Patents

Literature

44results about How to "Resistant to mechanical shock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low temperature curable bottom filling adhesive with heat transfer function and preparation method thereof

InactiveCN106753143AGuaranteed reliabilityGuaranteed storage stabilityNon-macromolecular adhesive additivesHeat-exchange elementsPolymer scienceLow temperature curing

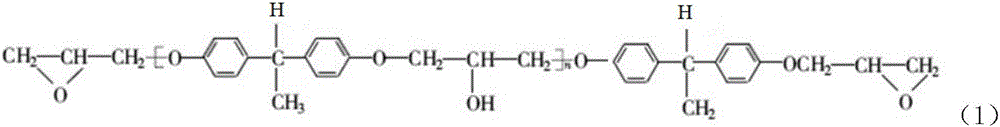

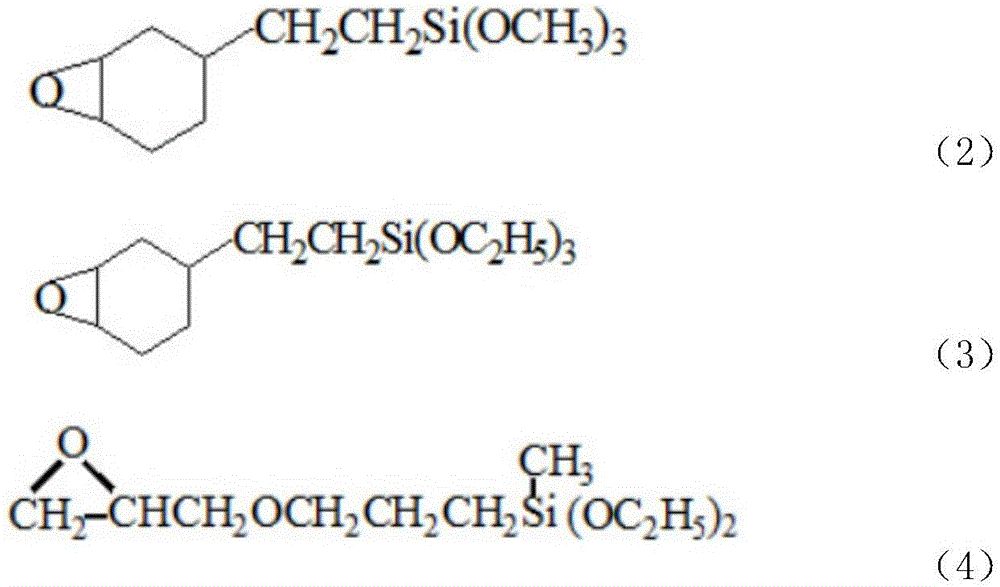

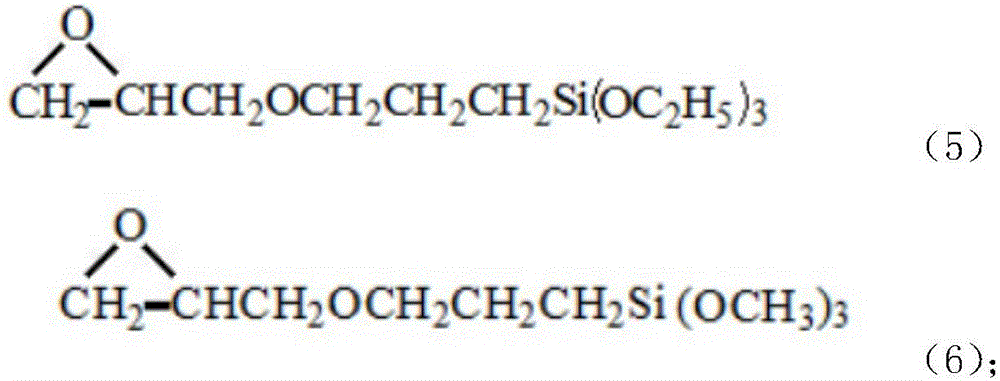

The invention relates to low temperature curable bottom filling adhesive with heat transfer function, comprising component A and component B; the component A is made from 100 parts of epoxy resin, 10-35 parts of modified epoxy resin, 0.5-5 parts of epoxy modified silicone oil, 5-15 parts of active diluent, 250-600 parts of heat transfer filler, 0.5-2 parts of a dispersant, 0.5-2 parts of a defoaming agent, and 0.2-4 parts of a rheological agent; the component B is made from 100 parts of liquid epoxy curing agent, 8-20 parts of a toughening agent, 250-600 parts of heat transfer filler, 0.5-5 parts of epoxy modified silicone oil, 0.5-2 parts of an adhesion promoter, 0.5-2 parts of a dispersant, 1-4 parts of a rheological agent, and 0.5-2 parts of a defoaming agent. The defects of low heat transfer coefficient, low temperature storage, high temperature curing and the like in existing filling adhesive can be overcome, and a chip packaged and cured by 3D MCP has high adhesive strength, good resistance to mechanical impact and good radiating performance.

Owner:NANJING NUOBANG NEW MATERIAL CO LTD

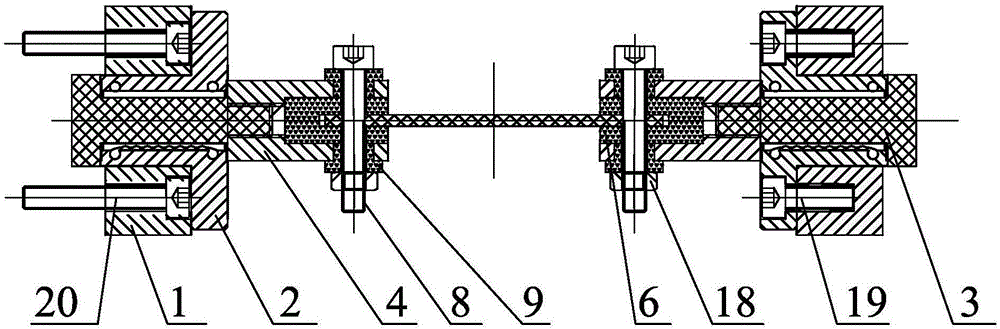

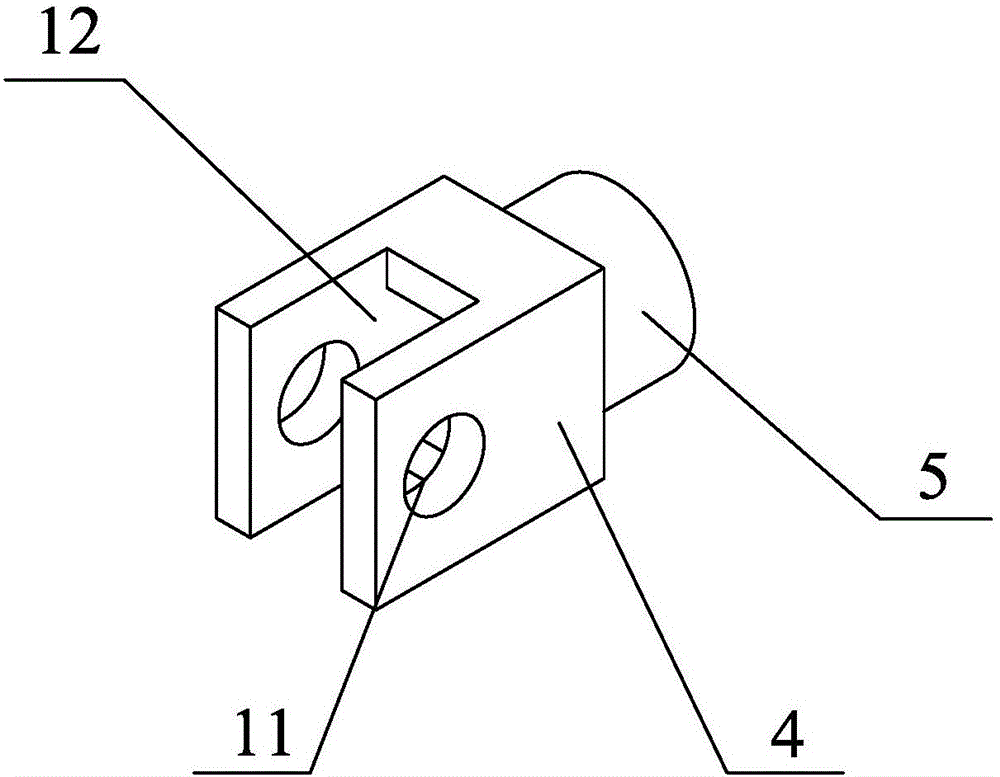

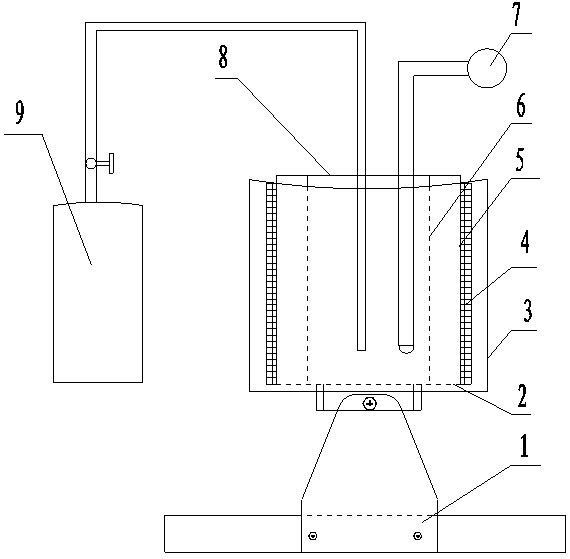

Method for improving temperature gradient in high-temperature tension sample of heat expansion phase change instrument

