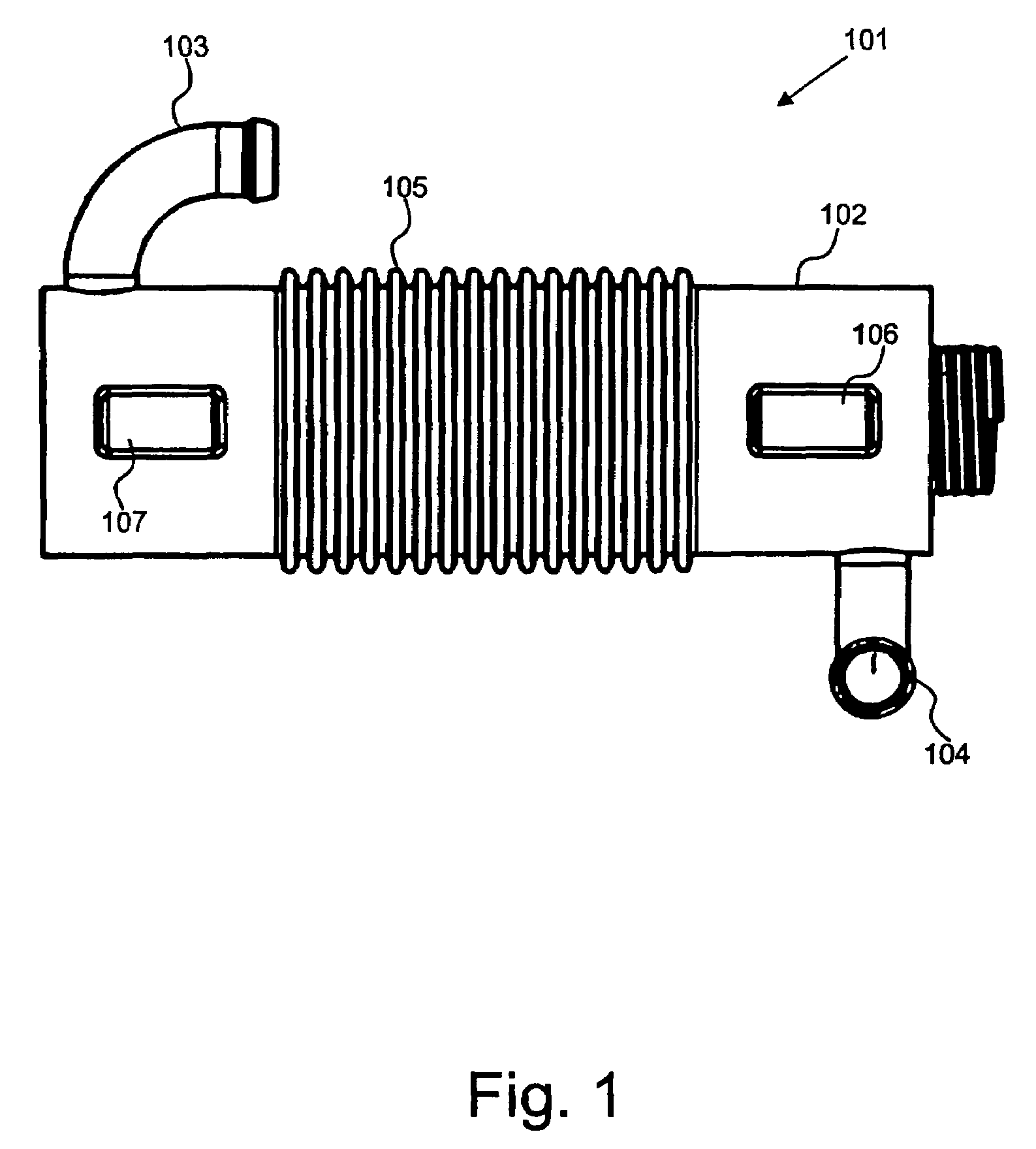

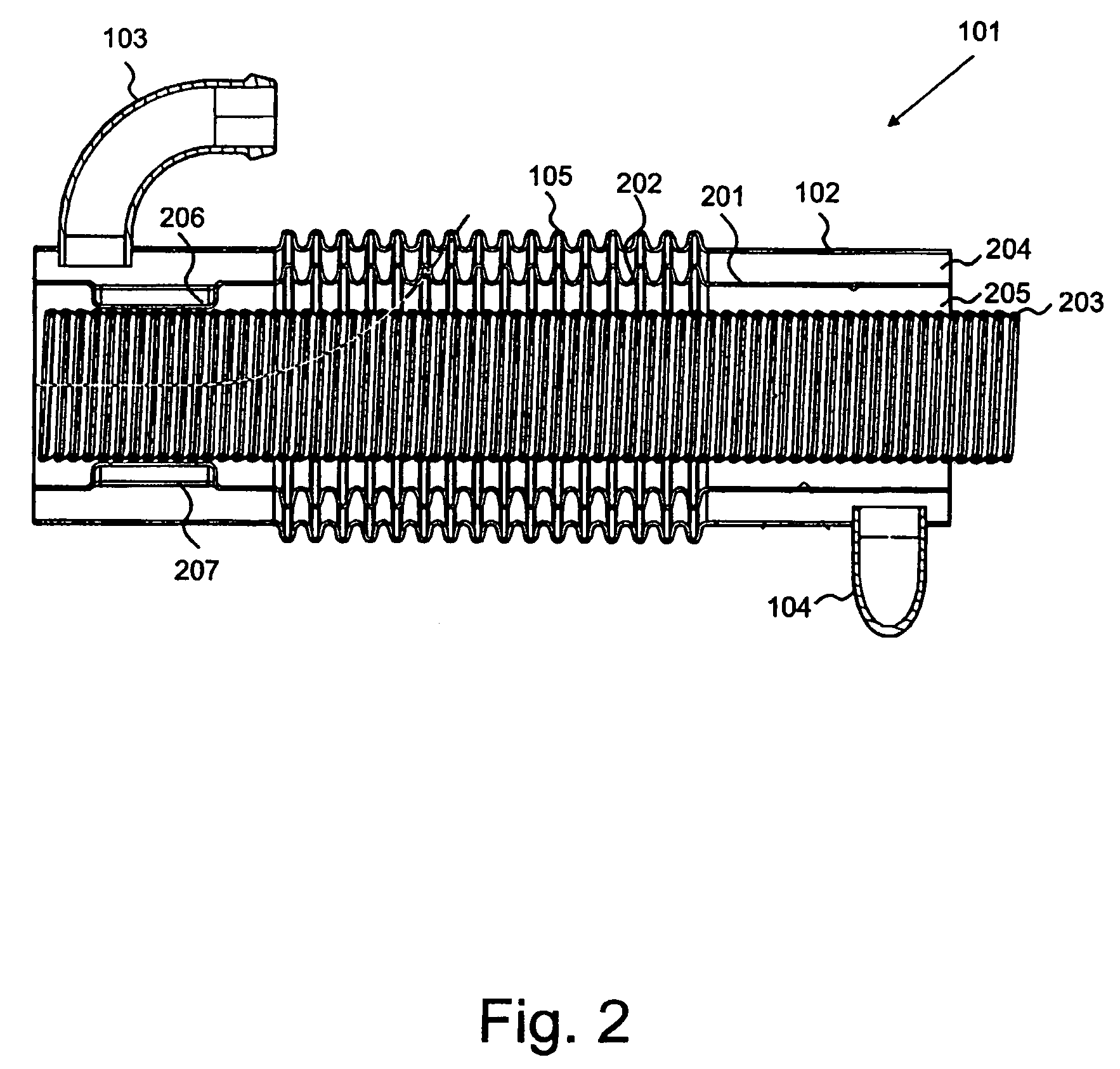

Gas heat exchanger

ActiveUS7255096B2Reduce exposureReduce heat exchangeSpacing meansInternal combustion piston enginesPlate heat exchangerNuclear engineering

