Patents

Literature

293results about How to "Improve liquid absorption capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

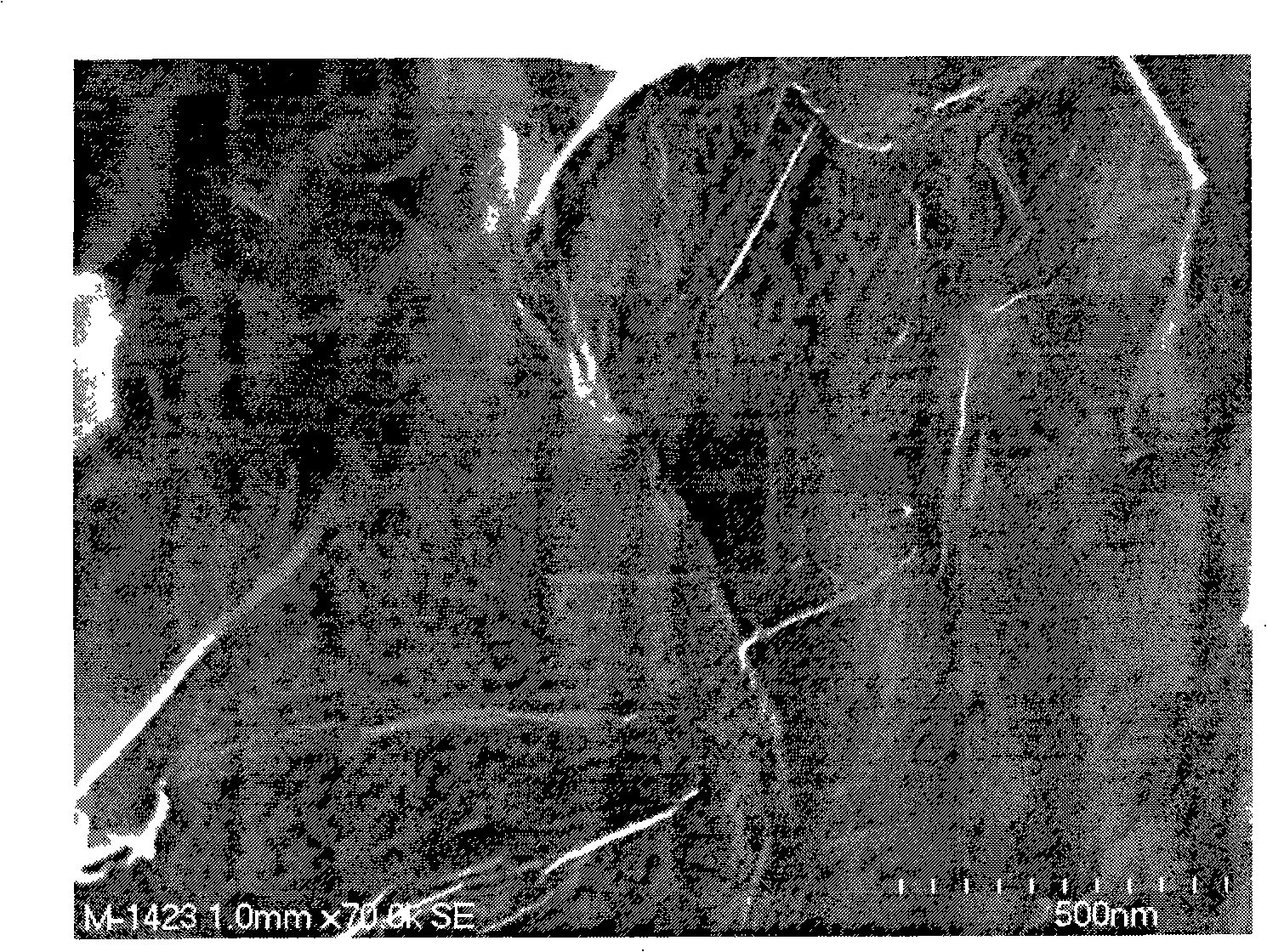

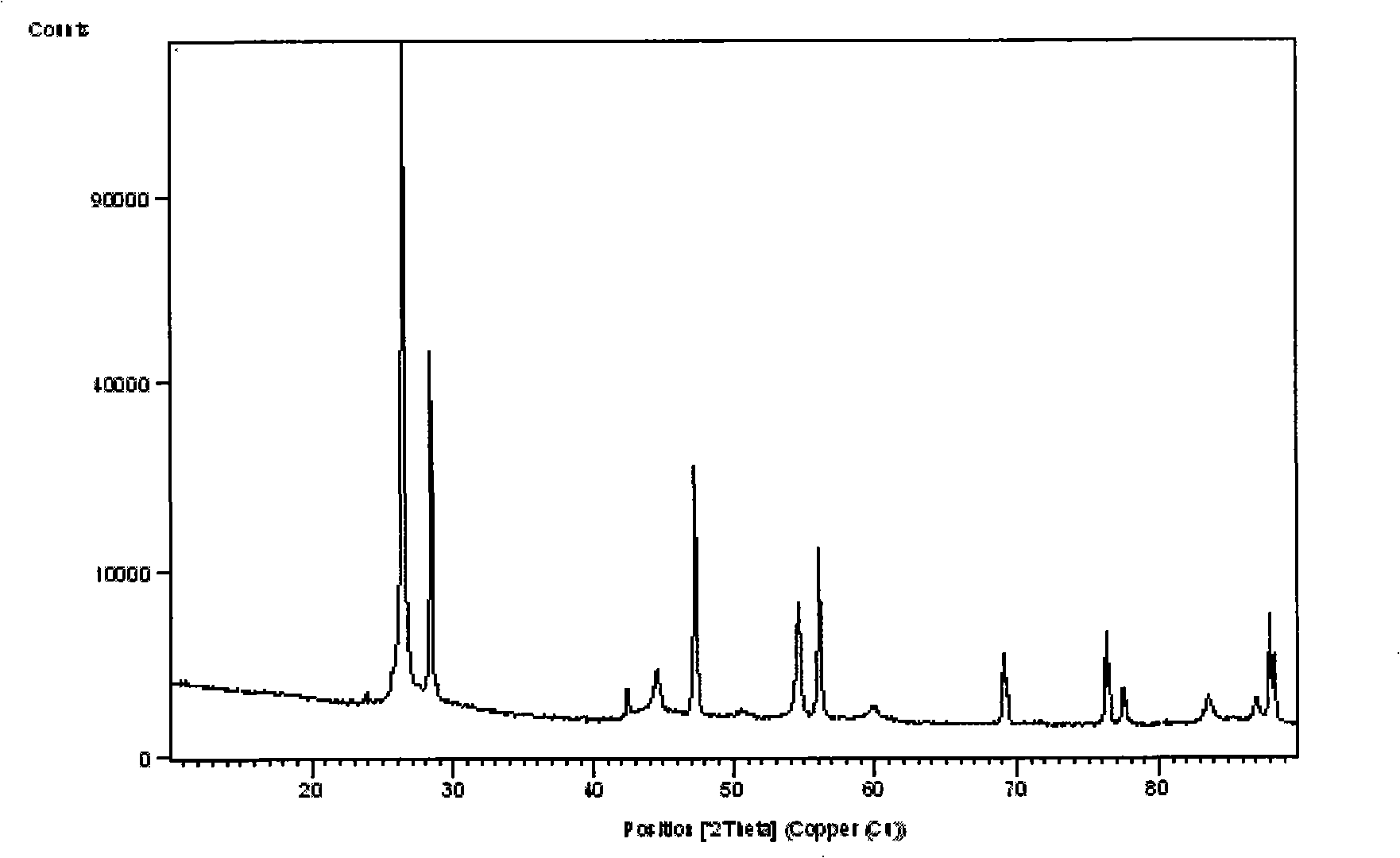

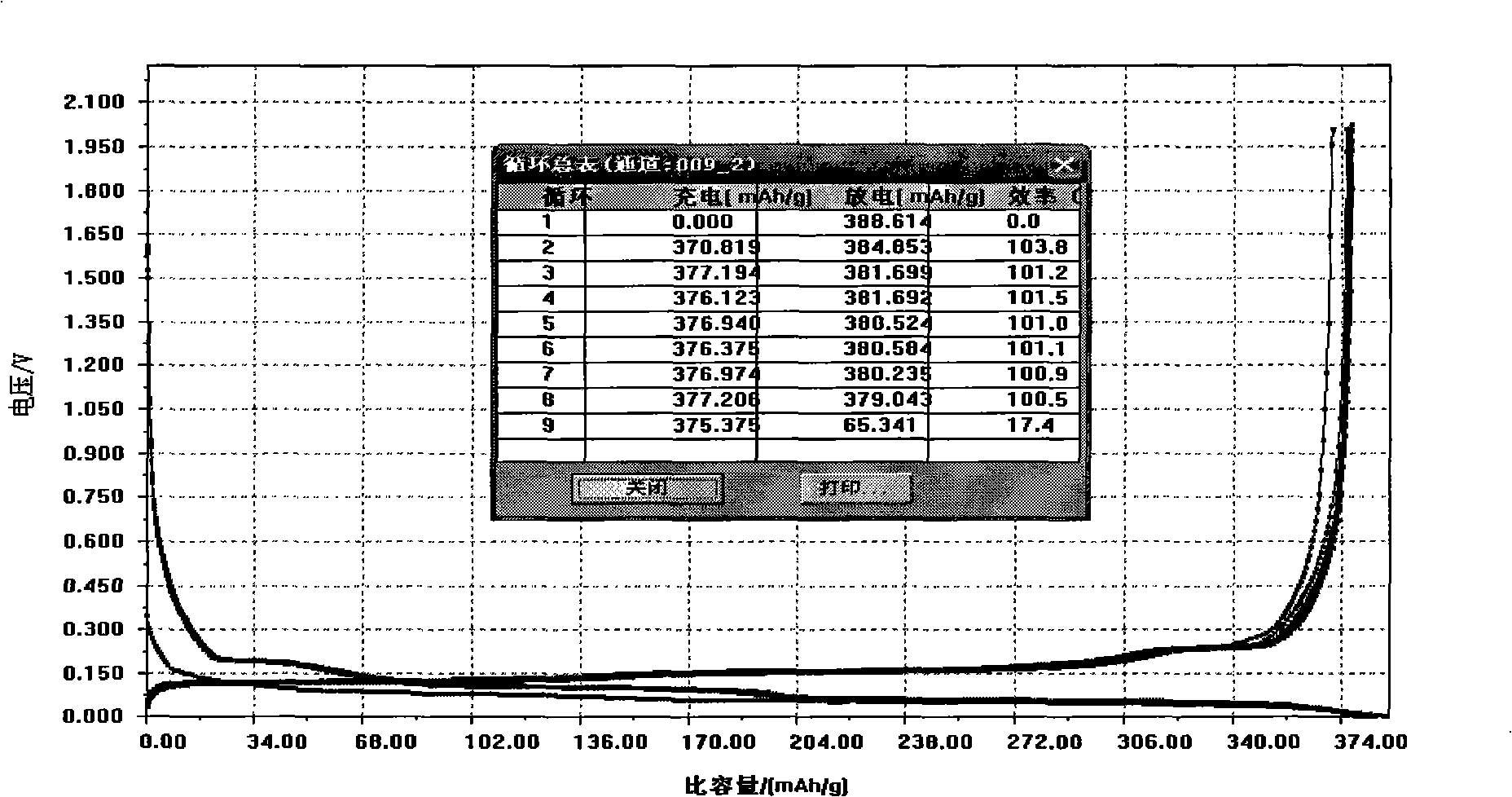

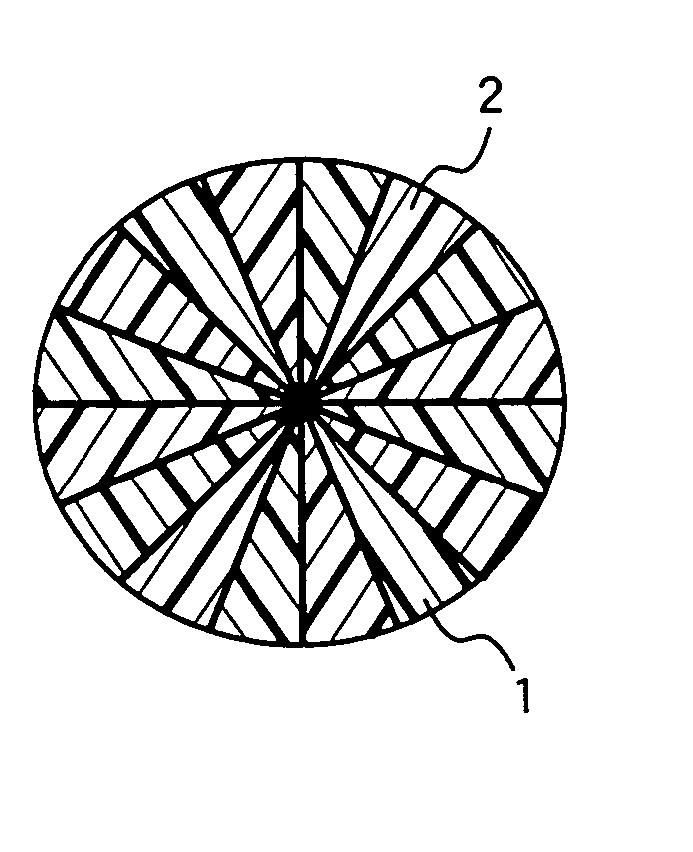

Graphite powder of lithium ionic cell cathode and preparation thereof

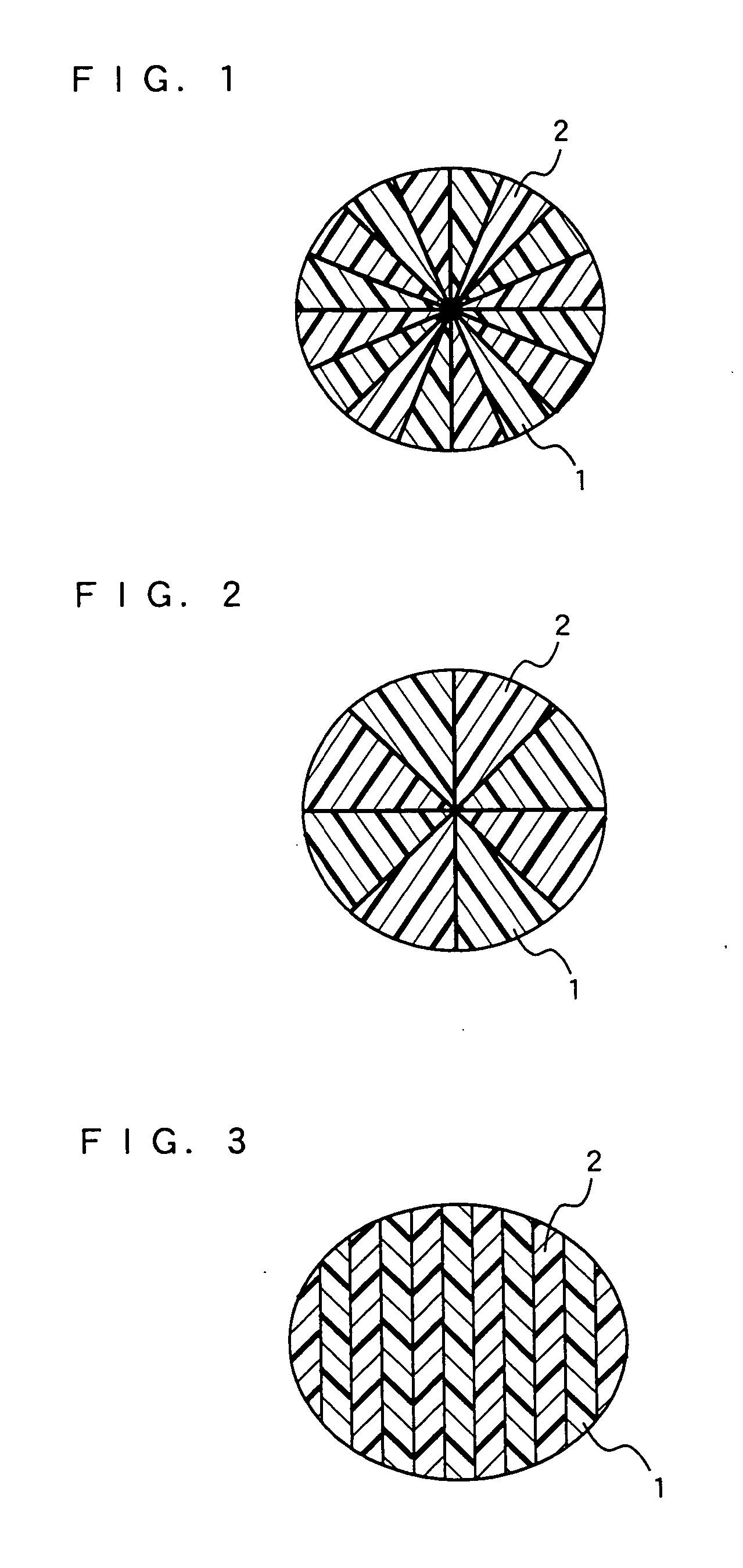

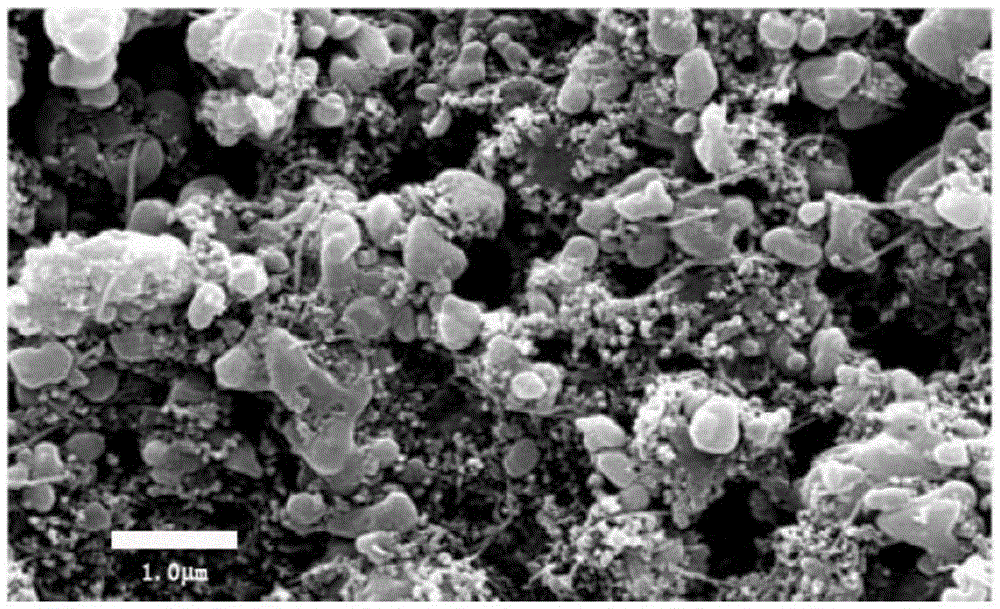

ActiveCN101323447AHigh purityImprove liquid absorption capacityCell electrodesSpherical shapedGraphite

The invention discloses a graphite powder of the cathode of a lithium ion battery, and a preparation method thereof; the technical problem to be solved is that the transmission speed of a lithium ion and an electrolyte to the inside of the electrode needs to be increased. The graphite powder of the cathode of the lithium ion battery of the invention has the microscopic feature of massive, spherical and near-spherical shapes and has the characteristics of nano-porous. The preparation method thereof comprises the following steps of: grinding, adding coating modifiers or / and catalysts, mixing, dissolving, and carrying out preheating treatment and heat treatment. Compared with the prior art, the invention carries out modifying treatment to graphite material and realizes the characteristic of nano-porous by adding pore-forming agents, thus being beneficial to the transmission of the lithium ion, improving the liquid-absorbing performance of a pole piece after compaction, reducing the content of impurity in the graphite, improving the liquid-absorbing performance and the magnification performance of the graphite material, meeting the requirements of the lithium ion dynamic battery for the compatibility and the charging and discharging performance with large magnification of the electrolyte of the graphite material and having the advantages of lower production cost, simple technique and easy industrialization.