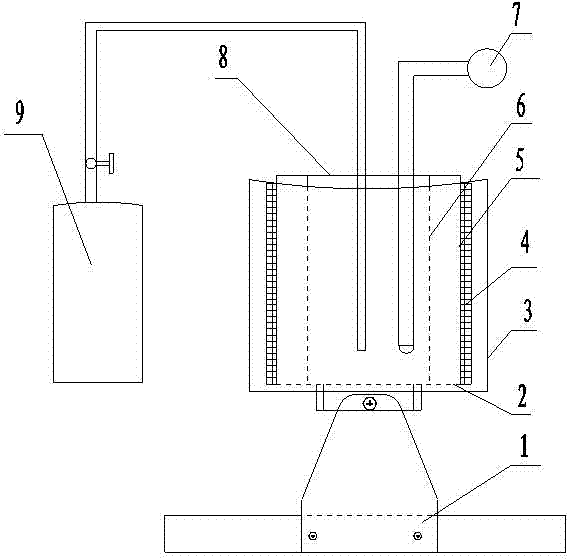

InactiveCN106769429AHigh temperature resistantResistant to mechanical shockMaterial strength using tensile/compressive forcesFiberExpansion phase

The invention provides a method for improving temperature gradient in a high-temperature tension sample of a heat expansion phase change instrument. The method is characterized in that one of following methods is improved in the tension test process: a clamp is prepared from austenitic stainless steel to replace the existing clamp to test; or, a U-shaped heat isolation sleeve and a fixed screw heat isolation ring are arranged at the contact part of the sample clamping end and the clamp to completely isolate the clamp, the fixed screw and the tension sample through the U-shaped heat insulation sleeve and the fixed screw heat isolation ring, and the clamp is prepared from austenitic stainless steel to replace the existing clamp to test. The method has the advantages that the austenitic stainless steel is used as the clamp preparation material and the ceramic fiber sheet is used as the heat isolation sleeve and the heat isolation sleeve, so that the heat radiation and heat conduction of high-temperature objects and low-temperature objects are effectively inhibited; the operation is easy, the detachment and installation of the sample are convenient, and the material stability is guaranteed.

Owner:NORTHEASTERN UNIV

Anti-aging ceramic insulator and preparation method thereof

The invention discloses an anti-aging ceramic insulator and a preparation method thereof, and relates to the technical field of an insulator. The anti-aging ceramic insulator is prepared from the following raw materials in parts by weight: 20 to 32 parts of potassium feldspar, 15 to 24 parts of zeolite, 25 to 30 parts of mica, 8 to 16 parts of kaolin, 15 to 22 parts of epoxy resin, 10 to 18 partsof organic silicon, 10 to 20 parts of ceramic fiber, 6 to 10 parts of zirconium dioxide, 7 to 15 parts of calcium silicate, 4 to 10 parts of nanometer silicon dioxide, 4 to 10 parts of nanometer titanium dioxide, 3 to 8 parts of nanometer silicon nitride, 3 to 6 parts of silane coupling agents, 3 to 6 parts of antioxidants, 2 to 5 parts of anti-freezing agents and 3 to 6 parts of surface active agents. The anti-aging ceramic insulator has the advantages that the property is stable; the corrosion resistant performance and the anti-aging performance are good; the low temperature and high temperature resistant performance is good; strong mechanical stress is realized; the preparation method is simple and easy; the manufacturing cost is low; good market application prospects are realized.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

Waterproof plastering gypsum and preparation method thereof

InactiveCN107226672ASmaller specific heatGuaranteed performancePolyethylene terephtalateAntibacterial agent

The invention discloses a waterproof plastering gypsum, and belongs to the technical field of plastering gypsums. The plastering gypsum comprises the following raw materials in parts by weight: 60-70 parts of desulphurization gypsum, 25-30 parts of silica sand, 14-18 parts of calcium carbonate, 13-15 parts of cement, 8-10 parts of polytrimethylene terephthalate fiber, 10-12 parts of ceramic fiber, 7-9 parts of modified magnesium hydroxide, 6-8 parts of kieselguhr, 5-7 parts of starch, 1-3 parts of hydroxy propyl methyl cellulose, 3-5 parts of an organosilicone water repellent, 1-2 parts of a retarder, 2-4 parts of an antibacterial agent, 14-16 parts of an acrylic emulsion and 5-15 parts of water. The invention further discloses a preparation method of the waterproof plastering gypsum, the preparation is simple, and the waterproof plastering gypsum has excellent waterproof, fireproof and high temperature resistant capabilities after being solidified.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

