Manufacturing method for vegetable fiber compound tableware

A plant fiber and manufacturing method technology, applied in the direction of manufacturing tools, wood processing equipment, wood compression, etc., can solve the problems of mechanical properties, water resistance, durability, too simple utilization of bamboo fiber, low utilization efficiency, etc., to achieve the appearance Improving, improving appearance and texture, and preventing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0045] Specific embodiment of the present invention 1: the formula of raw material is as table 1 in the present embodiment:

[0046] Table 1

[0047] components

Mass ratio (parts)

100

2

2

Titanium dioxide

5

Melamine resin

80

0.2

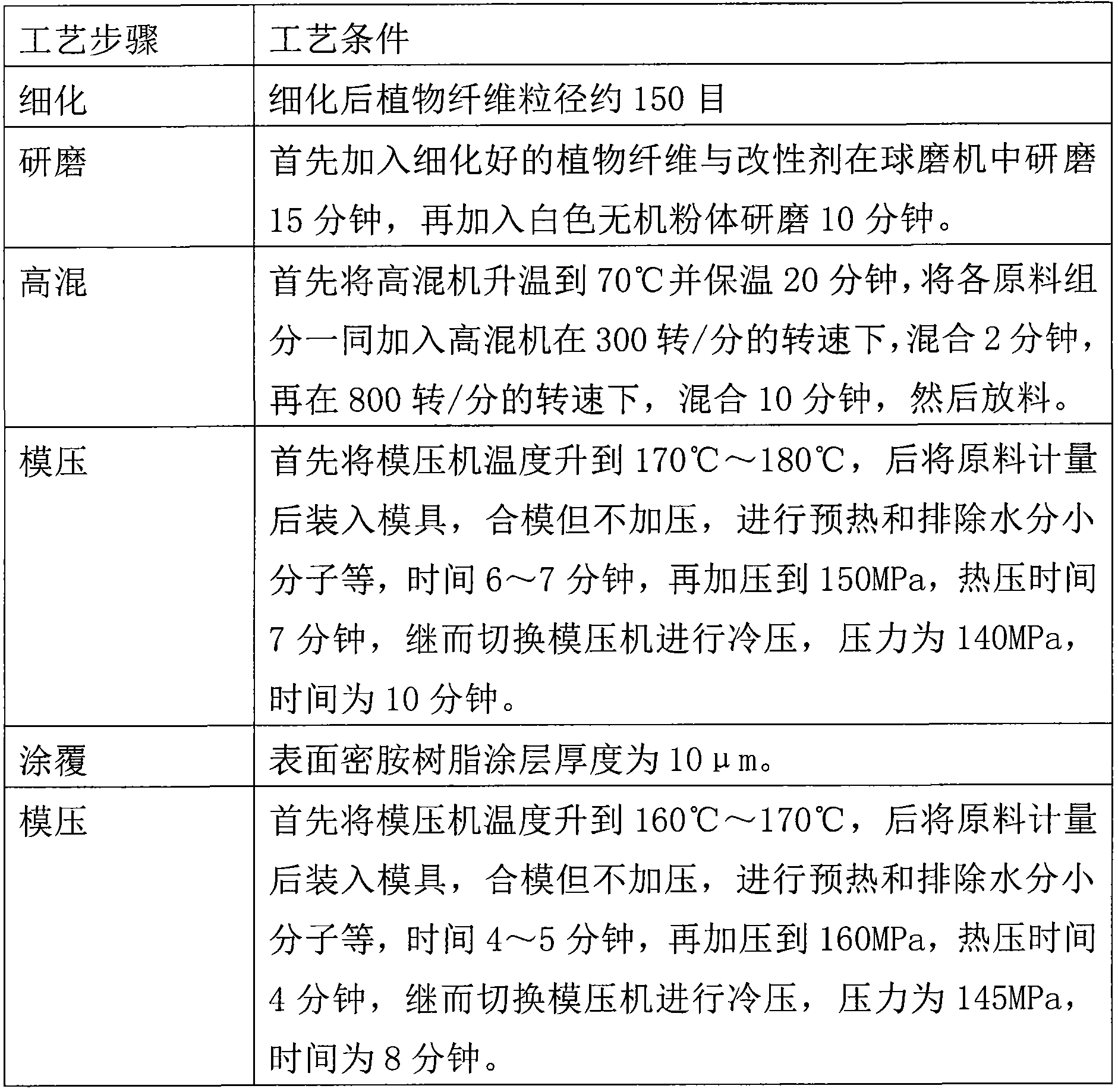

[0048] Each step processing condition is as table 2 in the present embodiment:

[0049] Table 2

[0050]

[0051] The plant fiber composite tableware manufactured in Example 1 was carried out in an anti-drop test and found that it was not damaged after being dropped from a height of 5 meters, while ordinary ceramic tableware was damaged when dropped from a height of 1 meter. It can be seen that its anti-drop performance is much better than that of ceramic tableware; implementation The plant fiber composite tableware manufactured in Example 1 was tested for water resistance and high temperature resis...

