Patents

Literature

648results about How to "Shiny" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coarse cereal instant rice and preparation method thereof

ActiveCN103564344ABlocking stickingPrevent too softFood ingredient functionsFood preparationPearl barleyGram

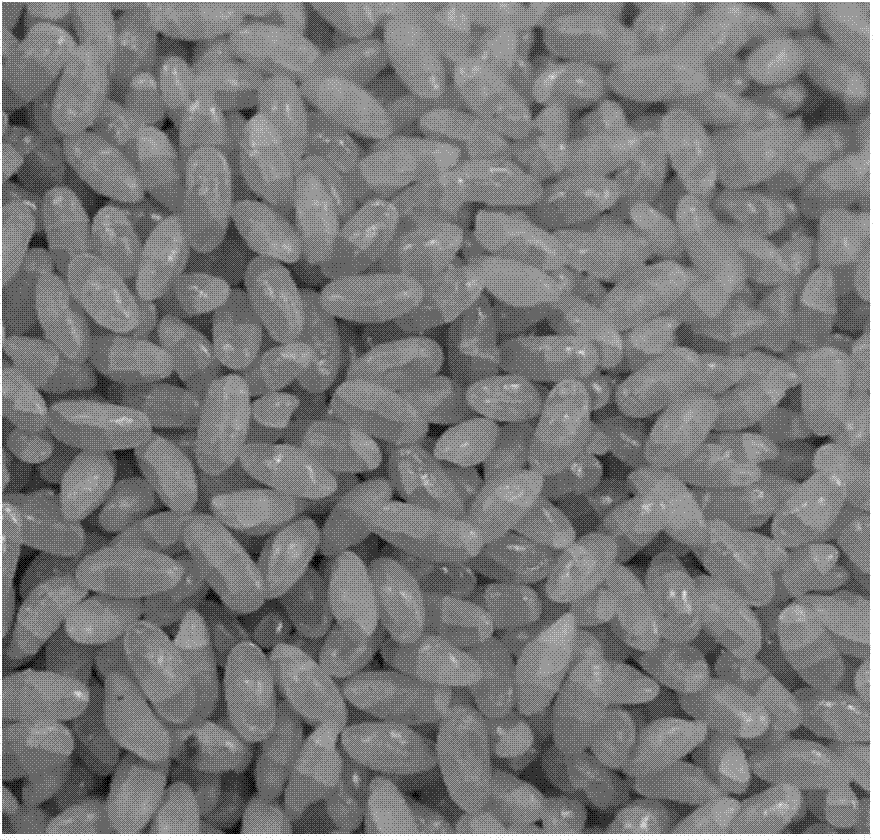

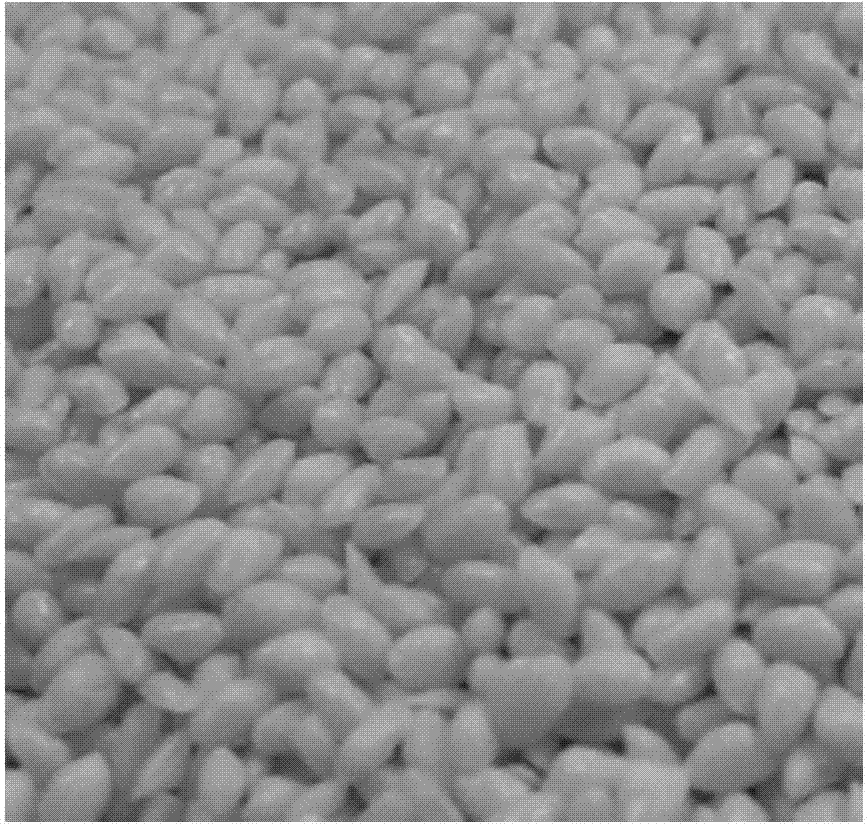

The invention discloses a coarse cereal instant rice and a preparation method of the coarse cereal instant rice. The coarse cereal instant rice is mainly prepared by conducting extrusion curing, cutting, pelletizing, drying, then baking and puffing on coarse cereal powder, starch and solid vegetable oil, wherein the coarse cereal is selected from one or combination of corn flour, rice flour, sorghum flour, buckwheat, pearl barley flour, black rice four, sweet potato flour, millet flour, coarse rice powder, glutinous rice flour, red rice flour, soybean flour, red bean flour, green gram starch, black bean flour, oat powder and wheat flour. The coarse cereal instant rice provided by the invention adopts a loose porous structure inside, so that the coarse cereal instant rice is good for digesting and absorbing and is excellent in rehydration property, the rehydration time is relatively short, the rehydrated rice is in full grain, and the coarse cereal instant rice is chewy and not hard or sticky when being eaten.

Owner:王金玺

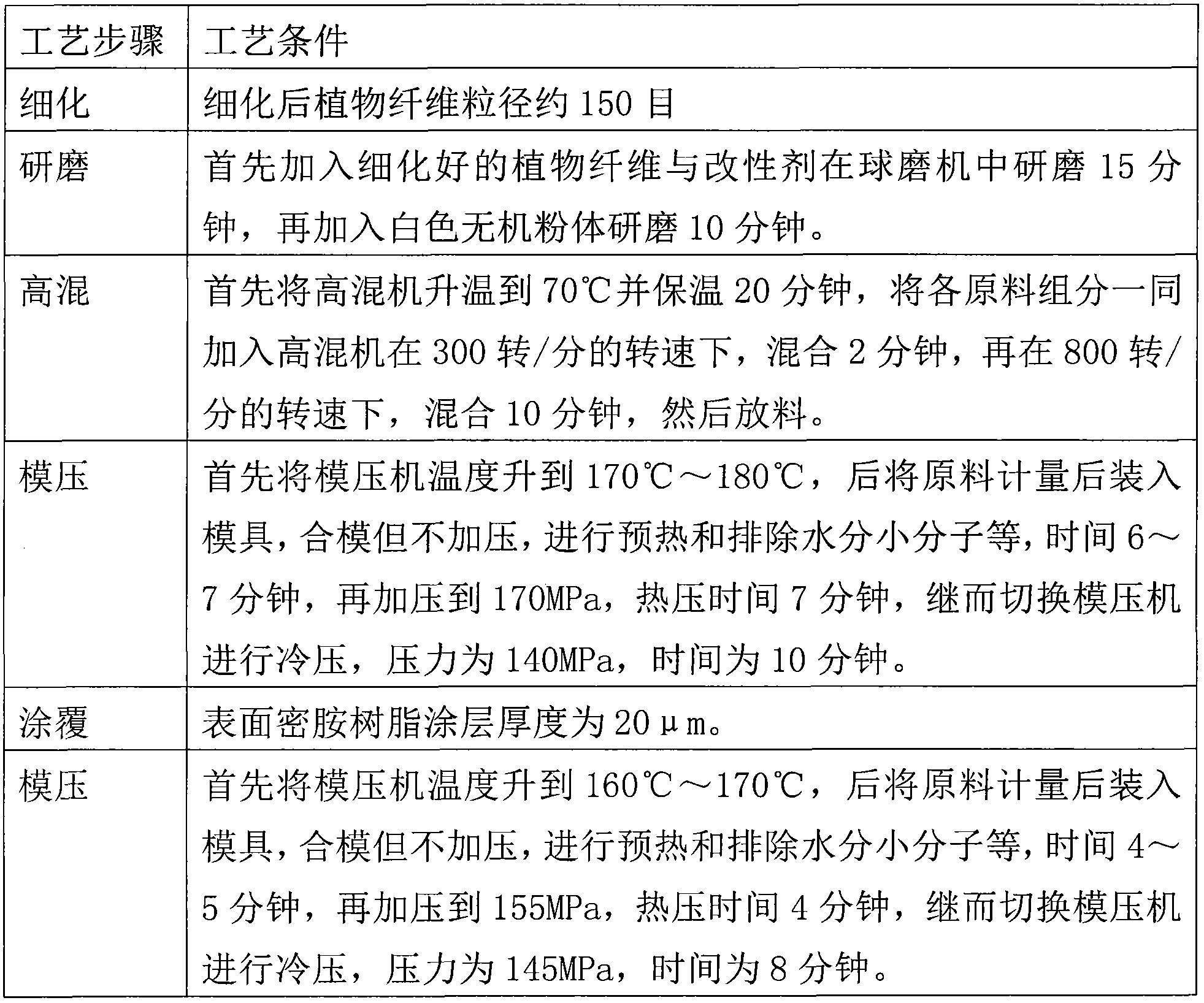

Manufacturing method for vegetable fiber compound tableware

ActiveCN102794803AControlled high temperature oxidative degradationControllable DurabilityWood compressionAviationHusk