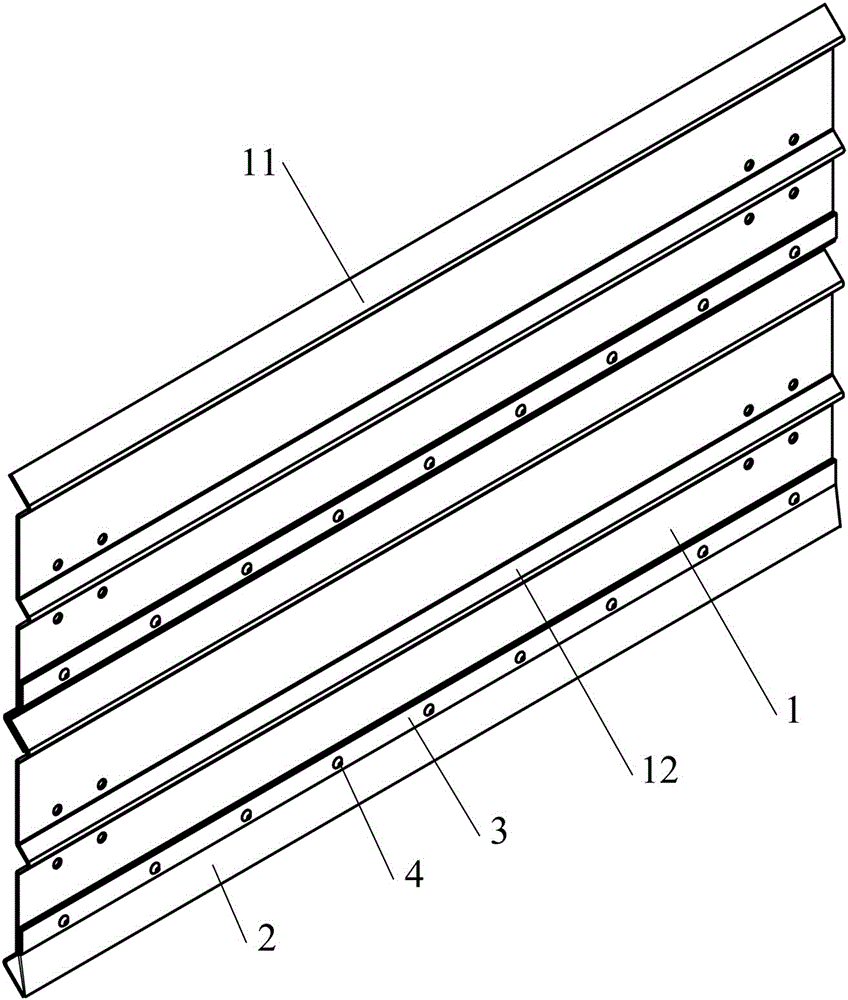

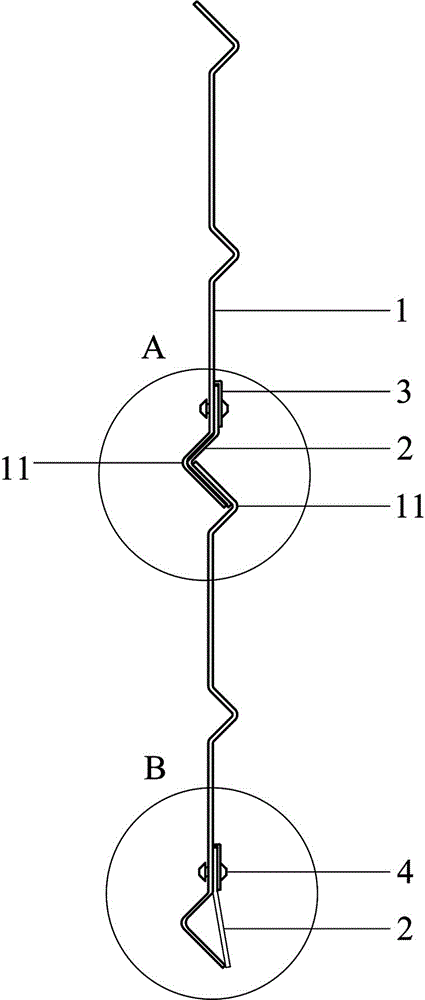

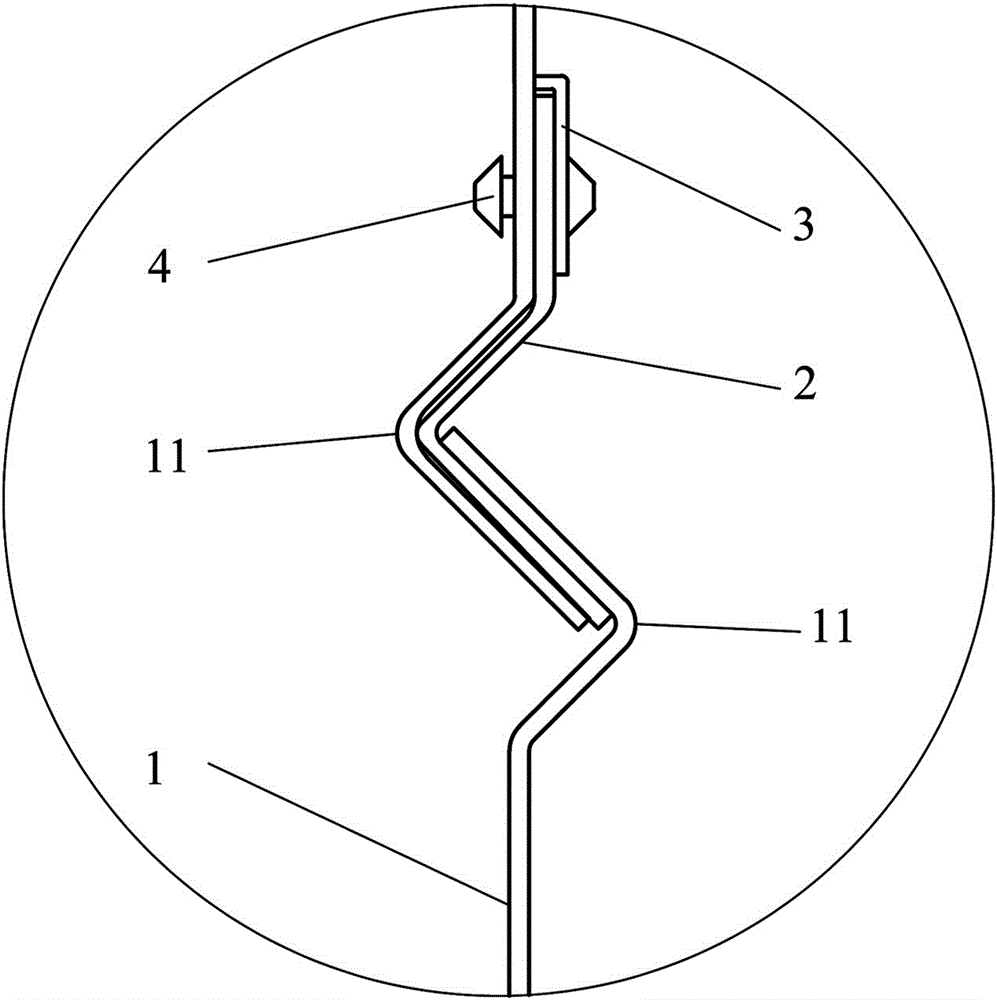

Vale blade sealing structure and air valve

The invention discloses a valve blade sealing structure and an air valve. The valve blade sealing structure comprises valve blades. The upper ends and the lower ends of the valve blades are provided with lap joint parts. The directions of the lap joint parts of every two adjacent valve blades are opposite. Each lap joint part is composed of a folding start face obliquely extending out and a folding stop face reversely folded back. A flexible sealing strip is arranged on one side of one end of the lap joint. A pressing strip is arranged at the upper end of the sealing strip. The pressing strip and the sealing strip are fixed to the valve blades through rivets in an inserting manner. The lower end of the sealing strip is squeezed by and attached to the folding stop faces of the two corresponding adjacent lap joint parts. The valve blade sealing structure is simple and convenient to install; and when the air valve is closed, the flexible sealing strip is deformed under the acting force of the lap joint parts of the valve blades so as to adaptively fill the connecting gaps between the lap joint parts of the valve blades, and therefore the leakage amount of air valves such as an air volume regulating valve, a fire valve, a smoke exhausting fire valve and a smoke exhausting valve is controlled to be reduced as much as possible.

Owner:ZHONGHANG DAJI ENG PRODS SHENZHEN

Ceramic fiber furnish composite paper and preparation method thereof

InactiveCN101649575ASave plant resourcesReduce weightInorganic fibres/flakesPaper/cardboardTemperature resistanceRosin

The invention discloses ceramic fiber furnish composite paper and a preparation method thereof. The invention aims to provide the ceramic fiber furnish composite paper and the preparation method thereof, which take ceramic fibers and plant fiber dry pulp as main materials, can save forest resources and grass resources and have excellent fire resistance and high strength. The composite paper comprises the main material and an auxiliary material, wherein the main material comprises 25-60% of ceramic fiber and 40-75% of plant fiber dry pulp by weight percentage, the auxiliary material comprises rosin size, and the weight portion percentage of the main material to the auxiliary material is 100:4-8. In the ceramic fiber furnish composite paper, ceramic fibers are utilized to replace the plant fiber pulp so as to save a mass of plant resources, simultaneously, the paper and the cardboard have the performances of anti-corrosion, high strength, fire-resistance, high-temperature resistance, andthe like, and the fire-resistance is excellent; furthermore, the ceramic fiber furnish composite paper has no toxicity or harmfulness and is environment-friendly. The preparation method of the ceramic fiber furnish composite paper reduces the displacement, the wastewater treatment cost, the manufacture cost and the environment pollution.

Owner:TIANJIN UNIV OF COMMERCE

Preparation method for friction plate

InactiveCN108443377AWith vibrationImprove vibrationOther chemical processesFriction liningMagnesiumHot pressing

The invention discloses a preparation method for a friction plate. Materials of the friction plate comprise an enhanced titanium alloy skeleton and filler. The enhanced type titanium alloy skeleton comprises titanium alloy powder, tungsten carbide and titanium hydride. The filler comprises graphene fiber, diatomite, brass powder, graphite, carbon fibers, silicon dioxide, Pbo fiber, adhesive spraying aluminum silicate fiber, nanometer phenolic resin, styrene butadiene rubber, aramid fiber, mineral fiber, copper fiber, polypropylene fiber, paper fiber, metallic aluminum powder, zinc powder, mica, calcined petroleum coke, red vermiculite, light magnesium oxide, precipitated barium sulfate, light calcium carbonate, modified phenolic resin, molybdenum powder, molybdenum disulfide, graphite, nitrile butadiene rubber, ferric oxide, chromium oxide and the like; and the four technological processes of burdening, mixing and stirring, hot pressing forming and curing are adopted to complete the preparation method for the friction plate. The friction plate prepared through the scheme is low in hardness, high in stability, low in noise generated when an automobile is used and good in safety performance.

Owner:HAIAN DONGYYANG TONGDA AUTO ACCESSORIES CO LTD

CPVC pipeline for fire protection engineering and preparation method of CPVC pipeline

The invention discloses a CPVC pipeline for fire protection engineering, belonging to the technical field of CPVC pipelines. The CPVC pipeline is prepared from the following raw materials in parts by weight: 80-90 parts of CPVC resin, 16-18 parts of ceramic fibers, 7-10 parts of glass fibers, 10-12 parts of magnesium oxide, 5-7 parts of calcium oxide, 8-10 parts of calcium carbonate, 2-4 parts of chlorinated paraffin, 2-4 parts of tributyl phosphate, 2-3 parts of an ACR machining modifier, 4-6 parts of a CPE impact modifier, 0.5-1 part of a pigment, 1-2 parts of an antioxidant, 4-5 parts of a heat stabilizer and 0.05-0.5 part of an ultraviolet light absorber. The invention further discloses a preparation method of the CPVC pipeline for fire protection engineering. The CPVC pipeline has relatively good mechanical property and strong fire resistance and high-temperature resistance.