Owner:SENIOR IP GMBH

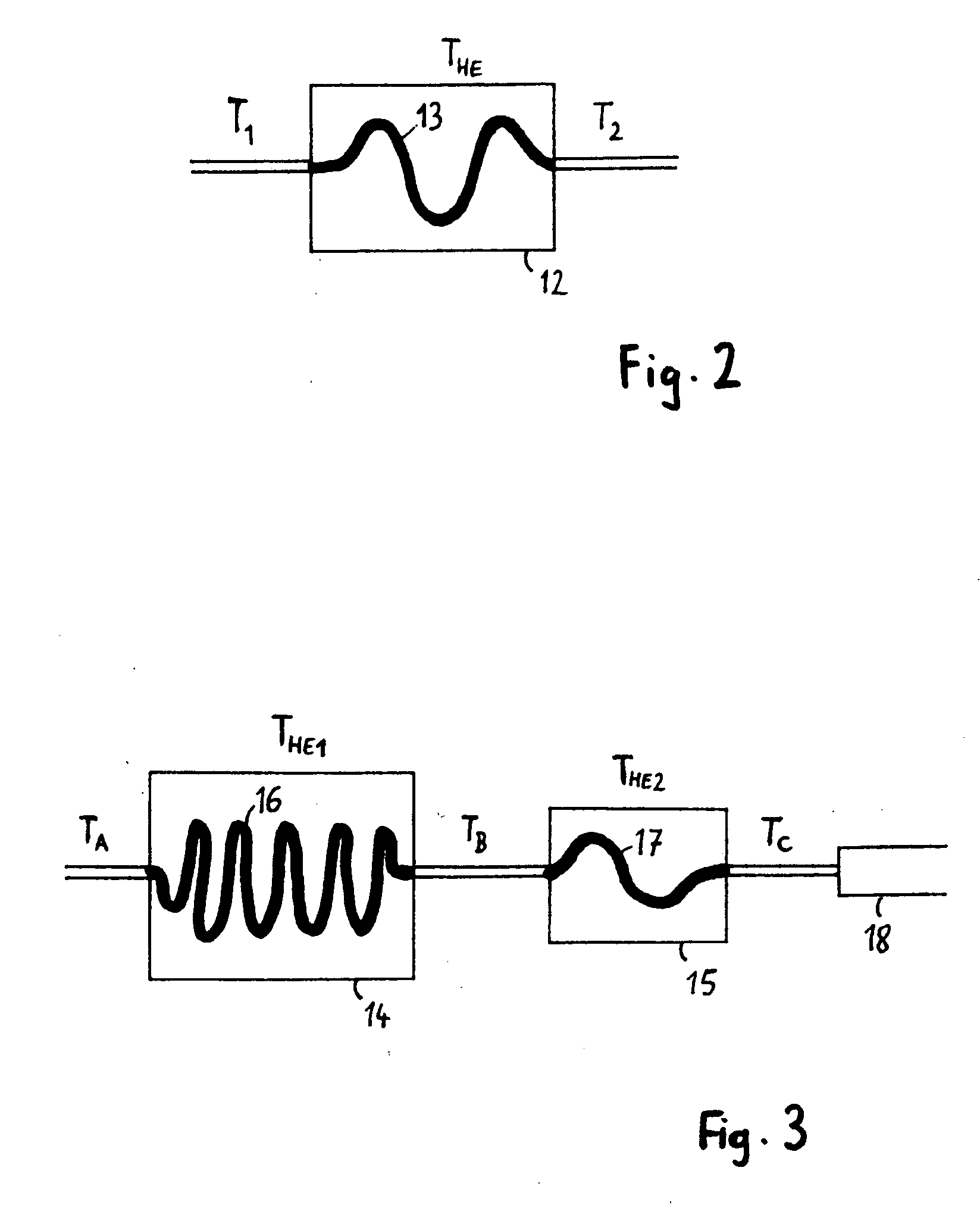

Fluid preheating

InactiveUS20070181702A1Reduction of half widthImprove resolutionComponent separationWater heatersHeating systemEngineering