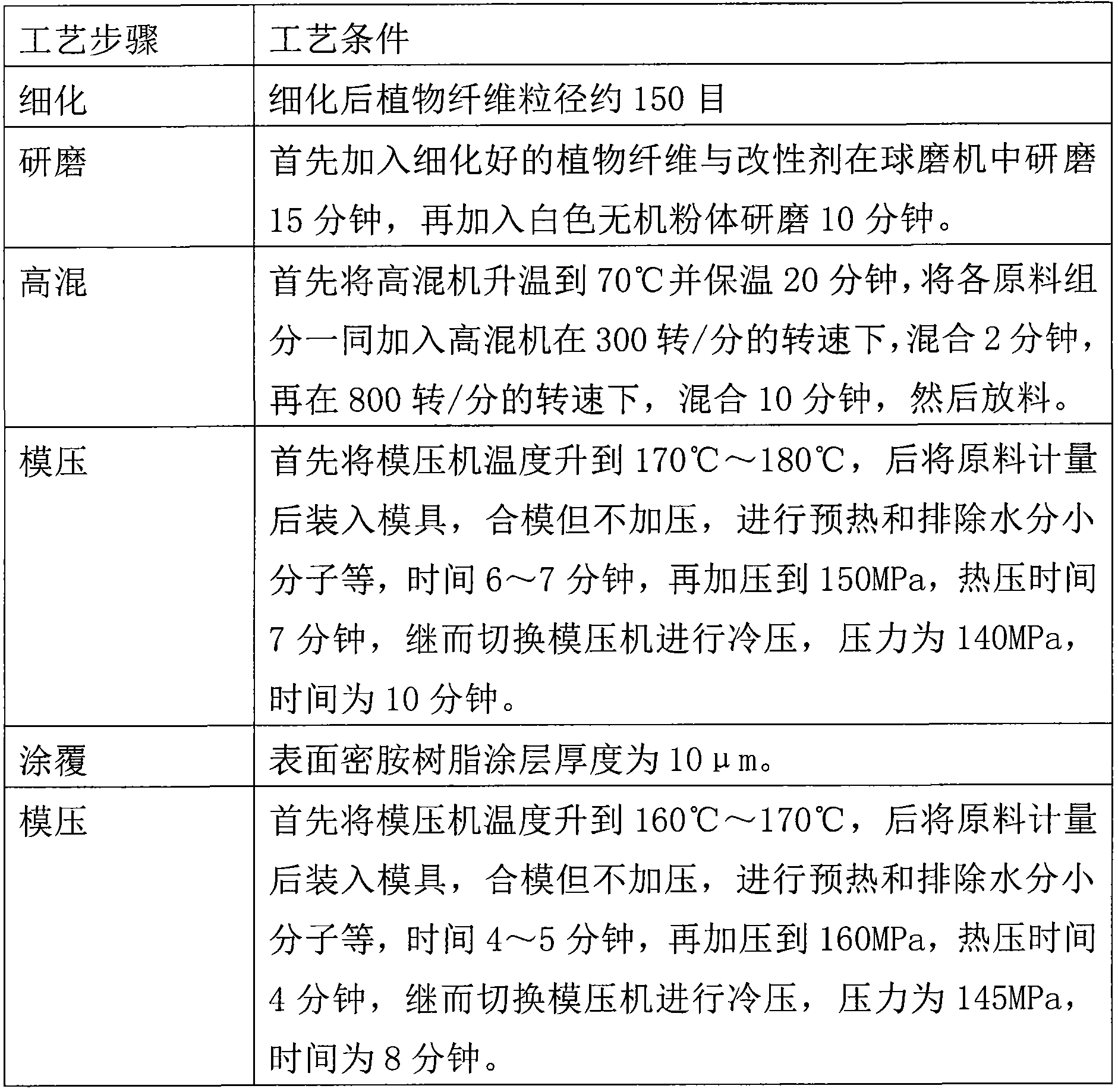

The invention belongs to the technical field of vegetable fiber compound tableware and specifically relates to a manufacturing method for the vegetable fiber compound tableware. The manufacturing method specifically comprises seven steps. The production cost of the vegetable fiber compound tableware is obviously lower than that of the traditional metal, ceramic and melamine tableware; the traditional metal, ceramic and melamine tableware can be replaced by the vegetable fiber compound tableware; a large quantity of vegetable fibers, such as, crop straws, rice husks, cobs, sawdust, and the like, are effectively utilized; the atmospheric pollution caused by vegetable fiber burning is effectively prevented and the waste is turned into the wealth; the main products are as follows: basins, bowls, cups, dishes, trays, snack boxes, soup ladles, soup spoons, chopsticks, aviation meal boxes, and the like; and the products have the characteristics of high ceramic simulating strength, good natural texture, clear and gorgeous grains, and the like.

Owner:安徽绿之态秸秆制品有限公司

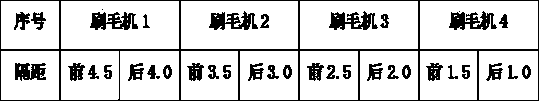

Printing method of different patterns of double surfaces of warp knitting plush single-layer blanket

ActiveCN103741364AAnti-stickingFeel smooth and plumpWarp knittingHeating/cooling textile fabricsRough surfaceEngineering

Provided is a printing method of different patterns of double surfaces of a warp knitting plush single-layer blanket. Appropriate raw materials are selected to be woven to form grey cloth, secondary removing presetting is conducted, and then pre-processing is conducted; after reverse-side napping tidying is conducted on the warp knitting plush grey cloth in a pre-processing procedure, various printing parameters are regulated according to gram weights and plush heights of the warp knitting plush single-layer blanket, the front side is printed firstly, then the reverse side is printed, and a semi-finished plush single-layer blanket with the different patterns on the front side and the reverse side is obtained; brushing, ironing, shearing, cloth cutting and edge covering are conducted on the front side and the reserve side of the semi-finished plush single-layer blanket, and the finished plush single-layer blanket is obtained. The printing method is reasonable in technology, the blanket with the different patterns on the front side and the reverse side can be obtained, product diversity is improved, the printing effect is good, white plush can not occur on the surface of the warp knitting plush single-layer blanket, the rough surface is glossy and bright, the plush surface is tidy, relatively elastic, and soft and smooth in hand feeling, and the warp knitting plush single-layer blanket achieves quality of a top-grade blanket.

Owner:连云港飞雁毛毯有限责任公司

Sterilizing bath lotion for furry pets

InactiveCN101810542AEasy to rinse offMild in natureCosmetic preparationsHair cosmeticsLotionSodium chlorite

The invention provides sterilizing bath lotion for furry pets, which comprises surfactant, humectant, hair care agent, chelating agent, bactericide, thickening agent and essence, wherein the bactericide is one of stable liquid chlorine dioxide, stable solid chlorine dioxide or sodium chlorite. The sterilizing bath lotion of the invention overcomes the defects of the existing product or the prior art, and really realizes synchronous completion of three effects of removing dirt, caring hair and quickly sterilizing. The sterilizing bath lotion has the advantages of mild property, no any stimulation to the fur of animals and the skin of people, good dirt removing and sterilizing effects, low foam, easy cleaning, no residue, safety and environment friendliness, and meanwhile plays a role in caring the fur of the animals so that the fur of the washed pet does not knot; and the sterilizing bath lotion is glossy, flexible and easy to card, and is quite suitable for the daily care of the furry pets.

Owner:BEIJING OKEANOS TECH

Mulberry silk and cuprammonium rayon yarn interwoven fabric and weaving method thereof

InactiveCN101532199ALow costImprove comfortLiquid/gas/vapor removalDyeing processYarnCuprammonium rayon

The invention provides a fabric, in particular to a mulberry silk and cuprammonium rayon yarn interwoven fabric. The fabric is interwoven by the mulberry silk and the cuprammonium rayon yarn, wherein warp is made of the mulberry silk, while weft is made of the cuprammonium rayon. The invention also provides a method for weaving the fabric, which is a method of interweaving the mulberry silk warp and the cuprammonium rayon yarn weft into the fabric, wherein the cuprammonium rayon yarn as the weft is subjected to predrying treatment before use; process steps of the warp and the weft are as follows: the warp adopts reeled silk to be subjected to rolling, primary twisting, doubling, second twisting, skeining, degumming, dyeing, rolling, warping and weaving; and the weft adopts cone winded yarns to be subjected to roll separating, twisting, skeining, dyeing, rolling, quilling, predrying and weaving. The method provides the product interwoven by the mulberry silk and the cuprammonium rayon yarn, and adds new content for colorful silk variety.

Owner:上海丝绸集团股份有限公司

Pieparation method for fabricating raw bamboo into spinnable bamboo fibers

A method for preparing primary bamboo to be spinnable bamboo fibre includes cutting bamboo into pieces, placing prepared bamboo pieces in pressure container for obtaining coarse fibre, using mildew aqueous solution to remove lignin, pectin, sugar and fat out from the fibre; rolling and dividing the fibre, bleaching and rinsing the fibre for softening; dewatering and adding reinforcer to enhance fibre strength; using emulsifier to process fibre for having desired compliance and drying it for obtaining spinnable bamboo fibre.