Owner:合肥博之泰电子科技有限公司

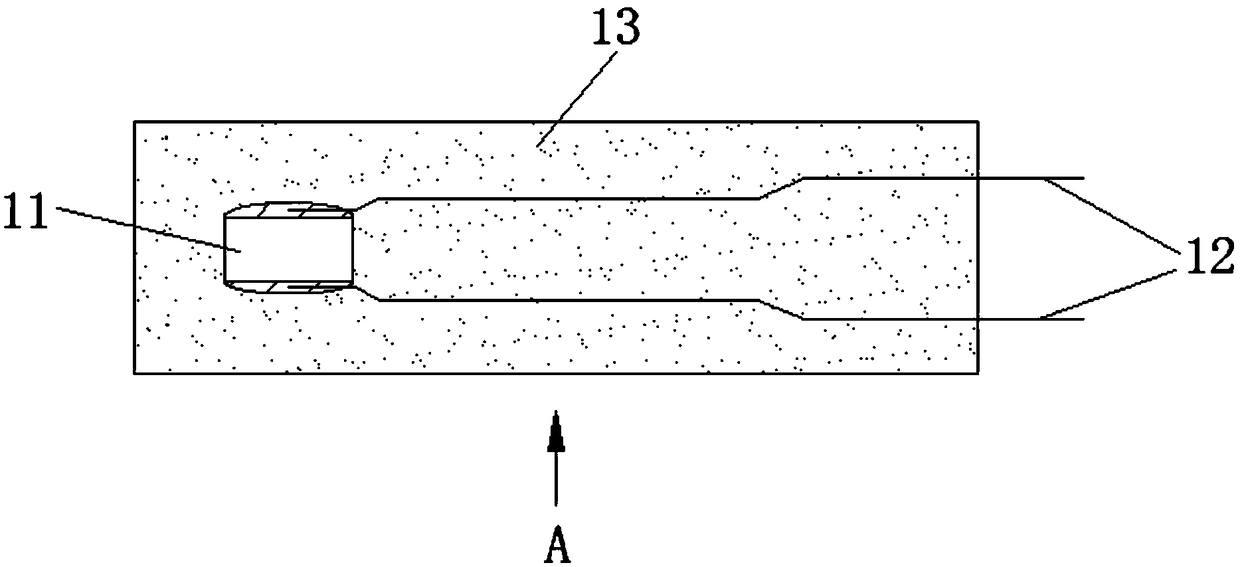

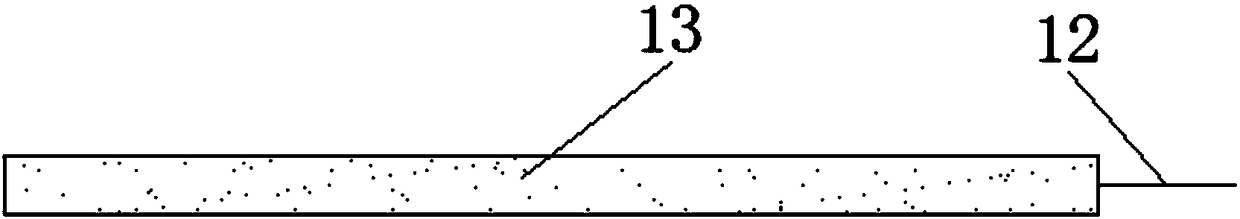

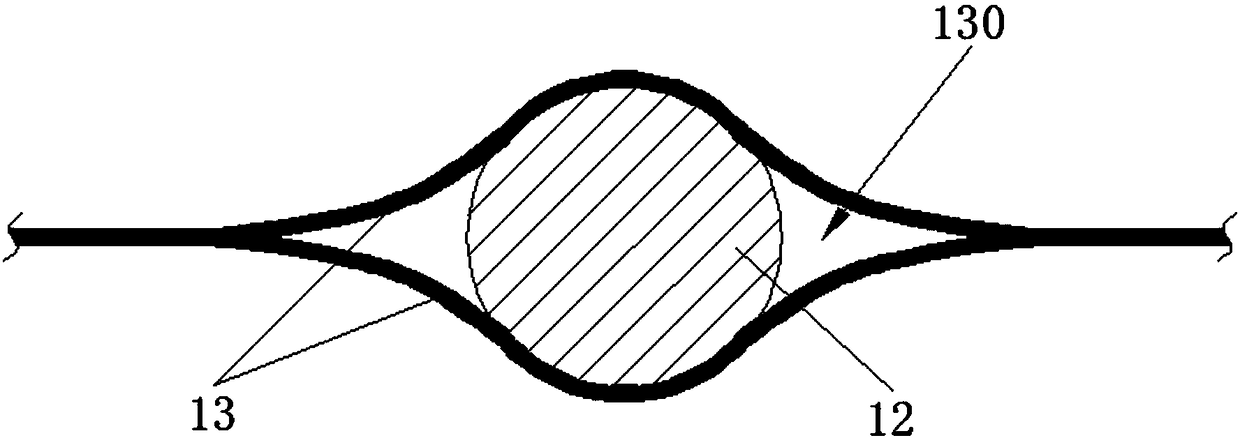

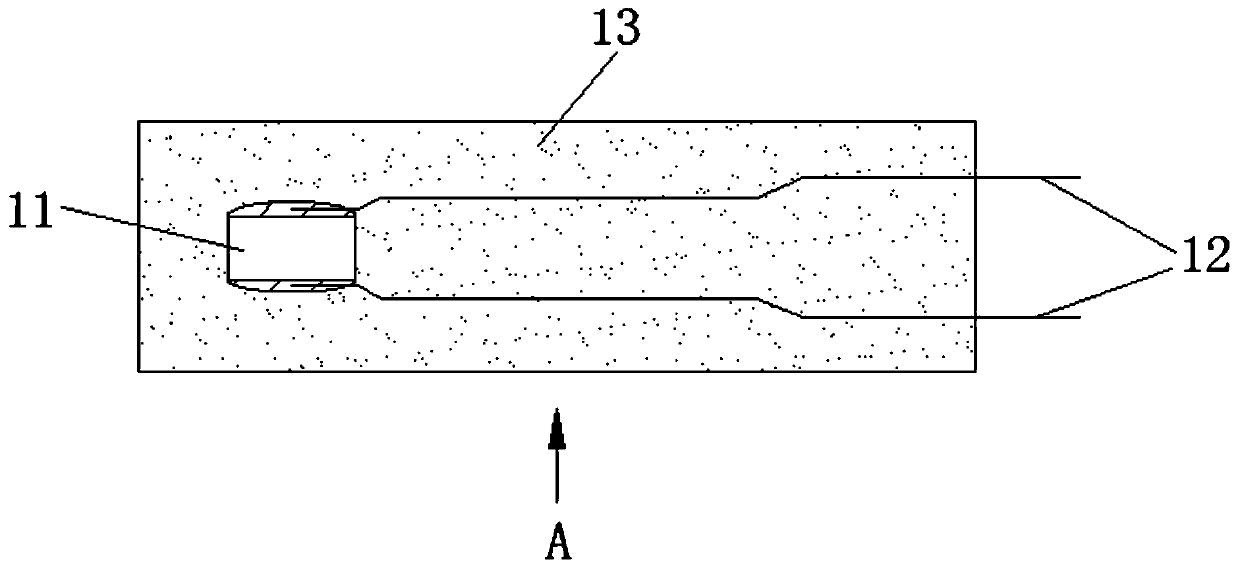

Slice-type temperature sensor and preparation method therefor

ActiveCN108106750AAvoid it happening againAvoid negative effectsThermometer detailsThermometers using electric/magnetic elementsMechanical impactThermistor

The invention relates to a slice-type temperature sensor, and the temperature sensor comprises a substrate film, a thermistor chip, a positive circuit layer, a negative circuit layer and a capping film, wherein the substrate film is provided with a chip slot, and the thermistor chip is disposed in the chip slot. The positive circuit layer and the negative circuit layer are disposed on the substrate film and are not in contact with each other, and are respectively connected with positive and negative electrodes of the thermistor chip. The capping film is attached to the substrate film, therebyenabling the thermistor chip, the positive circuit layer and the negative circuit layer to be packaged. The invention also relates to a preparation method for a thermistor with a substrate. The temperature sensor provided by the invention is good in sealing performance, is reliable in performances, is high in protection strength, is resistant to mechanical impact, is resistant to bending, is not liable to be damaged, is long in service life, and is easy to prepare.

Owner:肇庆爱晟传感器技术有限公司

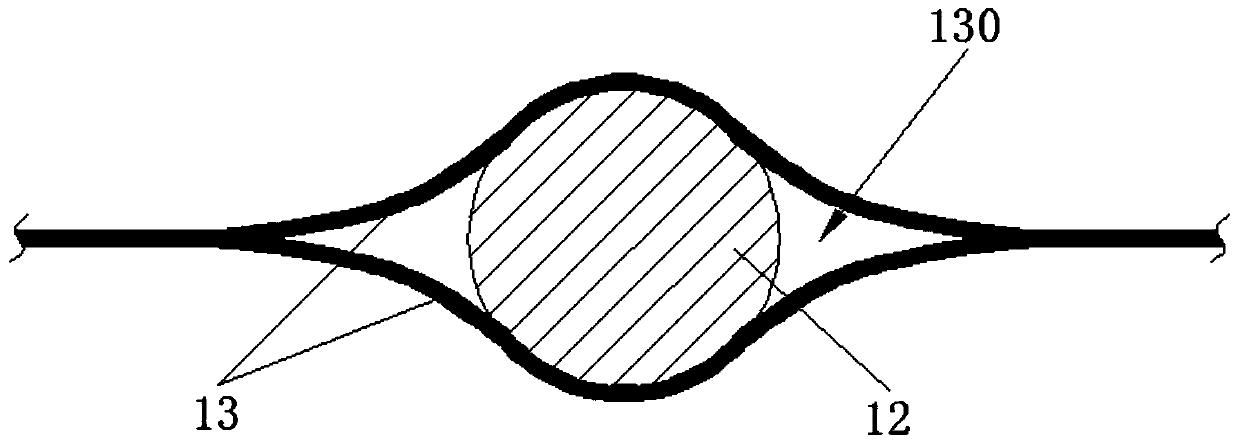

Heat insulation-type cable

InactiveCN105913945AAvoid breakingPlay a protective effectClimate change adaptationPower cables with screens/conductive layersFiberInsulation layer

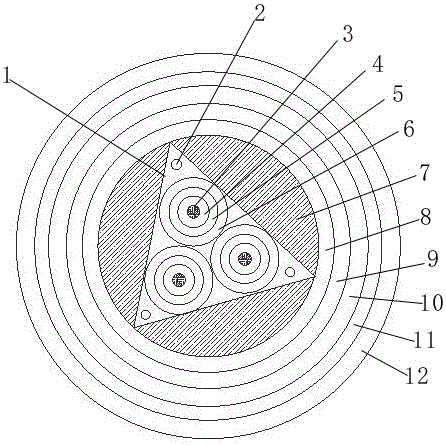

The invention discloses a heat insulation-type cable, which comprises a cable core. An inner sheath and an outer sheath are extruded outside the cable core; the cable core is composed of a triangular support, three insulated wire cores mutually extruded inside the triangular support and ground wires located at three vertex angles of the triangular support; a ceramic fiber is arranged between the triangular support and the inner sheath; and an elastic buffer layer with a thickness of 2 to 5 mm, a metal armored layer with a thickness of 2 to 4 mm and a rock wool heat insulation layer with a thickness of 3 to 6 mm are sequentially arranged between the inner sheath and the outer sheath. Through arranging multiple heat insulation structures, the cable of the invention has the advantages of good heat insulation performance, high temperature resistance, good heat stability, low heat conductivity and the like.