Owner:BTR NEW MATERIAL GRP CO LTD

Nonwoven fabric composed of ultra-fine continuous fibers, and production process and application thereof

InactiveUS20050079781A1Increase flexibilityIncrease softnessSynthetic resin layered productsFilament/thread formingPolymer sciencePolyvinyl alcohol

A nonwoven fabric composed of ultra-fine continuous fibers having a mean fineness of not more than 0.5 dtex is prepared. The nonwoven fabric comprises a water-soluble thermoplastic resin in a proportion of not more than 5% by weight relative to the nonwoven fabric, has an absorbing height of not less than 30 mm as determined at 20° C. after 10 minutes based on Byreck method when the nonwoven fabric immersion-treated for 60 minutes in a water of 80° C. is used, and satisfies the following formula: (B) / (A)≧0.25, wherein the symbol (B) represents a tensile strength [N / 5 cm] in the longitudinal direction and the lateral direction of the nonwoven fabric and the symbol (A) represents a fabric weight [g / m] of the nonwoven fabric. In the nonwoven fabric, not less than 30% of the surface may be coated with the water-soluble thermoplastic resin. The water-soluble thermoplastic resin may be a water-soluble thermoplastic polyvinyl alcohol, e.g., a modified polyvinyl alcohol containing an ethylene unit in a proportion of 3 to 20 mol %. The present invention provides a nonwoven fabric composed of ultra-fine continuous fibers, having a high flexibility or softness, and having a high mechanical strength even when the fiber diameter is small, and having an excellent water absorbency, as well as a production process and an application thereof.

Owner:KURARAY CO LTD

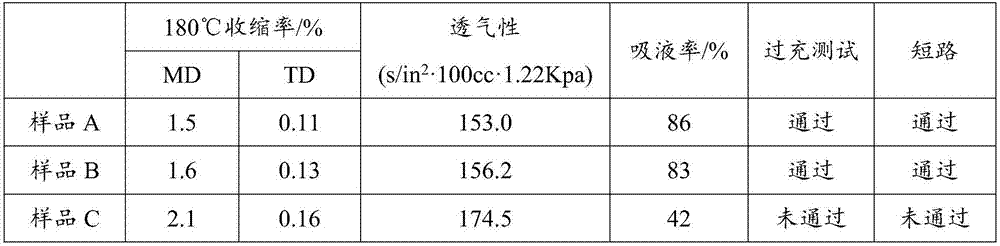

Ceramic diaphragm for lithium ion battery and preparation method of ceramic diaphragm

InactiveCN105514328AImproved cycle life and rate performanceImprove bindingCell component detailsSolventCeramic particle

The invention discloses a ceramic diaphragm for a lithium ion battery. The ceramic diaphragm comprises a diaphragm base material and a ceramic coating on the surface of the diaphragm base material, wherein ceramic particles having a porous structure and a high specific surface area are selected for the ceramic coating. A preparation method includes the following steps of firstly, evenly mixing ceramic particles, binder and solvent to obtain coating slurry; secondly, evenly coating the surface of the diaphragm base material with the coating slurry, and conducting drying to form the ceramic diaphragm. Quite strong binding force exists between the porous ceramic powder and the binder, and the powder falling phenomenon is effectively avoided; meanwhile, the ceramic diaphragm has high electrolyte wettability and quite strong liquid absorption capacity, the cycle life and rate capability of the lithium ion battery are increased, and excellent electrochemical performance is achieved; in addition, under the same thickness, the mass of the porous ceramic coating is far lower than that of an ordinary ceramic coating, and the energy density of the battery is improved.

Owner:TIANNENG SAFT ENERGY JOINT CO

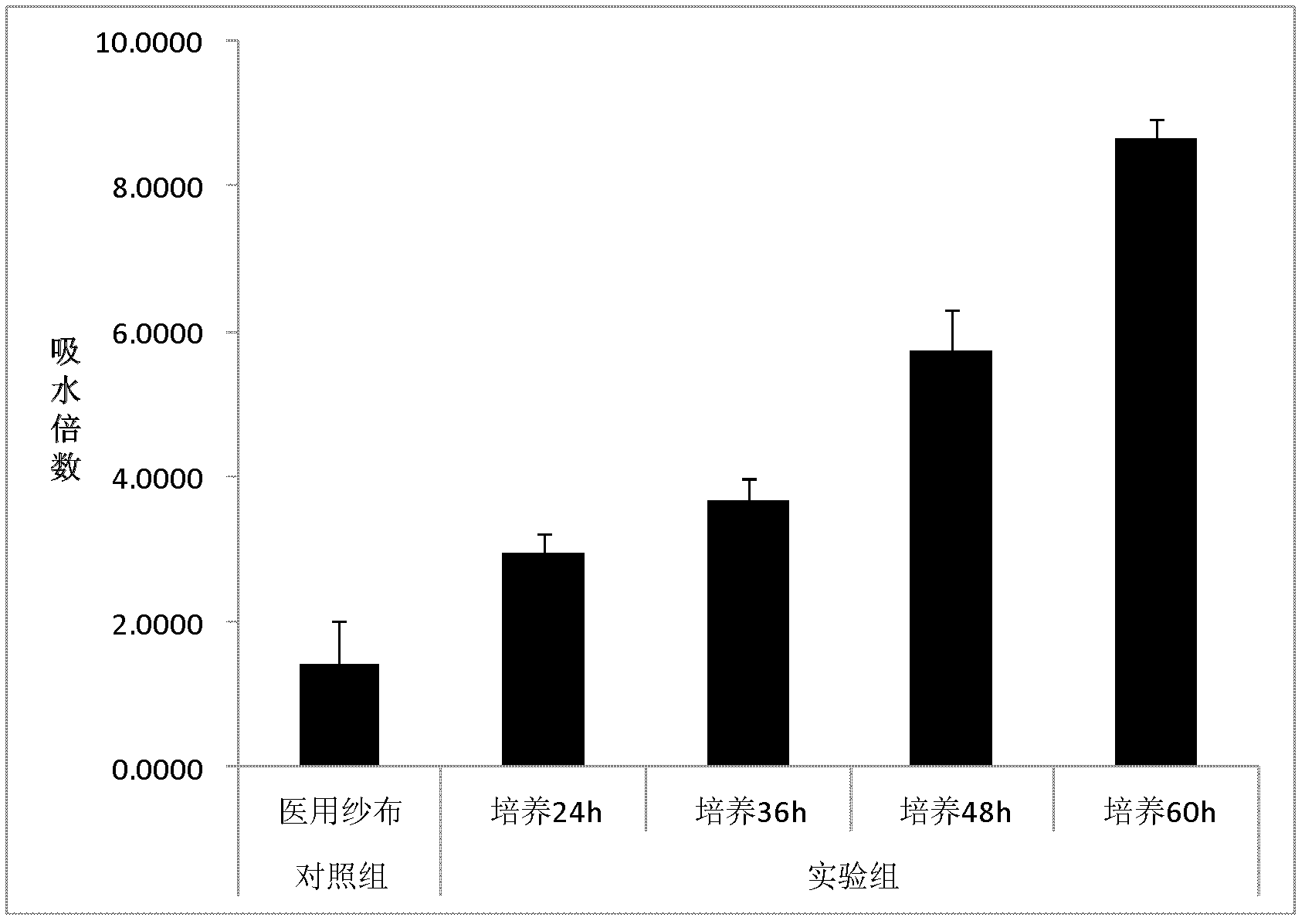

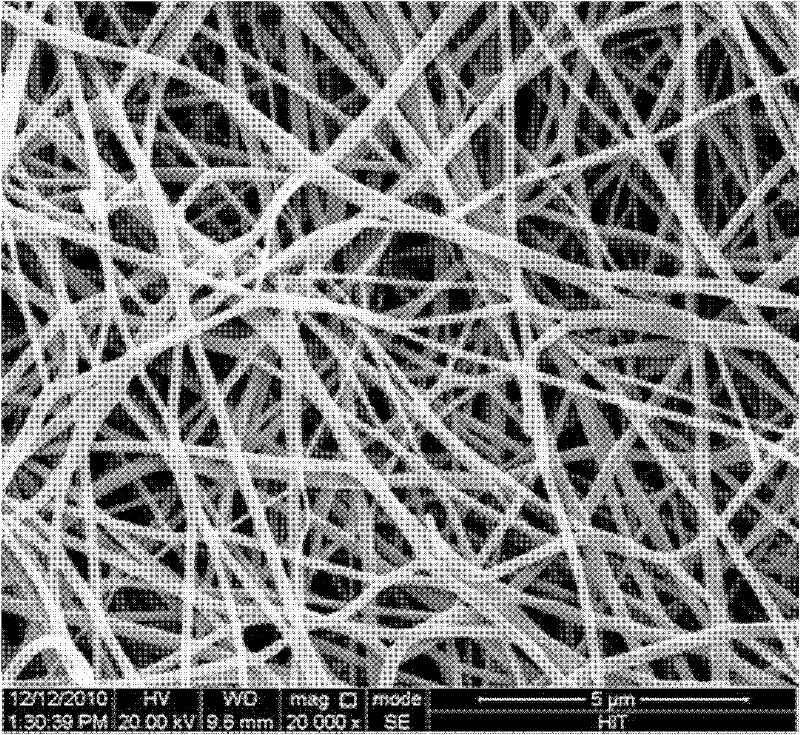

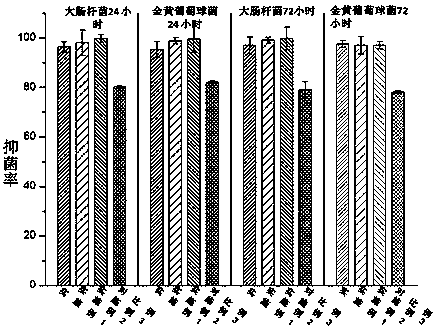

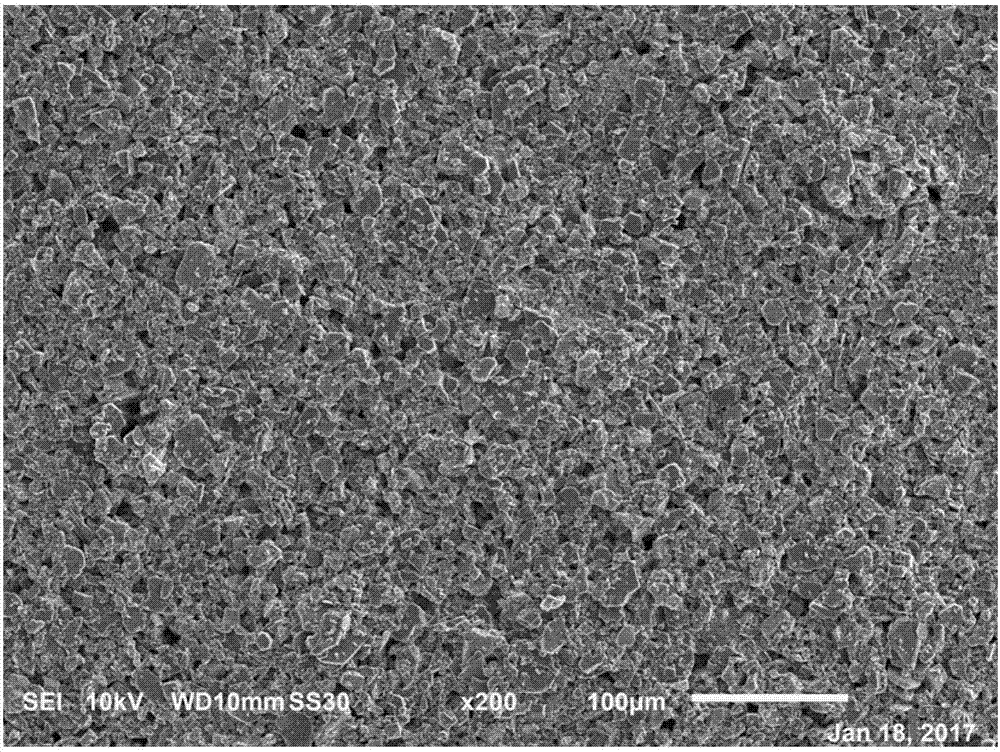

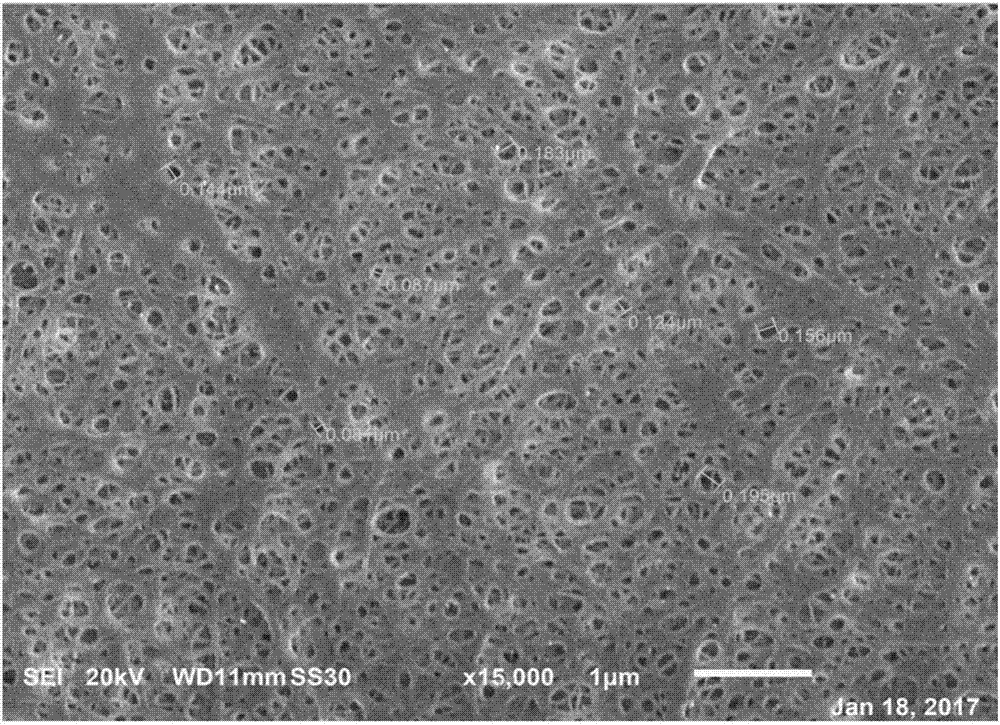

Method for preparing nano-cellulose antibacterial composite material through on-line culture

ActiveCN102552965ARealize fermentation productionImprove continuityCosmetic preparationsBacteriaWater bathsFiber

The invention relates to a method for preparing a nano-cellulose antibacterial composite material through on-line culture. The method comprises the following steps of: (1) inoculating an activated bacterial cellulose producing strain into a liquid culture medium, performing amplification culture, transferring the liquid culture medium into a bioreactor, culturing, adding an antibacterial material into the liquid culture medium, and continuing to culture to obtain an unpurified antibacterial bacterial cellulose composite material; and (2) peeling a bacterial cellulose membrane from a framework or directly soaking the composite material in a NaOH solution, treating in water bath, and washing until an obtained product is neutral to obtain the nano-cellulose antibacterial composite material. The preparation efficiency is high, and the method is simple, convenient, feasible and low in cost; and the surface of the bacterial cellulose composite material has a nanoscale three-dimensional fibrous mesh-shaped structure, the tensile strength of the material is greatly improved compared with that of a pure bacterial cellulose membrane, and the material can be widely applied to products such as facial masks, wound dressings, plasters, artificial skins and the like.