Owner:刘忆萍

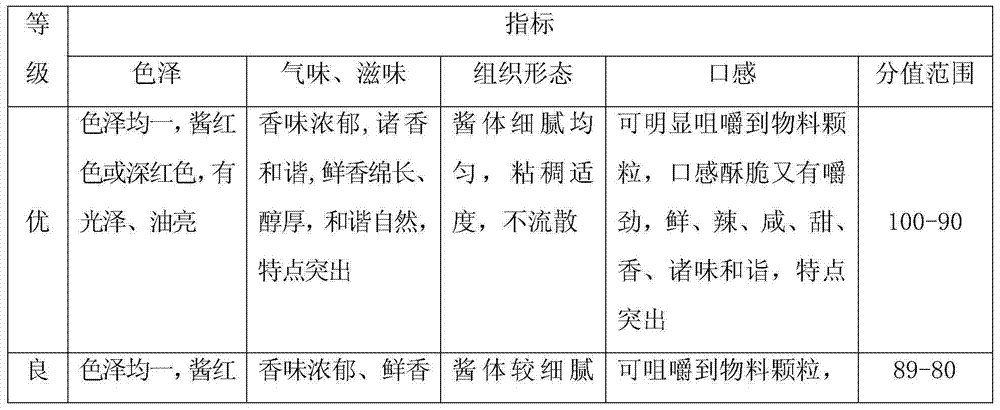

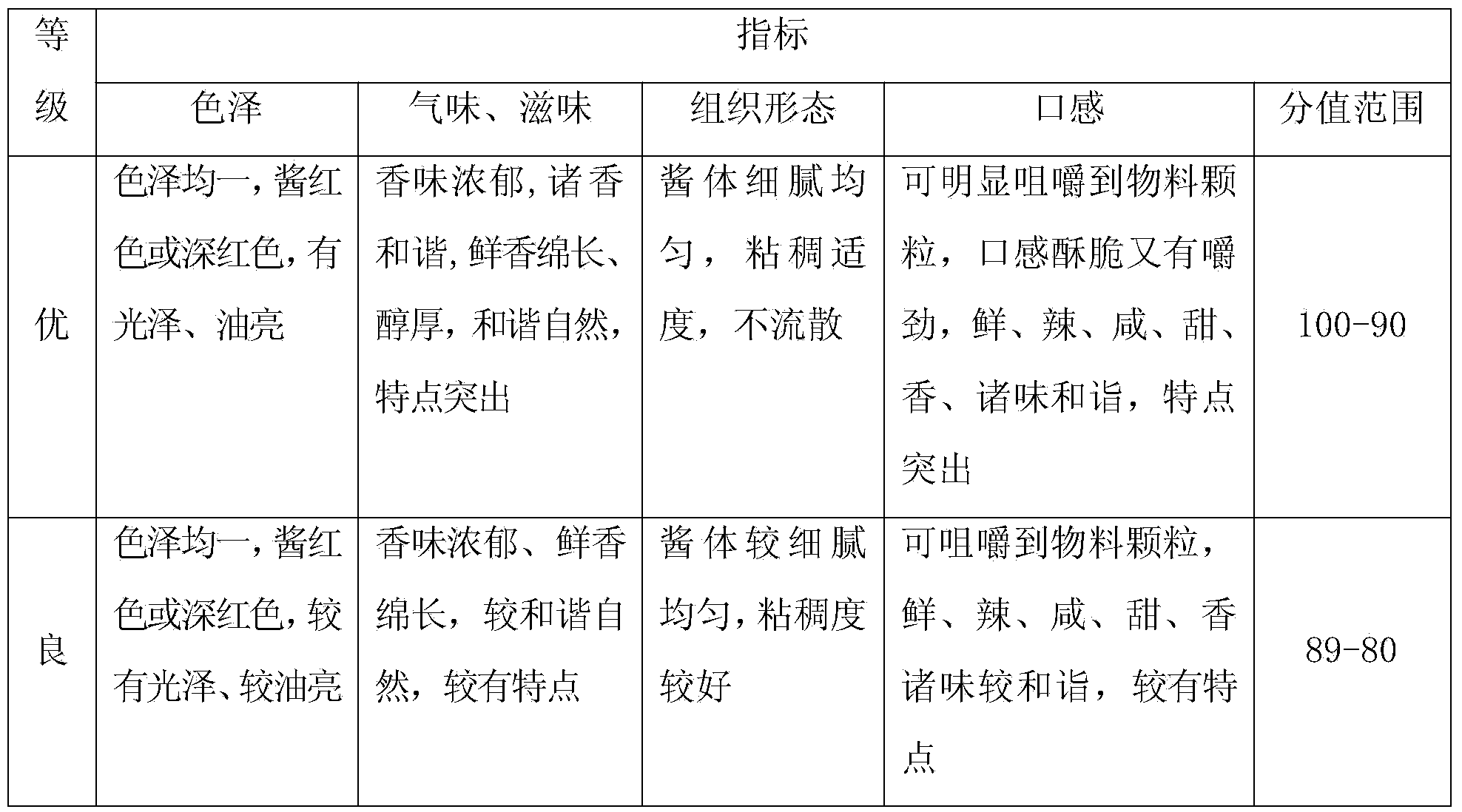

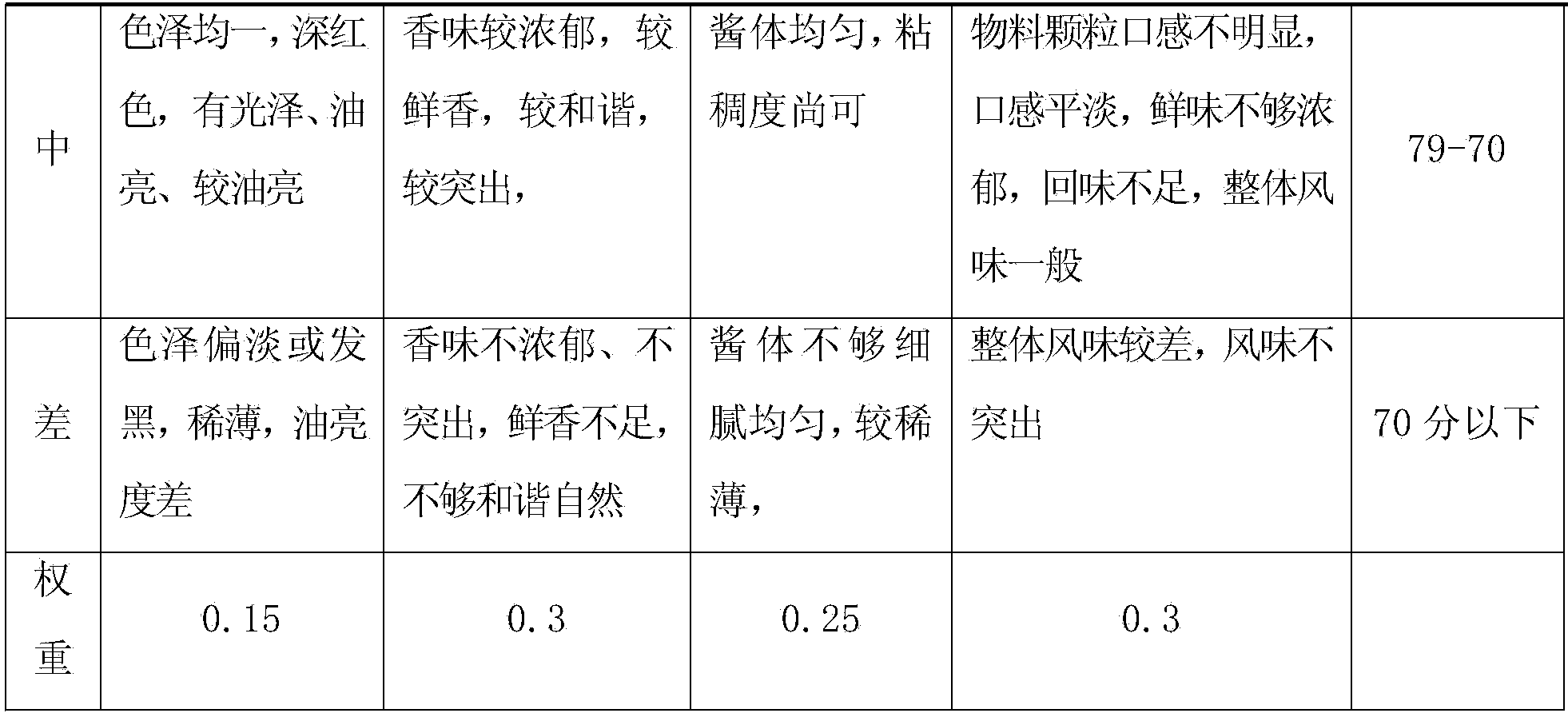

A hot and spicy sauce and a preparation method thereof

InactiveCN104489614AKeep the tasteSwelling and looseningFood ingredient as taste affecting agentFood ingredient as flavour affecting agentFood flavoringsBroad beans

The present invention discloses a hot and spicy sauce and a preparation method thereof, and belongs to the field of food seasoning technology. The preparation method comprises the following main steps: preparing each raw material according to characteristics of the raw materials, heating siritch to 180-200 DEG C, adding ginger and garlic into the siritch, sauting the ginger and garlic until fragrant, adding thick broad-bean sauce into the mixture, maintaining product temperature at about 95 DEG C and stir-frying the mixture for 3-6 minutes, frying the mixture with pepper, shii-take and chilli paste, edible fungus and diced tofu for about 10 minutes, adding inspissated juice of Chinese wolfberry, red date and apple, spice material and soy sauce into the mixture, frying the mixture for additional 5 minutes at a product temperature of about 95 DEG C, adding salt, edible fungus powder, crushed peanut and sesame, continuing frying the mixture for 5 minutes, adding zanthorylum oil, stopping the fire, and maintaining product temperature at above 65 DEG C for hot filling. The hot and spicy sauce prepared in accordance with the above-mentioned preparation method is rich in nutrition, beautiful, ruddy and shiny in color, rich in gloss, salty and spicy and natural in taste, harmonious in fragrance, and crispy and chewy in taste.

Owner:湖南辣啦食品科技有限公司

Biological protein hair fiber preparation method by dissolving animal hair and cellulose material mixture

InactiveCN1884642AReduce lossesReduce direct lossesConjugated cellulose/protein artificial filamentsCelluloseAdjuvant

The invention discloses a biological protein wool fiber preparing method, which comprises the following steps: blending animal fur and fiber to produce soluble liquid in the ion liquid with positive and negative ion of fusing condition at 100 deg.c and positive ion to form salt; solidifying in the water, carbinol, alcohol, cyanoethyl or (NH4)2SO4 solution; adding adjuvant in the soluble liquid; solidifying in the water, carbinol, alcohol, cyanoethyl or 30 percent (NH4)2SO4 solution; evolving biological protein fur fiber.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Channel catfish ictalurus punctatus deepfreezed fillets and processing technique

InactiveCN101032337AIncrease incomeGreat tasteMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsLeiocassis longirostrisIce water

The present invention discloses one kind of fast frozen white delicious fish fillet of spotted forked-tail Leiocassis longirostris and its production process. The production process includes the steps of temporarily raising, killing to eliminate blood, slicing, eliminating skin, trimming, soaking to sterilize, loading into tray and quick freezing, grading, coating with ice, packing, etc. The production process features complete elimination of blood, low temperature of fish fillet in icy water at 0-4 deg.c, soaking fish fillet in ozone icy water and ultralow temperature quick freezing at below -35 deg.c. The production process has high fish fillet yield and less nutrient loss, and the produced fish fillet is white, translucent and delicious.