Owner:WUXI NEW SUNSHINE CABLE

Performance testing of anti-pressure oil well anti-seepage well cementation briquette prepared from ceramic fiber and gangue

InactiveCN108007821ALow densityRelieve pressurePreparing sample for investigationPermeability/surface area analysisFiberMicrofine cement

The invention provides a performance testing of anti-pressure oil well anti-seepage well cementation briquette prepared from ceramic fiber and gangue. The performance testing comprises the following steps: preparing the ingredients of the anti-seepage well cementation briquette: 40wt% to 50wt% of G-level oil well cement, 10wt% to 15wt% of superfine cement, 25wt% to 35wt% of gangue close-hole hollow ceramic microbeads with the particle sizes of 50 to 350 microns, 5wt% to 7wt% of coal ash with the ignition loss of 1.1%, 1.5wt% to 2wt% of calcium oxide with the purity of 99.9%, 0.5wt% to 1.0wt% of sodium sulfate, 1wt% to 5wt% of silica powder and 1.0wt% to 2wt% of alumina powder for sampling to obtain a mixture, wherein the sum of the weight percentages of the components is 100%; and blendingthe obtained mixture with the water cement ratio being 0.5 to 0.7 for size mixing to prepare a sizing agent, then adding a foaming agent with the total weight of 0.2% to 0.5% of that of the mixture,then adding ceramic fiber, graphite microbeads and expansion resin in proportion, and stirring uniformly to carry out anti-seepage performance testing.

Owner:ZIBO VOCATIONAL INST

Architectural insulated board and preparation method thereof

The invention discloses an architectural insulated board and belongs to the technical field of building materials. The architectural insulated board comprises the following raw materials in parts by weight: 6-8 parts of polyvinyl acetate emulsion, 1-2 parts of butyl rubber, 5-10 parts of ceramic fibers, 4-8 parts of steel fibers, 15-20 parts of glass wool, 5-7 parts of expanded vermiculite, 5-7 parts of sepiolite powder, 12-15 parts of diatomite, 7-9 parts of talcum powder, 2-4 parts of asphalt, 1-3 parts of sodium silicate, 0.1-0.2 part of a light stabilizer, 0.1-1 part of a water reducing agent and 1-2 parts of a curing agent. The invention further discloses a preparation method of the architectural insulated board. The architectural insulated board disclosed by the invention is simple in preparation and high in strength and has excellent thermal insulation capacity.

Owner:温州月煌科技有限公司

Preparation method of novel wall building material

The invention provides a preparation method of novel wall building material The method comprises the following steps: a) taking straw, a clay material, calcium carbonate, blast furnace slag, feldsparpowder and calcium borate and respectively drying the materials, and performing ball milling; b) taking modified nanocrystalline fiber, modified polystyrene, hydroxypropyl methyl cellulose and butyl rubber, mixing the materials for banburying, after banburying, adding water for stirring, adding a chitosan-containing acetic acid solution and a promoter, placing the materials in a high mixing machine, stirring the materials to obtain a mixture 1; c) mixing mixed powder, the mixture 1 and ammonium polyphosphate, adding water for stirring the materials, and adding an anti-oxidant and a fire retardant drop by drop until addition is completed to obtain a mixture 2; and d) introducing the mixture 2 in a die, performing vibration under room temperature and normal pressure, uniformly dispersing thematerials to form a blank material, drying the blank material, and performing steps of demoulding, maintenance and solidification. The prepared material has the advantages of low heat conduction coefficient, high flame retardation performance, and good stability.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

Electric arc furnace lid and preparation method thereof

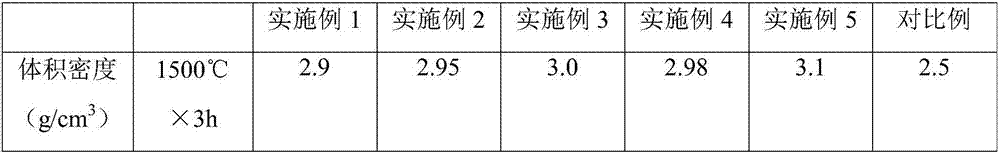

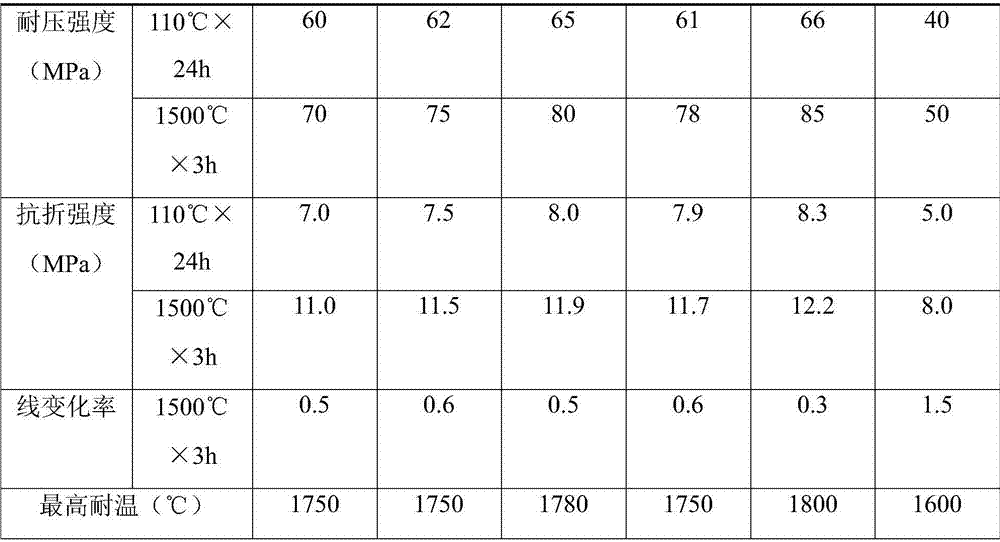

ActiveCN107285752AHigh hardnessGood weather resistanceProcess efficiency improvementElectric furnaceMetallic aluminumElectric arc furnace

The present invention discloses an electric arc furnace lid, which comprises, by weight, 5-10 parts of metallic aluminum powder, 10-14 parts of stainless steel fiber, 7-10 parts of chromium oxide green, 0.5-1.0 part of sodium tripolyphosphate, 0.1-0.3 part of sodium hexametaphosphate, 65-75 parts of 8-15 mm 85 bauxite, 70-75 parts of 1-3 mm 85 bauxite, 57-65 parts of 3-8 mm 70 sintered mullite, 75-85 parts of white fused alumina with a particle size of less than 1 mm, and the like. The preparation method comprises: mixing various components of the formula, uniformly stirring, adding water, uniformly stirring, carrying out vibration molding, and finally drying to prepare the electric arc furnace lid. According to the present invention, the prepared electric arc furnace lid has advantages of high bulk density, good compressive strength, good flexural strength and good erosion resistance, can provide advantages of good corrosion resistance and cracking resistance during the use, and further has advantages of significantly improved service lifer and effectively reduced raw material consumption.

Owner:SICHUAN HEYI ELECTRIC FURNACE TECH CO LTD

High-strength ceramic fiber filter filter-paper

InactiveCN106567285AReasonable formulaHigh strengthPaper coatingReinforcing agents additionEmulsionAdhesive

The invention discloses high-strength ceramic fiber filter filter-paper. The high-strength ceramic fiber filter filter-paper is prepared from, by weight, 60-80 parts of straw pulp, 1-2 parts of ceramic fibers, 8-10 parts of aluminum silicate fibers, 1-2 parts of sodium tripolyphosphate, 1-2 parts of an antioxidant DSTP, 0.2-0.8 part of erucyl amide, 0.5-0.6 part of zinc borate, 10-18 parts of tencel fibers, 1-2 parts of polyvinyl acetate emulsion adhesive, 1-2 parts of sodium hexametaphosphate, 1-2 parts of folium artemisiae argyi, 1-2 parts of folium isatidis, 0.1-0.2 part of melamine, 15-20 parts of styrene-acrylic emulsion, 2-4 parts of orange peels, 4-8 parts of durian shells, 5-6 parts of sugarcane peels, 1-2 parts of coconut fibers, 3-5 parts of sawdust, 0.02-0.05 part of citric acid, 0.1-0.2 part of zinc nitrate and 0.2-0.5 part of silver nitrate.

