Electric arc furnace lid and preparation method thereof

A technology of electric arc furnace and furnace cover, which is applied in the direction of electric furnace, furnace, furnace type, etc., can solve the problems of short service life and poor high temperature resistance, and achieve the effect of long service life, strong high temperature resistance and good compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

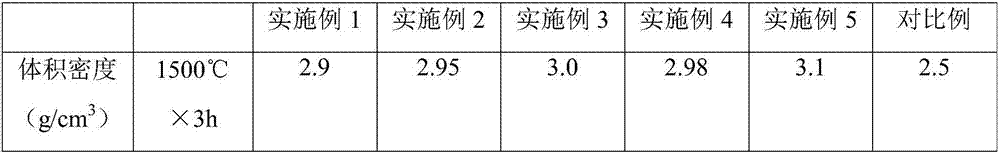

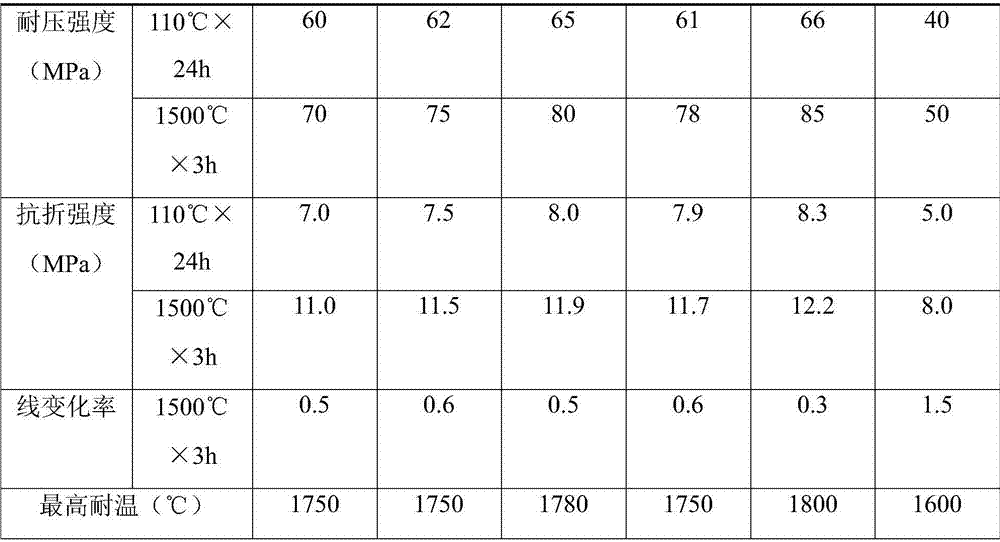

Examples

Embodiment 1

[0020] An electric arc furnace cover, comprising the following components in parts by weight: 5 parts of metal aluminum powder, 10 parts of stainless steel fiber, 7 parts of chromium oxide green, 0.5 part of sodium tripolyphosphate, 0.1 part of sodium hexametaphosphate, 8-15mm 65 parts of 85 bauxite, 70 parts of 85 bauxite of 1-3mm, 57 parts of 70 sintered mullite of 3-8mm, 75 parts of white corundum with particle size less than 1mm, 35 parts of F220 white corundum, and F325 white 30 parts of corundum, 15 parts of sintered spinel of F220, 25 parts of 71 aluminate cement and 8 parts of microsilica powder; the purity of microsilica powder is 92%.

[0021] The preparation method of the above-mentioned electric arc furnace cover includes: mixing each component in the formula, stirring evenly, then adding water and stirring evenly, then vibrating and molding, and finally drying to obtain the prepared.

Embodiment 2

[0023] An electric arc furnace cover, comprising the following components in parts by weight: 10 parts of metal aluminum powder, 14 parts of stainless steel fiber, 10 parts of chromium oxide green, 1.0 part of sodium tripolyphosphate, 0.3 part of sodium hexametaphosphate, 8-15mm 75 parts of 85 bauxite, 75 parts of 85 bauxite of 1-3mm, 65 parts of 70 sintered mullite of 3-8mm, 85 parts of white corundum with particle size less than 1mm, 45 parts of F220 white corundum, and F325 white 40 parts of corundum, 25 parts of sintered spinel of F220, 35 parts of 71 aluminate cement and 12 parts of microsilica powder; the purity of microsilica powder is 92%.

[0024] The preparation method of the above-mentioned electric arc furnace cover includes: mixing each component in the formula, stirring evenly, then adding water and stirring evenly, then vibrating and molding, and finally drying to obtain the prepared.

Embodiment 3

[0026] An electric arc furnace cover, comprising the following components in parts by weight: 6 parts of metal aluminum powder, 10 parts of stainless steel fiber, 7 parts of chromium oxide green, 0.5 part of sodium tripolyphosphate, 0.1 part of sodium hexametaphosphate, 8-15mm 68 parts of 85 bauxite, 70 parts of 85 bauxite of 1-3mm, 58 parts of 70 sintered mullite of 3-8mm, 78 parts of white corundum with particle size less than 1mm, 38 parts of F220 white corundum, and F325 white 33 parts of corundum, 18 parts of sintered spinel of F220, 28 parts of 71 aluminate cement and 8 parts of microsilica powder; the purity of microsilica powder is 92%.

[0027] The preparation method of the above-mentioned electric arc furnace cover includes: mixing each component in the formula, stirring evenly, then adding water and stirring evenly, then vibrating and molding, and finally drying to obtain the prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com