Owner:YIYANG YIHUA AQUATIC PRODS

Potato starch-based edible composite food packaging film and preparation method thereof

The invention relates to a potato starch-based edible composite food packaging film and a preparation method thereof, and belongs to the technical field of food packaging. According to the potato starch-based edible composite food packaging film, potato starch, pullulan polysaccharide and gelatin are used as main film-forming materials, and a plasticizer and a cross-linking agent are used as auxiliary materials. The preparation method comprises the following steps of: adding water into the potato starch, performing water bath, stirring and gelatinizing, adding the pullulan polysaccharide and the gelatin, adding the plasticizer and the cross-linking agent finally, and casting the prepared solution to form the film. The potato starch-based edible composite food packaging film has the advantages that the raw materials for preparing the film are edible, harmless to human bodies and environment-friendly, and the raw materials are can be degraded biologically after being discarded; defoaming is not required in the film preparation process, and the process is simple and low in production cost; and the prepared film is transparent and glossy, high in mechanical performance and obstruction performance and attractive in appearance. The prepared film can be used for the inner packaging of food, so that harm of nondegradable food packages to the human bodies and environment is avoided.

Owner:JIANGNAN UNIV

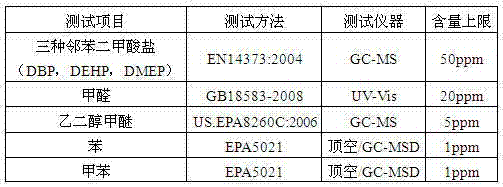

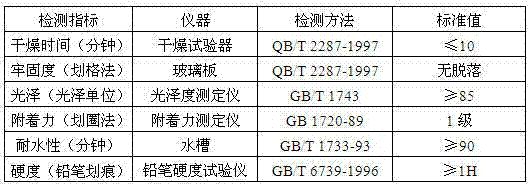

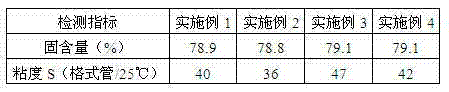

Preparation method of alkyd resin

InactiveCN102408551AImprove adhesionFullnessCosmetic preparationsToilet preparationsPolymer scienceNitrocellulose

The invention relates to a preparation method of alkyd resin. The preparation method comprises the following specific steps: (1) adding neopentyl glycol, trihydroxymethyl propane, phthalic anhydride, hydrogenated phthalic anhydride and antioxidant to a reaction container, and heating to carry out melt esterification on the materials at the temperature of 200-240 DEG C; (2) when esterification is carried out to an acid value being 40-45 mgKOH / g, cooling to 120-160 DEG C, and adding short-chain synthetic fatty acid and an aliphatic hydrocarbon solvent; (3) heating to carry out reflux esterification at the temperature of 180-200 DEG C, and diluting with acetic acid ester organic solvent when the acid value is smaller than or equal to 8 mgKOH / g; and (4) cooling to 100 DEG C and filtering to obtain alkyd resin. The paint prepared from the alkyd resin obtained in the invention and nitrocellulose has the characteristics of rapid drying, high hardness, good fullness, good adhesion force, and good water resistance.

Owner:JIANGSU SANMU GROUP CORPORATION

Method of processing oat grain

InactiveCN1883809AUniform sizeSmooth tasteFood preservationGrain treatmentsAmyrisDecortication procedure

Disclosed is a processing method for avena sativa rice, comprising selecting stock husk avena sativa seeds, grading, decorticating, enzymes inactivating, screening, drying, and packaging. A decortication machine is used to decorticating avena sativa seeds, without seeds breakage. The decortication ratio maintains at 6% by adjusting space according to seed size. Enzymes inactivation is carried out by treating with steam, at 100 DEG C, for 20min, or treating with high pressure water steam for 10min; by using a hyperthermia instant enzyme inactivation method, lypase, proteinase and amylase can be inactivated in 20s. After that, screeing, drying and packaging are carried out. The method is provided with simplicity, avena sativa rice produced thereby has a long preservation time, and the precessing time is short.

Owner:胡新中 +1

Terylene fine-denier triangle super bright FDY filament and preparation method thereof

InactiveCN101139741AGood flexibilityFeel goodFilament/thread formingMonocomponent polyesters artificial filamentMaterials scienceFilament yarn

The invention discloses a terylene fine denier triangular super-glossy FDY filament and relevant preparation method, and belongs to the technical field of terylene fibers. During the course of filature preparation, the invented fine denier triangular super-glossy terylene filament can lower filature speed, shorten calm zone distance and milden air blow cooling conditions; meanwhile, the fiber adopts nozzle oiling mode to improve oiling position, in order to successfully prepare fine denier triangular super-glossy FDY terylene filament with denier no more than 0.7dtex, fiber corss section similar to regular triangle and super-bright glossy. The terylene filament has advantages of extremely perfect flexibleness, excellent hand feeling, and moreover, the product is characterized by fewer broken filament, fewer short ends, more uniform yarn more stable quality.

Owner:JIANGSU HENGLI CHEM FIBER

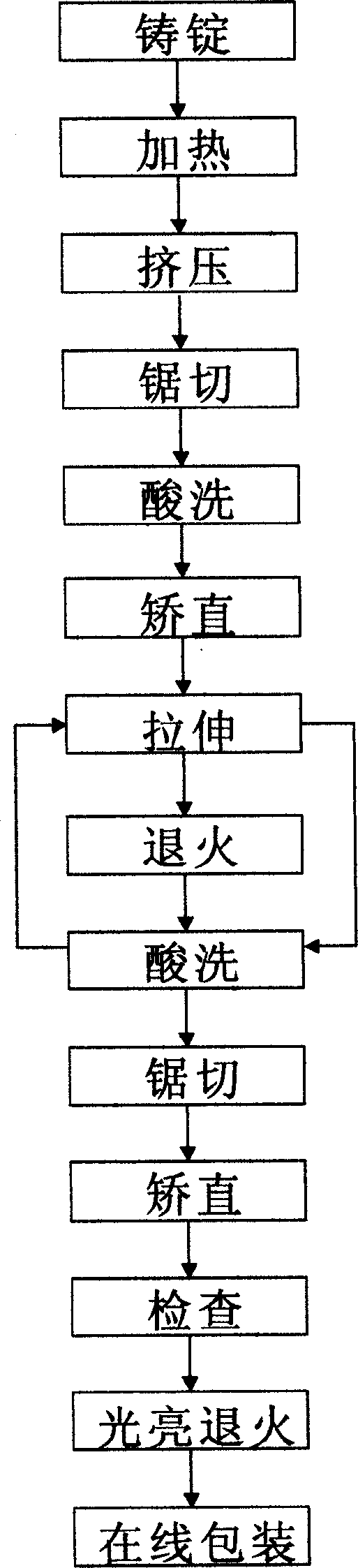

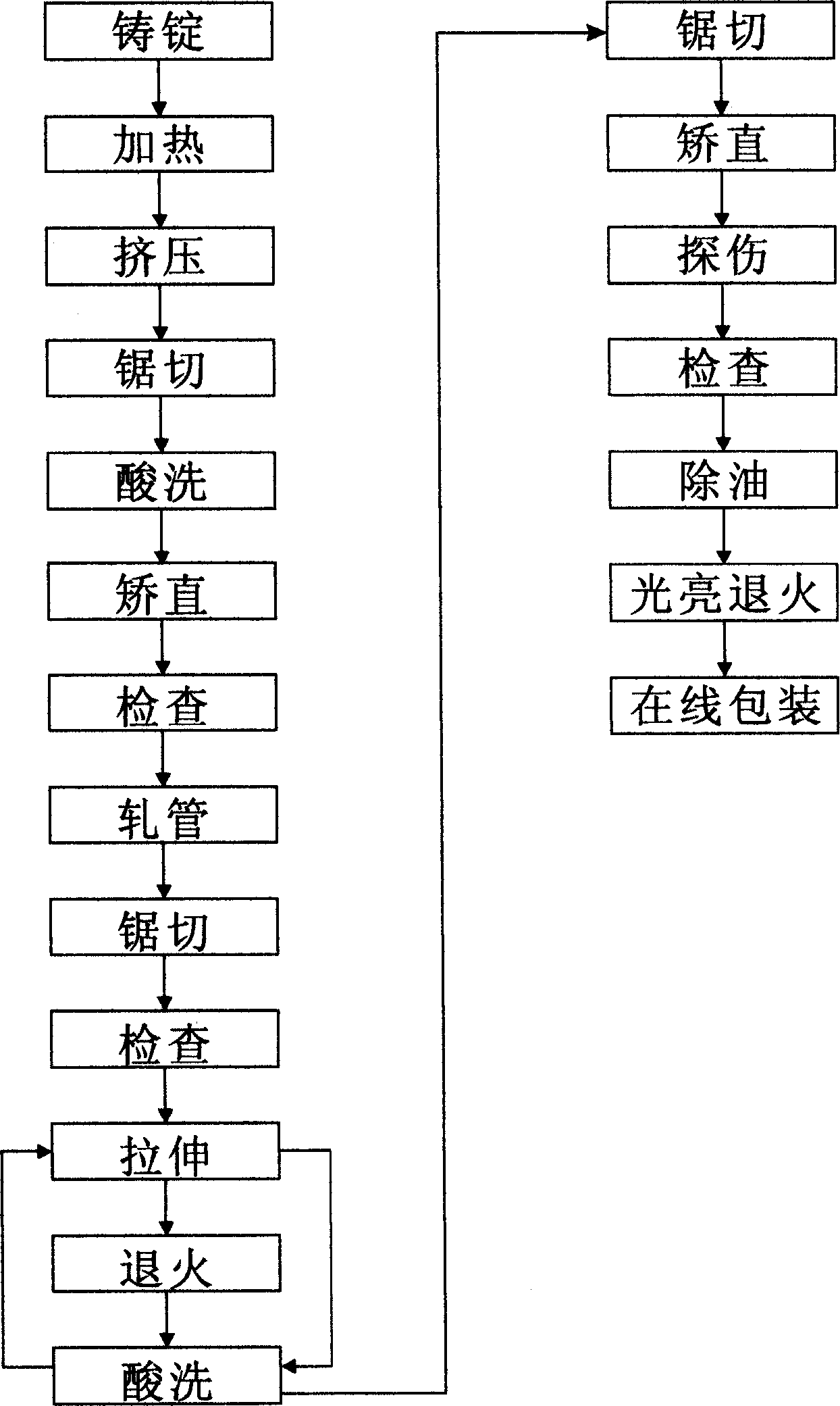

Method for producing red brass pipe

The production process of red brass pipe includes the steps of: fusion casting, heating, extruding, finishing, acid pickling, inspection, rolling, cutting to required size, inspection, annealing, acid pickling, forming head, drawing, finishing, inspection, deoiling, and product annealing. The present invention features that in common pressure processing apparatus, with common brass as material and through extrusion to generate red, acid pickling to increase color, drawing to decrease color, further acid pickling to increase color and annealing to maintain color, red brass pipe with high anticorrosion and homogeneous performance may be produced in low cost.