Embodiment 2

[0052] Embodiment two, the formula of raw material in the present embodiment is as table 3:

[0053] table 3

[0054] components

Mass ratio (parts)

100

1

2

Titanium dioxide

3

Kaolin

5

Melamine resin

80

blue paint

0.5

0.2

gloss agent

1

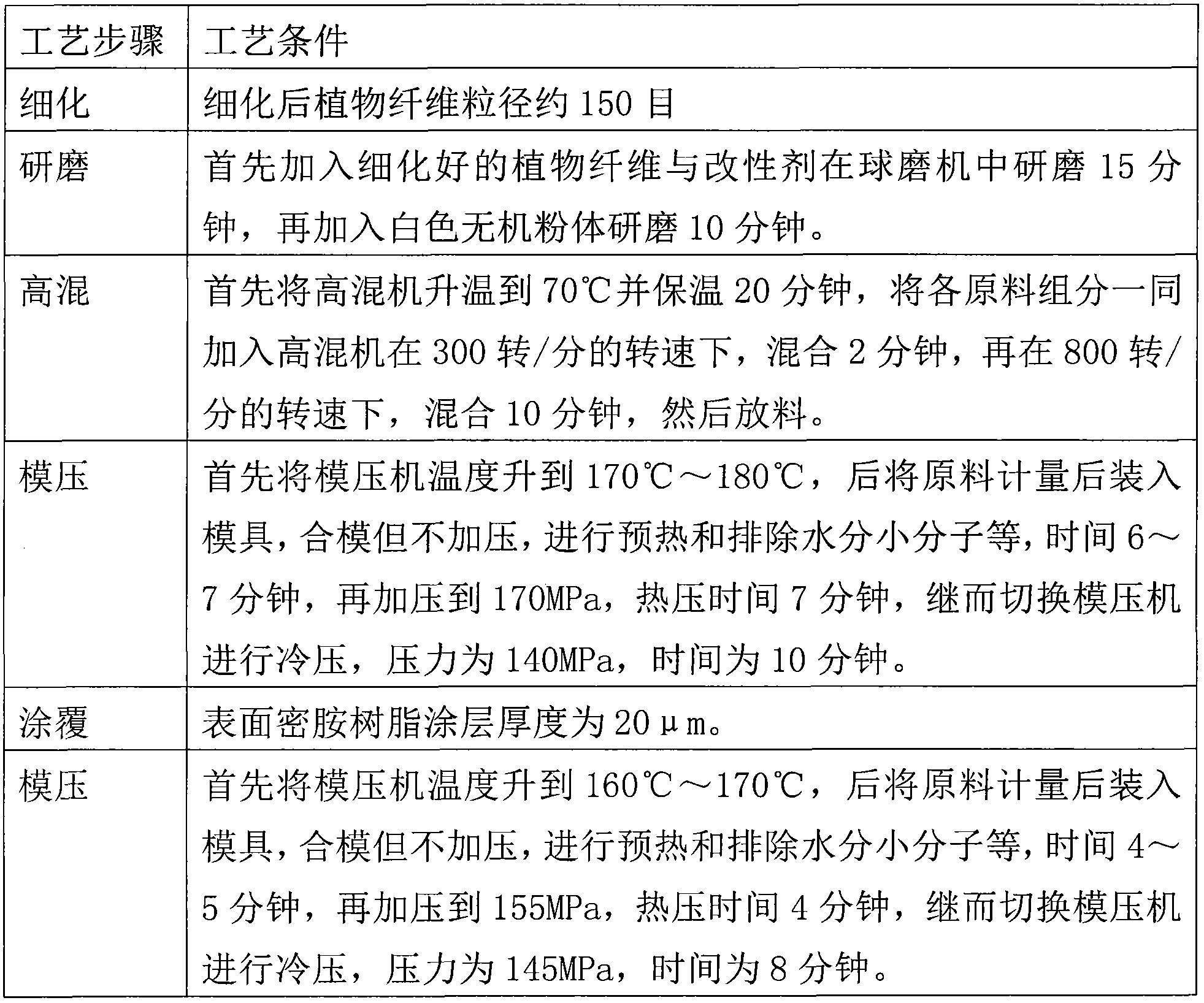

[0055] Each step processing condition is as table 4 in the present embodiment:

[0056] Table 4

[0057]

[0058] The plant fiber composite tableware manufactured in Example 2 is basically the same in terms of drop resistance, water resistance, high temperature resistance, durability, etc., while Example 2 has a slightly different appearance than Example 1 because of the addition of blue pigments and gloss agents. Enhanced, more beautiful and generous.

[0059] Application direction: tableware, kitchenware, ashtray, bathroom, photo frame, tissue box, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com