Owner:BENGBU FENGCHI FILTER

Method for molding low-temperature-resistant high-strength polyethylene pipe applied to water supply

InactiveCN108943654AHigh strengthImprove low temperature resistanceTubular articlesPolyolefinPolyvinyl chloride

The invention provides a method for molding a low-temperature-resistant high-strength polyethylene pipe applied to water supply. The method comprises the following steps: (1) preparing raw materials consisting of, by weight, 100 parts of polyethylene, 20 to 30 parts of polyolefin, 10 to 20 parts of CPVC resin, 1 to 5 parts of polyvinyl chloride resin, 1 to 3 parts of barium laurate, 1 to 2 parts of ACR-201, 5 to 10 parts of titanium dioxide, 1 to 3 parts of talcum powder and 1 to 2 parts of an anti-oxidant; (2) subjecting polyethylene, polyolefin, CPVC resin and polyvinyl chloride resin to vacuum-pumping; (3) adding polyethylene and polyolefin into a mixing pot at a low rotation speed, starting high-speed mixing, adding the CPVC resin polyvinyl chloride resin into the mixing pot at 70 DEGC, adding barium laurate at 80 DEG C, adding ACR-201, titanium dioxide and talcum powder at 110 DEG C; and (4) carrying out extruding via a conical twin-screw extruder so as to form a pipe, and afterextrusion, carrying out vacuum sizing and cooling so as to obtain the low-temperature-resistant high-strength polyethylene pipe. The method of the invention has the advantages of high extrusion speedand high production efficiency; and the prepared pipe is remarkably improved in strength, low temperature resistance and other performance.

Owner:胡建芳

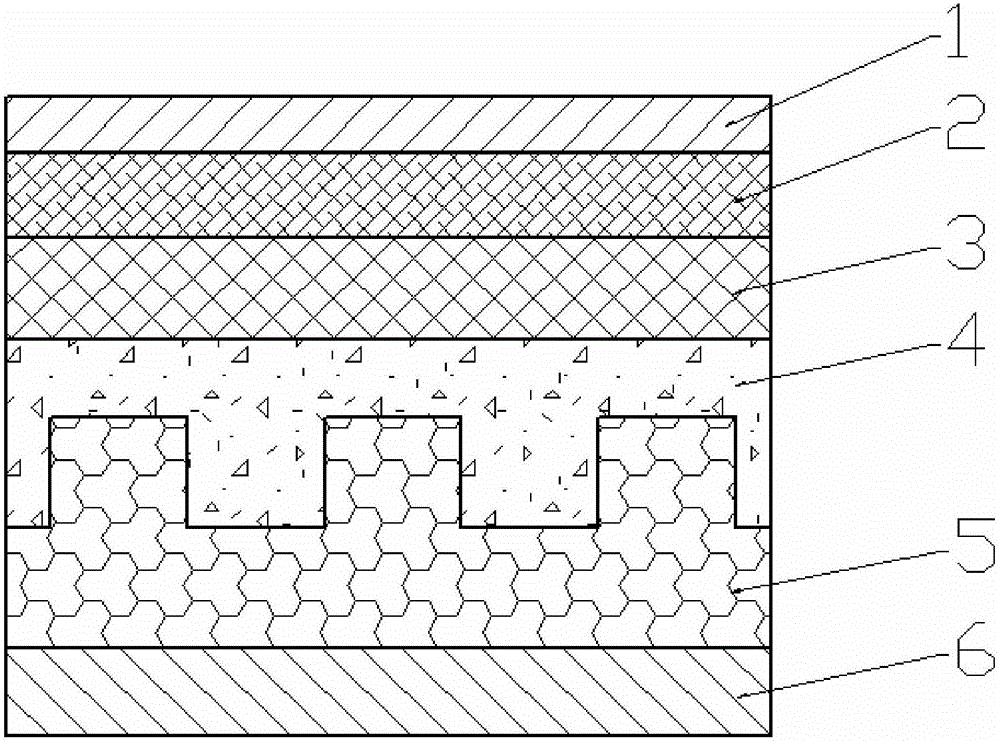

Tough and flexible PVC composite floor with UV protective layer structure

The invention discloses a tough and flexible PVC composite floor with a UV protective layer structure. The tough and flexible PVC composite floor comprises a PVC layer and a base gel layer coated on the lower surface of the PVC layer. The upper surface of the PVC layer is provided with an elastic layer. A printing layer is laid on the elastic layer. The upper surface of the printing layer is sequentially provided with a reinforcing layer and a UV protective layer from bottom to top. The upper surface of the PVC layer is provided with concave-convex grooves. The lower surface of the elastic layer is provided with concave-convex grooves corresponding to the upper surface of the PVC layer. The attaching faces of the PVC layer and the elastic layer are meshed with each other through the concave-convex grooves. The tough and flexible PVC composite floor with the UV protective layer structure is good in anti-skid property, high in surface stain resistance, resistant to corrosion, resistant to static electricity, free of burning, resistant to abrasion, resistant to aging, soft in texture and convenient to lay and mount.

Owner:JIANGSU RUISHENG NEW MATERIALS CO LTD

Ceramic fiber strengthened polyurethane foam plastic and preparation method thereof

The invention discloses a ceramic fiber strengthened polyurethane foam plastic and a preparation method thereof, and belongs to the technical field of materials. The foam plastic is composed of the following raw materials in parts by weight: 65 to 80 parts of polyurethane emulsion, 10 to 20 parts of ceramic fiber, 2 to 5 parts of tert-butyl peroxypivalate, 3 to 8 parts of tritolyl phosphate, 3 to 8 parts of polyamide, 3 to 7 parts of sodium borate, and 8 to 18 parts of sodium silicate. The preparation method comprises the following steps: (1) weighing; (2) putting the raw materials into an injection moulding machine; (3) cooling and moulding. The heat conductivity of the provided ceramic fiber strengthened polyurethane foam plastic is further reduced; the provided foam plastic has a good temperature-resistant and fireproof performance, at the same time the mechanical properties, corrosion resistant property and weatherability of the foam plastic are excellent, and thus the foam plastic is an ideal material.

Owner:SUZHOU POLYMER NEW MATERIALS TECH

Thermal insulation building material and preparation method thereof

InactiveCN108285635ALow thermal conductivityLarge heat storage coefficientCalcium silicateCrack resistance

The invention discloses a thermal insulation building material and preparation method thereof, and relates to the technical field of building materials. The building material is prepared from, by weight, 15-20 parts of epoxy resin, 14-18 parts of phenolic resin, 16-21 parts of polyurethane, 6-12 parts of vermiculite, 8-15 parts of perlite, 7-15 parts of volcanic ash, 9-14 parts of asbestos, 15-18parts of calcium silicate, 3-7 parts of calcium fluosilicate, 4-8 parts of nanometer aluminium oxide, 5-9 parts of nanosilicon dioxide, 4-8 parts of liquid water glass, 4-7 parts of ceramic fiber, 3-6parts of zinc oxide, 2-4 parts of carbon black, 3-5 parts of fire retardant, 2.5-4.5 parts of antioxygen, 1.2-2.1 parts of defoaming agent, 3-5 parts of photo-thermal stabilizer and 2-4 parts of curing agent; the thermal insulation building material is small in heat conductivity coefficient, large in heat storage coefficient, better in the thermal insulation performance, large in antiflaming coefficient, high in safety performance, good in cracking resistance, shock resistance and ageing resistance, long in service life, simple in the preparation method, low in raw material price, and betterin market application prospects.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Preparation method of high-toughness cyanate impeller cover plate

InactiveCN108610468AImproved mechanical properties with reduced wear resistanceImprove mechanical propertiesImpellerSurface cleaning

The invention relates to a preparation method of a high-toughness cyanate impeller cover plate. The preparation method comprises the following steps: firstly, preparing a casting mixture raw materialsaccording to mass percent; secondly, cleaning a die and smearing a releasing agent; thirdly, preparing a prepolymer; fourthly, preparing a cyanate prepolymer; fifthly, heating the die treated in thesecond step, enabling the temperature of the die to be kept at 60 to 70 DEG C, and keeping sprues at two ends of the die in a horizontal direction; sixthly, obtaining a casting mixture; seventhly, moulding by casting; eighthly, carrying out sulfidizing treatment; ninthly, taking a tube sulfidized in the eighth step and cleaning the inner and outer surfaces of the tube to obtain the high-toughnesscyanate impeller cover plate. According to the preparation method disclosed by the invention, wear resistance of the impeller cover plate is improved, the toughness of the impeller cover plate is enhanced, and the conditions that fracturing, breaking and the like easily occur when mechanical properties are reduced due to long-time use and materials are screened and classified are effectively prevented.