Owner:中铝洛阳铜业有限责任公司

Muslim spicy sauce and preparation method thereof

ActiveCN104323219AKeep the tasteSwelling and looseningNatural extract food ingredientsFood preparationVegetable oilFood flavorings

The invention relates to Muslim spicy sauce and a preparation method thereof, belonging to the technical field of food seasonings. The Muslim spicy sauce is prepared from the following raw materials in parts by weight: 30-300 parts of fresh chili sauce, 30-100 parts of edible vegetable oil, 10-100 parts of thick broad-bean sauce, 5-50 parts of capsicum frutescens, 10-50 parts of diced tofu, 10-20 parts of edible mushrooms, 1-10 parts of wolfberry concentrated juice, 2-5 parts of red date concentrated juice, 2-40 parts of soybean sauce, 5-50 parts of fresh gingers, 3-50 parts of garlic, 2-5 parts of table salt, 0.2-5 parts of spices and 1-3 parts of edible mushroom powder. The Muslim spicy sauce has the characteristics of fine material selection and rigorous and scientific formula; the requirements in all the aspects of nutrition, taste, color and the luster and the like are considered, and the process is scientific and reasonable; and the aromas of a lentinus edodes aroma, a chili sauce aroma, a spice aroma and the like are harmonious, and the Muslim spicy sauce crispy in taste and chewy.

Owner:甘肃清味缘商贸有限公司

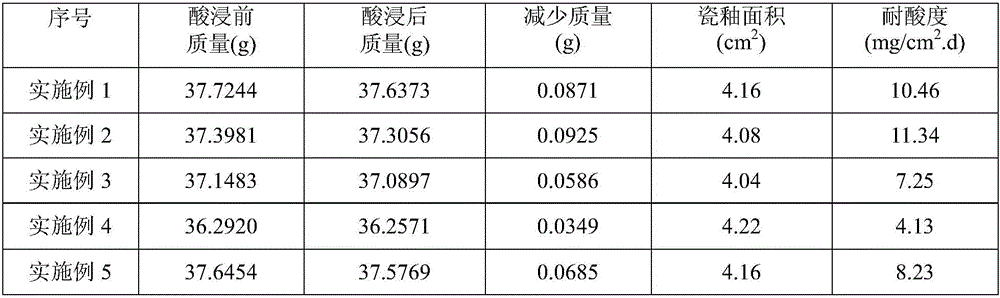

Enamel glaze material, enamel slurry, and preparation method and application thereof

The invention specifically relates to an enamel glaze material, an enamel slurry, and a preparation method and an application thereof. The invention relates to the technical field of enamel materials. The invention aims at solving a technical problem of providing an enamel glaze material. The enamel glaze material is prepared by uniformly mixing the following raw materials, by weight: 40-45 parts of quartz sand, 9.5-10 parts of feldspar powder, 24-26 parts of borax, 2.5-3 parts of cryolite, 5.5-7.5 parts of sodium nitrate, 3.5-4 parts of lithium carbonate, 3.5-4.5 parts of fluorite powder, 2-4 parts of calcium carbonate, 3-4 parts of cobalt nitrate, 0.8-1.2 parts of nickel nitrate, 2-2.2 parts of manganese oxide, and 3.4-3.8 parts of zirconium dioxide. The enamel glaze material can be combined well with glass powder to produce the enamel slurry. The enamel slurry can be coated on the surface of a metal substrate to form an enamel coating. The coating has the advantages of smooth glaze surface, good gloss, no bubble, and no scaling. The coating can be firmly combined with a carbon steel substrate, and has good acid resistance.

Owner:PANZHIHUA UNIV

Method for producing advanced triple-wire double-calcination pure cotton fabrics

InactiveCN101718022AIncrease reflective areaShinyMercerising of yarns/threads/filamentsSingeingLiquid ammoniaDyeing

The invention provides a method for producing advanced triple-wire double-calcination pure cotton fabrics, comprising the working procedures of yarn dyeing, weaving, fabrics singeing, desizing, alkali mercerization, tenter setting and preshrinking. The method is characterized in that before being dyed, grey yarns are mercerized and singed, and a liquid ammonia working procedure is added between alkali mercerization and tenter setting, thereby forming the whole processing steps sequentially including yarn mercerization, yarn singeing, yarn dyeing, weaving, fabrics singeing, desizing, alkali mercerization, liquid ammonia, tentering and preshrinking. Compared with the traditional mercerized pure cotton fabrics, the triple-mercerization pure cotton fabrics obtained by the method have the advantages of higher lustre and high tinctorial yieldof yarns, fresher color of fabrics, good moisture absorption and ventilation, soft handle and high resilience, and the triple-wire double-calcination pure cotton fabrics are softer after being washed and maintain other excellent performances thereof.

Owner:LUTAI TEXTILE

Cotton and wood composite cellulose pulp and method for producing same

InactiveCN1844497AShinyHigh whitenessConjugated cellulose/protein artificial filamentsVegetable materialWood fibreSlurry

This invention discloses a compound fiber new-type slurry pulp and it's making method. The compound fiber new-type pulp is composed of the materials that are two or more than two among velveteen, wood, hemp, bamboo. The making steps as follows: brewing, washing, syringing, beating, mixing up, removing impurities and washing, preparing acid, preparing chlorine, bleaching, acid dealing, removing impurities and washing. This invention can satisfy various needs of the pulp material for viscose.