Owner:DONGHUA UNIV

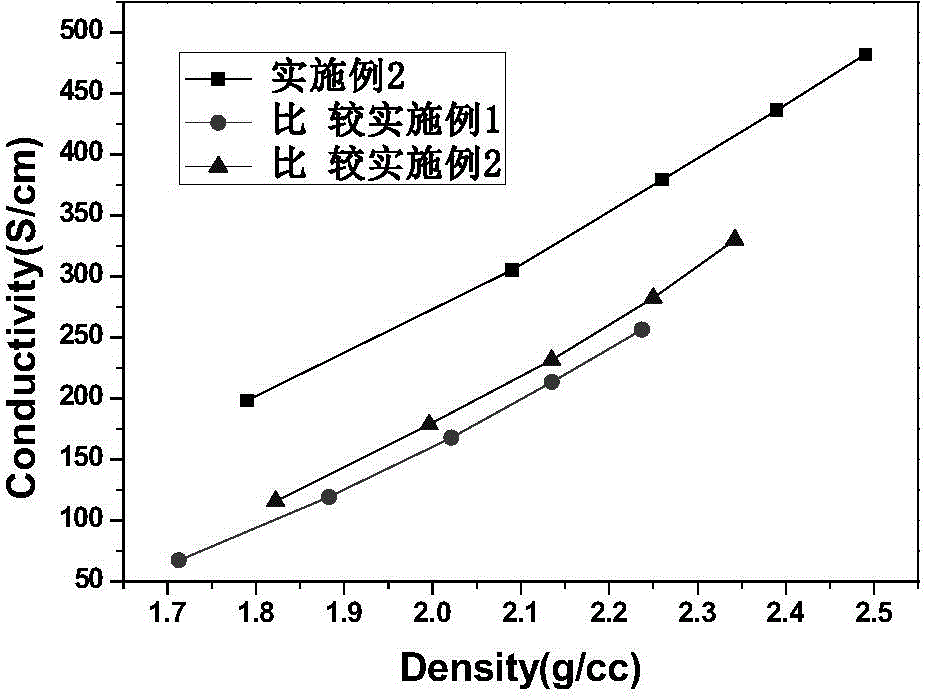

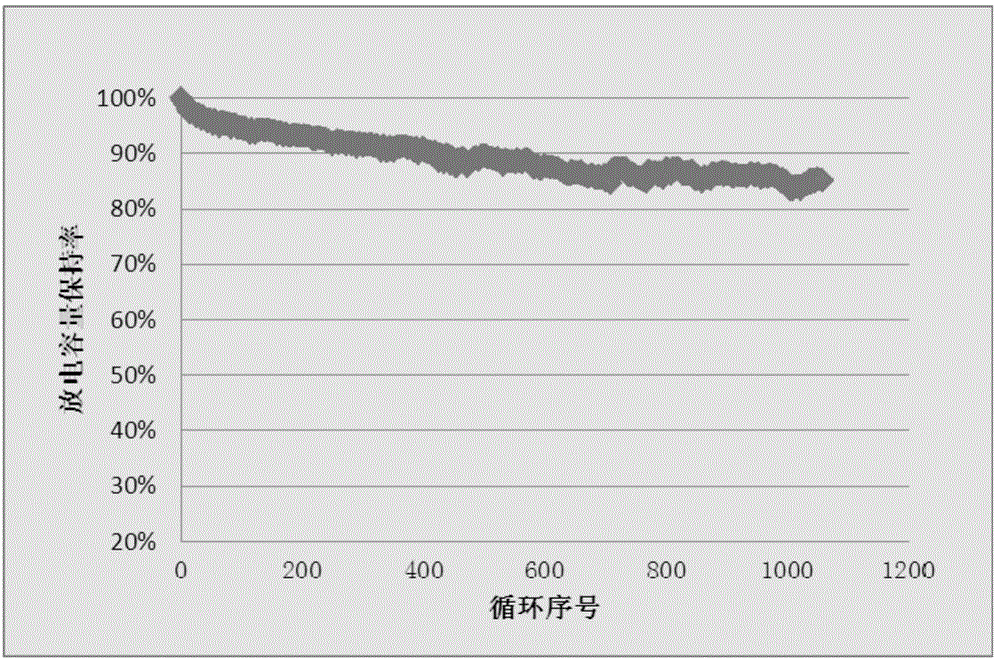

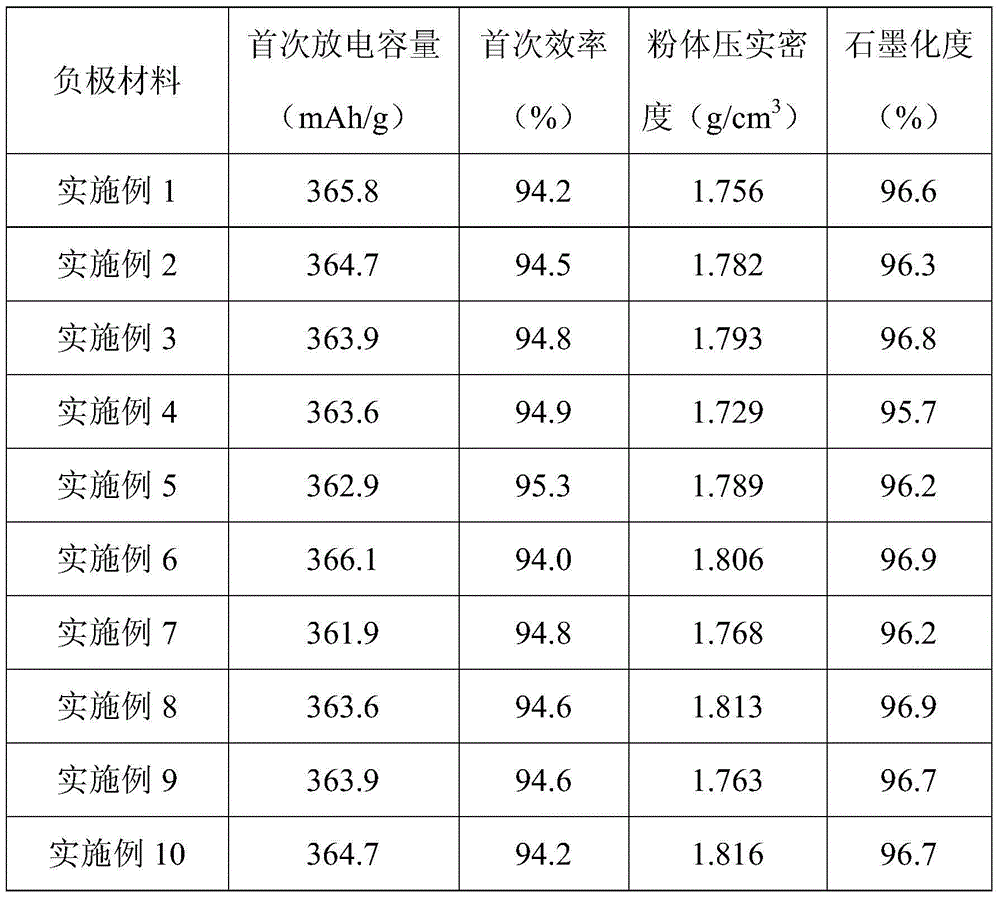

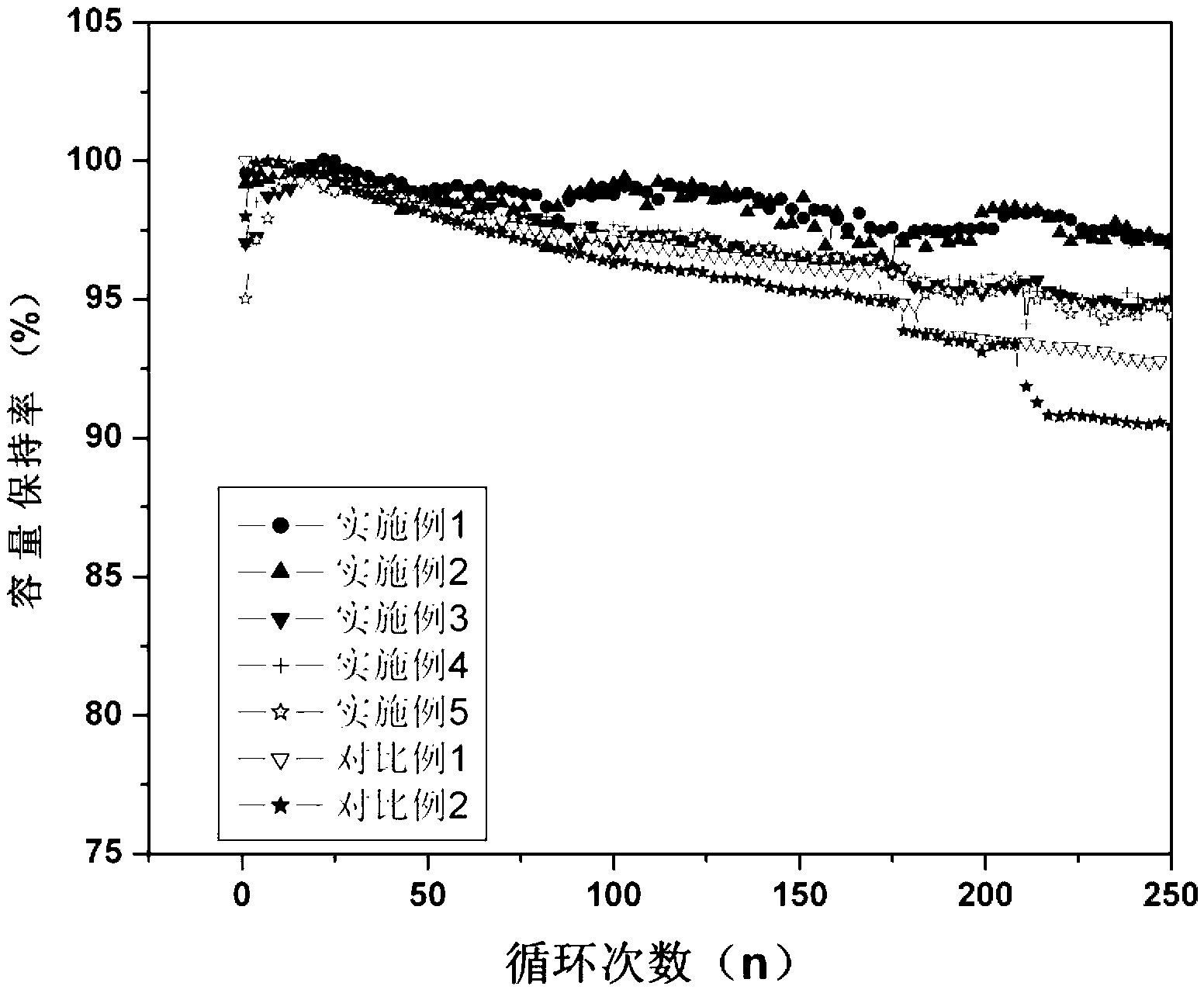

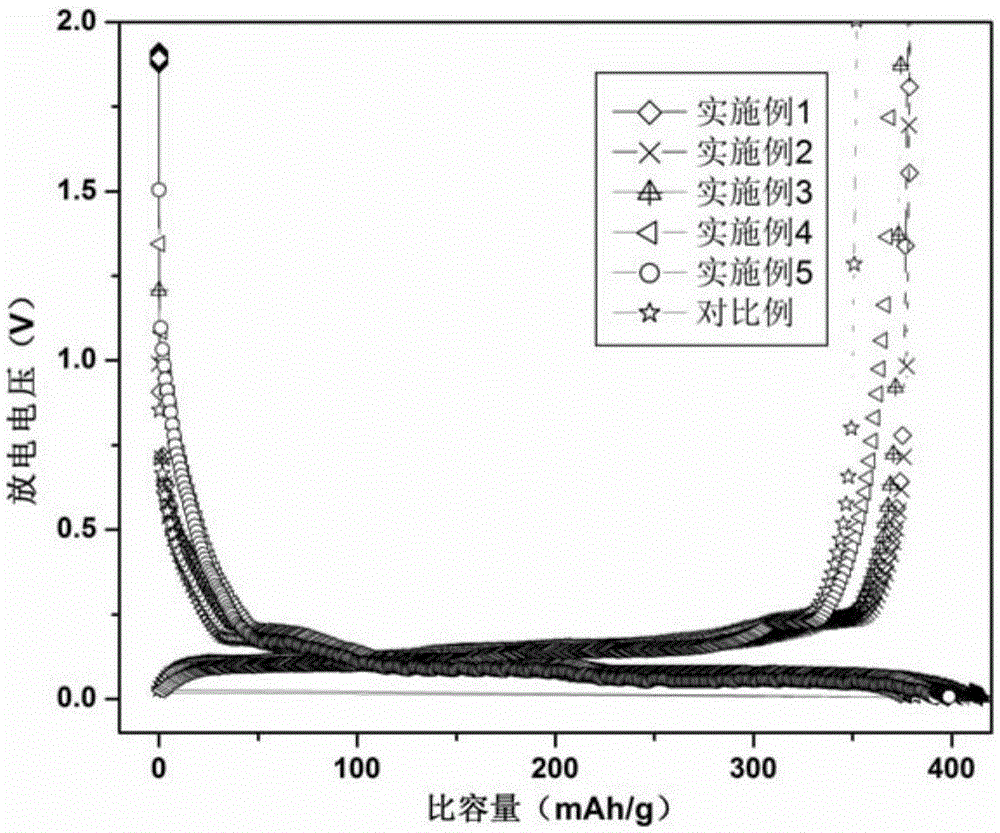

Artificial graphite negative electrode material for lithium ion battery and preparation method thereof

ActiveCN104085883AImprove cycle lifeImprove the degree of graphitizationCell electrodesSecondary cellsCompression moldingAluminium-ion battery

The invention discloses an artificial graphite negative electrode material for a lithium ion battery and a preparation method thereof. The preparation method for the artificial graphite negative electrode material comprises the following steps: preparing powder, adding a binder and / or a crystal nucleus-induced growth additive, kneading, carrying out compression molding, thermally roasting, carrying out nodulizing shaping and / or fusing, carrying out ultrahigh-temperature graphitization, screening, removing magnetism and screening. The preparation method disclosed by the invention is simple to operate, easy to control, lower in production cost and suitable for industrial production. The prepared artificial graphite negative electrode material has high graphitization degree, high compactness, high capacity, high coulombic efficiency, high conductivity and high multiplying power, and can be used for the lithium ion battery.

Owner:贝特瑞(江苏)新材料科技有限公司

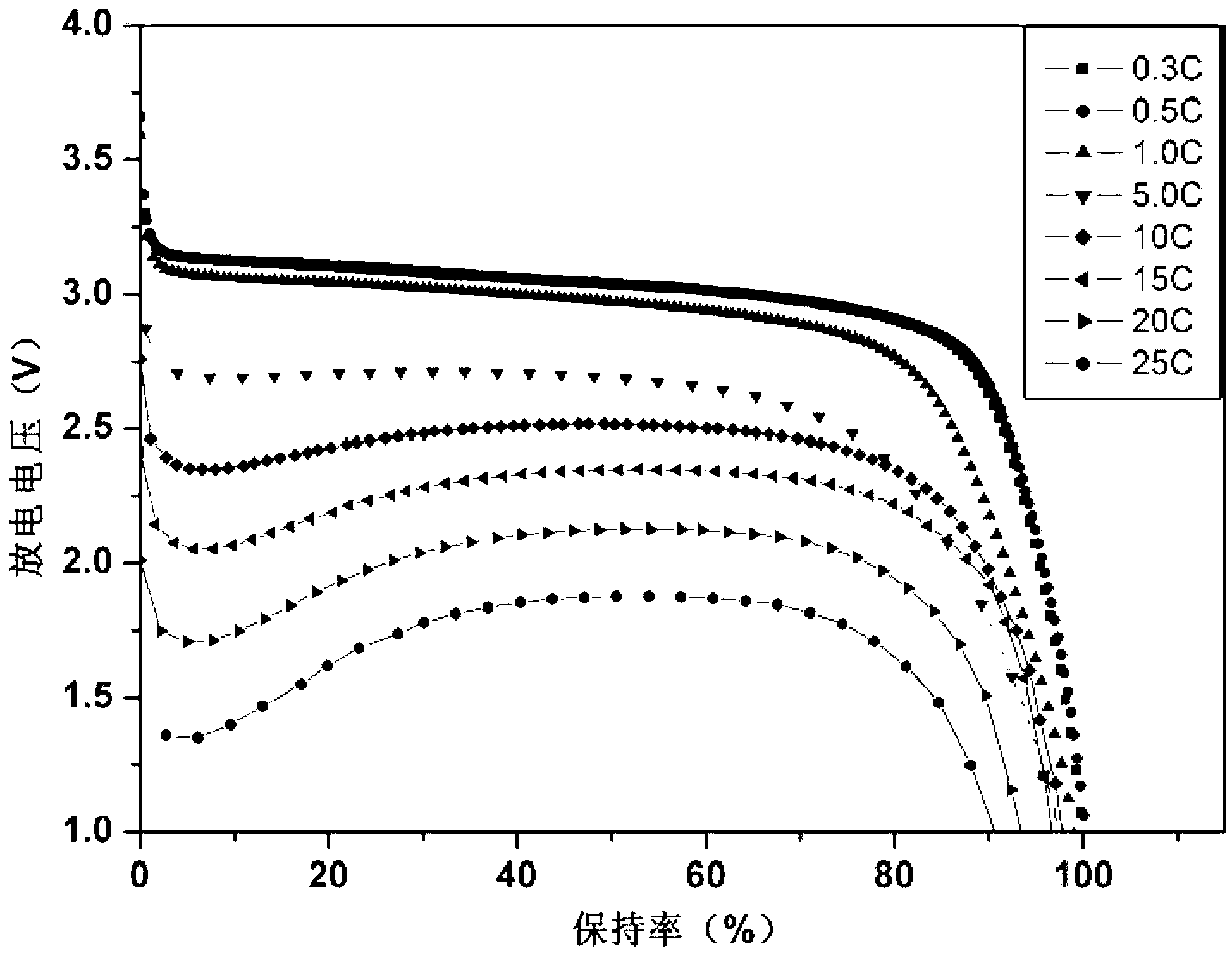

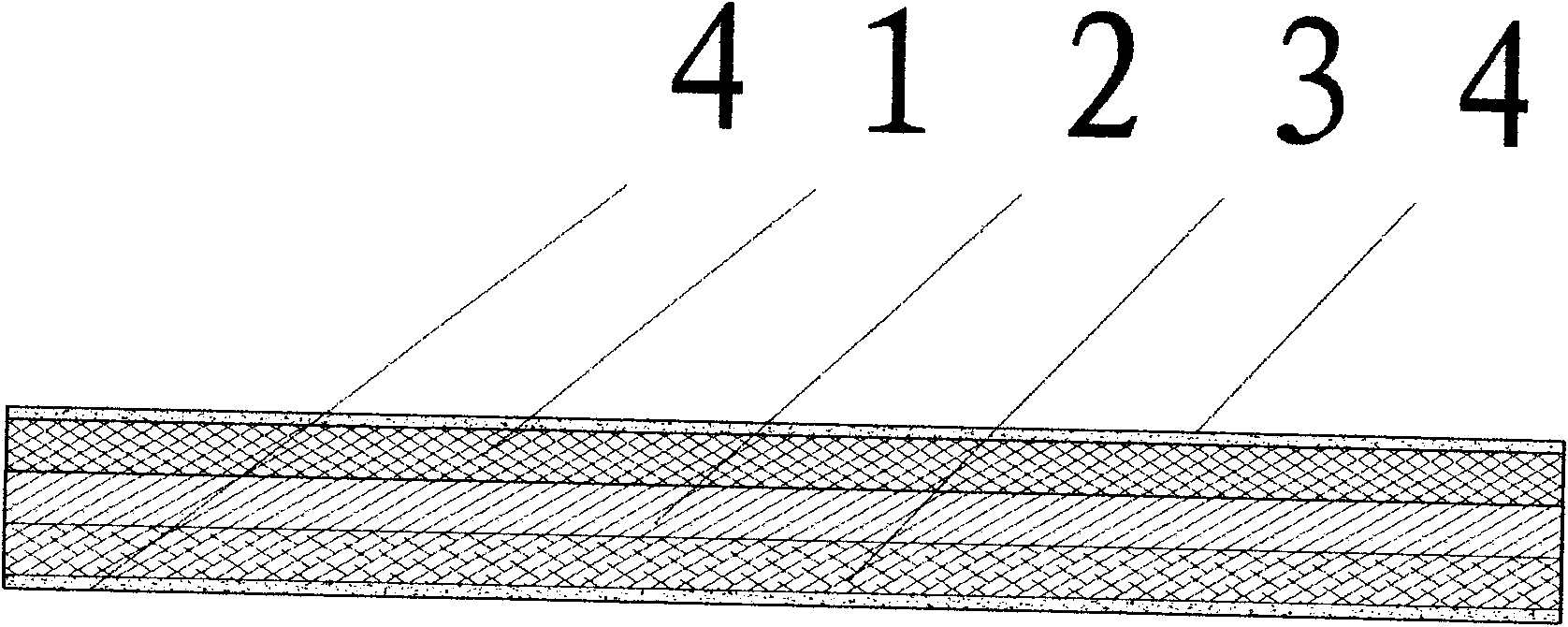

Lithium-sulfur battery

InactiveCN107665966ALower internal resistanceImprove cycle performanceCell seperators/membranes/diaphragms/spacersCell electrodesLithium–sulfur batteryPolymer

