A kind of sheet type temperature sensor and its preparation method

A temperature sensor and sheet technology, applied in thermometers, thermometer parts, thermometers with direct heat-sensitive electric/magnetic elements, etc., can solve the problems of reduced product reliability, poor performance reliability, and poor use effects, etc. , to achieve simple processing, low cost, and overcome negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

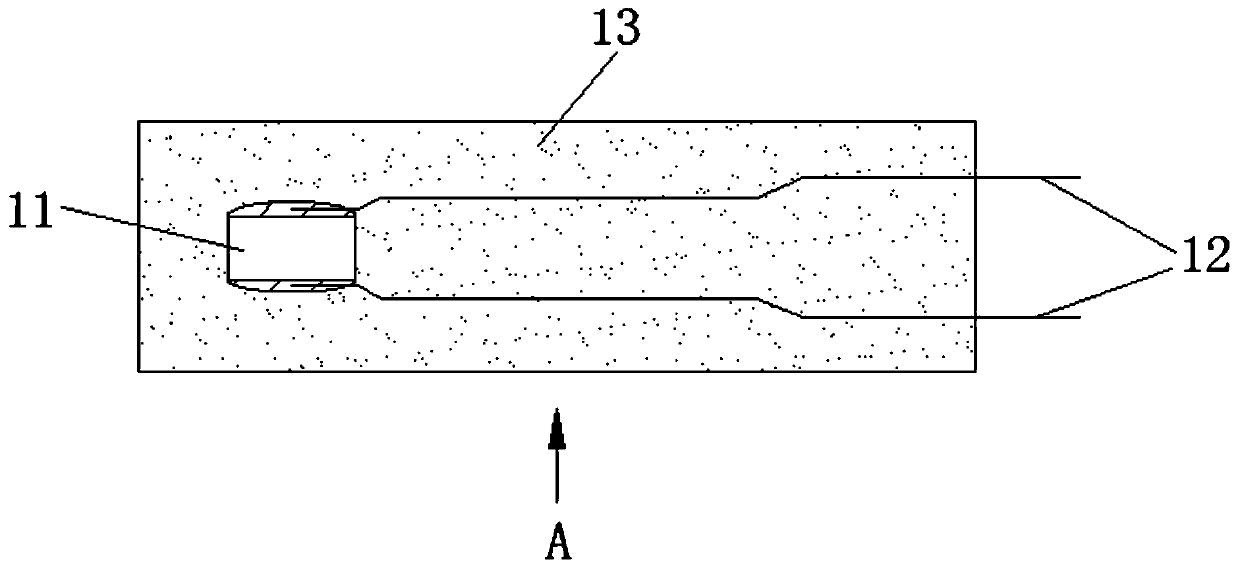

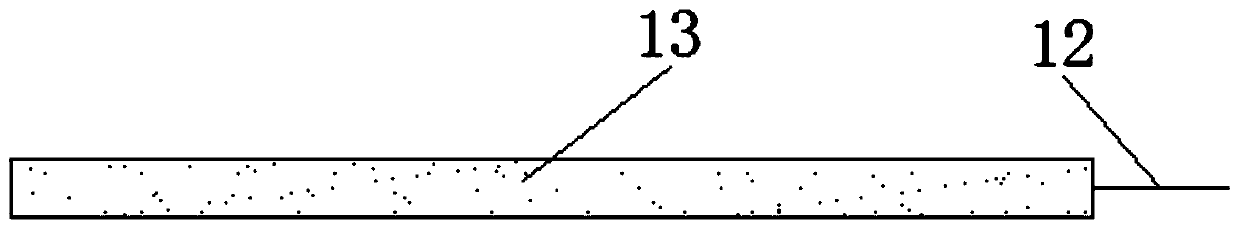

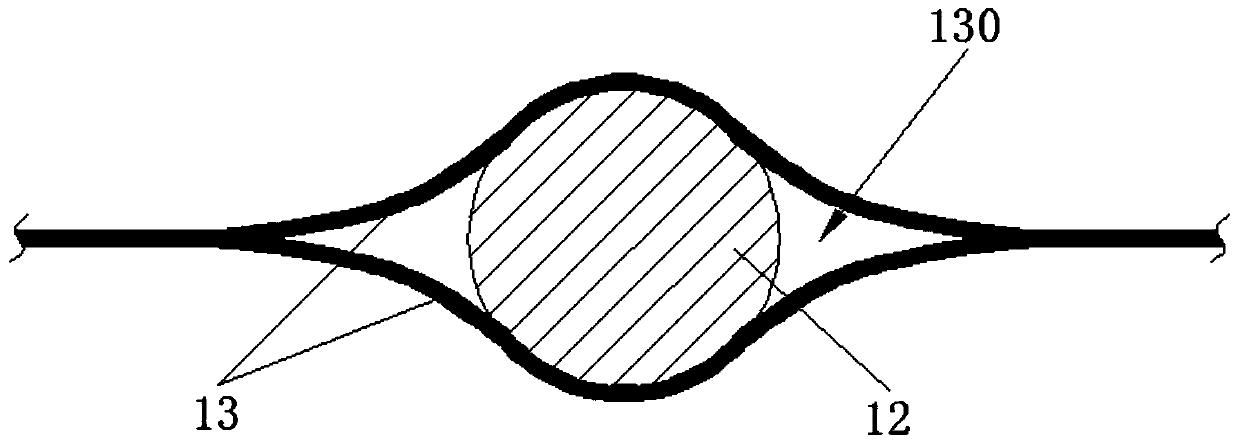

[0033] see Figure 4 with Figure 5 , Figure 4 It is the structural diagram of the sheet type temperature sensor of the present invention, Figure 5 for Figure 4 The cross-sectional view of the B-B direction in the middle. The sheet-type temperature sensor includes a base film 21 , a thermistor chip 22 , a positive circuit layer 23 , a negative circuit layer 24 , a protective hard ring 25 and a capping film 26 . The positive circuit layer 23 and the negative circuit layer 24 are respectively connected to the positive and negative poles of the thermistor chip 22, the protective hard ring 25 is arranged on the periphery of the thermistor chip 22, and the base film 21 and the capping film 26 are connected to each other. Bonding, the thermistor chip 22, the positive circuit layer 23, the negative circuit layer 24 and the protective hard ring 25 are packaged.

[0034] Specifically, the base film 21 is provided with a chip groove 211 and an anode groove 212 communicating with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com