Owner:YIBIN GRACE

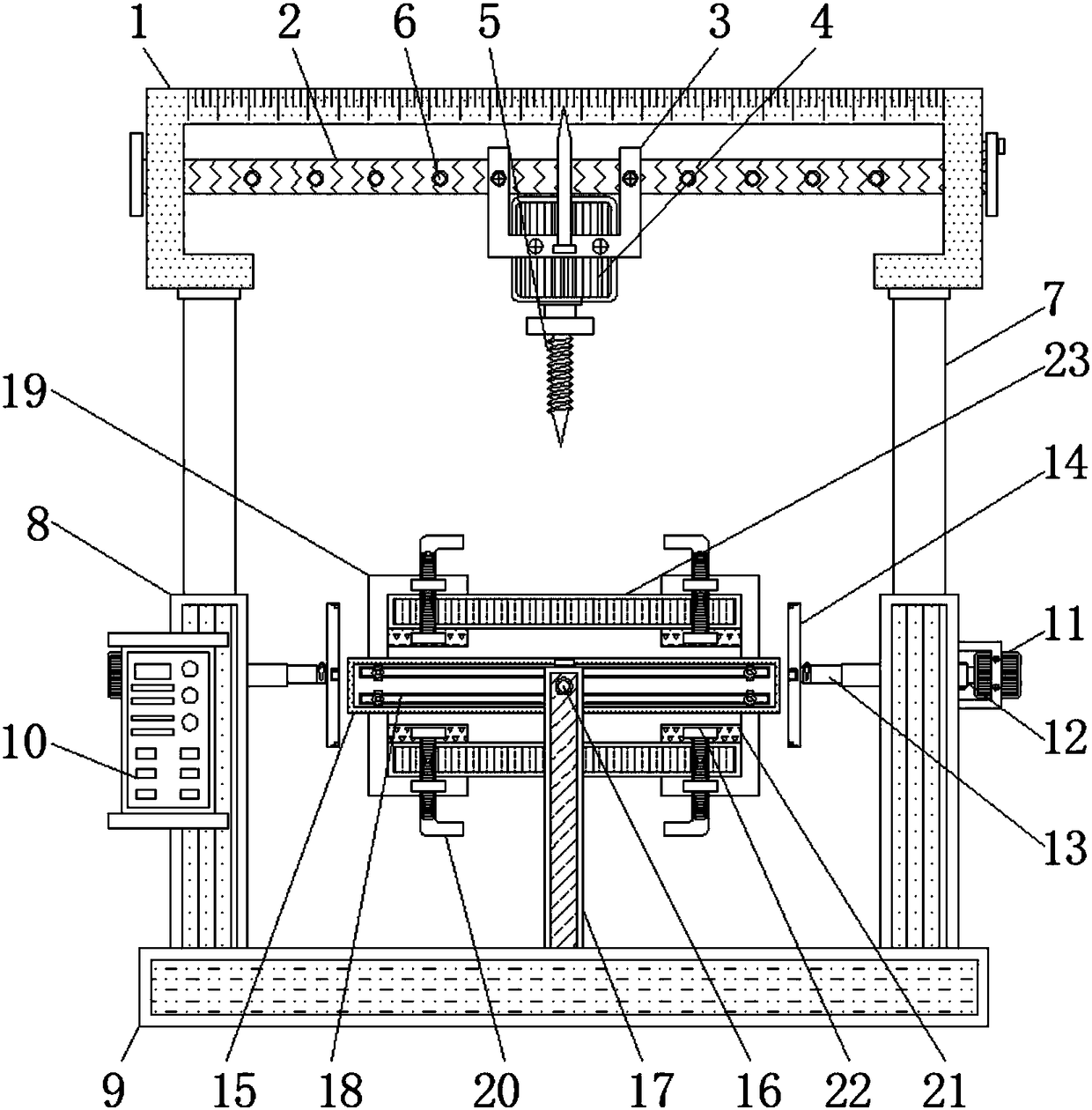

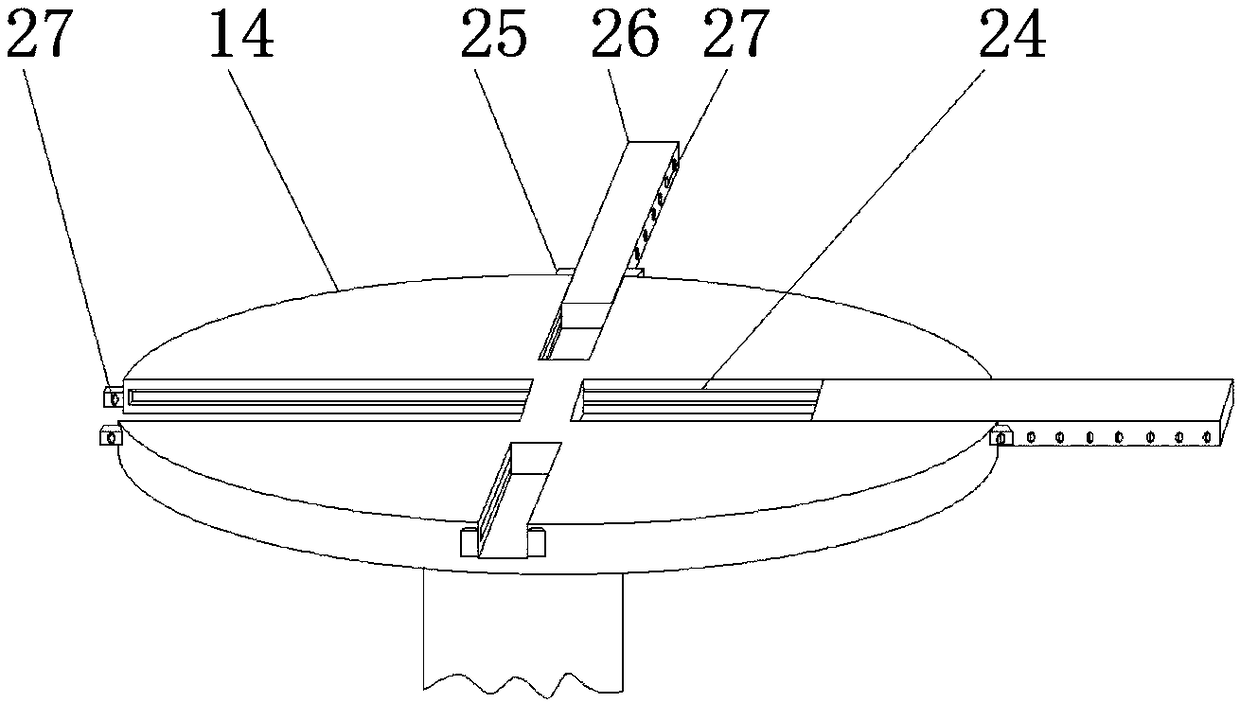

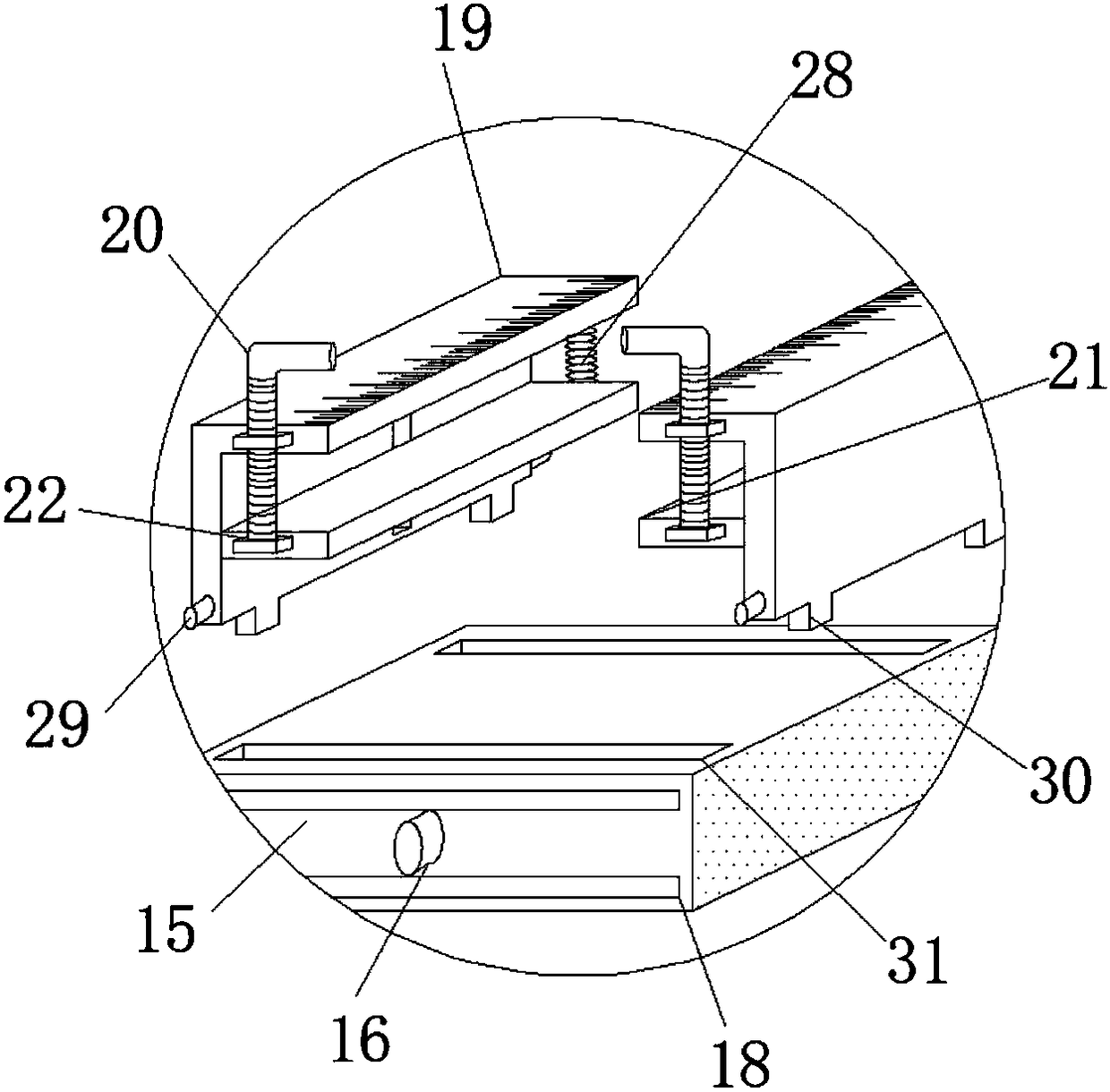

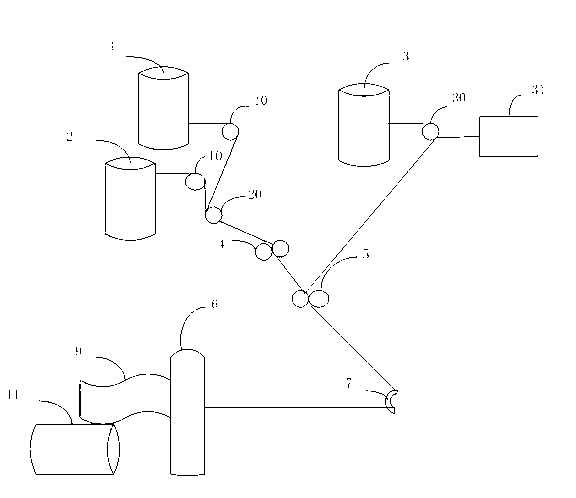

Drilling and grinding integrated machine for panel machining

ActiveCN108372405AIncrease flexibilityHigh precisionOther manufacturing equipments/toolsLarge fixed membersEngineeringMachining

The invention discloses a drilling and grinding integrated machine for panel machining. The drilling and grinding integrated machine comprises a top plate and a workbench. An installing base is arranged on a transverse rod installed below the interior of the top plate. The two sides of the lower portion of the top plate are connected with supporting plates through electric telescopic columns, wherein the supporting plates are symmetrically fixed to a base. A second motor fixed to one side of one supporting plate is connected with a manual telescopic rod through a connecting sleeve. The workbench is connected with a supporting rod through a connecting shaft. A grinding block is arranged in a groove formed in the surface of the grinding disc. One side of a first clamping plate and one side of a second clamping plate are connected through connecting springs. Surface sliding ways are reserved in the upper surface of the workbench. Movable grooves are symmetrically formed in the left side and the right side of the top plate, and inserting holes are reserved in the upper end, the lower end, the front face and the back face of the connecting shaft. The drilling and grinding integrated machine for panel machining can grind the surface of a panel after the panel is drilled, and accordingly later work proceeding is convenient.

Owner:杭州智安知识产权服务有限公司

Unsaturated fatty acid feed addictive capable of improving quality of skin and hair of cats and dogs

InactiveCN1631207AGuaranteed efficient growthImproves fur qualityAnimal feeding stuffAccessory food factorsNervous systemColneleic acid

The invention relates to an unsaturated fatty acid feed addictive capable of improving quality of skin and hair of cats and dogs, wherein the feed addictive comprises unsaturated fatty acids or their ester derivatives whose weight ratio is, linoleic acid 82.2-88.3, arachidonic acid 0.8-2.7, linolenic acid 8.5-14.8, EPA and DHA 0.5-2.2. The additive can reinforce the growth of fur-bearing animals especially the growth of nervous systems of cats and dogs.

Owner:王志文

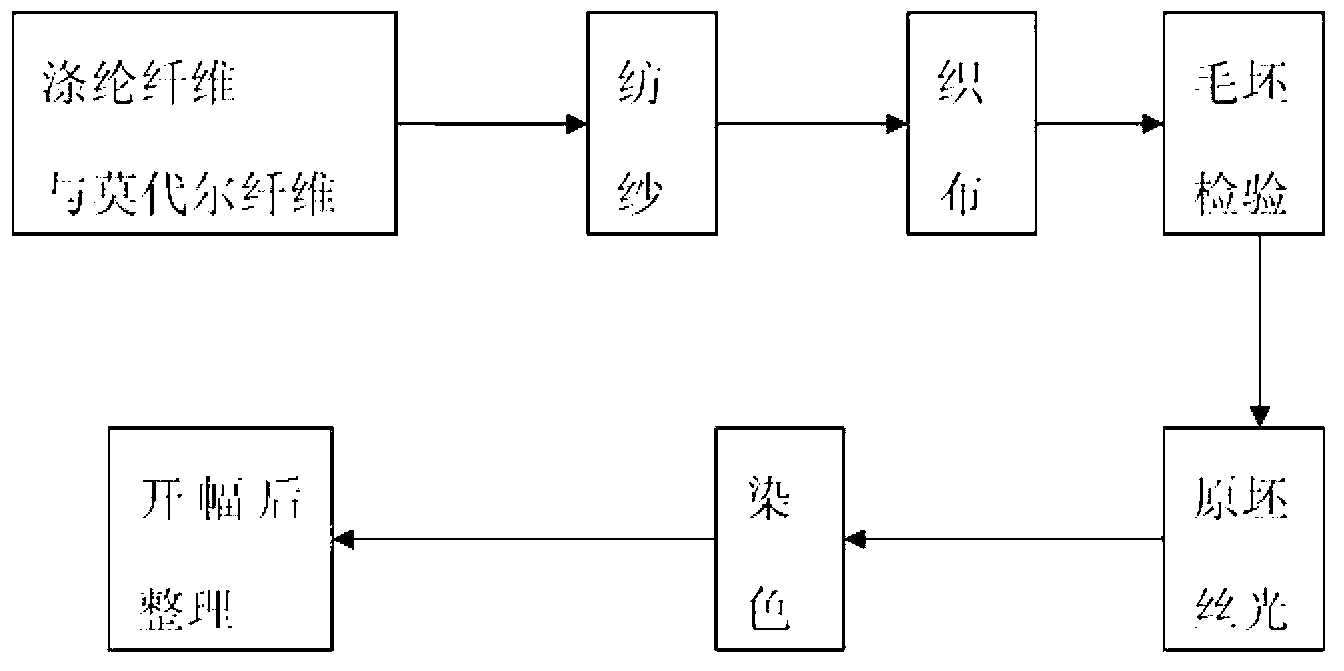

Blending silky single jersey cloth of polyester fiber and modal fiber and preparation method thereof