A heating system for preheating a fluid. The heating system comprises a heating unit with a heating flow path; wherein the heating unit is adapted to be operated at a first temperature and to provide a heat transfer between the heating unit and the fluid passing through the heating flow path, with the heat transfer not being sufficient for heating up the fluid passing through the heating flow path to the first temperature.

Owner:AGILENT TECH INC

Heat exchanger

InactiveUS20150292820A1Low heat transmitting rateImprove heat exchange capacityThermal insulationEvaporators/condensersPlate heat exchangerEngineering

In a composite-type heat exchanger capable of exchanging heat among three types of fluids, an outside air passage is provided in a periphery of refrigerant tubes and coolant tubes, and the outside air passage includes outer fins that promote heat exchange among a refrigerant, an outside air and a coolant. The outer fins include refrigerant side heat connecting portions configured to thermally connect the refrigerant tubes, and coolant side heat connecting portions configured to thermally connect the refrigerant tubes and the coolant tubes. In a first core portion including most downstream refrigerant tubes which constitute a final path, which is the most downstream side path in a direction of the refrigerant flow, the refrigerant side heat connecting portions is larger in number than the coolant side heat connecting portions.

Owner:DENSO CORP

Equipment and process for liquefaction of LNG boiloff gas

ActiveUS20070256450A1Reduce compressionReduce pressureSolidificationLiquefactionSingle stageProduct gas

A design for equipment and process for reliquefaction of LNG boiloff gas, primarily for shipboard installation, has high thermodynamic efficiency and lower capital cost, smaller size (volume, footprint), lower weight, and less need for maintenance than systems utilizing the prior art. The main refrigerant gas compressor is reduced to a single stage turbocompressor. Optional elements include: compression of boiloff gas at ambient temperature; compression of boiloff gas in one or two stages; turboexpansion of refrigerant gas incorporating one or two turboexpanders; turboexpander energy recovery by mechanical loading, compressor drive, or electric generator; refrigerant sidestream for cooling at the lowest temperatures.