Owner:胡建芳

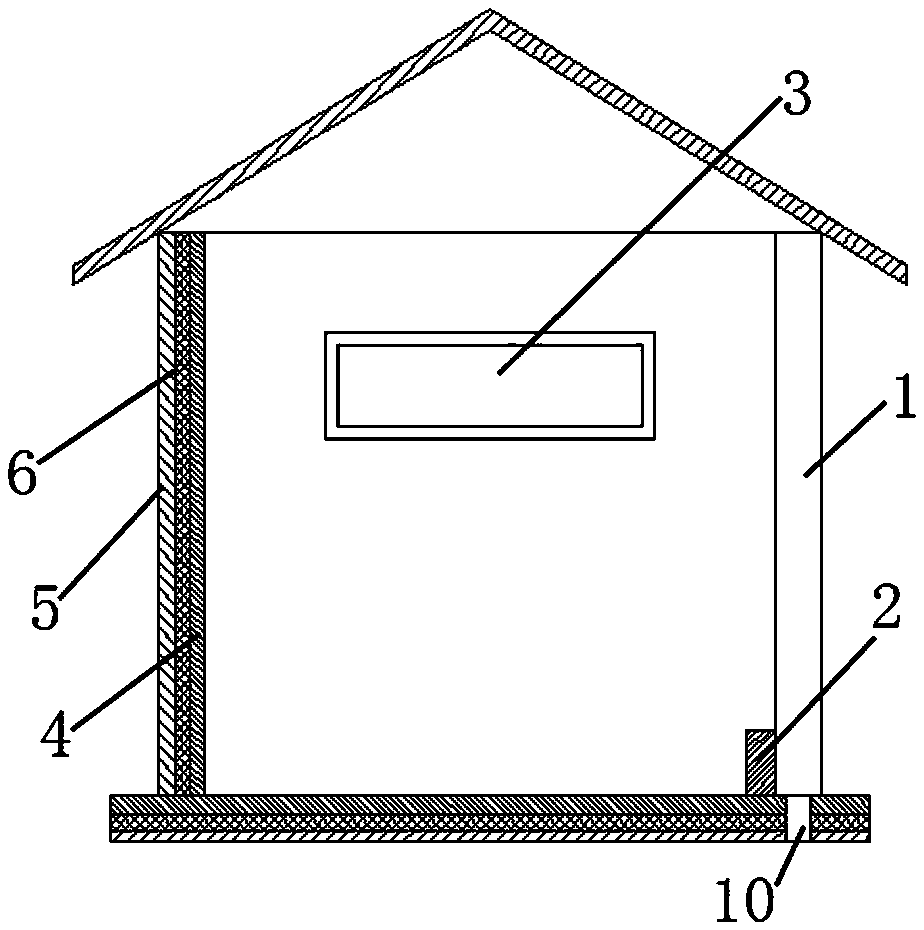

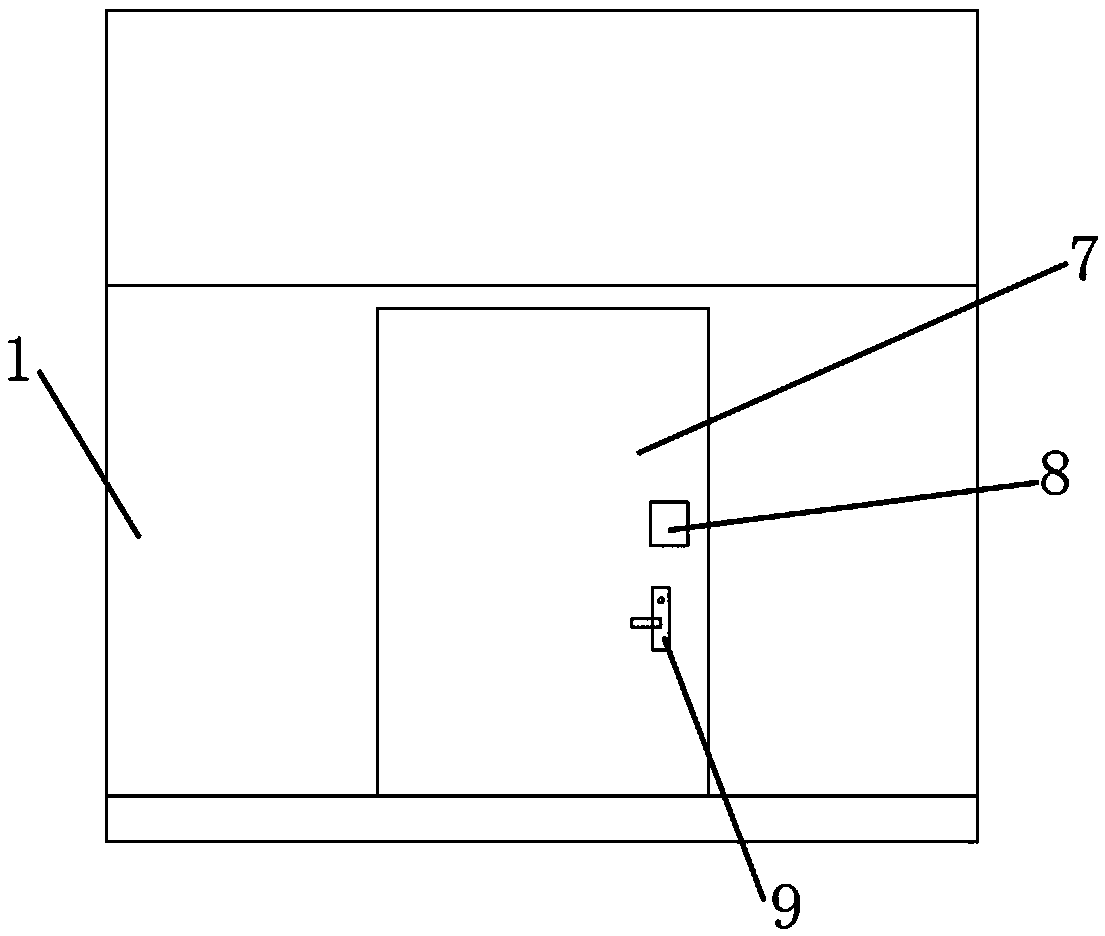

Fire-resistant electrical cabinet

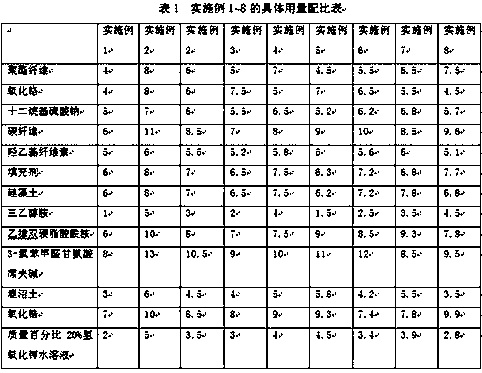

InactiveCN108123373ASmaller specific heatResistant to mechanical shockSubstation/switching arrangement casingsPolyesterFiber

The invention relates to a fire-resistant electrical cabinet, which comprises a cabinet body and a cabinet door, wherein the cabinet door is hinged on the cabinet body, the cabinet body is composed ofan outer shell, an inner shell and a fire-resistant layer, the fire-resistant layer is arranged between the outer shell and the inner shell, the outer shell and the inner shell are made of aluminum alloy base plates, the fire-resistant layer comprises fire-resistant ceramic fibers and thermosetting resin, the fire-resistant ceramic fibers comprises 4-8 parts of polyester fiber, 4-8 parts of chromium oxide, 5-7 parts of sodium dodecyl sulfate, 6-11 parts of carbon fibers, 5-6 parts of hydroxyethyl cellulose, 6-8 parts of filler, 6-8 parts of diatomite, 1-5 parts of triethanolamine, 6-10 partsof ethylene bis stearamide, 8-13 parts of 3-chlorobenzaldehyde glycine Schiff base, 3-6 parts of Kanuma mud, 7-10 parts of zirconia, and 2-5 parts of a potassium hydroxide solution being 20% in mass concentration. The fire-resistant electrical cabinet has the advantages of high strength, impact resistance, corrosion resistance and thermal insulation performance, and good fireproof effect.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ANYANG POWER SUPPLY

Preparation method of insulating material for pipelines

The invention belongs to the technical field of insulating material manufacturing and provides an insulating material for pipelines and a preparation method. The insulating material for pipelines is prepared from, by weight, 50-75 parts of silicon dioxide particles with the average particle size pf 60-70 nm, 15-23 parts of hollow ceramic fiber, 2-9 parts of attapulgite clay particles and 11-15 parts of hollow glass fiber. The prepared insulating material has good insulating properties and high strength.

Owner:HEFEI ZHENXUN LOW TEMPERATURE TECH CO LTD

High-temperature insulation sealing strip

The invention discloses a high-temperature insulation sealing strip. The high-temperature insulation sealing strip comprises a plurality of insulation chains with clamping openings, and a plurality of ceramic fiber blocks. The insulation chains are connected in an end-to-end hinged mode, and one ceramic fiber block is connected inside the clamping opening of each insulation chain in a clamping mode. The ceramic fiber blocks are connected to the insulation chains in a clamping mode, and the insulation chains are connected in the end-to-end hinged mode for forming the high-temperature insulation sealing strip. The high-temperature insulation sealing strip is simple in structure, convenient to manufacture and maintain, capable of meeting the requirement for high-temperature insulating and sealing, wide in use range and low in cost.

