Heat insulation-type cable

A cable and cable core technology, applied in the field of thermal insulation cables, can solve the problems of easy loosening of the cable core, affecting the current carrying capacity of the cable, and the inability of the cable to work, achieving good thermal stability, light weight, specific heat and mechanical vibration resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

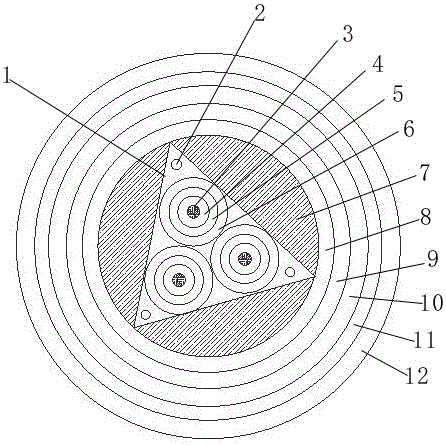

[0015] Such as figure 1 As shown, an insulated cable according to the present invention includes a cable core, and an inner sheath 8 and an outer sheath 12 are extruded outside the core; the cable core is formed by a triangular bracket 1, three extruded in each other The insulated wire core in the triangular bracket and the ground wire 2 located at the three top corners of the triangular bracket 1 are formed; the insulated wire core is composed of an aluminum conductor 3, an insulating layer 4 and an insulating shielding layer 5 that are sequentially extruded outside the aluminum conductor And a silicone fireproof sleeve 6 arranged outside the insulating shielding layer; ceramic fiber filaments 7 are arranged between the triangular bracket 1 and the inner sheath 8, which not only makes the cable light weight, high temperature resistance, good thermal stability, and thermal conductivity Low, low specific heat and resistance to mechanical vibration, it also has the ability to res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com