Owner:AIR WATER GAS SOLUTIONS INC

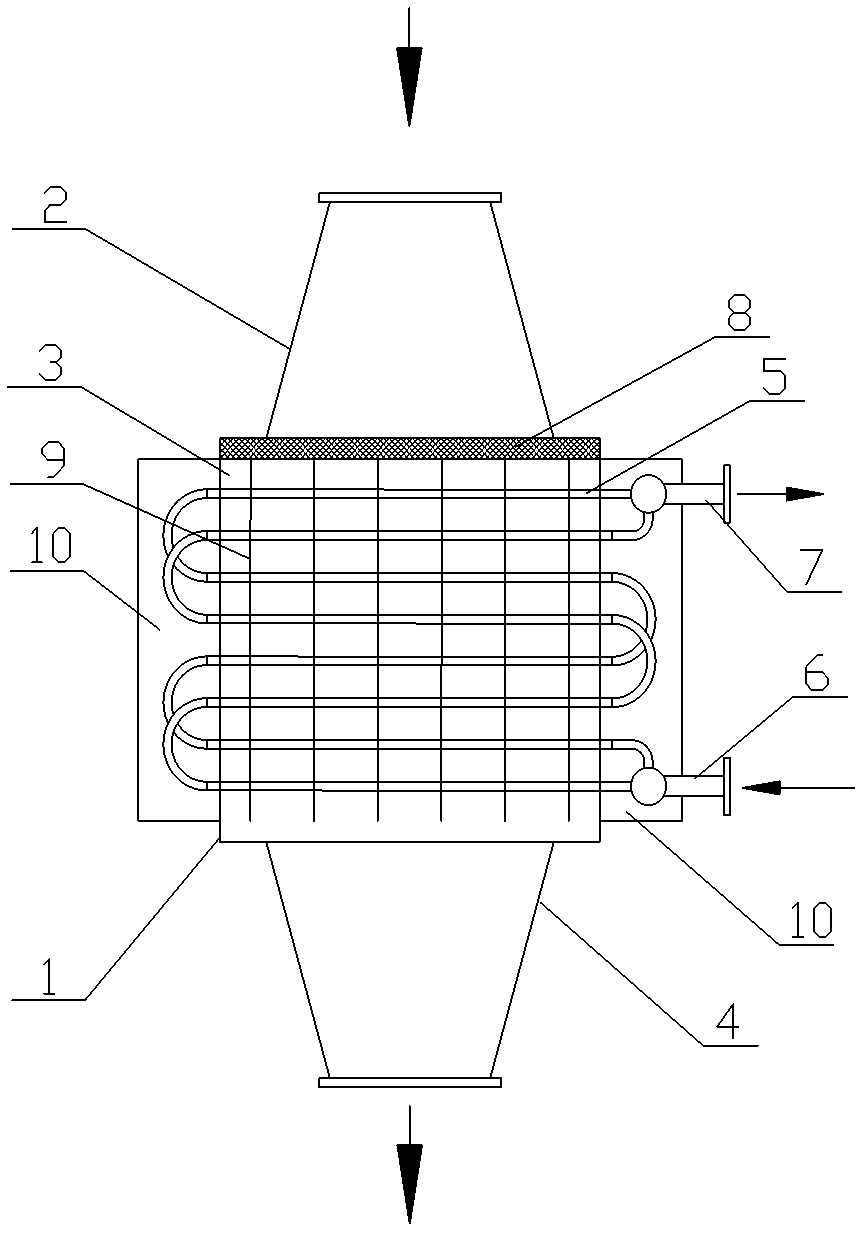

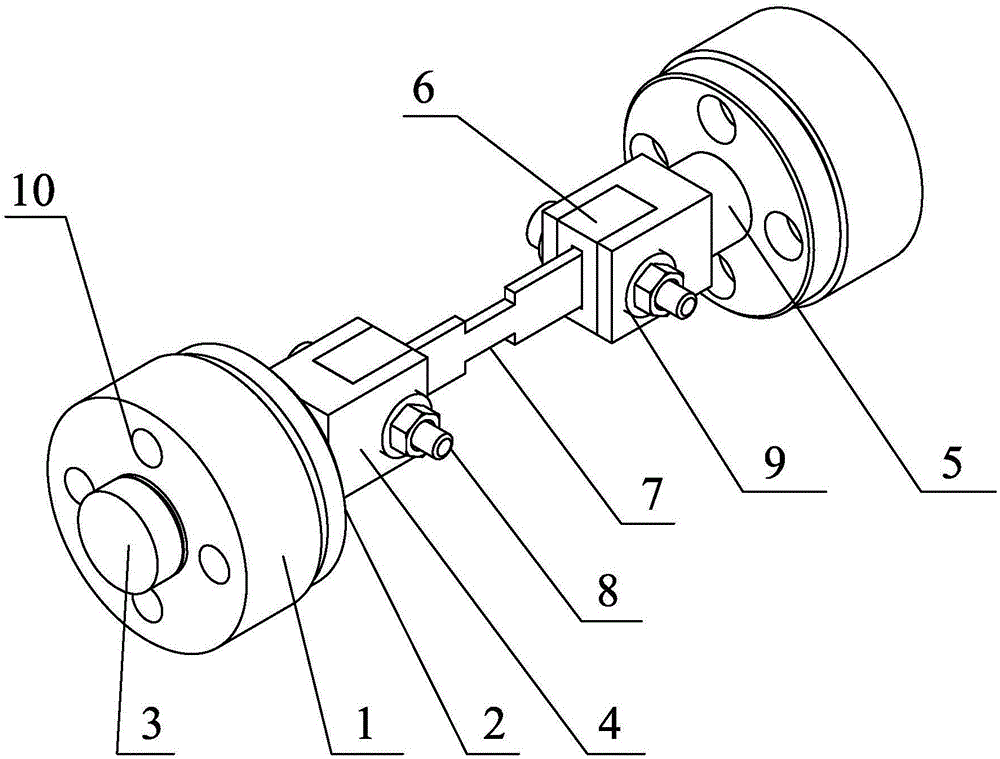

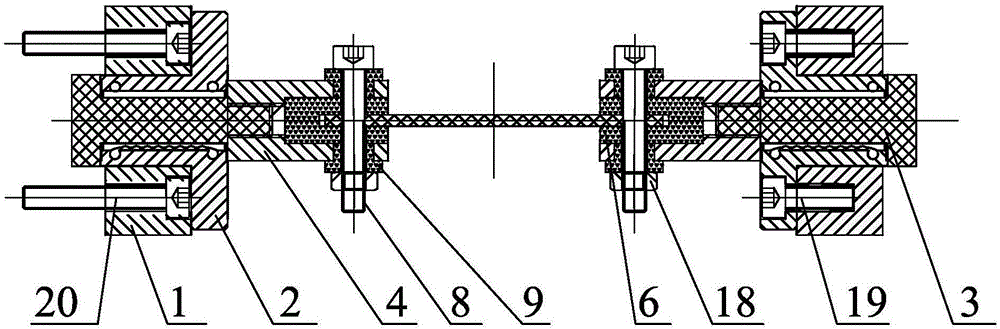

Solid particle heat exchanger

ActiveCN102322753ATemperature controlAdequate heat transferStationary tubular conduit assembliesHeat exchange apparatusSolid particleInductor

The invention relates to a solid particle heater exchanger, which comprises a cylindrical shell, wherein the top of the shell is provided with an upper connecting box for receiving particles, the middle part of the shell is provided with a heat exchange chamber, the bottom of the shell is provided with a lower connecting box for discharging the particles, a heat exchange pipe bundle is arranged in the heat exchange chamber, the heat exchange pipe bundle is provided with a fluid inlet and a fluid outlet on the shell, and a heat transfer fluid source is connected to the fluid inlet; a distributor is arranged between the upper boxing box and the heat exchange chamber; the distributor comprises a silk screen layer which is connected with a control device; the control device comprises a weight inductor and a vibrator, wherein the signal output end of the weight inductor is electrically connected with the controlled end of the vibrator, and the inducting end of the weight inductor and the output end of the vibrator are respectively connected with the silk screen layer. The invention also relates to a solid particle heat exchange system adopting the solid particle heat exchanger. According to the invention, sufficient heat transfer can be ensured, the particle discharge temperature can be controlled to meet the requirements, the discharging temperature of the heat transfer fluid can be ensured to be basically constant, and favorable energy-saving effect is achieved.