The invention discloses a lithium-sulfur battery adopting a multi-layer composite separator. The multi-layer composite separator is characterized in that one side surface of a substrate separator is coated with a polymer layer A, the other side surface of the substrate separator is coated with an inorganic solid material layer and a polymer layer B, and the inorganic solid material layer is located between the substrate separator and the polymer layer B. The mechanical strength of the separator can be improved by the inorganic solid material layer, when a ceramic material with a lithium ion conduction function is used, the ionic conductivity of the separator can be improved effectively, and a polarization effect in charge-discharge processes is reduced. An electrolyte of the lithium-sulfurbattery contains an additive, therefore, interface state of a cathode, an anode and the separator is improved, charge-discharge current on the lithium anode surface is more uniform, activity of the lithium anode in the lithium anode can be reduced effectively, possibility of formation of lithium dendrites is reduced greatly, and use stability of the lithium anode is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Bioabsorbable hemostatic gauze

InactiveUS20070104769A1Improved performance characteristicsImprove liquid absorption capacityOrganic active ingredientsBiocideCelluloseWater soluble polysaccharides

Bioabsorbable, water-soluble hemostatic cellulose based gauze matrix structures are described, including one or more species of chitosan, etherized cellulose, nonionic surfactant, water-soluble polysaccharide hydrocolloid and / or gum. Approximately 85% to 95% deacetylated decrystallized chitosan, present in an amount from about 2% to about 15% by weight, is found to be particularly advantageous. Favorable properties are found related to rapid stoppage of bleeding and bioabsorbability, among other properties.

Owner:LIFESCI PLUS

Composite material based on nanometer, preparation method of composite material and application in flexible energy storage device

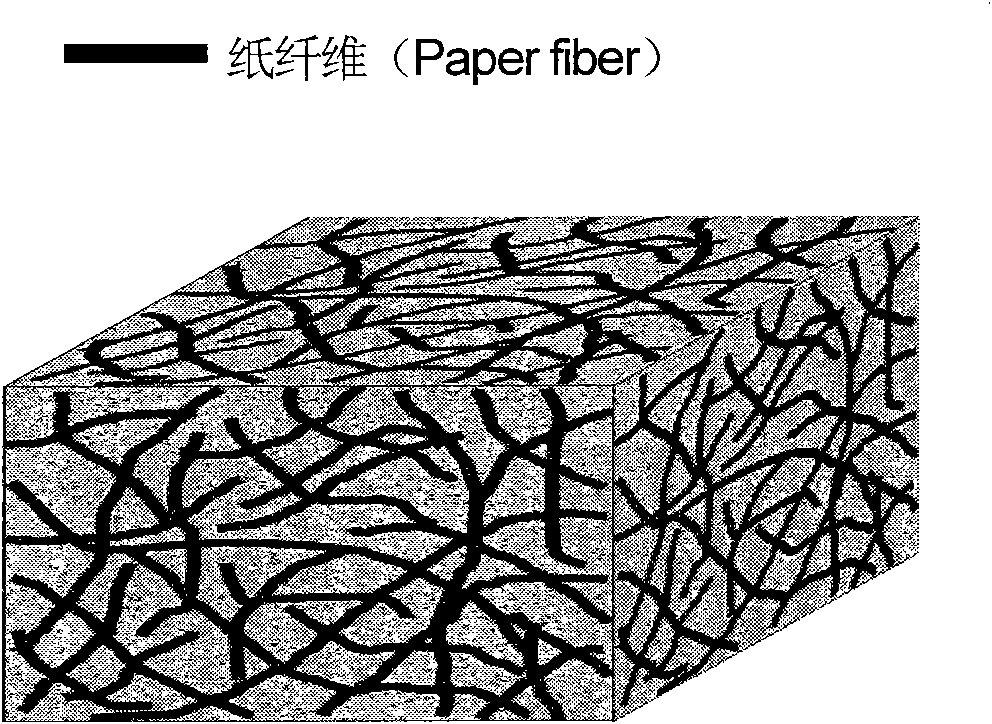

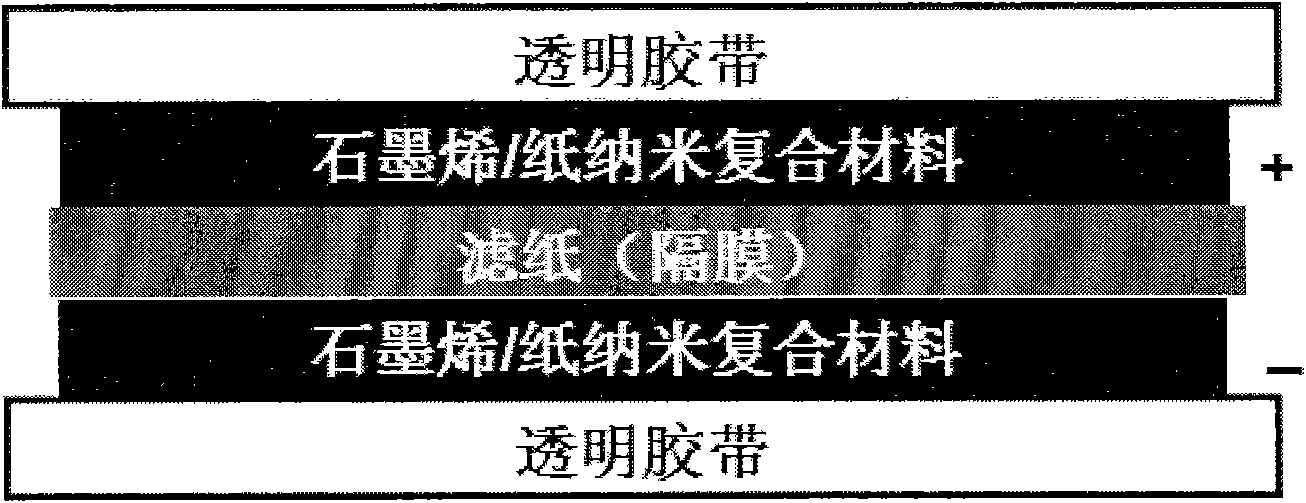

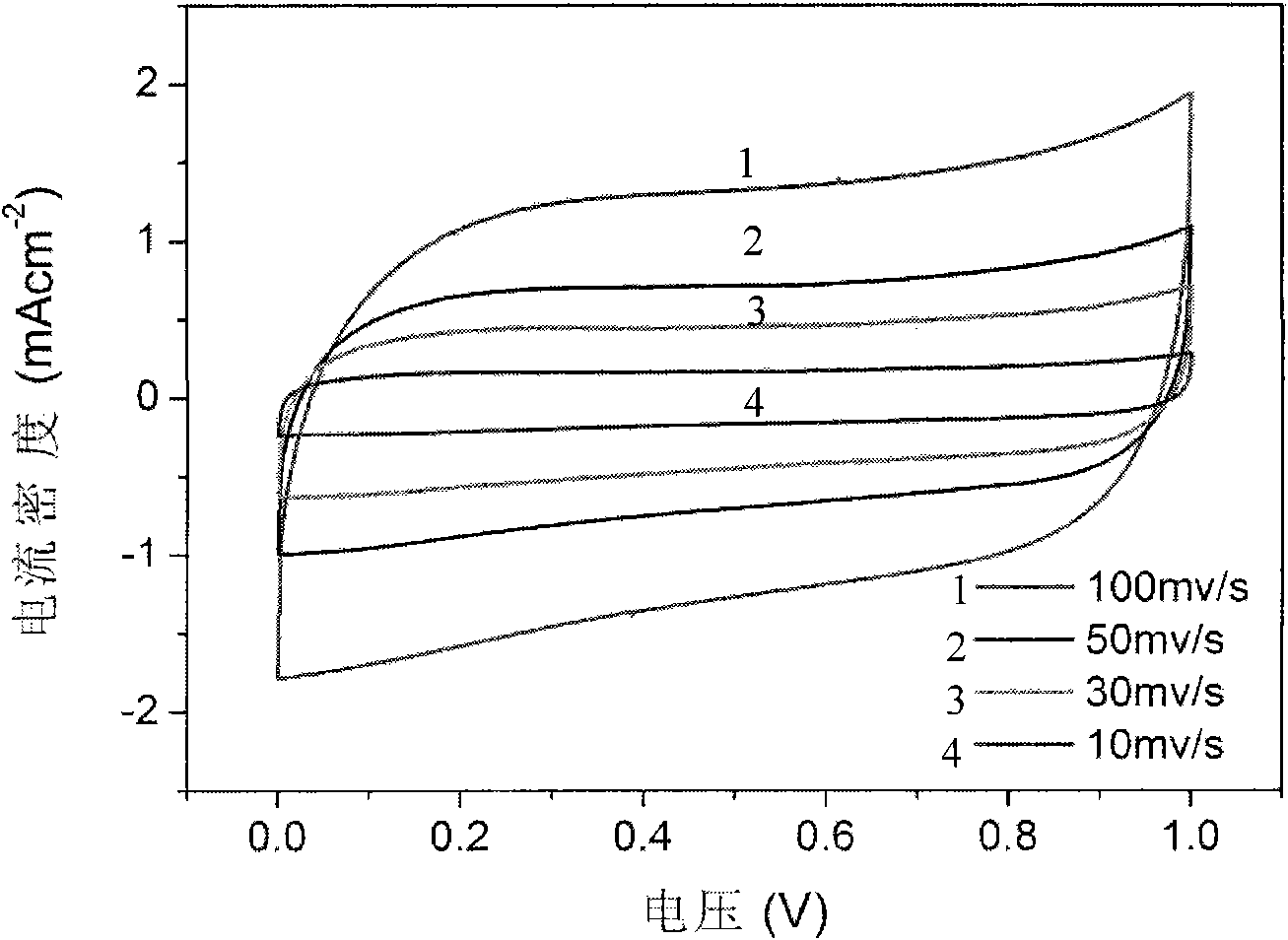

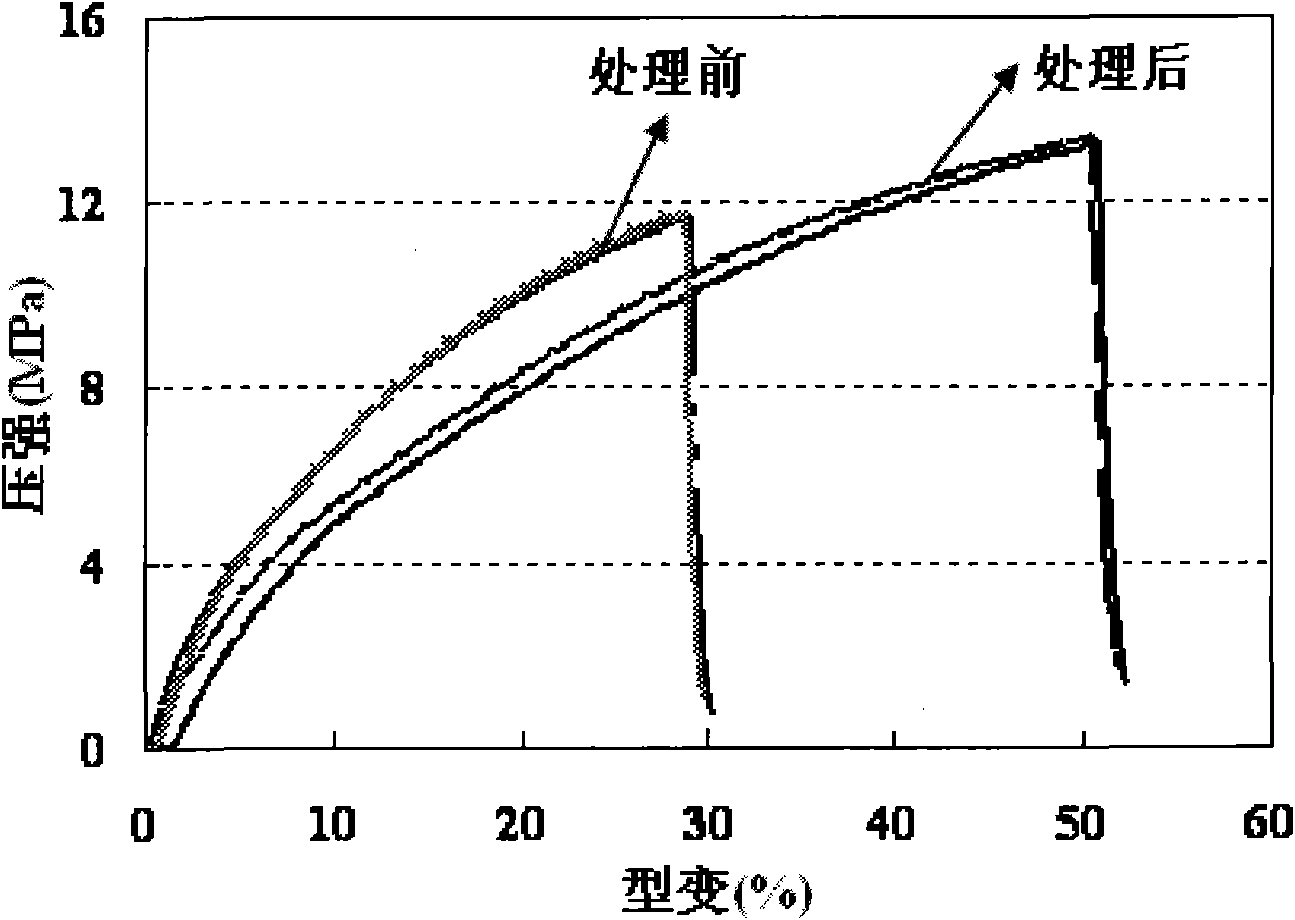

InactiveCN102403050AImprove energy storage characteristicsImprove mechanical propertiesElectrolytic capacitorsElectrode carriers/collectorsHigh energyNetwork structure

The invention relates to the field of chemical energy storage devices such as super capacitors, batteries and the like, and particularly discloses a composite material based on nanometer, a preparation method of the composite material and application in a flexible energy storage device, which solve the problem that common energy storage devices are difficult to be bent and deform. Nanometer active materials are compounded with flexible fibers, high-energy-storage characteristics of the nanometer active materials and excellent flexibility of flexible fiber materials are integrated, the quality percentage of the nanometer active materials ranges from 0.1% to 40%, the rest components of the composite material are the flexible fibers, the flexible nanometer composite material in a three-dimensional communication network structure is formed, furthermore, the composite material can be used as an electrode active material and a current collector simultaneously so as to be assembled to form the bendable flexible energy storage device, higher specific capacity can be realized under a bending condition and is equivalent to that when the flexible energy storage device is not bent, and the composite material can be expected to be applied to the field of flexible devices in the future.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

