Fluid preheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

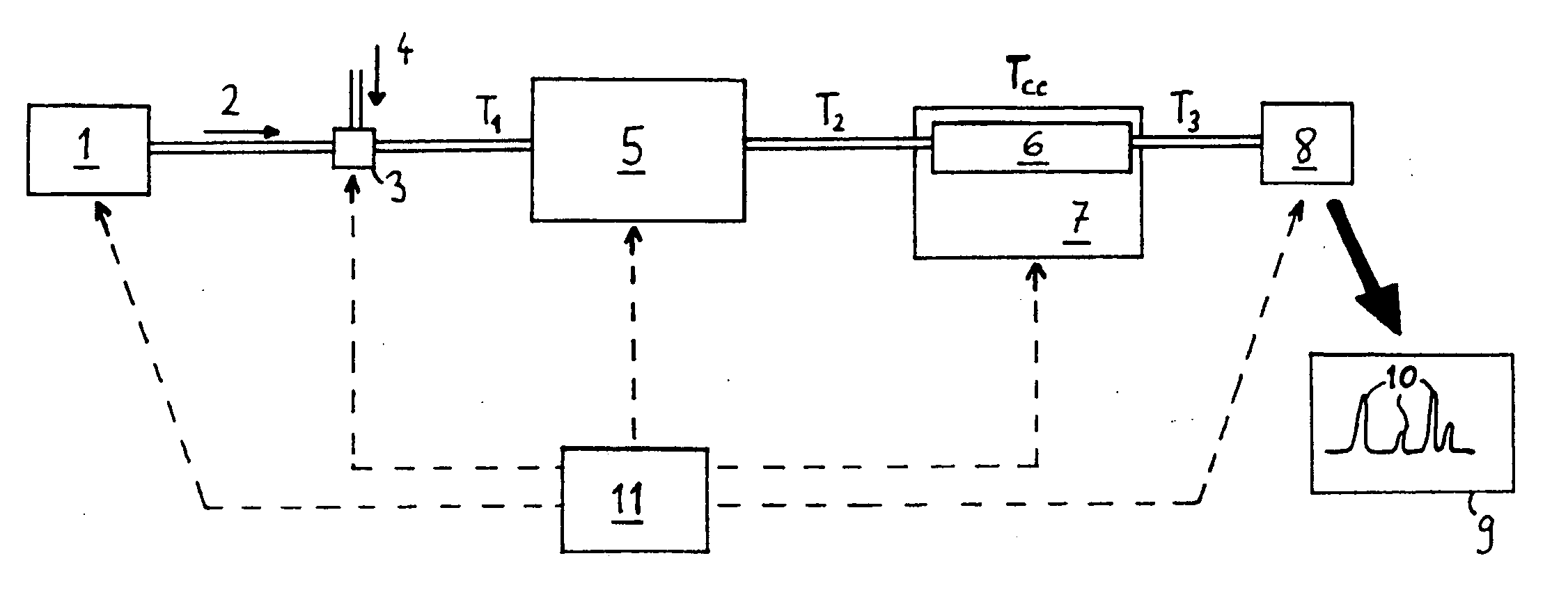

[0045]FIG. 1 gives an overview of a separation system adapted for separating compounds of a given sample. The separation system comprises a fluid delivery unit 1, e.g. a pump, for supplying a flow of eluent 2 to a sample injection unit 3. At the sample injection unit 3, a volume of fluid sample 4 may be injected. Both the eluent and the sample are supplied to a heating system 5. During the passage through the heating flow path of the heating system, the eluent and the sample are heated up. The eluent and the sample are supplied to a separation column 6 that is filled with a stationary phase. The separation system further comprises a thermostated column compartment 7 adapted for keeping the separation column 6 at a pre-defined temperature. The separation column 6 might e.g. be kept at a temperature of about 80° Celsius. Due to the interaction between the sample compounds and the packing material, the sample compounds appear at the separation column's outlet at different points of tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com