Owner:NANJING HUADIAN ENERGY SAVING & ENVIRONMENTAL PROTECTION EQUIP

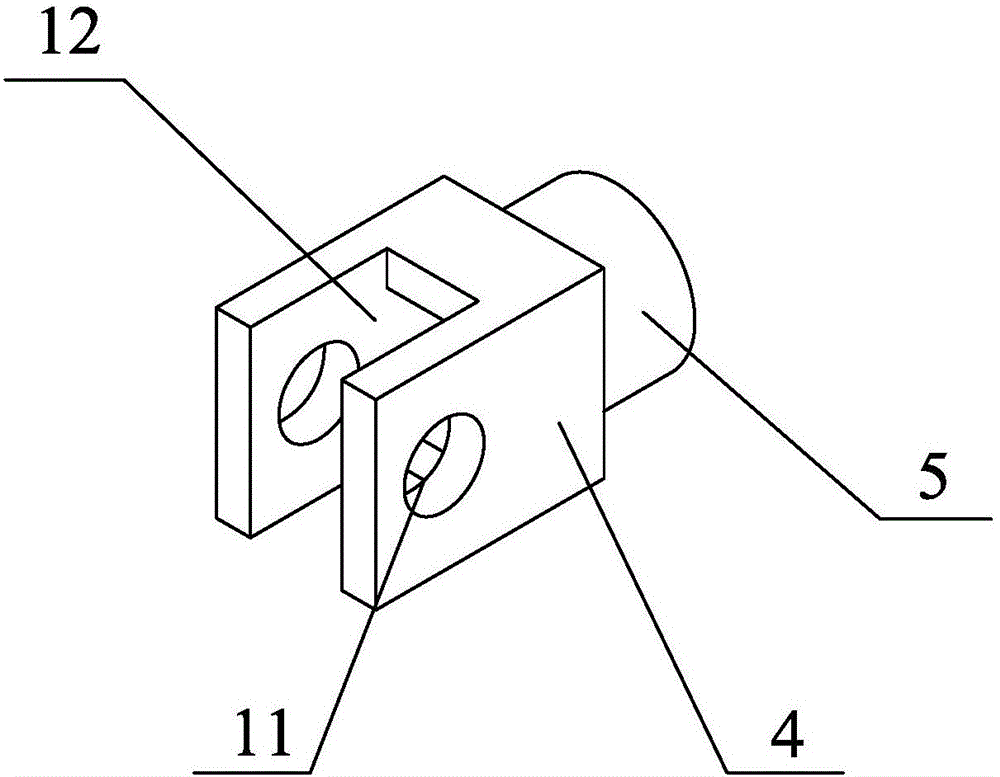

Method for improving temperature gradient in high-temperature tension sample of heat expansion phase change instrument

InactiveCN106769429AHigh temperature resistantResistant to mechanical shockMaterial strength using tensile/compressive forcesFiberExpansion phase

The invention provides a method for improving temperature gradient in a high-temperature tension sample of a heat expansion phase change instrument. The method is characterized in that one of following methods is improved in the tension test process: a clamp is prepared from austenitic stainless steel to replace the existing clamp to test; or, a U-shaped heat isolation sleeve and a fixed screw heat isolation ring are arranged at the contact part of the sample clamping end and the clamp to completely isolate the clamp, the fixed screw and the tension sample through the U-shaped heat insulation sleeve and the fixed screw heat isolation ring, and the clamp is prepared from austenitic stainless steel to replace the existing clamp to test. The method has the advantages that the austenitic stainless steel is used as the clamp preparation material and the ceramic fiber sheet is used as the heat isolation sleeve and the heat isolation sleeve, so that the heat radiation and heat conduction of high-temperature objects and low-temperature objects are effectively inhibited; the operation is easy, the detachment and installation of the sample are convenient, and the material stability is guaranteed.