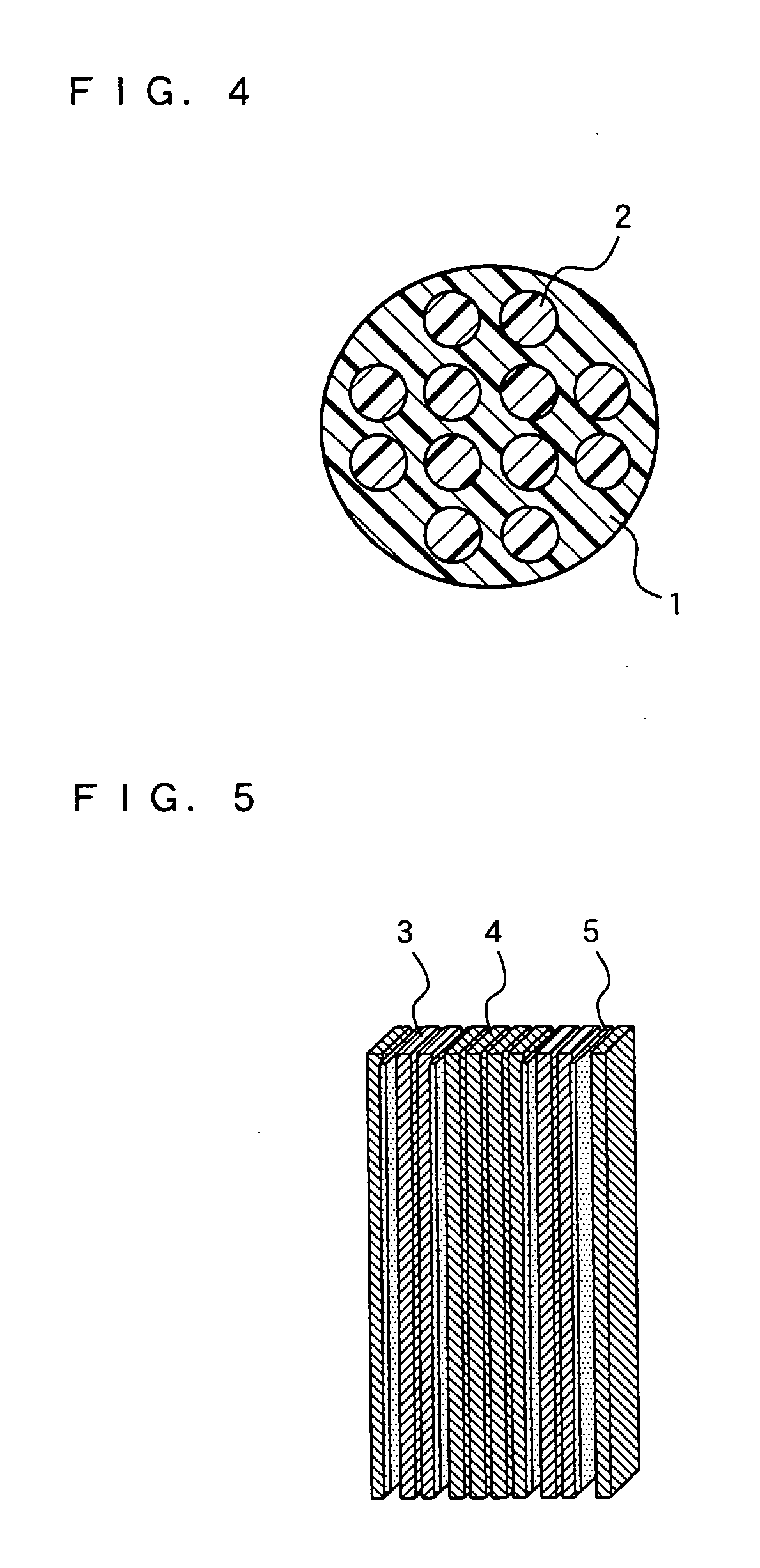

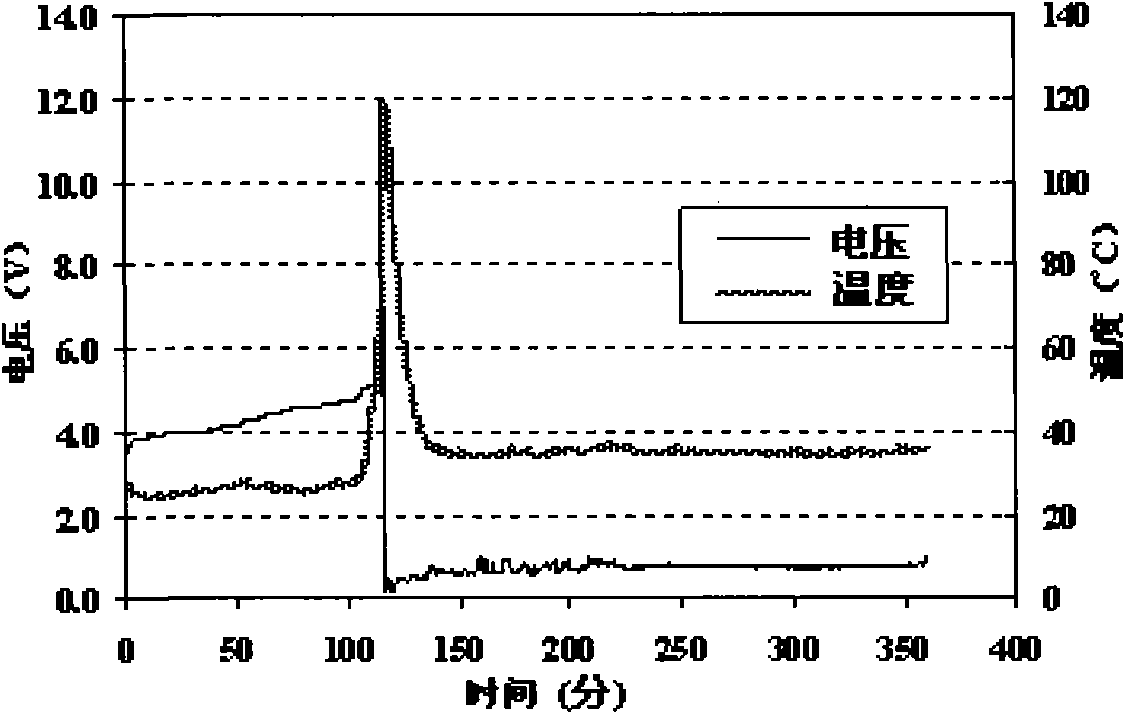

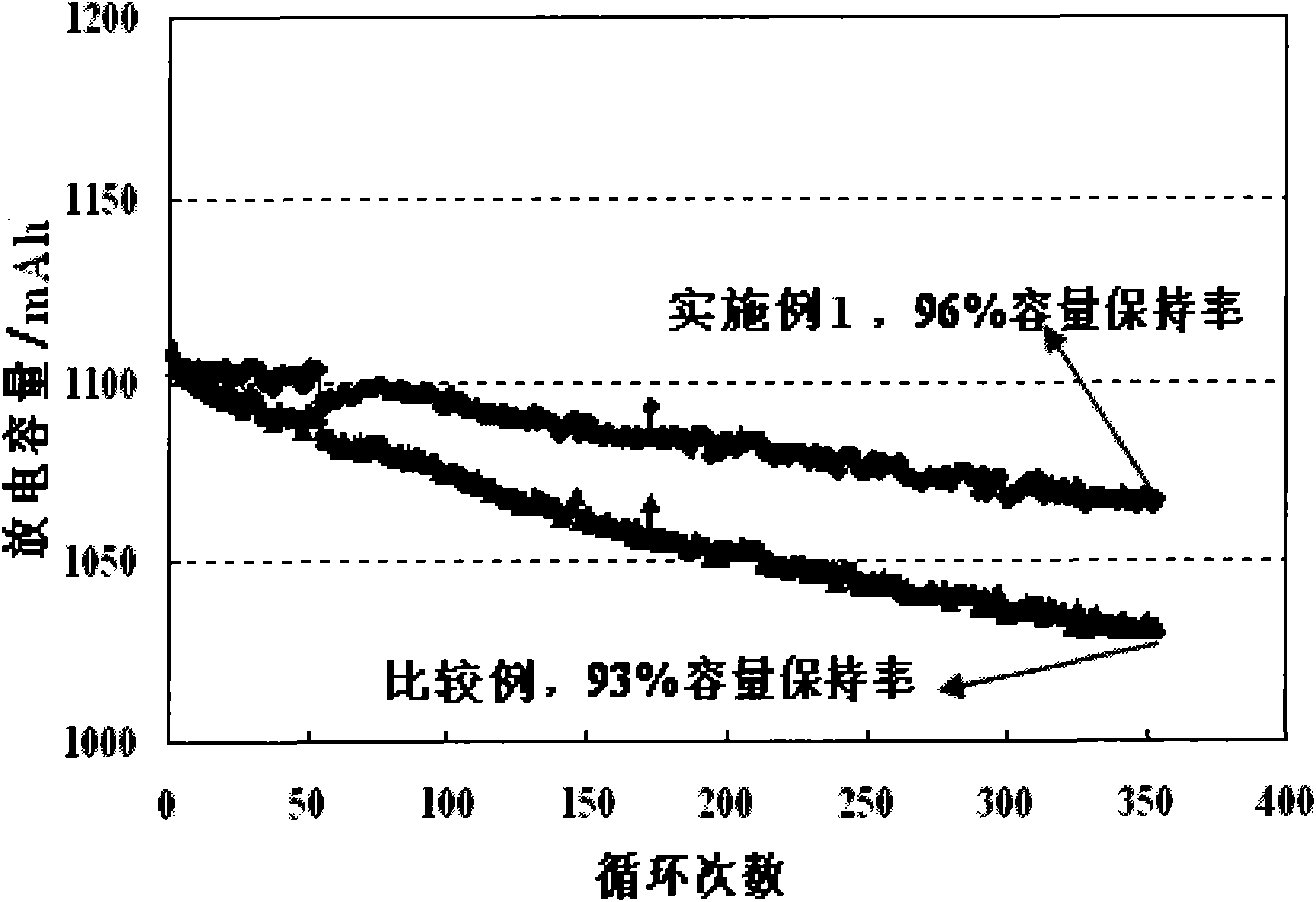

Polymer lithium ion secondary battery and isolating membrane thereof

ActiveCN101872853AImprove liquid absorption capacityStrong interfacial stabilityCell electrodesSecondary cellsPorous substrateAcrylonitrile

The invention discloses an isolating membrane of lithium ion secondary battery, comprising a porous substrate and a polymer coating distributed only on a surface of the porous substrate which faces an anode of the lithium ion secondary battery, wherein the polymer in the polymer coating is selected from poly(methyl methacrylate-acrylonitrile), poly(methyl methacrylate-vinyl acetate), poly(methyl methacrylate-acrylonitrile-vinyl acetate), poly(n-butyl methacrylate-styrene), or blends of the polymers. The polymer unit in the polymer coating of the isolating membrane of the lithium ion secondary battery contains carbonyl, wherein very strong effect exists between the carbonyl and oxygen in carbonic acid ester type organic solvent so as to have fine solution suction ability and good interface stability of lithium electrode or anode; the membrane has strong adhesive property and film formation, and can provide fine mechanical tensile strength; and the membrane has fine cycle performance and safety performance. The invention further discloses a polymer lithium ion secondary battery using the membrane.

Owner:DONGGUAN NEWPOWER ELECTRIC SCI & TECH +1

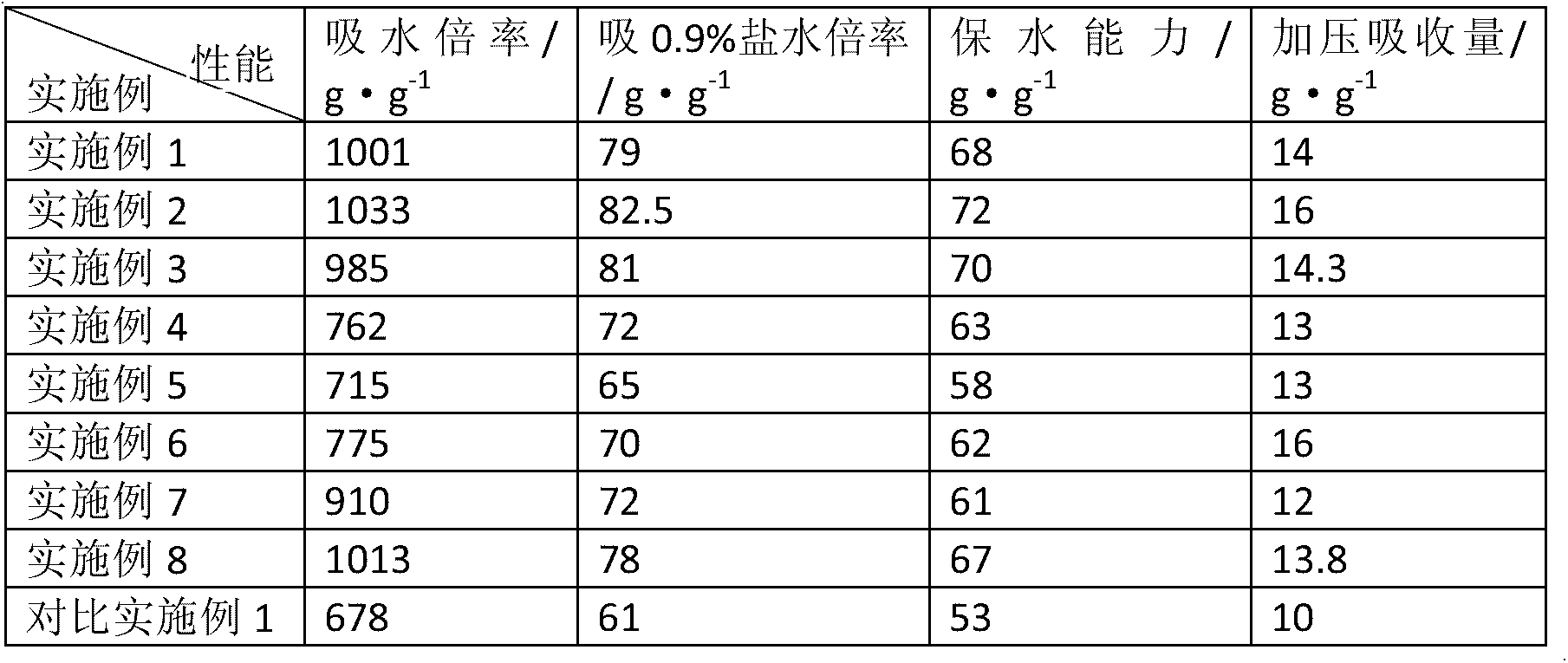

Preparation method of porous-super-absorbent resin

InactiveCN103214616AShorten the polymerization reaction timeIncrease productivityCross-linkSodium hydroxide

The invention discloses a preparation method of porous-super-absorbent resin. The preparation method comprises the following steps of: adding acyclic acid to deionized water, neutralizing with a sodium hydroxide aqueous solution, and controlling neutralization temperature at 50 DEG C to 80 DEG C and neutralization degree at 60-80%; mixing the solution; adding a cross-linking agent and stirring till completely dissolving, then adding an oxidant and a foaming agent, afterwards, adding a reducing agent, carrying out polymerization reaction by heat of neutralization, and generating porous-super-absorbent resin gel; and pelleting, drying, crushing and screening to obtain the porous-super-absorbent resin. Additional heating equipment is not needed in the porous-super-absorbent resin preparation method; heat released in neutralization process is directly used for enabling a polymerization reaction system to reach the temperature needed by the reaction; and an oxidation reduction initiating agent is added at high temperature, so that the whole polymerization reaction time is shortened, and the production efficiency is improved; and the added foaming agent can be used for preparing porous gel, so that the water retaining capacity and the water-absorption capability of the water-absorbent resin are improved.

Owner:SOUTH CHINA UNIV OF TECH

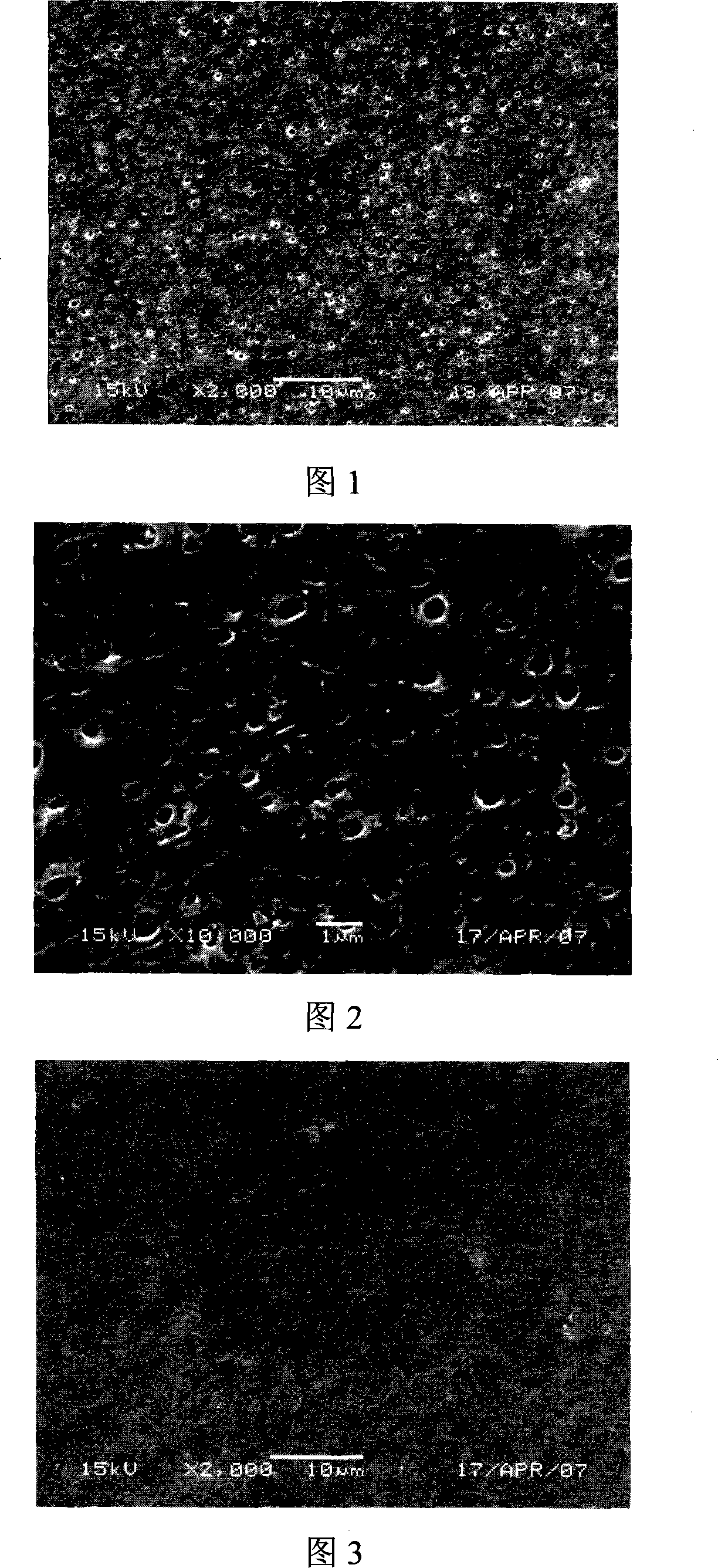

Electrolyte film and porous substrate and preparation thereof, lithium ion secondary battery

InactiveCN101388441AHave mechanical strengthGood flexibilitySecondary cellsCell component detailsPorous substratePolymer electrolytes

The invention relates to a gel-type polymer electrolyte film for a lithium ion secondary battery and a process for preparation, and a lithium ion secondary battery which contains the electrolyte film. The gel-type polymer electrolyte film for the lithium ion secondary battery can be obtained through the following method: preparing polyvinylidene fluoride nonwoven through the electrostatic spinning method, making the surface of the polyvinylidene fluoride nonwoven activate through radiating electron beams for the obtained the polyvinylidene fluoride nonwoven in air, contacting a methyl methacrylate monomer and the polyvinylidene fluoride nonwoven after the surface activation, thereby obtaining the polyvinylidene fluoride nonwoven whose surface is grafted with polymethyl methacryate. Furthermore, the lithium ion battery electrolyte film can be obtained through making the polyvinylidene fluoride nonwoven whose surface is grafted with polymethyl methacryate absorbs a certain amount of electrolytic solution. The invention develops the respective advantages in the lithium ion battery owing to using the polyvinylidene fluoride nonwoven whose surface is grafted with polymethyl methacryate, compared with singly using polyvinylidene fluoride or polymethyl methacryate or the both simple composite, and eliminates the disadvantages caused by singly using one material or several materials. The electrolyte film has high ion electrical conductivity under ambient temperature after absorbing the electrolytic solution, and can manifest excellent heavy-current discharge performance and circulation stability after being assembled in the batteries.

