Tough and flexible PVC composite floor with UV protective layer structure

A composite floor and protective layer technology, applied in building structure, floor, construction, etc., can solve the problem that solid wood composite floor cannot get rid of fire, water, moisture, not as environmentally friendly as PVC floor, and heavy laying and installation workload, etc. problem, to achieve the effect of excellent geometric stability, less environmental pollution and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

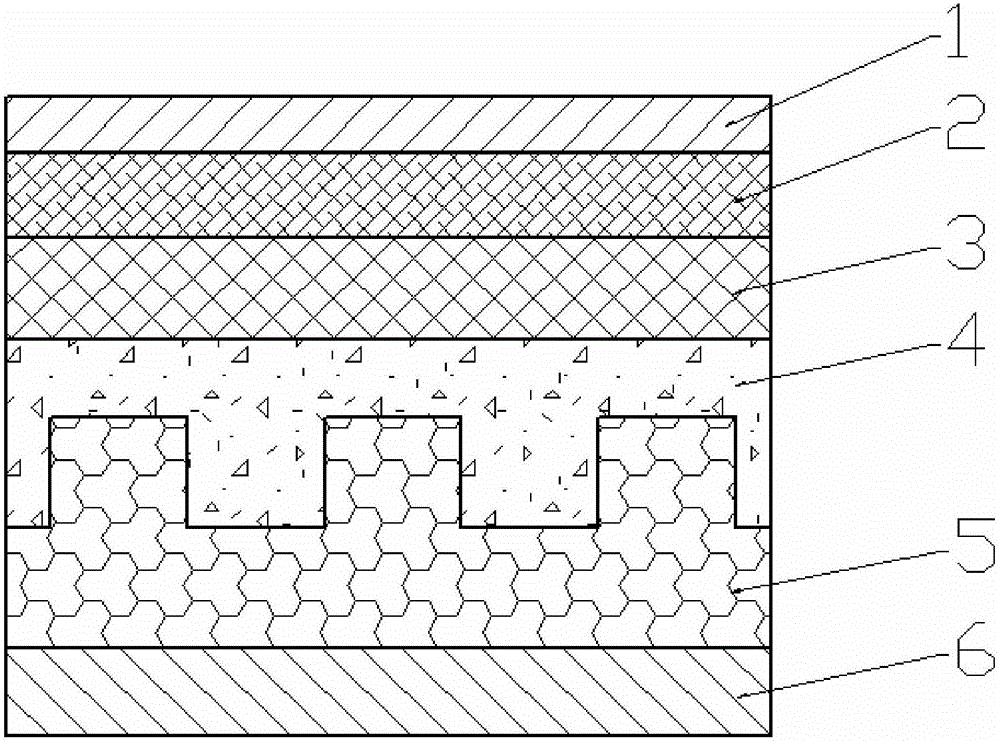

[0022] This embodiment provides a kind of strong and flexible PVC composite floor with UV protection layer structure, structure such as figure 1 As shown, it includes a PVC layer 5 and a primer layer 6 coated on the lower surface of the PVC layer 5. It is characterized in that an elastic layer 4 is provided on the upper surface of the PVC layer 5, and a printing layer 3 is laid on the upper surface of the elastic layer 4. The printing layer 3 The upper surface is provided with a reinforcement layer 2 and a UV protective layer 1 sequentially from bottom to top, the upper surface of the PVC layer 5 is provided with concave-convex grooves, and the lower surface of the elastic layer 4 is provided with concave-convex grooves corresponding to the upper surface of the PVC layer 5 , The mutual bonding surfaces between the PVC layer 5 and the elastic layer 4 are engaged through concave-convex grooves.

[0023] The aforementioned reinforcement layer 2 is a glass fiber layer; the elastic...

Embodiment 2

[0026] This embodiment provides a kind of strong and flexible PVC composite floor with UV protective layer structure, the preparation method of the UV protective coating that described UV protective layer 1 adopts, comprises the following concrete steps:

[0027] (1) Weigh the following raw materials in parts by weight: 32 parts of tripropylene glycol diacrylate, 17 parts of hydroxyacrylate, 8 parts of acrylic resin, 6 parts of ethyl 2,4,6-trimethylbenzoylphenylphosphonate , 1 part of 2,4,6-trimethylbenzoyl diphenylphosphine oxide, 4 parts of phosphate resin, 14 parts of epoxy phenolic resin, 11 parts of ethylenediamine, 2.2 parts of fumed silica, tannic acid 0.7 parts, active diluent 5 parts;

[0028] (2) Add tripropylene glycol diacrylate, hydroxyacrylate, acrylic resin, ethyl 2,4,6-trimethylbenzoylphenyl phosphonate, phosphate resin and epoxy phenolic resin to the reaction according to the ratio In the kettle, heat to 80°C and stir at a speed of 180r / min for 2.5h;

[0029...

Embodiment 3

[0032] This embodiment provides a kind of strong and flexible PVC composite floor with UV protective layer structure, the preparation method of the UV protective coating that described UV protective layer 1 adopts, comprises the following specific steps:

[0033] (1) Weigh the following raw materials in parts by weight: 38 parts of tripropylene glycol diacrylate, 19 parts of hydroxyacrylate, 12 parts of acrylic resin, and 10 parts of ethyl 2,4,6-trimethylbenzoylphenylphosphonate , 2 parts of 2,4,6-trimethylbenzoyl diphenyl phosphine oxide, 8 parts of phosphate resin, 18 parts of epoxy phenolic resin, 13 parts of ethylenediamine, 2.4 parts of fumed silica, tannic acid 1.5 parts, 7 parts of active diluent;

[0034] (2) Add tripropylene glycol diacrylate, hydroxyacrylate, acrylic resin, ethyl 2,4,6-trimethylbenzoylphenyl phosphonate, phosphate resin and epoxy phenolic resin to the reaction according to the ratio In the kettle, heat to 95°C and stir at a speed of 210r / min for 2h;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com