Owner:NORTHEASTERN UNIV

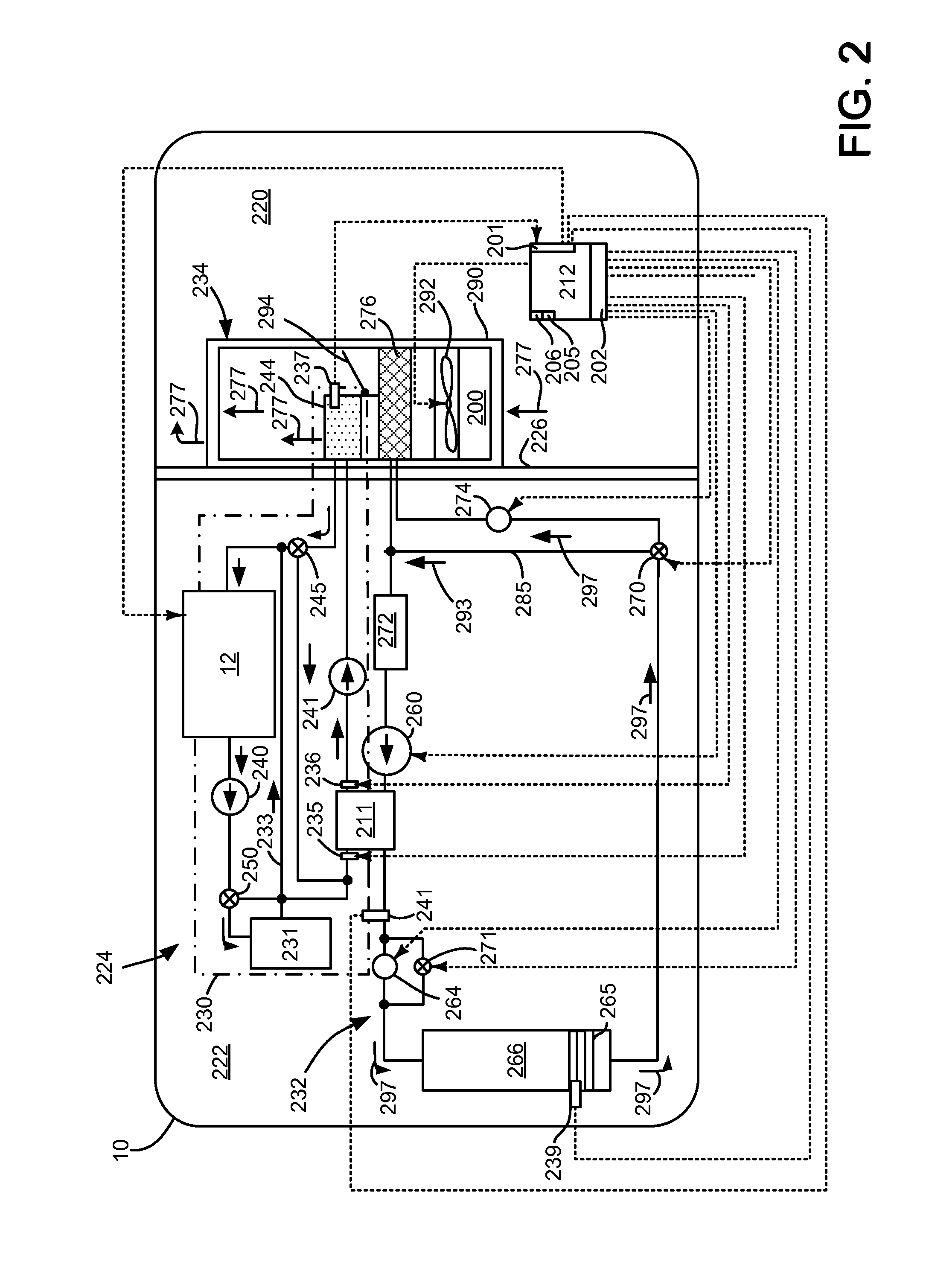

Thermal Management For High Pressure Storage Tanks

InactiveUS20080302110A1Increase profitImprove cooling effectSolidificationLiquefactionEngineeringHigh pressure

Apparatus for the thermal management of high pressure gas storage tanks wherein the compression heat of refueling the tank is evacuated from the interior of the tank in which a gas circulates within the tank powered by a pump powered and as the gas traverses from the high pressure refuel depot to the storage tank, the circulating gas absorbs the refueling heat and carries the heat to a cooling system having a supplemental heat exchange device before the gas is introduced into the tank. The apparatus may be operated in reverse to transfer heat from a source to the tank interior to provide more complete exhaustion of the tank during vehicle operation.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com