Owner:PANASONIC CORP +1

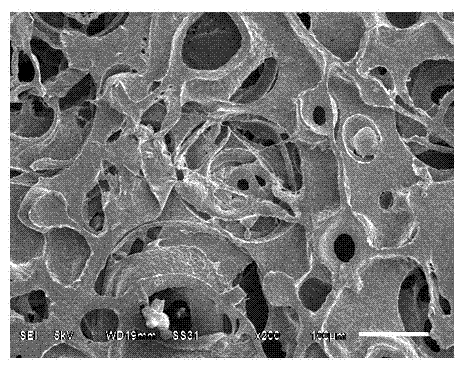

Chitosan/polyvinyl alcohol (PVA) porous composite material and preparation method thereof

InactiveCN102108172AGood biocompatibilityImprove liquid absorption capacityAbsorbent padsBandagesWound dressingBiocompatibility Testing

The invention relates to a chitosan / polyvinyl alcohol (PVA) porous composite material. The material is prepared from the following raw materials in percentage by weight: 1-5% of chitosan, 10-30% of PVA, 1-5% of acetic acid, 5-10% of inorganic acid, 5-10% of cross-linking agent, 6-10% of foaming agent, 0.5-2% of antibacterial agent, 1-5% of softening agent and the like. The preparation method of the material comprises the following steps: stirring for fully dissolving the PVA; pouring the dissolved PVA into the dissolved chitosan, adding the inorganic acid, the cross-linking agent, the foaming agent, the softening agent and the antibacterial agent to the obtained mixed solution, heating the solution to 90-100 DEG C, and pouring the solution into a die for continuously reacting at the temperature of 60-100 DEG C for 6-15 hours; and finally cooling and washing the obtained product with distilled water. The obtained material has the characteristics of good biocompatibility, excellent antibacterial effect, strong liquid absorption capability, biodegradability, good adhesion to skin and the like, and has functions of rapid hemostasis, antibiosis, anti-inflammation and acceleration of wound healing, thus the material is suitable for serving as various wound dressings.

Owner:WEIHAI SHICHUANGXIN MATERIAL TECH

Cathode diachylon used for power-type lead-acid storage battery and manufacture method thereof

InactiveCN102088088AStrong maneuverabilityHigh viscosityLead-acid accumulator electrodesIonActivated carbon

The invention discloses cathode diachylon used for a power-type lead-acid storage battery, comprising the following components: 100kg of lead powder, 0.10-0.12kg of short fiber, 0.40-0.60kg of humic acid, 0.12-0.30kg of sodium lignin sulfonate, 1.00-2.00kg of acetylene black, 1.00-1.50kg of conduction graphite, 2.00-3.00kg of activated carbon, 0.60-1.00kg of barium sulphate, 15000-22000g of deionized water and 7200-6000ml of sulfuric acid with the concentration of 1.30-1.40g / cm<3>(25 DEG C). The cathode diachylon has the beneficial effect that the power-type battery produced by the cathode diachylon has the advantages of high specific energy and good large current discharging capability, the low-temperature volume and cycle life are obviously improved.

Owner:SHANDONG SACRED SUN POWER SOURCES

Colloidal electrolyte of lead acid batteries

InactiveCN101291002AInhibition of hydrationPrevent severe crackingLead-acid accumulatorsPhosphoric acidSilicon dioxide

The invention discloses a lead-acid accumulator colloid electrolyte. The lead-acid accumulator colloid electrolyte comprises the following compositions in percentage by mass: 30 to 45 percent of sulphuric acid, 4 to 12 percent of nanometer silicon dioxide, 0.05 to 0.5 percent of macromolecular stabilizing agent, 0.1 to 0.5 percent of superfine glass fibre, 0.1 to 0.5 percent of boric acid, 0.1 to 1 percent of phosphoric acid, 0.3 to 2.5 percent of sodium sulfate and 50 to 57 percent of water. The electrolyte is added with the macromolecular stabilizing agent and the hydrophilic superfine glass fibre and sets up a strong network structure with the sulphuric acid and water molecules; the macromolecular stabilizing agent effectively prevents the delamination of various compositions and the hydration of the colloid electrolyte; the superfine glass fibre in the colloid electrolyte forms a reinforcing rib of the colloid electrolyte, effectively prevents the colloid electrolyte from seriously crazing, strengthens the tensile strength and vibration resistance performance of the colloid and has the strong liquid absorption capacity which improves the diffusing and transmitting speed of the electrolyte. The lead-acid accumulator colloid electrolyte improves the charging and receiving capacity, thereby increasing the cycle life of an accumulator.

Owner:CHAOWEI POWER CO LTD

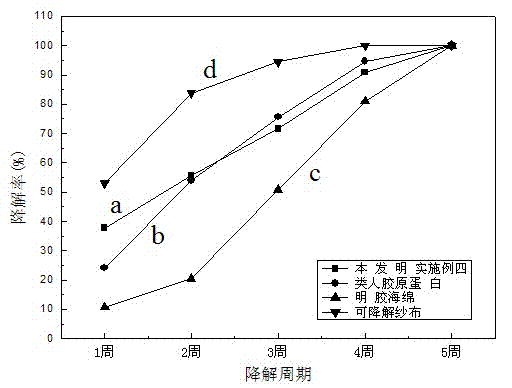

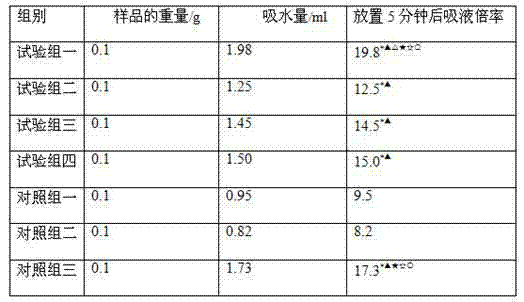

Starch-derived absorbable medical sponge and preparation method thereof

ActiveCN103394115AImprove stabilityNot easy to change colorSurgeryTissue cultureFoaming agentPolymer chemistry

The invention discloses a starch-derived absorbable medical sponge and a preparation method thereof. The starch-derived absorbable medical sponge is a composition comprising the following components by mass percent: 0.08-12% of absorbable starches, 0.0001-6% of foaming agents and 0.005-9% of moisturizing agents. According to the preparation method, the absorbable starches are utilized to prepare the starch sponge with better water-absorbing property and hemostasis property, and zoogenous extracts are unnecessary to be added. The starch sponge overcomes the defect that the existing starch sponge has fragile texture, and the starch sponge is loose and porous and has uniform holes and better hemostatic effect and internal degradation rate.

Owner:JIANGSU DIWO BIOLOGICAL PROD

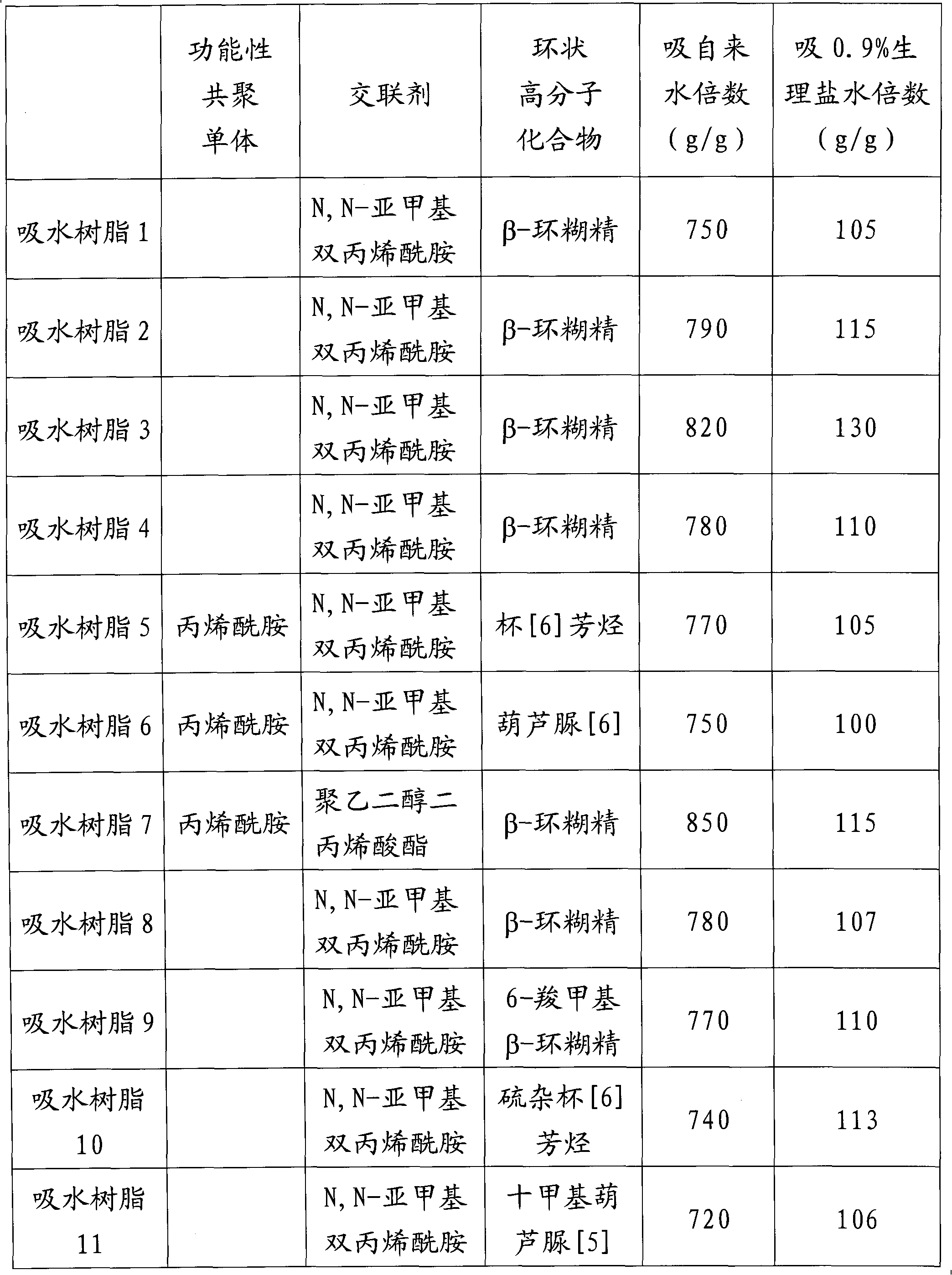

Salt-tolerant acrylic absorbent resin and method for preparing same

ActiveCN102153693AImprove liquid absorption capacityImprove adaptabilityOther chemical processesAcrylateAcrylic acid

The invention discloses salt-tolerant acrylic absorbent resin which is prepared from an acrylic monomer solution comprising acrylic acid and acrylate and a comonomer. The salt-tolerant acrylic absorbent resin comprises a ring polymer compound, wherein the ring polymer compound is 0.01-10 weight percent of the weight of the acrylic acid. The invention further discloses a method for preparing the salt-tolerant acrylic absorbent resin, comprising the following steps: adding the comonomer, a cross-linking agent and an initiator to the acrylic monomer solution to carry out polymerization reaction,washing, drying and pulverizing gel resin generated from reaction, uniformly spraying a surface cross-linking solution to the pulverized resin, stirring, and carrying out cross linking to prepare theproduct which is the salt-tolerant acrylic absorbent resin, wherein the ring polymer compound is added during polymerization reaction or / and surface cross-linking. Due to the adoption of the method, the salt tolerance of the acrylic absorbent resin can be improved, the smell can be reduced, the water retention capacity and the contaminant resistance can be enhanced, the influence and the toxic side effect to the skin can be decreased.

Owner:WANHUA CHEM GRP CO LTD

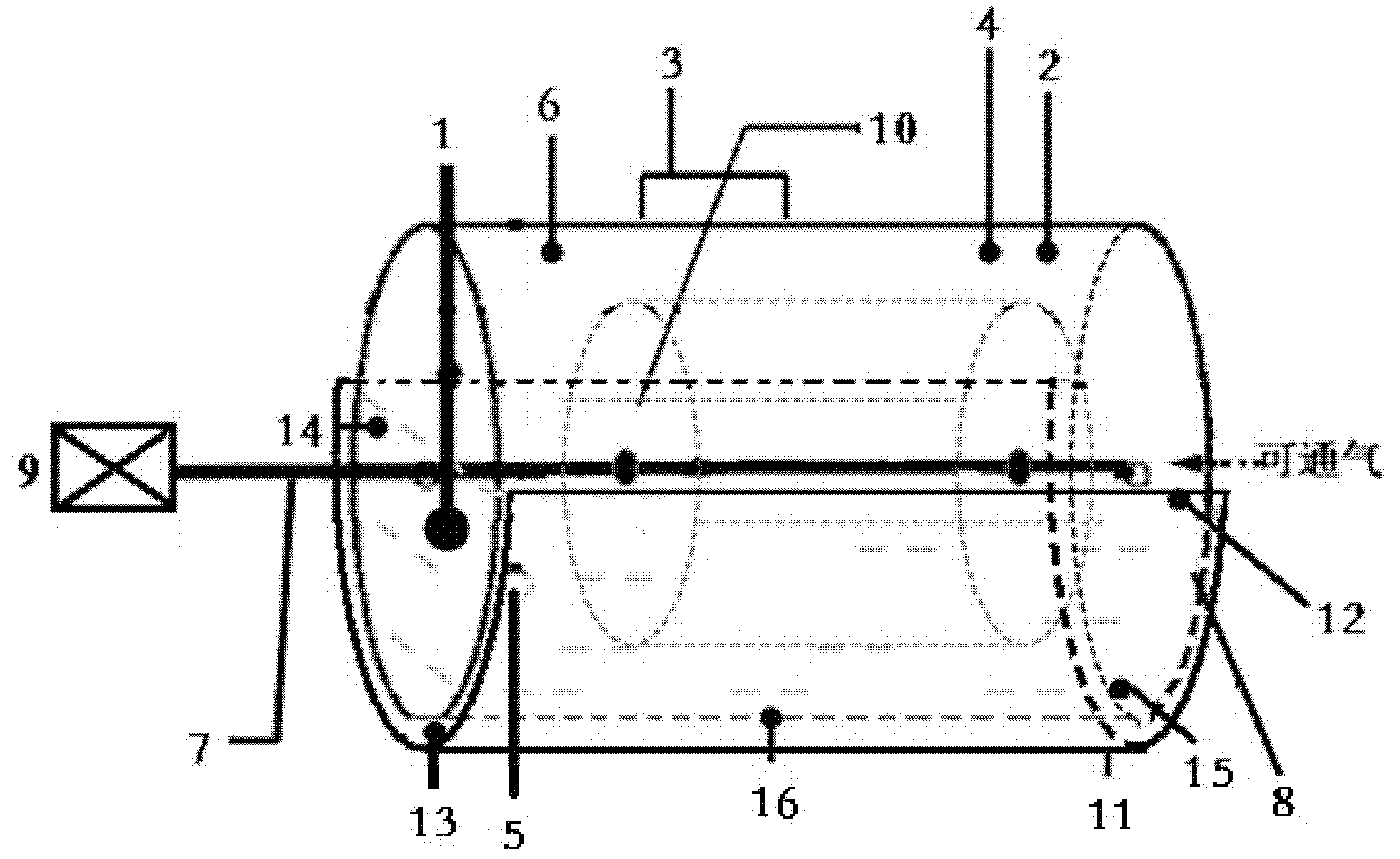

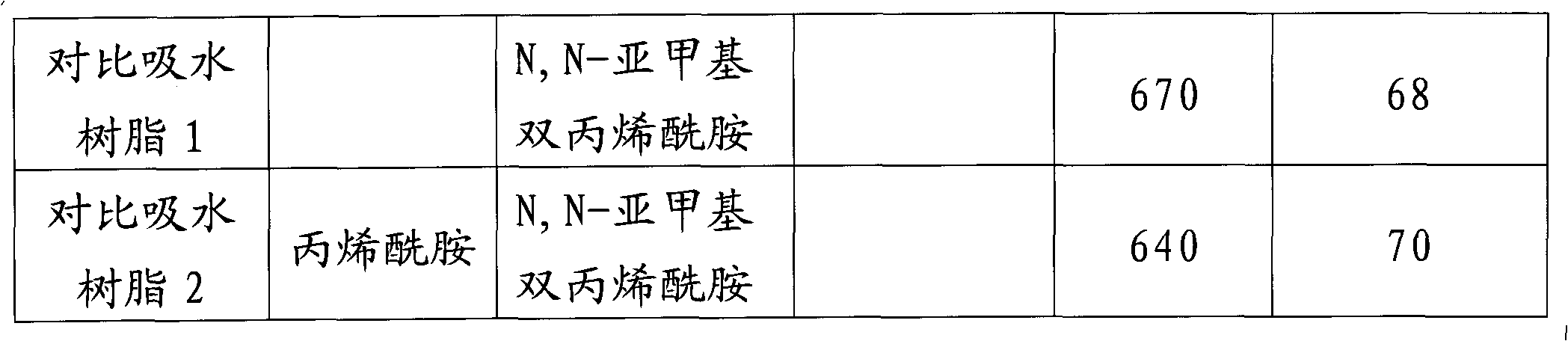

Health nursing pad absorber processing method and equipment thereof

ActiveCN103381114AImprove liquid absorption capacityIncrease liquid absorptionAbsorbent padsBaby linensEngineeringFiber

The invention discloses a health nursing pad absorber processing method and equipment thereof. The method comprises the following three steps: A, adsorbing wood pulp fiber and mixing the wood pulp fiber with polymer absorbent materials, B, compacting and dotted solidifying the absorber, and C, forming the absorber; the equipment is provided to realize the method. The method provided by the invention is suitable for various nursing pad products, can enhance extension strength of the nursing pad product, simplifies and realizes the manufacturing of absorber of nursing pad product, and reduces manufacturing cost of the nursing pad. The absorber produced by the invention adopts a novel structure made of polymer absorbent materials and wood pulp fiber, the polymer absorbent materials are uniformly disturbed in the wood pulp fiber, the sliding and moving of polymer absorbent materials are confined through doted solidification, so as to guarantee liquid absorption of the nursing pad product.

