Porous ultrafine X-shaped polyester fiber and preparation method thereof

A polyester fiber and polyester chips technology, applied in fiber processing, single-component polyester rayon, filament/thread forming, etc., can solve the problem of poor moisture absorption and water retention rate of fiber fabric products, which affects the wearing comfort of products , low degree of irregularity, etc., to achieve the effect of moisture conduction, moisture absorption and water retention, good air permeability, bright luster, and high degree of irregularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

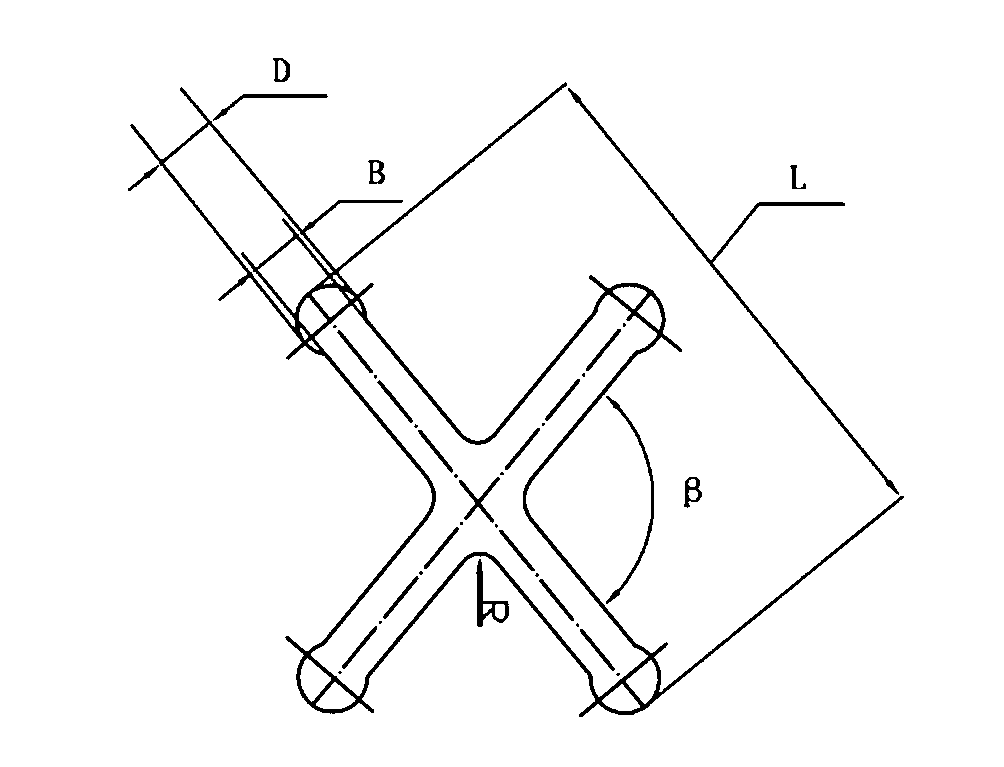

[0022] The parameters of the spinning forming processing process are: the viscosity of polyester slices is 0.648DL / g, and the spinning temperature is 291 ° C. See the attachment figure 1 , It is a schematic diagram of the spraying micropore structure provided by the embodiment of this embodiment. It is a symmetrical X -leaf shape. The blunt angle angle β is 105 °, the length of the leaf shape is 0.6mm, the width B is 0.1mm, the lengthThe width ratio is 6: 1, and the four outer ends of the leaf shape are arc -shaped, and the diameter D is 0.13 mm; the interception of the leaf shape is the arc transition, the radius is 0.04 mm; the radius is 0.04 mm;

[0023] The height of Xu Leng District is 140mm, the temperature of the Xu Leng District is 310 ° C, the winding wind pressure is 60Pa, and the temperature of the ring blowing air is 22 ± 2 ° C.It is made of 5DTEX / 72F X -shaped polyester fiber with a break -in strength of 3.65cn / dtex and a break -elongation rate of 20%.

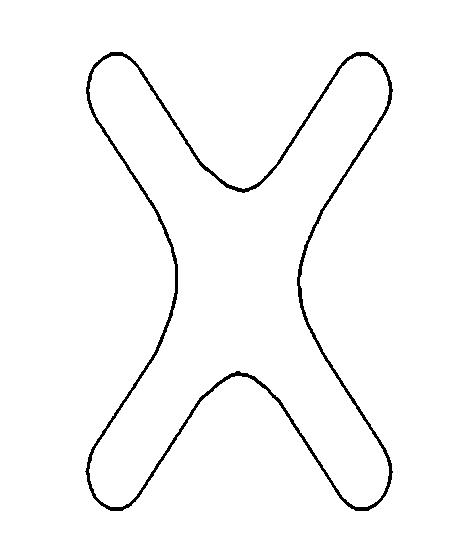

[0024] See fi...

Embodiment 2

[0027] The parameters of the spinning forming processing process are: the viscosity of polyester slices is 0.648DL / g, and the spinning temperature is 290 ° C. See the attachment figure 1 , It is a schematic diagram of the spraying micropore structure provided by this embodiment. It is a symmetrical X -leaf shape. The blunt angle angle β is 110 °, the length of the leaf shape is 0.6mm, the width B is 0.08mm, the length is longThe width ratio is 7.5: 1. The four outer ends of the leaf shape are arc -shaped, and the diameter D is 0.096 mm.

[0028] The height of Xu Leng District is 130mm, the temperature of the Xu Leng District is 315 ° C, the winding wind pressure of the outer ring is 60Pa, the temperature of the ring blowing air is 22 ° C, the temperature of the first heat roller is 91 ° C, the temperature of the second heat roller is 128 ° C, and the speed of the winding speed is 4450m / min.The fracture strength of the 76DTEX / 96FX polyester fiber obtained by the spinning is 3.45cn / ...

Embodiment 3

[0031] The height of Xu Leng District is 120mm, the temperature is 310 ° C, the winding wind pressure is 60Pa, the temperature of the ring blowing air is 22 ° C, the temperature of the first heat roller is 88 ° C, the temperature of the second heat roller is 125 ° C, the routing speed is 4350m / min, the textile is textured76DTex / 144FX -shaped polyester fiber has a break strength of 3.40cn / dtex, and the breakdown rate is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com