Owner:李留华

Novel polyvinyl chloride (PVC)+ medium composite (polypropylene) PP foamed sheet material

InactiveCN103386803AResistant to mechanical shockHigh temperature resistanceLamination ancillary operationsLaminationPolypropylenePolymer chemistry

The invention relates to a novel polyvinyl chloride (PVC)+ medium composite (polypropylene) PP foamed sheet material. The upper part of a multi-layer composite sheet material is provided with an upper press polishing wheel, and the lower part of the multi-layer composite sheet material is provided with a lower press polishing wheel; a substrate plate and a substrate-plate rolling wheel are arranged at entering ends of the upper press polishing wheel and the lower press polishing wheel; a two-side ultrasonic surface roughening device is arranged at a position for passing through the substrate plate; ultrasonic surface roughening pretreatment of the two sides of the substrate plate is carried out, and then the substrate plate passes through extinction ABS extruded by an extinction ABS extruder and PP foaming material extruded by a PP foaming extruder, and is extruded for molding, by the upper press polishing wheel and the lower press polishing wheel, to obtain the multi-layer composite sheet material. The ultrasonic surface roughening device is added for surface roughening before the substrate plate enters, so that the multi-layer composite sheet material is more resistant to mechanical impact, high temperature and low temperature, and no layer rising phenomenon may occur.

Owner:CHONGQING JUWENG PLASTIC MFG

Building adhesive for steel structure and preparation method of building adhesive

InactiveCN107254267AImprove heat resistanceImprove cold resistanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesFiberAdhesive

The invention discloses a building adhesive for a steel structure and belongs to the technical field of adhesives. The building adhesive comprises the following raw materials in parts by weight: 15-18 parts of silicate, 4-6 parts of starch, 15-17 parts of fluorinated silicone rubber, 70-80 parts of vinyl acetate resin, 7-9 parts of ceramic fiber, 12-16 parts of aluminum powder, 4-6 parts of titanium dioxide, 3-5 parts of molybdenum disulfide, 1-2 parts of a curing agent, 2-3 parts of an accelerant, 3-4 parts of an anti-rusting agent, 0.5-1 part of an anti-mold agent and 0.5-0.8 part of an anti-aging agent. The invention further discloses a preparation method of power equipment protection paint. The building adhesive is good in adhesion property, high in strength, good in rusting resistance, high temperature resistance and corrosion resistance and long in service life.

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

A kind of sheet type temperature sensor and its preparation method

ActiveCN108106750BImprove sealingImprove performanceThermometer detailsThermometers using electric/magnetic elementsThin membraneEngineering

The invention relates to a sheet-type temperature sensor. The sheet-type temperature sensor includes a base film, a thermistor chip, a positive circuit layer, a negative circuit layer, and a capping film. The base film is provided with a chip groove, and the thermistor The chip is arranged in the chip groove, the positive electrode circuit layer and the negative electrode circuit layer are arranged on the base film without contacting each other, and are respectively connected to the positive and negative electrodes of the thermistor chip, and the capping film and The base films are attached to each other to package the thermistor chip, the positive circuit layer and the negative circuit layer. The present invention also relates to a preparation method of the above-mentioned thermistor with a base. The sheet-type temperature sensor of the present invention has the advantages of good sealing, reliable performance, high protection strength, resistance to mechanical impact, resistance to bending, not easily damaged, long service life and simple preparation.

Owner:肇庆爱晟传感器技术有限公司

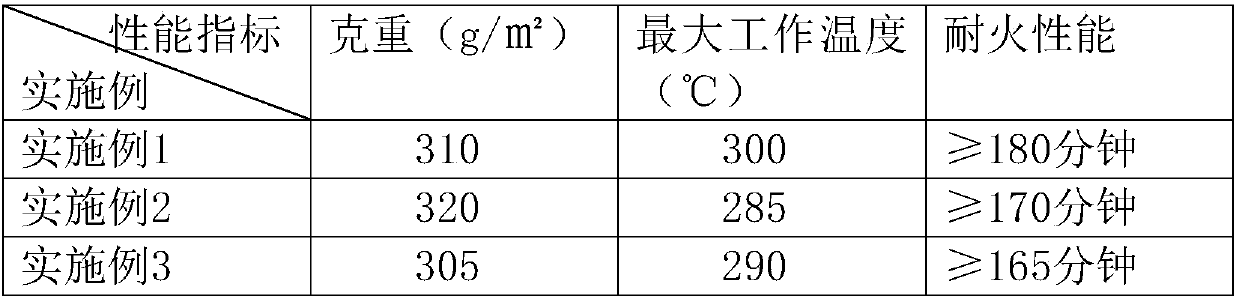

A kind of preparation method of ptfe and pps composite high temperature resistant filter material

ActiveCN112359490BLarge discrete finenessGood acid and alkali resistanceLayered productsWoven fabricsBonding processFilter material

The invention belongs to the technical field of high-temperature-resistant filter materials, in particular to a method for preparing a composite high-temperature-resistant filter material of PTFE and PPS, step 1, raw material preparation. The preparation method of the PTFE and PPS composite high-temperature-resistant filter material, by setting PTFE fibers, ceramic fibers, PPS fibers and graphene fibers, the PTFE fibers have large discrete fineness, good acid and alkali resistance, and the addition of graphene fibers makes the filter The material has the characteristics of high electron mobility, high thermal conductivity, good elasticity and stiffness. The ceramic fiber has the characteristics of light weight, high temperature resistance, good thermal stability, low thermal conductivity, small specific heat and mechanical vibration resistance. , has the characteristics of opening the surface PTFE fiber, entanglement effect of PTFE fiber and PPS fiber is good, the thickness of the filter material is small, and the tensile breaking strength of the filter material is high, thus solving the problem of the existing film-coated filter material The bonding process itself and the dragging during transportation make the PTFE membrane easy to peel off and break.

Owner:安徽中电环保材料股份有限公司

Melt-blow fireproof composite fiber non-woven fabric and preparation method thereof

InactiveCN107685511AResistant to burningHigh temperature resistantLaminationLamination apparatusLow speedPlant fibre

The invention discloses melt-blow fireproof composite fiber non-woven fabric and a preparation method thereof. The melt-blow fireproof composite fiber non-woven fabric is prepared from the following components in parts by mass: 20 to 40 parts of plant fiber, 30 to 50 parts of fireproof fiber and 15 to 25 parts of silicon rubber. The preparation method comprises the following steps: opening and scutching the plant fiber and the fireproof fiber for at least two times; lapping the opened and scutched plant fiber and fireproof fiber by a lapping machine and carding the opened and scutched plant fiber and fireproof fiber by a carding machine; performing hot air adhesion, spraying the adhered fiber to a receiving device which performs high-speed transverse motion and low-speed longitudinal motion, and performing air cooling to form fiber cloth; spreading the obtained fiber cloth, calendaring the silicon rubber on the fiber cloth uniformly by a calendaring machine to prepare the product. Thepreparation method has the advantages of high high-temperature resistance, excellent fireproof property and the like.

Owner:ANHUI YICAINI FIBER MATERIALS TECH

Test for performance of enhanced ceramic fiber cordierite-prepared oil well anti-water-seepage well cementing test block

InactiveCN107941580ALow densityRelieve pressureFlow propertiesPreparing sample for investigationMicrofine cementFiber

The invention provides a test for performance of an enhanced ceramic fiber cordierite-prepared oil well anti-water-seepage well cementing test block, wherein the test includes the following steps: preparing materials of an anti-water-seepage well cementing test block: taking 40-50 wt% of G-grade oil well cement, 10-15 wt% of superfine cement, 25-35 wt% of cordierite closed-pore hollow ceramic microbeads with the particle diameter of 50-250 [mu]m, 5-7 wt% of fly ash with loss on ignition of 1.1%, 1.5-2 wt% of calcium oxide with the purity of 99.9%, 0.5-1.0 wt% of sodium sulfate, 1-5 wt% of silica fume and 1.0-2 wt% of an aluminum oxide powder, to obtain a mixture, wherein the sum of the weight percentages of the components is 100%; and slurry-adjusting the obtained mixture with the water-cement ratio of 0.5-0.7 to prepare a slurry, then adding a foaming agent with the amount 0.2-0.5% of the total weight of the mixture, then adding ceramic fibers, graphite microbeads and expansion resinin proportion, stirring evenly, and carrying out anti-water-seepage performance test.

Owner:ZIBO VOCATIONAL INST

Method for preparing high-toughness cyanate ester seamless tube

The invention relates to a method for preparing a high-toughness cyanate ester seamless tube. The method comprises the following steps: 1) casting mixture raw materials according to mass percentages;2) preparing a steel tube; 3) preparing a prepolymer; 4) preparing a cyanate ester prepolymer; 5) mounting the steel tube obtained in the step 2) on a centrifuge with a mold, maintaining casting holesin two ends in a horizontal direction, heating the steel tube, and keeping the temperature at 60-70 DEG C; 6) preparing a cast mixture; 7) carrying out casting molding; 8) vulcanizing the steel tube;9) carrying out inner / outer surface cleaning treatment on the vulcanized steel tube, so as to obtain the cyanate ester seamless tube, wherein the cyanate ester seamless tube is stored in warehouses after inspection qualification. By adopting the production process provided by the invention, the wearing resistance of the tube is improved, the toughness of the tube is improved, and tube layering can be effectively prevented.

Owner:胡建芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com