Owner:BEIJING BEISHUTE MATERNITY & CHILD ARTICLES

High activity biological super-strong water absorption resin and preparation method thereof

The invention provides a high-activity biological super strong water absorbing resin, the process for preparation comprises adding acrylic acid in a catalyst case according to quality portion, adjusting the pH value to 5-7, and adding a certain amount of maize starch, inorganic mineral substance, cross linker solution and initiating agent in turn, evenly stirring, warming up to 35 to 45 DEG C, polymerizing for 1.5-2 hours, stopping stirring when the system takes semitransparent gel shape, continuously warming up to 55-70 DEG C to polymerize 1-2 hours again till the system is turned to be gelatin, taking granulations out, drying, grinding to be half-finished product, and adding cross linker solution whose half-finished product quality is 0.01-1% and 0.01-1% high-activity biological agent, evenly stirring, placing in a drier, warming up to 60-100 DEG C to have a secondary treatment of surface cross bonding, and getting high-activity biological super strong water absorbing resin. The strong water absorbing resin product has the advantages of fast water absorbing speed, strong water absorbing capability, excellent anti adhesive properties after absorbing water, and which has the functions of resisting bacterium, absorbing osmyl, health care and the like, and can be applied in the production of women sanitary napkins, paper diaper, the aged health shorts and the like.

Owner:师进

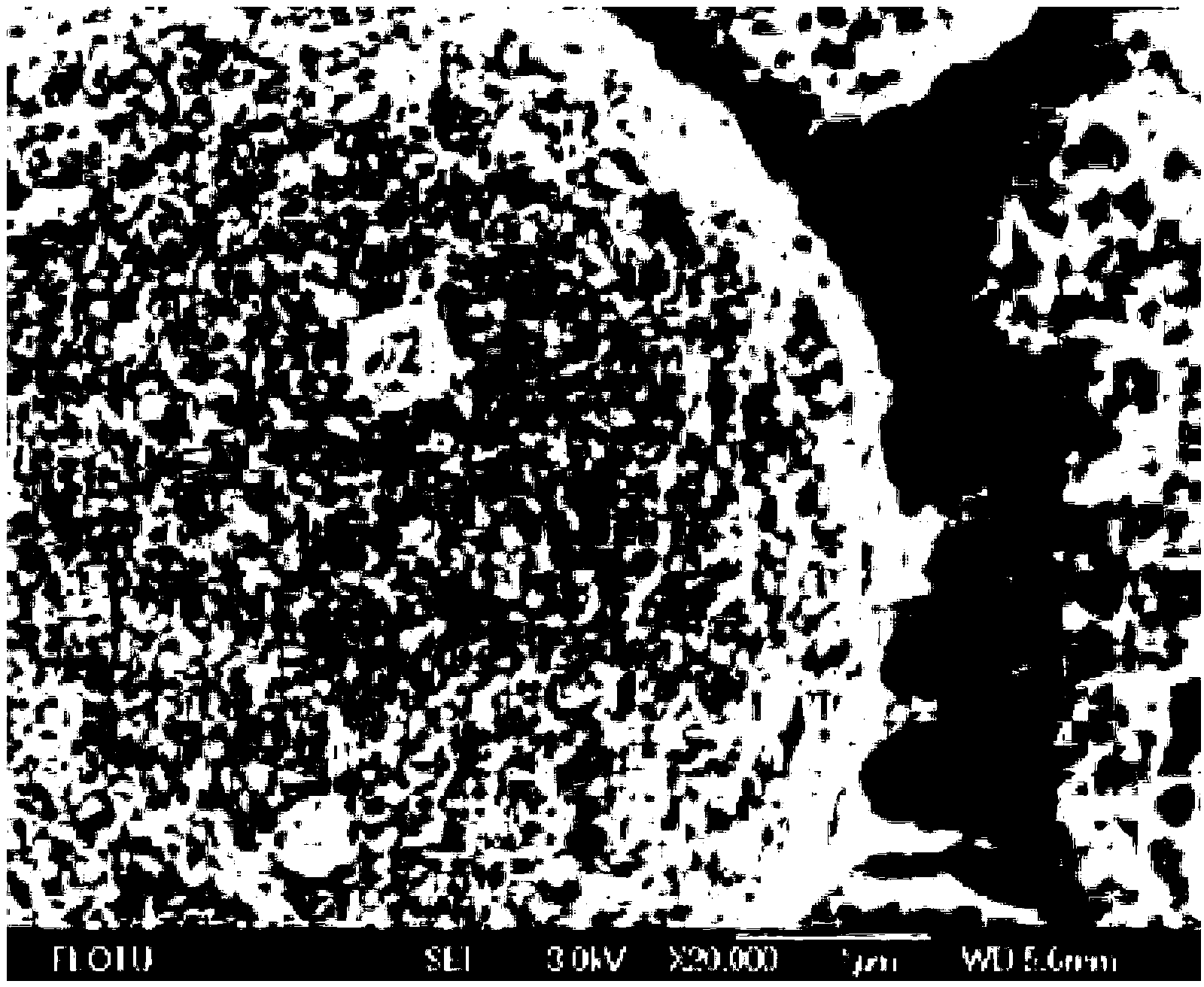

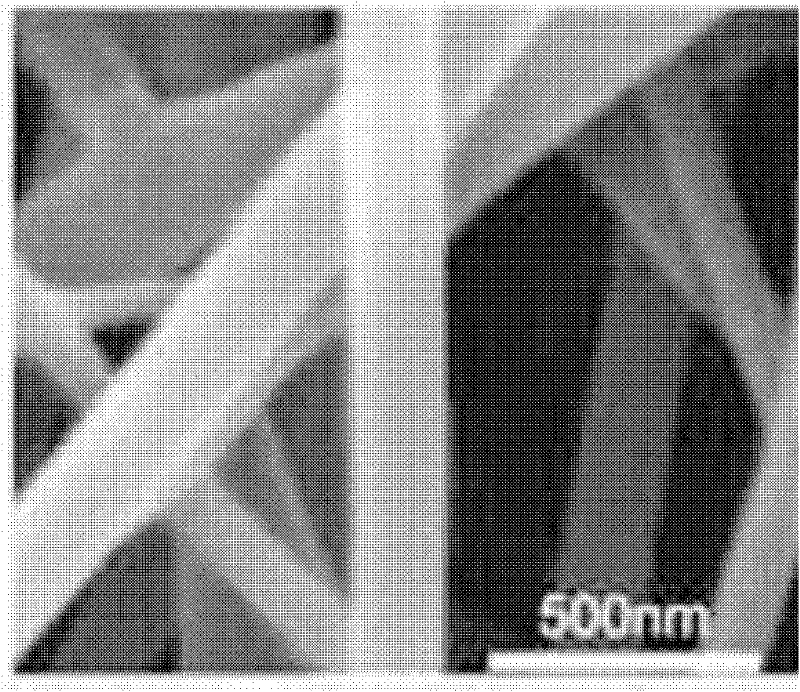

Preparation method of lithium titanate/carbon nano tube composite cathode material

The invention discloses a preparation method of a lithium titanate / carbon nano tube composite cathode material and belongs to the technical field of battery materials. A carbon nano tube grows on the surface of lithium titanate by a chemical vapour deposition method, and has the characteristics of uniform dispersion, high binding force and the like compared with a carbon nano tube directly doped in lithium titanate, the growing carbon nano tube can form a network structure on the surface of lithium titanate, and an important effect is exerted on improving structural stability of the material under the condition of high-rate discharge of a battery. The contact probability of the lithium ion battery with lithium titanate is increased and the internal resistance and polarization are reduced by using high conductivity of the carbon nano tube and the network structure formed by the carbon nano tube, the liquid absorption and keeping ability of the cathode material can be improved due to larger specific surface area of the carbon nano tube, and the high-rate discharge ability and recyclability of the battery are improved.

Owner:RIGHTFUL TECH

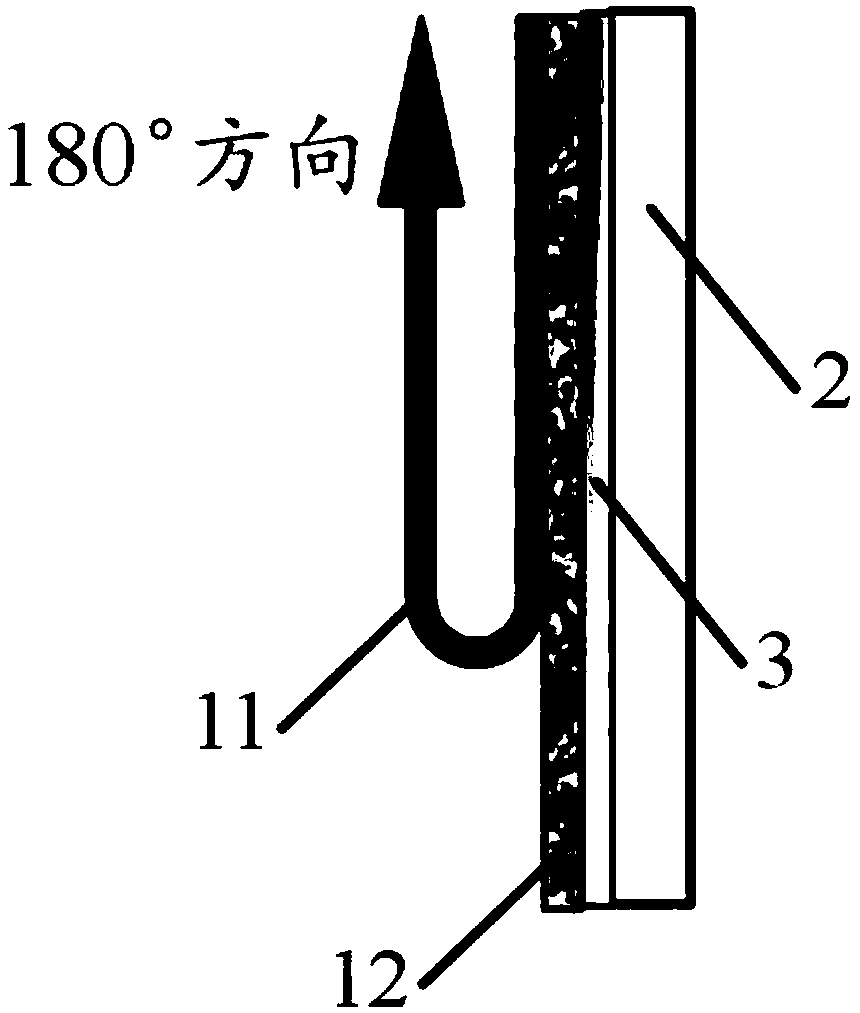

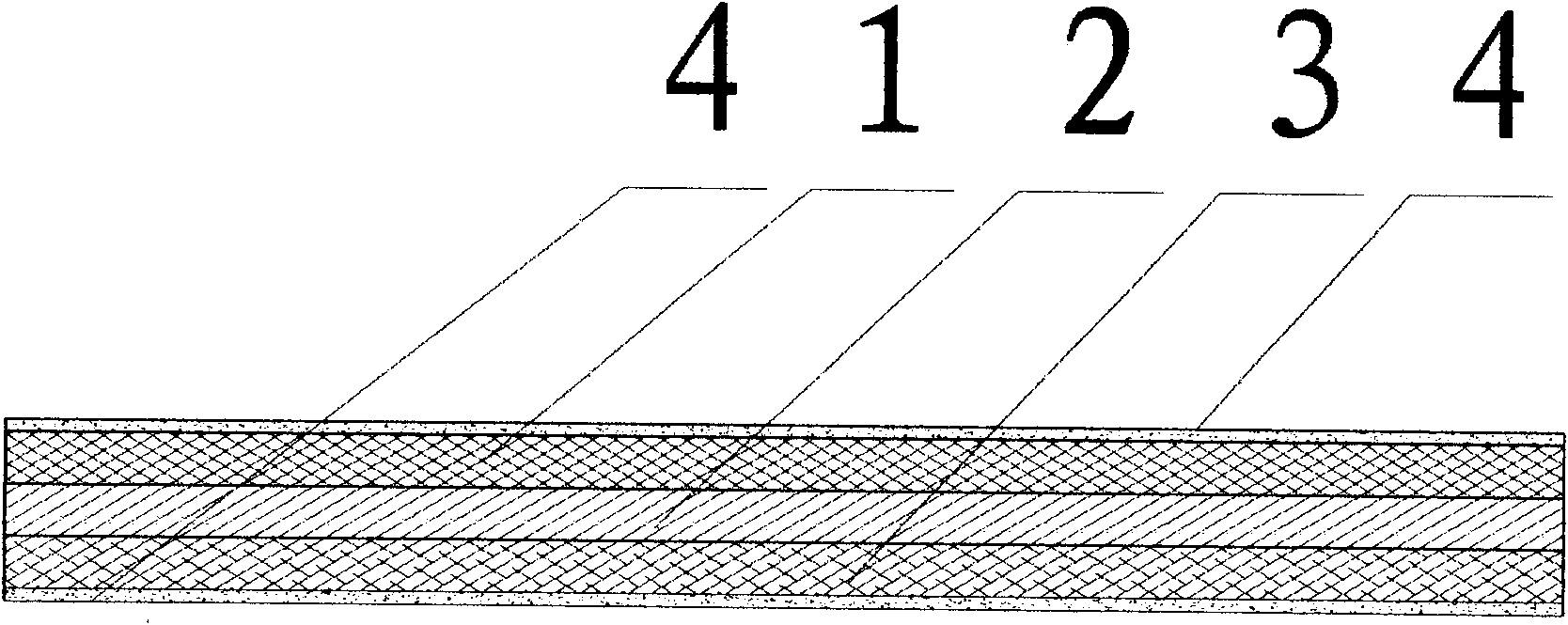

Separation membrane for gel-state polymer lithium-ion battery

ActiveCN102867931AImprove short circuit resistanceImprove securitySecondary cellsCell component detailsPorosityLithium electrode

The invention relates to a separation membrane for a gel-state polymer lithium-ion battery. The separation membrane is prepared by using a separation membrane body made of polypropylene and polyethylene materials as a substrate, and coating a layer of polymer colloid material and inorganic filler coating on the surface of substrate. The thickness of the polymer colloid material and inorganic filler coating is 1-5 mu m, and porosity of the separation membrane subjected to coating treatment ranges from 30%-50%. The polymer colloid material is a mixture composed of polyvinylidene fluoride, vinylidene fluoride-hexafluoropropylene copolymer, polyacrylonitrile and polymethyl methacrylate. The inorganic filler is composed of nanoscale inorganic powder material aluminium oxide, silica or their mixture, and the granularity ranges from 50nm to 200nm. The lithium-ion battery manufactured by the separation membrane is good in safety, short circuit resistance, needling resistance, impact resistance and extrusion resistance of the battery are improved, and the separation membrane for the gel-state polymer lithium-ion battery can be widely used in the field of electromobiles, electric motor cars, electric bicycles, large-medium type energy-storage batteries, photovoltaic stations and the like.

Owner:SHANDONG TIANYANG NEW ENERGY

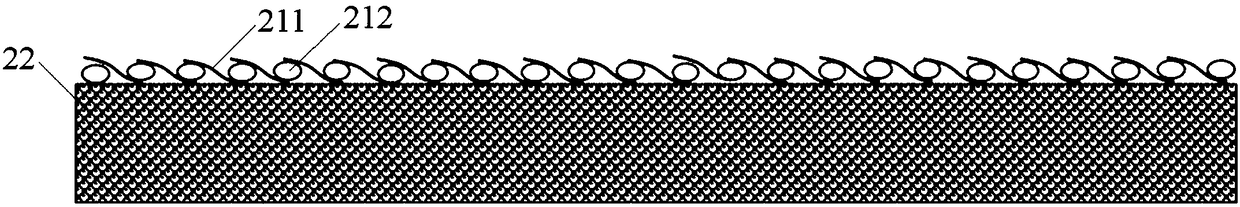

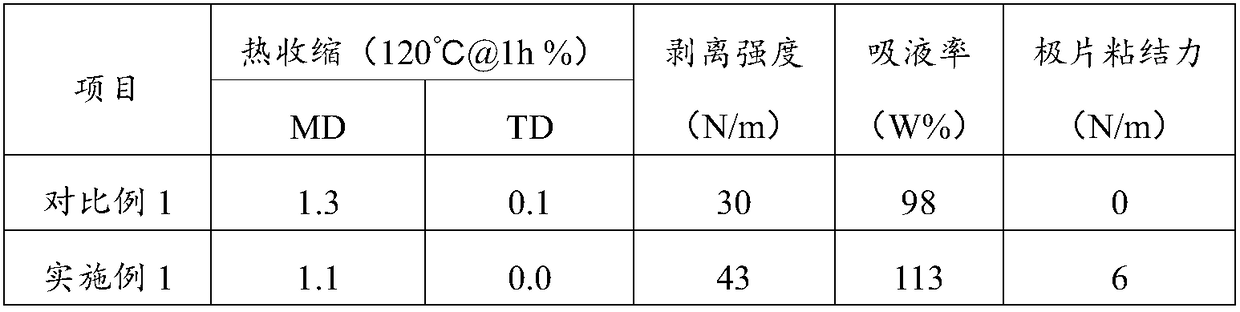

High-temperature resistant composite battery separator and preparation method thereof

ActiveCN108281592AGood thickening effectImprove hydrophilicityCell component detailsInorganic particleInorganic particles

The invention discloses a high-temperature resistant composite battery separator and a preparation method thereof. The high-temperature resistant composite battery separator comprises a base film anda high-temperature resistant coating layer, wherein the high-temperature resistant coating layer is coated on at least one surface of the base film and is formed by coating inorganic particles containing nanometer cellulose as a binding agent. In the composite battery separator, the nanometer cellulose is creatively used as the binding agent to prepare the high-temperature resistant coating layer,the interface bonding force of the coating layer and the base film is improved, the stripping strength of the composite battery separator is further improved, and the problems of falling and powder dropping of the coating layer are solved very well; with the addition of the nanometer cellulose, the inorganic particles are better in dispersion effect in water; moreover, the nanometer cellulose isused as the binding agent to form the coating layer, the high-temperature resistant composite battery separator is rapid in liquid conductivity and high in liquid absorption capability, gel is easilyformed after the electrolyte is absorbed, so that the composite battery separator can be attached onto a surface of an electrode very well, and the integral performance of the lithium ion battery is improved.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