ActiveCN103173916ABright colorGood moisture conductivityMercerising of indefinite length fabricsWeft knittingAnti wrinklePolyester

The invention relates to blending silky single jersey cloth of polyester fiber and modal fiber and a preparation method thereof. The polyester fiber and the modal fiber serve as raw materials and the single jersey cloth is prepared. According to weight percentages, the raw materials comprise 55% to 75% of the polyester fiber and 25% to 45% of the modal fiber. The cloth is glossy like silky cloth, bright in color, anti-fade after being washed for a plurality of times and good in wet permeability. The knitted cloth blended with the modal fiber has good wet permeable effect and is widely used for sewing top grade T-shirts and sportswear, sweat generated when a person does exercise can be discharged to surfaces of clothes rapidly and be evaporated, the skin stays fresh and cool and the exercise can be done comfortably. The size of the cloth is stable, hanging down feeling is good, the cloth is stiff and smooth, anti-wrinkle performance is good and teasing, pilling and wrinkling do not occur.

Owner:GAOMI FUYUAN PRINTING & DYEING

Hair dyeing, hairdressing agent and its making method

Disclosed is a hair dyeing, hairdressing agent and its making method, which comprises additive, dyestuff agent and metallic chelating agent, wherein the additive comprises the following raw materials, acetylcysteine hydrazine derivative, homologue and salts, sodium sulfite, sodium carboxymethylcellulose, disodium ethylenediamine tetraacetate, monoethanol-amine, and balancing deionized water.

Owner:北京精采日化有限公司

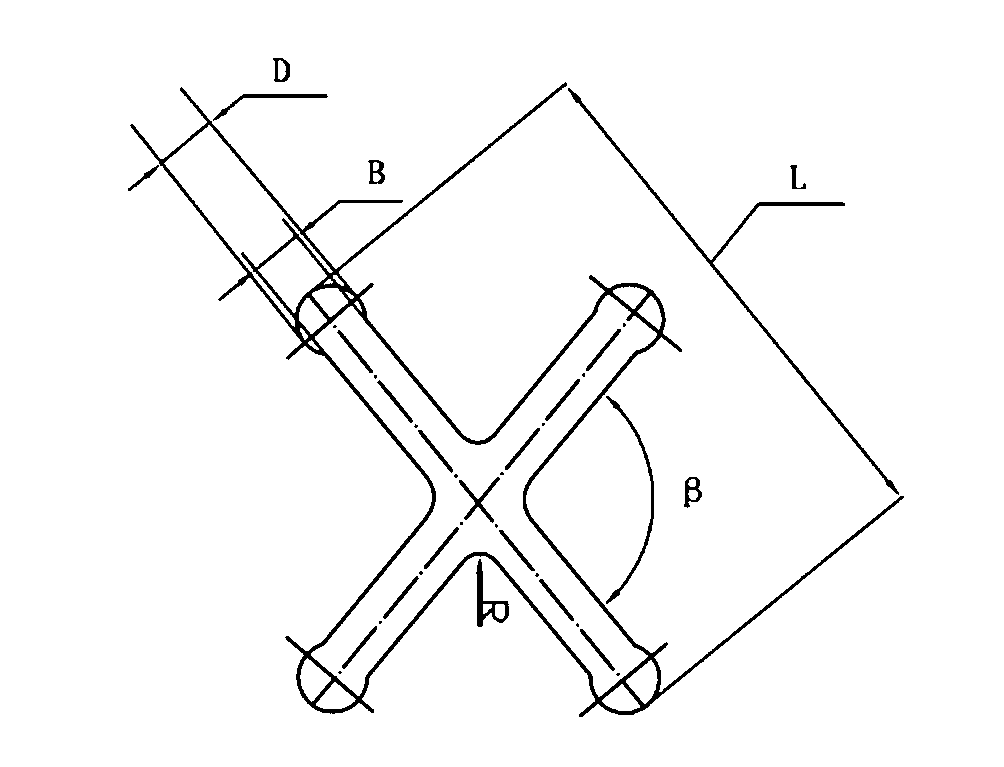

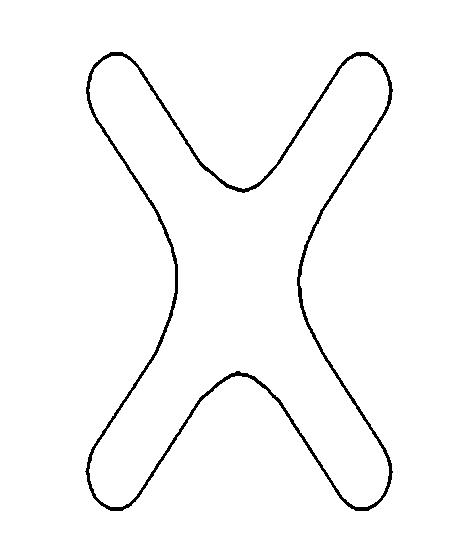

Porous ultrafine X-shaped polyester fiber and preparation method thereof

InactiveCN102851762AHigh porosityHigh degree of abnormalityFilament/thread formingMonocomponent polyesters artificial filamentPolyesterHeat setting

The invention discloses a porous ultrafine X-shaped polyester fiber and a preparation method of the porous ultrafine X-shaped polyester fiber. According to the porous ultrafine X-shaped polyester fiber, a spinning micropore structure of a spinning jet is in a shape of symmetric X blades; an obtuse angle ranges from100 to 110 degrees, and the length-width ratio of the blade is 5 to 8: 1; a cooling formation technology is the combination of annealing and cross air blow cooling; a first hot roll temperature under a thermal forming technology is at 88 to 92 DEG C, and a second hot roll temperature is at 125 to 130 DEG C, and the coiling is carried out at a speed of 3800 to 4200m / min. The fiber prepared by the preparation method provided by the invention is high in profile degree, and different fine groove capillary shapes are formed on the section; high porosity among the fibers is ensured, and the fibers are light in weight; the humidity conductivity and humidity absorbing performance of the fibers are effectively improved, and the water retaining performance and air permeability are effectively improved as well; and meanwhile, the fiber and fabric manufactured by the fiber have good effect of dyeing, and are easily dyed, and have the characteristics of being full in color and bright in gloss; and the fabric touches fluffy and elastic.

Owner:吴江赴东扬程化纤有限公司

Method for processing super-soft home textile fabric

ActiveCN102978959ANo pollution in the processRich sourcesBiochemical fibre treatmentDyeing processDefibrillationEnzyme

The invention aims to disclose a method for processing a super-soft home textile fabric. The method comprises the following steps: mixing, gray fabric pretreatment, primary fibrillation, enzyme treatment, dyeing, secondary fibrillation, softening and resin finishing. Compared with the prior art, the super-soft home textile fabric is formed by interweaving gossamer and high-grade cotton spun yarn, due to dyeing and finishing special process treatment, the gossamer fibrillation is controlled to obtain a flock effect, the style characteristics of the gossamer and cotton mixed fabrics are improved, enzyme treatment defibrillation is used for achieving the flock effect, the traditional napping process is avoided, the operation is simple, the process flow is shortened, the energy consumption is reduced, and the aim of the method is fulfilled.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Method of processing raw bamboo into spinnable bamboo fiber

InactiveCN1624212AEasy to operateGood flexibilityBiochemical fibre treatmentMechanical fibre separationSugarUltimate tensile strength

A method of processing original bamboo into spinnable bamboo fiber, in which original bamboo is reshaped according to stick length, and then putted into pressure container. After such extraneous components as lignin and pectin being deprived by steam, crude bamboo fiber is got. Then by the aid of water solution including plant fungus, the lignin, pectin, sugar, and fat are deprived after immersing and heating. The next step is to laminate and separate the crude bamboo fiber through flute separating machine, and at the same time, wash it with water in order to separate the extraneous components such as lignin and pectin from the fiber. After that, soften and whiten further the fiber by the process of whitening and poaching. Then, dehydration the fiber and add homogeneously proper amount of fiber reinforcement agent in order strengthen its endurance, then softening the fabrics by emulsifier. Finally, through drying process, spinnable bamboo fiber can be produced.