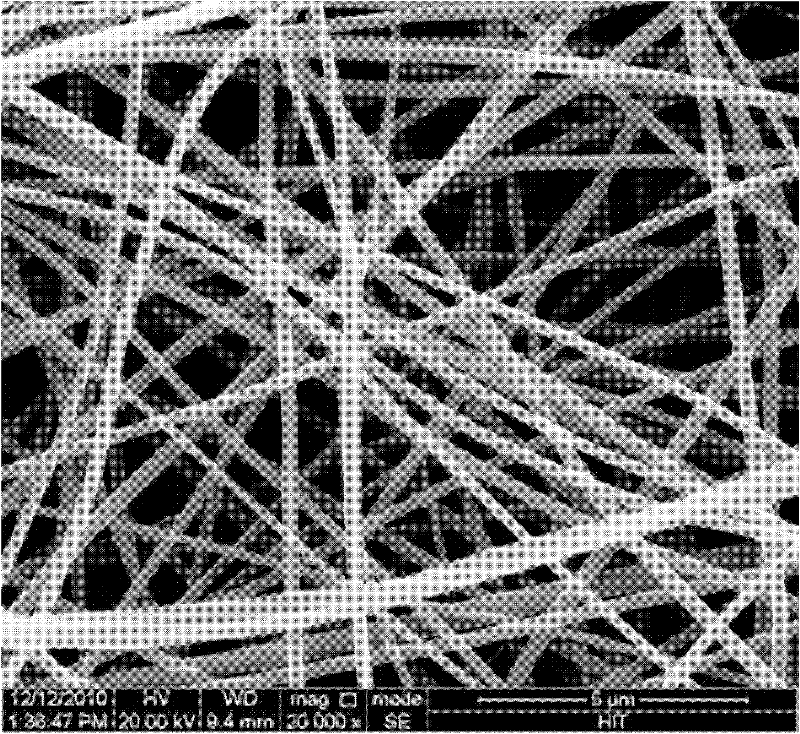

PAMPSLi fiber based polymer electrolyte membrane preparation method utilizing electrospinning method

ActiveCN102255106ALarge specific surface areaImprove liquid absorption capacityFinal product manufactureFilament/thread formingFiberPolymer science

A PAMPSLi (poly-vinylacetate-methyl methacrylate acid lithium) fiber based polymer electrolyte membrane preparation method utilizing an electrospinning method. The method belongs to the field of preparation of polymer electrolyte for polymer lithium ion battery. The invention mainly solves problems of concentration polarization phenomenon and low ion transport number in a salt polymer electrolytesystem. The PAMPSLi fiber based polymer electrolyte of the invention is prepared by employing a polymer electrolyte PAMPSLi as a polymer matrix and a lithium ion source to eliminate the concentrationpolarization phenomenon effectively, and the prepared membrane has a submicron pore structure, large specific surface area and high imbibition rate. In addition, a dual solvent system is employed to prepare a spinning liquid, so that shape and dimension of fiber can be controlled by adjusting the dual solvent composition. The PAMPSLi fiber based single ion polymer electrolyte has a conductivity reaching 2.12*10<-5>S / cm at room temperature, good electrochemical stability and an electrochemical window reaching 4.4V vs Li, so as to satisfy application requirements of a lithium ion battery. The preparation technology of the invention is simple, does not require a large consumption of solvents, has little environmental pollution, and is suitable for industrialized scale production.

Owner:HARBIN INST OF TECH

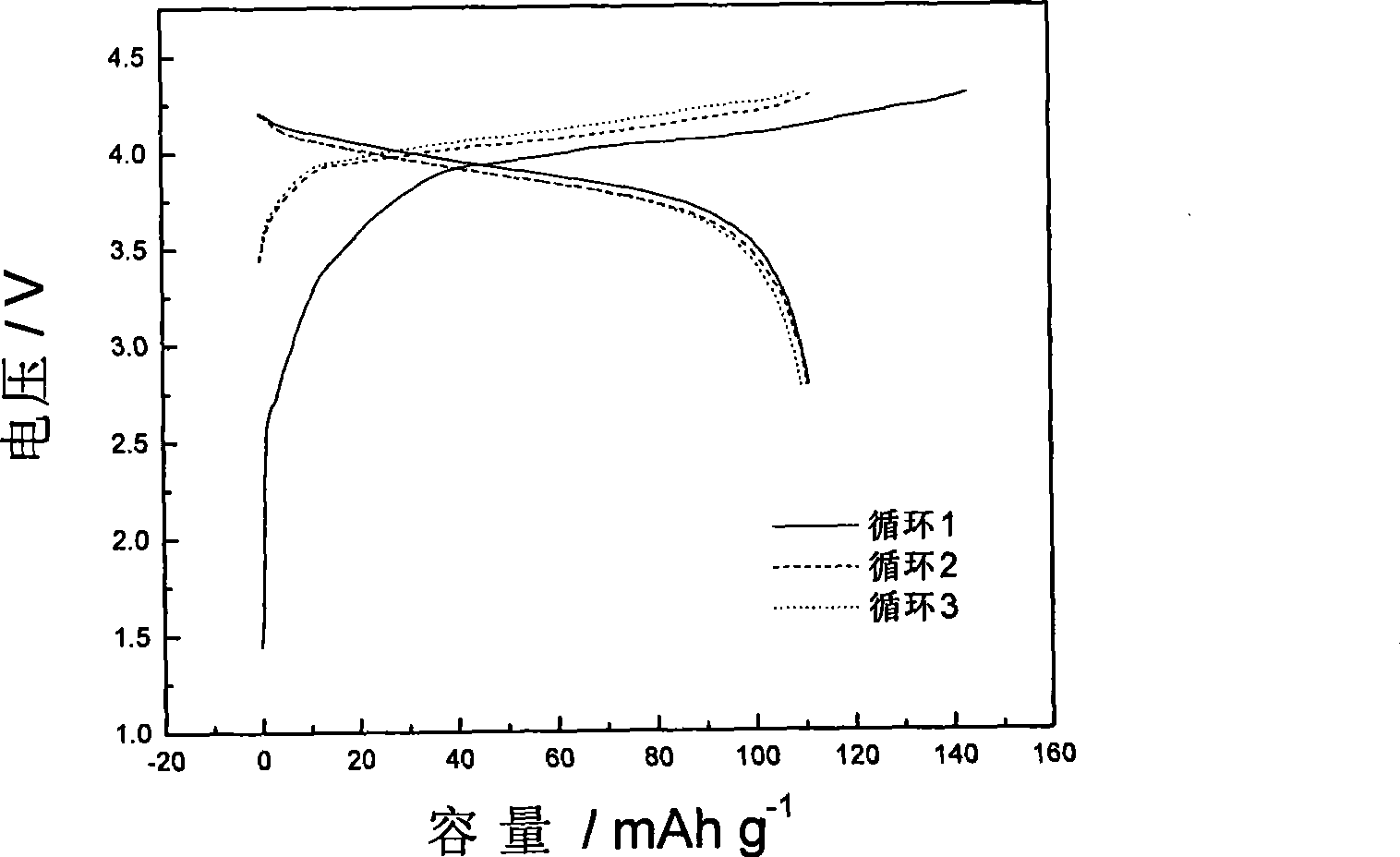

Lithium ion battery and combination electrode used for the same and production method thereof

ActiveCN101246958AGood compatibilityGood diaphragm wettingElectrode manufacturing processesSecondary cellsSolubilityHydrophilic monomer

The present invention relates to compound electrode slices applied in lithium ion battery and producing method thereof, which belongs to fields of battery production, in order to provide a new septum and cathode two-in-one electrode slices. The provided compound electrode slices is polymer colloid latex initiated, grafted and copolymerized by 1-5 portion initiator in aqueous solution containing 100 portion water-solubility polymer by 30-500 portion hydrophobic monomer and 0-200 portion hydrophilic monomer. Counted as that the solid content in the polymer colloid latex is 100%, the inorganic filler of 0-100% and the plasticizer of 20-100% are added, and the slurry is coated on the carbon cathode slice which is obtained by drying. The electrode slices has good heat stability and electrochemistry stability, super water absorptivity and rapid water absorption speed, and keeps higher water absorptivity in whole circle service life period. The battery has credible safety and circle service life, and the present invention provides a new thinking for lithium ion battery fields.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

Lithium ion battery and preparation method thereof

ActiveCN103633363AEasy to manufactureImprove securityFinal product manufactureCell component detailsHigh temperature storagePorous layer

The present invention provides a lithium ion battery and a preparation method thereof. The lithium ion battery comprises a housing, an electrode set and an electrolyte, wherein the electrode set and the electrolyte are sealed inside the housing, the electrode set comprises a positive electrode, a negative electrode and a separation membrane positioned between the positive electrode and the negative electrode, a porous layer is arranged between the negative electrode and the separation membrane, and comprises ceramic particles and a binder, the ceramic particles comprise 70-90 wt% of alumina and 10-30 wt% of silica, the average particle size of the alumina is 200-700 nm, and the average particle size of the silica is 200-500 nm. The prepared battery has characteristics of good rate charge and discharge property, high high-temperature cycle capacity retention rate, excellent high-temperature storage performance and ideal safety performance.

Owner:BYD CO LTD

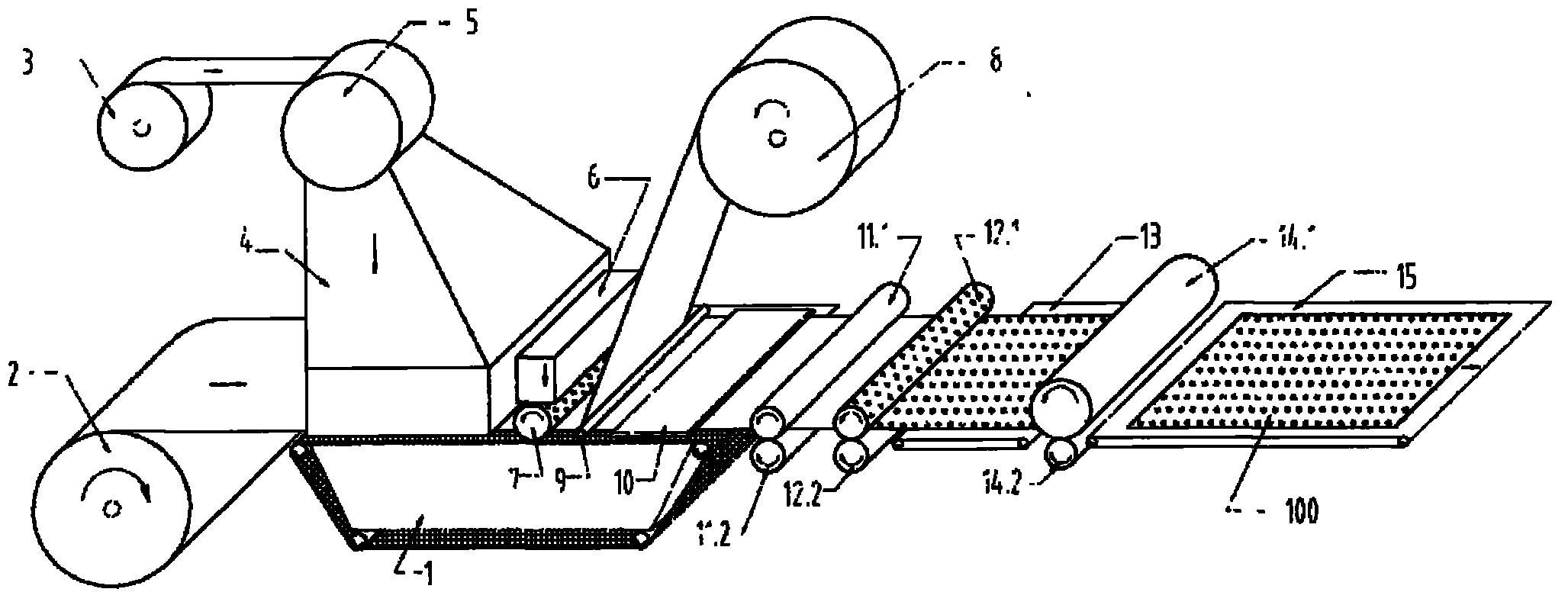

Process for producing high-molecular water-absorbent resin dust-free paper

InactiveCN102337701AEffective lockingReduce reverse osmosisNon-fibrous pulp additionSpecial paperReverse osmosisFluff pulp

The invention belongs to the papermaking technical field, more specifically relates to a process for producing the high-molecular water-absorbent resin dust-free paper. The process for producing the high-molecular water-absorbent resin dust-free paper takes fluff pulp wood pulp fiber, hot melt composite fiber and high-molecular water-absorbent resin (SAP) as the raw materials and the dust-free paper is composed of three-layer mixing layers. The process for producing high-molecular water-absorbent resin dust-free paper comprises the following steps: mixing the raw materials through a molding case, penetrating through hot air, wherein a heat bonding point between the hot melt fiber and wood pulp fiber formed by surface melting and flowing which are generated by the hot melt fiber during the heating process has the heat bonding effect, spraying latex on the double faces of the paper web and then drying by hot-air in a drying cylinder, rewinding to obtain the finished product. The present invention has the beneficial effects that the dust-free paper has good penetration performance and imbibition capability, is capable of effectively holding liquid, minimizing the reverse osmosis of liquid and maintaining the dry surface of the product, and has less dust and high tensile strength.

Owner:NANNING QIAOHONG NEW MATERIALS

Lithium battery cathode additive, lithium ion battery, preparation method and uses thereof

ActiveCN105355849AStrong metal activityHigh specific capacityNon-aqueous electrolyte accumulator electrodesSecondary cells servicing/maintenanceActive agentCarbon nanotube

The invention discloses a lithium battery cathode additive, a lithium ion battery, a preparation method and uses thereof, and belongs to the technical field of lithium secondary battery. The cathode additive is a core-shell structure, wherein the core is composed of nanometer silicon powder, lithium powder compound and hollow carbon spheres, and the shell is composed of carbon nanotubes, surfactants and doping agents; the mass proportion of the nanometer silicon powder, the lithium powder compound and the hollow carbon spheres is 10-70:0.1-10:20-80; the mass proportion of the carbon nanotubes, surfactants, doping agents and nanometer silicon powder is 5-20:2.5-10:0.5-7:10-70; the lithium powder compound is a core-shell capsule constituted by lithium powder and polymer wrapping the lithium powder; the doping agents are sodium chloride and / or sodium fluoride; the surfactants is sodium dodecyl benzene sulfonate. The cathode additive is added to the graphite cathode, thereby obviously promotes gram volume, initial efficiency and circulation performance of the cathode materials and absorbing ability of the cathode plate.

Owner:CALB CO LTD

Preparation method of chitosan oligosaccharide based polyelectrolyte sponge haemostatic dressing

The invention belongs to the field of biomedical material preparation, and relates to a preparation method of a chitosan oligosaccharide based polyelectrolyte sponge haemostatic dressing. At first, a proper amount of chitosan oligosaccharide and biocompatible anionic polyelectrolyte / amphoteric polyelectrolyte are dissolved into deionized water and then the mixture is injected into a mould. By reducing the pH value of the water solution of polyelectrolyte mixture, the amino group of the chitosan oligosaccharide molecules is protonated and carries positive charges. The chitosan oligosaccharide with positive charges interacts with anionic polyelectrolyte / amphoteric polyelectrolyte through the Coulomb force, compounds are formed, and gelation happens gradually. The compound gel is freeze-dried to obtain the sponge liked haemostatic dressing. The obtained haemostatic dressing has the advantages of good biocompatibility, good bacteriostatic activity, and excellent haemostatic performance, can be easily removed from wounds, and accelerates the healing speed of wounds. At the same time, the preparation technology is simple, and can be easily applied to industry.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Micro joint gel state lithium ion battery polymer electrolyte film and its making method

ActiveCN101127408AIncrease polarityImprove ionic conductivitySolid electrolyte cellsSecondary cellsAcrylonitrileElectrochemistry

The utility model relates to a polymer electrolyte film for a micro cross-linking gel state lithium-ion battery and a preparation method, which is used for making the battery. The utility model discloses the poly-acrylonitrile-methyl methacrylate with the cross-linking degree of 0.1 to 0.4 % is obtained after suspension polymerization with the monomer component mass ratio of a methyl methacrylate and an acrylonitrile of 1:9 to 4:6, then the poly-acrylonitrile-methyl methacrylate is dissolved by a polar organic solvent and coated on a formed die, finally the micro cross-linking degree polymer electrolyte film is obtained when the film is removed from the formed die, the thickness of the film is 20 to 50um, the tensile strength is 7 to 22Mpa, and the average hole diameter is 0.1to 3um. The utility model has advantages of good conductivity, good absorbing capability, good heat stability, good electrochemical stability and good mechanical property under the ambient temperature, and simple manufacturing operation, high transforming rate of polymer, economy and environmental friendliness.

Owner:GUANGZHOU TINCI MATERIALS TECH

Antibacterial alginate hydrocolloid dressing and preparation method thereof

InactiveCN107693836AIncrease liquid absorptionGood moisturizing effectAbsorbent padsBandagesPolyethylene glycolColloid

The invention belongs to the technical field of a medical apparatus, and discloses an antibacterial alginate hydrocolloid dressing and a preparation method thereof. The antibacterial alginate hydrocolloid dressing comprises, by weight, 10-30 parts of gelatin, 5-15 parts of modified sodium alginate, 10-20 parts of polyethylene glycol, 20-40 parts of polyvinyl alcohol and 0.05-0.1 part of antibacterial peptide D2A21. The preparation method includes preparation of a gelatin-modified alginate composite material, preparation of a polyvinyl alcohol and antibacterial peptide D2A21 fibrous membrane, and preparation of a hydrocolloid dressing. The method is simple and is low in cost. The prepared hydrocolloid dressing is great in water absorption and excellent in performance, and has good compatibility and antibacterial effect.

Owner:GUANGDONG TAIBAO MEDICAL SCI TECH

Ceramic separator and lithium ion battery

PendingCN107195837AImprove liquid absorption capacityLarge specific surface areaCell component detailsSecondary cells servicing/maintenanceSolventLithium-ion battery

The invention provides a ceramic separator. The ceramic separator comprises a separator substrate, wherein ceramic paste is coated on a surface of at least one side of the separator substrate, a protection layer is formed on a surface of the separator substrate after the ceramic paste is dried, the ceramic paste is formed by mixing ceramic powder with mass percent of 20-70%, a flame retardant with mass percent of 20-70%, a binding agent with mass percent of 5-30% and a solvent, and the ceramic powder is of a hollow spherical or hollow pipe structure. The safety of a lithium ion battery employing the ceramic separator can be improved.

Owner:OPTIMUM BATTERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com