Owner:刘忆萍

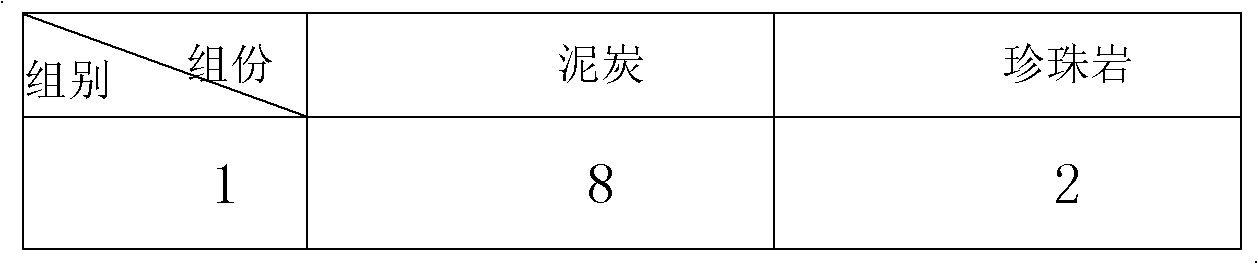

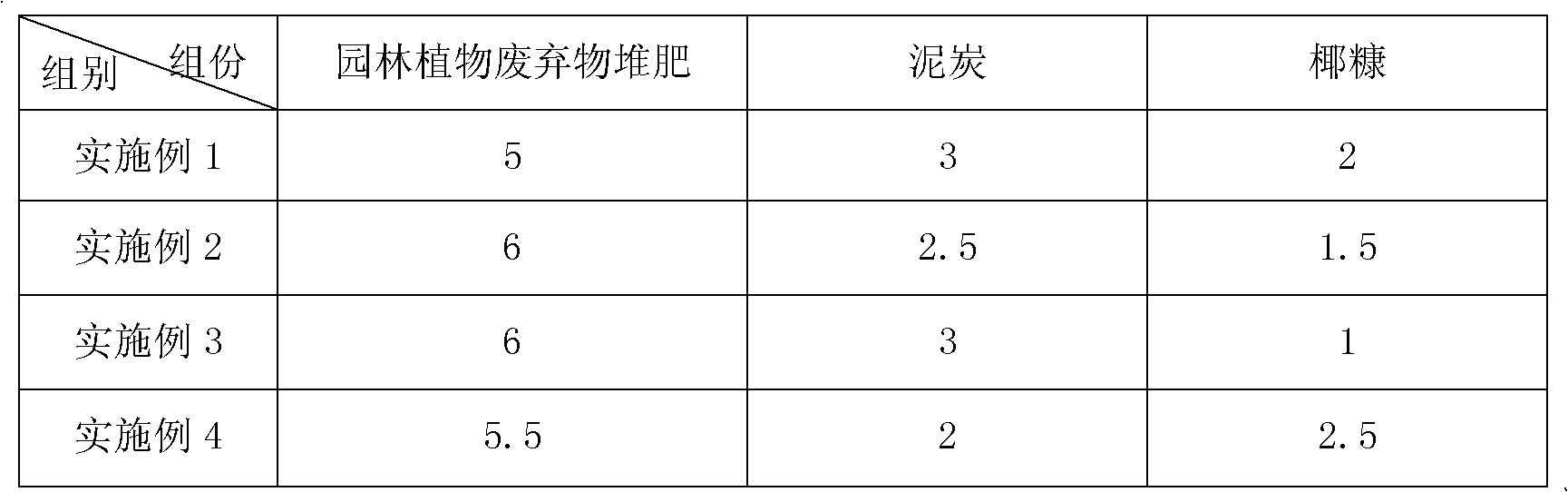

Scindapsus aureus cultivation medium and preparation method thereof

ActiveCN102976839AImprove survival rateMeet the requirements of cutting growth and developmentFertilizer mixturesSocial benefitsEnvironment of Albania

The invention discloses a scindapsus aureus cultivation medium and a preparation method thereof. The scindapsus aureus cultivation medium is prepared by mixing landscape plant waste compost and auxiliary materials according to a certain volume ratio. The landscape plant waste compost is prepared by cutting, crushing, urea and water addition, turning and fermentation. The scindapsus aureus cultivation medium improves physicochemical properties of the original medium, adopts raw materials which have wide sources, are convenient for acquisition and have low prices, utilizes a landscape plant waste compost part to replace non-renewable peat massively used in flower production, improves ornamental plant quality, reduces a production cost, is beneficial for landscape waste utilization and environmental protection, and has good environmental ecological, economic and social benefits.

Owner:SHENZHEN TECHAND ECOLOGY & ENVIRONMENT CO LTD

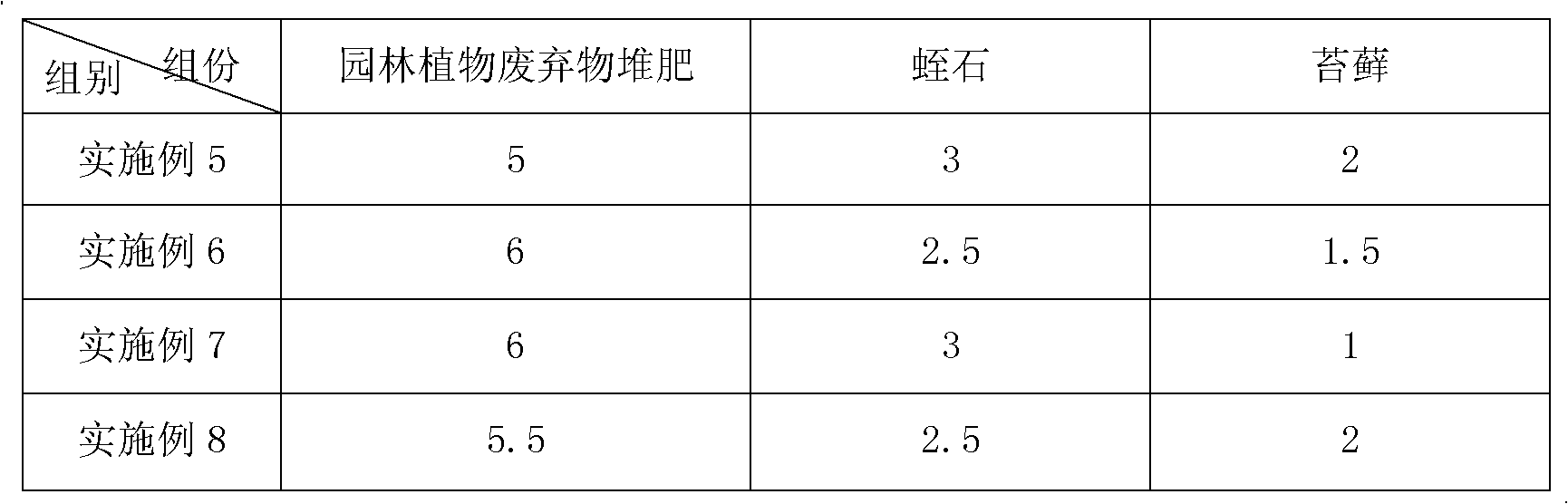

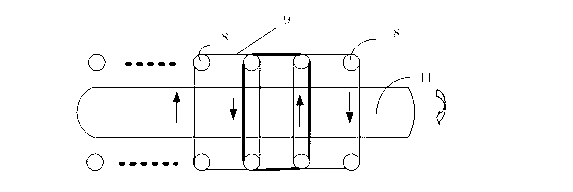

Flax wet-spun blended yarn and preparation method and spinning frame of flax wet-spun blended yarn

ActiveCN102704109AShinyColorfulBiochemical fibre treatmentDry-cleaning apparatus for textilesPolymer sciencePolymer chemistry

The invention discloses a flax wet-spun blended yarn comprising flax roves, wherein the flax roves comprise first flax roves and second flax roves, the number difference of the first flax roves and the second flax roves is not larger than 1.2, polyester filament yarns are added in the flax roves to form a flax wet-spun blended yarn main body, and the flax wet-spun blended yarn main body is in an S direction of twist. The invention also discloses a preparation method of flax wet-spun blended yarn. The invention also discloses a spinning frame for preparing the flax wet-spun blended yarn. The preparation method of the flax wet-spun blended yarn comprises the steps of: threading the polyester filaments with the first flax roves and the second flax roves to form the flax wet-spun blended yarn, wherein the flax wet-spun blended yarn is in the S direction of twist. The flax wet-spun blended yarn disclosed by the invention has the advantages of being gorgeous, glossy, stiff and smooth and durable, and needing no ironing.

Owner:JIANGSU HUAXIN LINEN TEXTILE

Mullite fiber surface modification method

The invention relates to a mullite fiber surface modification method which comprises the following specific steps: 1, compounding a surface modifier; 2, performing surface modification, namely (1) hydrolyzing, (2) infiltrating and grafting, namely immersing the surface modifier from the fibers for infiltrating, enabling the hydroxyl groups of silanol or the hydroxyl groups and -Si-OH on the fiber surface to be subjected to etherification reaction so as to form a Si-O-Si structure, so that the structure is grafted to the fiber surface; then enabling active groups at the other end of a silane coupling agent to react with organic components in an impregnating compound, thereby obtaining the modified mullite fibers; and (3) drying and forming, namely infiltrating within 90 minutes, drying the taken mullite fibers in a drying box at the temperature of 105 DEG C to constant weight. According to the mullite fibers subjected to surface modification, silanol generated by hydrolyzing the silane coupling agent is enabled to act with the -OH on the fiber surface so as to form the Si-O-Si structure, the surface of the modified fiber sample contains coupling agent and film-forming agent components, the fibers are adhered to one another, the surface of the fiber sample is glossy, the softness is greatly improved, and the fiber surface properties are improved.

Owner:EAST CHINA UNIV OF SCI & TECH

Feed additive for improving quality of furs of fur-bearing animals

The invention provides a feed additive for improving the quality of furs of fur-bearing animals, which is prepared from the following components in percentage by weight: 30-40% of Chinese herbal medicine mixture, 2-5% of unsaturated fatty acid composition, 10-15% of compound vitamin, 10-15% of composite trace element and the balance of carrier, wherein the Chinese herbal medicine mixture is prepared from the following components in parts by weight: 3-5 parts of epimedium, 1-3 parts of dodder, 2-5 parts of fleece-flower root, 3-5 parts of angelica, 1-2 parts of radix astragali, and 4-6 parts of codonopsis.

Owner:铜陵王燕堂生物科技有限公司

Solidified goat yogurt containing probiotics and preparation method thereof

InactiveCN101700060ANot prone to demulsificationHigh solidification strengthMilk preparationFlavorSugar

The invention relates to a solidified goat yogurt containing probiotics and a preparation method thereof, and main raw materials comprise non-antibiotic fresh goat milk, non-antibiotic goat milk powder, white sugar, streptococcus thermophilus, lactobacillus bulgaricus and lactobacillus casei. The product can improve the content of solid matters in the goat milk, realize the high solidification strength of the product and be difficult to produce the phenomenon of demulsification by adding the goat milk powder into the fresh goat milk. The solidified goat yogurt has the advantages of smooth surface, luster, smooth taste, mellow and thick milky scent and no goat flavor. The lactobacillus casei is simultaneously added, thereby being more conductive to regulating the intestinal health of human body.

Owner:张忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com